Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Meet spinning requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber pretreatment device and method

InactiveCN102453982AReduce labor intensitySave spaceContinuous processingLiquid/gas/vapor removalYarnFiber

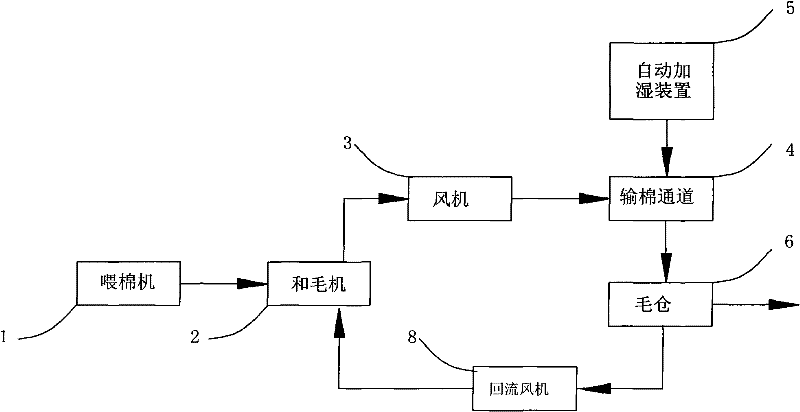

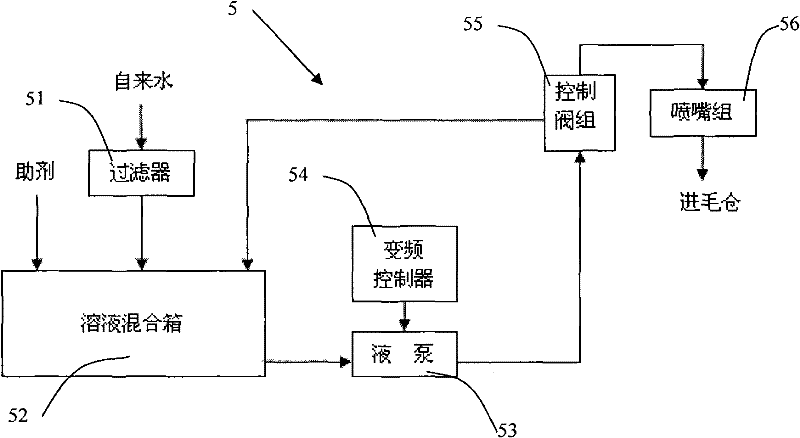

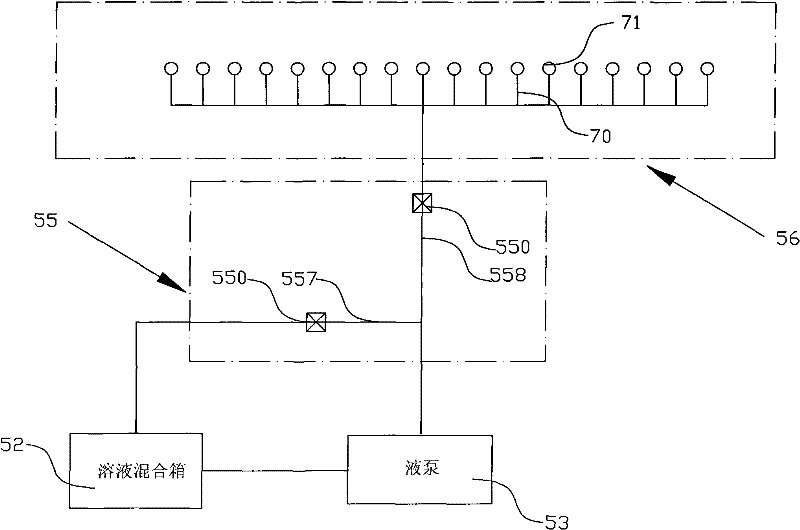

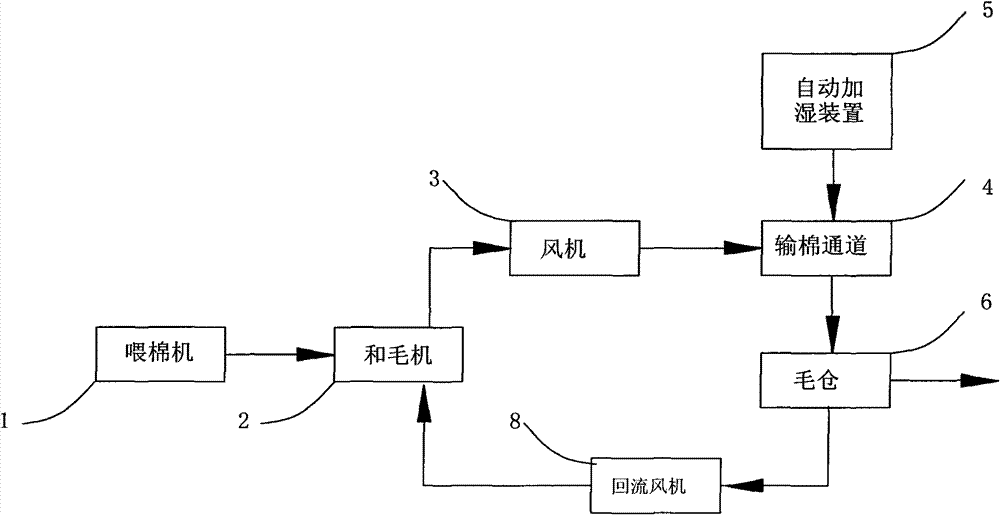

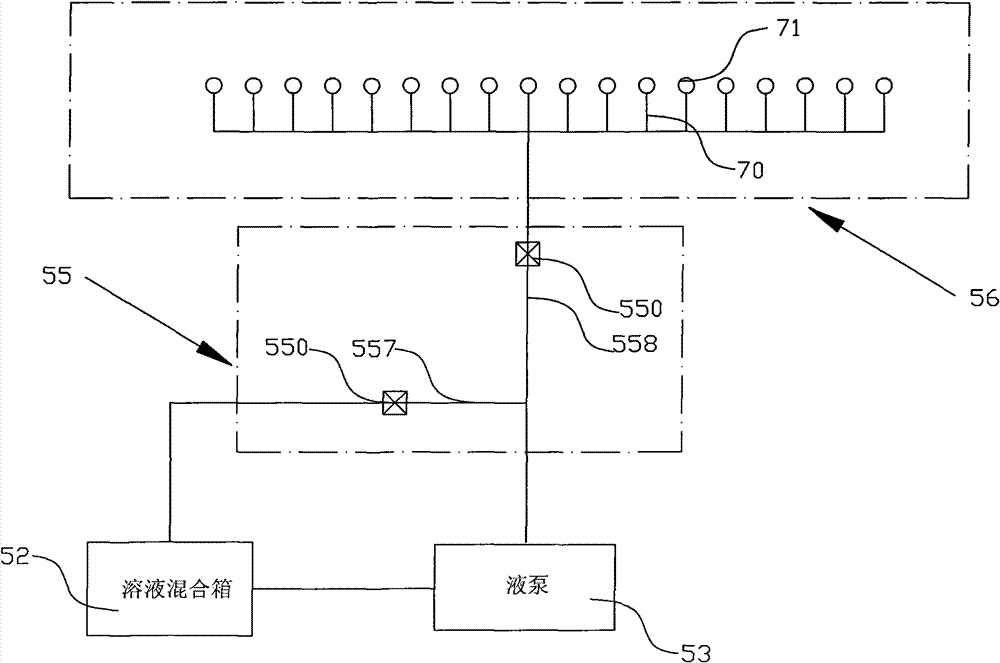

The invention discloses a fiber pretreatment device and method. The fiber pretreatment device comprises a cotton feeder, a wool mixer, a fan, a cotton conveying channel, an automatic humidification device and a wool bin which are connected in sequence by pipes; the automatic humidification device is connected with the cotton conveying channel; the fiber pretreatment device further comprises a reflow fan; the reflow fan is connected with the wool mixer and the wool bin through pipes; the wool bin is provided with an air blowing device; and the air blowing device is a ventilating pipe which is connected with an air blower. The method for humidifying manually for fiber pretreatment for a long time is changed, the working labor intensity is reduced, the defect of incontinuous production caused by manual humidification is overcome, and the reflow step, namely the secondary humidification step is adopted so that the fiber pretreatment can further meet the yarn spinning requirement and the fiber spinnability is improved.

Owner:上海第三十六棉纺针织服装厂有限公司

Stock solution for spinning phenolic fibers (PFs) and preparation method for stock solution

ActiveCN102532444AGood dispersionSynthetic conditions are mild and controllableMonocomponent synthetic polymer artificial filamentFiberTO-18

The invention relates to a stock solution for spinning phenolic fibers (PFs). The stock solution comprises the following raw materials: phenol, a 30 to 40 weight percent formaldehyde solution, a 6 to 18 weight percent polyvinyl alcohol (PVA) solution and a catalyst in a mass ratio of 100:(90-200):(40-250):(8-40). The stock solution has the advantages that: spinnability is high, the spinnable viscosity interval is wide, and the intrinsic properties of the PFs are not influenced by an additive.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Processing method of novel cashmere-like fabric

The invention discloses a processing method of a novel cashmere-like fabric. The processing method comprises the following steps of raw material selecting, spinning, yarn space dyeing, weaving, post-finishing and finished product packaging. According to the method, dyed wool and space dyed diamond velvet yarn are interwoven, the diamond velvet yarn does not have feltability, longitudinal creases are formed due to the feltability of the wool, and a visual transverse crease effect is formed after the diamond velvet yarn is subjected to space dyeing. The matching style is novel and unique, and the style of a common knitted fabric is fundamentally changed; the surface of the fabric is raised by using a light pilling process during post-finishing, the style characteristic to be expressed on the surface of the fabric is not covered, colors are regular, the texture of the fabric surface is irregular and creased, and the hand feeling of the novel high-grade fabric is close to that of cashmere.

Owner:IANGSU COLLEGE OF ENG & TECH

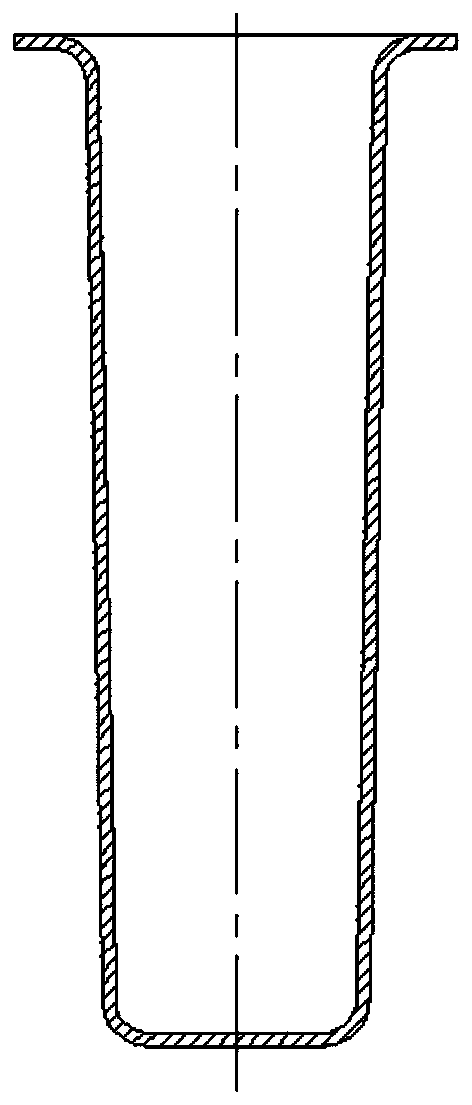

Ultra-high-molecular-weight polyethylene monofilament filter cloth and preparation method thereof

InactiveCN104492160AReduce processing costsShort processSpinnerette packsHeating/cooling textile fabricsEngineeringUltimate tensile strength

The invention discloses ultra-high-molecular-weight polyethylene monofilament filter cloth and a preparation method thereof. The filter cloth is in a single-layer structure or a double-layer structure, wherein warps of the filter cloth with the single-layer structure are woven by one monofilament and wefts are woven by another monofilament; the diameter of each monofilament is 0.07mm-0.2mm; the arraying ratio of exterior and interior warps to exterior and interior wefts of the filter cloth with the double-layer structure is 4 to 1; a tying method is a tying weft method; the warps of exterior tissues and interior tissues are woven by one monofilament and the wefts are woven by another monofilament; the diameter of the monofilament of each exterior tissue is 0.07mm-0.2mm and the tensile strength is more than 1100MPa; and the diameter of the monofilament of each tissue is 0.6mm and the tensile strength is more than 1000MPa. The monofilaments are woven by ultra-high molecular weight polyethylene through a melt spinning method, and are obtained by heat shaping and calendering treatment in sequence after weaving. The filter cloth disclosed by the invention has the advantages of high strength, good surface performance, long service life and the like; and the preparation process is simple and the cost is low.

Owner:王庆昭

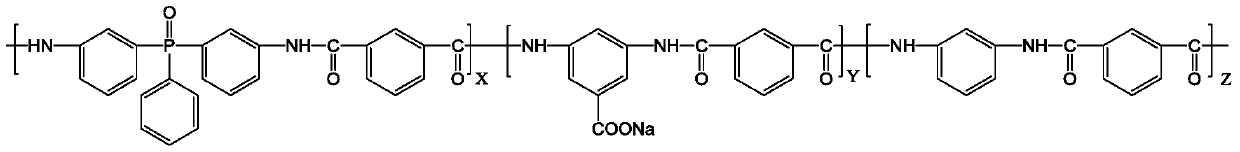

Dyeability modified meta-aramid fibers and preparation method therefor

InactiveCN110527082AIncrease capacityImprove dye uptake and color fastnessMonocomponent copolyamides artificial filamentWet spinning methodsSolubilityOxide

The invention discloses dyeability modified meta-aramid fibers and a preparation method therefor. According to the method, m-phthaloyl chloride, m-phenylenediamine, sodium 3,5-diaminobenzoate and bis(3-aminophenyl)phenylphosphorus oxide serve as monomers, a modified polymetaphenylene isophthamide spinning solution is prepared in an organic solvent by employing low-temperature polycondensation, andprepared fibers have good affinity and excellent flame retardance to cationic dyes; and carboxylic acid group containing 3,5-diaminobenzoic acid monomer is added during preparation and participates in copolymerization, and a carboxylic acid group is an anionic group and can be combined with the cationic dyes by ionic bonds so as to achieve dyeability of the cationic dyes. A spinning dope of the dyeability modified meta-aramid fibers prepared by the method has good solubility and spinnability, and prepared fibers maintain original high-temperature resistance and mechanical properties, have relatively high dye uptake in the cationic dyes and are sharp in color and good in light fastness.

Owner:YANTAI TAYHO ADVANCED MATERIALS

Process formula of emulsified liquid for refining linen fibers by pretreatment of wetting and oiling

The invention discloses a process formula of emulsified liquid for refining linen fibers by pretreatment of wetting and oiling. The formula comprises the following ingredients in percentage by weight, which are added in 100 parts of linen fibers: 1to 2 parts of softening agents, 0.8 to 1.5 parts of electrostatic agents, 0.5 part of kerosene and 10 to 15 parts of water, wherein the softening agents can be Peregal O, and the electrostatic agents are antistatic agent SN. The obtained process formula of emulsified liquid for refining linen fibers by pretreatment of wetting and oiling has the advantages of stable process, convenient operation, no influence from other conditions, low running cost and easy application to industrialization, and can thoroughly permeate the interior of the linen fibers to achieve the soft and smooth effect, which enhances the cohesive force among the linen fibers and improves the spinnability, thereby meeting the requirement on spinning.

Owner:TONGXIANG YIDE TEXTILE

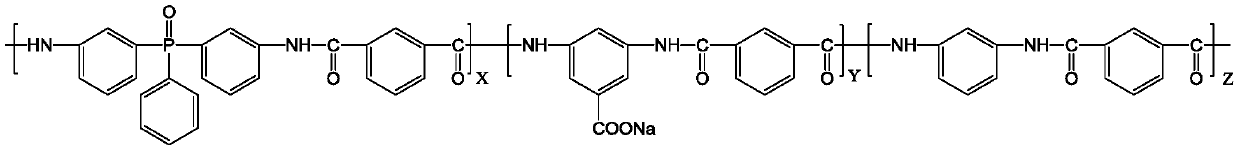

Energy-saving loose fiber cake opener

InactiveCN105316800AAvoid hurting handsReduce labor intensityFibre breaking machinesFibre breaking by toothed membersElectricityYarn

The invention discloses an energy-saving loose fiber cake opener which comprises an opening unit, a cotton bin unit and a feeding unit. The opening unit and the cotton bin unit are communicated, and the cotton bin unit and the feeding unit are communicated. The opening unit, the cotton bin unit and the feeding unit are provided with an opening bin, a cotton bin and a feeding bin respectively. A first belt type conveyor and an opening mechanism are arranged in the opening bin. A second belt type conveyor is arranged in the cotton bin. A third belt type conveyor is arranged in the feeding bin. A conveying belt on the third belt type conveyor is provided with a steel nail for conveying. The energy-saving loose fiber cake opener is characterized in that the opening mechanism comprises a first opening roller, a second opening roller and a third opening roller, the outer circles of the first, second and third opening rollers are provided with radial steel nails respectively, and one ends of the first, second and third opening rollers are connected with first, second and third power mechanisms through a transmission mechanism respectively. By the adoption of the opener, the processed loose fiber is good in quality, the spinning requirement for high-quality cotton yarn can be met, and the opener saves electricity, does not injure hands, and is low in labor intensity, high in production efficiency and suitable for opening dehydrated cotton loose fiber cakes.

Owner:WUXI QIANZHOU YAODA MACHINERY FACTORY

Pretreatment process of deodorization cotton

InactiveCN102493023AHigh moisture regainIncrease cohesionFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersPre treatmentEngineering

The invention relates to the textile technical field, in particular to a pretreatment process of deodorization cotton. The process comprises the following process steps: 1) cotton conveying shutters are used to send deodorization cotton to a vibration opener; 2) a kirschner beater is used to perform first opening on the deodorization cotton; 3) Brad shutters are used to convey the deodorization cotton to an evener roller to perform second opening; 4) Brad shutters are used to send the deodorization cotton to a stripper roller to peel the deodorization cotton from the Brad shutters; 5) after the obtained deodorization cotton passes through a left vibration plate and a right vibration plate, the deodorization cotton is output to a container by a pair of cotton outputting rollers; and 6) after the output deodorization cotton is humidified uniformly, the combed sliver broken by a breaker is packaged and boxed. Compared with the prior art, the vibration opener is used to perform opening on the deodorization cotton twice and the output deodorization cotton is humidified uniformly, thus the moisture regain of the deodorization cotton can be increased, the cohesive force of the deodorization cotton fiber can be increased and the deodorization cotton becomes more fluffy. Therefore, the deodorization cotton can meet the spinning requirement.

Owner:SHANGHAI SHENAN TEXTILE

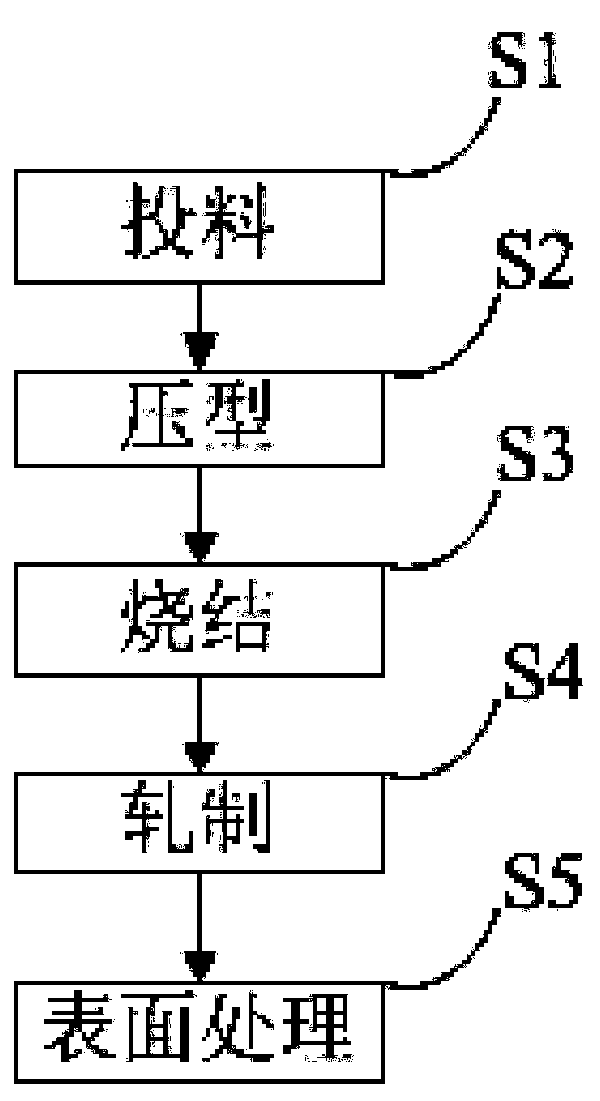

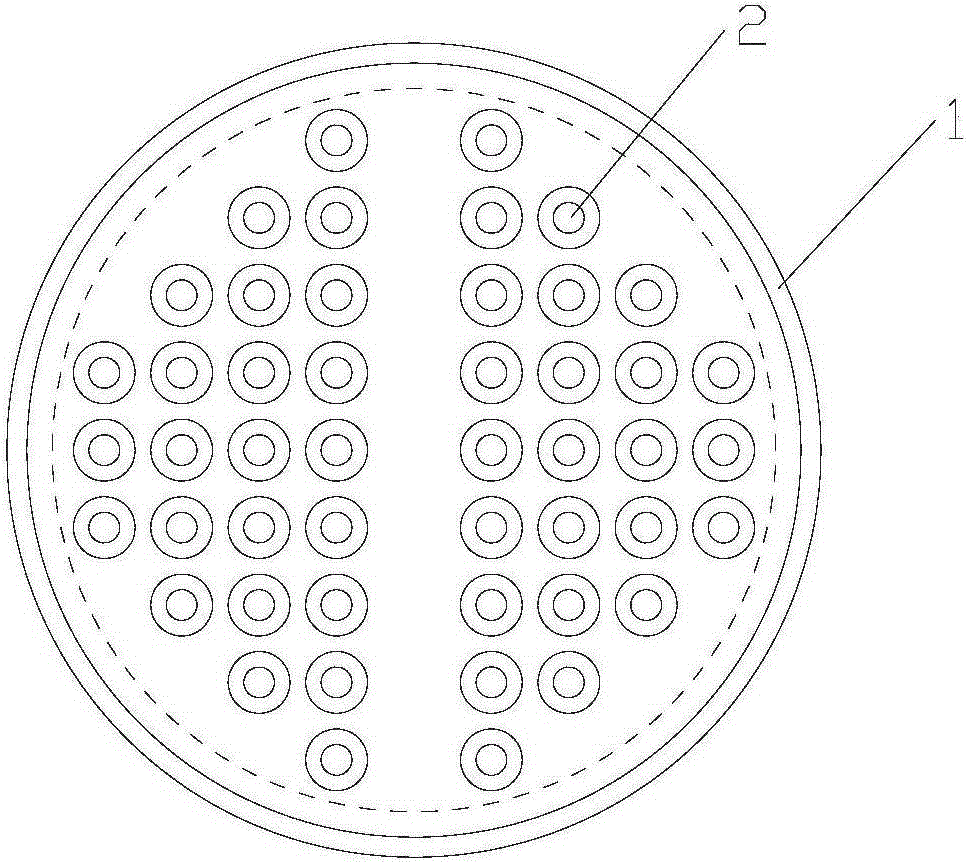

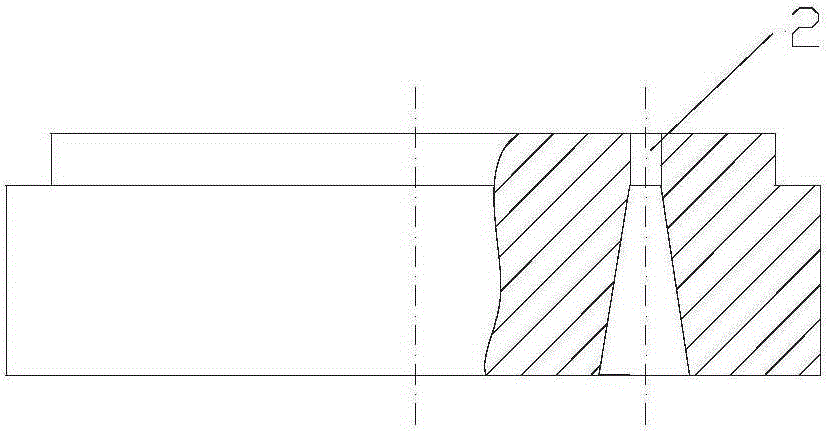

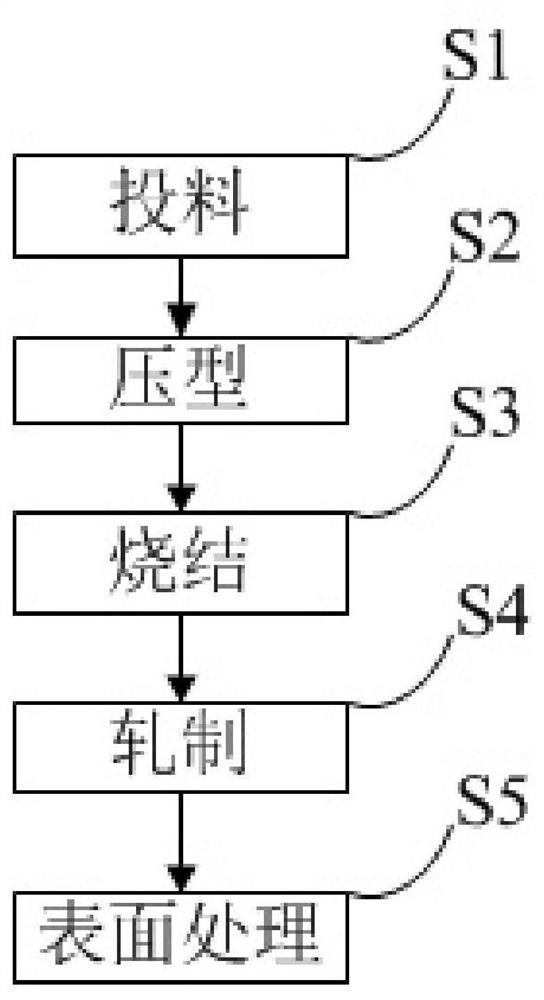

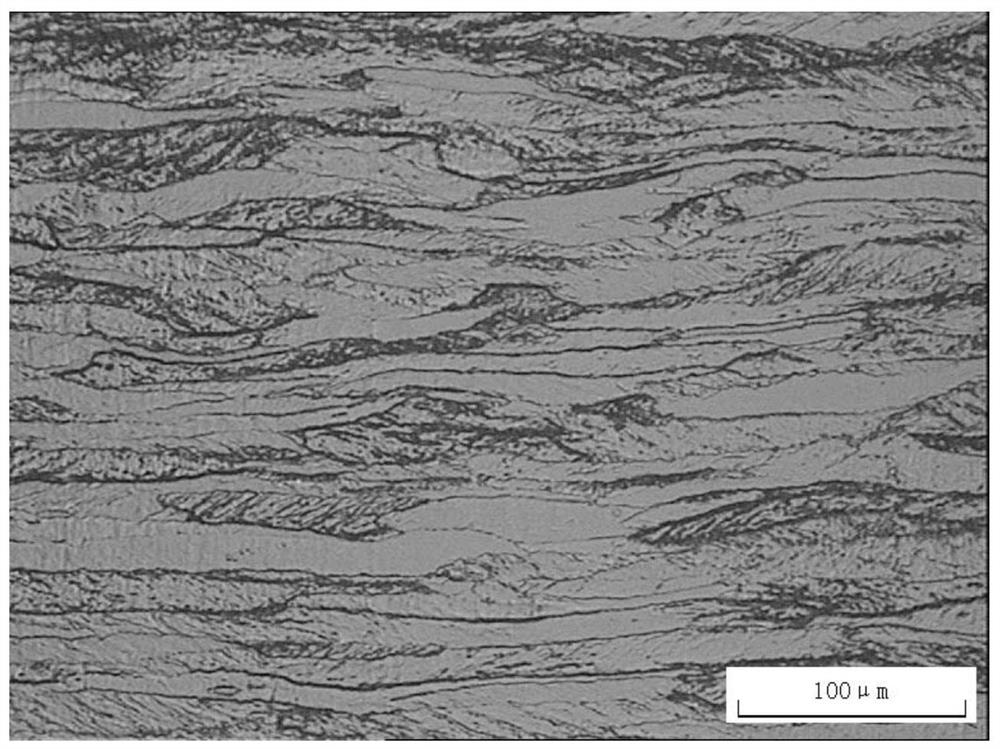

Rolling method of molybdenum plate for spinning large-length-diameter-ratio molybdenum crucible

ActiveCN109894472AImprove bindingQuality improvementMetal rolling arrangementsDiameter ratioBinding force

The invention provides a rolling method of a molybdenum plate for spinning a large-length-diameter-ratio molybdenum crucible. The method comprises firstly, a proper mold is selected according to the size of a required molybdenum slab to carry out powder loading, then compression molding is carried out on the mold containing the powder to prepare the slab, then sintering is carried out on the pressed slab, large-deformation rolling is carried out on the sintered slab by using a cross rolling method, so that the binding force between the internal tissues of the slab is improved, isotropic fine fiber tissues can be obtained through cross rolling, moreover, the longitudinal and transverse tissues are in staggered lap joint, so that the tissues are more uniform, the defects which are generateddue to the fact that the stress is not uniform in all directions can be effectively avoided, and favorable conditions are provided for follow-up spinnin. According to the rolling method, the molybdenum raw material slab is processed by adopting the cross rolling method of isostatic cool pressing, sintering and large deformation, so that the spinning requirement of the large-length-diameter-ratio molybdenum crucible is met, and important significance on the production of the large-length-diameter-ratio molybdenum crucible is achieved.

Owner:安泰天龙钨钼科技有限公司 +1

Method for manufacturing cellulose/ion liquid spinning liquid with double-screw extrusion machine

InactiveCN101220522BShorten the dissolution timeEasy to industrializeArtificial filaments from cellulose solutionsSpinning solutions preparationDiameter ratioEngineering

The invention relates to a method for using a double screw extruder to prepare celluloses / ionic liquids spinning solution and the preparation comprises that the celluloses are uniformly mixed with the ionic liquids according to the weight ratio of 5:95 to 25:75, and then the mixture is put into the double screw extruder which has two vacuum orifices and the screw length diameter ratio of which is36:1 to 60:1, the control range of temperature is 40 to 120 DEG C, and the light brown and transparent celluloses / ionic liquids spinning solution is formed after strongly mixing and dissolving for 8 to 40 minutes and vacuum dehydration; the obtained celluloses / ionic liquids spinning solution is supercharged by a booster pump and sprayed from a spinneret after coming into a metering pump by a pre-filter, and then cellulose fibers are formed by a plurality of steps such as solidification, washing, cutting and drying, etc. The invention not only shortens the dissolution time of the celluloses but also leads to the more fully mixing and dissolving of materials, and achieves the purposes of energy-saving, high efficiency, decreasing degradation and improving the quality of spinning original solution, so the industrialization becomes easier.

Owner:DONGHUA UNIV +1

Fiber pretreatment device and method

InactiveCN102453982BImprove spinnabilityReduce labor intensityContinuous processingLiquid/gas/vapor removalYarnFiber

Owner:上海第三十六棉纺针织服装厂有限公司

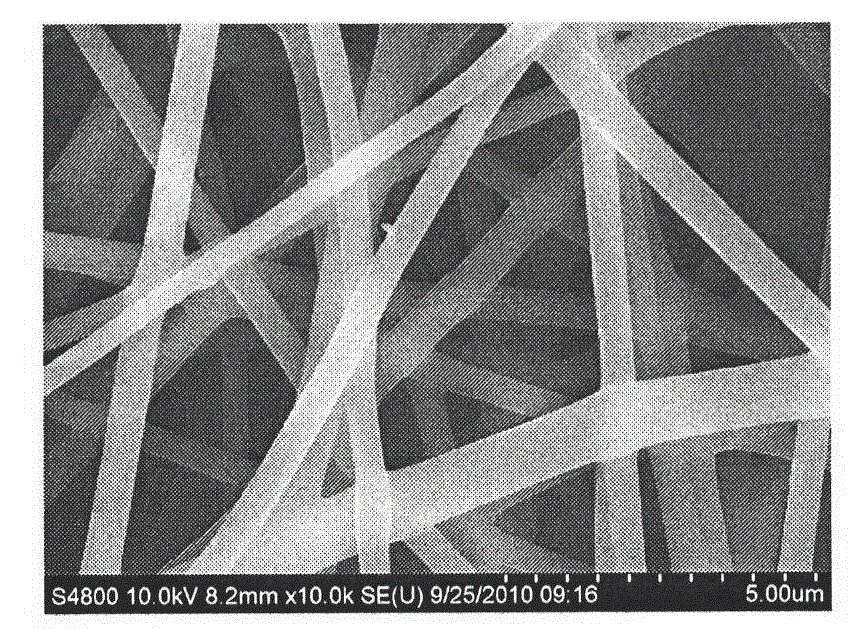

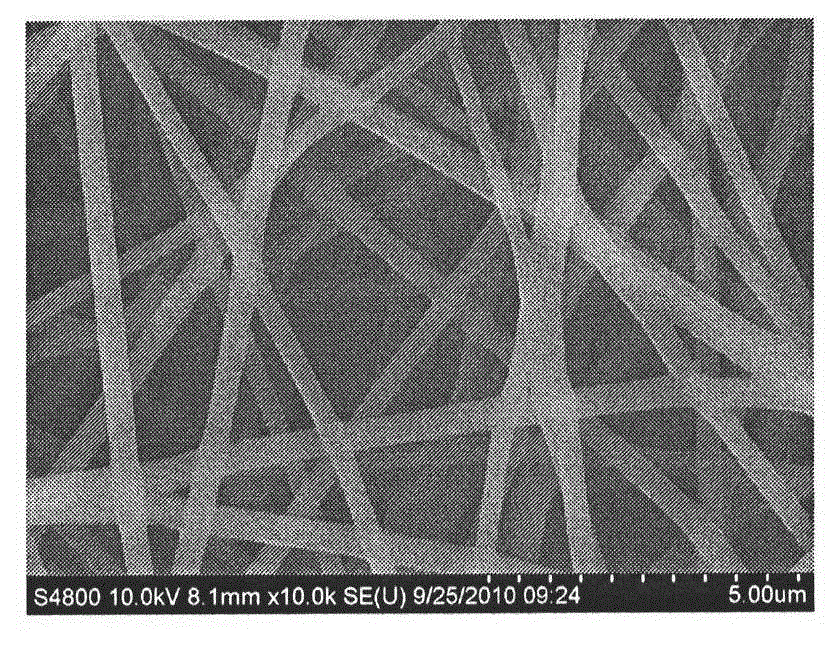

Water treatment sponge material

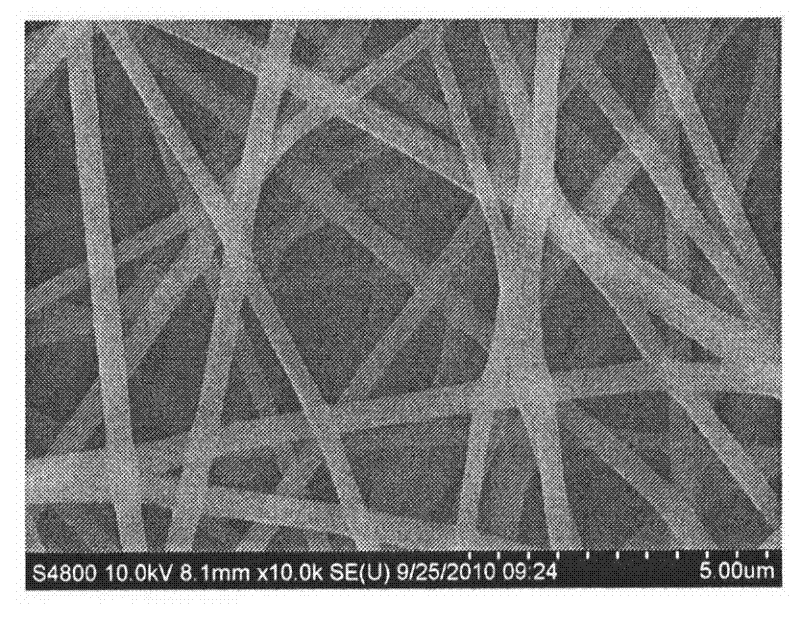

InactiveCN105297181AImprove adsorption capacityHigh strengthOther chemical processesFibre typesFiberPolyester

The invention discloses a water treatment sponge material. Modified polyester undergoes melt-blown spinning and is braided to obtain water treatment sponge, and a modifier is added to regulate the structure of a fiber and improve the strength of the fiber; a cross-linking layer is formed on the surface of the fiber through rapid cross-linking, and nano-particles are introduced to further guarantee the strength of the fiber and improve the adsorption capacity of the water treatment sponge. The above water treatment fiber disclosed in the invention has a large content of oil suction groups, the application range of the water treatment sponge made by using the water treatment fiber can be greatly widened, and the water treatment sponge plays a positive role in the field of organic liquid pollution treatment; and a preparation method of the water treatment sponge material has the advantages of simplicity, easy operation and short preparation time, and the water treatment sponge prepared through the method has the characteristics of excellent adsorption performance, good strength, small density and repeated use, and is suitable for industrial production.

Owner:孟森

Cradle pressurizing component

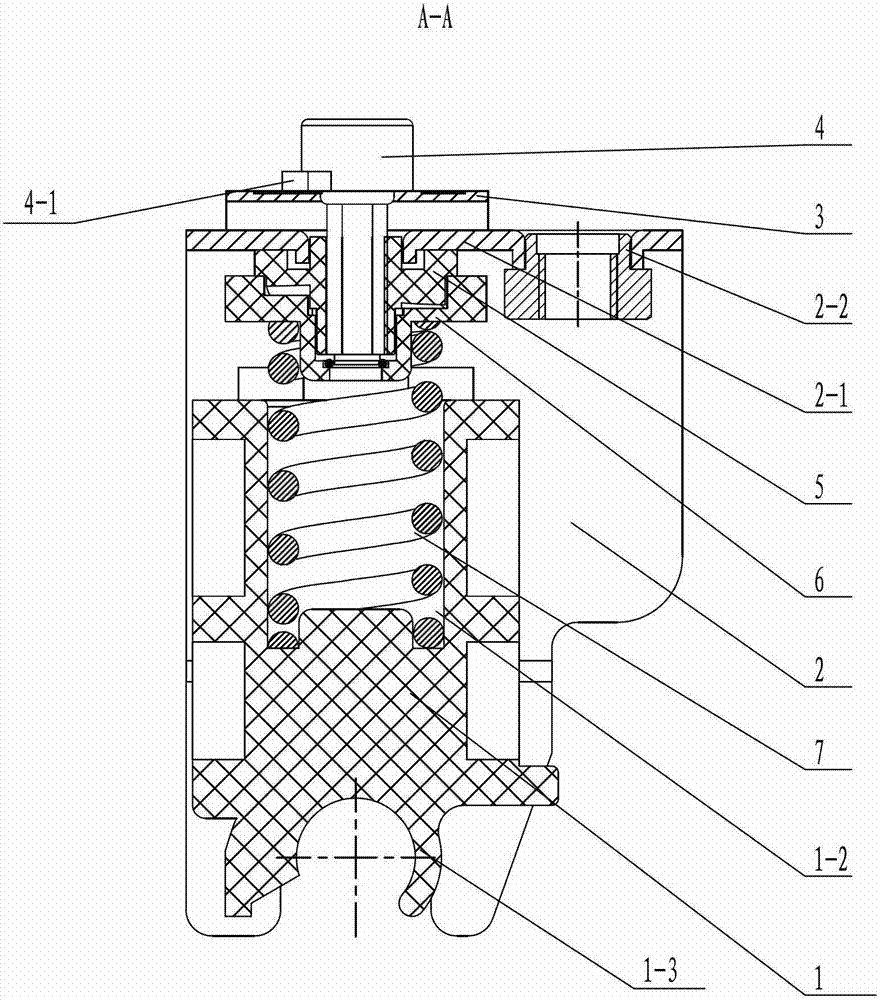

ActiveCN102691146BImprove parallelismPlay a guiding roleDrafting machinesEngineeringMechanical engineering

The invention relates to a cradle pressurizing component, which comprises a parallel bracket, a roller seat, a spring and a pressure regulating mechanism, wherein a through hole and a mounting hole are arranged in the top plate of the parallel bracket, the upper parts of two side plates of the parallel bracket are provided with upper notches, and the lower parts of the two side plates of the parallel bracket are provided with lower notches; the bottom of the roller seat is provided with a roller claw, and guiding bulges on two sides of the roller seat are arranged in the upper notches arranged on the upper parts of the two side plates and can move up and down; the pressure regulating mechanism comprises an indicator board, a pressure regulating rod, an upper pressure regulating block and a lower pressure regulating block, the indicator board is arranged on the parallel bracket, the pressure regulating rod with a pressure pointer is connected with the upper pressure regulating block, the indicator board is provided with a gears indicating sign, the upper pressure regulating block is arranged in the lower pressure regulating block and can be rotated, one upper pressure regulating plane of the upper pressure regulating block is connected with one lower pressure regulating plane of the lower pressure regulating block, and the spring arranged in the roller seat is propped on the lower pressure regulating block. The cradle pressurizing component disclosed by the invention has a reasonable structure, the pressure regulating operation is simple and convenient, and the requirement on degree of parallelism of the roller can be met.

Owner:常州市同和纺织机械制造有限公司

Surface treatment method of tantalum spinneret

ActiveCN108531906BReduce roughnessImprove the finishSpinnerette packsElectrolytic inorganic material coatingSpinningElectrolysis

A surface treatment method for a tantalum spinneret for wet spinning, characterized in that: comprising the following steps: (a) processing a metal tantalum plate into a tantalum spinneret; (a) 1 The tantalum spinneret prepared in step (a) is subjected to nitriding treatment or non-nitriding treatment according to the method of step (b) of the inventor's patent ZL02106915.8, and directly enters the next step (b) of the present invention. (b) The method of making tantalum anode with prior art tantalum electrolytic capacitor generates a layer of suitable amorphous Ta on the tantalum spinneret 2 o 5 (c) polishing: the surface of the tantalum spinneret processed in step (b) is polished to remove the insulating amorphous Ta 2 o 5 Film (d) coating, a layer of amorphous Ta 2 o 5 The tantalum spinneret of the film is coated with a molten salt electrochemical method to form a film layer containing a lithium-containing compound; (e) polishing: the tantalum spinneret processed in step (d) The surface is polished to remove the insulating lithium-containing compound film on the surface of the wire outlet.

Owner:BEIJING HUAYU CHUANGXIN TA NB SCI&TECH CO LTD +1

Polyester chip for producing vehicle-mounted perfume rods and fiber pen points and preparation method of polyester chip

PendingCN113736070AImprove firmnessLarge specific heat capacityMonocomponent polyesters artificial filamentArtifical filament manufactureIn vehiclePolyester

The invention discloses a polyester chip for producing a vehicle-mounted perfume rod and a fiber pen point and a preparation method thereof. The preparation method comprises the steps that firstly, the polyester chip meeting the technological requirement is synthesized, specifically, a semi-continuous production synthesis device is adopted, and an acid isomer and an alcohol homologue are introduced in the esterification reaction process to improve the melting range of a product; then, a dihydric alcohol alcoholysis and blending melting control process is adopted in the secondary esterification reaction, and a modification additive is prepared into a liquid mixture capable of participating in polymerization, so that the final crystallization property of the product is improved; finally, the target polyester chip base material is synthesized with the intrinsic viscosity of 0.700-0.730 dl / g by compounding a catalyst by controlling the reaction temperature and the vacuum degree; and solid-phase crystallization is carried out on the synthesized product to complete pre-crystallization of polyester chips, and then the polyester chips are dried under the conditions of program temperature control, vacuum state and the like, wherein the moisture content of the dried polyester chips is not higher than 0.05%, and the intrinsic viscosity is not lower than 0.670 dl / g to produce the polyester chips meeting the production requirements of vehicle-mounted perfume rods and fiber pen points.

Owner:TIANJIN HUAXIN YINGJU POLYESTER MATERIAL SCI & TECH

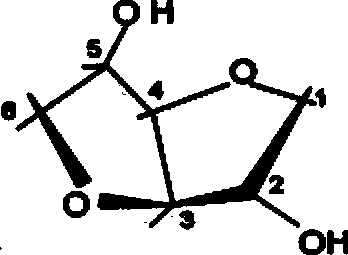

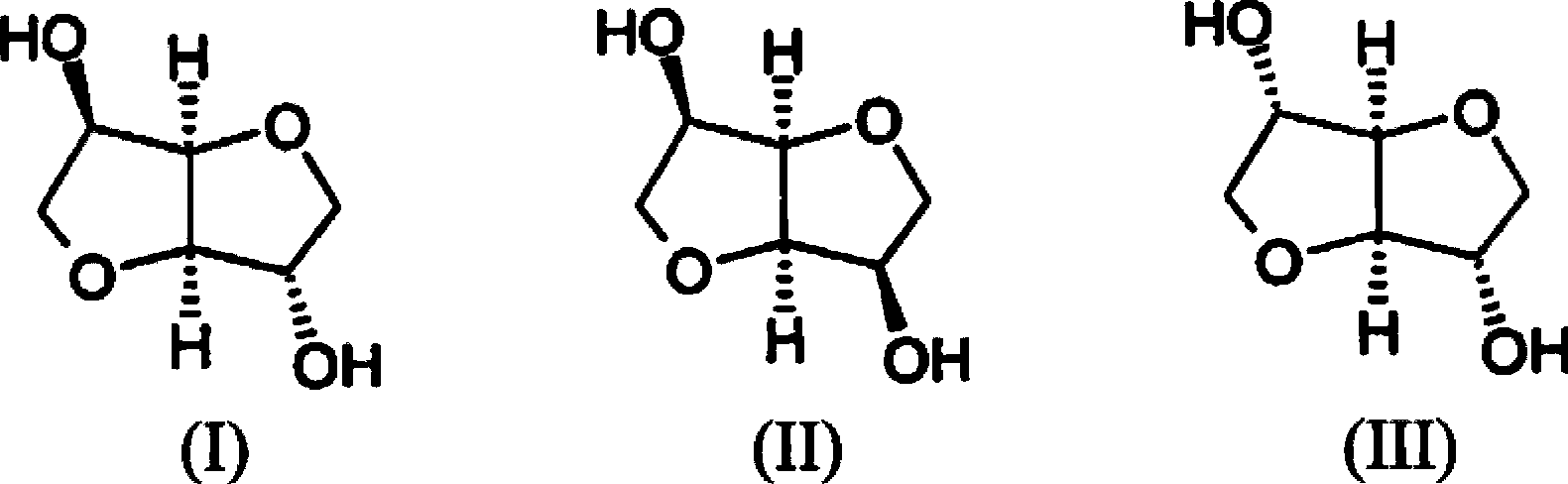

A kind of preparation method containing dianhydrosugar alcohol copolyester

ActiveCN103044671BHigh strengthEasy to processMonocomponent copolyesters artificial filamentFiberAlcohol sugars

The invention provides a preparation method for bis-anhydro sugar alcohol contained copolyester. The method comprises the following steps: (1) aromatic binary acid, fatty dihydric alcohol and reaction assistant are esterified after being fully mixed; and (2) when the esterification is implemented until the esterification rate is high above 90%, bis-anhydrohexitol solution is added, and is condensed and polymerized after being fully mixed and reacted in a reaction system so as to obtain bis-anhydrohexitol contained polyester, wherein the intrinsic viscosity of the bis-anhydrohexitol contained polyester is high above 0.6. The method can obtain high-molecular weight polymer copolyester, can satisfy the spinning requirements to meet the demands of clothes fiber material production, can further satisfy the fiber application requirements in the industrial field, and can synchronously apply and develop the high-performance material aspect in the non-fiber field.

Owner:CHINESE TEXTILE ACAD

A kind of industrial purification method of fiber grade methanol protein

ActiveCN107805613BEfficient wall breakingHigh yieldFungiMicroorganism lysisProtein solutionPichia pastoris

Owner:义马煤业集团煤生化高科技工程有限公司

A kind of water treatment sponge material

InactiveCN105297181BImprove adsorption capacityHigh strengthOther chemical processesFibre typesFiberPolyester

The invention discloses a water treatment sponge material. Modified polyester undergoes melt-blown spinning and is braided to obtain water treatment sponge, and a modifier is added to regulate the structure of a fiber and improve the strength of the fiber; a cross-linking layer is formed on the surface of the fiber through rapid cross-linking, and nano-particles are introduced to further guarantee the strength of the fiber and improve the adsorption capacity of the water treatment sponge. The above water treatment fiber disclosed in the invention has a large content of oil suction groups, the application range of the water treatment sponge made by using the water treatment fiber can be greatly widened, and the water treatment sponge plays a positive role in the field of organic liquid pollution treatment; and a preparation method of the water treatment sponge material has the advantages of simplicity, easy operation and short preparation time, and the water treatment sponge prepared through the method has the characteristics of excellent adsorption performance, good strength, small density and repeated use, and is suitable for industrial production.

Owner:孟森

Spring cradle

ActiveCN102704063BImprove loading and unloading efficiencyEasy to operateDrafting machinesLocking mechanismEngineering

The invention relates to a novel spring cradle. A compression seat is hinged on a cradle seat body, a connecting bolt penetrates through a fixed block in the cradle seat body and is screwed on a nut of the compression seat, the arc surface of the cradle seat body and the arc surface of the compression seat form a supporting rod shaft hole, and a raised V-shaped positioning block is arranged on the arc surface of the compression seat; a locking mechanism comprises a supporting sheet and a locking sheet; a pressing assembly comprises parallel brackets, leather roller seats, springs and pressure adjusting mechanisms; and the leather roller seats are arranged in the parallel brackets and guided by the parallel brackets, a leather roller claw connected with a leather roller shaft is arranged at the bottom of each leather roller seat, indicating plates of the pressure adjusting mechanism are arranged on the parallel brackets, pressure adjusting rods are connected with upper pressure adjusting blocks, the upper pressure adjusting planes of the upper pressure adjusting blocks in work are connected with the lower pressure adjusting planes of lower pressure adjusting blocks, pressure gear indicating marks are arranged on the indicating plates, and the springs arranged in the leather roller seats press against the lower pressure adjusting blocks. The spring cradle is reasonable in structure and simple and convenient in pressure adjusting operation, and leather rollers can keep parallel and have auxiliary pressure adjusting functions.

Owner:常州市同和纺织机械制造有限公司

A kind of preparation method of dope dyed elastic polyester fiber

ActiveCN109082726BDistributePlay a role in toughening and elasticizingPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention provides a method for preparing stock solution dyed elastomeric polyester fiber. The method includes: preparing a colorant and an elastomer toughening agent into PET (polyester) masterbatch; then adding the PET masterbatch into a PET spinning stock solution for stock solution dyeing to obtain the dyed elastomeric polyester fiber directly by spinning. In the method, the colorant and the elastomer toughening agent are taken as the masterbatch and added to the spinning stock solution of the polyester fiber, and technical problems existing in dyeing properties and resilience broughtby the fact that traditional fiber needs to be dyed with dyes after forming are solved; the method is simple in operation and favorable for environmental friendliness, and the obtained polyester fiberis high in color fastness, bright in color, soft in handfeel and good in resilience.

Owner:BEIJING UNIV OF CHEM TECH

Device and method for judging quality of regenerated raw materials through filtering pressure difference

PendingCN111795924AMeet spinning requirementsMeet the requirement of melt filtrationSpinning solution de-aeratingSpinning head liquid feederSpinningPhysical chemistry

The invention relates to a device and method for judging the quality of regenerated raw materials through filtering pressure difference, and belongs to the field of light industry spinning and regenerated polyester filament yarn production. The device comprises a shell, a screw rod, a screw rod sleeve, a heating sleeve, a metering pump, a filter screen inserting plate, a discharging hopper, a discharging pipe and a cooling water pipe. The screw rod is installed in the shell, the screw rod sleeve is installed on the screw rod in a sleeving mode, the heating sleeve is installed on the screw rodsleeve in a sleeving mode, the metering pump is installed on the shell, the filter screen inserting plate is installed on the metering pump, the discharging hopper is connected with the discharging pipe, the discharging pipe is connected with the shell, and the cooling water pipe makes contact with the discharging pipe. The discharging hopper is enlarged, so the discharging is smooth. Due to the fact that some regeneration raw materials are not small pieces of particles, the density is small, and the weight is light, discharging is not smooth. A cooling water pipe is added to protect smooth discharging of a discharging pipe, and due to the fact that the temperature of a discharging opening is too high, abnormal discharging is caused by the fact that raw materials are carbonized on a screw.

Owner:嘉兴海利再生塑业有限公司

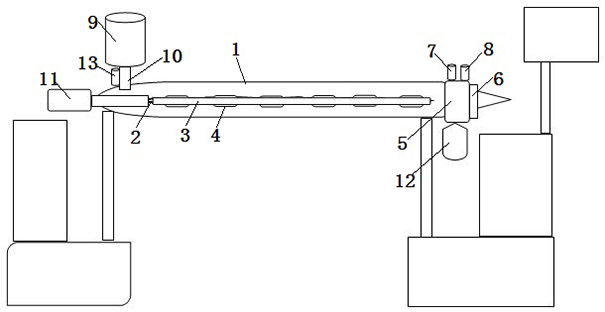

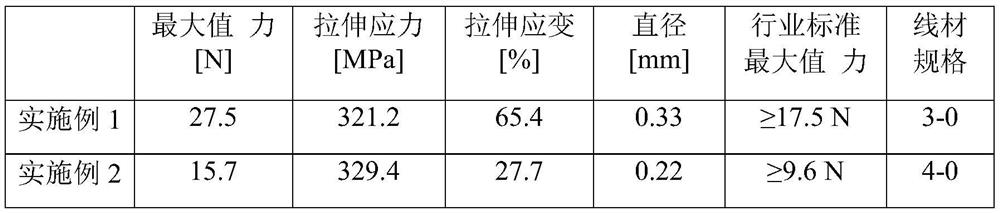

Biomedical poly(4-hydroxybutyrate) absorbable surgical suture and preparation method thereof

PendingCN113368297APromote degradationGuaranteed mechanical propertiesSuture equipmentsFibre typesHuman bodyMedical equipment

The invention discloses a biomedical poly(4-hydroxybutyrate) absorbable surgical suture and a preparation method thereof, belongs to the technical field of preparation of biomedical absorbable surgical sutures, and provides a method for preparing a high-strength, functional and absorbable surgical suture by using domestic autonomously innovated biomedical raw materials and a process technology. The technical problem that most biomedical materials in China depend on import and medical equipment preparation is solved, and foreign monopoly is broken fundamentally. The biomedical poly(4-hydroxybutyrate) absorbable surgical suture is prepared from the raw materials in parts: 90-95 parts of biomedical grade poly(4-hydroxybutyrate)(P4HB), 1-3 parts of a nucleation inducer, 1-2 parts of a natural antioxidant and 0-2 parts of a chain extender. The preparation method comprises the following steps that firstly, a P4HB modified material is prepared by adopting proper process temperature and shearing conditions, and then surgical suture wires with different specifications are prepared by adopting a melt spinning method through two-stage stretching and surface coating spraying. Compared with a P4HB suture obtained by an imported biological fermentation method, the biomedical poly(4-hydroxybutyrate) absorbable surgical suture has similar mechanical properties, is low in cost and stable in quality, and has more excellent human body compatibility and in-vivo degradability.

Owner:青岛博远高分子材料研究院有限公司

Ultra-high molecular weight polyethylene monofilament filter cloth and preparation method thereof

InactiveCN104492160BReduce processing costsShort processSpinnerette packsHeating/cooling textile fabricsPolymer scienceUltimate tensile strength

The invention discloses an ultra-high molecular weight polyethylene monofilament filter cloth and a preparation method thereof. The filter cloth has a single-layer structure or a double-layer structure; the filter cloth in the form of a single-layer structure has a warp thread woven by a single monofilament, The weft is woven from another monofilament, and the diameter of the monofilament is 0.07-0.2mm; the filter cloth with double-layer structure has an arrangement ratio of 4:1 between the outer and inner warp and the outer and inner weft, and the binding method is joint Weft-knotting method, the warp of the surface tissue and the inner structure are respectively woven from one monofilament, and the weft is woven from another monofilament; the diameter of the monofilament of the above-mentioned surface tissue is 0.07-0.2mm, and the tensile strength is above 1100MPa ; The diameter of the monofilament in the tissue is 0.6mm, and the tensile strength is above 1000MPa. The above-mentioned monofilaments are all spun from ultra-high molecular weight polyethylene by melt spinning method, and are processed by heat setting and calendering in turn after weaving. The filter cloth of the invention has the advantages of high strength, good surface performance, long service life, etc., and the preparation process is simple and the cost is low.

Owner:王庆昭

Antibacterial meta-aramid fiber and preparation method thereof

PendingCN113981560ASolve the problem of low dispersionAvoid reunionArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceMesoporous material

The invention discloses an antibacterial meta-aramid fiber and a preparation method thereof. The preparation method comprises the following steps: dispersing a mesoporous material in a silver nitrate solution, heating and dipping, washing with water, filtering and drying to obtain a mesoporous material loaded with silver ions; calcining the silver ion-loaded mesoporous material, cooling, dispersing in water, adding a reducing agent, washing, filtering, and drying to obtain the mesoporous material silver-loaded antibacterial agent. carrying out polymerization reaction on m-phenylenediamine and isophthaloyl chloride to generate a polyisophthaloyl m-phenylenediamine polymer solution; adding a mesoporous material silver-loaded antibacterial agent into a polyisophthaloyl metaphenylene diamine polymer solution, uniformly mixing, and carrying out solidification forming, water washing, drying, hot stretching and heat setting to obtain the antibacterial meta-aramid fiber.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

A kind of production method of yak wool and spun silk blending

The invention discloses a production method of a yakwool and spun silk blended yarn, and belongs to the technical field of spinning. The yakwool and spun silk blended yarn is prepared through the process of wool blending, wool carding, spinning, spooling, doubling and two-for-one twisting. Compared with the prior art, the yakwool and spun silk blended yarn is added in the method, through the highstrength advantage of spun silk, in cooperation of a small ratio of spun silk, the spinning requirements can be met, the style of yakwool is kept to the maximum extent, and meanwhile the specific color, luster and hand feel of spun silk can be embodied, the application range of yakwool fibers is expanded, and the current situation that a yakwool product is monotonous is broken.

Owner:CONSINEE GRP CO LTD

High-speed spinning device capable of reducing hairiness

PendingCN113322551AIncrease spinning speedGuaranteed twisting qualityContinuous wound-up machinesOpen-end spinning machinesPhysicsYarn

The invention discloses a high-speed spinning device capable of reducing hairiness. The high-speed spinning device comprises a top air supply device; a blending chamber is arranged below the top air supply device; twisting devices are arranged on the outer wall of the upper portion of the blending chamber in the circumferential direction; pinch twisting adjusting devices are arranged on the inner wall of the upper portion of the blending chamber in the circumferential direction; the pinch twisting adjusting devices and the twisting devices are arranged in a one-to-one correspondence mode; a pinch twisting traction device is arranged at the bottom of the blending chamber; and a dust collection box is arranged outside the lower portion of the blending chamber. The invention relates to the technical field of textile equipment. According to the high-speed spinning device capable of reducing the hairiness, through the arrangement of the blending chamber, the twisting devices, the pinch twisting adjusting devices and the pinch twisting traction device, continuous cotton slivers subjected to drawing are fed from the outer end of the twisting devices and twisted through the twisting devices, two-way pinch twisting of preliminary spun yarn is conducted through the pinch twisting adjusting devices, and twisting or blending is conducted in the blending chamber, so that the problems that most mechanical spinning is relatively low in spinning speed and generates more floating dust, and yarn spun by air-flowing spinning is relatively low in strength and relatively long in hairiness can be solved.

Owner:王明远

Surface treatment method of tantalum spinning nozzle

ActiveCN108531906AReduce roughnessImprove the finishSpinnerette packsElectrolytic inorganic material coatingLithiumElectrolysis

A surface treatment method of a tantalum spinning nozzle is characterized by comprising the following steps: (a) processing a metal tantalum sheet to produce the tantalum spinning nozzle; (a1), processing the tantalum spinning nozzle manufactured in step (a) by nitriding based on the method in step (b) of the patent ZL02106915.8 of the inventor, or skipping processing and directly entering the next step (b); (b) forming a proper amorphous Ta2O5 film on the tantalum spinning nozzle by a method for manufacturing a tantalum anode through a tantalum electrolyzing capacitor in the prior art; (c) polishing: polishing a silk yielding surface of the tantalum spinning nozzle processed in step (b), and grinding to remove the insulated amorphous Ta2O5 film on the surface of the silk yielding surface;(d) coating: coating the tantalum spinning head which is provided with the amorphous Ta2O5 film by anode oxidizing so as to form a film containing a lithium-containing compound; (e) polishing: polishing the silk yielding surface of the tantalum spinning nozzle processed in step (d), and grinding to remove the insulated film layer containing the lithium-containing compound on the silk yielding surface.

Owner:BEIJING HUAYU CHUANGXIN TA NB SCI&TECH CO LTD +1

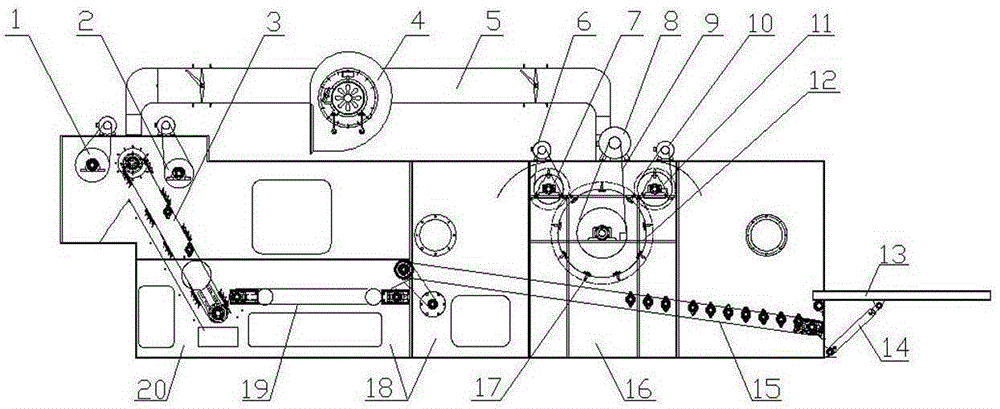

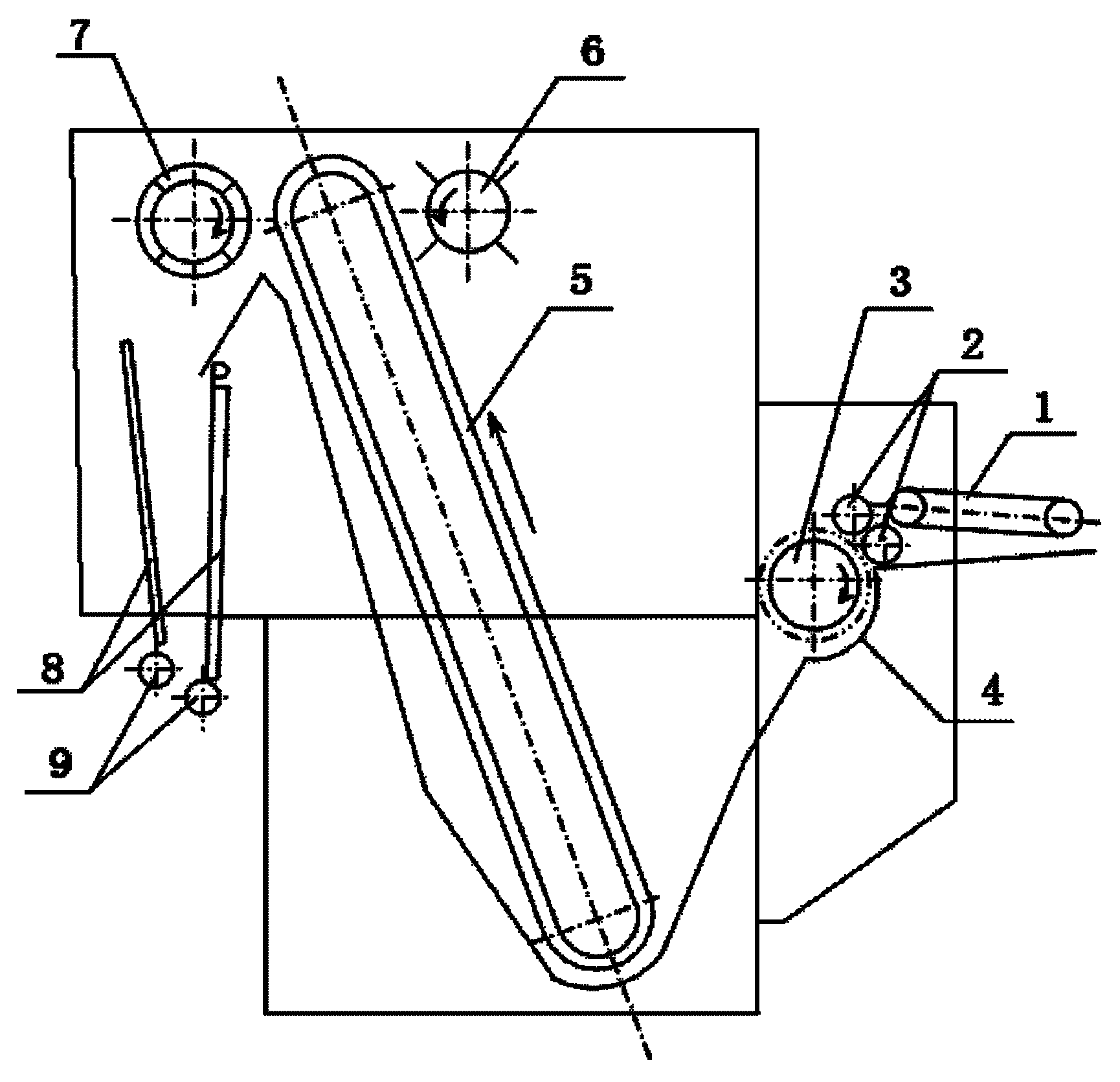

Automatic fibre humidifying and pre-processing device and processing method thereof

InactiveCN102454074BImprove spinnabilityReduce labor intensityTextile treatment machine partsTextile treatment by spraying/projectingFiberEngineering

The invention discloses an automatic fibre humidifying and pre-processing device and a processing method thereof. The automatic fibre humidifying and pre-processing device comprises a cotton feeding machine (1), a fur machine (2), a fan (3), a cotton conveying channel (4), an automatic humidifying device (5) and a fur cabin (6). The cotton feeding machine (1), the fur machine (2), the fan (3), the cotton conveying channel (4) and the fur cabin (6) are connected through a pipeline in sequence. The automatic humidifying device (5) is connected with the cotton conveying channel (4). The automatic fibre humidifying and pre-processing device further comprises a backflow fan (8). The backflow fan (8) is connected to the fur cabin (6) and the fur machine (2) through a pipeline. According to the automatic fibre humidifying and pre-processing device and the processing method thereof disclosed by the invention, the fibre pre-processing humidification which is artificially carried out for a longtime is changed; the labour operation intensity is reduced; the disadvantage of being incapable of continuously producing while humidifying resulted from artificial humidification is overcome; the backflow step, namely the secondary humidifying step, is increased; therefore, the fibre pre-processing can satisfy spinning requirements better; and the fibre spinnability is increased.

Owner:上海第三十六棉纺针织服装厂有限公司

A rolling method of molybdenum plate for molybdenum crucible spinning with large length-to-diameter ratio

ActiveCN109894472BImprove bindingQuality improvementMetal rolling arrangementsCompression moldingFiber

The invention provides a rolling method of a molybdenum plate for spinning a large-length-diameter-ratio molybdenum crucible. The method comprises firstly, a proper mold is selected according to the size of a required molybdenum slab to carry out powder loading, then compression molding is carried out on the mold containing the powder to prepare the slab, then sintering is carried out on the pressed slab, large-deformation rolling is carried out on the sintered slab by using a cross rolling method, so that the binding force between the internal tissues of the slab is improved, isotropic fine fiber tissues can be obtained through cross rolling, moreover, the longitudinal and transverse tissues are in staggered lap joint, so that the tissues are more uniform, the defects which are generateddue to the fact that the stress is not uniform in all directions can be effectively avoided, and favorable conditions are provided for follow-up spinnin. According to the rolling method, the molybdenum raw material slab is processed by adopting the cross rolling method of isostatic cool pressing, sintering and large deformation, so that the spinning requirement of the large-length-diameter-ratio molybdenum crucible is met, and important significance on the production of the large-length-diameter-ratio molybdenum crucible is achieved.

Owner:安泰天龙钨钼科技有限公司 +1

Stock solution for spinning phenolic fibers (PFs) and preparation method for stock solution

ActiveCN102532444BGood dispersionSynthetic conditions are mild and controllableMonocomponent synthetic polymer artificial filamentFiberPolyvinyl alcohol

The invention relates to a stock solution for spinning phenolic fibers (PFs). The stock solution comprises the following raw materials: phenol, a 30 to 40 weight percent formaldehyde solution, a 6 to 18 weight percent polyvinyl alcohol (PVA) solution and a catalyst in a mass ratio of 100:(90-200):(40-250):(8-40). The stock solution has the advantages that: spinnability is high, the spinnable viscosity interval is wide, and the intrinsic properties of the PFs are not influenced by an additive.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com