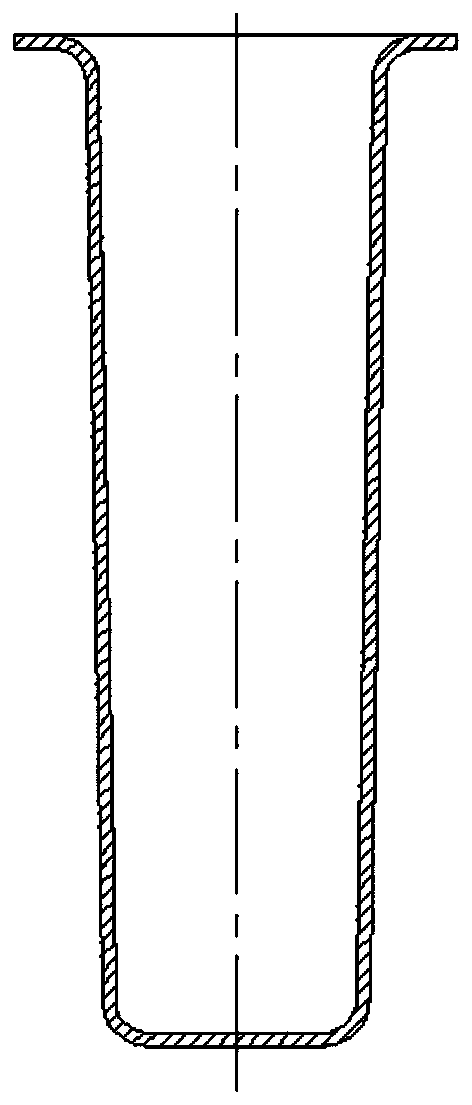

Rolling method of molybdenum plate for spinning large-length-diameter-ratio molybdenum crucible

A large aspect ratio, molybdenum crucible technology, applied in the direction of metal rolling, can solve the problems of unfavorable spinning deformation, poor ductility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

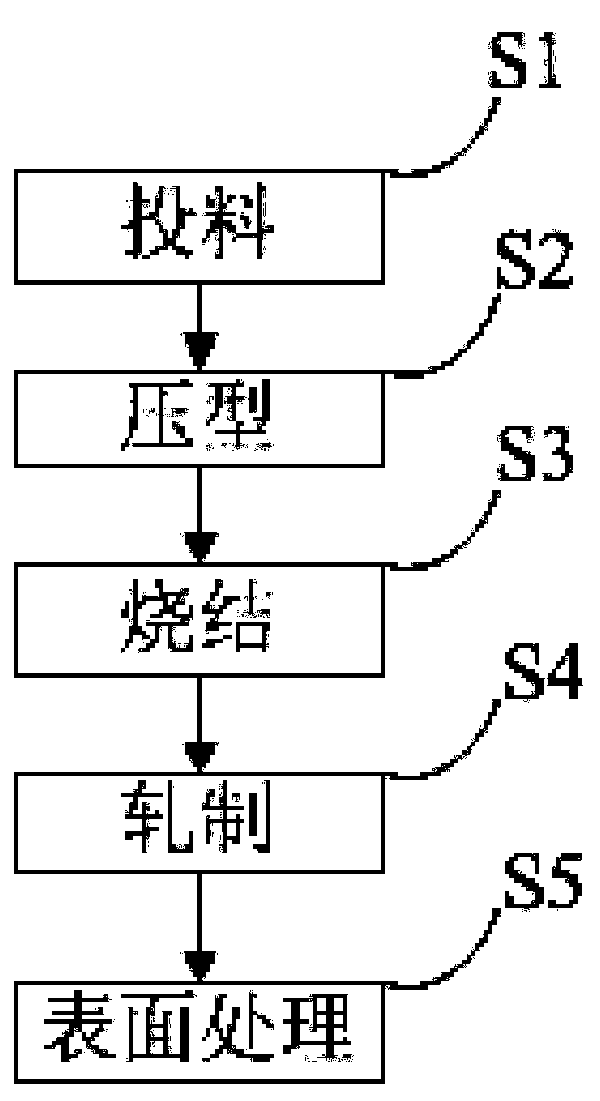

[0044] The preparation of a molybdenum plate for spinning with a thickness of 4.8 mm specifically includes the following steps:

[0045] S1, feeding materials, select a mold with a thickness of 60mm such as a rubber sleeve mold, and load molybdenum powder.

[0046] S2, molding, using cold isostatic pressing to mold the mold containing the powder selected in step S1; the pressure used for molding is 220 MPa, and the pressure is maintained for 20 minutes. After the pressing process, the pressed slab is shaped according to the shrinkage ratio in the sintering process, so as to ensure that the sintered slab is flat and intact.

[0047] S3, sintering, sintering the shaped slab in step S2; placing the shaped slab in an intermediate frequency furnace for sintering, heating the molybdenum slab to 600°C, keeping it warm for 1 hour, and then heating to 900°C, Keep warm for 2 hours, then heat to 1200°C, keep hold for 4 hours, then heat to 1300°C, keep hold for 2 hours, then heat to 1600...

Embodiment 2

[0054] The preparation of a molybdenum plate for spinning with a thickness of 2.5 mm specifically includes the following steps:

[0055] S1, feeding materials, select a mold with a thickness of 50mm such as a rubber sleeve mold, and load molybdenum powder.

[0056] S2, molding, using cold isostatic pressing to mold the mold containing the powder selected in step S1; the pressure used for molding is 200 MPa, and the pressure is maintained for 30 minutes. After the pressing process, the pressed slab is shaped according to the shrinkage ratio in the sintering process, so as to ensure that the sintered slab is flat and intact.

[0057] S3, sintering, heating the molybdenum slab to 700°C, holding it for 2 hours, then heating to 1000°C, holding it for 2 hours, then heating it to 1200°C, holding it for 2 hours, then heating it to 1400°C, holding it for 3 hours, then heating it to 1500°C, hold for 3 hours, then heat to 1800°C, hold for 2 hours, and finally heat to 2100°C, hold for 5 ...

Embodiment 3

[0064] In this embodiment, except that the sintering process is different from embodiment 1, other process steps are the same as embodiment 1. The sintering process of this example is to raise the temperature to 2000°C at a rate of 10°C / min, and keep it warm for 5 hours. The density of the obtained molybdenum slab is 9.6cm 3 / g.

[0065] The elongation at break in the longitudinal direction of the rolled piece obtained after rolling by the rolling process of Example 1 reaches 15%, and the elongation at break in the transverse direction of the rolled piece reaches 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com