Biomedical poly(4-hydroxybutyrate) absorbable surgical suture and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

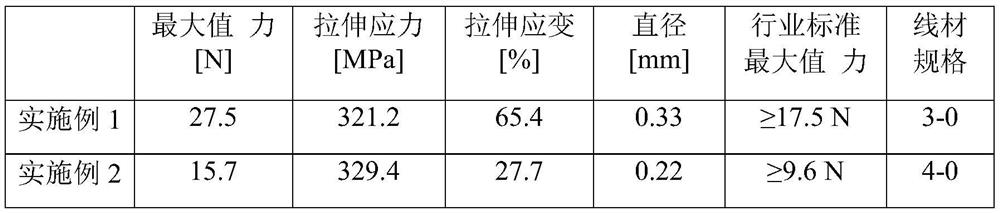

Embodiment 1

[0029] A biomedical P4HB absorbable surgical suture is made of the following raw materials in parts by weight:

[0030] Biomedical grade P4HB (molecular weight 158,000, melt index 2.5) 96 parts, P3HB 1.5 parts, VC 2 parts, epoxy polymer chain extender ADR-4468 0.5 parts.

[0031] The method for preparing the above-mentioned P4HB absorbable surgical suture comprises the following steps:

[0032] Step 1. Weigh P4HB, P3HB, ADR-4468, and VC according to the formula and put them into a high-speed mixer, stir and blend evenly, and prepare the modified P4HB through a twin-screw extruder from the obtained blend. The processing temperature of the twin-screw extruder is 80°C, 100°C, 100°C, 120°C, 120°C, 120°C, 100°C, the screw speed is 150rpm, the screw combination is high shear, and the cooling water temperature is 7°C.

[0033] Step 2: Add the modified P4HB particles into the melt spinning process, the processing temperature is 80°C, 100°C, 120°C, 150°C, 150°C, 150°C, the screw speed...

Embodiment 2

[0036] A biomedical P4HB absorbable surgical suture is made of the following raw materials in parts by weight:

[0037] Biomedical grade P4HB (molecular weight 158,000, melt index 2.5) 96 parts, PDO 1 part, VE 2 parts, epoxy polymer chain extender ADR-4468 1 part.

[0038] The method for preparing the above-mentioned P4HB absorbable surgical suture comprises the following steps:

[0039] Step 1. Weigh P4HB, PDO, ADR-4468, and VE according to the formula and put them into a high-speed mixer, stir and blend evenly, and prepare the modified P4HB through a twin-screw extruder from the obtained blend. The processing temperature of the twin-screw extruder is 80°C, 100°C, 100°C, 120°C, 130°C, 130°C, 120°C, the screw speed is 150rpm, the screw combination is high shear, and the cooling water temperature is 7°C.

[0040] Step 2: Add the modified P4HB particles into the melt spinning process, the processing temperature is 80°C, 100°C, 120°C, 150°C, 150°C, 150°C, the screw speed is 30rp...

Embodiment 3

[0043] A biomedical P4HB absorbable surgical suture is made of the following raw materials in parts by weight:

[0044] Biomedical grade P4HB (molecular weight 158,000, melt index 2.5) 96.5 parts, cellulose nanocrystal 1 part, carotene 2 parts, maleic anhydride 0.5 parts.

[0045] The method for preparing the above-mentioned P4HB absorbable surgical suture comprises the following steps:

[0046] Step 1. Weigh P4HB, cellulose nanocrystals, carotene, and maleic anhydride according to the formula and put them into a high-speed mixer, stir and blend evenly, and prepare the modified P4HB through a twin-screw extruder from the obtained blend. The processing temperature of the twin-screw extruder is 80°C, 100°C, 100°C, 120°C, 120°C, 120°C, 100°C, the screw speed is 150rpm, the screw combination is high shear, and the cooling water temperature is 7°C.

[0047] Step 2: Add the modified P4HB particles into the melt spinning process, the processing temperature is 80°C, 100°C, 120°C, 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com