Ultra-high molecular weight polyethylene monofilament filter cloth and preparation method thereof

A technology of ultra-high molecular weight and polyethylene, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of high-viscosity materials that are not easy to peel off, high filter resistance of filter cloth, short filter cloth replacement cycle, etc., to achieve filtration Outstanding effect, smooth surface, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

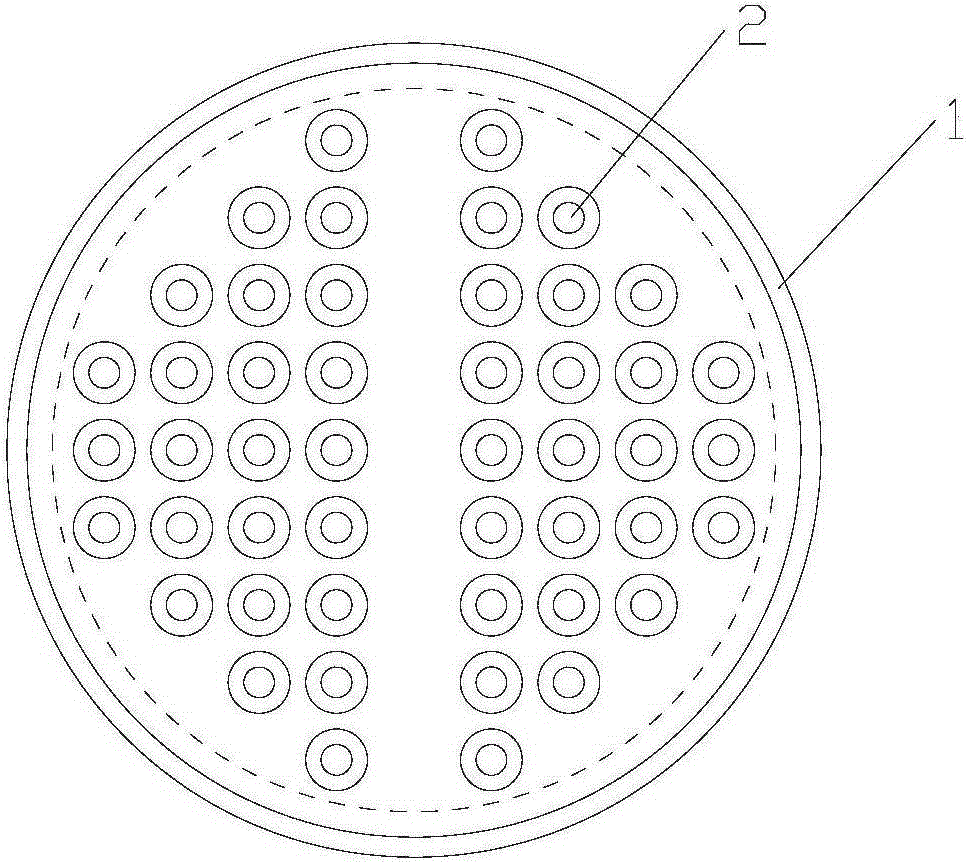

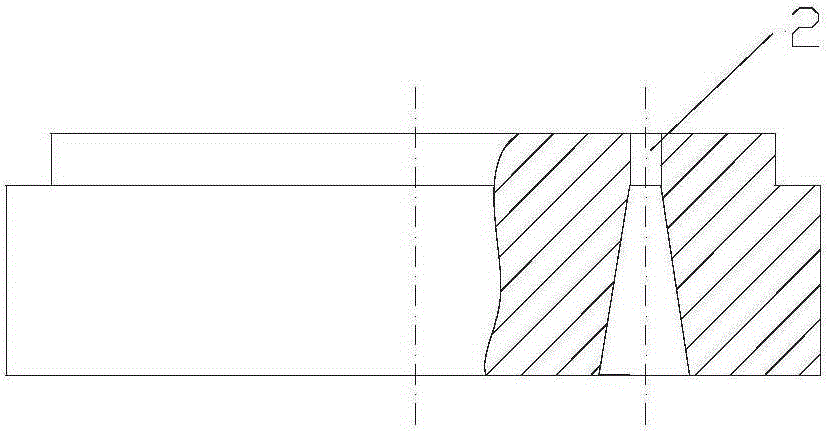

[0061] It is an ultra-high molecular weight polyethylene monofilament filter cloth in the form of a single layer structure. The warp is woven from one monofilament and the weft is woven from another monofilament. The diameters of the warp and weft are both 0.07mm and the monofilament The tensile strength is above 1100MPa;

[0062] The tensile strength unevenness of the monofilament is within 5%, the elongation at break is less than 10%, the elongation at break unevenness is within 2%, and the elastic modulus is 20-60Gpa.

[0063] The thickness of the filter cloth is 0.35mm, the average pore diameter is 20μm, the pore diameter ratio is 0.8, and the weight is 280g / m 2 , ventilation rate 0.8m 3 / m 2 Min;

[0064] The width of the filter cloth is 1.8m, and the pattern is plain weave.

Embodiment 2

[0066] The diameters of warp and weft are both 0.10mm; the pattern is twill.

[0067] It is the same as Example 1.

Embodiment 3

[0069] The diameter of the warp and weft is 0.15mm; the pattern is satin.

[0070] It is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com