Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

628results about How to "Improve product performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear-resistant thermoplastic elastomer and preparation method thereof

The invention discloses a wear-resistant thermoplastic elastomer, which is prepared from the following raw materials in percentage by weight: 10 to 80 percent of matrix resin, 10 to 60 percent of master batch, 0 to 42 percent of extending oil, 0 to 20 percent of thermoplastic resin, 0 to 30 percent of mineral filler, 0 to 1.5 percent of coupling agent, 0.1 to 2 percent of processing aid and 0.1 to 2 percent of stabilizing agent. The invention also discloses a method for preparing the wear-resistant thermoplastic elastomer. SBS, SEBS and the like are adopted as the matrix resin, and the problem of poor wear resistance of SBC thermoplastic elastomers is solved through improvement of a mixing formular and a process; the prepared thermoplastic elastomer has good wear resistance; compared with the TPU products with good wear resistance, the thermoplastic elastomer has low cost; in the whole process of modifying and producing the material, chemical solvents are not used, the influence on the environment is small, the halogen is free and the environment is protected; and the leftover material of the thermoplastic elastomer can be repeatedly used.

Owner:CGN JUNER NEW MATERIALS +1

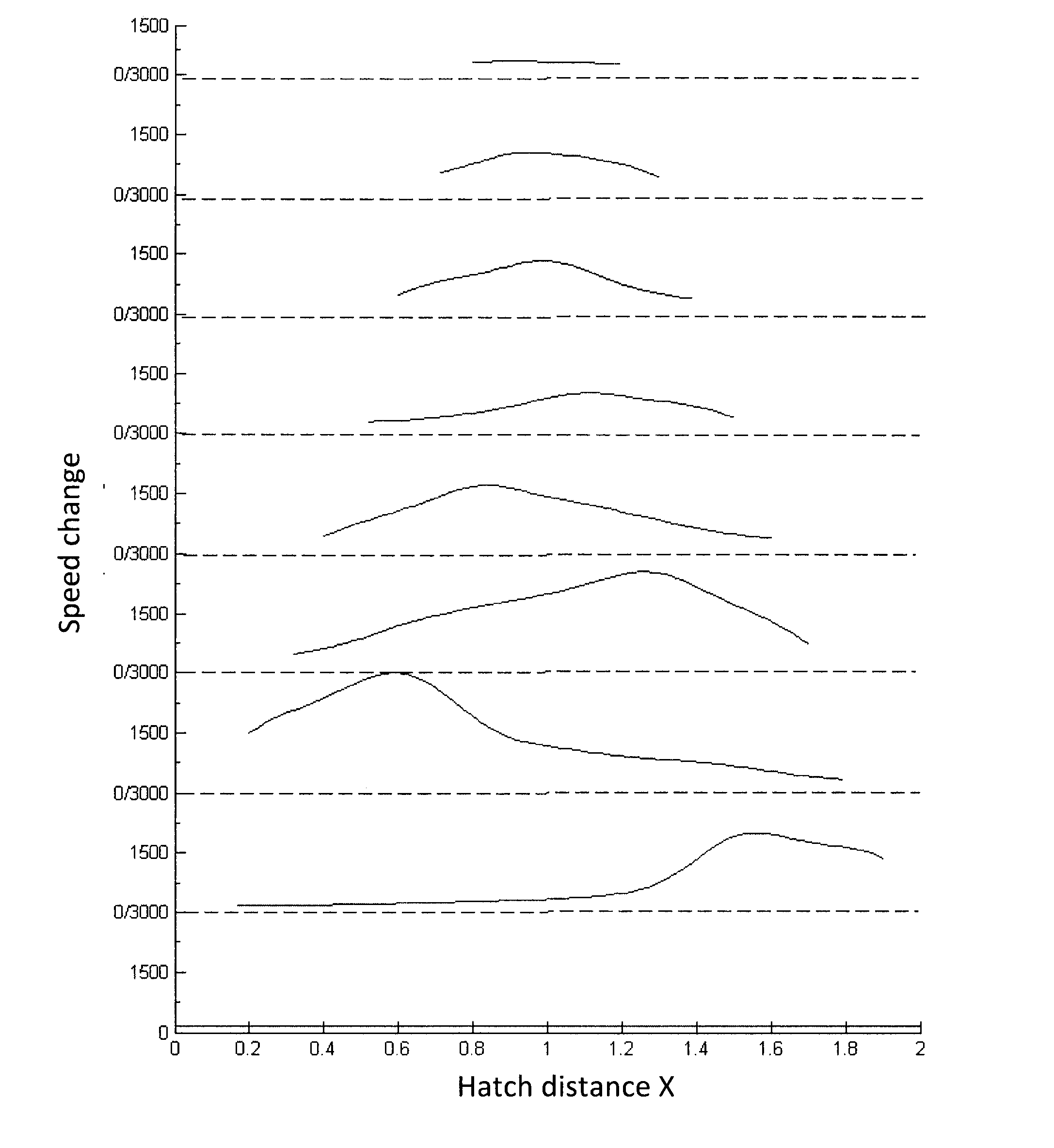

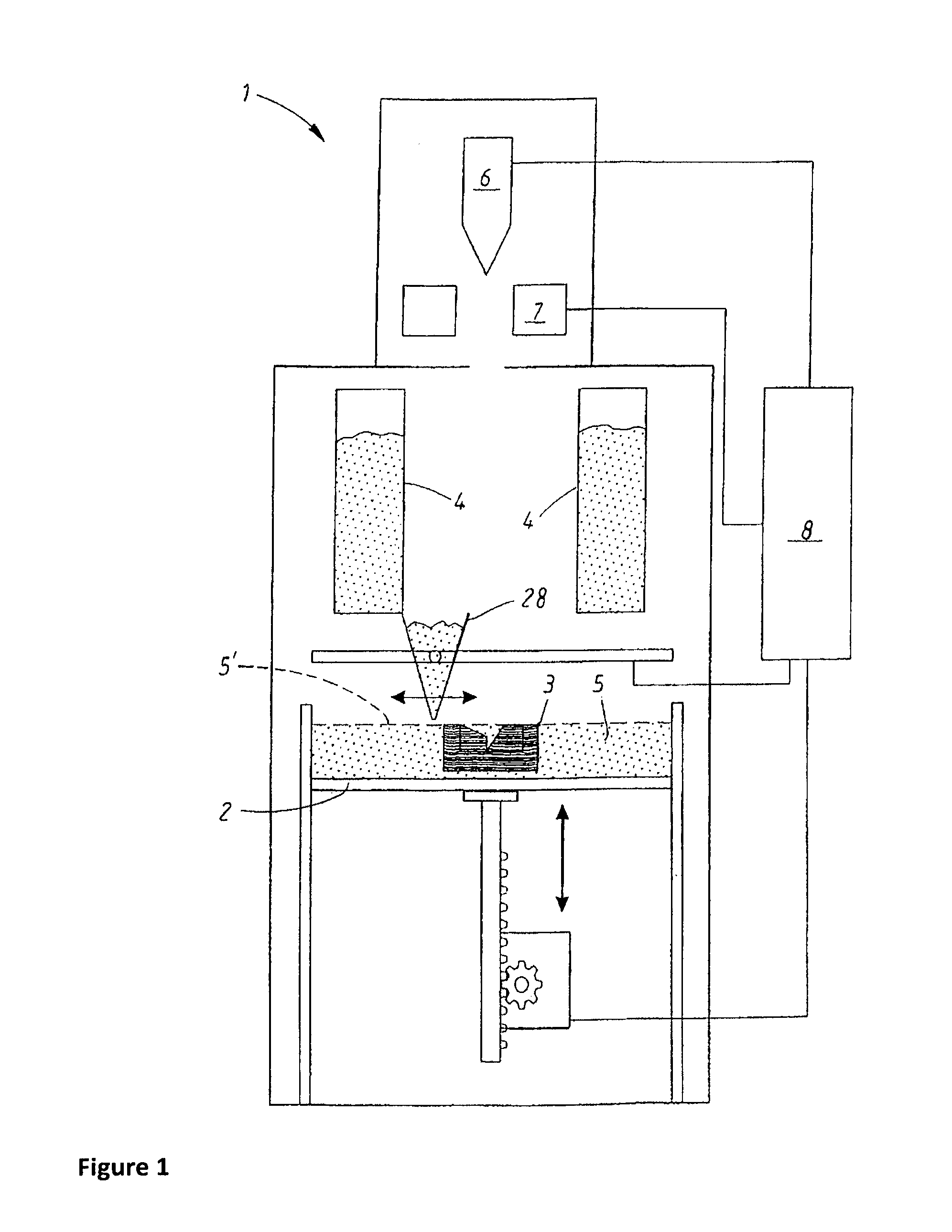

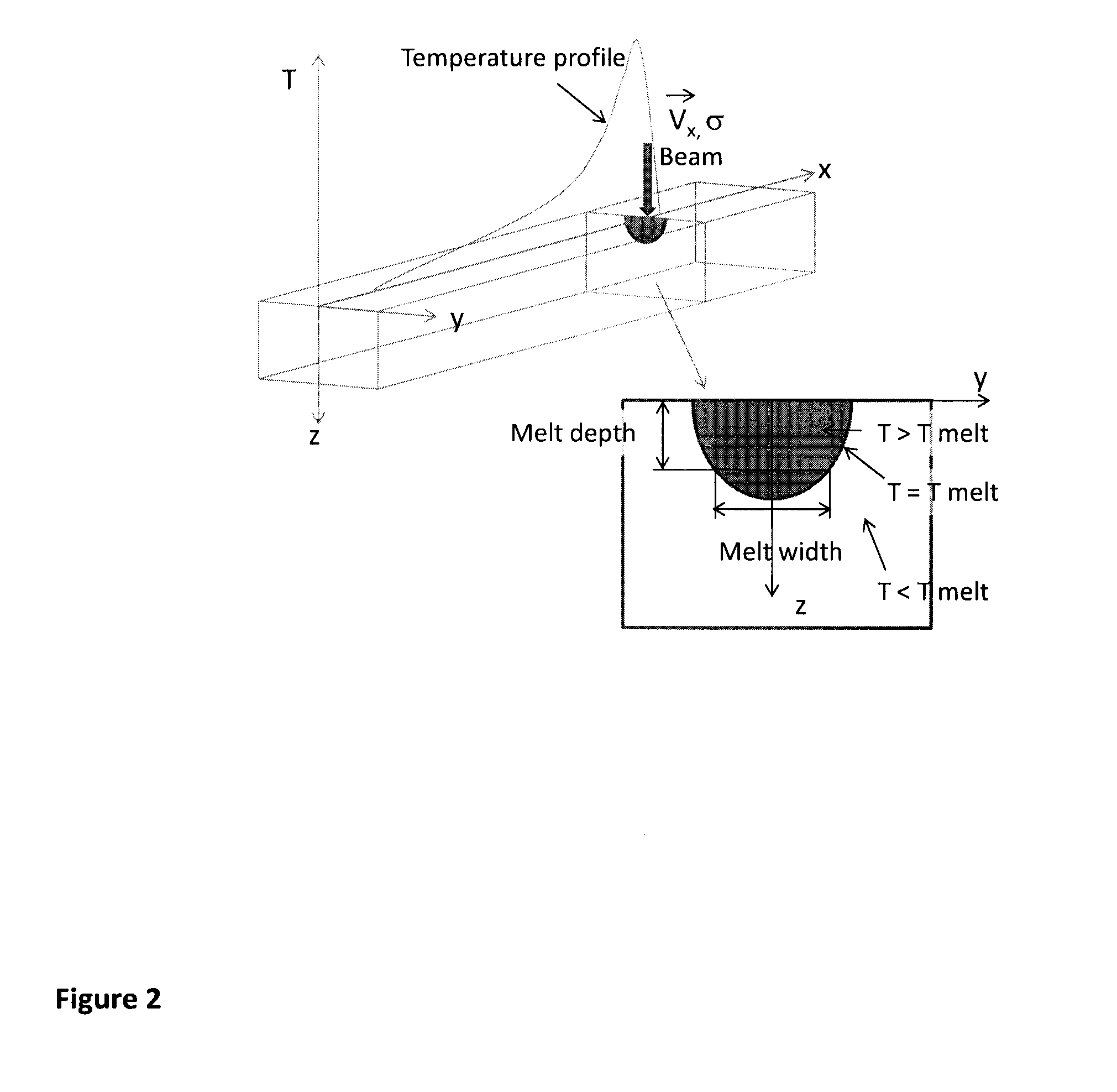

Method for production of a three-dimensional body

ActiveUS20130300035A1Improve product performanceRelieve pressureAdditive manufacturing apparatusTemperatue controlLight beamSupply energy

The invention concerns a method for production of a three-dimensional body by successively providing powder layers and fusing together of selected areas of said layers, which areas correspond to successive cross sections of the three-dimensional body, wherein the method comprises the following steps for at least one of said layers: applying the at least one powder layer onto a working area, and fusing together a selected area of the at least one powder layer by supplying energy from a radiation gun to the selected area. The invention is characterized in that it comprises the steps of: establishing an intended beam path that is to be used when fusing together the selected area of the at least one powder layer, calculating a temperature in the at least one powder layer along the intended beam path as a function of a specific energy deposition of an imaginary beam that is assumed to move along the intended beam path, adjusting the specific energy deposition of the imaginary beam along the intended beam path depending on the calculated temperature and on conditions set for the step of fusing together the selected area, and providing, based on the calculations and the adjustments, an operating scheme for the specific energy deposition of the real beam to be used for the intended beam path when fusing together the selected area of the at least one layer.

Owner:ARCAM AB

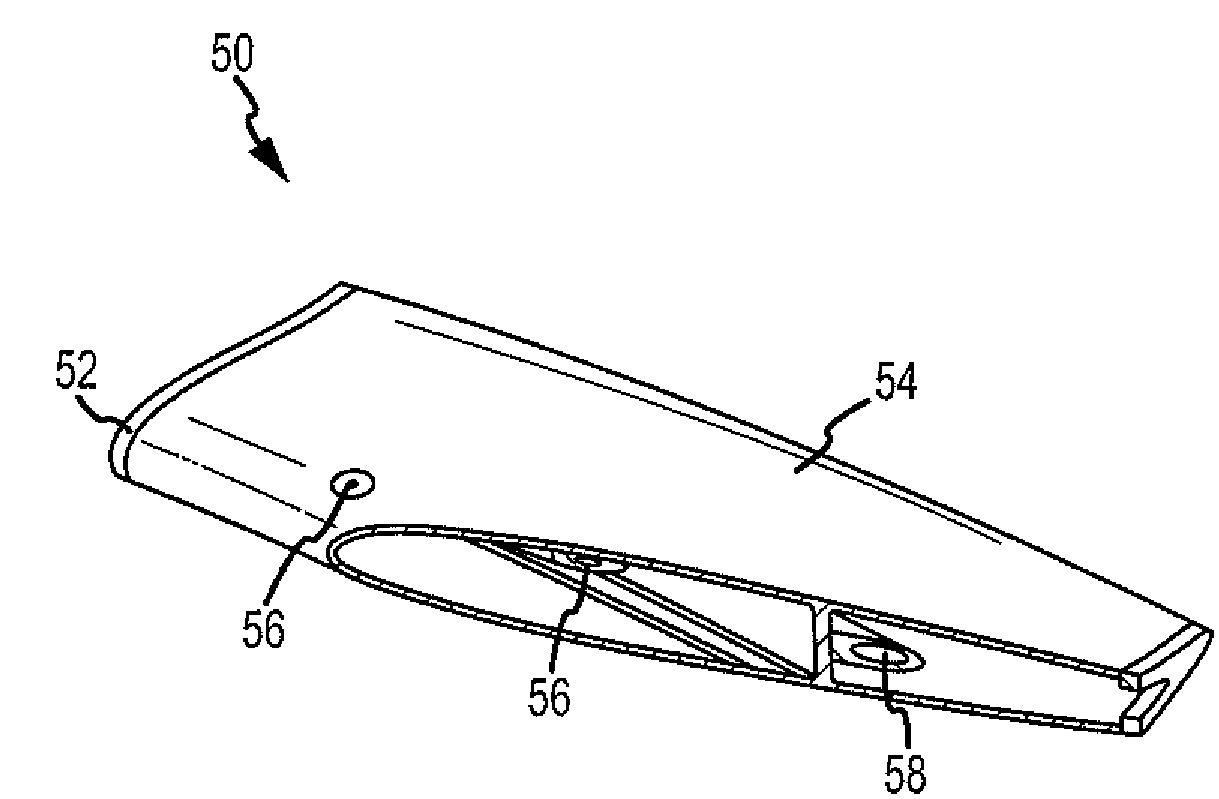

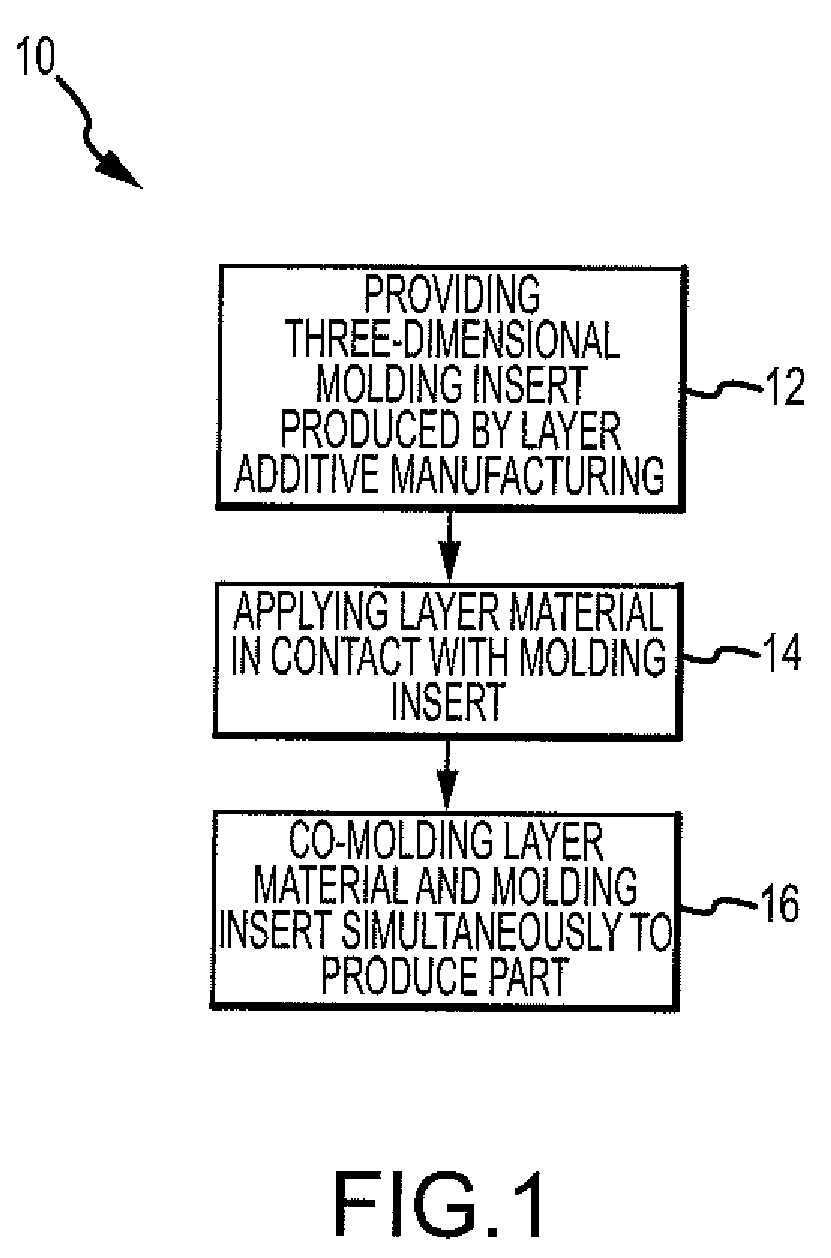

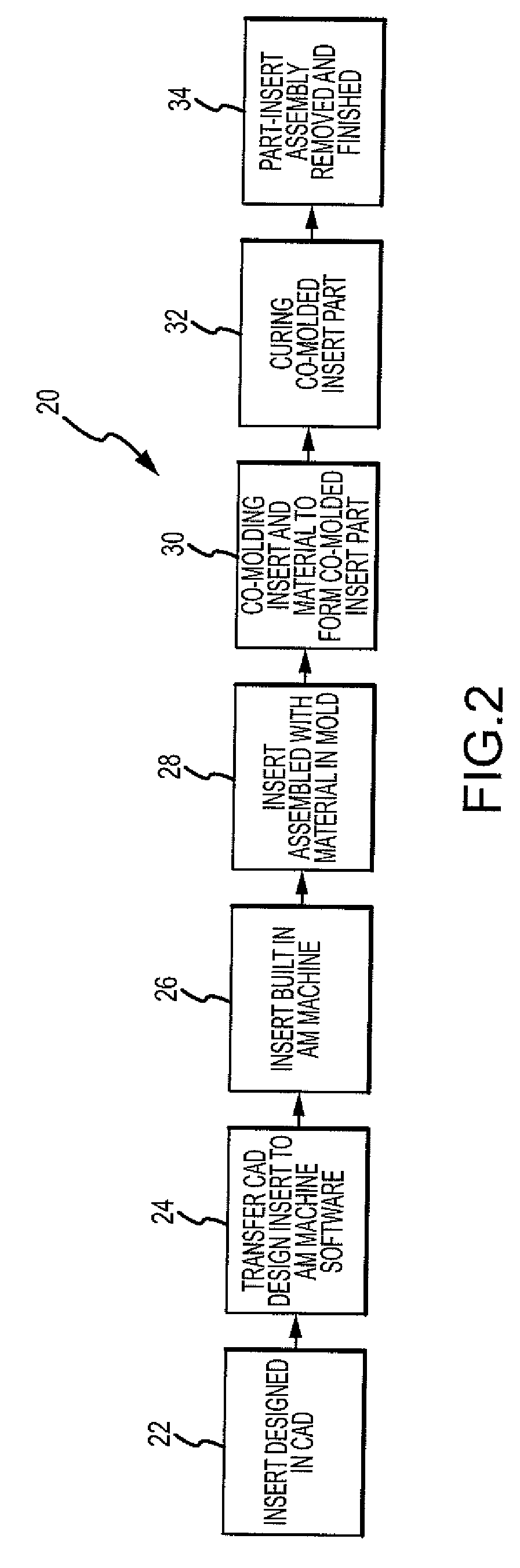

Method of manufacturing co-molded inserts

ActiveUS8383028B2Little costsLittle timeAdditive manufacturing apparatusLamination ancillary operationsMaterials scienceMetal

A method for manufacturing a co-molded insert part for use in composite, plastic, or metal parts is disclosed. The method comprises the step of providing a three-dimensional molding insert produced by a layer additive manufacturing process. The method further comprises the step of applying a layer material in contact with at least a portion of the molding insert. The method further comprises the step of co-molding the layer material and the molding insert simultaneously to produce a co-molded insert part.

Owner:THE BOEING CO

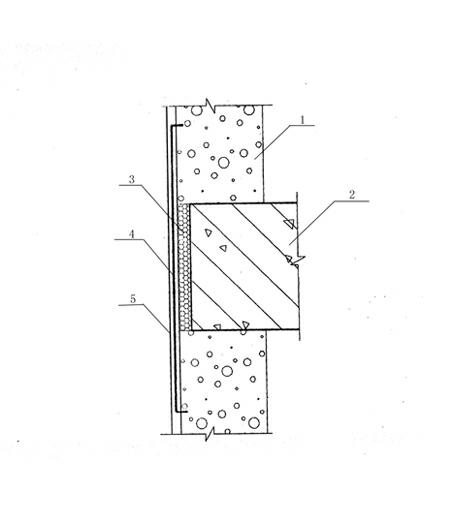

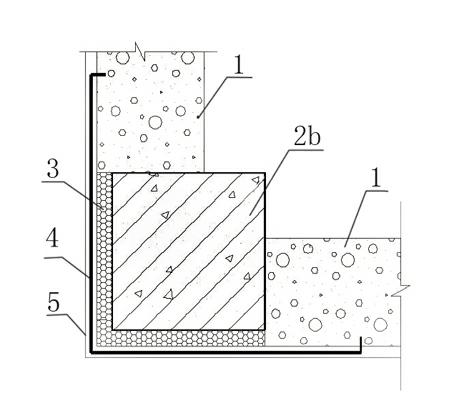

Automatic heat preservation, energy saving and air-entrapping concrete brick wall and manufacturing method thereof

InactiveCN102162282AImprove performanceMeet the requirements of the outer protective structureConstruction materialSolid waste managementInsulation layerThermal bridge

The invention relates to an automatic heat preservation, energy saving and air-entrapping concrete brick wall and a manufacturing method thereof. The invention is characterized that: a heat preservation wall plate is protruded, relative to the outer surfaces of a beam and a stand column or a concrete plate, 20 to 50 millimeters or flatly bricked; beam and column part heat preservation layers are bonded on the outer surfaces of the beam and the stand column or the concrete plate; and alkali-proof grids or steel mesh sheets are paved on the surfaces of the heat preservation layers. During bricking of the wall, the comprehensive performance of the heat preservation wall can be enhanced under the condition of no addition of the heat preservation layers on the whole wall by using energy saving and air-entrapping concrete bricks and heat preservation bricking mortar as well as heat preservation processing measures taken on hot bridge parts such as the beam, the column and the like, so the requirement of a periphery protective structure of a building wall can be met, and heat energy loss due to the hot bridges formed in mortar joints of the wall can be avoided effectively; therefore, the design standard requirement of China on heat preservation and energy saving of a building is met, and the manufacturing cost of the wall and the comprehensive cost of the building are reduced greatly.

Owner:徐振飞

Long glass fibre reinforced nylon material and preparing method thereof

The present invention belongs to high polymer material and forming and processing field thereof, and provides a long glass fibre reinforced nylon material and preparing method thereof, wherein the constituents comprise: 29-67wt% of nylons, 30-60wt% of long glass fibre, 2-10wt% of compatilizer and 0.3-1.0wt% of antioxidants. The preparing method comprises the following steps: first mixing the nylons, compatilizer and antioxidants; adding the mixture into a double-screw extruder, wherein the processing temperature is 235-300 DEG C; extruding resin fondants into a dipping mould connected to the double-screw extruder; enabling the long glass fibre to pass through the dipping mould, wherein the dipping temperature of the dipping mould is 260-300 DEG C, dipping the long glass fibre completely in by the fondants, cooling, dragging and granulating the long glass fibre to obtain the long glass fibre reinforced nylon materials. The method of the present invention can strengthen the dipping effect of glass fibre in nylon fondant, eliminate or decrease harmful substances, reduce environmental pollution, and improve the dipping effect and mechanical property of materials effectively.

Owner:NANJING JULONG SCI&TECH CO LTD

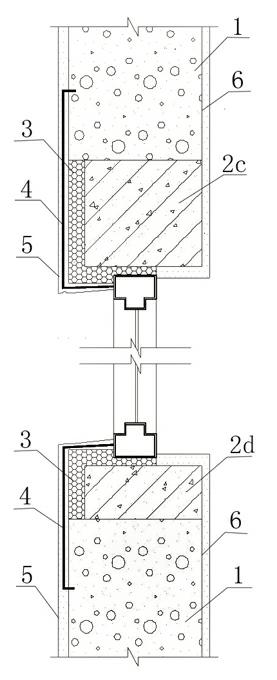

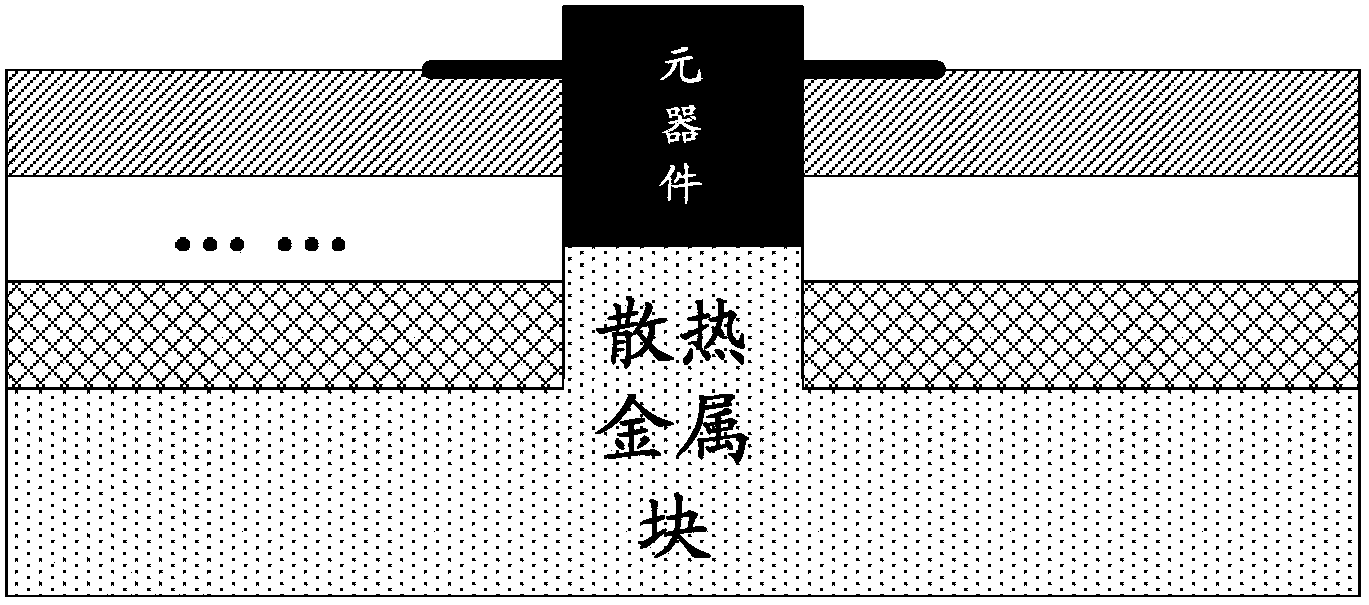

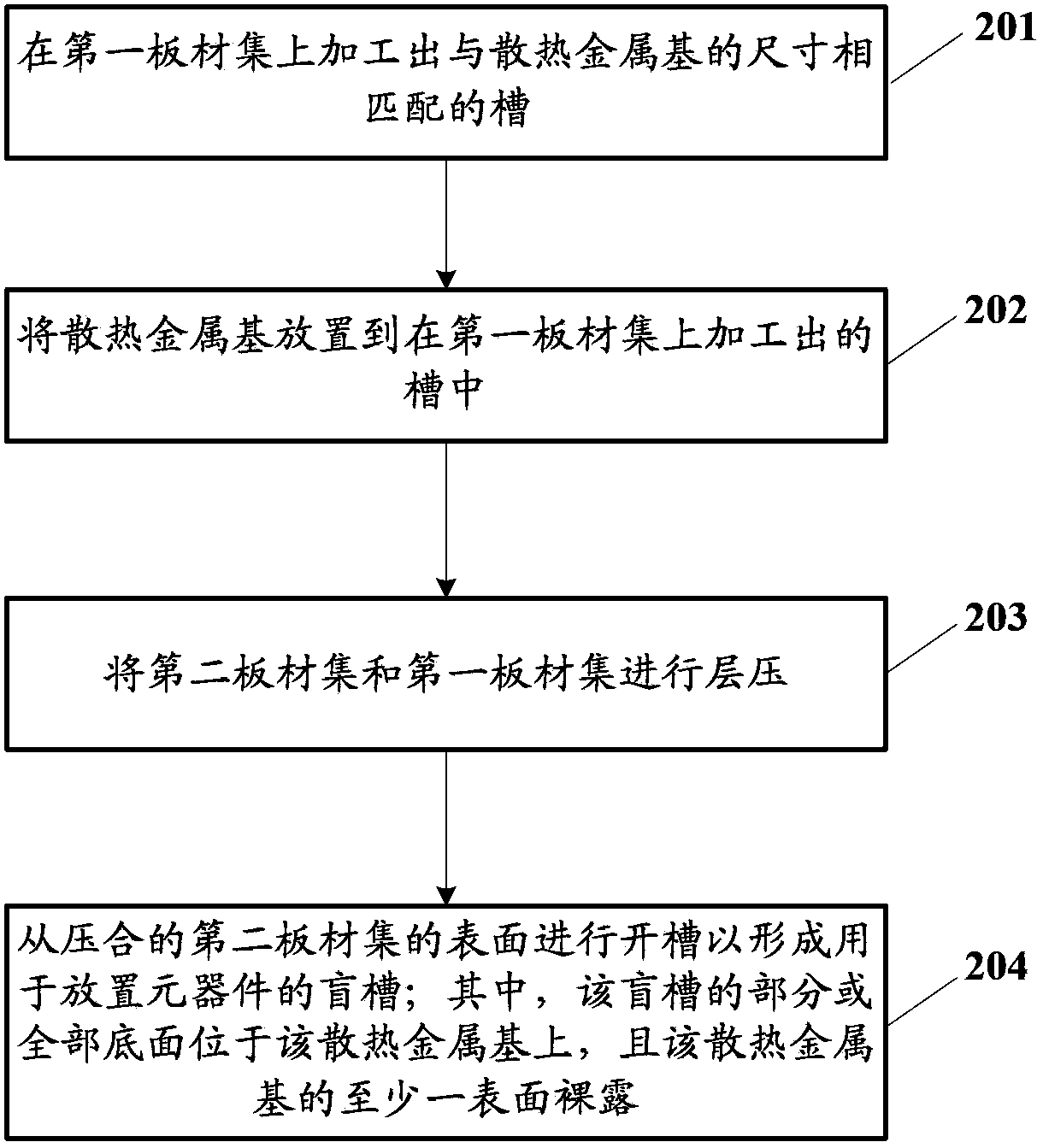

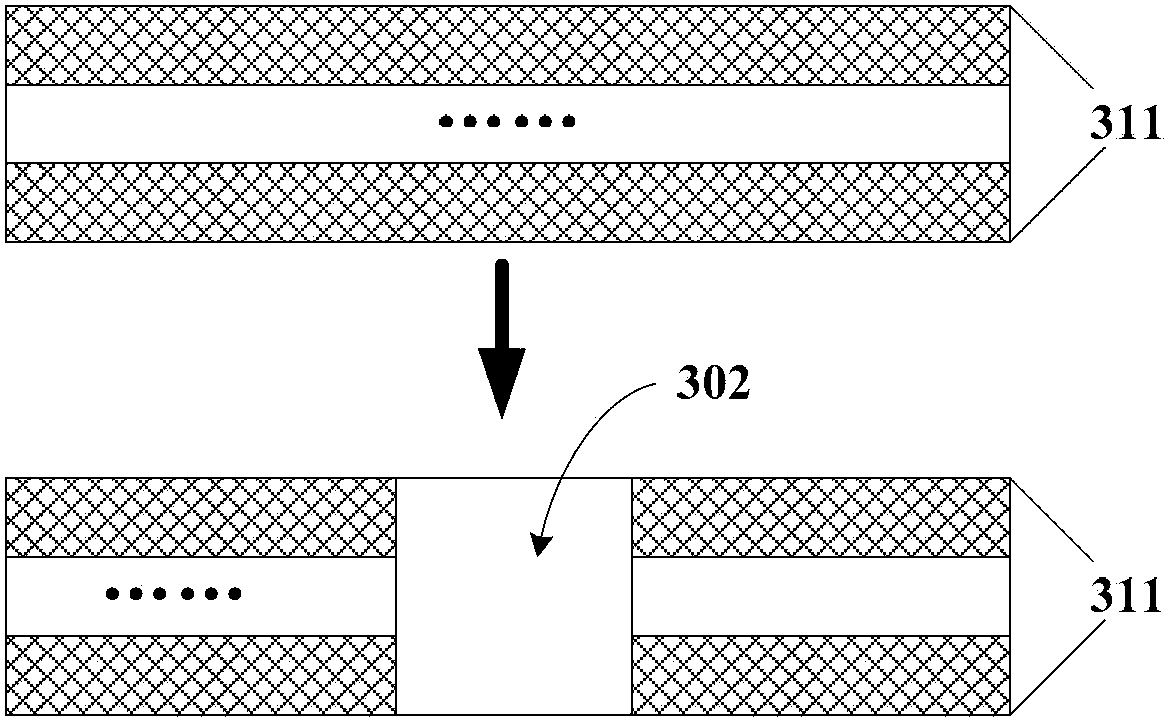

Method for processing groove on printed circuit board, printed circuit board and electronic device

ActiveCN103517557AShorten the processing cycleLow costPrinted circuit assemblingPrinted circuit detailsPrinted circuit boardElectronic equipment

Embodiments of the invention disclose a method for processing a groove on a printed circuit board, the printed circuit board and an electronic device. The method for processing the groove on the printed circuit board comprises: processing the groove, the dimension of which is matched with that of a heat-dissipating metal base on a first board set; fixedly arranging the heat-dissipating metal base in the groove processed in the first board set; stitching a second board set with the first board set and thus a third board set is formed; providing a groove in the surface of the second board set after stitching so as to form a blind groove for installing components, wherein partial or all bottom surface of the blind groove is arranged on the heat-dissipating metal base and at least one surface of the heat-dissipating metal base is exposed; and the depth of the blind groove in the vertical direction on the surface of the third board set is larger than the thickness of the second board set after stitching. The scheme provided in the embodiments of the invention is benefit to promote product miniaturization, integration and cost control.

Owner:WUXI SHENNAN CIRCUITS CO LTD

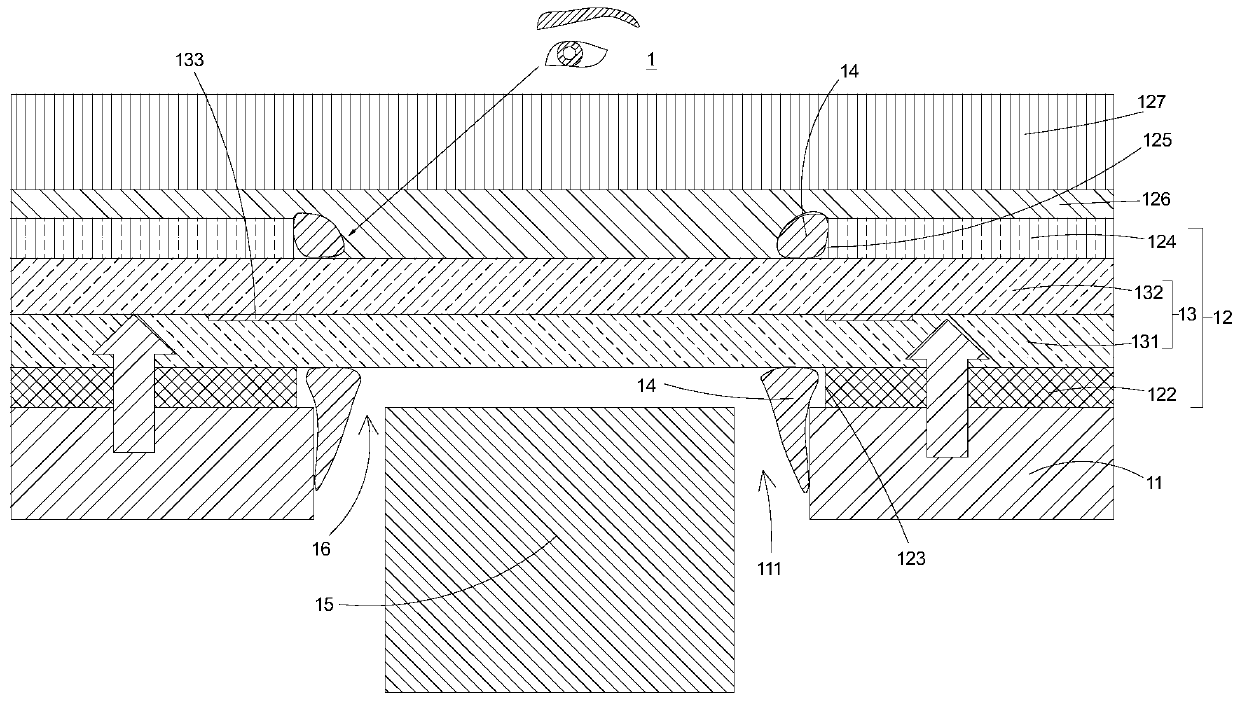

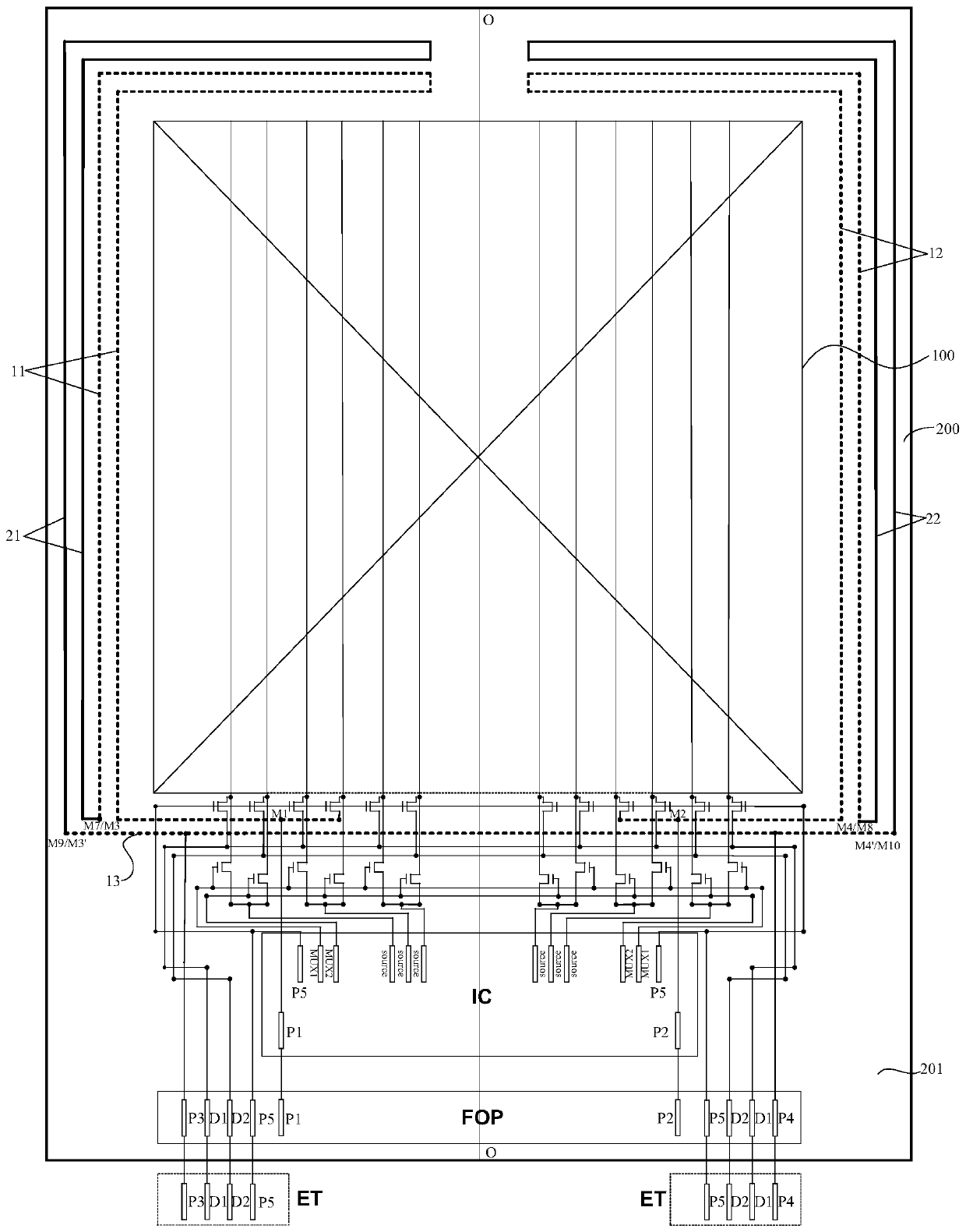

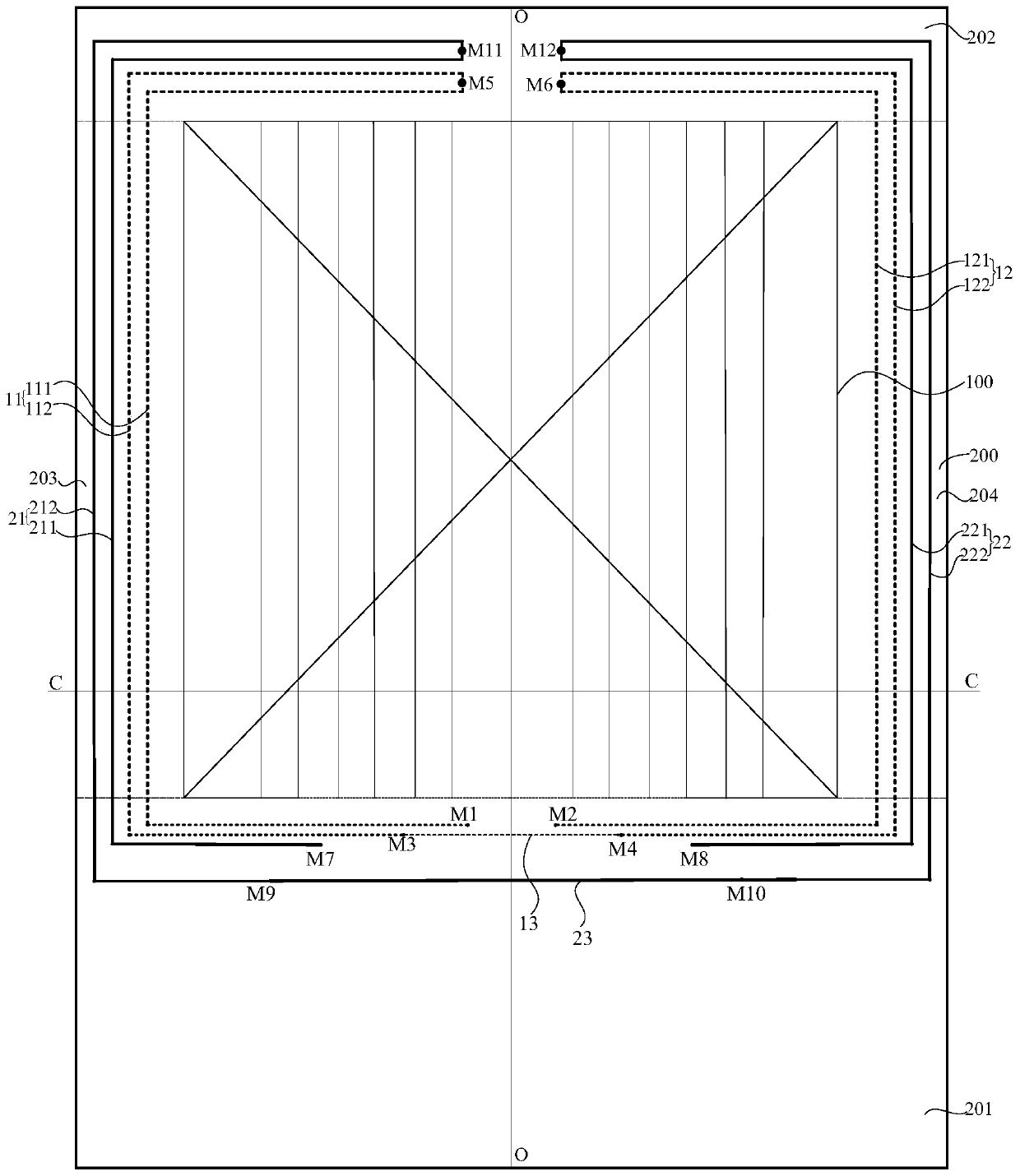

Display device

InactiveCN110426878AIncrease the screen ratioTo achieve the appearance effectTelevision system detailsColor television detailsLiquid-crystal displayComputer module

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

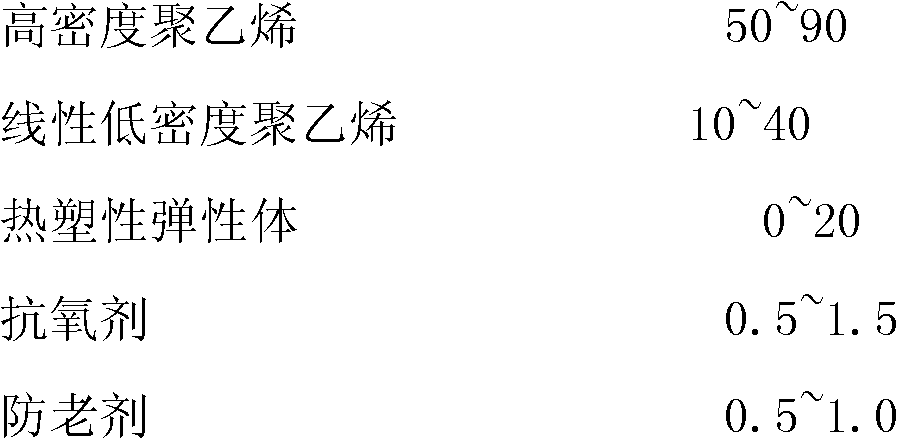

Composite macromolecular waterproof board and preparation method thereof

The invention discloses a composite macromolecular waterproof board, which consists of high density polyethylene, linear low density polyethylene, a thermoplastic elastomer, an antioxidant, an anti-ageing agent and a filler. The composite macromolecular waterproof board has high permeability resistance, high barrier property, high penetration resistance, resistance to acid, alkali and various chemical substances, high elongation and wear resistance, is free from chemical pollution, and can effectively improve the surface energy of polyethylene. The invention also discloses a method for preparing the composite macromolecular waterproof board.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

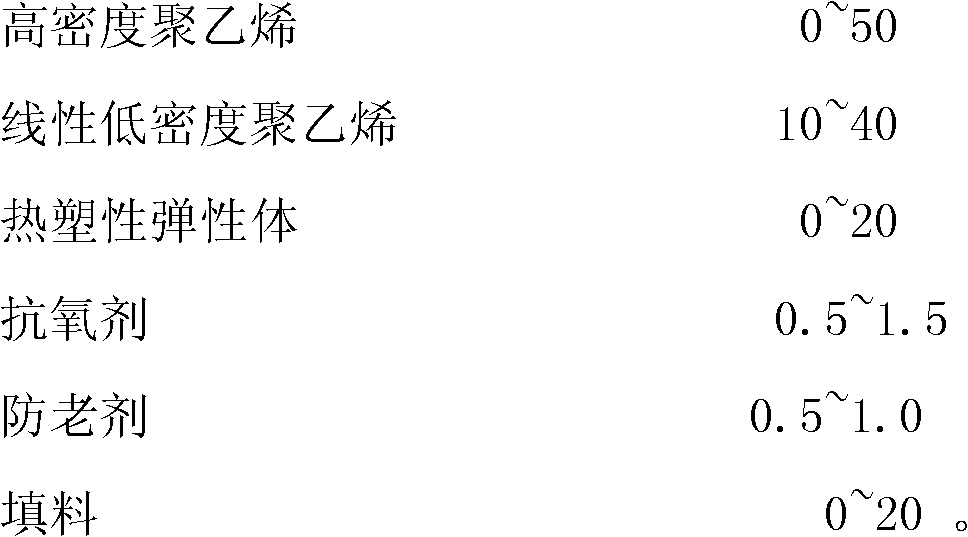

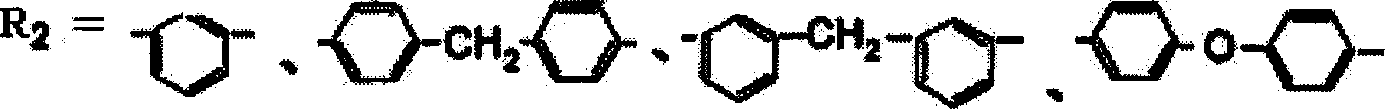

Benzoxazine resin containing aralkyl structure, its preparation method and use

The preparation method for benzoazine with aralkyl group comprises: adding phenols compound as 80-100 weight shares and 80-120 aralkyl compound into the reaction kettle; with 1-4 acidic catalyst, stirring to react for 1-3h at 80-140Deg; cooling to below 50Deg; adding 30-40% formaldehyde liquid as 160-360 weight shares and 4-8 basic catalyst to adjust pH value within 6-9; adding solvent and 40-120 diamine to reflux reaction for 2-8h at 85-95Deg; finally, vacuum dewatering at 80-40Deg. This product is used mainly to manufacture high-performance constructional material fit more than 180Deg, the electrically insulating material, or glass fabric and extruding material with vitrifying temperature more than 175Deg.

Owner:SICHUAN DONGCAI ENTERPRISE GRP CO LTD

Preparation method of fiber with high water absorption

ActiveCN103160952ASpinning solution stabilityGood physical and mechanical propertiesFilament/thread formingArtificial filament heat treatmentPolyvinyl alcoholAcrylic acid

The invention relates to a preparation method of a fiber with high water absorption, which is a method for preparing the fiber with high water absorption by a post-crosslinking agent. According to the preparation method, the fiber with high water absorption is prepared from acrylic acid (AA) and acrylamide (AM) which are partly neutralized and taken as polymerized monomers through the steps of: blending the polymerized monomers with polyving akohol (PVA), initiating by potassium persulfate (KPS), blending and polymerizing in an aqueous solution, adding a dialdehyde solution to obtain a mixed solution serving as a post-crosslinking agent solution, mixing to be uniform and defoaming to obtain a spinning stock solution; dry-wet spinning the spinning stock solution to form a nascent fiber; and heat-treating the nascent fiber at a certain temperature to generate a crosslinking reaction, thereby forming the three-dimensional net-structured fiber with high water absorption. According to the preparation method, the implosion phenomenon which easily occurs during polymerization of the traditional polymer solution with high water absorption is avoided, the preparation technology is simple and safe, the production cost is reduced, and the production efficiency is increased; and the obtained water-absorbing fiber has high and controllable water adsorption, thermostability, capability of being repeatedly used, and long residual action.

Owner:DONGHUA UNIV

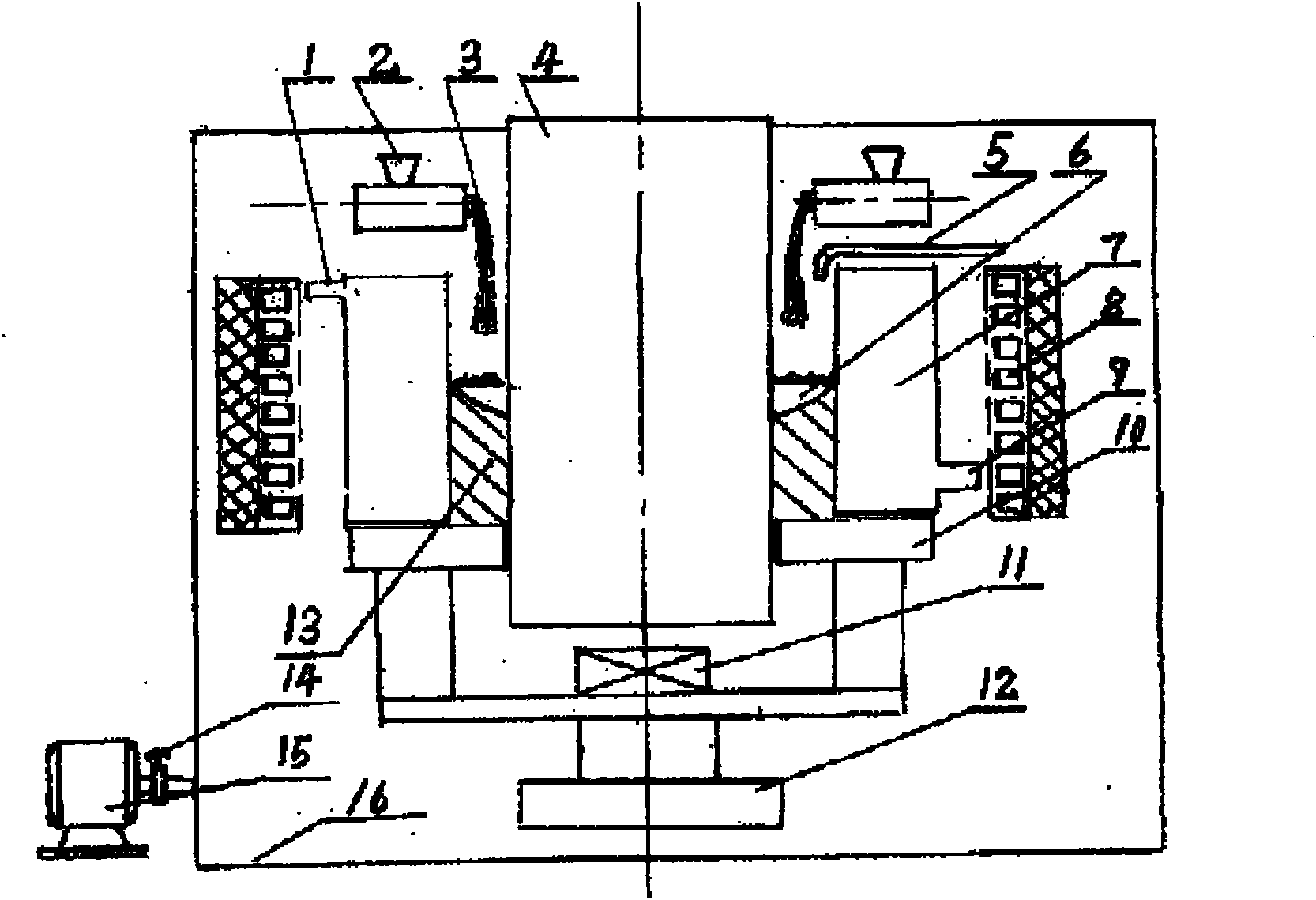

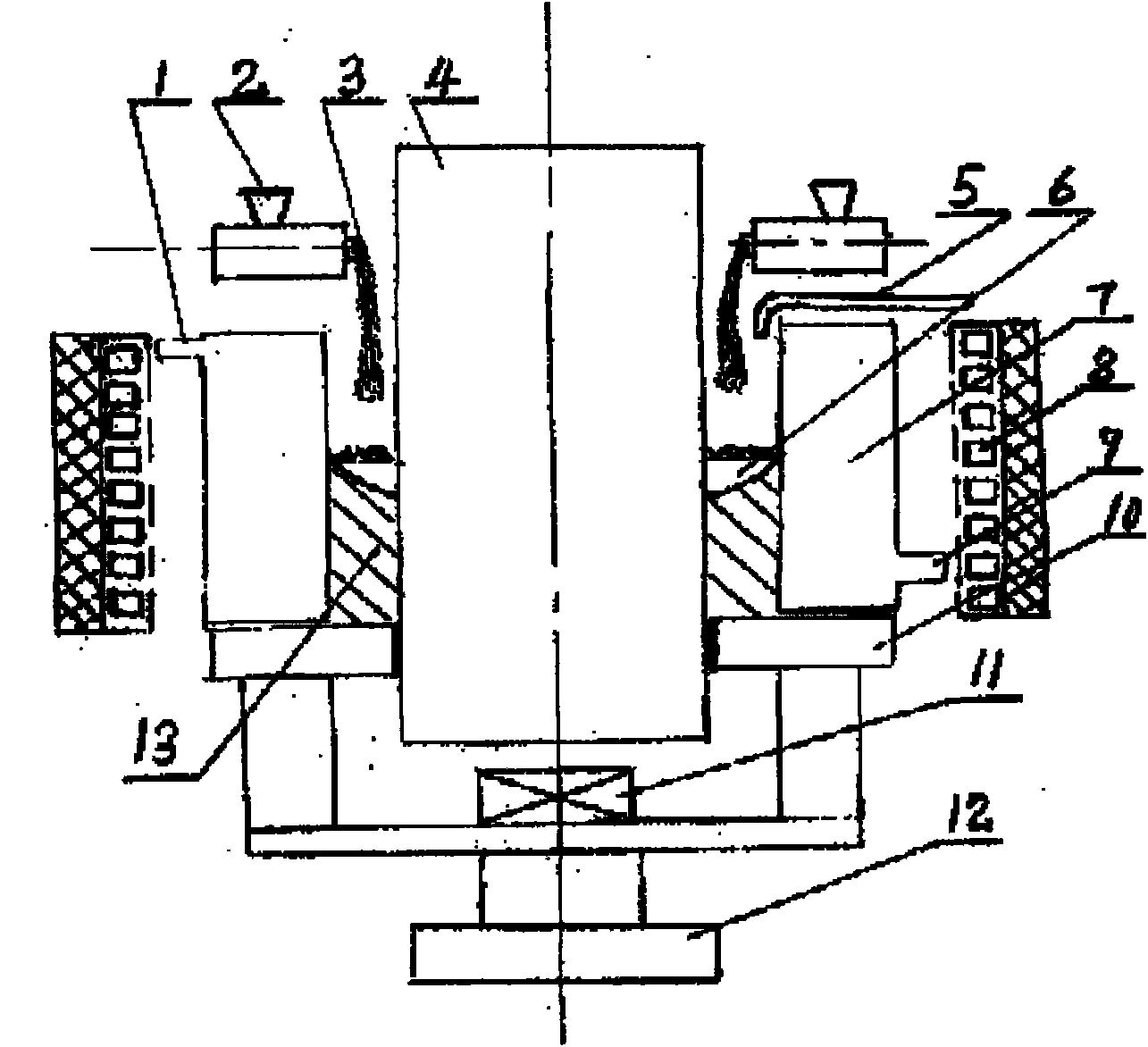

Micro-nano-alloy bimetal composite material preparation technique and device thereof

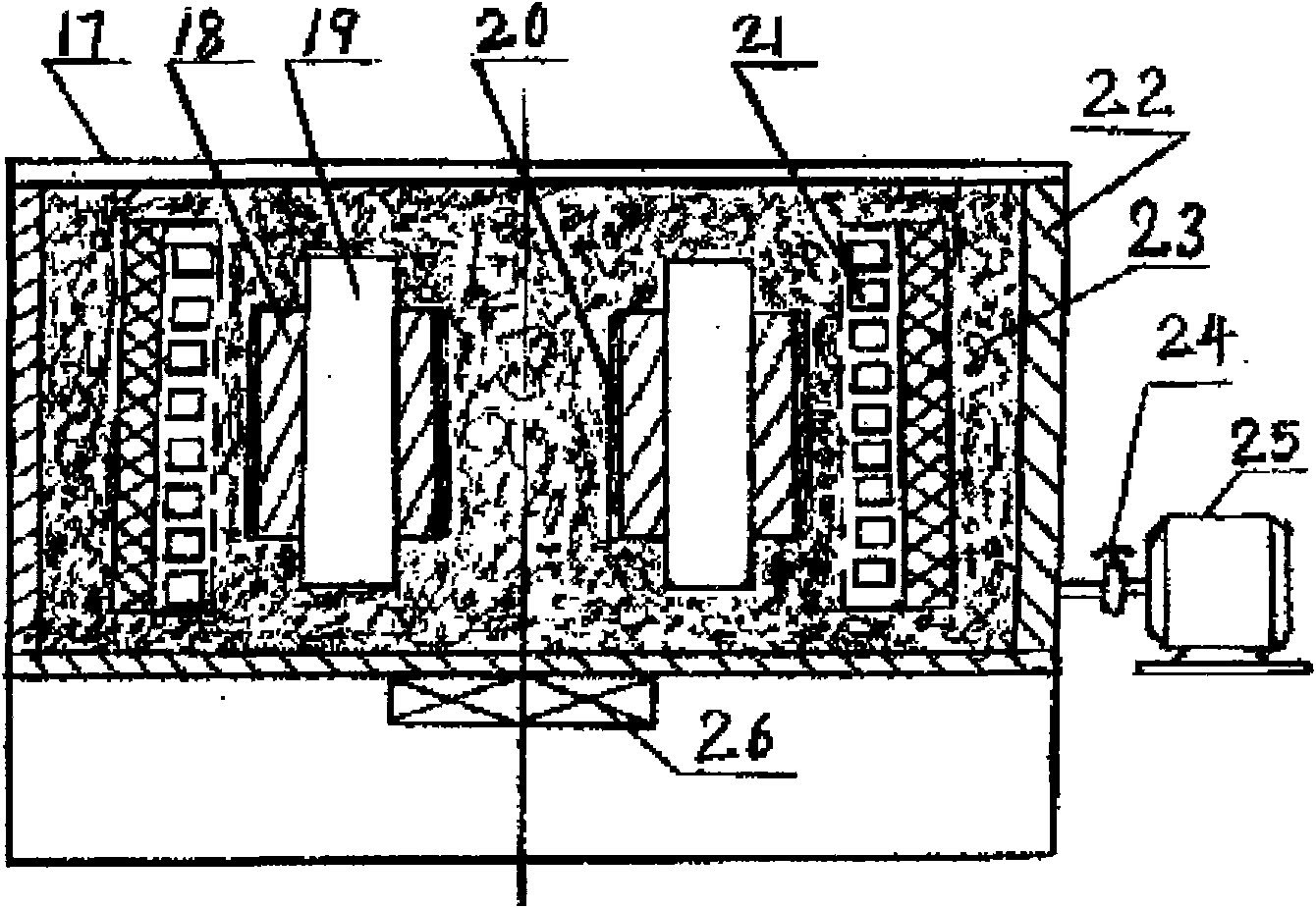

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

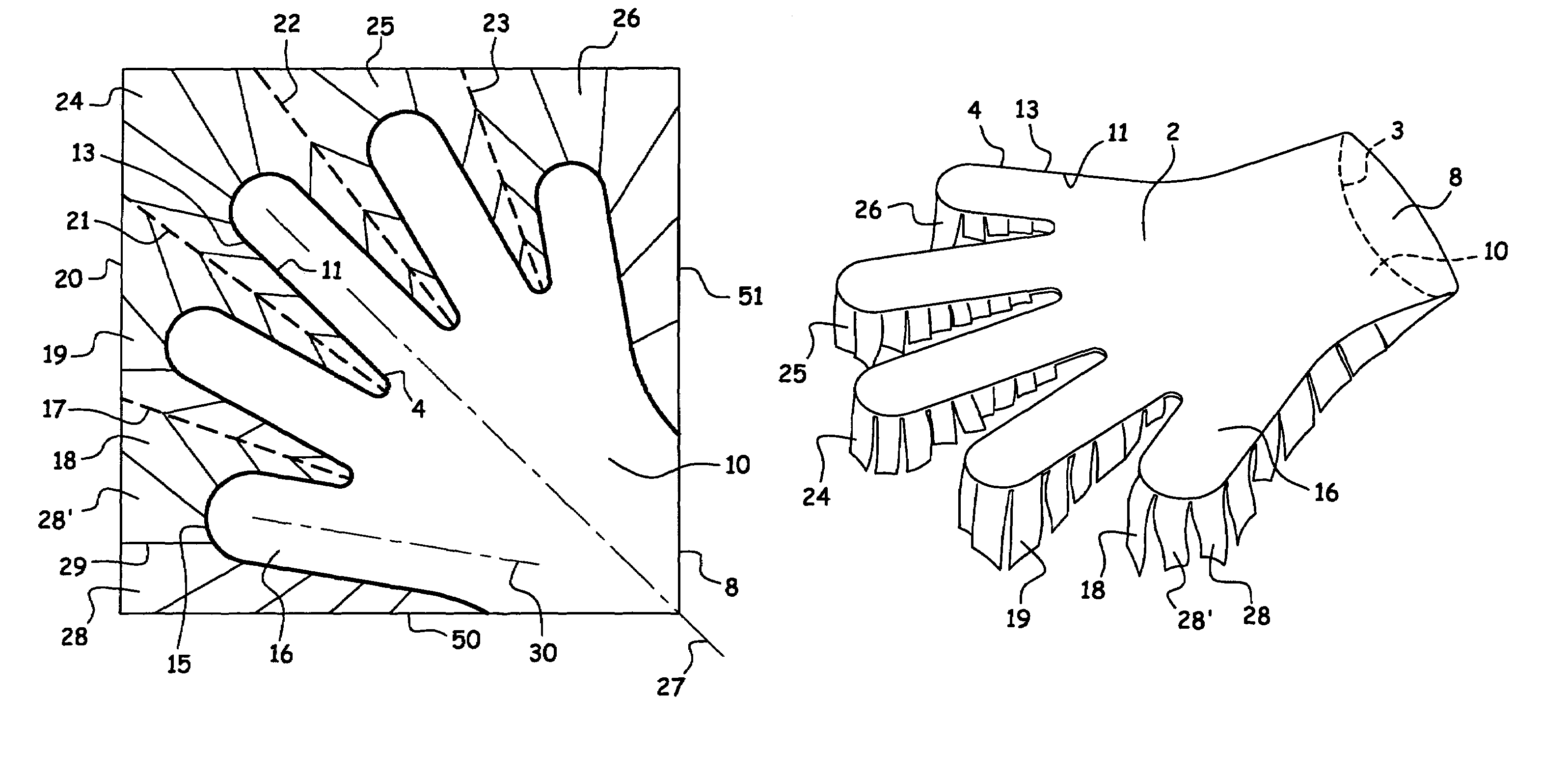

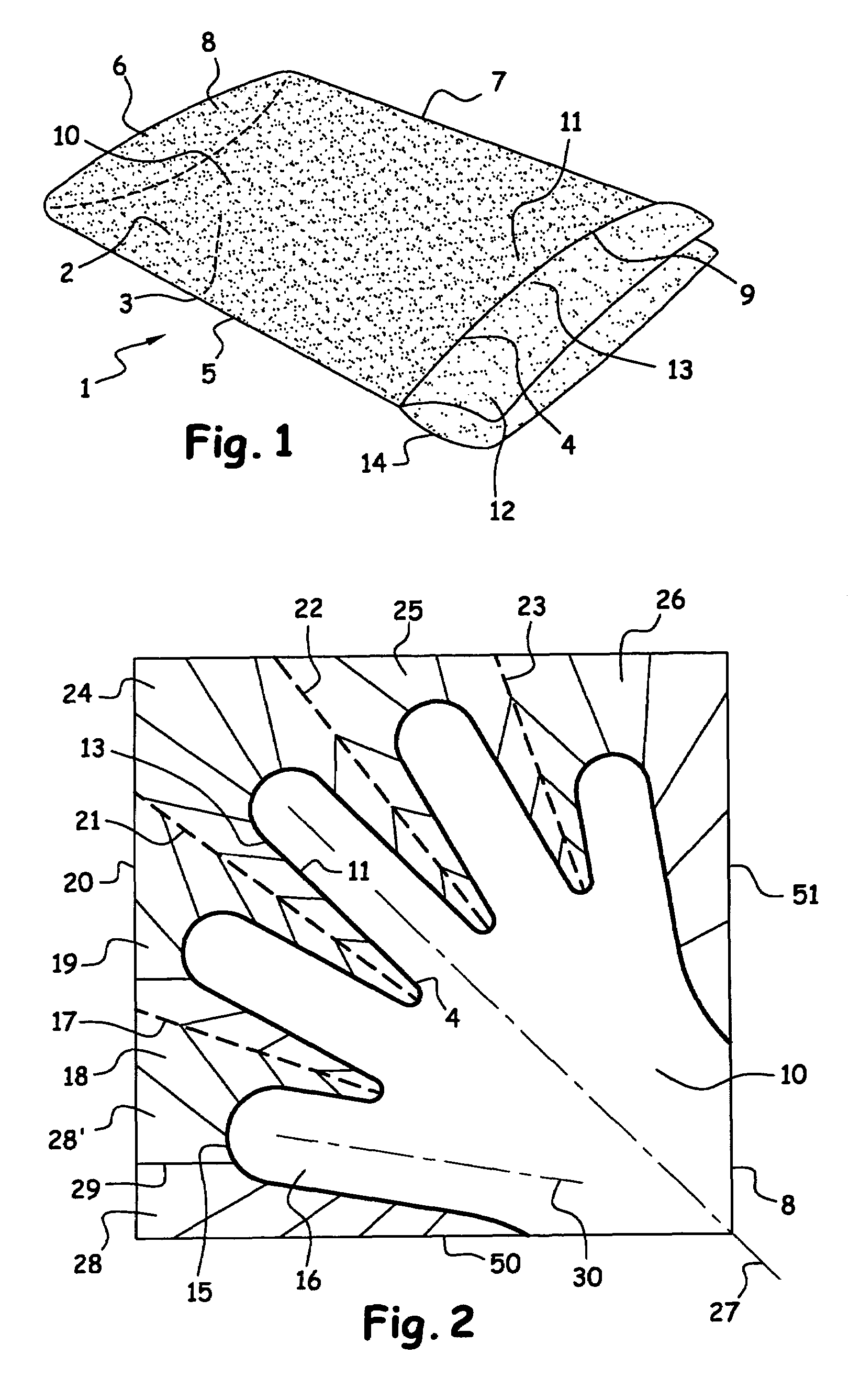

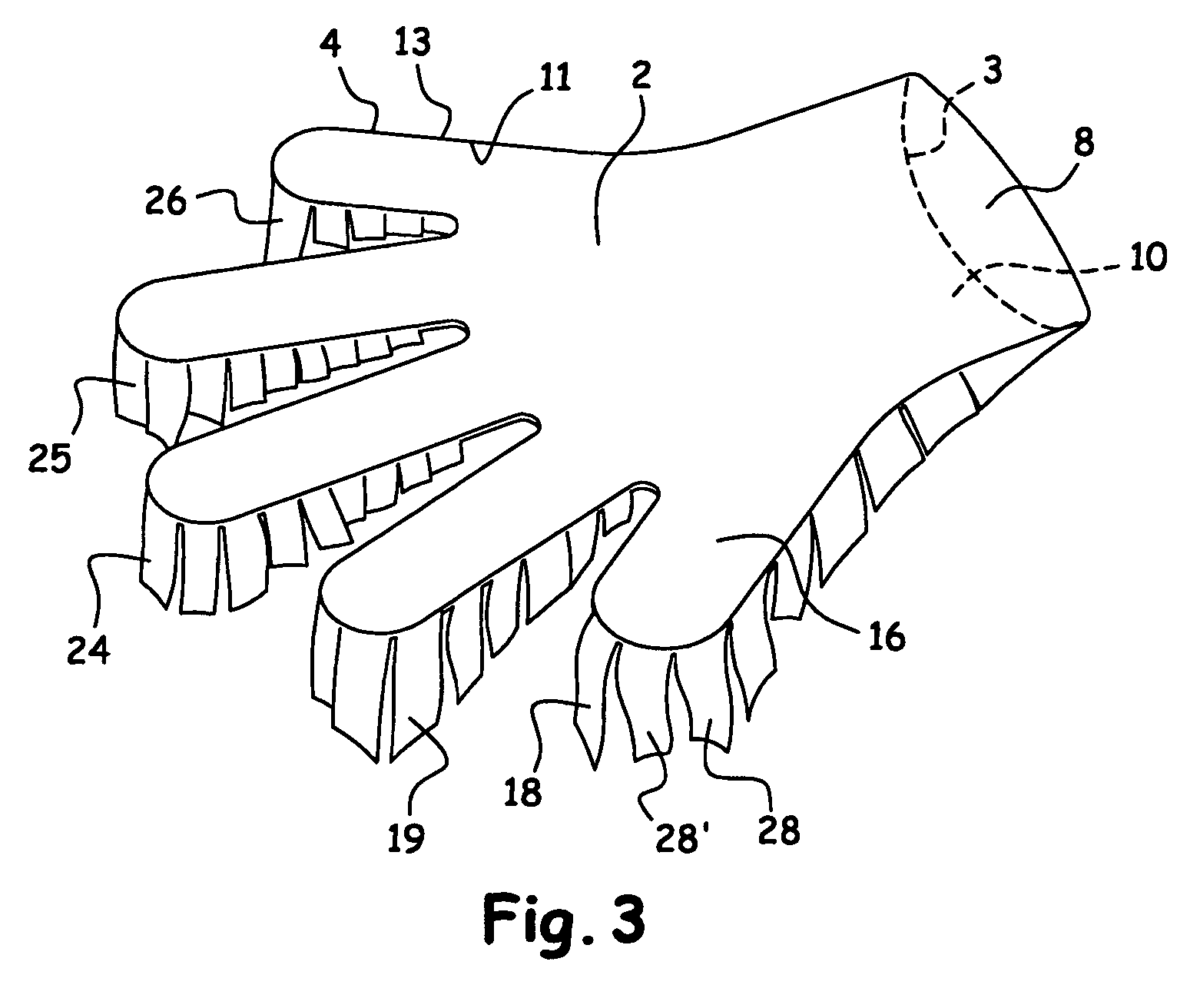

Applicator structure in the form of a glove

InactiveUS7346955B2Improve product performanceHold steadyBoard cleaning devicesCarpet cleanersEngineering

A device that can be used, for example, for application or use with hair care products. The device includes two sheets connected to one another by a connecting region which defines a cavity on a first side of the connecting region, such that a user's hand can be inserted into the cavity. A flexible strip preferably cut into fringes and flaps, is provided on a second side of the connecting region. A method for manufacturing a device of this kind is also provided in which two webs of strip material are unrolled simultaneously, connected, and then cut. Parts of the webs, including both the connecting region and the cut fringes and flaps, are then separated. The device can optionally be impregnated with a product, for example, a hair care product.

Owner:LOREAL SA

Surfactant-containing insulation binder

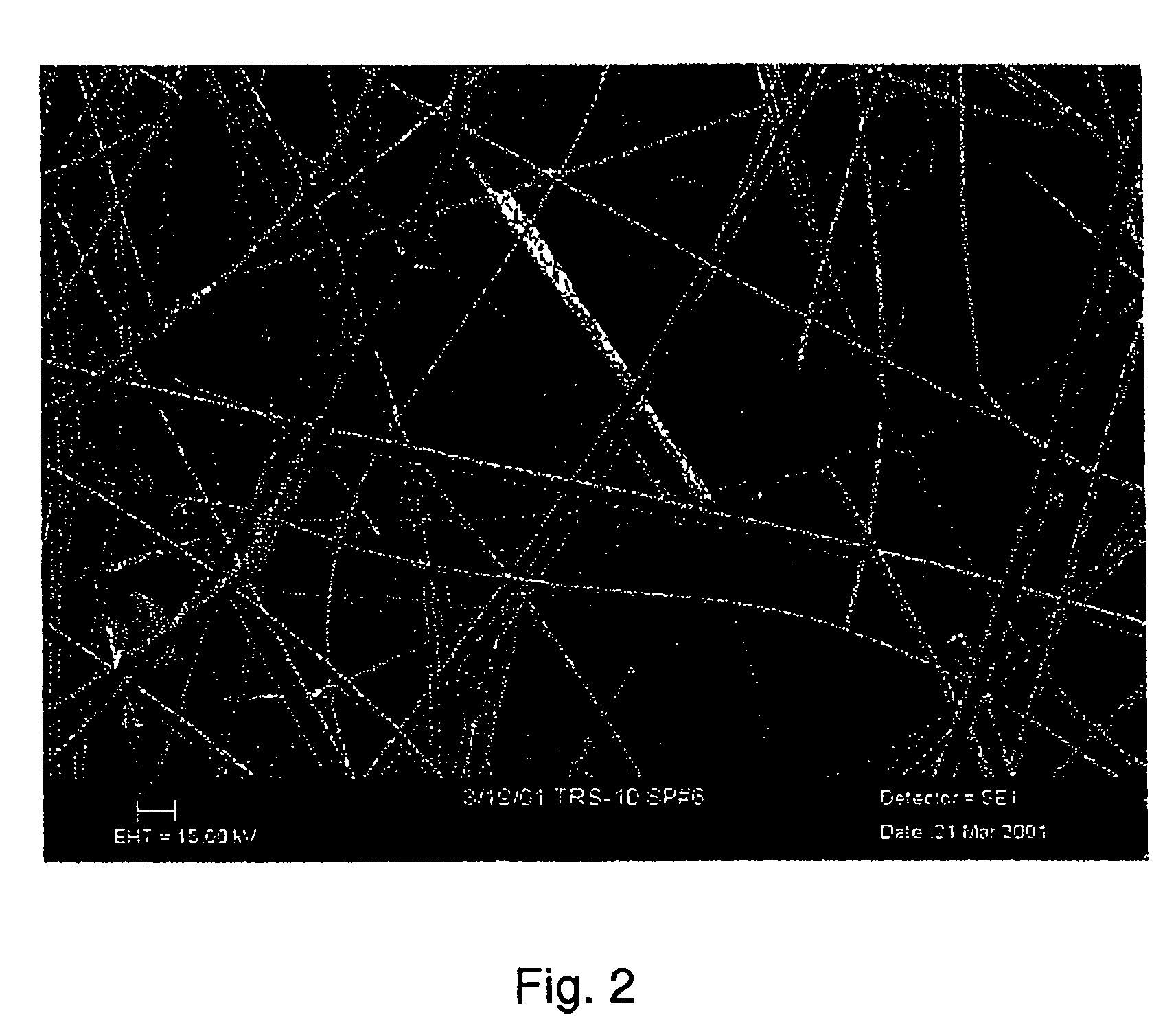

InactiveUS20050192390A1Reduce surface tensionImprove protectionFilm/foil adhesivesSpecial tyresGlass fiberFiber

A fiberglass insulation binder composition made from a polycarboxy polymer, a polyhydroxy crosslinking agent, and a cationic surfactant, amphoteric surfactant, nonionic surfactant, or mixture thereof. Also, a process for manufacturing a fiberglass insulation product, which involves a step of applying the binder composition onto a fiberglass substrate and curing the fiberglass substrate so treated. Binders produced in accordance with the present invention are characterized by improved atomization, improved binder dispersion and fiber wetting properties, and improved protection of individual fibers during processing.

Owner:DOBROWOLSKI RICHARD +3

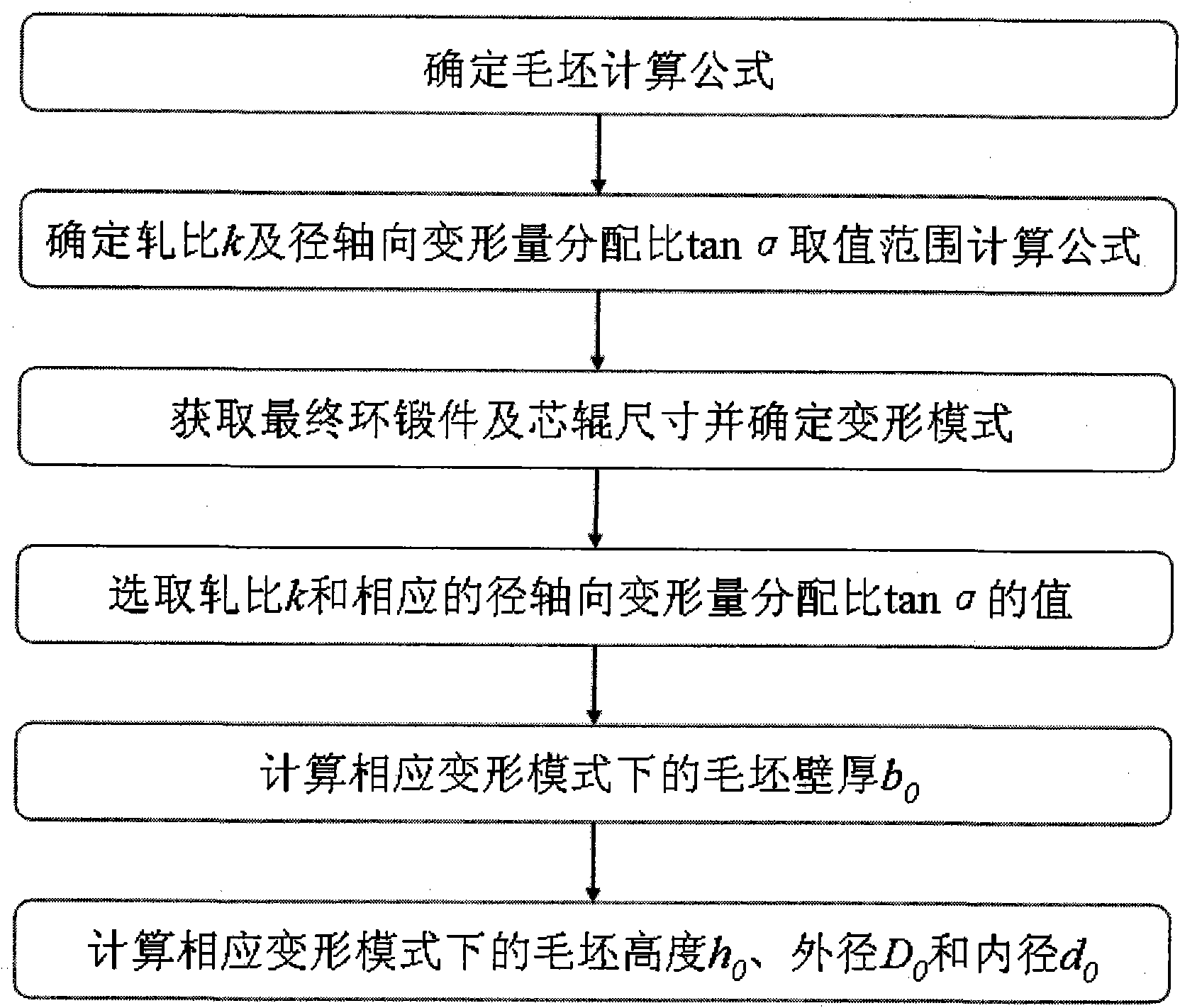

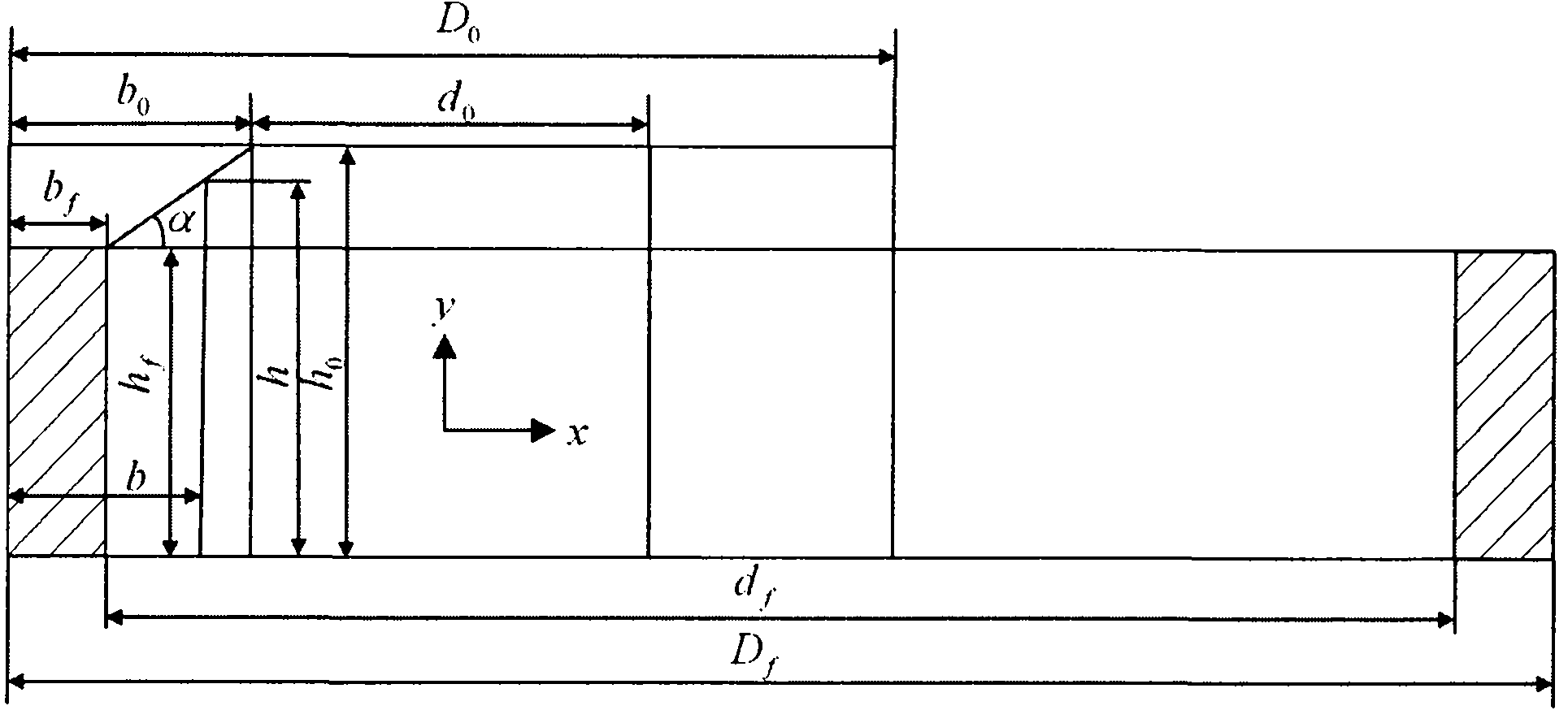

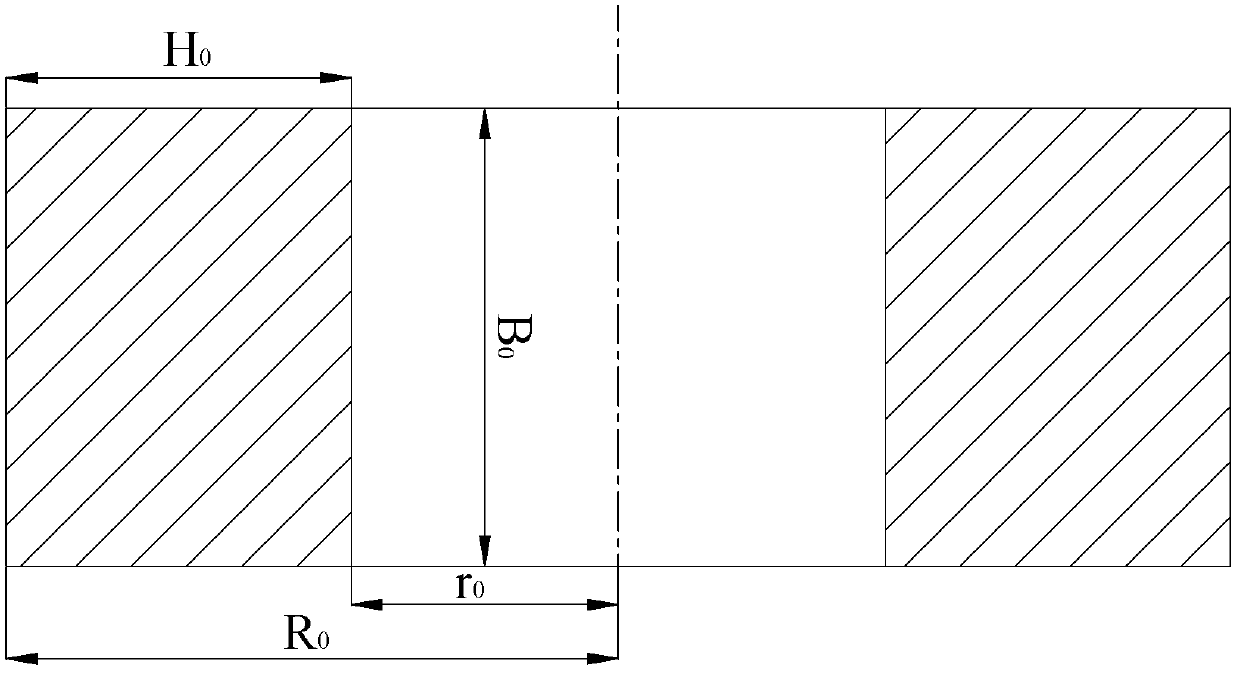

Method for determining dimensions of ring radially-axially rolled blank

InactiveCN101829686AImprove design efficiencyImprove product performanceRoll mill control devicesMetal rolling arrangementsMaterials scienceProduction cycle

The invention discloses a method for determining the dimensions of a ring radially-axially rolled blank, which comprises: firstly, determining a blank dimension calculation formula and the ranges of the values of a rolling ratio k and a radial-axial deformation distribution ratio tana and obtaining the outside diameter Df, inside diameter df, height hf and wall thickness bf of a ring forging and the diameter dm of a core roller; secondly, determining the deformation mode for ring radial-axial rolling; thirdly, calculating and determining the ranges of the values of the rolling ratio k and the radial-axial deformation distribution ratio tana according to the obtained dimensions of the ring forging and the core roller and the determined deformation mode; and finally, selecting a value of the rolling ratio k and the value of the corresponding radial-axial deformation distribution ratio tana according to determined ranges of the values and the deformation mode, calculating the wall thickness b0 of the blank in the corresponding deformation mode, and finally obtaining the height h0, outside diameter D0 and inside diameter d0 of the blank in the corresponding deformation mode. In the invention, for the rolling of a certain ring forging, a series of different rolling ratios k and radial-axial deformation distribution ratios tana of the blank can be designed, the design efficiency and product performance of the ring radially-axially rolled blank are improved, the production period is shortened, the production cost is reduced, and an important method and foundation are provided for researches on the optimization design of the rolling processes (including the rolling process of the blank).

Owner:NORTHWESTERN POLYTECHNICAL UNIV

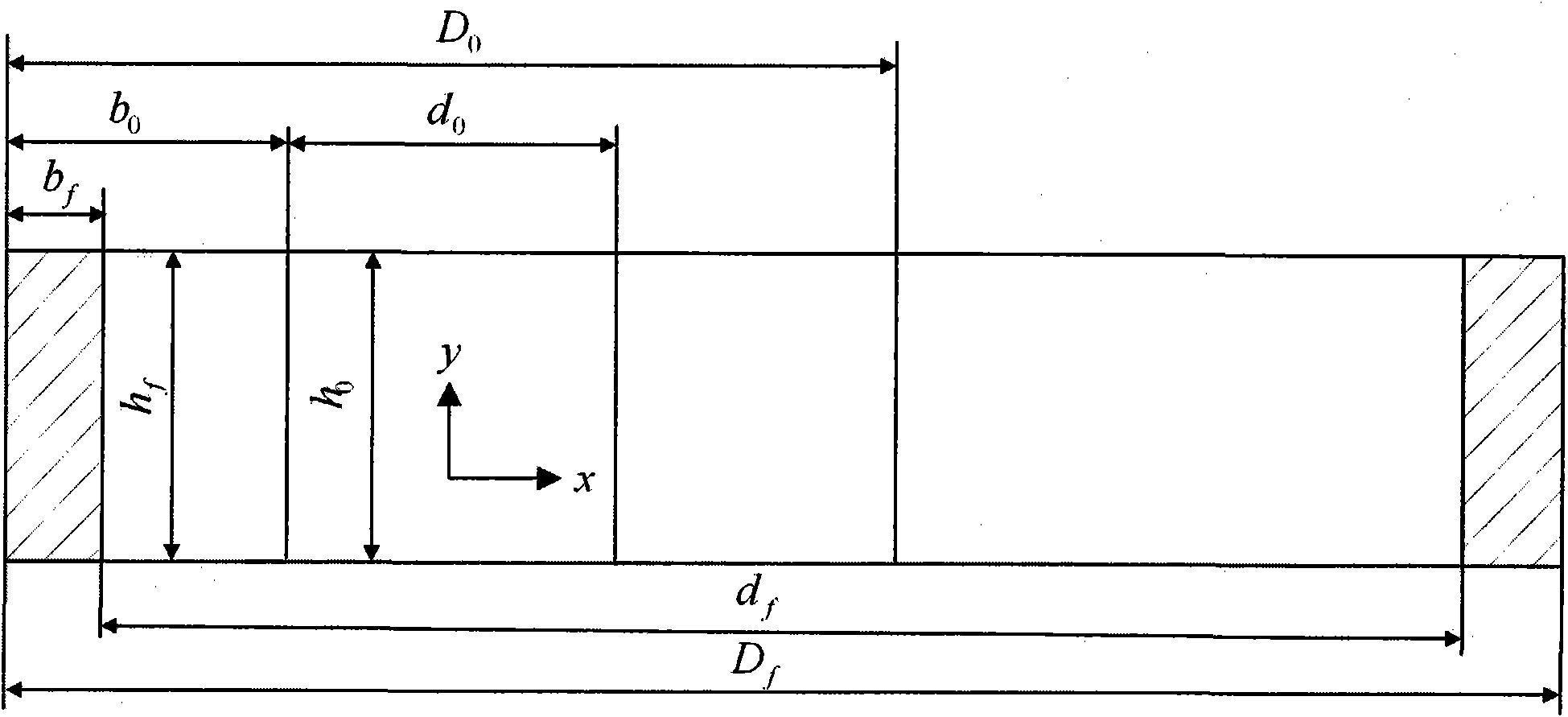

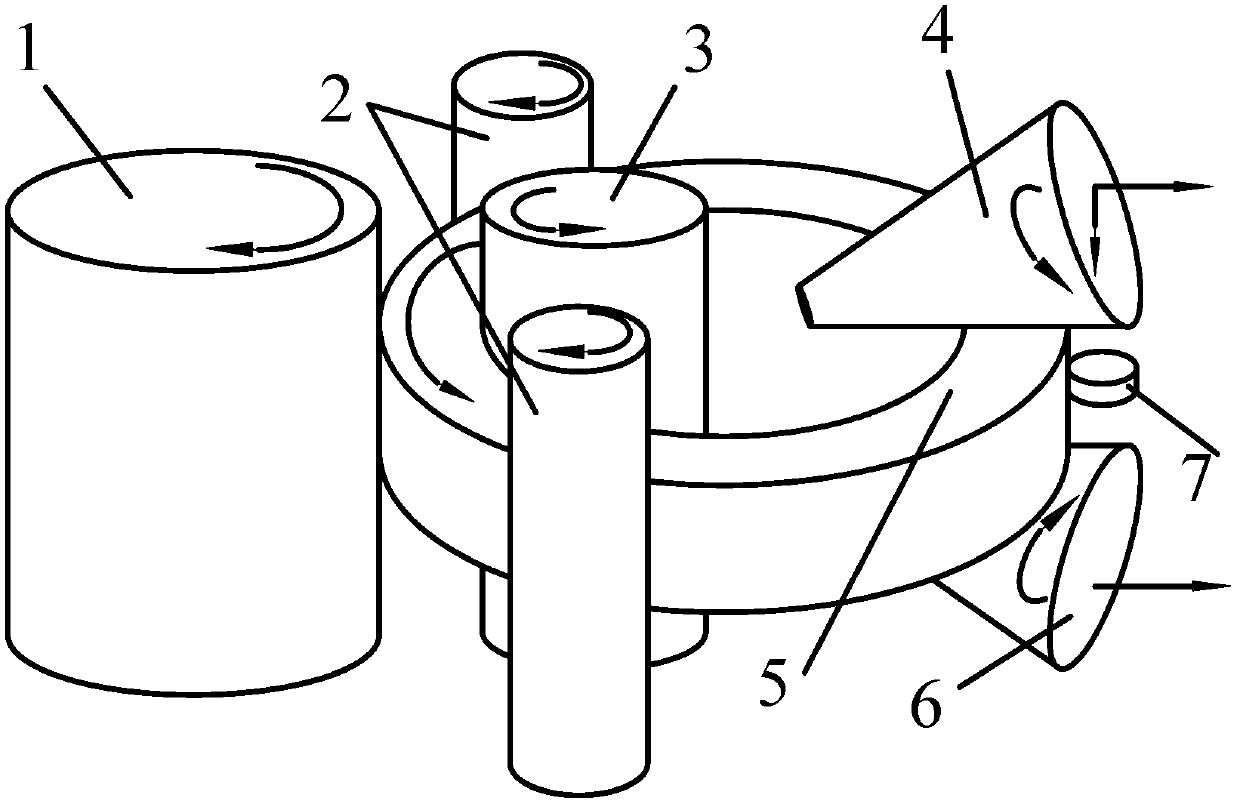

Method for radially and axially rolling and forming large-sized double-edge stepped ring parts

ActiveCN102601278AAvoid damageIncrease productivityMetal rollingStructural engineeringMechanical engineering

The invention relates to a method for radially and axially rolling and forming large-sized double-edge stepped ring parts. The method includes reasonably designing a ring part blank and a rolled hole, controlling a rolling process, directly rolling the rectangular ring part blank to form a double-edge stepped ring part, rolling the hole by a working surface of a driving roll and a working surface of a core roll, and determining the size of the working surface of the driving roll and the size of the working surface of the core roll according to rolling linear speed, equipment parameters, rolling deformation conditions, the size of the ring part blank and the size of the ring part; controlling the rolling process according to a pre-rolling stage, a main rolling stage and an integral rolling stage; and completing the rolling process when the measured outer diameter of the ring part reaches a preset value. By the aid of accumulation of continuous local plastic deformation, the diameter of the ring part is enlarged, the outline of the double-edge stepped section of the ring part is integrally formed, energy, material and working hour consumption is effectively reduced, metal flow line distribution of the ring part is improved, production efficiency and performances of the product are enhanced, and production cost is reduced.

Owner:WUHAN UNIV OF TECH +1

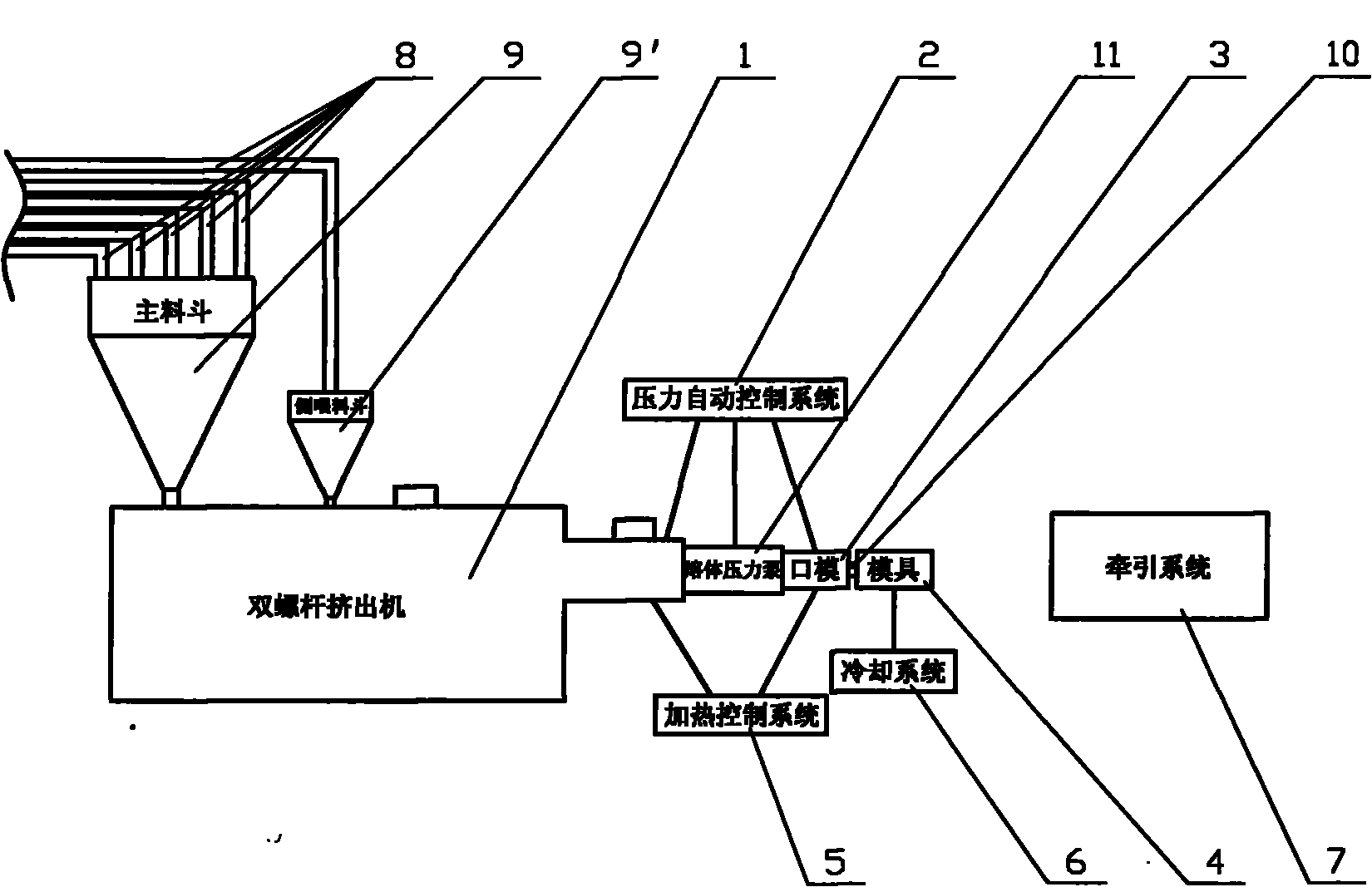

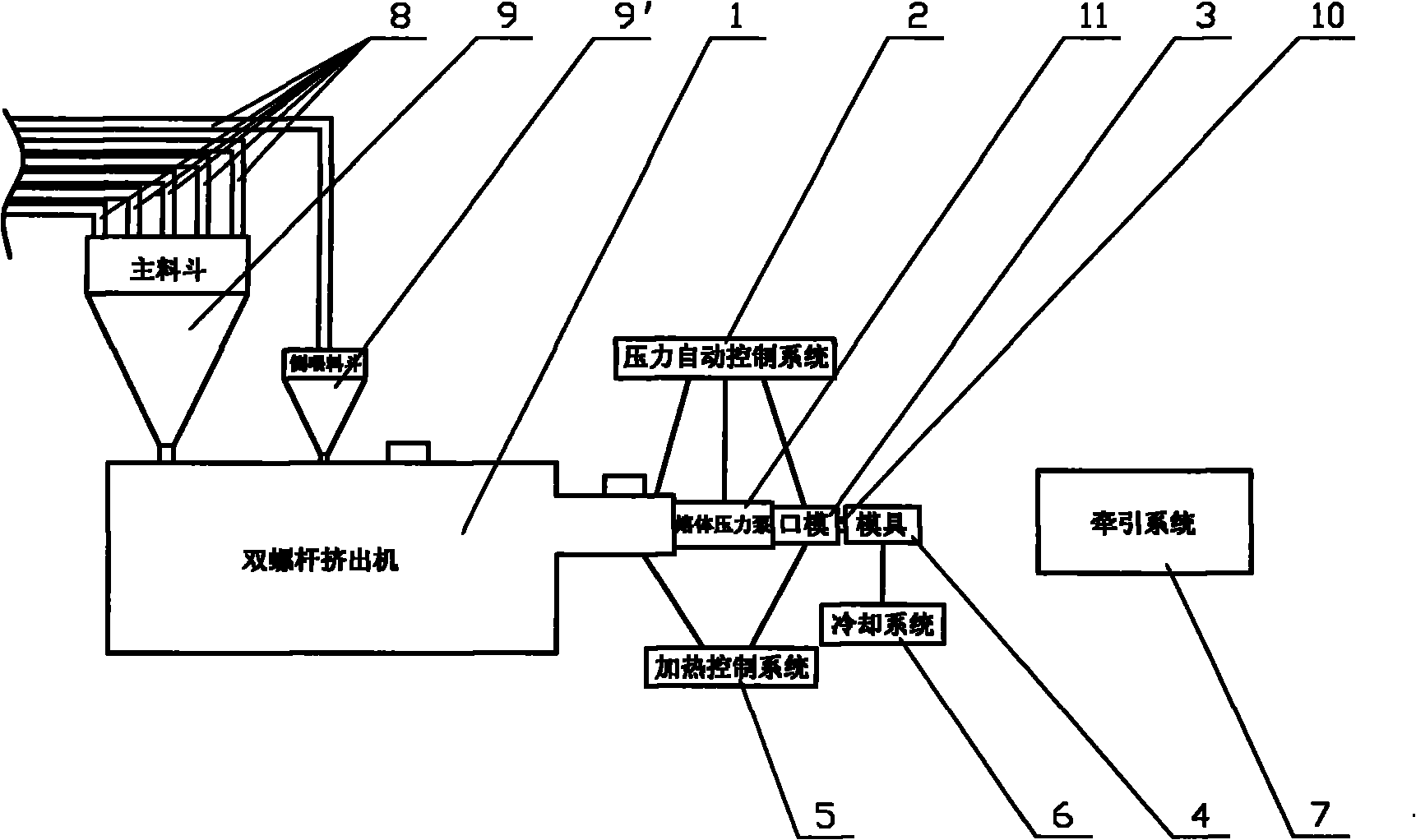

Device and method for manufacturing glass fibre reinforced nylon 66 heat-insulating strips

InactiveCN101791844AImprove product performanceEasy to recrystallizeNylon 66Manufacturing engineering

The invention discloses a device for manufacturing glass fibre reinforced nylon 66 heat-insulating strips, which comprises a feeding system, an extruder, a pressure control system, a die, a shaping die, a heating control system, a cooling system and a pull system. The feeding system comprises conveying pipelines and a hopper and each conveying pipeline conveys a single component of raw materials to the hopper and then feeds the material to the extruder; and the extruder is a double-screw extruder. The invention also discloses a method for manufacturing the glass fibre reinforced nylon 66 heat-insulating strips on the basis of the manufacturing device. In the device and the method, each component of the raw materials does not need to be mixed for pelletizing in advance, and a mode of conveying the single component of the raw materials with each conveying pipeline is adopted, so a pelletizing process and a melting and plasticizing process of the materials are reduced; the heat-insulating strip product with high performance and stable quality can be obtained to meet using requirements; and the application and development of the heat-insulating strip product and the manufacturing process technology are promoted.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

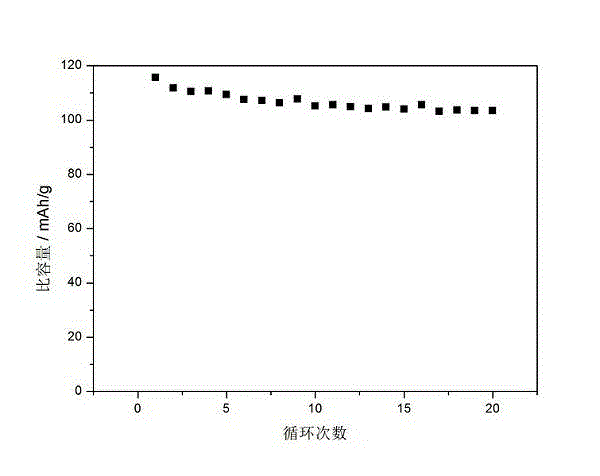

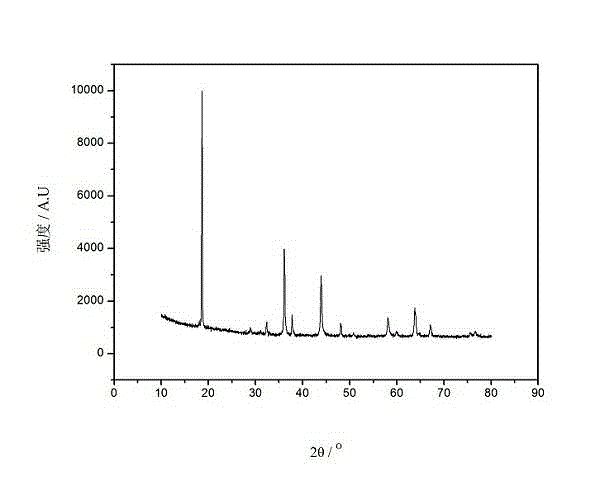

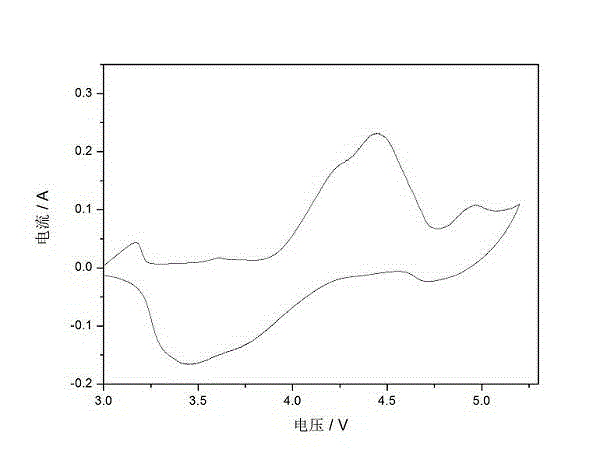

High-voltage lithium ion battery cathode material of copper-doped lithium manganate and preparation method thereof

InactiveCN102723495AStable host latticeImprove structural stabilityCell electrodesEvaporationManganate

The invention discloses a high-voltage lithium ion battery cathode material of copper-doped lithium manganate. The high-voltage lithium ion battery cathode material is characterized in that the general formula is LiMn2-xCuxO4, wherein x is more than or equal to 0.1 and less than or equal to 0.5. The modified cathode material is prepared by adopting a sol-gel method, and the preparation method comprises the following steps of: dissolving a soluble lithium salt, a soluble manganese salt and a soluble copper salt in deionized water to prepare a mixed solution; mixing with an acidic complexing agent solution to react, controlling the reaction temperature to be between 60 and 90 DEG C, and adjusting the pH value to be 6 to 8 by using ammonia water; continuously stirring and drying by evaporation; after drying, pre-burning the obtained gel precursor for 1 to 10 hours at 400 to 500 DEG C; and calcining the gel precursor for 8 to 16 hours at 600 to 900 DEG C to obtain a final product. The high-voltage lithium ion battery cathode material of copper-doped lithium manganate is uniform in grain diameter and stable in structure, the technical process is simple, the production cost is low, and a prepared lithium ion secondary battery has high charge-discharge cycle performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

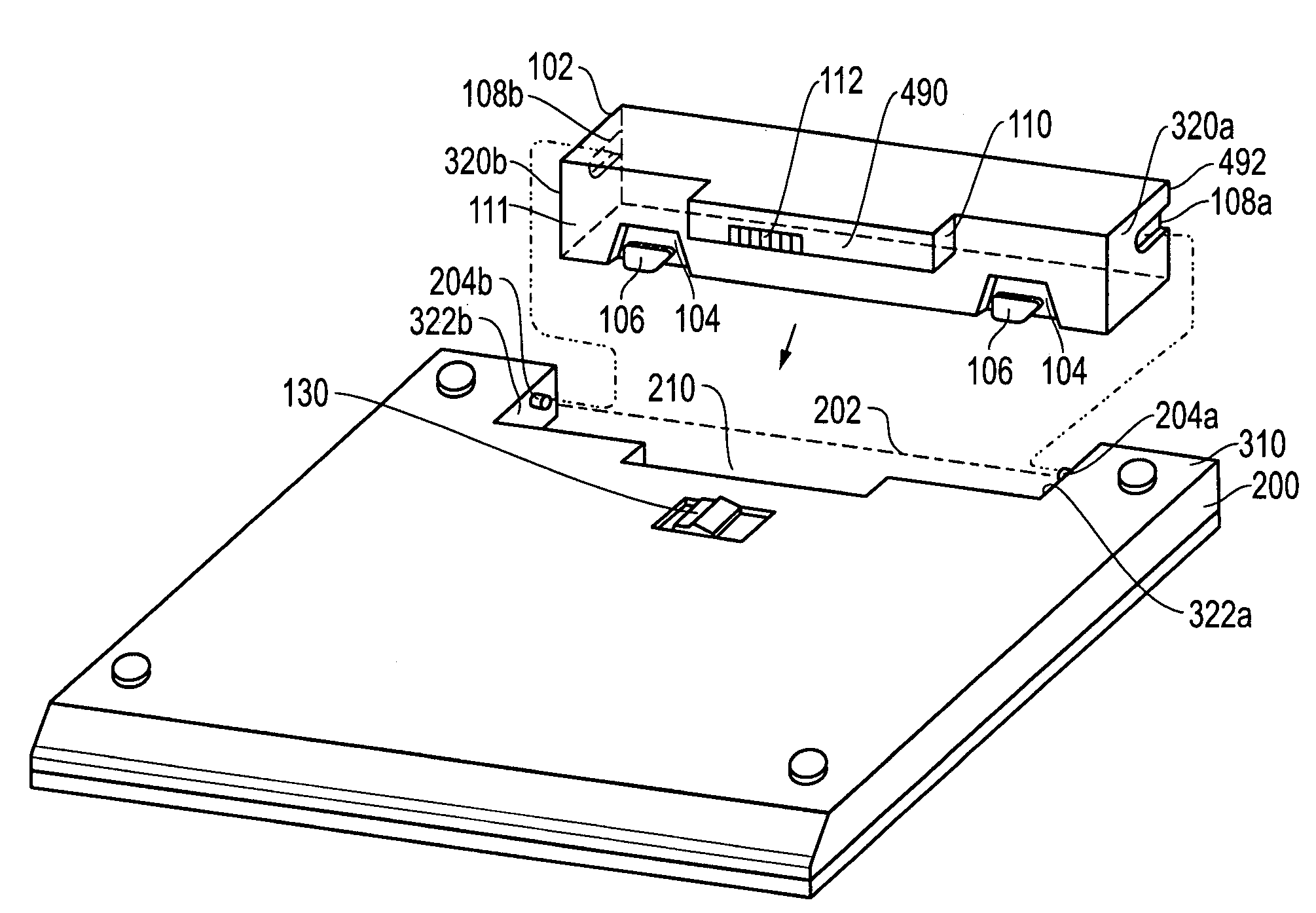

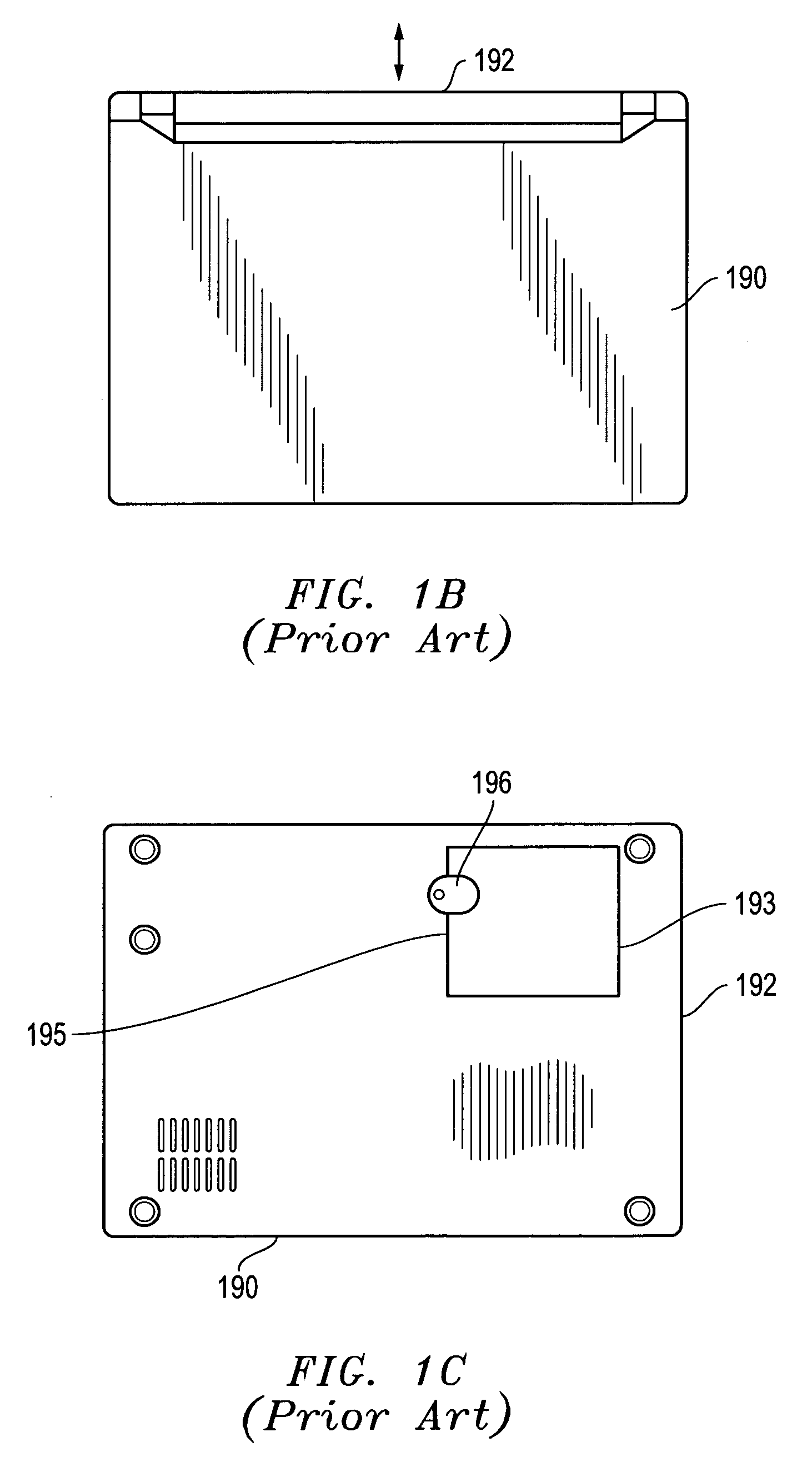

Apparatus and methods for battery installation

ActiveUS8399117B2Small sizeImprove usabilityDigital data processing detailsSecondary cells charging/dischargingDisplay deviceHandling system

Apparatus and methods for placement of battery packs in portable information handling systems such as notebook and netbook computers. A first set of pivot features may be provided on opposing sidewalls of a battery well that interface with a corresponding set of mating pivot features provided on exterior end surfaces of a battery pack such that the battery pack may be pivoted into and out from the battery well to install or release it from the system, e.g., pivoted from the bottom of the portable information handling system in a manner that does not interfere with, or require modification to, the lid and display of the portable information handling system. A latch mechanism and battery release feature may be further provided that acts to transfer horizontal manipulation (e.g., horizontal sliding motion) of the battery release feature to a vertical latching action that acts to lift the battery pack out from the portable information handling system chassis when releasing the battery pack from the chassis.

Owner:DELL PROD LP

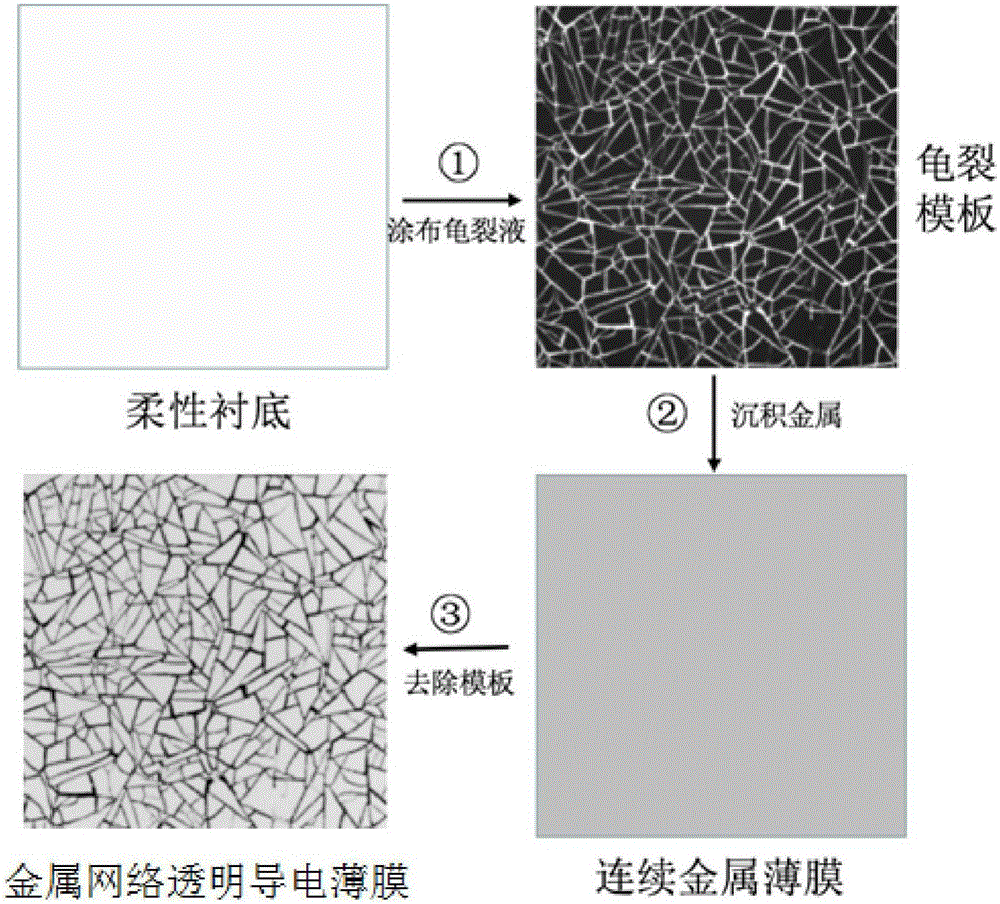

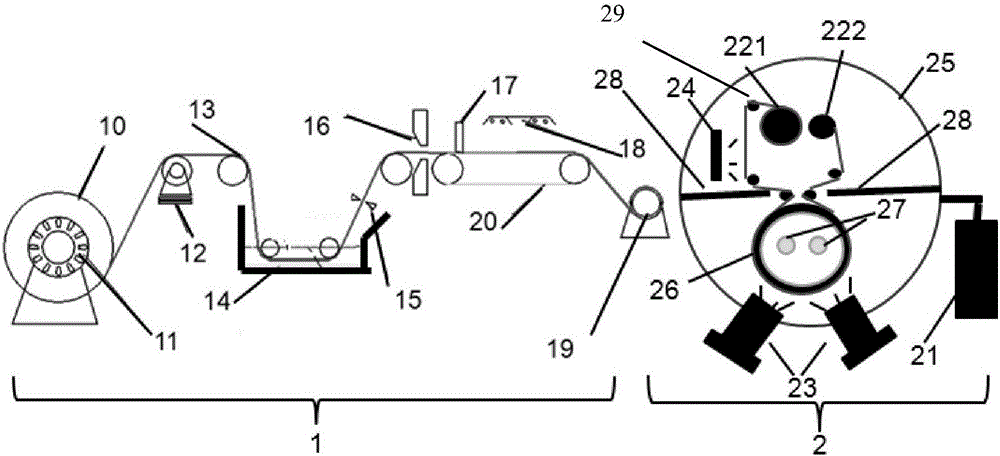

Method and apparatus for continuous production of flexible micro-nano metal network transparent conductive film

ActiveCN106244989AImprove uniformityImprove transmittanceVacuum evaporation coatingSputtering coatingEngineeringVacuum pump

The invention discloses a method and apparatus for continuous production of a flexible micro-nano metal network transparent conductive film. The method comprises the steps of: continuously conveying a flexible substrate to undergo pre-cleaning, air drying, atmospheric pressure plasma cleaning, cracking liquid coating and heating in order, thus forming a craquelure template on the flexible substrate; placing the flexible substrate in a vacuum chamber and performing vacuum pumping on the vacuum chamber; subjecting the flexible substrate to secondary plasma cleaning, then coating a compact metal film, and filling the craquelures on the craquelure template with a metal film material in the process so as to obtain a flexible micro-nano metal network transparent conductive film semi-finished product; releasing vacuum, taking out the semi-finished product from the vacuum chamber, and removing the craquelure template from the flexible substrate, thus obtaining the product. The method and apparatus provided by the invention realize continuous and large-area production of the flexible micro-nano metal network transparent conductive film. The film coating mode is suitable for industrial automatic continuous magnetron sputtering production lines, can greatly shorten the production cycle, and substantially improves the productivity.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

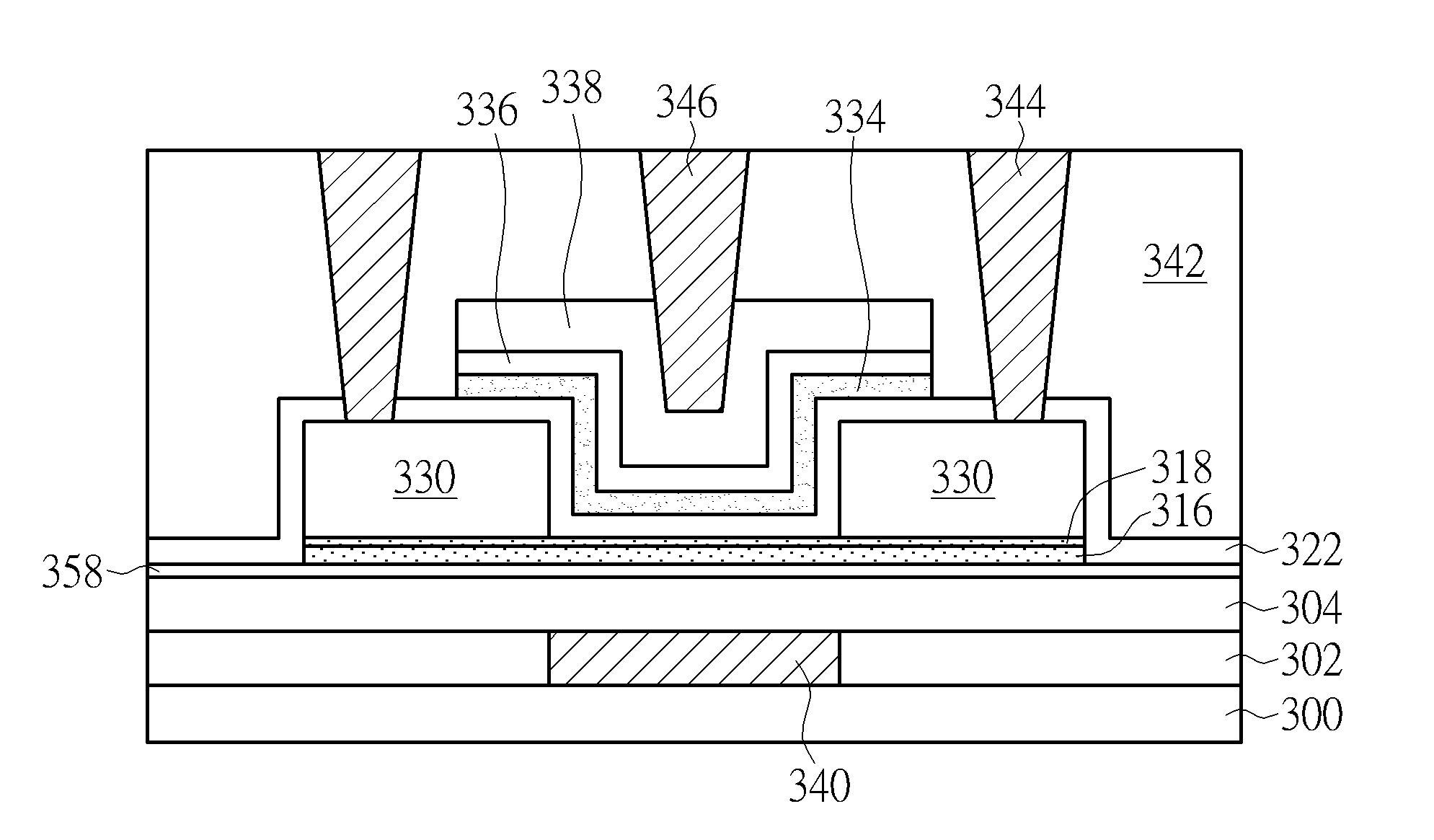

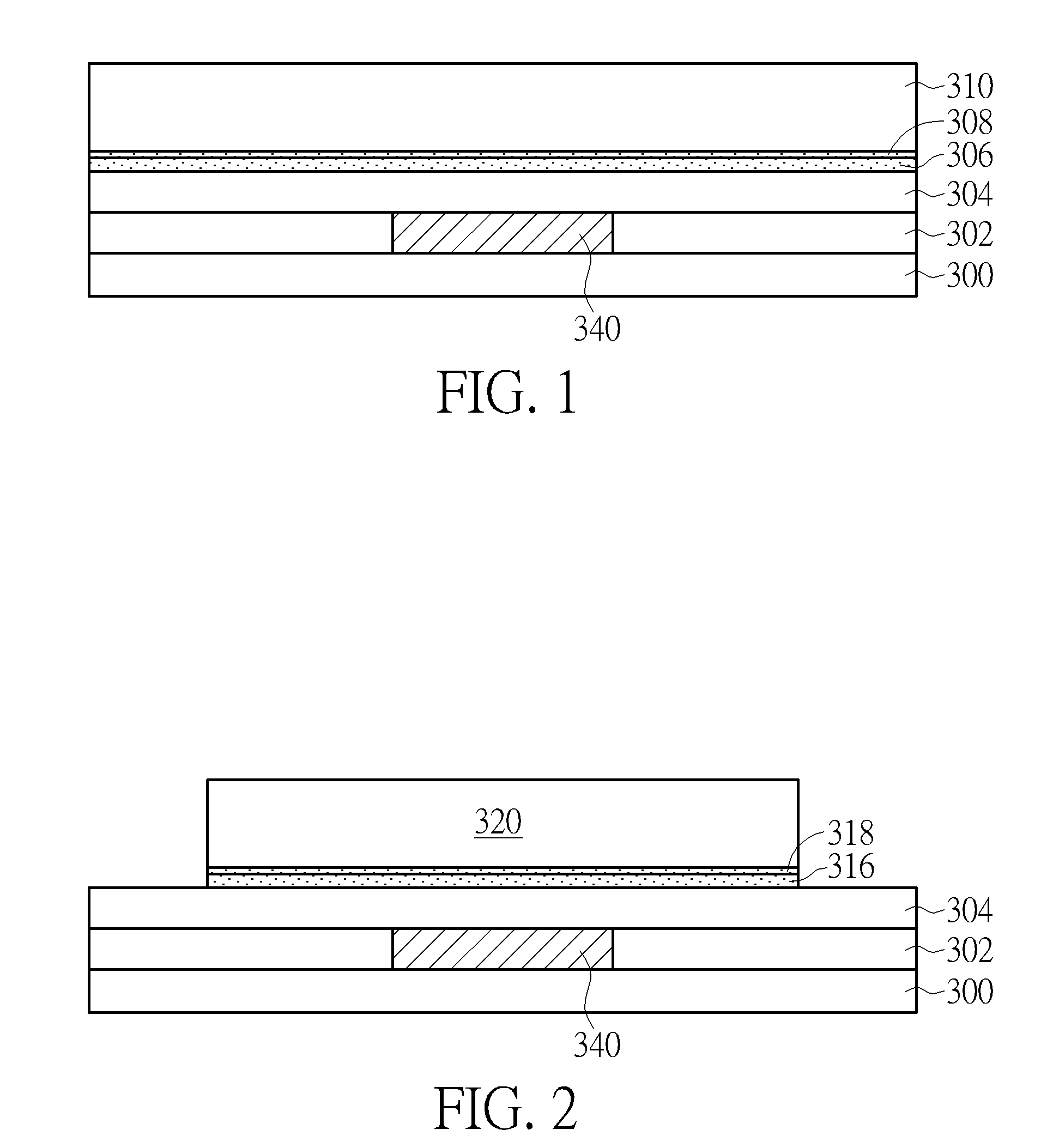

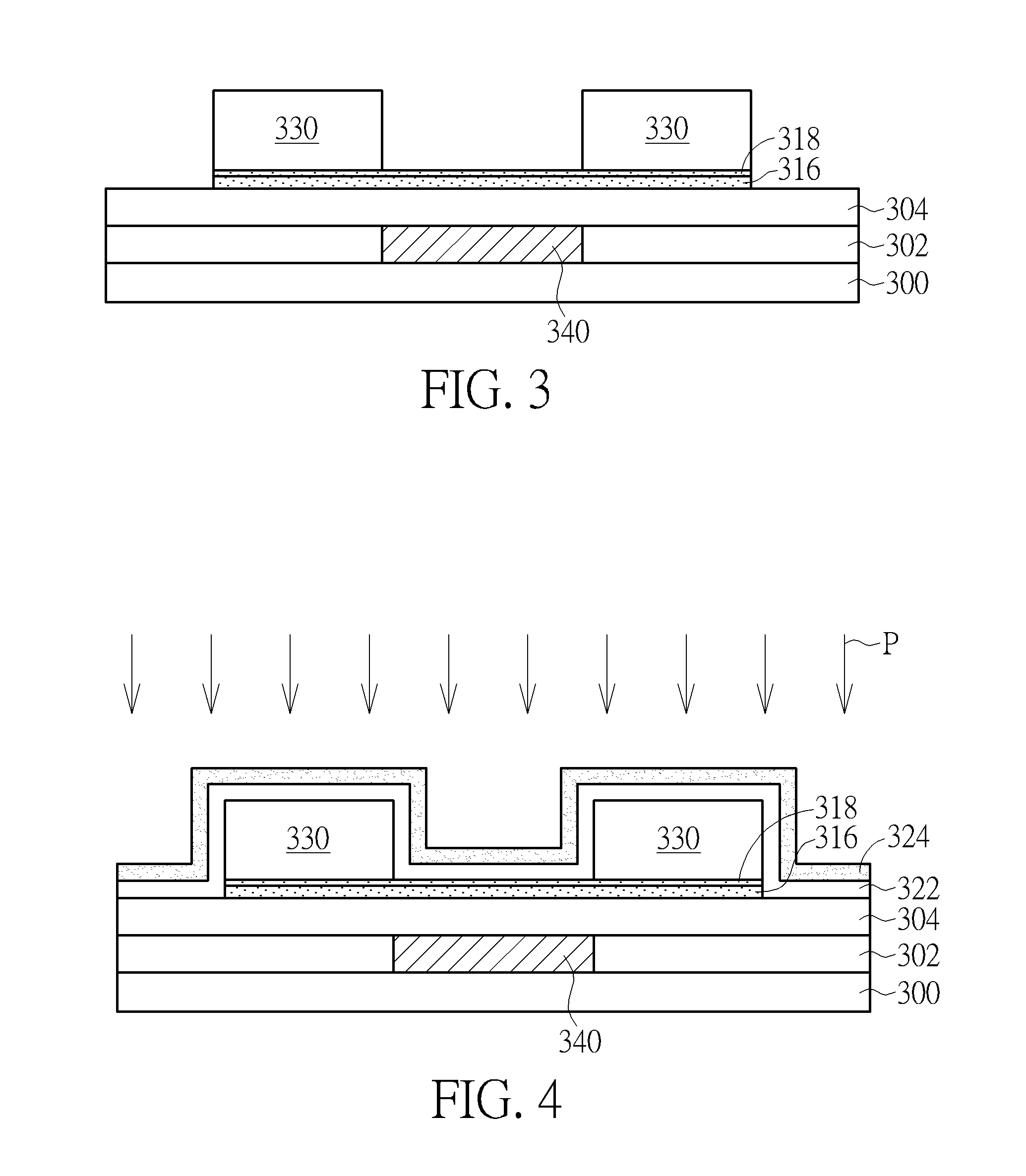

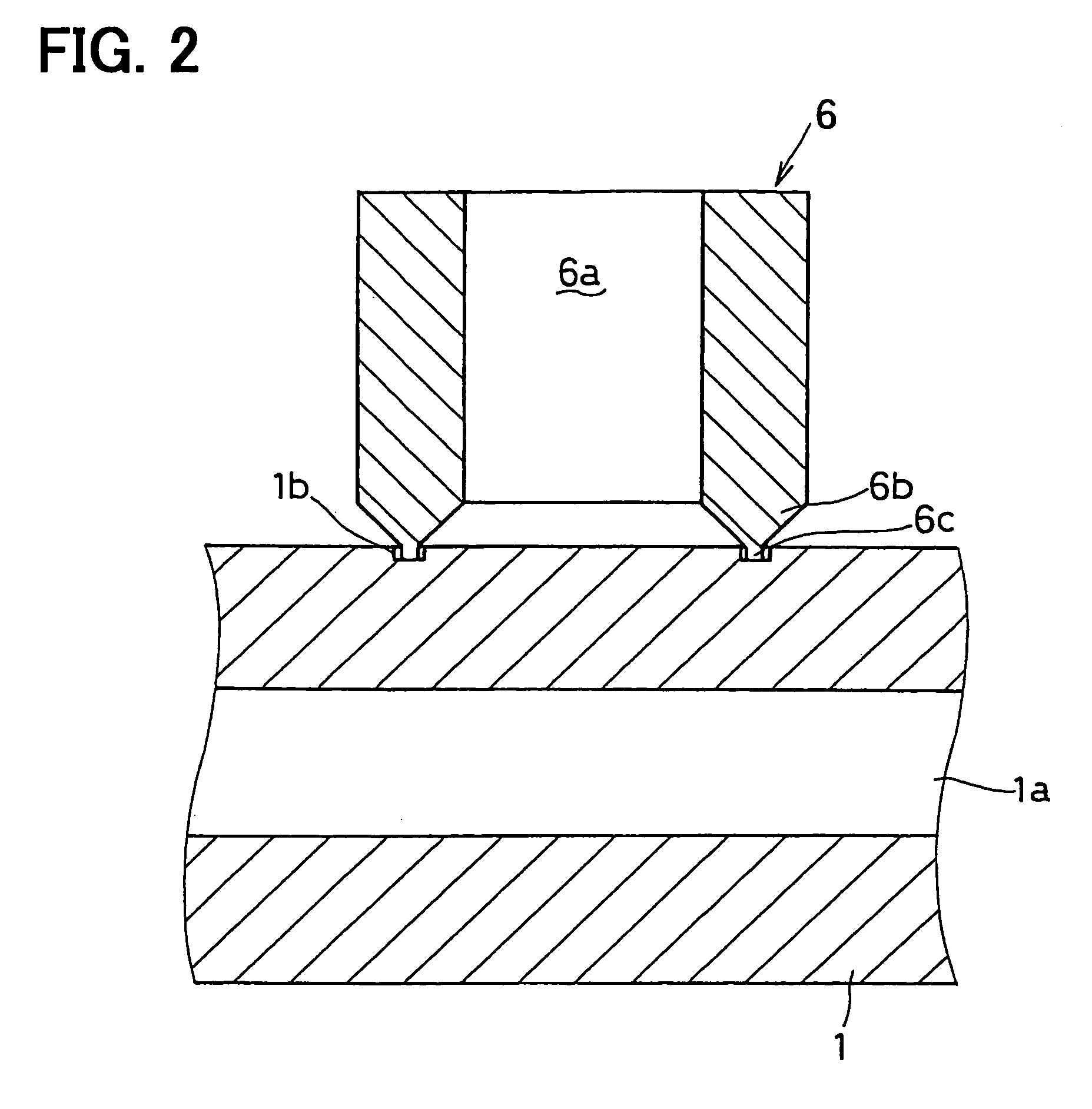

Semiconductor device and method for forming the same

ActiveUS20170062484A1Improve qualityAvoid oxygen vacancy phenomenonTransistorSemiconductor/solid-state device detailsOxide semiconductorSource structure

The present invention provides a semiconductor device and a method of forming the same, and the semiconductor device including a substrate, an oxide semiconductor layer, two source / drain regions, a high-k dielectric layer and a bottom oxide layer. The oxide semiconductor layer is disposed on a first insulating layer disposed on the substrate. The source / drain regions are disposed on the oxide semiconductor layer. The high-k dielectric layer covers the oxide semiconductor layer and the source structure and the drain regions. The bottom oxide layer is disposed between the high-k dielectric layer and the source / drain regions, wherein the bottom oxide layer covers the source / drain regions and the oxide semiconductor layer.

Owner:UNITED MICROELECTRONICS CORP

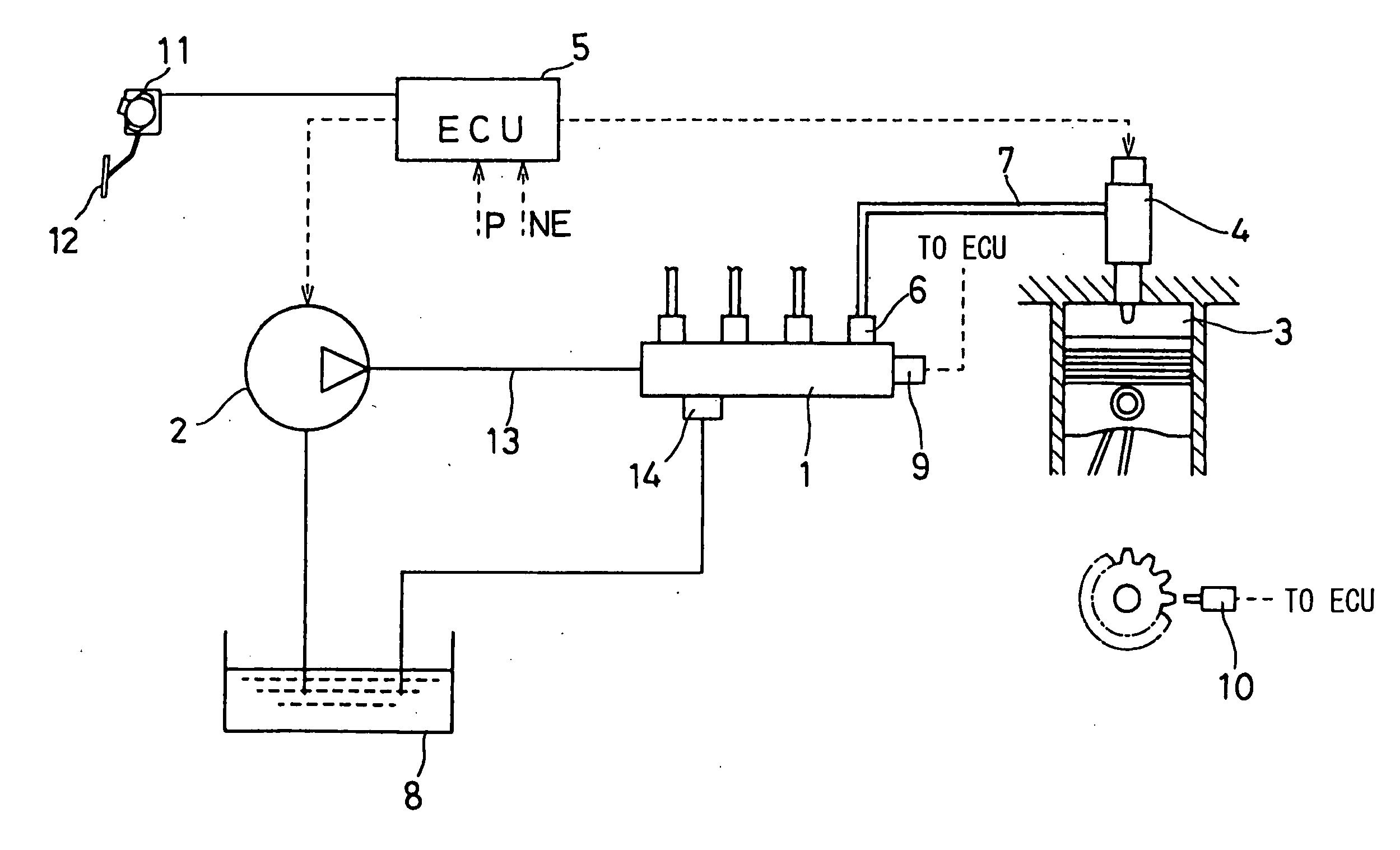

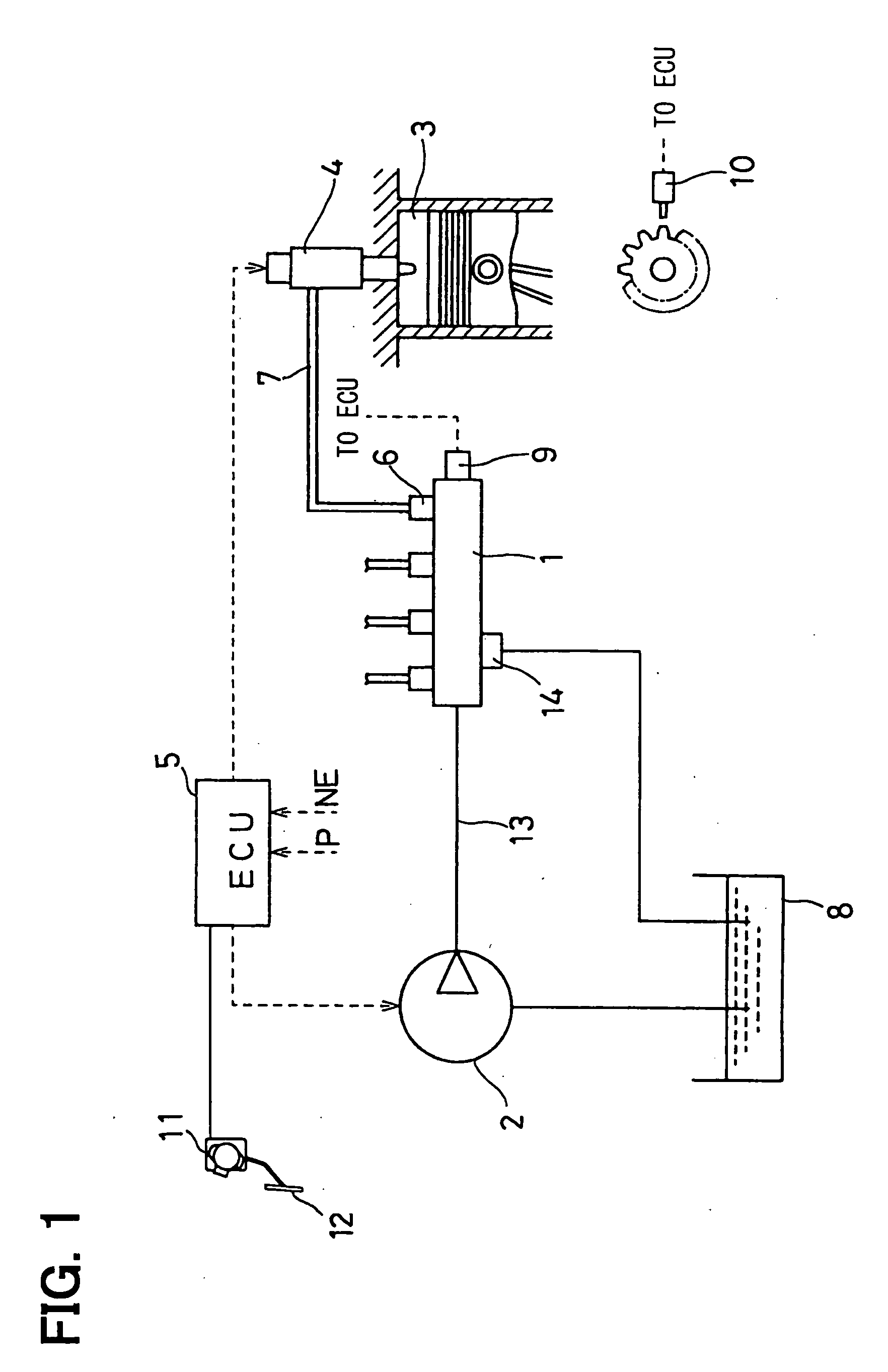

Common rail

ActiveUS20060054139A1Bonding accuracyImprove fitting accuracyPipeline expansion-compensationFluid pressure sealed jointsCommon railEngineering

A ring-shaped connecting portion is formed on a seat surface side of a pipe connector. The connecting portion is tapered so that thickness thereof gradually reduces toward a tip end thereof. A protrusion is formed on the tip end of the connecting portion. A ring-shaped groove is formed on a flat outer peripheral surface of a common rail. By fitting the protrusion into the groove, the connector can be positioned to a predetermined position of the common rail. In this structure, current can be concentrated to the protrusion and current density can be increased. As a result, sufficient bonding strength can be attained.

Owner:DENSO CORP

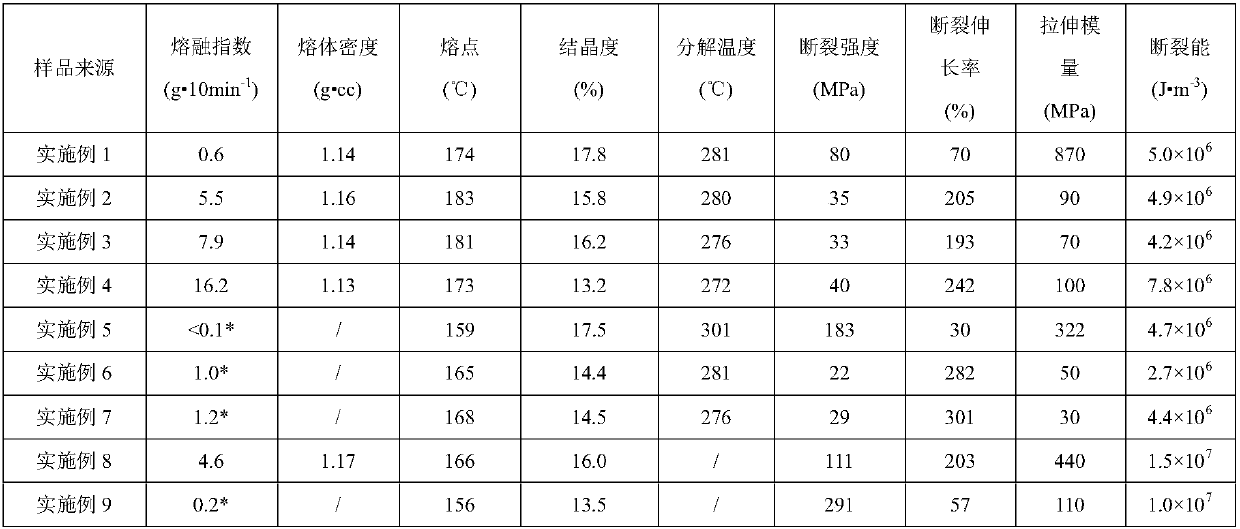

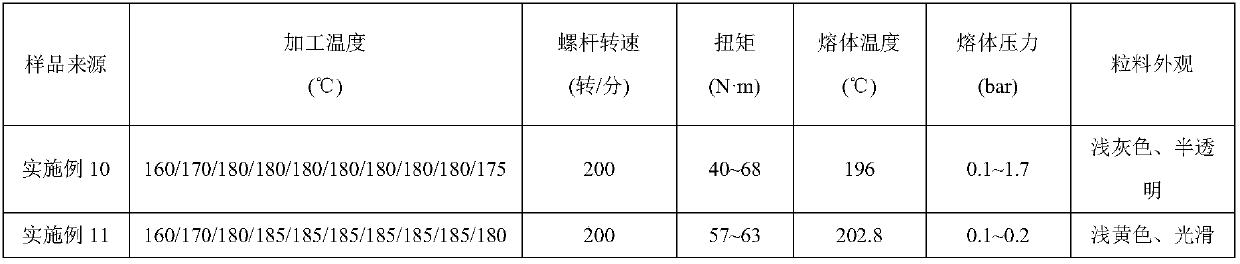

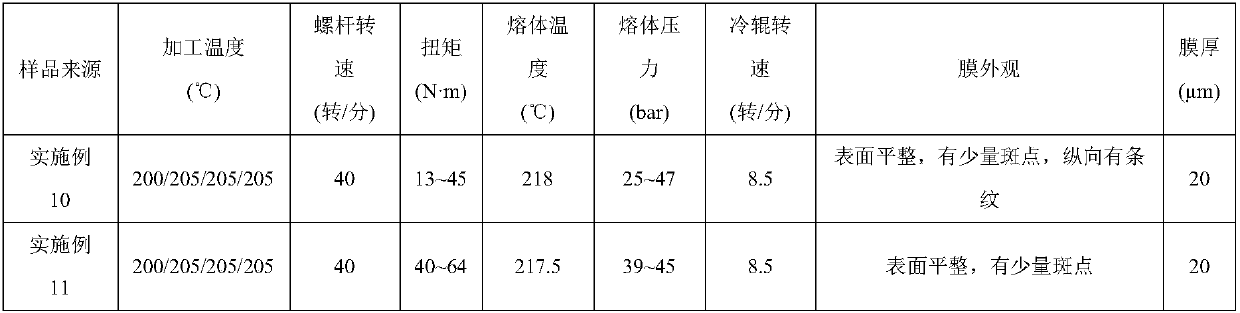

Thermoplastically modified high-fluidity polyvinyl alcohol, and thermoplastically modified high-fluidity polyvinyl alcohol casting film material and preparation method thereof

InactiveCN107936430AExpanded processing windowGood thermoplastic processabilityFlat articlesPolymer sciencePlasticizer

The invention relates to a thermoplastically modified high-fluidity polyvinyl alcohol casting film material and a preparation method thereof. A purpose of the present invention is mainly to solve theproblems of poor thermoplasticity, difficult processing, poor melt fluidity, easy thermal-oxidation degradation, difficult casting film preparation and poor mechanical property of polyvinyl alcohol inthe prior art. The technical scheme comprises that the thermoplastically modified high-fluidity polyvinyl alcohol is used, and comprises, by mass, 1) 70-99.9 parts f polyvinyl alcohol, and 2) 0.1-30parts of a plasticizer, the polyvinyl alcohol and the plasticizer are respectively introduced into a twin-screw extruder, and melt extrusion and granulation are performed through a screw rod extrusionprocessing technology to obtain the thermoplastically modified high-fluidity polyvinyl alcohol. With the technical scheme, the problems in the prior art are well solved. The method of the present invention can be used for industrial production of polyvinyl alcohol casting film materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

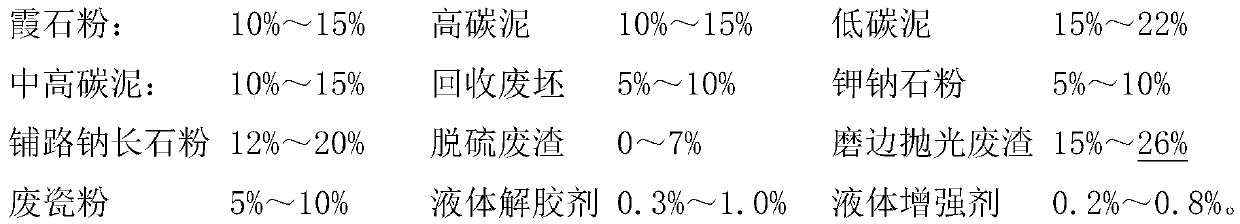

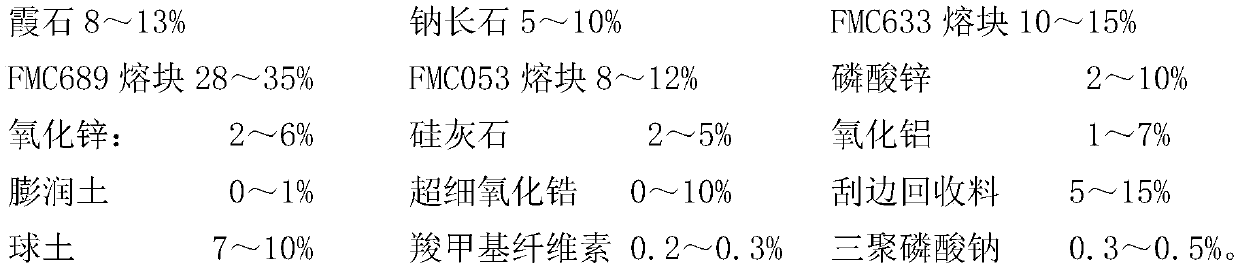

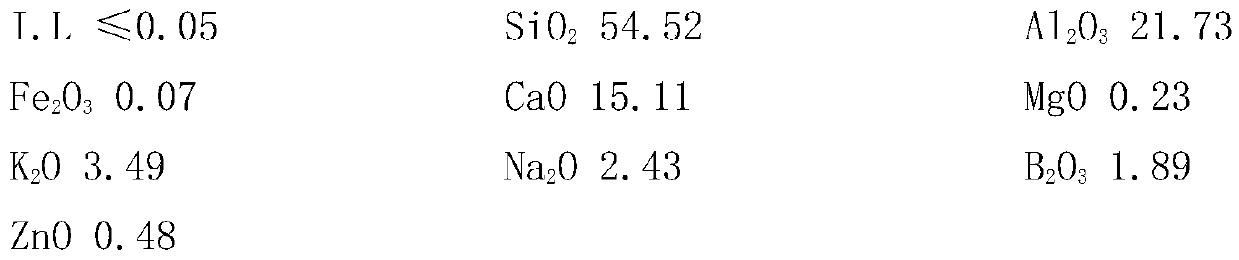

Silky fine matt ceramic tile and production method thereof

ActiveCN110204306AReduce consumptionSimplify product processCeramic shaping apparatusCeramic materials productionCeramic tilesPotassium

The invention relates to a silky fine matt ceramic tile and a production method thereof. The blank material of the ceramic brick comprises 10-15% of nepheline powder, 5-10% of high-carbon mud, 20-25%of low-carbon mud, 10-15% of medium-and-high-carbon mud, 5-10% of recovered waste blanks, 5-10% of potassium and sodium stone powder, 20-25% of paving albite powder, 5-10% of waste porcelain powder, 0-7% of desulfurization waste residues, 20-30% of edging and polishing waste residues, 0.3-1.0% of a liquid dispergator and 0.2-0.8% of a liquid reinforcing agent. The production method comprises the following processes: proportioning and ball milling of blank raw materials, spray drying, aging, blank compression molding, drying, blank polishing, water spraying, glazing, pattern decoration and firing.

Owner:JIANGXI HEMEI CERAMICS +4

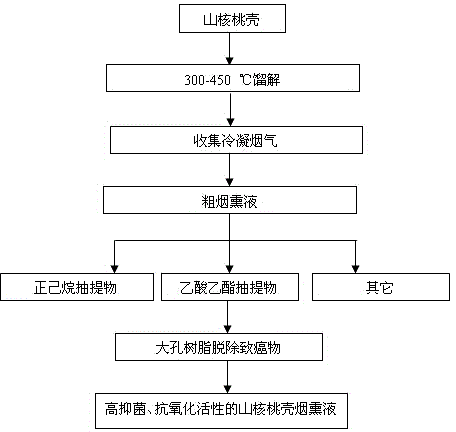

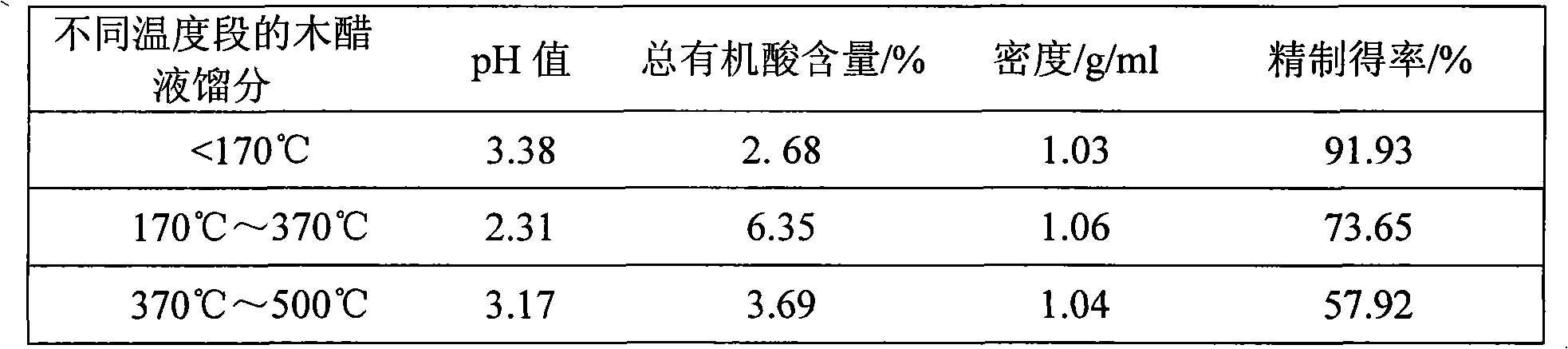

Preparation method for pecan shell smoke solution with high antibacterial and antioxidant activity

InactiveCN104783295AImprove utilizationImprove product performanceFood preservationFood ingredient for microbe protectionSucroseCarcinogen

The invention discloses a preparation method for a pecan shell smoke solution with high antibacterial and antioxidant activity, and belongs to the technical field of aquatic product processing. The preparation method comprises the following steps: using pecan shells as raw materials, adding the pecan shells and sucrose into a dry distillation device in proportion, performing dry distillation decomposition and smoke cooling to obtain a crude smoke solution, refining the crude smoke solution with ethyl acetate, and removing carcinogens with a macroporous resin to obtain the pecan shell smoke solution with high antibacterial and antioxidant activity. The pecan shell smoke solution prepared according to the method contains 18.1-20.5 mg / mL of polyphenols and 9.5-10.8 mg / mL of carbonyl compounds, and has a pH value of 2.3-2.6; 3,4-benzopyrene is not detected. The pecan shell smoke solution can be applied to aquatic products in two ways, namely, atomizing and soaking, has excellent antibacterial and antioxidant effects, and enables the aquatic products to have rich smoky flavor.

Owner:ZHEJIANG OCEAN UNIV

Method for preparing magnesium slag aerated concrete building block added with cinder

InactiveCN101190834AHigh strengthReduce pollutionSolid waste managementCeramicwareSmelting processEconomic benefits

The invention discloses a magnesium slag aerated concrete block and a preparation method thereof, which takes the raw materials at the weight ratio of: magnesium-reduced slag of 50-87 portions, cement of 5-30 portions, gypsum of 3-10 portions, coal cinder of 5-25 portions and gas former of 0.05-0.15 portions, and then the product is obtained by adding water of 20-60 percent at the weight proportion of all the dry materials. The product is obtained according to the methods as follows: magnesium-reduced slag, coal cinder, cement, gypsum, water and gas former are mixed evenly at certain proportion and then are treated with standing and maintaining, inverting and incising, autoclaving and conserving. The invention adopts the magnesium slag generated from the magnesium-smelting process as the main raw material to produce 4MPa building aerated concrete block to be conducive to the reuse of the waste, thereby the enterprise not only is free from the expense of waste treatment, but also has new economic benefit, thus avoiding the occupation of land.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

Energy-absorbing foam aluminum material for manufacturing vehicle bumper

The invention discloses an energy-absorbing foam aluminum material for manufacturing a vehicle bumper. The material is characterized by being prepared by the following components in parts by weight: 100 parts of aluminum powder, 5 parts of tungstate, 5 parts of silicon carbide, 2 parts of iron ore powder, 1 part of silicotungstic acid, 0.5 part of magnesium oxide, and 0.5 part of modified foaming agent. The material is simple in preparation method, excellent in product effect, low in cost of the foaming agent and economical and effective, reduces traditional preparation steps, and reduces the production cost; and the porosity of foam aluminum is increased through dual functions of thickening and foaming of the foaming agent.

Owner:柳培健

Display panel and crack detection method thereof and display device

ActiveCN111509026AAchieving individual detectionPrecise positioningStatic indicating devicesSolid-state devicesDisplay deviceStructural engineering

The invention provides a display panel and a crack detection method thereof and a display device. The display panel comprises a first insulation structure layer, a first crack detection line, a secondinsulation structure layer and a second crack detection line which are sequentially arranged on a substrate, the first crack detection line and the second crack detection line are both located in theperipheral area and arranged around the display area. One end of the first crack detection line is configured to receive a detection signal, the other end is configured to output a first output signal, one end of the second crack detection line is configured to receive the detection signal, and the other end is configured to output a second output signal. According to the display panel, whether cracks are generated in the positions where the first crack detection line and the second crack detection line are located or not can be judged according to the first output signal and the second output signal, independent detection of the cracks is achieved, accurate positioning of the cracks in the product production and related bad analysis process is facilitated, and the productivity and the product performance are improved.

Owner:BOE TECH GRP CO LTD +1

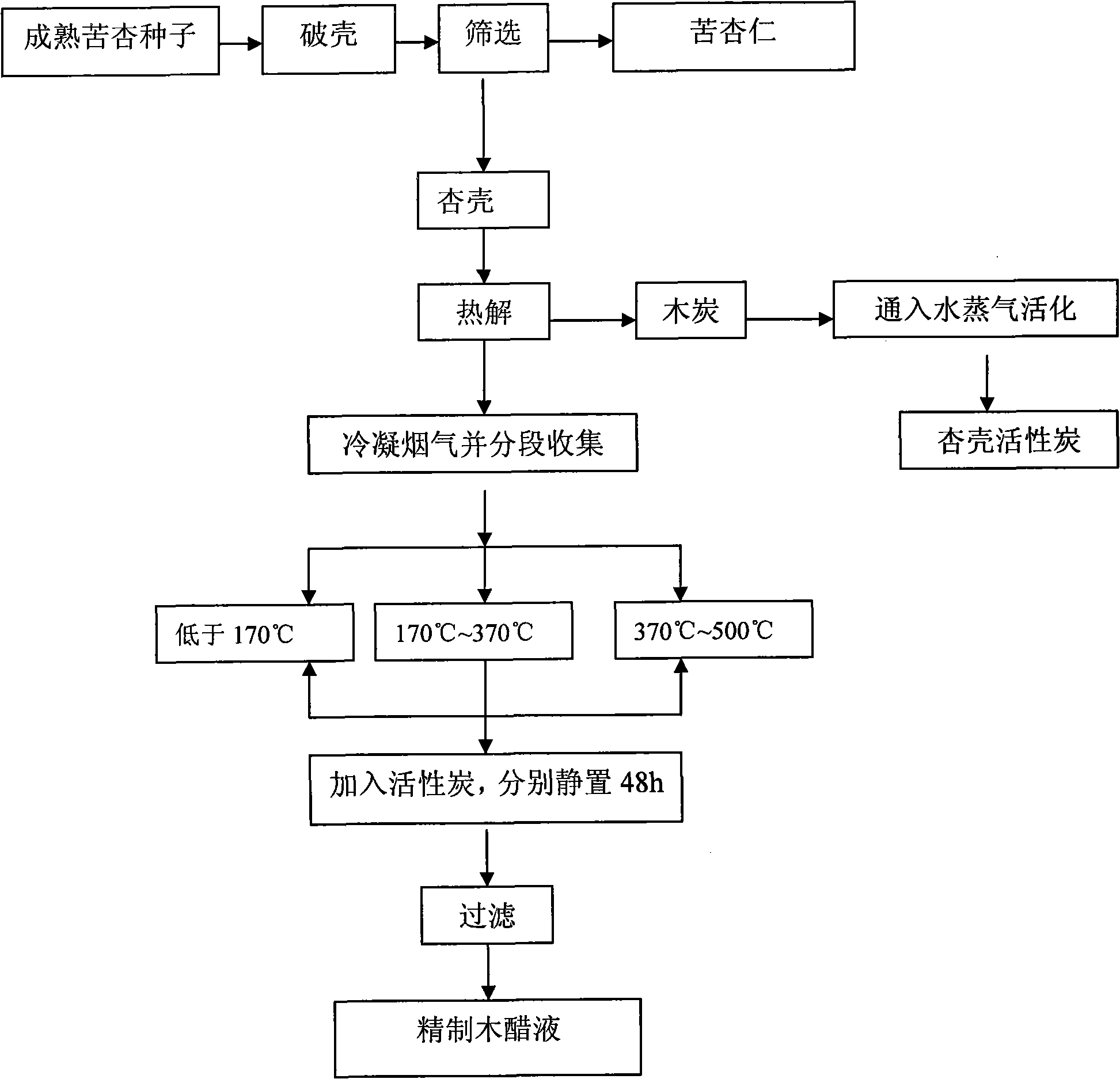

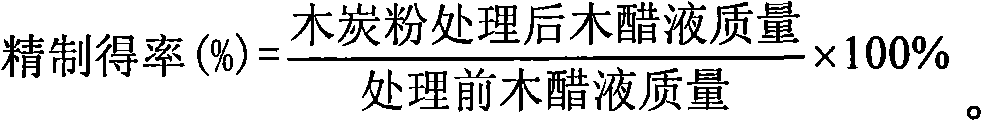

Method for preparing pyroligneous by utilizing apricot shells

InactiveCN101538474AIncrease added valueSimple production processCarbon compoundsBiofuelsPlant growthImpurity

The invention discloses a method for preparing pyroligneous by utilizing apricot shells and preparation of apricot shell active carbon based on the method. The method uses seeds of almonds as raw materials and prepares natural and environmental-friendly apricot shell pyroligneous as a bacteriostatic agent and the active carbon as a byproduct through the steps of breaking the shells, grinding, pyrolyzing, removing impurities, standing still, refining, and the like. The prepared pyroligneous has medicinal effects and quite wide application space in various industries such as bacteriostasis, antisepsis, deodorization, plant growth promotion, beverages, cosmetics, and the like. The active carbon as the byproduct has powerful adsorption capacity and is widely applied to the aspects of food industries, decolorization, air purification, deodorization, catalyst carriers, precious metal purification, electric conductors, and the like so as to further facilitate the life of people. The method has quite important social, environmental protection and economic benefit.

Owner:NORTHWEST A & F UNIV

Method of preparing functional ceramic part of complex structure by powder injection molding

ActiveCN110480016AImprove product performanceShort degreasing cycleTransportation and packagingMetal-working apparatusAir atmosphereAdhesive

The invention relates to a method of preparing a functional ceramic part of complex structure by powder injection molding. The method is characterized by comprising the following steps: S1, feed preparation: uniformly mixing functional ceramic powder with an adhesive to form a feed; S2, injection moulding: putting the feed prepared in the S1 in a powder injection moulding machine, and injecting the feed into a mold cavity under conditions of an injection pressure of 80-200 MPa and an injection temperature of 160-200 DEG C to form an injection blank; S3, degreasing: catalytically degreasing theinjection blank prepared in the S2 to form a catalytically degreased blank; S4, thermal degreasing: thermally degreasing the catalytically degreased blank prepared in the S3 to obtain a thermally degreased blank; and S5, sintering: putting the thermally degreased blank prepared in the S4 in a sintering furnace, and sintering the thermally degreased blank in an air atmosphere to obtain a sinteredblank. By setting a volume ratio range of the functional ceramic powder and the adhesive, the functional ceramic powder can be totally coated by the adhesive, so that the flawless injection blank is more easily obtained.

Owner:CHANGZHOU GIAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com