Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Good thermoplastic processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

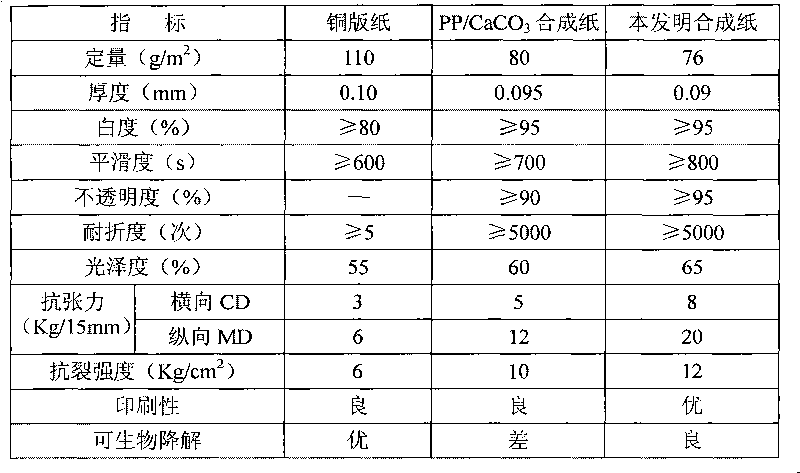

Paper making material, preparation method and paper making method of environment-friendly synthetic paper

ActiveCN101760990AImprove stabilityImprove heat resistanceNon-fibrous pulp additionSpecial paperFiberBlow molding

The invention relates to a paper making material, a preparation method and a paper making method of environment-friendly synthetic paper. The material comprises modified mineral fiber, thermoplastic starch, cellulose derivative, compatilizer, auxiliary components and the like, wherein the average particle diameter of the modified mineral fiber is 5-10 micrometers, the ratio of the length of the modified mineral fiber to the diameter of the modified mineral fiber is 8-15:1, and the modified mineral fiber is treated by fibrosis ultrafine grinding and surface recombination modification; the thermoplastic starch is formed by performing micronization and plasticization modification on norm starch; and the auxiliary components comprise lubricant and colorant. The paper making material is prepared by sequentially mixing the raw material components fully and then extruding and granulating the mixture by a screw extruder at 60-180 DEG C. According to the plastic process mode, the material can be treated by blow molding through a calender or a paper film machine for carrying out two-way stretch to prepare corresponding paper products. The paper making material can overcome the defects of the current synthetic paper and can be widely applied to the fields of commercial printing, publications, office paper, packing and the like, and the processing procedure of making paper by using plastic processing equipment has environmental protection and low cost.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Thermoplasticity environmentally-friendly stone paper and preparation method

InactiveCN101871182AGood thermoplastic processabilityImprove stiffnessPaper/cardboardInorganic compound additionButyl acrylateLubrication

The invention discloses a thermoplasticity environmentally-friendly stone paper and a preparation method. The thermoplasticity environmentally-friendly stone paper comprises the following components in parts by weight: 80-90 parts of inorganic mineral powder, 3-5 parts of surface active ingredient, 2-3 parts of polymer monomer, 0.01-0.05 part of initiator and 5-15 parts of lubrication accessory ingredient, wherein the inorganic mineral powder is at least one of various inorganic mineral powders, such as wollastonite of which the grain diameter is 5-10 mu m, bentonite and the like; the surface active ingredient comprises at least one of anion surface active ingredient comprising inorganic acid ester; and the polymer monomer is one of methyl methacrylate, methyl acrylate, butyl acrylate and styrene. The thermoplasticity environmentally-friendly stone paper contains 90% of inorganic mineral powder, has favoarble thermoplasticity processing performance and can use the thermoplasticity processing equipment to carry out quick blow molding or calendaring and drawing shaping; and paper has obvious vertical and horizontal orientation, good deflection and strong rigidity, and appearance texture more approaches the traditional paper. The thermoplasticity environmentally-friendly stone paper is a novel environmentally-friendly paper.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

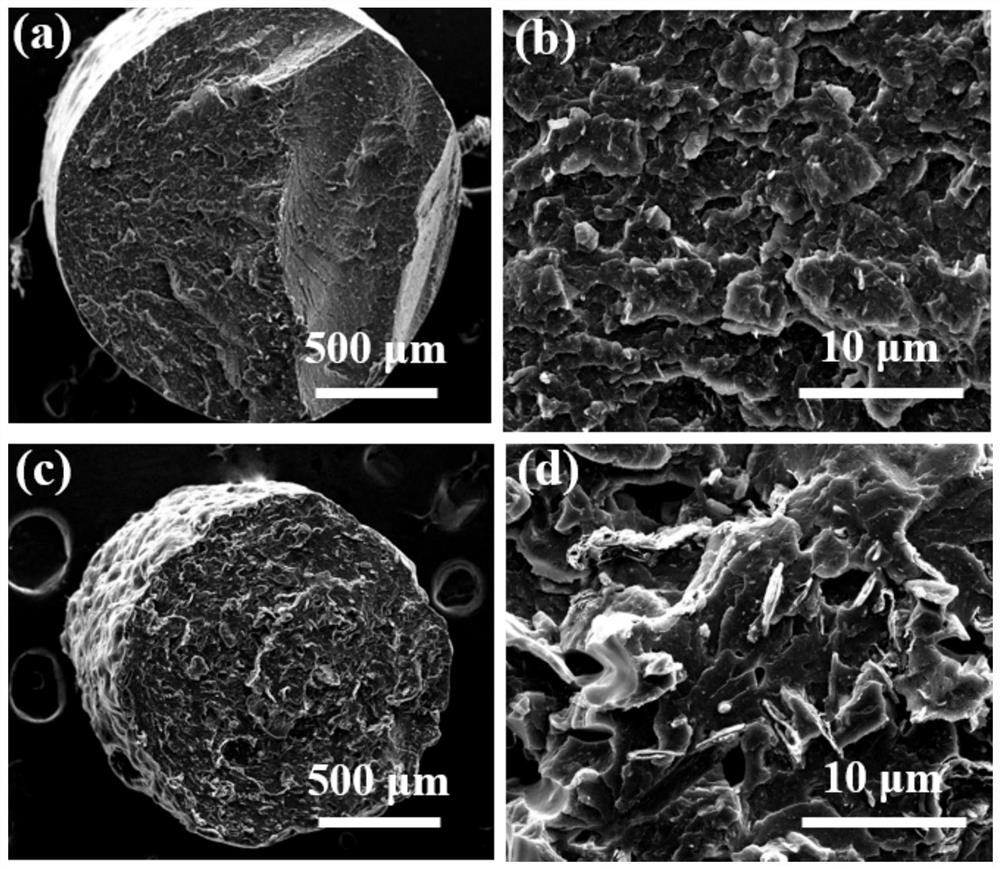

Ceramic material for 3D printing and manufacturing method thereof

ActiveCN105645840AGood thermoplastic processabilityLow densityAdditive manufacturing apparatusPelletizingEnvironmentally friendly

The invention discloses a porous ceramic microsphere composite material for 3D printing. The porous ceramic microsphere composite material is mainly composed of porous ceramic microspheres and thermoplastic resin, wherein the porous ceramic microspheres account for 80-99% of total weight, and the thermoplastic resin accounts for 1-20% of the total weight. The raw materials undergo extrusion pelletization through a twin-screw extruder so as to prepare the ceramic material for 3D printing. By characteristics of good fluidity and low density of the porous ceramic microspheres and by combination of thermoplastic processability of the thermoplastic resin, the characteristic of low thermoplastic processability of the ceramic material is overcome, and more selections are provided for a 3D printing material. The invention also discloses a preparation method of the ceramic material. More printing material selection spaces are provided for a three-dimensional printing technology, and a three-dimensional structured product of the ceramic material is prepared by a fused deposition modeling 3D printing technology. The production technology is simple, low-cost, safe and environmentally friendly, and has a market application prospect.

Owner:安徽长朗三维科技有限公司

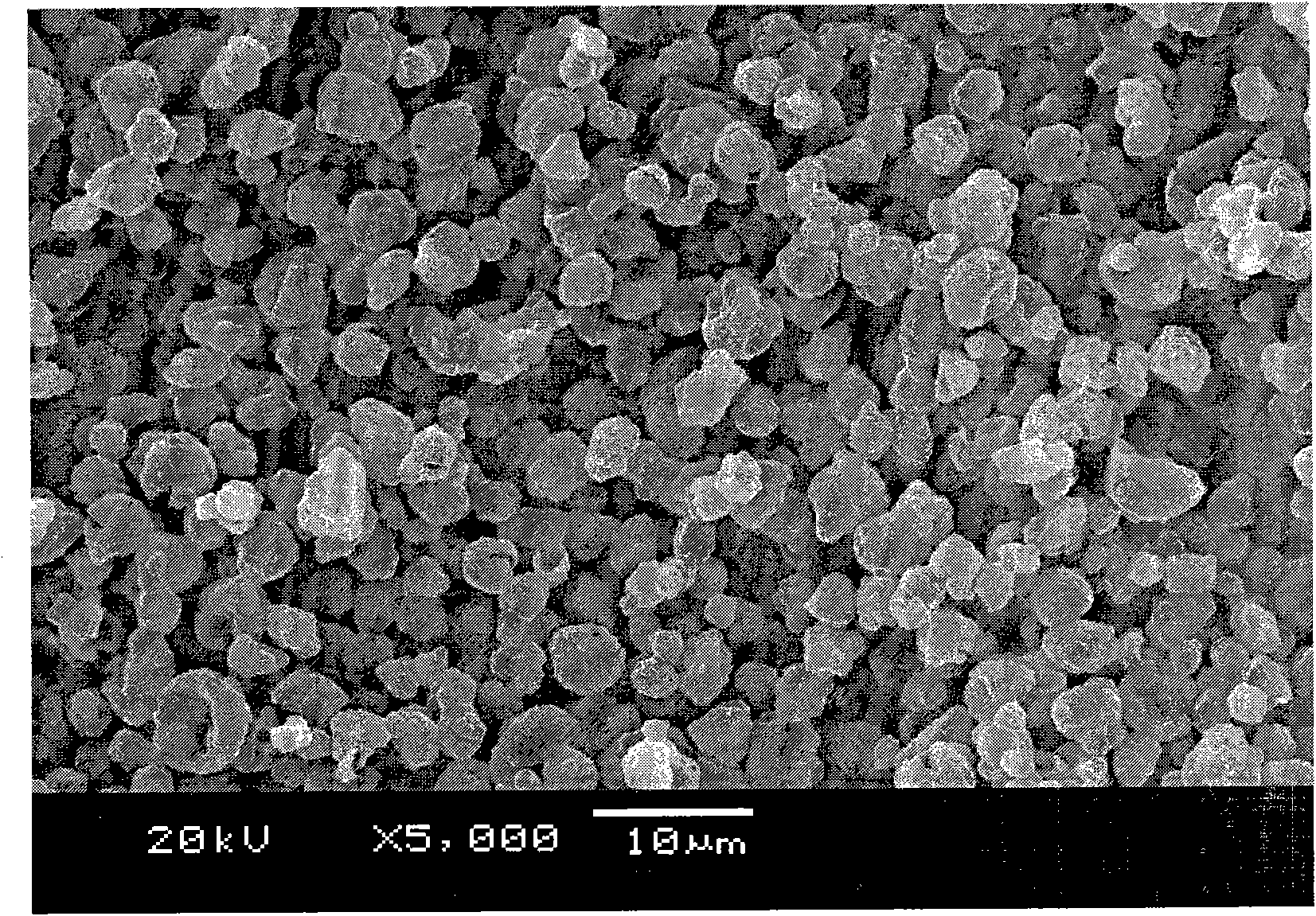

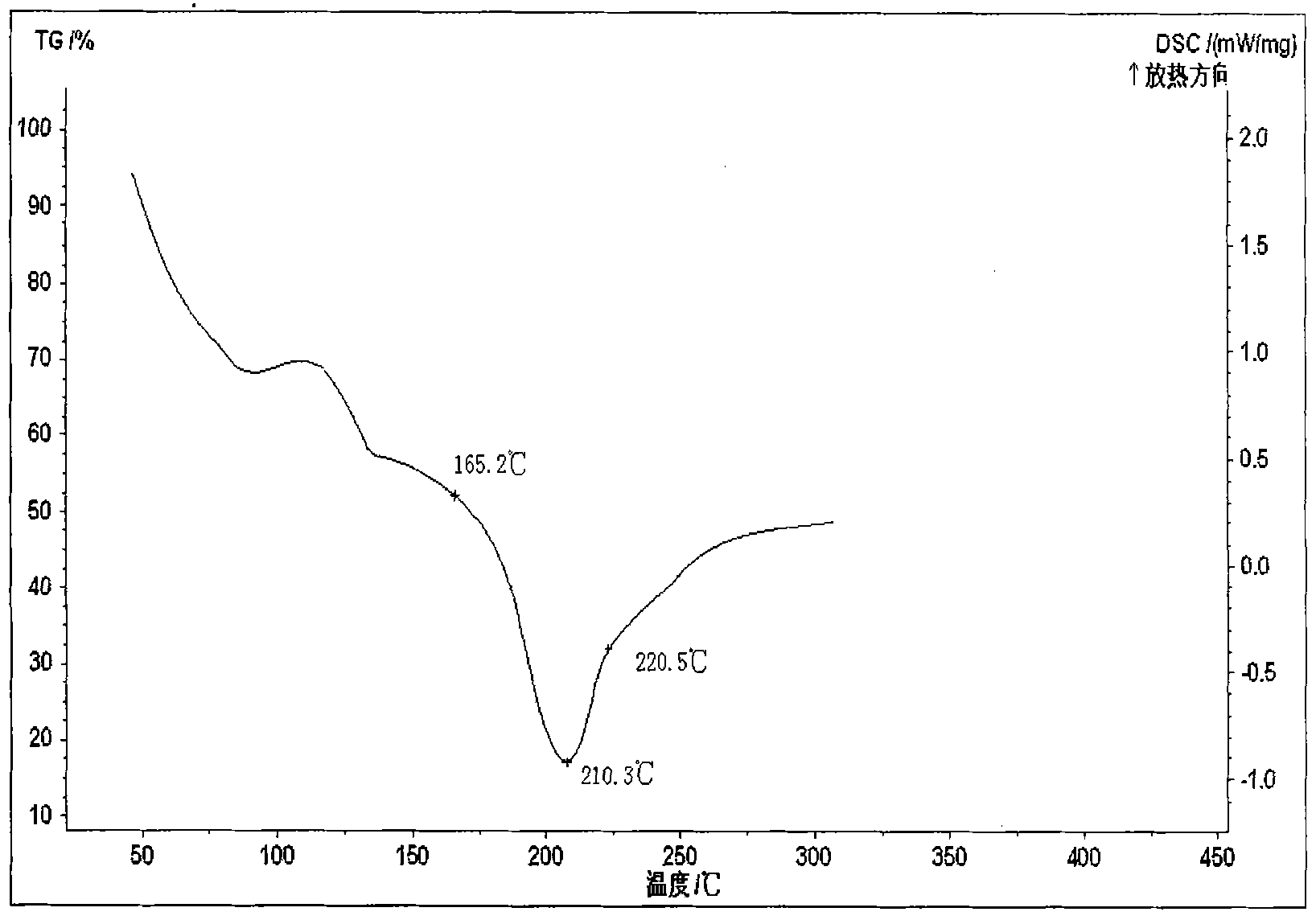

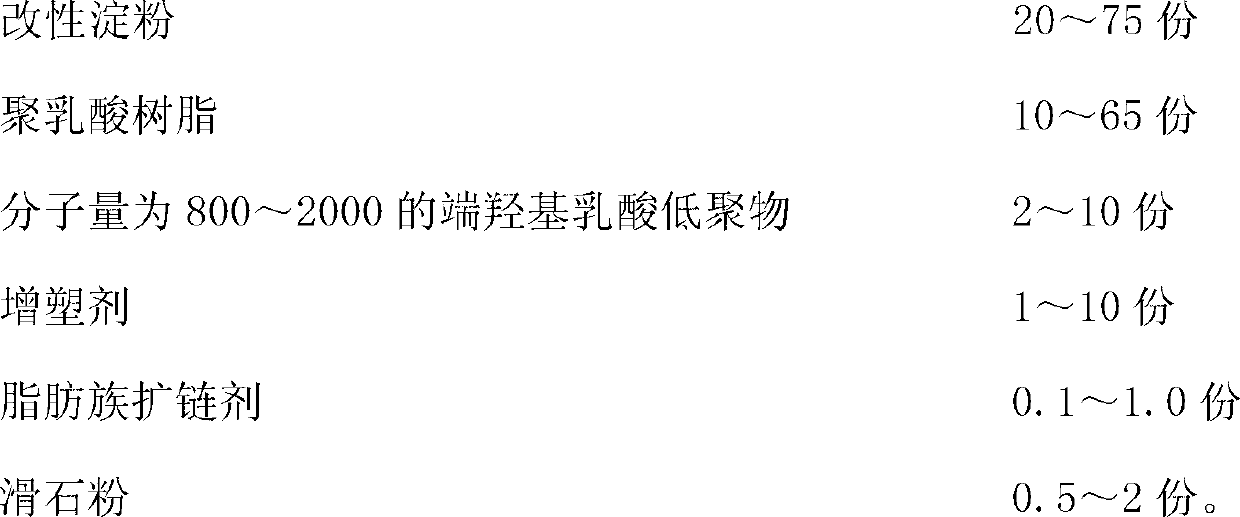

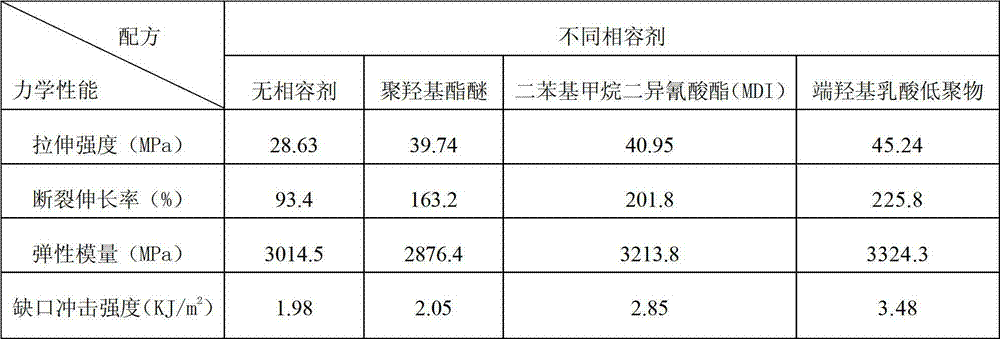

Starch and polylactic acid composite material and preparation method thereof

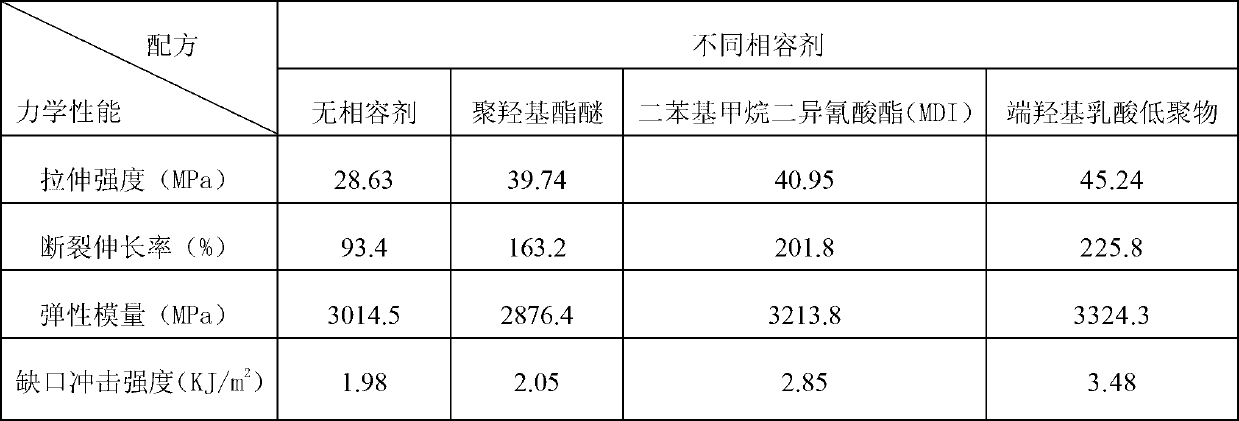

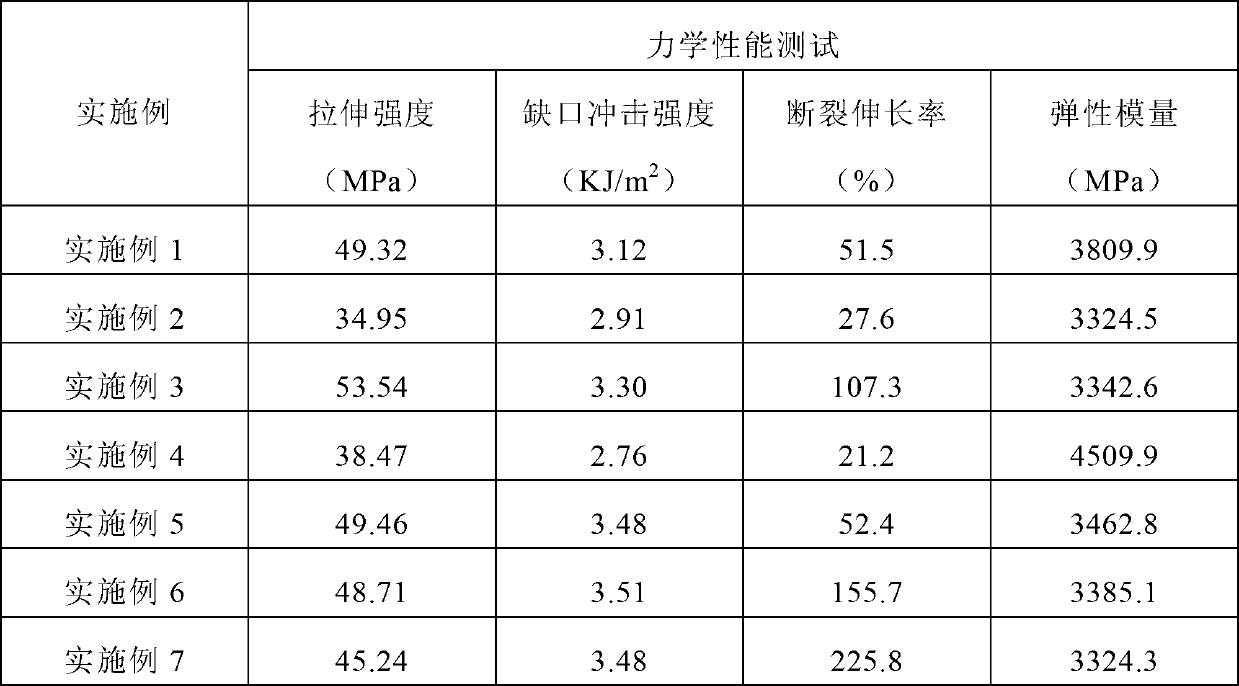

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

Thermoplastically modified high-fluidity polyvinyl alcohol, and thermoplastically modified high-fluidity polyvinyl alcohol casting film material and preparation method thereof

InactiveCN107936430AExpanded processing windowGood thermoplastic processabilityFlat articlesPolymer sciencePlasticizer

The invention relates to a thermoplastically modified high-fluidity polyvinyl alcohol casting film material and a preparation method thereof. A purpose of the present invention is mainly to solve theproblems of poor thermoplasticity, difficult processing, poor melt fluidity, easy thermal-oxidation degradation, difficult casting film preparation and poor mechanical property of polyvinyl alcohol inthe prior art. The technical scheme comprises that the thermoplastically modified high-fluidity polyvinyl alcohol is used, and comprises, by mass, 1) 70-99.9 parts f polyvinyl alcohol, and 2) 0.1-30parts of a plasticizer, the polyvinyl alcohol and the plasticizer are respectively introduced into a twin-screw extruder, and melt extrusion and granulation are performed through a screw rod extrusionprocessing technology to obtain the thermoplastically modified high-fluidity polyvinyl alcohol. With the technical scheme, the problems in the prior art are well solved. The method of the present invention can be used for industrial production of polyvinyl alcohol casting film materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

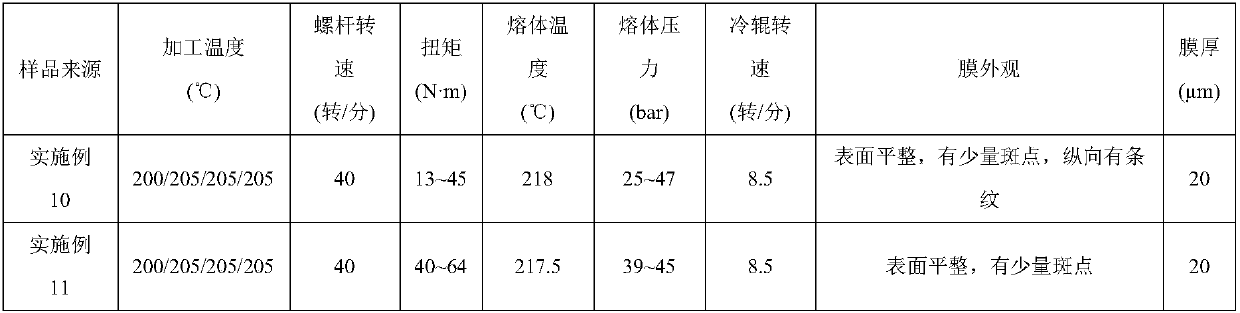

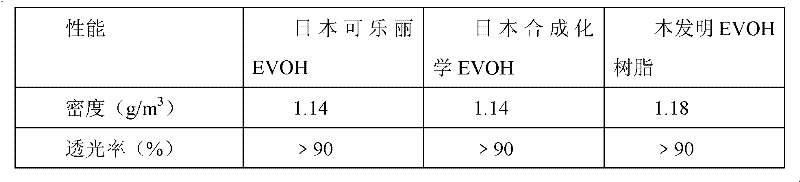

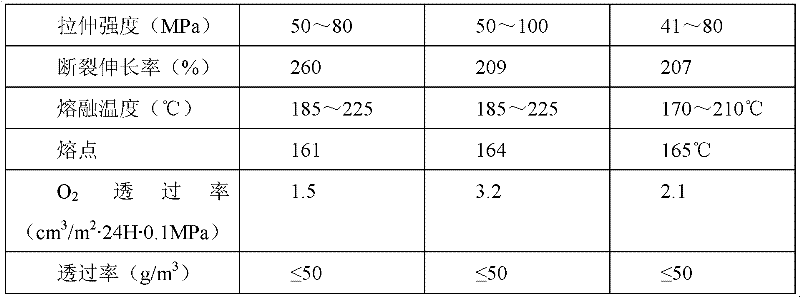

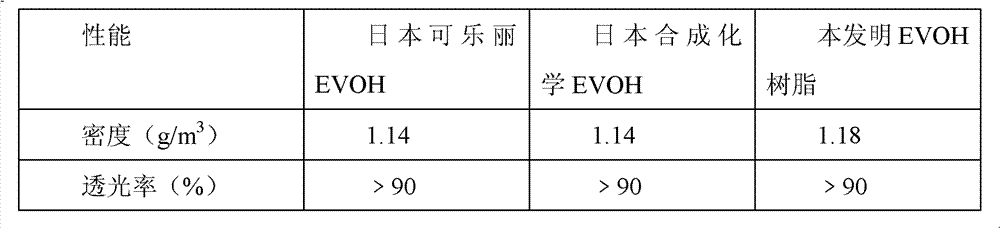

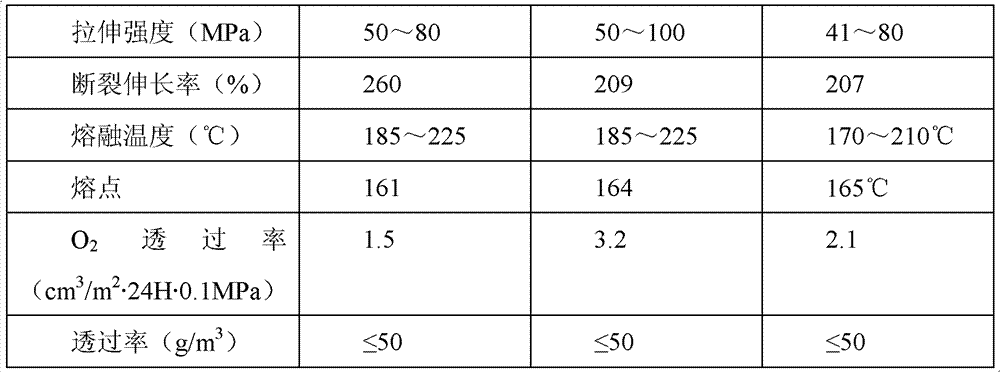

EVOH (ethylene vinyl alcohol) resin and preparation method thereof

The invention discloses an EVOH (ethylene vinyl alcohol) resin and a preparation method thereof and relates to a resin and a preparation method thereof, and the method provided by the invention can be used for solving the problems of complex process for the production of the EVOH resin and large production difficulty in traditional methods. The EVOH resin is prepared through the following steps: stirring polyvinyl alcohol, a plasticizer, an ethylene unsaturated monomer, maleic anhydride graft polypropylene resin, an initiator, a catalyst, an anti-yellowing agent and a surfactant, and then pelletizing the mixture in a double-screw extruder. The method provided by the invention is simple in process and small in equipment investment, and the EVOH resin has the advantage of stable quality.

Owner:WEIFANG HUAWEI MATERIALS TECH CO LTD

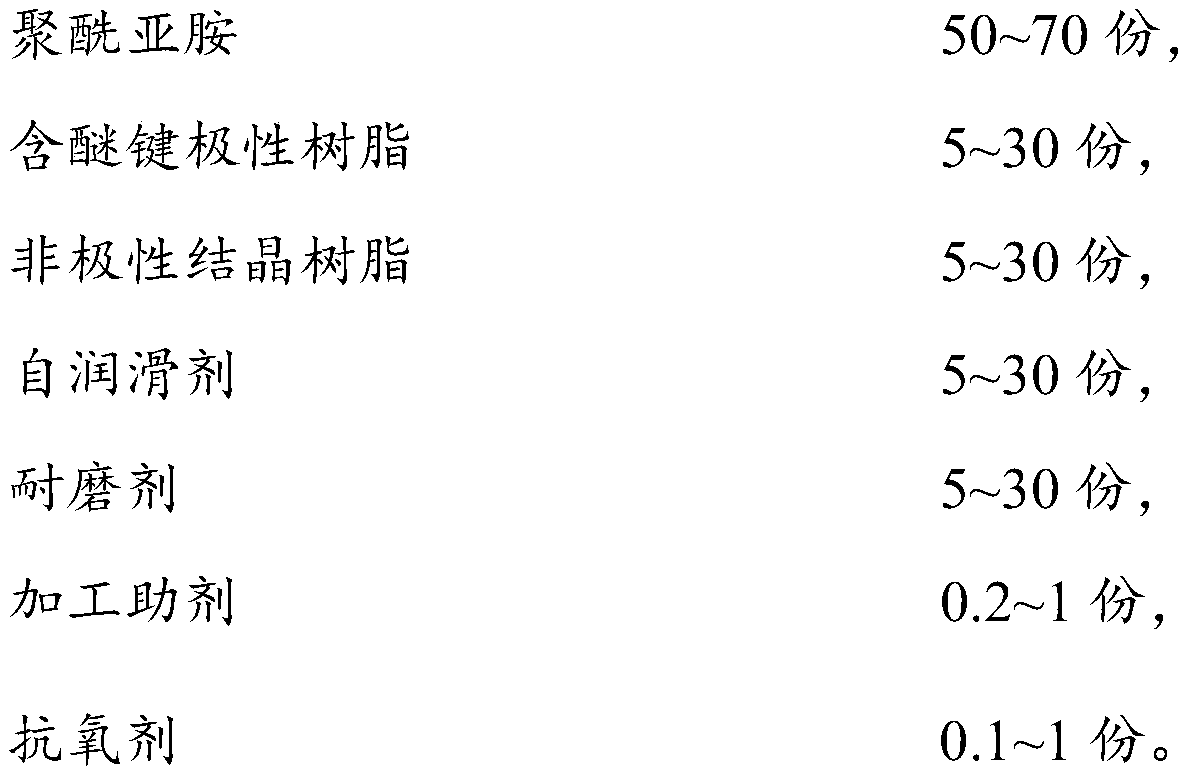

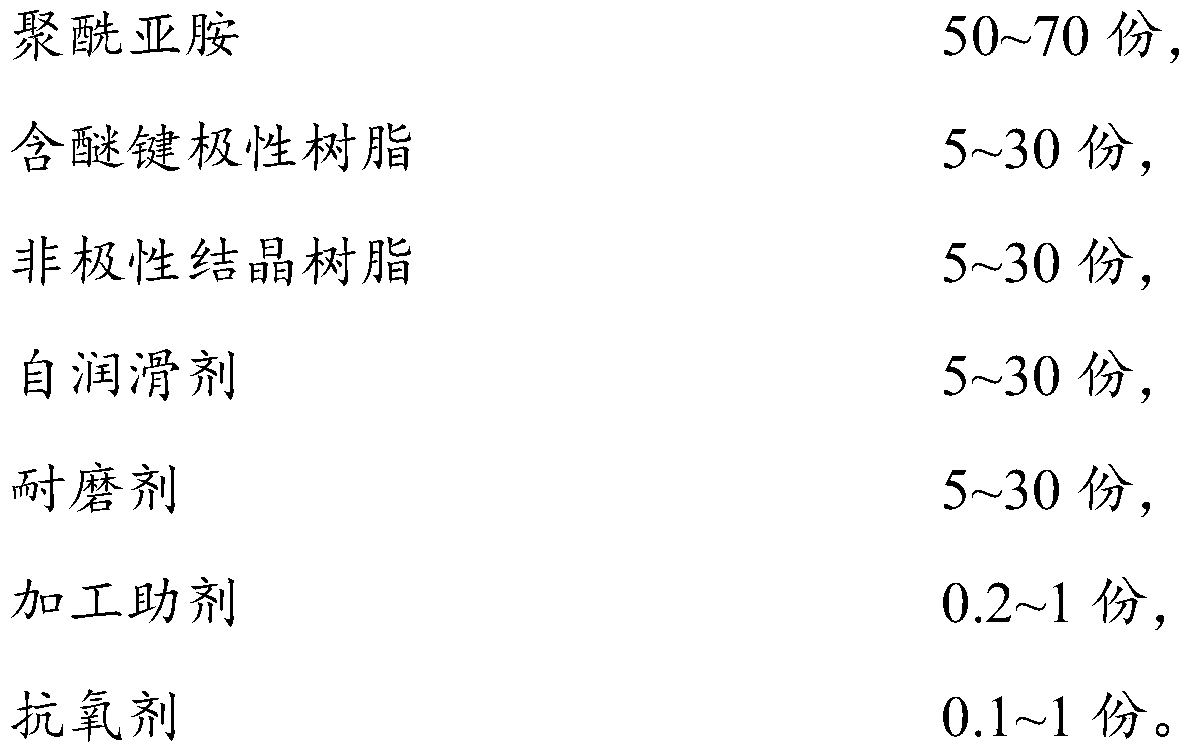

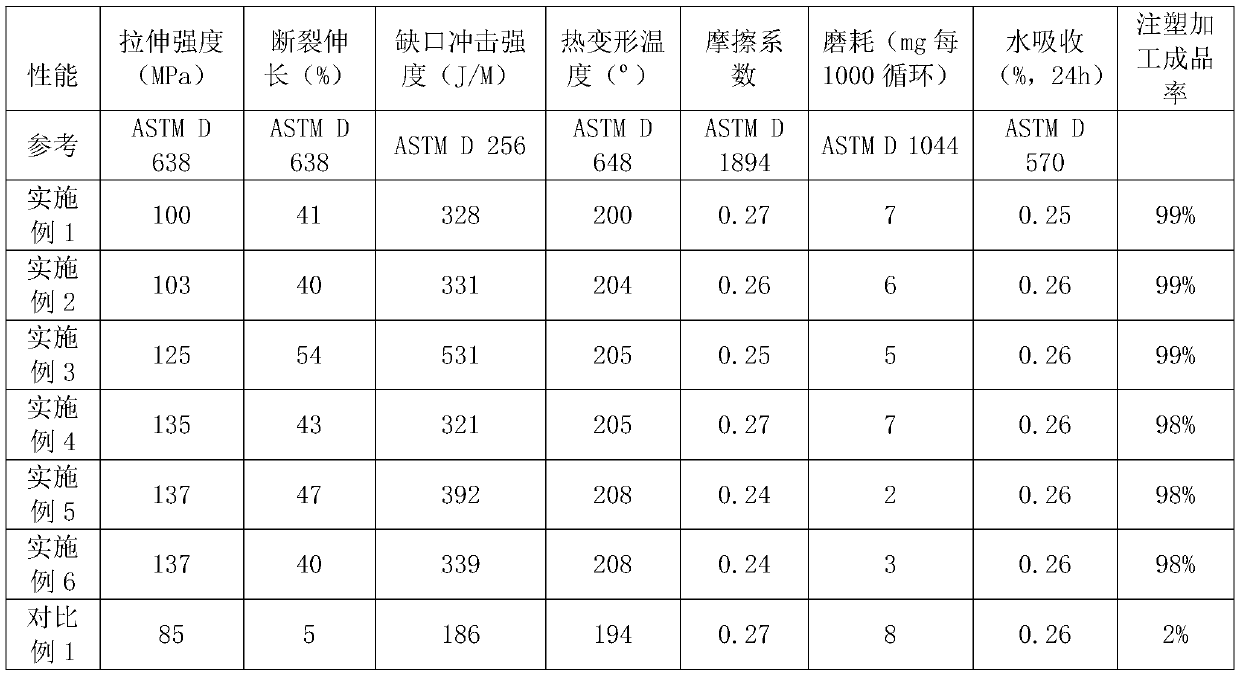

Wear-resistant self-lubricating thermoplastic polyimide composite material and preparation method thereof

InactiveCN109705576AIncrease melt viscosityGood thermoplastic processabilityWear resistantAntioxidant

The invention discloses a wear-resistant self-lubricating thermoplastic polyimide composite material which comprises the following components in parts by mass: 50-70 parts of polyimide, 5-30 parts ofether- bond -containing polar resin, 5-30 parts of non-polar crystalline resin, 5-30 parts of a self-lubricating agent, 5-30 parts of a wear-resistant agent, 0.2-1 part of a processing aid and 0.1-1 part of an antioxidant. According to the invention, by virtue of the synergistic modification effect of the two kinds of high-molecular resin of the ether- bond -containing polar resin and the non-polar crystalline resin, the thermoplastic processing property of the polyimide composite material can be obviously improved, and the excellent comprehensive performance of polyimide can be maintained.

Owner:中广核高新核材科技(苏州)有限公司 +1

Aliphatic polyester/starch/clay ternary degradable resin and production thereof

A fat polyester / starch / clay ternary degradable resin and its production are disclosed. The resin consists of vegetable starch, fat polyester, clay mineral material, gel promoter, plasticizer, antioxiant, lubricant and compatibilizer. The process is carried out by weighing raw materials proportionally, mixing vegetable starch with plasticizer and gel promoter from high-speed mixer, stirring for 5-30mins, laying aside for 1-2 day, preplasticizing mixture, adding mixture, fat polyester, clay mineral material, antioxidant and lubricant into double-screw extruder, melting and mixing from double-screw extruder, reacting and extruding, and obtaining the product. It achieves simple process, good biological degradability and no environmental pollution.

Owner:TONGJI UNIV

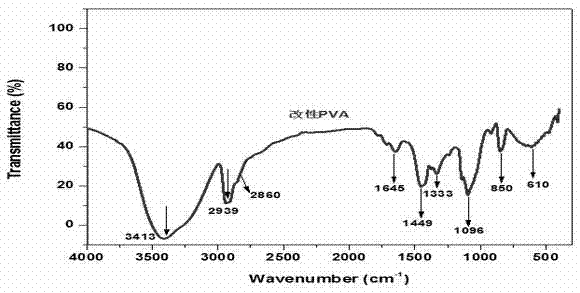

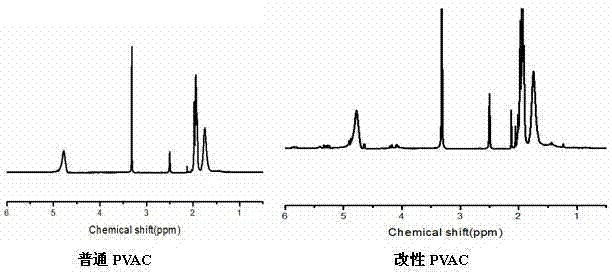

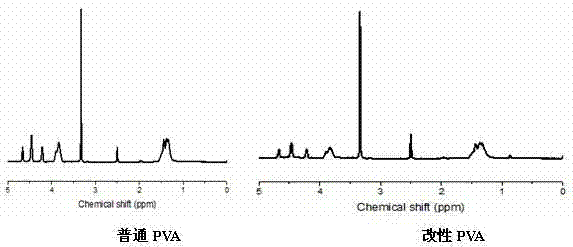

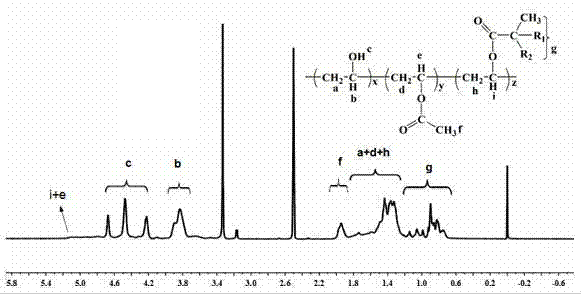

Modified polyvinyl alcohol and preparation method thereof

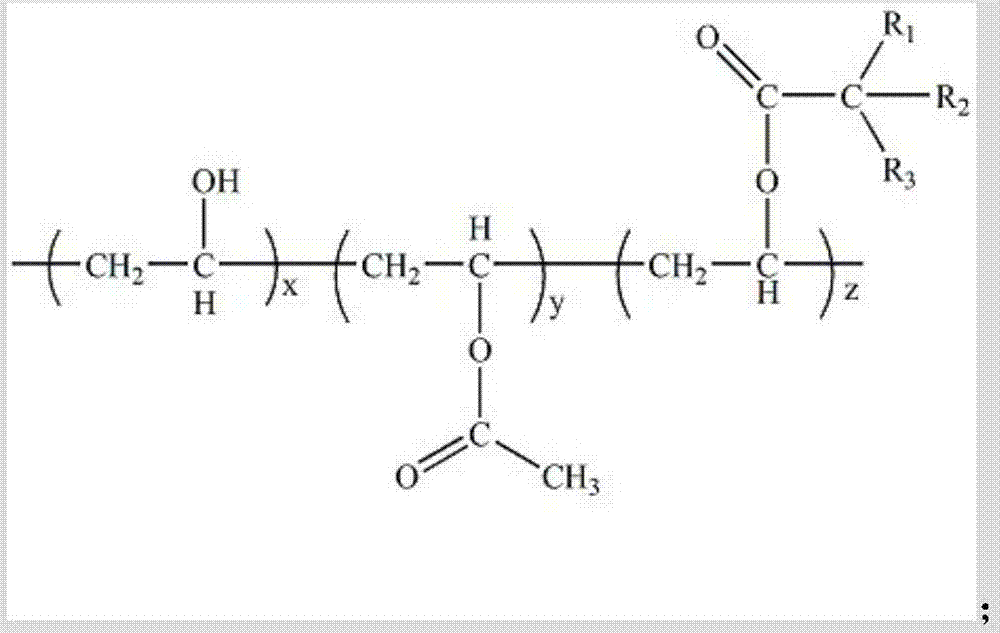

The invention relates to modified polyvinyl alcohol, which has the following structure formula defined in the specification, wherein x, y and z are integers, x is more than 1 and is less than or equal to 500, y is more than 1 and is less than or equal to 2000, z is more than 1 and is less than or equal to 200, y is more than x, y is more than z, R1 is an oxygen atom or -CO- or -(CH-OH)-, and R2 is alkyl, alkoxy or hydroxyl-terminated alkyl. According to the present invention, the monomer copolymerization consumption is less, the reaction rate is moderate, the conversion rate of the prepared vinyl acetate-branched vinyl copolymer is 40-80%, the alcoholysis degree of the alcoholysis product is 98-99.8 mol%, the crystallinity is less than 20%, the melting point is 160-195 DEG C, the viscosity is 3.0-25.0 mPa.S (20 DEG C, 4% aqueous solution), and the obtained product can be subjected to melting processing and has good processability.

Owner:SINOPEC SICHUAN VINYLON FACTORY +2

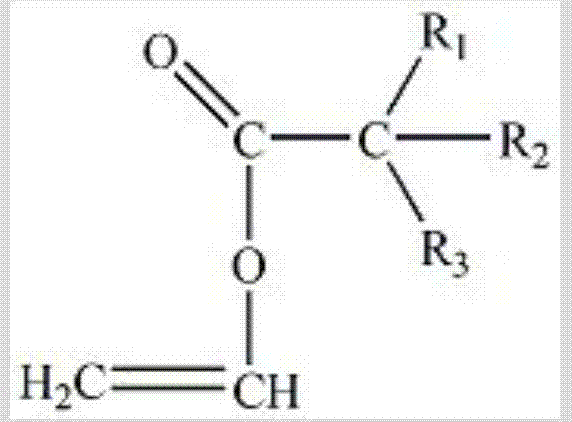

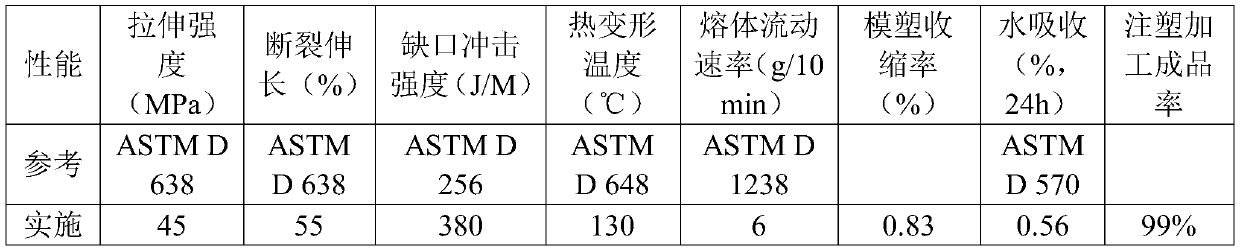

Polyvinyl alcohol capable of being subjected to melting processing modification, and preparation method thereof

ActiveCN106854256AGood thermoplastic processabilityInjection moldingPolymer sciencePolyvinyl alcohol

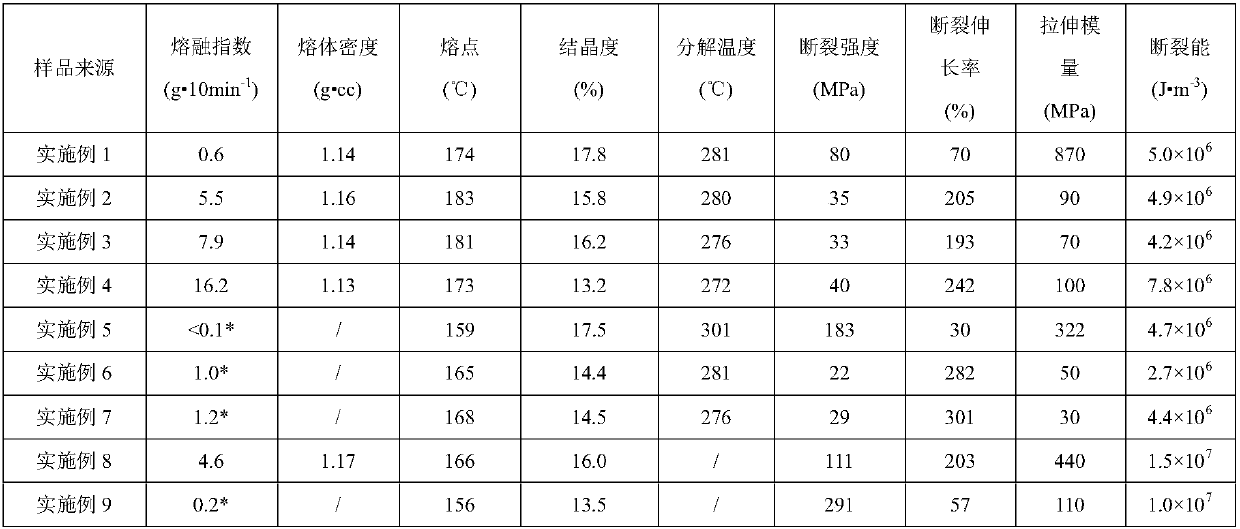

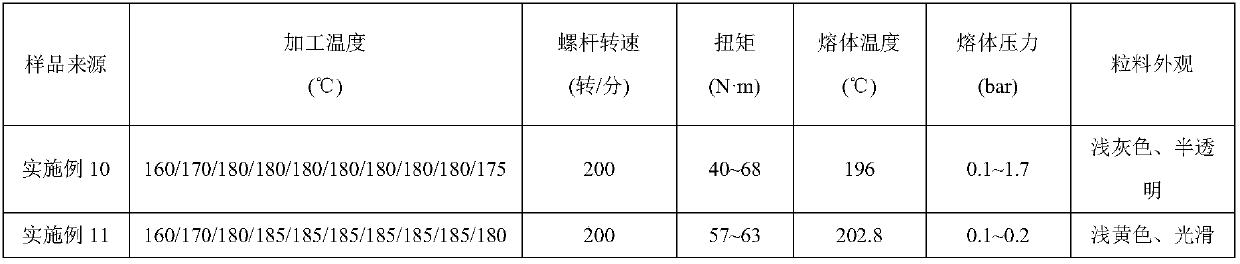

The invention discloses polyvinyl alcohol capable of being subjected to melting processing modification, wherein the modified polyvinyl alcohol is a random copolymer and has the following structure general formula defined in the specification, R1, R2 and R3 are alkyl substituents, at least one of the substituents is methyl, the sum of the carbon atoms in R1, R2 and R3 is 7-9, x is more than 1, y is more than 1, z is more than 1, a molar ratio of x to y to z is (81-93):(4-12):(2-8), the polymerization degree is 500-1000, the melting temperature is 180-220 DEG C, the decomposition temperature is 260-290 DEG C, the melt index MI is 1.0-5.0 g / 10 min (10 kg 210 DEG C), the tensile strength is 80-110 MPa, the elongation at break is 20-40%, and the notch impact strength is 6-10 KJ / m<2>. The invention further discloses a preparation method of the modified polyvinyl alcohol, wherein the preparation method has characteristics of easily available raw materials and simple operation, and is suitable for industrial production.

Owner:SINOPEC SICHUAN VINYLON FACTORY +2

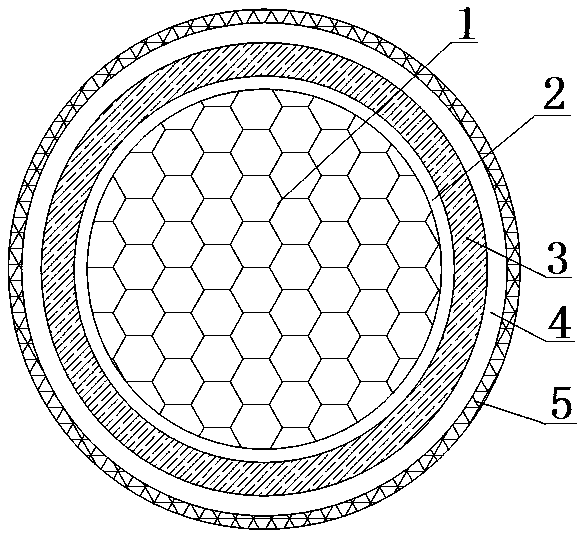

Thermoplastic polyimide cable material for nuclear power aviation

InactiveCN111040448AIncrease melt viscosityMelt viscosity does not affectPlastic/resin/waxes insulatorsImidePolymer science

The invention relates to a thermoplastic polyimide cable material for nuclear power aviation. The thermoplastic polyimide cable material comprises, by weight, 5-30 parts of polyimide, 5-30 parts of polyetherimide, 30-70 parts of siloxane-containing polyetherimide, 5-30 parts of ether bond-containing polar resin, 5-30 parts of a liquid crystal polymer, 5-30 parts of non-polar crystalline resin, 5-30 parts of silicon resin, 5-20 parts of talcum powder, 0.2-1 part of a processing aid, 0.1-1 part of an antioxidant and 0.1-10 parts of an additive. Different types of polyimide base resins are mixedand used, and the polar resin containing ether bonds, the liquid crystal polymer, the non-polar crystalline resin, the silicon resin, the talcum powder and the like are used to improve the proecsing properties of the material, so the heat resistance and the processing properties are improved, and the radiation resistance, the high flame retardant property, the high insulating property and other comprehensive properties of the base material are also improved; and the cable material can be processed by using traditional thermoplastic cable processing equipment, so the cable processing technologyis simplified.

Owner:中广核高新核材科技(苏州)有限公司 +1

Method for processing scrap wire and cable

InactiveCN105355338AAnti-lightOil resistantBasic electric elementsElectronic waste recyclingPolyesterSodium bicarbonate

The present invention discloses a method for processing a scrap wire and cable. The method comprises the steps of (1) carrying out pretreatment of the skin materials of a scrap wire and cable as raw materials, crushing the materials and then screening the materials, taking the granules of 5 to 20 meshes, and mixing the granules and sodium bicarbonate to obtain a mixed material, (2) winding a layer of polyester film around the outer part of a oxygen-free copper and tinned copper compound stranded wire which is taken as a soft conductor to be a winded polyester belt layer, (3) extruding an insulating layer outside the conductor winded in the step (2) with the mixed material obtained in the step (1) as a raw material by using an SJ-65 / 25 extruder, wherein the extrusion should be uniform, the thickness is consistent, the surface is smooth, and the color is consistent, (4) winding a layer of fire-resistant ceramic silicone rubber belt outside the insulation layer to be a fire-resistant layer, wherein the winding should be uniform without wrinkles, the thickness is consistent, the surface is smooth, and the color is consistent, and (5) extruding an insulation layer outside the fire-resistant layer completed in the step (4) with the mixed material obtained in the step (1) as a raw material by using an SJ-90 or120 extruder to obtain a product.

Owner:JIANGSU SAIER RUBBER CO LTD

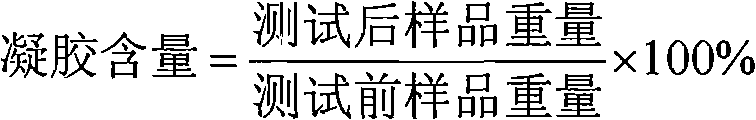

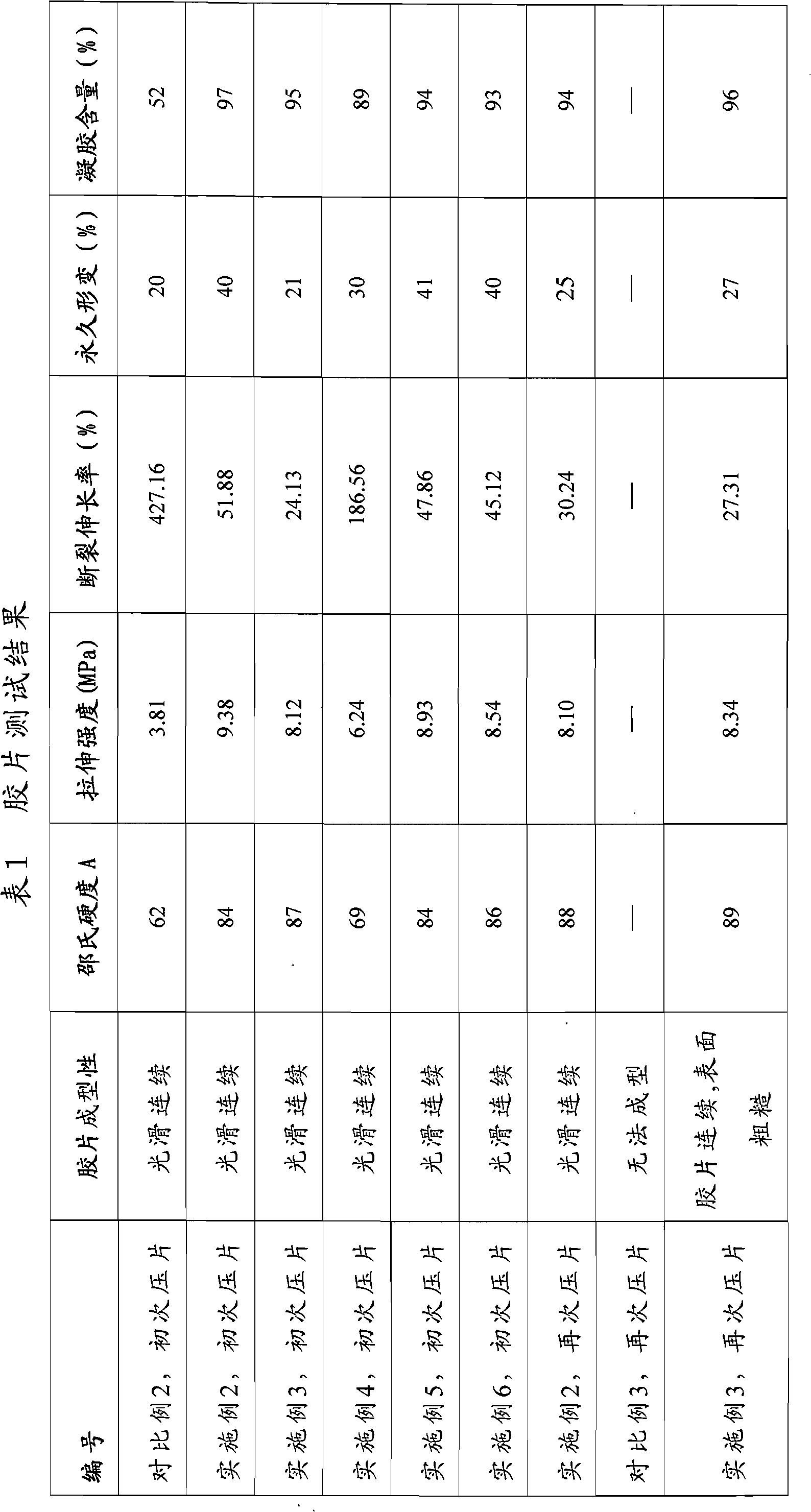

Application of polymer particle with tertiary amine group on the surface as thermal reversible reactive filler and composition of polymer particle with chlorine on the surface

The invention relates to an application of a polymer particle with tertiary amine group on the surface as thermal reversible reactive filler which includes halogen pendant group. The polymer particle with tertiary amine group on the surface is prepared with vinyl monomer and monomer including tertiary amine group through emulsion copolymerization, wherein the monomer including tertiary amine group is chosen from vinyl pyridine and derivatives thereof as well as crylic acid dimethylamino ester and derivatives thereof. When linetype polymer material is filled with the reactive cross-linked polymer particle filler with tertiary amine group on the surface, cross-linked polymer material for filling and reinforcing is obtained without other cross-linked agents, and the cross-linked polymer material can be heated and formed. Therefore, problems that permanent cross link in polymer material and products are difficult to process and utilize again caused by traditional reactive reinforcing filler are solved, and implementation art is simple.

Owner:BEIJING UNIV OF CHEM TECH +1

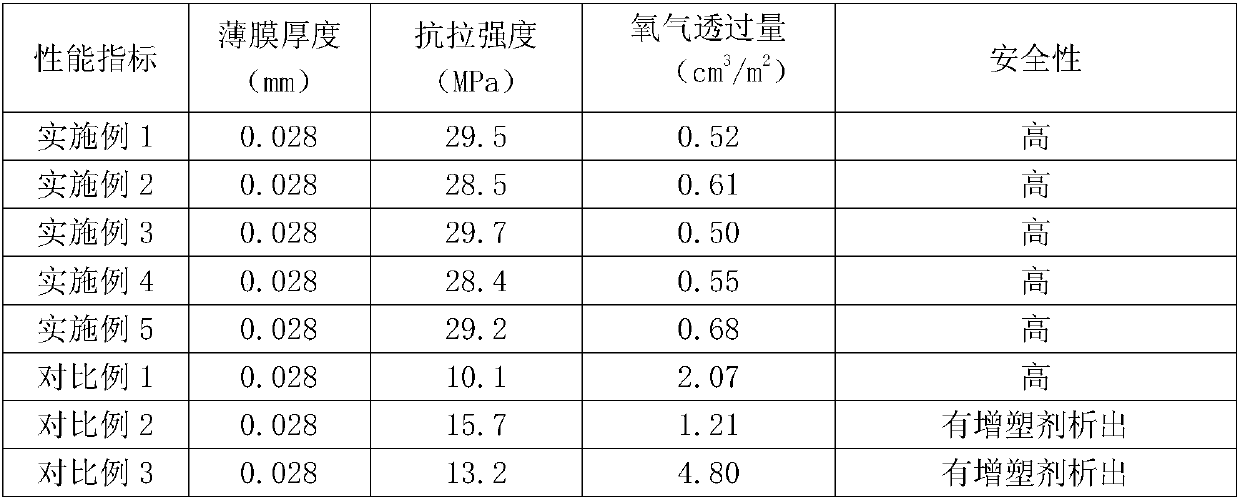

Lignocellulose-ellagic acid bio-plastic food packaging film and preparation method

InactiveCN107934198AReduce crystallizationChange crystal structureFlexible coversWrappersUltravioletCrystallinity

The invention discloses a lignocellulose-ellagic acid bio-plastic food packaging film and a preparation method. Lignocellulose is preliminarily fermented through cellulase, then an ellagic acid aqueous solution, ultraviolet curable acrylate resin and others are added, intense stirring is conducted, a panel is evenly coated with materials, and a film is formed through curing with ultraviolet irradiation. The lignocellulose is modified with ellagic acid, the function of hydrogen bonds is greatly weakened, the degree of crystallinity is decreased, and the crystal structure of cellulose is changed. The lignocellulose-ellagic acid bio-plastic food packaging film and the preparation method have the beneficial effects that the thermoplastic processing performance of celluloses is greatly improved, meanwhile, the thermal stability is ensured, a plasticizer does not need to be used, the safety of the film making contact with food is ensured, and the lignocellulose-ellagic acid bio-plastic foodpackaging film and the preparation method have the great advantages compared with traditional processes; and the ellagic acid is further used as a free radical collecting addition agent, and the barrier property is improved.

Owner:临沂彩丰包装有限公司

High-strength rubber insulated cable and manufacturing method thereof

InactiveCN103779009AReduce weightGood value for moneyRubber insulatorsFlexible cablesPolyesterElectrical conductor

The invention discloses a high-strength rubber insulated cable. The high-strength rubber insulated cable comprises conductors, wherein a wrapping polyester tape layer is arranged outside the conductors, an insulating layer is arranged outside the wrapping polyester tape layer, a fireproof layer is arranged outside the insulating layer, and a sheath is arranged outside the fireproof layer. The high-strength rubber insulated cable has the advantages that high strength is more than two to three times that of a traditional rubber insulated cable sheath, and the highest strength can reach 30 Mpa; the international advanced levels of low temperature resistance (minus 40 DEG C) and torsion resistance (minus 50 DEG C) are achieved; excellent resistance to light, heat, aging, oil, water, acid and alkali salt is obtained; flame retardance, cleanliness, environment friendliness and nontoxicity are achieved, and the flame retardance can reach the UL-Vo level; excellent thermoplastic processing performance is achieved, clean materials can be directly recovered and processed again, and the materials are saved; the small specific gravity is 0.91 g / cm<3> and is 0.64 time that of common rubber, the weight of the cable can be reduced, and very high cost performance is obtained; excellent electrical insulation performance is obtained; dielectric strength is greater than or equal to 20 kv / mm, and the volume resistivity at 20 DEG C is greater than or equal to 10<15> omega*cm.

Owner:JIANGSU ZHENGTAI ELECTRIC CABLE

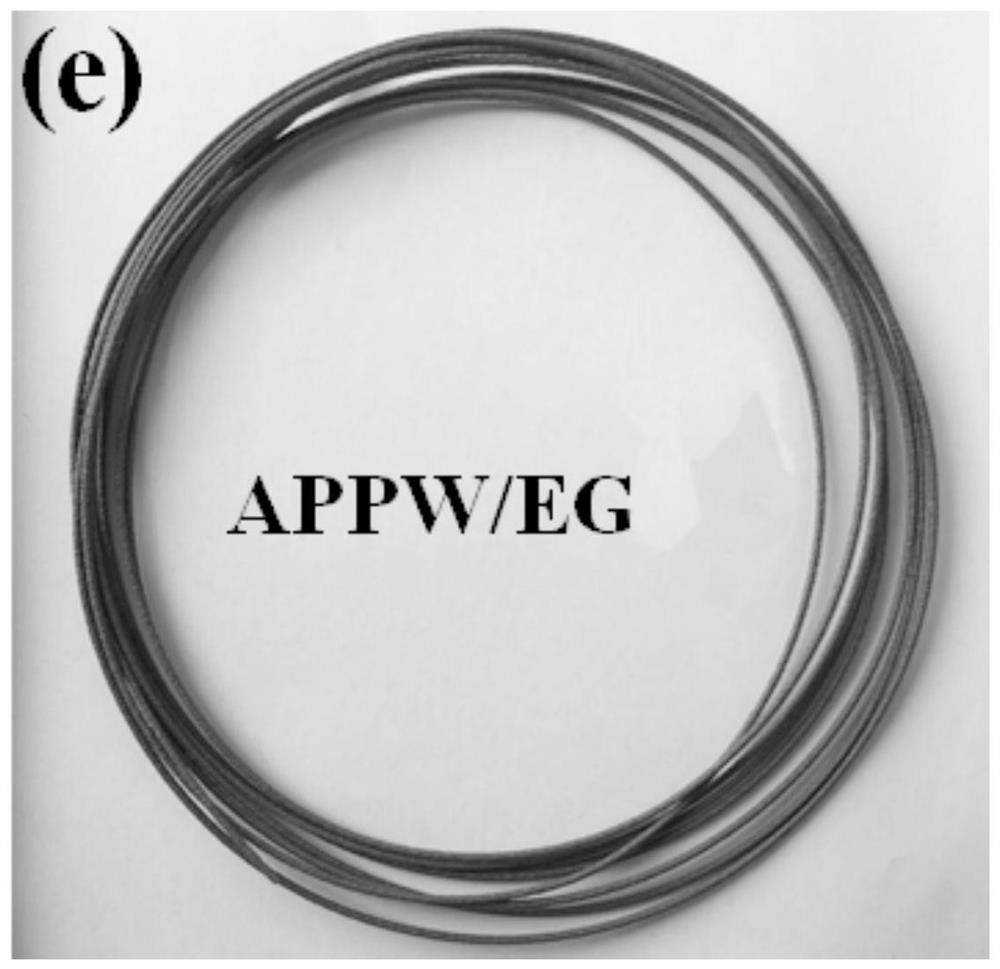

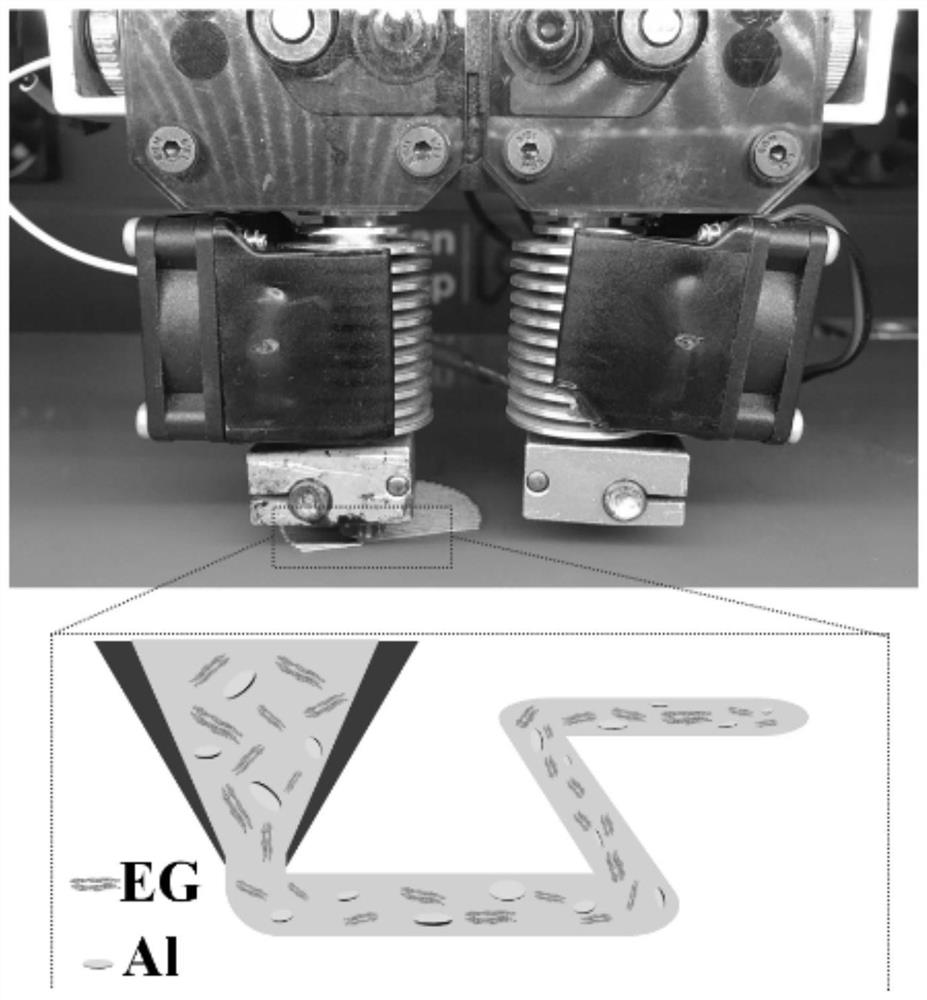

Method for preparing high thermal conductivity insulating 3D printed products by using waste aluminum-plastic packaging

ActiveCN112793152BGood thermoplastic processabilityNo secondary pollutionAdditive manufacturing apparatusPlastic recycling3d printPlastic packaging

The invention provides a method for preparing high thermal conductivity and insulation 3D printing products by using waste aluminum-plastic packaging materials. Ultrafine powder, blended and extruded into 3D printing filaments, the unique process temperature conditions in the process of fused deposition molding 3D printing make the expandable graphite expand in situ, and release the intercalation agent in the confined space, so that The in-situ oxidation reaction occurs on the surface of aluminum metal, and at the same time, the high shear force in the fused deposition molding 3D printing process is used to realize the special orientation and network structure construction of two-dimensional nanomaterials, thereby preparing high-performance thermally conductive and insulating 3D printed products. The thermal conductivity of the 3D printed product prepared by the present invention is not less than 2.5W / mK, and the electrical conductivity is less than 10 ‑10 S / cm, the tensile strength is not less than 12Mpa.

Owner:SICHUAN UNIV

Method for cleanly preparing bioplastic food packaging film at low cost

InactiveCN107903421AGood thermoplastic processabilityImprove tensile propertiesFlat articlesCoatingsHigh energyGlycerol

The invention belongs to the technical field of preparation of packaging films and provides a method for cleanly preparing a bioplastic food packaging film at low cost. The method comprises the following steps: preparing modified cellulose by utilizing hydrogen bonds of ultra ultraviolet radiation high-energy bombardment destroyed cellulose in a vacuum environment, wherein the modified cellulose has a good thermoplastic property; matching polylactic acid, gallic acid and glycerol for calendaring to obtain a prototype film; further melting polyadipic acid-butylene terephthalate and polycarbonate into slurry and coating the surface of the prototype film with the slurry; carrying out rolling, stretching and shaping, thus obtaining a food packaging film. The packaging film prepared by the method has the advantages of stretch resistance, barrier property and good contacting safety with food; in addition, the method has the advantages of simple technological operation in the whole process, high production efficiency, low production cost and capability of realizing batch production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Starch and polylactic acid composite material and preparation method thereof

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

EVOH (ethylene vinyl alcohol) resin and preparation method thereof

ActiveCN102229733BWeaken the intermolecular forcesIntermolecular forces breakPolymer sciencePlasticizer

The invention discloses an EVOH (ethylene vinyl alcohol) resin and a preparation method thereof and relates to a resin and a preparation method thereof, and the method provided by the invention can be used for solving the problems of complex process for the production of the EVOH resin and large production difficulty in traditional methods. The EVOH resin is prepared through the following steps: stirring polyvinyl alcohol, a plasticizer, an ethylene unsaturated monomer, maleic anhydride graft polypropylene resin, an initiator, a catalyst, an anti-yellowing agent and a surfactant, and then pelletizing the mixture in a double-screw extruder. The method provided by the invention is simple in process and small in equipment investment, and the EVOH resin has the advantage of stable quality.

Owner:WEIFANG HUAWEI MATERIALS TECH CO LTD

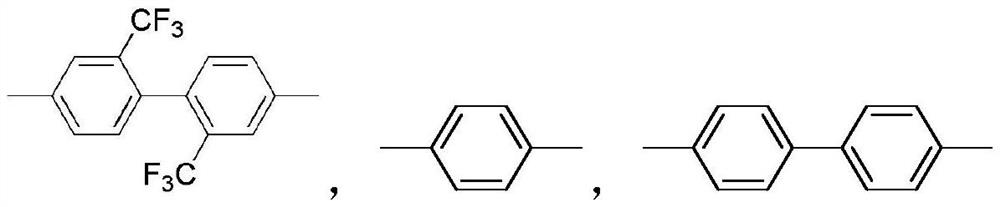

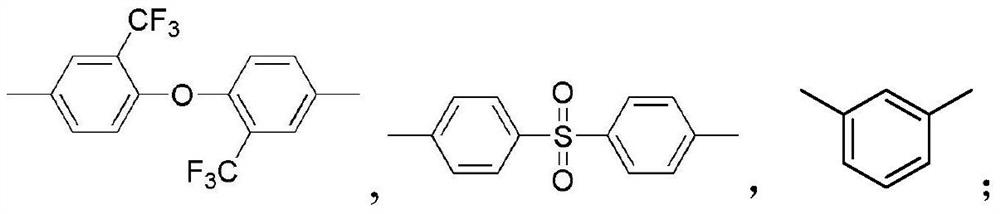

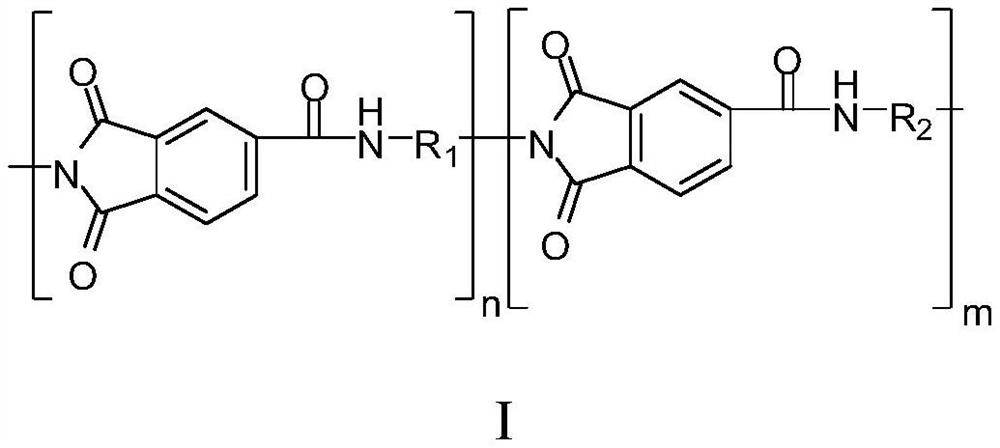

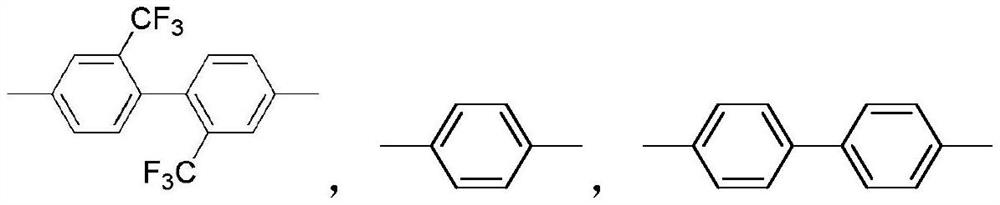

High-temperature-resistant easy-to-process thermoplastic transparent polyimide resin material with low thermal expansion coefficient and preparation method thereof

PendingCN112852154AImprove thermoplastic processabilityReduce processing temperature and melt viscosityMelt flow indexImide

The invention discloses a high-temperature-resistant easy-to-process thermoplastic transparent polyimide resin material with a low thermal expansion coefficient and a preparation method thereof. High-molecular-weight high-temperature-resistant thermoplastic transparent polyimide resin with a glass transition temperature being greater than 240 DEG C and a thermal expansion coefficient being less than 45ppm / K, an antioxidant, a lubricant and low-molecular-weight polyimide resin are blended and extruded to obtain aggregates, due to adoption of thelow-molecular-weight polyimide resinwith good compatibility with the thermoplastic polyimide body, the antioxidant and the lubricant, the melt index of the resin is greatly increased, the processing temperature is greatly reduced, the resin can be subjected to melt extrusion for many times subsequently, the processing stability of the resin is improved, and the material can be used for processing such as multi-time extrusion injection molding.

Owner:宁波惠璞新材料有限公司

Thermoplastic polyimide resin material with low thermal expansion coefficient and preparation method thereof

PendingCN114456597AGood thermoplastic processabilityImprove high temperature stabilityThermal dilatationPolymer science

The invention discloses a thermoplastic polyimide resin material with a low thermal expansion coefficient. The thermoplastic polyimide resin material is prepared from the following components in percentage by mass: 80-99% of high-temperature-resistant thermoplastic polyimide resin of which the glass transition temperature is greater than 250 DEG C and the thermal expansion coefficient is less than 40ppm / K; 0.1-15% of thermoplastic polyimide resin having a glass transition temperature of less than 220 DEG C and a logarithmic viscosity of more than 0.30 dL / g; 0.2 to 5% of an antioxidant; and 0.2-5% of a lubricant. The invention further provides a preparation method. According to the invention, by blending with the high-molecular-weight and high-melt-index thermoplastic polyimide resin with the glass transition temperature of less than 220 DEG C and the logarithmic viscosity of more than 0.30 dL / g, and matching with the antioxidant and the lubricant, the thermoplastic processability of the resin is improved, the processing temperature and melt viscosity are reduced, and the mechanical properties of the resin are improved. The melt index, the thermoplastic stability and the service life of the product are improved.

Owner:宁波惠璞新材料有限公司

a to indicate co 2 Food Freshness Indicator Cards for Characteristic Gases

InactiveCN104048958BEasy to identifyBiodegradableMaterial analysis by observing effect on chemical indicatorCoatingsMethylcellulose PowderPolyethylene glycol

The invention relates to a food freshness indicator card taking indicated CO2 as a characteristic gas and a manufacturing method of the food freshness indicator card. The manufacturing method comprises the following steps: firstly, crushing a polylactic acid sample, dissolving by chloroform, after heating in water bath, laying on a clean glass grinding tool through a tape-casting process, and drying to prepare a basal membrane; and dissolving bromothymol blue powder and methyl red powder in an ethanol solution, after stirring, uniformly mixing with polyethylene glycol and methylcellulose powder, laying on the basal membrane, drying to obtain the indicator card, independently packing the indicator card, and adding a drying agent into the indicator card for controlling the humidity surrounding the indicator card and improving the accuracy of discoloring generated after CO2 is absorbed by the indicator card. According to the manufacturing method, a self-made polylactic acid membrane is used as the indicator card basal membrane and is smooth in surface, uniform in texture and bright and translucent in appearance, and thus vision errors are furthest reduced. Due to invention and application of the freshness indicator card, consumers can purchase healthy and high-quality foods, and Chinese food safety is greatly improved.

Owner:TIANJIN UNIV OF SCI & TECH

A kind of thermoplastic phosphogypsum filling material and preparation method thereof

ActiveCN105837857BIncrease added valueSustainable Consumption GuaranteeThermoplasticFilling materials

The invention relates to deep processing modification and application of phosphorus ore byproduct phosphorus gypsum, and discloses a phosphorus gypsum filling material with thermoplastic processing performance. The phosphorus gypsum filling material is characterized in that a first cladding layer with flowing lubricity is formed on the surface of dry powdery phosphorus gypsum, a second hydrophobic layer is formed on the first cladding layer, and a third hot melt layer is formed on the second hydrophobic layer. The invention further provides a preparation method. Inorganic lubricant powder and the phosphorus gypsum are collided, ground and refined under the action of a high-speed jet mill by virtue of flowing lubricity of the inorganic lubricant powder, and anchoring groups of a dispersing agent are embedded with the phosphorus gypsum in a refining process of the dry powdery phosphorus gypsum, so that the phosphorus gypsum is endowed with high rheological processability, problems about high-filling application of the phosphorus gypsum filling material to plastics are radically solved, the phosphorus gypsum filling material is used for large products such as PVC enclosure wall baffle plates, agricultural seedling growing flowerpots, stone paper and garbage bags, the consumption of the phosphorus gypsum can be greatly improved, and the industrial application of the phosphorus gypsum to plastics is promoted.

Owner:陕西睿智环保建材有限公司

A kind of ceramic material and its manufacturing method for 3D printing

The invention discloses a porous ceramic microsphere composite material for 3D printing. The porous ceramic microsphere composite material is mainly composed of porous ceramic microspheres and thermoplastic resin, wherein the porous ceramic microspheres account for 80-99% of total weight, and the thermoplastic resin accounts for 1-20% of the total weight. The raw materials undergo extrusion pelletization through a twin-screw extruder so as to prepare the ceramic material for 3D printing. By characteristics of good fluidity and low density of the porous ceramic microspheres and by combination of thermoplastic processability of the thermoplastic resin, the characteristic of low thermoplastic processability of the ceramic material is overcome, and more selections are provided for a 3D printing material. The invention also discloses a preparation method of the ceramic material. More printing material selection spaces are provided for a three-dimensional printing technology, and a three-dimensional structured product of the ceramic material is prepared by a fused deposition modeling 3D printing technology. The production technology is simple, low-cost, safe and environmentally friendly, and has a market application prospect.

Owner:安徽长朗三维科技有限公司

A kind of polyvinyl alcohol/shell powder biomass composite material and preparation method thereof

The present invention discloses a polyvinyl alcohol / shell powder biomass composite material. The polyvinyl alcohol / shell powder biomass composite material is formed by fusing and blending the following components in parts by weight: 20-80 parts of polyvinyl alcohol, 20-80 parts of shell powder and 10-30 parts of a plasticizer; and the fusing point of the composite material is 155-200 DEG C, the thermal decomposition temperature is 230-270 DEG C, the tensile strength is 30-80MPa and the elongation at break is 80-300%. The present invention further discloses a preparation method for the polyvinyl alcohol / shell powder biomass composite material. Polyvinyl alcohol and the polar shell powder in the composite material disclosed by the present invention have good natural compatibility, and the shell powder is uniformly dispersed in a polyvinyl alcohol base body by adopting a milling-disc-shaped force chemical reactor, so that the filling amount of the shell powder is greatly increased under the condition of not adding a surface modifying agent and a mobile modifying agent, and the mechanical property and elongation at break of the composite material are also improved; and meanwhile, the preparation method has a simple process and short flow, and has no three-waste pollution in a production process, and the industrialized production is liable to realize.

Owner:安徽瑞鸿新材料科技有限公司

Formula of bio-based degradable material and preparation method and application thereof

The invention discloses a formula of a bio-based degradable material. The formula comprises the following raw materials in parts by weight: 30-100 parts of biological filler, 1-10 parts of PCL and 1-10 parts of a degradable liquid toughening agent. The preparation method of the bio-based degradable material comprises the following steps: weighing the raw materials in proportion, putting the raw materials into a high-speed stirrer to be uniformly stirred, and then pouring the raw materials into an annular mill or a flat mill to be granulated so as to form the bio-based degradable material. According to the invention, the interface bonding force between the degradable resin and the filler can be increased, the overall thermoplastic processability of the degradable material can be improved, and the cost can be reduced.

Owner:XIAMEN LONAKO MATERIAL TECH CO LTD

A low-cost room temperature high plastic deformation magnesium alloy material and its preparation process

The invention discloses a low-cost magnesium alloy with the high room-temperature plastic deformation and a preparation process thereof, and belongs to the technical field of metal materials. The magnesium alloy comprises, by weight, 0.1%-0.9% of zinc, 0.1%-0.4% of calcium, 0-0.05% of manganese and the balance magnesium. The magnesium alloy does not contain rare earth elements or the Zr element and is low in alloy cost, an ingot of the magnesium alloy has good thermoplastic machining performance, large-rolling-reduction rolling with the rolling reduction being 80% at most in one pass can be achieved during hot rolling, and cracks in the surface are avoided. The ingot is subjected to thermoplastic machining and then annealing, the obtained magnesium alloy has a weak non-basal texture, the maximum density value of the magnesium alloy is not greater than 5, and the room-temperature elongation of the magnesium alloy is high and can reach 25%-40%.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Application of polymer particle with chlorine on the surface as thermal reversible reactive filler and composition of polymer particle with chlorine on the surface

Owner:BEIJING UNIV OF CHEM TECH +1

Paper-imitating biodegradable resin and preparation method

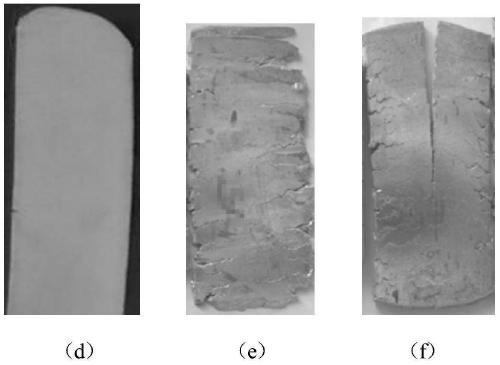

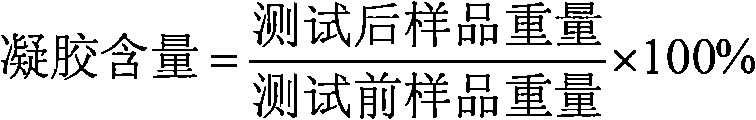

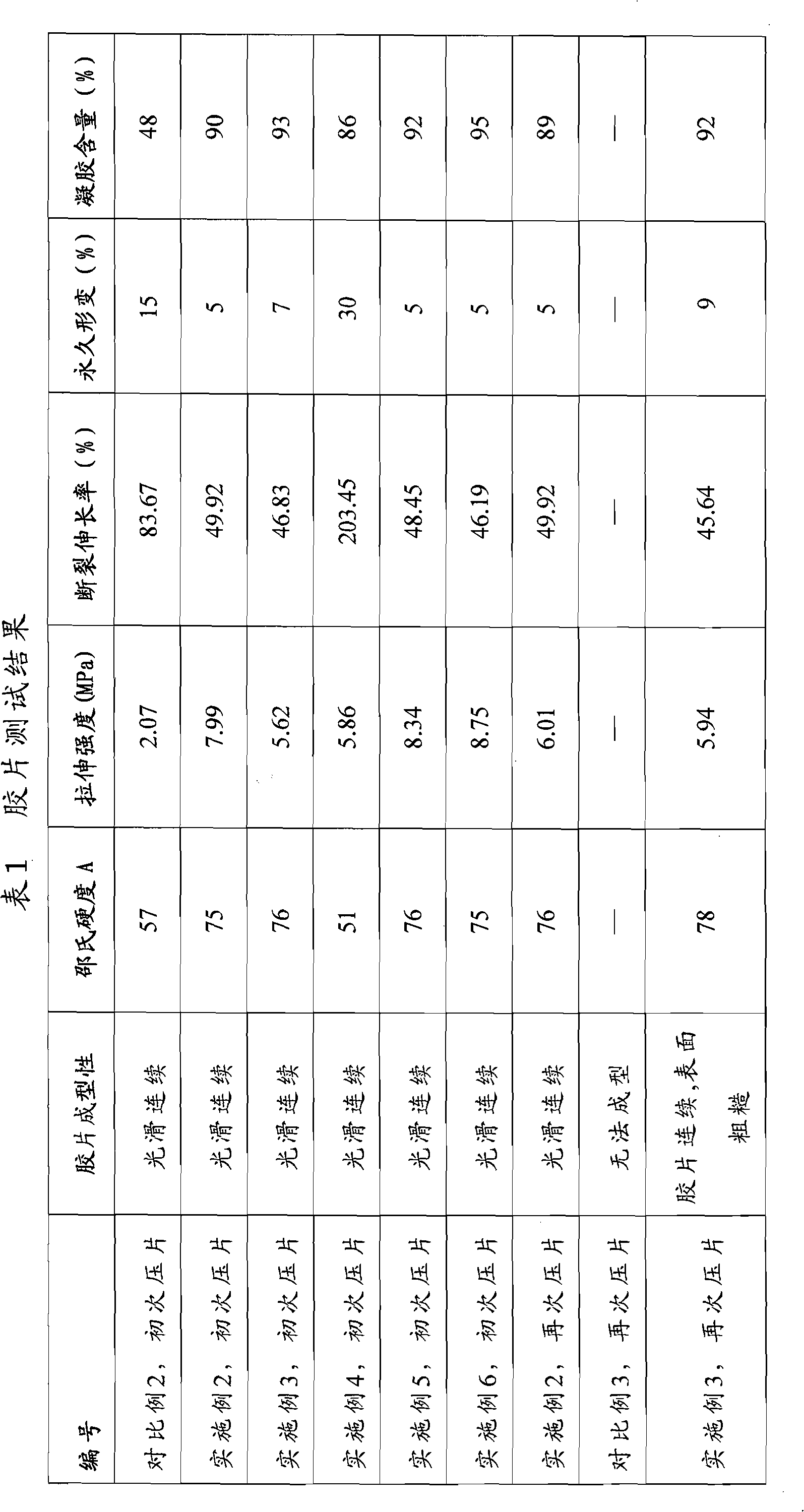

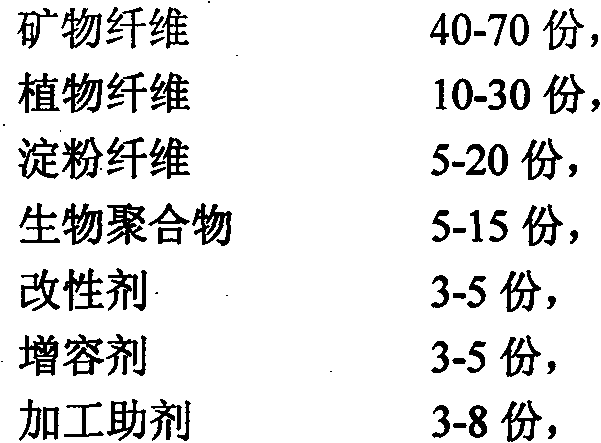

ActiveCN101914294BAvoid pollutionImprove rigidityInorganic fibres/flakesPaper/cardboardBiopolymerVegetable fibers

The invention discloses a paper-imitating biodegradable resin and a preparation method. For improving the degradability and natural recoverability of paper-imitating materials and making the paper-imitating materials have similar lightness, foldability and printing and writing performance as the conventional paper. The paper-imitating biodegradable resin uses mineral fibers, vegetable fibers and starch fibers as main components, and concretely comprises the following components in part by weight: 40 to 70 parts of mineral fibers, 10 to 30 parts of vegetable fibers, 5 to 20 parts of starch fibers, 5 to 15 parts of biopolymer, 3 to 5 parts of modifier, 3 to 5 parts of compatibilizer and 3 to 8 parts of processing assistant. The mineral fibers, vegetable fibers and starch fibers are interweaved through thermoplastic processing, and the preparation process is clear and pollution-free. The paper-imitating biodegradable resin can be processed into various paper-imitating products by hot plasticizing equipment, and the products, when discarded, can be swallowed and decomposed by microbes without polluting the environment.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

A laser modification method for preparing thermoplastic starch for biodegradable plastics

The invention provides a method for preparing thermoplastic starch special for biodegradable plastic through laser modification. The method comprises the following steps: performing enzymolysis on starch granules by high-temperature-resistant alpha-amylase, further damaging a hydrogen bond in molecules in the microstructure of the starch granules by using laser, and introducing the starch modulesinto a block polymer during monomer block polymerization to obtain starch with high thermoplasticity. The thermoplastic starch can be widely applied to preparation of biodegradable plastic. The product obtained by the method has high quality and safety, the process limit in the field of starch modification is overcome, the preparation process is simple in operation, time-saving, labor-saving and easy in large-scale production, and the practical value is extremely high.

Owner:合肥科拜尔新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com