Method for preparing high thermal conductivity insulating 3D printed products by using waste aluminum-plastic packaging

An aluminum-plastic packaging and 3D printing technology, applied in recycling technology, 3D object support structure, manufacturing tools, etc., can solve problems such as inability to smoothly produce silk products, limited oxygen pathways, clogging of 3D printing flow channels, etc. The effect of continuous automatic processing, improved mechanical strength and thermal conductivity, and good thermoplastic processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

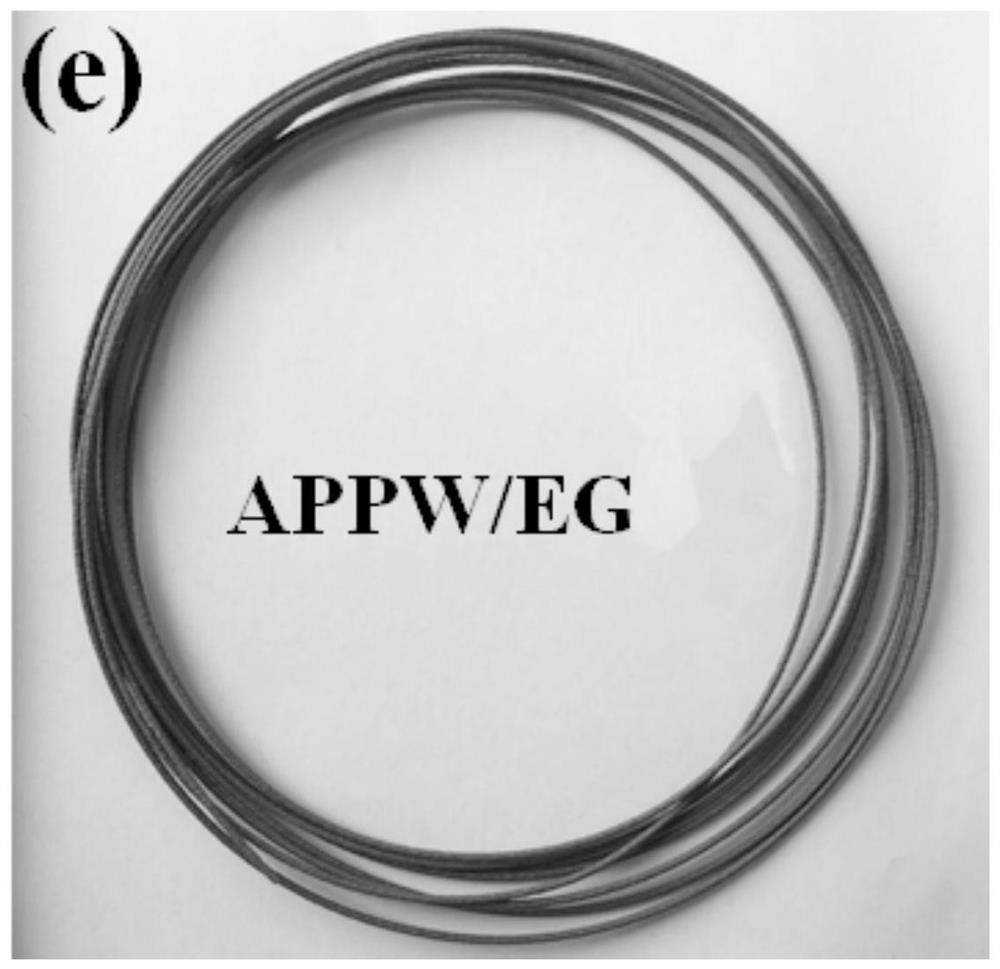

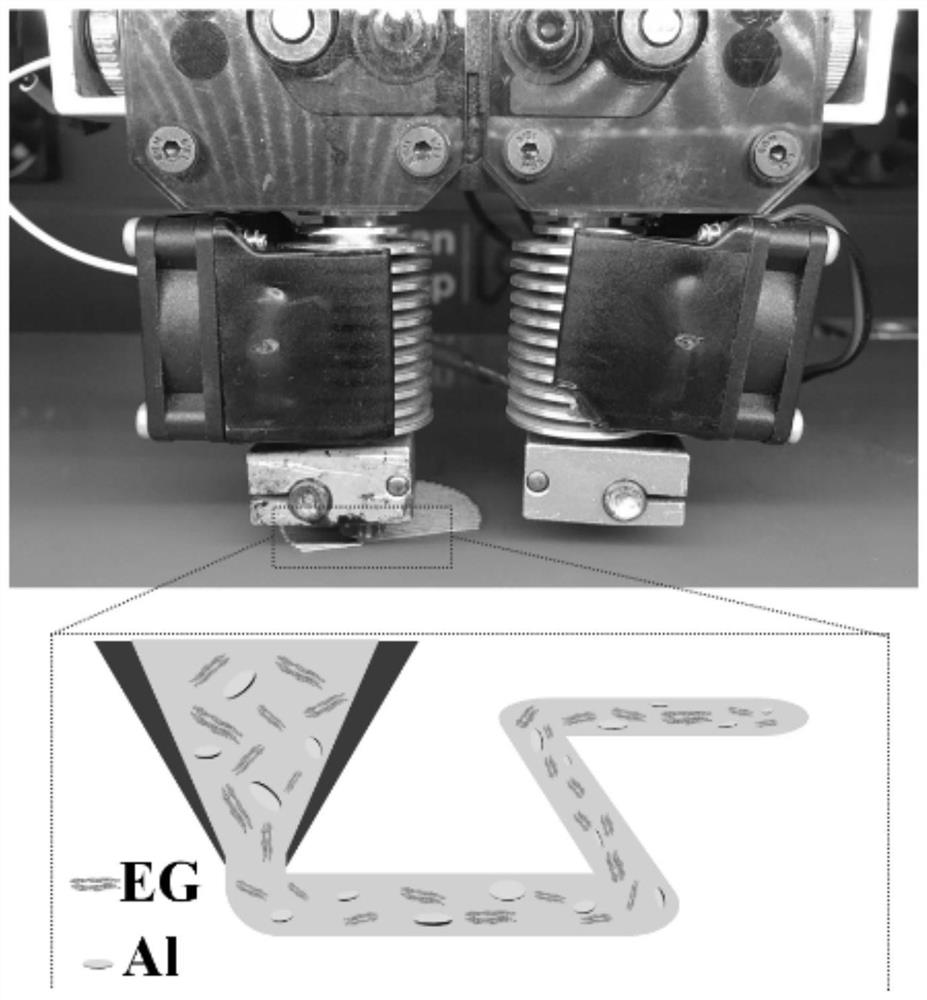

[0051] In this embodiment, a method for preparing high thermal conductivity and insulating 3D printing products by using waste aluminum-plastic packaging materials includes the following steps:

[0052] (1) Select waste aluminum-plastic packaging materials (polyethylene / aluminum, with an aluminum content of 15%), and after pretreatment including washing, process and pulverize them into waste aluminum-plastic packaging powders with an average particle size of 100um;

[0053] (2) Put the waste aluminum-plastic packaging powder into a millstone-type solid-phase force chemical reactor for grinding and pulverization. After the grinding is completed, the waste aluminum-plastic ultrafine powder is collected; wherein, the millstone-type solid-phase force chemical reaction The process parameters of the device are as follows: the grinding pressure is 6 MPa, the temperature of the disc surface is controlled by feeding circulating cooling liquid to 15°C, and the grinding cycle is 10 times;...

Embodiment 2

[0058] In this embodiment, a method for preparing high thermal conductivity and insulating 3D printing products by using waste aluminum-plastic packaging materials includes the following steps:

[0059] (1) Select waste aluminum-plastic packaging materials (polyethylene / aluminum, with an aluminum content of 15%), and after pretreatment including washing, process and pulverize them into waste aluminum-plastic packaging powders with an average particle size of 100um;

[0060] (2) Put the waste aluminum-plastic packaging powder into a millstone-type solid-phase force chemical reactor for grinding and pulverization. After the grinding is completed, the waste aluminum-plastic ultrafine powder is collected; wherein, the millstone-type solid-phase force chemical reaction The process parameters of the device are as follows: the grinding pressure is 8MPa, the temperature of the disc surface is controlled to 0°C by feeding circulating cooling liquid, and the grinding cycle is 10 times; ...

Embodiment 3

[0065] In this embodiment, a method for preparing high thermal conductivity and insulating 3D printing products by using waste aluminum-plastic packaging materials includes the following steps:

[0066] (1) Select waste aluminum-plastic packaging materials (polyethylene terephthalate base / aluminum, aluminum content is 10%), after pretreatment including washing, it is processed and crushed to an average particle size of 100um Waste aluminum-plastic packaging powder;

[0067] (2) Put the waste aluminum-plastic packaging powder into a millstone-type solid-phase force chemical reactor for grinding and pulverization. After the grinding is completed, the waste aluminum-plastic ultrafine powder is collected; wherein, the millstone-type solid-phase force chemical reaction The process parameters of the device are as follows: the grinding pressure is 5 MPa, the temperature of the disc surface is controlled by feeding circulating cooling liquid to 15°C, and the grinding cycle is 15 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com