Formula of bio-based degradable material and preparation method and application thereof

A biodegradable material and bio-based technology, applied in the field of degradable composite materials, can solve the problems of difficult marketing, no way to widely promote, poor fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

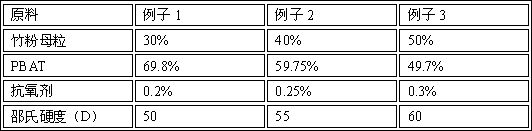

Examples

preparation example Construction

[0016] The present invention also discloses a preparation method of the above-mentioned bio-based degradable material, which includes the following steps: after weighing the raw materials in the above-mentioned bio-based degradable material formula in proportion, putting the three kinds of raw materials into a high-speed mixer and stirring them evenly, and then Pour directly into ring mill or flat mill for granulation to form bio-based degradable material.

[0017] The bio-based degradable materials produced by the above method form pellets, which can be used as intermediate materials in the preparation of degradable materials. The bio-based degradable materials are directly mixed with degradable resins, additives and other raw materials, and then poured into double Granulated in a screw extruder to make degradable material. Among them, the degradable resin can be PBAT, PBS, PLA, PHA, PVA, PHB or PHBV, etc., and the additive can be an antioxidant. Since most of the antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com