Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

951results about How to "Improve interfacial adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

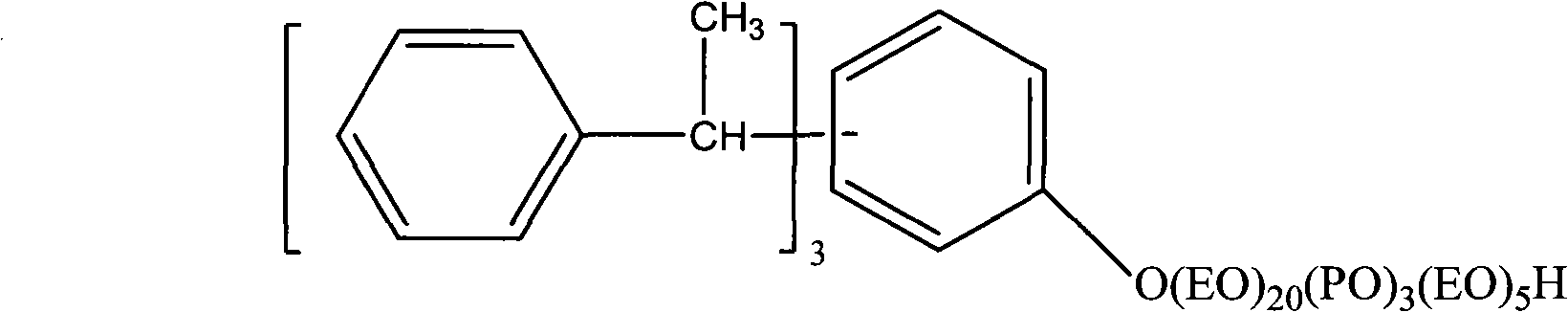

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized water to the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

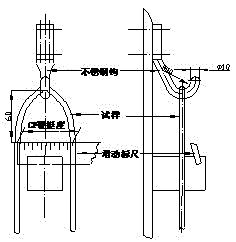

Processing method for silane coupling agent modified carbon fiber surface

ActiveCN103643503AIncreased monofilament tensile strengthGood processing effectCarbon fibresUltrasonic/sonic fibre treatmentChemistryLithium aluminium hydride

A processing method for silane coupling agent modified carbon fiber surface comprises the following steps: removing the sizing agent coated on the sizing carbon fiber surface by using acetone, drying, then carrying out oxidation etching on the fiber surface by using concentrated nitric acid, water-washing until the pH reaches 6 to 8, drying, then dispersing the fiber into tetrahydrofuran, adding lithium aluminium hydride to reduce the oxygen containing groups on the fiber surface and convert all the oxygen containing groups into hydroxyl groups, then adding hydrochloric acid, stirring for 1 to 2 hours, filtering so as to obtain carbon fibers, soaking and washing the carbon fibers with tetrahydrofuran, drying, then dispersing the carbon fiber into a silane coupling agent hydrolysate, stirring or subjecting the carbon fiber to an ultrasonic treatment, filtering so as to obtain the carbon fiber, and drying the carbon fiber. The method improves the surface activity of the carbon fiber, does not harm the fiber body, and is capable of being applied to mass production.

Owner:山西泰宝科技有限公司

Preparation method of polylactic acid/nano-cellulose composite material

The invention provides a preparation method of a polylactic acid / nano cellulose composite material. The composite material comprises the following components in percentage by weight: 55 to 99.8% of polylactic acid, 0.1 to 15% of nano cellulose, and 0.1 to 30% of polyethylene glycol. The method comprises the following steps of: preparing a 5 to 15% an aqueous solution of microcrystalline cellulose, dripping concentrated sulfuric acid until the concentration of sulfuric acid reaches 40 to 60%, stirring and reacting for 1 to 2hours, carrying out centrifugation, ultrasound treatment and adjusting pH value to be neutral to obtain a nano cellulose suspension; dissolving polyethylene glycol, mixing with the nano cellulose suspension, stirring for 1 to 3hours at the temperature of 90 DEG C and carrying out vacuum drying to obtain a polyethylene glycol / nano cellulose comixture; and carrying out melt blending on the polyethylene glycol / nano cellulose comixture and polylactic acid for 5 to 8minutes at the temperature of 120 to 170 DEG C to obtain the composite material. The method is convenient and simple to operate, short in the time of the preparation process and solves the problem of uniform dispersion of nano-cellulose in the polylactic acid.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

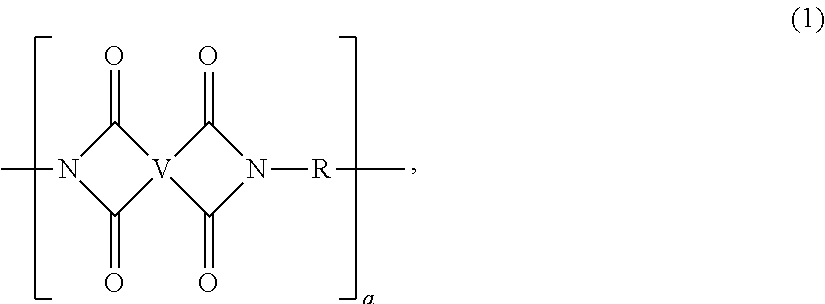

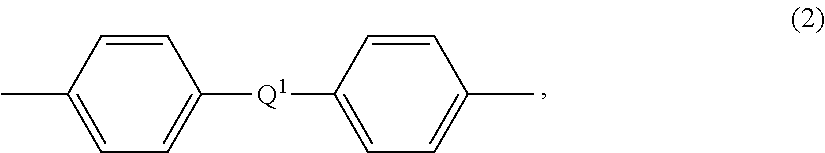

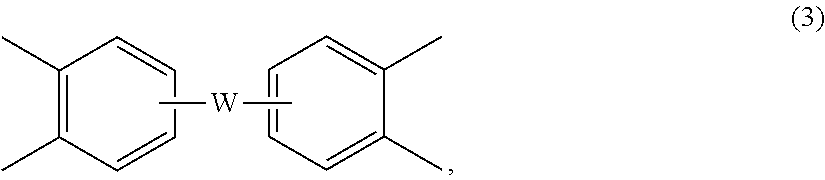

Process of making dispersed polyetherimide micronized particles and process of coating and further forming of these particles products made therefrom

InactiveUS20140272430A1Improve interface adhesionImprove performanceSynthetic resin layered productsPretreated surfacesFiberPolymer science

Processes involving wetting fibers with an aqueous dispersion of micronized thermoplastic powders; processes for producing an aqueous dispersion of micronized thermoplastic powders; processes of chemically surface cross-linking micronized particles; and articles of produced therefrom.

Owner:SABIC GLOBAL TECH BV

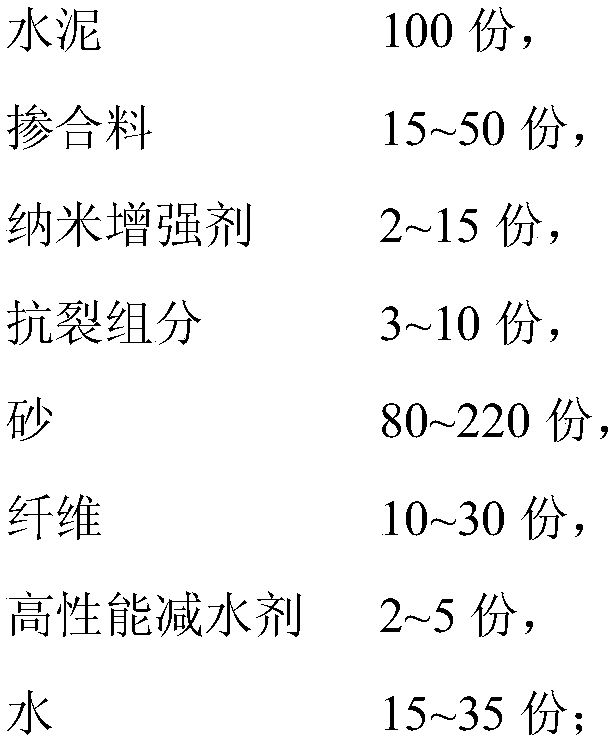

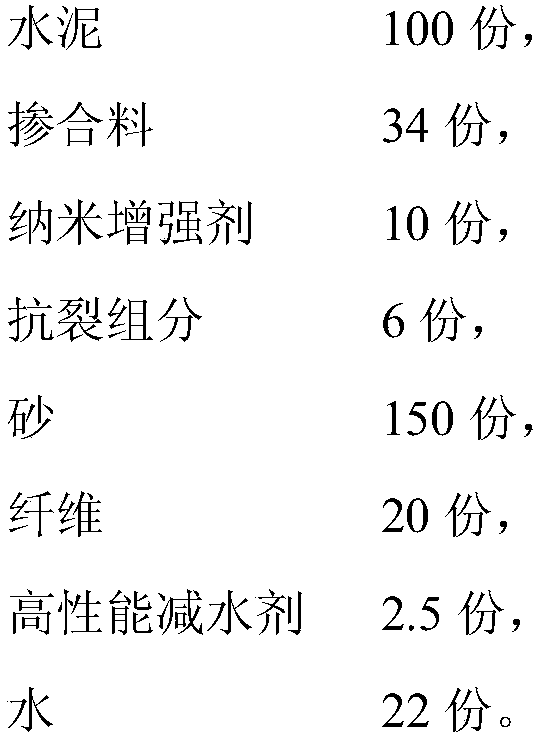

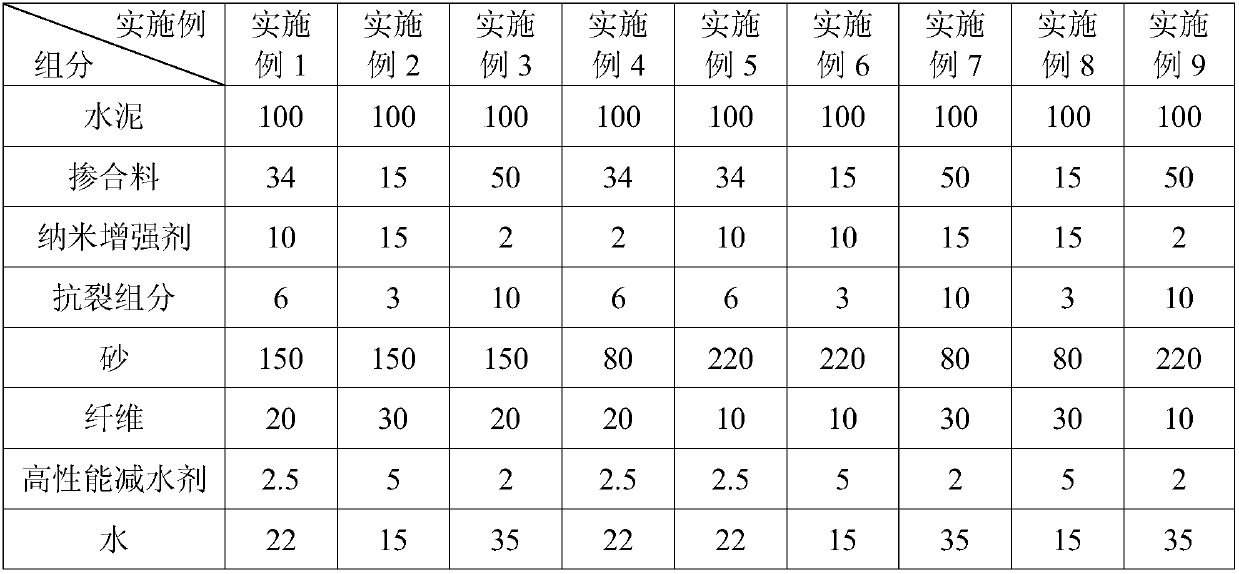

Super-high-performance cement base repairing material and preparing method thereof

The invention discloses a super-high-performance cement base repairing material and a preparing method thereof. The repairing material is prepared from, by mass, 100 parts of cement, 15-50 parts of admixture, 2-15 parts of nanometer reinforcing agent, 3-10 parts of crack resistance component, 80-220 parts of sand, 10-30 parts of fiber, 2-5 parts of high-performance water reducing agent and 15-35 parts of water. The super-high-performance cement base repairing material has super-high tensile strength, bending resistance and adhesive strength and extremely low shrinkage performance, and has excellent construction performance, high elasticity modulus and super-high durability. The material has effects of repairing, reinforcing, seepage preventing, preventing and the like, and therefore the service life of the repairing material and a structure is prolonged. In addition, the material can be used as a joint material of a structural joint.

Owner:JIANGSU SOBUTE NEW MATERIALS

Novel bamboo-plastic composite material

The invention relates to a preparation method of a novel bamboo-plastic composite material, in particular to a bamboo-plastic composite material which has excellent mechanical property and is prepared by the step of adding reinforcing material bamboo powder (or bamboo fabric), a flexibilizer and other assistants to polypropylene used as a substrate resin, wherein the bamboo-plastic composite material comprises the following components in parts by mass: 40-100 parts of polypropylene, 40-100 parts of bamboo powder or bamboo fabric, 3-15 parts of compatilizer, 3-15 parts of flexibilizer, 0-5 parts of coupling agent, 0.5-8 parts of lubricant, 0-15 parts of nucleator and 0-8 parts of other assistants. According to the invention, by selecting proper types and proportions of flexibilizer, compatilizer and other assistants, the defect that the impact strength of the composite material is reduced greatly due to the addition of fiber is overcome.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing modified white carbon black

The invention discloses a method for preparing modified white carbon black, which comprises the following steps of: under the protection of nitrogen, heating and activating white carbon black for 4 to 5 hours; mixing the activated white carbon black and toluenediisocyanate, wherein the use amount of the toluenediisocyanate is 10 to 20 percent of that of the white carbon black; adding anhydrous dimethylbenzene into the mixture, wherein the ratio of the volume of the anhydrous dimethylbenzene to the mass of the white carbon black is 5-8:1; under the protection of nitrogen, stirring and dispersing at room temperature, and heating to the temperature of between 60 and 85 DEG C; and filtering and drying to obtain the modified white carbon black.

Owner:甘肃银光聚银化工有限公司

Lightweight, high-toughness, high-rigidity polypropylene composition and manufacturing method thereof

InactiveUS20200216651A1Enhanced interface bindingImprove impact resistanceMasterbatchPolymer science

A polypropylene composition provided with lightweight, highly tough and highly rigid as well as having a specific weight of 1.0-1.05 is made of a polypropylene resin, inorganic powder, a toughener, a coupling agent, a compatibilizer and an anti-oxidant; a method of manufacturing the composition involves grafting the inorganic powder onto the polypropylene resin and the coupling agent to form a masterbatch, and mixing the masterbatch with the other additives to enhance bonding ability of the inorganic powder inside the polypropylene composition to endow the composite with good toughness, rigidity and mobility, and reducing undesirable dust.

Owner:NANYA PLASTICS CORP

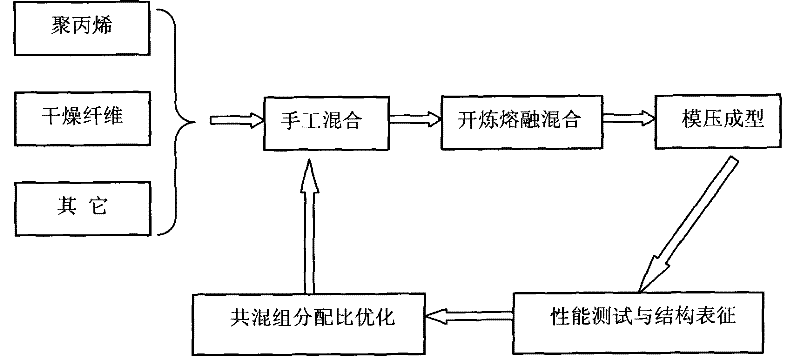

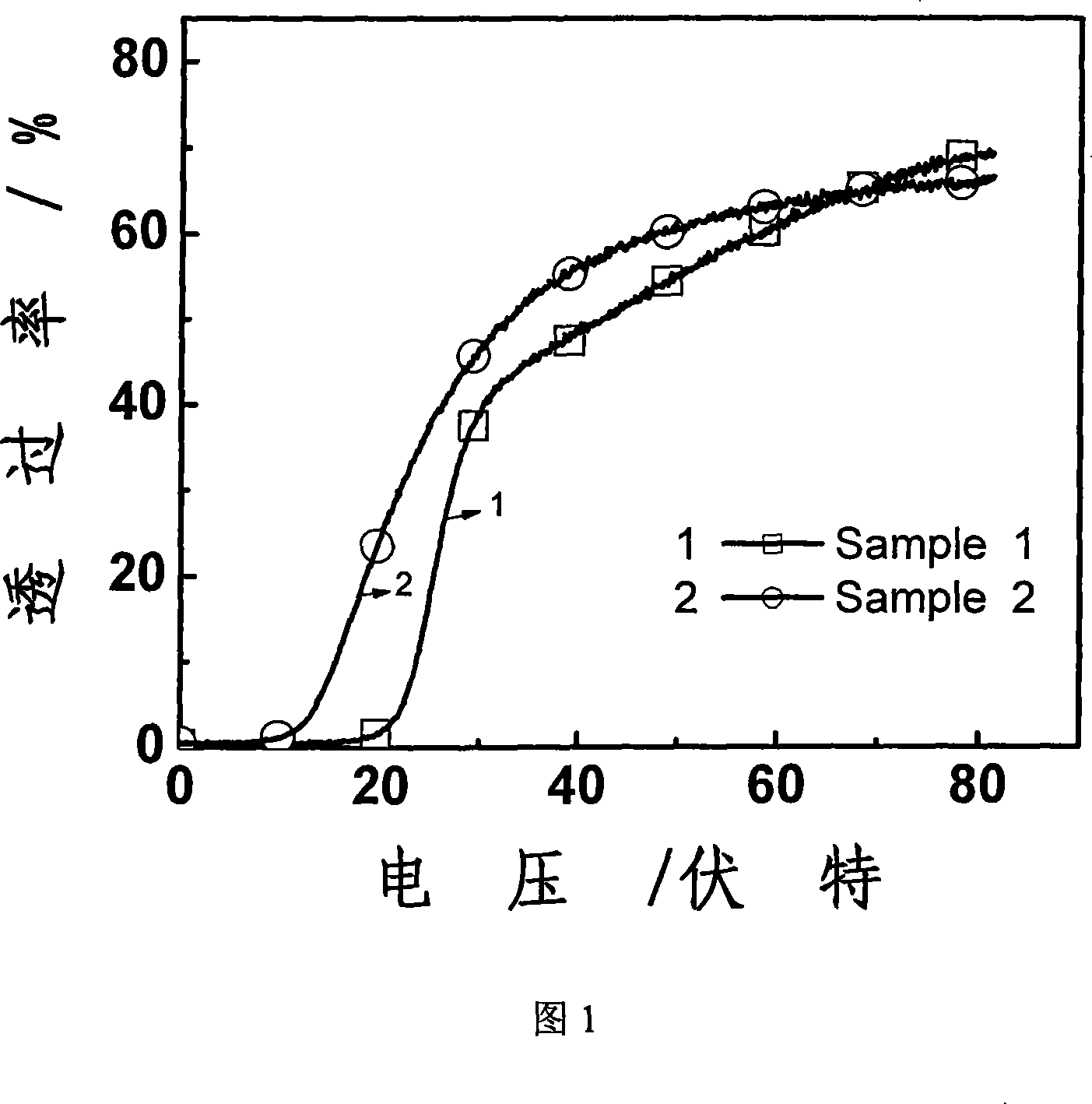

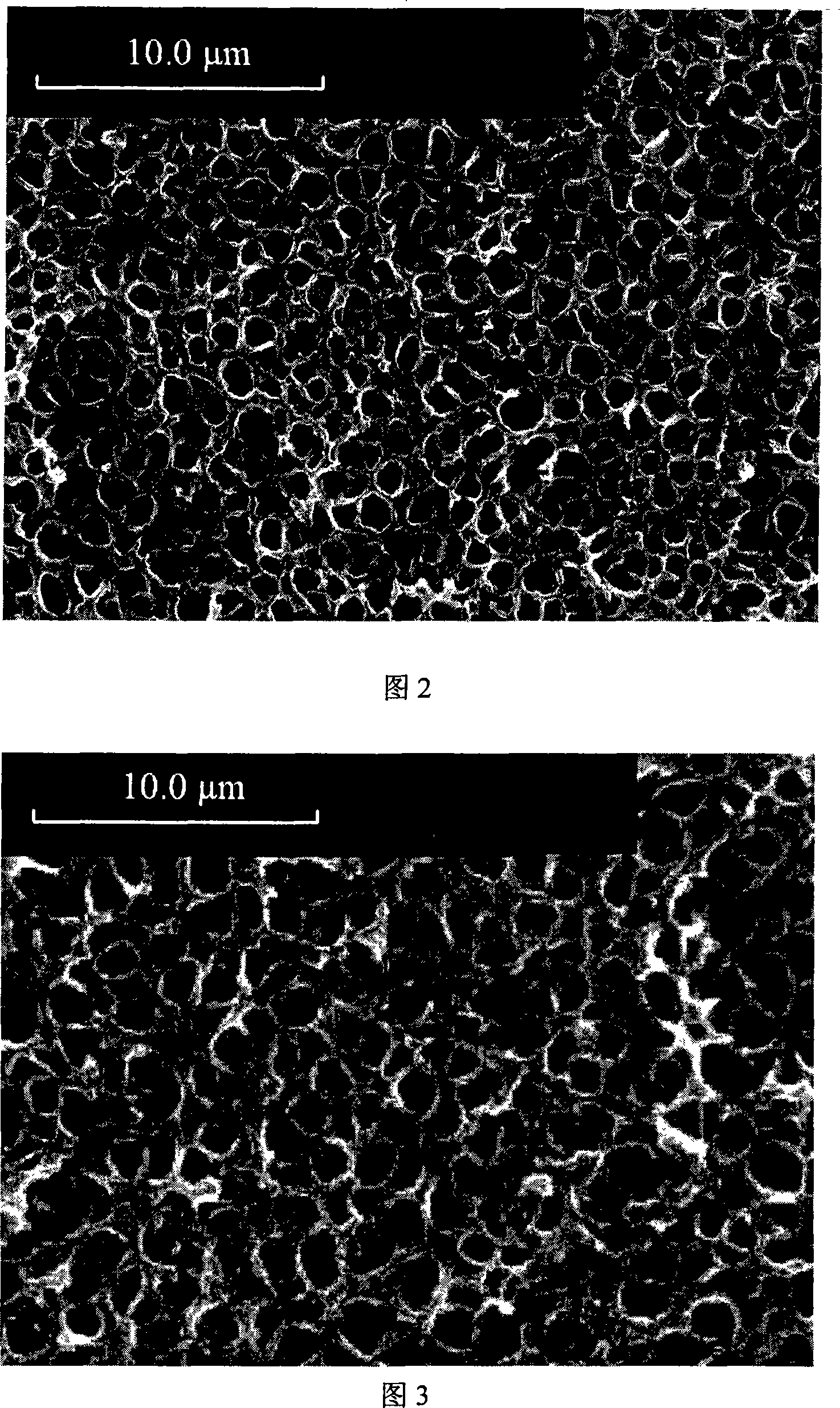

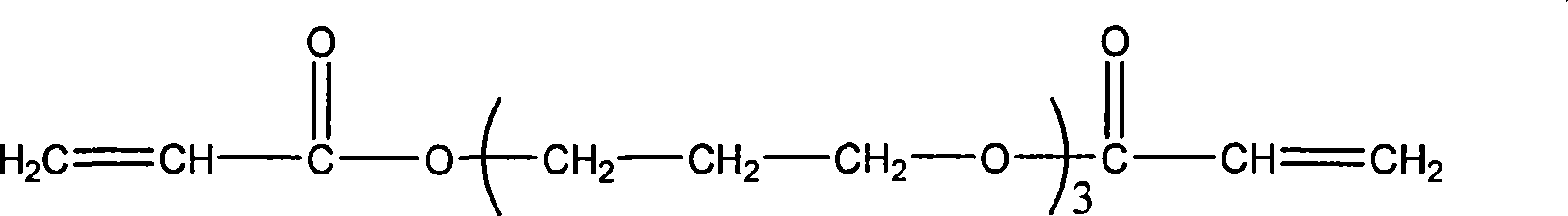

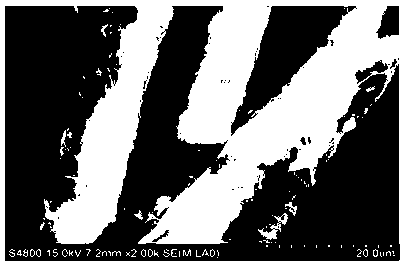

Method for preparing polymer dispersion liquid crystal material by ultraviolet-heating step-polymerization process

ActiveCN101225308AIncrease crosslink densityImprove interfacial adhesionLiquid crystal compositionsUltraviolet lightsPolymer network

The invention in particular relates to a preparation method of polymer dispersing liquid crystal film by an ultraviolet irradiating-heating plus stepwise initiated polymerization and phase separation method, belonging to the functional material field, which is applied in the preparation of electric controlled intelligent glass. The preparation method is characterized in that: the nematic liquid crystal, the monomer which can be polymerized under ultraviolet light, the light initiator, the thermal polymerized monomer and the glass microsphere is blended and then are clipped between two pieces of transparent conductive film plated with indium tin oxide, and then film with the thickness of 20 Mum if formed and is irradiated by the ultraviolet light with the wavelength of 365nm at 0 to 25 degrees; the intensity of the ultraviolet light is 20.0mW / m<2> and the illumination time is 1 to 10 minutes; the thermal polymerization temperature is 60 to 100 degrees, the holding time is 5 to 8 hours, at last the PDLC film is prepared by solidification. The polymer dispersing liquid crystal film has the advantages that: because of the stepwise polymerization crosslinking reaction which is carried out by selecting the monomer polymerized by ultraviolet and thermal polymerized monomer and irradiating and heating under ultraviolet light, the electro-optic performance the PDLC film is improved, the network strength of the polymer is enhanced, meanwhile, the bonding force of the interface between the polymer network and the ITO film are reinforced.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of aging resistant modified natural rubber

The invention belongs to the technical field of white carbon black modified natural rubber, and more specifically relates to a preparation method of an aging resistant modified natural rubber. The preparation method comprises steps of white carbon black modification and rubber master batch preparation. Compared with the prior art, the preparation method possesses following advantages: pre-drying process of white carbon black is capable of influencing water content and properties of white carbon black, and then influencing reaction degree of molecular chains with groups in modification process, and influencing product heat stability; modification of white carbon black is capable of increasing interface adhesive force, and increasing the dispersibility of white carbon black, chemical bonds are formed via chemical reaction of a part of hydroxy groups on the surface of white carbon black, and crosslinking and winding of long chain groups with natural rubber are capable of improving the heat stability of modified natural rubber; modified white carbon black is capable of inhibiting sliding of natural rubber chain segments in a finished compound product, reducing cross section deformation, and improving mechanical properties of the compound.

Owner:ANHUI JINHUA ZINC OXIDE CO LTD

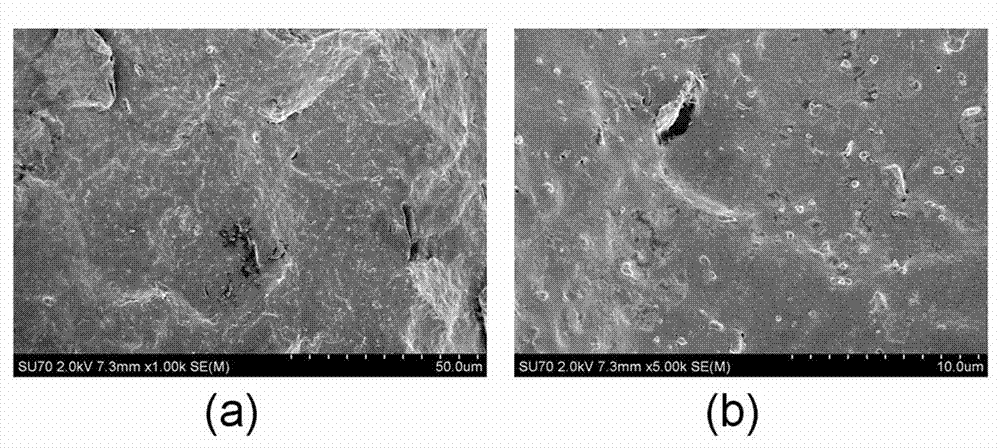

Carbon fiber emulsion sizing agent and preparation method and application thereof

The invention discloses a carbon fiber emulsion sizing agent. The sizing agent comprises a main sizing agent, an auxiliary agent, an organic solvent and de-ionized water, wherein the auxiliary agent accounts for 5 to 15 percent of the mass of the main sizing agent; the mass ratio of the organic solvent to the main sizing agent is 20-50 to 50-80; and the mass ratio of the de-ionized water to the main sizing agent is 50-90 to 10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent has low cost and environment friendliness and can be applied to different types of resin matrixes by varying the ratio of the components in the sizing agent. The preparation method is simple to operate and easy to implement. The sizing agent can improve the processability of the carbon fiber and the mechanical property of carbon fiber-enhanced resin-based composite materials when used in carbon fiber.

Owner:UNIV OF JINAN

Resistive nanocomposite compositions

InactiveUS6617377B2Increased mechanical and wear and electrical and thermal propertyImprove material performanceNanotechPrinted electric component incorporationScreen printingOrganic solvent

A resistive composition for screen printing onto a substrate. The resistive composition, based on total composition has a) 5-30 wt. % of polymer resin, b) greater than 0 up to and including 10 wt. % of thermosetting resin, c) 10-30 wt. % conductive particles selected from the group consisting of carbon black, graphite and mixtures thereof and d) 0.025-20 wt. % carbon nanoparticles, wherein all of (a), (b), (c) and (d) are dispersed in a 60-80 wt. % organic solvent.

Owner:CTS CORP ELKHART

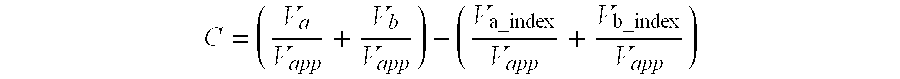

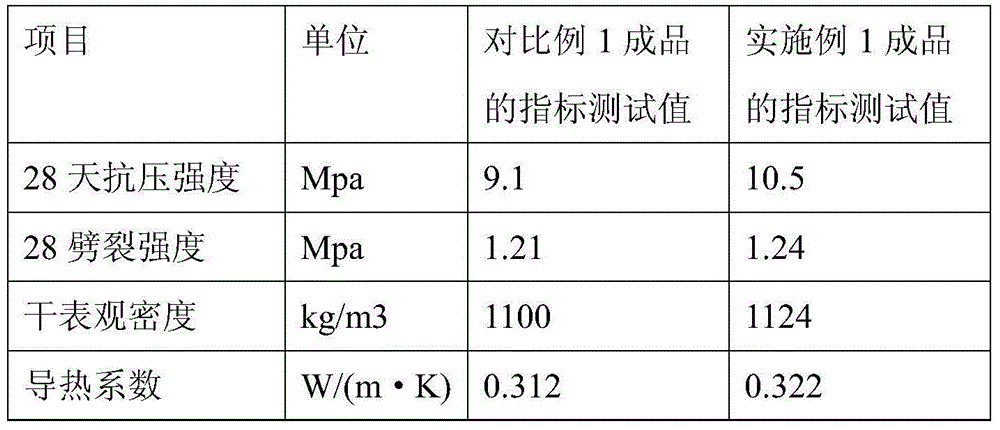

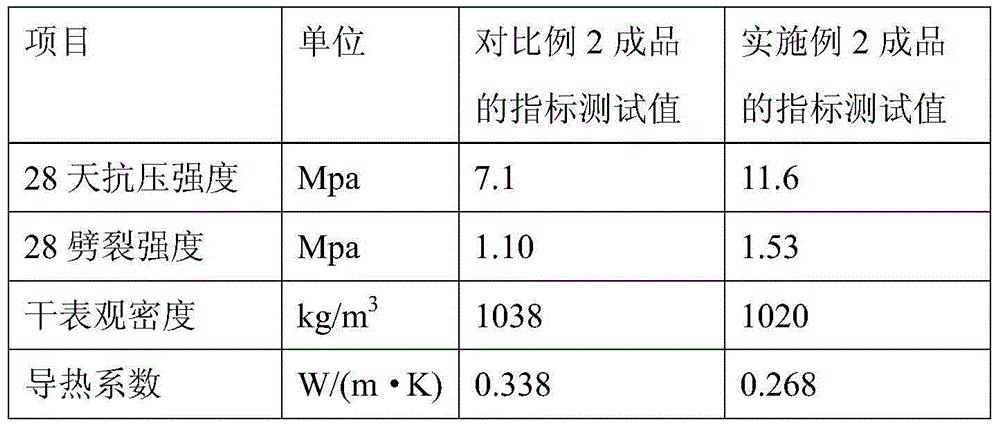

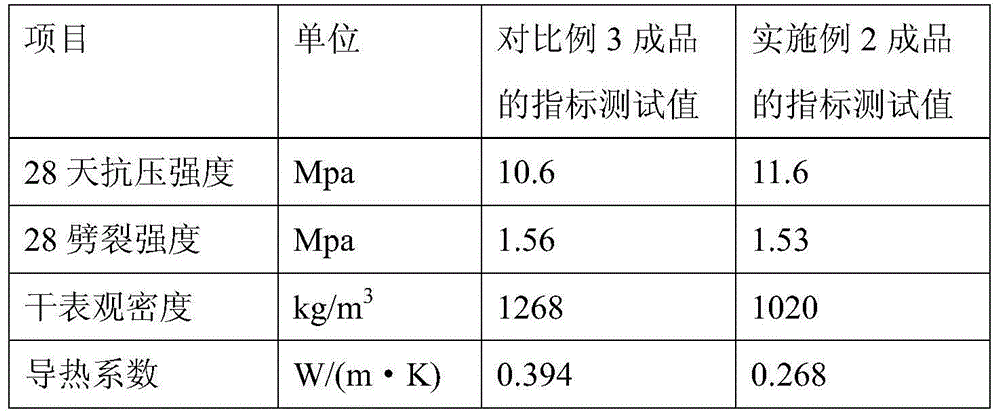

Lightweight aggregate concrete for heat preservation of structures

ActiveCN103951350ACompact structureHigh strengthSolid waste managementApparent densityExpanded clay aggregate

The invention relates to lightweight aggregate concrete for heat preservation of structures, and belongs to the technical field of building materials for civilian use. The lightweight aggregate concrete for heat preservation of structures comprises the following raw materials in parts by mass: 360-460 parts of cement-based cementing material, 410-460 parts of ceramsite, 110-120 parts of modified vitrified micro balls, 15-20 parts of concrete modifier, 260-290 parts of water and 3.6-4.6 parts of water reducing agent. The lightweight aggregate concrete for heat preservation of structures with the heat conductivity coefficient of 0.25-0.4W / (m.K) and the dry apparent density of 900-1200kg / m<3> is obtained by using the modified vitrified micro balls and the ceramsite as aggregates under the synergistic effect of the components according to a reasonable component proportion, and after the lightweight aggregate concrete is cured for 28 days, the compressive strength of the lightweight aggregate concrete is 8-15MPa. The lightweight aggregate concrete for heat preservation of structures has good heat preservation performance and relatively high strength. Compared with the strength of a full lightweight concrete material prepared from ceramsite perlite, the strength of the lightweight aggregate concrete is obviously improved; compared with the heat conductivity coefficient of a full lightweight concrete material prepared from ceramsite pottery sand, the heat conductivity coefficient of the lightweight aggregate concrete is obviously reduced; and the lightweight aggregate concrete can be used as a lightweight aggregate concrete material for heat preservation of structures.

Owner:CENT SOUTH UNIV

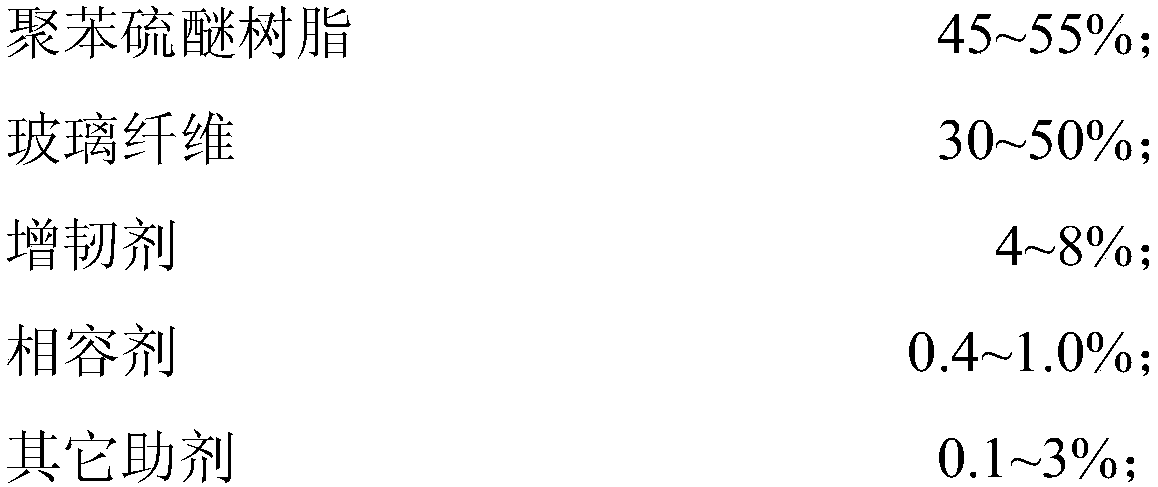

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

Rapid-hardening early-strengthening wearable concrete material for road repair and its preparation method

ActiveCN1699243AHave fast hardening and early strength requirementsSmall shrinkageSolid waste managementSlagMetakaolin

The invention provides a rapid-hardening early-strengthening wearable concrete material for road repair and its preparation, wherein the material mainly comprises the following ingredients, steel slag powdered ore 40-80kg / m3, metakaolin 320-560kg / m3, alkaline exciting agent solution 200-300kg / m3, steel slag fine aggregates 630-1800kg / m3, steel fiber 62-156kg / m3, and polypropylene fiber 1kg / m3.

Owner:WUHAN MUNICIPAL CONSTR GROUP

A kind of PBT material with good epoxy resin adhesion and preparation method thereof

Owner:上海日之升科技有限公司

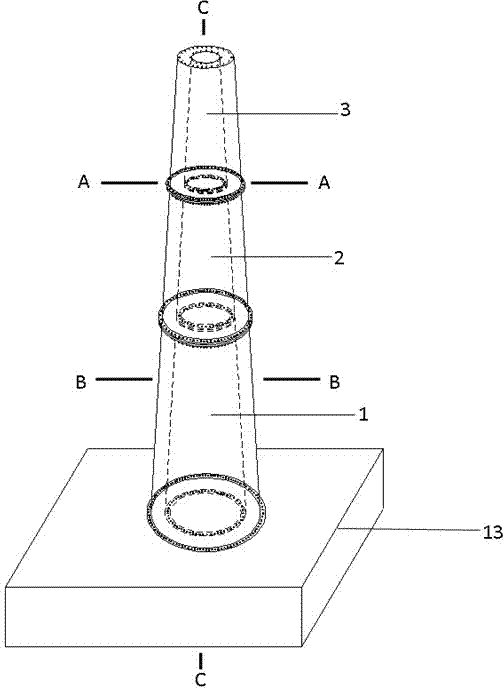

Hollow interlayer pipe wall compound steel pipe concrete wind power tower with ribs

The invention discloses a hollow interlayer pipe wall compound steel pipe concrete wind power tower with ribs. The tower comprises a cast-in-place reinforced concrete foundation and a steel pipe concrete tower section set. Steel pipe concrete tower sections are connected through horizontal flange discs to form a vertical tower cylinder, meanwhile, the bottom of the tower cylinder is fixed on the cast-in-place reinforced concrete foundation, the steel pipe concrete tower sections comprise inner steel pipes, outer steel pipes and concrete layers cast in the interlayers between the inner steel pipes and the outer steel pipes, first reinforced ribs are arranged on the peripheries of the outer walls of the inner steel pipes, and second reinforced ribs are arranged on the peripheries of the inner walls of the outer steel pipes. Compared with an existing steel tower, the compound steel pipe concrete structure with a hollow interlayer and with the pipe walls provided with the ribs is used, the reinforced ribs are arranged on the pipe wall sides where the inner steel pipes and the outer steel pipes are in contact with concrete, the interface binding force of the steel pipes and the concrete is enhanced, the bearing capacity and the ductility of the tower are improved, and early local buckling damage of the thin-wall steel pipes can be avoided or delayed.

Owner:HOHAI UNIV

Negative electrode of lithium ion battery and preparation method thereof

InactiveCN103985841AImprove convenienceImprove adhesionCell electrodesSecondary cellsAdhesivePhysical chemistry

The invention belongs to the field of materials of lithium ion batteries, and particularly relates to a negative electrode of the lithium ion battery and a preparation method thereof. The negative electrode of the lithium ion battery comprises a current collector and negative electrode paste for coating the current collector, wherein the negative electrode paste comprises the following dry ingredients by weight percent: 92-99% of active material and 1-8% of an adhesive; the active material is graphite or graphite alloy; the adhesive is waterborne multi-component copolymerization emulsion. The waterborne multi-component copolymerization emulsion is used for replacing conventional butadiene styrene rubber and serves as the adhesive for the lithium ion battery, so that the more excellent adhesive performance is realized in comparison with the adhesive performance of a conventional adhesive, and meanwhile, the prepared battery has prominently excellent performances such as good low temperature characteristics, low circulation expansion rate, good long cycling performance and relatively excellent processing characteristics; the negative electrode prepared by using the method has relatively small impedance and relatively good dynamic performance and is capable of effectively solving the problem of risk of separation of lithium in the lithium ion battery at low temperature; the prepared battery has the characteristics of safety, reliability and long cycle life.

Owner:MCNAIR TECH +1

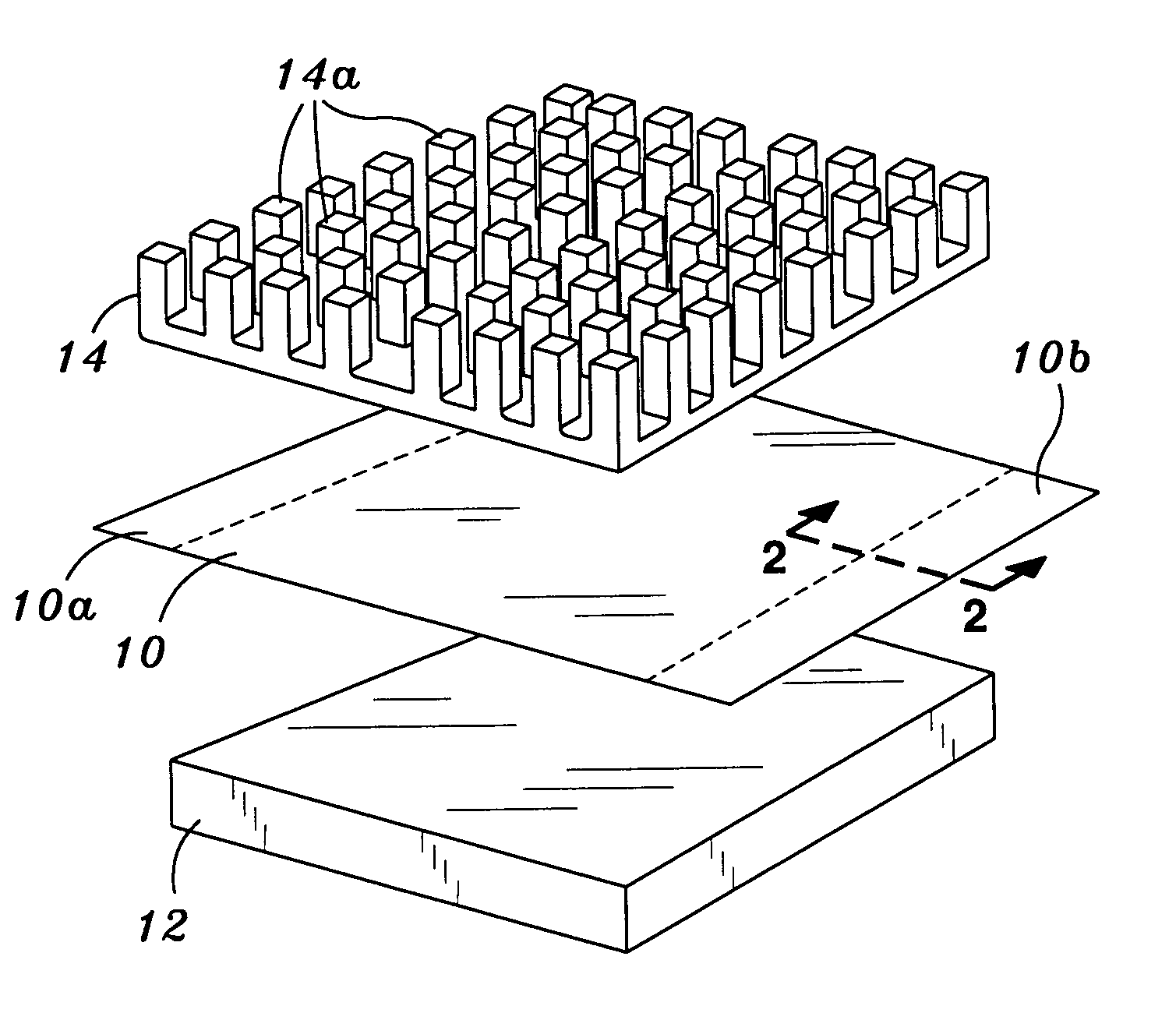

Preappliable phase change thermal interface pad

InactiveUS7056566B2Easy constructionEasy to makePrinted circuit assemblingSemiconductor/solid-state device detailsPlanar substrateAdhesive

A thermal interface for facilitating heat transfer from an electronic component to a heat sink. According to a preferred embodiment, the thermal interface comprises a first planar substrate that defines a first continuous peripheral edge, at least a portion of which extends beyond the interface mating surface between the electronic component and heat sink. Formed upon opposed sides of the substrate are layers of thermally conductive compositions, which preferably comprise certain novel graphitic allotrope compounds. The thermal interface further includes an adhesive deposited upon such portion of the peripheral edge extending beyond the mating surface between the electronic component and heat sink such that the thermal interface may be adhesively secured into position without forming an additional layer at the mating juncture between the electronic component and the heat sink.

Owner:HENKEL CORP

Anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and preparation method thereof

ActiveCN103173087ANovel structureImprove conductivityAnti-corrosive paintsElectrically-conductive paintsEpoxyEmulsion

The invention discloses an anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and a preparation method thereof and relates to the technical field of production of a coating. According to the invention, carbon nano tube is selected as an antistatic additive; and a film forming matter is waterborne acrylate grafted epoxy resin emulsion. The characteristics of the acrylate resin and epoxy resin can be effectively integrated into a whole; the prepared anti-corrosion antistatic coating is good in storage stability, good in construction property, fast to dry after being coated, smooth in dried film, and excellent in mechanical behavior, antistatic property, acid resistance, alkali resistance, salt water resistance and the like.

Owner:扬州市伊丽特高分子材料科技有限公司

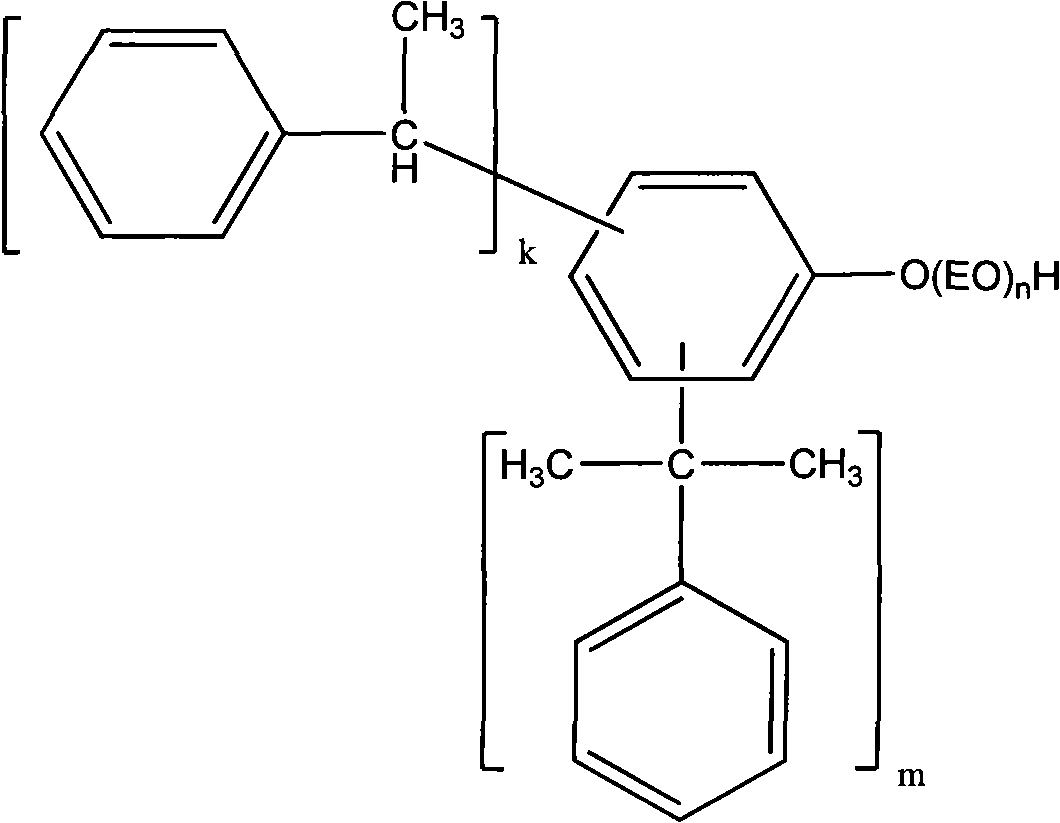

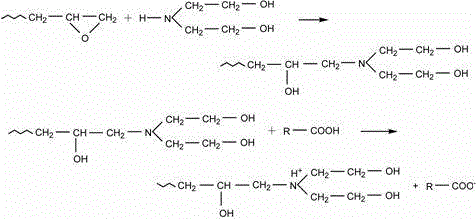

Carbon fiber water-soluble epoxy resin sizing agent

The invention discloses a carbon fiber water-soluble epoxy resin sizing agent and a preparation method thereof. The sizing agent comprises main slurry and deionized water as main components, wherein the mass ratio of the main slurry to the deionized water is (50-80):(20-50); and the main slurry consists of modified phenol-formaldehyde epoxy resin and allyl polyoxylethylene ether (AEPH), and the mass ratio of the modified phenol-formaldehyde epoxy resin to AEPH is (60-90):(10-40). The preparation method of the sizing agent comprises the following steps: firstly reacting phenol-formaldehyde epoxy resin with diethanolamine to obtain water-soluble phenol-formaldehyde epoxy resin; and then mixing the water-soluble resin with AEPH in proportion, and performing dilution to reach a certain concentration by using the deionized water to obtain the sizing agent. The sizing agent disclosed by the invention is good in stability and low in cost, cannot cause environmental pollution, and is simple in preparation method; good post-processing performance of carbon fibers can be provided by adding flexible molecular AEPH; experiments show that after the carbon fibers are coated with a proper amount of the sizing agent, the post-processing performance can be significantly improved; and the performance of a carbon fiber epoxy resin composite material can be improved.

Owner:UNIV OF JINAN

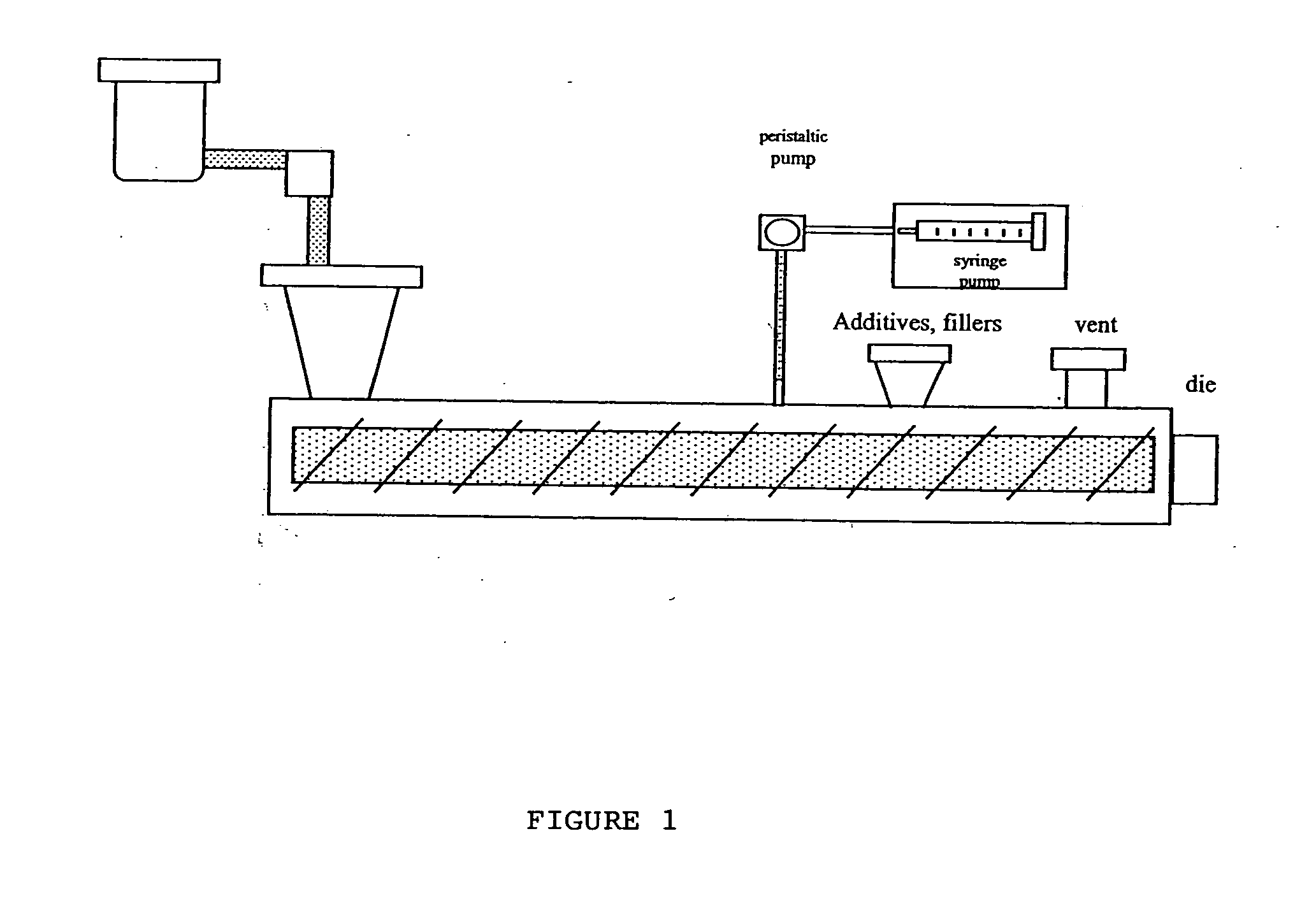

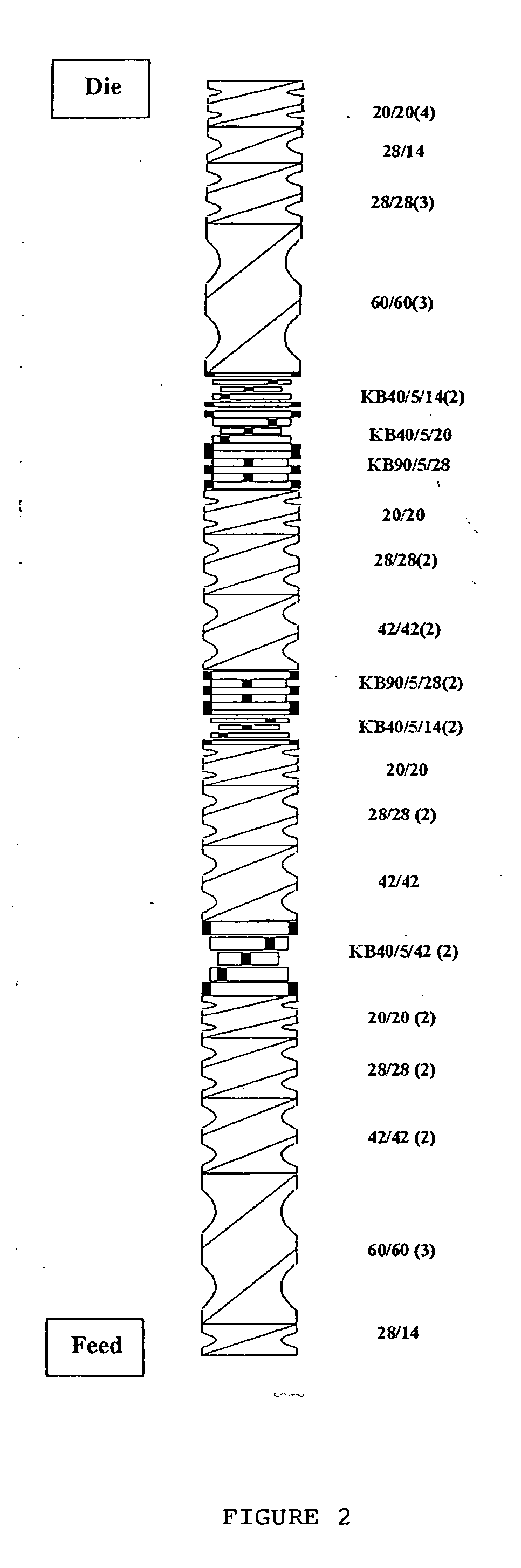

Reactively blended polyester and filler composite compositions and process

InactiveUS20070203261A1Improve interfacial adhesionFacilitates chemical bondingPolyester compositeReactive extrusion

High-performance inorganic filled thermoplastic polyester composites are provided, and the process for preparing thereof. Biodegradable inorganic filled thermoplastic polyester composites are provided by reactive melt-blending of biodegradable thermoplastic polyesters with inorganic fillers using a reactive extrusion processing.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

High-toughness halogen-free flame-retardanting reclaimed polycarbonate compound and preparation method thereof

InactiveCN101709142AIn line with the development trend of non-halogenated flame retardantImprove flame retardant performanceAntioxidantUltraviolet

The invention relates to a high-toughness halogen-free flame-retardanting reclaimed polycarbonate compound and a preparation method thereof, belonging to the field of reclaimed plastic flame-retardanting and toughening-modified products. The invention aims to provide a high-toughness halogen-free flame-retardanting reclaimed polycarbonate compound which uses reclaimed polycarbonate as a matrix. The invention is characterized in that the compound comprises the following components by weight percent: 81.0-93.4% of reclaimed polycarbonate, 3.0-10.0% of latex particles of core-shell silicon rubber, 1.0-7.0% of bulking agent, 0.1-0.5% of antioxidant, 0.1-0.5% of light stabilizer, 0.1-0.5% of ultra-violet absorber, 0.8-1.2% of heat barrier and 0.3-0.5% of anti-dripping agent. The preparation method of the compound comprises the following steps: evenly mixing the components, melting the components on a double-screw extruder, blending, extruding, cooling and pelleting the melted components to prepare the reclaimed polycarbonate compound. The compound has the advantages of good anti-impact properties, retardanting level of UL94 V-0 and low cost, thereby meeting the requirements of industries such as electronic and electric products and the like on the high-property polycarbonate engineering plastics.

Owner:BEIJING UNIV OF CHEM TECH

Flame-retardant antistatic high-wear-resistance paint and manufacturing method thereof

InactiveCN104130664AImprove antistatic performanceLow smokeFireproof paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to a flame-retardant antistatic high-wear-resistance paint and a manufacturing method thereof. The invention relates to the field of surface paints used on substrates such as metal, composite materials, hard plastic, and the like, and the preparation method thereof. The paint can be widely applied in coatings of equipment in coal mines, oil tanks, coal transportation, wharfs, and the like. The paint comprises dual components of A and B. The component A is composed of epoxy resin, an active diluting agent, a levelling agent, a de-foaming agent, a silane coupling agent, a conductive filling agent, a wear-resistant filling agent, and a flame retardant. The B component comprises an amine type curing agent and an accelerator. The paint is characterized in that the component A also comprises a levelling agent c, a levelling agent D, zinc oxide whiskers, and conductive mica powder. The flame-retardant antistatic high-wear-resistance paint provided by the invention has the characteristics of normal-temperature curing and low smoke during combustion. The paint has excellent adhesion force on a polar surface, and is especially suitable for coating on polar surfaces such as glass fiber reinforced plastic and metal. The paint has excellent anti-corrosive property.

Owner:RIZHAO XURI COMPOSITE MATERIALS

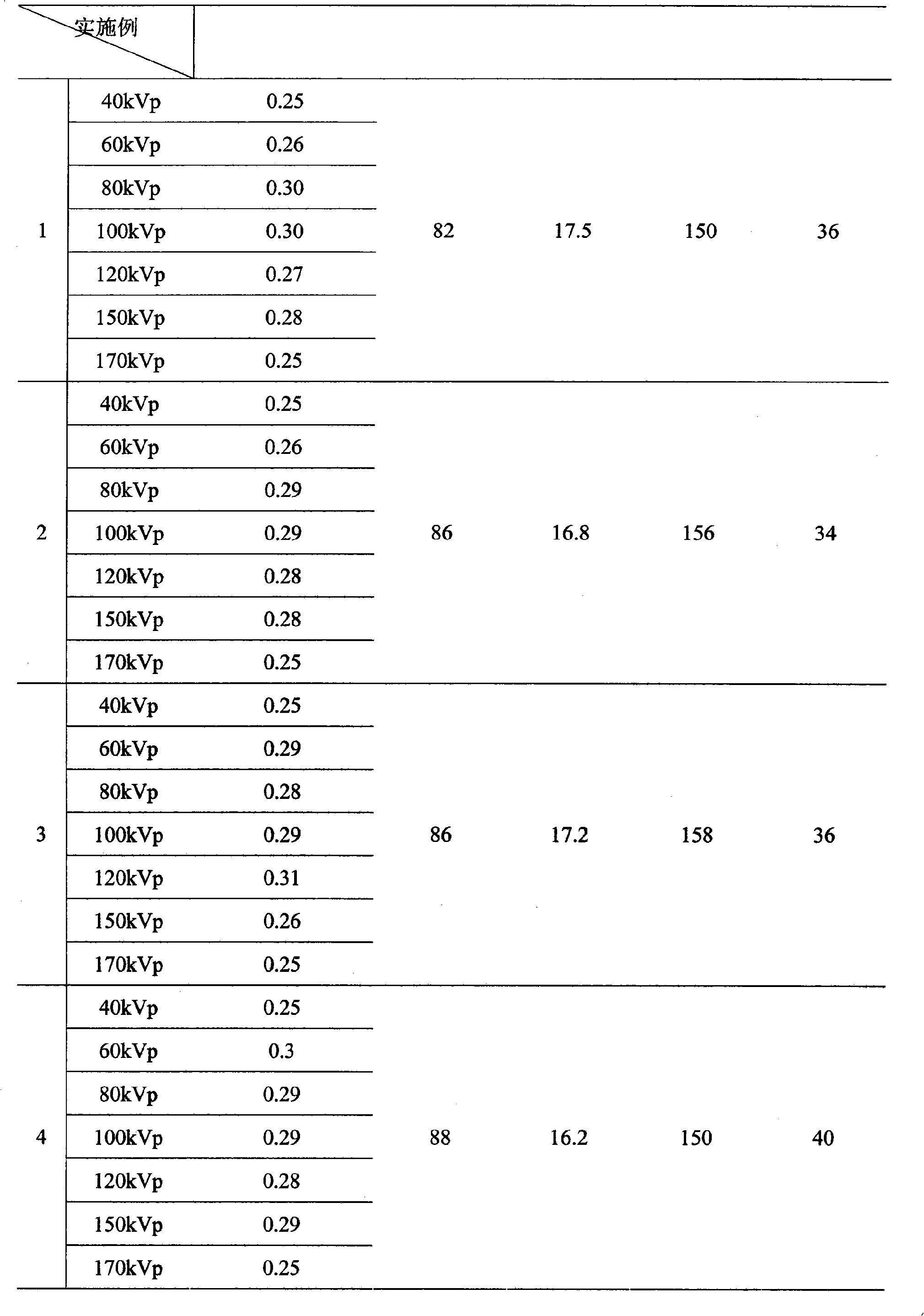

Overall lead-free X-ray shielding plastic compound material

InactiveCN101572129AEvenly distributedExcellent conventional physical and mechanical propertiesShieldingCoatingsX-ray shieldInorganic compound

The invention relates to an overall lead-free X-ray shielding plastic compound material. The overall lead-free X-ray shielding plastic compound material uses rare earth mixture to replace lead, simultaneously adds metal tin and compounds thereof, metal tungsten and the compounds thereof and bismuth and the compounds thereof as shielding main materials and is further compounded with plastic to prepare the compound material which can realize the overall shielding and the complete lead-free property within the energy range of 40-170kVp. When in use of rare earth and bismuth materials, the way of combined use of the two metal element inorganic compounds and unsaturated organic complexes is adopted, and the in-situ reaction and the compounding with a polymer matrix are carried out, thereby leading the shielding element disperse phase to form nano-micro-level dispersed particles. The prepared material combines the X-ray shielding performance of shielding elements and the good conventional physical mechanical performance of matrix polymer material and can be widely used in medical diagnostic X-ray machines, X-ray diffraction instruments and occasions accompanied with X-ray generation for ray protection for working staff.

Owner:BEIJING UNIV OF CHEM TECH

Reactive monomer modified nano calcium carbonate/polypropylene master batch and its preparing method

The present invention relates to a reactive monomer modified nano calcium carbonate / polypropylene mother material and its production method. Said mother material is formed from polypropylene base body, nano calcium carbonate filling material, reactive monomer (including maleic anhydride, acrylic acid and its esters and styrene) and universal stabilizing agent D of PP material. Its preparation method includes the steps of uniformly mixing by using high-speed mixing machine and extruding by means of twin screw extruder machine. Said invention can raise the mechanical property of nano calcium carbonate filled polypropylene material.

Owner:SUN YAT SEN UNIV

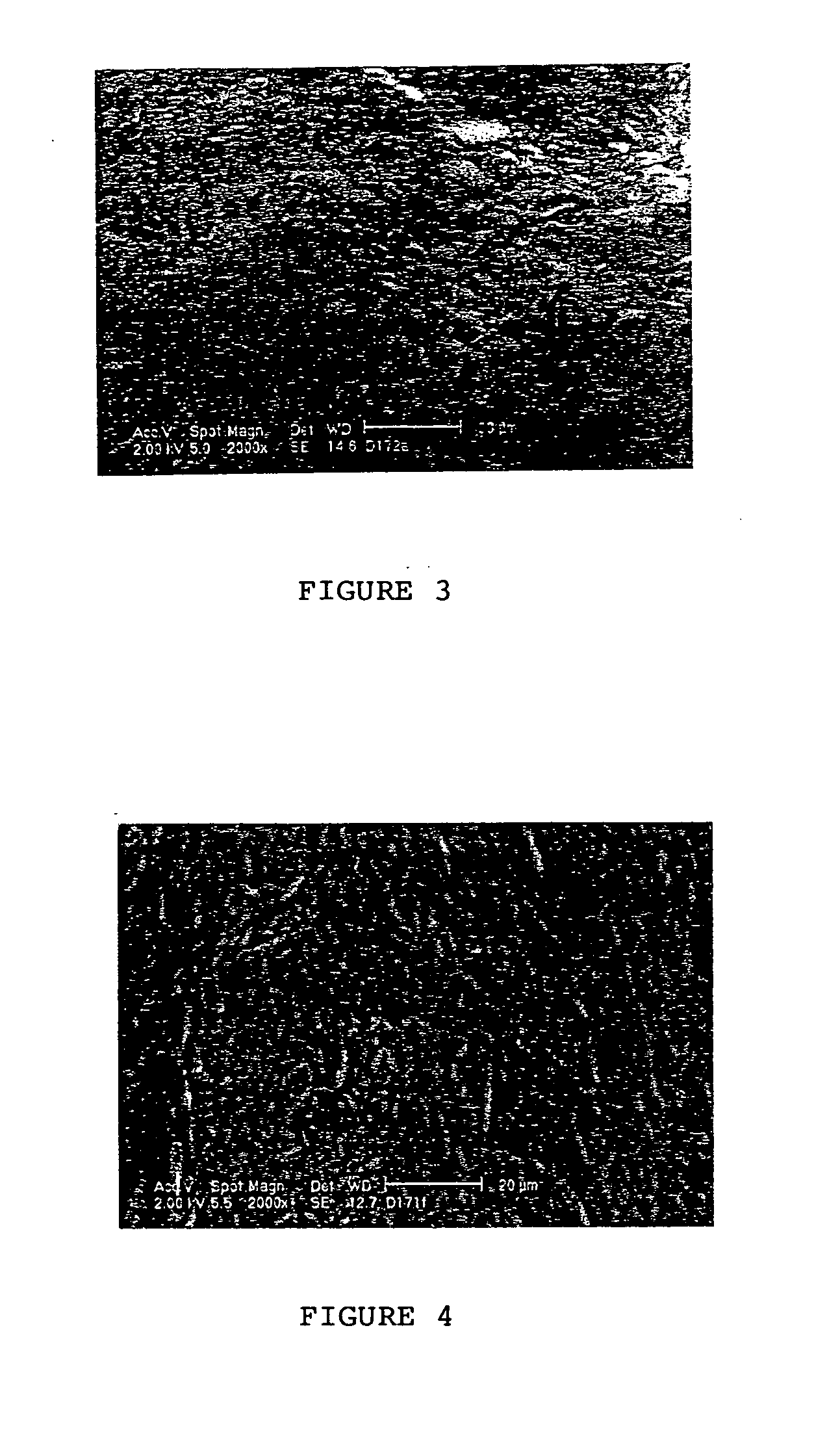

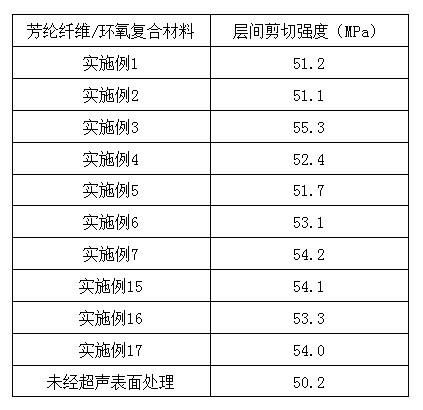

Ultrasonic surface modification treatment method for aramid fibers

InactiveCN102605606AImprove surface conditionQuality improvementFibre typesUltrasonic/sonic fibre treatmentPolymer scienceOrganic solvent

The invention provides an ultrasonic surface modification treatment method for aramid fibers. One or more amidic organic solvents in any proportion are selected as an ultrasonic treatment medium; under an ultrasonic action, fiber surfaces can be etched effectively by the amidic solvents; simultaneously, the sticking points among aramid fiber filaments can be reduced, and the state of the surfaces can be improved, so that the bonding strength between a resin and a fiber is increased; and meanwhile, the online treatment of the fibers is easy to realize by the ultrasonic treatment, and the time for modifying the fiber surfaces is shortened.

Owner:中蓝晨光化工有限公司

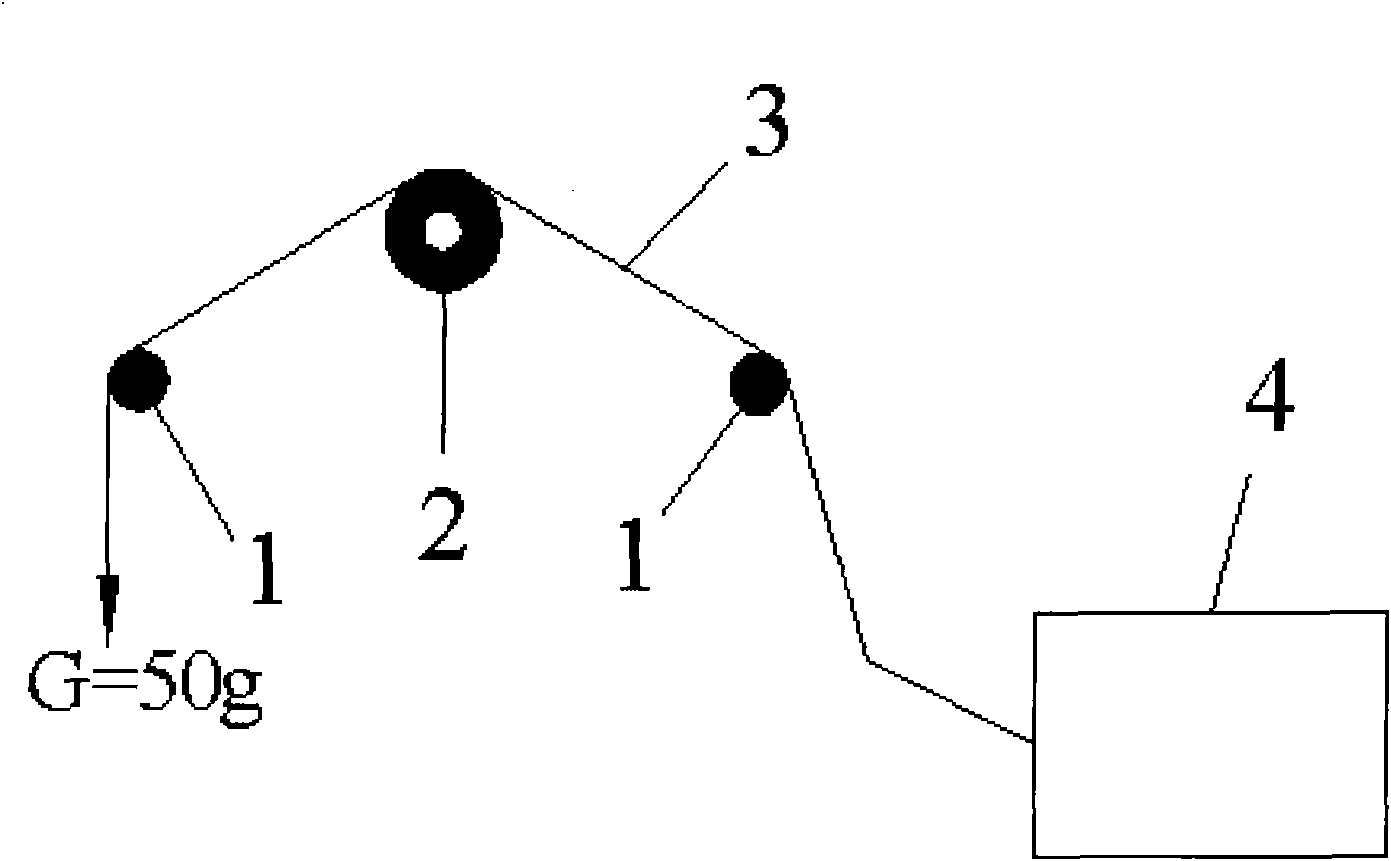

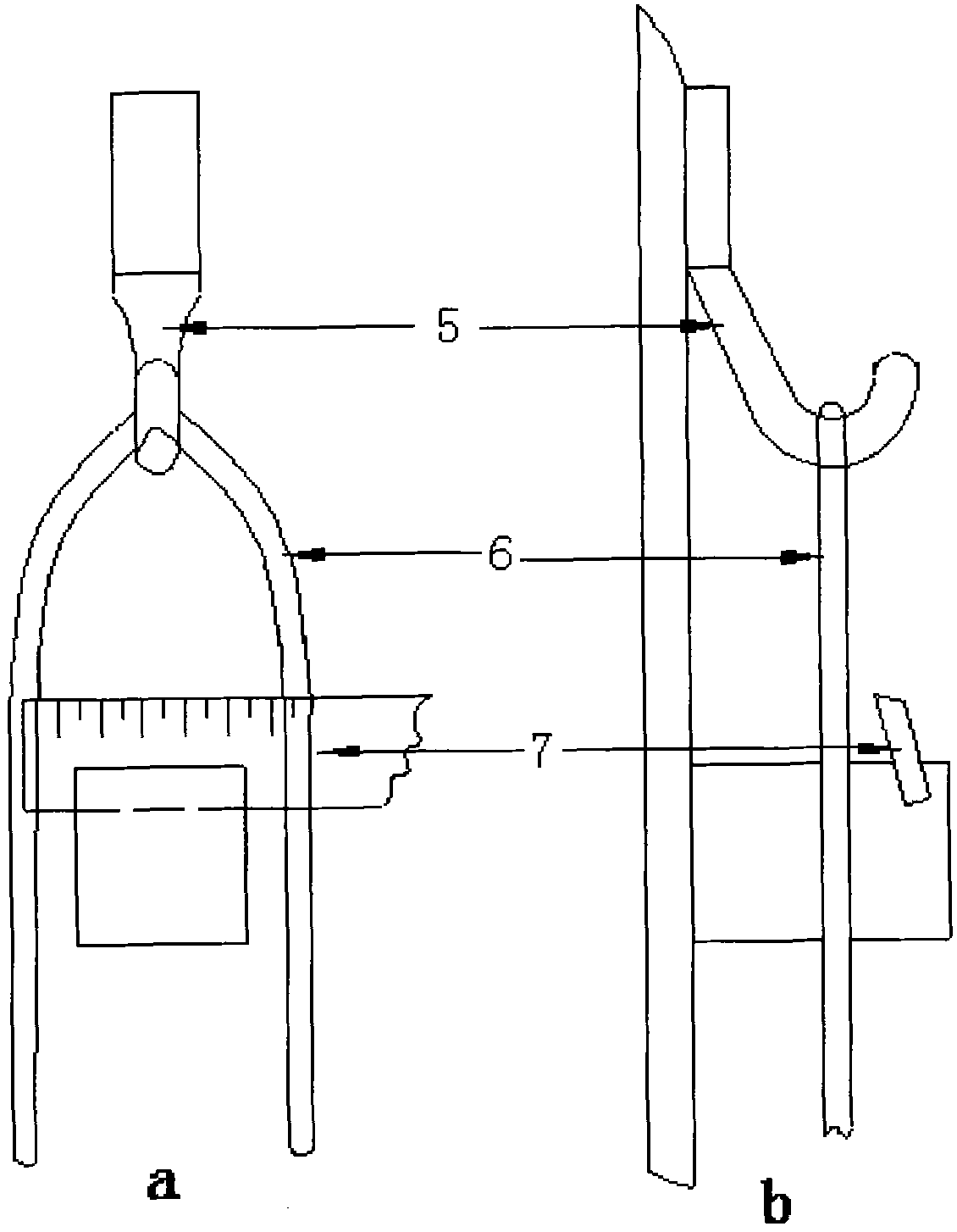

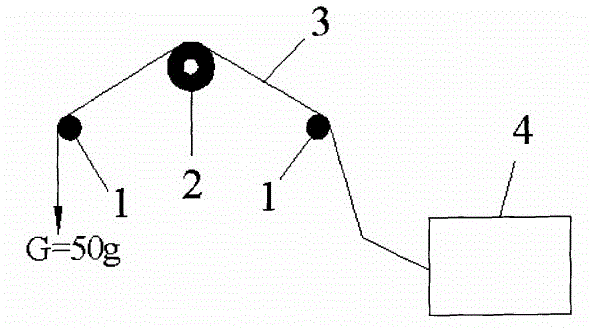

Laminar flow plasma spraying equipment and method

InactiveCN1421278AEffective meltingImprove interfacial adhesionLiquid spraying plantsLiquid surface applicatorsPlasma jetPlasma generator

The present invention is laminar flow plasma spraying equipment and method. A laminator flow plasma generator with different powder feeding modes, inside the gun or outside the gun and single port ormultiple ports, is used. While maintaining the laminar flow plasma jetting state in small power, air flow rate is increased to raise the heat efficiency of the jet. According to powder sort, materialproperty and particle size, proper jet energy and distribution and carrying air flow rate are selected to obtain high-quality coating. The present invention has les sintroduced impurity, high jet energy utilization, capacity of spraying high-smelting point coating at relatively low power condition, less oxidation of non-oxide coating and full heating of the powder material.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

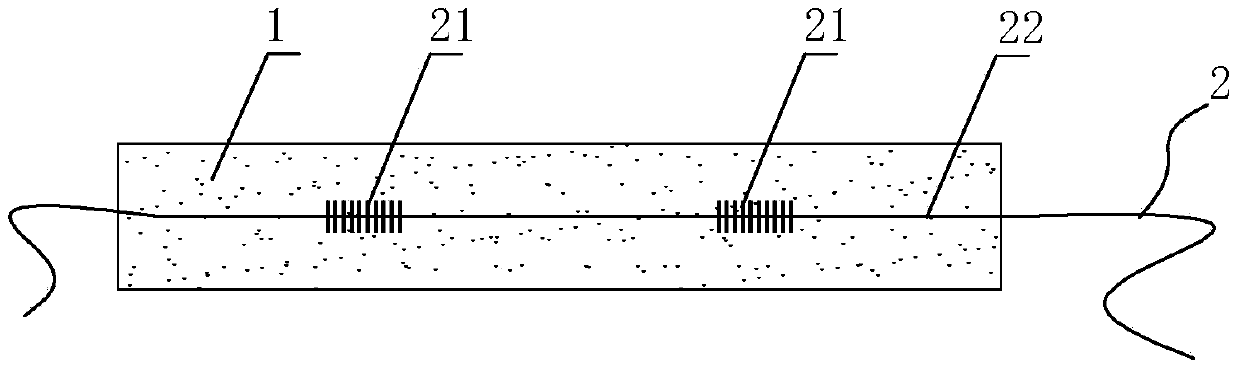

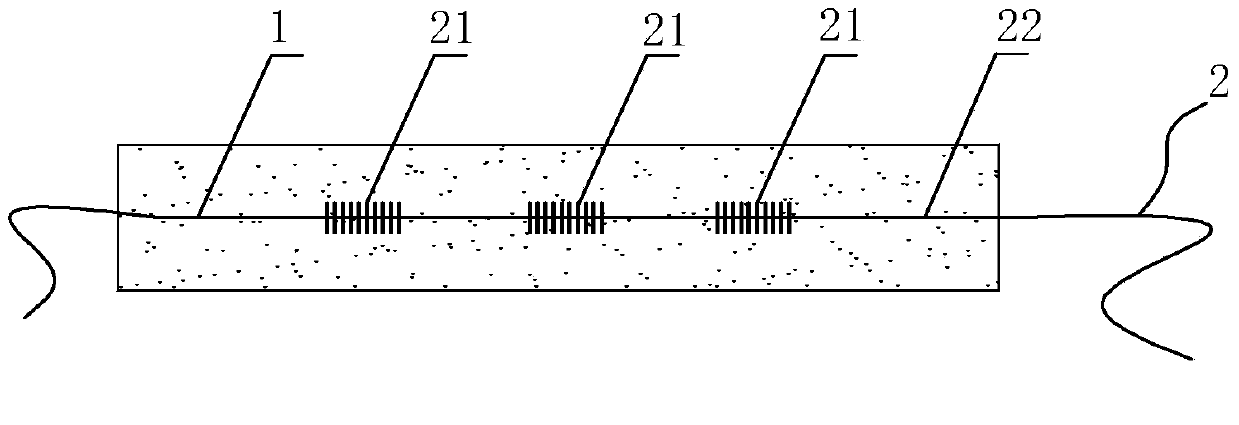

Fiber grating intelligent plate made of fiber reinforced polymer in pulling extrusion and continuous forming mode and manufacturing method thereof

InactiveCN103628697AAchieve securityRealize health diagnosisBuilding repairsBuilding componentsGratingFiber orientation

The invention relates to a fiber grating intelligent plate made of fiber reinforced polymer in a pulling extrusion and continuous forming mode and a manufacturing method thereof. The intelligent plate has civil engineering structural stress and self-monitoring double functions. The intelligent plate comprises a plate body composed of fiber grey yarns and matrix resin, wherein the plate body is filled with sensor fibers containing fiber grating sensors and transmission fibers in the fiber direction, the number of the sensor fibers is m, m is an integer larger than or equal to one, each sensor fiber is provided with n fiber grating sensors, and n is an integer larger than or equal to one. The intelligent plate is manufactured in a pulling extrusion and continuous forming process, the fiber volume content of the intelligent plate is no less than 60%, and the intelligent plate facilitates accurate control of tension control stress of fiber plates, compensation of lost prestress and real-time monitoring of reinforced structures when the fiber plates, especially prestress fiber plates are used for reinforcing and repairing concrete structures and steel structures.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

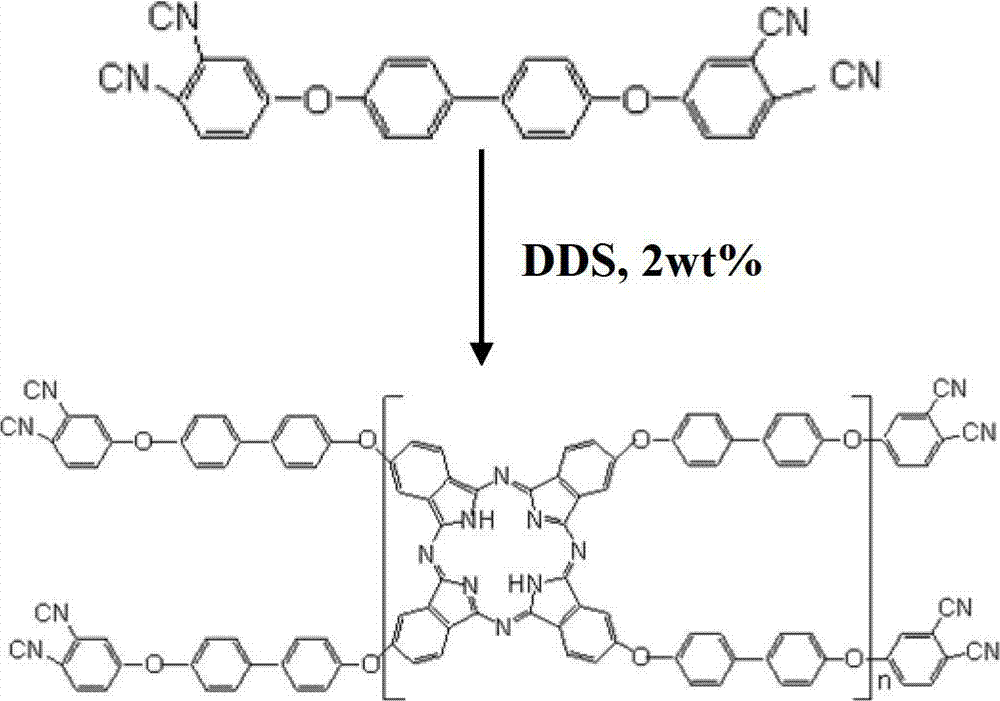

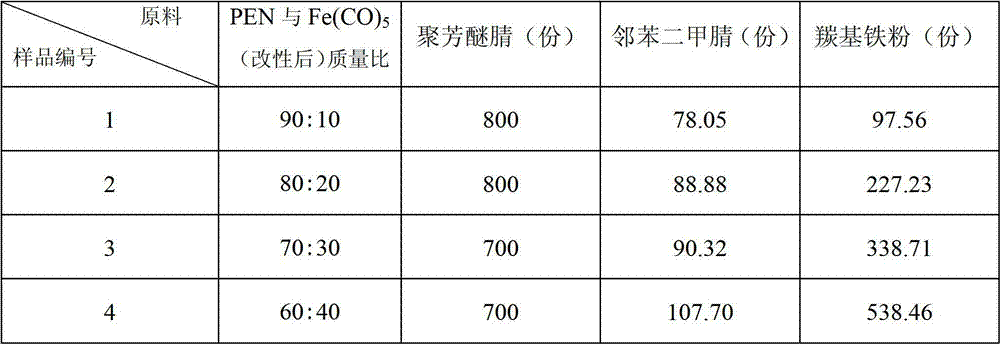

Polyaryl ether nitrile (PEN) and carbonyl iron powder (Fe(CO)5) composite magnetic material and preparation method thereof

ActiveCN102775755AImprove mechanical propertiesHigh strengthOrganic/organic-metallic materials magnetismPigment treatment with macromolecular organic compoundsPhthalonitrileMechanical property

The invention discloses a PEN and Fe(CO)5 composite magnetic material and a preparation method thereof, and belongs to the technical field of magnetic polymer materials. PEN serves as an organic matrix, Fe(CO)5 serves as an inorganic filler, and the composite magnetic material is obtained after blending and prilling. Firstly, the Fe(CO)5 is subjected to surface modification, and a layer of phthalonitrile prepolymer is generated on the surface of the Fe(CO)5; due to a layer of organic matters rich in cyan coated on the surface, the Fe(CO)5 after surface modification can improve the interfacial adhesive force between the Fe(CO)5 inorganic filler and the PEN organic matrix, so that the PEN and the Fe(CO)5 are provided with a high-strength magnetic property while maintain an excellent mechanical property of the PEN after composition. According to the magnetic material and the preparation method thereof, the Fe(CO)5 can be filled as much as possible on the premise that the good mechanical property of the composite material is maintained, so that magnetic saturation strength of the composite material can be improved, the compatibility of inorganic fillers with polymers is improved, and processing defects are overcome.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com