High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

A technology of strengthening and toughening polyphenylene sulfide, applied in the field of polyphenylene sulfide, to achieve good impact toughness, increased interface bonding force, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

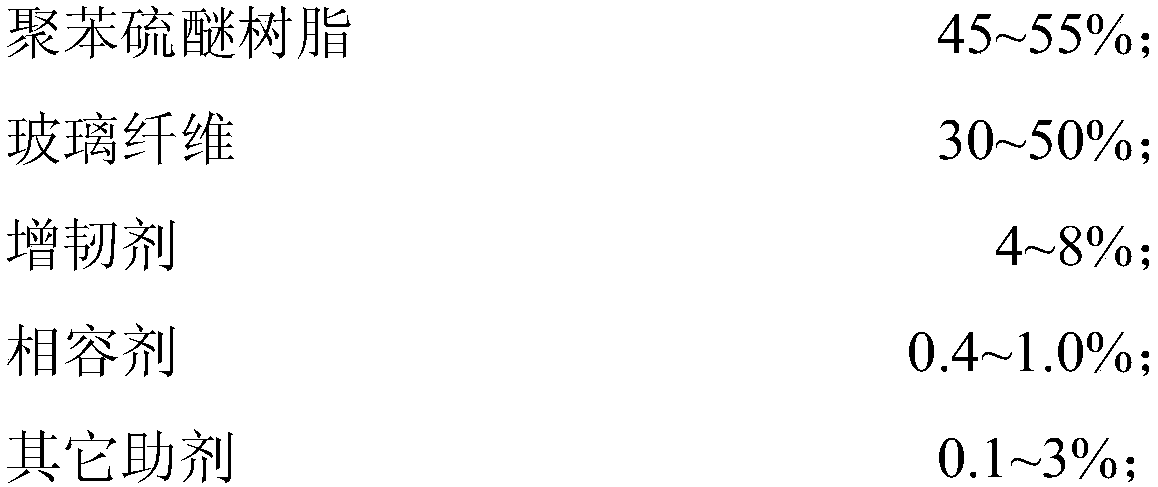

Method used

Image

Examples

Embodiment 1

[0059] (1) The percentage by weight is: 54% polyphenylene sulfide, 2.0% PA6, 3.0% SEBS-g-MAH, 0.5% compatibilizer 1, 0.1% antioxidant 1908, 0.1% antioxidant 9228, 0.5% The materials of silicone powder are mixed evenly in the high mixer to obtain the mixed materials;

[0060] (2) The mixed material prepared in step (1) is added from the hopper of the extruder, and the glass fiber 1 with a weight ratio of 40% is added from the side feed hopper of the extruder, and melted, extruded, cooled, and granulated and drying to prepare a highly reinforced and toughened polyphenylene sulfide composite material.

Embodiment 2

[0062] (1) The percentage by weight is: 54.5% polyphenylene sulfide, 4.0% PA6, 1.0% compatibilizer 1, 0.1% antioxidant 1010, 0.1% antioxidant 9228, 0.5% silicone powder in high mixing Mix evenly in the machine to obtain the mixed material;

[0063] (2) The mixed material prepared in step (1) is added from the hopper of the extruder, and the glass fiber 1 with a weight ratio of 40% is added from the side feed hopper of the extruder, and melted, extruded, cooled, and granulated and drying to prepare a highly reinforced and toughened polyphenylene sulfide composite material.

Embodiment 3

[0065] (1) The percentage by weight is: 52% polyphenylene sulfide, 3.0% PA66, 4.0% SEBS-g-MAH, 0.5% compatibilizer 1, 0.1% antioxidant 1010, 0.1% antioxidant 1908, 0.5% The materials of silicone powder are mixed evenly in the high mixer to obtain the mixed materials;

[0066] (2) The mixed material prepared in step (1) is added from the hopper of the extruder, and the glass fiber 1 with a weight ratio of 40% is added from the side feed hopper of the extruder, and melted, extruded, cooled, and granulated and drying to prepare a highly reinforced and toughened polyphenylene sulfide composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com