Anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and preparation method thereof

A technology of water-based acrylate and anti-static coatings, which is applied in the direction of anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problems of incompatibility between coating anti-corrosion and conductivity, poor anti-corrosion and adhesion, and short service life. Significant social and economic benefits, high cost performance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of color paste:

[0031] Weigh 367g of water, then add 9g of dispersant (SF-03), 4g of wetting agent (BYK-181), 1g of hydroxyethyl cellulose, 1g of defoamer (BYK-025), 1g of fungicide (981), pH adjuster (AMP-95) 2g, antifreeze agent ethylene glycol 20g, film-forming aid A (dodecyl alcohol ester) 25g, stir for about 15min to form a uniformly dispersed system; then add iron oxide red 100g, mica Powder (800 mesh) 40g, talc powder (1250 mesh) 50g, barium sulfate (1250 mesh) 180g, aluminum tripolyphosphate 135g, zinc phosphate 45g, high-speed stirring and grinding (2500 rpm) 1.5h, fineness ≤ 45μm .

[0032] 2. Preparation of film-forming agent:

[0033] Take 1000g of the above slurry, add 800g of acrylate grafted epoxy resin emulsion, 4.5g of anti-flash rust agent, 2g of thickener B (polyurethane associative thickener), 3.6g of polyurethane rheological thickener, and form a film Auxiliary ethylene glycol monobutyl ether 24g, stir evenly to obtain film-formi...

Embodiment 2

[0042] 1. Purification of carbon nanotubes: use 5% HF and 5% HNO to 2 g carbon nanotubes 3 Washing is performed to remove impurities from the carbon nanotubes, followed by a deionized water wash to remove residual acid.

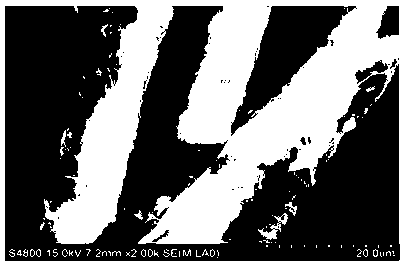

[0043] figure 1 is the scanning electron micrograph of unpurified carbon nanotubes, figure 2 SEM images of purified carbon nanotubes. Compared figure 1 , 2 , it can be seen that impurities on the surface of carbon nanotubes are significantly reduced after treatment, indicating that carbon nanotubes are purified, which is conducive to improving the antistatic performance of the matrix material.

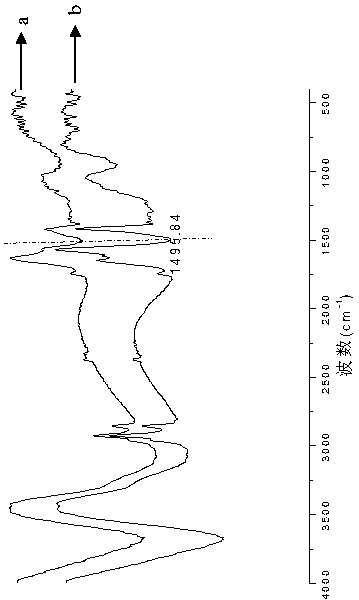

[0044] image 3 Among them, curve a is the infrared spectrum of carbon nanotubes without purification treatment, and curve b is the infrared spectrum of carbon nanotubes after purification treatment. The contrast between the two curves can be seen: at 1495cm -1The stretching vibration peak of the hydroxyl group is obviously enhanced, indicating that the carbox...

Embodiment 3

[0055] 1. Purification of carbon nanotubes: use 5% HF and 5% HNO to 10 g carbon nanotubes 3 Washing is performed to remove impurities from the carbon nanotubes, followed by a deionized water wash to remove residual acid.

[0056] 2. Dispersion of carbon nanotubes: Add the carbon nanotubes obtained in the previous step to 357g water containing 9g of dispersant SF-03 for high-speed shearing (2500 rpm) for 0.5h, forming a mass fraction of carbon nanotubes of 23.5 % of purified carbon nanotube dispersion.

[0057] 3. Preparation of anti-corrosion and anti-static slurry: Add 4 g of wetting agent (BYK-181), 1 g of hydroxymethyl cellulose, 1 g of defoamer (BYK-025), and bactericide ( 981) 1g, pH adjuster (AMP-95) 2g, antifreeze agent ethylene glycol 20g, film-forming aid A (dodecyl alcohol ester) 25g, stir for about 15min to form a uniformly dispersed system; then add iron oxide red 100g, mica powder (800 mesh) 40g, talc powder (1250 mesh) 50g, barium sulfate (1250 mesh) 180g, alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com