Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

541 results about "Structural stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural stress is anything that puts stress on the nerves, muscles, joints and soft tissues of the body. The #1 root cause of structural stress is misalignments of the spine and other joints called subluxations.

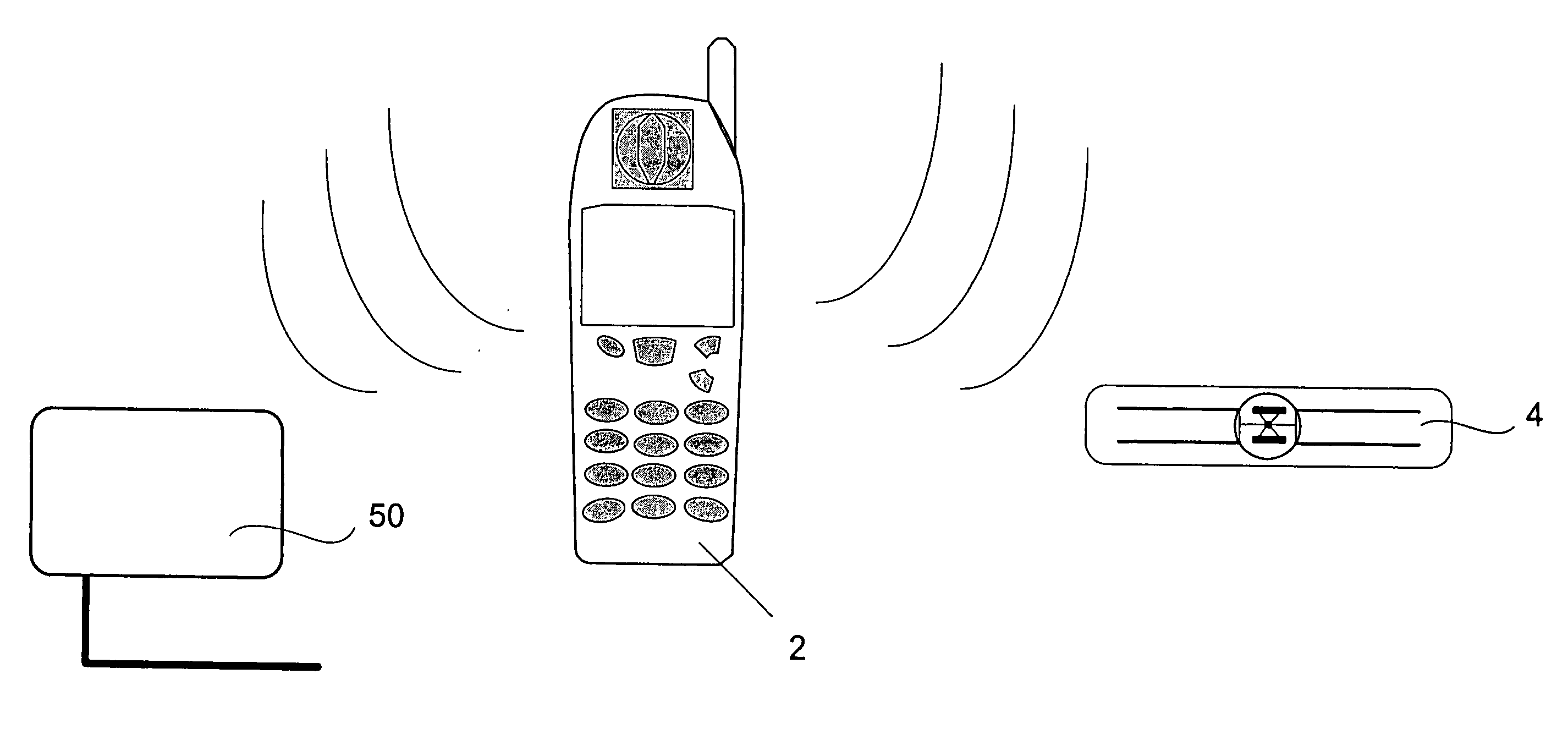

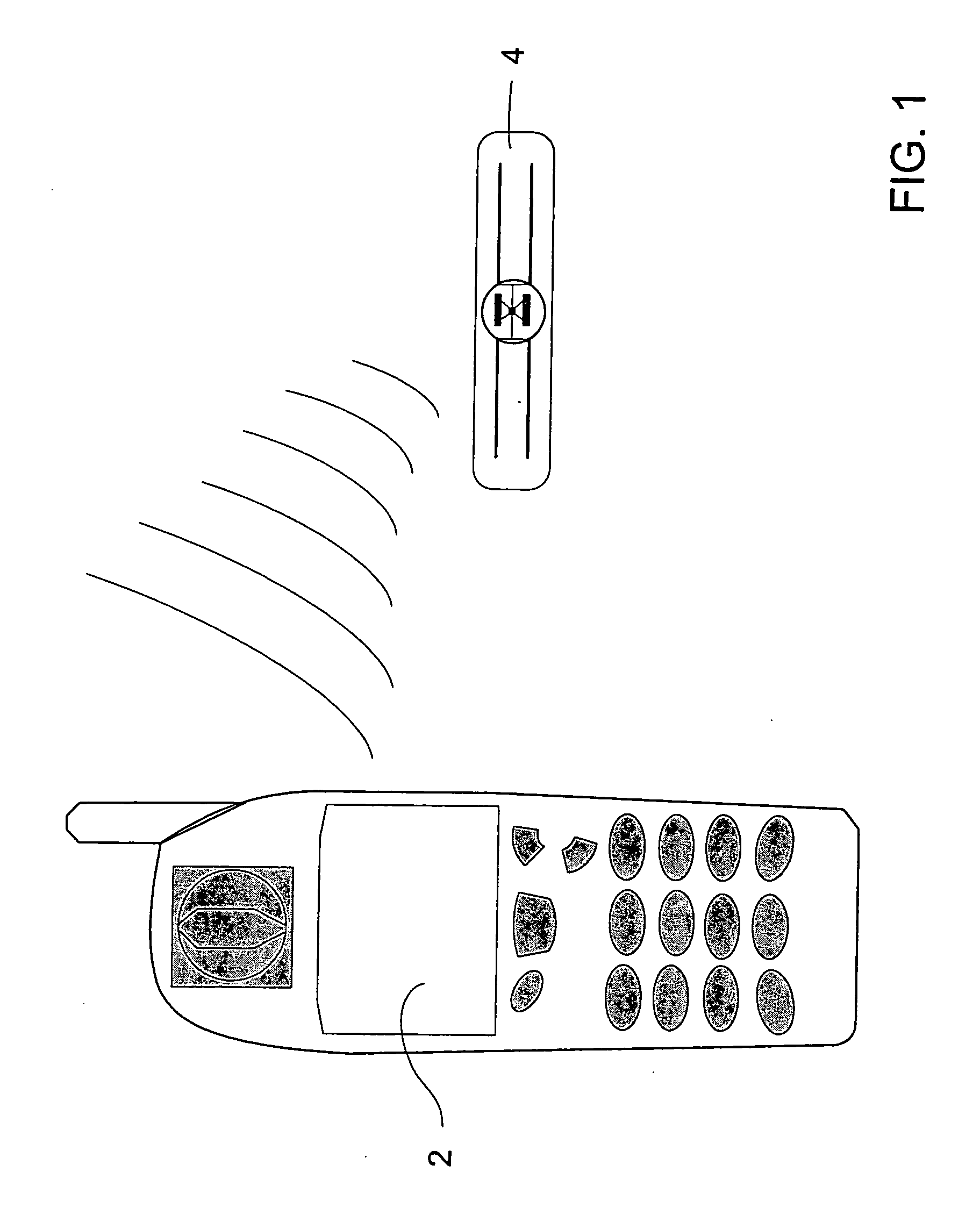

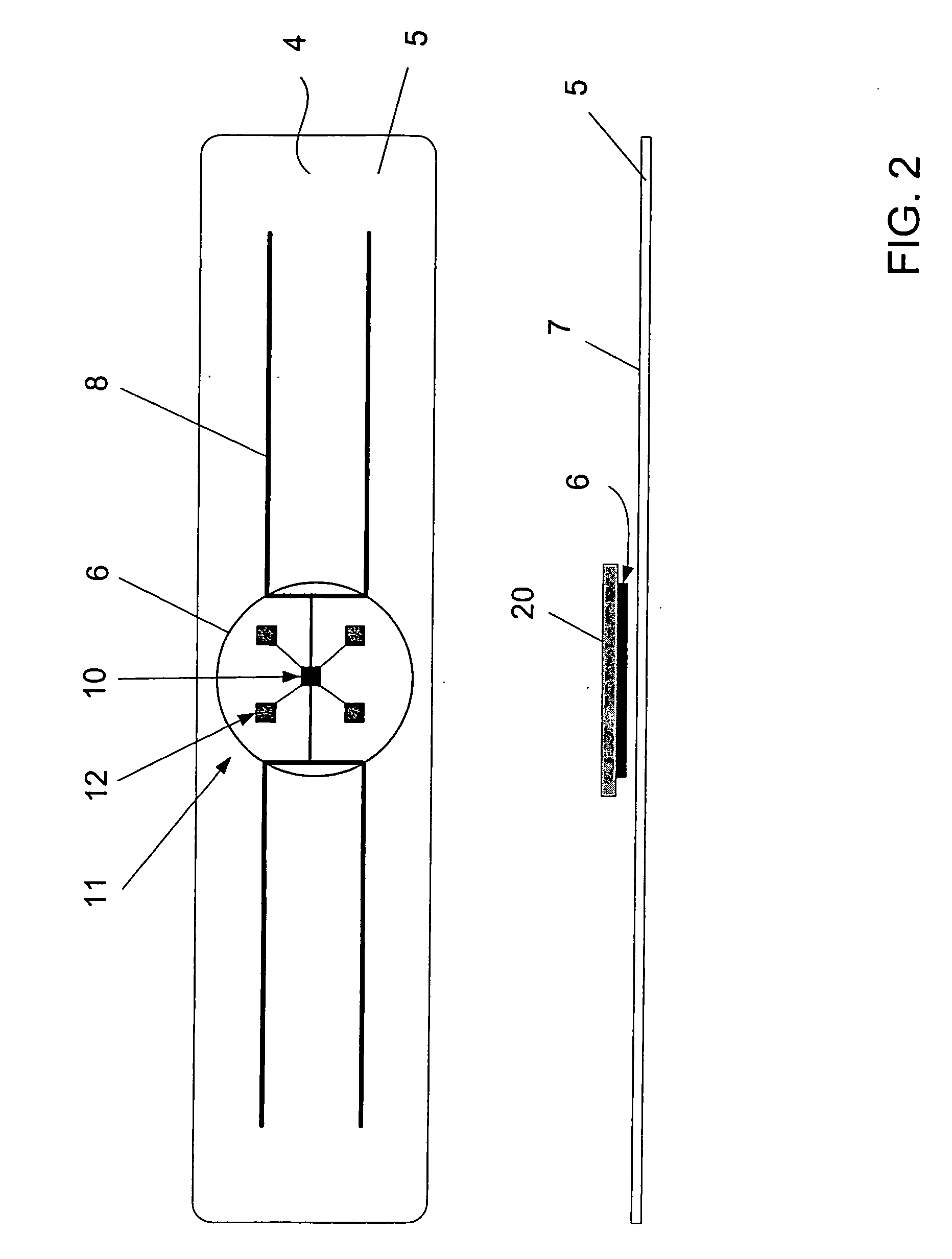

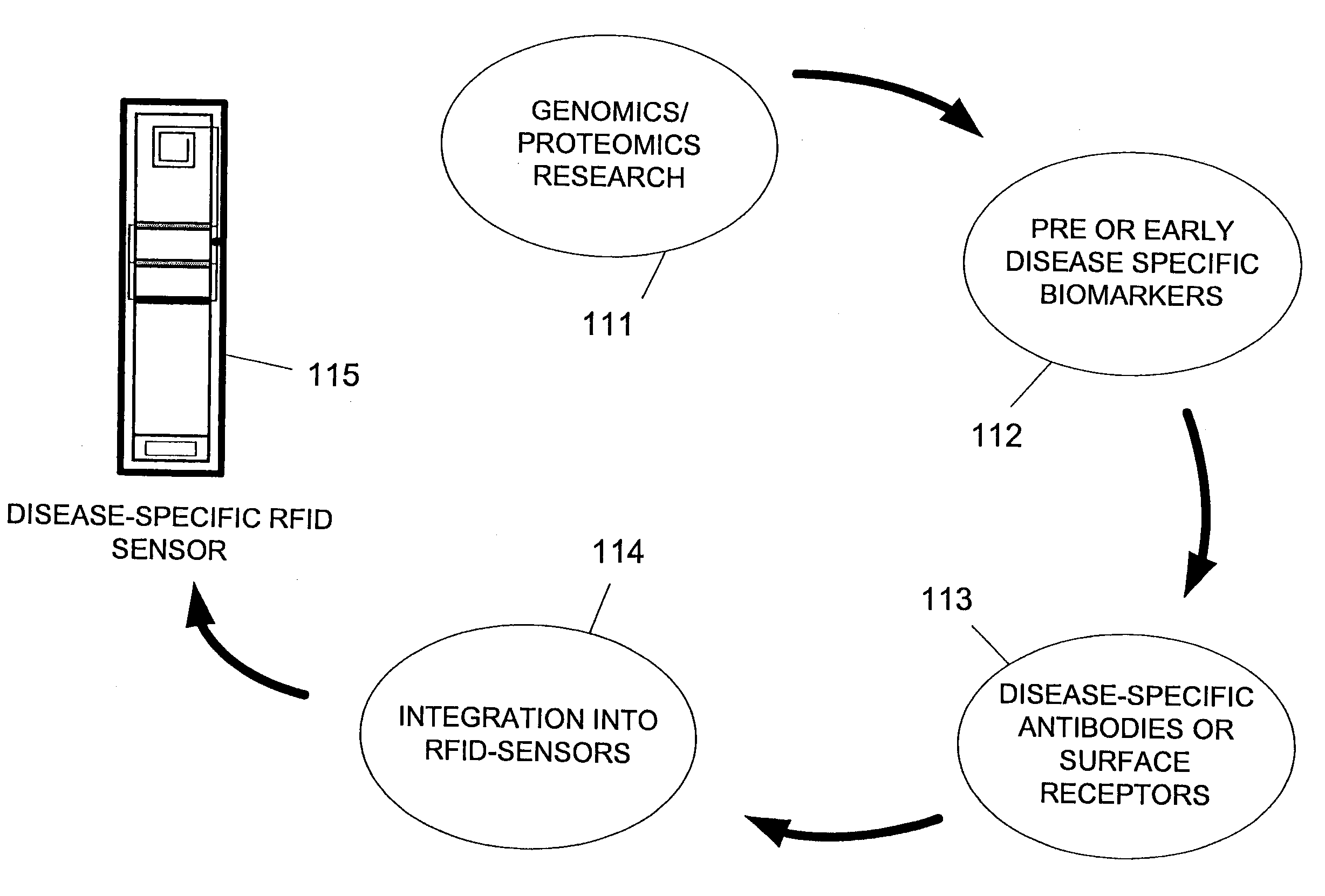

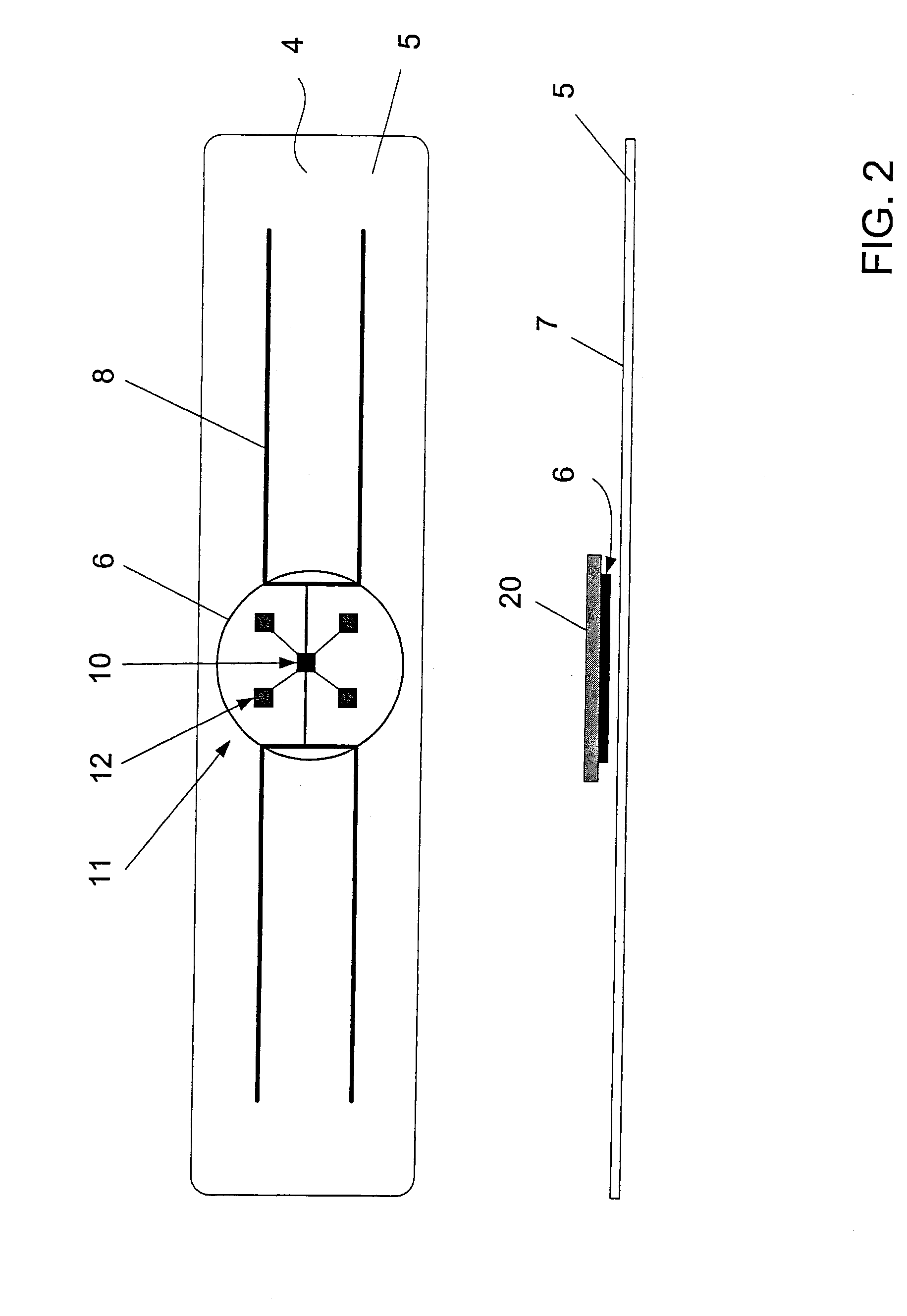

Diagnostic radio frequency identification sensors and applications thereof

ActiveUS20060290496A1Low costDevices with bluetooth interfacesBurglar alarm mechanical actuationPower sensorPoint of care

An integrated passive wireless chip diagnostic sensor system is described that can be interrogated remotely with a wireless device such as a modified cell phone incorporating multi-protocol RFID reader capabilities (such as the emerging Gen-2 standard) or Bluetooth, providing universal easy to use, low cost and immediate quantitative analyses, geolocation and sensor networking capabilities to users of the technology. The present invention can be integrated into various diagnostic platforms and is applicable for use with low power sensors such as thin films, MEMS, electrochemical, thermal, resistive, nano or microfluidic sensor technologies. Applications of the present invention include on-the-spot medical and self-diagnostics on smart skin patches, Point of Care (POC) analyses, food diagnostics, pathogen detection, disease-specific wireless biomarker detection, remote structural stresses detection and sensor networks for industrial or Homeland Security using low cost wireless devices such as modified cell phones.

Owner:ALTIVERA

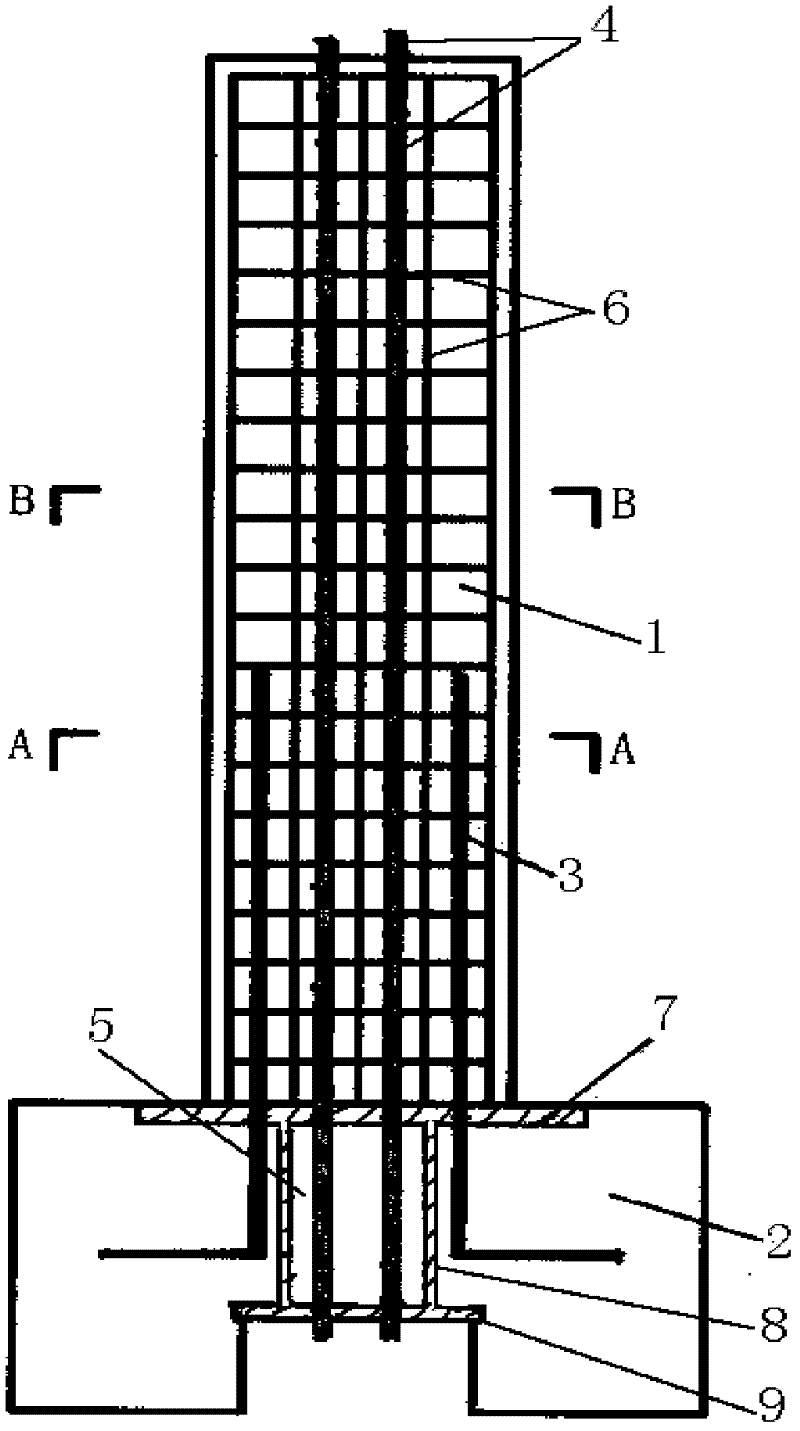

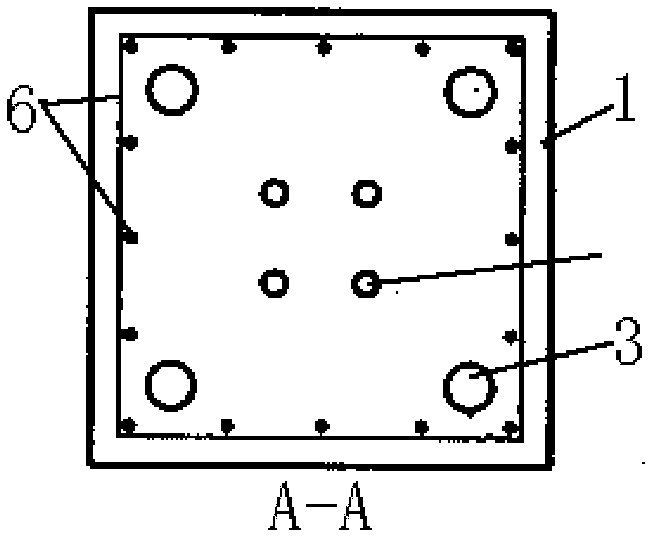

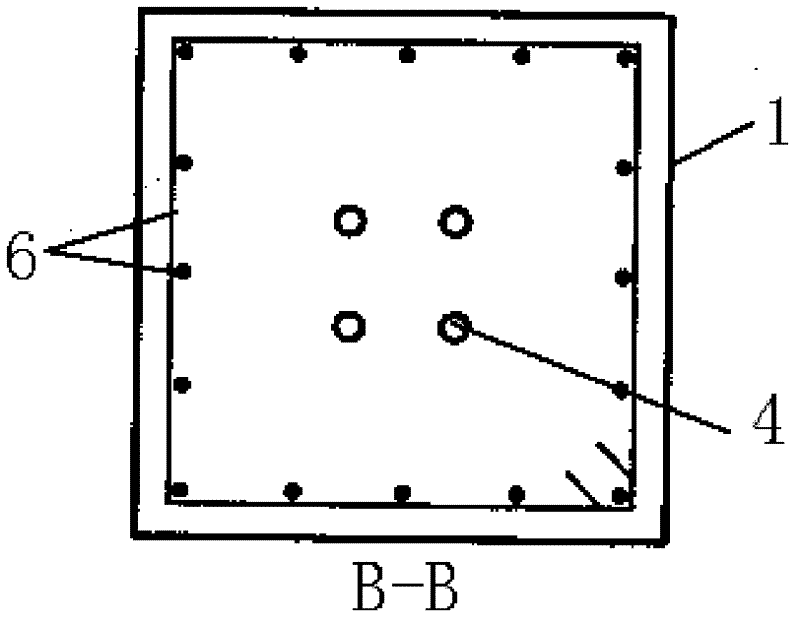

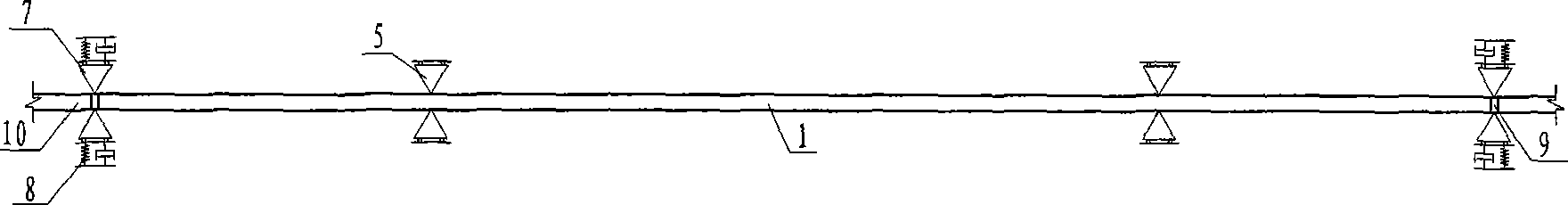

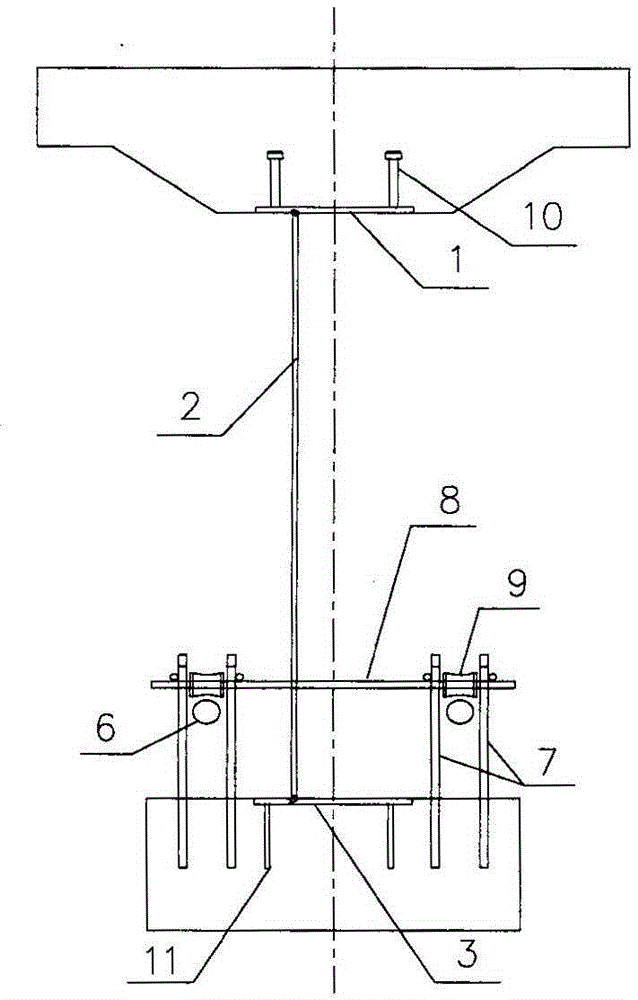

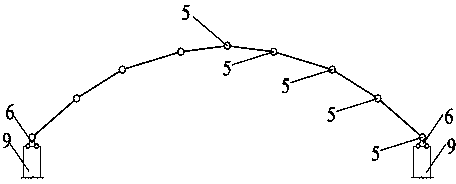

Self-resetting pier column structural system with built-in energy dissipation assembly and implementing method for self-resetting piper column structural system

InactiveCN102409606ASufficient ductility and energy dissipation capacityStrong enoughBridge structural detailsBridge erection/assemblyBridge engineeringResidual deformation

The invention discloses a self-resetting pier column structural system with a built-in energy dissipation assembly and an implementing method for the self-resetting pier column structural system, and belongs to the field of bridge engineering. The self-resetting pier column structural system consists of a pier column, a bridge abutment, energy dissipation steel bars, non-adhesion prestressed steel bars with an elastic resetting function and an embedded part; in the novel pier column structural system capable of effectively reducing residual deformation and ensuring sufficient energy dissipation, a pier is connected with the bridge abutment through the energy dissipation steel bars and the non-adhesion prestressed steel bars. Compared with the conventional pier column node, the self-resetting pier column structural system has the advantages that: the non-adhesion prestressed steel bars are positioned in the axle center of the pier column, a self-resetting restoring force can be generated, and the problem that the conventional pier has large residual deformation under the action of an earthquake load and cannot serve people any longer can be solved well; the self-resetting pier column structural system is flexible in design and definite in structural stress; the pier is ensured to have sufficient strength and rigidity; and the self-resetting pier column structural system can be implemented by a prefabricating or on-site pouring method, is easy and convenient to construct, and is an advanced and practical novel pier column system.

Owner:TSINGHUA UNIV

Diagnostic Radio Frequency Identification Sensors And Applications Thereof

ActiveUS20090209904A1Low costDevices with bluetooth interfacesSubstation equipmentPower sensorPoint of care

An integrated passive wireless chip diagnostic sensor system is described that can be interrogated remotely with a wireless device such as a modified cell phone incorporating multi-protocol RFID reader capabilities (such as the emerging Gen-2 standard) or Bluetooth, providing universal easy to use, low cost and immediate quantitative analyses, geolocation and sensor networking capabilities to users of the technology. The present invention can be integrated into various diagnostic platforms and is applicable for use with low power sensors such as thin films, MEMS, electrochemical, thermal, resistive, nano or microfluidic sensor technologies. Applications of the present invention include on-the-spot medical and self-diagnostics on smart skin patches, Point-of-Care (POC) analyses, food diagnostics, pathogen detection, disease-specific wireless biomarker detection, remote structural stresses detection and sensor networks for industrial or Homeland Security using low cost wireless devices such as modified cell phones.

Owner:ALTIVERA

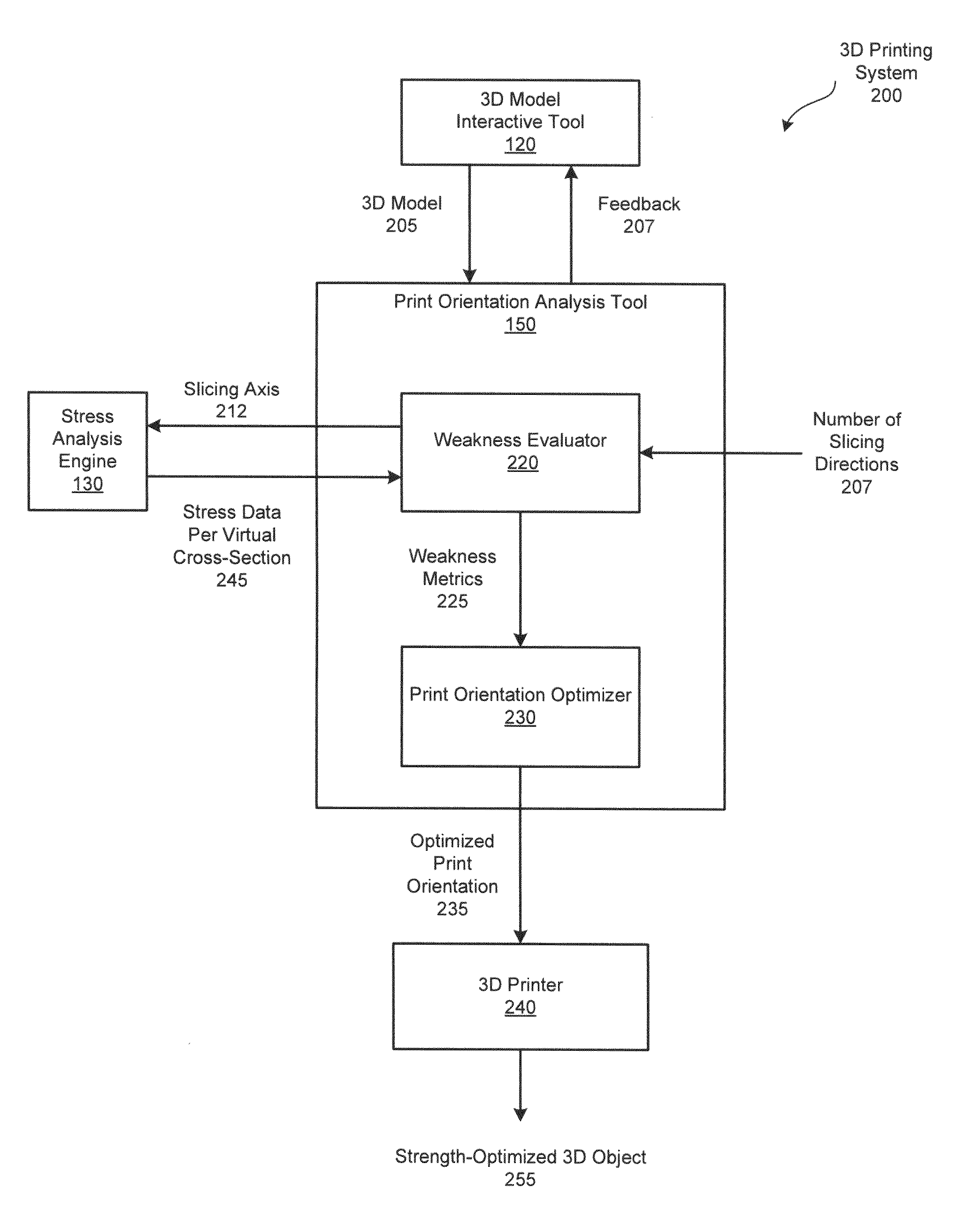

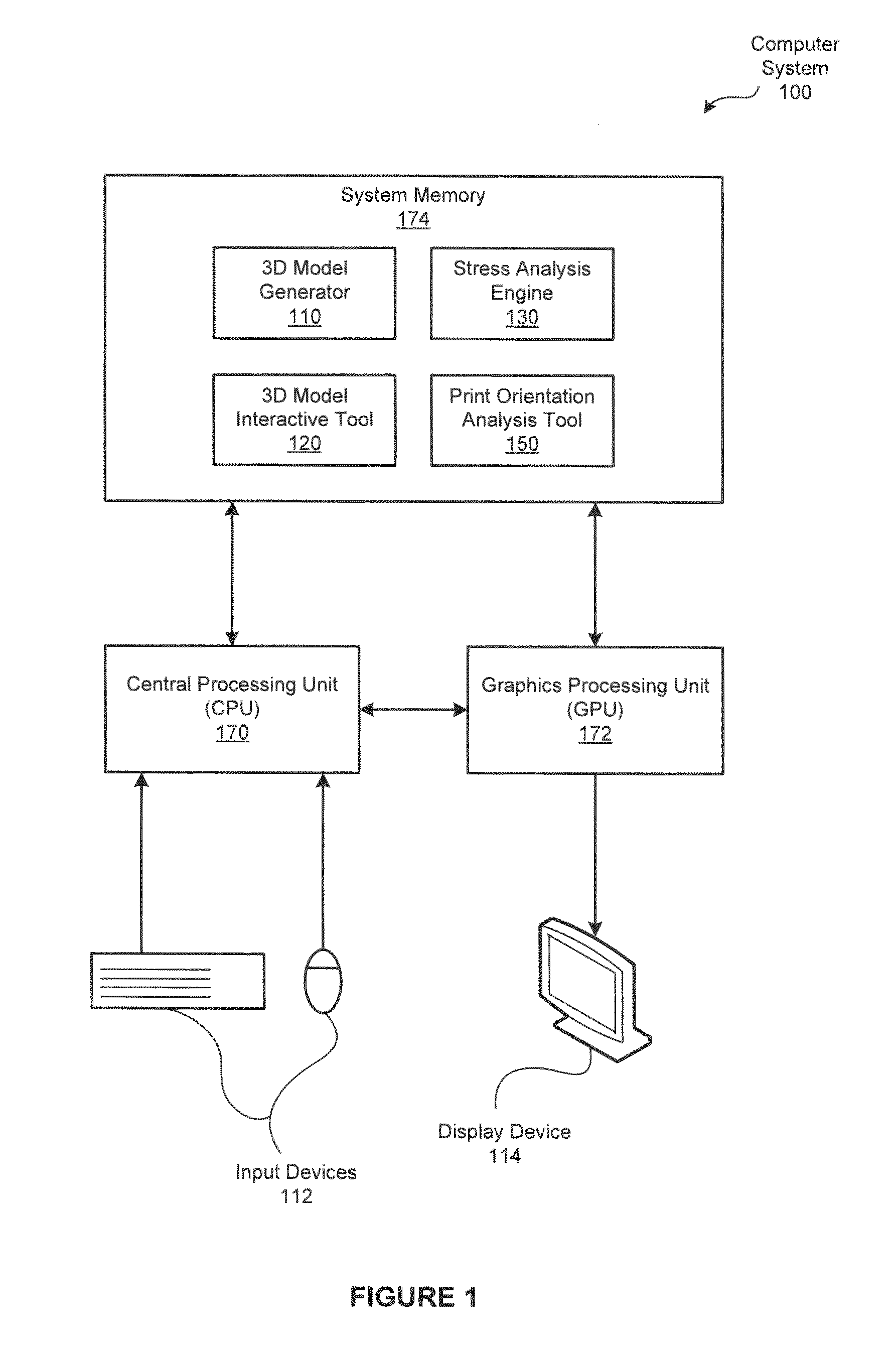

Techniques for optimizing orientation of models for three-dimensional printing

ActiveUS20150154321A1Automatically and efficiently mitigate undesirable weaknessReduce vulnerabilityProgramme controlAdditive manufacturing apparatusComputer graphics (images)Structural stress

In one embodiment of the present invention, a print orientation tool efficiently determines an orientation of a three-dimensional (3D) model such that, when 3D printed, the structural integrity of the resulting 3D object is optimized. In operation, the print orientation tool configures a stress analysis engine to slice the 3D model into two-dimensional (2D) cross-sections. The stress analysis engine then compute structural stresses associated with the 2D cross-sections. The print orientation tool translates the structural stresses to weakness metrics. Subsequently, the print orientation tool evaluates the orientations of the cross-sections in conjunction with the corresponding weakness metrics to select a printing orientation that minimizes weaknesses in the 3D model. Advantageously, by aligning the 3D model to the print bed based on the optimized printing orientation, the user mitigates weaknesses in the corresponding 3D object attributable to the 3D printing manufacturing process.

Owner:AUTODESK INC

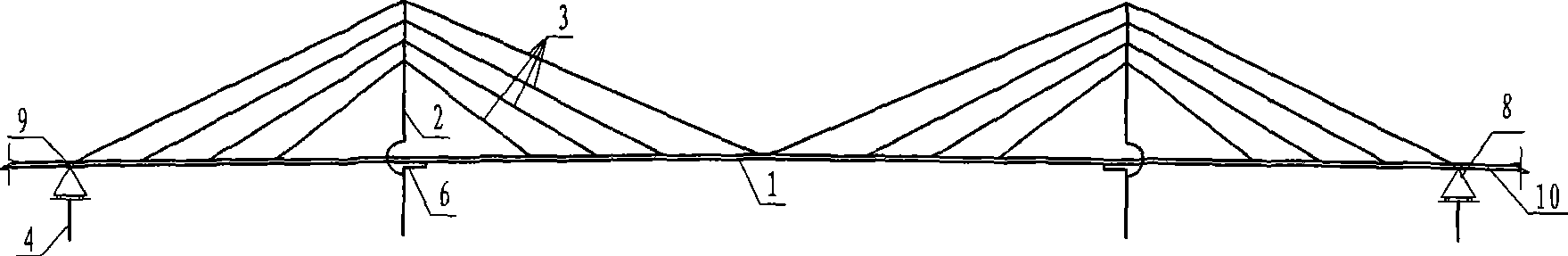

Supporting system of long span stayed-cable bridge

InactiveCN101424071AReduce beam end displacementReduce bending momentCable-stayed bridgeBridge engineeringSupporting system

The invention discloses a support system for a long-span cable-stayed bridge, which relates to the technical field of bridge engineering. The support system consists of nine parts including main girders, bridge towers, stay cables, transitional piers, transverse wind resisting bearings, longitudinal viscous dampers with limiting function, longitudinal sliding bearings with limited transverse rigidity, transverse dampers, and telescopic devices. Compared with the prior support system for the long-span cable-stayed bridge, the support system of the invention has the characteristics that the longitudinal viscous dampers with limiting function are arranged between the main girders and the bridge towers; and the longitudinal sliding bearings with limited transverse rigidity and the transverse dampers are arranged between the main girders and the transitional piers. The support system provides effective rigidity and damping for the long-span cable-stayed bridge to ensure that the static force and the dynamic force responses of the bridge are controlled in an acceptable scope; the structural stress is definite; and the applicability is strong.

Owner:CCCC HIGHWAY CONSULTANTS

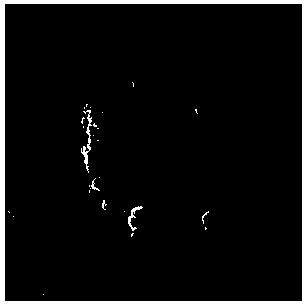

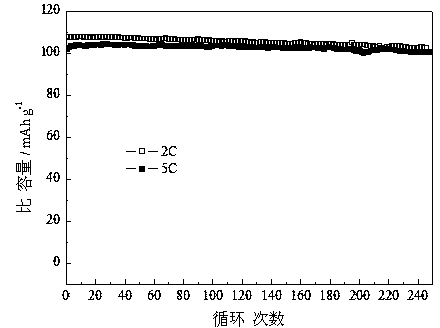

Method for preparing hollow high voltage nickel manganese acid lithium anode material

ActiveCN103474650ACalcination temperature is highIncrease shell thicknessCell electrodesParticulatesManganese

The invention discloses a method for preparing hollow high voltage nickel manganese acid lithium anode material, and belongs to the technical field of material synthesis. The method includes the steps that firstly, manganese carbonate is prepared and then calcined under a certain temperature to make the outer shell of the manganese carbonate become manganese dioxide, then, the inner core of the manganese carbonate is dissolved away with dilute acid, the manganese dioxide outer shell is left and mixed with a lithium source and a nickel source, and the hollow nickel manganese acid lithium material is obtained in a calcined mode. The nickel manganese acid lithium material prepared with the method is of a uniform micrometer / nanometer structure and is 1-5um secondary particulates formed by 30-400nm particulates, and primary particulates in small sizes shorten the transmission distance of lithium ions, increase the area of contact between electrodes and electrolytes, and improve the rate capacity. The nickel manganese acid lithium material particulates prepared with the method are of a hollow structure, gaps can buffer structural stress and size changes caused by ithiation, and circulating performance is improved.

Owner:南京时拓能源科技有限公司

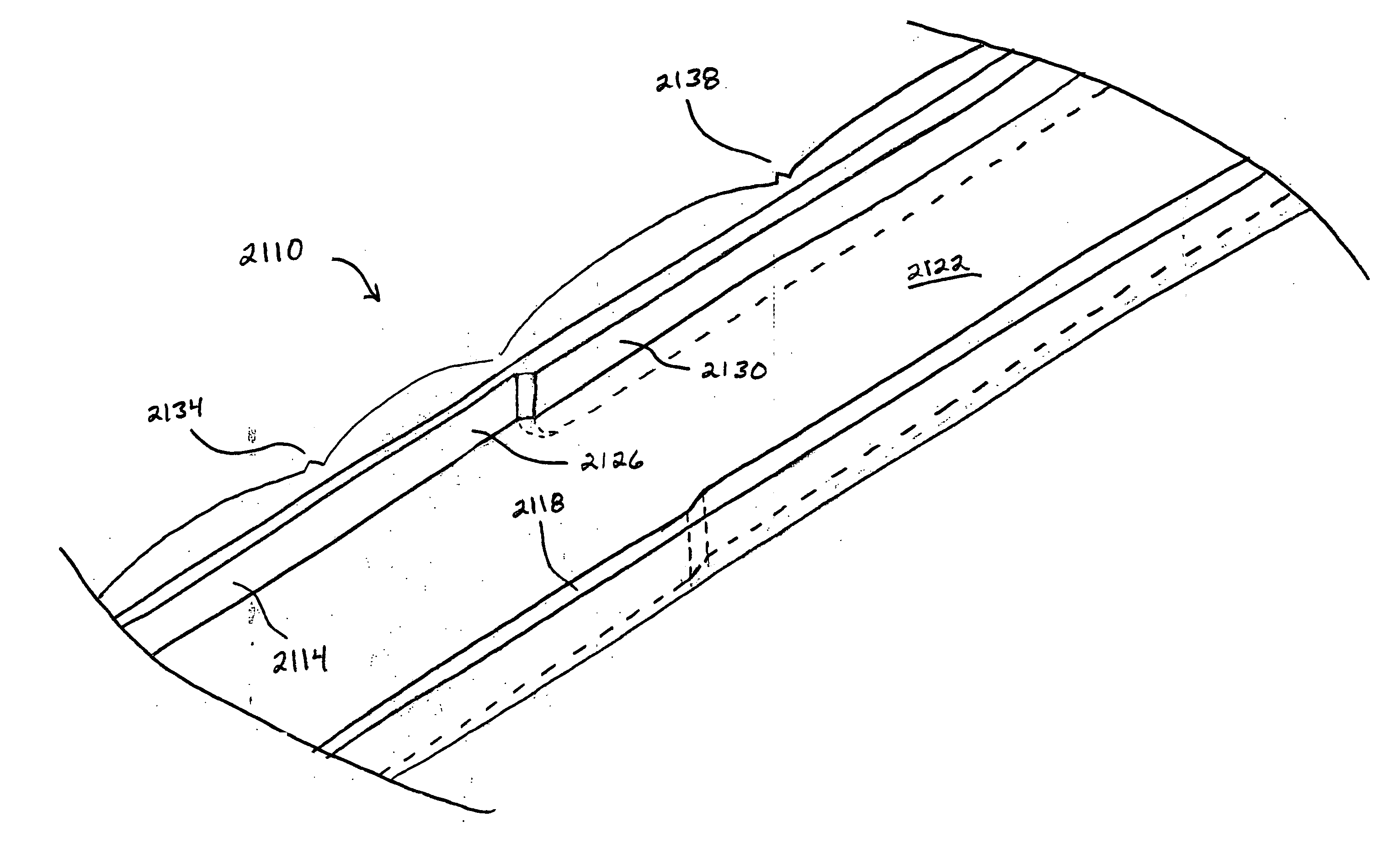

Molded composite climbing structures utilizing selective localized reinforcement

InactiveUS20070205053A1Increase volumeLess structural stressDomestic articlesLaddersFiberEngineering

A method and system for fabricating molded composite support members for use in climbing structures, which molded composite support members comprise variable performance properties along a longitudinal length thereof. The variable performance properties are achieved or provided by selectively reinforcing one or more regions determined to be subject to greater stress, thus allowing a minimum amount of material to be used in other areas that will subject to less structural stress. Selective reinforcement is accomplished by adapting one or more regions of a primary composite material composition with a supplemental composite material composition, wherein the supplemental composite material composition increases the amount of composite material fibers within that particular region.

Owner:CMX TECH

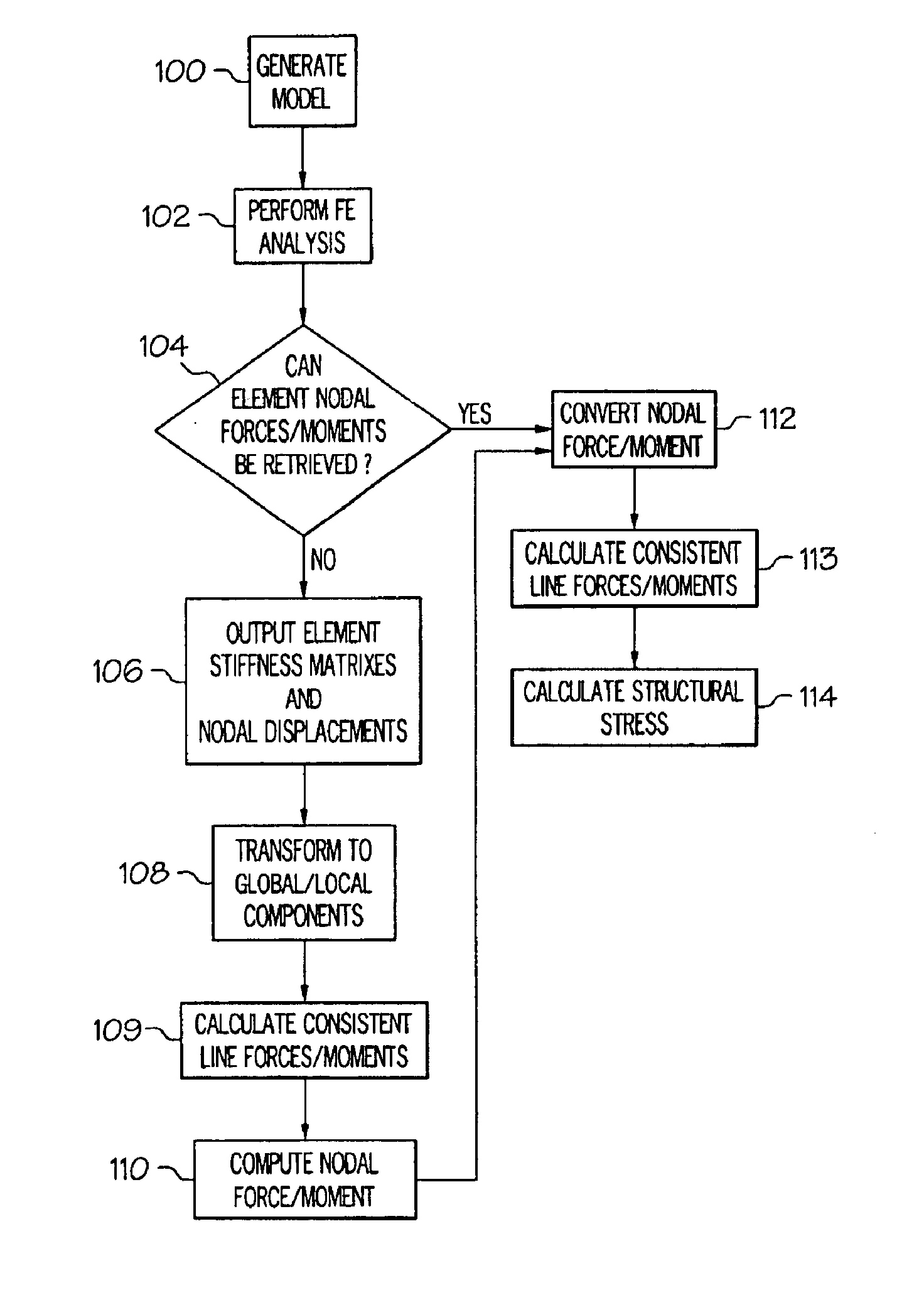

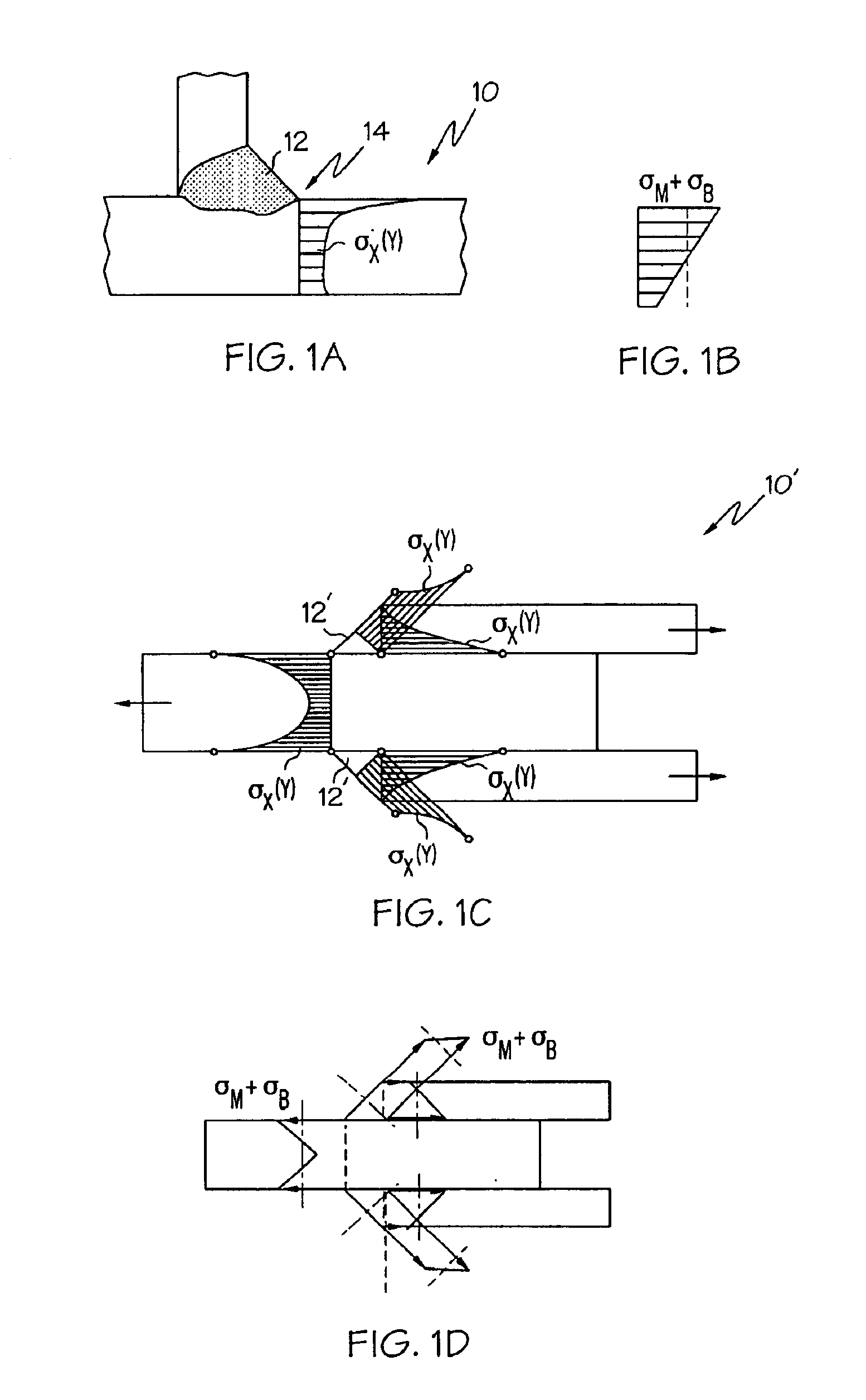

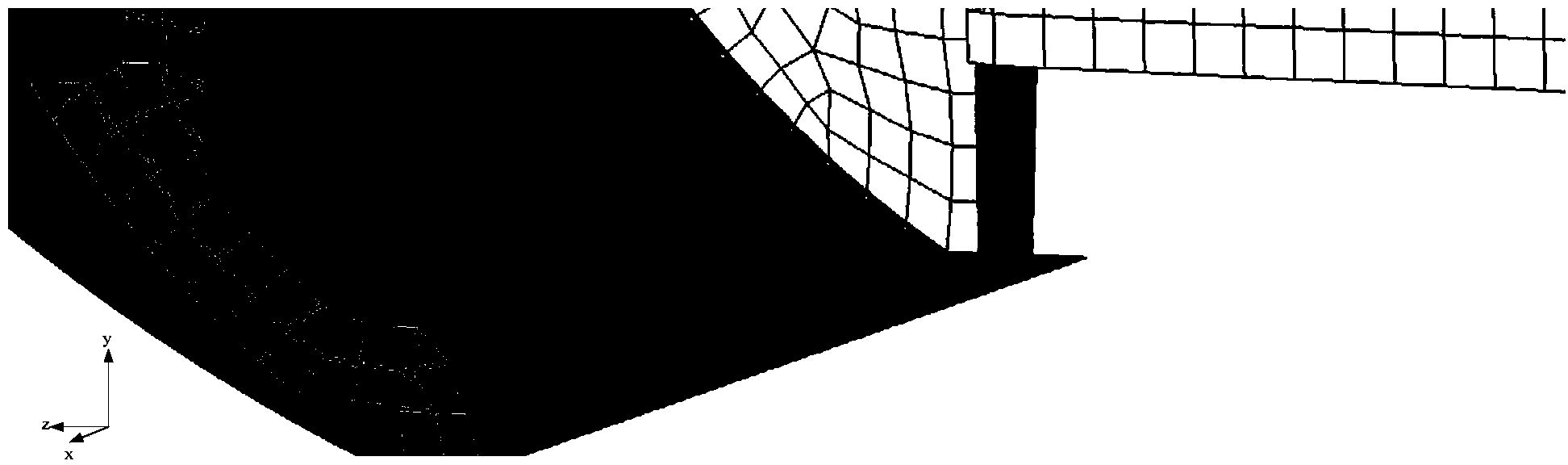

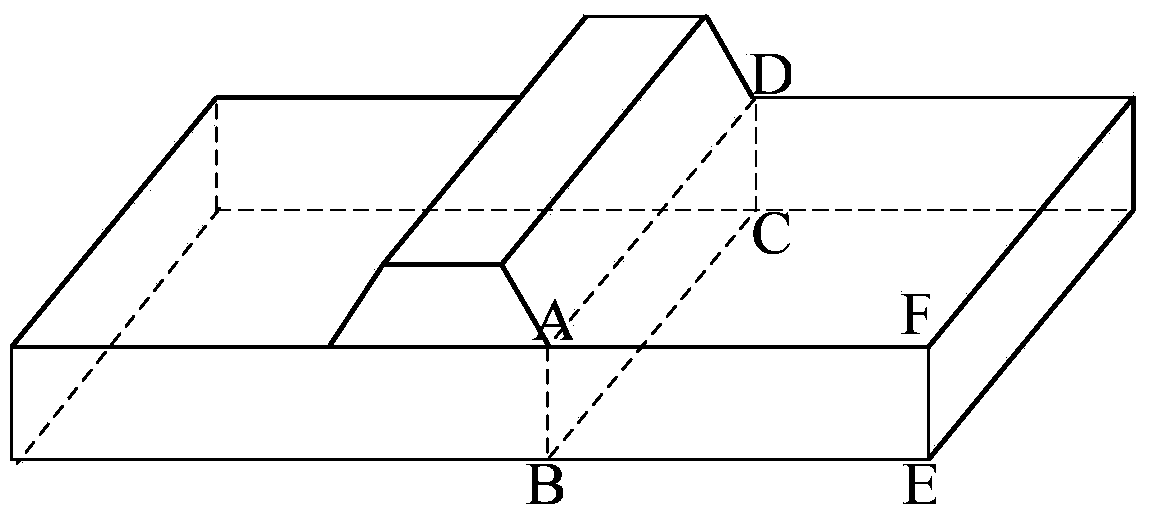

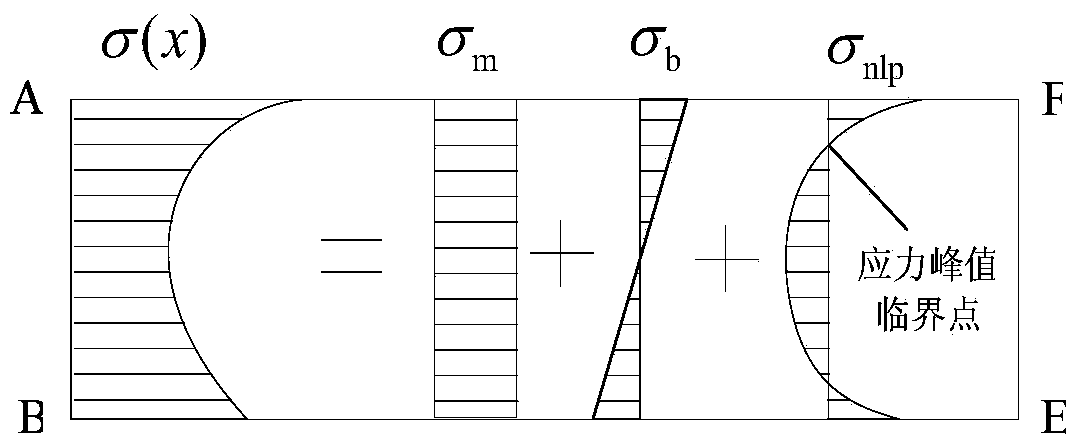

Structural stress analysis

InactiveUS6901809B2Measurement arrangements for variableMaterial strength using steady bending forcesNODALEngineering

This need is met by the present invention wherein structural stress in a fatigue-prone region of a structure is determined by using the nodal forces and displacement values in the fatigue-prone region, or equilibrium-equivalent simple stress states consistent with elementary structural mechanics in the fatigue-prone region. The determination is substantially independent of mesh size and is particularly well-suited for applications where S-N curves are used in weld fatigue design and evaluation, where S represents nominal stress or stress range and N represents the number of cycles to failure. The present invention is directed to structural stress analysis through various combinations of modeling, calculation, and direct measurement schemes.

Owner:BATTELLE MEMORIAL INST

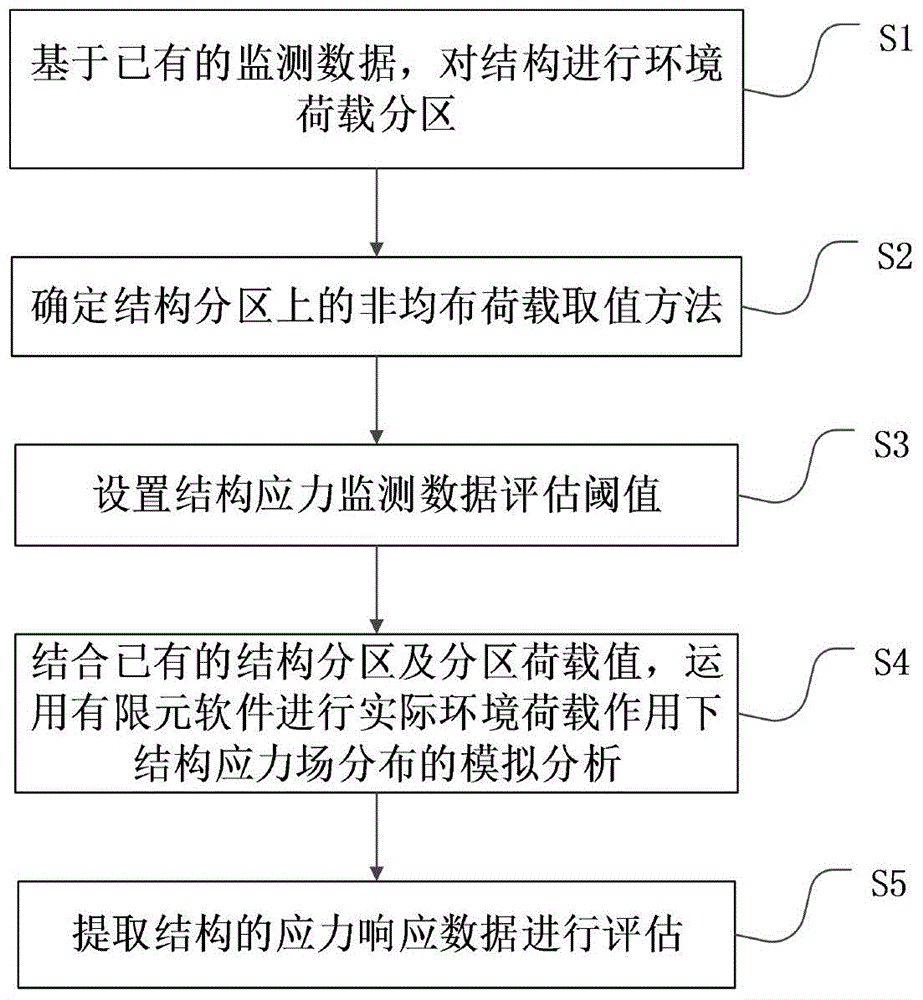

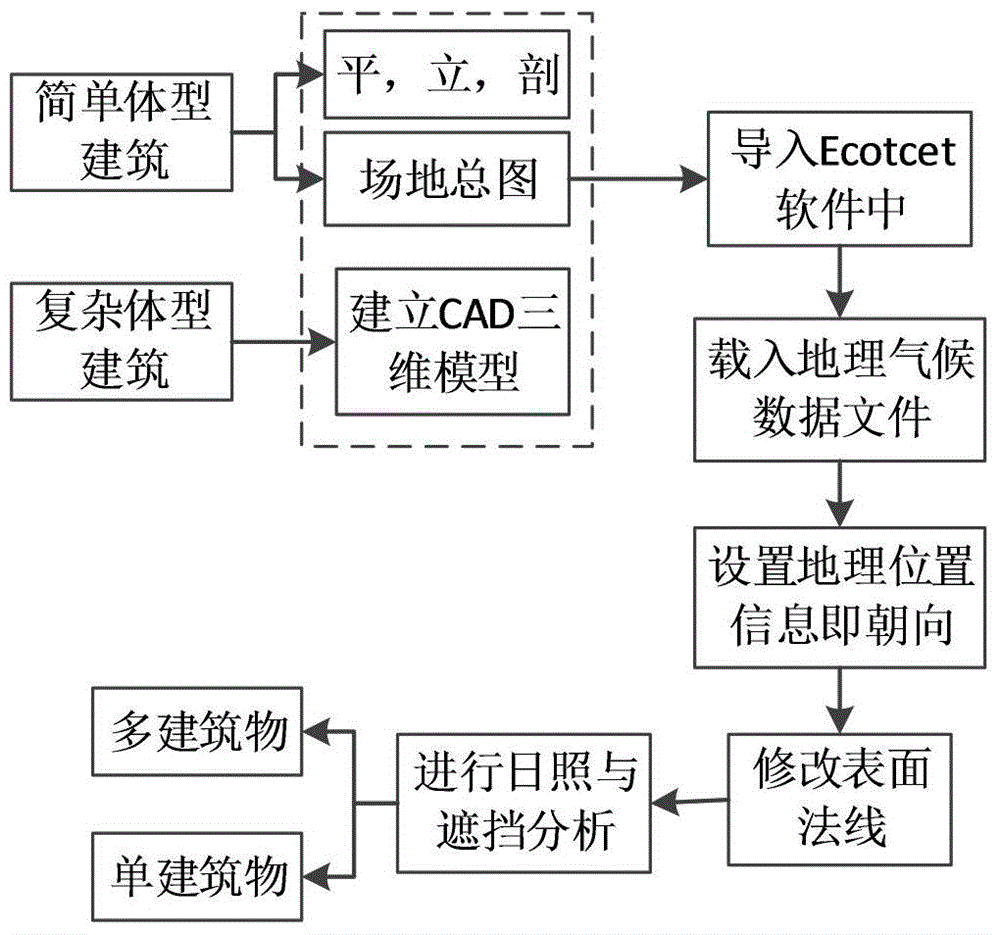

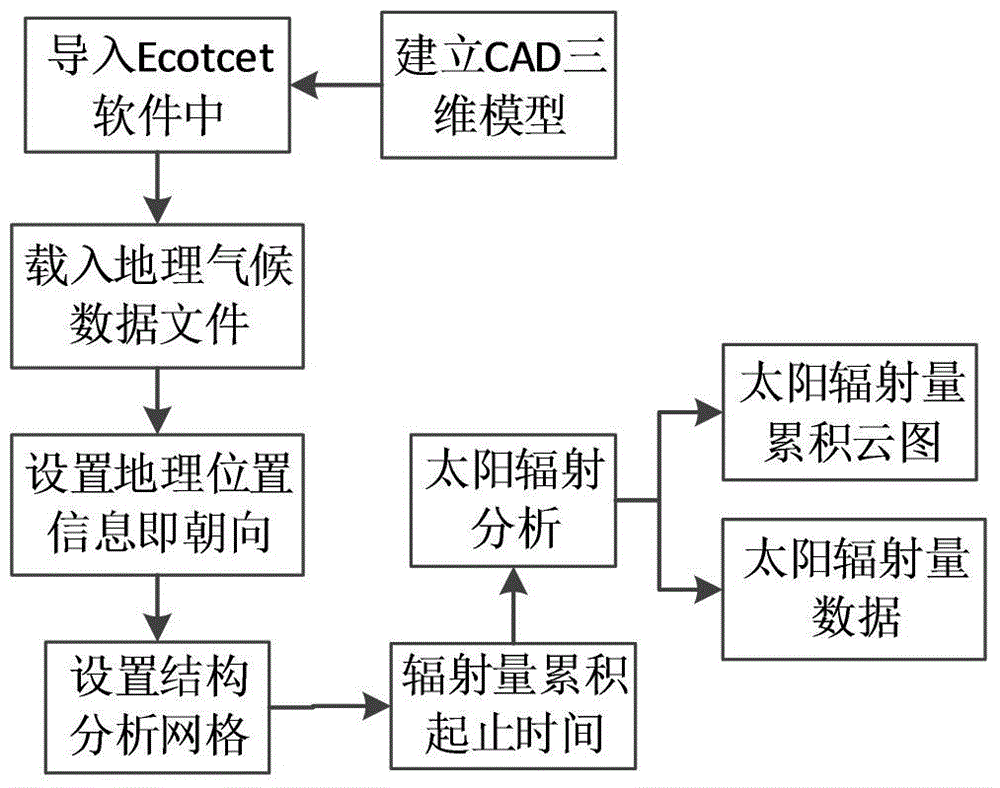

Structure safety evaluation method under action of environmental loads of space steel structure

ActiveCN104899388AAvoid possible problems in the assessment of stress safetyRealize identificationSpecial data processing applicationsEngineeringFinite element software

The invention provides a structure safety evaluation method under the action of environmental loads of a space steel structure. The structure safety evaluation method under the action of the environmental loads of the space steel structure comprises the steps that S1, environmental load partitioning is conducted on the structure on the basis of existing monitoring data; S2, a method for determining values of non-uniform distributed loads on structure partitions is determined; S3, a structural stress monitoring data evaluation threshold is set; S4, simulation analysis of structural stress field distribution under the action of the actual environmental loads is conducted through operation of finite element software and combination between the existing structure partitions and partition load values; S5, stress response data of the structure are extracted to be evaluated. According to the structure safety evaluation method under the action of the environmental loads of the space steel structure, good simulation of non-uniform distribution of actual temperature loads and actual wind loads of the space steel structure is achieved through utilization of existing temperature measured data and wind speed and pressure monitoring data of a health monitoring system, and therefore identification of a whole stress field under the action of the environmental loads of the structure is achieved; meanwhile, due to the fact that stress of rod pieces at measuring points and rod pieces which are not arranged at the measuring points is evaluated, the problems which can be caused in the process that whole stress safety of the structure is evaluated only through the finite stress measuring points are solved.

Owner:卢伟

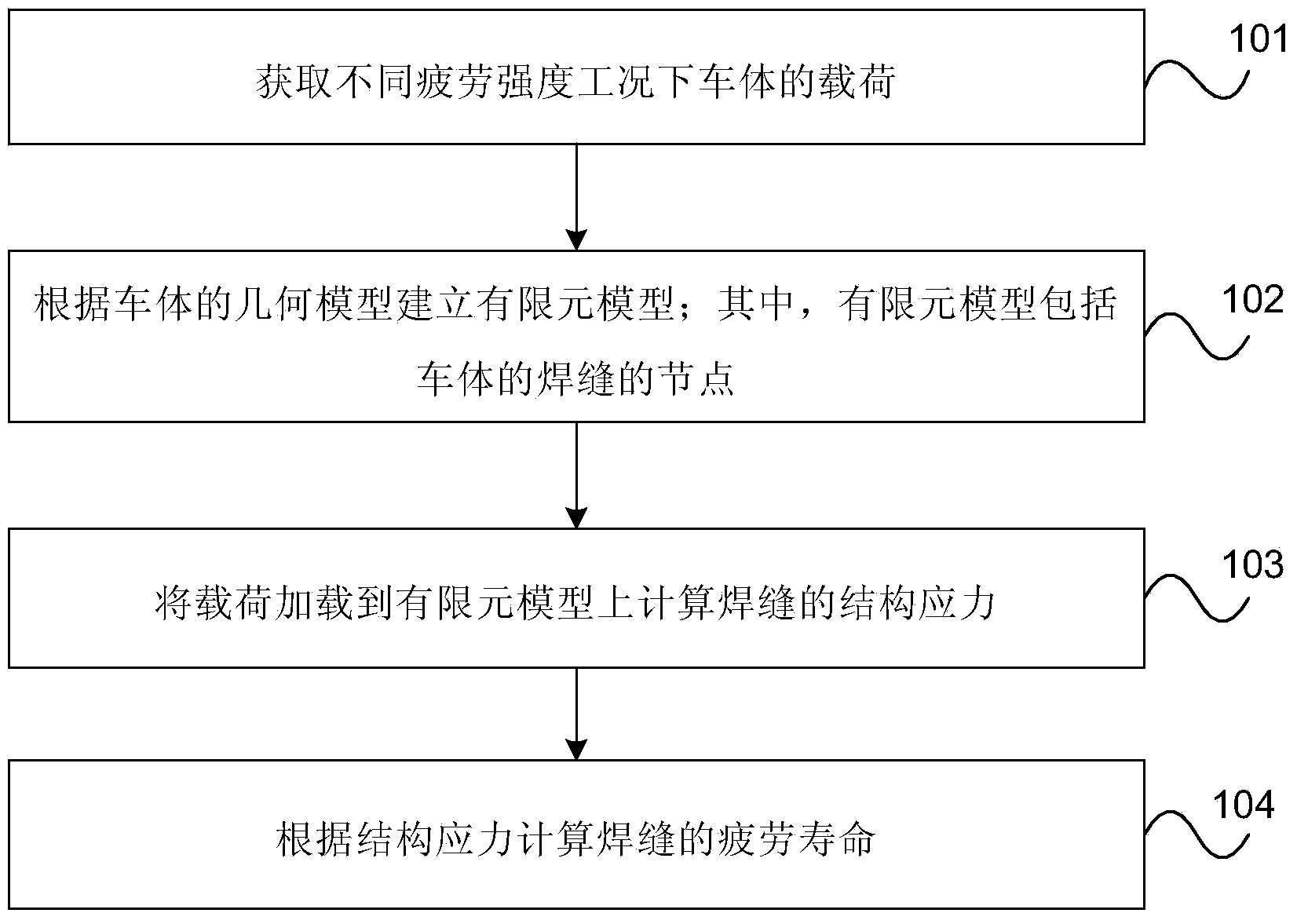

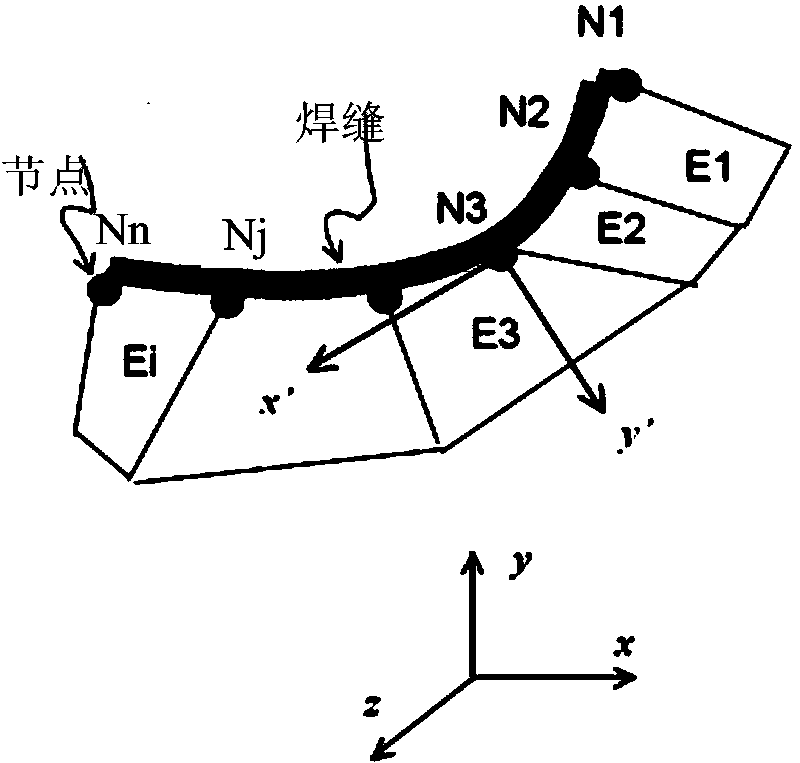

Method and device for calculating fatigue life of vehicle welding lines

InactiveCN103838975ARealization of fatigue life calculationSpecial data processing applicationsAnalysis dataElement model

The invention provides a method and device for calculating the fatigue life of vehicle welding lines. The method for calculating the fatigue life of the vehicle welding lines comprises the step of acquiring the loads of a vehicle under different fatigue strength working conditions, the step of establishing a finite element model comprising the joints of the vehicle welding lines according to the geometric model of the vehicle, the step of loading the loads into the finite element model to calculate the structural stress of the welding lines, and the step of calculating the fatigue life of the welding lines according to the structural stress. By means of the method, the fatigue life of the welding lines of the vehicle made of aluminum alloy is calculated, the main factors affecting the fatigue resistance of the welding lines of the vehicle made of the aluminum alloy are shown through a structural stress body, and the problem that fatigue life analysis data errors of the welding lines are large through the nominal stress method in the prior art is solved.

Owner:CRRC TANGSHAN CO LTD

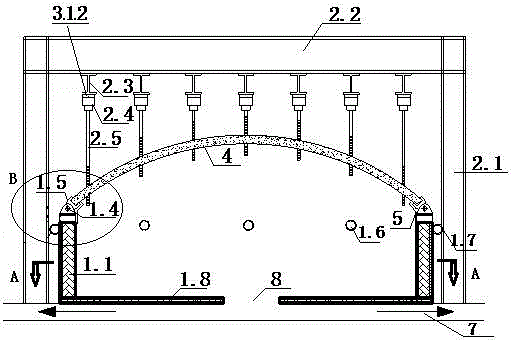

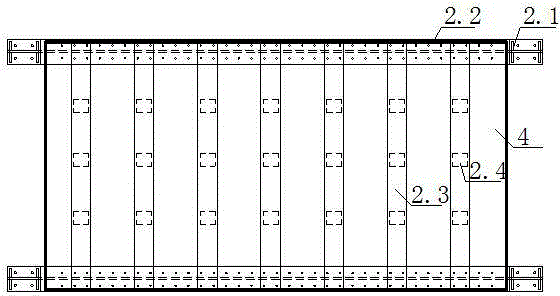

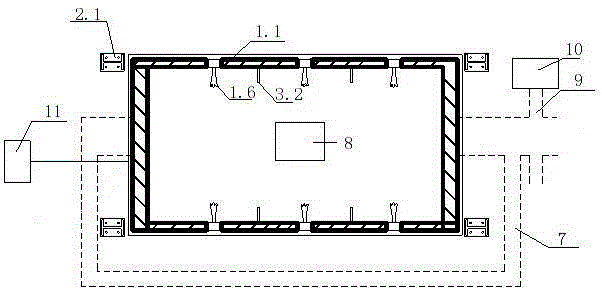

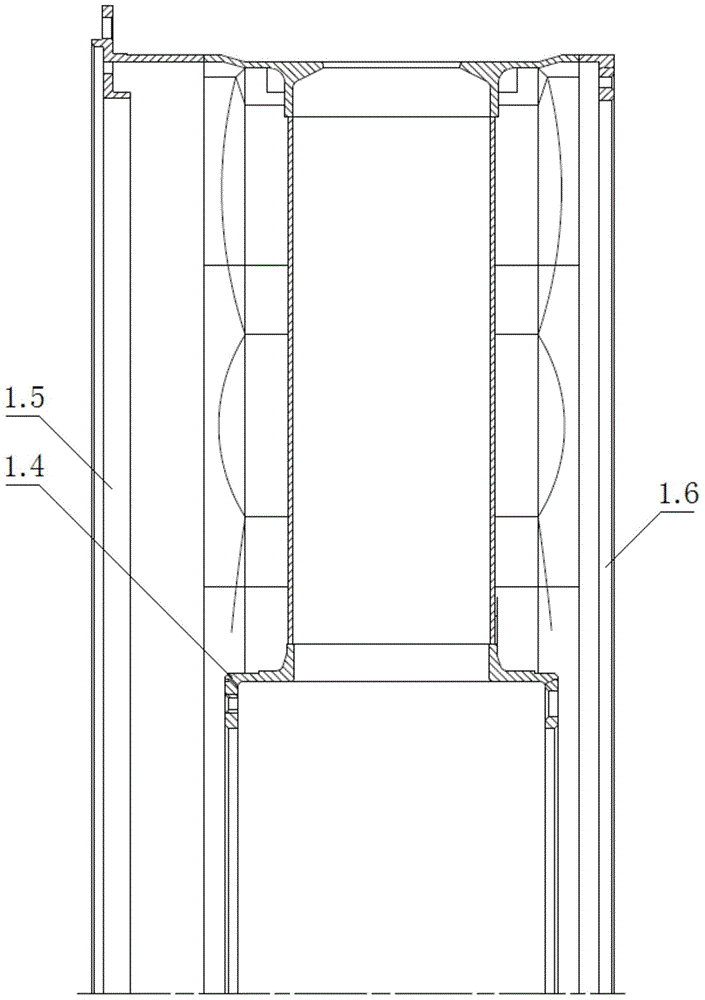

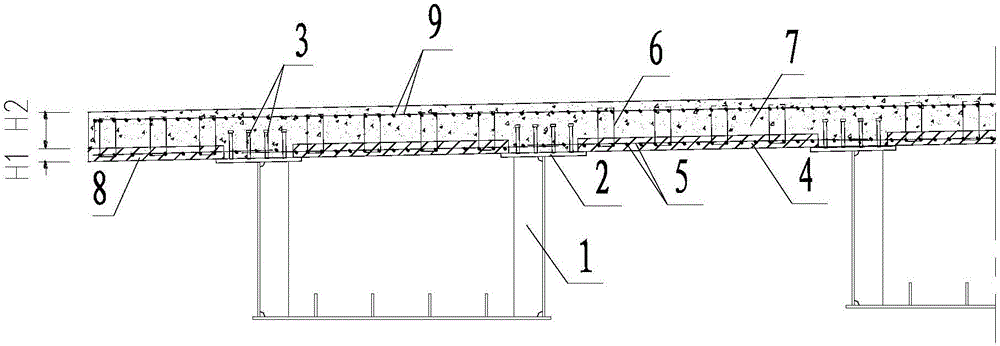

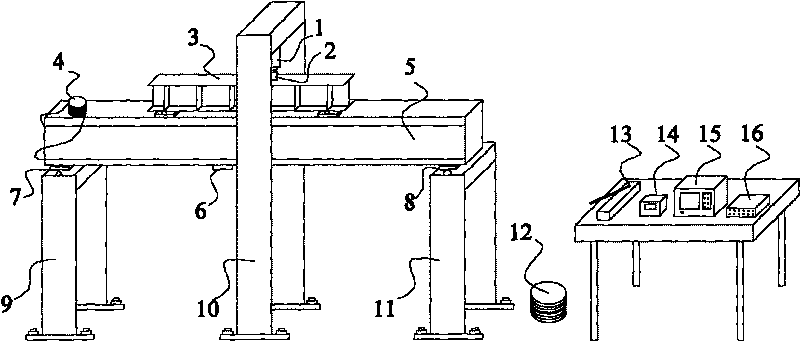

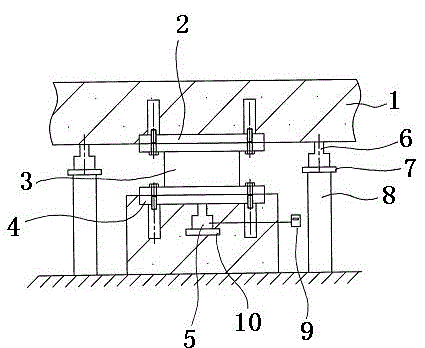

Reinforced concrete shell fire resistance testing system

ActiveCN104677940AEasy to installEasy to disassembleMaterial heat developmentElectricityTension compression

The invention discloses a reinforced concrete shell fire resistance testing system. The system comprises a test furnace, a loading device and a control and data acquisition device; one or more tension-compression sensors (3.1.2) electrically connected to the strain acquisition circuit of the control and data acquisition device are distributed on bottom of a loading beam (2.3); each tension-compression sensor (3.1.2) is connected with a jack (2.4); each jack (2.4) is fixedly connected with a force transfer rod (2.5) which extends into the reinforced concrete shell (4). According to the reinforced concrete shell fire resistance testing system, the jacks are adopted for performing vertical loading so as to simulate the structural stress in the reality; the fire behaviors of the reinforced concrete shell and the influence rule of vertical uniform distribution or integrated tension-compression load effect on the fire resistance of the reinforced concrete shell can be deeply studied, and then the fire resisting design of the reinforced concrete shell can be guided according to the test data and the fire resistance of the reinforced concrete shell can be improved.

Owner:CHINA UNIV OF MINING & TECH

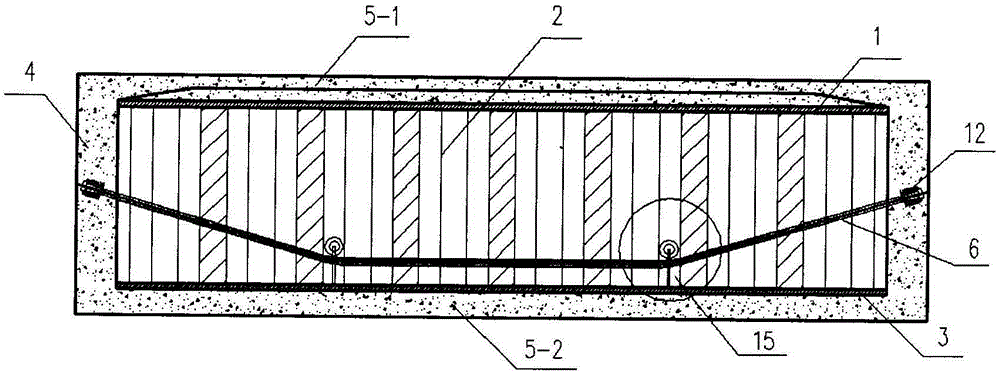

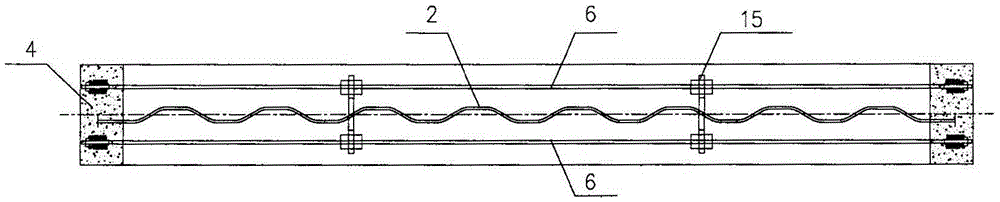

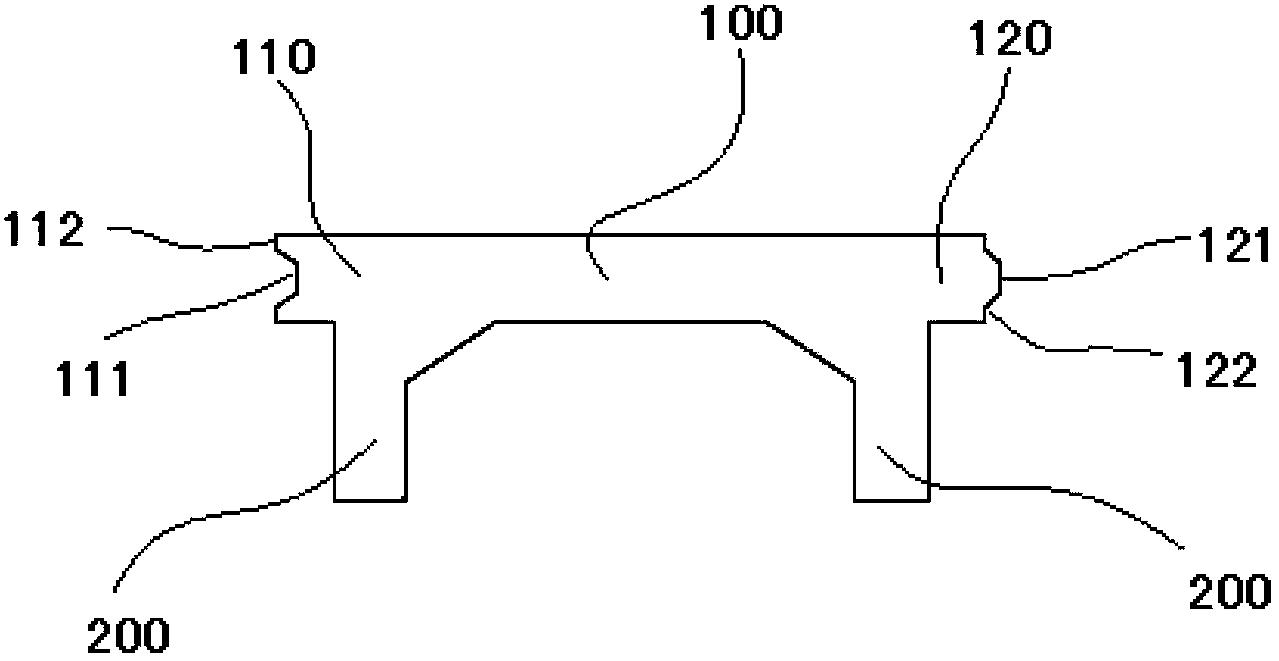

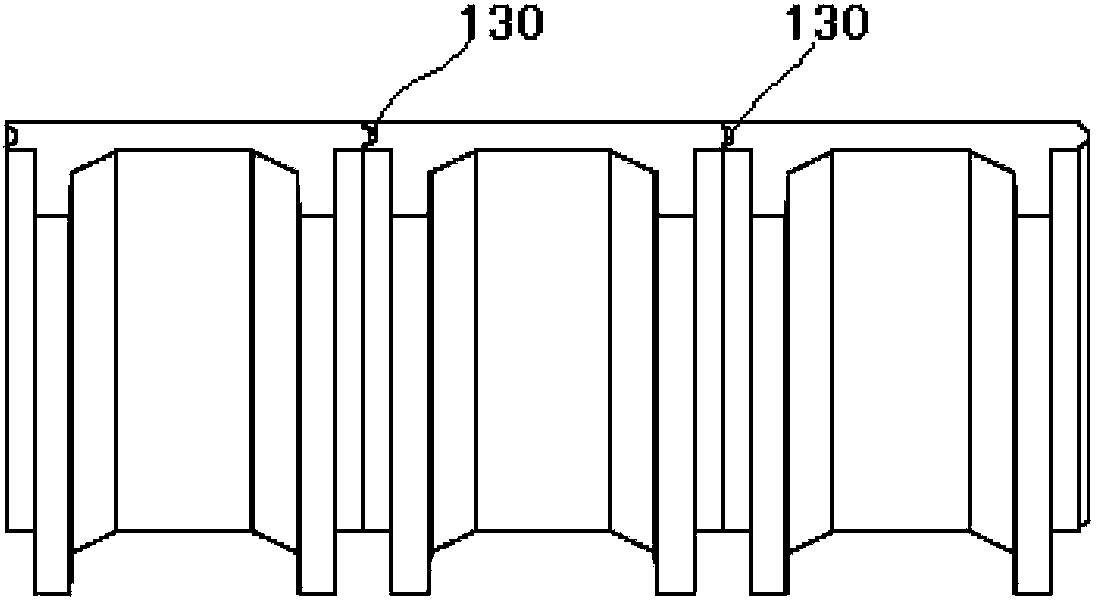

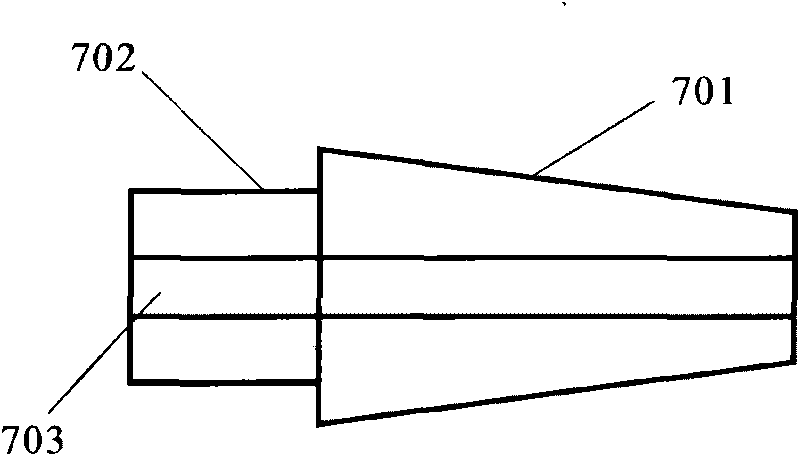

External prestressing corrugated steel web T-shaped beam and construction method

InactiveCN105369729AReduce usageLight weightBridge structural detailsBridge erection/assemblyShaped beamPre stress

The invention discloses an external prestressing corrugated steel web T-shaped beam and a construction method. The T-shaped beam comprises a concrete top plate, a concrete bottom plate, end cross beams, a corrugated steel web, shear connectors and external prestressing cables. The concrete top plate and the concrete bottom plate are connected with the corrugated steel web through the shear connectors to form a T-shaped beam section. The end cross beams are arranged at the two ends of the T-shaped beam and connected with the concrete top plate, the concrete bottom plate and the corrugated steel web. The external prestressing cables are steered at the break angle through steering devices and anchored to the end cross beams. The external prestressing corrugated steel web T-shaped beam has the advantages of stress performance, the material utilization rate and durability of a common corrugated steel web T-shaped beam, structural stress is optimized, the member structure is simplified, the amount of adopted prestressed reinforcement is reduced, and manufacturing cost is reduced; the problems that during internal prestressing construction, stretch-draw porous channels are blocked, and grouting is not compact after stretching and drawing are carried out are solved, the construction quality is ensured, and the bridge structure can be maintained and reinforced easily during the later stage.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

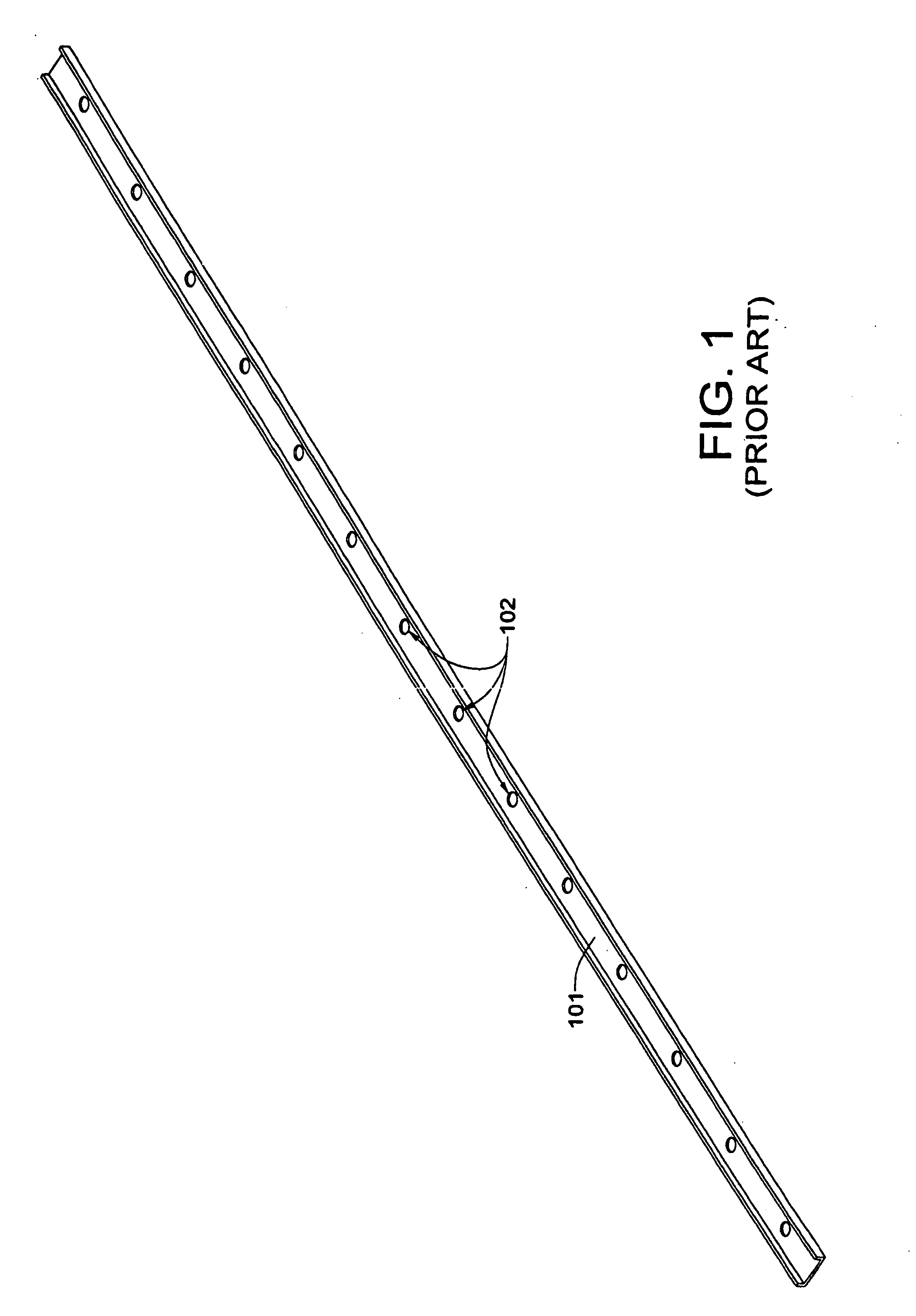

Lightweight composite ladder rail having supplemental reinforcement in regions subject to greater structural stress

A molding process, other than pultrusion, is used to manufacture composite ladder rails of non-uniform cross-sectional area and non-uniform strength throughout their lengths. Each ladder rail includes a structural fiber preform embedded in a cured polymeric resin. Fiberglass preforms are preferred because they are electrically non-conductive. Resin transfer molding processes, using either polyester or epoxy resins, are ideally suited for such manufacture. Vacuum-bagged, open-mold processes may also be used, as may be compression molding processes. Regions of the rails subject to greater stress during usage are strategically reinforced with additional structural fibers, and have greater cross-sectional area than regions subjected to lesser stress. The differential cross-sectional area permits the construction of ladders which are optimized for both strength and lightness of weight. Ladders of all types may be constructed with rails incorporating the invention.

Owner:CMX TECH

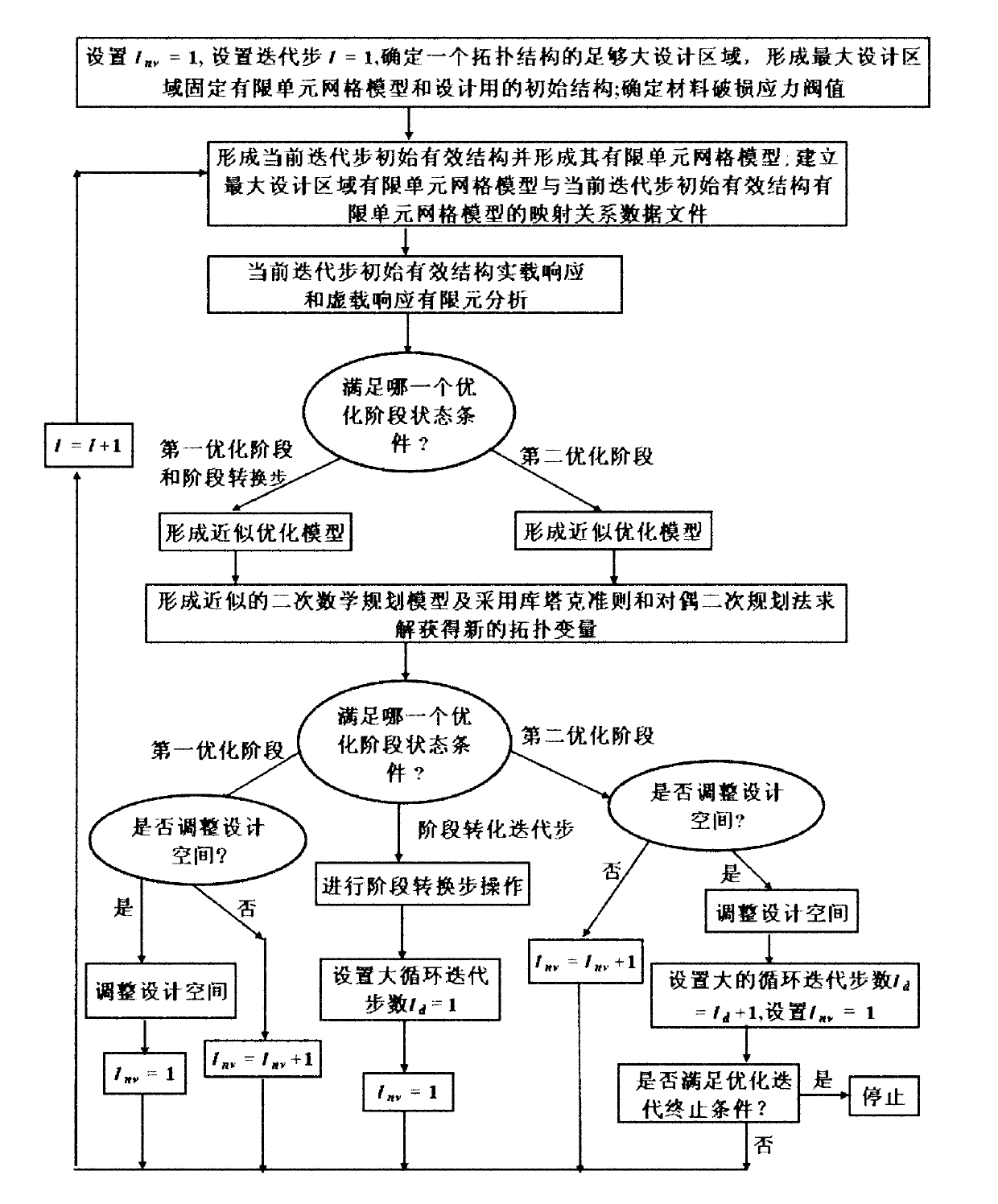

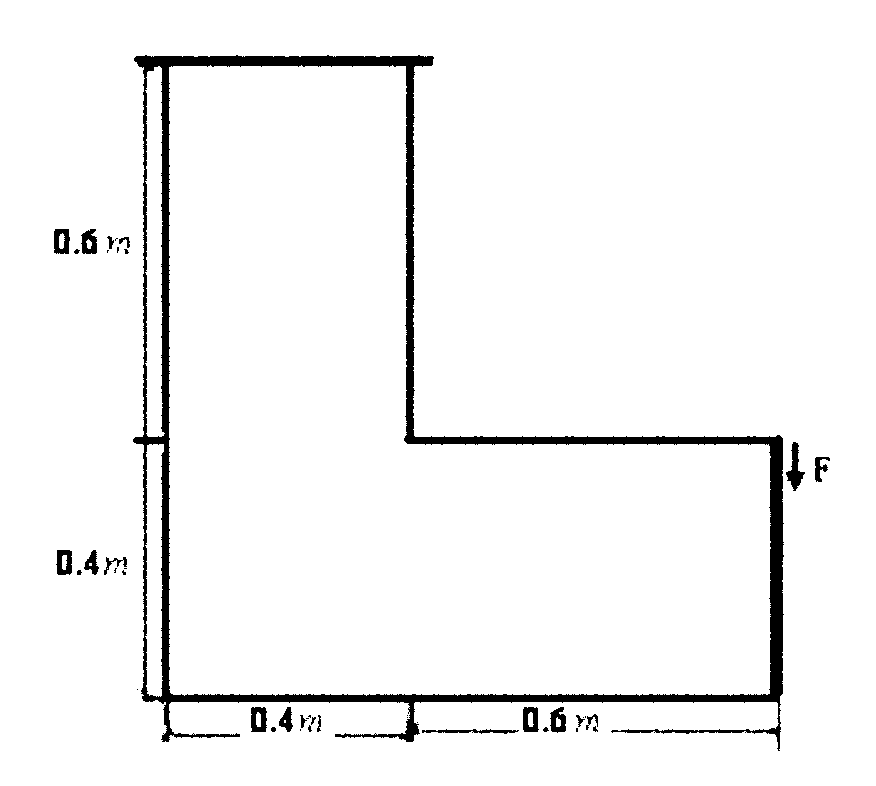

Material breakage constraint-based continuum structure topology design modeling and optimization design method

InactiveCN102043883AReduced maximum stress fluctuationsAddress stressSpecial data processing applicationsStress concentrationStress level

The invention discloses a material breakage constraint-based continuum structure topology design modeling and optimization design method, which is used for solving (a) problems of stress concentration and singularity, and (b) a problem of maximum stress fluctuation and a problem of high analyzed and calculated quantity in different degrees in the prior art. In the method, effective stress constraint relaxation is adopted to treat the phenomenon of stress singularity. In the process of optimizing problem approximation modeling, a q1 norm metrical function of the structural stress serves as a penalty function, all unit stress constraints are replaced by q2 norm metrical function constraint of the structural stress, the most potential active unit stress constraints and the introduced volume constraints, and the local stress level is controlled by combining variable constraint limit. The optimization process of the method is divided into two optimization stages and a conversion stage, and the design space is automatically expanded and reduced. A quadratic programming method is utilized to solve each stage, a pure optimized structural topology in black / white distribution can be obtained, and the method has high optimization design efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

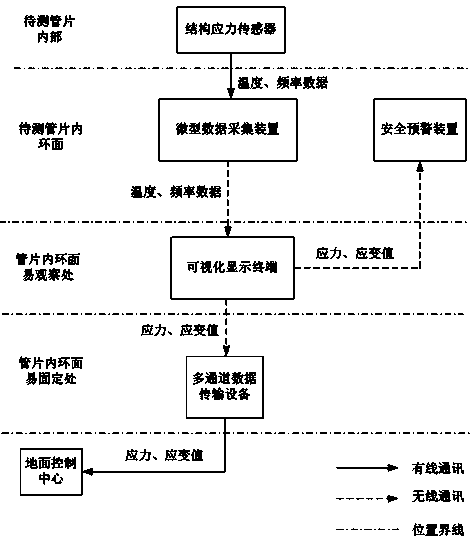

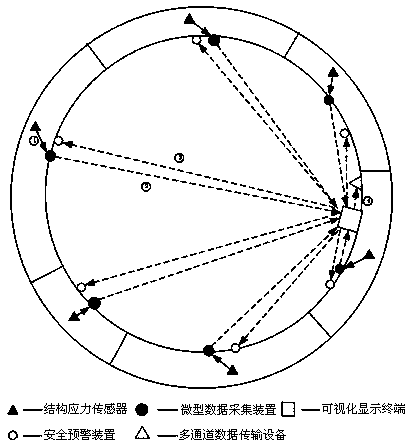

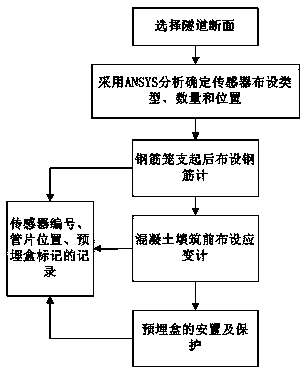

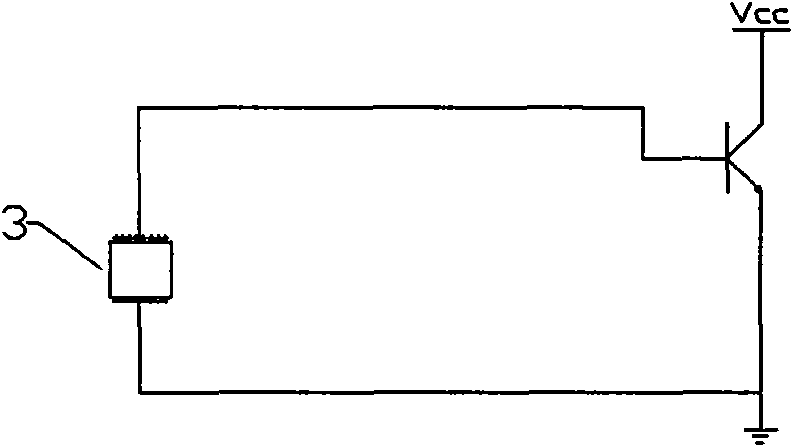

Subway shield tunnel segment structural stress visual warning device and operating method thereof

The invention belongs to the technical field of shield tunnel segment structure safety monitoring, and provides a subway shield tunnel segment structural stress visual warning device and an operating method thereof. The device comprises a structural stress sensor, a micro data acquiring device, a visual display terminal, a multi-channel data transmitting device and a safety warning device. By the aid of the device and the operating method, subway shield tunnel segment reinforcement stress values and concrete strain values can be acquired continuously, acquired results can be displayed in real time on the inner annular face of a segment to the detected to provide convenience to operators in a tunnel for observing in real time, real-time warning of segment stress can be realized in a manner of photochromic warning, requirements of grasping segment structure stress data information by the operators in the tunnel are met, and automatic safety warning is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

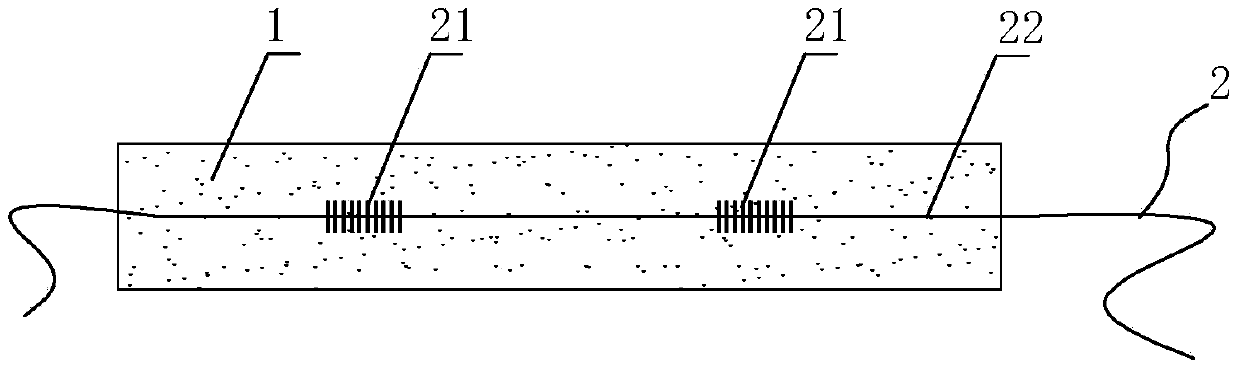

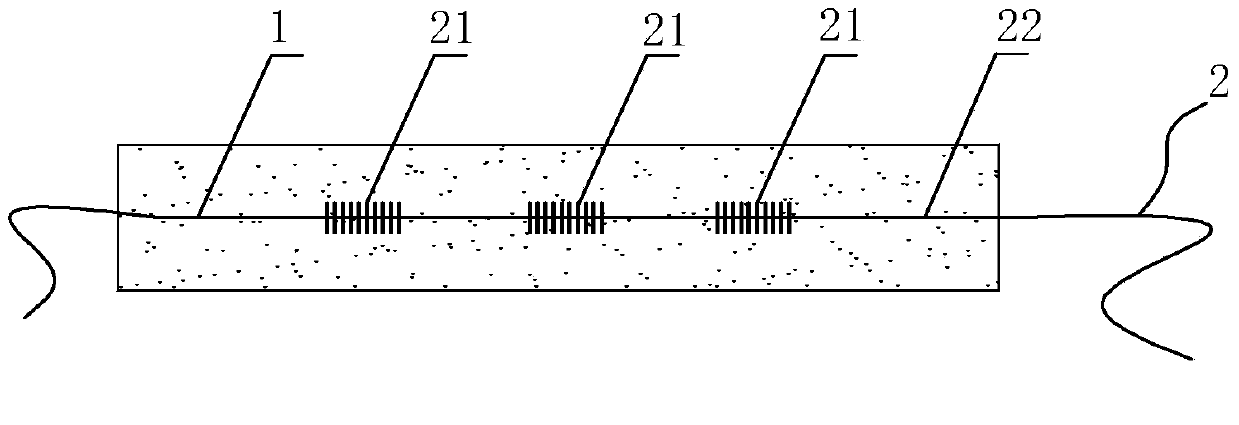

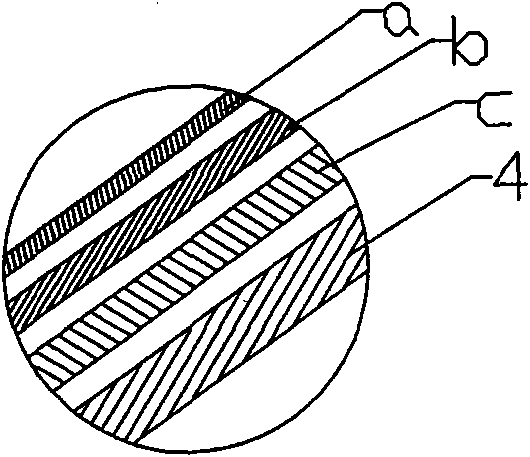

Fiber grating intelligent plate made of fiber reinforced polymer in pulling extrusion and continuous forming mode and manufacturing method thereof

InactiveCN103628697AAchieve securityRealize health diagnosisBuilding repairsBuilding componentsGratingFiber orientation

The invention relates to a fiber grating intelligent plate made of fiber reinforced polymer in a pulling extrusion and continuous forming mode and a manufacturing method thereof. The intelligent plate has civil engineering structural stress and self-monitoring double functions. The intelligent plate comprises a plate body composed of fiber grey yarns and matrix resin, wherein the plate body is filled with sensor fibers containing fiber grating sensors and transmission fibers in the fiber direction, the number of the sensor fibers is m, m is an integer larger than or equal to one, each sensor fiber is provided with n fiber grating sensors, and n is an integer larger than or equal to one. The intelligent plate is manufactured in a pulling extrusion and continuous forming process, the fiber volume content of the intelligent plate is no less than 60%, and the intelligent plate facilitates accurate control of tension control stress of fiber plates, compensation of lost prestress and real-time monitoring of reinforced structures when the fiber plates, especially prestress fiber plates are used for reinforcing and repairing concrete structures and steel structures.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

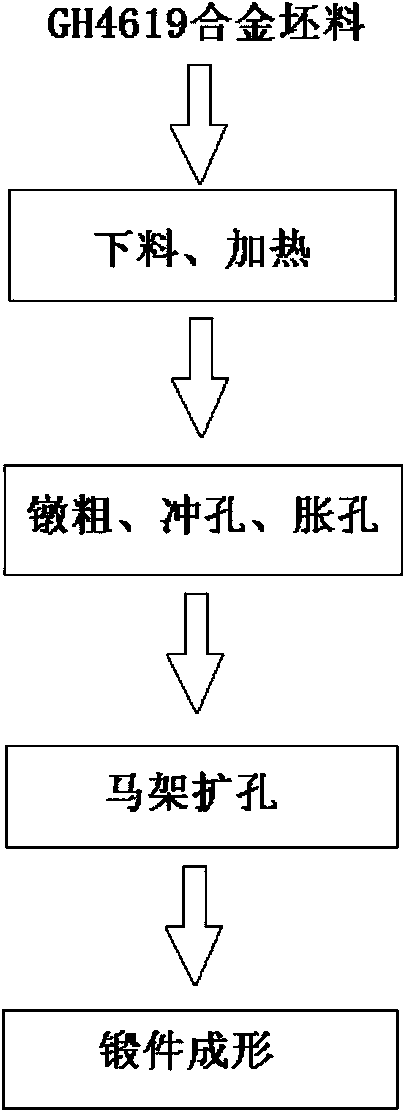

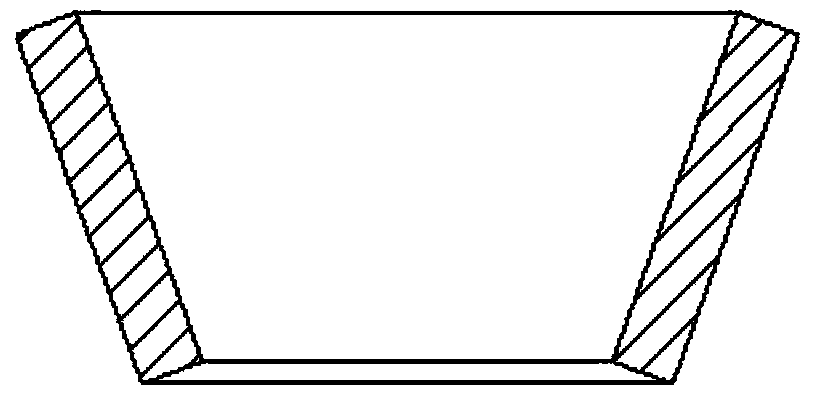

Method for manufacturing box shell of large special-shaped low-pressure turbine used for aircraft engine

The invention discloses a method for manufacturing a box shell of a large special-shaped low-pressure turbine used for an aircraft engine. A GH 4169 alloy blank is chamfered by R20mm and is heated in a three-section heating mode at the temperature of 845-855 DEG C, 975-985 DEG C and 1015-1025 DEG C, the heat-preservation time of each heating temperature section is 6min / 10mm, then upsetting, punching, hole expanding and trestle chambering are carried out, and ultimately the box shell is finished through forged forming. According to the method, a large special-shaped bearing ring supercritical rolling technique replaces a traditional rectangular ring rolling technique, part metal flow lines are complete, large amounts of mechanical machining is needless, performance is excellent, the use rate of materials is high, raw materials are saved, manufacturing cost is low, the manufacturing cycle is short, structural stress inside a product is basically eliminated, and follow-up machining performance of the product is guaranteed.

Owner:GUIZHOU AVIATION TECHN DEV

Rear casing assembly manufacturing method capable of solving problems of deformation and cracking

InactiveCN104439926AAvoid deformationReduce stress concentration stress stateAircraft componentsStress concentrationManufacturing technology

The invention provides a rear casing assembly manufacturing method capable of solving the problems of deformation and cracking and belongs to the technical field of aero-engine part manufacture. When webs and supporting board heads are preassembled, welding joint shrinkage deformation is considered in the preassembly size aspect, it is guaranteed that the size generated after welding operation is identical to the design size of an outer casing, shrinkage stress can not be generated on welding joints, stress concentration is avoided, and cracks are prevented from being generated. Due to the fact that shrinkage stress can not be generated on the welding joints, the situation that a front installation edge and a rear installation edge are deformed due to the shrinkage stress effect is avoided; an inner ring and a flat supporting board pipe are preassembled and welded, the flat supporting board pipe with the inner ring and the supporting board heads of the outer casing are assembled and welded in a butt joint mode, the welded flat supporting board pipe bears tensile stress, the tensile stress exactly counteracts pressure stress borne by the flat supporting board pipe in the operation process of an engine, the stress concentration force receiving state is reduced, and cracks and deformation are avoided. In the thermal treatment process, structural stress is distributed in a balanced mode through a thermal treatment clamp and the situation that a rear casing assembly is deformed due to stress release is avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

System for monitoring crack of piezoelectric-array converged alertness network structure and monitoring and installing methods

InactiveCN101561430APrecise structureEasy to useMaterial analysis by electric/magnetic meansForce measurement using piezo-electric devicesElectricityMonitoring system

The invention discloses a system for monitoring crack of piezoelectric-array converged alertness-network structure; on the basis of a bionic monitoring unit formed by the crossing of a plurality of mutually-insulated alertness lines, a piezoelectric array consisting of piezoelectric sensing elements is added; therefore, not only structural surface crack is accurately judged by the monitoring of the alertness line, but also structural internal stress field quantity is judged by piezoelectric signals of the piezoelectric elements, thereby acquiring analysis results such as potential bearing capacity and hazardous state pre-judgment before the crack appears and the depth and structural stress release state after the crack appears. The system can realize all-around and tri-dimensional damage detection of the engineering structure, which is a monitoring system with reliable use, high efficiency, low cost and correct result; simultaneously, the invention also discloses monitoring and installing methods of the piezoelectric-array converged alertness network structure crack monitoring system.

Owner:CHONGQING JIAOTONG UNIVERSITY

Spatial flexible filter supporting mechanism and method for mounting filter

The invention relates to a spatial flexible filter supporting mechanism, which comprises a mirror seat and at least three flexible supporting pieces, wherein each flexible supporting piece consists of a fixed end, an axial stress unloading part, a radial stress unloading part and an adhesive boss; the fixed ends are connected with the mirror seat through screws; the axial stress unloading parts are positioned between the fixed ends and the radial stress unloading parts; the adhesive bosses are arranged at the ends of the radial stress unloading parts; the part of the filter, which is close to the rim, is adhered with the adhesive bosses through adhesives; and the gravity of the filter is positioned in a polygon consisting of the adhesive bosses. The structural stress resistance and the thermal stress resistance of the filter supporting mechanism are improved; due to the flexible shock absorption function, the filter supporting structure can resist the impact shock at a rocket launch section, and can be used in the fields of designing aerospace and aviation filter supporting structures, designing structures of optical active supporting mirrors, designing structural shock absorption and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

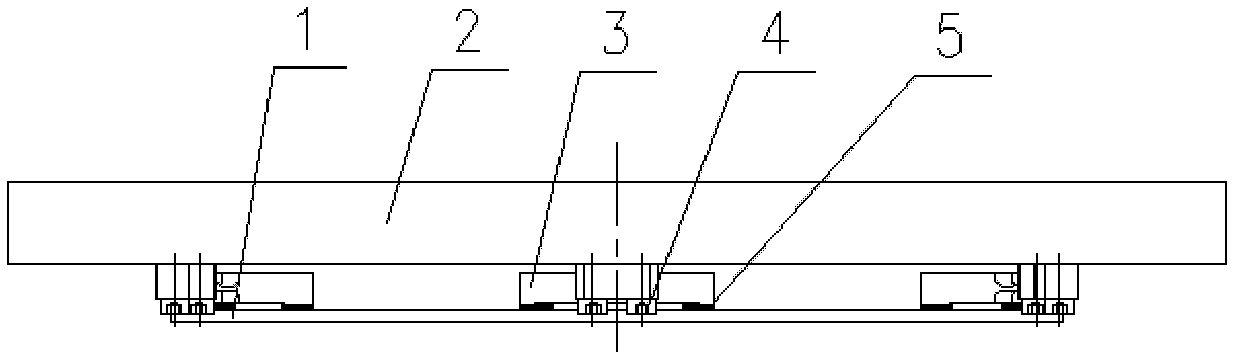

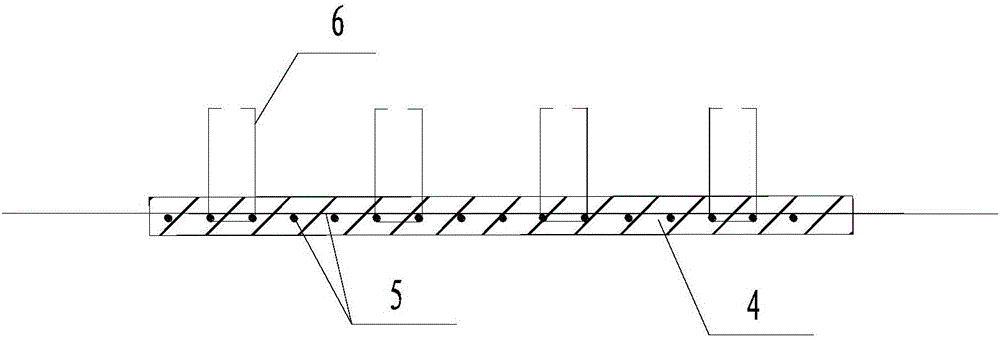

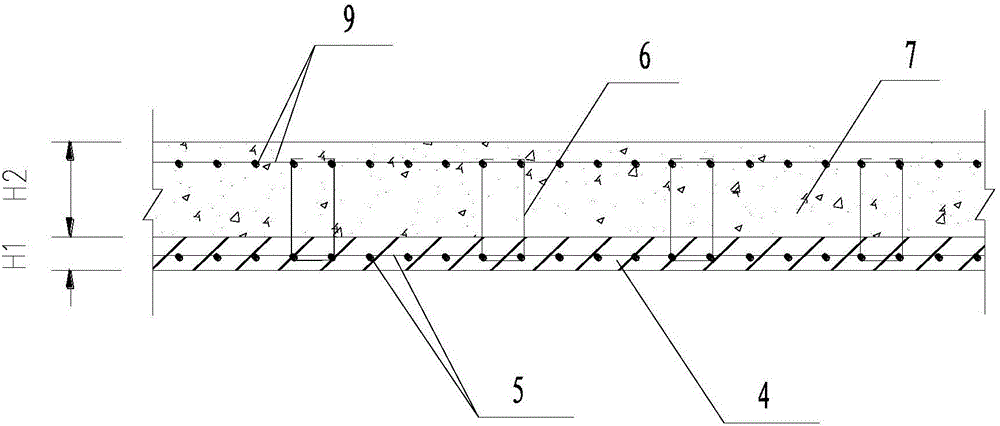

UHPC-common-concrete-lamination composite bridge-deck-slab construction and constructing method thereof

ActiveCN106638304ACancellation of transverse prestressRealize no support constructionBridge structural detailsBridge erection/assemblyBridge deckRebar

The invention discloses a UHPC-common-concrete-lamination composite bridge-deck-slab construction and a constructing method thereof. The UHPC-common-concrete-lamination composite bridge-deck-slab construction comprises UHPC prefabricated slabs, horizontal pre-embedded reinforcing steel bars, U-shaped vertical pre-embedded bars, lamination cast-in-place concrete, vertical-and-horizontal whole reinforcing steel bar nets, wet-connection-band concrete and steel-beam-flange-slab shearing nails. The steel-beam-flange-slab shearing nail are welded on the surfaces of flange slabs of steel beams, the UHPC prefabricated slabs are supported on the flange slabs of the steel beams, and the horizontal pre-embedded reinforcing steel bars between the adjacent UHPC prefabricated slabs are in lap joint; the vertical-and-horizontal whole reinforcing steel bar nets are arranged on the flange slabs of the steel beams and the UHPC prefabricated slabs and poured with the lamination cast-in-place concrete, and the UHPC prefabricated slabs are poured with the wet-connection-band concrete. A UHPC-common-concrete-lamination composite bridge deck slab has the advantages that the structural stress performance is excellent, the weight of the bridge deck slab is light, the performance cost ratio is high, shear transferring is continuous, transverse prestress is not required, and support-free constructing can be achieved, cooperative work of the steel beams and the concrete bridge deck slab can be achieved, and carrying capacities of composite beams are improved.

Owner:SOUTHEAST UNIV

Calibration method and device of embedded-type long-distance optical fiber sensor

The invention discloses a calibration method of an embedded-type long-distance optical fiber sensor. The calibration method comprises the following steps of: (A) embedding tensed micro-pipes and pressed micro-pipes along the length direction of a reinforced concrete beam; (B) respectively pasting resistance-type strain gauges on the surface of tensed reinforced concrete bars and pressed reinforced concrete bars; (C) casting the reinforced concrete beam; penetrating sensor optical fibers to be calibrated; (D) pasting a resistance-type strain gauge on the outer surface of the reinforced concrete beam; (E) applying a load to the midspan of the reinforced concrete beam; (F) collecting the stress data of the optical fibers under every load level and comprehending temperature; (G) collecting the stress data of all the resistance-type strain gauges under every load level; and (G) fitting the data acquired by the step (F) and the step (G) to acquire the stress transfer coefficient of the sensor optical fiber to be calibrated. The invention can calibrate the embedded-type long-distance optical fiber sensor formed by the tensed micro-pipes in different pipe diameters and the sensor optical fibers of different types and realize the accurate measurement of structural stress.

Owner:ZHEJIANG UNIV

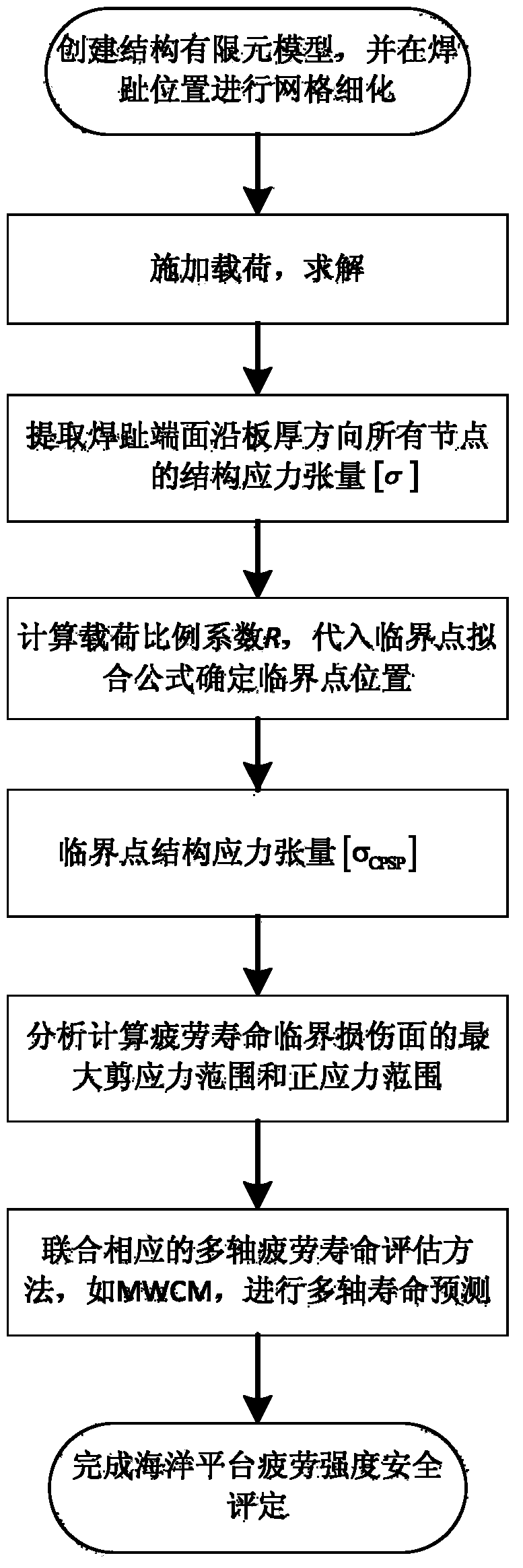

Welding structure multi-axial fatigue life evaluation method

The invention discloses a welding structure multi-axial fatigue life evaluation method. The method includes the following steps that a finite element model of a welding structure to be measured is established; multiple test loads are applied to the welding structure, and structural stress tensors [sigma] of all joints of the end face of a weld toe in the board thickness direction are obtained through solving; corresponding load proportionality coefficients R of the joints are worked out according to the structural stress tensors [sigma] of the joints, and then the position of a stress peak critical point is determined; the structural stress tensor [sigma CPSP] of the stress peak critical point is obtained through the interpolation method; the maximum shear stress and normal stress range of a fatigue life critical damage plane are worked out according to the structural stress tensor [sigma CPSP] of the stress peak critical point, and multi-axial fatigue life evaluation is carried out through the union multi-axial fatigue life evaluation method MWCM.

Owner:DALIAN UNIV OF TECH

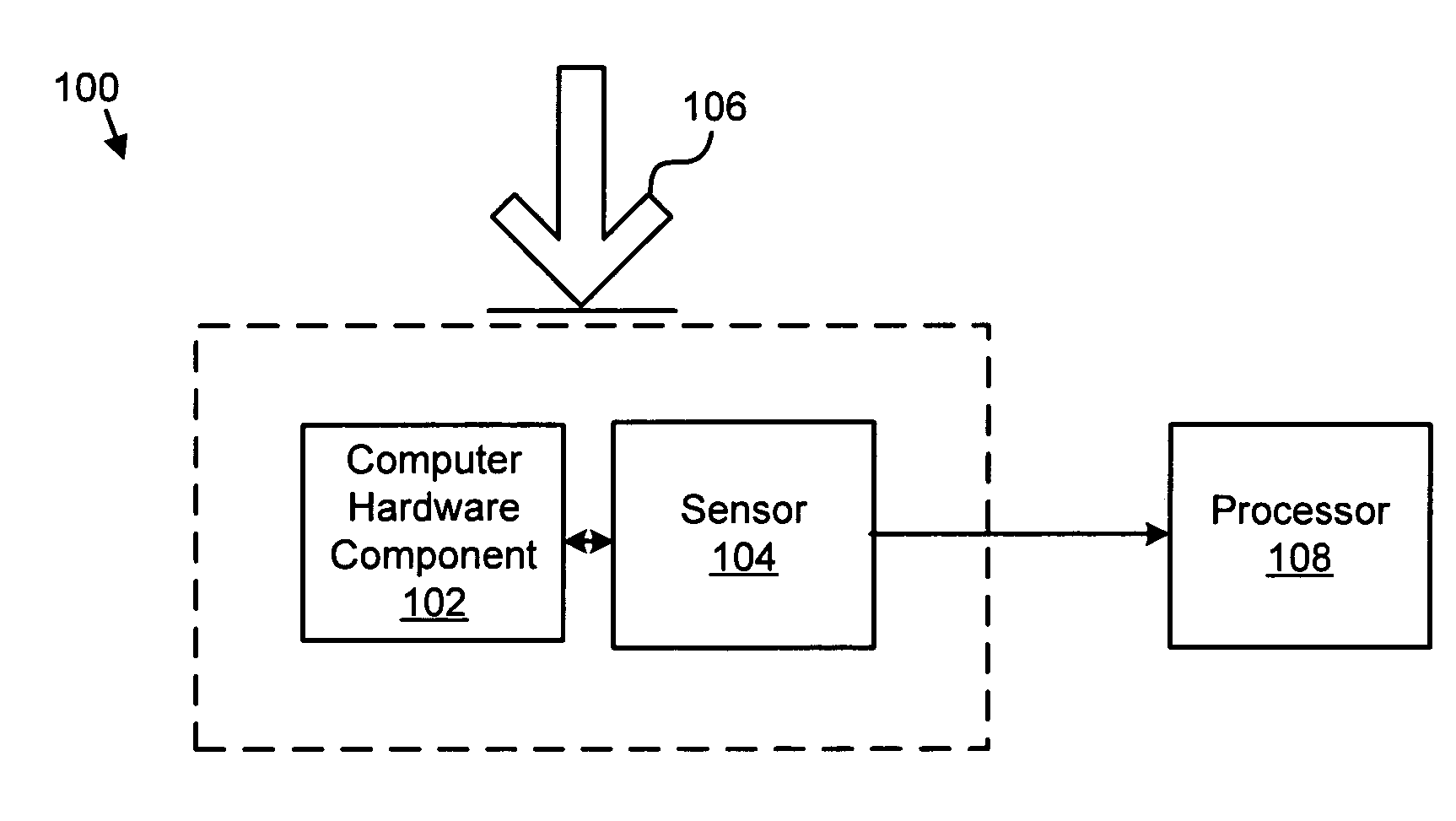

Apparatus, system, and method for identifying structural stress conditions for computer hardware

An apparatus, system, and method are disclosed for identifying structural stress conditions for computer hardware. The apparatus includes a plurality of modules configured to functionally execute the necessary steps of monitoring a physical condition affecting a computer hardware component, recognizing a potential damage condition based on a threshold, and responding to the potential damage condition. These modules in the described embodiments include a monitoring module, a recognition module, and a response module. Beneficially, such an apparatus, system, and method would identify potential damage conditions and alert a user to the potential damage condition before physical damage to the computer hardware component occurs. The user can then alleviate the physical condition affecting the computer component and avoid component damage.

Owner:LENOVO PC INT

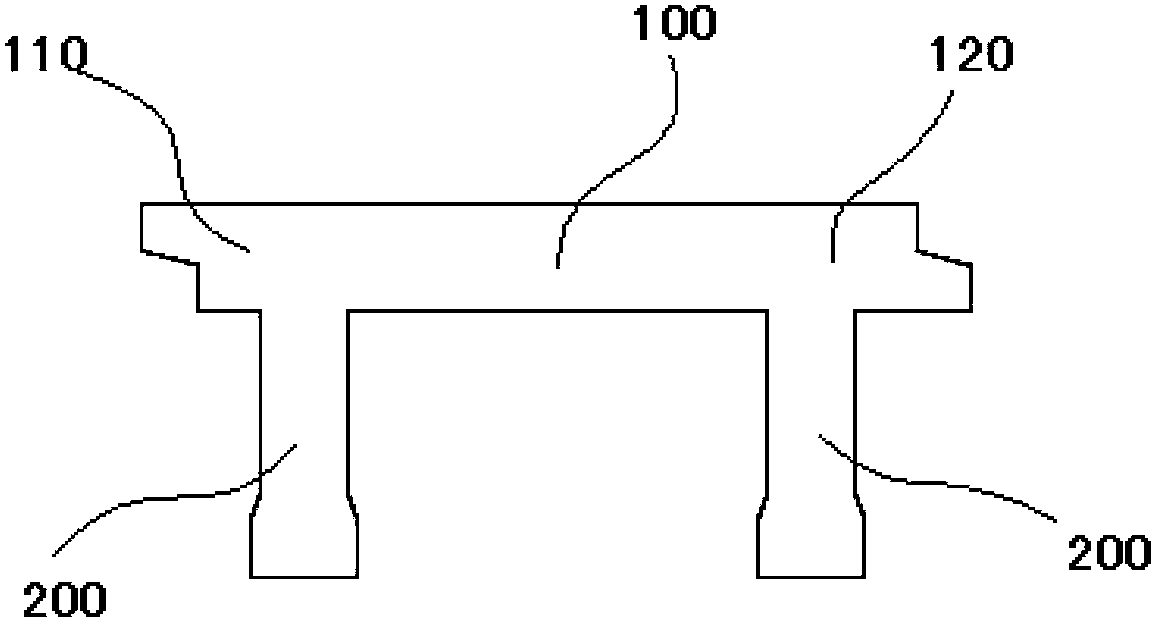

Pi-shaped concrete pile

InactiveCN103726488AWith load-bearing functionImprove bending resistanceArtificial islandsUnderwater structuresEngineeringUltimate tensile strength

The invention discloses a pi-shaped concrete pile which is made of concrete and comprises a pile body with a pi-shaped cross section. The pile body is composed of a cross beam located on the upper portion of the pile body and a supporting leg component located on the lower portion of the pile body and connected with the cross beam, the two sides of the cross beam are provided with a first connecting portion and a second connecting portion playing a connection role respectively, a gap is formed between matching faces of the first connecting portion and the second connecting portion, the matching faces are matched in shape in an abutting against mode, and the gap is filled with concrete grout and water-stopping rubber bars or sealing materials. The cross section of the pile body is in the pi shape, and the pile body has high bending resistance and high shear resistance in structural stress, and has a certain load bearing function. In addition, the connecting portions on the two sides are equivalent to buckling plates, the gap can be formed between the connecting portions after connectors are spliced and can be filled with the grout materials or other connecting materials, the water stopping effect and connecting strength can be guaranteed, and the pile can be used as a permanent supporting structure.

Owner:SHANGHAI ZHONGJI PILE IND

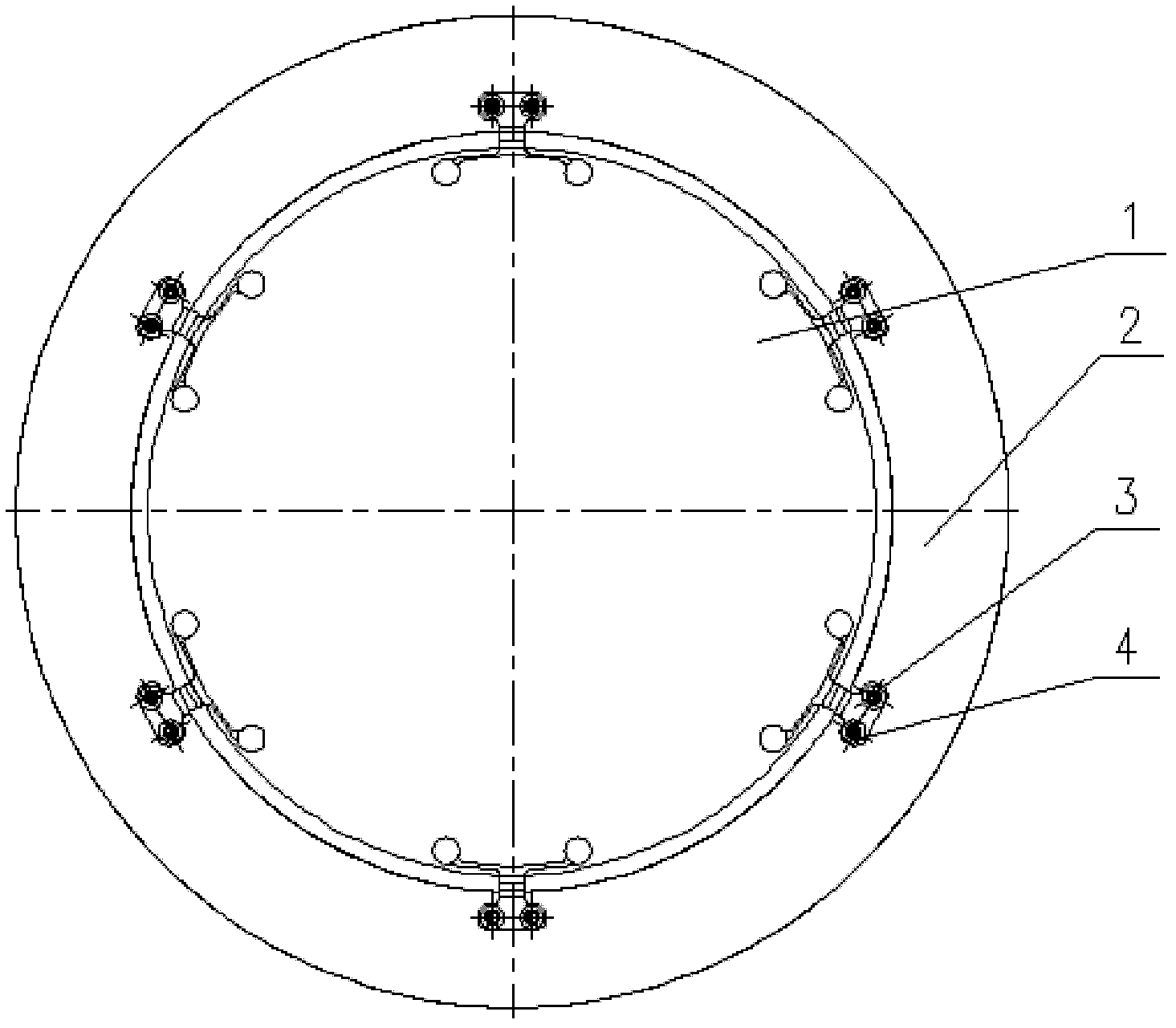

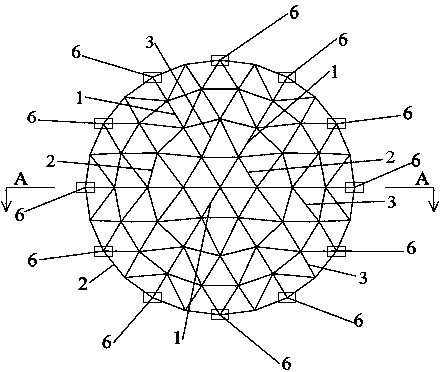

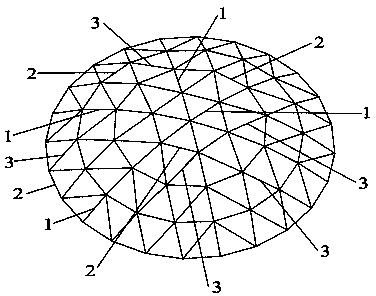

Bamboo-structure single-layer spherical latticed shell and assembling method

InactiveCN103469890ALight weightReduce labor intensityBuilding roofsArched structuresEngineeringStructural stress

The invention relates to a bamboo-structure single-layer spherical latticed shell and an assembling method. The bamboo-structure single-layer spherical latticed shell structurally comprises L bamboo rod pieces, M bamboo connecting pieces and N fixed hinge supports, wherein a single-layer spherical latticed shell main body is formed in a way that two ends of each radial bamboo rod, each weft bamboo rod and each diagonal bamboo rod of the L bamboo rod pieces are connected through the bamboo connecting pieces; the bamboo connecting pieces comprise steel inserting pieces, hollow balls, stiffening steel sheets and bolts; arc-shaped notches are reserved at one ends of the steel inserting pieces and are welded on the hollow balls; bolt holes are reserved at the other ends of the steel inserting pieces, and the bolts are respectively connected to the radial bamboo rods, the weft bamboo rods and the diagonal bamboo rods through the bolt holes; the stiffening steel sheets are welded in connecting positions between the steel inserting pieces and the radial bamboo rods, the weft bamboo rods as well as the diagonal bamboo rods; the upper ends of multiple fixed hinge supports are arranged on the hollow balls of the bamboo connecting pieces which are arranged at the bottom part, and the lower ends of the multiple fixed hinge supports are arranged at the top part of a supporting structure which is arranged at the lower part. The bamboo-structure single-layer spherical latticed shell disclosed by the invention has the advantages that the self weight is light, the construction is convenient, the structural stress is reasonable, the safety is high, the connecting joint is simple and reliable, the maintenance is easy, and environment-friendly effects are realized.

Owner:NANJING FORESTRY UNIV

System and method for embedding optical fiber grating sensor in fiber high polymer composite material

InactiveCN101738214ASimplify the manufacturing processEasy to embedForce measurementUsing optical meansFiber bundleGrating

The invention discloses a system for embedding an optical fiber grating sensor in a fiber high polymer composite material, which comprises a fiber frame, a fiber guiding stranding device, a resin impregnating bath, a fiber tension distributor, a pultrusion die head, a degumming device, a thermosetting device and a towing device through which a fiber bundle and an optical fiber grating sensor sequentially pass, wherein a leading-in die pin is built in the pultrusion die head. The invention also discloses a corresponding method which comprises the following steps: when the fiber bundle and the optical fiber grating sensor enter the pultrusion die head, the fiber bundle is dispersed on the peripheral circumference of the leading-in die pin; the optical fiber grating sensor penetrates out from a leading-in hole of the leading-in die pin and is led into the fiber bundle; the optical fiber grating sensor is wrapped in the fiber bundle and passes through the pultrusion die head together withthe fiber bundle; and finally, the optical fiber grating sensor embedded fiber high polymer composite material is produced. The optical fiber grating sensor embedded fiber high polymer composite material produced in the invention can be used as a structural stress part and can also be widely applied to health monitoring of constructions and structures of buildings, roads, bridges and the like.

Owner:SHANGHAI KNP CHEM +3

Method for replacing building shock insulation rubber support

ActiveCN104018434AGuaranteed StrengthAvoid uneven forceBuilding repairsBridge structural detailsDesign loadStructural stress

The invention belongs to the technical field of methods for replacing rubber supports, and discloses a method for replacing a building shock insulation rubber support. The method is mainly technically characterized in that supporting force generated when temporary support bodies are arranged is the same as the design load of the building shock insulation rubber support, then the support is demounted, concrete on the top of a pier column is removed at the same time, a new shock insulation rubber support is jacked through force measurement jacks, the design load is reached, a pier top and pre-buried boards are connected, concrete is poured to the pier top and the pre-buried boards, and finally the temporary support bodies are demounted. By the adoption of the mode of combining column top descending with support jacking, space is provided for replacement of the support, stress evenness of supports for supporting a building is guaranteed, the situation that the structural stress changes due to the fact that one support does not bear force is avoided, needed jacking force of the jacks is small, replacement is quick and safe, and construction cost is low.

Owner:丰泽智能装备股份有限公司

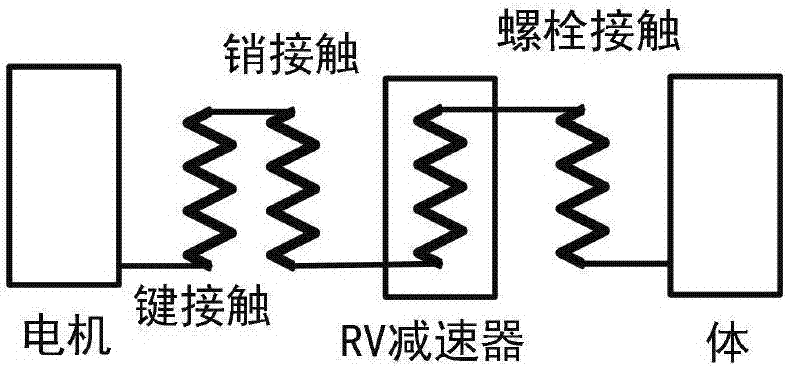

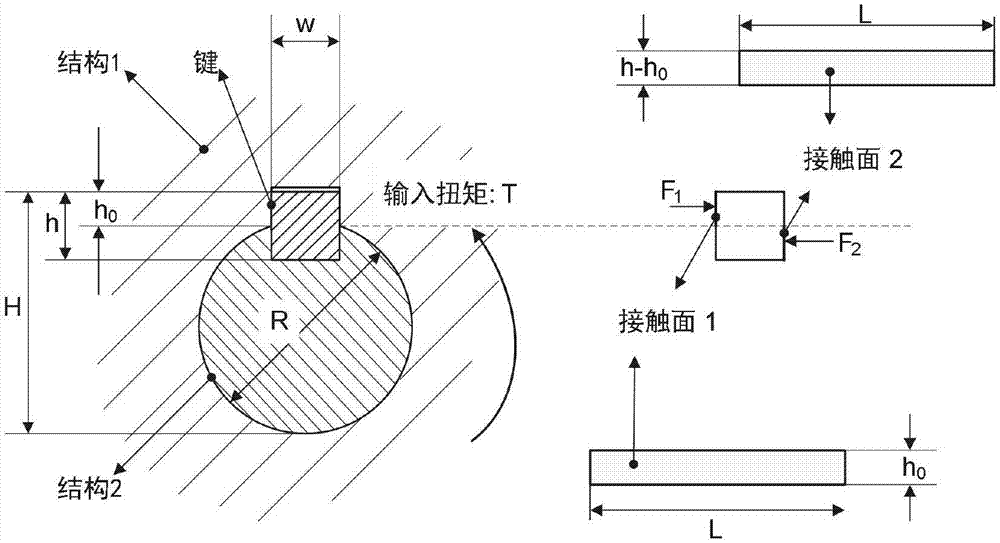

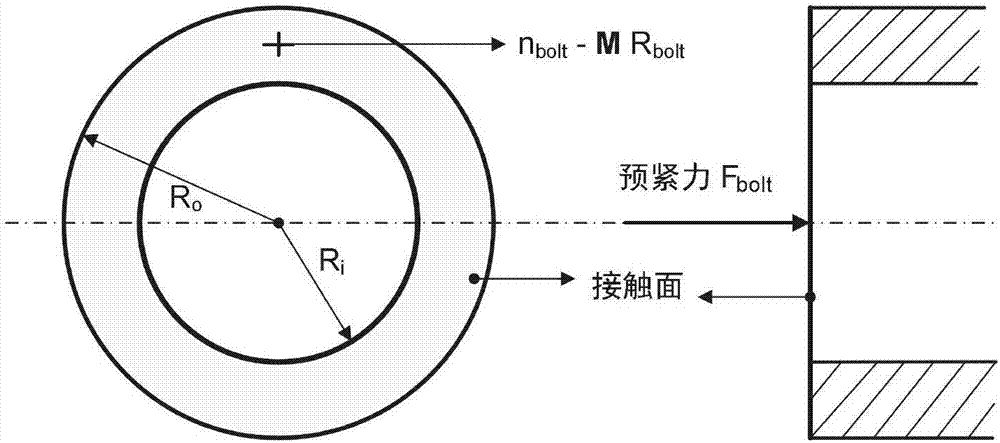

Industrial robot joint rigidity modeling method which considers contact

ActiveCN107545127AAccurate Theoretical Estimation of Joint StiffnessProgramme-controlled manipulatorSpecial data processing applicationsContact pressureAnalysis study

The invention discloses an industrial robot joint rigidity modeling method which considers contact, and belongs to the field of industrial robot dynamic characteristic analysis study. By extracting key contact structure characteristics of each industrial robot joint, contact structures are assumed to be spring structures with a certain torsional rigidity, and an equivalent system model of all thejoints is built. According to measurement data, based on a power spectrum density method, three-dimensional surface fractal parameters and surface roughness parameters are calculated. All the contactstructures are subjected to stress analysis, and all contact pressure values corresponding to different joint input torques of the contact structures are calculated. By building an equivalent torsional rigidity model of springs in parallel connection and by making all contact rigidity and a reducer rigidity connected in parallel, a joint equivalent torsional rigidity is calculated. Through the combination of a fractal theory and structural stress analysis, an industrial robot joint rigidity model is built, by considering a contact rigidity, a more accurate theoretical estimation joint rigidityis calculated, and a certain method basis is provided for dynamic error compensation analysis at the tail end of the robot.

Owner:BEIJING UNIV OF TECH

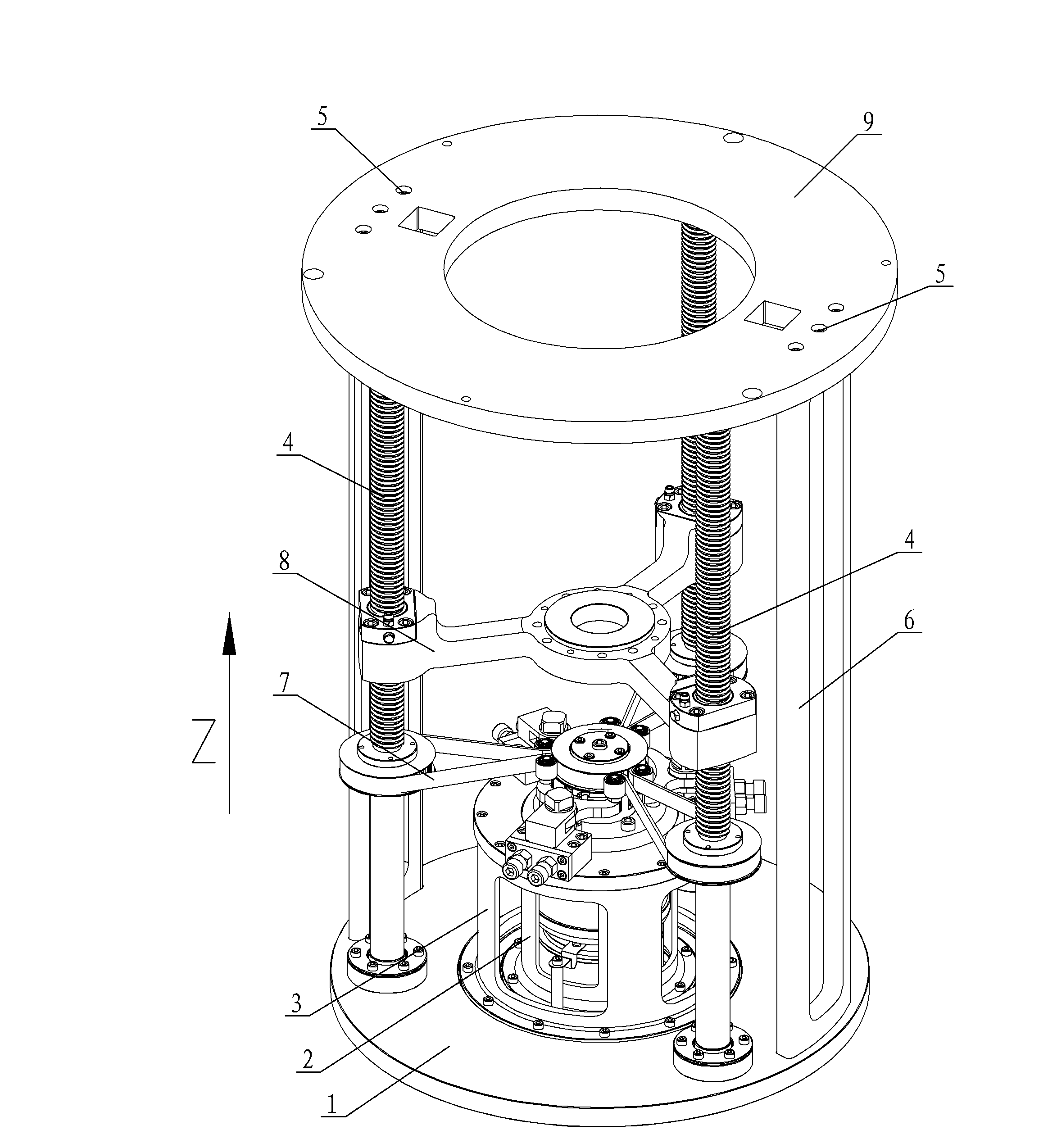

Z-axis lifting mechanism with stress state balancing function

InactiveCN102623375ACorrect the problem of unstable center of gravityStable center of gravityGearingConveyor partsBall bearingBall screw

A Z-axis lifting mechanism with a stress state balancing function relates to the manufacturing field of semiconductor silicon wafer transmission robots, and solves the problems of a conventional Z-axis transmission lifting mechanism, such as poor structural stress state and larger micro-deformation of ball guide rails. The Z-axis lifting mechanism with the stress state balancing function adopts the structure that an upper mounting cover and a lower mounting cover are oppositely arranged up and down, a Z-axis driving device component is connected with a lower mounting seat, a pre-tightening wheel support frame is sleeved on the Z-axis driving device component and connected with the lower mounting seat, three lead screw transmission mechanisms are uniformly distributed between the upper mounting cover and the lower mounting cover along the same circumference, the center end of a synchronous gear transmission belt is sleeved on a synchronous transmission driving gear, three outer side ends of the synchronous gear transmission belt are respectively sleeved on three synchronous transmission driven gears, three ball screws are respectively in threaded connected with three turn-screws; a lower deep-groove ball bearing is mounted in a lower bearing mounting hole of the lower mounting seat, and an upper deep-groove ball bearing is mounted in an upper bearing mounting hole. The Z-axis lifting mechanism provided by the invention is used on a silicon chip transmission robot.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com