Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

655results about How to "Avoid uneven force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

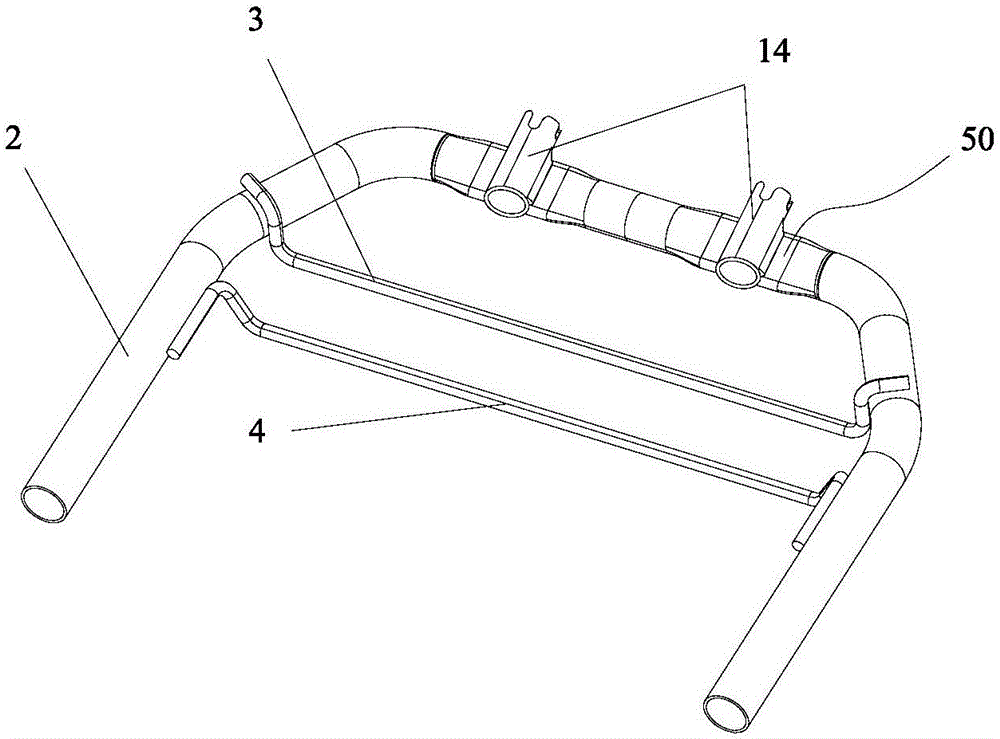

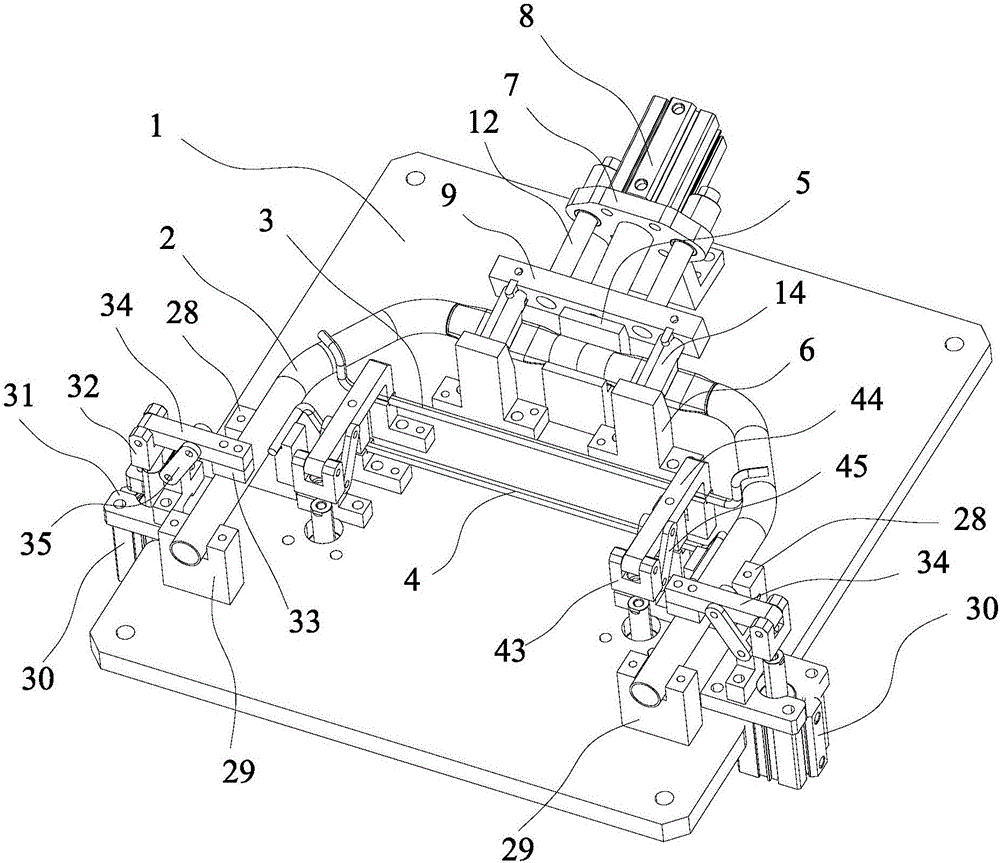

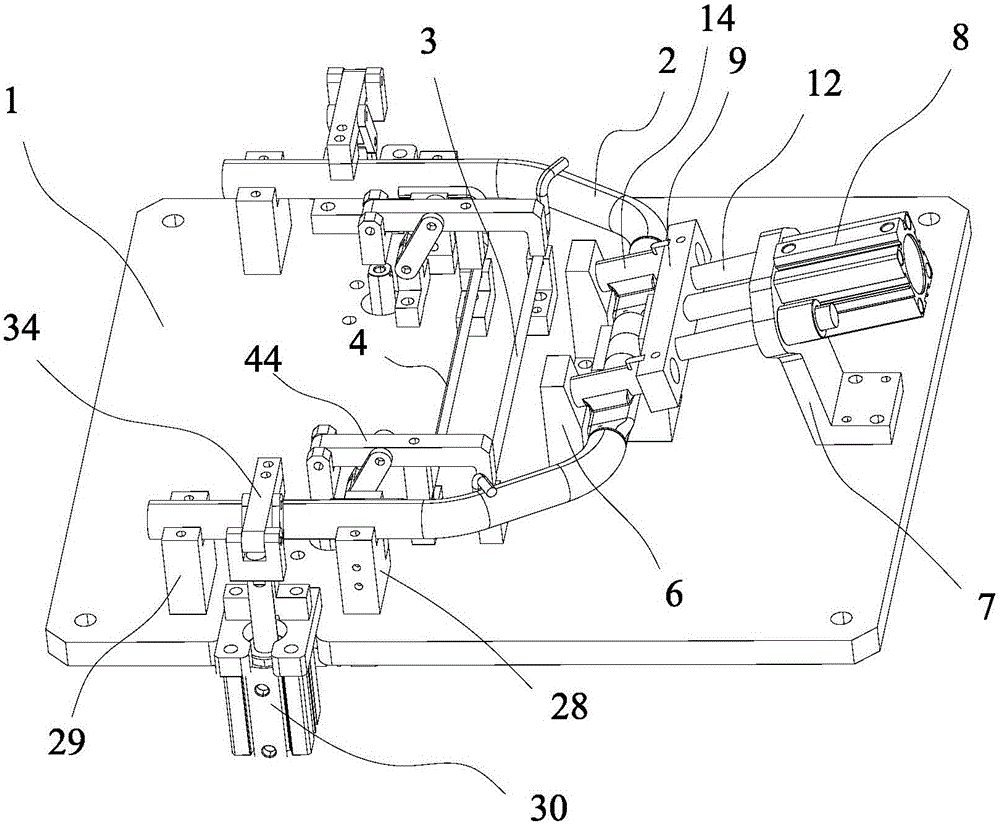

Welding tool for production of automobile seat framework

ActiveCN106112371AEnsure consistencyGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesLap jointEngineering

The invention discloses a welding tool for production of an automobile seat framework. The welding tool for production of the automobile seat framework comprises a base (1), a feed clamping device, two side section clamping devices and a supporting bar clamping device, wherein the feed clamping device is provided with a sleeve (14) in advance and pushes the sleeve to the position above a slope (50) of the bottom section of a U-shaped bent pipe (2) in the automobile seat framework, the two side section clamping devices are used for fixedly clamping two side sections of the U-shaped bent pipe (2), and the supporting bar clamping device is used for fixedly clamping a first supporting bar (3) and a second supporting bar (4) so that the two ends of the first supporting bar (3) and the two ends of the second supporting bar (4) can be in fixed lap joint to the two side sections of the U-shaped bent pipe (2) correspondingly. By the adoption of the structure, the U-shaped bent pipe, the first supporting bar and the second supporting bar can be fixedly clamped, and therefore the welding tool for production of the automobile seat framework can guarantee fixed clamping of the U-shaped bent pipe and the welding precision and the product consistency of the first supporting bar and the second supporting bar during automatic welding.

Owner:宁波明望汽车饰件有限公司

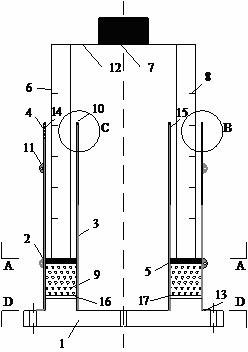

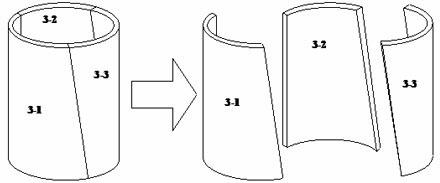

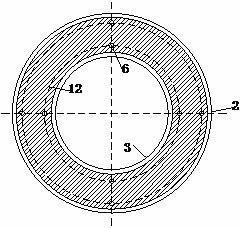

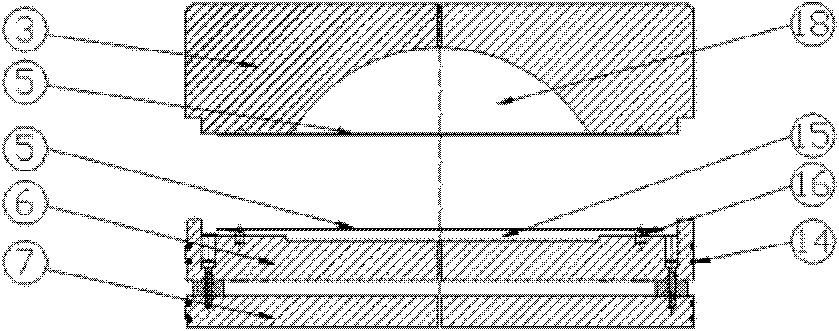

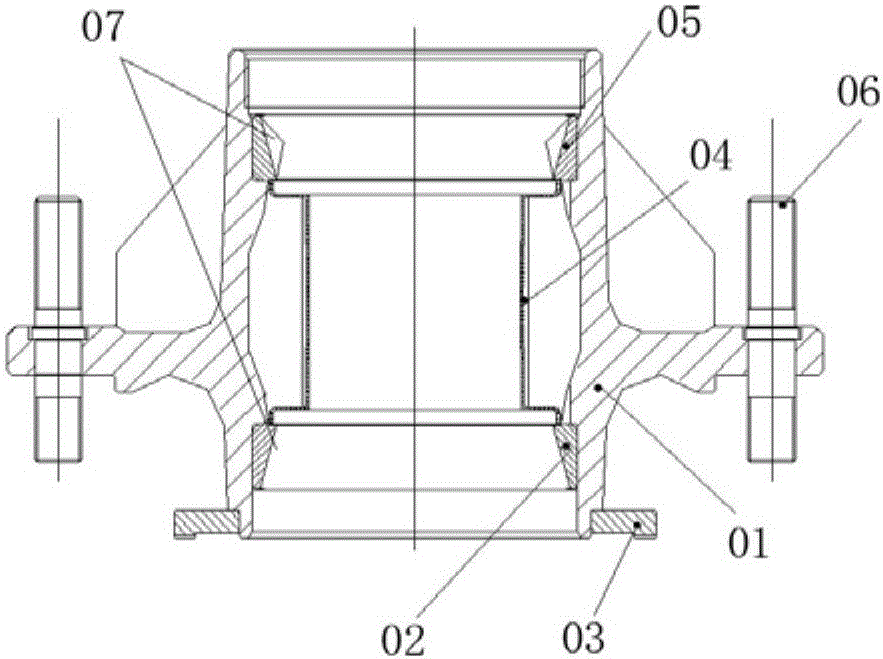

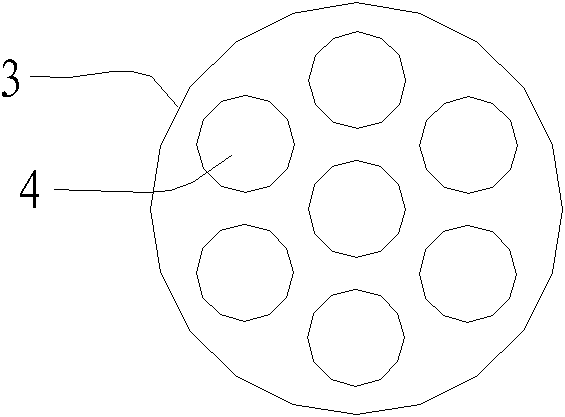

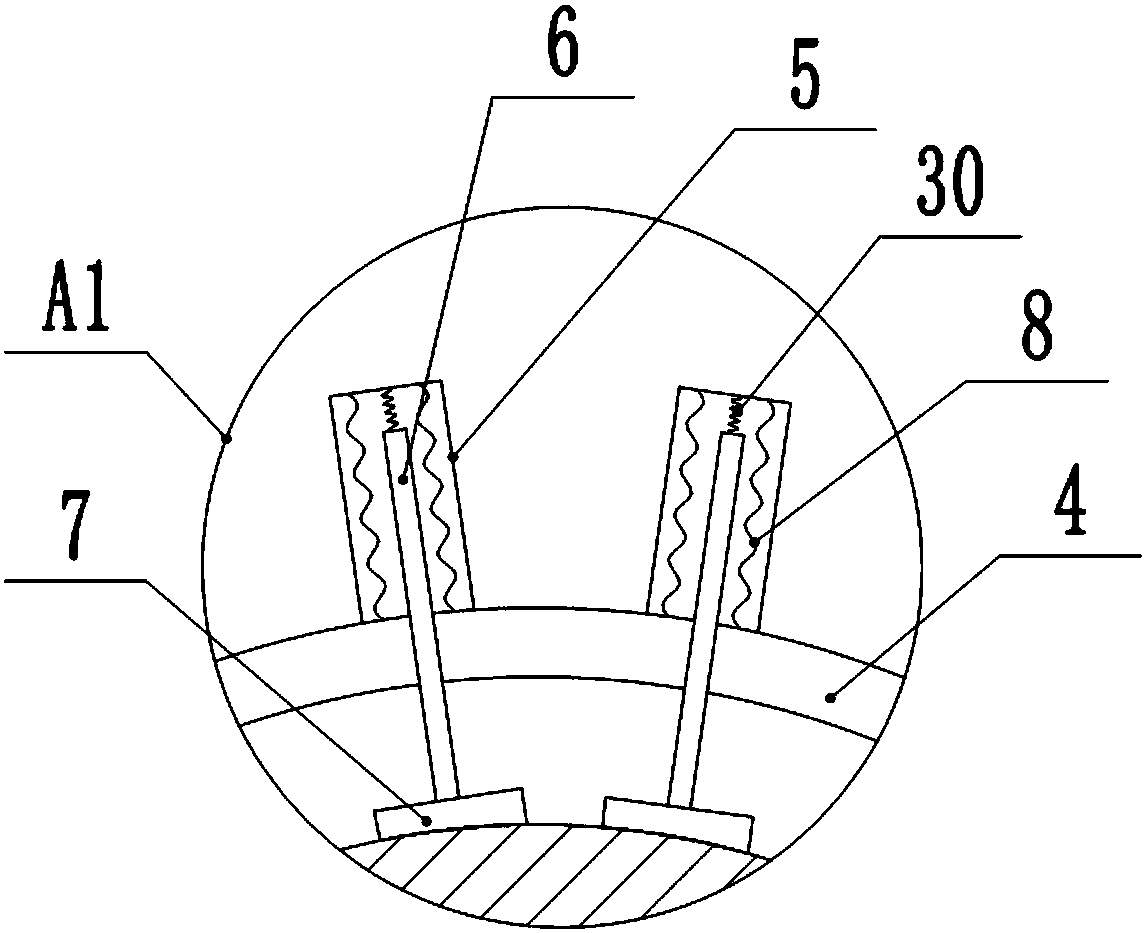

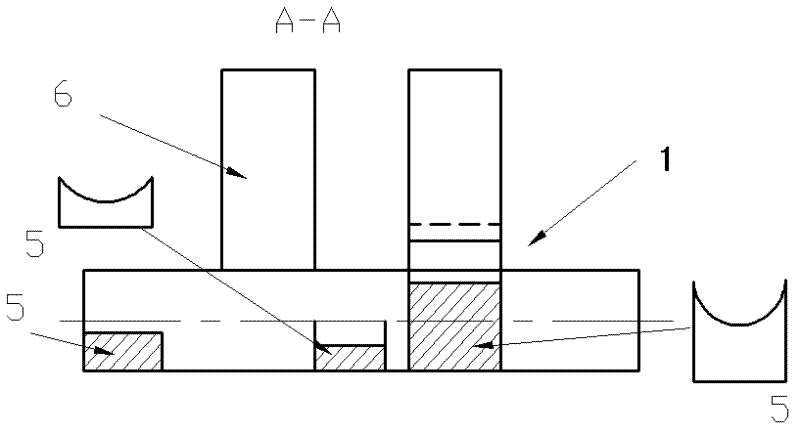

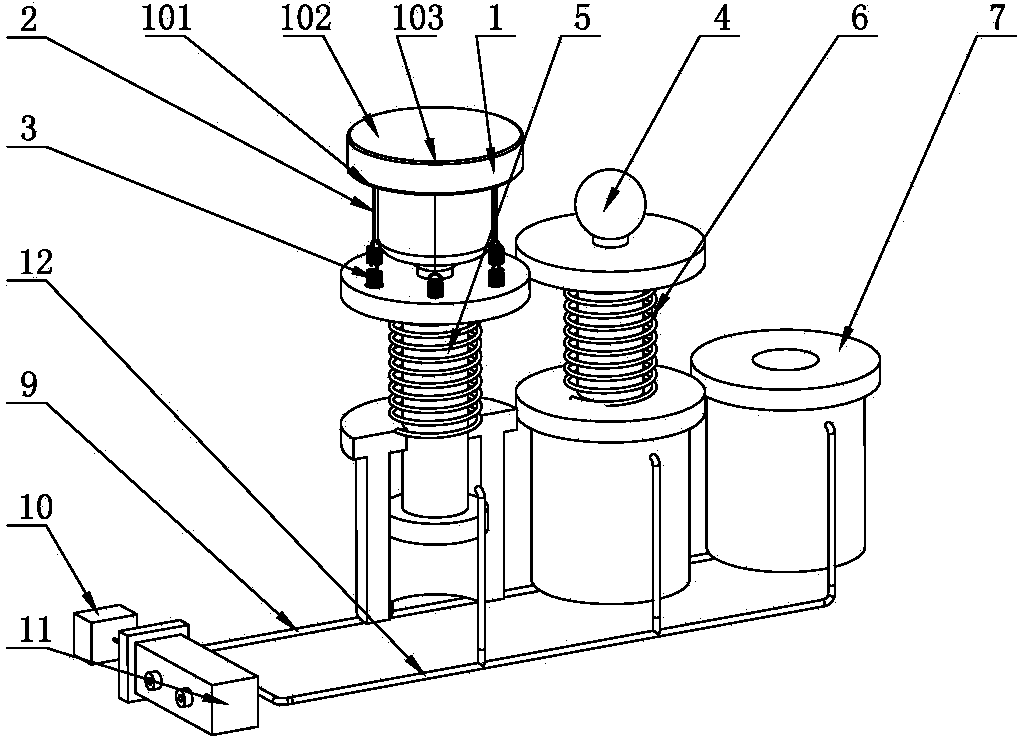

A large hollow cylinder sample maker for coarse-grained soil and its use method

ActiveCN102288461AAvoid uneven forceFlexible accessPreparing sample for investigationSoil scienceTest sample

The invention discloses a large-sized hollow cylindrical sampler for coarse grained soil and a use method thereof. The sampler comprises an annular sleeve and a vibrating compacter, two parts in all, wherein the annular sleeve comprises an annular base (1), an annular outer sleeve (2), an annular inner sleeve (3) and an annular extension barrel (4); and the vibrating compacter comprises a vibrating motor (7), a circular iron plate (12), a dowel bar (6), a positioner (8) and an annular iron plate (5). While using the instrument, a soil sample (9) is paved at first and then put into the annulariron plate (5); next, the vibrating motor (7) is turned on; when the edge of the annular outer sleeve (2) is level with the positioner (8), the vibrating motor (7) stops vibration and the next layer of soil sample (9) is added; and then vibration compaction is performed until the soil samples reach a predetermined height. The sampler is simple to use, convenient for operation and control, and capable of preparing a highly compact and even test sample, so that the time and labour for preparing the test sample are saved.

Owner:HOHAI UNIV

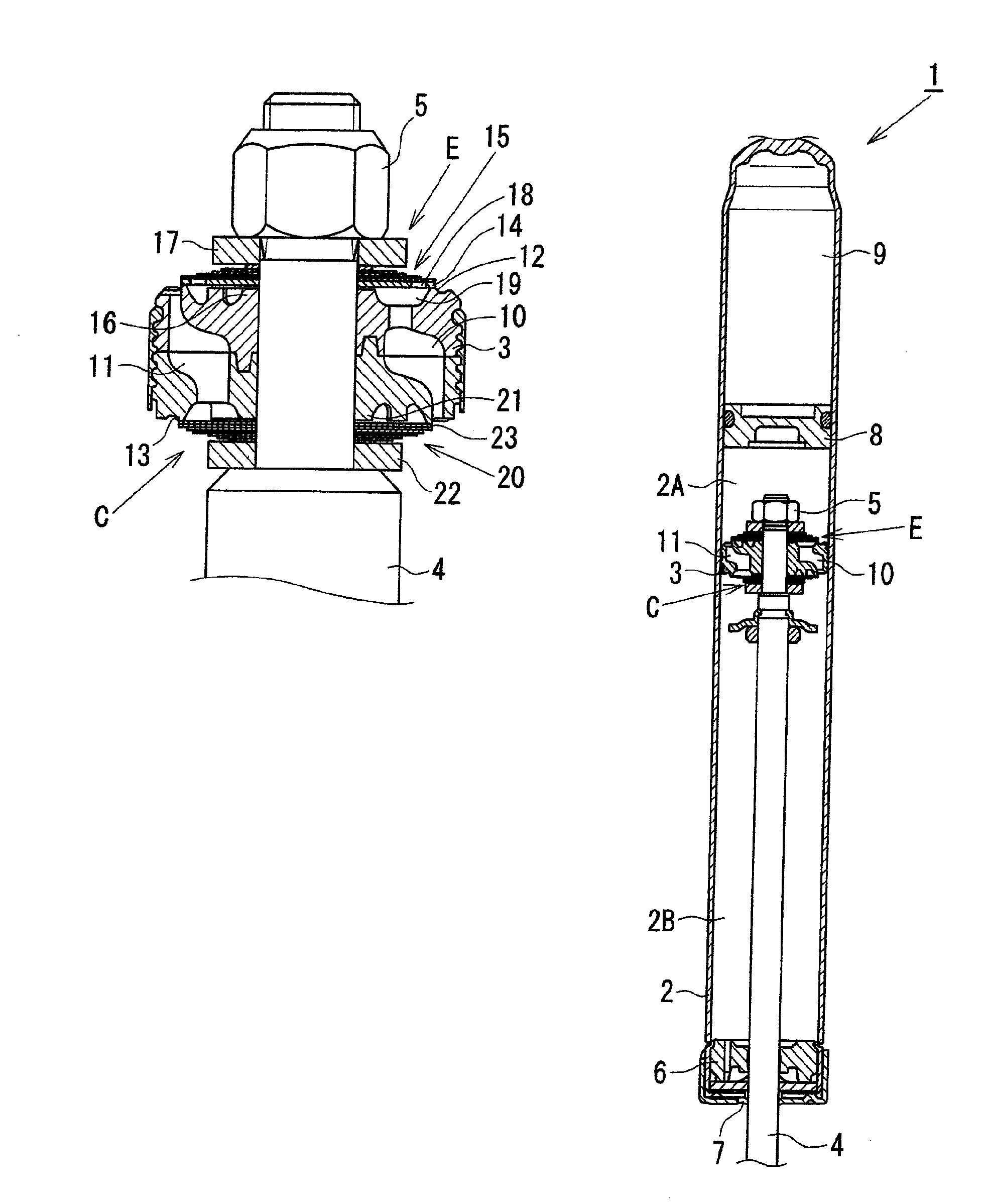

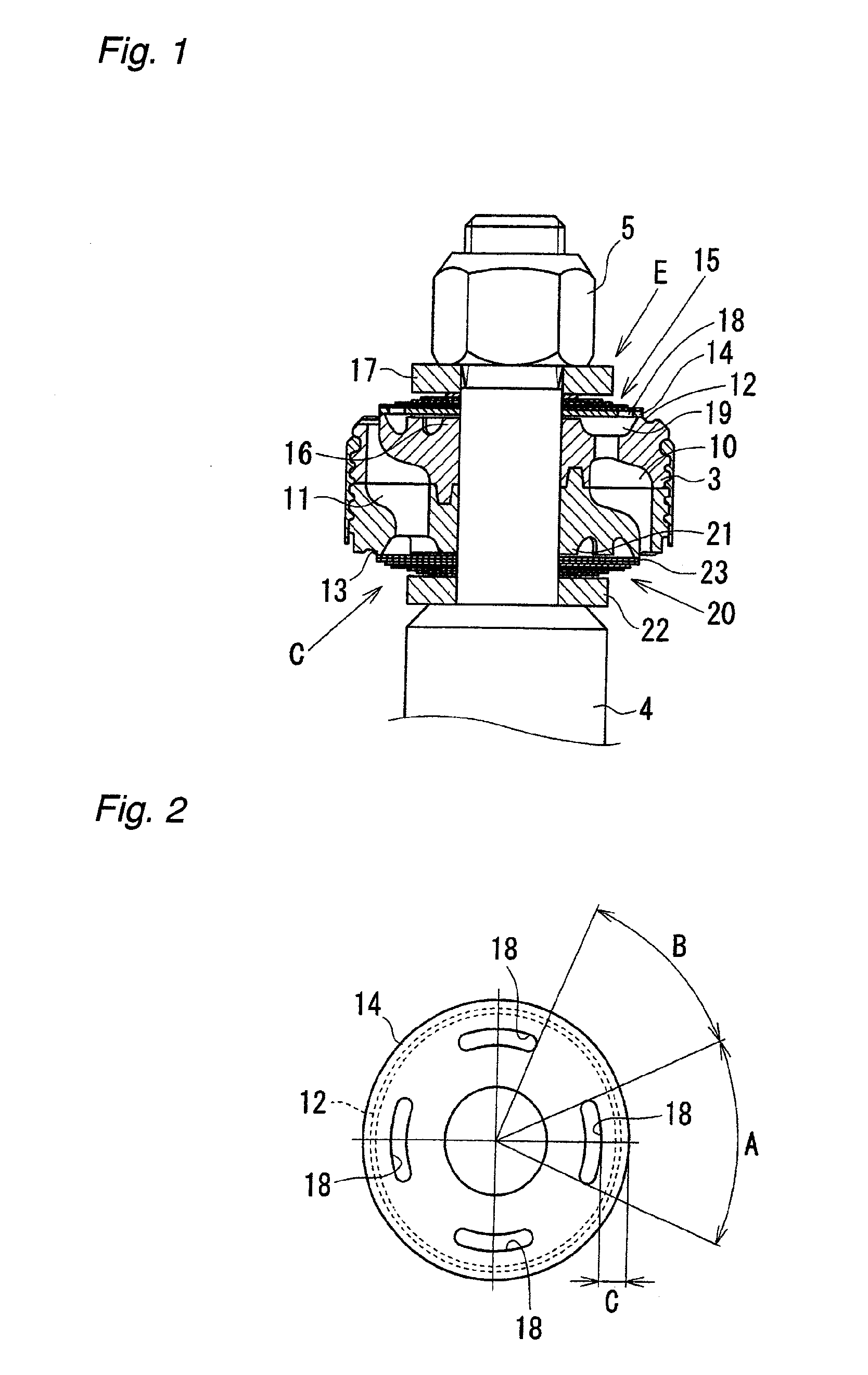

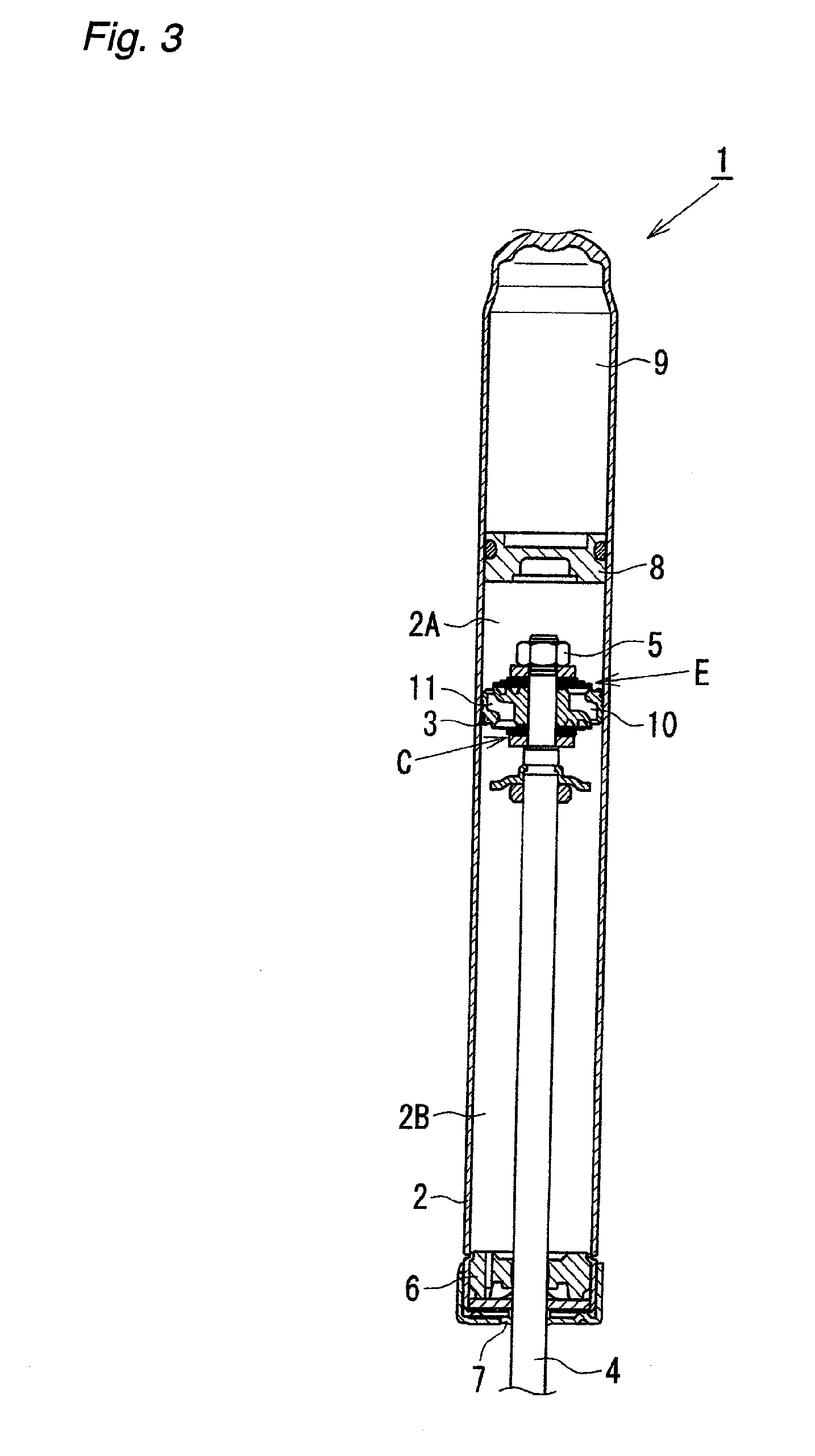

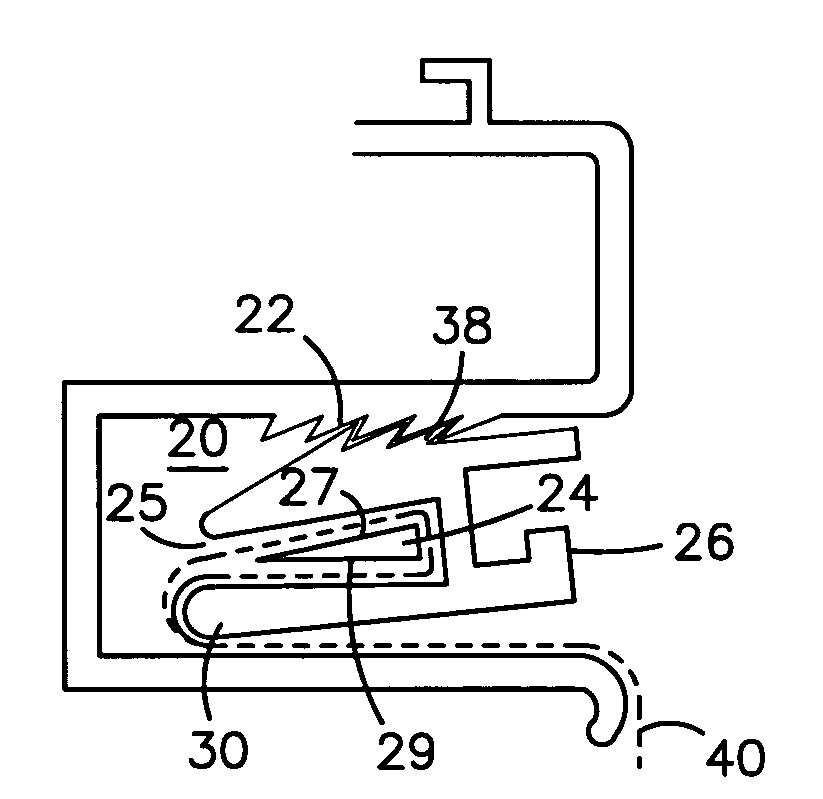

Shock absorber

InactiveUS20090260938A1Avoid drastic changesSmooth damping force characteristicSpringsShock absorbersTransitional RegionEngineering

A shock absorber has a seat disk seated on a valve seat of a piston. A disk valve opens and closes a slot provided in the seat disk to extend in the circumferential direction thereof. In a low piston speed region, an orifice passage generates a damping force of orifice characteristics. In an intermediate piston speed region, the disk valve opens to generate a damping force of valve characteristics. In a high piston speed region, the seat disk opens to prevent an excessive increase in damping force. The disk valve partially opens the slot relative to the circumferential direction to gradually increase the flow path area, thereby preventing a sharp change in damping force in a transitional region from the low to intermediate piston speed region.

Owner:HITACHI LTD

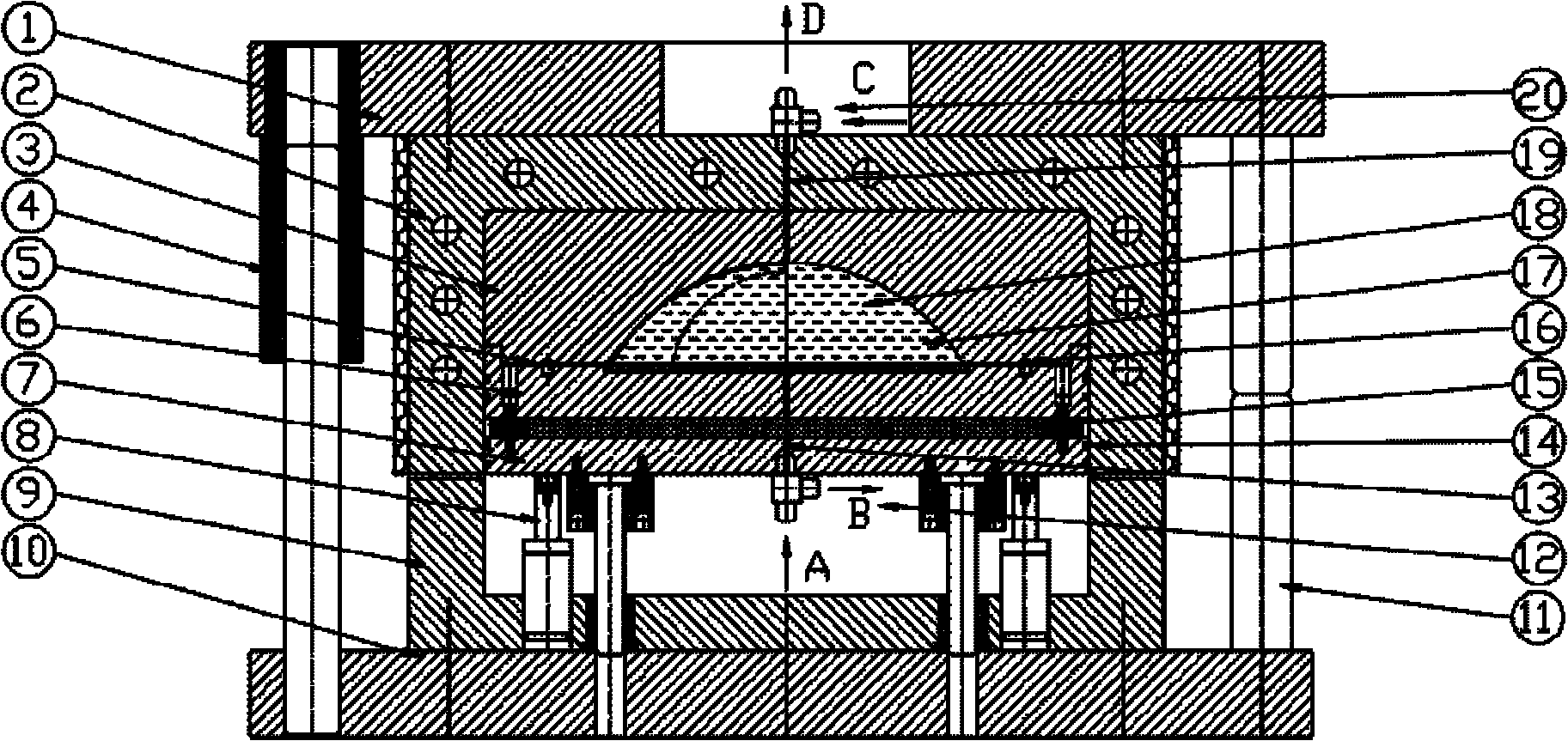

High-pressure gradual change forming device for inside of sheet

The invention relates to a high-pressure gradual change forming device for the inside of sheet, which belongs to the technical field of metal forming. The high-pressure gradual change forming device comprises an upper die assembly, a lower die assembly, a guide mechanism and a plate pressing mechanism, wherein the upper end and the lower end of the guide mechanism are respectively movably connected with the upper die assembly and the lower die assembly; the plate pressing mechanism is movably arranged on the lower die assembly and is directly opposite to the upper die assembly; and the sheet to be pressed is positioned between the upper die assembly and the plate pressing mechanism. A pressure medium is adopted for forming in the forward direction and the backward direction, the forward pressure medium in a lower hydraulic chamber has the effects that force on the sheet is balanced and the imbalanced force on the edge of a rigid convex die can be avoided; and the backward pressure medium in an upper hydraulic chamber has the effect on preventing a part of the sheet contacting a concave die to cause the part of the sheet to be seriously deformed and damaged.

Owner:SHANGHAI JIAO TONG UNIV

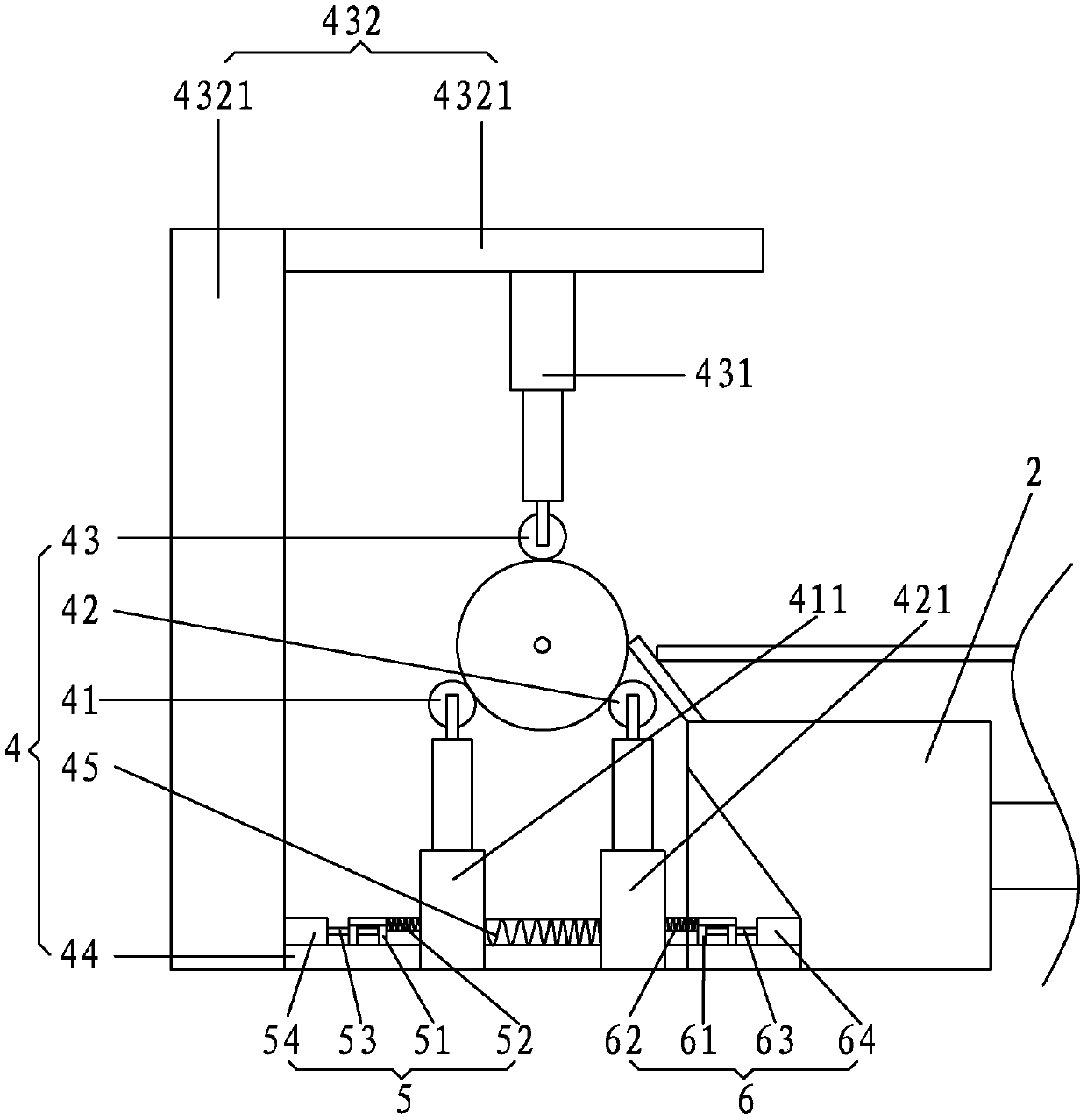

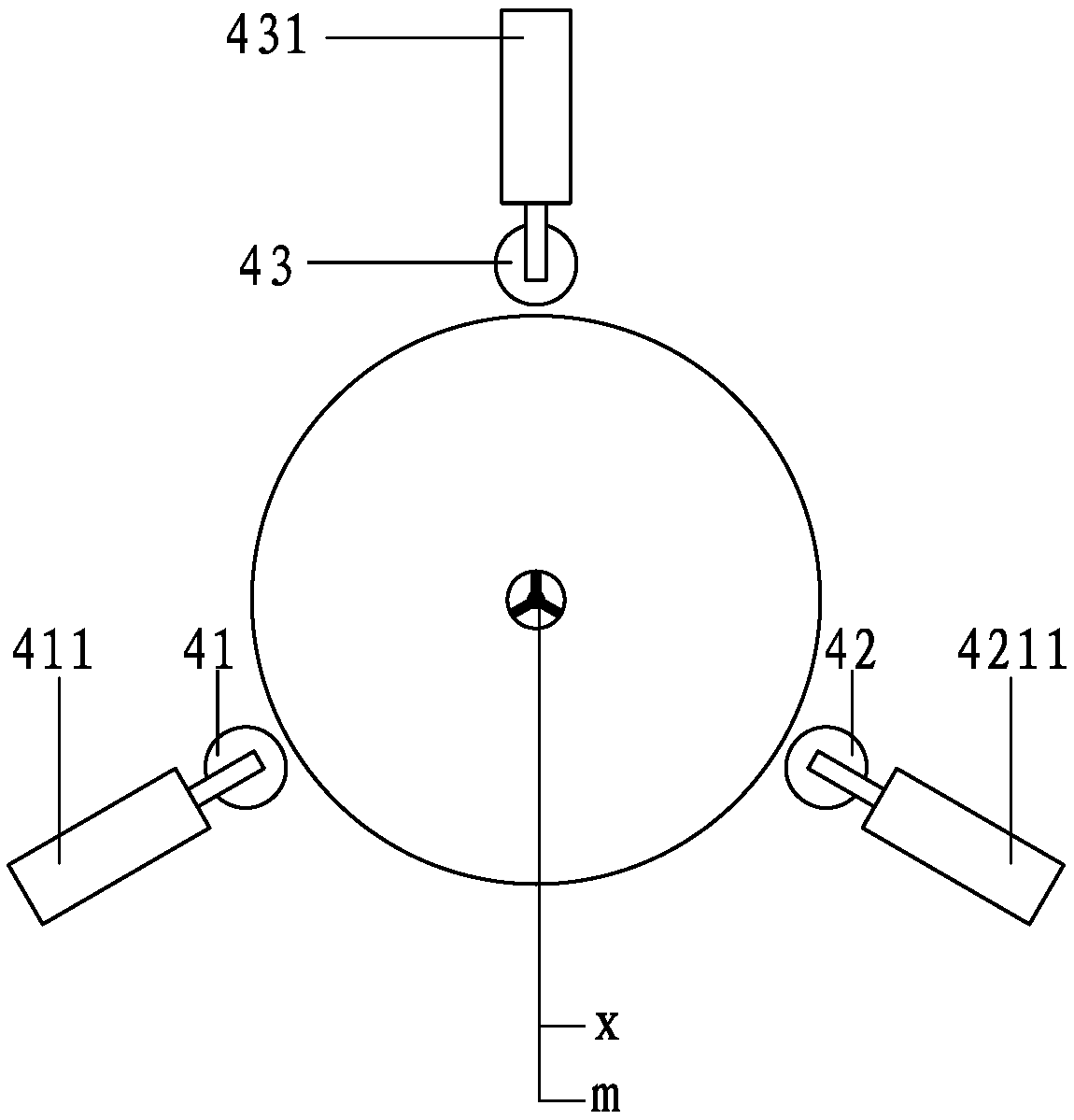

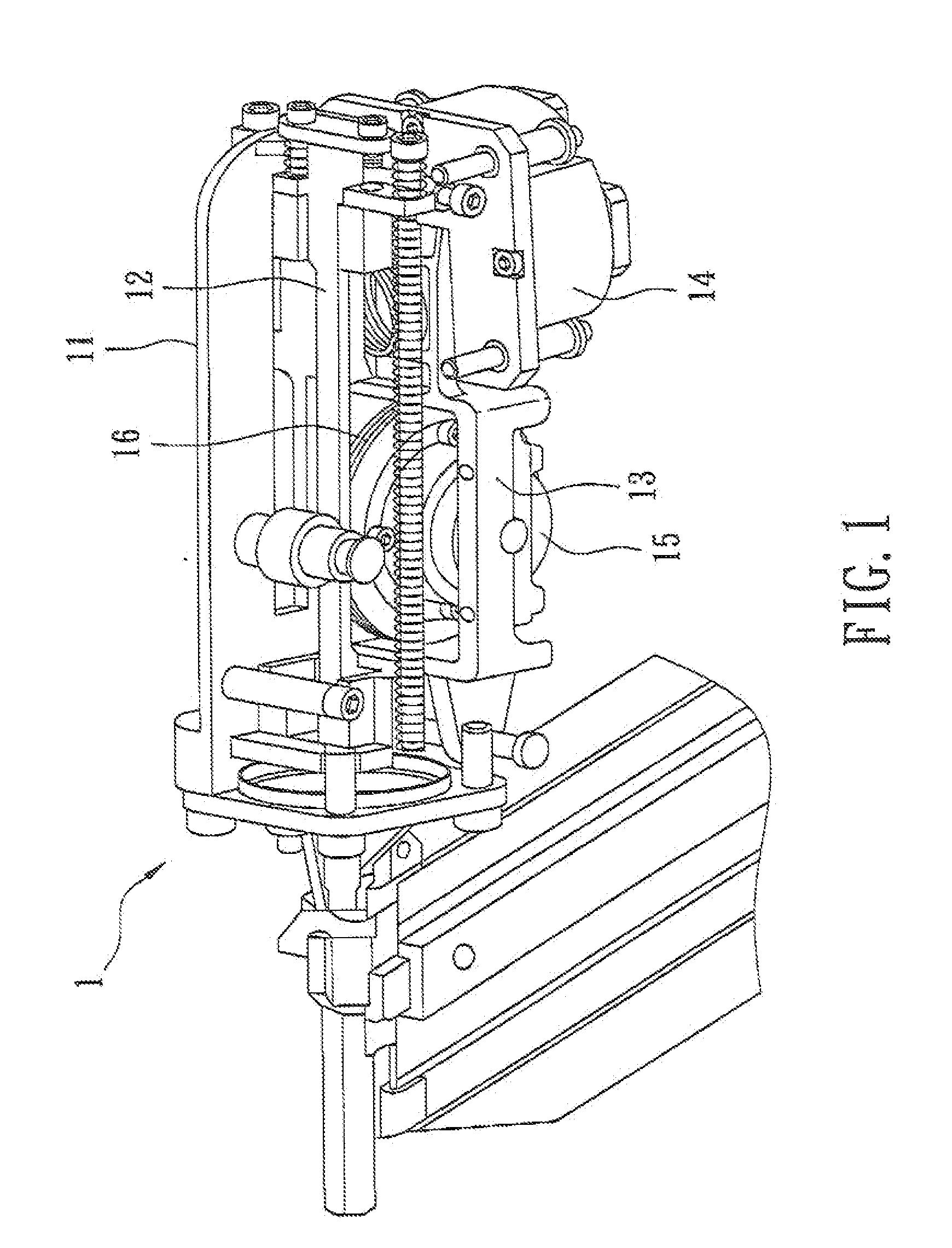

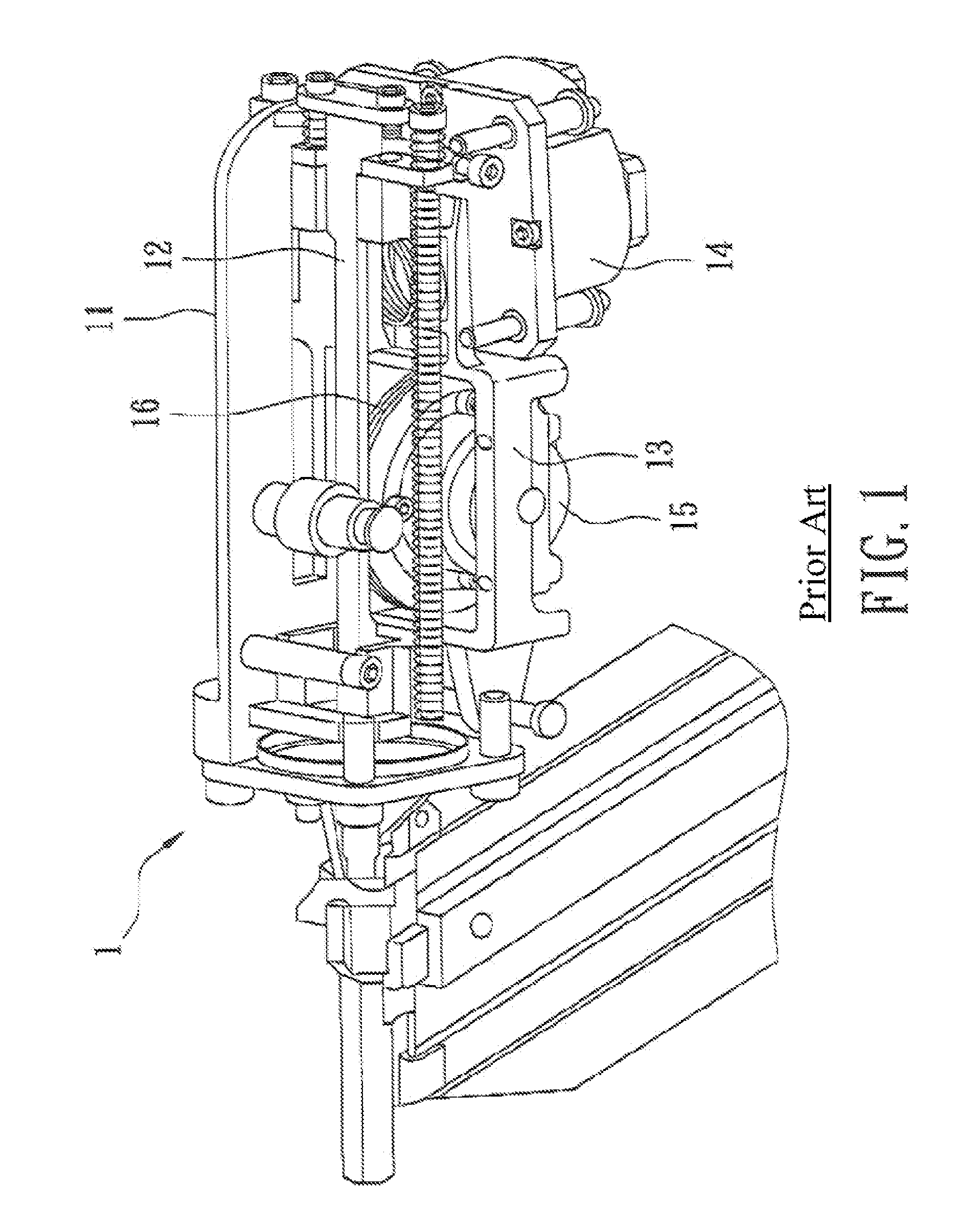

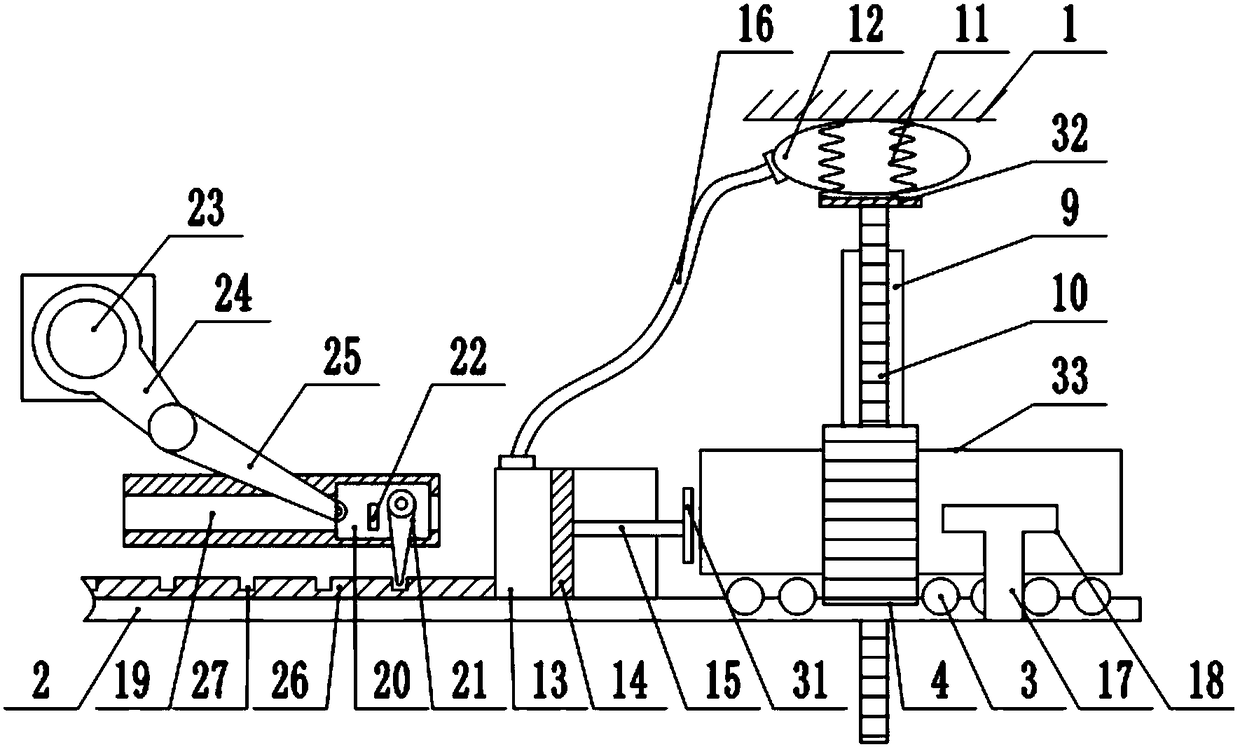

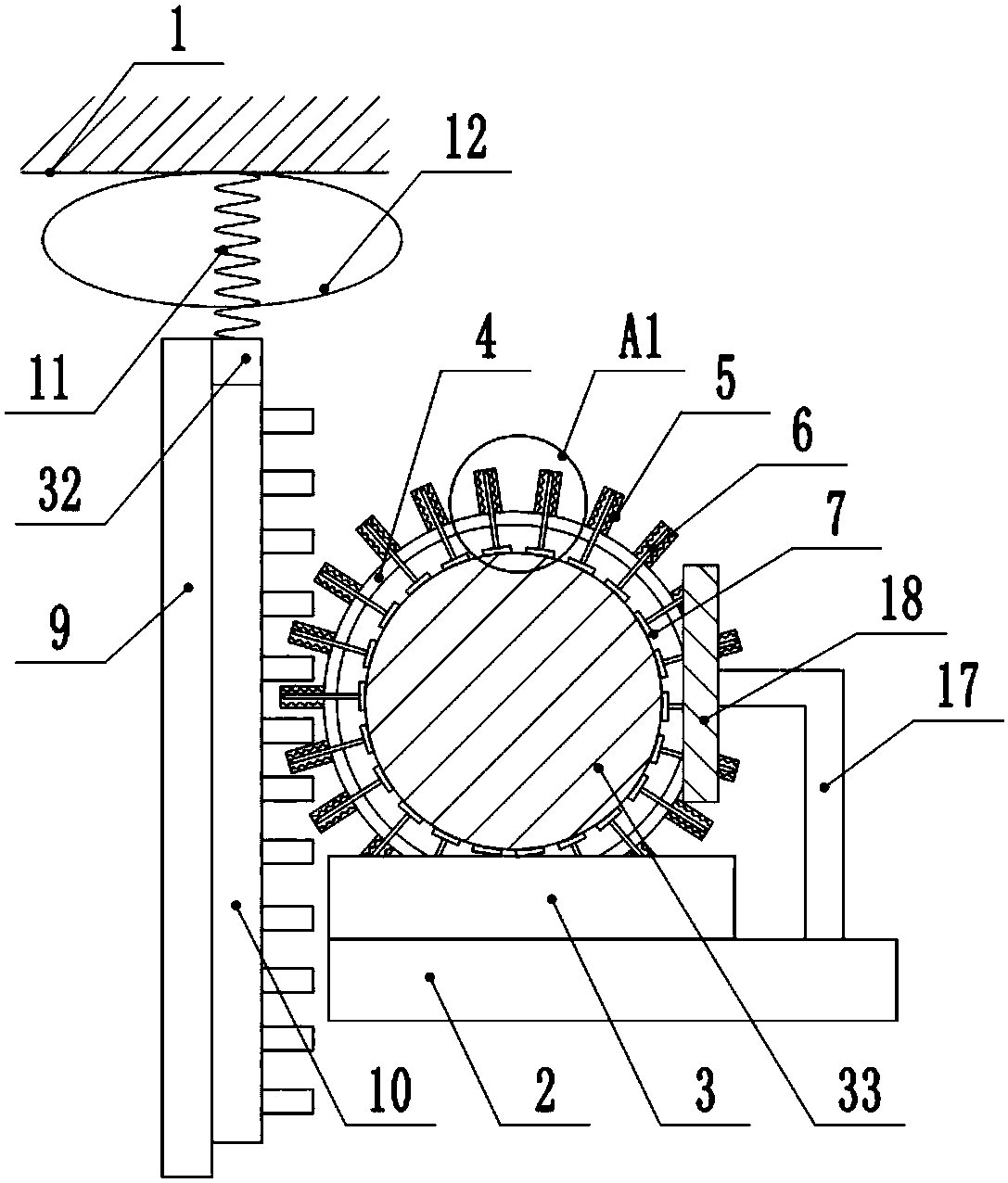

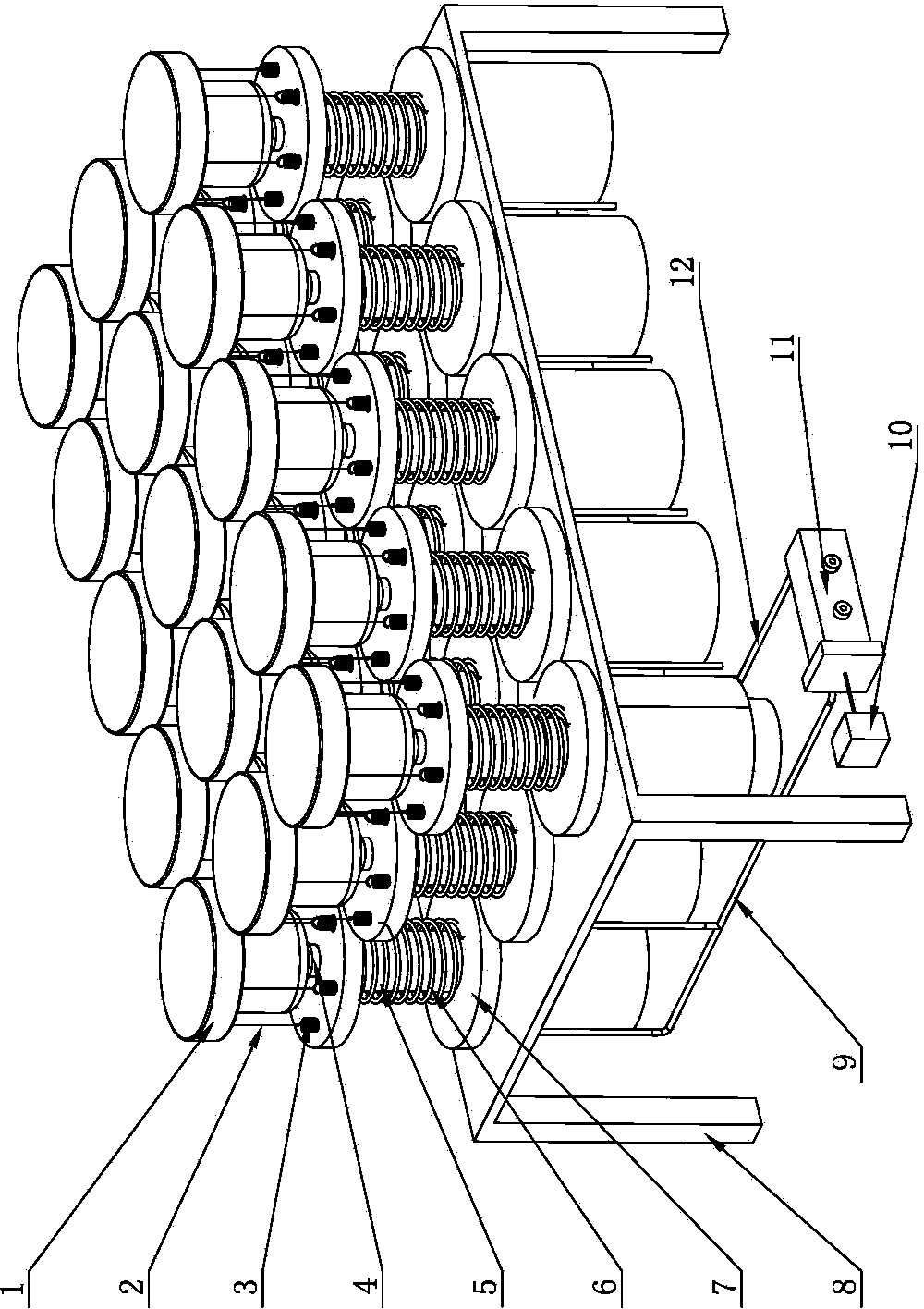

Automatic precision rotary cutting machine

ActiveCN108673686APrecise positioningEasy to holdProfiling/shaping machinesVeneer manufactureMotor driveEngineering

The invention puts forwards an automatic precision rotary cutting machine. Before a rotary cutting device begins to perform rotary cutting, a first lifting driving device slides away from a second clamping part along a first horizontal guiding rail, a first lower telescopic supporting rod and a second lower telescopic supporting rod slide to make contact with a log in an abutting manner, the log is supported to abut against an upper driving wheel single body, a first advancing and retreating motor drives a first rotating shaft to move away from a second clamping part, a first lifting frame moves to the height, corresponding to the circle center of the log, of a first cutter, a worker rotates a first operating handle for adjustment, the first clamping arm clamps the log, a controller controls driving of a first lifting motor, the pressure applied by a first main base plate to the first lifting frame before the log is clamped is equal to the pressure after the log is clamped, the first lifting driving device slides towards the second clamping part along the first horizontal guiding rail, the first rotating shaft moves towards the second clamping part, and the first cutter is automatically aligned to the log.

Owner:漳州市炯辉机械有限公司

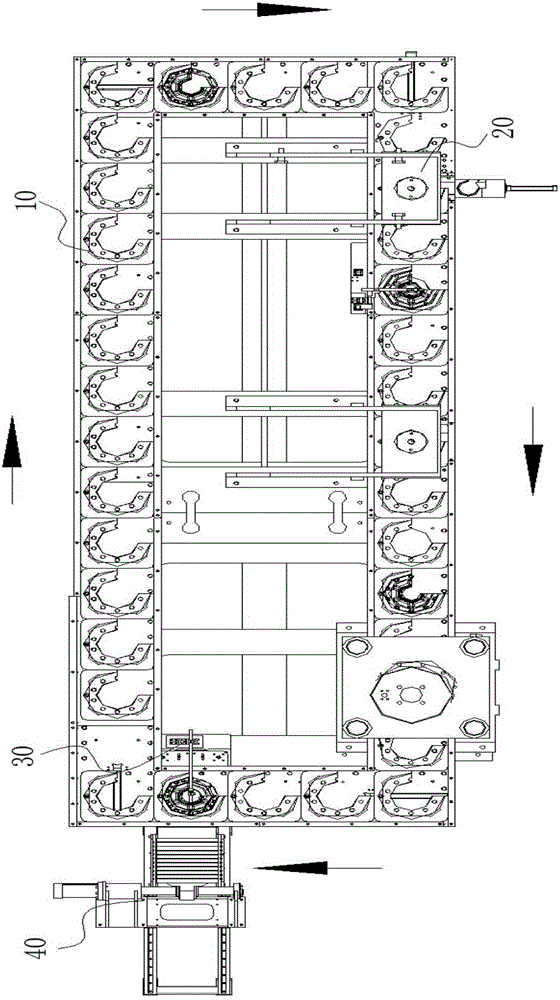

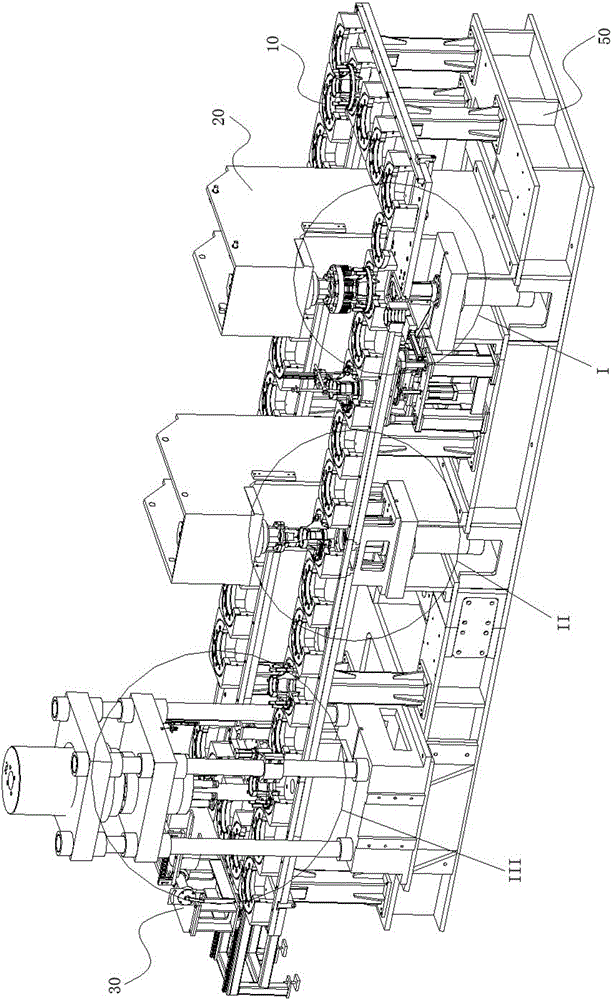

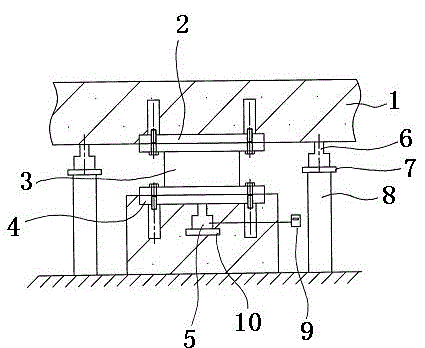

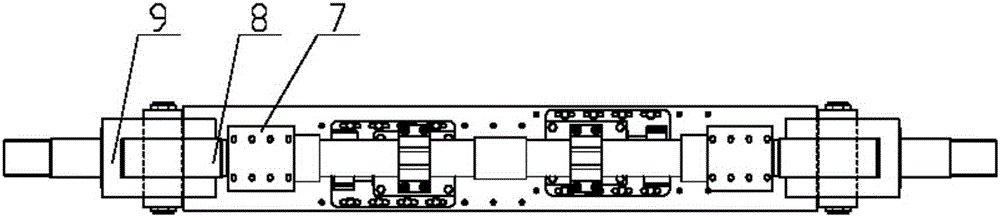

Press-fitting production line for hub assemblies

ActiveCN106112511AHigh degree of automationIncrease productivityAssembly machinesVehicle componentsAutomationProduction line

The invention discloses a press-fitting production line for hub assemblies. The press-fitting production line comprises a circulatory conveying assembly and a part press-fitting mechanism; the circulatory conveying assembly comprises a support and a plurality of supporting brackets arranged on the support, and the multiple supporting brackets are used for conveying hubs on the support in a circulation mode so that the hubs can undergo the press-fitting work of each process; and the part press-fitting mechanism comprises a lower bearing outer ring pressing machine, an upper bearing outer ring pressing machine, an ABS gear ring pressing machine and a bolt pressing machine, wherein the lower bearing outer ring pressing machine, the upper bearing outer ring pressing machine, the ABS gear ring pressing machine and the bolt pressing machine are arranged along the support, the lower bearing outer ring pressing machine is used for carrying out press-fitting on lower bearing outer rings of the hubs, the upper bearing outer ring pressing machine is used for carrying out press-fitting on upper bearing outer rings of the hubs, the ABS gear ring pressing machine is used for pressing ABS gear rings on the hubs, and the bolt pressing machine is used for pressing bolts on the hubs. The press-fitting production line for the hub assemblies has the advantages of being high in automation level and safe and saving energy and is suitable for being widely popularized and used.

Owner:GUANGDONG FUWA HEAVY IND

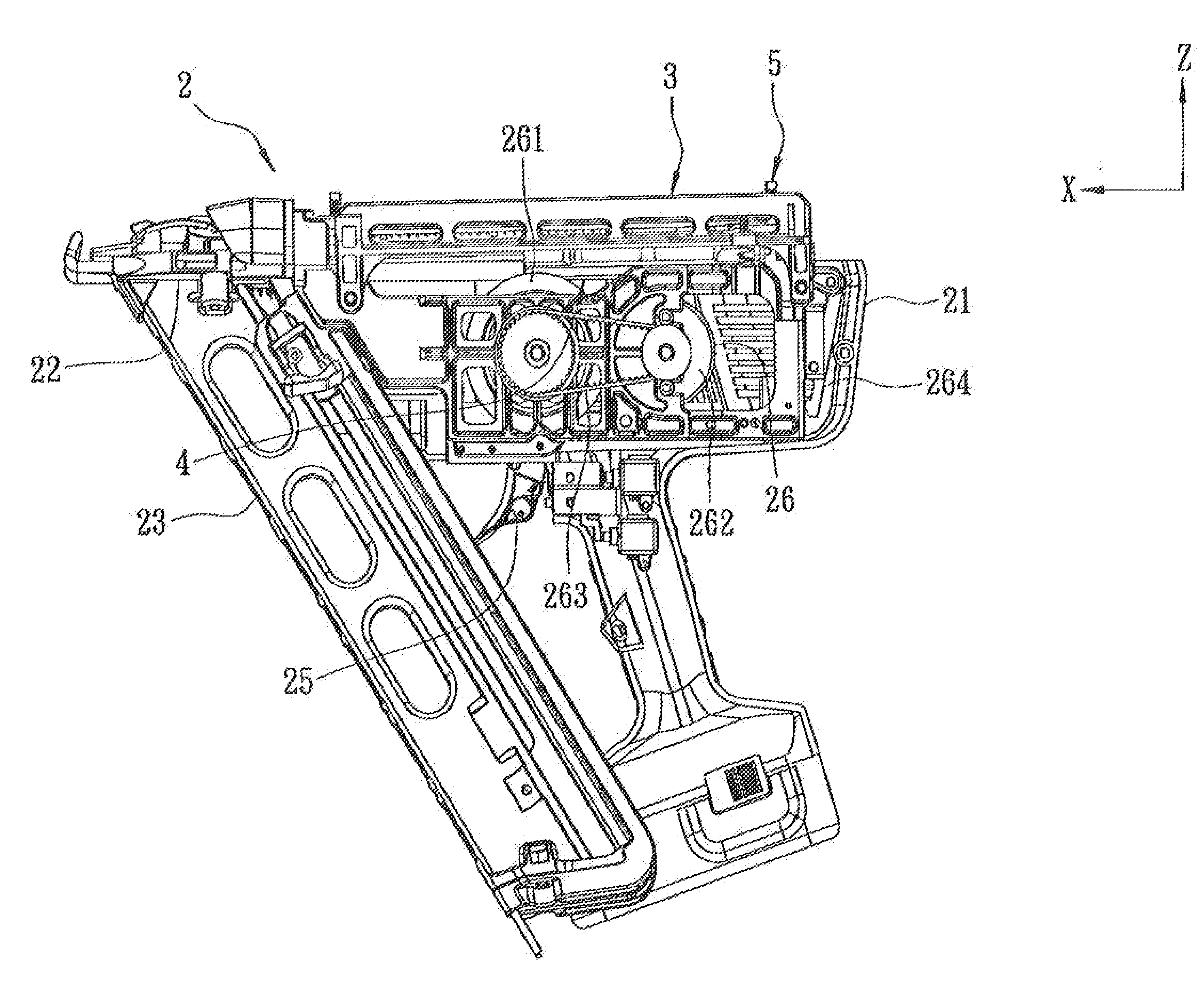

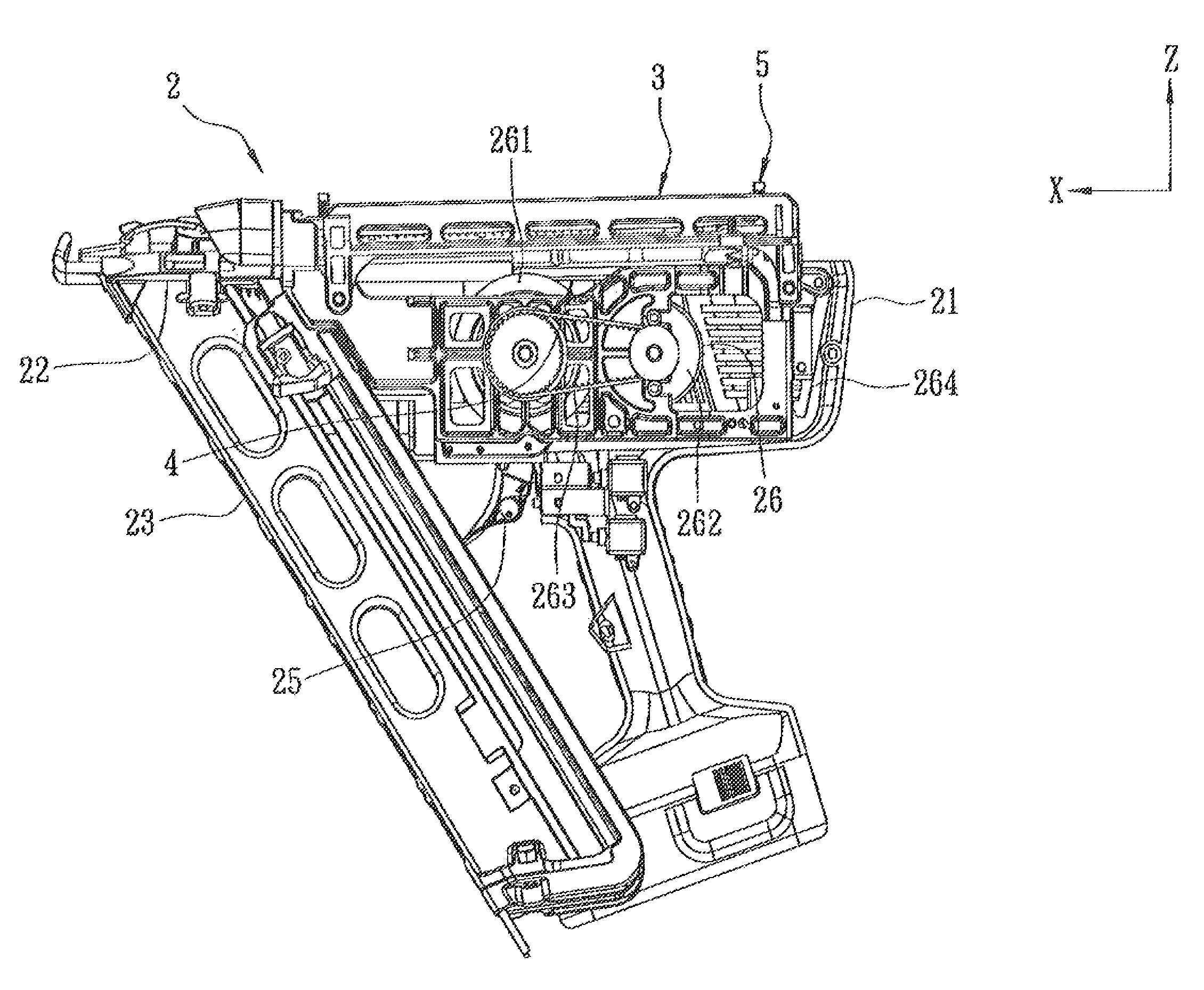

Floating impact apparatus for electrical nail gun

ActiveUS20110259938A1Avoid uneven forceGuaranteed uptimeStapling toolsPortable power-driven toolsEngineeringPulley

A floating impact apparatus for an electrical nail gun includes a carrier, an impact unit, and a floating unit. The impact unit includes an impact member, and at least one sliding, wheel disposed pivotally on the impact member. The floating unit includes a guiding rod together with the impact member being connected movably to the carrier, two floating members extending through the carrier to connect with the guiding rod at positions proximate to a first side of the carrier, and at least two resilient members disposed between a second side of the carrier and the floating members for biasing the guiding rod and the impact member to move relative to the carrier to thereby maintain contact between the sliding wheel and the first side of the carrier, so as to promote smooth movement and nail-striking force of the impact member.

Owner:BASSO IND CORP

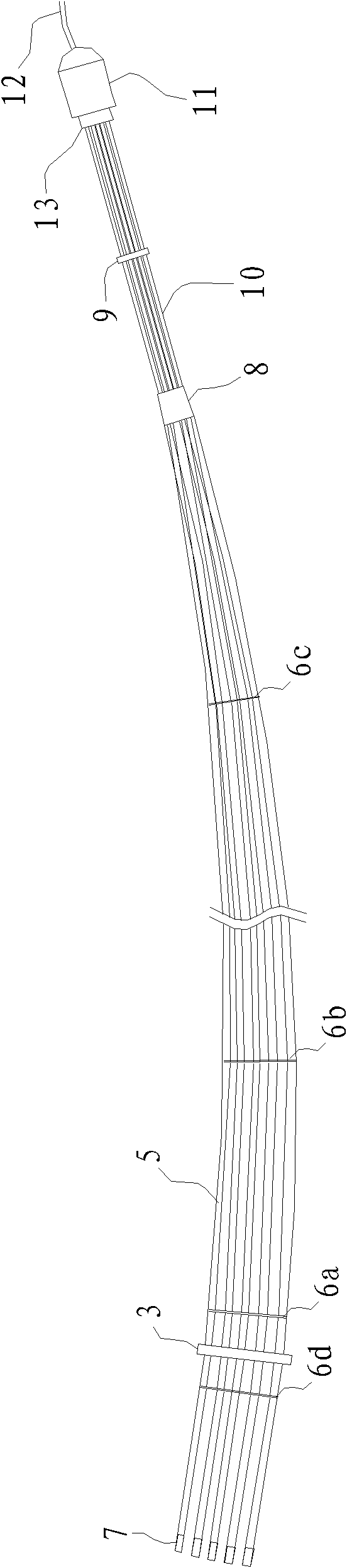

Steel strand bundle-weaving and crossing construction method

InactiveCN102003072AAvoid entanglementAvoid uneven forceBuilding reinforcementsBuilding material handlingMetallurgyPre stress

The invention discloses a steel strand bundle-weaving and crossing construction method, comprising the following steps of: intercepting a steel strand; peeling and cutting an outer-layer steel wire at one end of the steel strand; drawing the steel strand to pass through a through hole corresponding to a duplicating wire combing board; enabling the central steel wire to pass through the duplicating wire combing board according to the position of the steel strand in the duplicating wire combing board; installing the end of the central steel wire, passing through the duplicating wire combing board, in a cross guiding base; coating the end of the steel strand and the part of the steel strand with the out-layer steel wire peeled; introducing a cross guiding head to pass through a corrugated pipe or a sheath in a pre-stress member to be fixed with the cross guiding base; drawing the steel strand to enter the corrugated pipe or sheath in the pre-stress member in a guiding mode; and cutting off the central steel wire exposing from one end of the steel strand, together with the cross guiding base. The invention can effectively avoid uneven stress of the steel strand during tensioning when the steel strands are wound to each other caused by improper bundle crossing, improve the construction quality of a pre-stress structure and save the working time.

Owner:TIANJIN BINHAI YINGXIN INVESTMENT

Method for replacing building shock insulation rubber support

ActiveCN104018434AGuaranteed StrengthAvoid uneven forceBuilding repairsBridge structural detailsDesign loadStructural stress

The invention belongs to the technical field of methods for replacing rubber supports, and discloses a method for replacing a building shock insulation rubber support. The method is mainly technically characterized in that supporting force generated when temporary support bodies are arranged is the same as the design load of the building shock insulation rubber support, then the support is demounted, concrete on the top of a pier column is removed at the same time, a new shock insulation rubber support is jacked through force measurement jacks, the design load is reached, a pier top and pre-buried boards are connected, concrete is poured to the pier top and the pre-buried boards, and finally the temporary support bodies are demounted. By the adoption of the mode of combining column top descending with support jacking, space is provided for replacement of the support, stress evenness of supports for supporting a building is guaranteed, the situation that the structural stress changes due to the fact that one support does not bear force is avoided, needed jacking force of the jacks is small, replacement is quick and safe, and construction cost is low.

Owner:丰泽智能装备股份有限公司

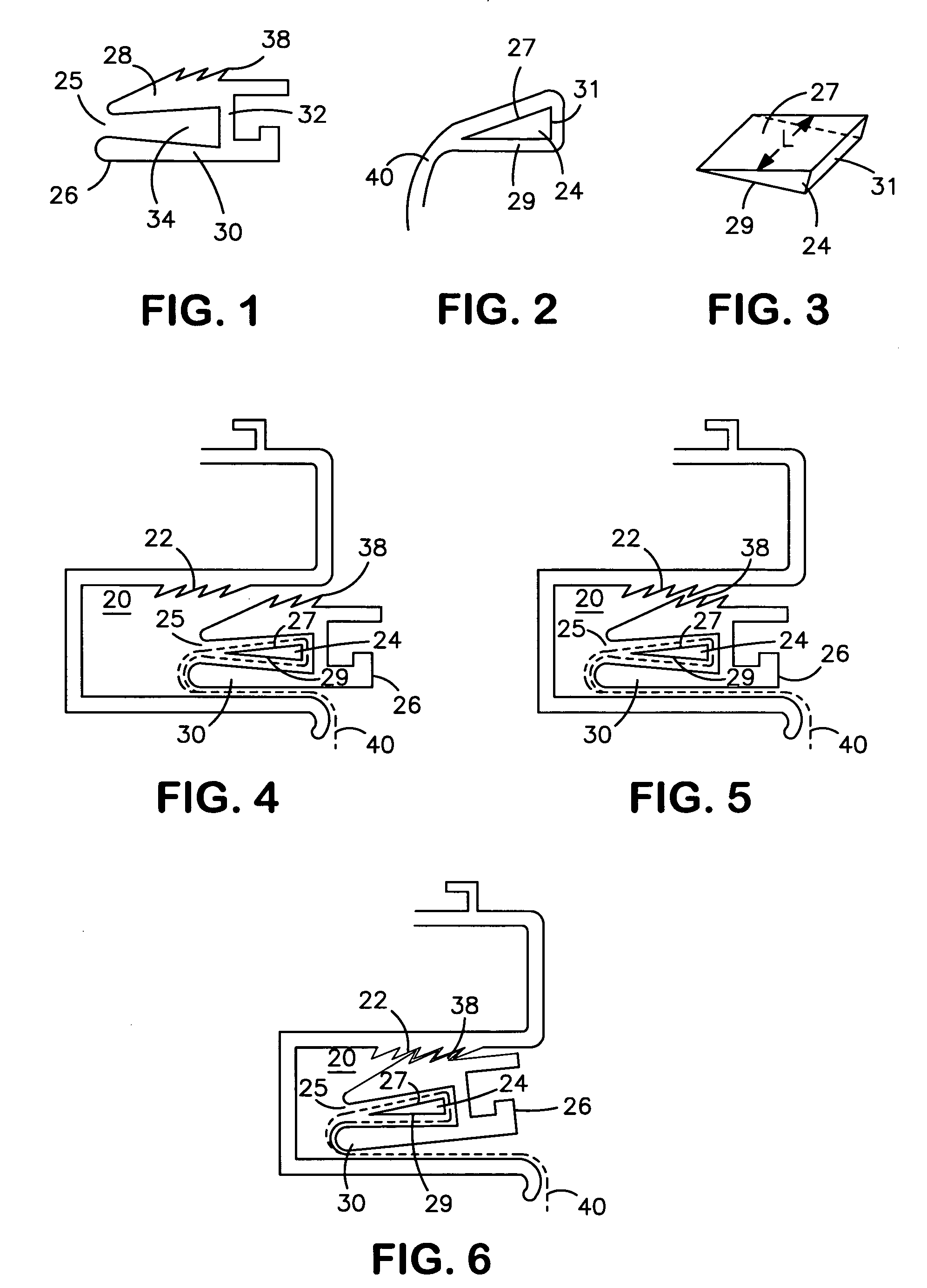

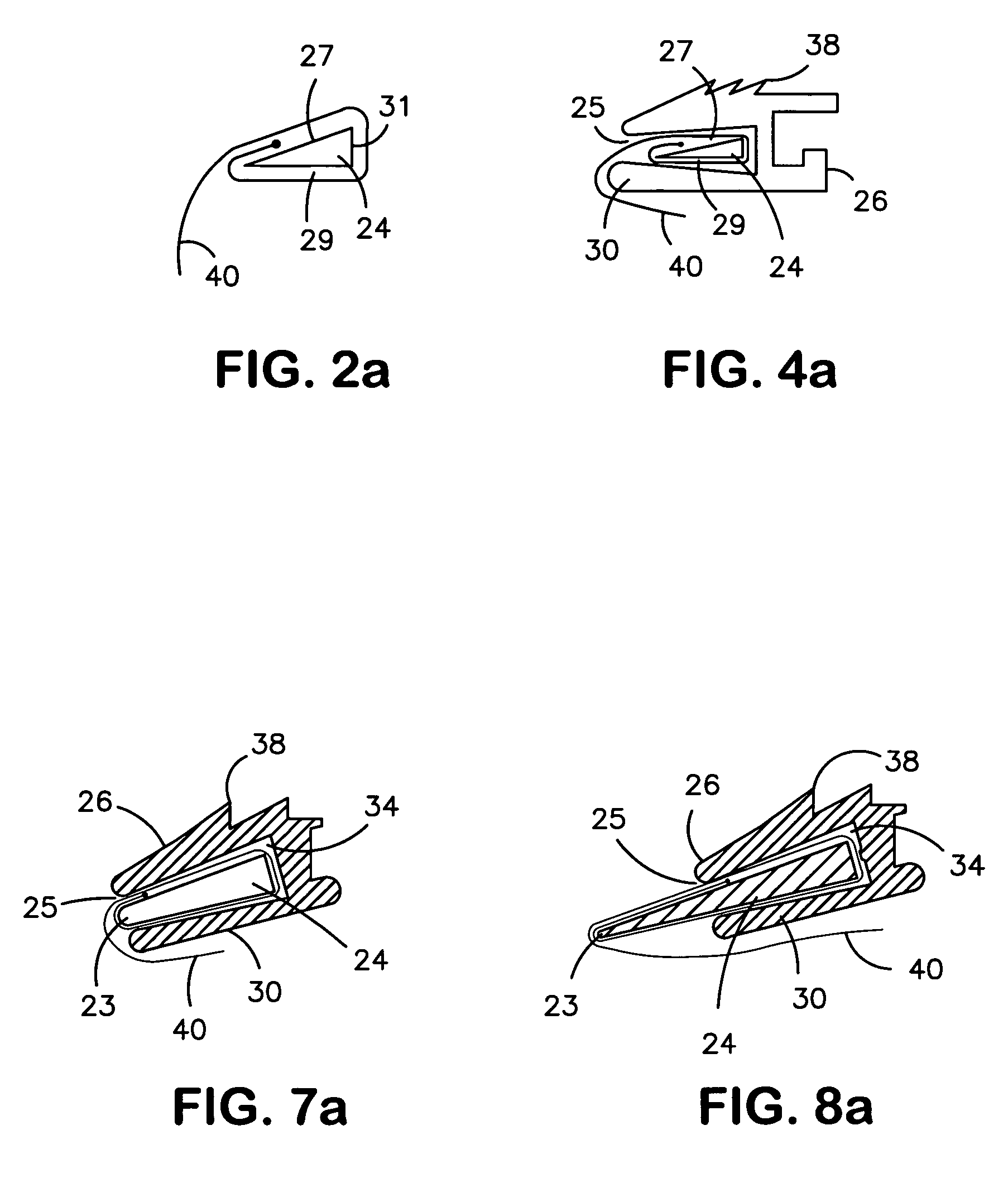

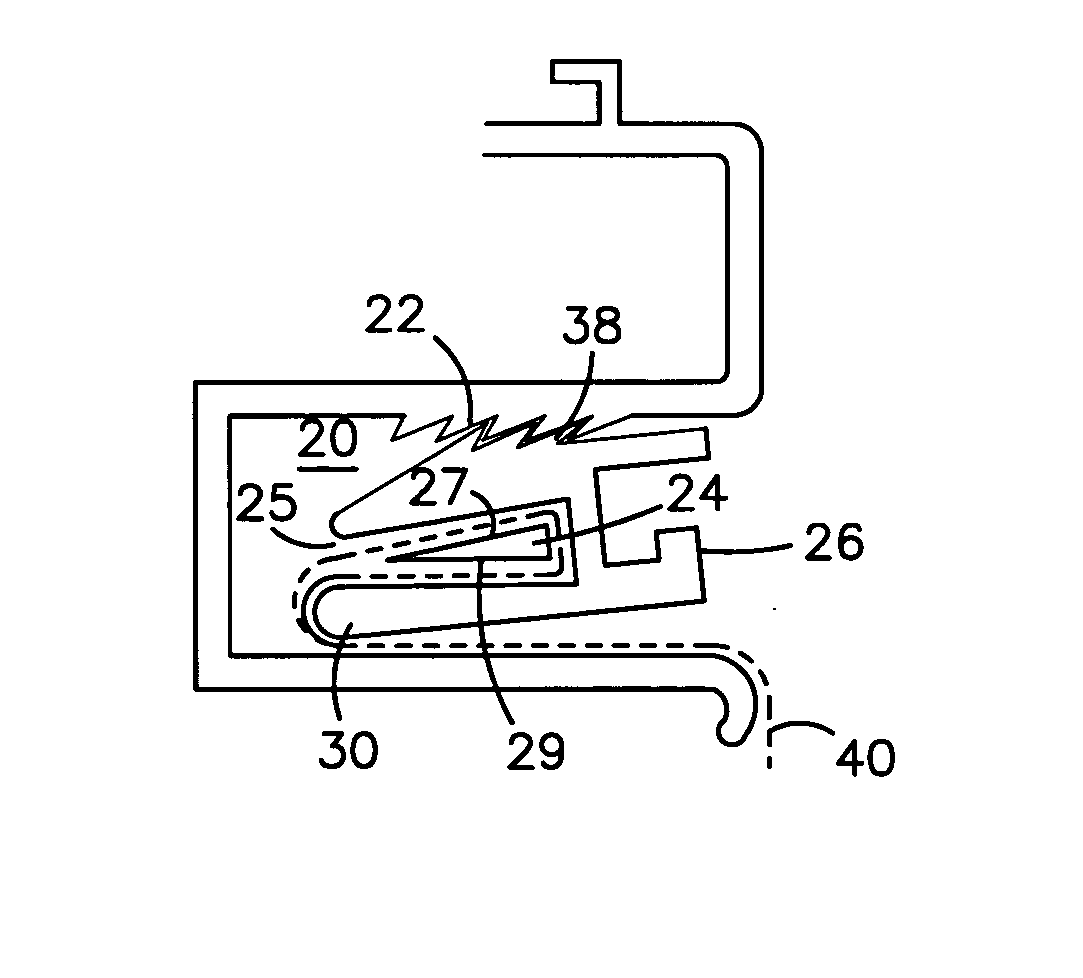

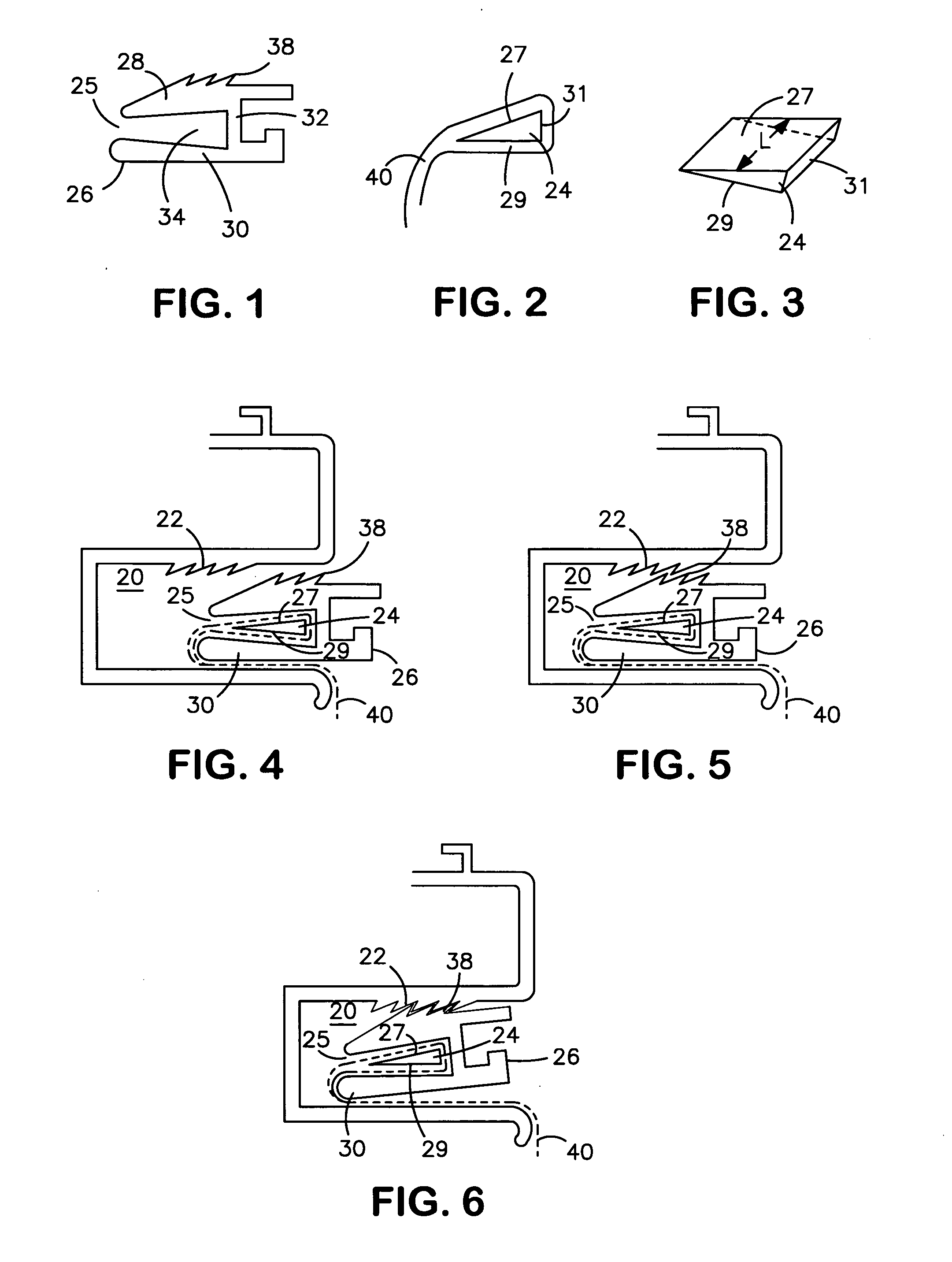

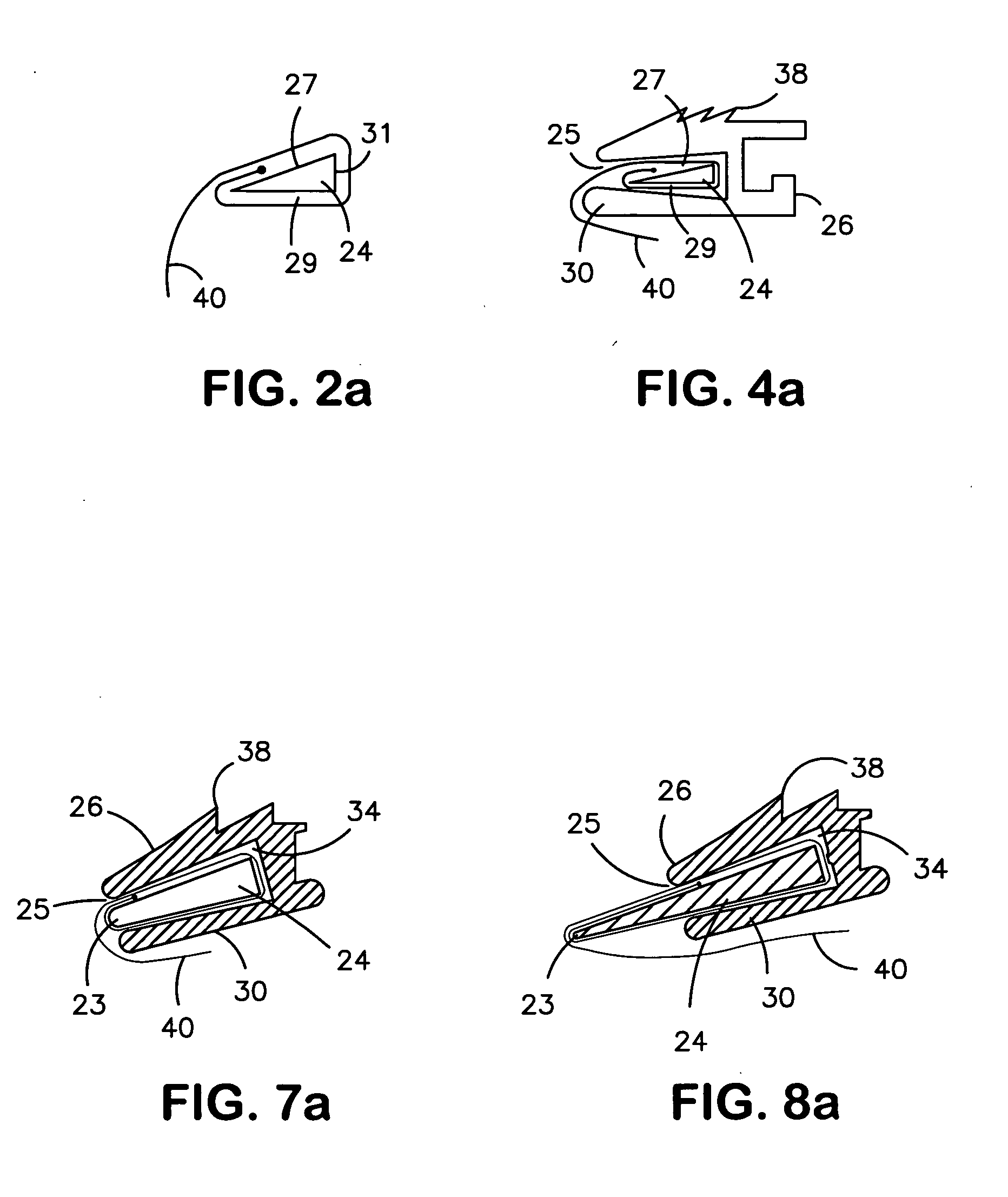

Flexible material tri-wedge bar and clamp assembly for use with a tensioning device

ActiveUS7165296B2Maximum gripping propertyMinimal strainSnap fastenersSheet joiningAcute angleEngineering

Flexible material clamp discloses two parts, triangular bar and rigid clamp having congruent triangular channel. The bar has base and two major inclined surfaces meeting at acute angle, length of the major surfaces being at least three times base height. Clamp has internal triangular channel whose major surfaces are congruent to major surfaces of triangular bar. One clamp end opens into apex of the channel and at least one side of clamp opens to triangular channel. One end of flexible material to be clamped is wrapped about triangular bar and overlapped upon itself. The wrapped bar is inserted into clamp channel though the at least one open side of clamp and flexible material is passed through clamp opening at channel apex. Assembled wrapped bar and clamp connect to tensioning means causing clamp and bar to move relative to one another to lock flexible material between major surfaces of triangular bar and corresponding major surfaces of triangular clamp channel, locking flexible material in channel.

Owner:COLEMAN KELLY R

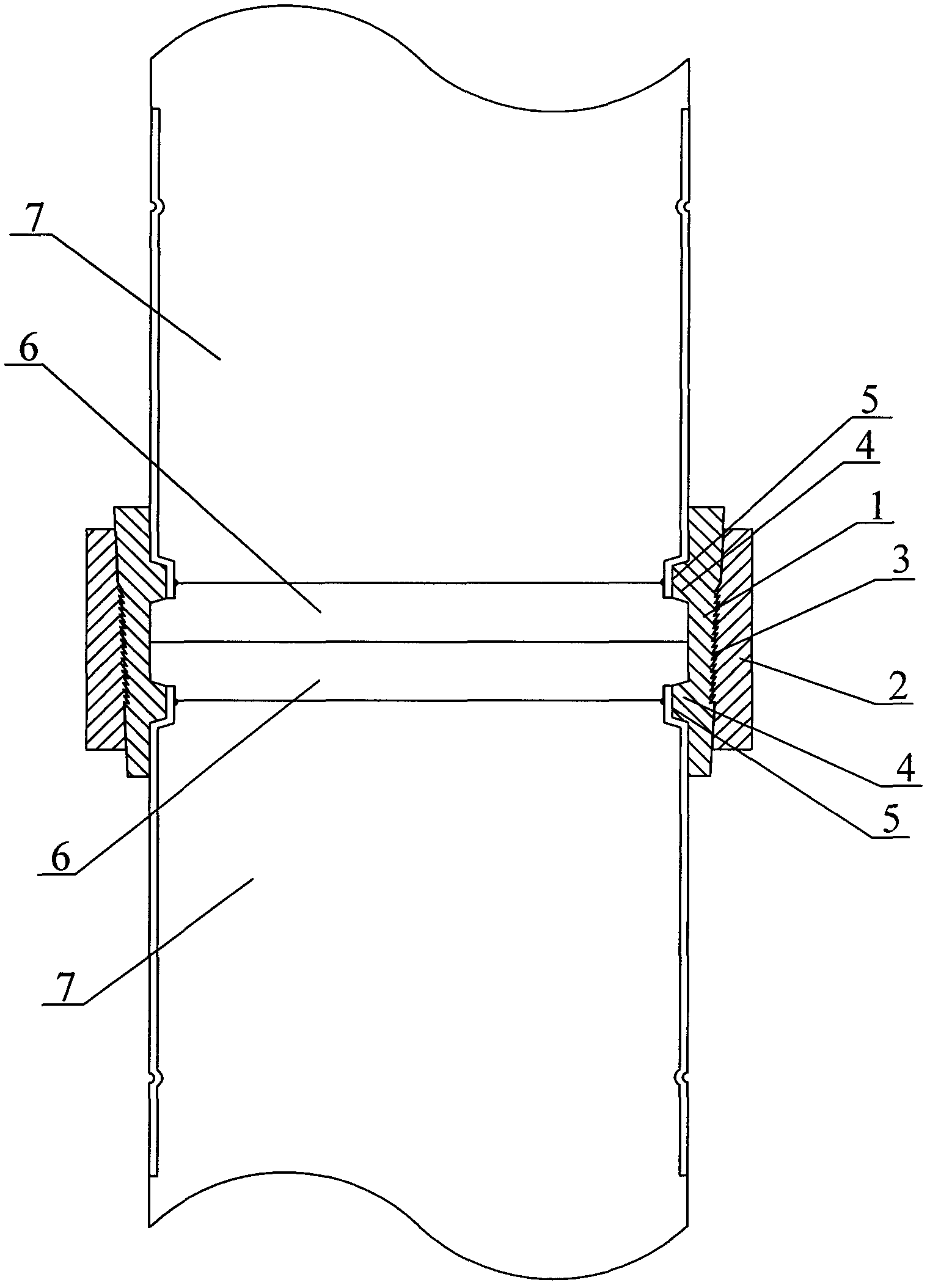

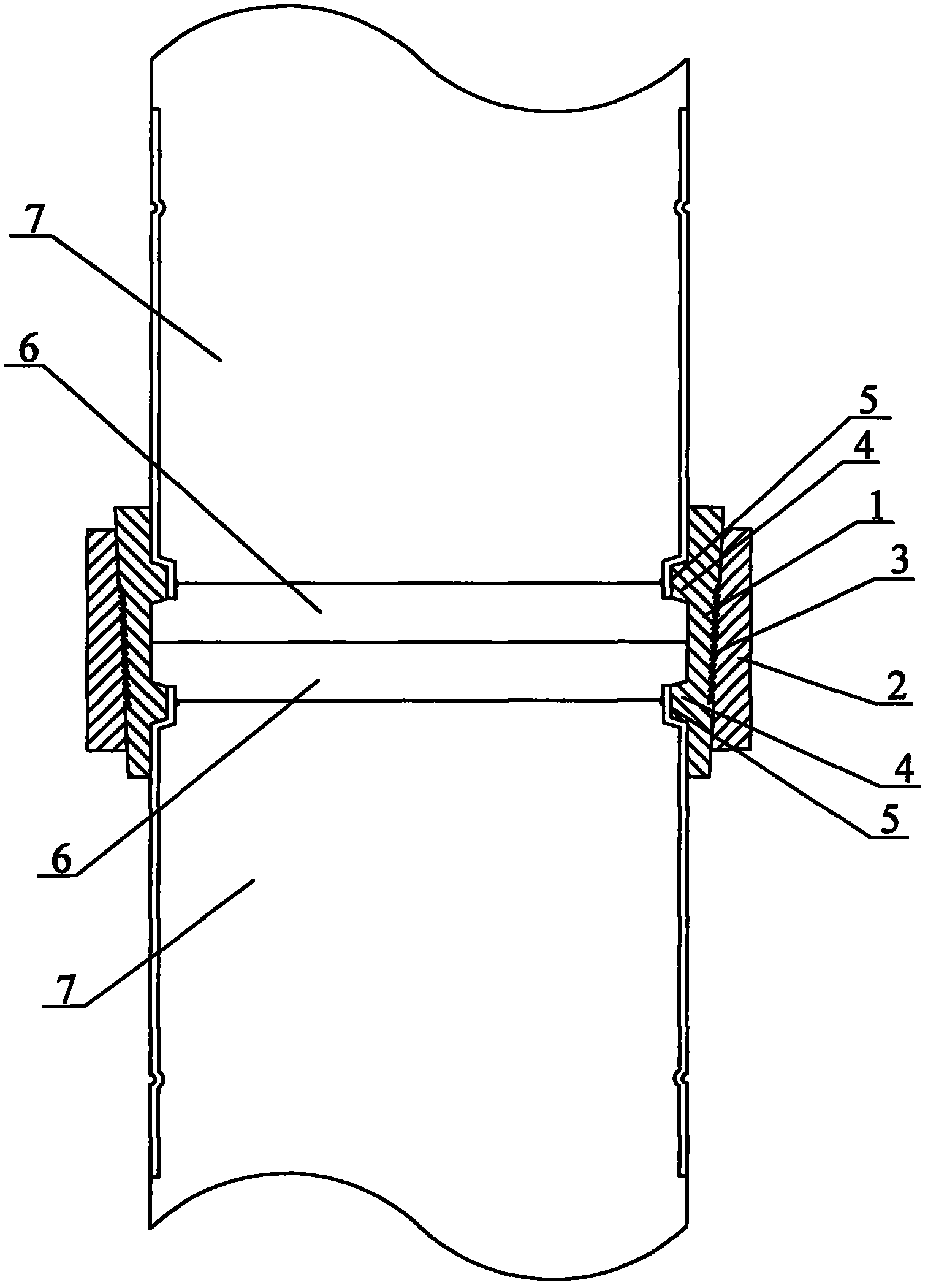

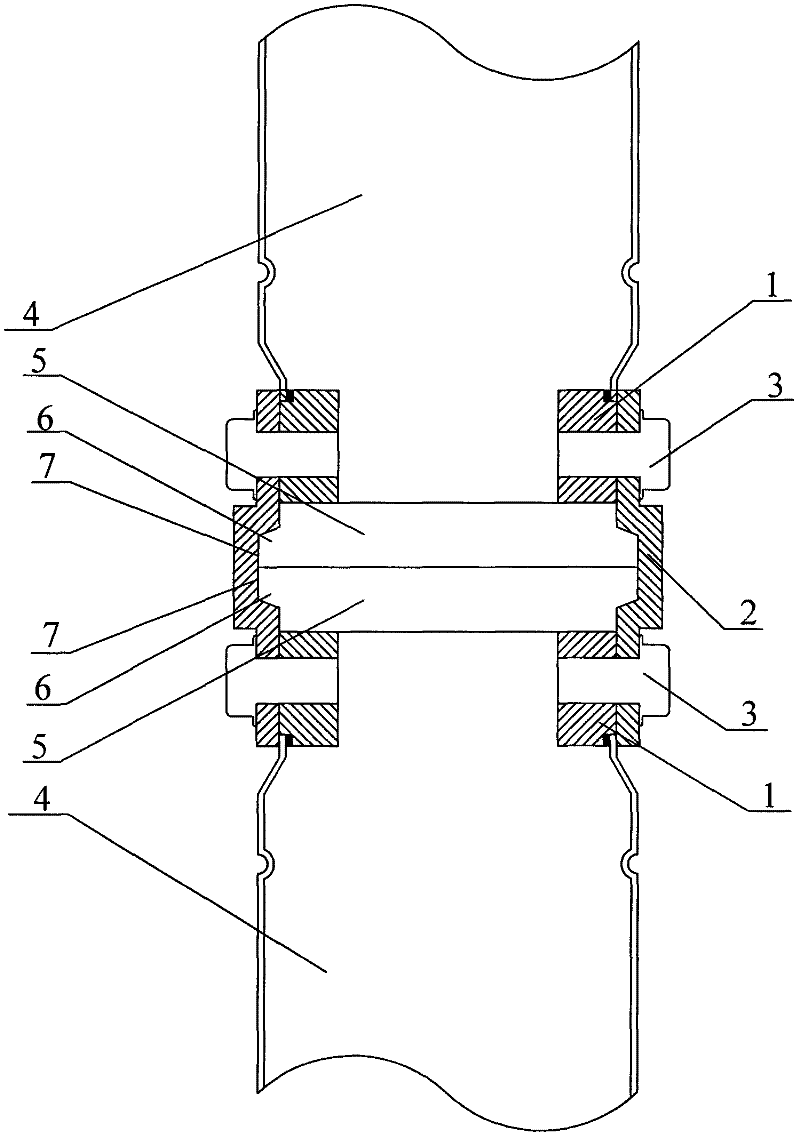

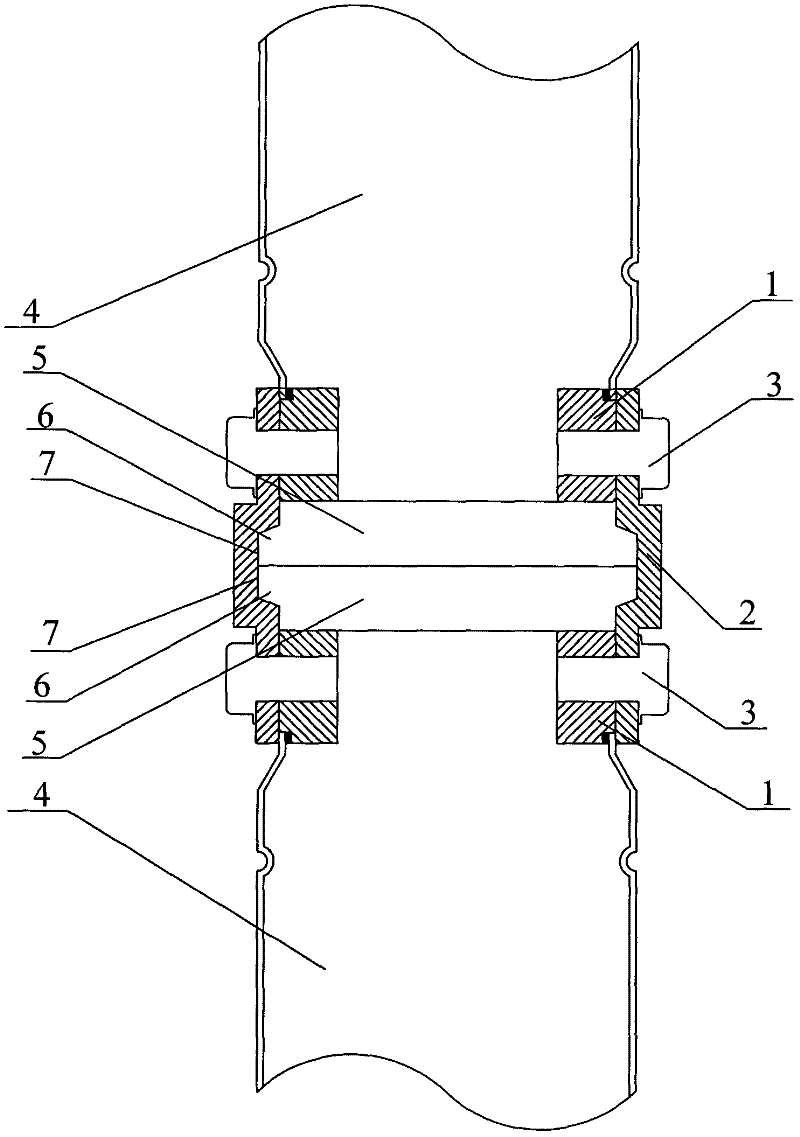

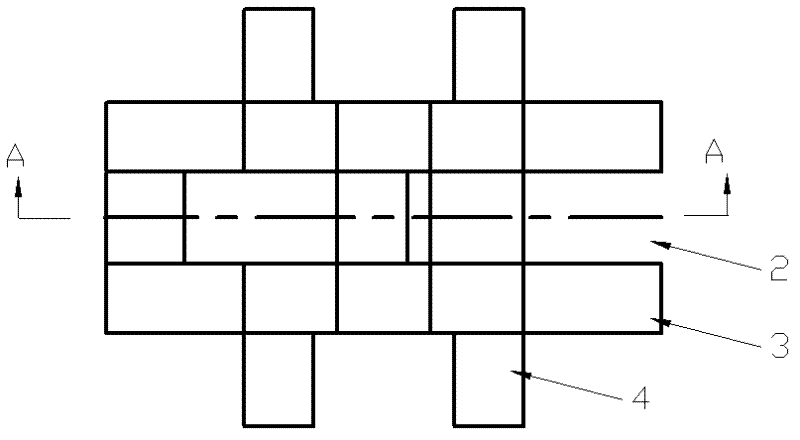

Pile splicing structure for precast piles

The invention discloses a pile splicing structure for precast piles, which comprises inner hoops (1) and outer hoops (2), wherein the inner hoops (1) are sheathed at the peripheries of two pile splicing parts required to perform pile splicing on the precast piles; the outer hoops (2) are sheathed and fastened onto the peripheries of the inner hoops (1); each inner hoop (1) is formed in a way that two or more than two arc-shaped components are spliced to form a ring; the inner ring of the inner hoop (1) is provided with at least two radial bulge loops (4); and the periphery of each pile splicing part required to perform the pile splicing on the precast piles is provided with a groove (5) matched with the radial bulge loops (4). By adopting the pile splicing structure for the precast piles, the pile splicing among the precast piles is firm, and the pile splicing parts reach the stress requirement.

Owner:ZHONGCHUN GAOKE PILE IND

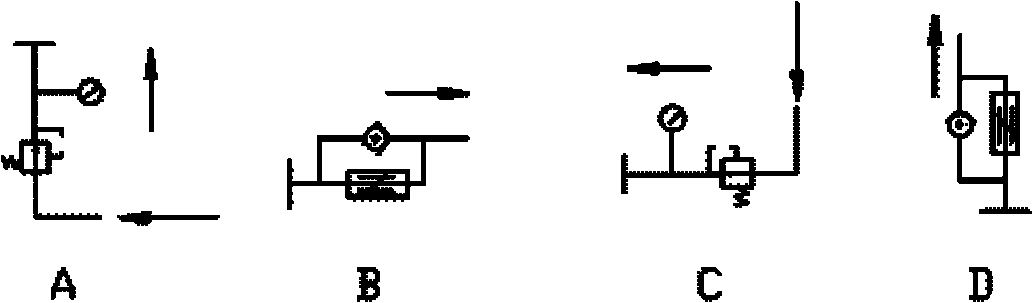

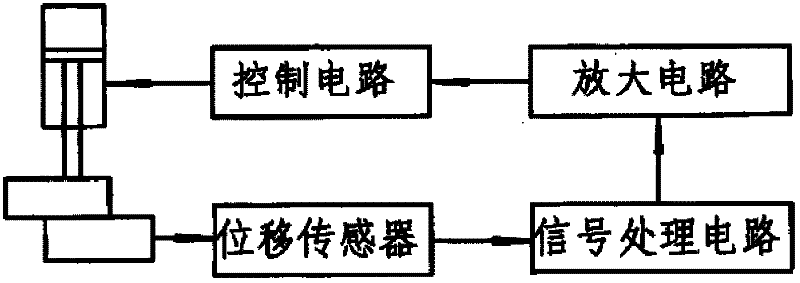

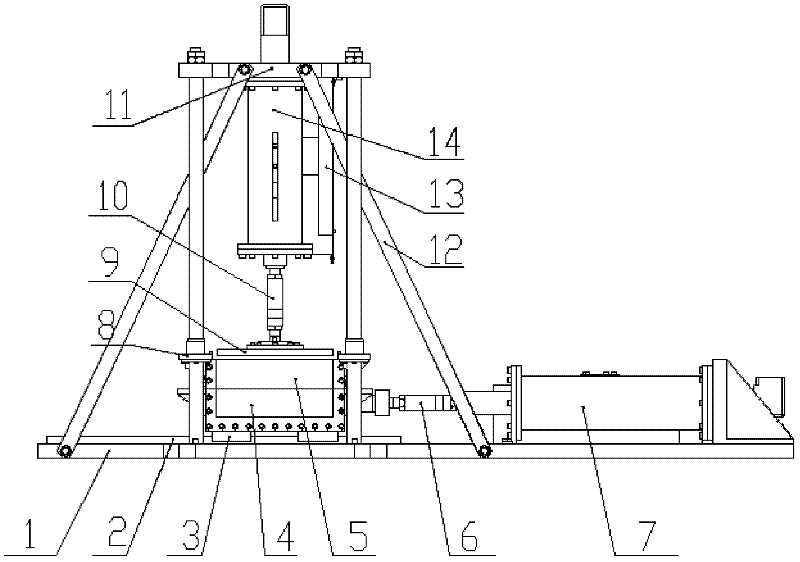

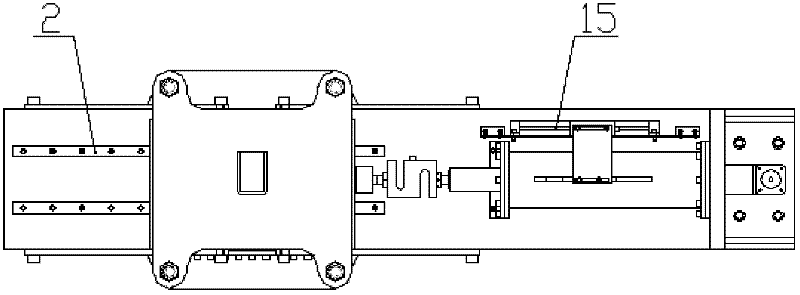

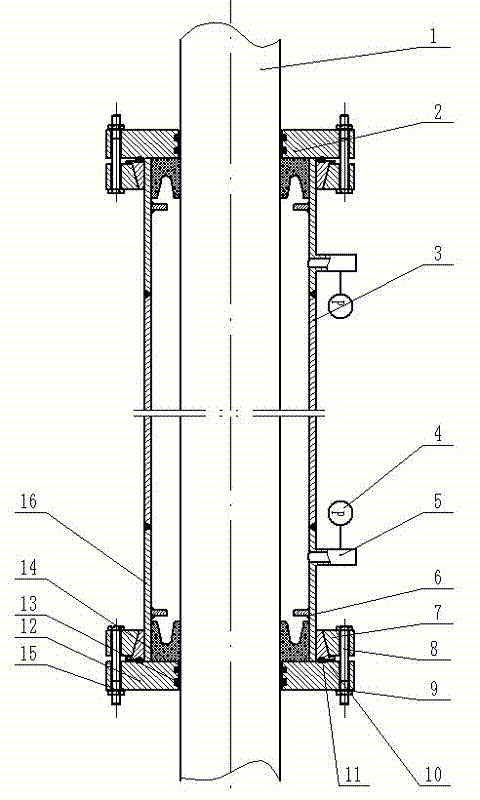

Midsize direct shear apparatus with non-lever type loading

InactiveCN102252917AFix stability issuesSolve the deformationMaterial strength using steady shearing forcesVertical displacementToughened glass

The invention discloses a midsize direct shear apparatus with non-lever type loading, comprising dual rails, a base, a lower shear box, an upper shear box, a pressure transferring plate, a horizontal loading device and a vertical loading device mounted on a beam, wherein the horizontal and vertical loading devices are respectively realized by the way of a stepping motor and a lead screw. Both the load applied to the vertical direction and the load applied to the horizontal direction are measured by a load sensor. The vertical displacement and the horizontal displacement are measured and further controlled by a grating ruler displacement sensor fixed on the lead screw. The shearing area reducing value can be indirectly obtained through the measured value of the vertical displacement and the horizontal displacement, so as to control the loading force of the vertical loading device, that is to say the vertical normal stress can keep a dynamic constant. The direct shear test can more realistically reflect the actual shear strength characteristics of the rock and the soil. Due to the adoption of a transparent toughened glass mode and a matched digital camera, the development change process of the shear surface can be tracked and observed in a real-time manner.

Owner:DALIAN UNIV OF TECH

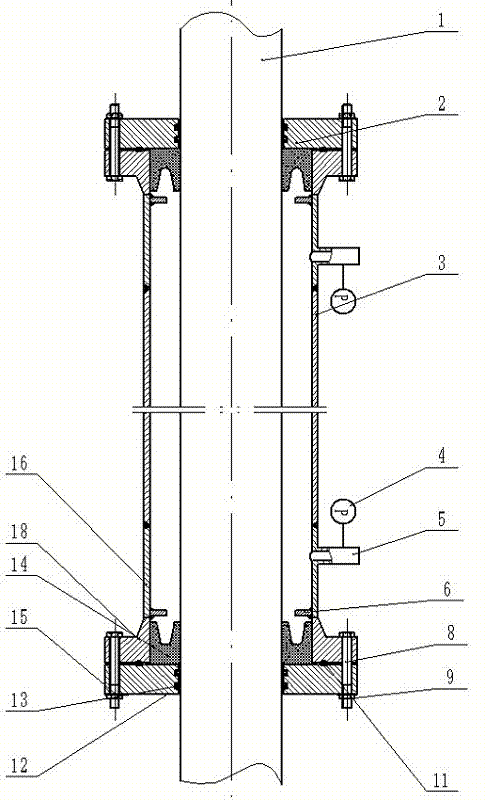

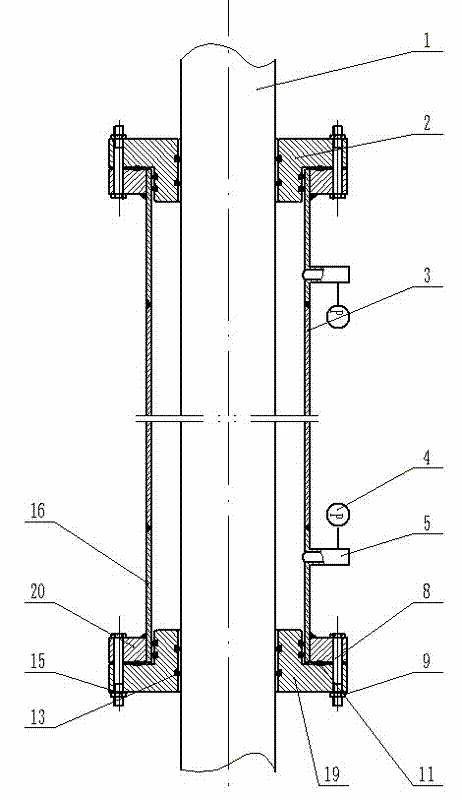

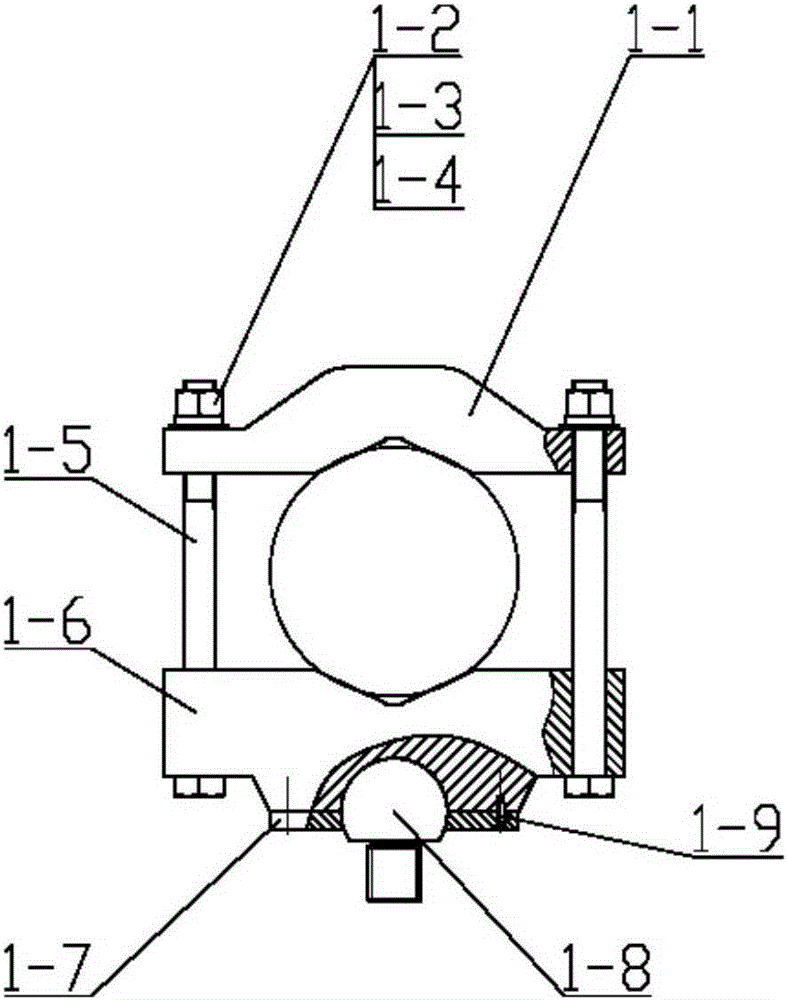

Non-excavation sunken pipe protecting device

InactiveCN103672297AGuarantee long-term normal deliveryAvoid uneven forcePipe supportsPipe protection against damage/wearEngineeringWellbore instability

The invention relates to a non-excavation sunken pipe protecting device which can prevent the accidents that sunken pipes are squashed, crushed and partially deformed due to wellbore instability, and the process that the sunken pipes are repaired and replaced or a new pipe is rearranged is omitted. The protecting device is composed of a sunken pipe, blocking devices and a protecting pipe, wherein the sunken pipe penetrates into the protecting pipe, the length of the protecting pipe is equal to the length of the sunken pipe needing protection, the blocking devices are mounted at the two ends of the protecting pipe, the annular space between the protecting pipe and the sunken pipe is filled with fluid, and the pressure of the fluid is smaller than or equal to the pressure of media in the sunken pipe; each blocking device is composed of a slips structure or a flange structure, a Y-shaped sealing ring, a pressure gage, a fluid inlet pipe and an O-shaped sealing ring, so that the fluid in the annular space is sealed, and pressure detection and fluid supplement are achieved. The non-excavation sunken pipe protecting device is simple in structure, convenient to operate and suitable for protecting pipes which penetrate through railways, roads, buildings, soft soil sections and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Flexible material tri-wedge bar and clamp assembly for use with a tensioning device

ActiveUS20060242805A1Maximum gripping propertyMinimal strainSnap fastenersSheet joiningAcute angleEngineering

Flexible material clamp discloses two parts, triangular bar and rigid clamp having congruent triangular channel. The bar has base and two major inclined surfaces meeting at acute angle, length of the major surfaces being at least three times base height. Clamp has internal triangular channel whose major surfaces are congruent to major surfaces of triangular bar. One clamp end opens into apex of the channel and at least one side of clamp opens to triangular channel. One end of flexible material to be clamped is wrapped about triangular bar and overlapped upon itself. The wrapped bar is inserted into clamp channel though the at least one open side of clamp and flexible material is passed through clamp opening at channel apex. Assembled wrapped bar and clamp connect to tensioning means causing clamp and bar to move relative to one another to lock flexible material between major surfaces of triangular bar and corresponding major surfaces of triangular clamp channel, locking flexible material in channel.

Owner:COLEMAN KELLY R

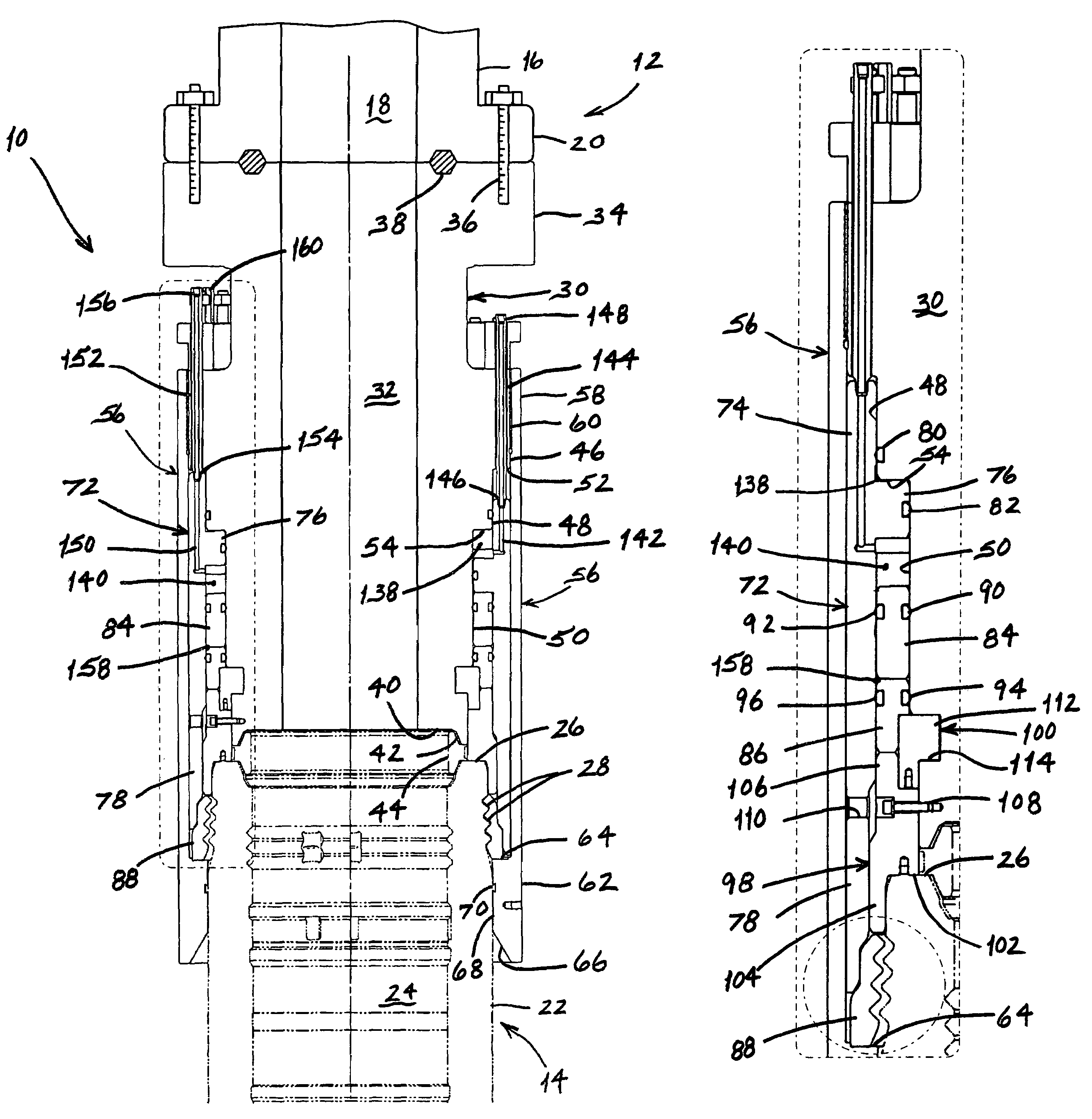

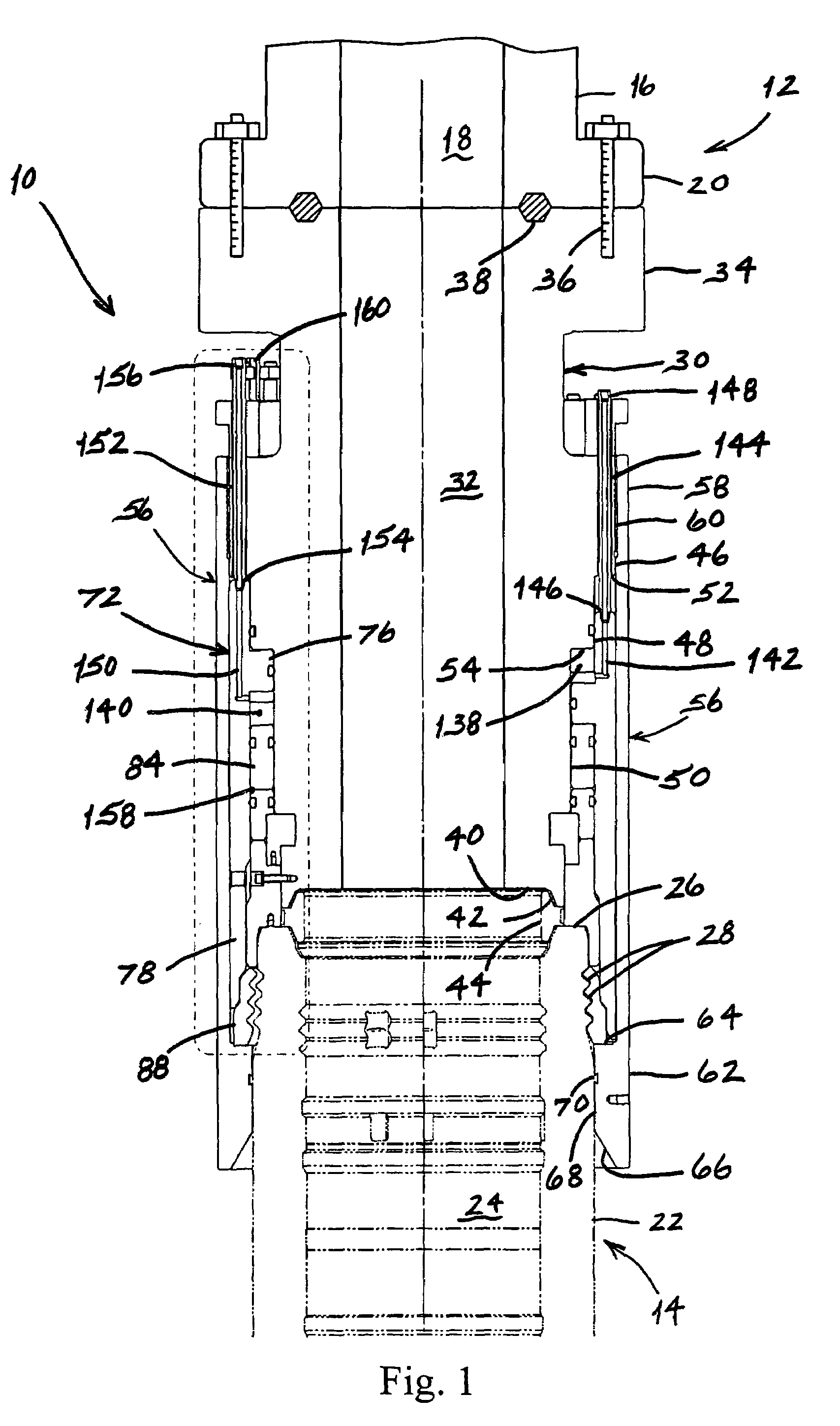

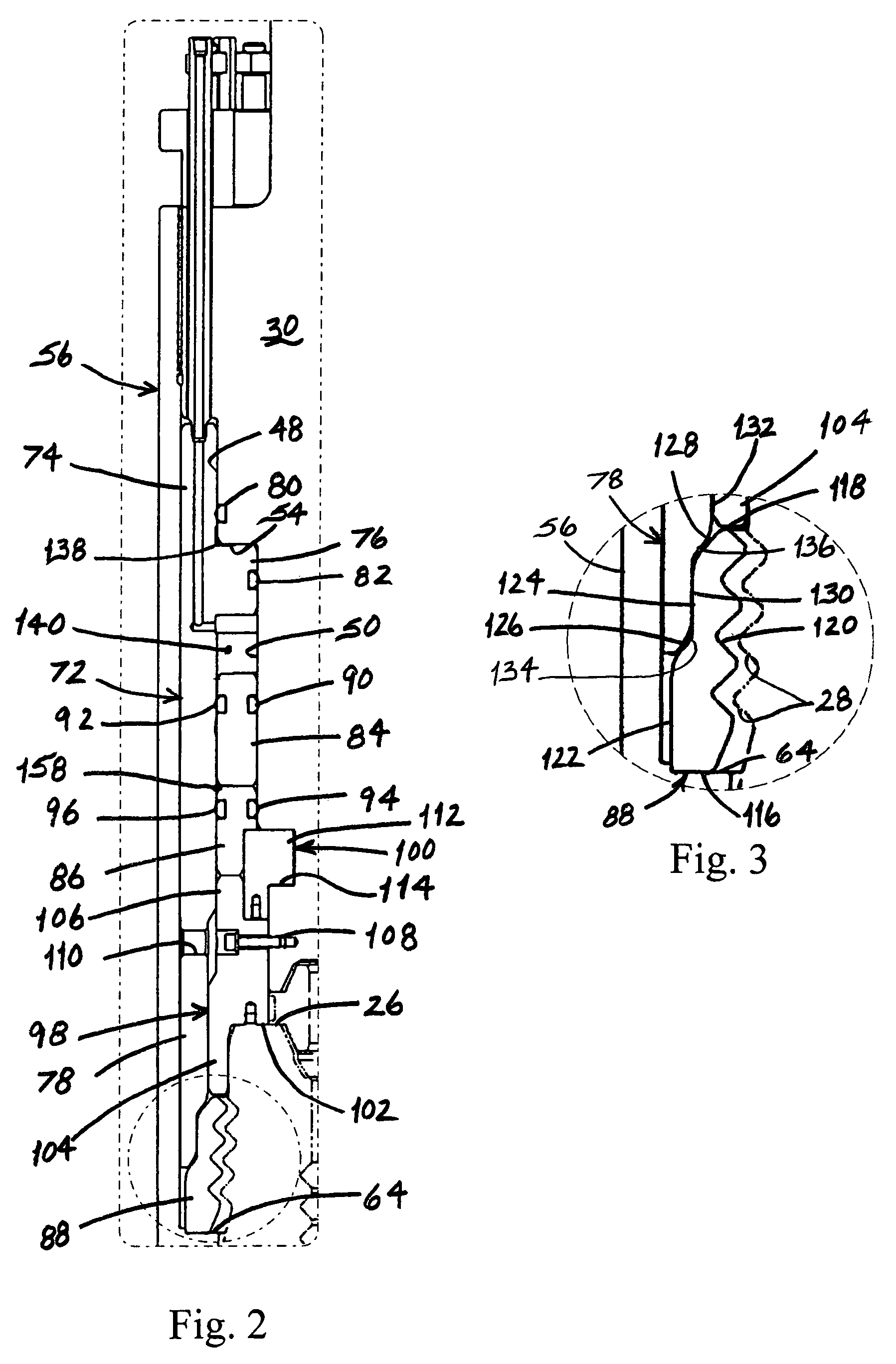

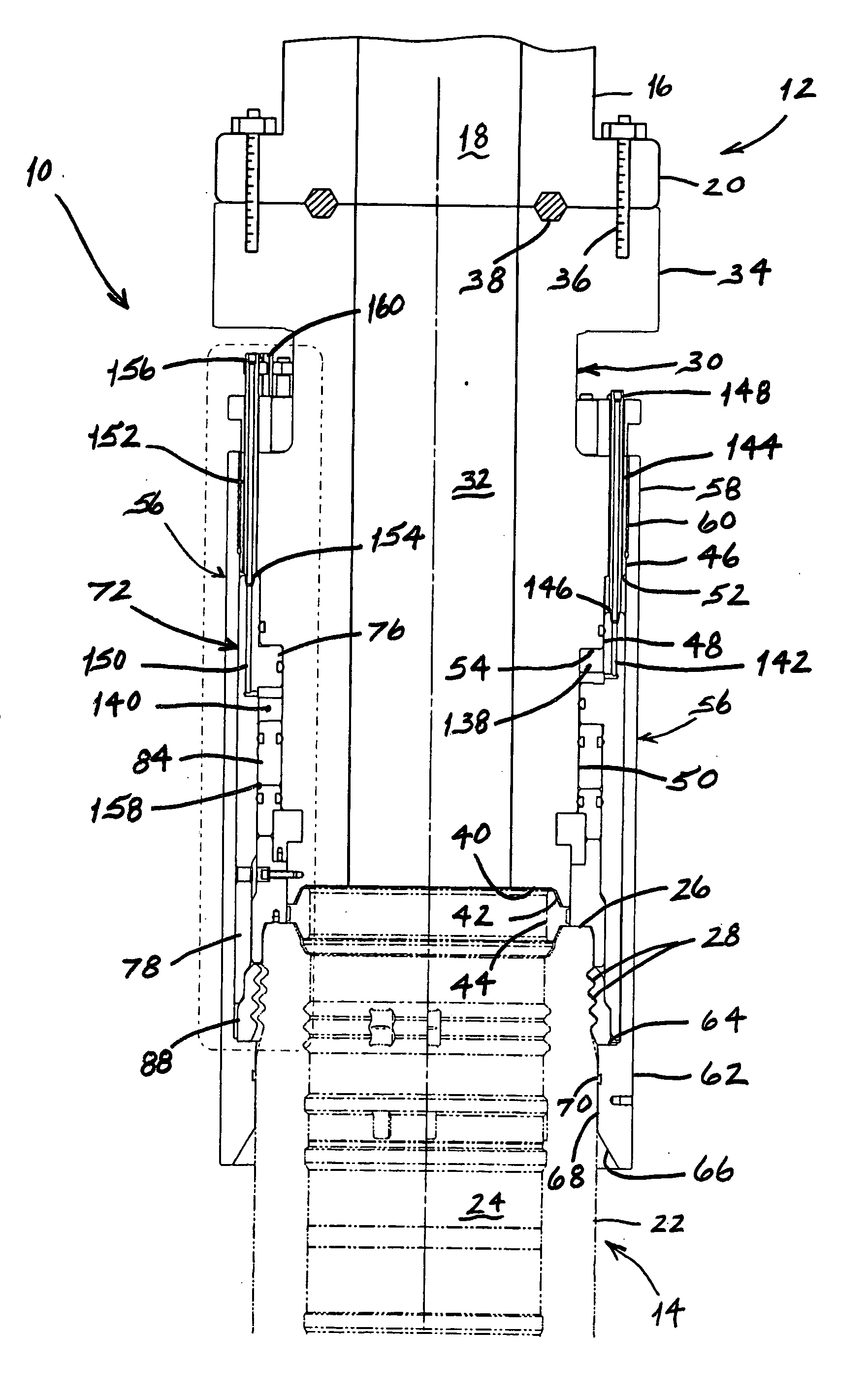

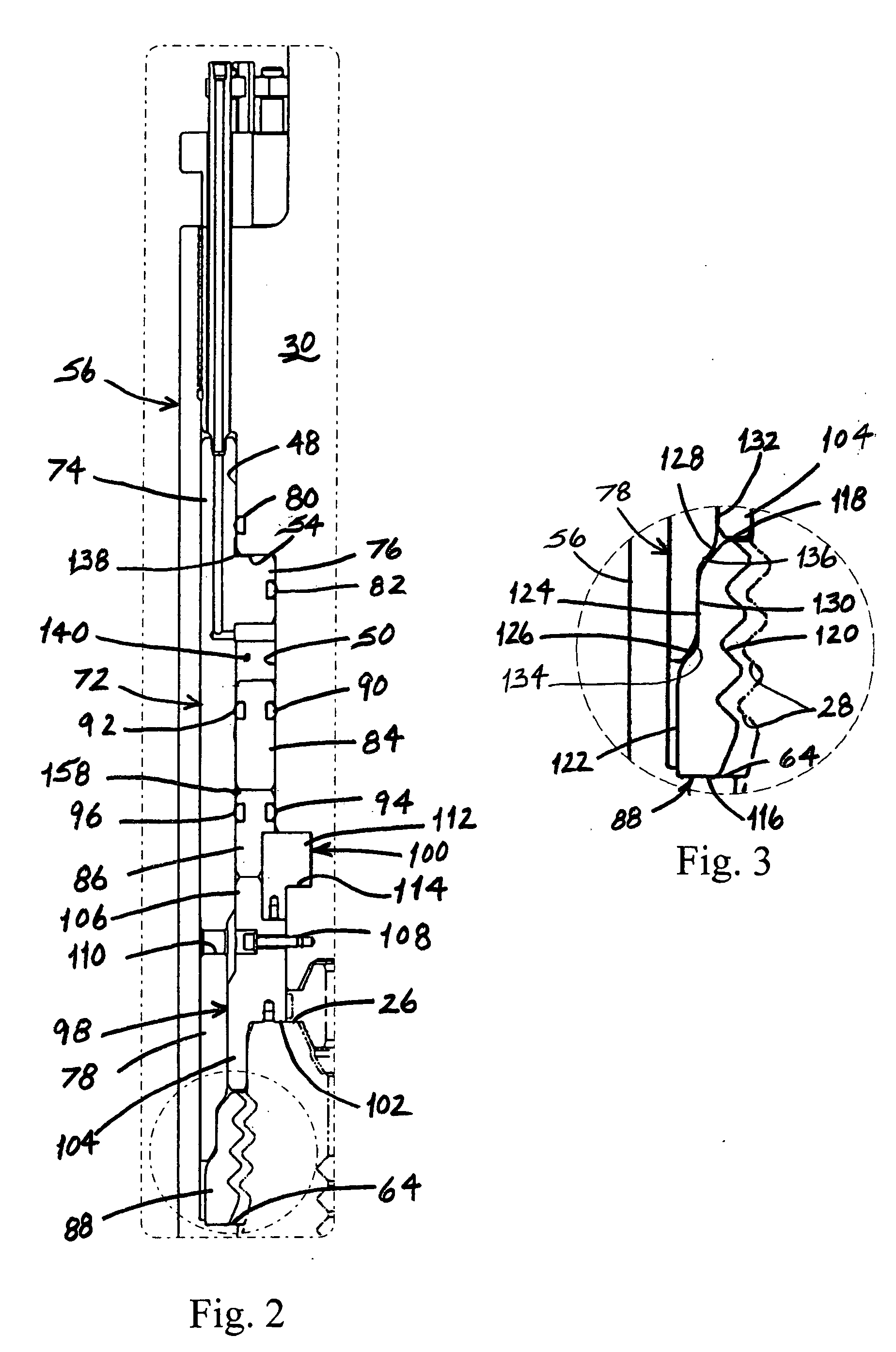

Slimline tieback connector

ActiveUS7537057B2Avoid uneven forceReduce the overall diameterFluid removalPipe elementsEngineeringMechanical engineering

A connector for securing a first cylindrical member to a second cylindrical member comprises a cylindrical body which includes a first end that is attached to the first member and a second end that is positioned proximate the second member, a cylindrical housing sleeve which is positioned concentrically over the body and which includes an upper end portion that is secured to the body and a lower end portion that is disposed adjacent the second member, a cylindrical primary piston that is positioned between the body and the housing sleeve, a locking mandrel which is connected to or formed integrally with the primary piston and which includes at least first and second annular portions that have different diameters, and a split lock ring which is supported by the lower end portion adjacent a number of locking grooves in the second member and which includes at least first and second cylindrical portions that correspond to the first and second annular portions of the locking mandrel. In operation, movement of the primary piston from a first position to a second position will force the first and second annular portions of the locking mandrel into engagement with the first and second cylindrical portions of the lock ring, respectively, and consequently force the lock ring into engagement with the locking grooves to thereby lock the connector to the second member.

Owner:FMC TECH INC

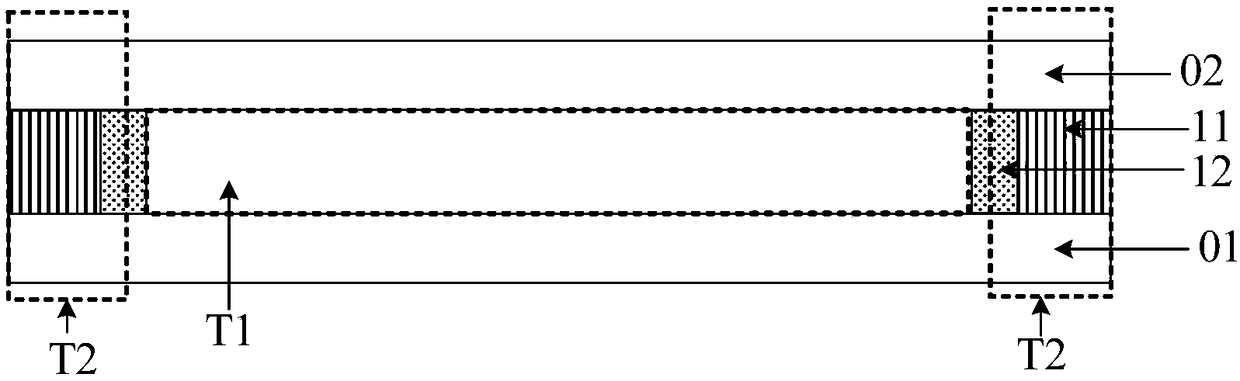

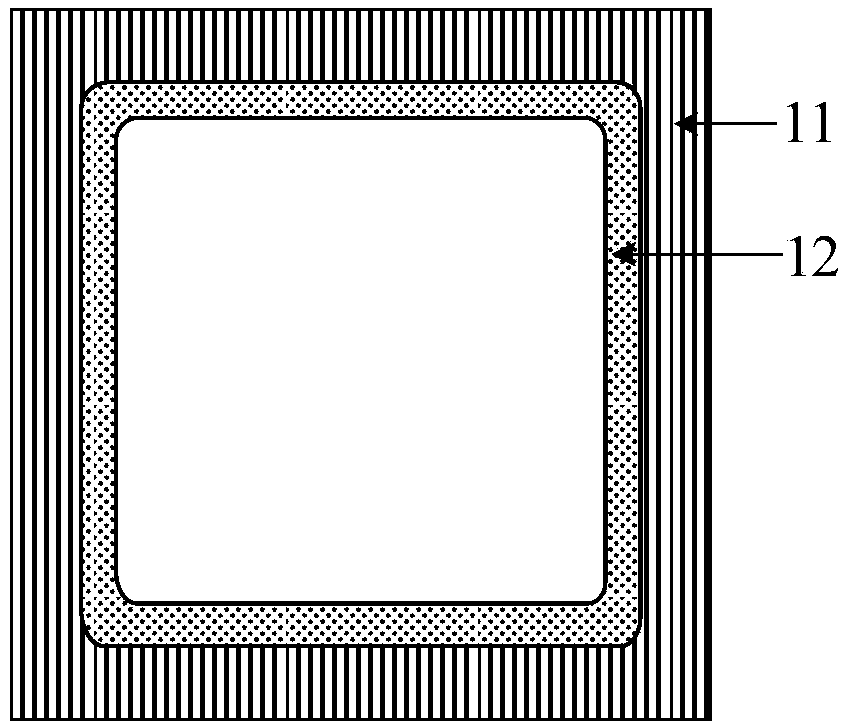

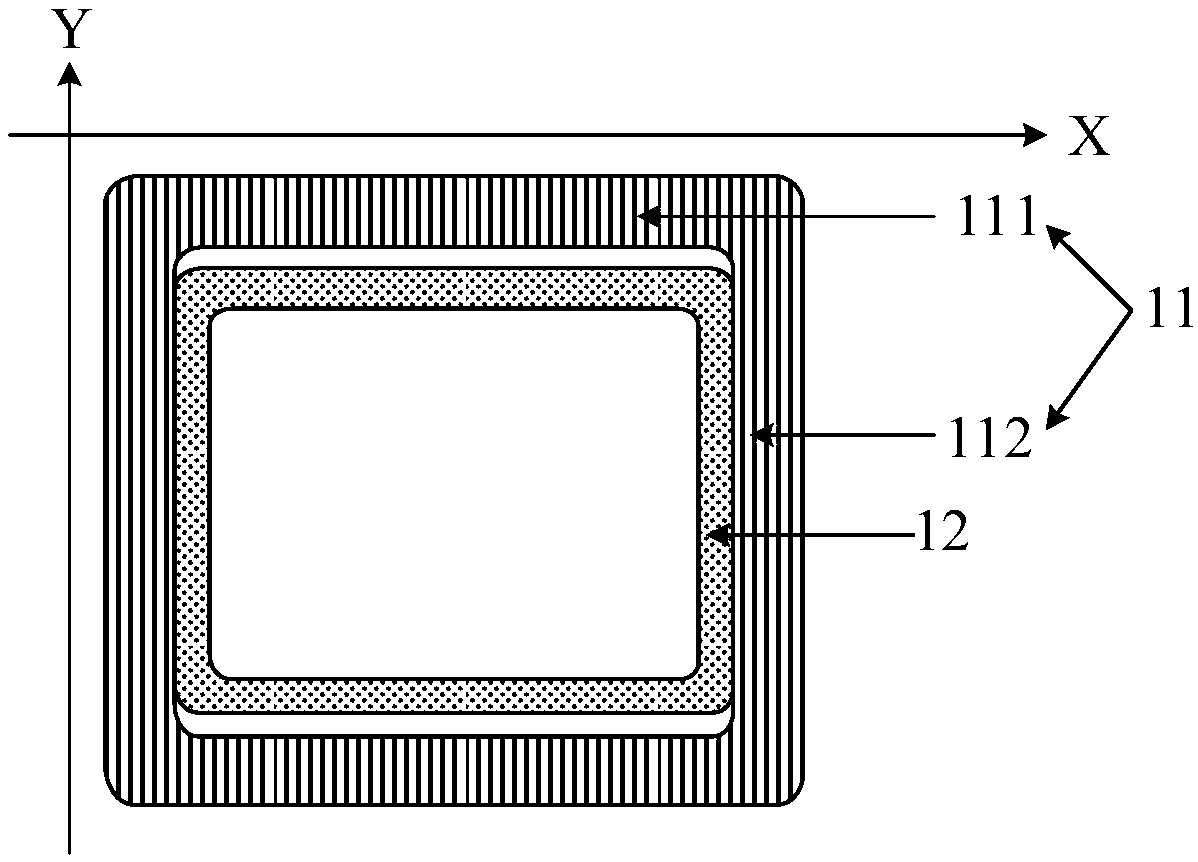

Display panel, manufacturing method of display panel and display device

PendingCN108232043AAvoid uneven forceGuaranteed appearanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display panel, a manufacturing method of the display panel and a display device, and belongs to the technical field of display. The display panel comprises an array substrateand a packaging cover plate which are oppositely arranged, at least one target substrate is arranged in the array substrate and the packaging cover plate, and the target substrate is provided with adisplay area and a non-display area; a supporting structure is arranged in the non-display area, and the side, away from the display area, of the supporting structure is coplanar with one side face ofthe array substrate or the packaging cover plate; the supporting structure is obtained from a cutting supporting structure in a display mother board when the display mother board is cut along a cutting line to form the display panel; the orthographic projection of the cutting supporting structure on the target substrate covers the area where the cutting line is located, so that when the display mother board is cut, the display mother board is cut along the cutting supporting structure, the problem that the stress of the display mother board is uneven due to cutting of other areas is avoided,and the appearance and quality of the display panel are ensured.

Owner:BOE TECH GRP CO LTD +1

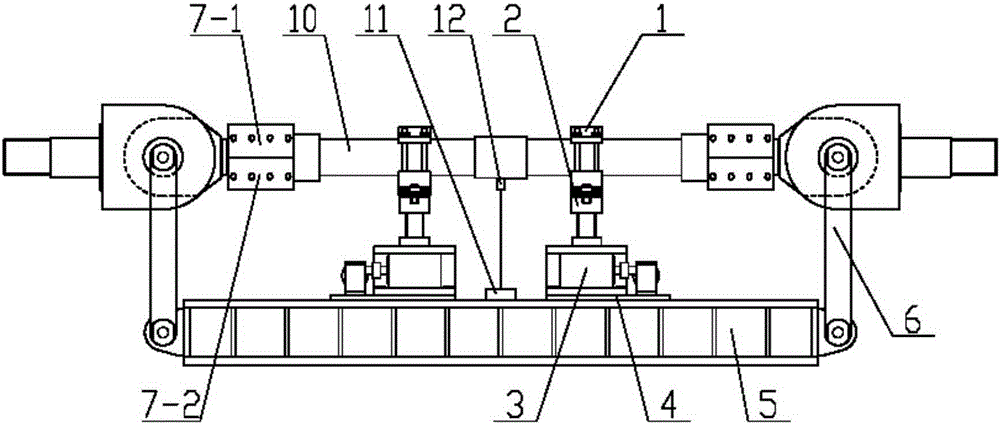

Four-point bending test device for pipe full-size evaluation

PendingCN106610359ALarge supporting loadAccurate loading dataMaterial strength using steady bending forcesConnection formTest fixture

The invention discloses a four-point bending test device for pipe full-size evaluation, and relates to the technical field of testing device of engineering pipes and supporting components. A device of the prior art cannot meet engineering requirements in the aspects of test precision, load capacity, test safety and the like. For overcoming the shortcomings of the prior art, the technical scheme provided by the invention comprises that the four-point bending test device for pipe full-size evaluation includes an electric lifter, a force measuring sensor, a clamp assembly, a guyed displacement sensor, a magnetic suction block for connecting the displacement sensor and a sample, a lifting bridge, and lifting lugs for connecting the lifting bridge and a full-size evaluation test machine. With a ball head connection form of the clamp assembly, the test is closer to on-service real working conditions of a pipe, the electric lifter is used as a bending load loading mechanism, the supporting load is large, safe and stable, and loaded data are accurate; the displacement sensor replaces a strain gage acquisition system, so the efficiency is improved, and the financial resources are saved; and the four-point bending test device can meet the needs of engineering technology.

Owner:BAOJI PETROLEUM STEEL PIPE

Floating impact apparatus for electrical nail gun

ActiveUS8479966B2Avoid uneven forceGuaranteed uptimeStapling toolsReciprocating drilling machinesEngineeringPulley

A floating impact apparatus for an electrical nail gun includes a carrier, an impact unit, and a floating unit. The impact unit includes an impact member, and at least one sliding, wheel disposed pivotally on the impact member. The floating unit includes a guiding rod together with the impact member being connected movably to the carrier, two floating members extending through the carrier to connect with the guiding rod at positions proximate to a first side of the carrier, and at least two resilient members disposed between a second side of the carrier and the floating members for biasing the guiding rod and the impact member to move relative to the carrier to thereby maintain contact between the sliding wheel and the first side of the carrier, so as to promote smooth movement and nail-striking force of the impact member.

Owner:BASSO IND CORP

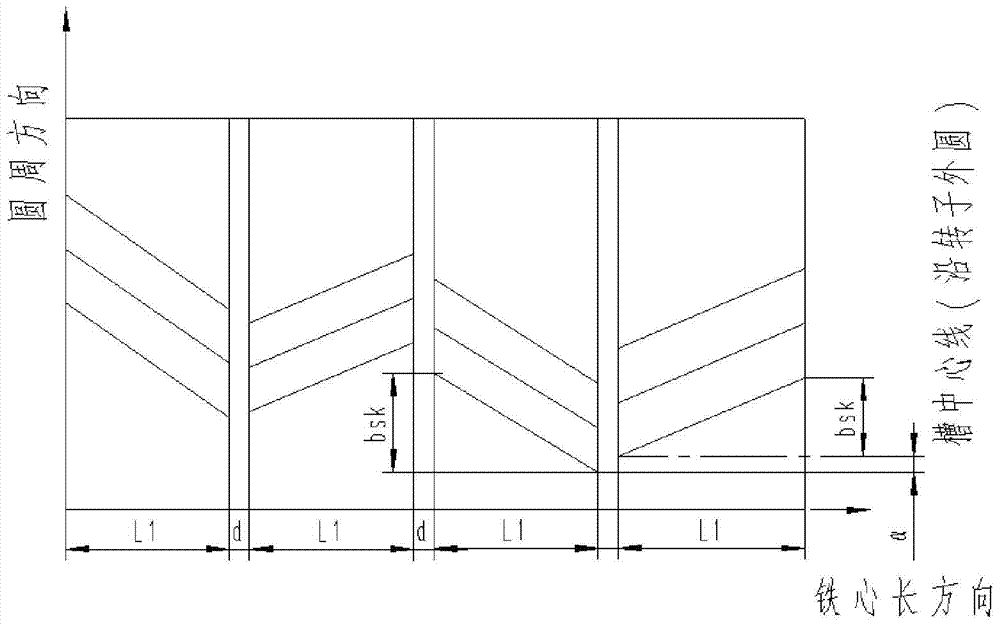

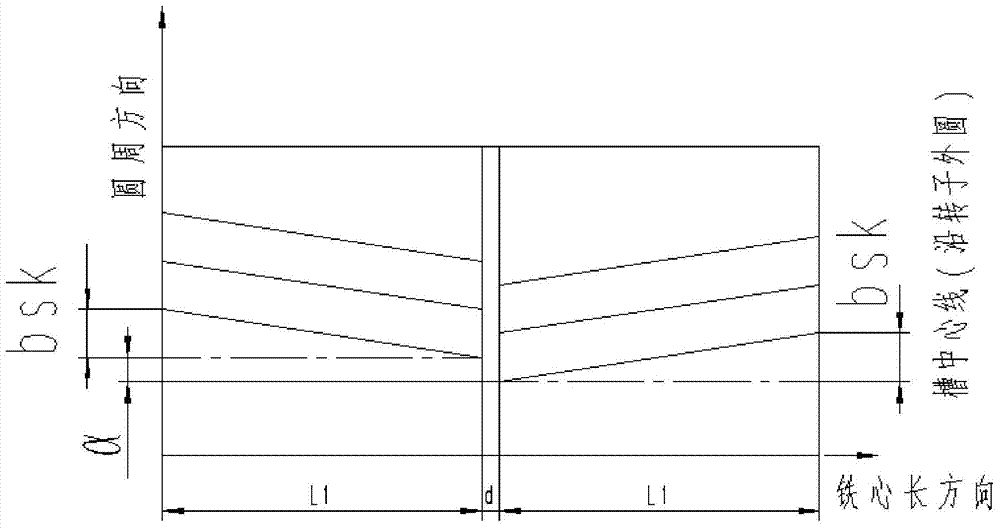

Chute low-noise motor

ActiveCN103501065AEliminate axialEliminate torsional vibrationMagnetic circuit rotating partsLow noiseElectric machine

The invention relates to a motor, in particular to a chute low-noise motor, which comprises a machine seat, a stator, a rotor and a rotating shaft, wherein the stator, the rotor and the rotating shaft are arranged on the machine seat, the rotor comprises at least two sections of rotor iron cores, the rotor iron cores are punched and laminated by a false axis inclination angle taper key method to form chute iron cores; chutes of the adjacent chute iron cores are in opposite directions and are in arrangement in a way of staggering for an angle alpha. Therefore, the chute low-noise motor has the following advantages that 1, great-degree optimization is respectively realized in aspects of vibration, noise, iron core laminating quality, cast aluminum quality and chute cast aluminum rotor structure adopted by a high-power motor, and the chute low-noise motor is suitable for small and medium-sized cast aluminum rotor structure alternating current motors with higher vibration and noise requirements; 2, the stress uniformity and the rigidity of iron core laminating punching are fundamentally ensured, the iron core laminating quality is improved, the influence of deformation on vibration noise is reduced, the aluminum overflowing and bubble problems are solved, and the quality of the cast aluminum rotor and the motor performance reliability are improved.

Owner:中国船舶重工集团公司第七一二研究所

Pipe fitting polishing device

InactiveCN108515403AAvoid over sandingAvoid the problem of uneven sandingEdge grinding machinesGrinding carriagesPipe fittingEngineering

The invention relates to the field of pipe fitting polishing, and discloses a pipe fitting polishing device. The pipe fitting polishing device comprises a machine frame and a supporting table, a conveying roller is rotationally connected to the supporting table, a clamping ring is rotationally connected to the supporting table, a through hole is formed in the middle portion of the clamping ring, driving teeth are arranged on the outer wall of the clamping ring, the interiors of the driving teeth are hollow, abutting-against rods are fixedly connected to the top ends of the interiors of the driving teeth, the other ends of the abutting-against rods are fixedly connected with abutting-against blocks, first supporting springs are fixedly connected between the top ends of the interiors of thedriving teeth and the outer wall of the clamping ring, a rack is in sliding connection to one side of the supporting table, a reset spring is fixedly connected to the upper portion of the rack, and anair bag is arranged above the rack and is opposite to the rack; and an air cylinder is in sliding connection to the supporting table, a guide pipe is connected between the air cylinder and the air bag, polishing strips are fixedly connected to the supporting table and are located on the opposite sides of the supporting plate, and the supporting table is further provided with a pushing mechanism used for pushing and abutting against the air cylinder. By means of device, the problem that a traditional polishing device cannot evenly polish a pipe fitting or local polishing is excessive is solved.

Owner:NINGBO HAIMAN AUTOMOTIVE TECH CO LTD

Preformed pile connecting structure

The invention discloses a preformed pile connecting structure which comprises positioning rings (1) and connecting hoops (2). The positioning rings (1) are preformed at the periphery of the connection parts of preformed piles (4); the connecting hoops (2) are sleeved at the periphery of the two positioning rings (1) of the two preformed piles (4) needing to be connected; and the connecting hoops (2) and the positioning rings (1) are fastened by a plurality of bolts. Due to the adoption of the preformed pile connecting structure, the preformed piles can be connected firmly, and the connection parts of preformed piles can meet the force bearing requirement.

Owner:ZHONGCHUN GAOKE PILE IND

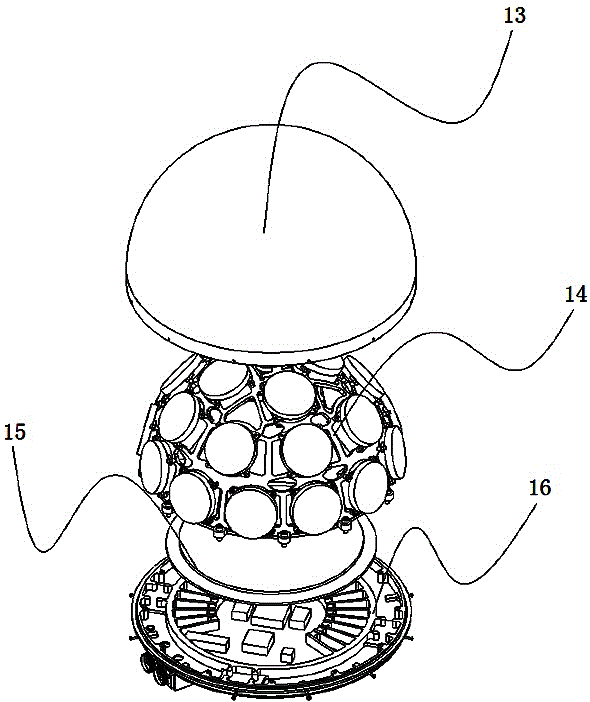

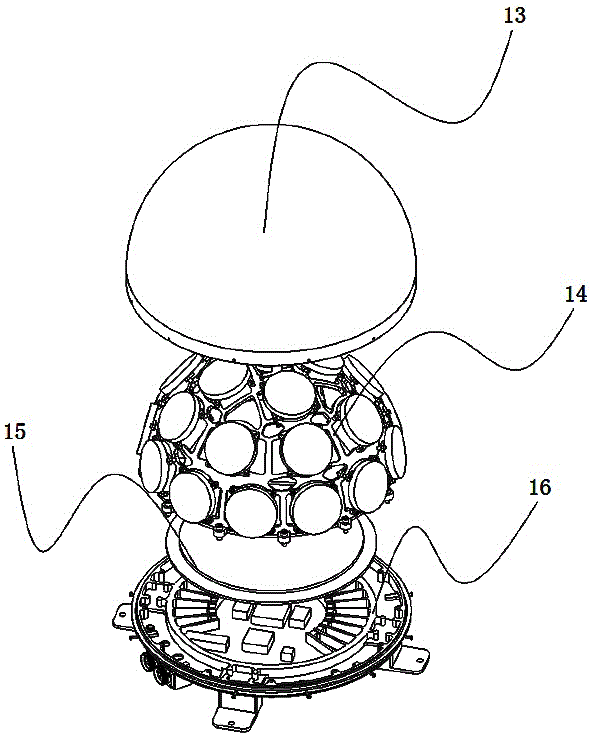

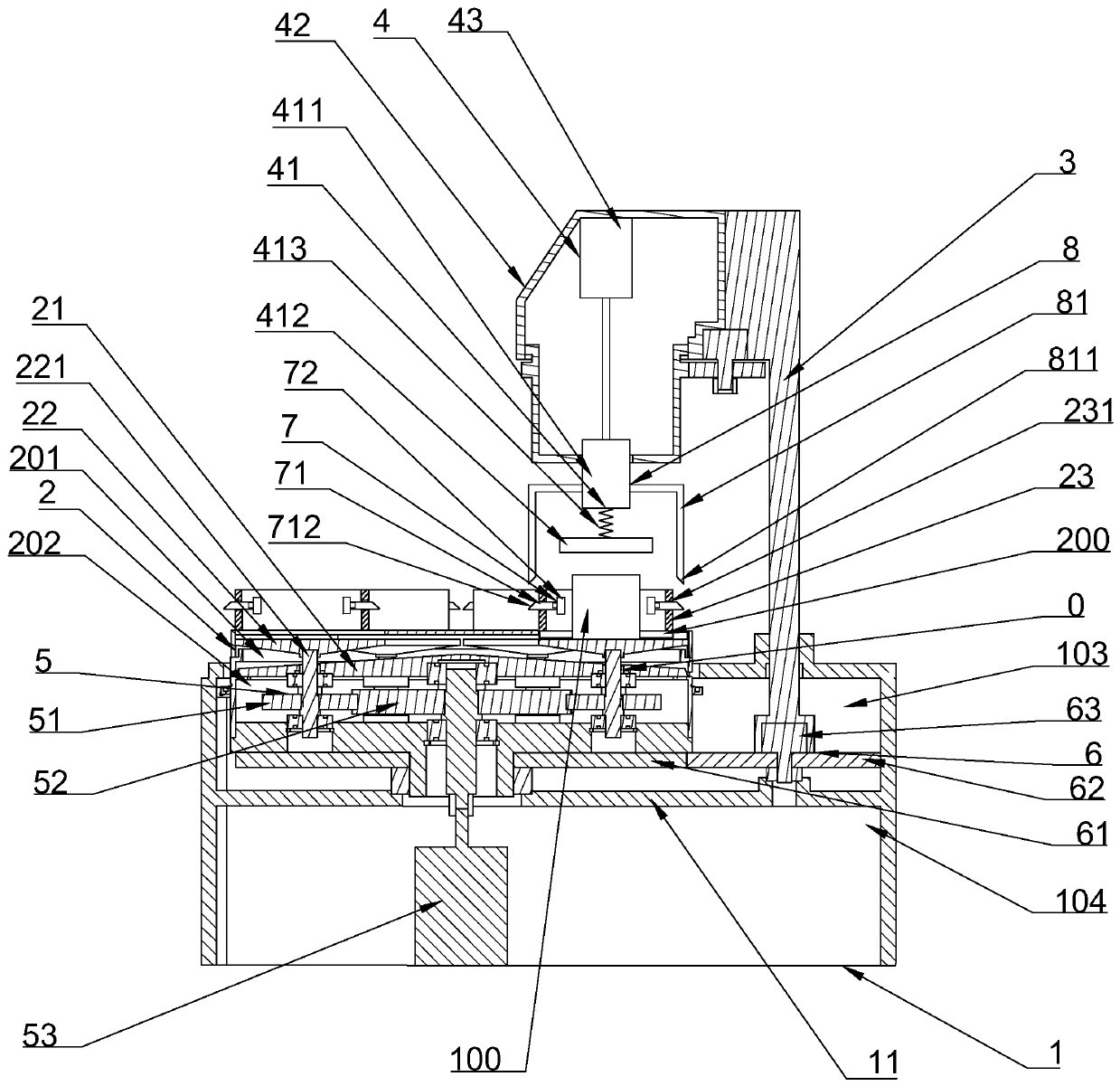

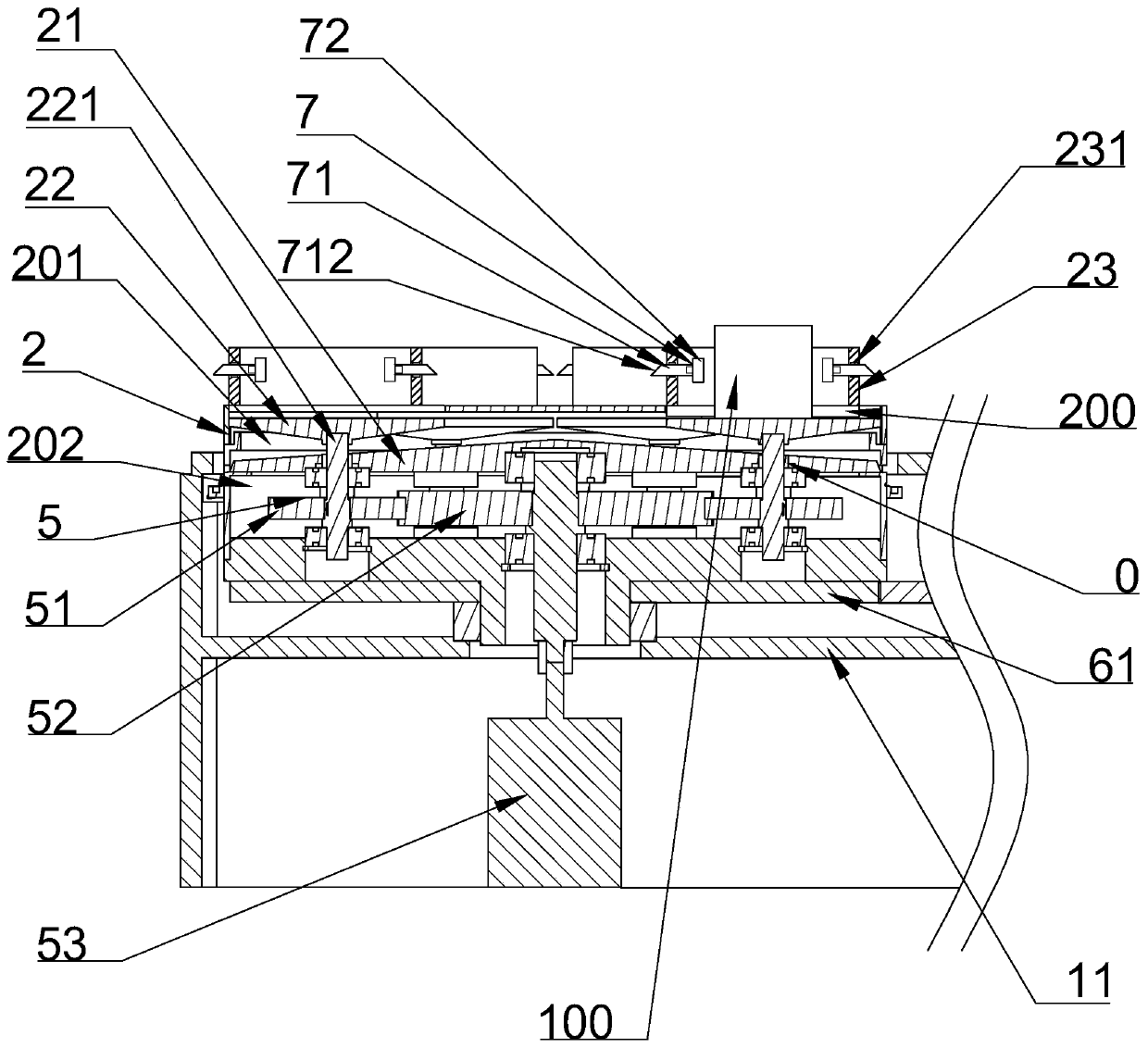

Conformal spherical antenna array

ActiveCN106025578AImprove versatilityReduce weightAntenna supports/mountingsRadiating elements structural formsEngineeringStructural stability

The invention discloses a conformal spherical antenna array which comprises a radome, an antenna array, a shield cover, a base plate and a supporting device. The antenna array is arranged on the base plate. The shield cover is located between the antenna array and the base plate. The antenna array is covered by the radome. The base plate is provided with an annular groove. The lower edge of the radome is inserted into the annular groove and is positioned by a locking positioning mechanism. The supporting device is arranged at the bottom of the base plate. The antenna array comprises a first skeleton, a second skeleton, a third skeleton and an antenna. The first skeleton, the second skeleton and the third skeleton are all arranged within the same ellipsoidal plane. The inclination angle of each skeleton is different. The first skeleton and the second skeleton are tangent to the ellipsoidal plane. The sphere tangent lines of the third skeleton and the second skeleton form a tangent angle a. The conformal spherical antenna array provided by the invention has the advantages of high antenna radiation uniformity, low production cost and stable structure.

Owner:成都泰格微电子研究所有限责任公司

Metallographic grinding and polishing machine

ActiveCN111069995AQuality improvementAvoid uneven forceGrinding carriagesGrinding drivesEmery paperGrinding

The invention discloses a metallographic grinding and polishing machine. According to the technical scheme, the metallographic grinding and polishing machine is characterized by comprising a base plate, an object carrying plate, a supporting rod and a pressing device, wherein the object carrying plate is rotationally arranged on the upper end face of the base plate, the supporting rod is arrangedon the upper end face of the base plate, and the pressing device is connected to the end, far away from the base plate, of the supporting rod; a first cavity is formed in the object carrying plate, aplurality of object storage holes communicating with the first cavity are formed in the upper end face of the object carrying plate, a plurality of grinding plates are rotationally arranged in the first cavity, and abrasive paper with different particle sizes is detachably arranged on the faces, facing the object storage holes, of the grinding plates; and the pressing device is used for abutting samples below the pressing device against the grinding plates, and the metallographic grinding and polishing machine is further provided with a grinding mechanism used for driving the grinding plates to rotate and a switching mechanism used for driving the object carrying plate to rotate. According to the metallographic grinding and polishing machine, the grinding plates provided with the abrasivepaper with different particle sizes and the switching mechanism are arranged so that the different grinding plates can be selected through the switching mechanism to control the grinding degree of themetallographic samples, and meanwhile the grinding efficiency is improved.

Owner:浙江杭途机械制造有限公司

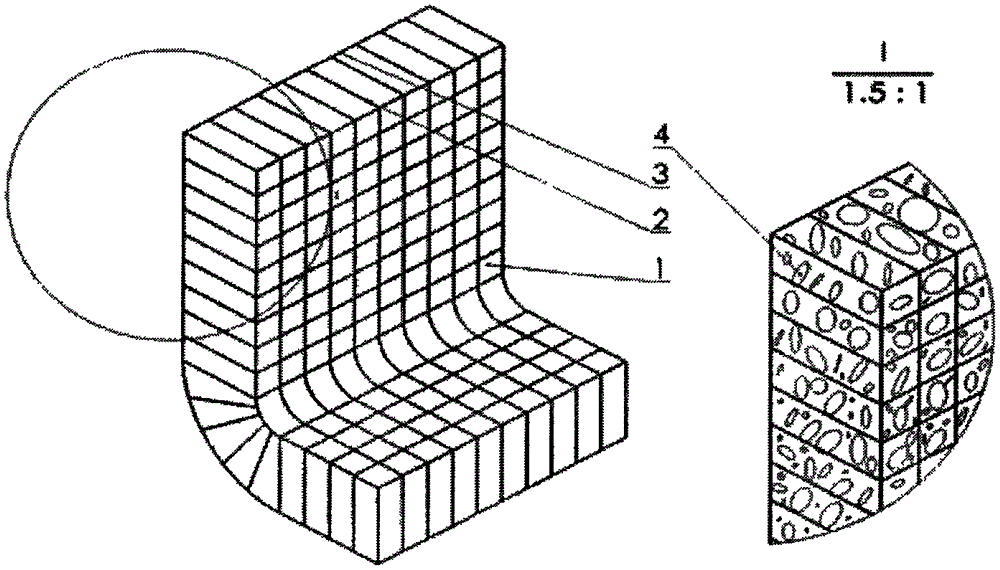

Three-dimensional spacer fabric reinforced cement-based composite material and preparation method thereof

InactiveCN106316177AFind the junctionImprove integritySurface layering apparatusShell moldingTransfer molding

The invention provides a three-dimensional spacer fabric reinforced cement-based composite material and a preparation method thereof and relates to a cement-based composite material. The preparation method comprises the following steps: putting a three-dimensional spacer fabric into a mold, and compositing resin with the three-dimensional spacer fabric by virtue of a resin transfer molding technique; curing the resin, so as to obtain a three-dimensional spacer fabric composite material skeleton; and uniformly mixing and stirring a cement binding material, water and an additive, pouring the mixture into the three-dimensional spacer fabric composite material skeleton, and carrying out compacting, hardening and maintenance forming, so as to obtain the three-dimensional spacer fabric reinforced cement-based composite material. According to the preparation method, composite material skeletons of various shapes can be obtained by virtue of the compositing of the three-dimensional spacer fabric and the resin and can be produced into building components of various shapes through cement pouring and solidification. Furthermore, the cement-based composite material has the advantages that the strength of common concrete is greatly improved, the construction is simple and convenient, and the performance is excellent.

Owner:TIANJIN POLYTECHNIC UNIV

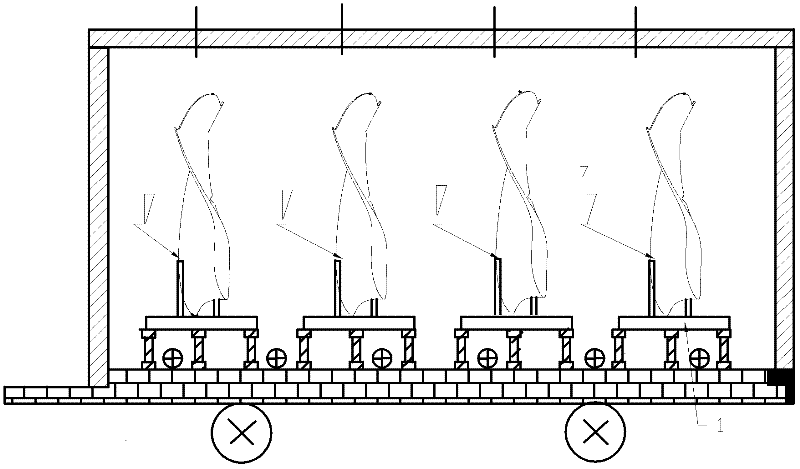

High and medium-temperature heat treatment deformation preventing device for large turbine blades

ActiveCN102560053AUnique structureWon't fallFurnace typesHeat treatment furnacesWater turbineTurbine blade

The invention relates to a deformation preventing device, in particular to a high and medium-temperature heat treatment deformation preventing device for large turbine blades. The device is characterized by being formed by assembling a casting support frame and supporting cushion blocks for supporting the casting support frame; the casting support frame is formed by assembling a U-shaped groove in the middle, groove walls on two sides of the U-shaped groove and a triangular side support which is fixed at each of two ends of the outer side of each groove wall; three cross beams with arc-shapedtops and different heights are fixed in the U-shaped groove at intervals; and two groove columns are fixed at each edge of the U-shaped groove. The device can make up the defects of the conventional blade heat treatment technology and prevent deformation of the blades in the heat treatment process according to the conventional heat treatment process mode, the characteristics of a trolley furnace and the overall dimension of the blades of different types.

Owner:KOCEL EQUIP

Treatment couch specific to rehabilitation of bedridden patient

ActiveCN104173159AImprove recovery effectImprove the quality of lifeNursing bedsLife qualityProgrammable logic controller

The invention discloses a treatment couch specific to rehabilitation of a bedridden patient and belongs to the field of medical facilities. The treatment couch comprises an elastic mattress which is installed on a couch frame, the elastic mattress is composed of a plurality of elastic supporting columns which are distributed in a rectangular array, the elastic supporting columns comprise oil cylinders which are disposed on the couch frame, cylinder bodies of the oil cylinders are fixedly arranged on the couch frame, ends of piston rods of the oil cylinders are machined to form circular truncated cones, ball heads are fixedly disposed on the circular truncated cones, universal supporting seats are installed on the ball heads in a matching mode, reset springs sleeve the piston rods of the oil cylinders, two ends of the reset springs abut against bottom surfaces of the circular truncated cones and top surfaces of the cylinder bodies respectively, side walls of the cylinder bodies are communicated with an oil inlet pipe and an oil return pipe, and the oil inlet pipe and the oil return pipe are connected with a double-position on-off valve which is controlled by a programmable logic controller (PLC). According to the treatment couch specific to rehabilitation of the bedridden patient, local skin parts of a human body contact with the mattress through alternating control so that the local skin parts of the human body can contact with air in an alternating mode, the ventilating effect can be achieved, the rehabilitation effect of the patient can be improved, living qualities can be improved, and the treatment couch can be applied to rehabilitation of the patient.

Owner:YANGZHOU UNIV

Slimline tieback connector

ActiveUS20070181309A1Reduce the overall diameterEqually distributedFluid removalPipe elementsEngineeringMechanical engineering

A connector for securing a first cylindrical member to a second cylindrical member comprises a cylindrical body which includes a first end that is attached to the first member and a second end that is positioned proximate the second member, a cylindrical housing sleeve which is positioned concentrically over the body and which includes an upper end portion that is secured to the body and a lower end portion that is disposed adjacent the second member, a cylindrical primary piston that is positioned between the body and the housing sleeve, a locking mandrel which is connected to or formed integrally with the primary piston and which includes at least first and second annular portions that have different diameters, and a split lock ring which is supported by the lower end portion adjacent a number of locking grooves in the second member and which includes at least first and second cylindrical portions that correspond to the first and second annular portions of the locking mandrel. In operation, movement of the primary piston from a first position to a second position will force the first and second annular portions of the locking mandrel into engagement with the first and second cylindrical portions of the lock ring, respectively, and consequently force the lock ring into engagement with the locking grooves to thereby lock the connector to the second member.

Owner:FMC TECH INC

Light-weight and shock-absorbing combined shoe sole and production method thereof

InactiveCN107400268APrevent vomiting creamCream SuppressionSolesDomestic footwearRubber materialEngineering

The invention relates to a production technology of a shoe sole, in particular to a light-weight and shock-absorbing combined shoe sole and a production method thereof. The combined shoe sole consists of an outsole and a midsole, wherein the outsole is produced from a rubber material by mixing, performing open mixing, vulcanizing and other processes; the midsole is produced from an EVA material by mixing, performing open mixing, granulating, foaming once, and performing oil pressing twice. The raw materials and the processes of the light-weight and shock-absorbing combined shoe sole provided by the invention are optimized, so that various problems of the rubber material and the EVA material in application are effectively solved; a finished product is light in weight, good in resilience and excellent in shock-absorbing effect, and is not prone to aging and frosting problems.

Owner:LILANG CHINA

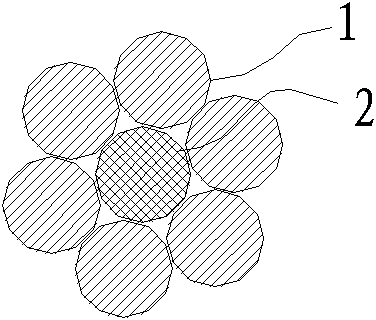

Method for producing glass fiber reinforced plastic anchor pole

The invention discloses a method for producing a glass fiber reinforced plastic anchor pole, especially a method for producing a highly torsion-resistant, anti-shearing prestressing glass fiber reinforced plastic anchor pole, comprising the following steps of: mixing unsaturated polyester resin, nanometer mullite, aluminium hydroxide, polyurethane, zine stearate, white carbon black, methylethyl ketone peroxide, TBPB and a mould release agent according to a mass ratio in a resin solution groove with stirring to produce a resin solution, followed by vacuum-pumping and bubble-removing; towing glass fibres from a filament rack, twisting the glass fibres on a twisting support to form a twist of 10-30 degrees by rotating and towing the twisted glass fibres into the resin solution groove for impregnation; towing the twisted and impregnated glass fibres into a cone-shaped sleeve for folding and bundle-forming as well as preforming; finally continuously towing the folded bundles of glass fibres into a hot pressing die, followed by molding at the temperature of 160-180 DEG C. The method provided by the invention is simple, and the anchor pole produced by the invention has high torsion-resistant and anti-shearing performance as well as low cost.

Owner:扬州中矿矿业技术发展有限公司 +1

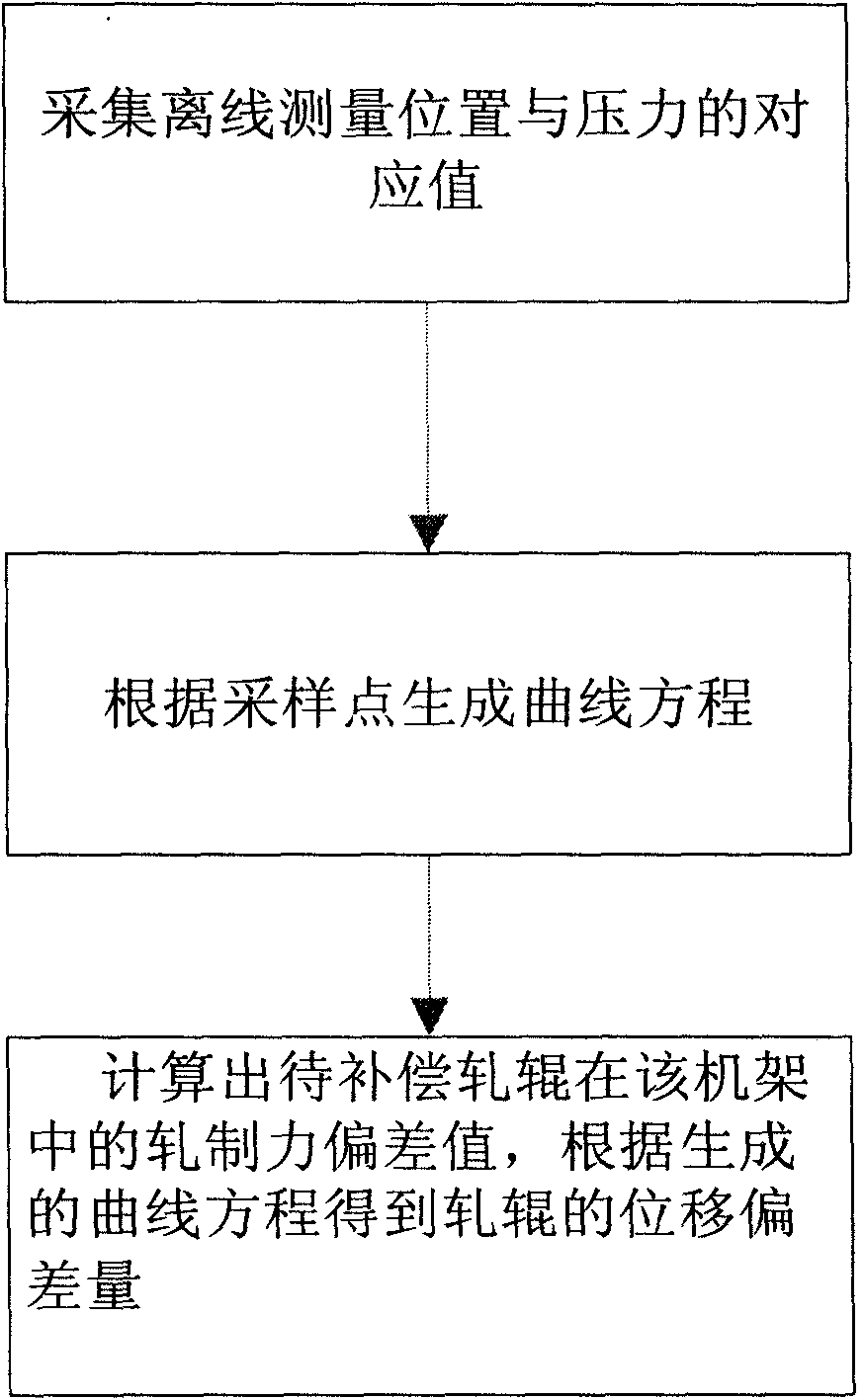

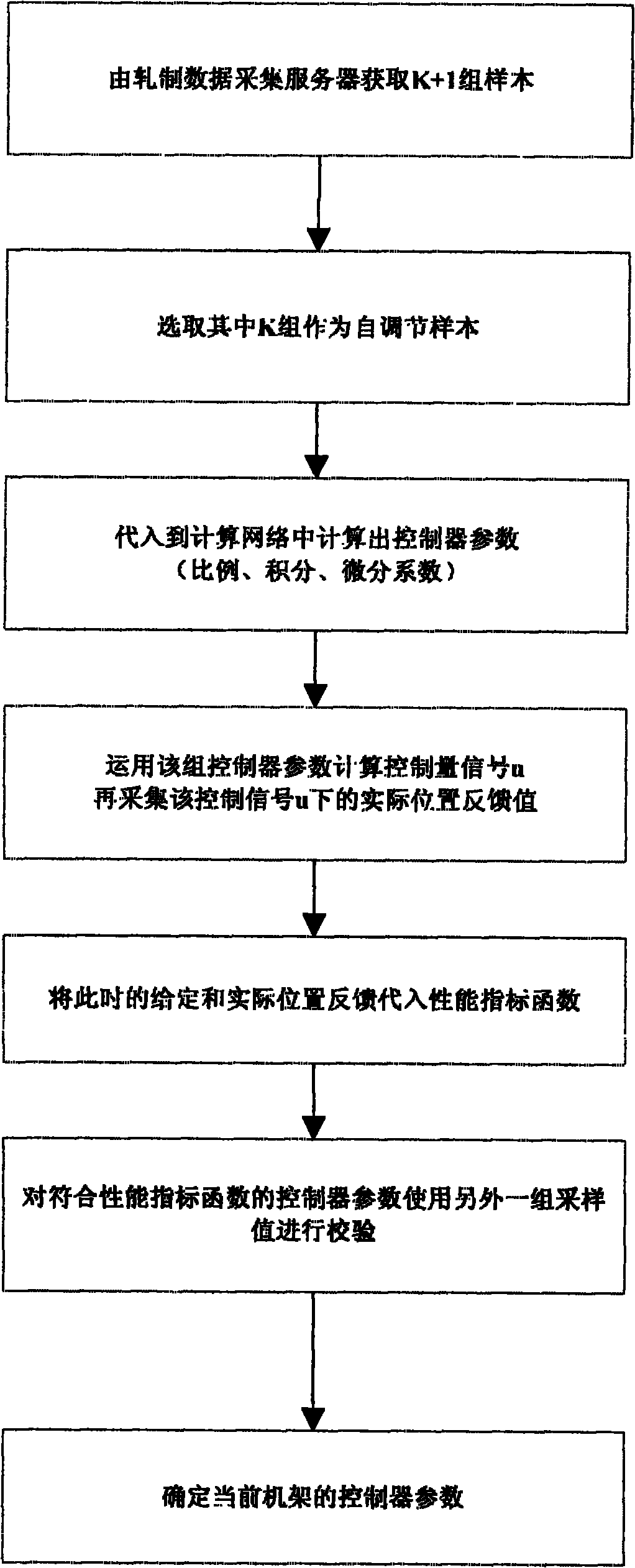

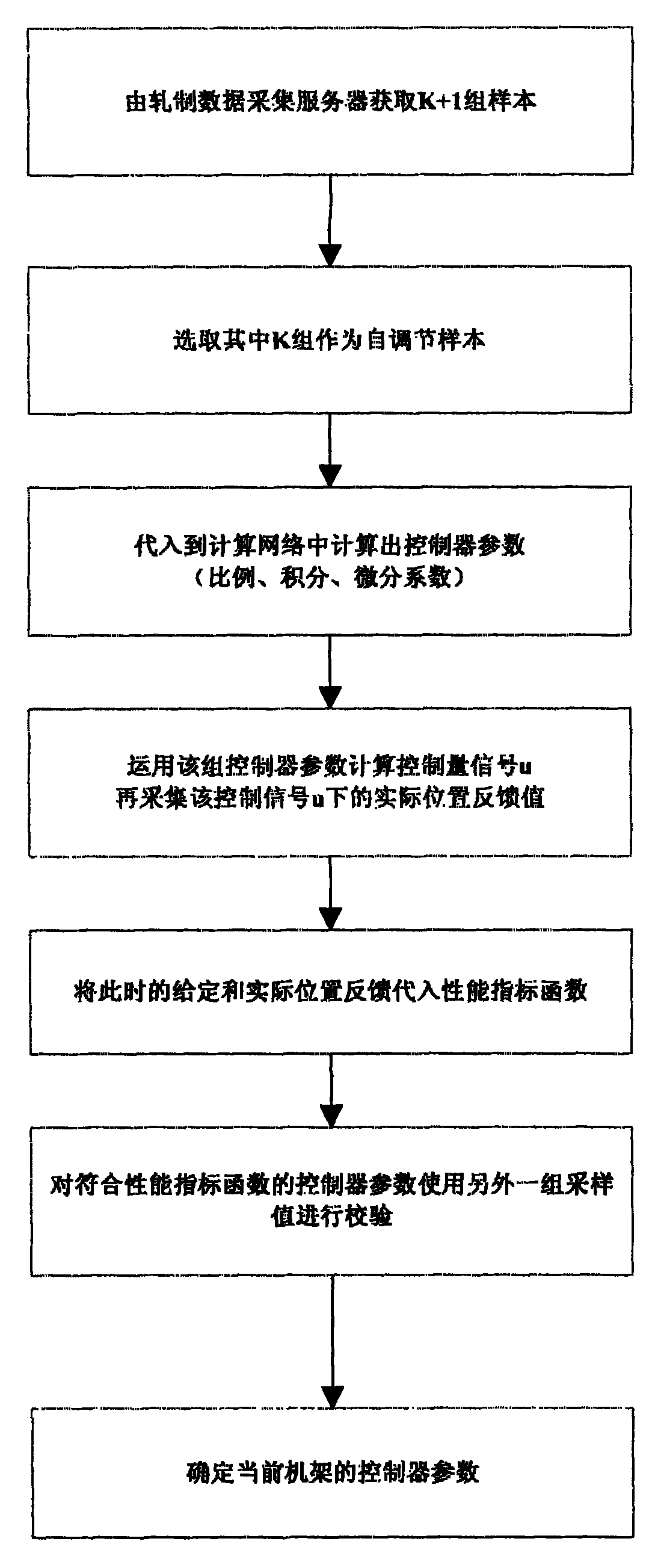

Method for adjusting three-roll mill roll gap controller

InactiveCN101927269ASolve the problem of position offsetAvoid uneven forceRoll force/gap control deviceAdaptive controlControl signalEngineering

The invention discloses a method for adjusting a three-roll mill roll gap controller. The roll gap controller is characterized in that the adjusting method comprises the steps of: A. deducing controller parameters Kp, Ki and Kd through a neural network and calculating control signals by increment control equations for adjusting the controller; and B. Balancing a rolling force: acquiring corresponding values of a off-line measuring position and pressure, calculating rolling force deviation of the roll to be compensated on a stand according to a curvilinear equation generated from a sampling point, and compensating the control signals through the calculated displacement deviation. The invention uses the neural network to calculate proper controller parameters so as to make the control more accurate. Meanwhile, the roll gap controller adopts a centering compensating method, thus the roll gap controller can avoid position deviation of roll gap resulted under the action of rolling pressure. In addition, the adjusting method for balancing rolling force solves the problem of uneven load distribution in different directions of a pipe so as to achieve uniformity of wall thickness of a product and improve productivity of the product.

Owner:CISDI ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com