Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

921 results about "Nail gun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nail gun, nailgun or nailer is a type of tool used to drive nails into wood or some other kind of material. It is usually driven by compressed air (pneumatic), electromagnetism, highly flammable gases such as butane or propane, or, for powder-actuated tools, a small explosive charge. Nail guns have in many ways replaced hammers as tools of choice among builders.

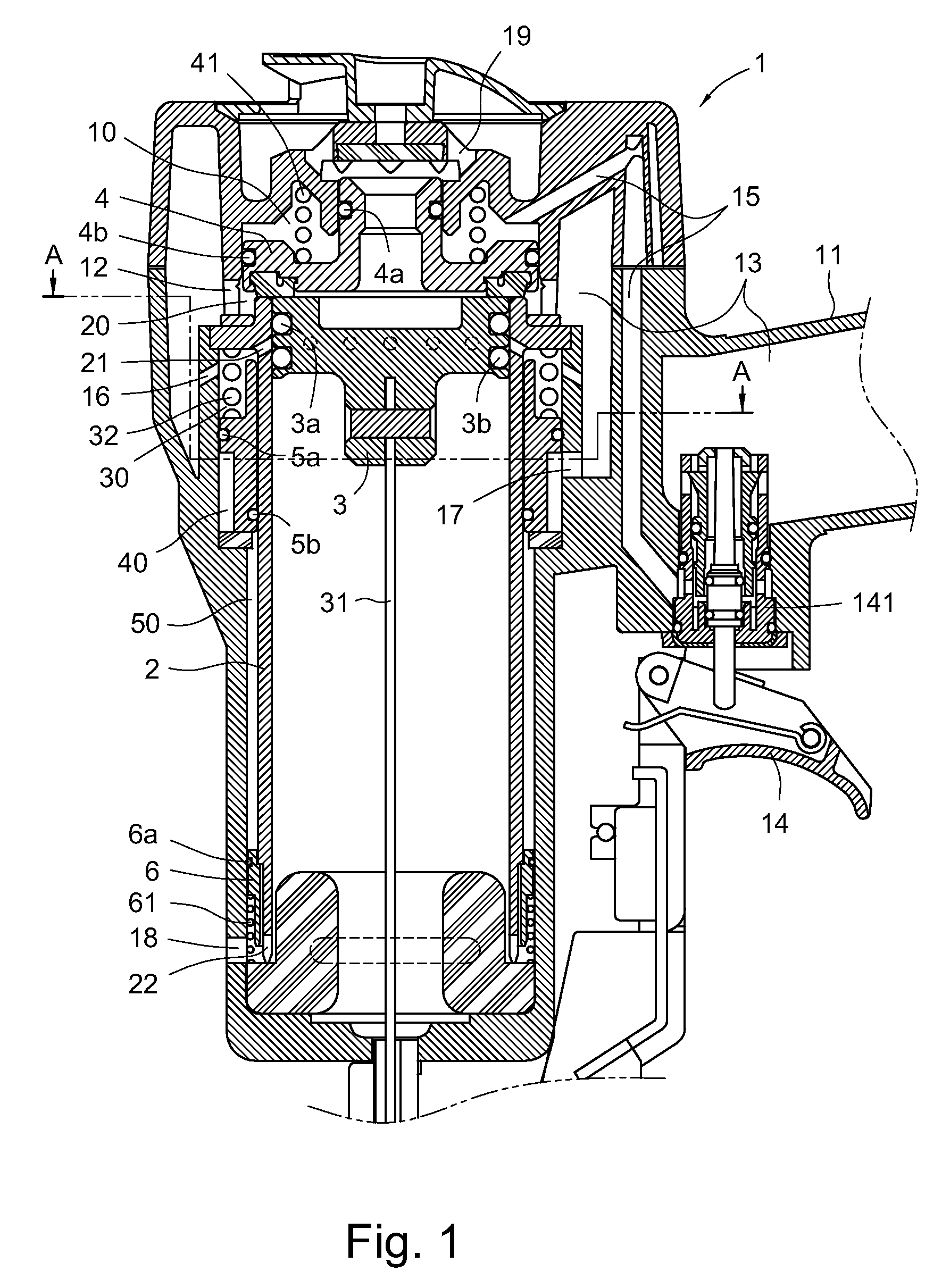

Electrical motor driven nail gun

InactiveUS6705503B1Easy to handleReduce wearStapling toolsReciprocating drilling machinesEngineeringFlywheel

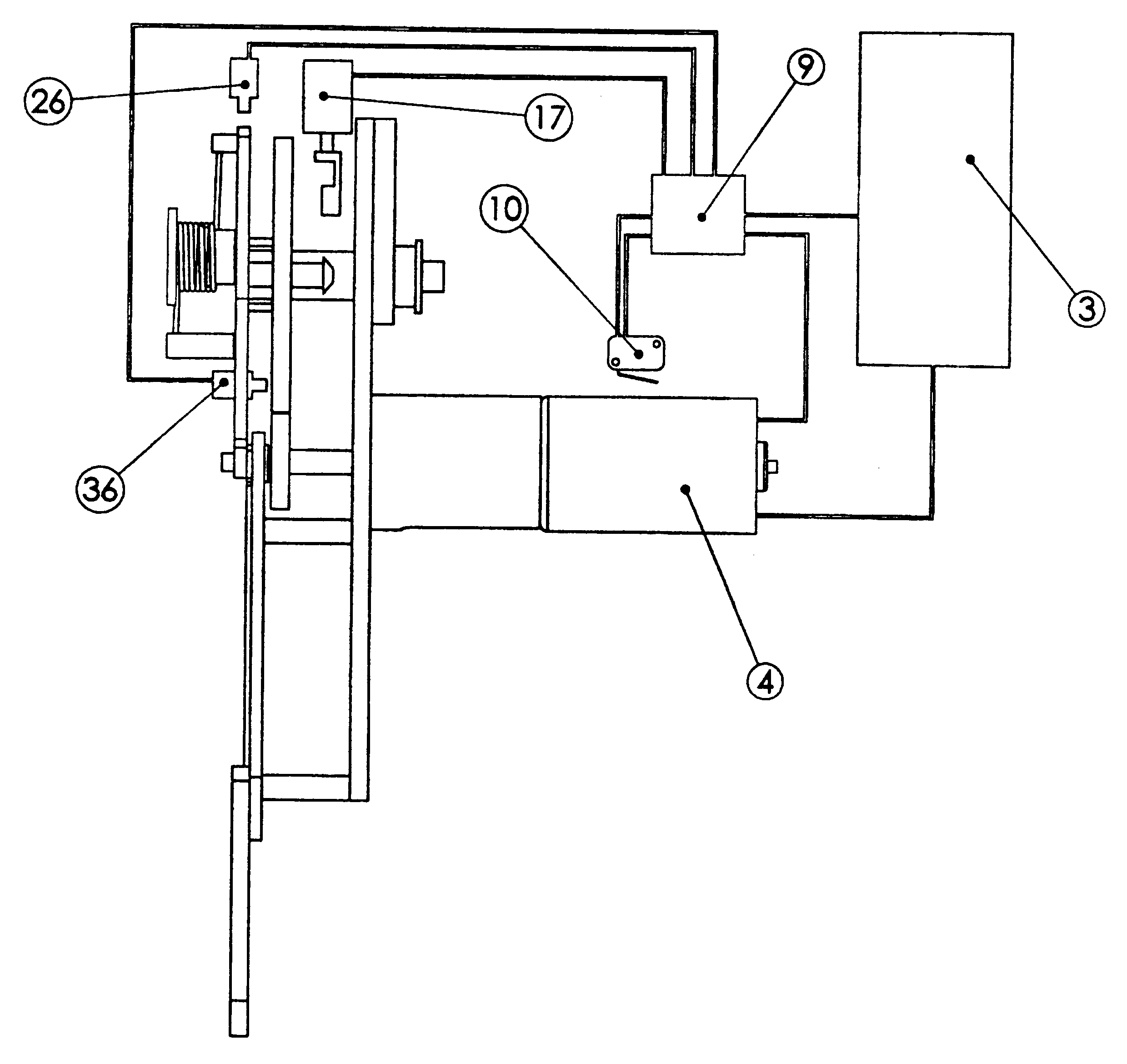

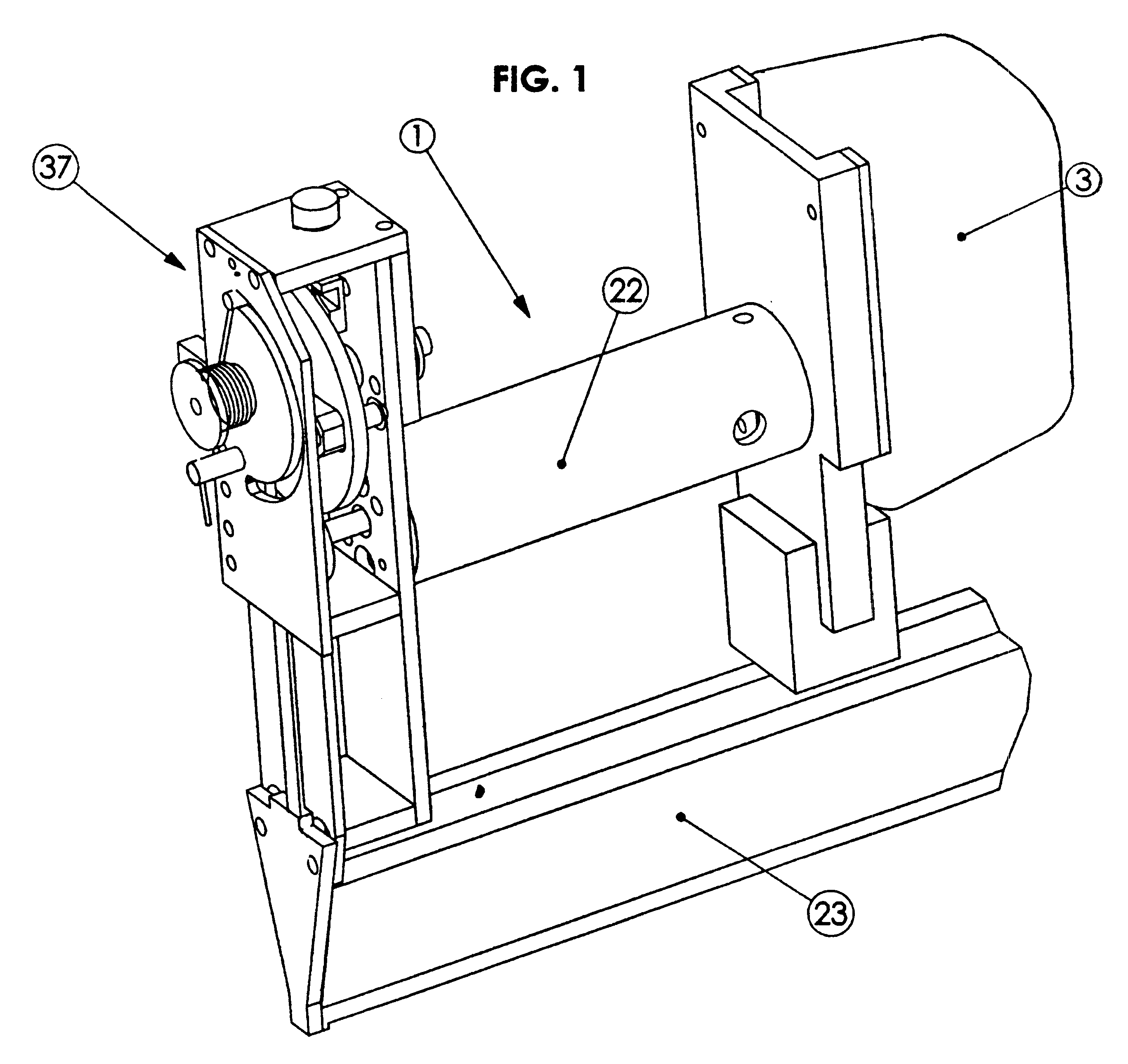

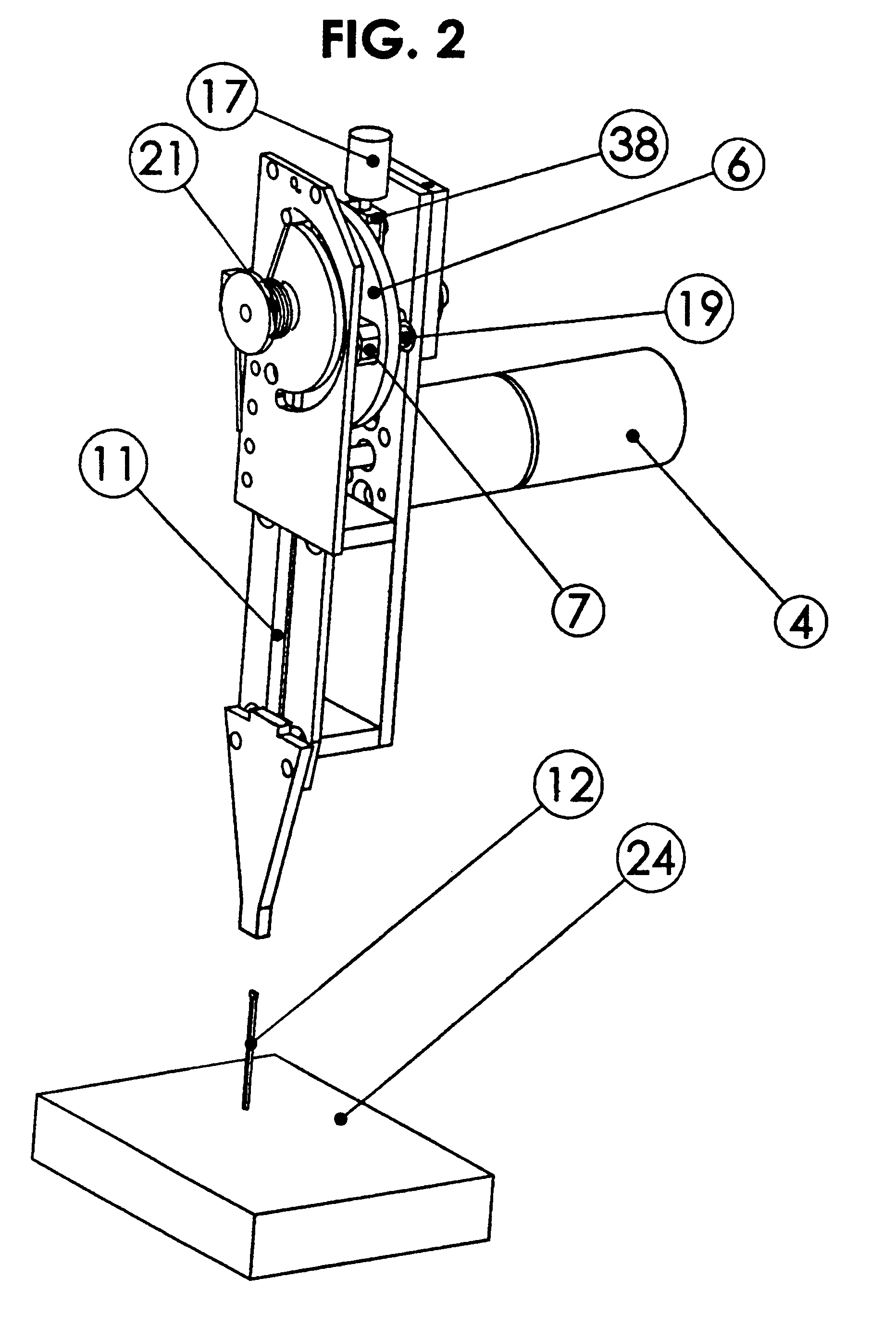

A portable electric nailing gun operating from a power supply. The motor accelerates a flywheel, which at the appropriate energy state is coupled through a mechanism to an anvil acting directly on the nail. The actuation is governed by a control circuit and initiated from a trigger switch. The stored energy delivered from the motor is coupled to the output anvil drives the nail. At least one position of the output anvil is sensed and once the nail is driven, the power is disconnected from the motor. This method uses a direct acting clutch and a harmonic motion nailing mechanism to reduce wear and increase robustness of the nailer. Elastic elements are used to limit stresses during the impact periods. The electrical control circuit and sensors allow precise control and improve safety. The power supply is preferably a rechargeable low impedance battery pack.

Owner:TRICORD SOLUTIONS

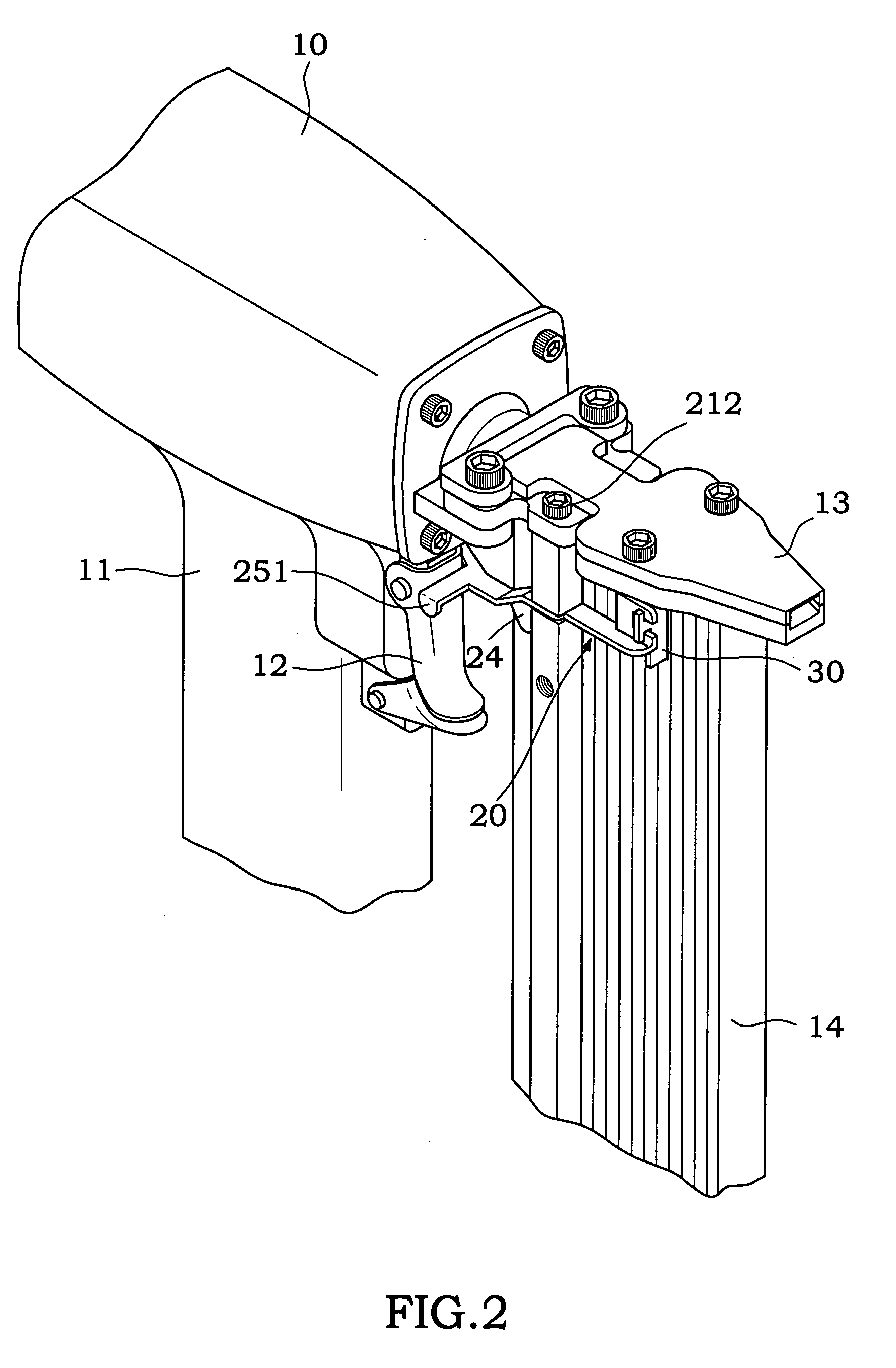

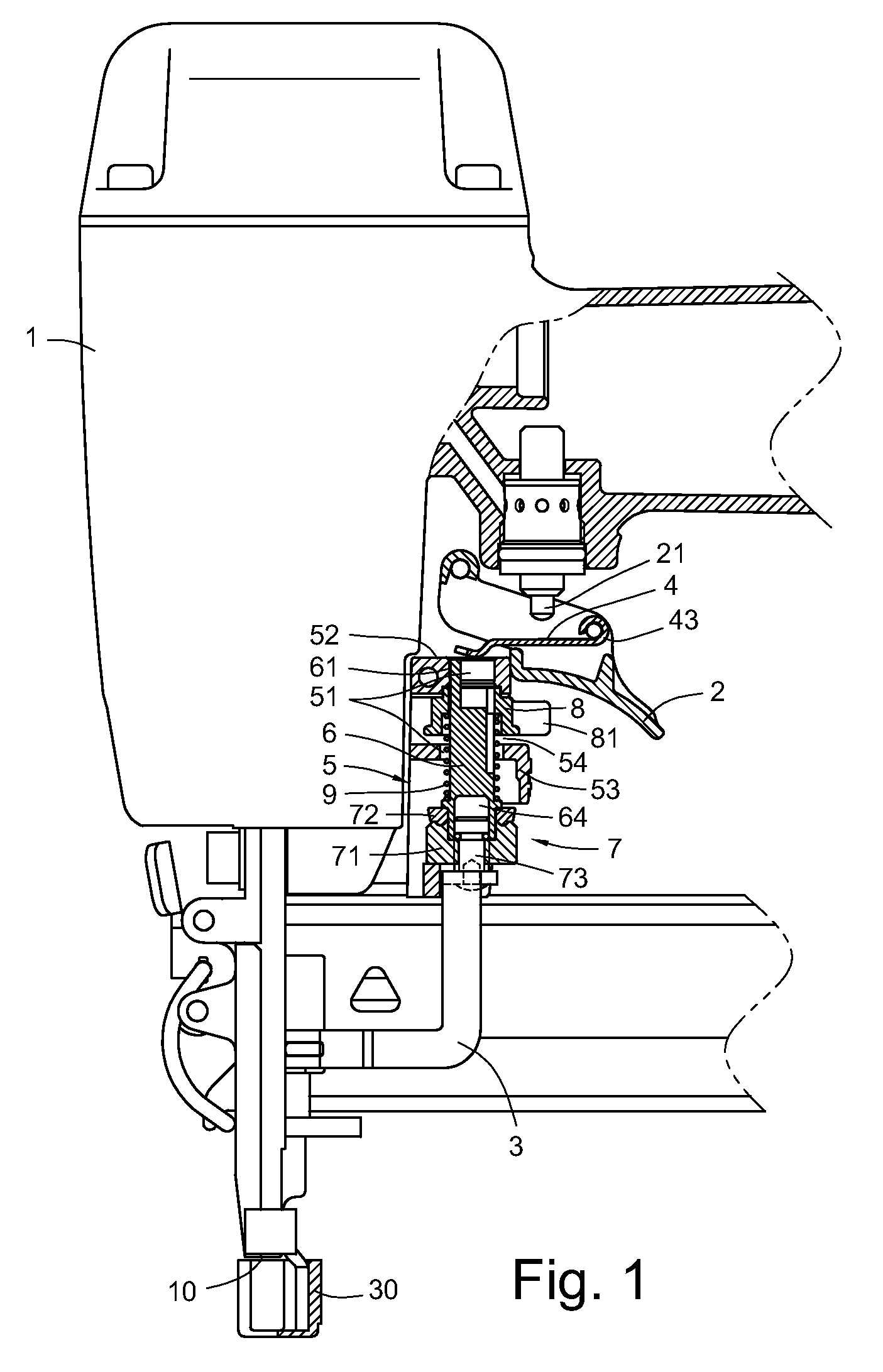

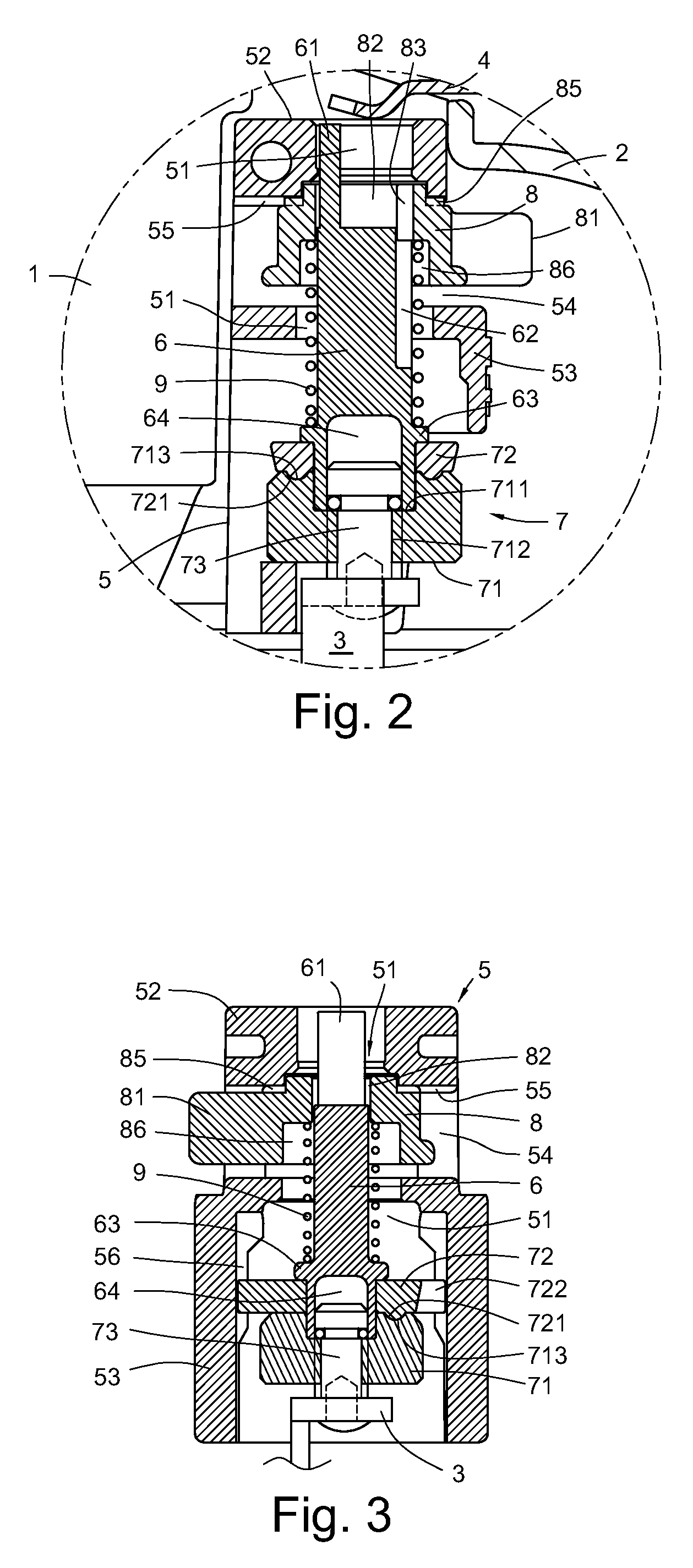

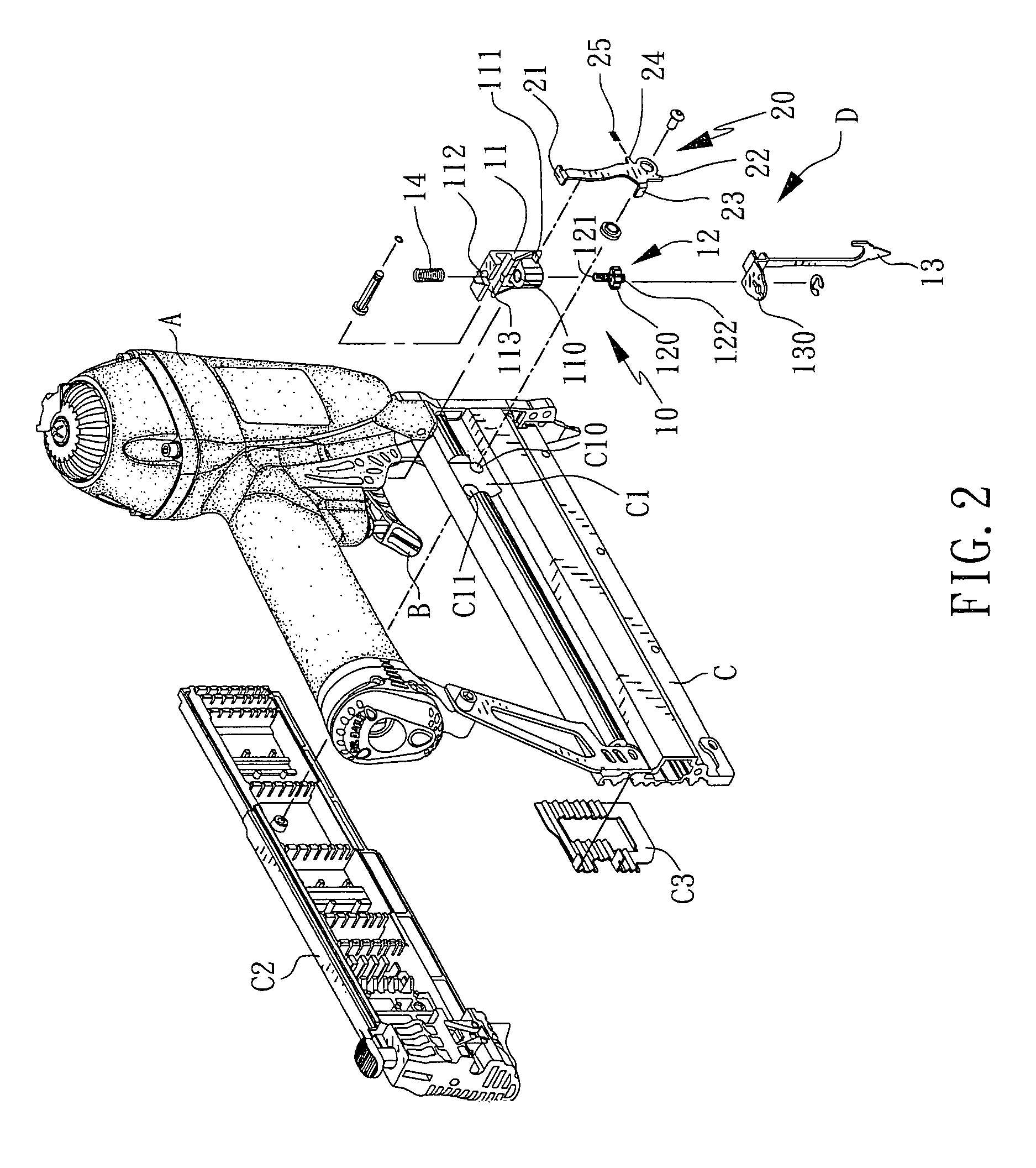

Pneumatic nail gun

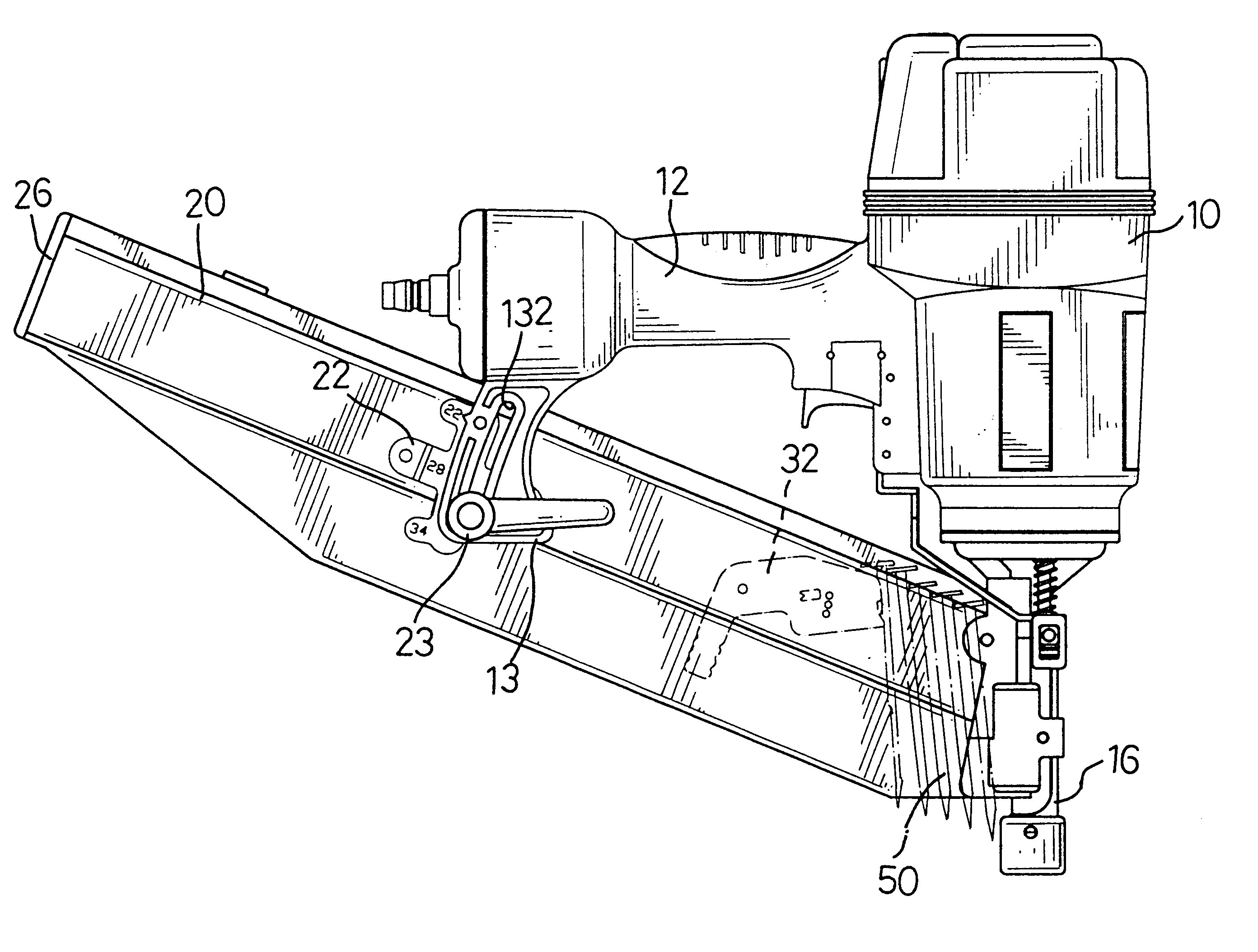

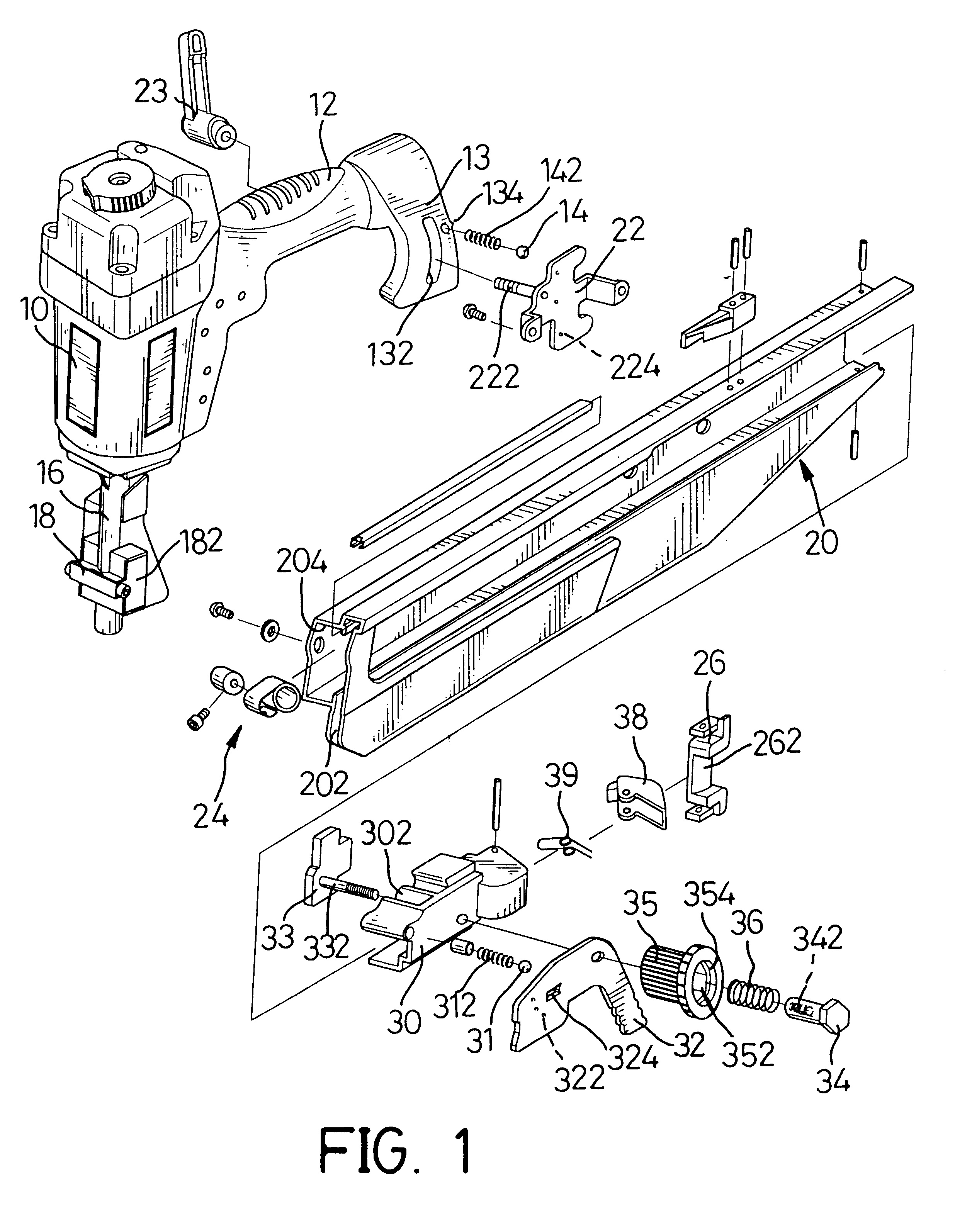

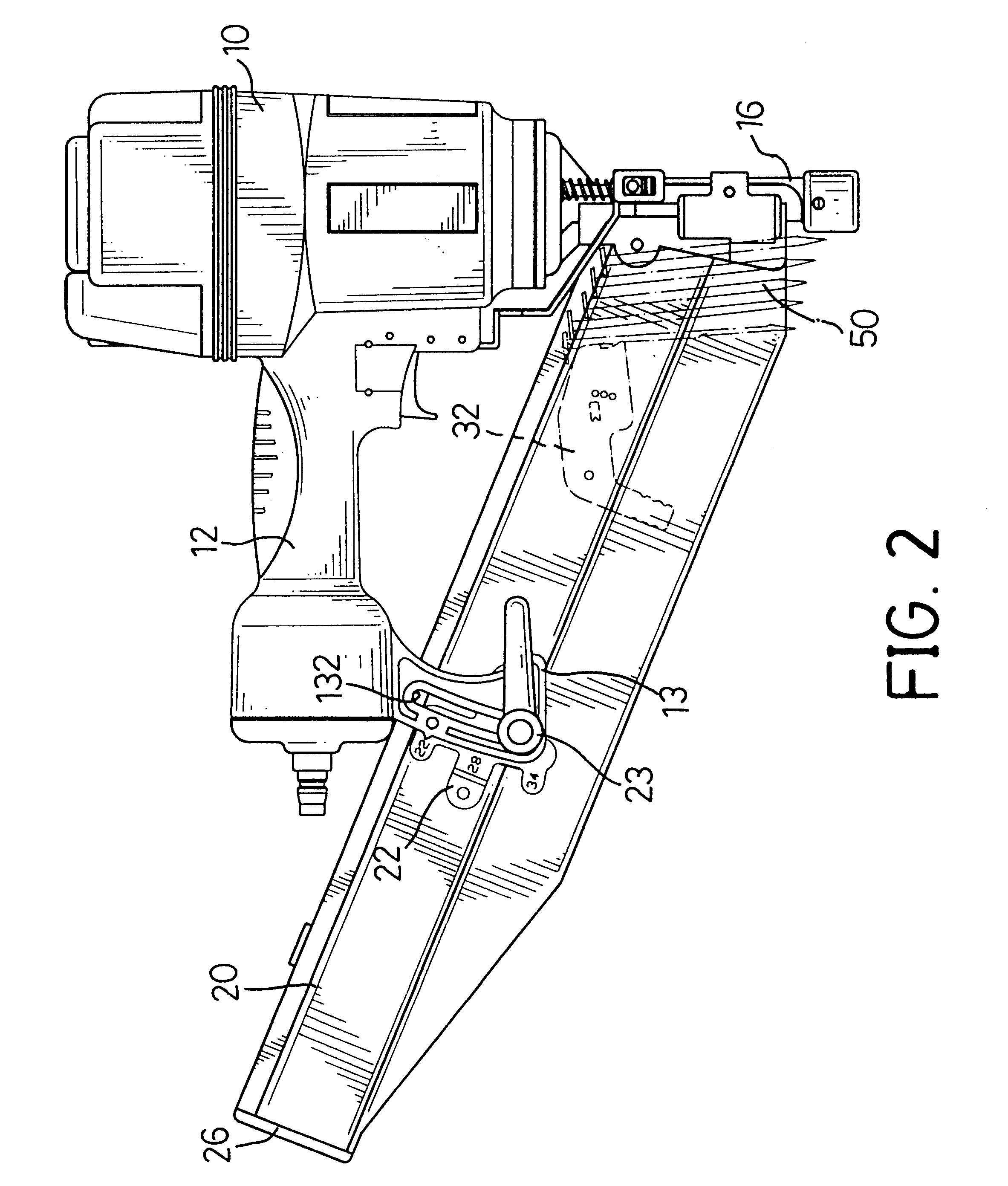

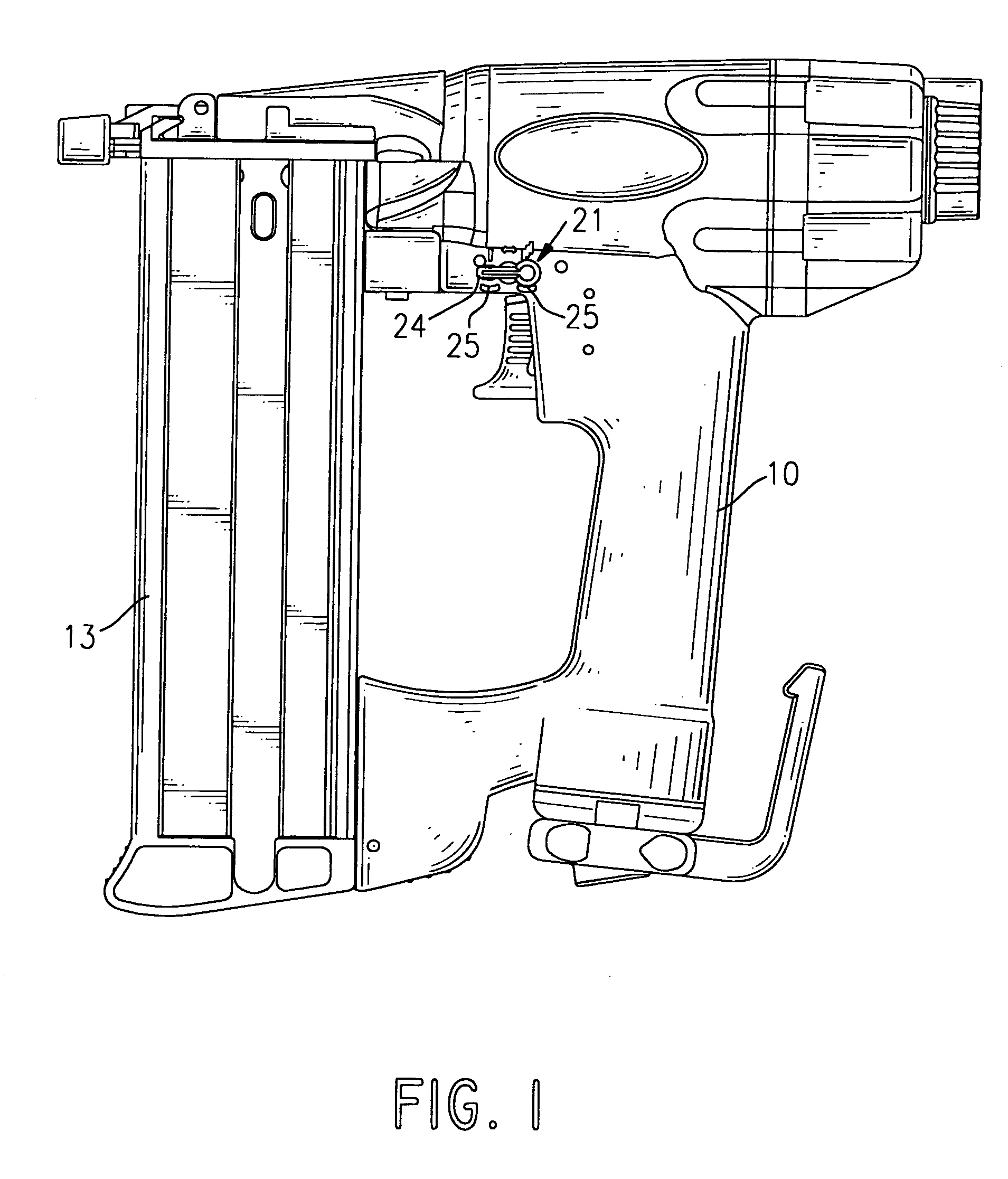

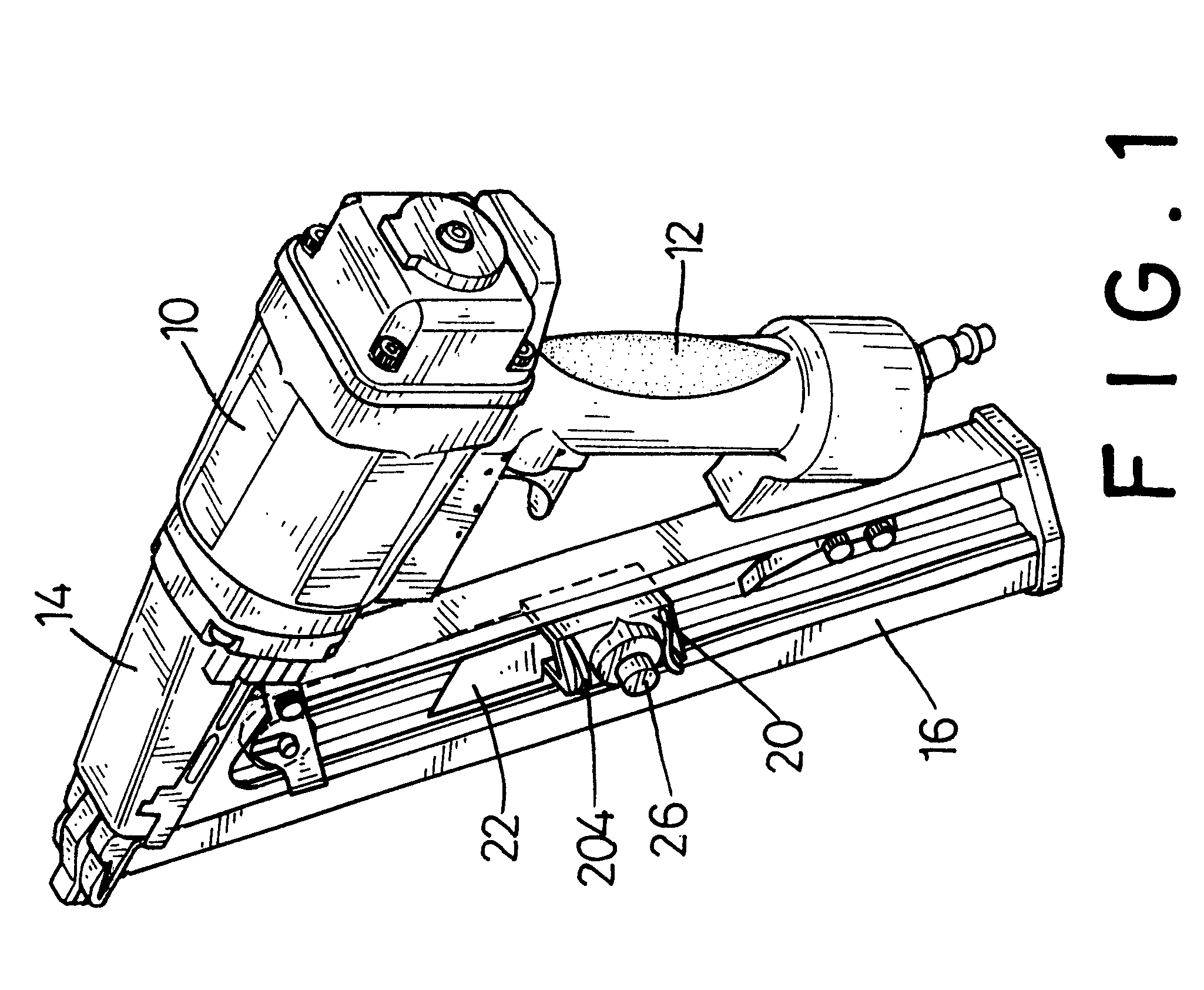

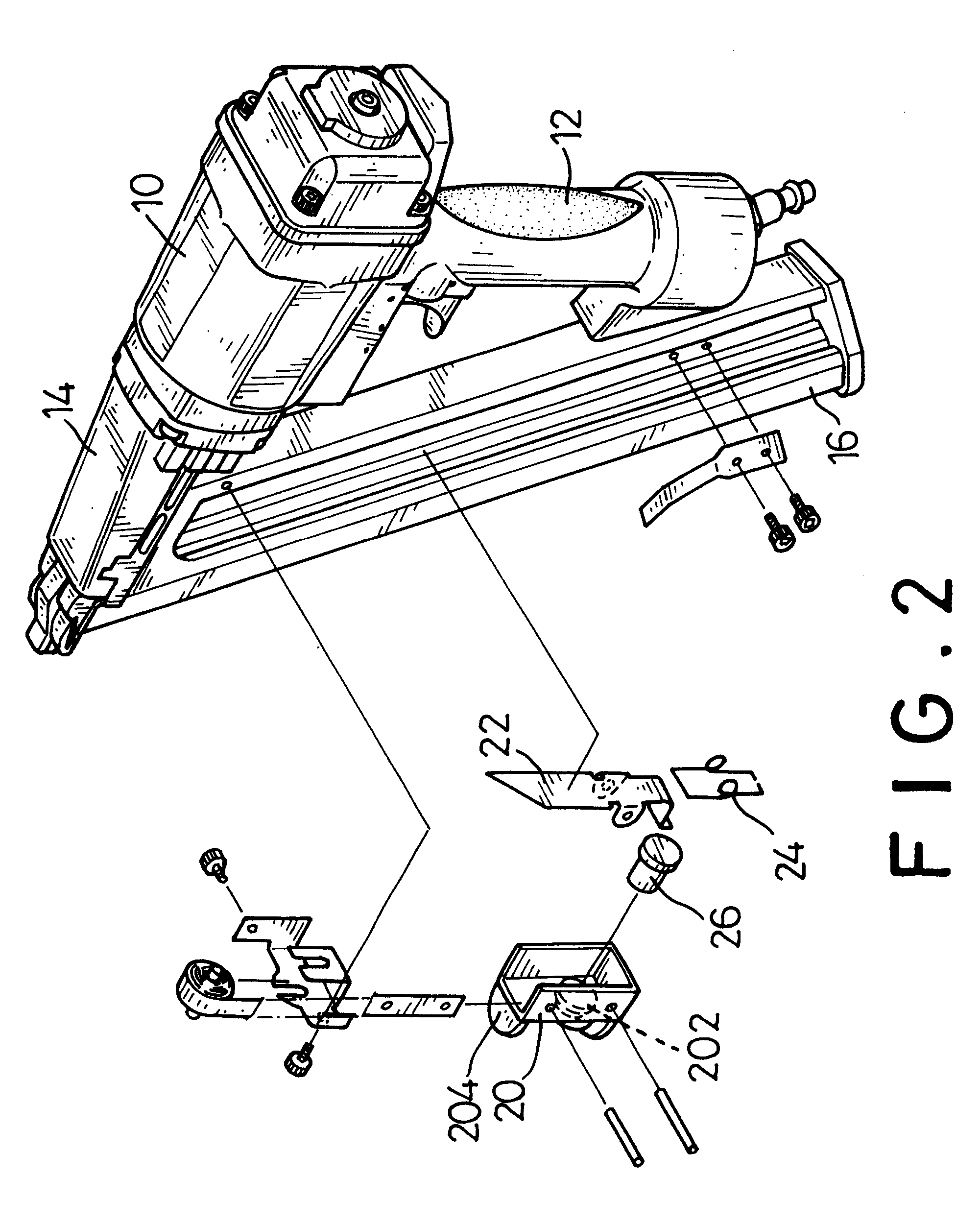

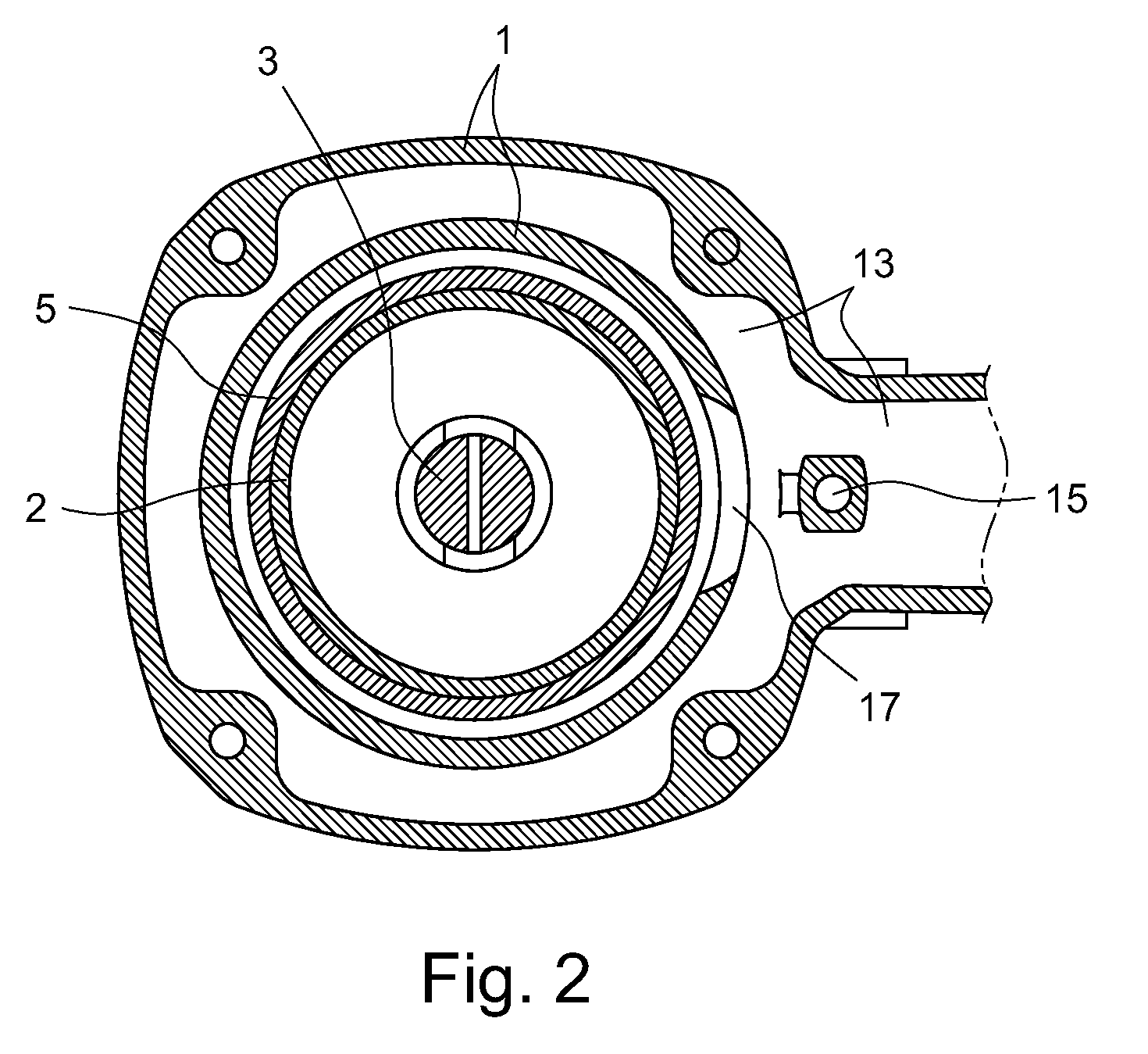

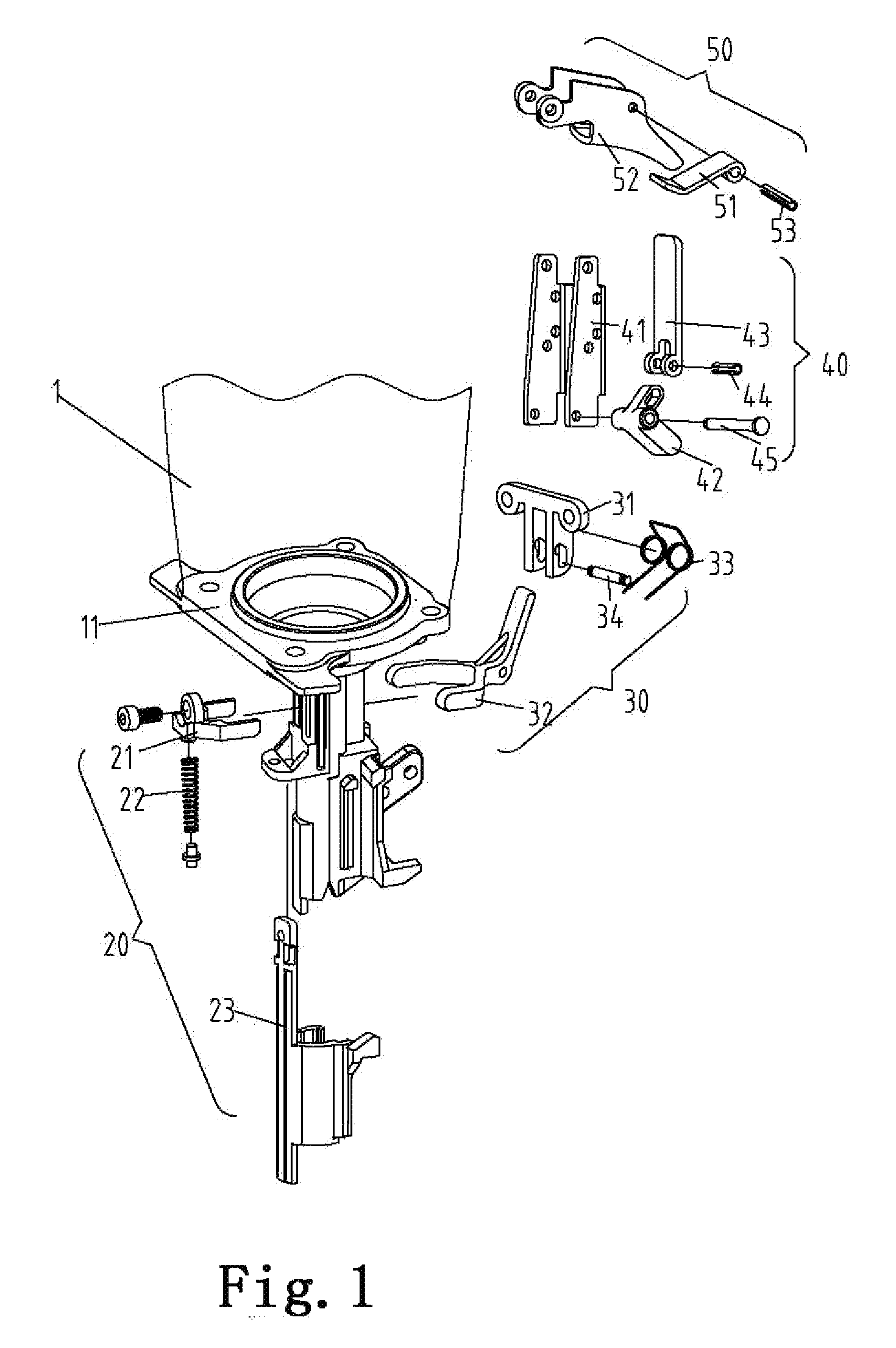

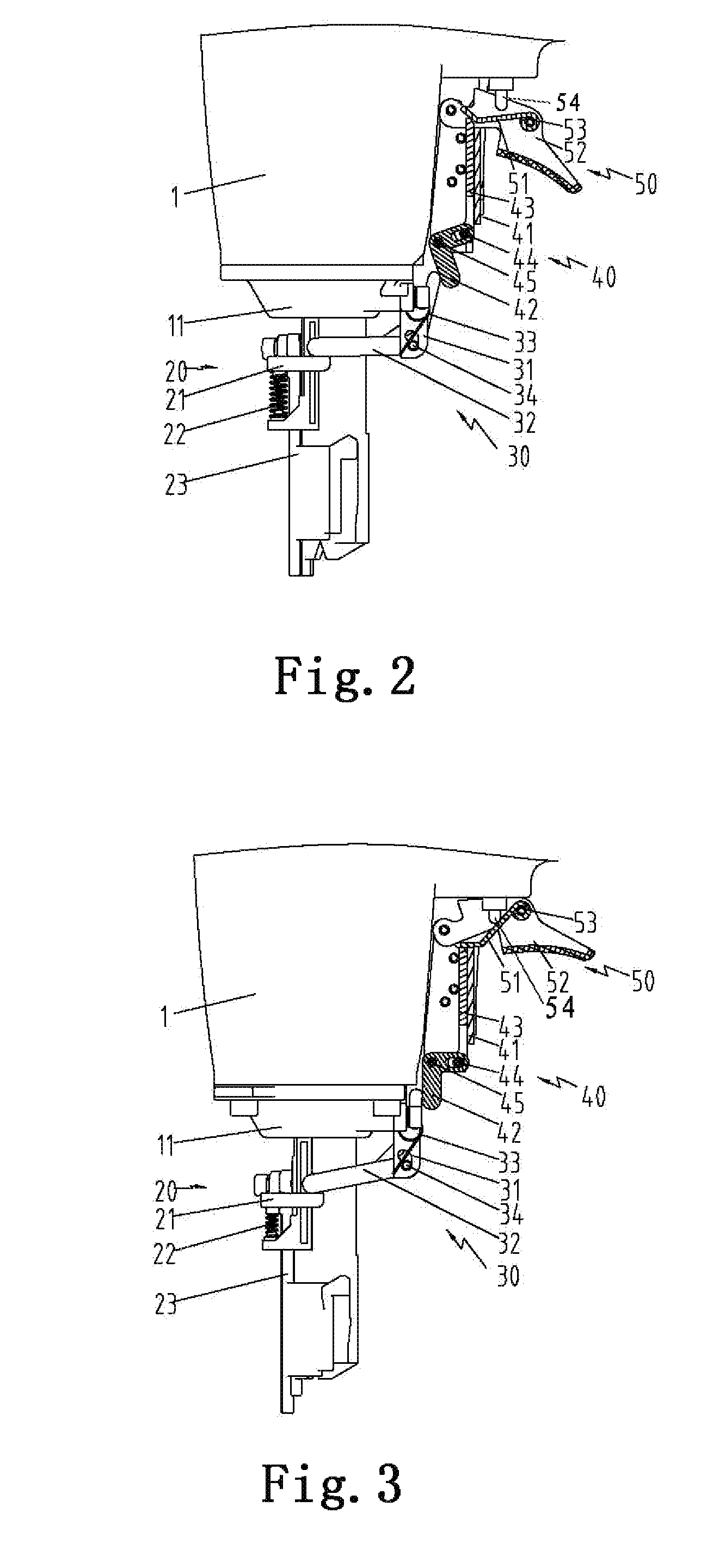

A pneumatic nail gun has a body, a handle extending from one end of the body, a barrel mounted on the other end of the body, a magazine pivotally connected to the barrel and assembly for positioning the magazine arranged in the body. With such a pneumatic nail gun, the magazine can be rotated and positioned to a desired angle relative to the barrel. Consequently, the pneumatic nail gun can accommodate different types of nails without changing to a different magazine.

Owner:REXON IND CORP LTD

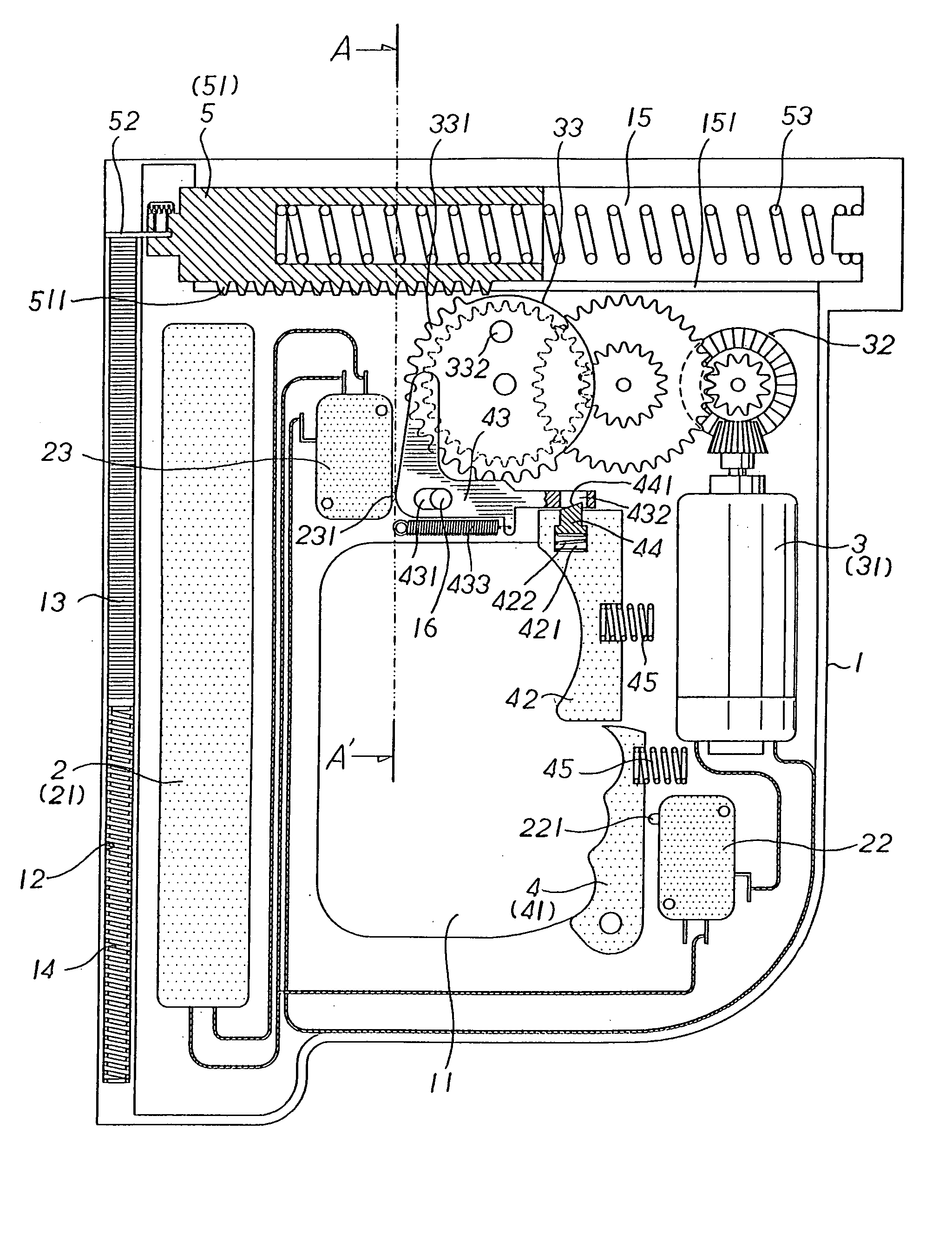

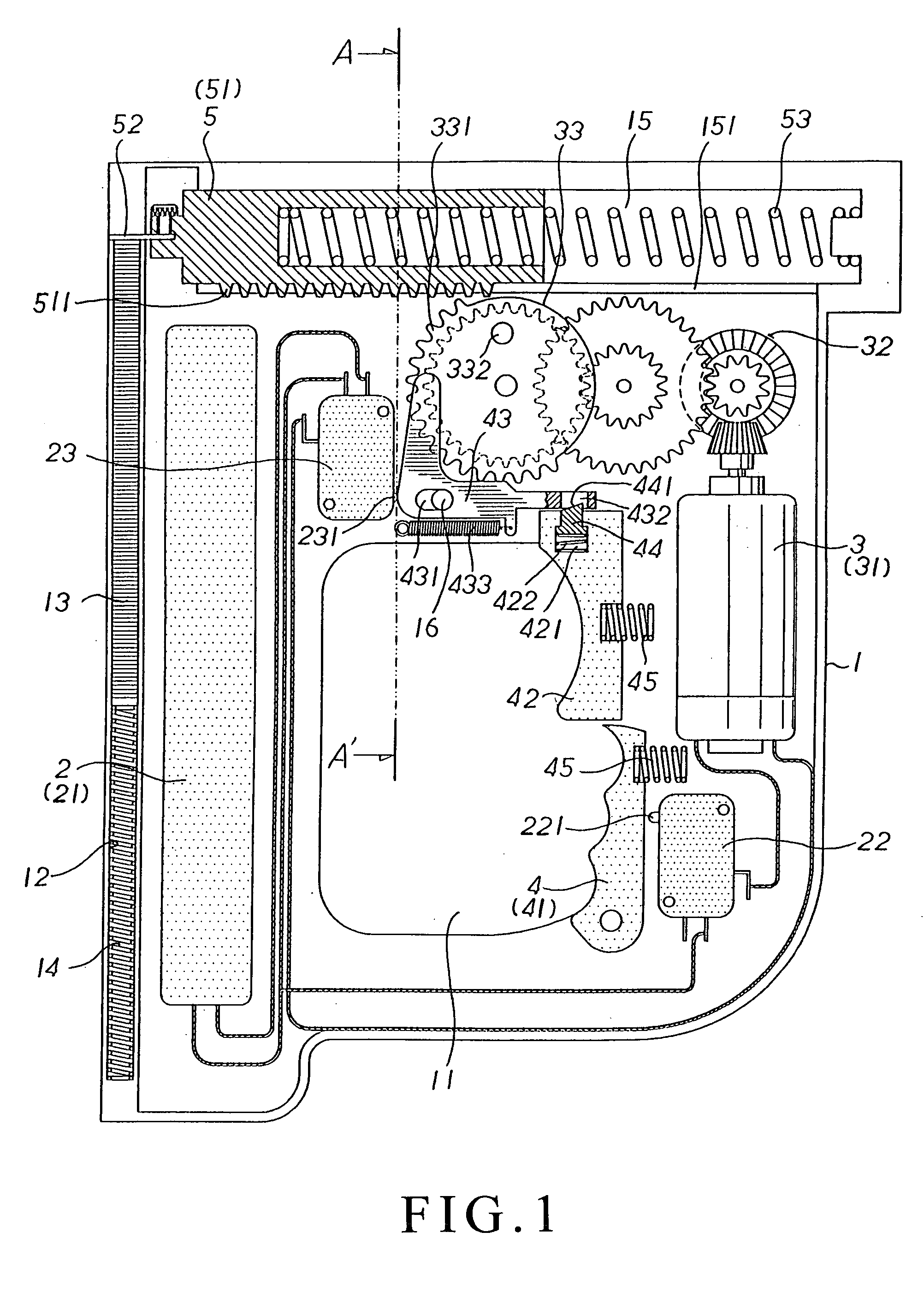

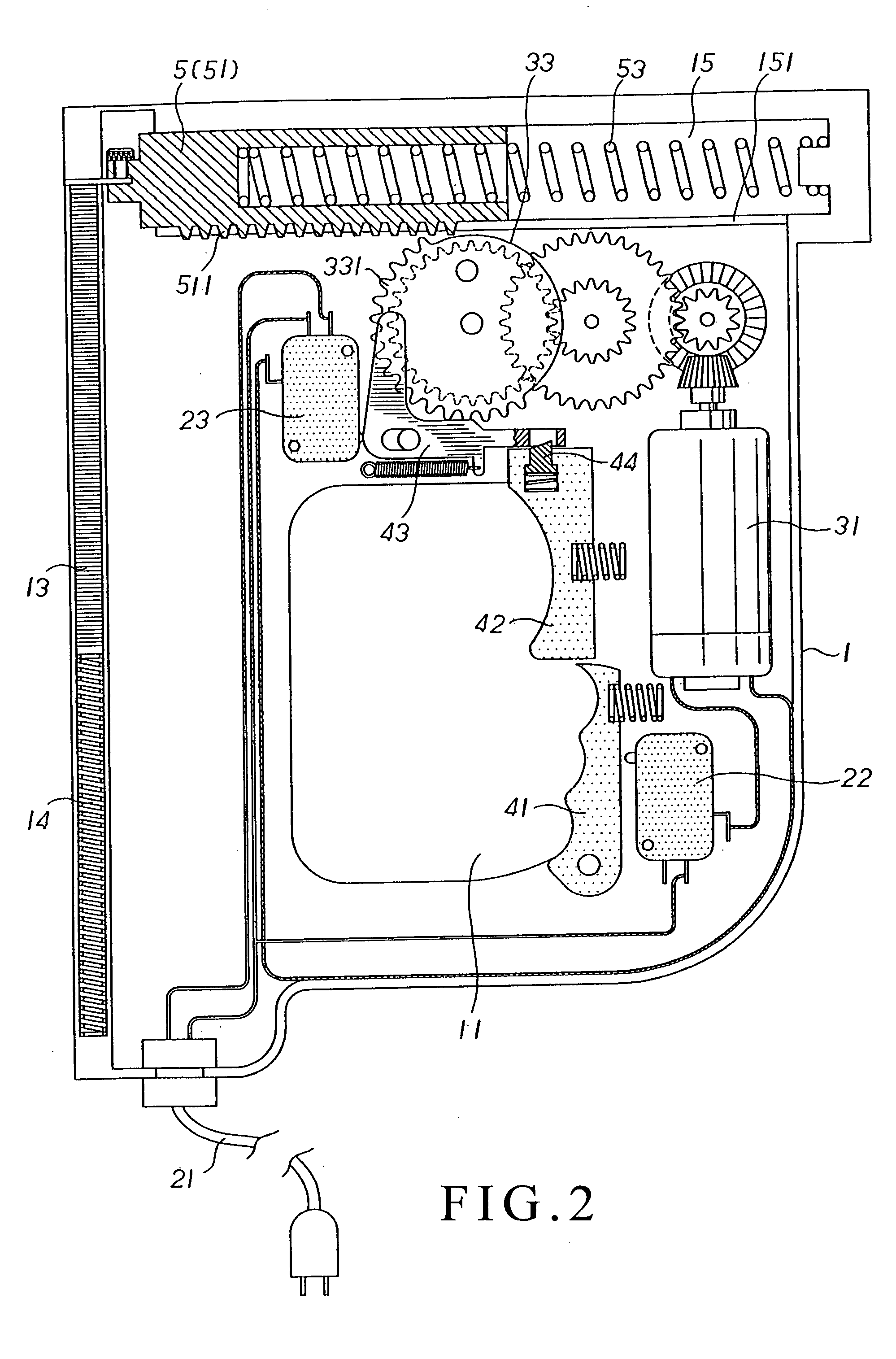

Hand-held nailing tool

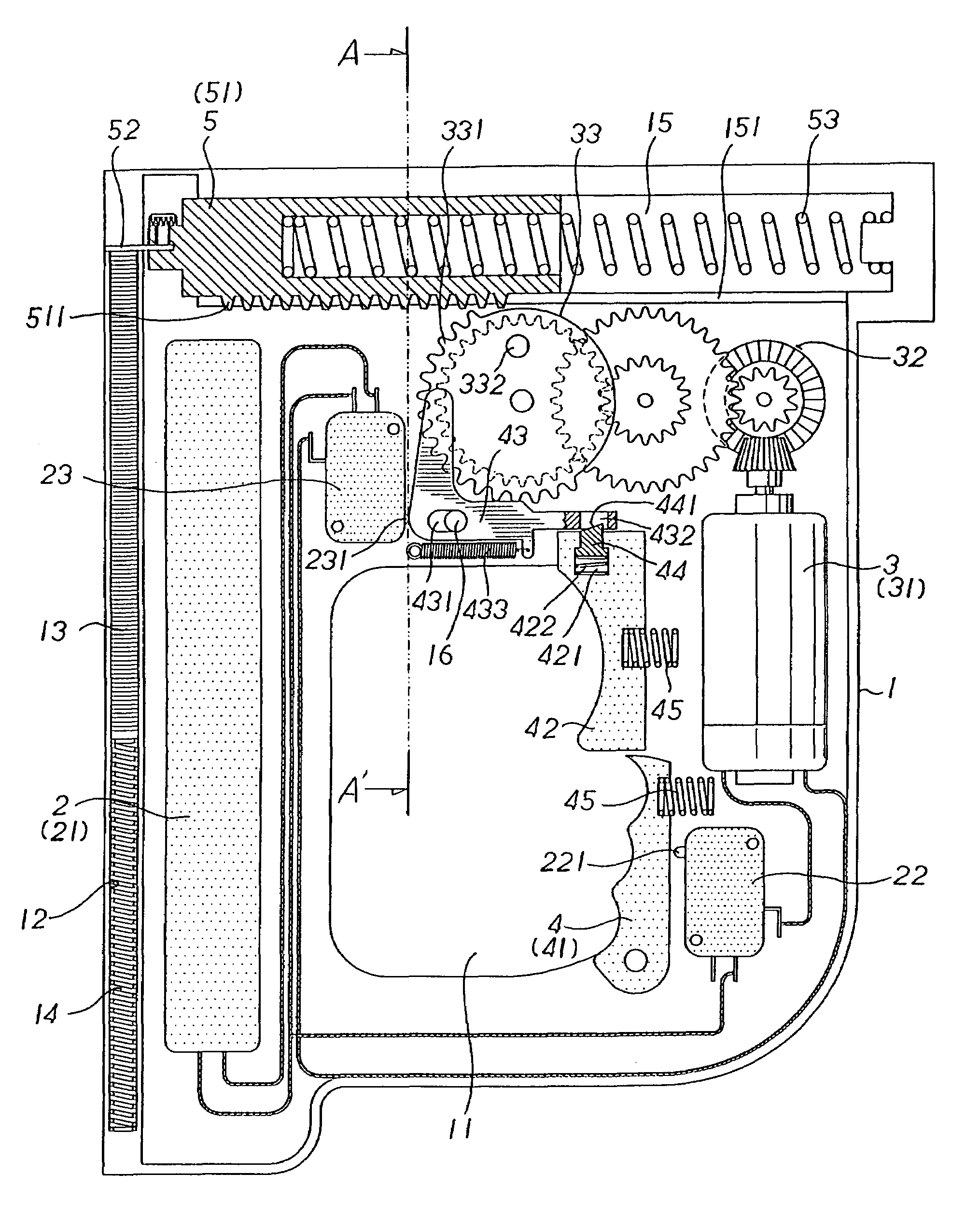

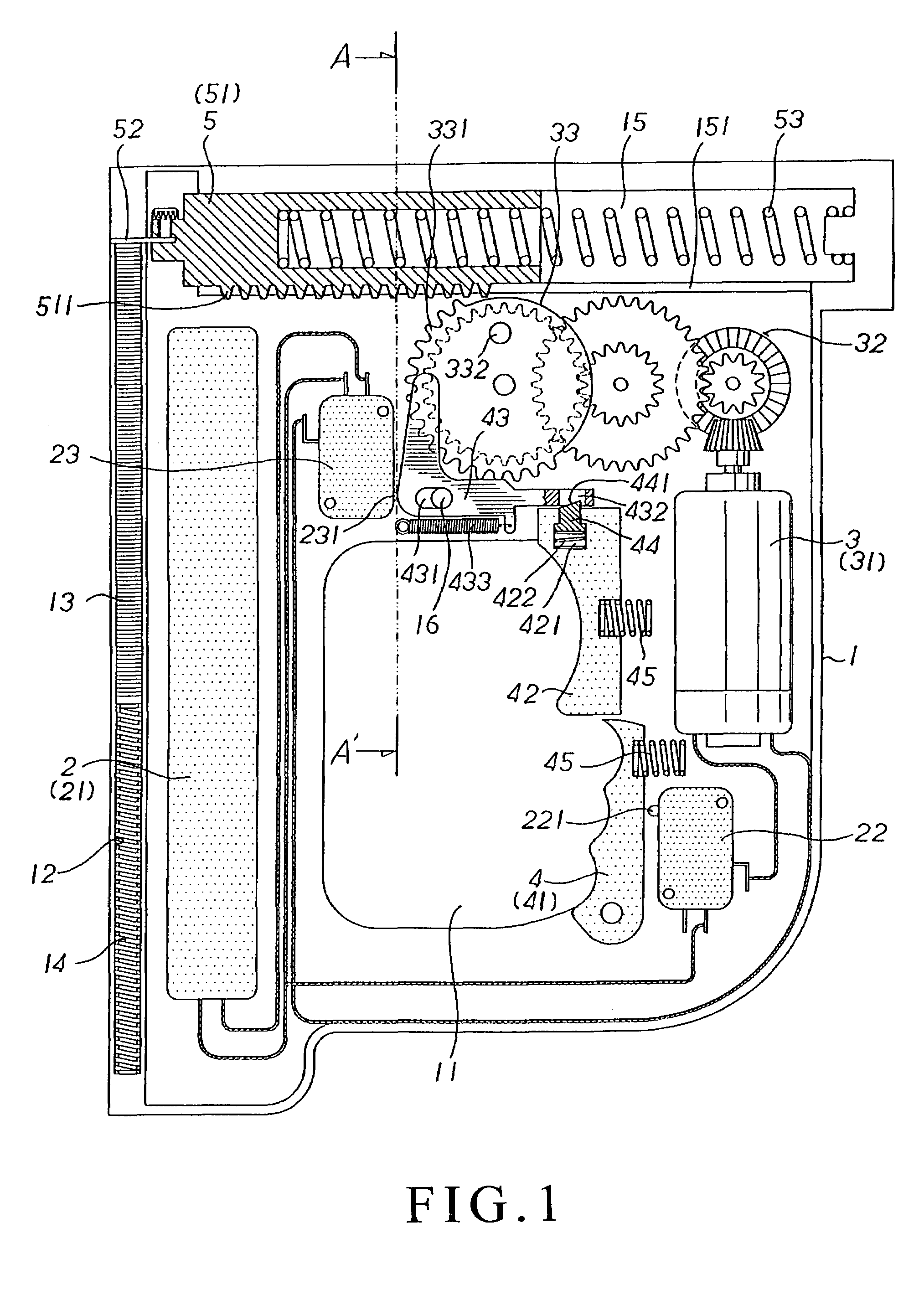

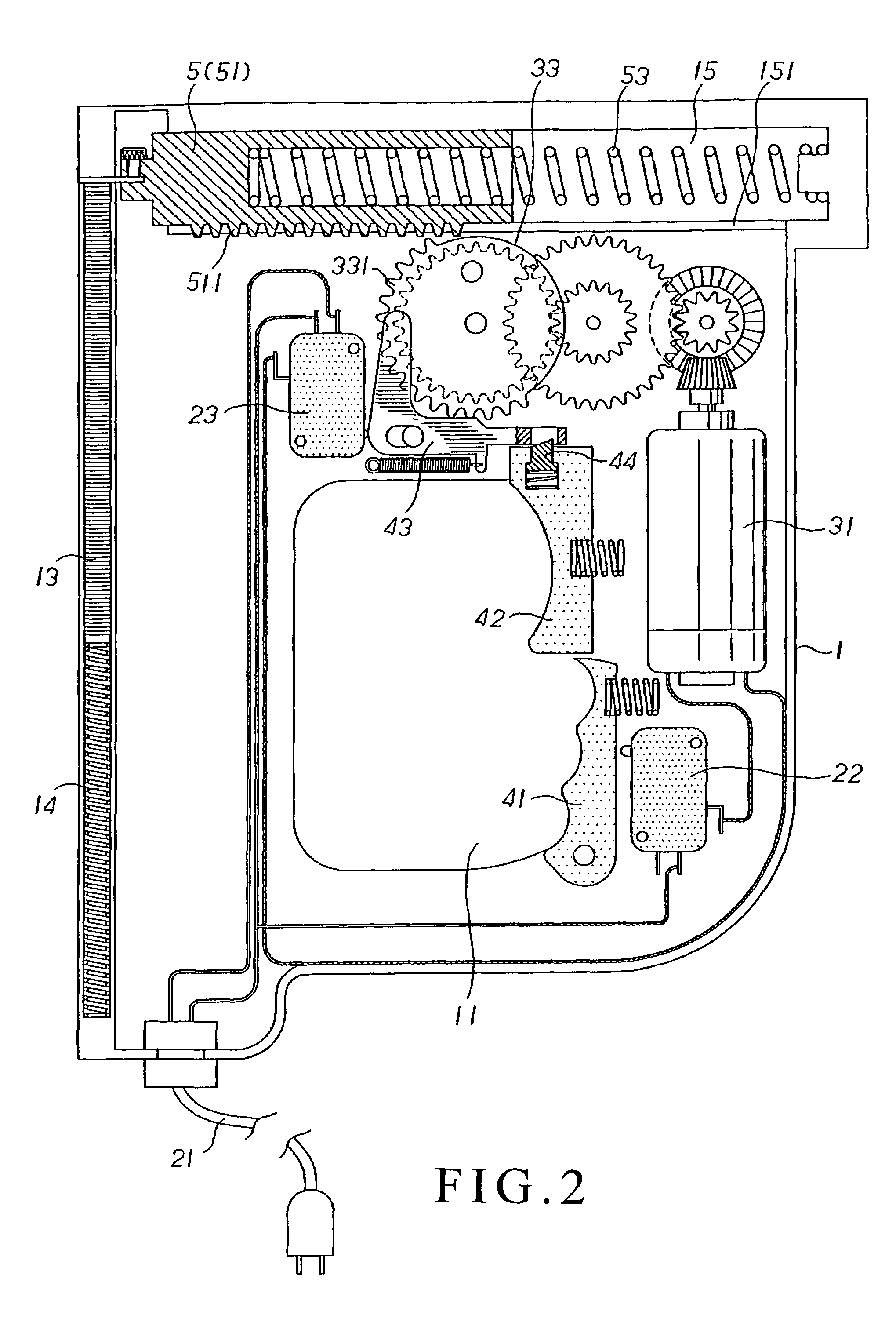

A handy electric nailing gun includes a firing pin, a firing spring for pushing the firing pin to drive nails into workpiece, an output gear rotatable by a motor through a transmission gear set to retract the firing pin during the first half run of each rotation cycle and to release the firing pin during the second half run of each rotation cycle, and three power switches electrically connected in series between the motor and the power source (AC adapter / rechargeable battery) for operation by the user to control the operation of the motor.

Owner:YIH KAI ENTERPRISE

Pneumatic nail gun

A pneumatic nail gun has a body, a nail magazine, an actuating device, a trigger assembly and a push bar assembly. The body has a housing, a handle and a nail firing device. The actuating device is mounted between the housing and the handle. The actuating device has a channel, a piston rod, an O-ring and a first spring to provide a restitute force to the piston rod. The trigger assembly is attached to the body and has an inner cap pivotally attached to the body, an outer cap slidably attached outside the inner cap, an actuating lever pivotally attached inside the inner cap and a second spring. Accordingly, the outer cap can be moved to a lock position to keep the nails from being fired unintentionally, and the pneumatic nail gun is safe in use.

Owner:REXON IND CORP LTD

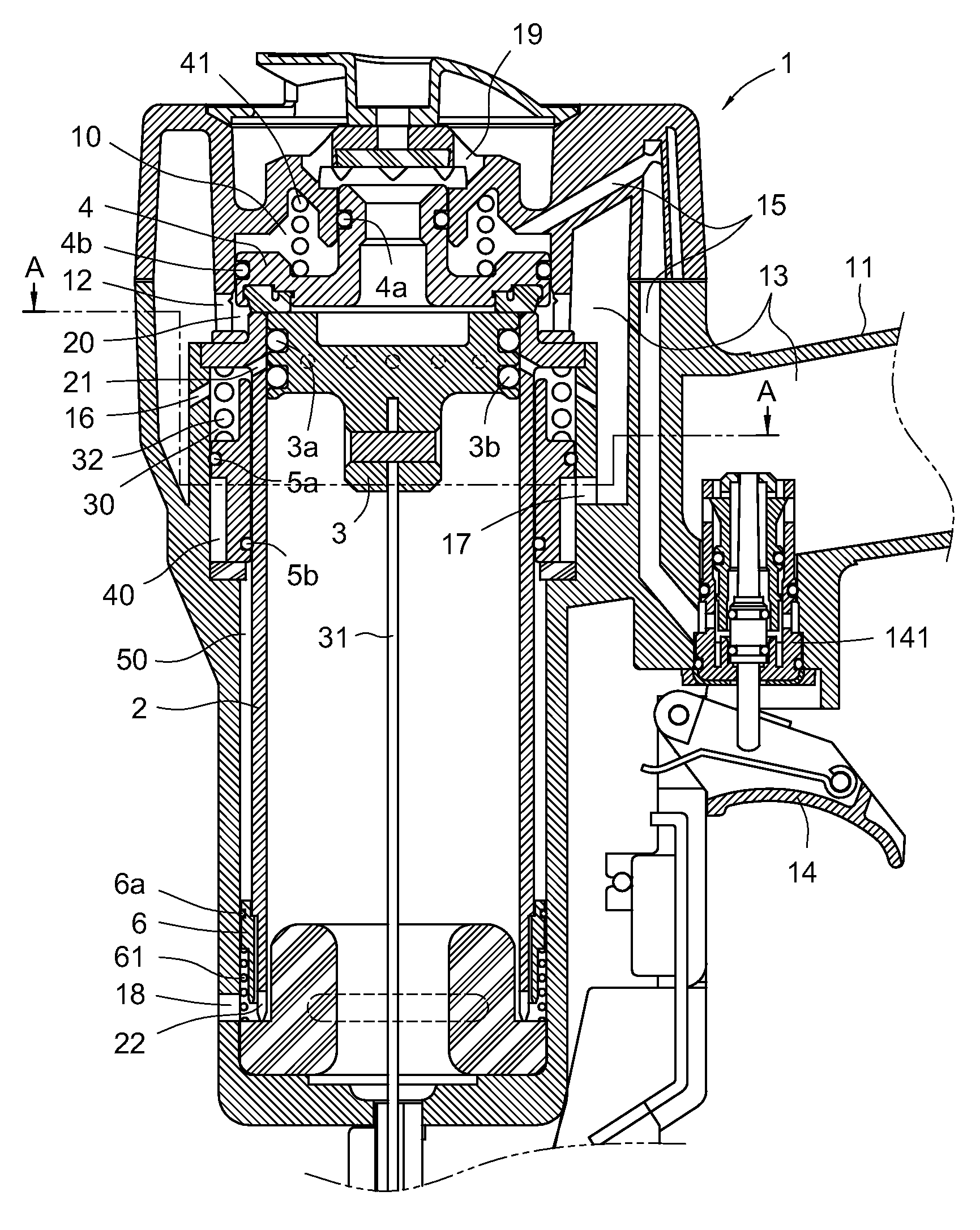

Portable electrical motor driven nail gun

A portable electric nailing gun operating from a power supply. The motor accelerates a flywheel which at the appropriate energy state is coupled through a mechanism to an anvil acting directly on the nail. The actuation is governed by a control circuit and initiated from a trigger switch. The motor accelerates a flywheel that is then clutched to the output anvil causing the nail to be driven. The position of the output anvil is sensed and once the nail is driven, the motor is dynamically braked reducing the excess energy in the flywheel. This method uses a highly responsive motor and power supply which enables the motor to come up to speed, drive the nail and return to a low energy condition in less than 2 seconds. The electrical control circuit and brake allow precise control and improve safety. The power supply is preferably a rechargeable low impedance battery.

Owner:TRICORD SOLUTIONS

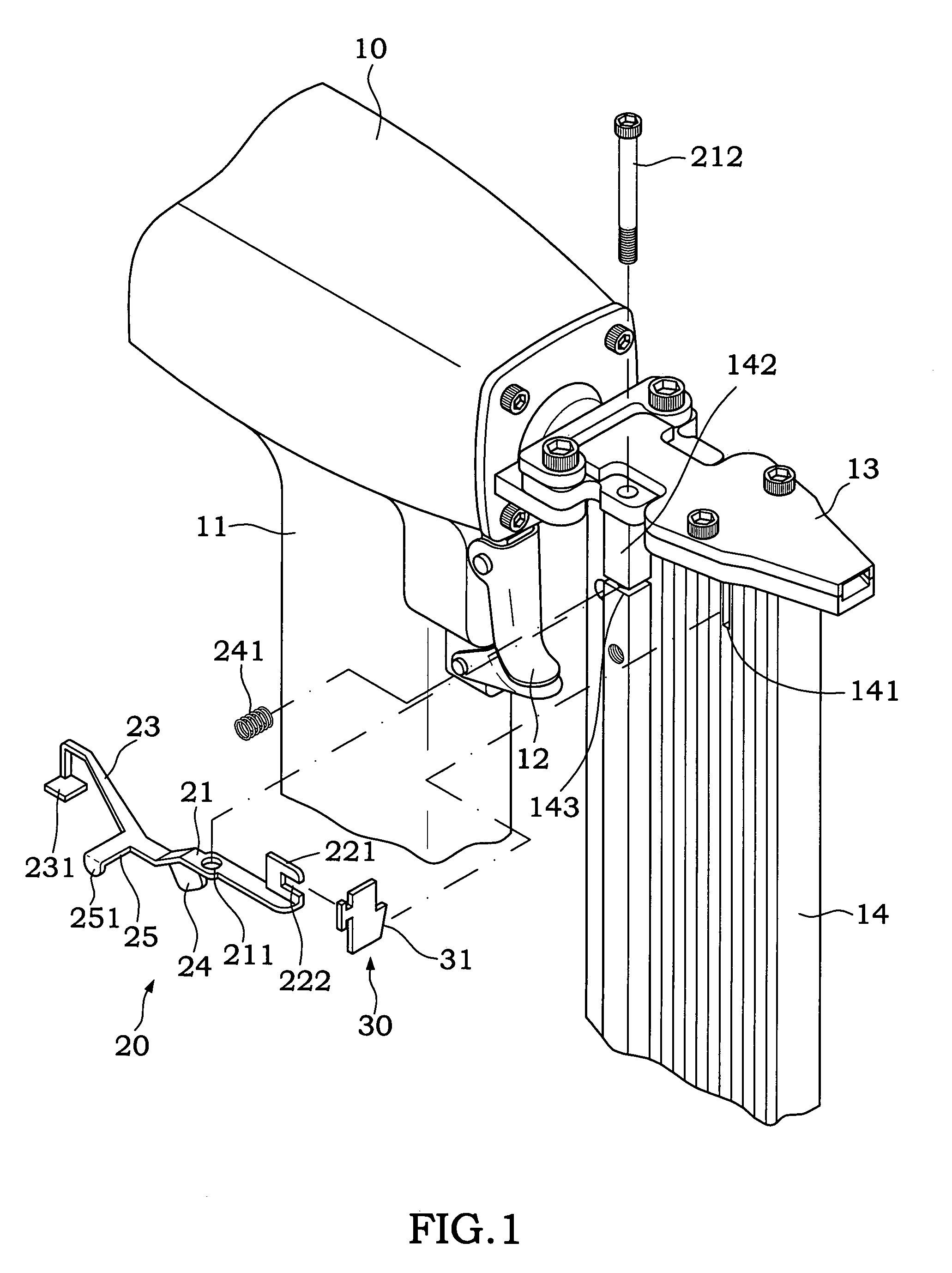

Quick-release device for a pneumatic nail gun magazine

A quick-release device for a pneumatic nail gun with a magazine has a base, a pusher plate, a spring and a button. The base has a through hole defined in the top of the base. The pusher plate has a first end that normally extends into the channel of the magazine and a second end. The spring abuts the second end of the pusher plate. The button is moveably mounted in the base and extends out from the through hole. The button abuts the second end of the pusher plate, such that the pusher plate can be pivoted by pressing the exposed button. The finger of the user does not extend into the device. Consequently, the operation of the quick-release device is simplified, and the finger of the user will not be injured during the process of clearing jammed nails.

Owner:REXON IND CORP LTD

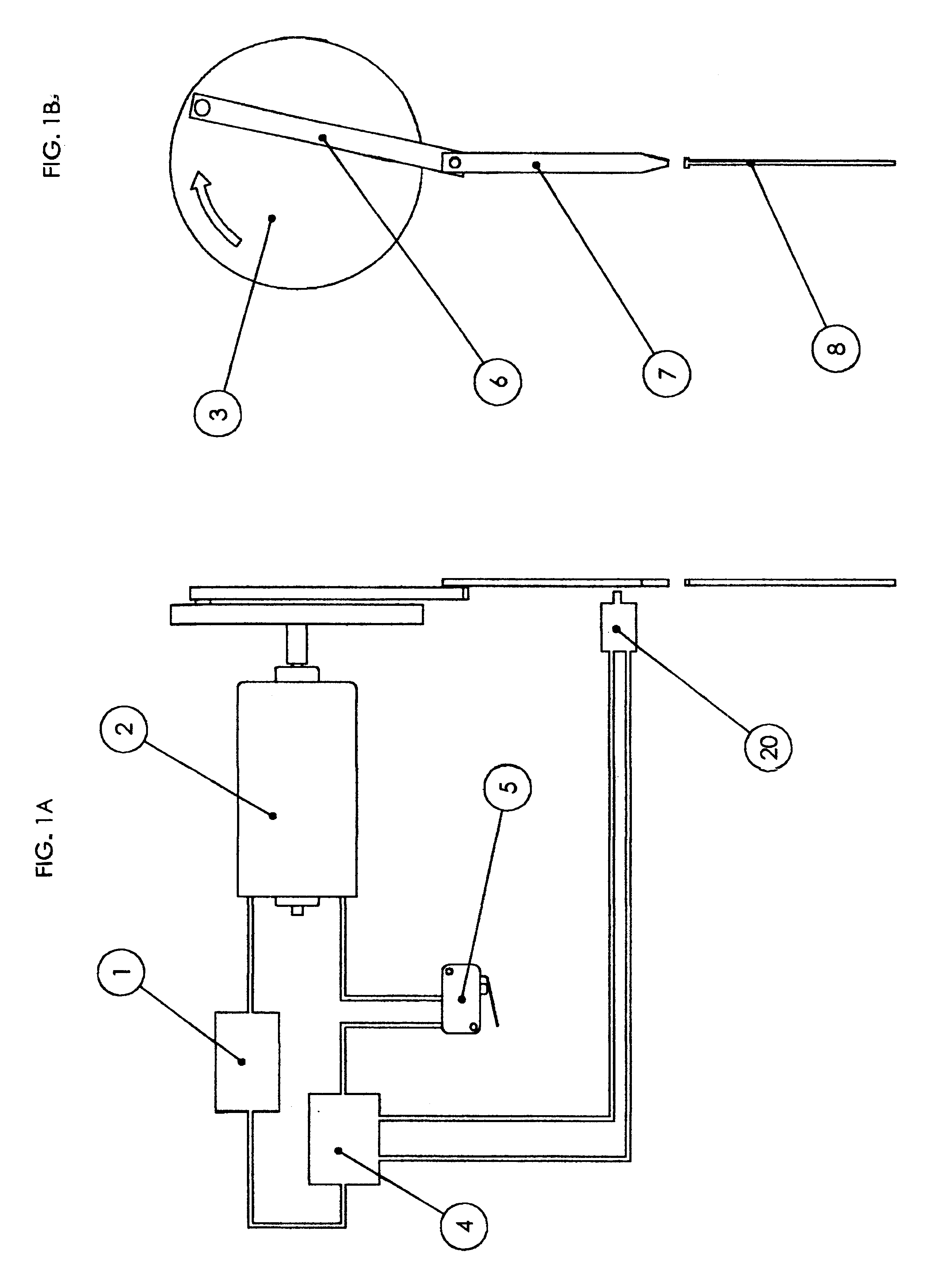

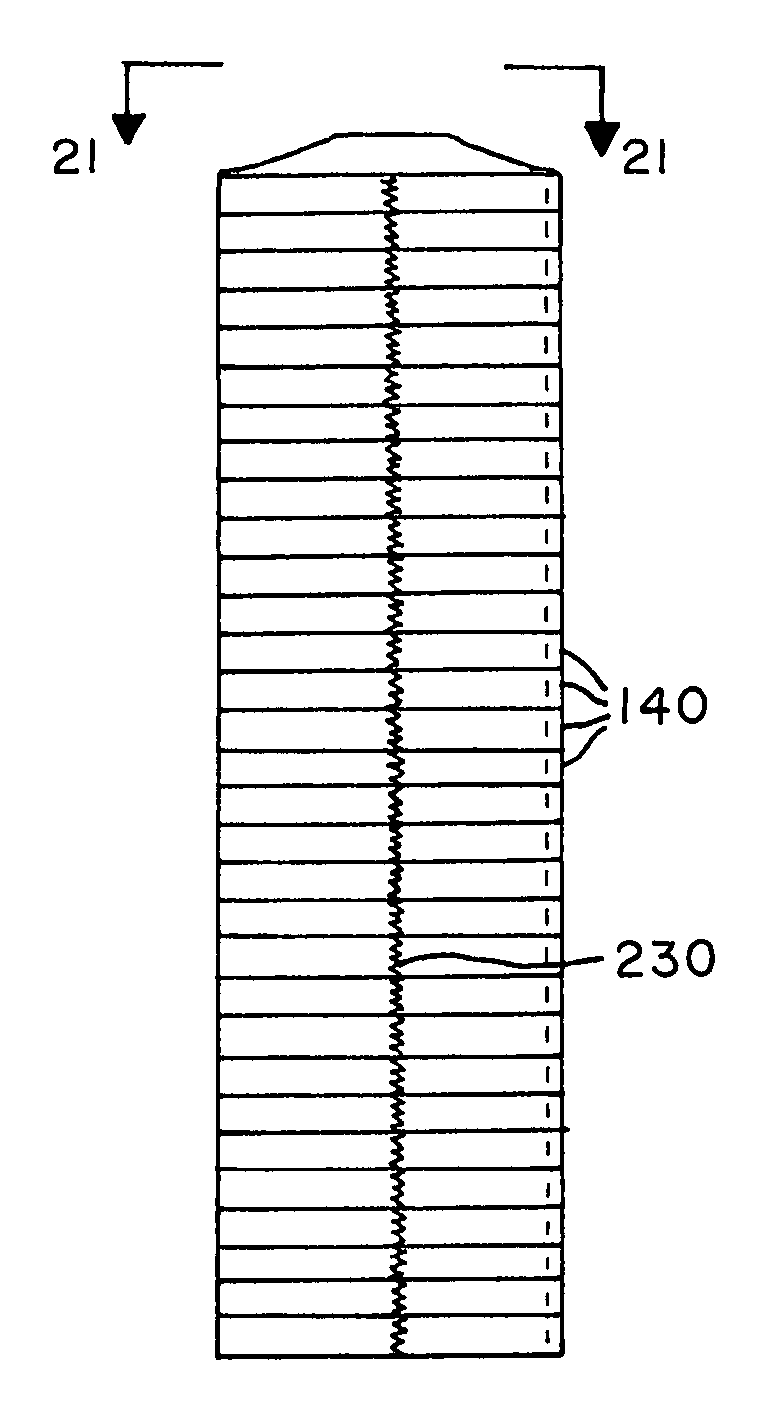

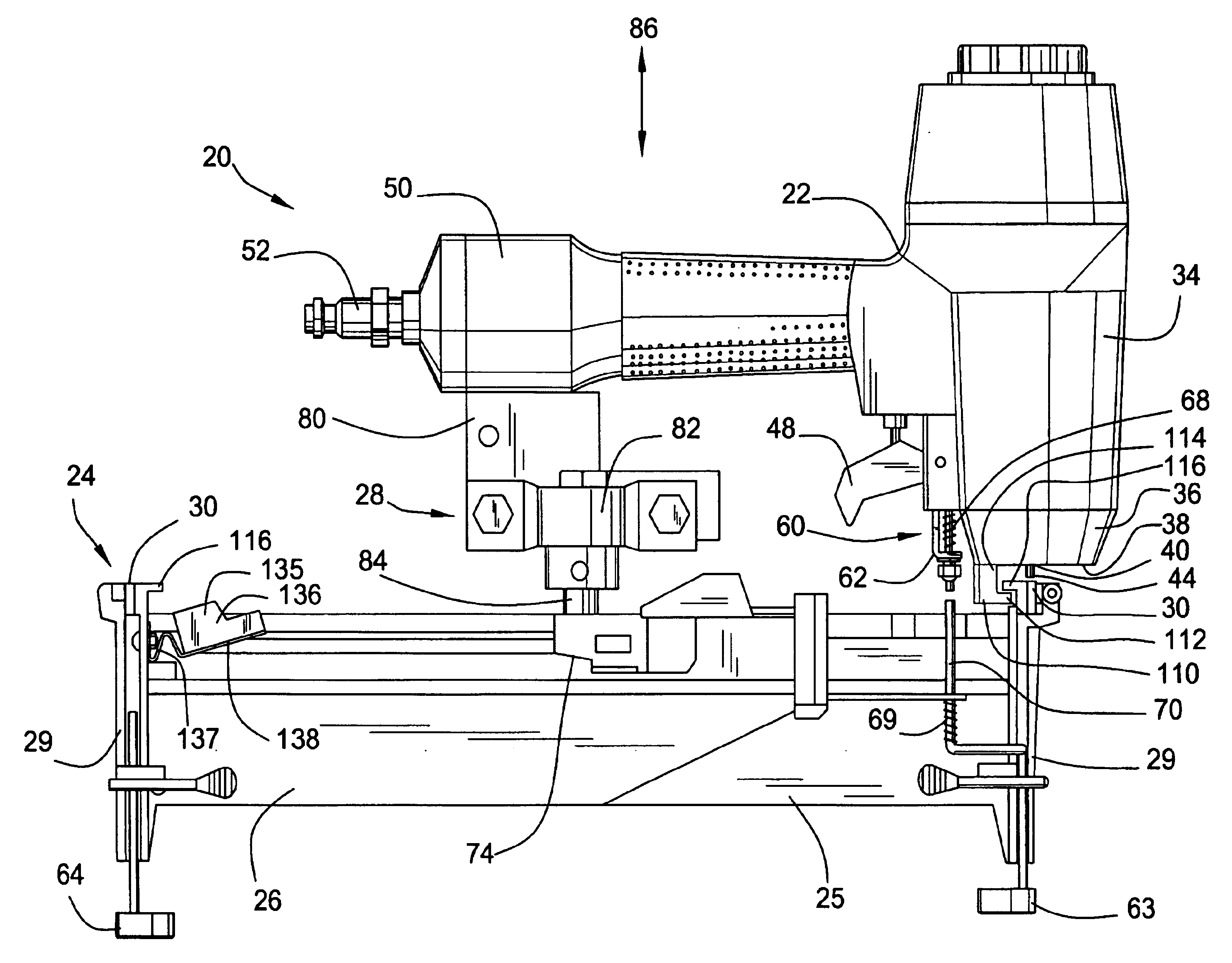

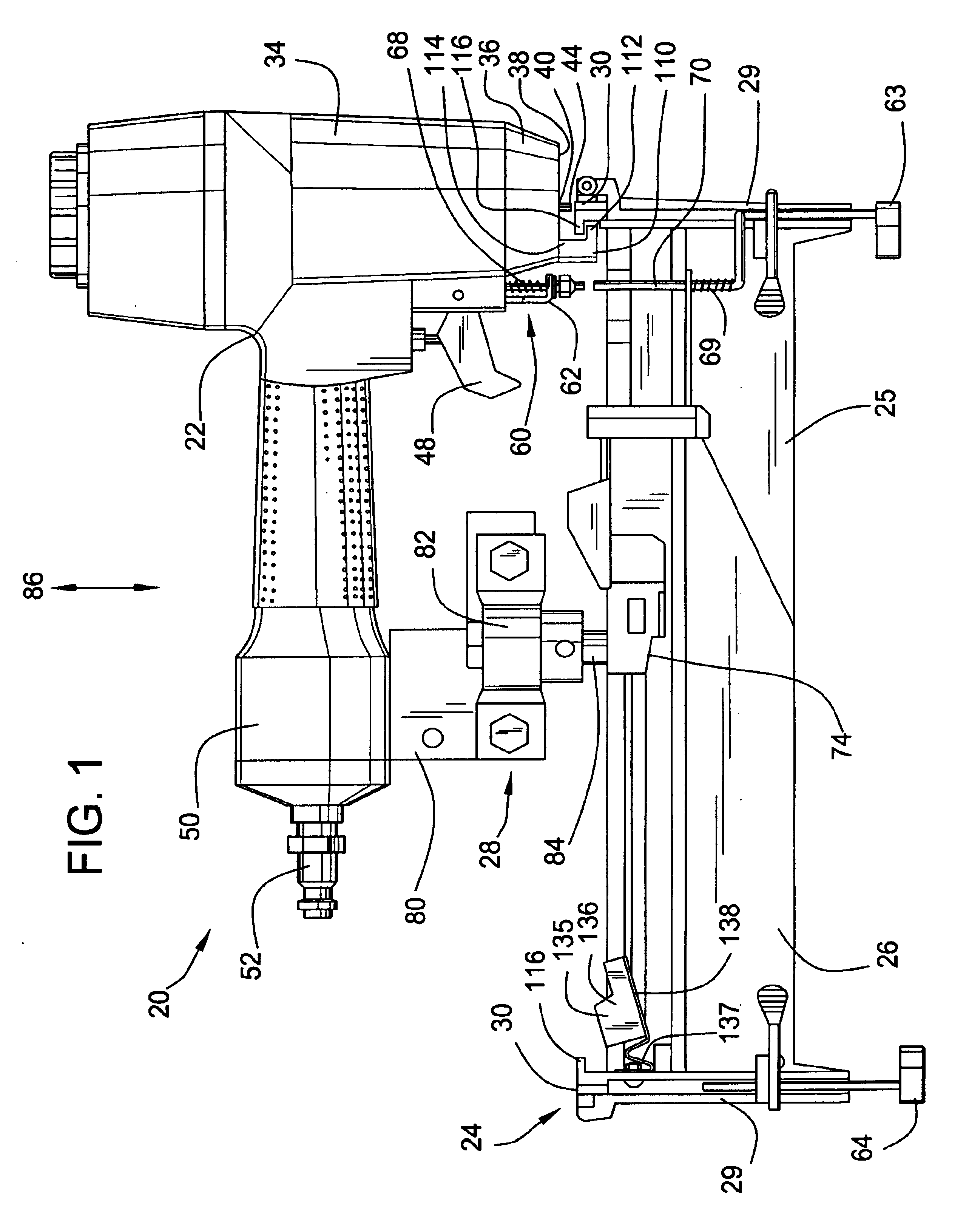

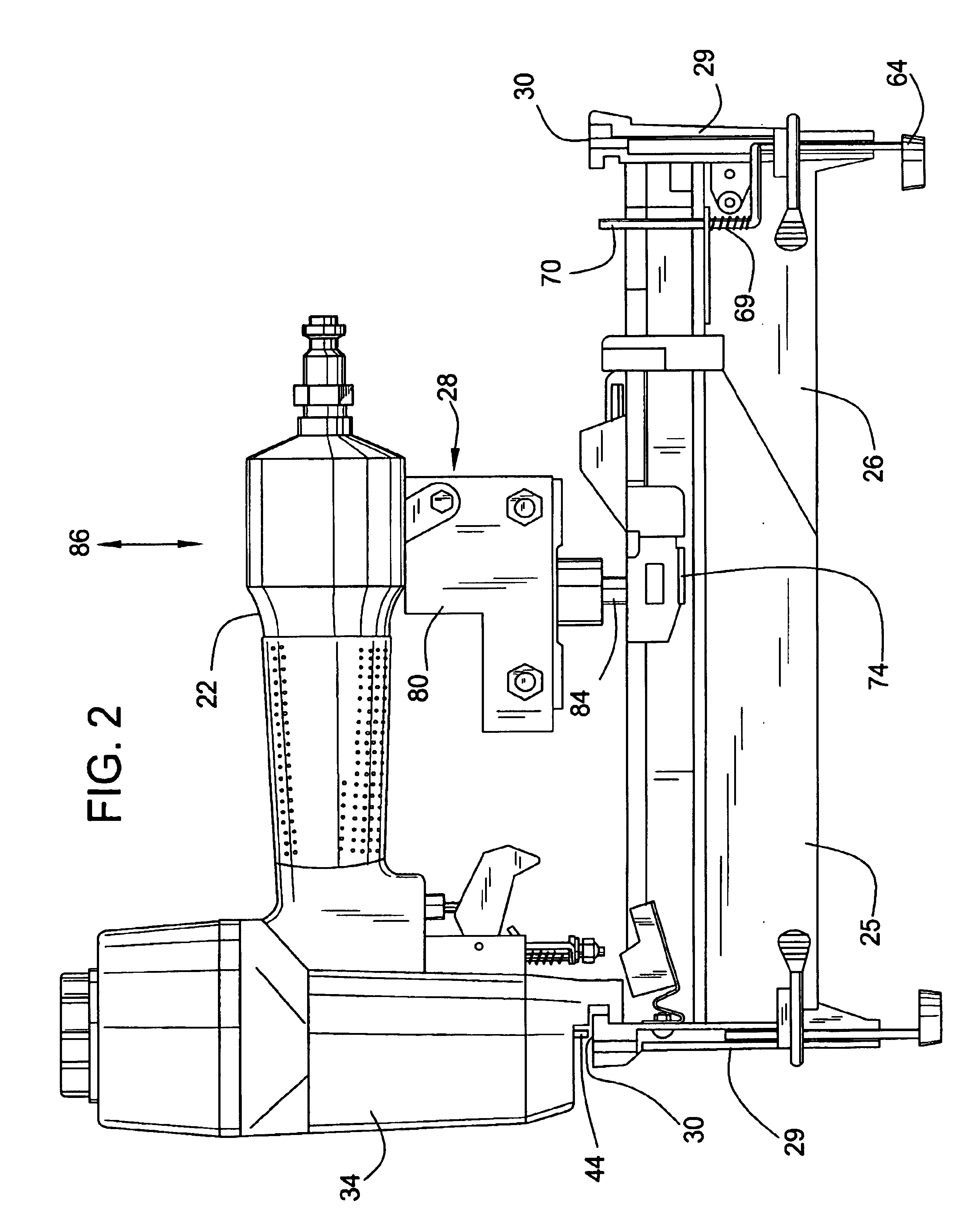

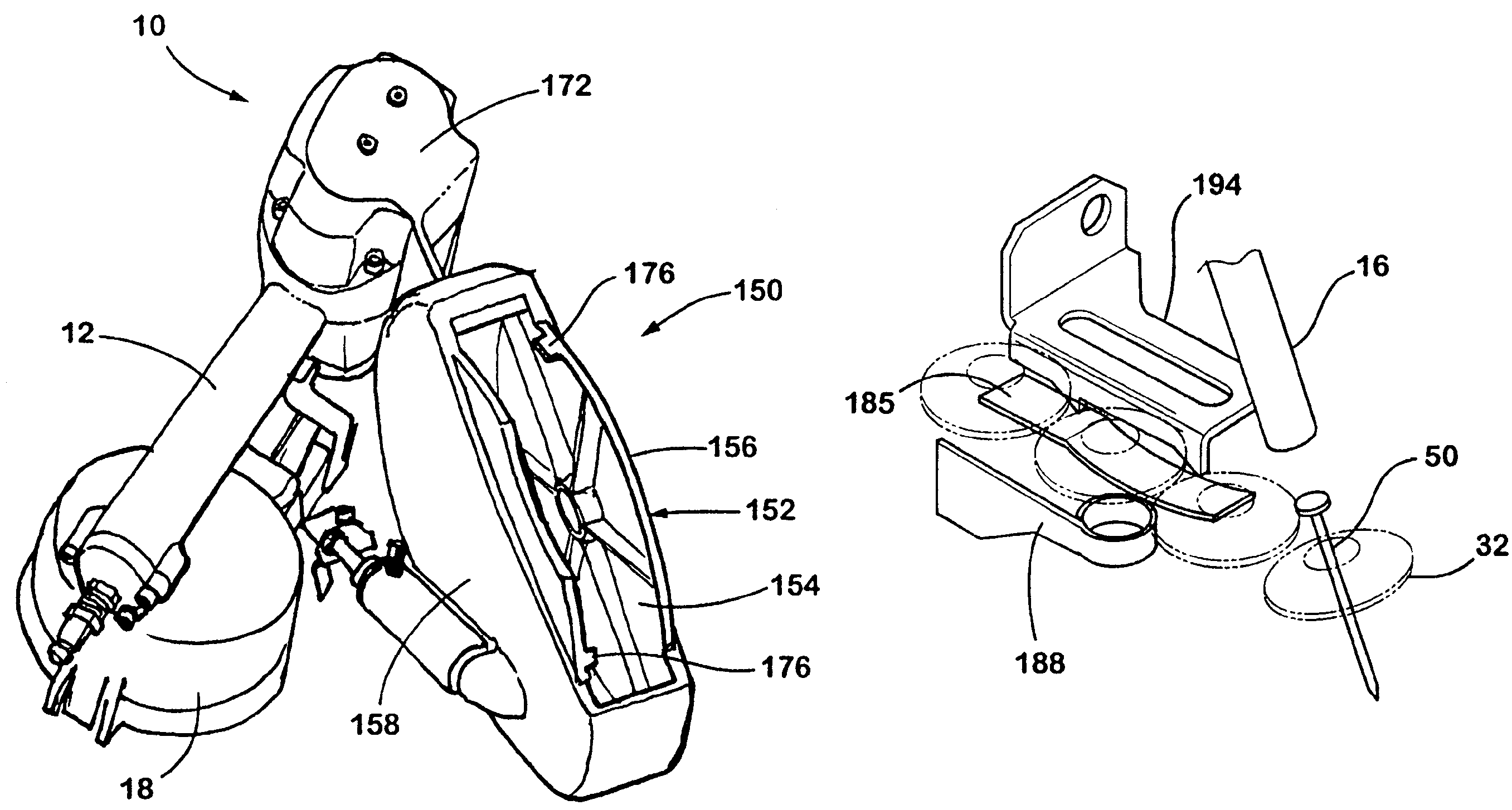

Stacked assembly of roofing caps

A staple or nail gun assembly includes a staple or nail gun, a cap feeding device and a cap having a peripheral rim disposed on its underside, a marginal edge on its upper side adjacent a central portion having the shape of a truncated cone. The staple or nail gun and the cap feeding device are generally disposed at opposite ends of the handle of the staple or nail gun. The cap feeding device includes a base, a cap container and a shuttle, and feeds caps sequentially as they are affixed by the gun. The caps are coaxially stacked by means of a coaxial plastic cord or wire with retaining means at the respective ends or in a tubular container with a flanged end. The caps may also be stacked on a rod or held together by melting.

Owner:PNEUTOOLS

Hand-held nailing tool

InactiveUS20050082334A1Handy and convenient for home useStapling toolsReciprocating drilling machinesAC adapterPower switching

A handy electric nailing gun includes a firing pin, a firing spring for pushing the firing pin to drive nails into workpiece, an output gear rotatable by a motor through a transmission gear set to retract the firing pin during the first half run of each rotation cycle and to release the firing pin during the second half run of each rotation cycle, and three power switches electrically connected in series between the motor and the power source (AC adapter / rechargeable battery) for operation by the user to control the operation of the motor.

Owner:YIH KAI ENTERPRISE

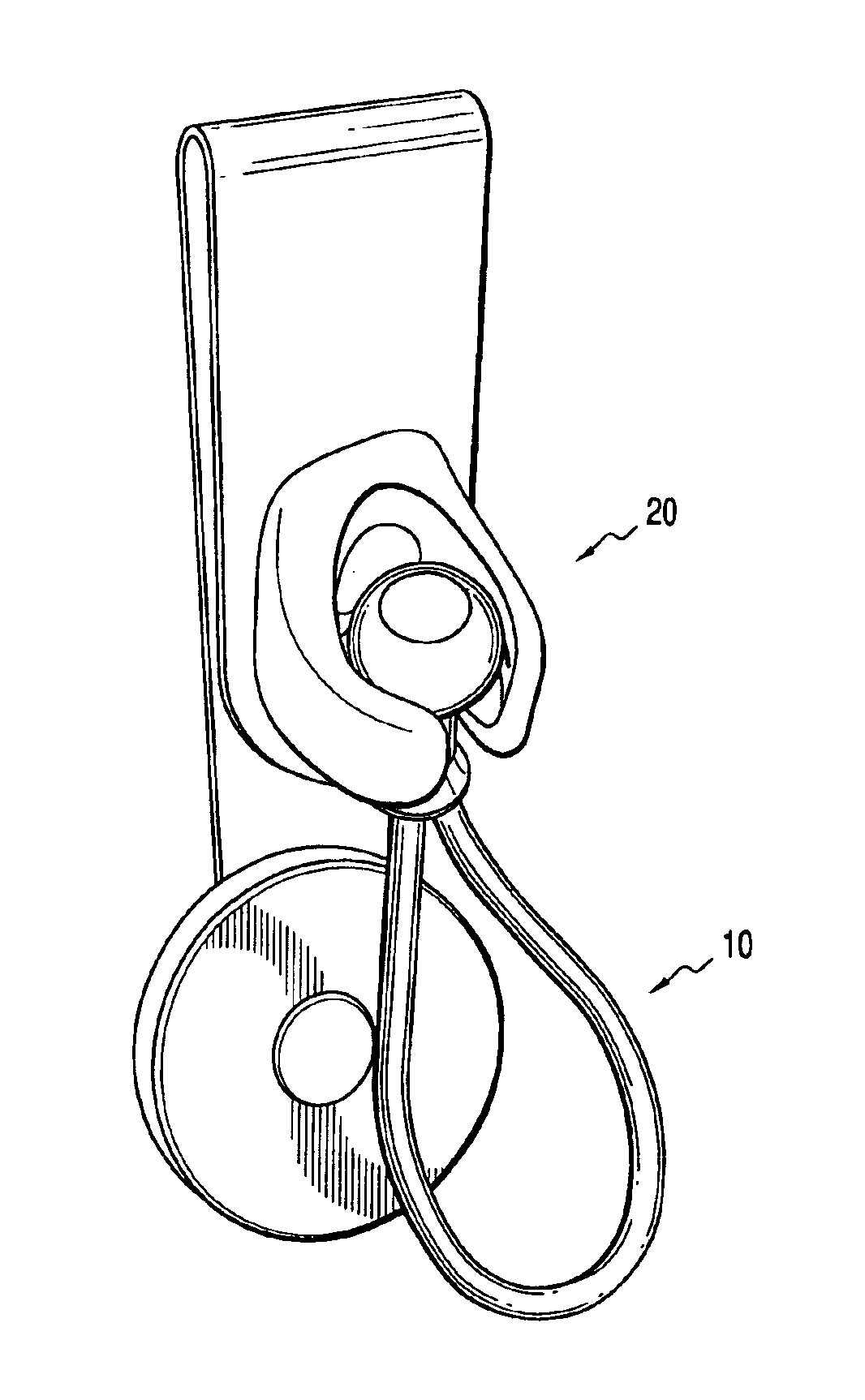

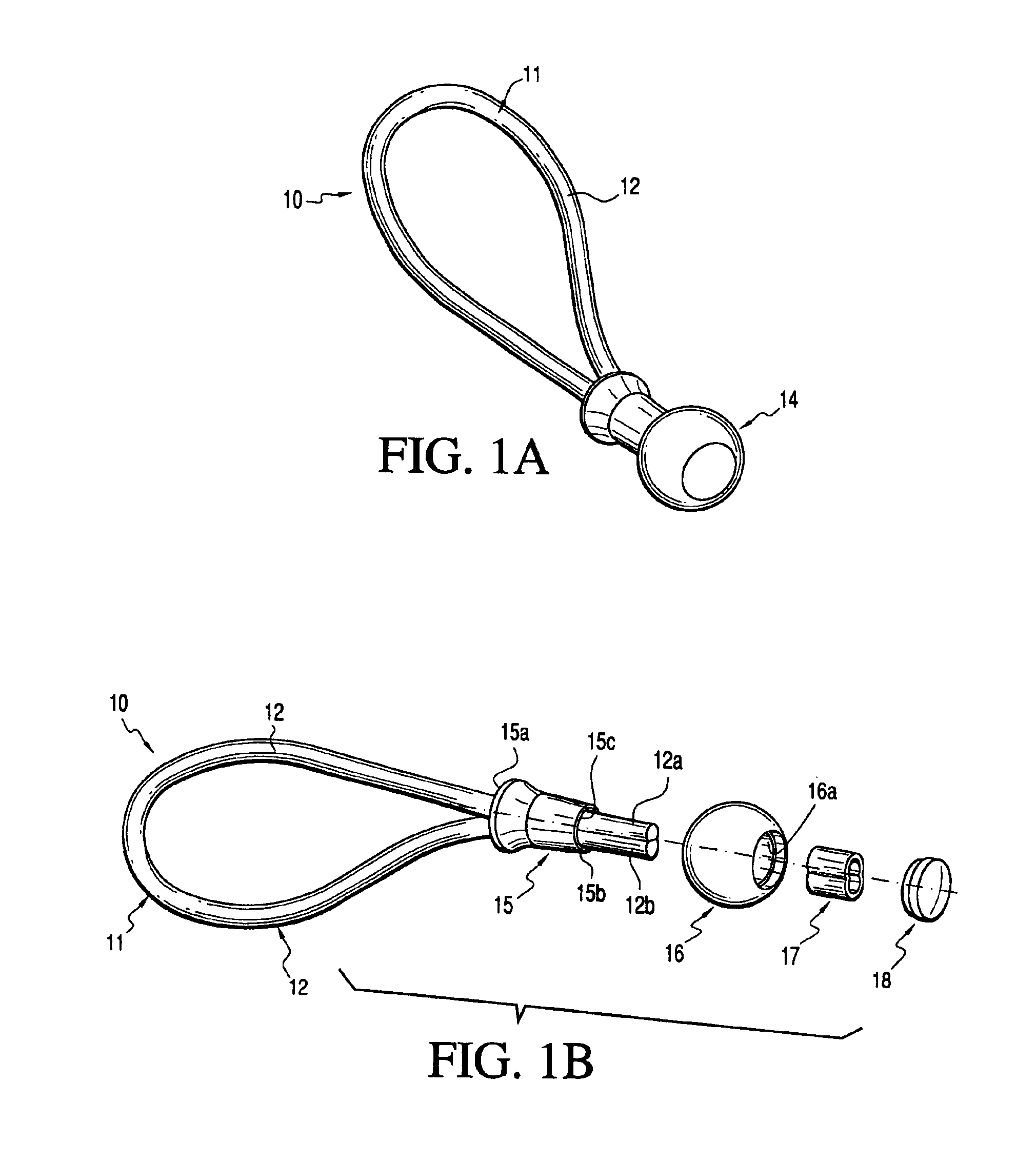

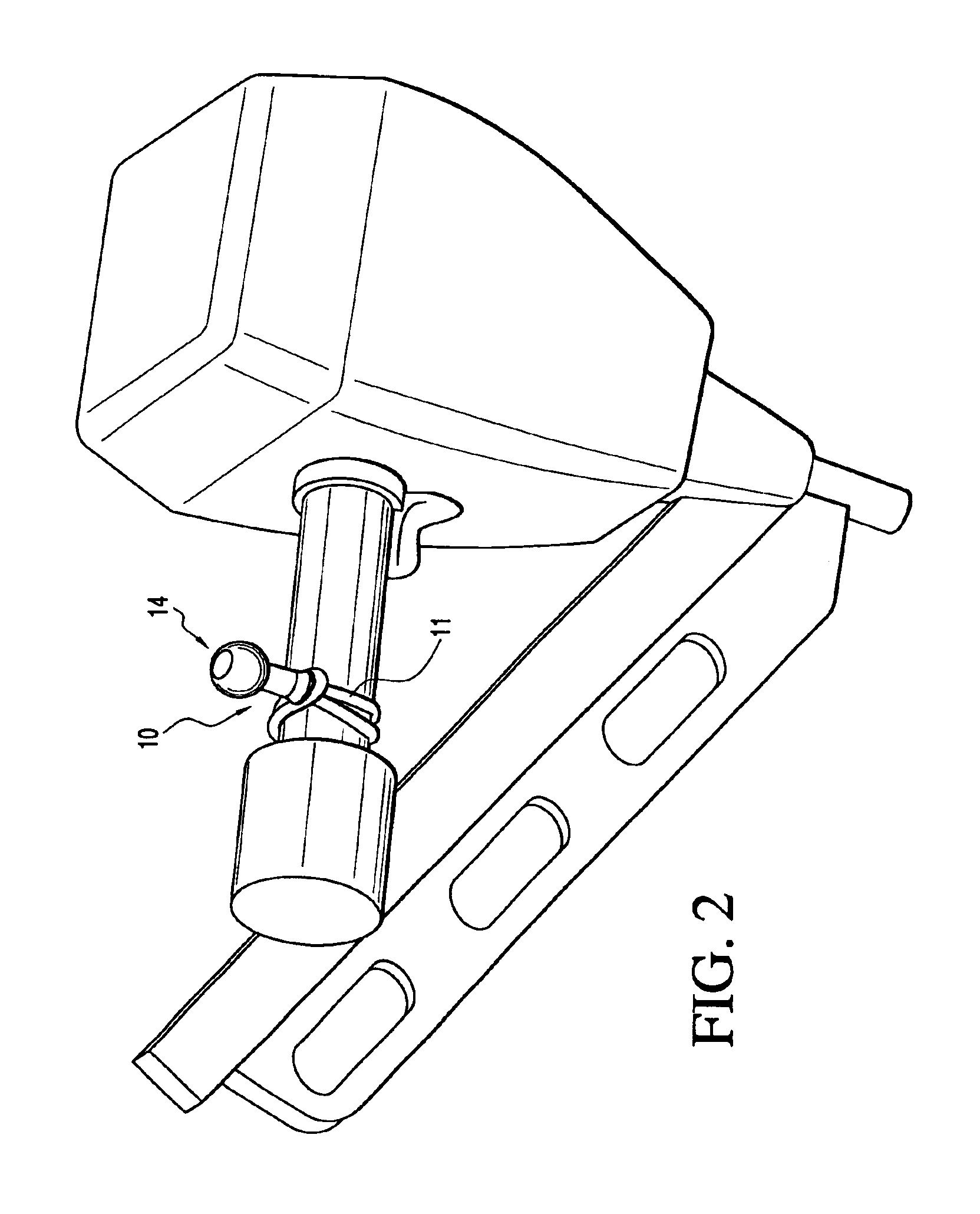

Universal tool holder

ActiveUS6880794B1Removably attachEasily and quickly introduced into retaining receiverSnap fastenersTravelling carriersDrillWall mount

A universal tool holder for carrying a tool or other article, for example, a cordless drill, nail gun, hammer or shovel is provided comprising a stretchable cord that is formed into a looped end and adapted to be wrapped about the handle of a tool in such a manner that it tightly engages the tool, and a second end having a retainable object, such as a ball, that is configured to be safely and securely held within a retaining receiver. The retaining receiver is in the form of a socket-type receiver configured to correspond to the geometrical shape of the retainable object such it can removably secure the retainable object. The socket-shaped retaining receiver can be incorporated into a variety of articles usefull in carrying and storing tools, including a belt clip, a wall mounting implement or a ladder mounting implement. By integrating the retaining receiver into such a variety of articles, any tool carried by the universal tool holder can be removably secured to the retaining receiver, thereby enabling a user to suspend the tool from a belt clip, ladder or wall.

Owner:KAHN PETER P

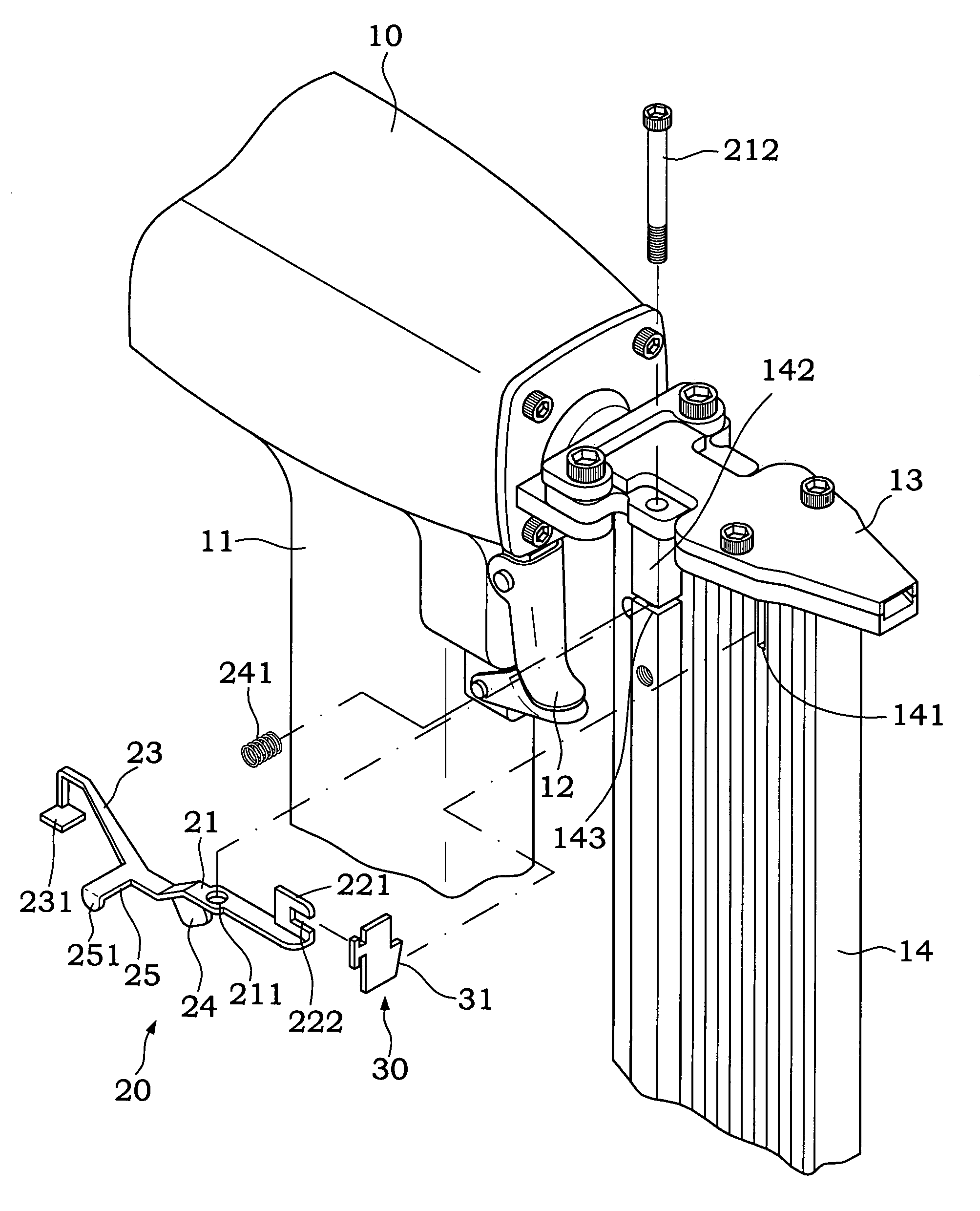

Safety catch mechanism of nail guns

A safety catch mechanism for nail guns comprises a through hole at the upper end of a magazine of the nail gun, an axle section protruded from one side of the magazine and pivotally coupled with a rotary rod, a blocking arm extended from the rear end of the rotary rod, a blocking plate bent from the rear end of the blocking arm for being extended and blocking the rear of the trigger; wherein a push arm is extended from the front end of the rotary rod; a limit bracket is movably embedded at the end of the push arm; a latch is defined on the limit plate to be protruded from an inner wall of the magazine; by means of the foregoing structure, if the magazine is loaded with nails, the latch can be pushed outward to drive the rotary rod to rotate, so that the blocking plate is separated from the rear of the trigger and allows users to cock the trigger.

Owner:NAILERMATE ENTERPRISE

Pneumatic nail gun

A pneumatic nail gun has a gun body having a main air housing; a cylinder fixed in the main air housing; a hitting piston slidably movable in the cylinder; a dish-shaped piston disposed at a top end portion of the cylinder; an upper slidable sleeve valve disposed at a top portion of an out peripheral surface of the cylinder, which is driven to move upward by the high pressure air in the main air housing; and a lower slidable sleeve valve disposed at a lower portion of an outer peripheral surface of the cylinder, which is driven to move downward for guiding the high pressure air into the cylinder for upward deposition of the hitting piston when the upper slidable sleeve valve moves upward, and is driven to upward reposite when the hitting piston moves to its upper dead center.

Owner:DE POAN PNEUMATIC

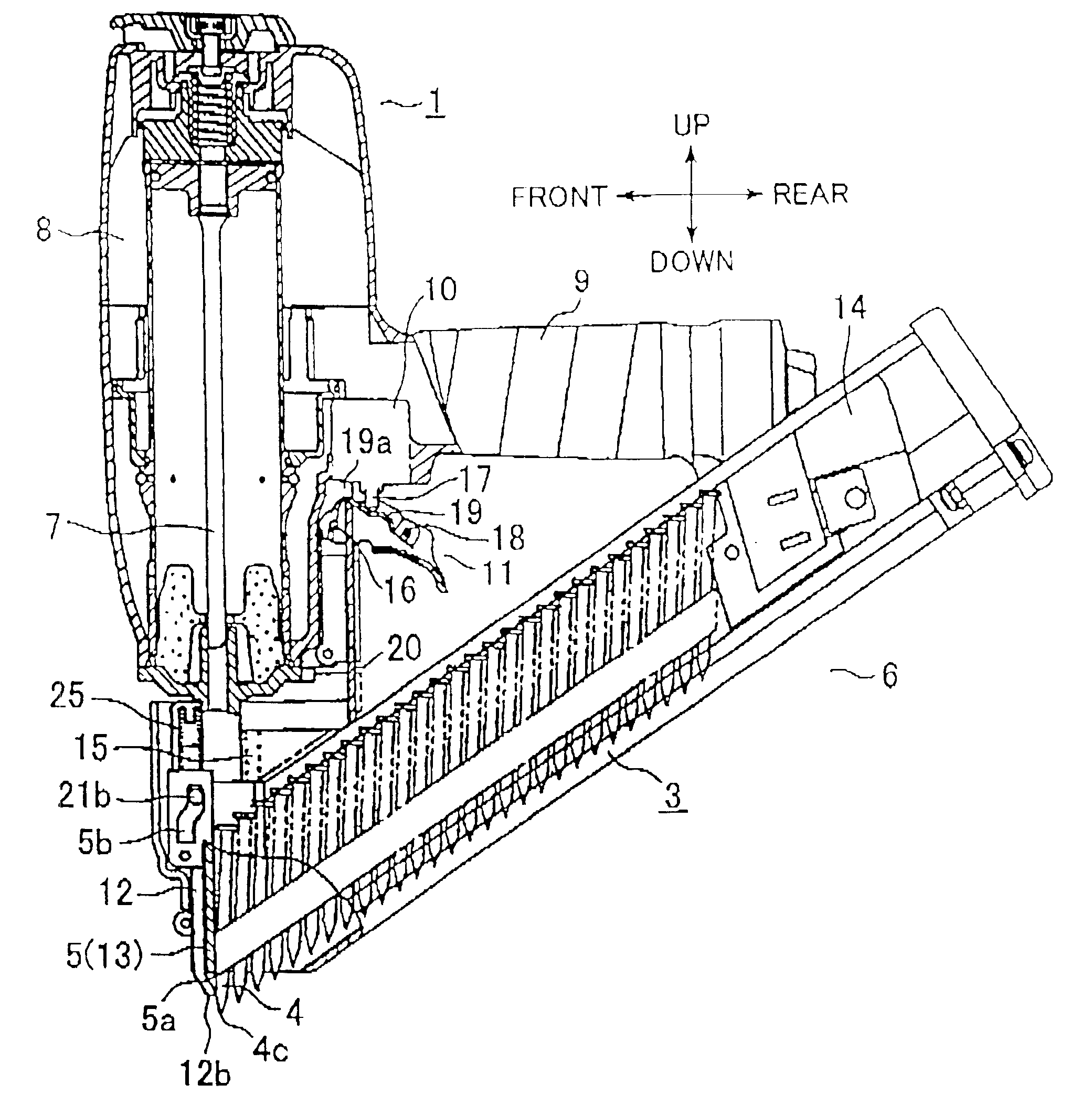

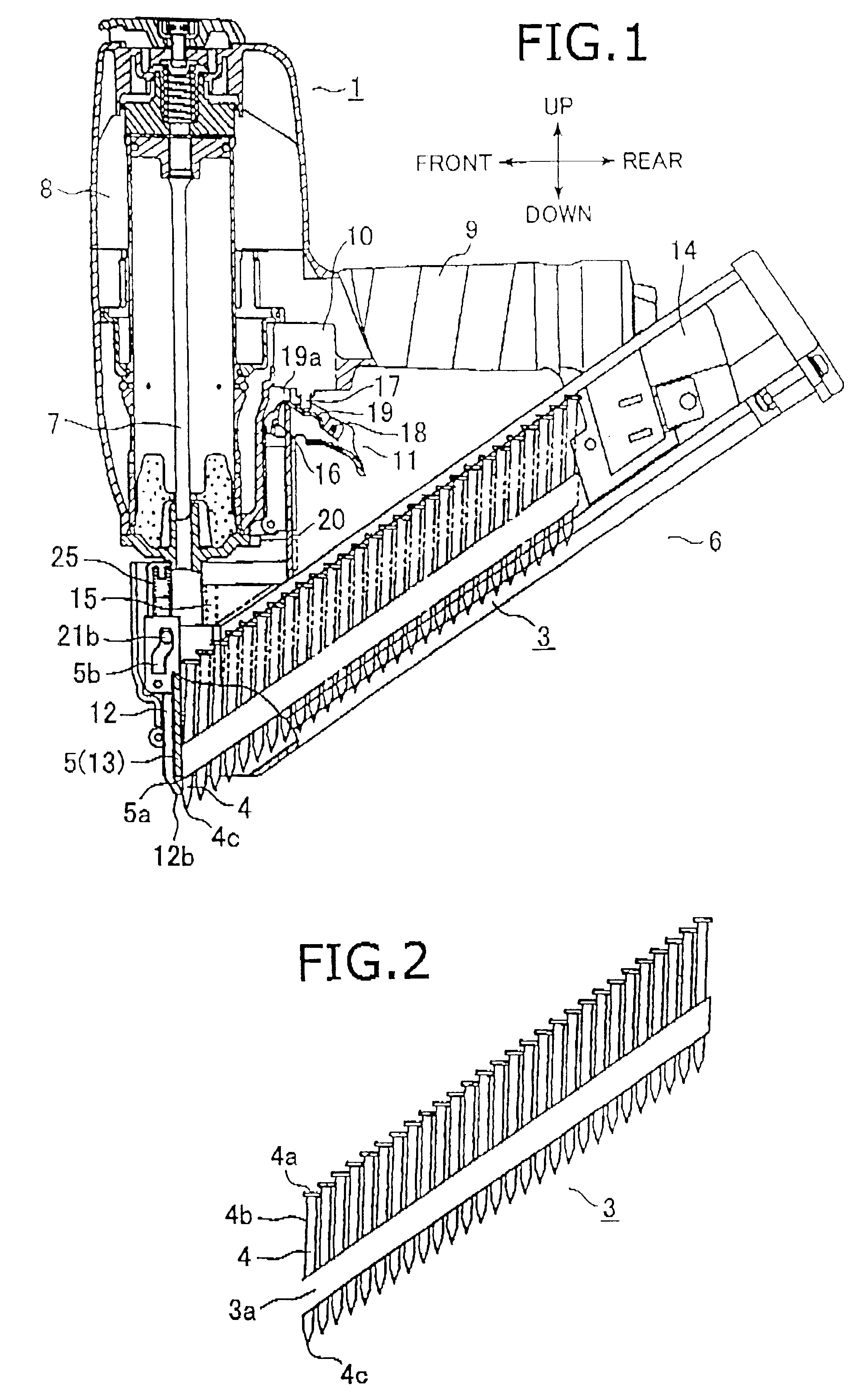

Combustion-powered nail gun

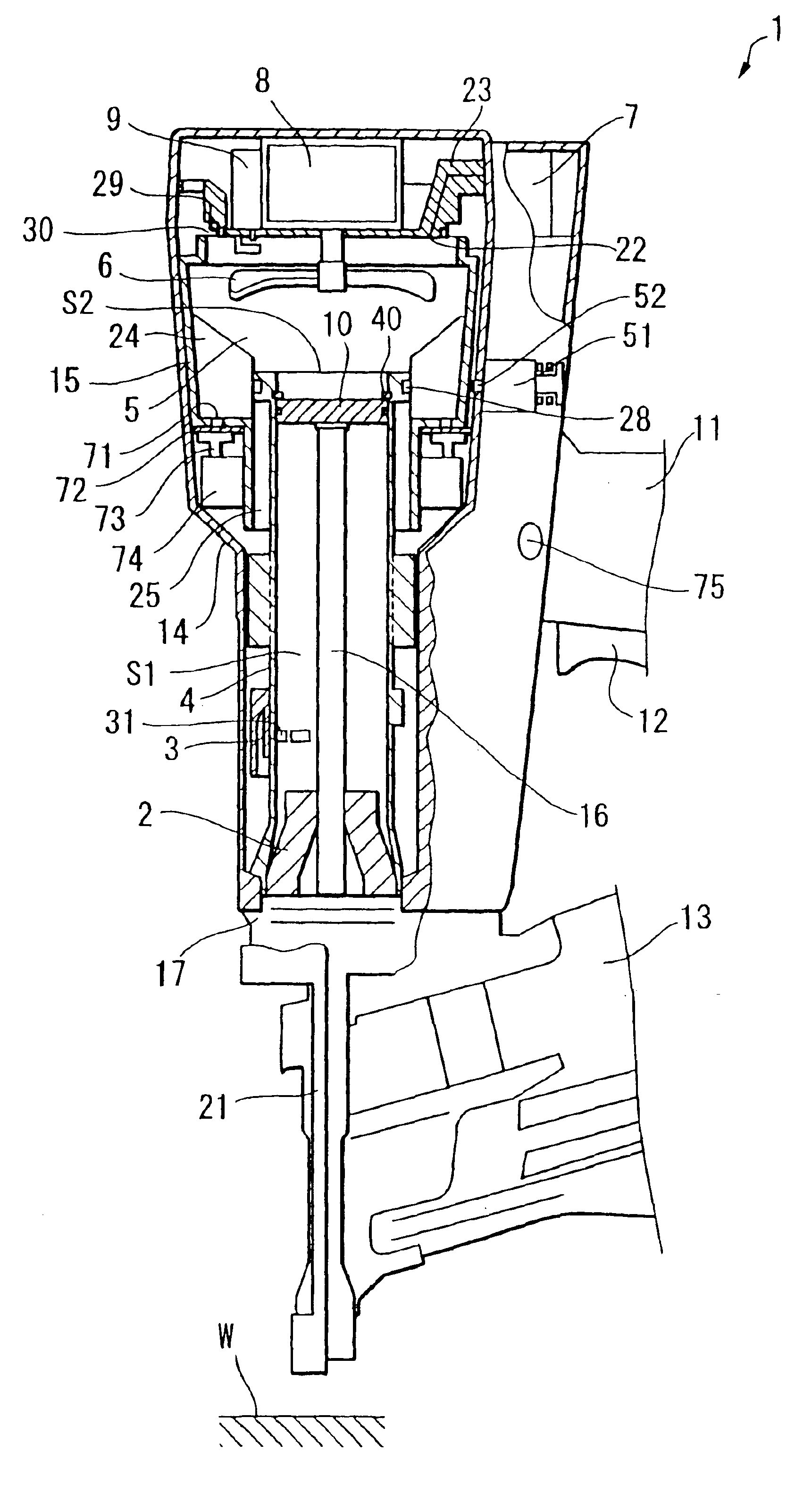

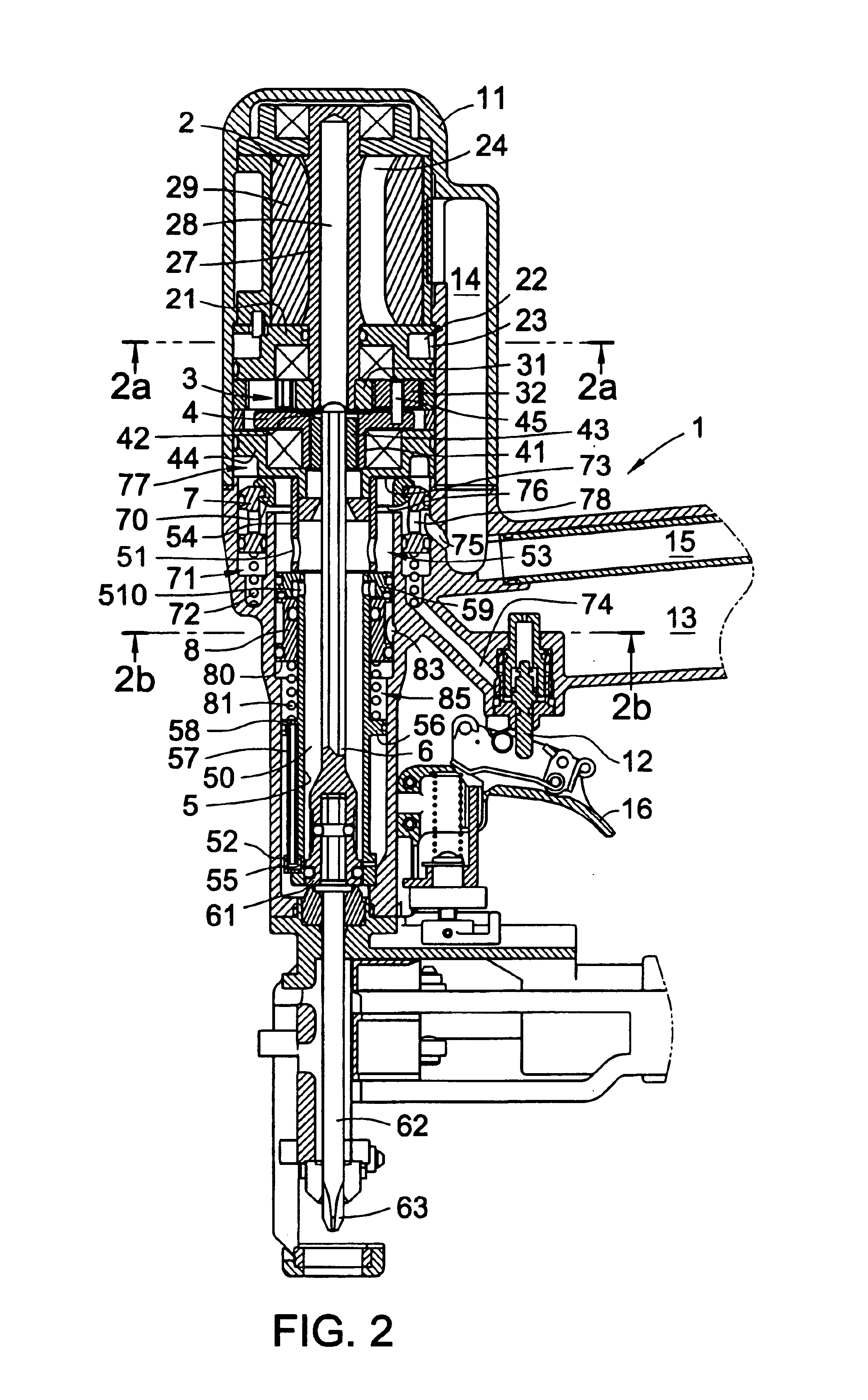

InactiveUS6889885B2Reduce fatigueRapid piston returningStapling toolsNailing toolsCombustion chamberEngineering

A combustion-powered nail gun including an arrangement for promoting a piston returning motion to its upper dead center. A combustion chamber frame is movable toward and away from a head cover at which a spark plug is provided. When the combustion chamber frame is in close contact with the head cover, a combustion chamber is provided among the combustion chamber frame, the head cover, a part of a cylinder and a piston. After the piston reaches the lower dead center as a result of combustion, a thermal vacuum is provided in the combustion chamber for allowing the piston to move toward the upper dead center. The combustion chamber frame has a through-hole, and a valve is provided for normally closing the through-hole. A solenoid is provided to selectively open the valve for leaking an increased pressure in the combustion chamber through the through-hole during the return stroke of the piston.

Owner:KOKI HLDG CO LTD

Pneumatic nail gun

InactiveUS7293684B1Increase airflowSimplifies valve controlling mechanismStapling toolsFree piston enginesEngineeringHigh pressure

A pneumatic nail gun includes a gun body with a trigger, collecting a compressed high pressure air with a constant pressure, a movable cylinder installed in the gun body, a hitting piston disposed in the cylinder, a valve ring formed outside the cylinder, a head valve disposed on the top of the cylinder, at least one return passage formed outside the cylinder, and a valve bolt disposed in the return passage. Before the trigger is pressed, the high pressure air drives the valve ring to keep the cylinder at the upper position to close the head valve. When the trigger is pressed, the high pressure air drives the cylinder move downwardly to open the head valve for guiding the high pressure air to drive the piston downwardly move to hit nails. When the trigger is released, the high pressure air drives the valve bolt open for guiding the high pressure air via the return passage to drive the piston rapidly move upwardly to reposit.

Owner:DE POAN PNEUMATIC

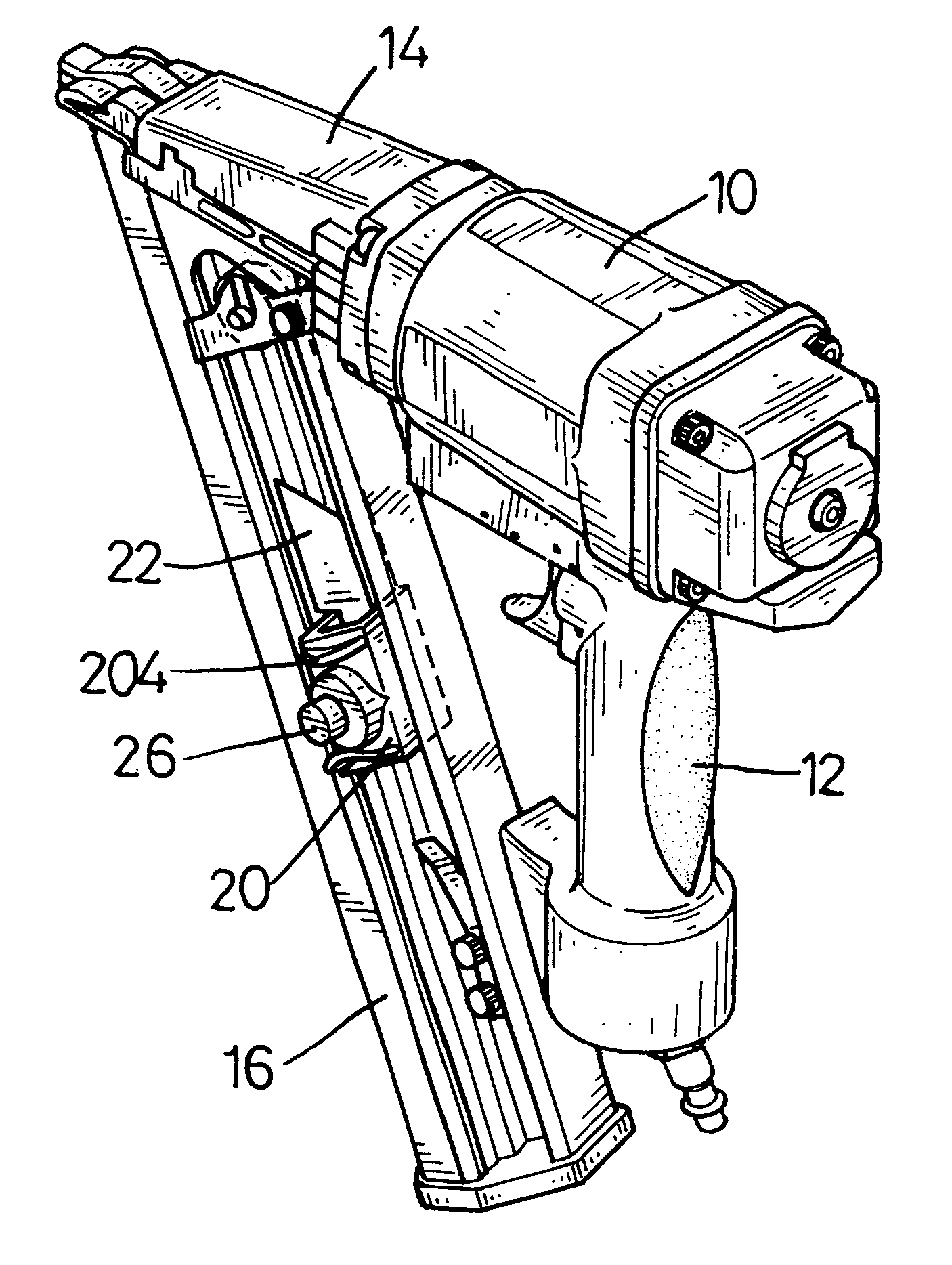

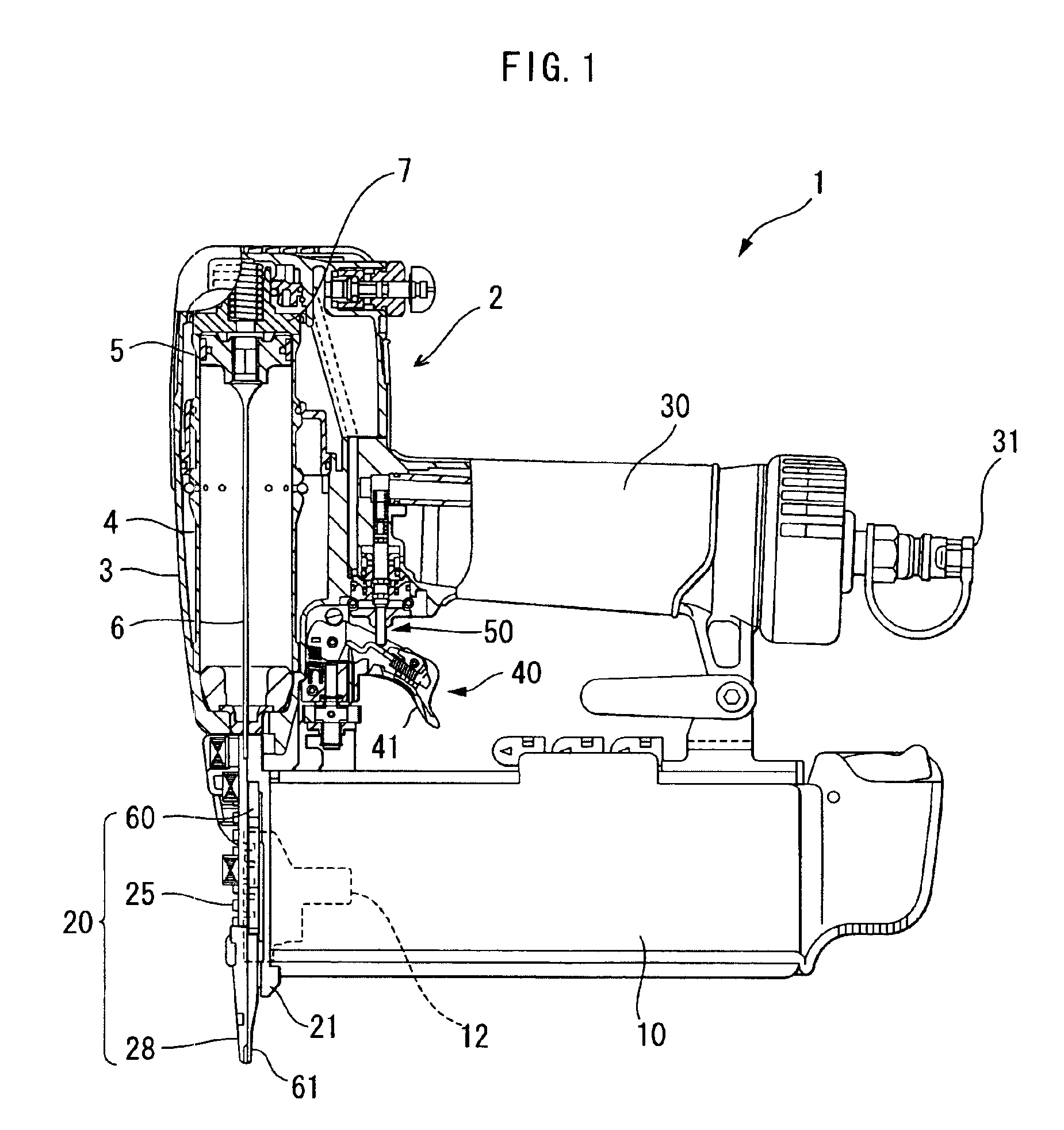

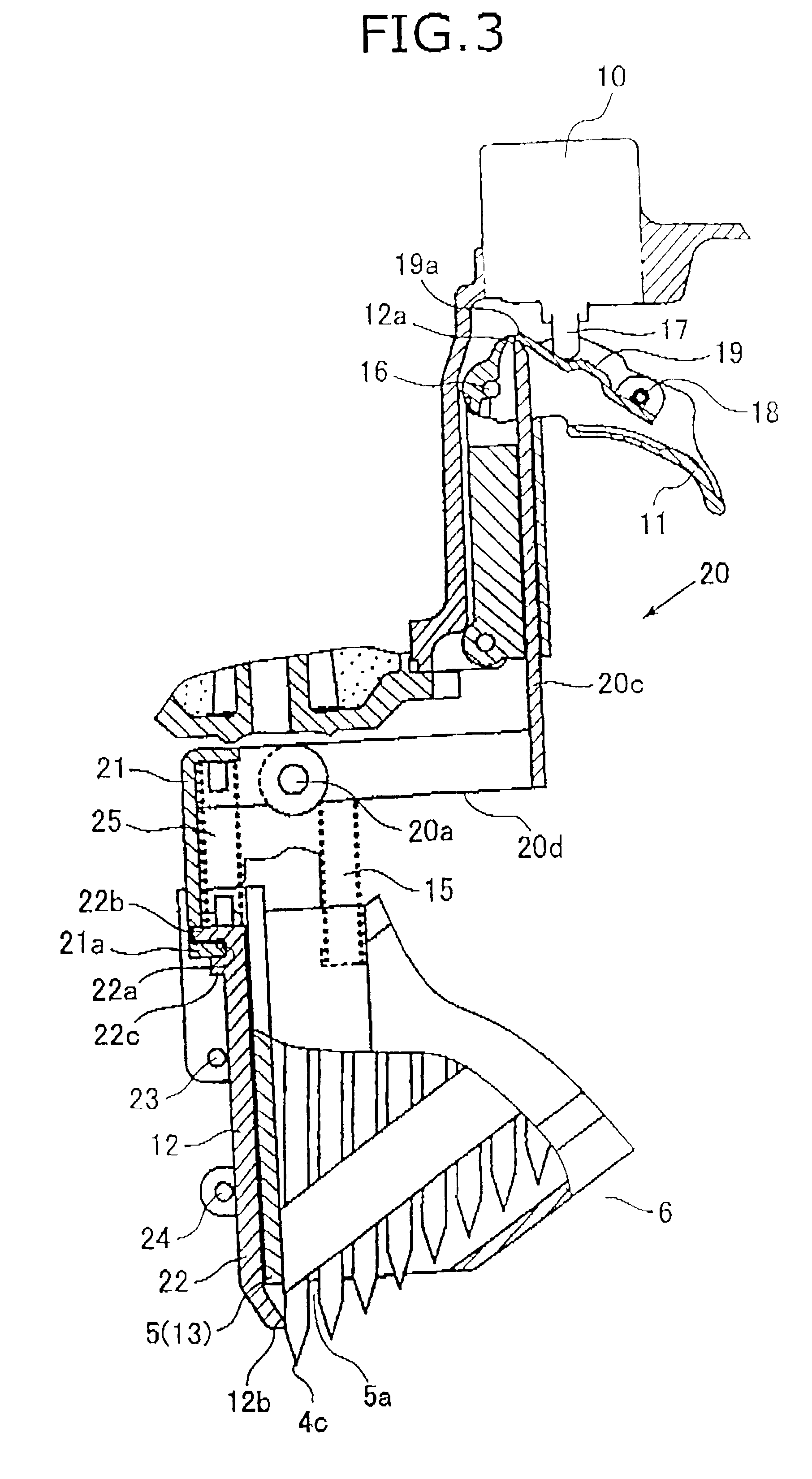

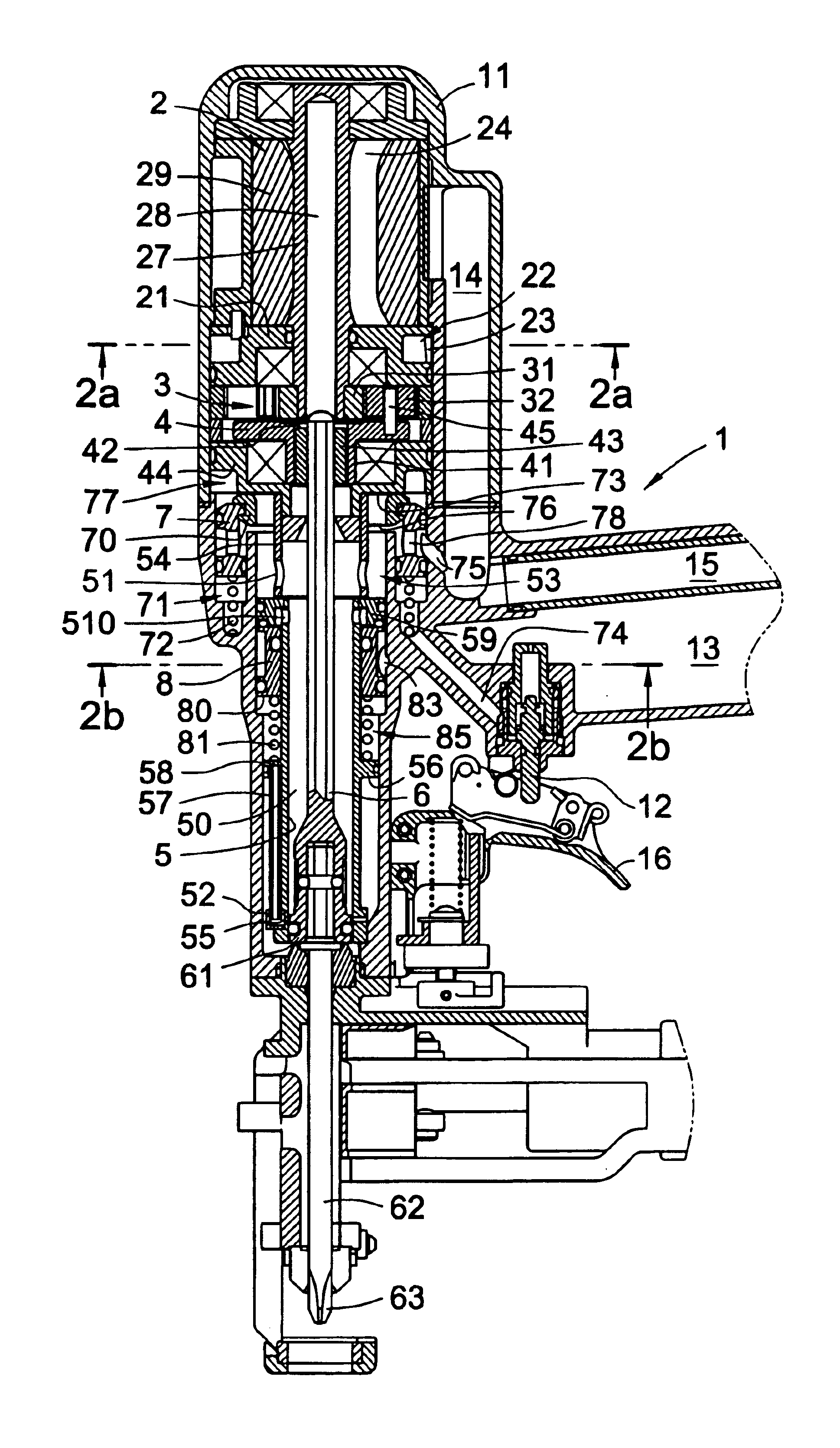

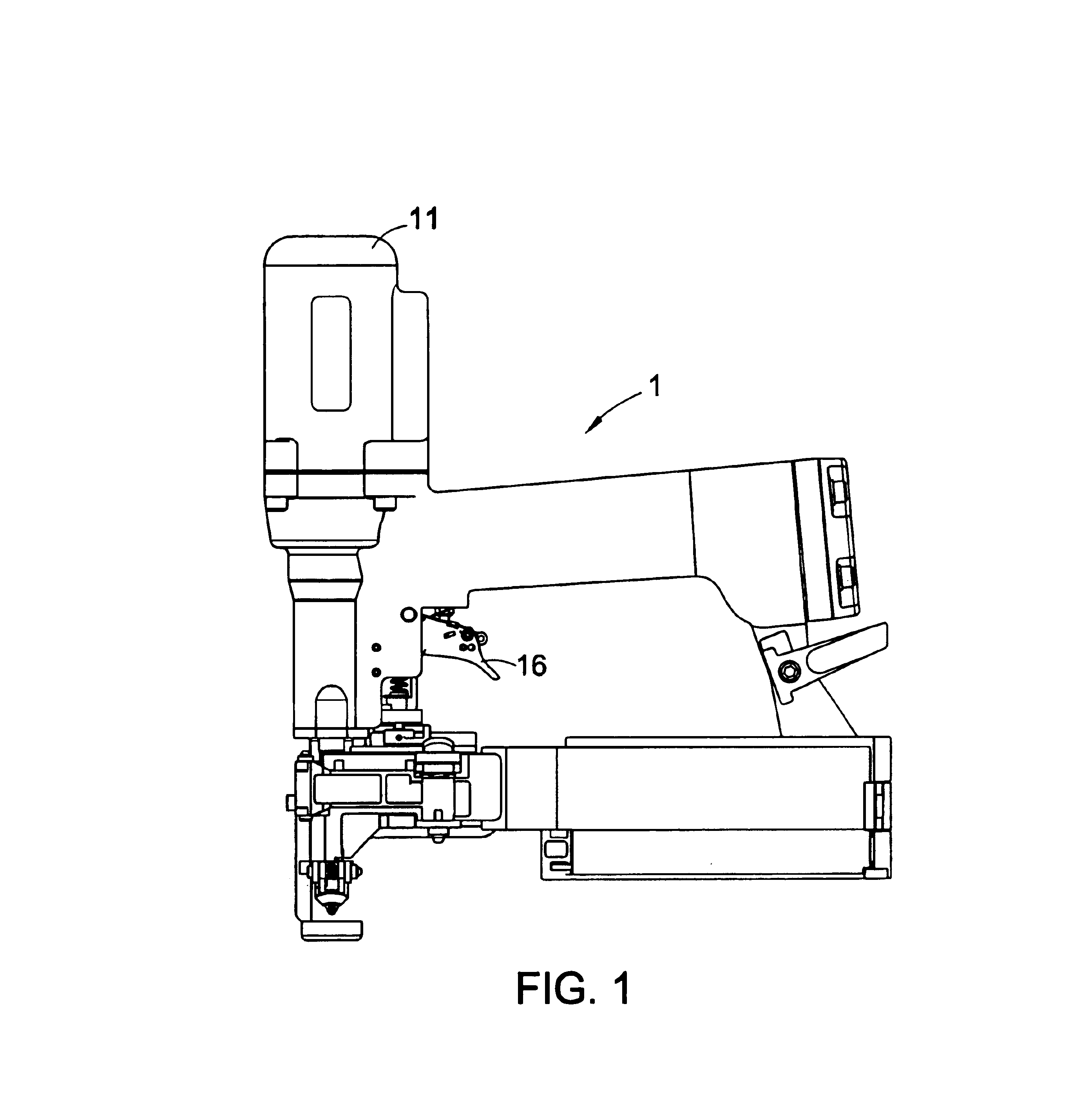

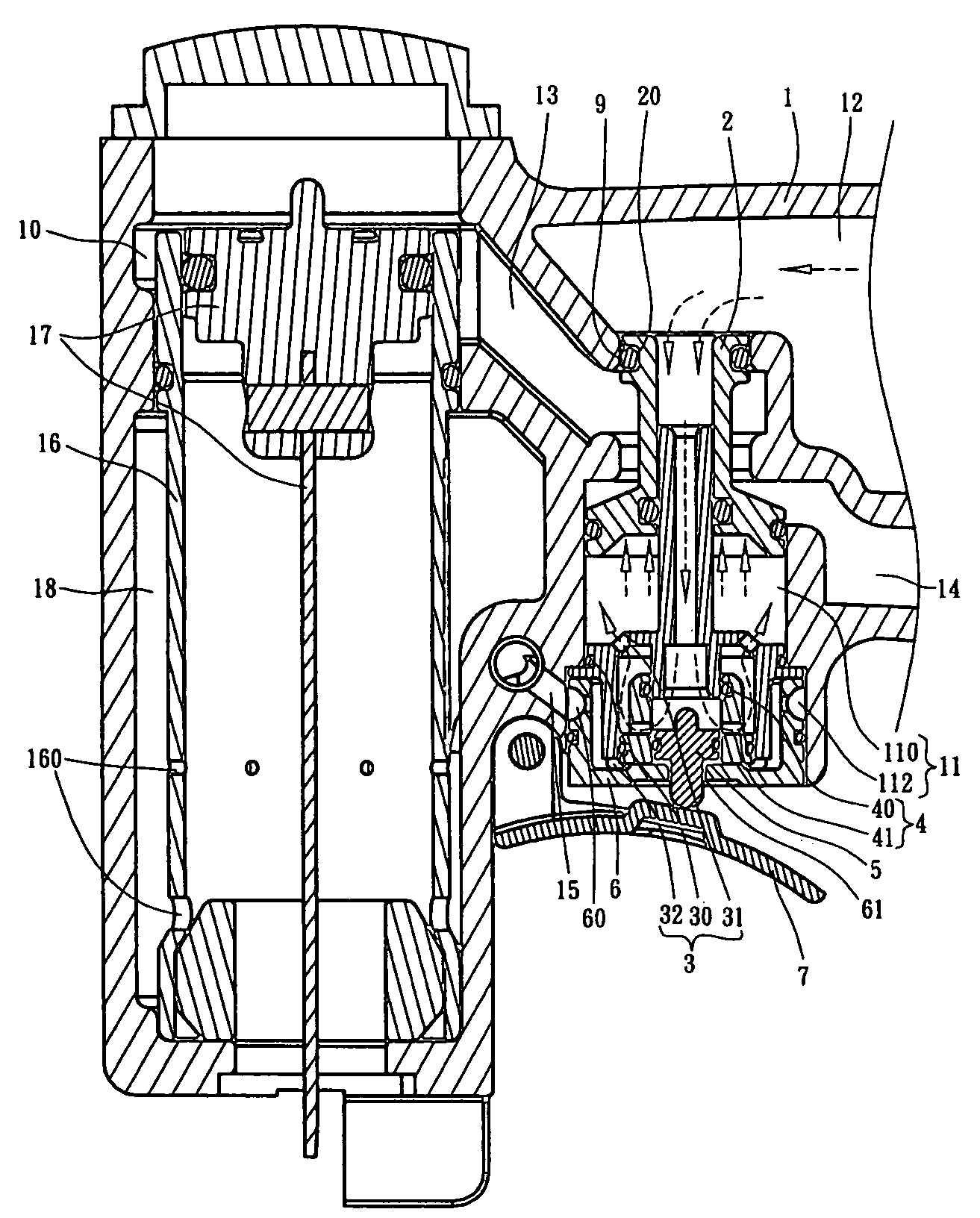

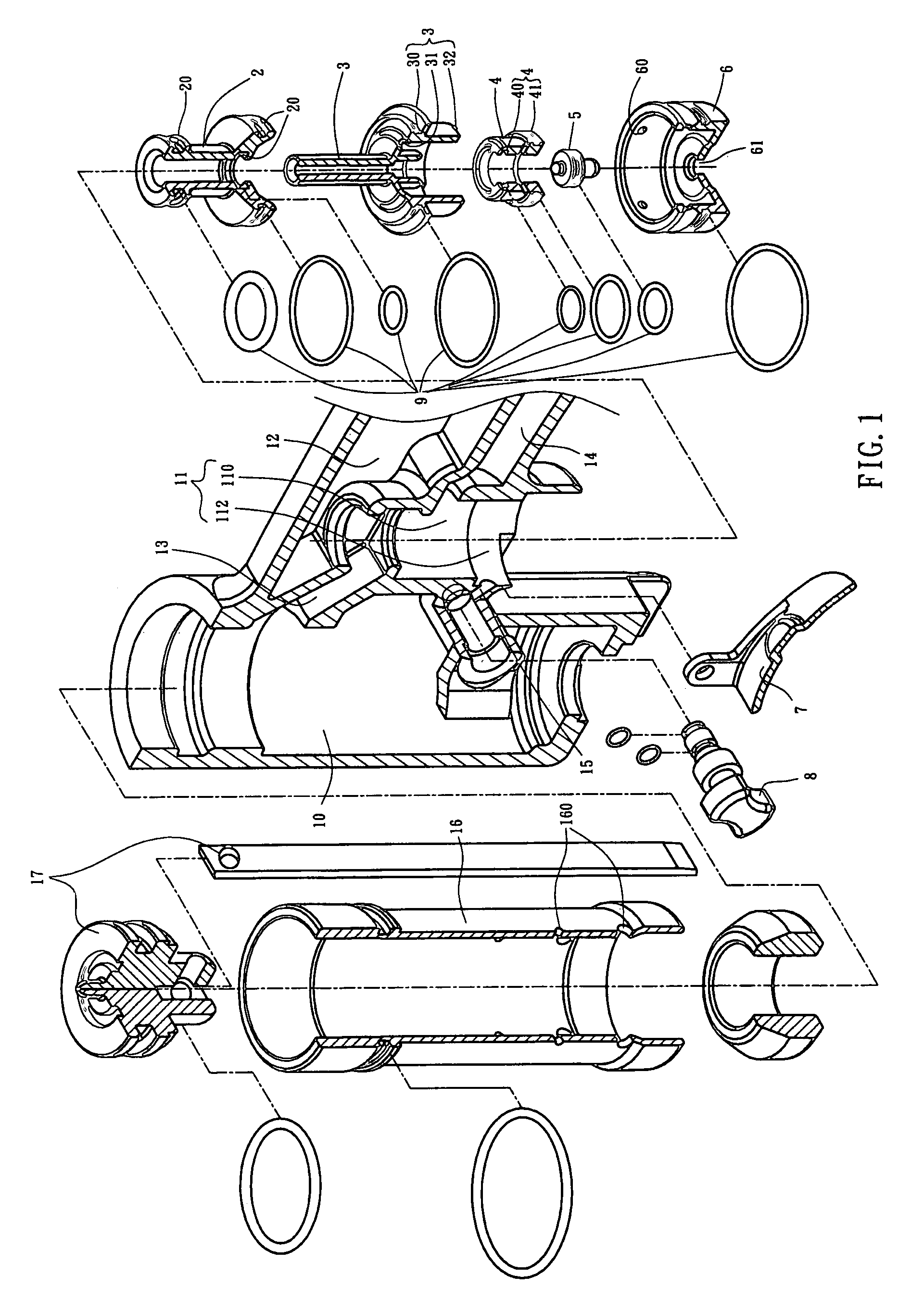

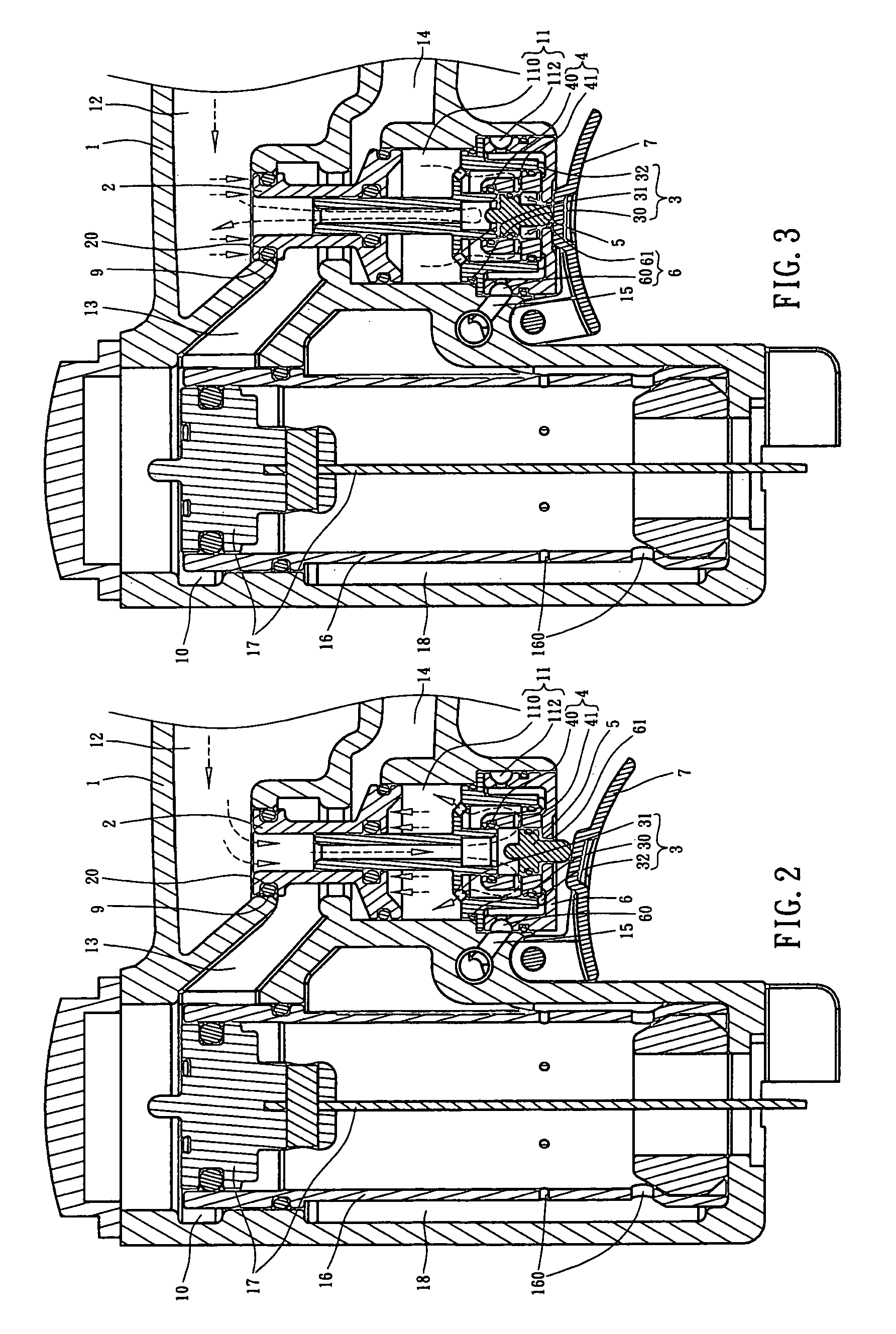

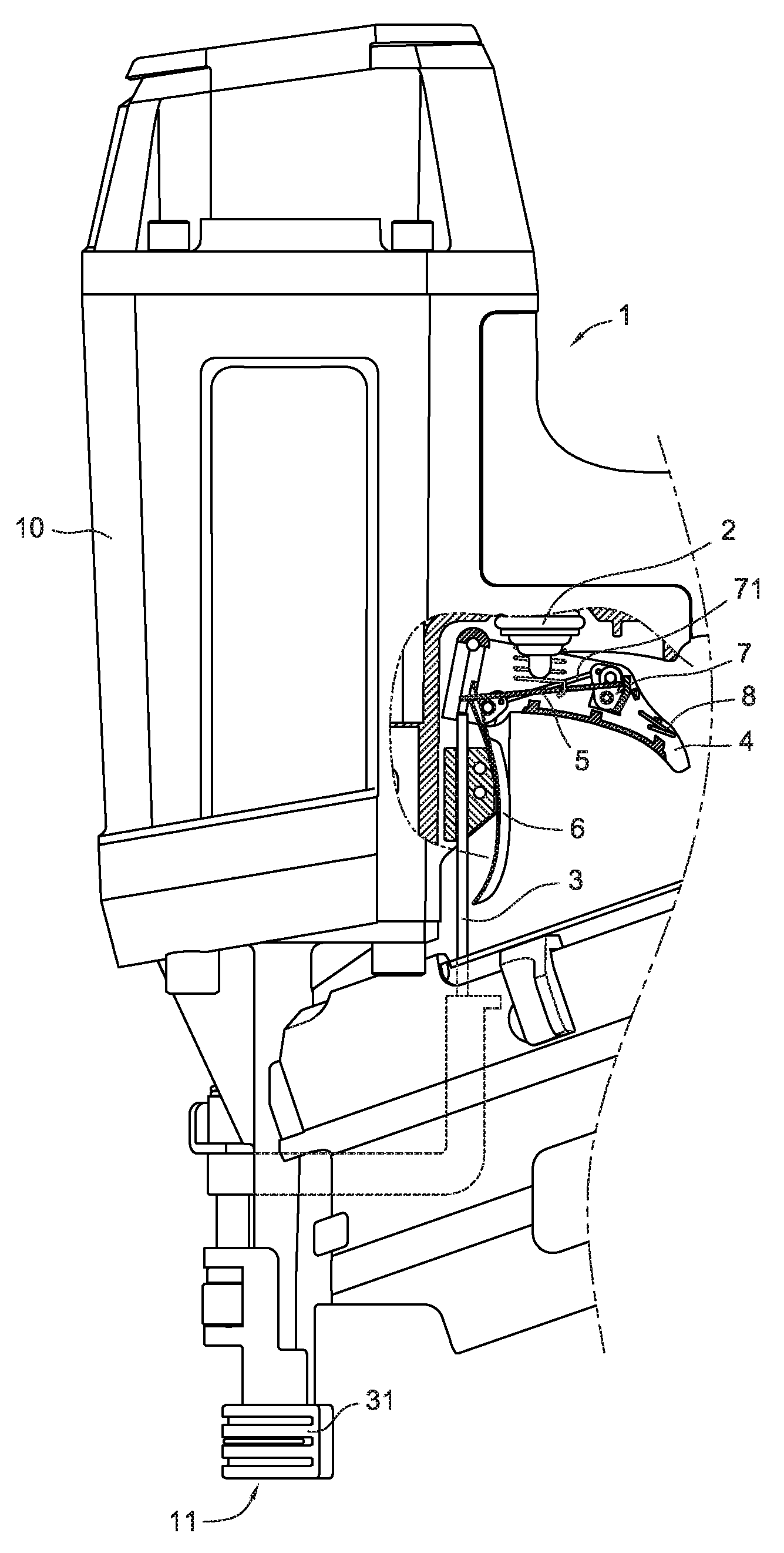

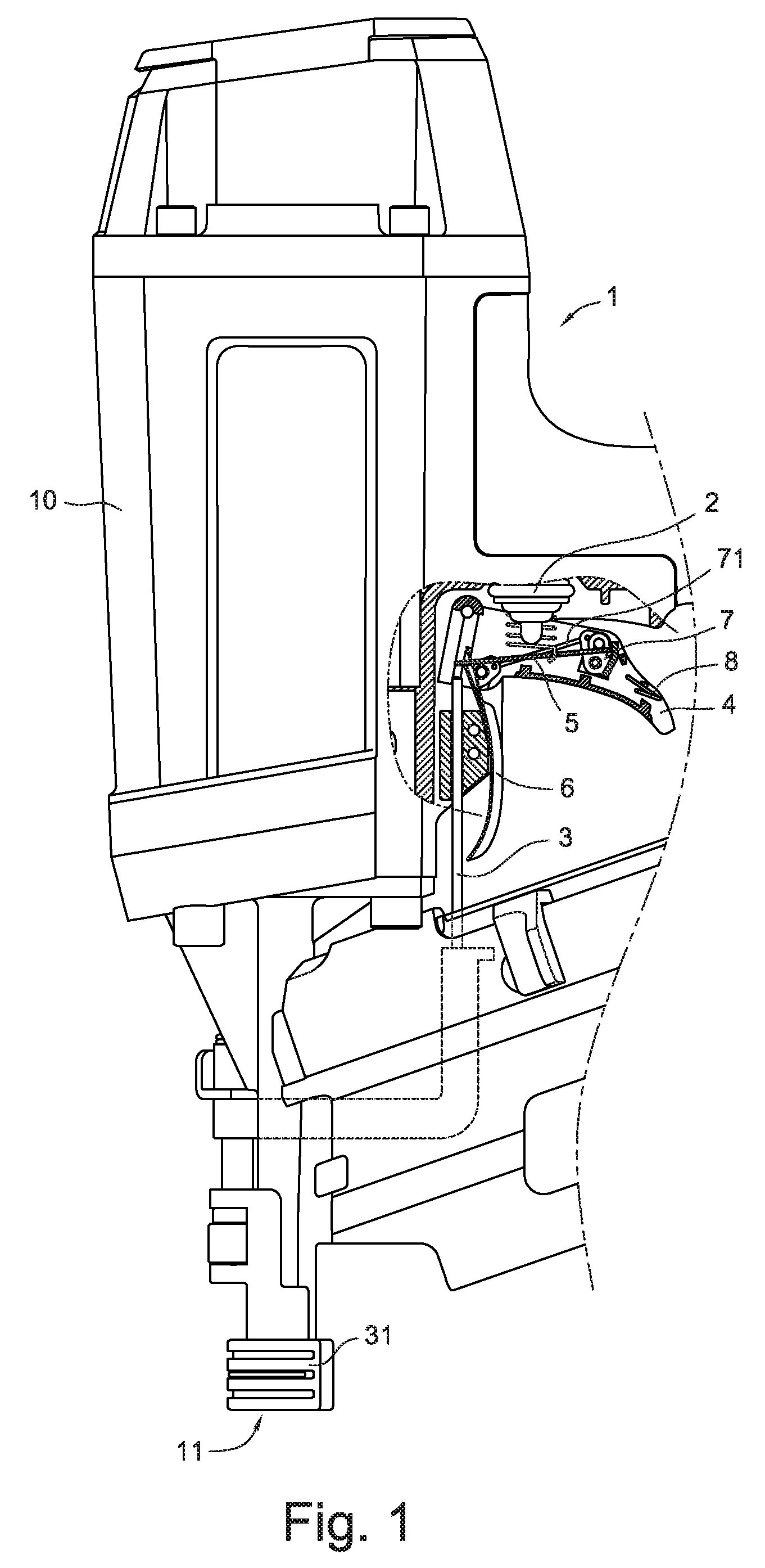

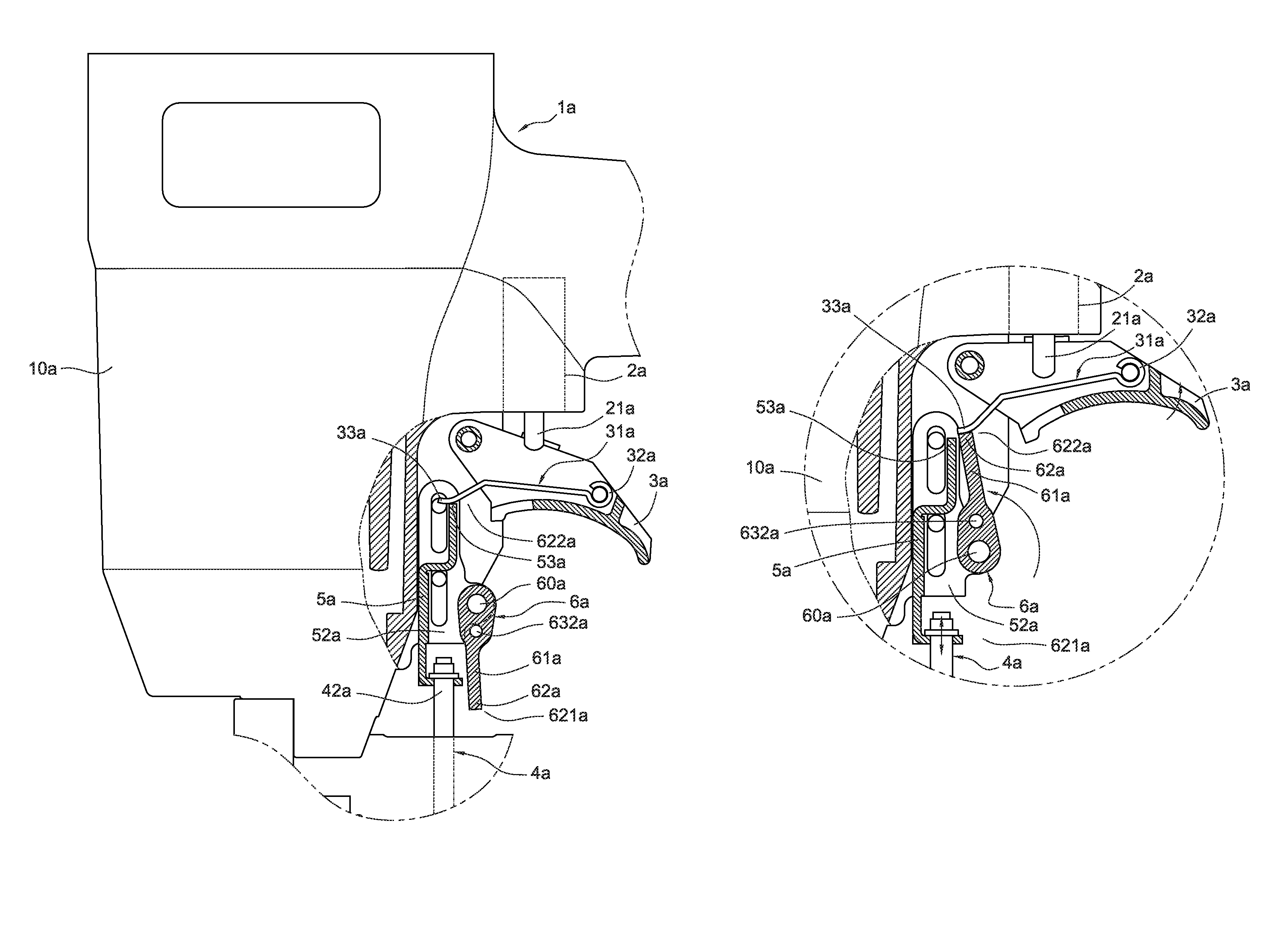

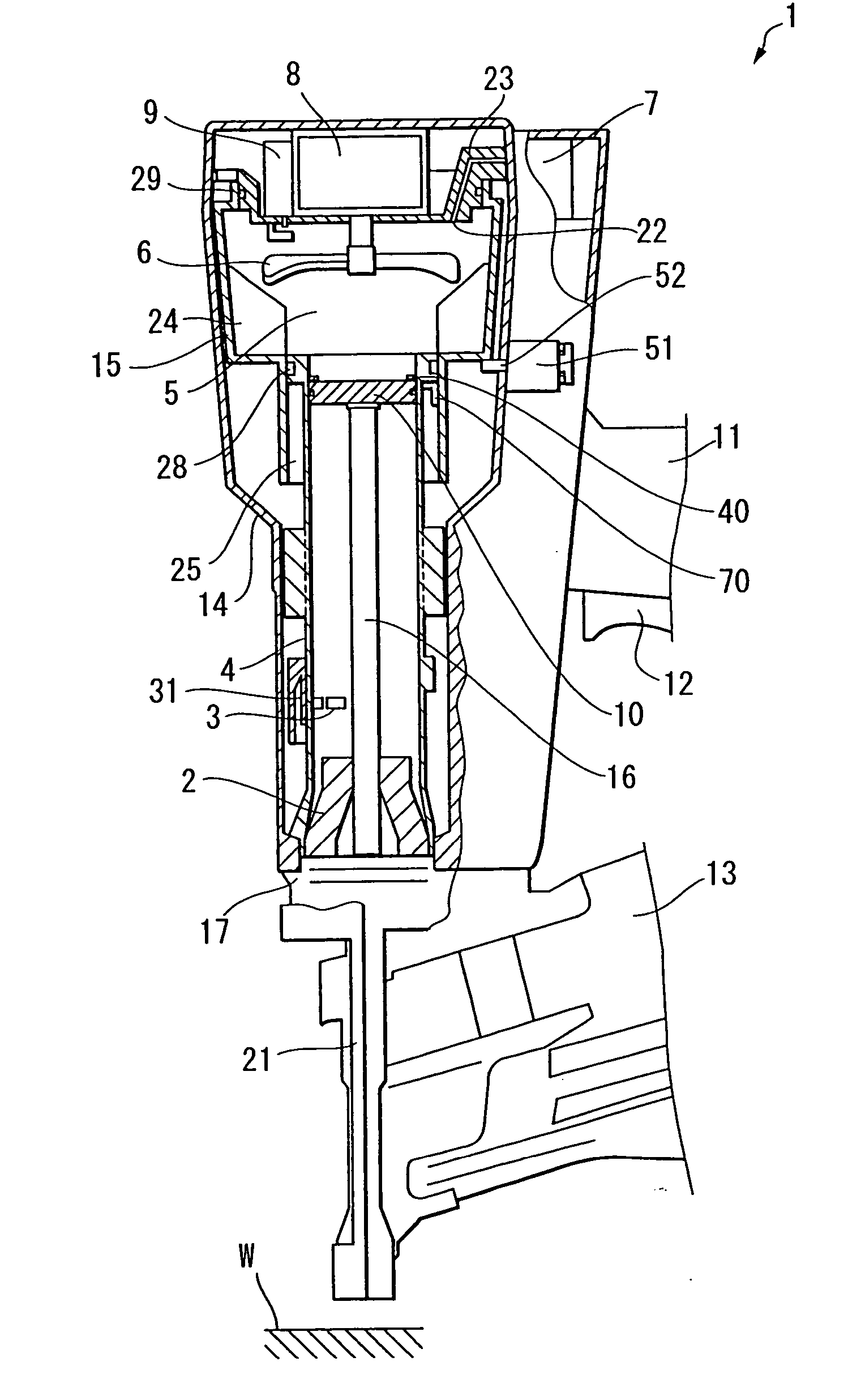

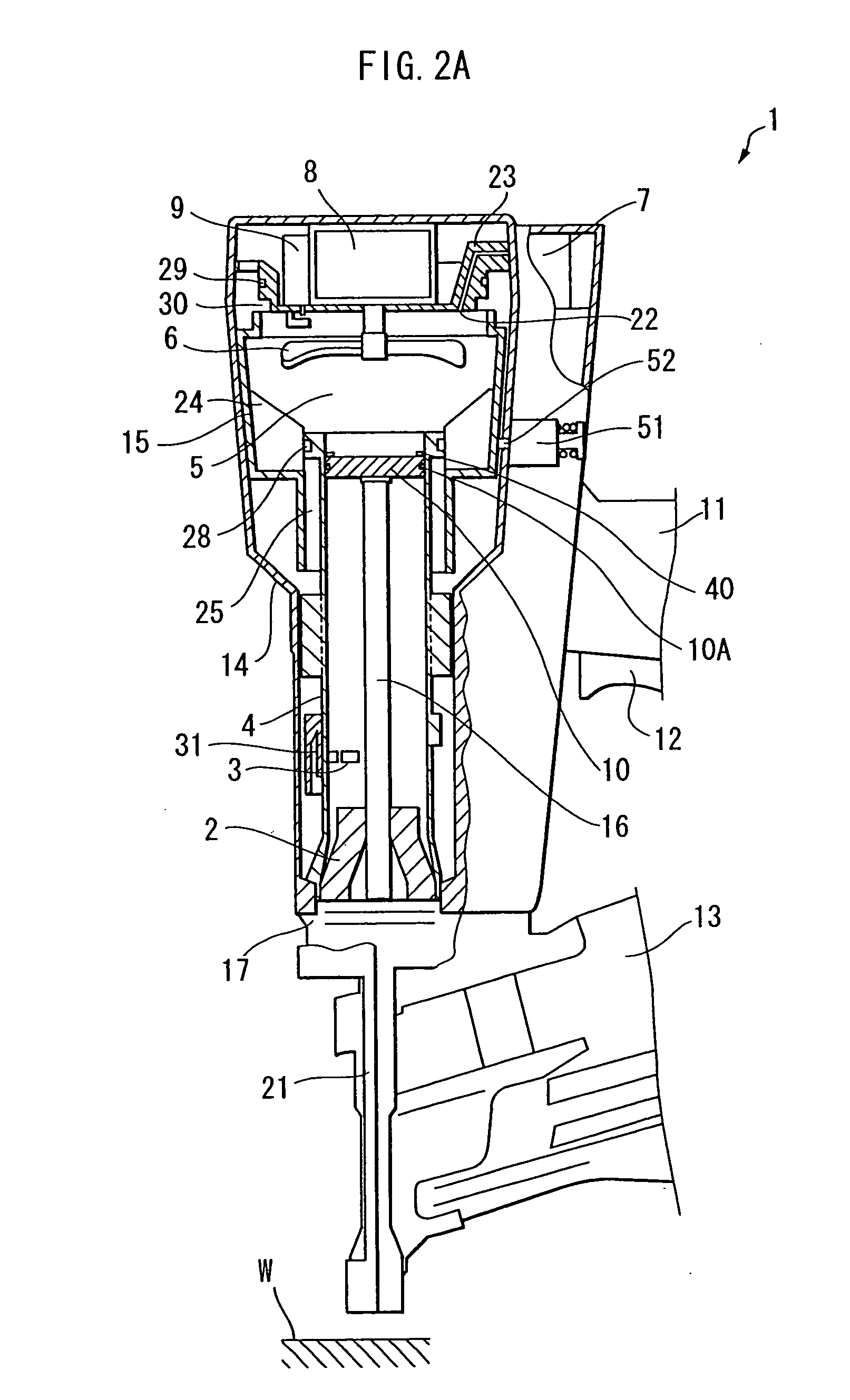

Fastener driving tool having contact arm in contact with workpiece

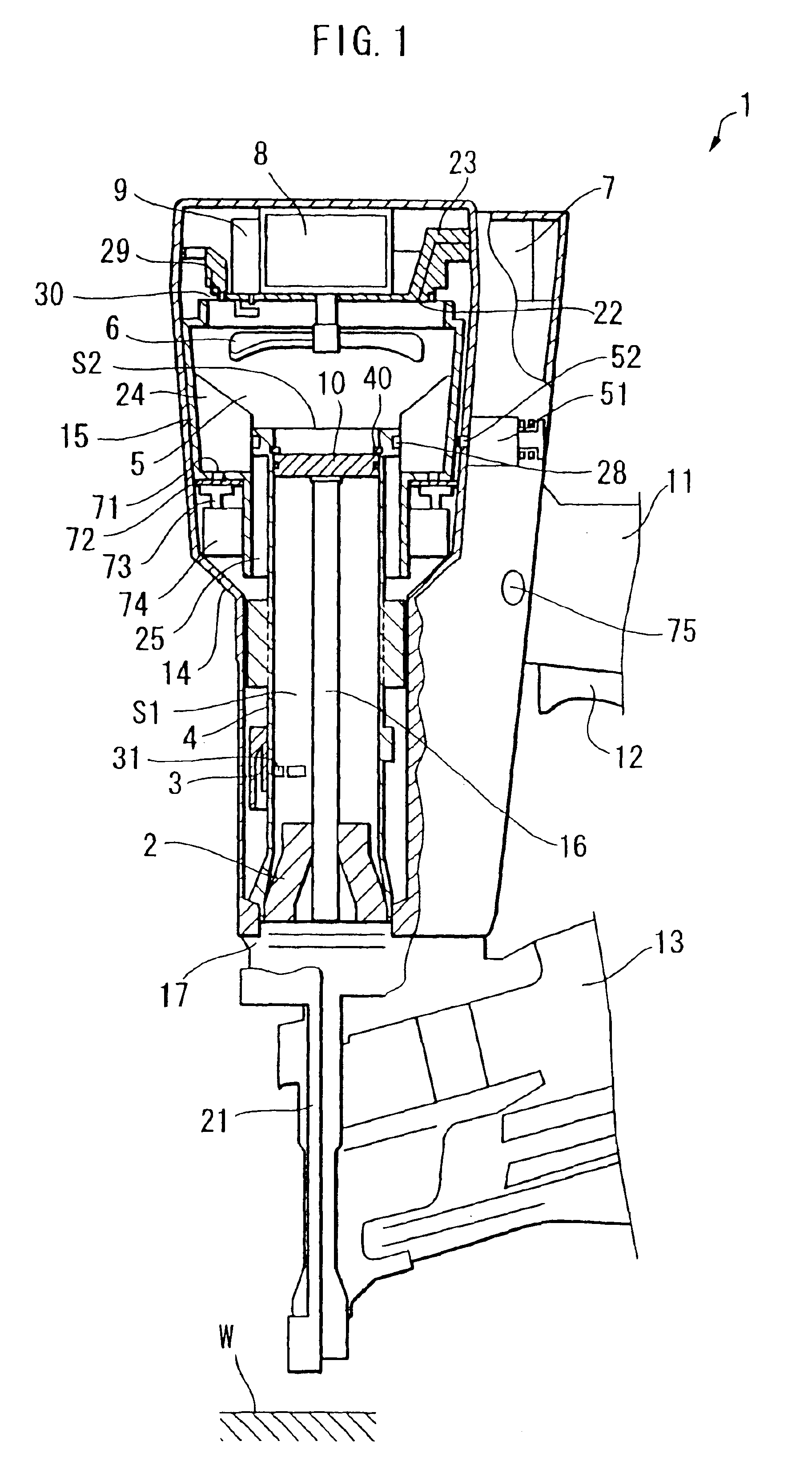

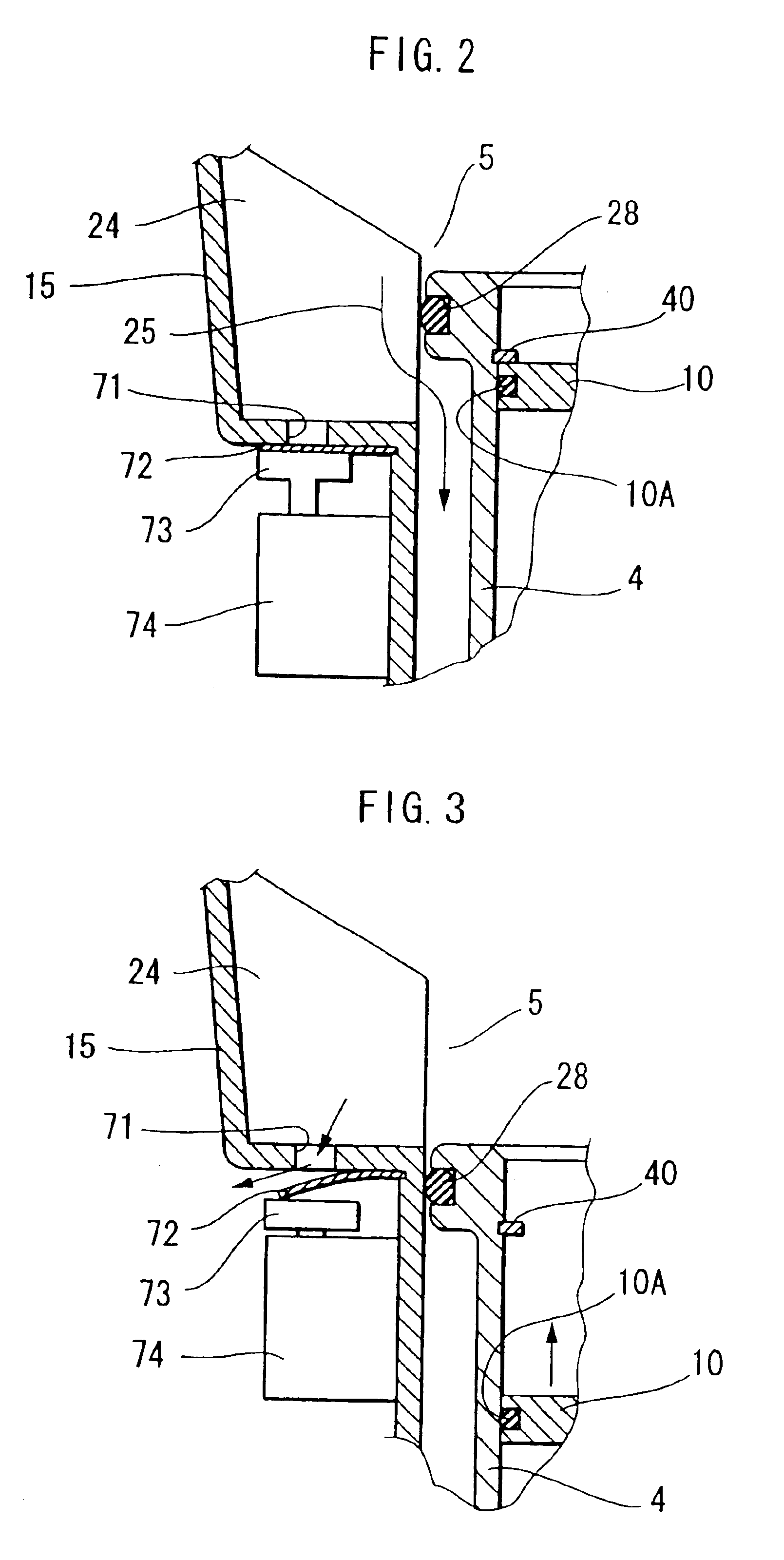

ActiveUS6953137B2Sufficient operabilitySufficient workabilityStapling toolsNailing toolsRelative motionEngineering

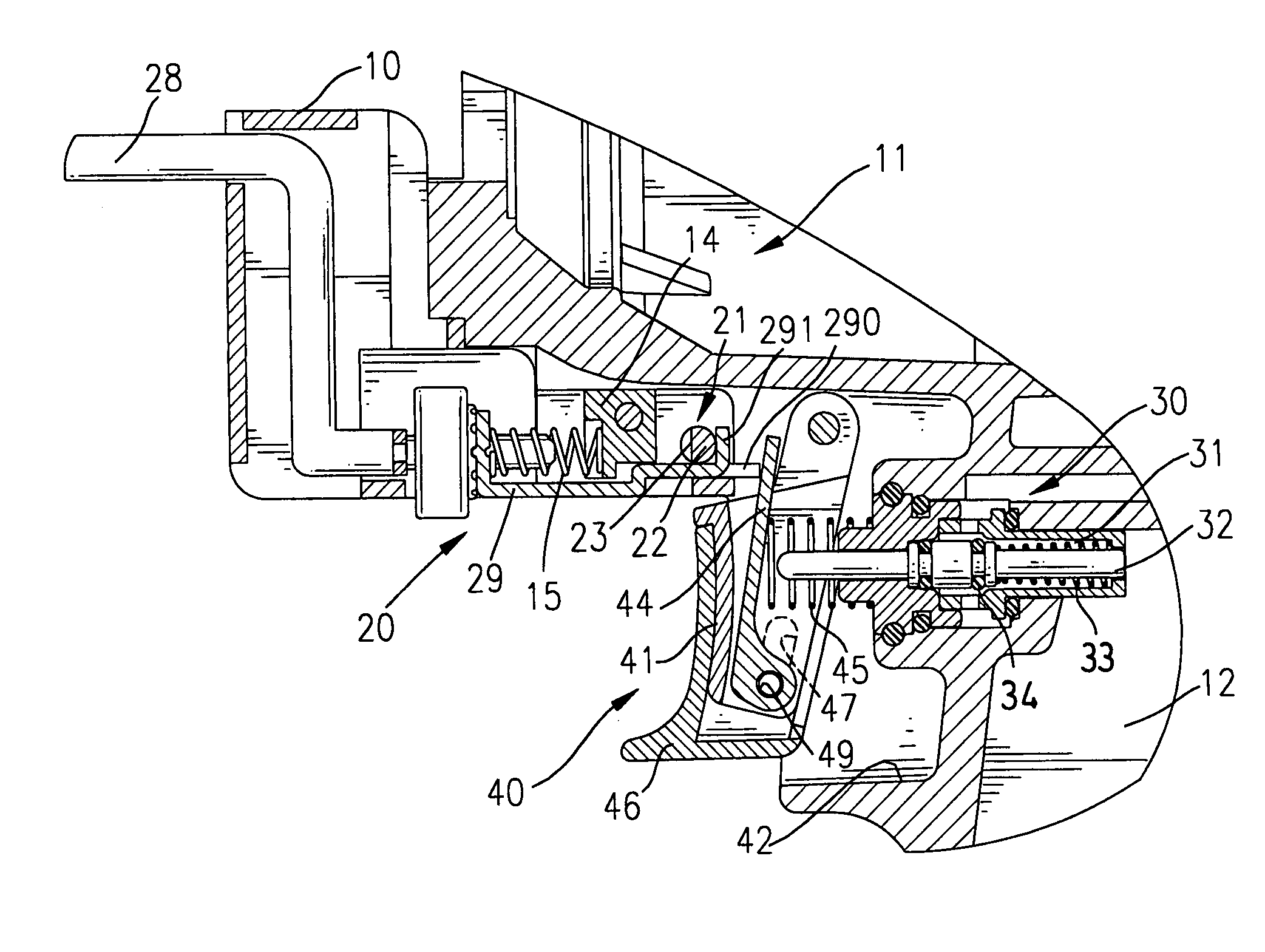

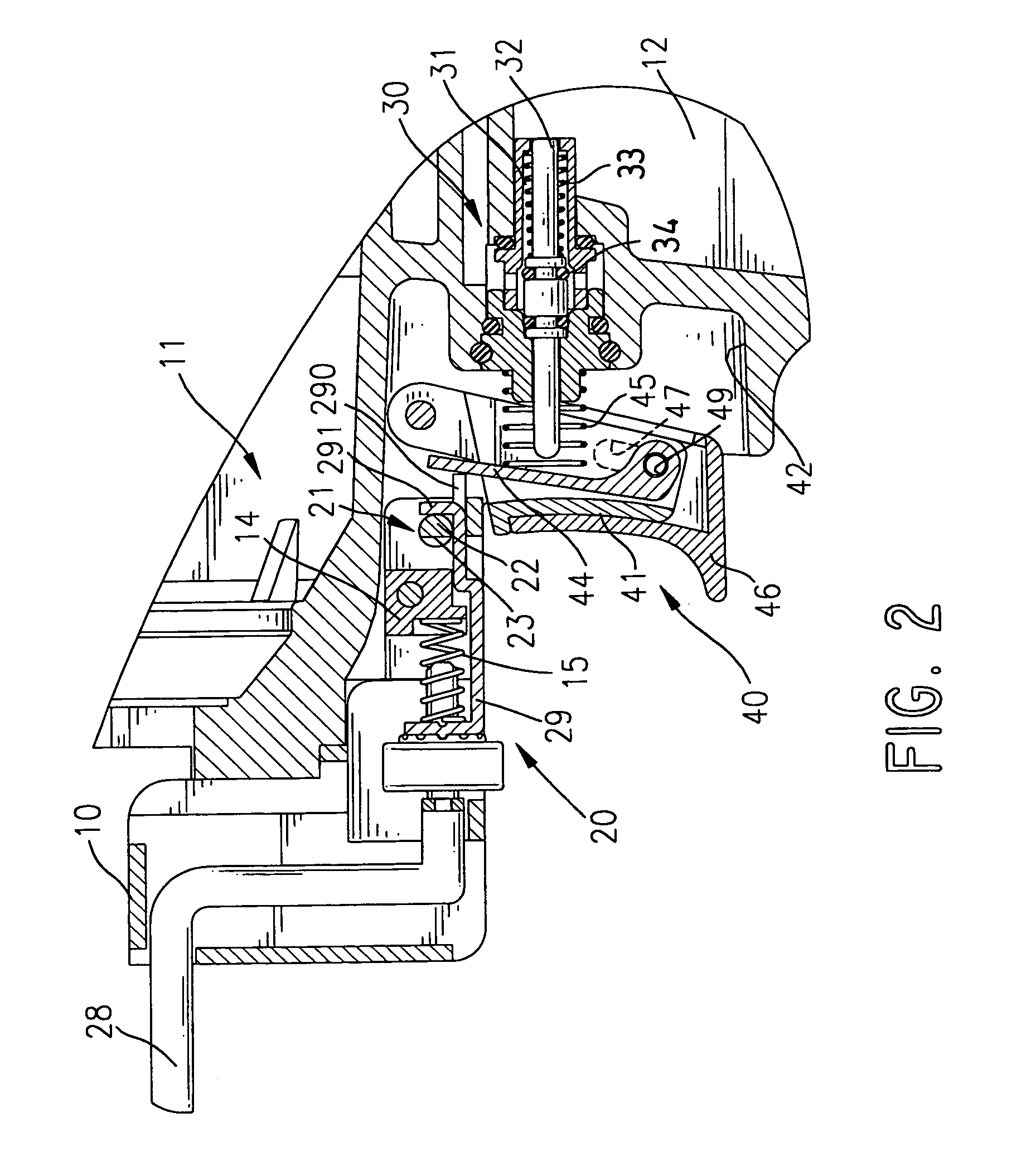

A nail gun having a contact arm normally biased in a direction away from a workpiece by compression springs. A free end of the contact arm is brought into abutment with a workpiece and a trigger is pulled for driving a nail thereinto. In the trigger pulling operation, an inner end of the contact arm is engaged with a trigger arm which is biased by a plunger spring through a plunger. Because the contact arm is held on the workpiece, the plunger is moved to provide ON state against biasing force of the plunger spring. Immediately after the nail driving, a nail gun body is moved in a direction away from the workpiece relative to the contact arm. This causes disengagement of the trigger arm from the inner end, to relatively move the nail gun body toward the workpiece by the biasing force of the compression springs. This means relative movement of the contact arm in the direction away from the workpiece. If the trigger is released, the trigger arm is again brought into engagement with the inner end, because the trigger arm is normally urged toward the inner end by a trigger arm spring.

Owner:KOKI HLDG CO LTD

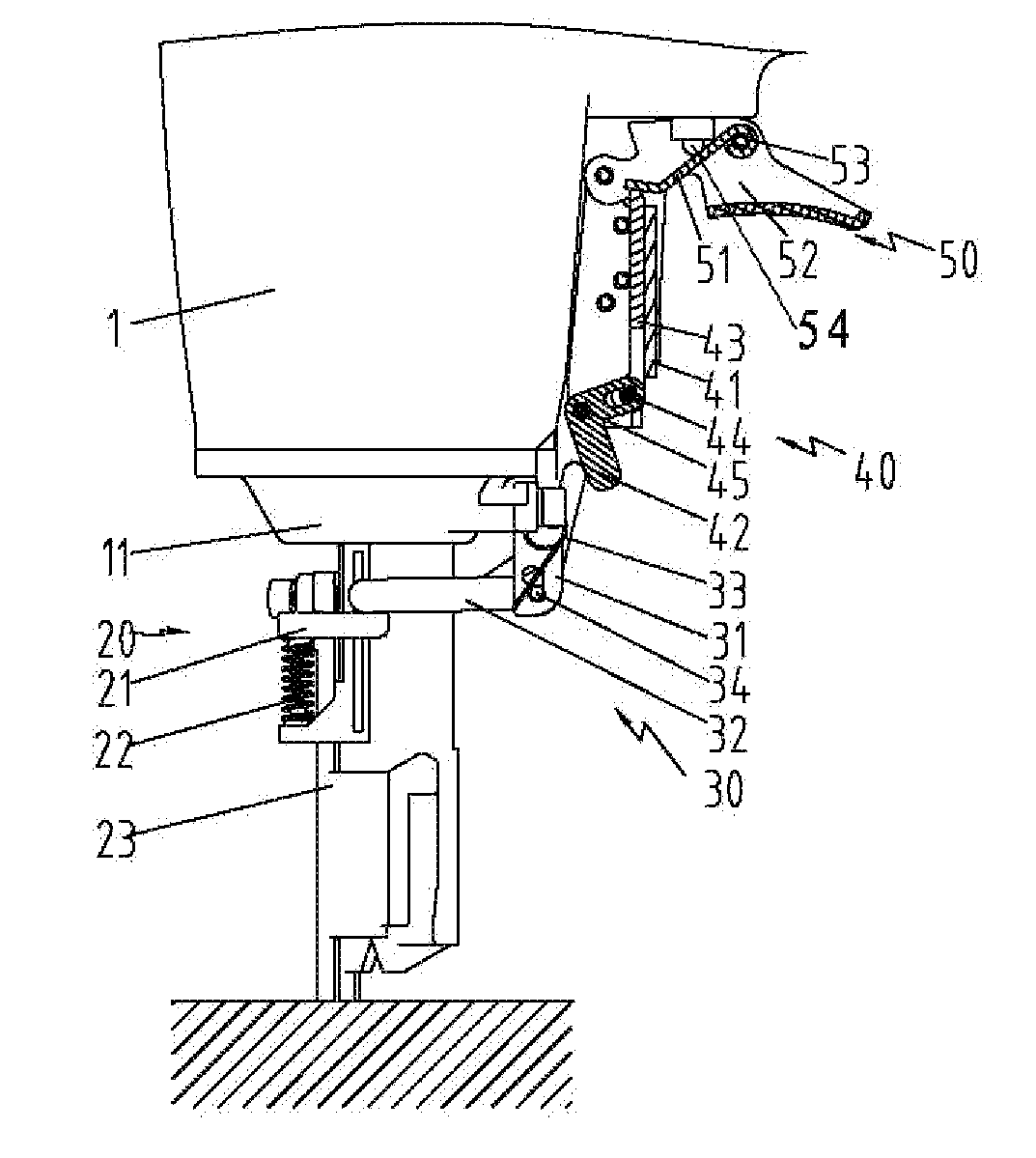

Nail gun with safety portion mechanism for preventing misfires

A nail gun has a free end 19a and central potion of a trigger arm 19 positioned within a trigger 11, on an upper end 12a of a safety portion 12 and at a plunger 17, respectively. When the trigger 11 is pivoted on its pivot end 16, pivoting movement of the trigger 11 moves a pivot end 18 of the trigger arm 19 to press the central portion of the trigger arm 19 into contact with the plunger 17 and, with the plunger 17 serving as a fulcrum, to press the free end 19a downward against the upper end 12a of the safety portion 12. If downward movement of the safety portion 12 is obstructed when the trigger 11 is pivoted, the upper end 12a contacted by the free end 19a of the trigger arm 19 serves as a fulcrum around which the trigger arm 19 pivots with movement of the trigger 11, whereupon the central portion of the trigger arm 19 presses the plunger 17 inward so that an activation switch 10 activates a blade 7 to eject a nail through a nose piece 5.

Owner:KOKI HLDG CO LTD

Nail gun

A nail gun for conveniently nailing fasteners of different sizes and / or types is disclosed. The nail gun includes a body and a nail storage mechanism. The body includes a selectively operable drive mechanism. The nail storage mechanism includes first and second supply magazines movably mounted to the body whereby each supply magazine is selectively moved into position for use. Each supply magazine is loaded with nails of different sizes and / or types. Each supply magazine is selectively moved relative to the drive mechanism to a drive position wherein the supply magazine is operably arranged with the drive mechanism to selectively discharge a nail in a firing position from the supply magazine. A mounting mechanism is provided to pivotally mount the supply magazines to the body. The body includes a supply magazine support mechanism, which is selectively cooperate with the supply magazine in the drive position to support that supply magazine.

Owner:SCHUSTER GEORGE A

Nail gun switch mechanism for switching dual actuation modes

InactiveUS7213733B1Improve safety factorEasy to operateStapling toolsNailing toolsEngineeringNail gun

A nail gun switch mechanism has a trigger valve bar received in a trigger of the nail gun; a trigger lever pivotally disposed on the trigger; a safety slidable bar pivotally disposed on a gun body; a longitudinal guiding hole formed at a peripheral side of the gun body; a shaft slidably received in the guiding hole; a switch bar arranged on the shaft, which the switch bar can bring the shaft to rotate in the longitudinally guiding hole; and a hitting base of the safety slidable bar extending out from an hitting mouth formed at a bottom portion of the gun body. The shaft has a bias pole disposed at a top portion thereof, which the bias pole can synchronously rotate with the shaft and can be reposited by the adjusting of the switch bar. The trigger lever has a shorter end portion; a longer end portion; and an opening.

Owner:DE POAN PNEUMATIC

Pneumatic motor driving valve of screw nail gun

A pneumatic motor driving valve of a screw nail gun has a driving valve for control the pneumatic motor to be operated steadily. A downward pressing spring is installed around an outer wall of the cylinder of the gun body and an annular control valve is installed around the outer wall of the cylinder so that the annular control valve presses the downward pressing spring for actuating of the opening of the air inlet valve of the air inlet channel of the pneumatic motor. An annular control valve around an outer wall of the cylinder can accumulate the pressure in the gun body to a predetermined value so as to open the driving valve. Thereby, the pneumatic motor can provide a larger stable twisting force to beat and rotate a screw nail.

Owner:DE POAN PNEUMATIC

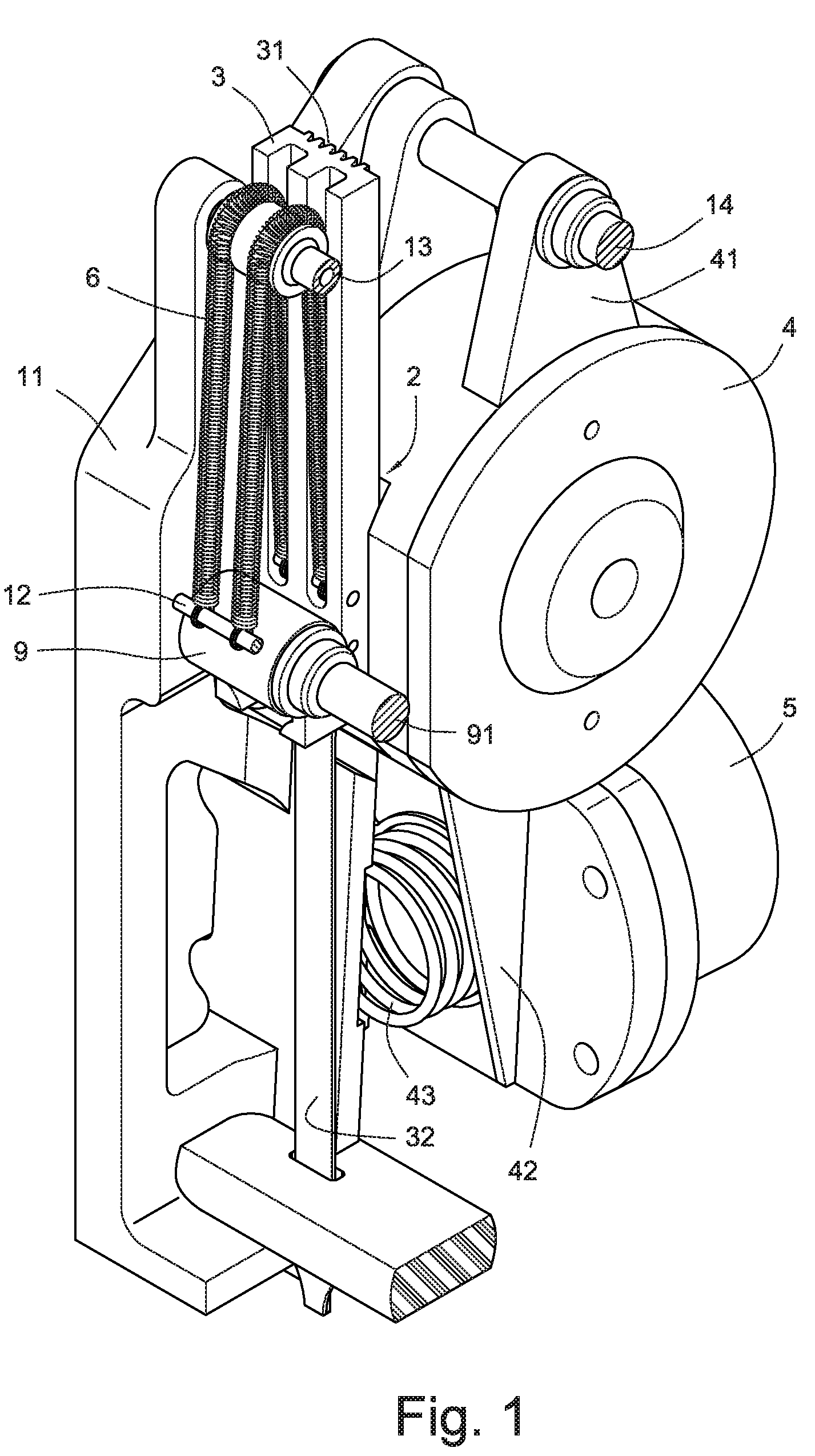

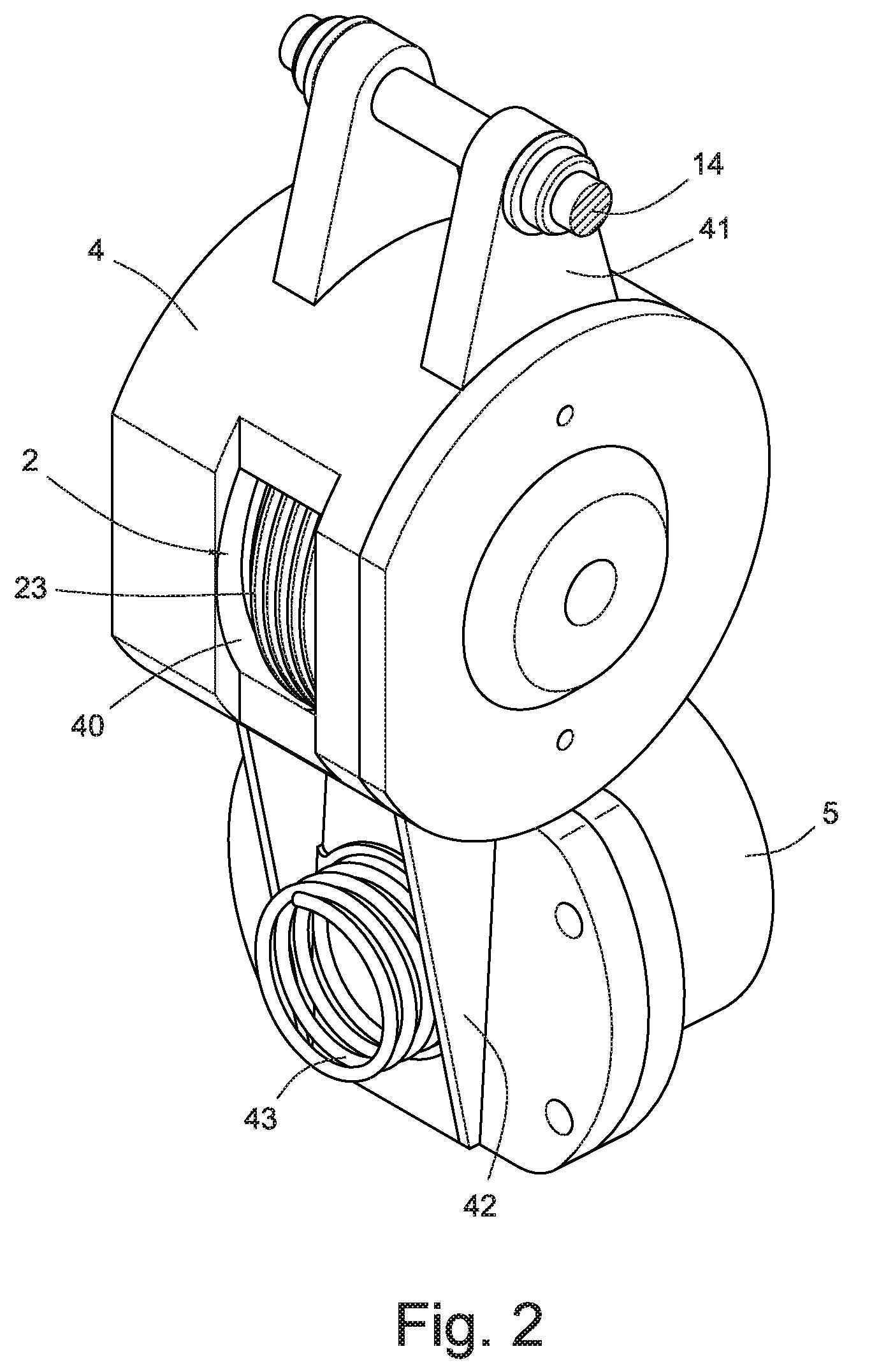

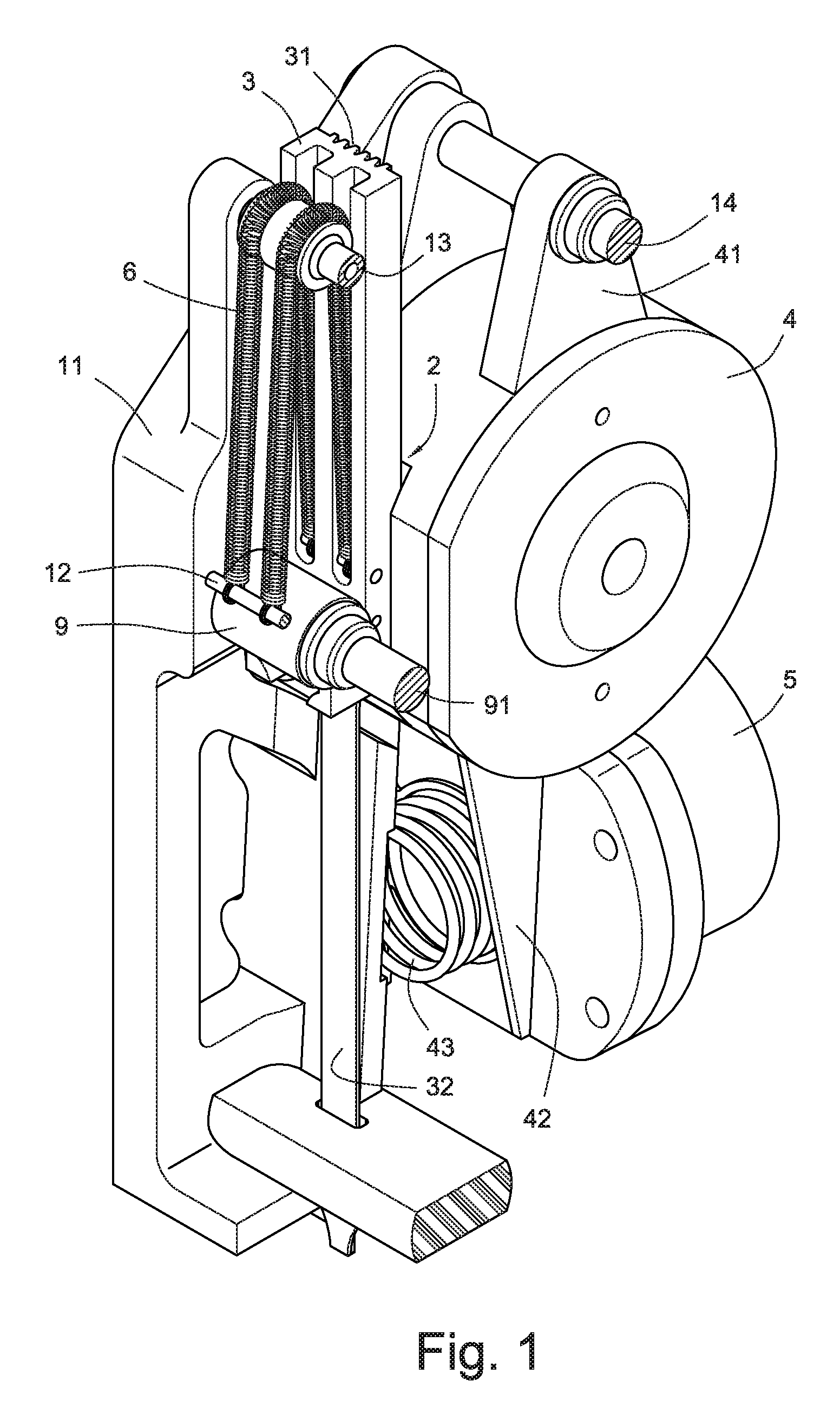

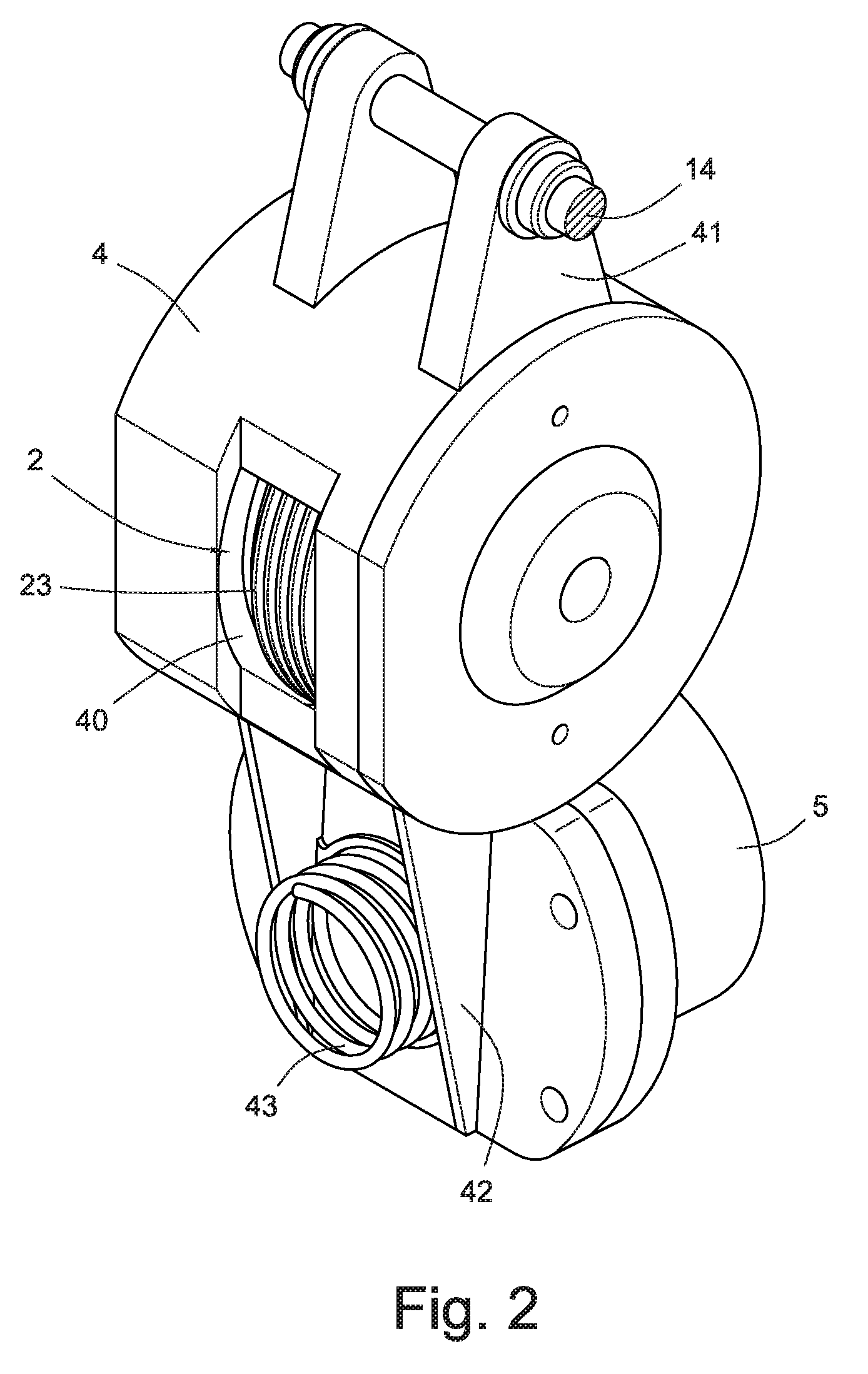

Actuator for electrical nail gun

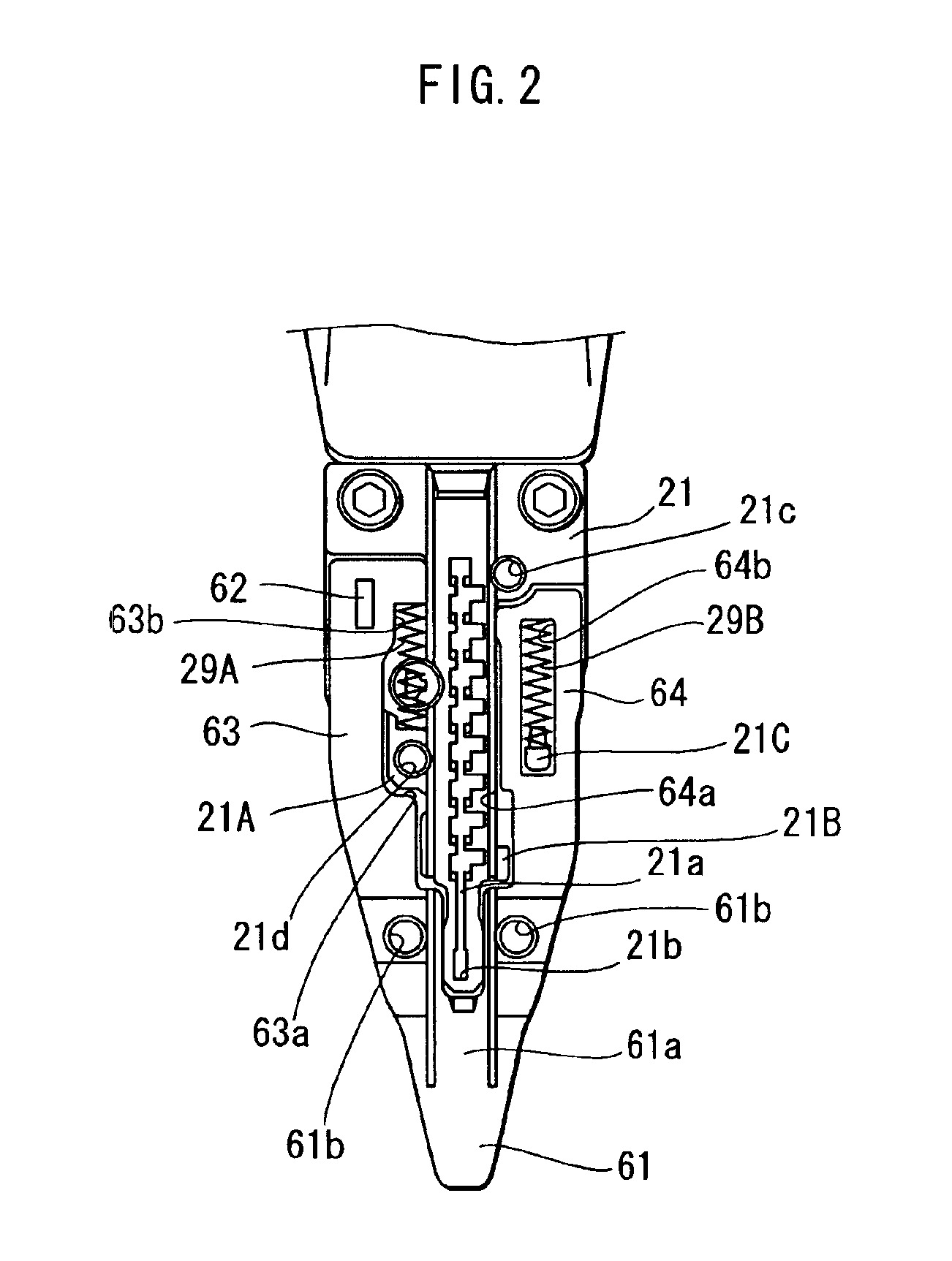

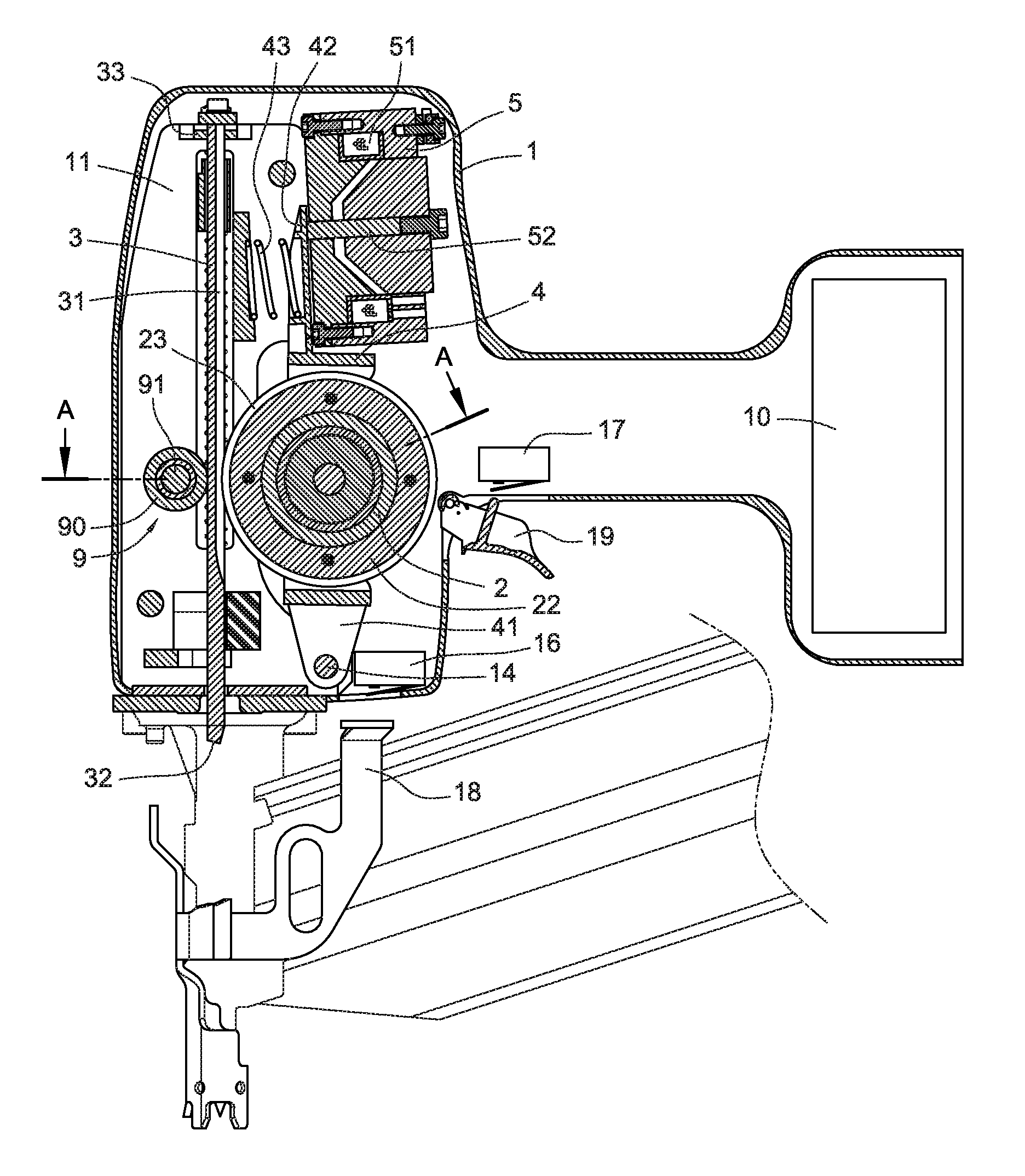

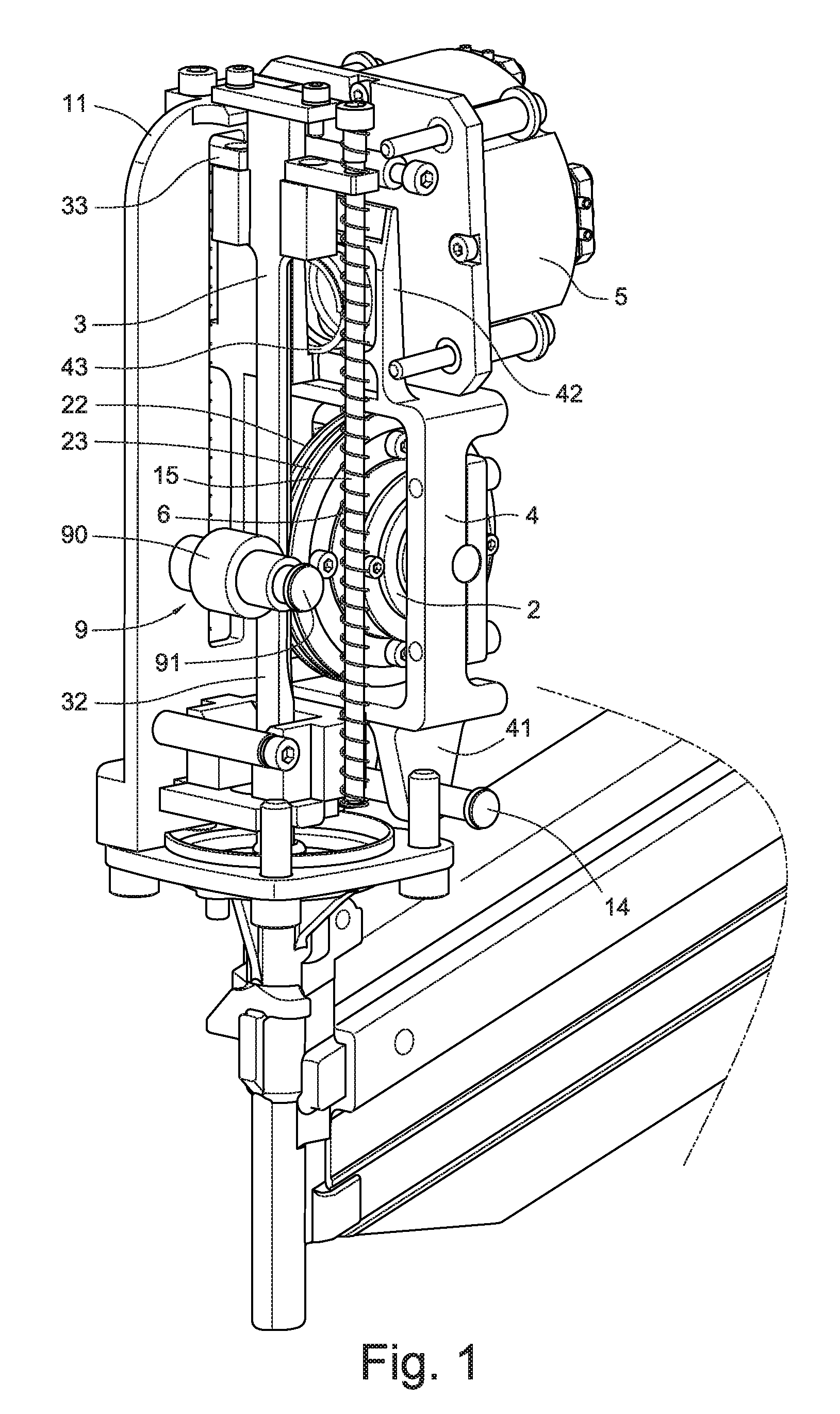

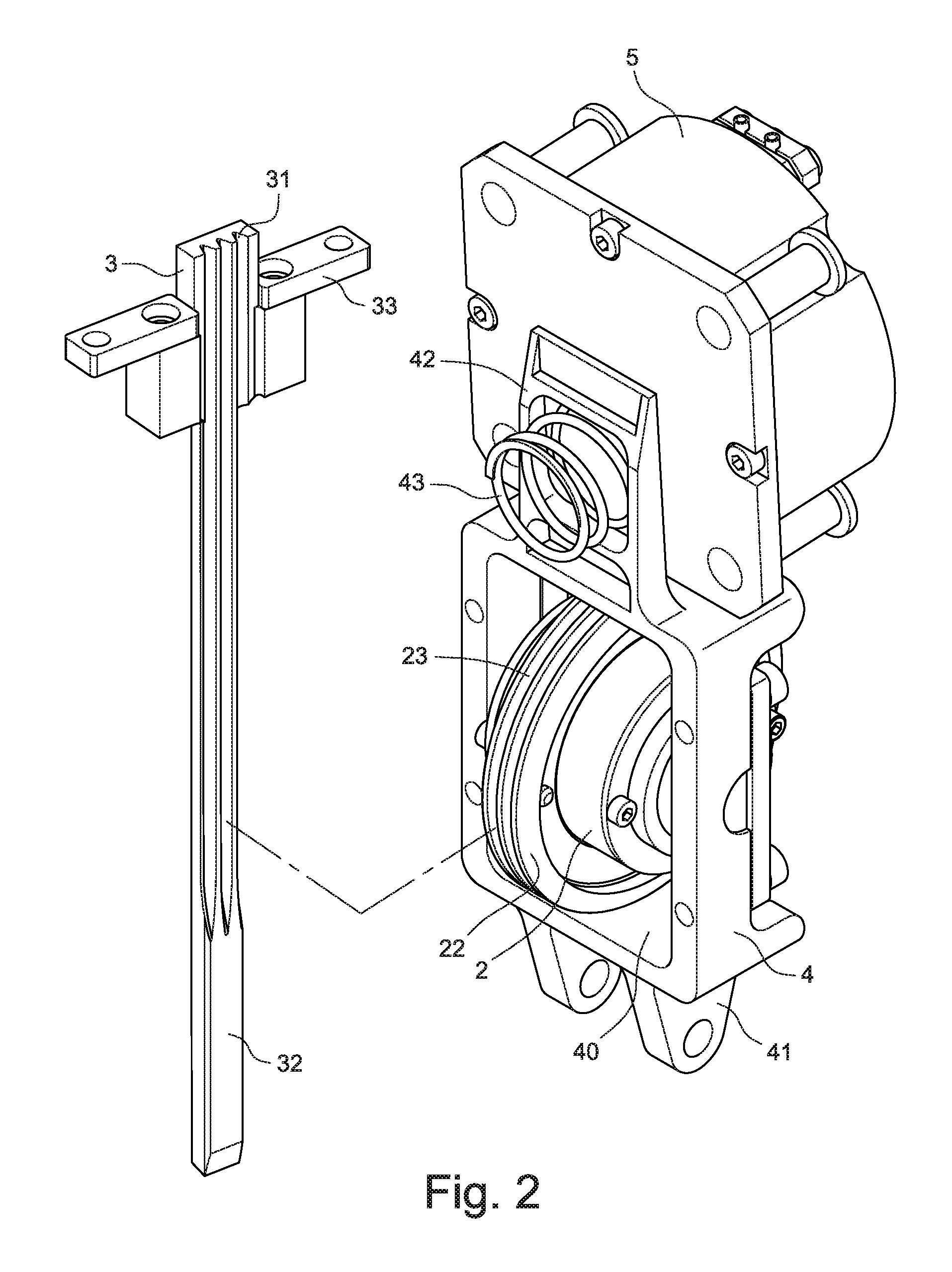

ActiveUS7575141B1Simplifying complicated configurationProlong lifeStapling toolsReciprocating drilling machinesElectricityFreewheel

An actuator is arranged in a housing of an electrical nail gun. The actuator includes a sliding base, an external-running brushless direct current motor, a swing base and an electric driver. The sliding base is slidably disposed on an end of a located supporter which is positioned in the housing. The sliding base loads a spring and forms a hitting nail bar thereon. The motor has a stator and a rotator attached on an outer wall of the stator. A flywheel is driven by the motor and is configured to engage or disengage with / from the sliding base. The swing base is pivotally mounted on the housing. The swing base is adjacent to the sliding base and the supporter. The motor is installed in the swing base. The electric driver is attached to the housing and is adjacent to an end side of the swing base. The electric driver has a rod member driven by electricity. The rod member drives the swing base to swing to a first position where the flywheel meshes with the sliding base to thereby drive the sliding base to move downwards, and a second position where the flywheel disengages from the sliding base to thereby cause the sliding base to reposit. It is advantage to simplify the configuration of the actuator for the flywheel and is useful for the miniaturization of the electrical nail gun.

Owner:ROBERT BOSCH TOOL +1

Air path arrangement for pneumatic nail gun

An air path arrangement for a pneumatic nail gun includes cylinder received in a barrel and a handle is connected to the barrel. A space is defined between the cylinder and an inner periphery of the barrel. A connection path communicates between the interior and a first partition of the chamber. A side path communicates between a space between the cylinder and an inner periphery of the barrel, and a second partition of the chamber. The first partition communicates with an inlet and an outlet in the handle. A movable member, a guide member, a valve, an axle and a base are received in the chamber. The guide member is located between the first and second partitions. The guide member has apertures which communicates with the first and second partitions so that the movable member and the valve are movably received in the first partition and the second partition.

Owner:SAMSON POWER TOOL

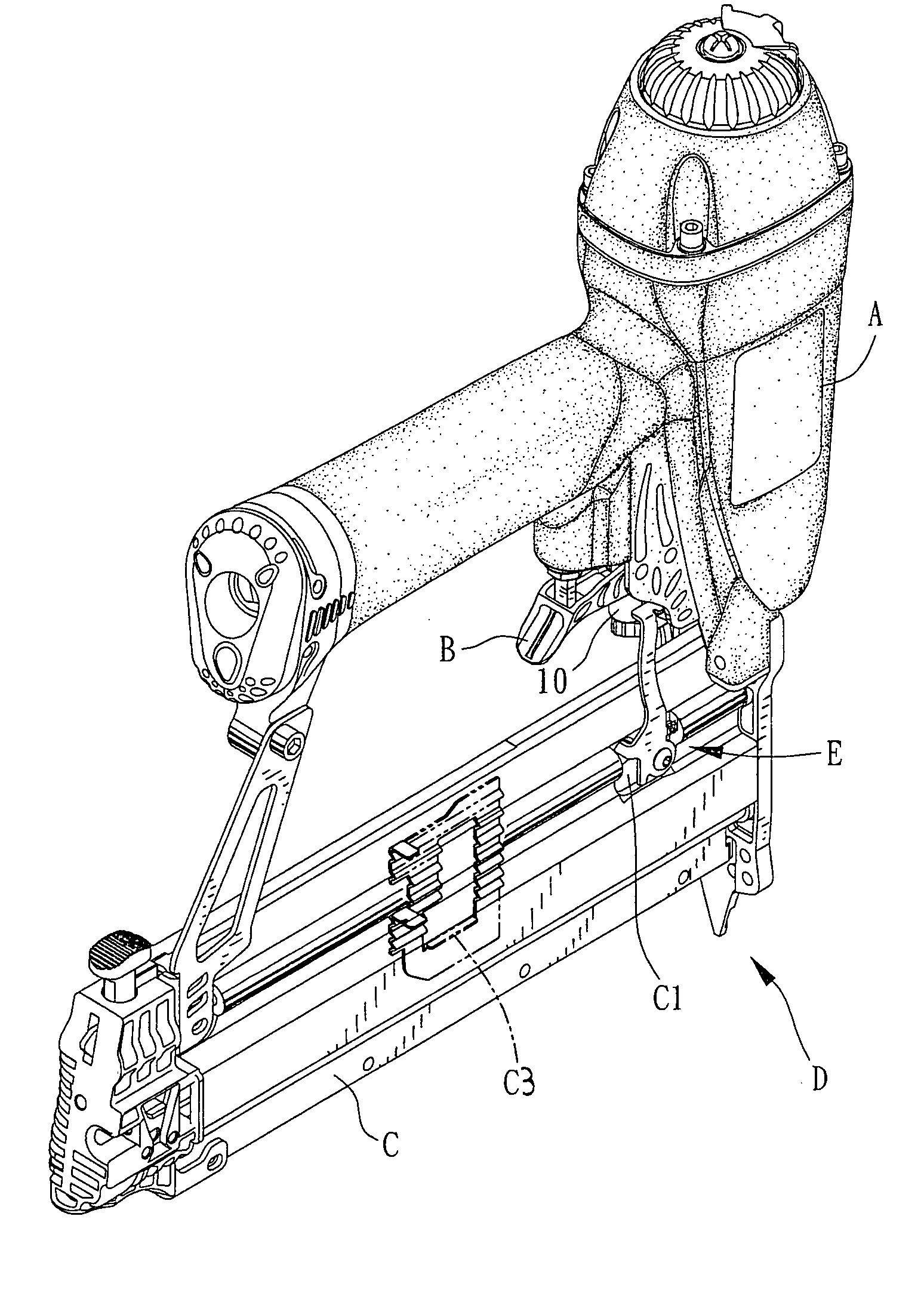

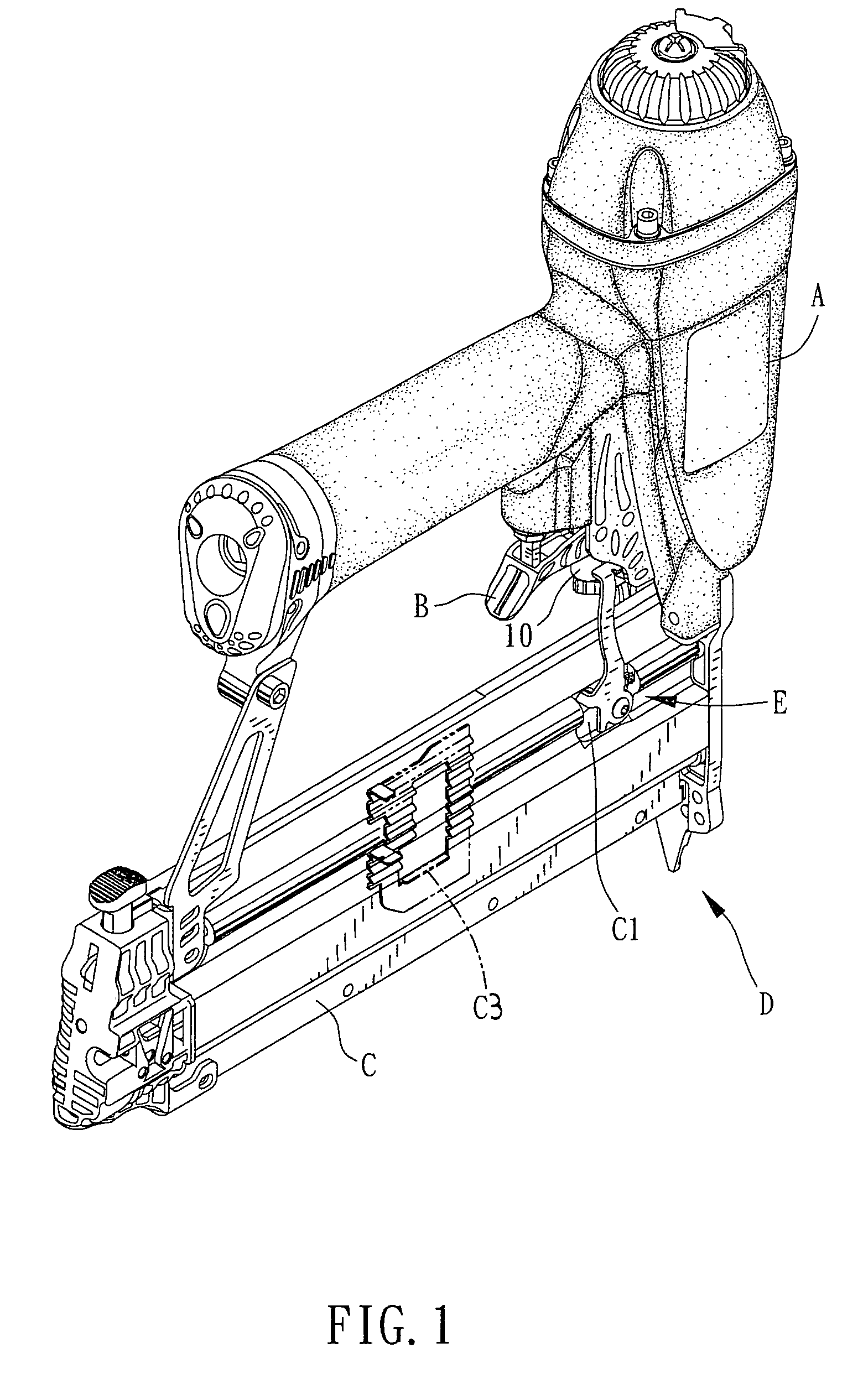

Trigger Switch Mechanism for Nail Gun

InactiveUS20090108046A1Good choiceStapling toolsNailing toolsNail gunElectrical and Electronics engineering

A trigger switch mechanism for a nail gun includes a trigger valve formed on the nail gun for trigger nail shooting, a safety slidable rod configured to push against a workpiece and indirectly drive the trigger valve, a main trigger arranged between the safety slidable rod and the trigger valve, and an inner trigger disposed in the main trigger for touching the trigger valve to switch on the trigger valve. The main trigger drives the inner trigger to extend to or to leave a touchable position of the safety slidable rod, and thereby the nail gun performs in a sequential actuation mode. An outer trigger is arranged on an outer side of the main trigger for driving the inner trigger to hold the inner trigger at a position where the safety slidable rod can touch the inner trigger, and thereby the nail gun performs in a contact actuation mode.

Owner:ROBERT BOSCH TOOL +1

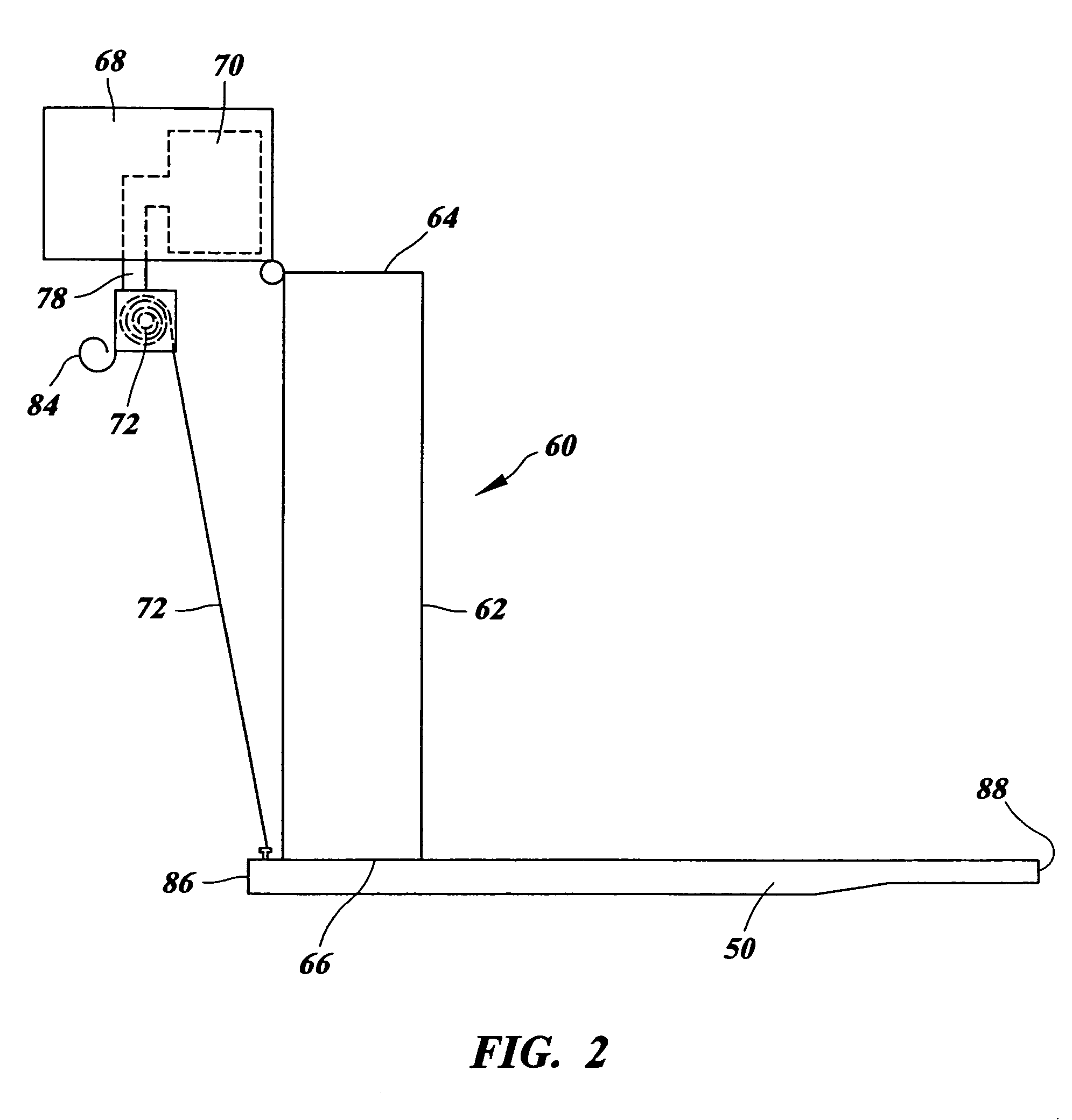

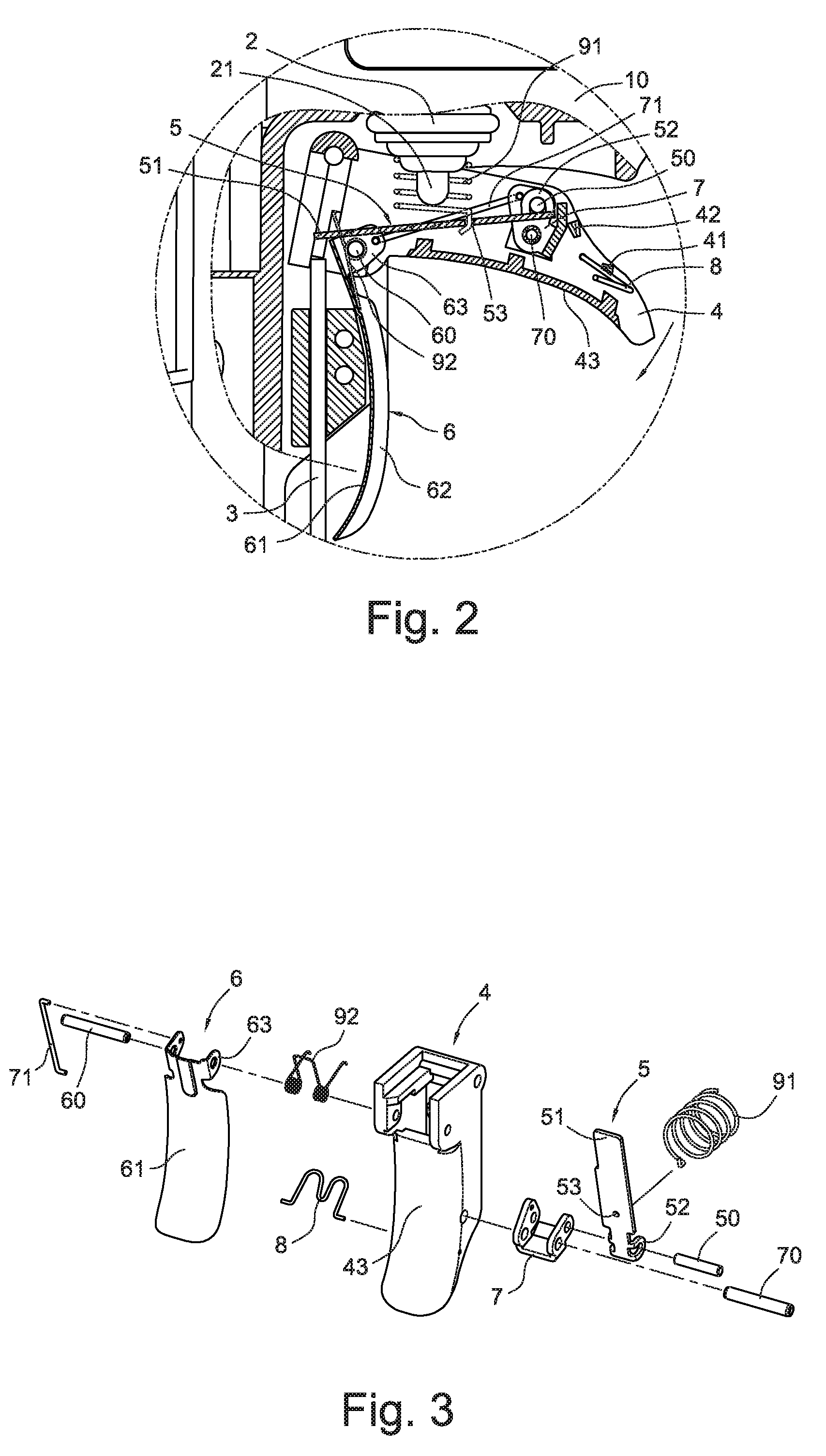

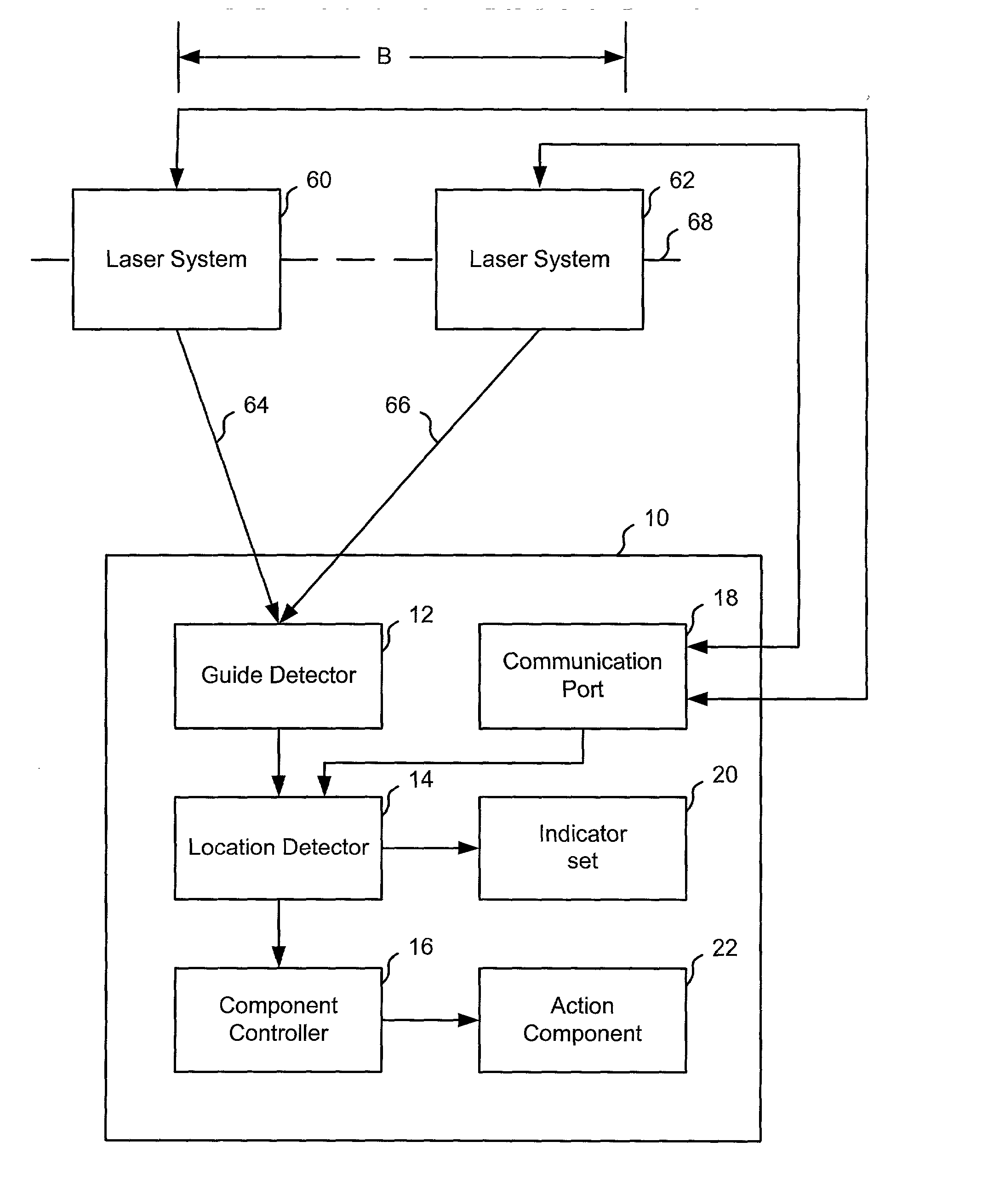

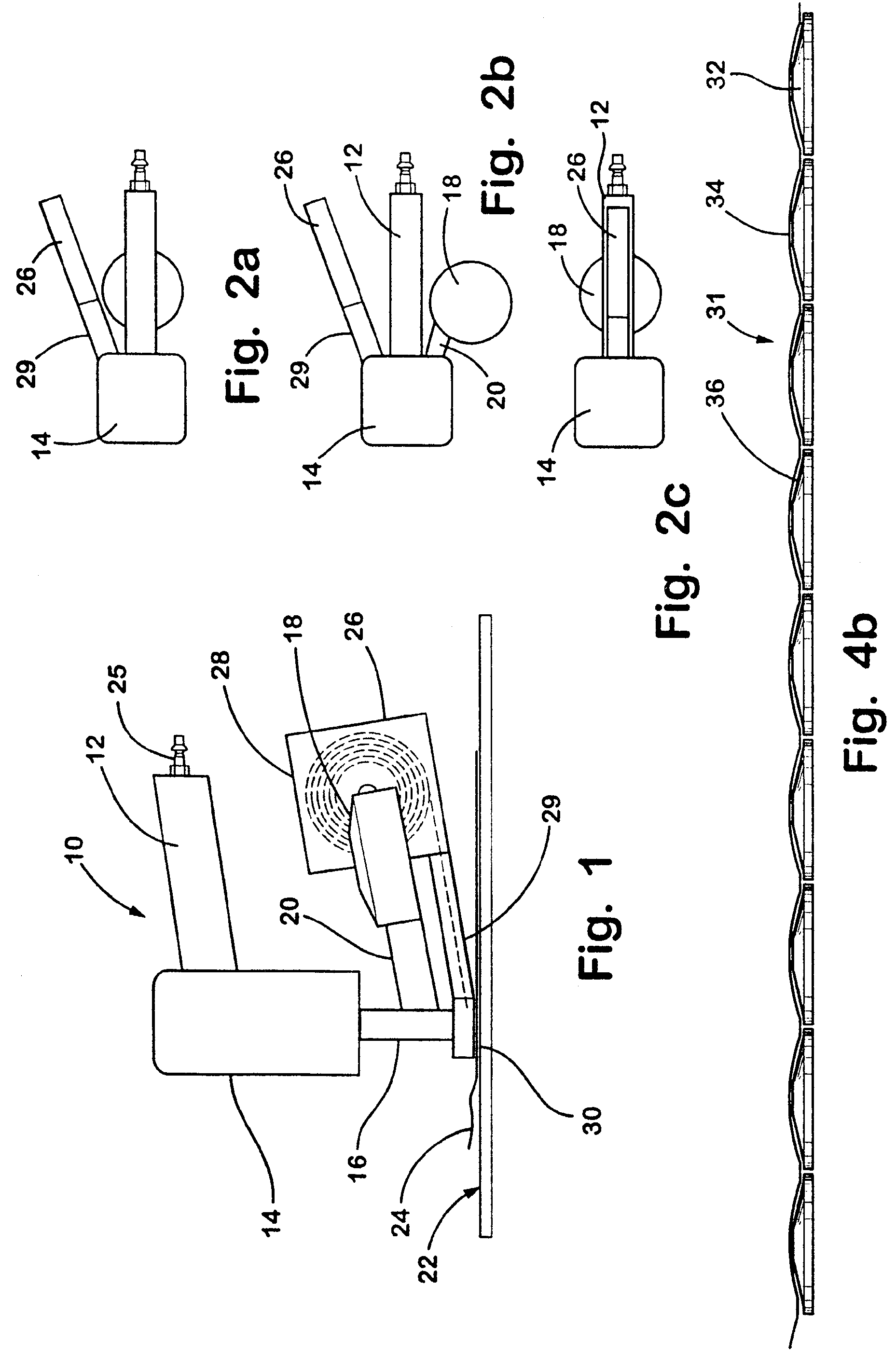

Detecting tool orientation, alignment, depth, and leveling

A tool is employed in conjunction with alignment, depth, and level detectors. The tool can use all or some of these detectors. The alignment detector provides an orthogonal laser line grid on an incident surface when the detector has a predefined relationship with the surface. The depth detector emits two sets of parallel laser planes that converge with each other. When the laser planes impact on an incident surface two sets of lines are formed. The laser lines from one laser plane set move closer to the lines from the other laser plane set as the depth detector moves closer to the surface-showing changes in depth or distance. The level detector employs two converging laser planes. An operator positions the level detector above an incident surface, so the laser planes' line of intersection appears on the surface if the surface is level. If the surface is not level, lines separate from each laser plane appear on the surface-signaling the need for a level adjustment. Some versions of the tool have the ability to detect their own orientation and make adjustments based on the orientation. Example tools include nail guns, jigsaws, circular saws, routers, and drills.

Owner:ROBERT BOSCH CO LTD

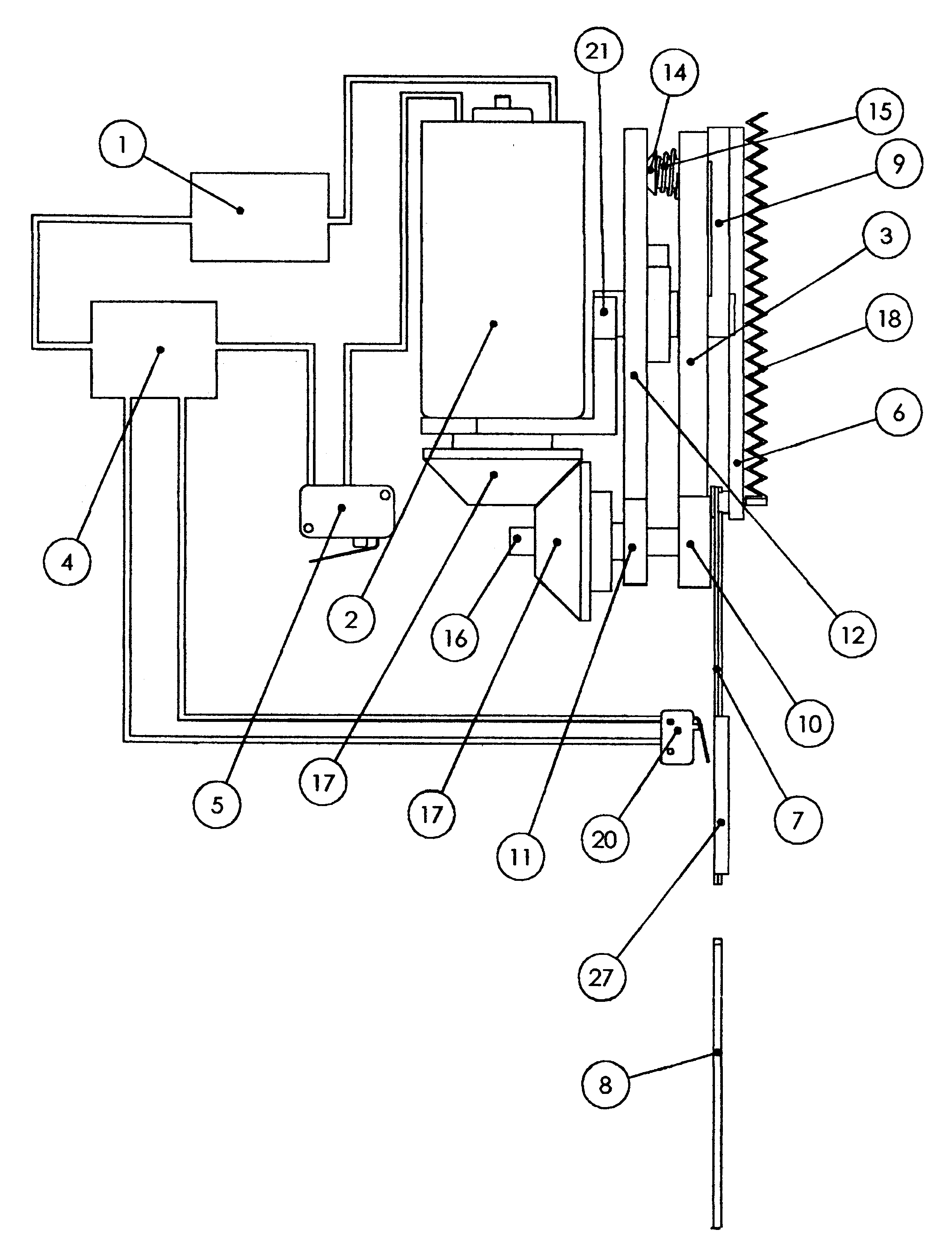

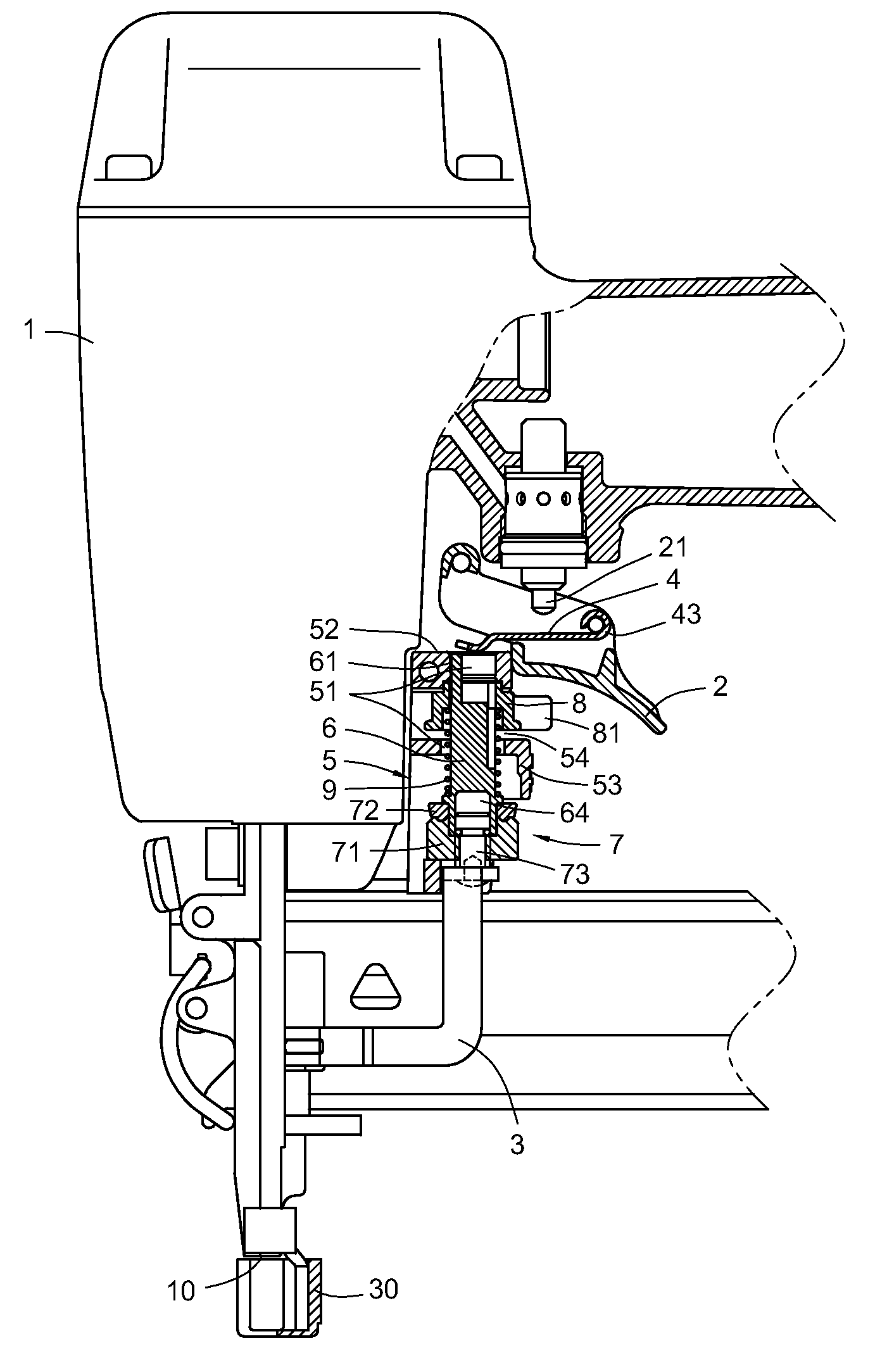

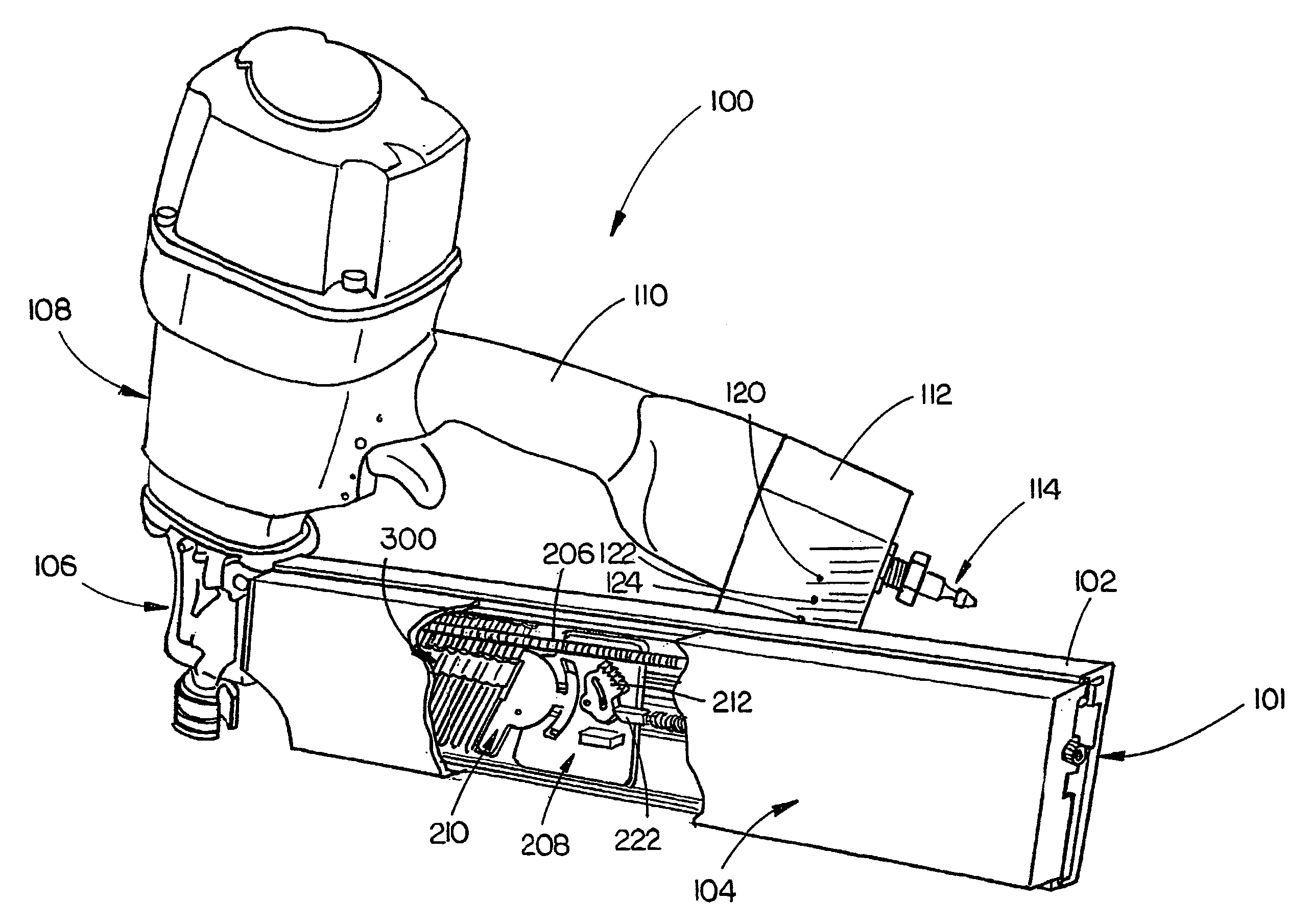

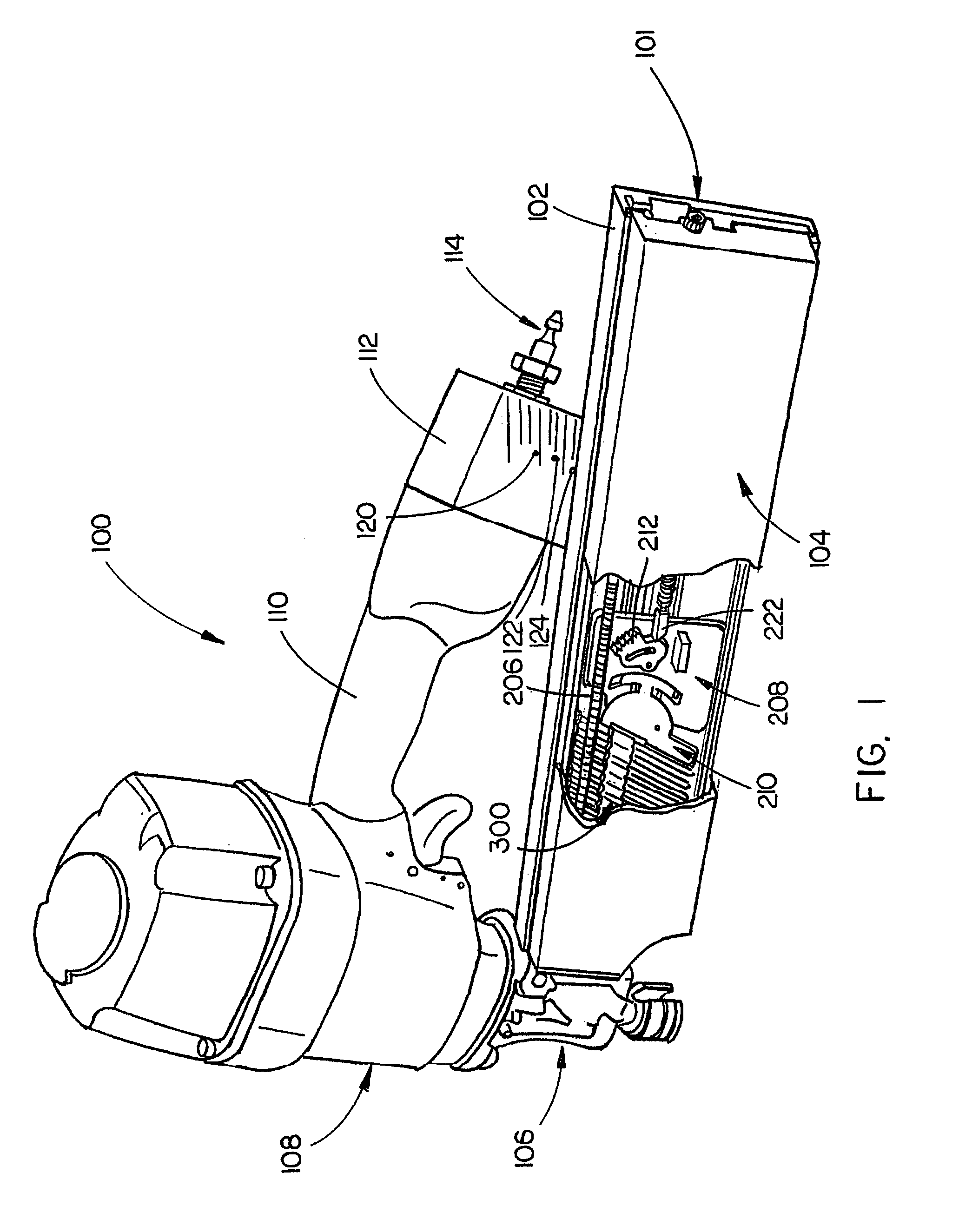

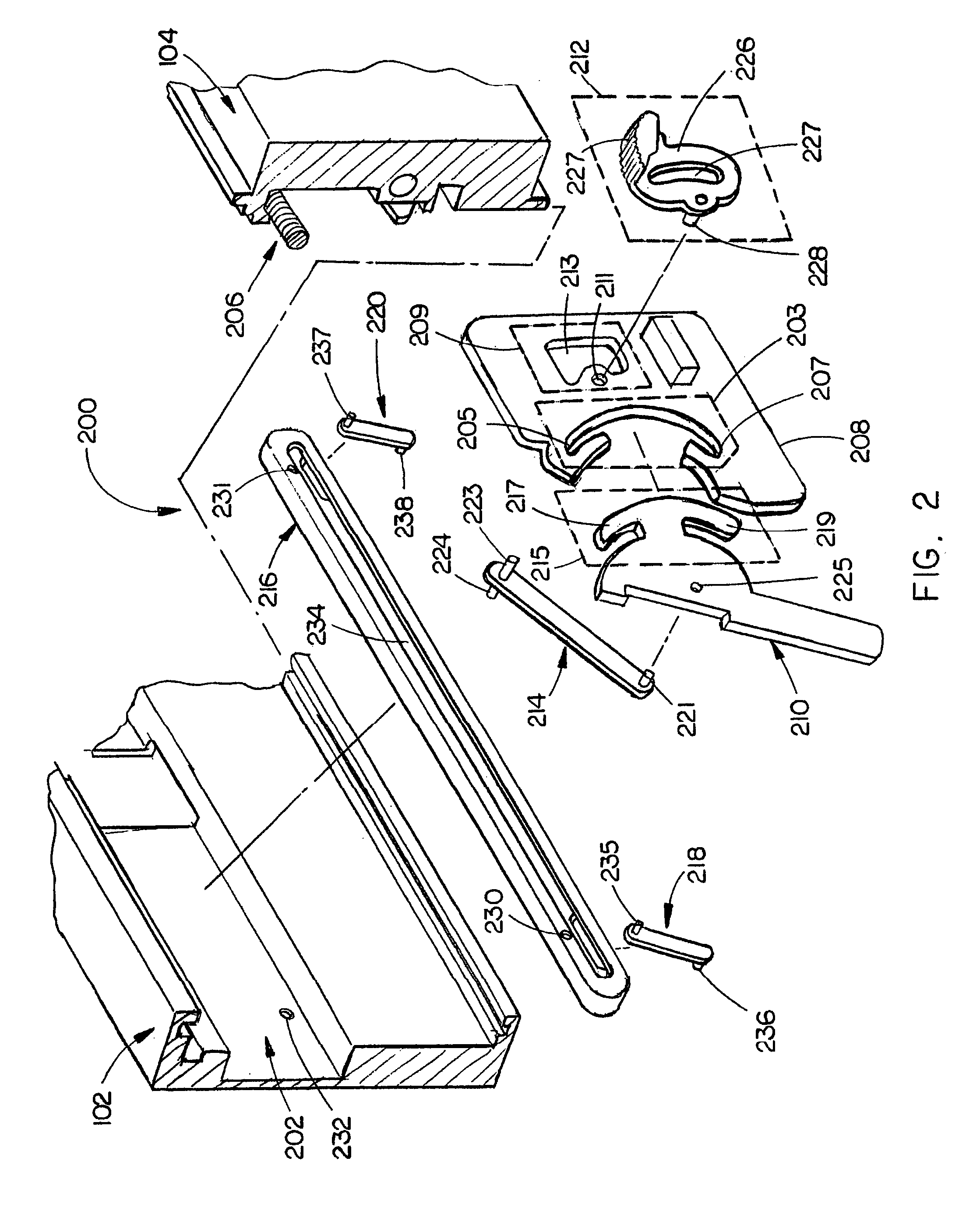

Nail lockout assembly

A nail lockout assembly provides a way for an operator of a nail gun to have determined whether the nails being employed are properly aligned to allow for efficient operation of the nail gun. The nail lockout assembly may be employed in a nail loading assembly, such as an adjustable angle magazine, which is coupled with a nail driving assembly. A slotted guide member disposed in a housing of the nail loading assembly provides a determination of the angle of the nail loading assembly relative to the nail driving assembly through operational engagement with a projection. A linkage bar is coupled with the slotted guide member and translates the angle of the nail loading assembly to a pusher which engages a nail loaded in the nail loading assembly. A cover serrated member is coupled with a cover of the nail loading assembly. A pawl assembly is coupled with the linkage bar and may engage with the cover serrated member. An adapter couples with the pusher and the pawl assembly enabling rotational movement in each. The nail improperly aligned with the pusher causes the pawl assembly to engage with the cover serrated member and prevents the cover from closing along with preventing the pusher from advancing the nail in the nail loading assembly.

Owner:BLACK & DECKER INC

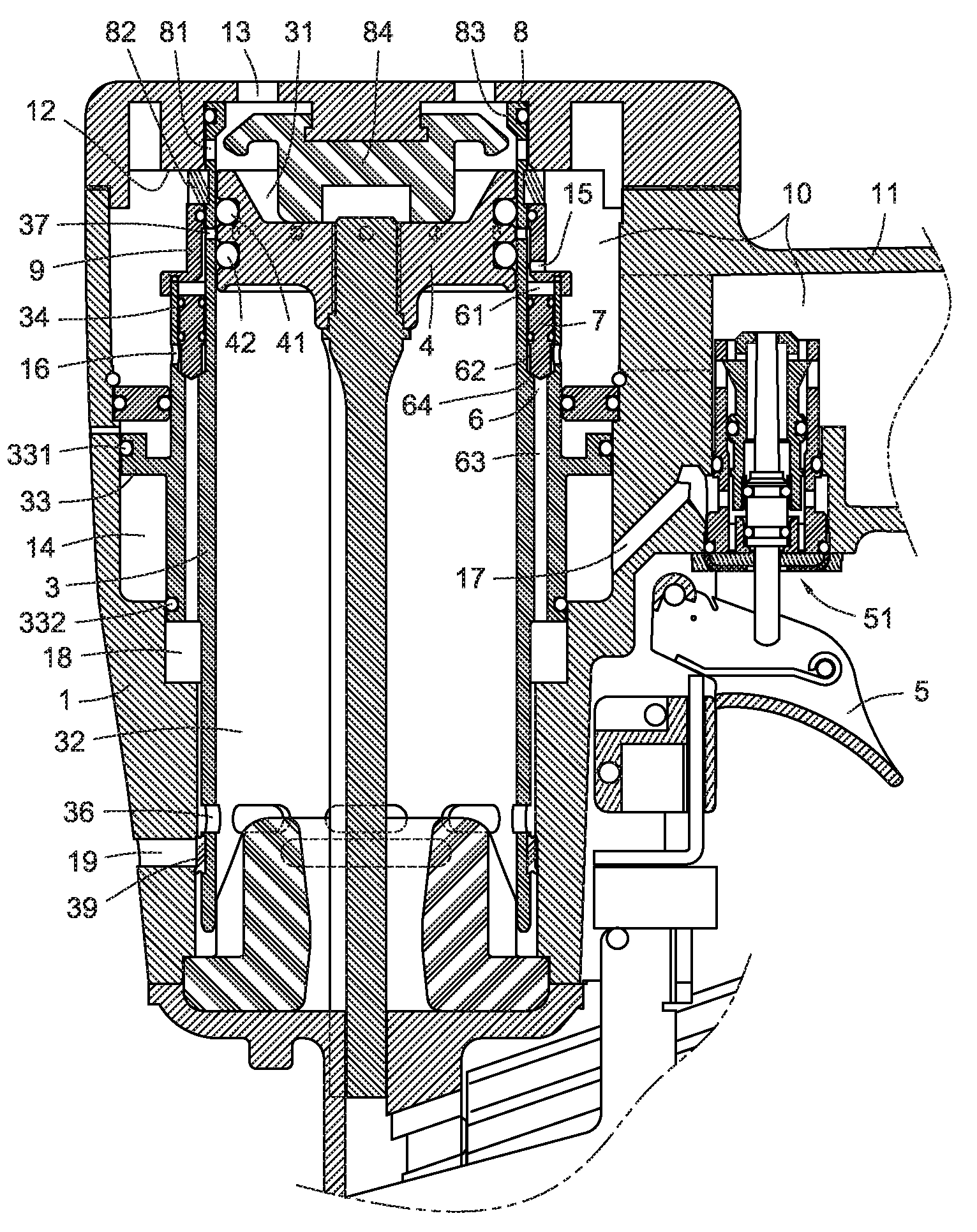

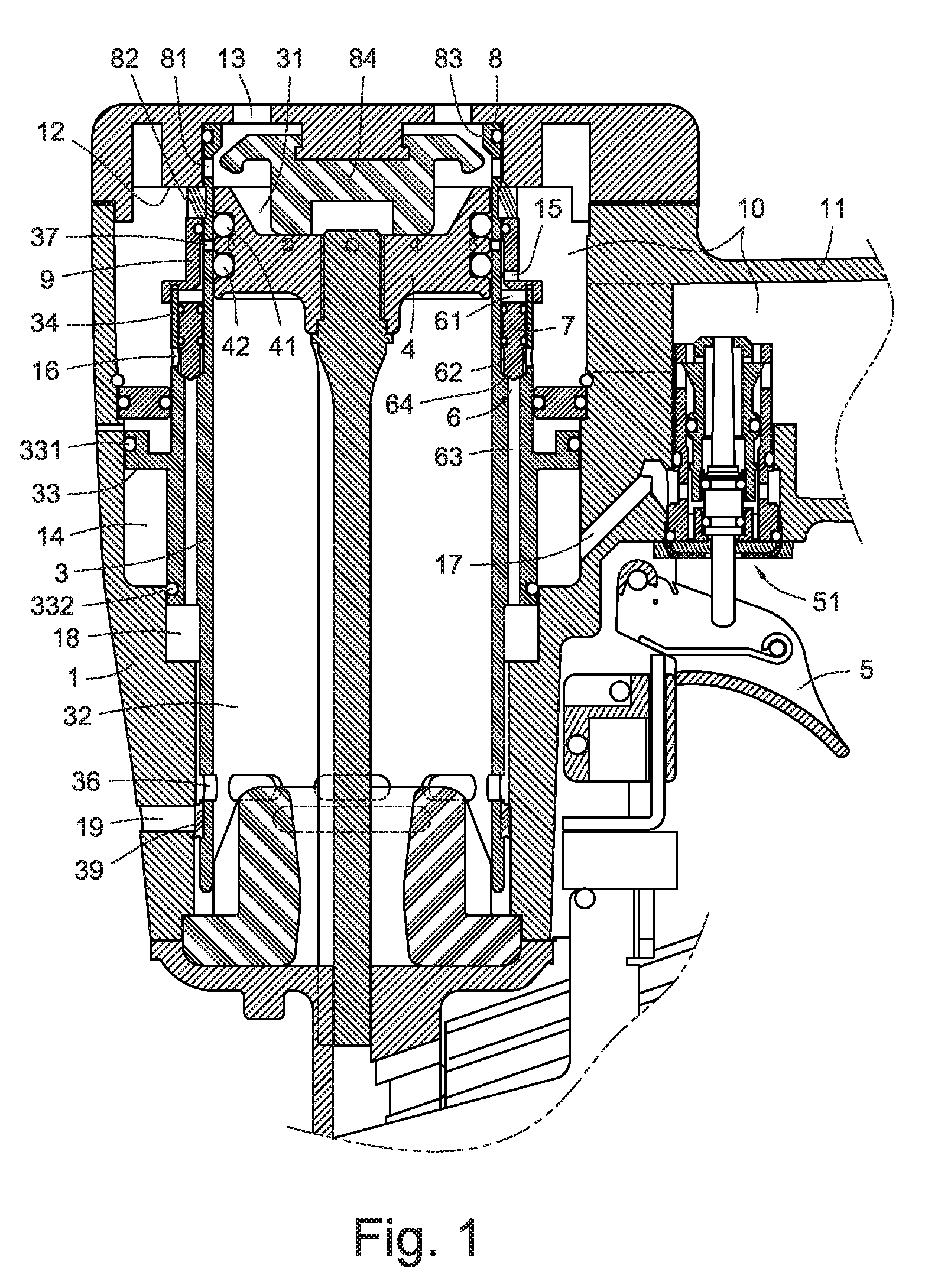

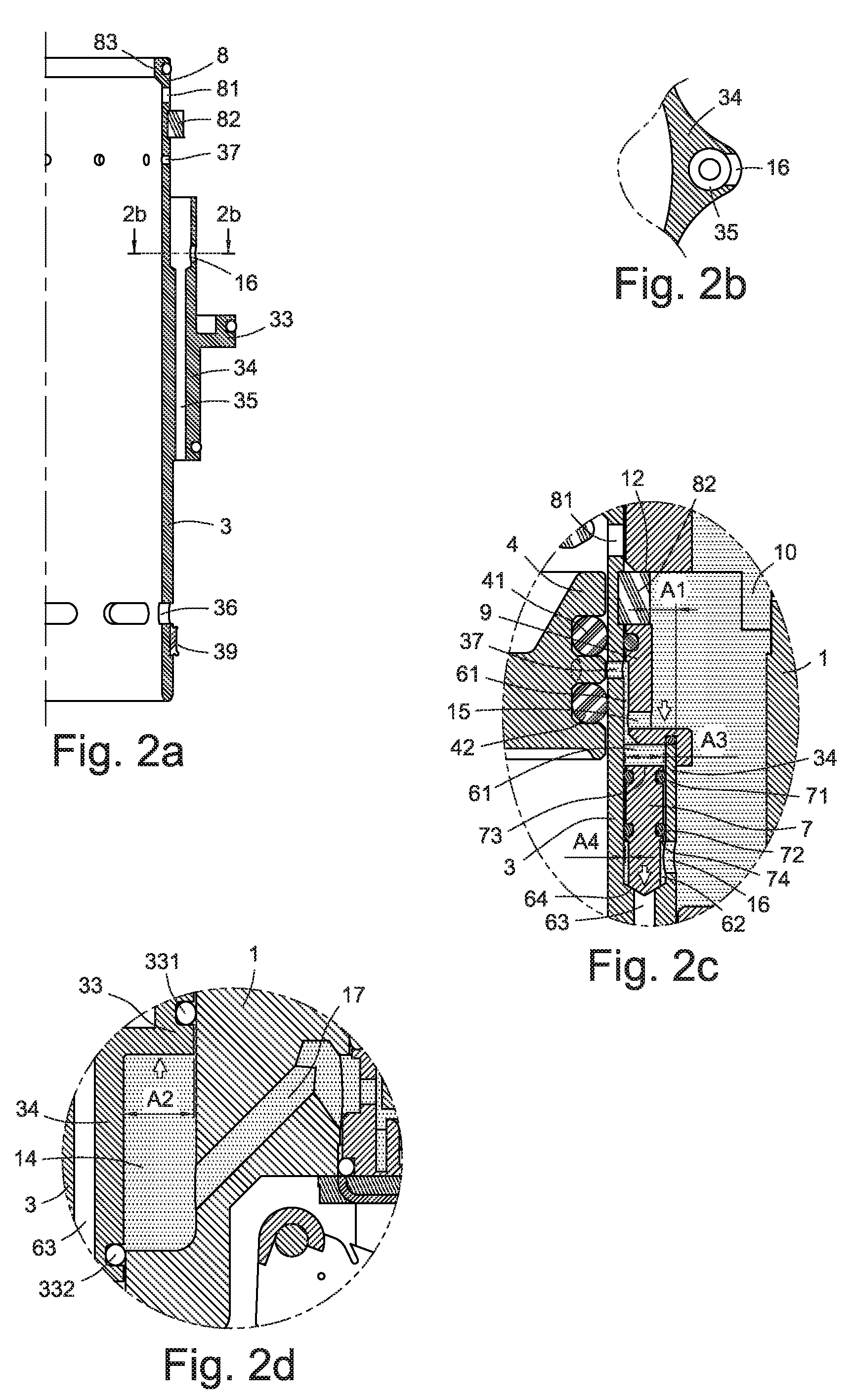

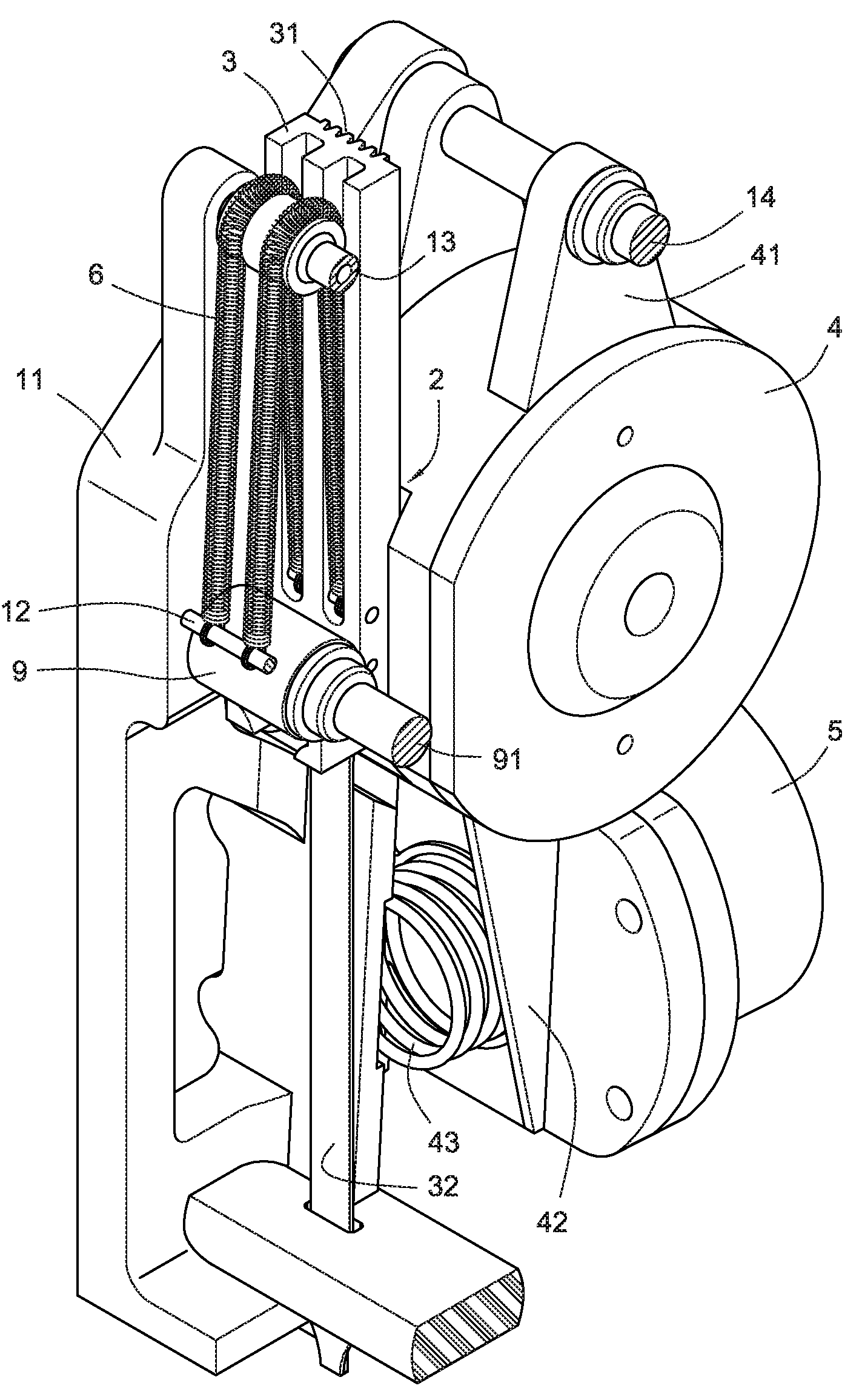

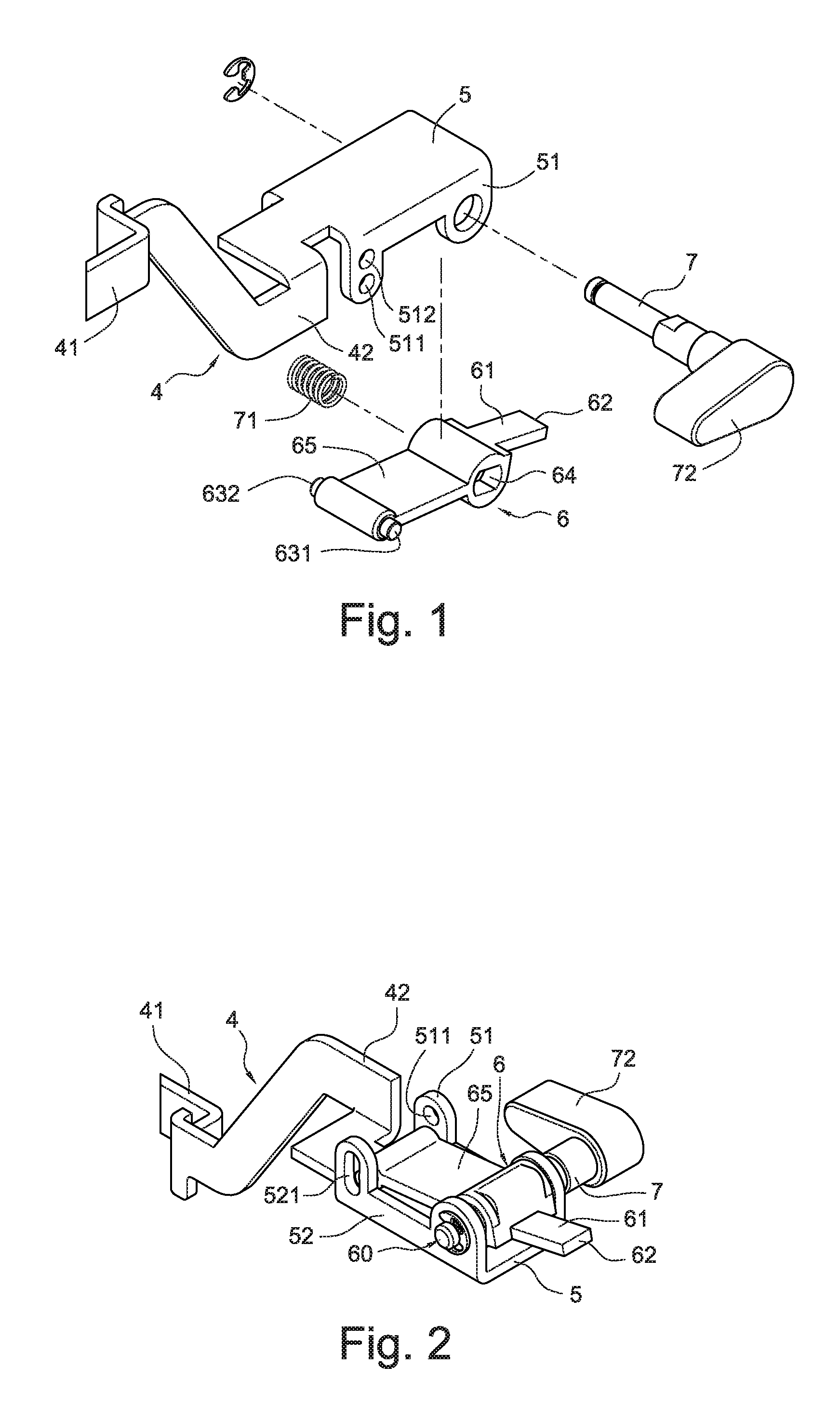

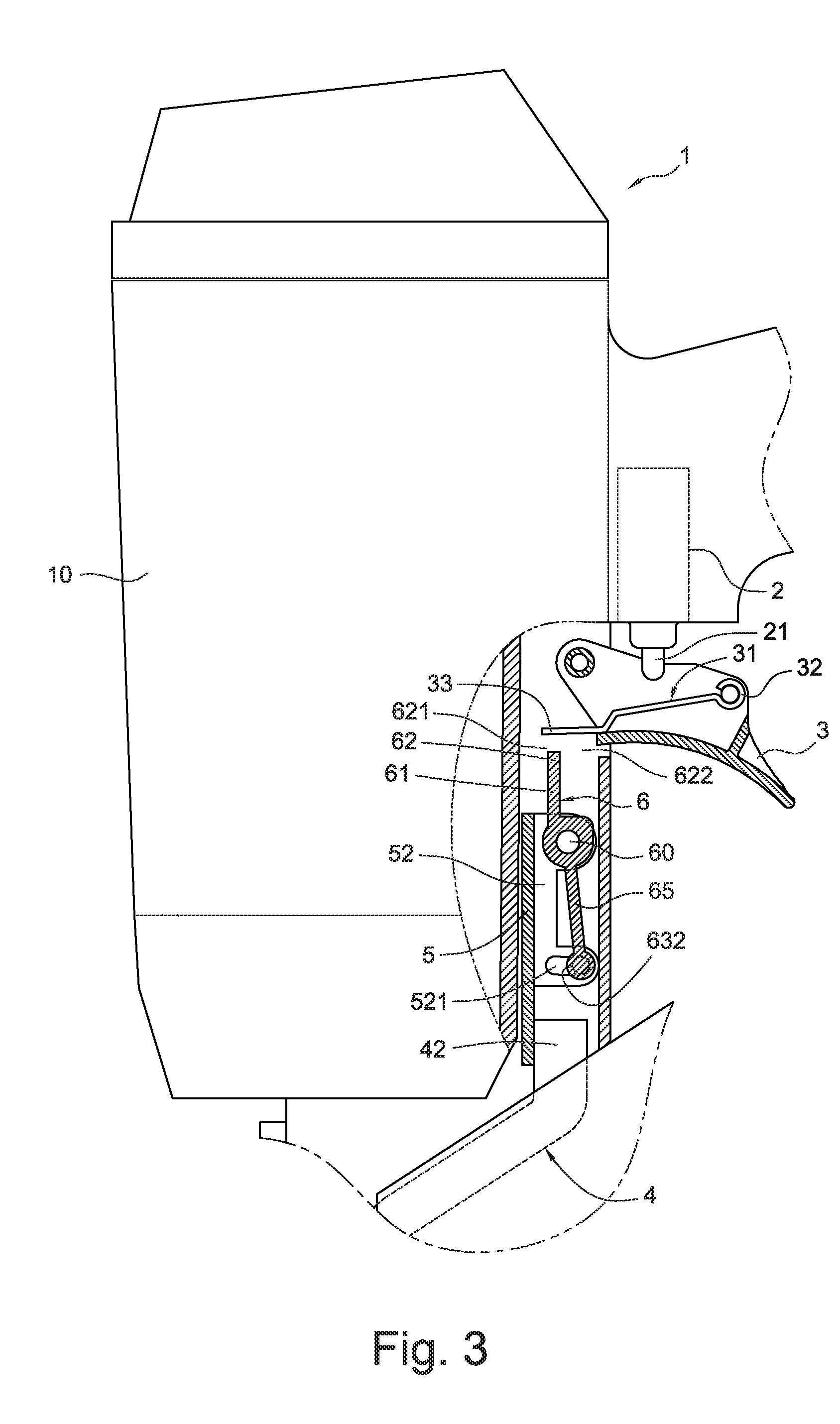

Clutch mechanism for electrical nail gun

ActiveUS7575142B2Reduce decreaseExtended service lifeStapling toolsNailing toolsFreewheelElectricity

A clutch mechanism arranged in a housing of an electrical nail gun includes a sliding base, a driver driven by electricity, a swing base pivotally mounted on the housing, and an electric driver attached to the housing and being adjacent to an end side of the swing base. The sliding base is slidably disposed on an end of a free roller positioned in the housing, and the sliding base loads a spring and forms a hitting nail bar thereon. The driver has a motor and a flywheel driven by the motor, and the flywheel is configured to engage or disengage with / from the sliding base. The swing base is adjacent to the sliding base and the free roller and receives the driver therein. The electric driver has a rod member driven by electricity, and the rod member drives the swing base to swing to a first position where the flywheel meshes with the sliding base to thereby drive the sliding base to move downwards, and a second position where the flywheel disengages from the sliding base to thereby cause the sliding base to reposit. Thus, it is an advantage to improve service life and stability of the electrical nail gun.

Owner:ROBERT BOSCH TOOL +1

Dry firing prevention device for nail gun

InactiveUS7413103B1Protection from damageEasy to operateStapling toolsNailing toolsEngineeringSafety status

The present invention refers to a dry firing prevention device, especially for use in a nail gun with a drawer type magazine, in which the main body of the nail gun is equipped with a safety apparatus and a dry firing prevention device near a trigger. The dry firing prevention device is disposed on the magazine. When a nail pusher pushes nails until where last few nails are left, the nail pusher will contact with one end of the dry firing prevention device and the other end of the dry firing prevention device blocks the safety apparatus, so that the safety apparatus retains in a safety status to prevent the nail gun from dry firing, so as to prolong the lifetime of the nail gun.

Owner:APACH IND CO LTD

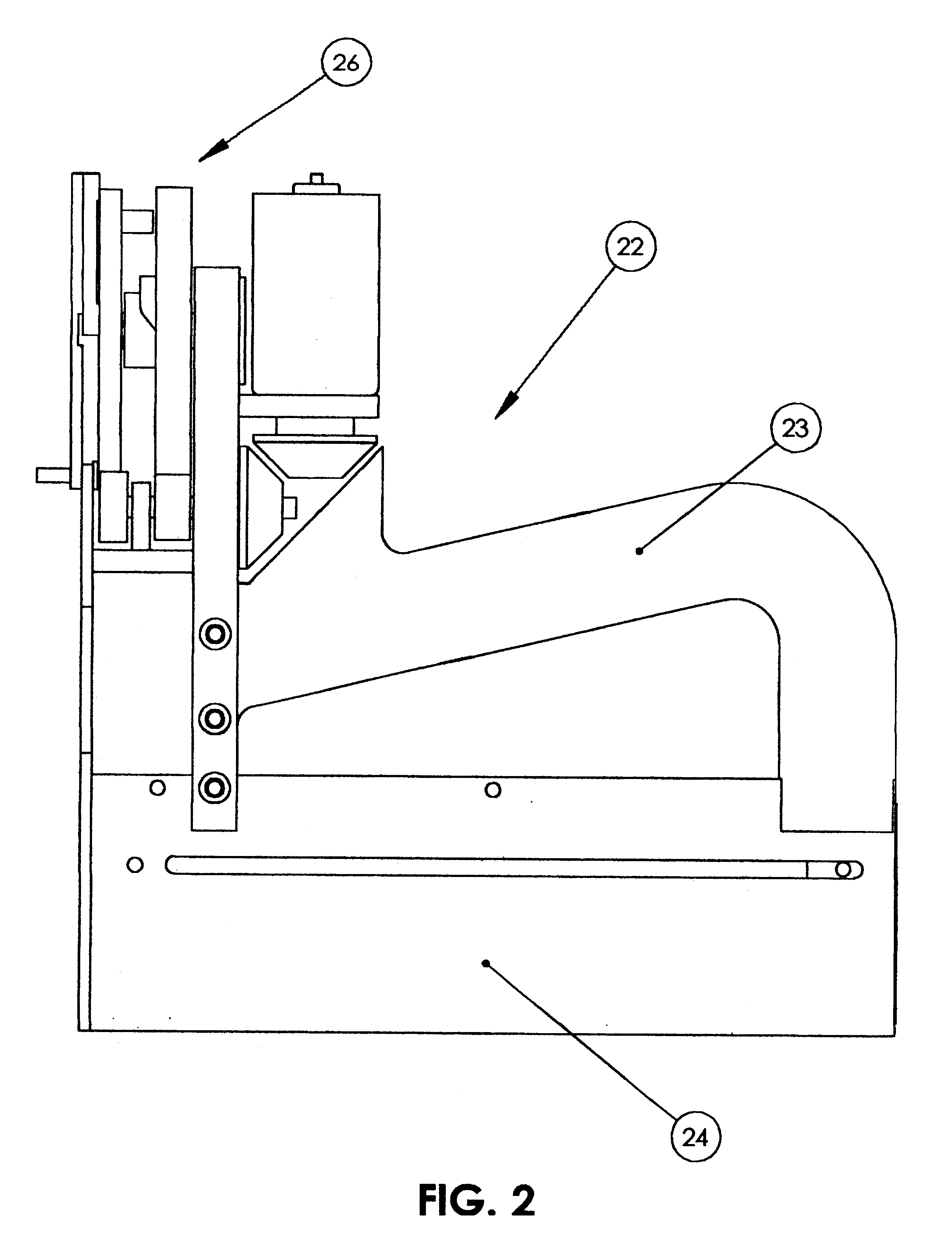

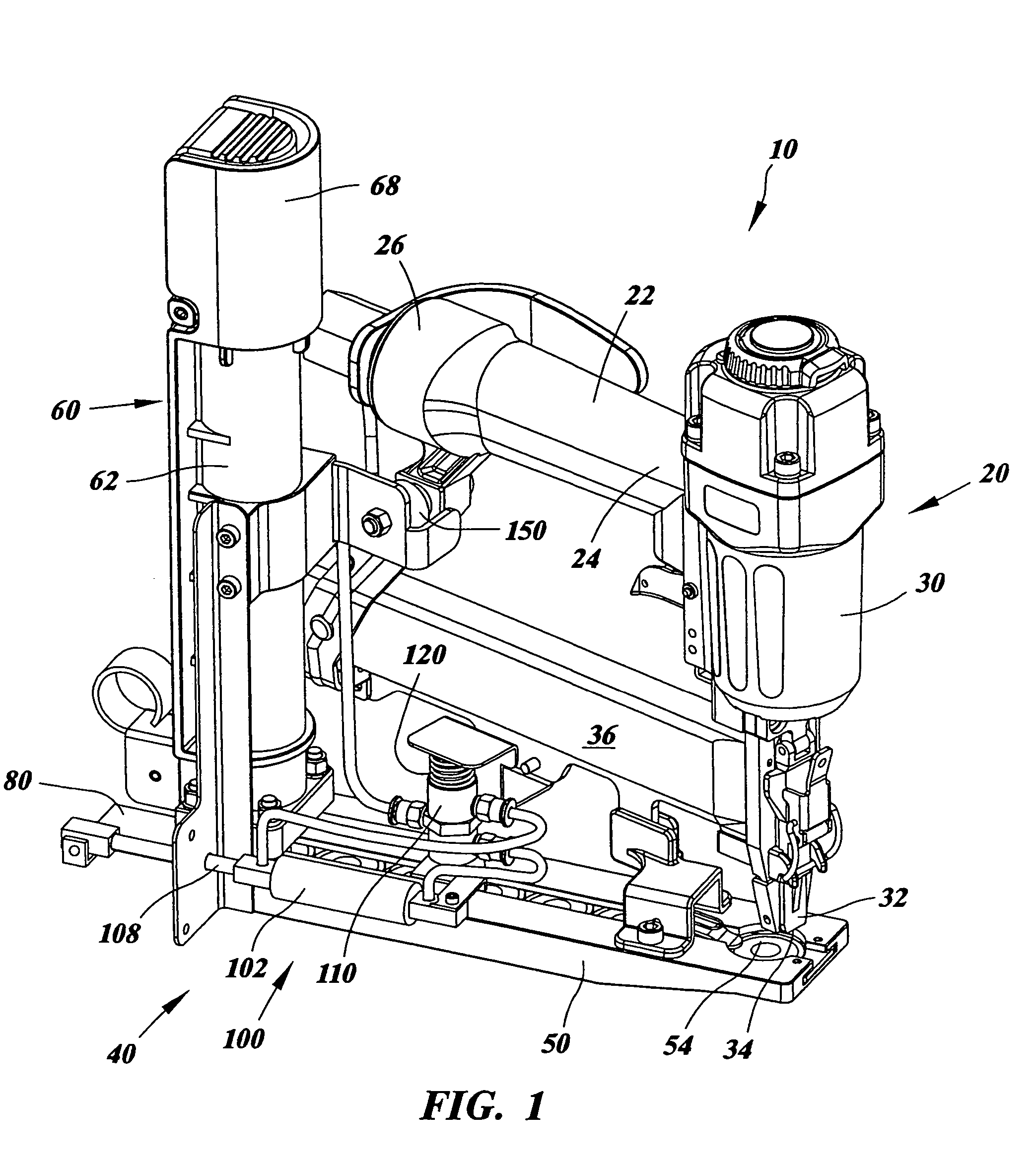

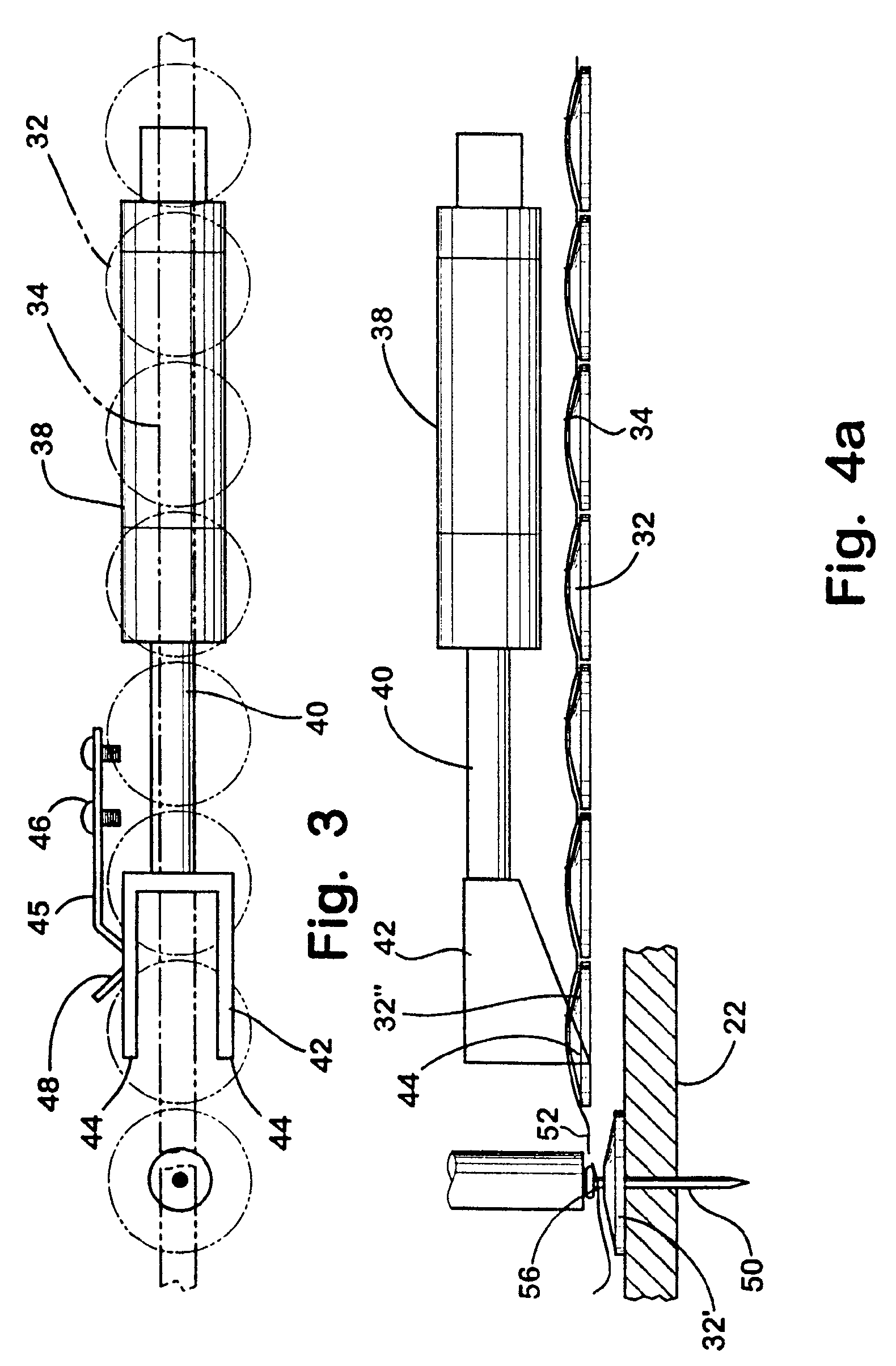

Automatic washer feeder for automatic nailer

An automatic washer feeder for an automatic nail gun comprises a washer storage container that stores a coil of washers interconnected together edge-to-edge and a feeding mechanism that uncoils the washers and feeds them one at a time into a position wherein the washers are in alignment with nails being driven by the nail gun. The feeding mechanism is synchronized with the nail in driver such that one washer is placed in line with each nail before it is driven. The washers are attached together edge-to-edge by a breakable linkage which is broken or cut whet a washer is driven into contact with a substrate surface being nailed by the action of the nail gun. The linkage can be an adhesive tape that breaks when the tape is pierced by a nail and the washer is driven into a substrate. Alternatively, the linkage can be formed by integrally molding the washers with an interconnecting link or by string collation.

Owner:NAT NAIL

Nail gun switch mechanism

InactiveUS7810688B2Simple structureRapid mass productionStapling toolsNailing toolsEngineeringNail gun

A nail gun switch mechanism includes a gun body and a trigger. A safety slidable bar has a bottom part which extends outside of a hitting mouth at a bottom of the gun body. The trigger has a trigger lever being pivotably disposed therein. A top part of the safety slidable bar extends near to an end of the trigger and a swing arm is pivotably disposed on the top part of the safety slidable bar. The swing arm includes an arm part extending from a pivotal center of the swing arm and a push part extending from the arm part toward outside. The push part is configured to be switched to a first or a second swing position and thus driven by the safety slidable bar to touch the trigger lever so as to operate the nail gun in a sequential or a contact actuation mode.

Owner:ROBERT BOSCH TOOL +1

Nailing Gun Trigger Safety Device and Nailing Gun Provided with the Same

Owner:TAIZHOU DAJIANG IND

Combustion-powered nail gun

InactiveUS20050029323A1Degradation of combustionEasy to driveStapling toolsNailing toolsCombustion chamberEngineering

A combustion-powered nail gun drives nails into a workpiece when both a head switch and a trigger switch are turned ON while a safety switch is turned ON. The nail driving operation cannot be performed if the safety switch is not ON even if both the head switch and the trigger switch are ON. The head switch is turned ON when a push lever is urged against the workpiece. Fuel / air mixture in a combustion chamber is ignited when the head switch and the trigger switch are turned ON irrespective of an order in which the head switch and the trigger switch are turned ON, whereby “successive-shot driving” can be performed in which the trigger switch is maintained in its ON position while successively driving a plurality of nails at different locations of the workpiece by repeatedly pushing and releasing the push lever toward and away from the workpiece.

Owner:HITACHI KOKI CO LTD

Clutch Mechanism for Electrical Nail Gun

ActiveUS20090032567A1Reduce decreaseExtended service lifeStapling toolsNailing toolsFreewheelElectricity

A clutch mechanism arranged in a housing of an electrical nail gun includes a sliding base, a driver driven by electricity, a swing base pivotally mounted on the housing, and an electric driver attached to the housing and being adjacent to an end side of the swing base. The sliding base is slidably disposed on an end of a free roller positioned in the housing, and the sliding base loads a spring and forms a hitting nail bar thereon. The driver has a motor and a flywheel driven by the motor, and the flywheel is configured to engage or disengage with / from the sliding base. The swing base is adjacent to the sliding base and the free roller and receives the driver therein. The electric driver has a rod member driven by electricity, and the rod member drives the swing base to swing to a first position where the flywheel meshes with the sliding base to thereby drive the sliding base to move downwards, and a second position where the flywheel disengages from the sliding base to thereby cause the sliding base to reposit. Thus, it is an advantage to improve service life and stability of the electrical nail gun.

Owner:ROBERT BOSCH TOOL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com