Pile splicing structure for precast piles

A prefabricated pile and peripheral technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of not being able to guarantee the force requirements of the pile connection part, and it is difficult to have the same force on the connecting pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

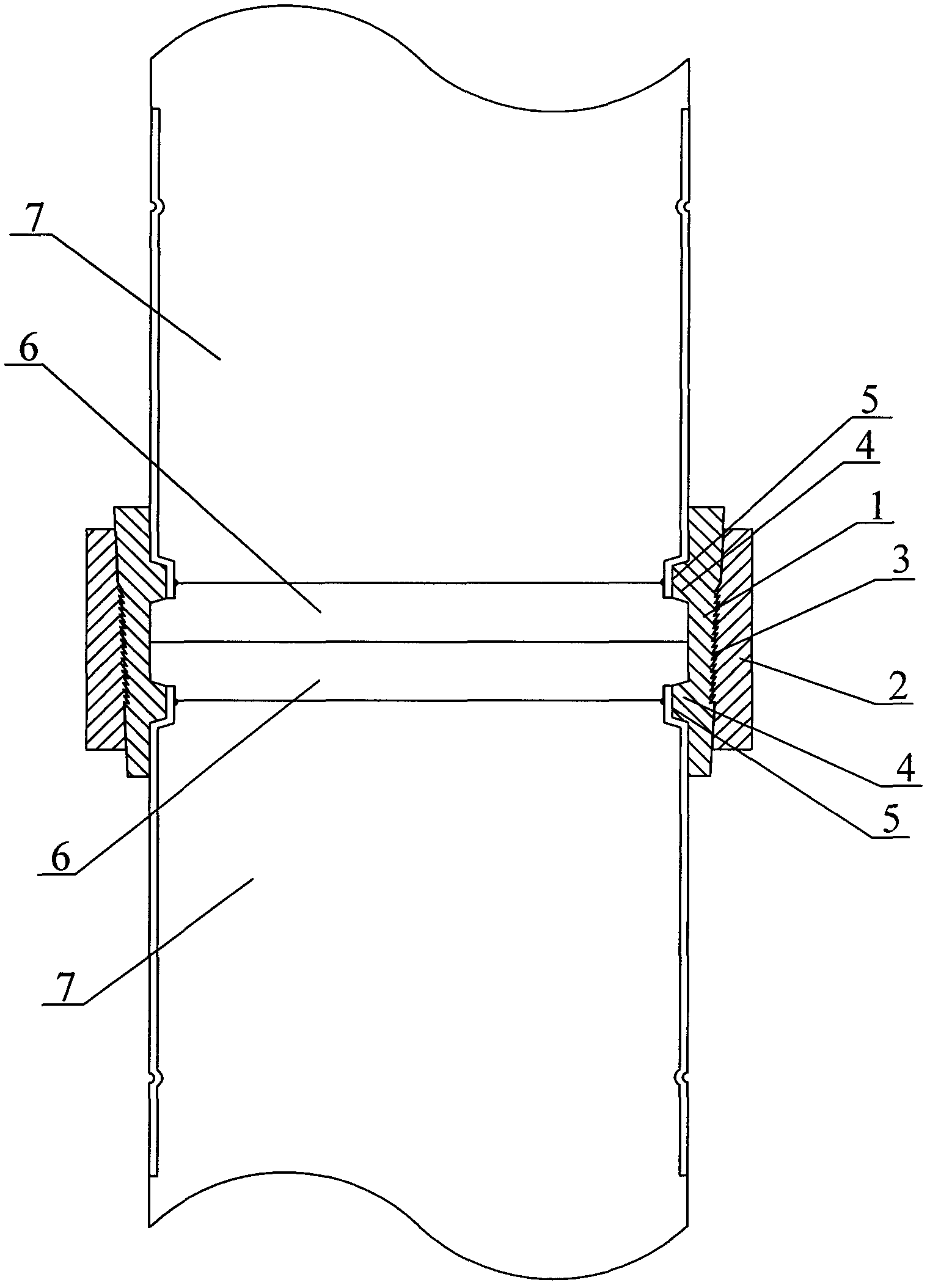

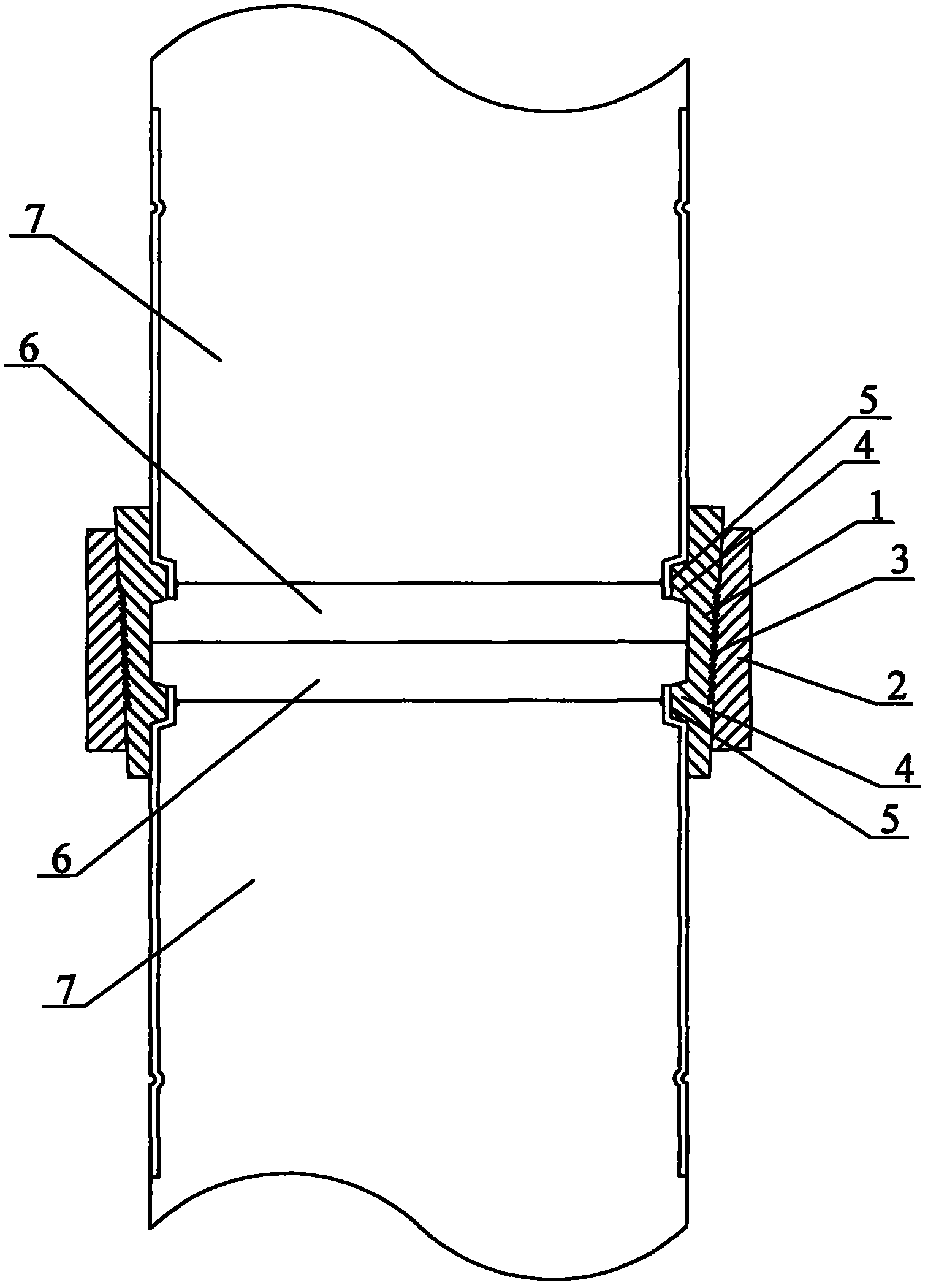

[0019] As shown in the drawings, the prefabricated pile connection structure of the present invention includes an inner hoop 1 sleeved on the periphery of two pile joints that need to be piled to prefabricated piles, and an outer hoop 2 sleeved and fastened on the periphery of the inner hoop 1 . The inner hoop 1 is composed of two semicircles spliced into a ring, and the inner ring of the inner hoop 1 is provided with two radial protruding rings 4, and each of the pile joints that need to be piled to the prefabricated pile is provided with a radial ring 4 on the periphery of the pile joint. The raised ring 4 matches the groove 5 . The outer wall of the inner hoop 1 and the inner wall of the outer hoop 2 are conical table surfaces that match each other, and the serrations 3 that can clamp the inner hoop 1 and the outer hoop 2 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com