Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

268 results about "Methylethyl ketone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

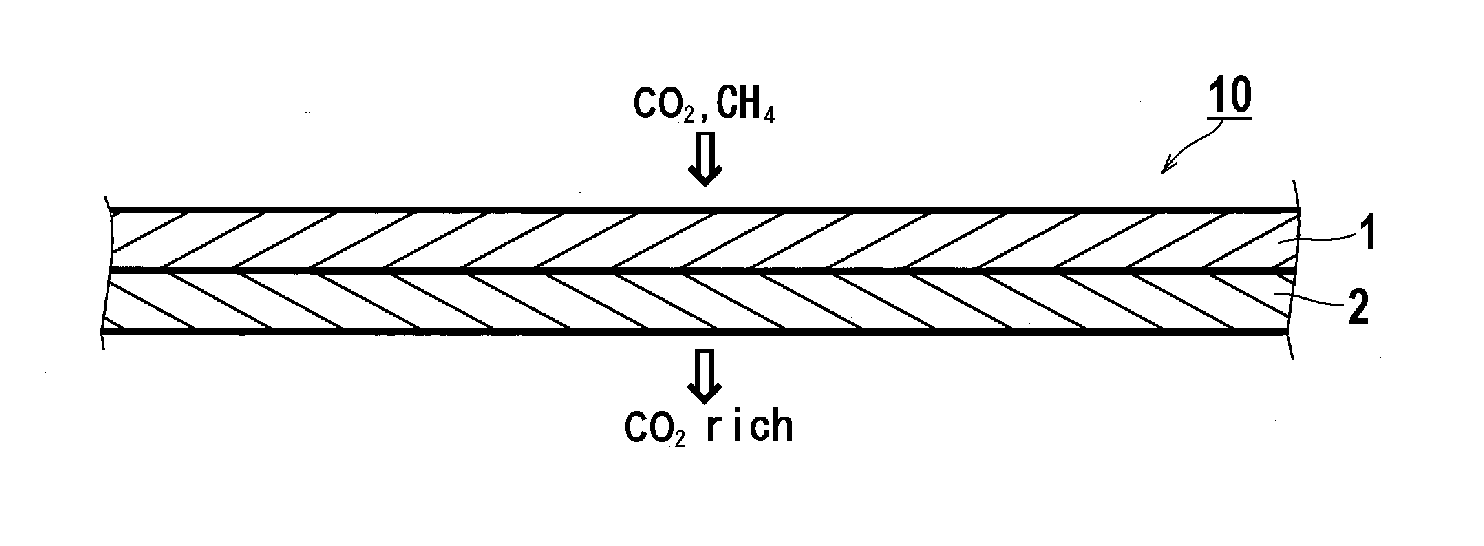

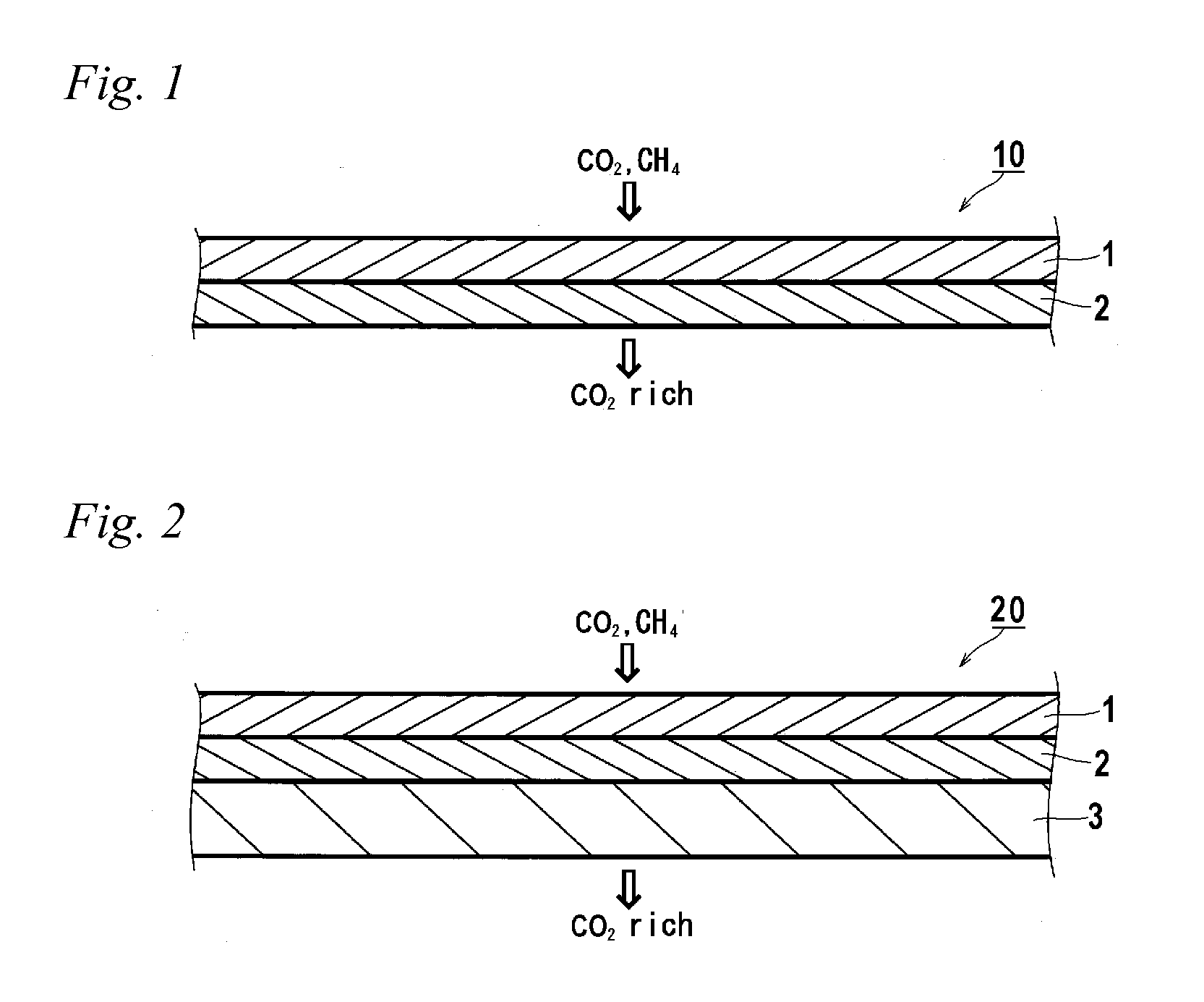

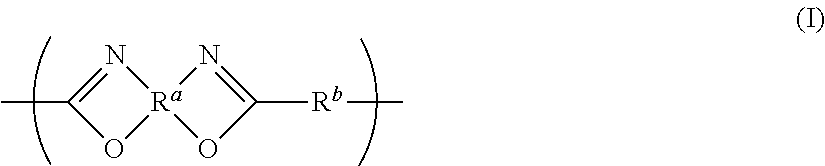

Gas separation membrane, gas separation module, gas separation apparatus, and gas separation method

InactiveUS20150258505A1Satisfactory mechanical strengthImprove permeabilitySemi-permeable membranesMembranesBenzoxazoleSolubility

A gas separation membrane having a gas separating layer containing a polybenzoxazole resin, in which the polybenzoxazole exhibits a solubility of 1% by mass or more to any one solvent selected from tetrahydrofuran, chloroform, methyl ethyl ketone, and N-methylpyrrolidone, at a temperature of 30° C., a gas separation module utilizing the gas separation membrane, a gas separation apparatus, and a gas separation method.

Owner:FUJIFILM CORP

Preparation method of low shrink air dry vinyl ester heavy-duty anti-corrosive paint

InactiveCN101760115AStrong resistance to media penetrationImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsGas phaseSilicon dioxide

The invention discloses a preparation method of low shrink air dry vinyl ester heavy-duty anti-corrosive paint. The anti-corrosive paint comprises a first component of the dry vinyl ester heavy-duty anti-corrosive paint and a second component of the dry vinyl ester heavy-duty anti-corrosive paint, wherein the first component of the dry vinyl ester heavy-duty anti-corrosive pain t comprises vinyl ester resin, titanium pigment, French chalk, mica powder, gas phase silicon dioxide, styrene, BYK-410, BYK-555, glass scales and like, the second component of the dry vinyl ester heavy-duty anti-corrosive paint comprises dibutyl phthalate, methylethyl ketone peroxide and cobalt naphthenate. The defects of low air dry capability and high cure shrinkage of the traditional vinyl ester glass scale heavy-duty anti-corrosive paint are solved by introducing the air dry addition product group to synthesize low shrink air dry resin, and the paint has the advantages of high media penetrability resistance, abrasive resistance and the like. The low shrink air dry vinyl ester heavy-duty anti-corrosive paint has the characteristics of simple preparation process, abundant raw materials and stable performance, and is suitable for large-scale industrial production.

Owner:中昊北方涂料工业研究设计院有限公司

Polyurethane cured acrylic resin anti-fogging and abrasion-resistant paint and preparation method thereof

InactiveCN102086348AStrong anti-fogHigh transparencyPolyurea/polyurethane coatingsAcrylic resinPolypropylene glycol

The invention discloses polyurethane cured acrylic resin anti-fogging and abrasion-resistant paint and a preparation method thereof. The paint is prepared from the following components in parts by weight: 130-190 parts of hydrophilic acrylic resin, 210-525 parts of blocked polyether-isocyanate used as curing agent and 2.00-5.00 parts of butyltin dilaurate used as catalyst, wherein the blocked polyether-isocyanate curing agent uses polypropylene glycol and isophorone diisocyanate as raw materials. The preparation method of the paint comprises the following steps: reacting to obtain polyether-isocyanate prepolymer and then reacting with methyl ethyl ketoxime used as sealing agent. The test result shows that the paint prepared by the method has high anti-fogging property, good transparency and abrasion resistance and low production cost; and under the premise of ensuring the good anti-fogging property of the paint, the surface wear resistance can be increased and the application prospectis wide.

Owner:上海旺俊化工有限公司

Ketone catalyst fabricated by dehydrogenating alcohol, and preparation method

ActiveCN1872412ASimple preparation processEasy to operateCatalyst activation/preparationCarbonyl compound preparation by oxidationAlcoholPtru catalyst

A catalyst for preparing ketone by dehydrogenating alcohol is prepared from Cu as active component, Zn, Cr, or K as active assistant and alumina as carrier through co-depositing, coating alkali metal by immersing or spraying, drying, and calcining. It has high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for fabricating artificial stone, and artificial stone with luminescence function, and products

A process for preparing artificial stone and artificial luminous stone includes such steps as proportionally adding phthalate and tetramethyl (or pentamethyl) derivative to unsaturated resin, stirring, adding the vinyl derivative of benzene, stirring, adding MMA, high-speed stirring, adding filler, pigment, modified resin, methylethyl ketone peroxide and cobalt nephthenate, stirring, filling the mixture in mould, vacuumizing, heating at 50-70 deg.C for 1-3 hr, heating at 75-85 deg.C for 1-3 hr, natural cooling, and demoulding. Its products are also disclosed.

Owner:金国华

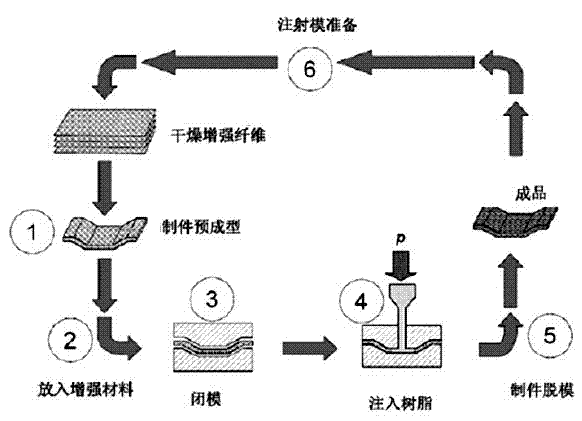

HP-RTM technology based method for molding automobile surface external decorative parts

The invention discloses an HP-RTM technology based method for molding automobile surface external decorative parts. Matrixes of epoxy resin, phenolic resin or vinyl resin and a reinforcement of carbon fiber are added with fire retardant and antistatic agent; and a high pressure resin transfer molding technology is employed to mold automobile surface external decorative parts. The method comprises steps of: mixing well the matrixes, the fire retardant and the antistatic agent to obtain a first resin system; mixing the first resin system and methylethyl ketone peroxide in a mass ratio of 100:0.5-1 to obtain a second resin system; placing pre-molded reinforcement of carbon fiber in a die, injecting the well mixed second resin system into a mould cavity by the high pressure resin transfer molding technology to dip the reinforcement of carbon fiber with the resin system; solidifying and demoulding to obtain a product. The method of the invention enhances size precision of the product, lowers amount of porosity of the product and reduces production costs through high degree of automation.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive and preparation method thereof

The invention is a breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive and a preparation method thereof. The breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive is prepared by compounding water-based breathable anti-static polyurethane resin, a blocked polyurethane crosslinking agent, nano zinc oxide and a thickening agent, wherein the water-based breathable anti-static polyurethane resin is prepared from components A, the blocked polyurethane crosslinking agent is prepared from components B, the components A comprise 50-200 parts of polyoxyethylene ether glycol, 50-200 parts of polyoxypropylene ether glycol, 1-5 parts of trimethylolpropane, 40-200 parts of polyisocyanate, 3-10 parts of a chain extender, 0.02-0.06 part of a catalyst, 30-60 parts of a solvent, 3-10 parts of sodium hydrogen carbonate, 3-10 parts of sodium hydrogen sulfite and 500-1,500 parts of deionized water, and the components B comprise 100-200 parts of 1.6-hexylidene diisocyanate trimer, 42-92 parts of acetone oxime or methyl ethyl methyl ethyl ketoxime, 0.02-0.06 part of a catalyst, 400-900 parts of a solvent and 30-80 parts of an ultraviolet-resistant additive. The breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive has excellent air permeability, ultraviolet resistance and static resistance and has good dry and wet rubbing fastness.

Owner:LIAONING FIXED STAR FINE CHEM

High-hardness unsaturated polyester full-bright top-coat paint and preparation method thereof

The invention relates to a chemical technology field, concretely, discloses high-hardness unsaturated polyester full-bright top-coat paint and a preparation method thereof. The priming paint contains a first component, cobalt isocaprylate (blue wate), methylethyl ketone peroxide (white water), and styrene, wherein the weight ratio of the first component, to cobalt isocaprylate (blue wate), to methylethyl ketone peroxide (white water) and to styrene is 100:(0.8-2):(1-2.5):(30-40). The high-hardness white unsaturated polyester priming paint and the preparation method resolve the problem that the PU polyurethane paint and nitro cellulose paint have bad hardness, the unsaturated polyester coating has high hardness, and simultaneously, the high-hardness unsaturated polyester full-bright top-coat paint has good fullness, clunging and minute surface effect.

Owner:AODA KOALA PAINT HUIZHOU

Ultraviolet light curing coating and production thereof

InactiveCN1778850AImprove wear resistanceHigh hardnessPolyurea/polyurethane coatingsUltraviolet lightsKetone

A ultraviolet curing coating and its production are disclosed. The coating consists of filming substance, diluent and light initiating agent or assistants. The diluent is a organic solvent which comprises one of several from toluene, acetic ether, acetate butyrin, isobutyl acetate, propyl acetate, alcohol, n-butyl alcohol, ethylene ketone, dimethyl benzene, methyl isobutyl ketone, acetone, methyl ethyl ketone, ethanediol butyl ester and propylene butyl ester. It costs low, has better abrasive-resistance, hardness and adhesion.

Owner:BYD CO LTD

High-hardness white unsaturated polyester priming paint and preparation method thereof

The invention relates to a chemical technology field, concretely, discloses high-hardness white unsaturated polyester priming paint and a preparation method thereof. The priming paint contains a first component, cobalt isocaprylate (blue wate), methylethyl ketone peroxide (white water), and a diluent, wherein the weight ratio of the first component, to cobalt isocaprylate (blue wate), to methylethyl ketone peroxide (white water) and to diluent is 100:(0.8-2):(1-2.5):(30-40). The high-hardness white unsaturated polyester priming paint and the preparation method resolve the problem that the PU polyurethane paint has bad hardness, the usage of unsaturated polyester paint reduces the VOC content of the paint, and the high-hardness white unsaturated polyester priming paint has good fullness and filling effect.

Owner:AODA KOALA PAINT HUIZHOU

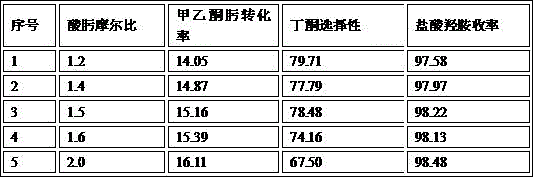

Method used for preparing methylethyl ketone peroxide by taking acidic ion exchange resin as catalyst

ActiveCN105237453AStrong acidLarge apertureOrganic compound preparationChemical recyclingOil phaseOxygen

The invention provides a method used for preparing methylethyl ketone peroxide by taking an acidic ion exchange resin as a catalyst. According to the method, butanone and hydrogen peroxide are taken as raw materials, the acidic ion exchange resin is taken as the catalyst, dibutyl phthalate is taken as a diluent, after constant temperature stirring reaction, an obtained mixture is allowed to stand for separation, and an obtained oil phase is methylethyl ketone peroxide. According to the method, the heterogeneous catalyst is adopted, so that the catalyst and the reaction materials can be separated easily, and the catalyst can be recycled for a plurality of times; reaction is stable, the temperature is increased slowly, and reaction is continuous and stable; product active oxygen content is 13%, and economic value is high; application of strong such as sulfuric acid is avoided, so that corrosion on equipment is less, environment pollution is not caused, and environmental benefit is relatively high.

Owner:兰州助剂厂有限责任公司

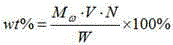

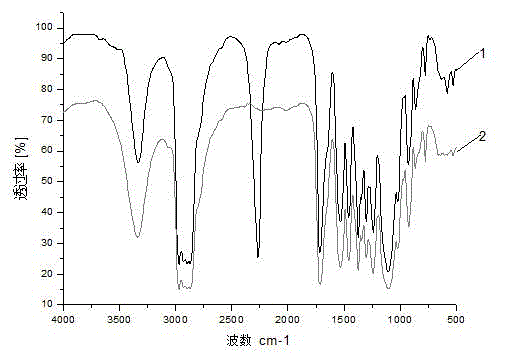

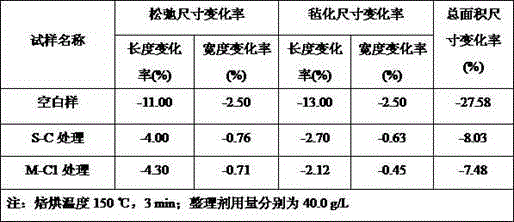

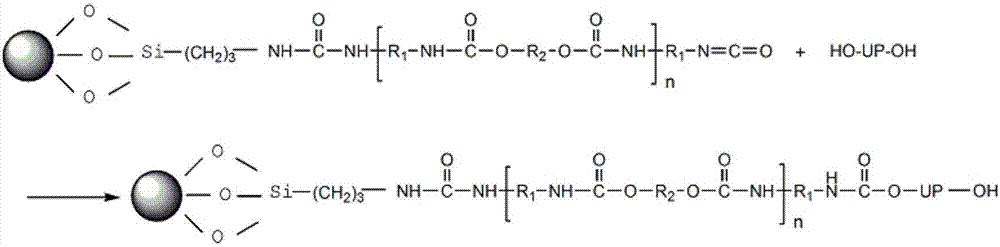

Preparation method of cation-type waterborne polyurethane wool anti-felting emulsion

InactiveCN104878604AGood storage stabilitySolid content adjustableAnimal fibresBursting strengthPolymer science

The invention relates to a preparation method of cation-type waterborne polyurethane wool anti-felting emulsion, and belongs to the field of wool fabric finishing auxiliaries. According to the preparation method of the cation-type waterborne polyurethane wool anti-felting emulsion, polyisocyanate is used as a hard segment, polyether polyol is used as a soft segment, an amine compound is used as a cation chain extender and sodium hydrogen sulfite or methyl ethyl ketoxime is used as an end-capping reagent; the adopted technical route is pre-polymerization reaction-hydrophilic chain extending reaction-end capping reaction-neutralization reaction-self-emulsifying reaction. The anti-felting emulsion synthesized by a self-emulsifying method has the characteristics of being excellent in storage stability, adjustable in solid content and convenient to use, the size change of wool knitting fabrics caused by felting during washing is remarkably reduced, the bursting strength, dyeing depth and dyeing fastness of the wool knitting fabrics are improved, and good application prospect is provided.

Owner:XINJIANG UNIVERSITY +1

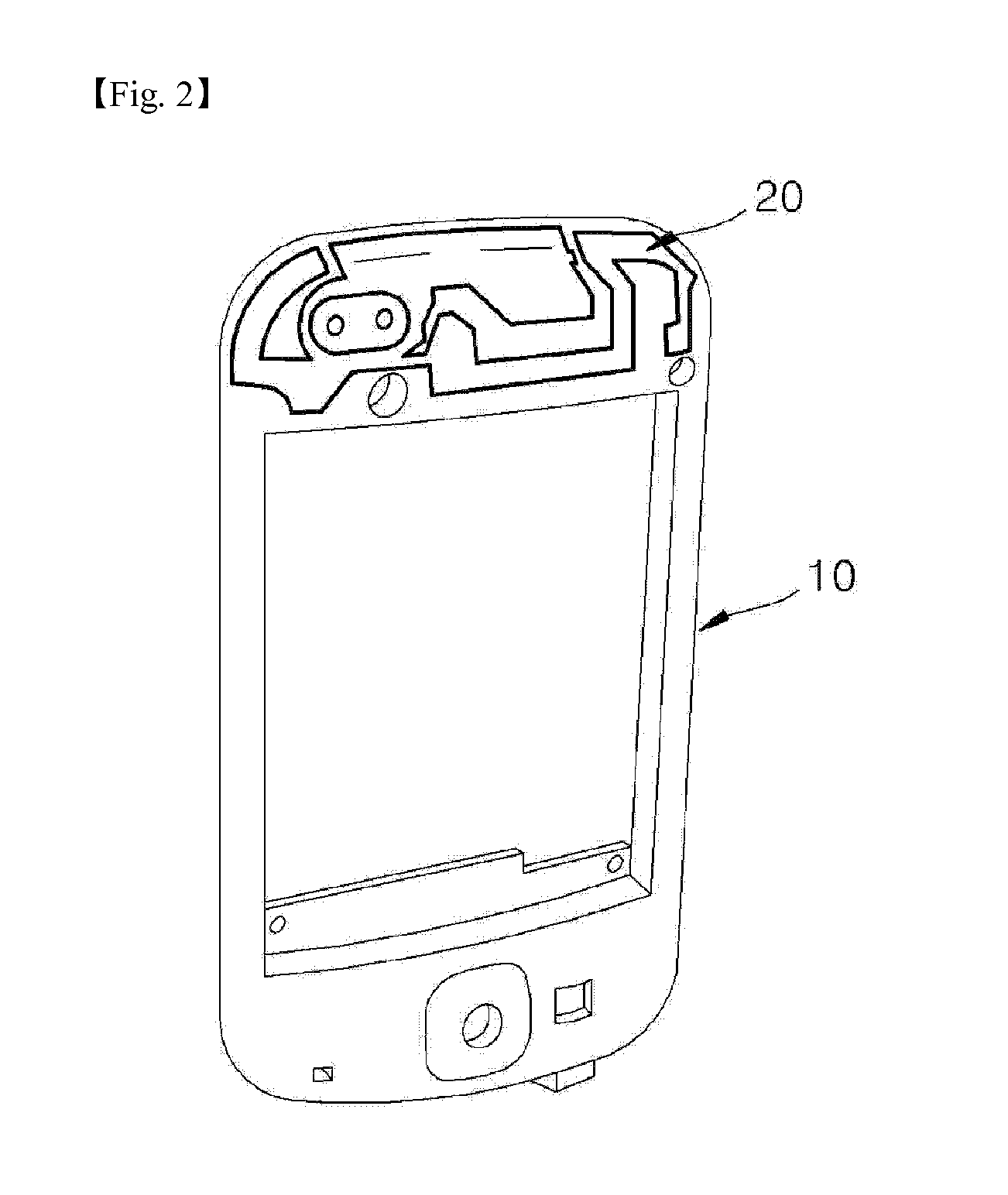

Ink for printing a mobile phone antenna pattern, method for manufacturing a synthetic resin part for a mobile phone on which an antenna pattern is printed using the ink, and synthetic resin part for a mobile phone on which an antenna pattern is printed

InactiveUS20130076572A1Improve manufacturing productivityReduce the environmentSimultaneous aerial operationsConductive materialProduction ratePolystyrene

The ink for printing an antenna pattern for a mobile phone according to an embodiment of the present invention includes a mixture of one of silver (Ag) powder, nickel (Ni) powder, copper (Cu) powder, and gold (Au) powder, liquid acrylonitrile, liquid polystyrene, liquid butadiene, and methyl ethyl ketone (MEK) as a diluent. The present invention does not include a plating process, and thus allows a significant improvement in productivity.

Owner:YEN AN TECH +1

Impact and bending resistant environmentally-friendly rostone sheet

The invention discloses an impact and bending resistant environmentally-friendly rostone sheet. Raw materials of the sheet comprise, by weight, 8-12 parts of aluminum hydroxide powder, 3-7 parts of quartz sand, 50-60 parts of granite powder, 0.3-0.5 parts of gamma-trimethoxysilyl propyl methacrylate, 30-40 parts of isophthalic acid-neopentylene glycol resin, 5-9 parts of modified negative ion powder, 6-8 parts of glass fibers, 0.4-0.6 parts of cobalt isooctoate, 0.7-1 part of methylethyl ketone peroxide, 0.2-1 part of a higher alcohol fatty acid ester complex, 0.5-1.5 parts of an antioxidant 1010 and 0.3-0.7 parts of a pigment. The rostone sheet has strong impact and bending resistance, and can purify air to realize an environmental protection effect.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

Preparation method of polyurethane coating and adhesive with flame retardance and light resistance

ActiveCN105176368ALow toxicityReduce the amount of smoke releasedNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses a preparation method of a polyurethane coating and adhesive with flame retardance and light resistance. The preparation method comprises the following steps: in the presence of a catalyst dibutyltin dilaurate, mixing polytetrahydrofuran ether glycol with isophorone diisocyanate to react at 70-100 DEG C for 1-3 hours to obtain a polyurethane prepolymer A; and adding a chain extender and methyl ethyl ketone to the prepolymer A to react at 65-85 DEG C for 1.5-3.5 hours, adding modified manganese hypophosphite and 4-carboxyphenylboronic acid to react at 75-95 DEG C for 1-2 hours, adding triethylamine for neutralization, adding a substance B and adding water for emulsification, thus obtaining the polyurethane coating and adhesive with flame retardance and light resistance. The prepared polyurethane coating and adhesive with flame retardance and light resistance is environment-friendly in preparation method and is low in price, is widely applied to the surfaces of walls, furniture and metalware and serves as the adhesive of plastics, glass, paper and textiles.

Owner:广东合顺涂层材料有限公司

Ketone catalyst fabricated by dehydrogenating alcohol, and preparation method

ActiveCN100360228CSimple preparation processEasy to operateCatalyst activation/preparationCarbonyl compound preparation by oxidationAlcoholPtru catalyst

A catalyst for preparing ketone by dehydrogenating alcohol is prepared from Cu as active component, Zn, Cr, or K as active assistant and alumina as carrier through co-depositing, coating alkali metal by immersing or spraying, drying, and calcining. It has high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing glass fiber reinforced plastic anchor pole

The invention discloses a method for producing a glass fiber reinforced plastic anchor pole, especially a method for producing a highly torsion-resistant, anti-shearing prestressing glass fiber reinforced plastic anchor pole, comprising the following steps of: mixing unsaturated polyester resin, nanometer mullite, aluminium hydroxide, polyurethane, zine stearate, white carbon black, methylethyl ketone peroxide, TBPB and a mould release agent according to a mass ratio in a resin solution groove with stirring to produce a resin solution, followed by vacuum-pumping and bubble-removing; towing glass fibres from a filament rack, twisting the glass fibres on a twisting support to form a twist of 10-30 degrees by rotating and towing the twisted glass fibres into the resin solution groove for impregnation; towing the twisted and impregnated glass fibres into a cone-shaped sleeve for folding and bundle-forming as well as preforming; finally continuously towing the folded bundles of glass fibres into a hot pressing die, followed by molding at the temperature of 160-180 DEG C. The method provided by the invention is simple, and the anchor pole produced by the invention has high torsion-resistant and anti-shearing performance as well as low cost.

Owner:扬州中矿矿业技术发展有限公司 +1

Process for preparing hydroxylamine hydrochloride by adopting oxime acidolysis method

InactiveCN107522181AIncrease profitReduce manufacturing costOrganic compound preparationHydroxy compound preparationAlcoholHydroxylamine Hydrochloride

The invention belongs to the technical field of hydroxylamine hydrochloride, and discloses a process for preparing hydroxylamine hydrochloride by adopting an oxime acidolysis method. The method comprises the following steps: a) a raw material cache configuration process; b) an acidolysis reaction process; c) a ketoxime rectification process; d) a dehydration and drying process; e) an alcohol recycling process; and f) an acetaldehyde oximation process. By adopting the process, the process route and technical parameters of hydroxylamine hydrochloride production by methyl ethyl ketone acidolysis are optimized, a pervaporation coupling technology is applied, the product yield and quality can be improved, further improvement of the industrial technology is promoted, related industries can be driven to develop, and resource reasonable utilization can be realized.

Owner:临沭县华盛化工有限公司

Polyurethane elastomer for coating equipment and preparation method thereof

ActiveCN105111408AImprove mechanical propertiesGood solvent resistancePolyurea/polyurethane coatingsPolyesterPolymer science

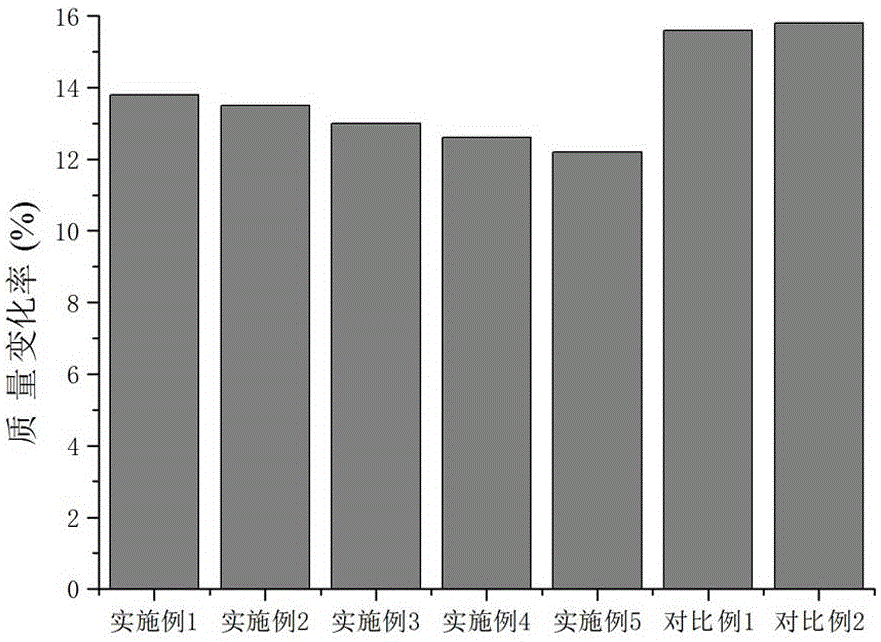

The invention discloses a polyurethane elastomer for coating equipment and a preparation method thereof. A mixture of mixed polyester polyol and diisocyanate reacts in a reaction kettle, a polyurethane quasi-prepolymer with isocyanato-NCO end capping is prepared, the polyurethane quasi-prepolymer reacts with hydroxyl containing resin, a polyurethane prepolymer with and end groups being in -NCO end capping is obtained; a chain extender and an organic bismuth catalyst are added; through vacuum defoamation and depressurization, materials are poured into a die, and through vulcanization and a step type aftertreatment process and through demolding, the polyurethane elastomer is obtained. The hardness of the elastomer is not lower than shore A 90; when the elastomer is soaked for 24 h in methyl ethyl ketone, the weight rate of the elastomer is not higher than 14%, and the industrial requirements of the coating equipment are completely met. The preparation method is low in cost, simple in process, green and environmentally friendly in the synthetic process and has good processing performance.

Owner:SUZHOU UNIV

Alcohol acid ripple finish and preparation method thereof

ActiveCN103468106ASimple production processReduce security risksPolyester coatingsCalcium EDTASkin agent

The invention provides alcohol acid ripple finish and a preparation method thereof. The alcohol acid ripple finish comprises, by weight, 50-60 parts of alcohol acid ripple resin (having solid content of 60+ / -3wt%), 5-10 parts of polymerized oil pattern-adjustment resin, 2-3 parts of carbon black, 20-35 parts of light calcium, 0.5-1.5 parts of bentonite HFGEL-40A, 1-2.5 parts of lead naphthenate having the content of 10%, 2-3.5% of cobalt naphthenate having the content of 4%, 0.1-0.3 parts of an anti-skinning agent and 5-10 parts of toluene. The anti-skinning agent is methyl ethyl ketoxime, butyraldehyde oxime or cyclohexanone-oxime and is obtained by mixing. The film of the alcohol acid ripple finish has excellent characters, realizes a flexible change of ripple patterns according to user demands and can be prepared by a simple method.

Owner:天津灯塔涂料工业发展有限公司

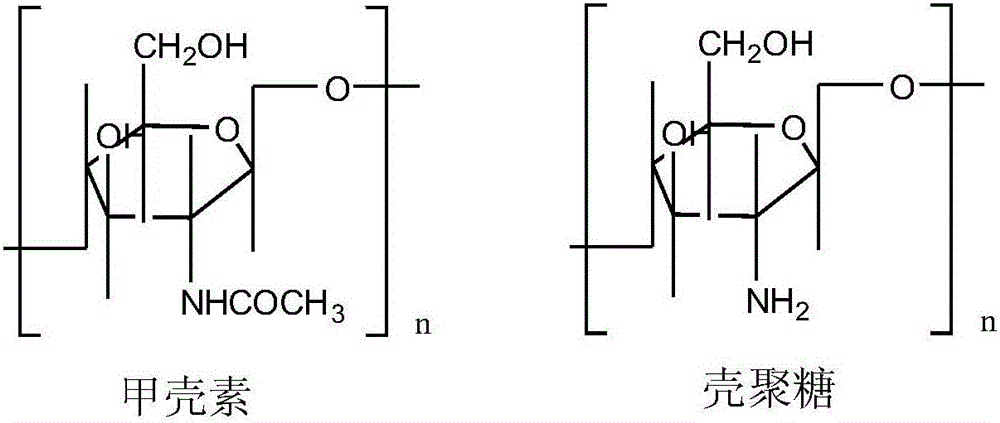

Chitosan quaternary ammonium salt antibacterial fiber, fabric and hygienic product and their preparation processes

ActiveCN106436313AGood cross-linking effectImprove antibacterial propertiesBiochemical fibre treatmentFiberQuaternary ammonium cation

The invention discloses a preparation process of chitosan quaternary ammonium salt antibacterial fiber, comprising: preparing chitosan and epoxypropyltrimethyl ammonium chloride into a chitosan quaternary ammonium salt with certain degree of substitution, reacting methyl ethyl ketoxime terminated isocyanate with the chitosan quaternary ammonium salt to obtain a reactive chitosan quaternary ammonium salt antibacterial agent or chitosan quaternary ammonium salt antibacterial liquid; dissolving the chitosan quaternary ammonium salt antibacterial agent or chitosan quaternary ammonium salt antibacterial liquid in water, and soaking the obtained fiber. The invention also discloses a chitosan quaternary ammonium salt antibacterial fabric and hygienic product and their preparation processes. Quaternary ammonium salt modified chitosan is synthesized herein, single-terminated isocyanate is introduced to the chitosan, the reactive quaternary ammonium salt chitosan has good antibacterial property far better than that of chitosan; by inoculating chitosan to isocyanate reaction groups, good reactiveness is provided; crystallinity of chitosan is decreased through quaternary ammonium salt salifying, it is possible for the isocyanate to react evenly with the fabric, the crosslinking effect is good, the antibacterial property of the fabric can be significantly improved, and the fabric has a promising application prospect.

Owner:QUANZHOU YALIN NEW MATERIAL TECH

High-temperature-resistant corrosion-resistant modified unsaturated polyester resin fiberglass-reinforced plastic grille

InactiveCN105907070AExtended service lifeImprove high temperature resistanceTemperature resistanceUnsaturated polyester

The invention discloses a high-temperature-resistant corrosion-resistant modified unsaturated polyester resin fiberglass-reinforced plastic grille. The fiberglass-reinforced plastic grille is prepared from the raw materials in parts by weight: 50-150 parts of modified unsaturated polyester resin, 20-60 parts of phenol-formaldehyde resin, 5-15 parts of acrylic acid modified alkyd resin, 2-5 parts of silicon carbide, 1-4 parts of aluminum hydroxide, 3-9 parts of magnesium hydroxide, 2-6 parts of talcum powder, 1-4 parts of paraffin, 2-5 parts of zinc oxide, 3-5 parts of fiberglass, 1-4 parts of hydroxy silicone oil, 1-6 parts of wetting dispersant BYK-W940, 2-8 parts of anti-aging agent D, 1-4 parts of ammonium polyphosphate, 2-5 parts of hydroxyethyl methacrylate, 1-5 parts of tin dibutyl dilaurate, 1-4 parts of dicumyl peroxide, 3-5 parts of propenyl ether glycol peroxide, 1-5 parts of silane coupling agent KH-570, 2-5 parts of methylethyl ketone peroxide and 3-6 parts of cobalt naphthenate. The fiberglass-reinforced plastic grille disclosed by the invention has excellent high-temperature resistance and corrosion resistance.

Owner:NINGGUO CITY OF CAPE COMPOSITE MATERIAL LIMITED

Chitosan-quaternary-ammonium-salt antibacterial agent and antibacterial liquid, preparing technology of chitosan-quaternary-ammonium-salt antibacterial agent and preparing technology of chitosan-quaternary-ammonium-salt antibacterial liquid

ActiveCN106366214AGood cross-linking effectImprove antibacterial propertiesOrganic active ingredientsAntisepticsChlorideCrystallinity

The invention discloses a preparing technology of a chitosan-quaternary-ammonium-salt antibacterial agent. The preparing technology includes the following steps that chitosan and epoxypropyltrimethylammonium chloride are prepared into chitosan quaternary ammonium salt with the substitution degree, then the chitosan quaternary ammonium salt is reacted with isocyanate closed by methyl ethyl ketoxime, and the reactive chitosan-quaternary-ammonium-salt antibacterial agent can be obtained. The invention discloses the chitosan-quaternary-ammonium-salt antibacterial agent, chitosan-quaternary-ammonium-salt antibacterial liquid and the preparing technology of the chitosan-quaternary-ammonium-salt antibacterial agent and a preparing technology of the chitosan-quaternary-ammonium-salt antibacterial liquid. Synthesized quaternary ammonium salt modified chitosan is adopted, and single-closed isocyanate is introduced on the chitosan. The antibacterial performance of the reactive quaternary-ammonium-salt chitosan is good and is far higher than that of the chitosan; the chitosan is introduced into an isocyanate reaction group, and the good reactivity is achieved; the crystallinity of the quaternary-ammonium-salt chitosan is reduced, the isocyanate can be evenly reacted with fabric, the crosslinking effect is good, and the antibacterial performance can be remarkably improved.

Owner:福建省隆丰生物科技有限公司

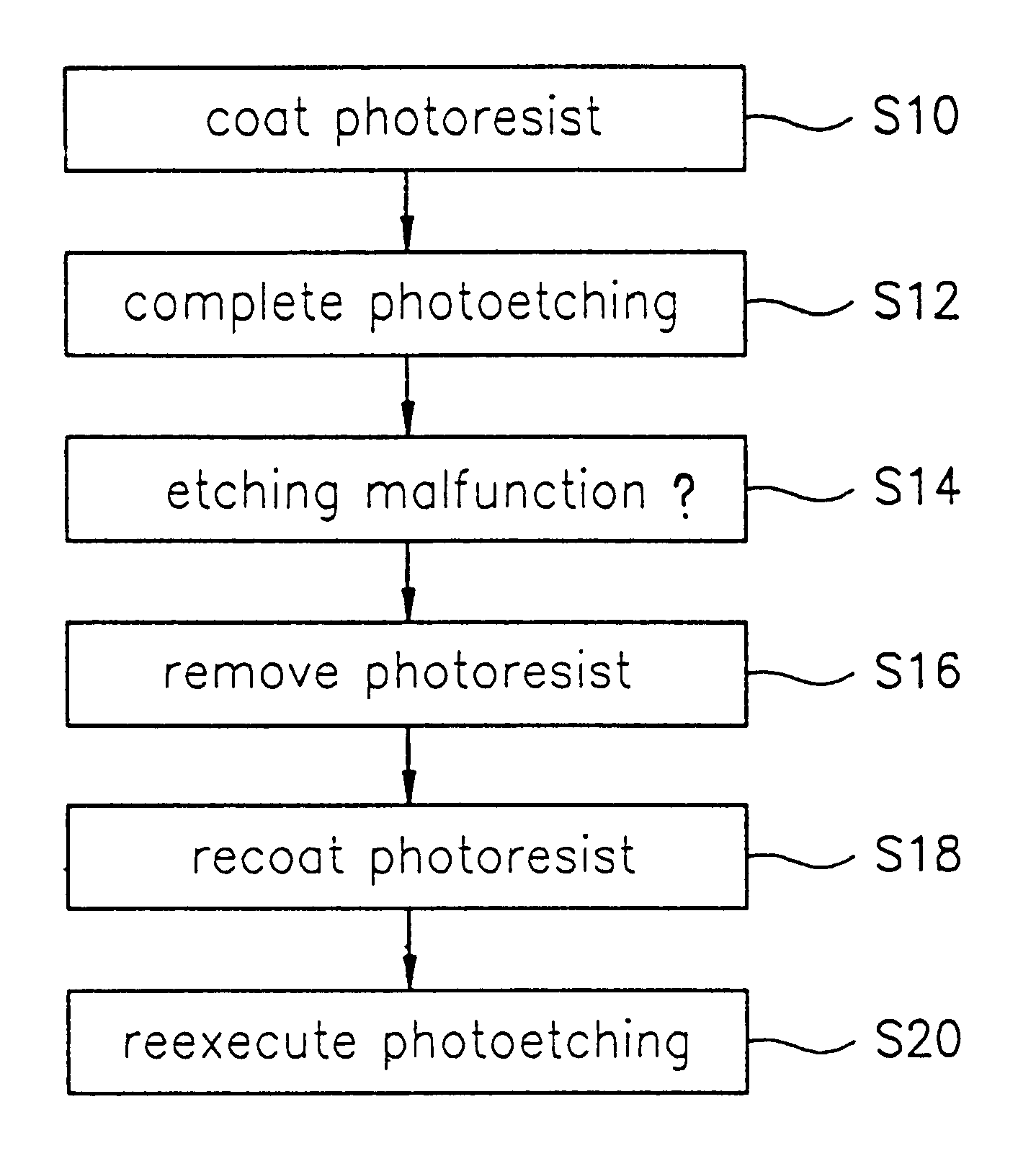

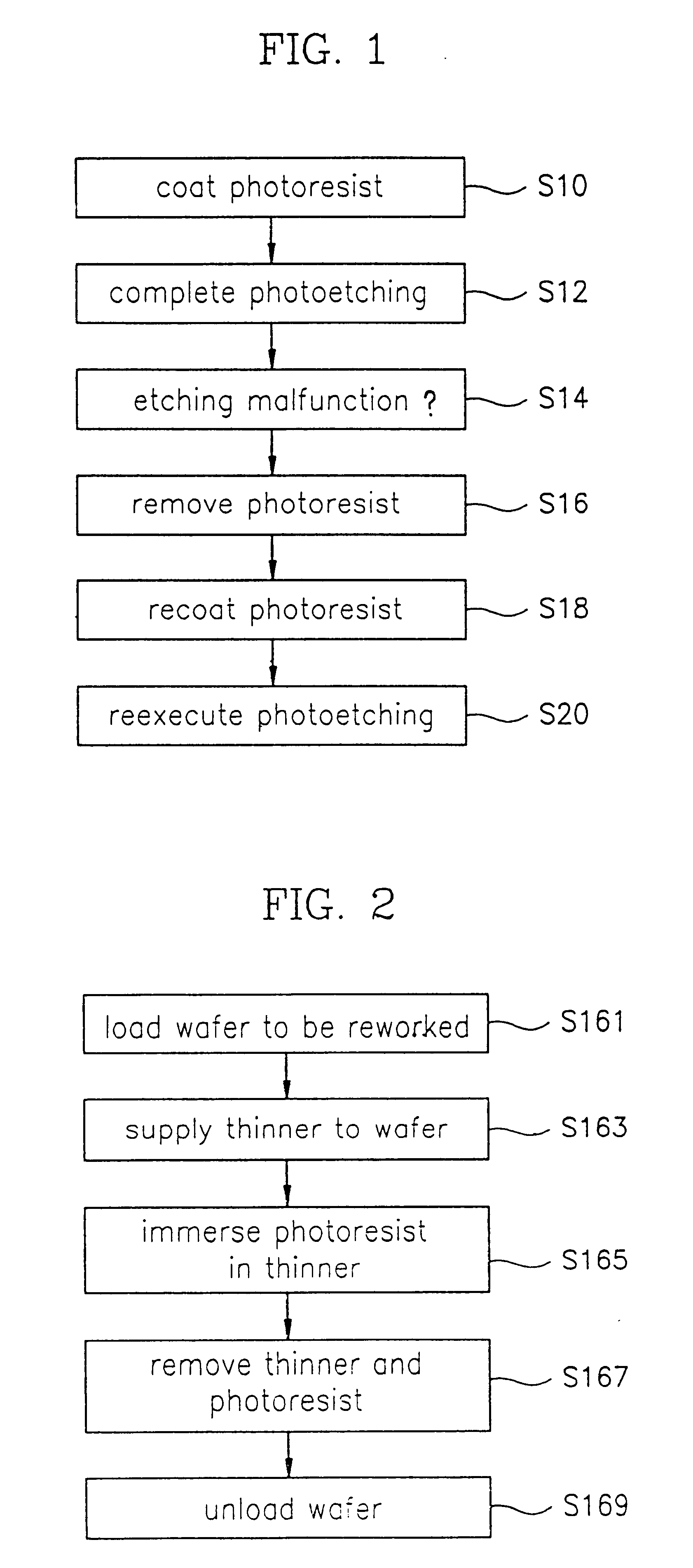

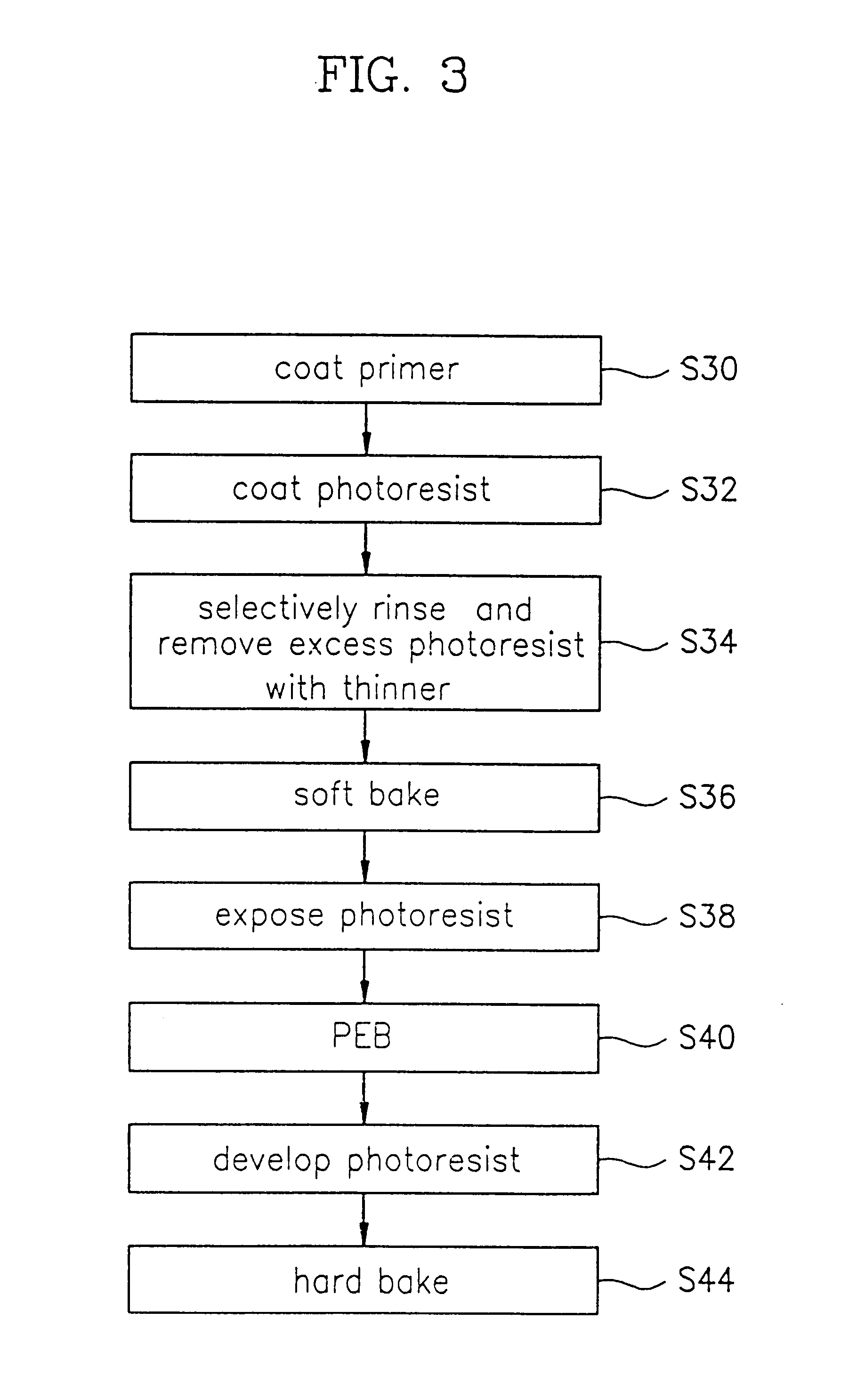

Thinner composition and methods and systems for using the thinner composition

InactiveUS6261970B1Semiconductor/solid-state device manufacturingPhotosensitive material processingPropionateDevice material

Thinner compositions for effectively removing photoresist. The thinner compositions may be used in reworking a semiconductor substrate or in rinsing semiconductor devices. The thinner composition may be a mixture of n-butyl acetate (n-BA) and ethyl acetate (EA), a mixture of n-butyl acetate (n-BA) and methyl methoxy propionate (MMP), or a mixture of n-butyl acetate (n-BA) and methyl ethyl ketone (MEK).

Owner:SAMSUNG ELECTRONICS CO LTD

Semi-enclosed organic amine curing agent and application thereof to anti-corrosive coating

ActiveCN102153729AExtend the usable timeGood effectAnti-corrosive paintsEpoxy resin coatingsCross-linkKetone

The invention discloses a semi-enclosed organic amine curing agent, which is characterized by being obtained by mixing and reacting the following substances in percentage by weight: 15-40 percent of epoxy resin, 5-12 percent of amine, 15-35 percent of ketone and 20-35 percent of solvent, wherein the epoxy resin is bisphenol A epoxy resin or bisphenol F epoxy resin; the amine is diethylenetriamineor triethylene tetramine; the ketone is methyl isobutyl ketone or ethyl methyl ketone; and the solvent is toluene or xylene or a mixture of toluene and xylene in any ratio or normal butanol or isobutyl alcohol or a mixture of normal butanol and isobutyl alcohol in any ratio. Semi-enclosed organic amine obtained by multi-step synthesis is cross-linked with epoxy resin and naturally dried into a film, the cross-linked product is de-capsulated into primary amine for further curing with moisture in the air or moisture on the surface of a substrate, and the curing agent is partially enclosed, so that the service life of reactive double-component paint can be greatly prolonged after mixing; and epoxy resin is introduced into the curing agent to form a multi-aromatic ring anti-corrosive prepolymer, so that the corrosion resistance of a final film forming substance is further enhanced.

Owner:CHONGQING SANXIA PAINTS CO LTD

Polyester powder furniture coating and preparation method thereof

InactiveCN105969122AIncrease crosslink densityHigh tensile strengthPowdery paintsPolyester coatingsAluminatePolyester

The invention discloses a polyester powder furniture coating, which is composed of the following raw materials (by weight): 0.4-14 parts of lecithin, 0.1-0.2 part of 1,2-epoxy-4-vinylcyclohexane, 1-2 parts of polybenzimidazole, 0.7-1 part of triethanolamine oleate, 2-3 parts of diacetone alcohol, 10-12 parts of tung oil, 0.06-0.07 part of sodium hydroxide, 3-4 parts of methanol, 0.1-0.2 part of perfluorosulfonate resin, 6-8 parts of acetic acid, 10-15 parts of 26-30% hydrogen peroxide, 10-17 parts of tetraethyl orthosilicate, 0.1-0.2 parts of Y-chloropropyltrimethoxysilane, 70-80 parts of unsaturated polyester resin, 0.6-1 part of methylethyl ketone peroxide, 0.1-0.2 part of aminoethylpiperazine, 10-14 parts of calsite powder, 0.6-1 part of formamide, 2-4 parts of tetrabutyl titanate and 3-4 parts of calcium aluminate.

Owner:刘辉

Hollow glass bead and polyurethane cooperated-modified unsaturated polyester composite material and preparation method thereof

The invention discloses a hollow glass bead and polyurethane cooperated-modified unsaturated polyester composite material and a preparation method thereof. The composite material is prepared from the following ingredients in parts by weight: 100 parts of unsaturated polyester resin, 15-40 parts of hollow glass bead-polyurethane prepolymer, 5-10 parts of diluent styrene, 1.5-3 parts of initiator methylethyl ketone peroxide, 0.3-0.6 part of accelerant cobalt naphthenate and 0.3-0.6 part of antifoamer simethicone. The prepared composite material has good mechanical strength and toughness while the density is effectively lowered, and meanwhile, the composite material further has special properties such as heat insulation, heat preservation and silencing.

Owner:WUHAN UNIV OF TECH

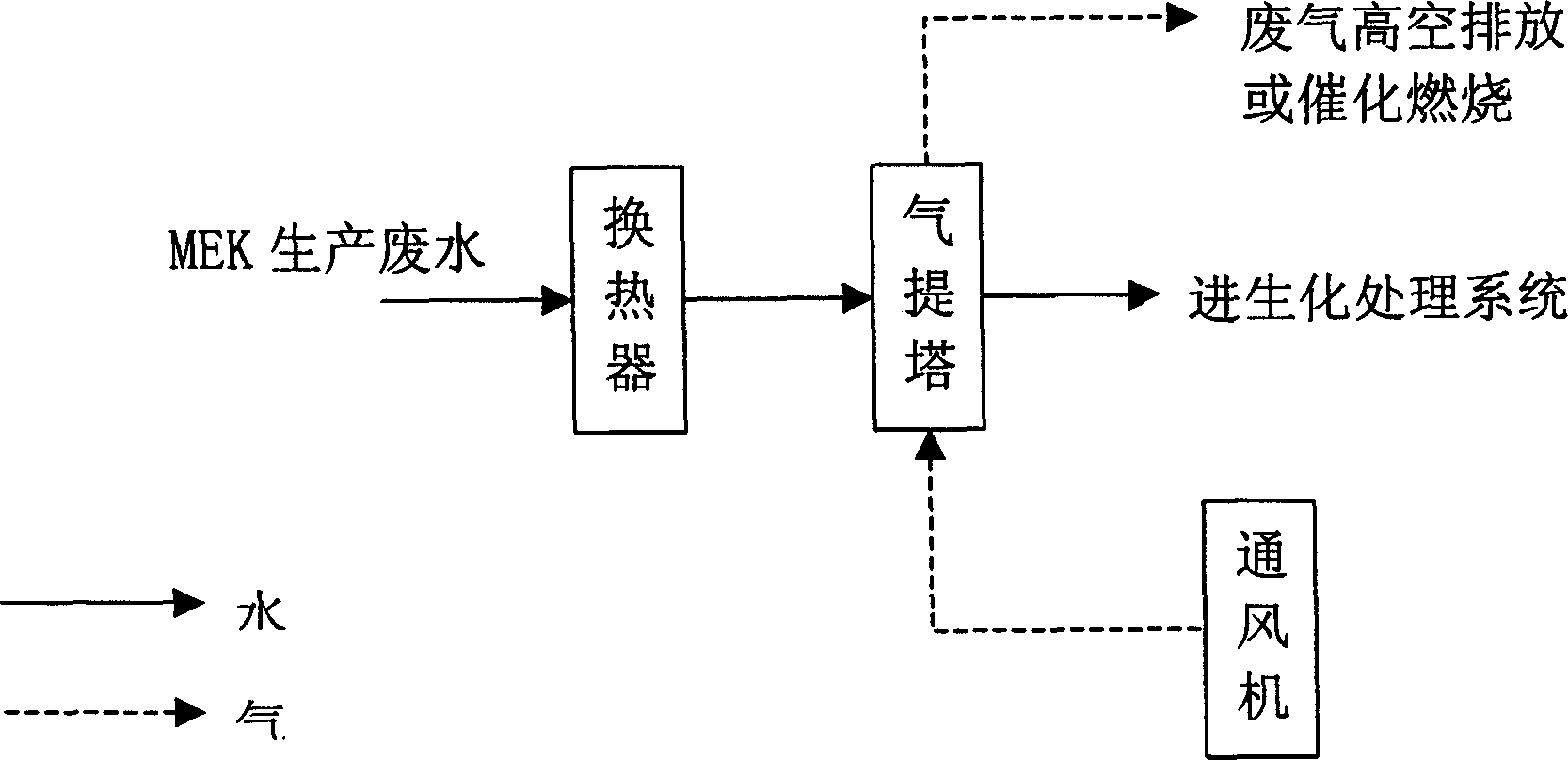

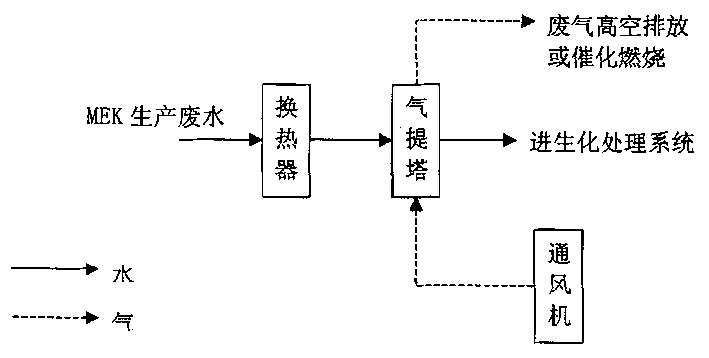

Waste water treating method for methyl ethyl ketone production

InactiveCN1490253AEasy to handleImprove processing efficiencyWater/sewage treatmentMultistage water/sewage treatmentPretreatment methodBiochemical engineering

A process for treating the sewage discharged in production of paramethadione includes such steps as heating it to a certain temp, pumping it in stripping tower containing filler, counter-current stripping, biochemical treating, and exhausting the waste gas to high space or catalytic burning it. Its advantages are high effect and high biochemical treating efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-water-resistance ultraviolet-curing wood paint

InactiveCN104629614AFast curingImprove water resistanceAntifouling/underwater paintsPaints with biocidesPhosphinePeroxide

The invention discloses a high-water-resistance ultraviolet-curing wood paint which is prepared from polyurethane acrylate, epoxy resin modified acrylate, epoxy soybean oil acrylate, fluorinated acrylate, modified nano titanium dioxide, water, 1,6-hexanediol diacrylate, trimethylolpropane triacrylate, 2-hydroxyethyl acrylate, methylethyl ketone peroxide, phosphine 2,4,6-trimethylphenylformacyldiphenyl oxide, ethylene glycol, ethyl acetate, glycol ether, triethanolamine, thickener, a defoaming agent, a wax emulsion, a leveling agent, an epoxy curing agent and a dispersing agent. The high-water-resistance ultraviolet-curing wood paint has the advantages of high curing speed, favorable water resistance, favorable weather resistance and long service life.

Owner:安徽嘉年华漆业有限公司

Geopolymer grouting material

ActiveCN106699037AThere is stable and adjustable performanceLow costCement productionAlkaneALUMINUM STEARATES

A geopolymer grouting material is prepared from, by weight, 20-40 parts of stone flour, 30-45 parts of fly ash, 10-25 parts of silicon micro-powder, 25-35 parts of mineral slag powder, 5-10 parts of an alkali exciting agent, 5-10 parts of sodium hydroxide, 0.5-1 part of sugar calcium, 3-5 parts of re-dispersible latex powder, 1-3 parts of a polycarboxylic water reducer, 1-3 parts of sodium alkane sulfonate, 1-3 parts of aluminum stearate, 10-15 parts of phenolic resin, 0.5-1 part of N,N-dimethylaniline, 0.5-1 part of methylethyl ketone peroxide, 0.5-1 part of sodium polyacrylate, 0.5-1 part of triethanolamine and 0.5-1 part of citric acid. The 1d strength of the prepared grouting material is not less than 20.0 MPa, the flowability is not more than 20 s, the initial setting time is not less than 25 min, and the final setting time is not more than 60 min. The grouting material is widely suitable for rapid repairing of roads, underside grouting of cement concrete pavement soft base processing, bridge reinforcing and crack repairing, deep curtain grouting, lower margin bolt anchoring and other engineering positions. Compared with traditional cement-based grouting materials, the grouting material disclosed in the invention has the advantages of low cost, good corrosion resistance, good heatproof stability, good erosion resistance and good durability.

Owner:CHENGDU JIAXIN TECH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com