Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123 results about "Aminoethylpiperazine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aminoethylpiperazine is a derivative of piperazine. This ethyleneamine contains three nitrogen atoms; one primary, one secondary and one tertiary. It is a corrosive liquid and can cause second or third degree burns. Aminoethylpiperazine can also cause pulmonary edema as a result of inhalation. Uses include inhibition of corrosion, epoxy curing, surface activation, and as an asphalt additive. When used as an epoxy resin curing agent, it is usually used in conjunction with other amines as an accelerator as it only has 3 amine hydrogens for cross-linking.

Wear-resistant epoxy glue and preparation method thereof

InactiveCN102040933AIncrease elasticityImprove wear resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesGas phaseMicrosphere

The invention relates to wear-resistant epoxy glue and a preparation method thereof. The epoxy glue is prepared by mixing a component A and a component B based on a weight ratio of (100:11.1)-(100:13.3), wherein the component A comprises the following raw materials in parts by weight: 10-20 parts of liquid epoxy resin, 10-20 parts of bisphenol F epoxy resin with modified nano rubber particles, 2.5-5 parts of epoxy resin activity diluent, 0.5-1.0 part of coupling agent, 53-61 parts of aluminum oxide ceramic microsphere, 4-6 parts of white alundum powder, 3-5 parts of glass fiber powder, 0.5-1.2 parts of chopped nylon fiber and 1-2 parts of gas-phase silicon dioxide; and the component B comprises the following raw materials in percentage by weight: 55-65 parts of polyamide, 12-18 parts of isophorone diamine, 4-7.5 parts of AEPHP (N-Aminoethylpiperazine), 1-2 parts of solidification accelerating agent, 8-10 parts of kaolin, 3-6 parts of glass fiber powder and 3-5 parts of gas-phase silicon dioxide. The preparation method comprises the following steps: preparing the bisphenol F epoxy resin with modified nano rubber particles; respectively preparing the component A and the component B;and mixing the component A and the component B in proportion when the epoxy glue is used.

Owner:YANTAI DARBOND TECH

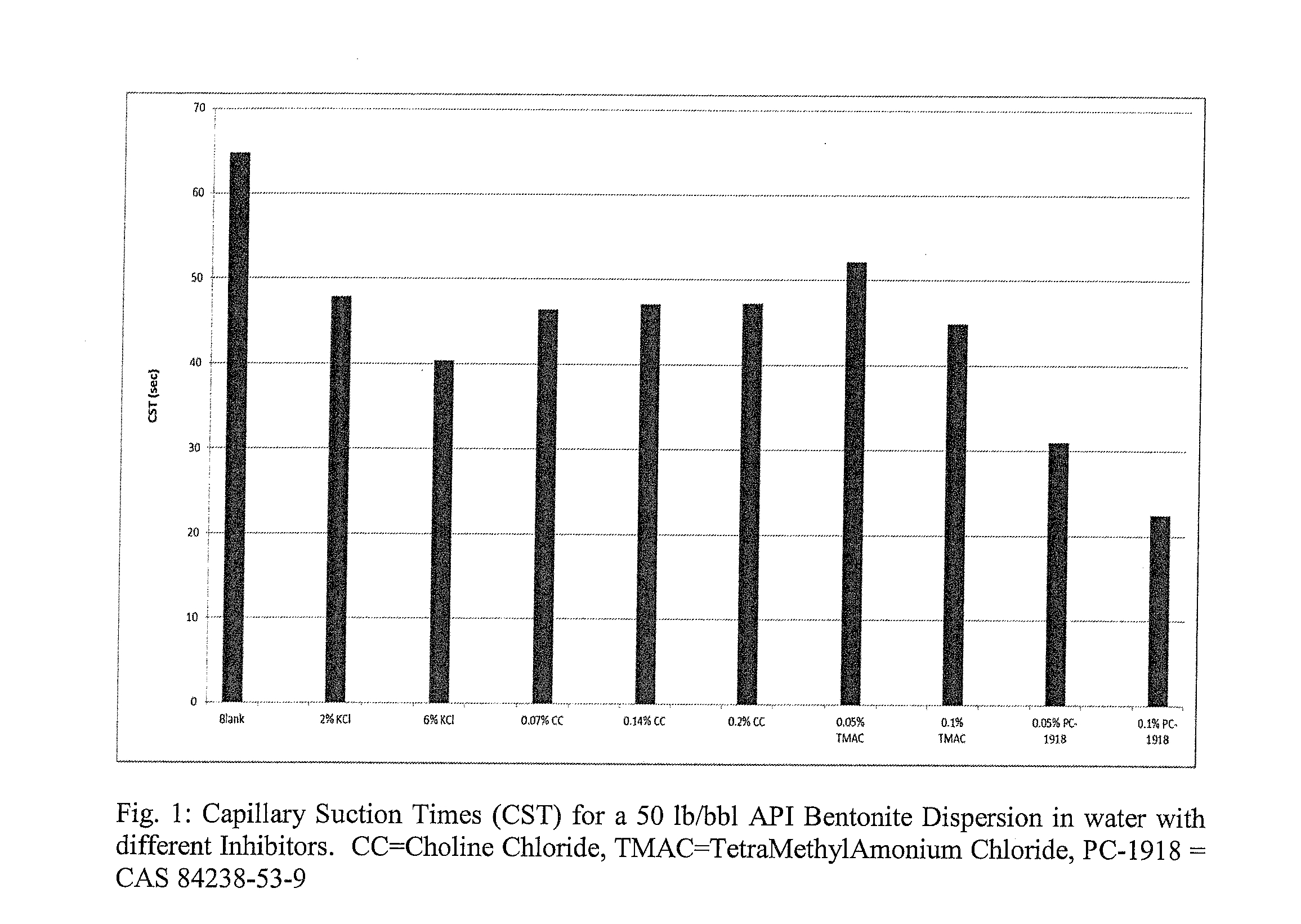

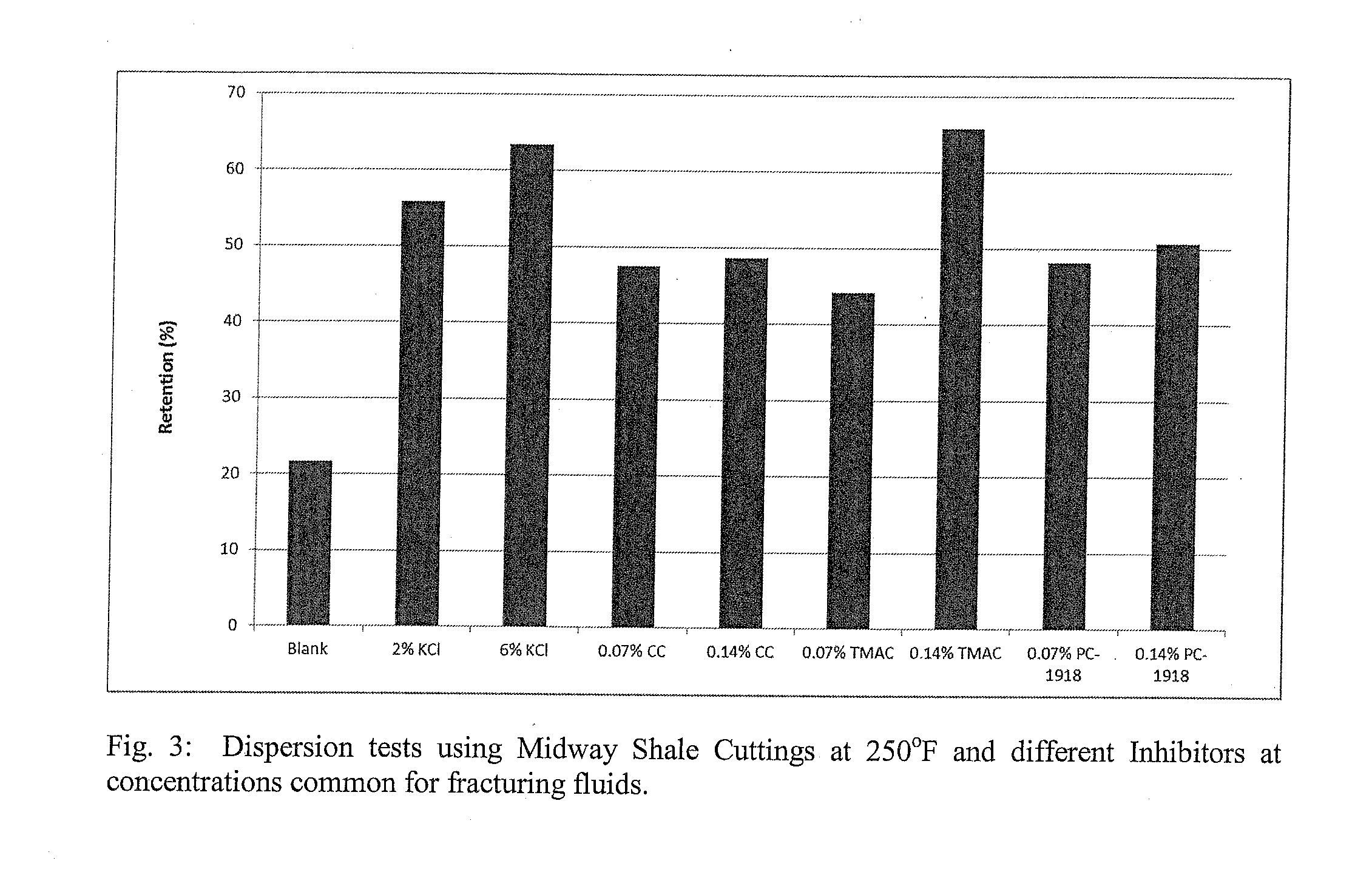

Amine-based shale inhibitor and methods for drilling, fracturing, and well treatment

InactiveUS20160208158A1Low toxicityLow costFluid removalDrilling compositionWater basedWell drilling

A composition including triethylenetetramine and aminoethylpiperazine is used as a clay inhibitor in water-based drilling fluids and in hydraulic fracturing fluids for drilling wells and for fracturing subterranean formations, and is also used as a clay inhibitor in other treatment fluids for treating wells or subterranean formations.

Owner:INGEVITY SOUTH CAROLINA

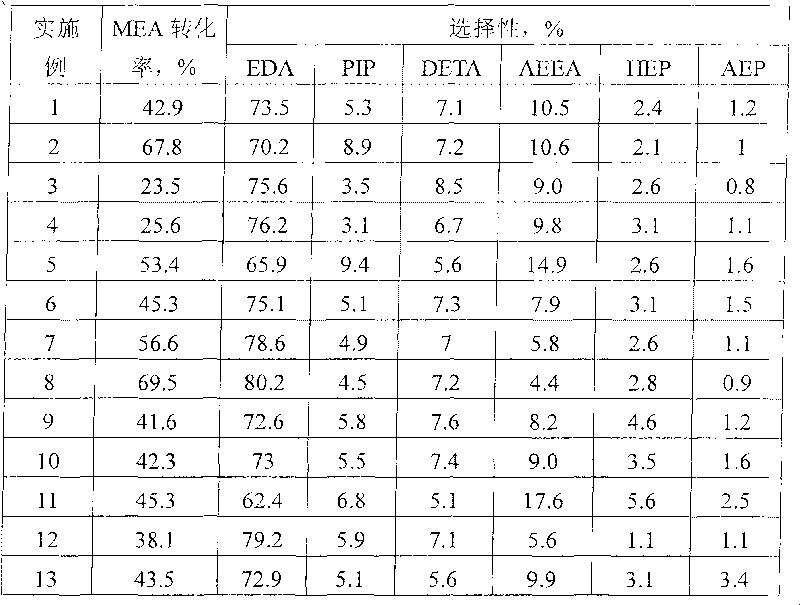

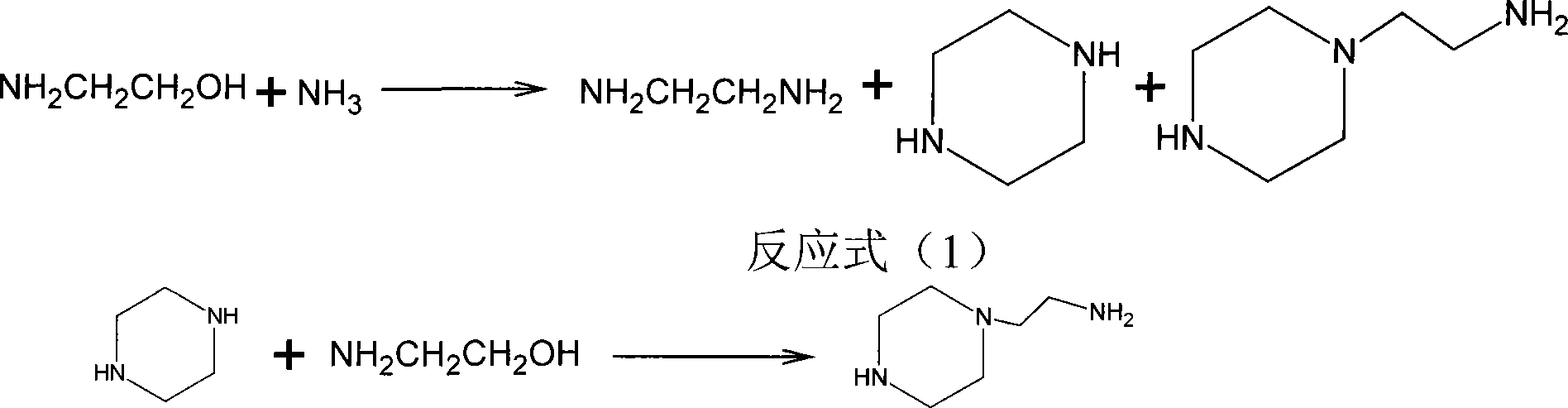

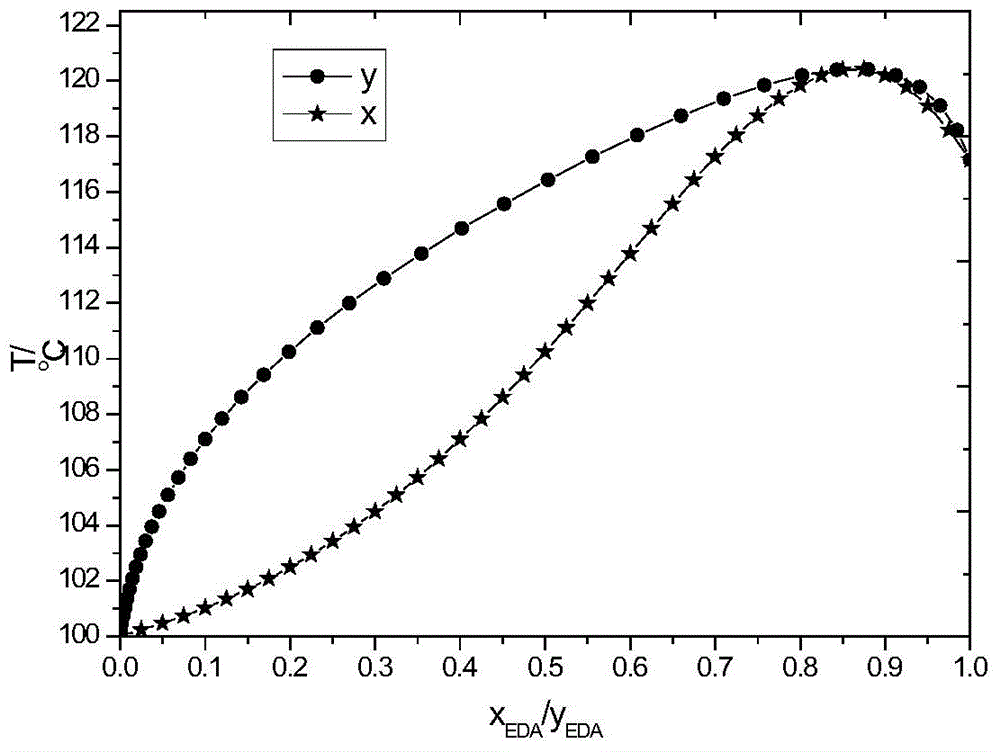

Method for preparing ethylene diamine from ethanolamine and ammonia serving as raw materials under hydrogen condition

InactiveCN101704753ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationAmino compound preparationEthylenediamineReaction temperature

The invention discloses a method for preparing ethylene diamine from ethanolamine and ammonia serving as raw materials under a hydrogen condition. A reaction system consists of the ethanolamine, the ammonia, hydrogen and a catalyst, wherein the reaction temperature is 100 to 190 DEG C, the reaction pressure is 6.0 to 25.0MPa, the molar ratio of the ammonia to the ethanolamine is 1-20 and the molar ratio of the H2 to the ethanolamine is 0.008-0.05, and the air speed of the ethanolamine liquid is 0.1 to 1.5h-1; the catalyst takes Al2O3 or SiO2 as a carrier and one or more of Ru, Ni, Pd, B, Fe, Co, Re and Cu as carried active components; and the ethanolamine and the liquid ammonia can be transformed into the ethylene diamine (EDA) in high activity and high selectivity, along with by products such as diethylenetriamine (DETA), a piperazine (PIP), an aminoethylpipe (AEP), a hydroxyethylpiperazine (HEP), a hydroxyethyl ethylene diamine (AEEA) and the like under the hydrogen condition and the action of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

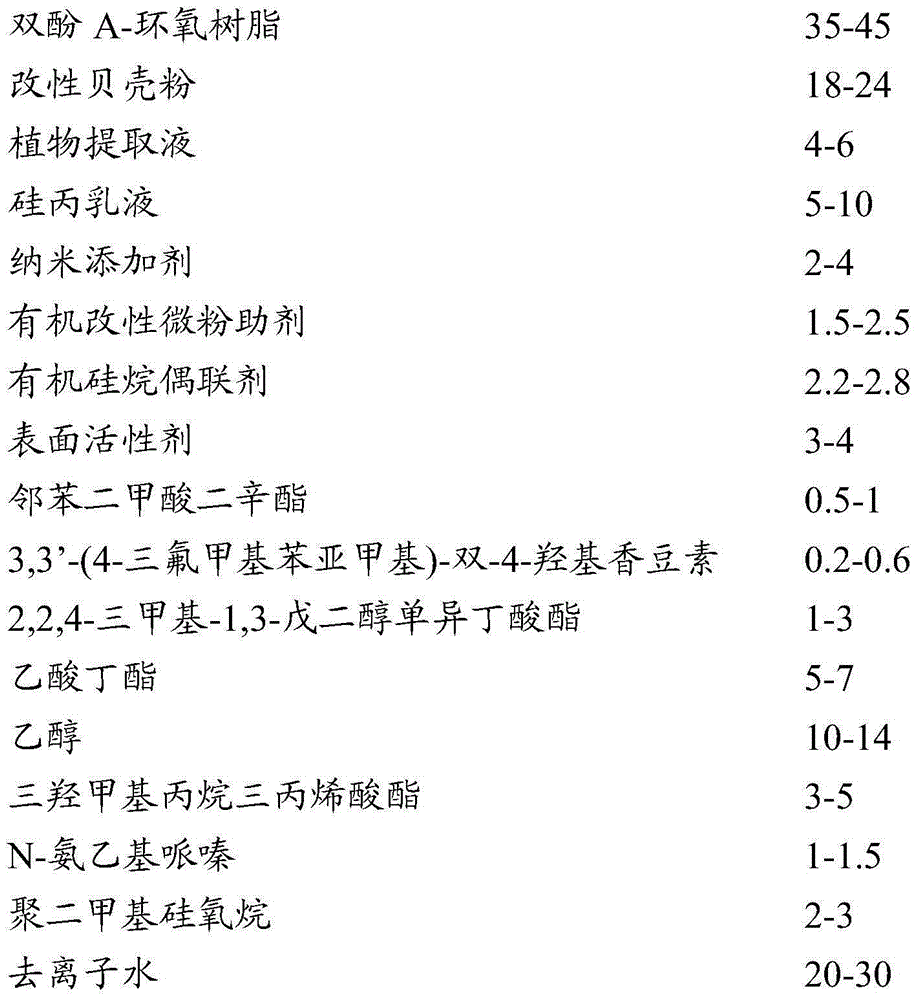

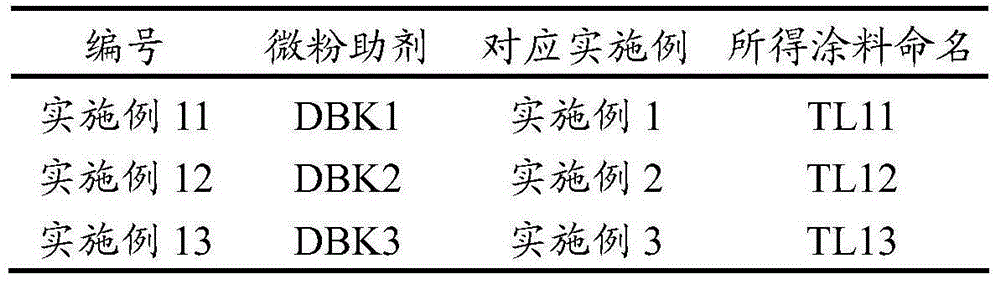

Environmentally friendly shell powder functional coating and preparation method therefor and uses thereof

ActiveCN104987808AImprove performancePractical application value is greatEpoxy resin coatingsDimethyl siloxaneIsoprene

The present invention relates to an environmentally friendly shell powder functional coating, a preparation method therefor and uses thereof. The coating comprises: bisphenol A-epon, modified shell powder, vegetable extract, propyl silicone emulsion, a nano additive, a modified organic micro powder agent, a surfactant, dioctylphthalate, 3, 3'-(4-trifluoromethyl methyl)-bi-4-hydroxy coumarin, 2,2,4-amino trimethyl-1,3-isoprene glycol mono iso-butyl methacrylate, butyl acetate, ethanol, trimethylol propane triacrylate, N-ammonia amino ethyl piperazine, polydimethylsiloxane and deionized water. In the present invention, by modification of a variety of components and materials, selection and collocation of specific components and a specific preparation method, the variety of components exert a synergistic effect, so as to make the prepared coating have significant antimicrobial, environmental-cleaning and wear-resisting properties. The coating has a huge application potential and extensive value in industrial production.

Owner:广西世家丽环保投资有限公司

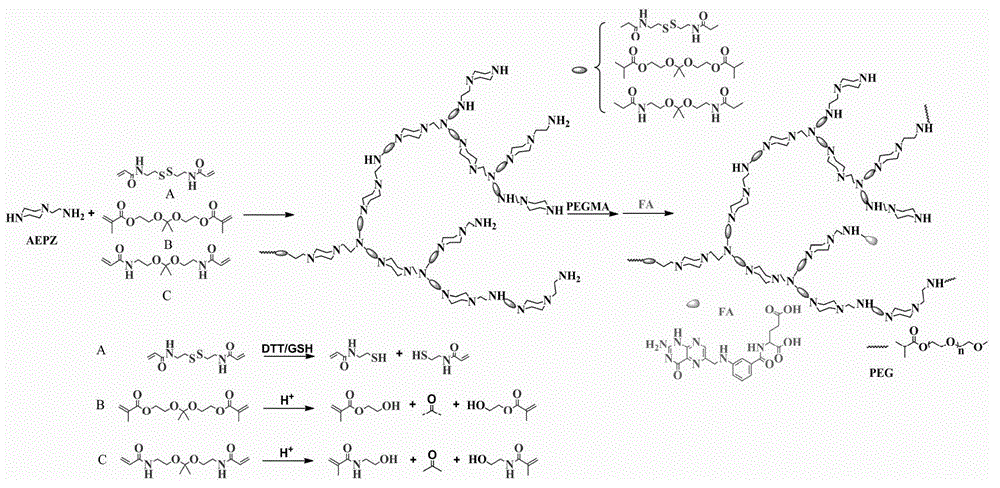

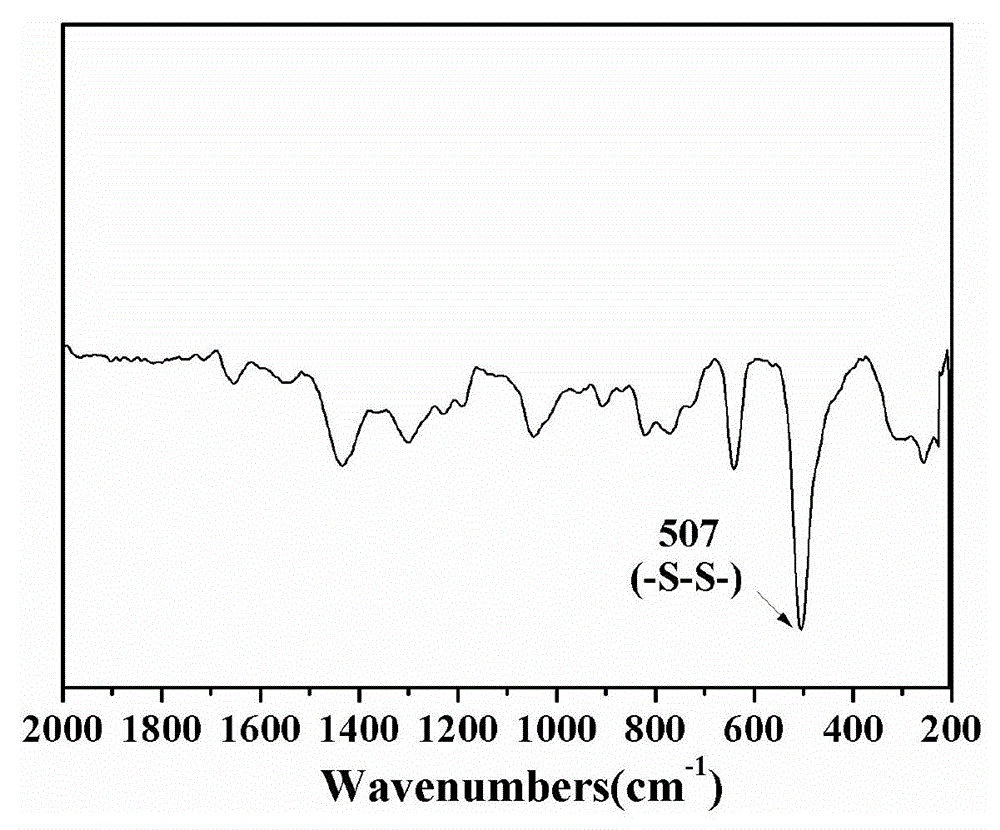

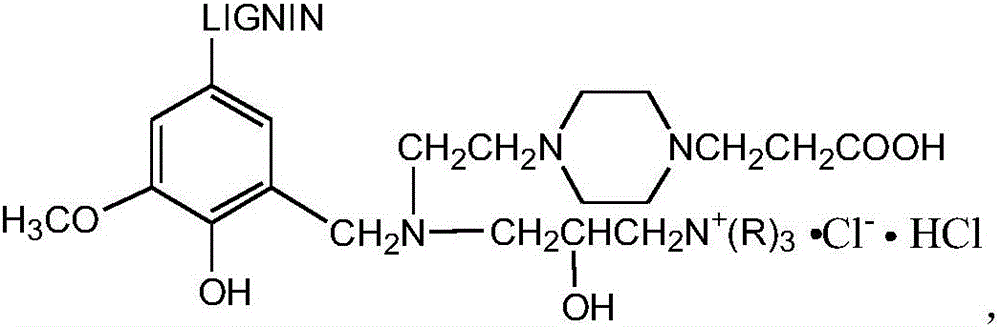

Preparation method and application of degradable hyperbranched polyamidoamine

ActiveCN104004196AWith environmentDegradableGenetic material ingredientsPharmaceutical non-active ingredientsSolubilityPolymer science

The invention discloses a preparation method and application of degradable hyperbranched polyamidoamine. Degradable hyperbranched polyamidoamine is prepared by taking a bifunctional monomer containing a disulfide bond or a ketal bond and an amino-containing trifunctional monomer N-aminoethylpiperazine (AEPZ) or diethylenetriamine (DETA) as main raw materials and employing a one-pot method to perform Michael addition polymerization reaction. By coupling polyethylene glycol (PEG) and folic acid (FA) with degradable hyperbranched polyamidoamine, folic-acid-targeted PEGylated degradable hyperbranched polyamidoamine is obtained. The raw materials are easily available, the preparation method is simple, and the prepared polymer medicine carrier has the advantages of hyperbranched polyamidoamine, such as three-dimension branching structure, a lot of cavities at the interior of molecules, low viscosity, a lot of functional groups, simple preparation method, biodegradability, and the like. Additionally, the water solubility and the stability of the carrier material are improved by grafting a PEG chain segment to the terminal, and the carrier is endowed with active targeting property on tumor cells through coupling of FA.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

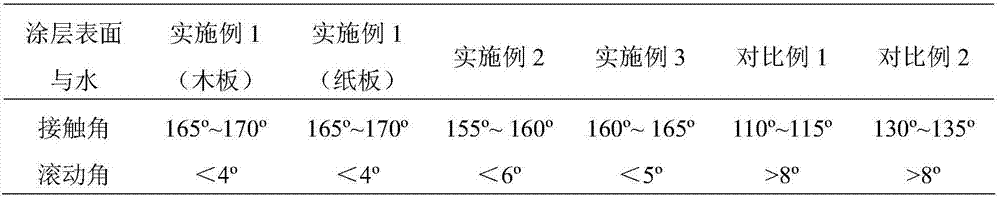

Super-hydrophobic oleophobic coating, preparation method thereof and use method

ActiveCN106905816AImprove wear resistanceGood resistance to water impactAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention discloses a super-hydrophobic oleophobic fluorocarbon coating which comprises a component A and a component B. The component A comprises epoxy resin, graphite fluoride, ammonium carbonate, polyoxyethylene ether and an organic solvent a, and the mass ratio of the epoxy resin, the graphite fluoride, the ammonium carbonate to the polyoxyethylene ether is 1:(0.5-3):(0.25-0.5):(0.25-0.5). The component B comprises a curing agent and an organic solvent b, wherein the curing agent is aminoethyl piperazine, and the mass ratio of the epoxy resin to the curing agent is 10:(2-4). The invention further discloses a preparation method and a use method of the super-hydrophobic oleophobic fluorocarbon coating. The super-hydrophobic oleophobic fluorocarbon coating has excellent super-hydrophobic oleophobic performances, good wear resistance, water flow impact resistance, corrosion resistance and adhesion performance and can be widely used.

Owner:EAST CHINA UNIV OF SCI & TECH

Modified polyether amine epoxy curing agent and preparation method thereof

The invention discloses a modified polyether amine epoxy curing agent. The modified polyether amine epoxy curing agent comprises the following raw materials in parts by weight: 45-60 parts of amine-terminated polyether (D-230), 2-5 parts of N-aminoethylpiperazine (N-AEP), 4-10 parts of benzyl alcohol, 3-8 parts of an accelerant (DMP (Dimethyl Phthalate)-30), 20-30 parts of nonyl phenol or tert-butyl phenol and 6-10 parts of epoxy resin (E-51). The modified polyether amine epoxy curing agent is scientific and reasonable in raw material component ratio; the modified polyether amine epoxy curing agent is low in viscosity, high in hardness and good in glossiness; the adhesive force, the solvent property, the low-temperature resistance and high wet resistance can be remarkably improved; the temperature and time of reaction in the preparation process can be effectively controlled; the cost is lowered; therefore, the modified polyether amine epoxy curing agent has a broad market application prospect.

Owner:宋良俊

Metal wear resistant repairing composite coating material and preparation method of metal wear resistant repairing composite coating material

InactiveCN102585746ASimple preparation conditionsGood dispersionNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyWear resistant

The invention discloses a metal wear resistant repairing composite coating material and a preparation method of the metal wear resistant repairing composite coating material, wherein the metal wear resistant repairing composite coating material comprises a main agent which is prepared by mixing a silane coupling agent, epoxy resin, diisoamyl naphthalene, silicon carbide particles, aluminium oxide powder and fumed silica, and a curing agent which is prepared by mixing a silane coupling agent, triethylenetetramine, N-aminoethyl piperazine, aluminium oxide powder and fumed silica. A two-component room temperature curing composite coating with good anti-corrosion performance and abrasive resistance is prepared by optimizing the performance of epoxy coating inorganic powder filled and modified with inorganic powder, the prepared wear-resistant coating has good bonding effect to the metal, the cured coating has excellent abrasive resistance and can be applied for building and repairing the inner layer of a liquid slurry delivery pump, and an anti-corrosion wear-resistant coating of blades, and building an anti-corrosion wear-resistant coating of the inner surface of a gas transmission pipeline, a powder transmission pipeline and a liquid transmission pipeline.

Owner:依工聚合工业(吴江)有限公司

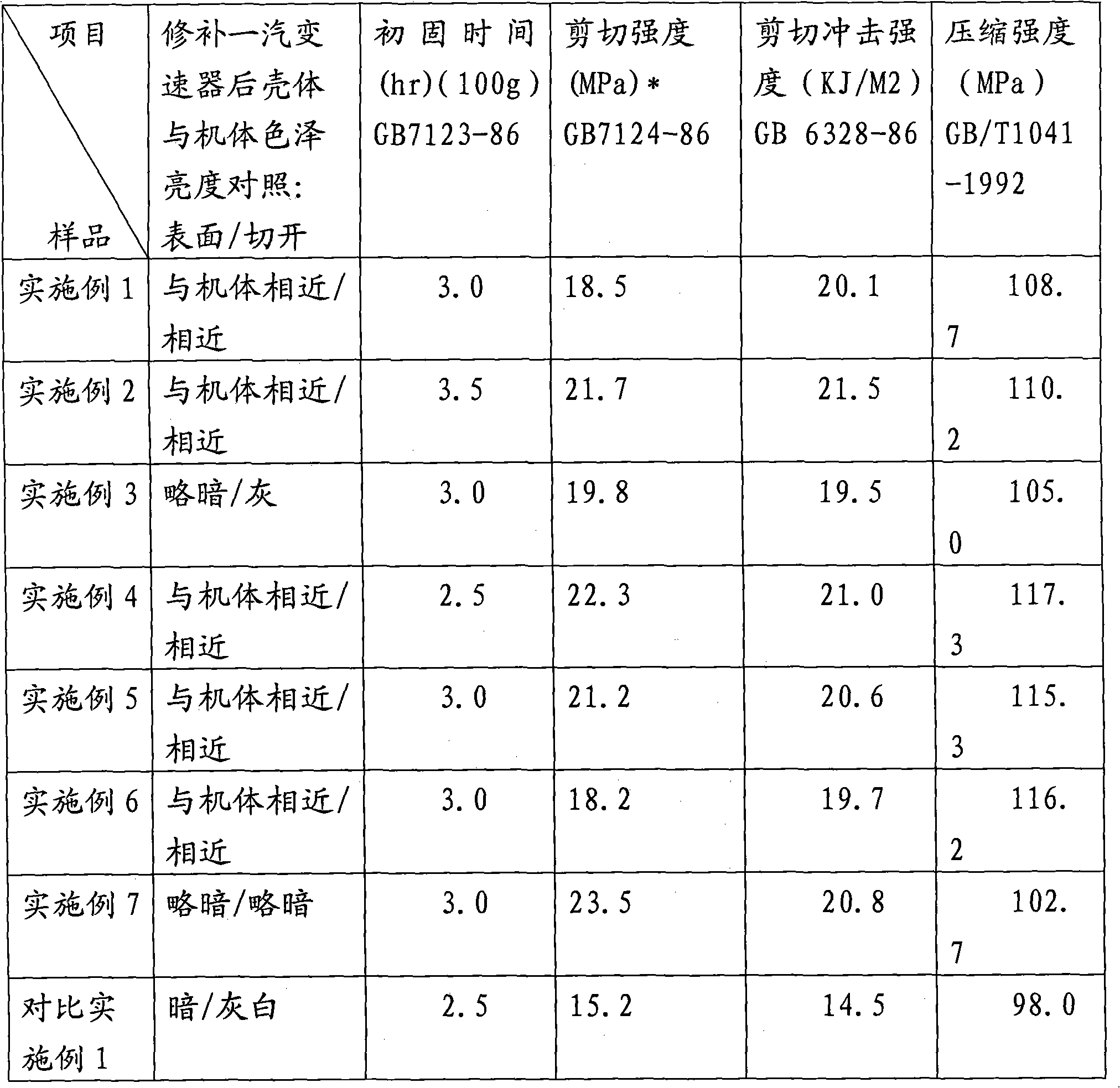

High-brightness impact-resistant aluminum epoxy repair adhesive and preparation method thereof

InactiveCN101974303AGood thixotropyGood construction performanceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesDiamineCarbon black

The invention relates to high-brightness impact-resistant aluminum epoxy repair adhesive and a preparation method thereof. The epoxy repair adhesive is composed of component A and component B based in the weight ratio of 100:12.5-16.6 (i.e. 8:1-6:1), wherein the component A is composed of the following raw materials in weight ratio: 16-30 parts of bisphenol A epoxy resin, 15-25 parts of superfine full-vulcanized carboxylic nitrile butadiene rubber particle modified bisphenol A epoxy resin, 2.5-5 parts of an epoxy resin reactive diluent, 0.6-1.2 parts of a coupling agent, 28-32 parts of spherical metallic aluminum powder, 7-12 parts of spherical-like alumina powder, 5-10 parts of aluminum powder and 3-5 parts of white carbon black; and the component B is composed of the following raw materials in weight ratio: 6-10 parts of aminoethyl piperazine, 10-15 parts of isophorone diamine, 30-40 parts of modified aromatic amine, 25-35 parts of polyether amine, 9-15 parts of spherical-like alumina powder and 3-6 parts of white carbon black. The preparation method comprises the steps of preparation of the component A and the component B; and the component A and the component B are mixed according to the ratio when in use.

Owner:YANTAI DARBOND TECH

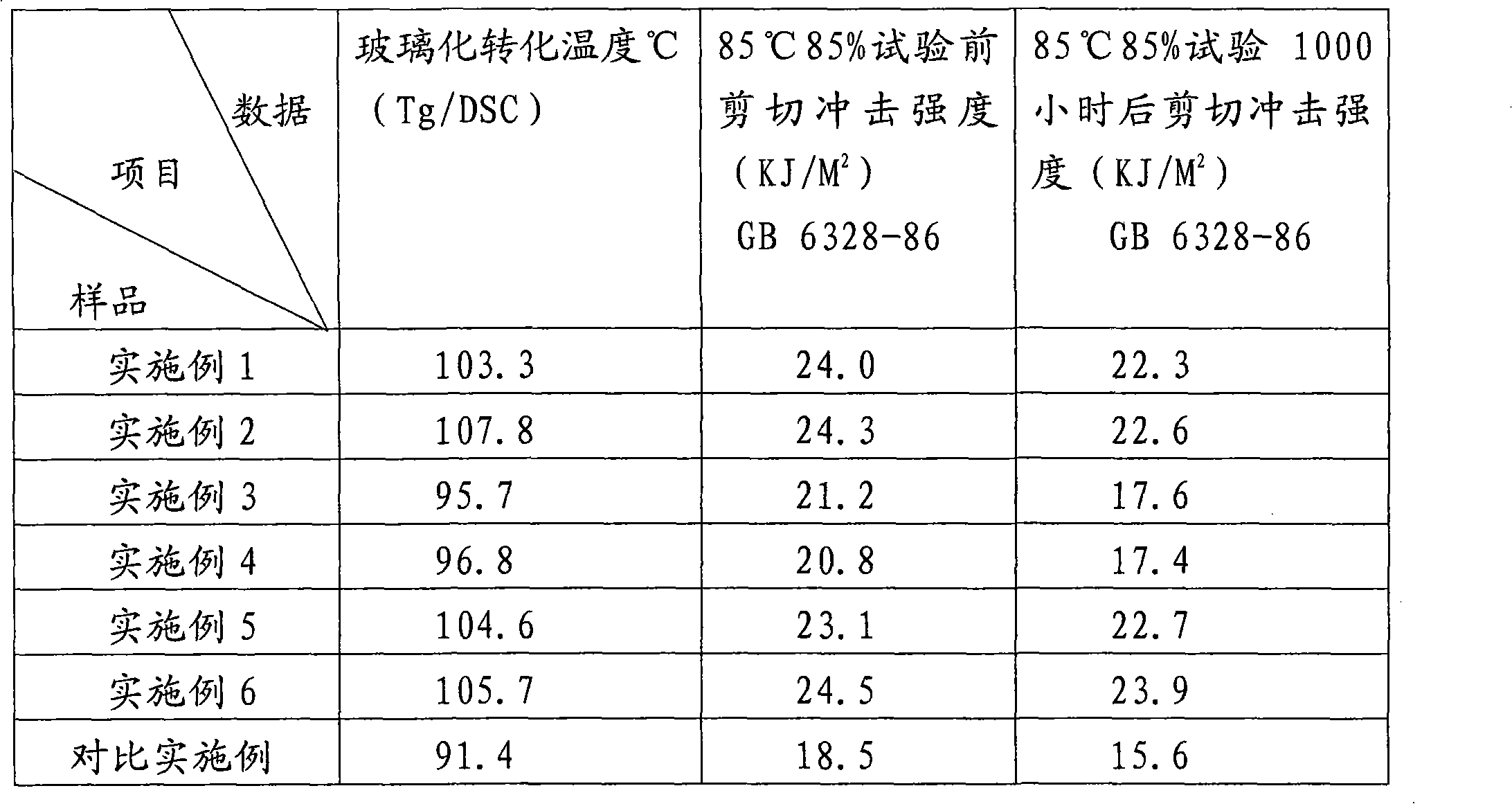

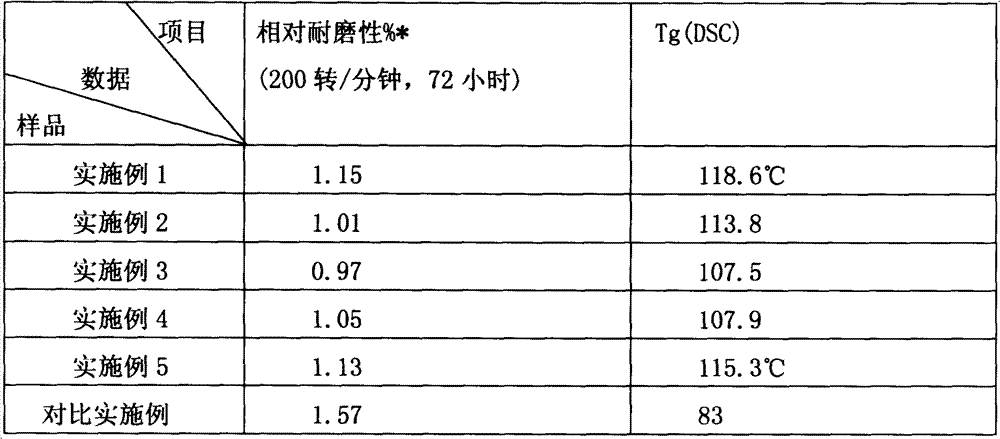

Wear-resistant and weather-resistant epoxy resin coating adhesive and its preparation method

ActiveCN102732201ANotable featuresSignificant and substantial progressNon-macromolecular adhesive additivesEpoxynovolac adhesivesWear resistantAdhesive

The invention which relates to a wear-resistant and weather-resistant epoxy resin coating adhesive and its preparation method belongs to the technical field of adhesives. The adhesive comprises a component A and a component B, wherein the component A comprises 6-16 parts of an alicyclic glycidyl ether epoxy resin, 15-25 parts of a novolac epoxy resin, 4-6 parts of an epoxy active diluent, 4-6 parts of a responsive flexibilizer, 0.5-1.2 parts of a coupling agent, 0.4-0.8 parts of organic bentonite, 0.3-0.5 parts of an antioxidant, 0.4-0.8 parts of an ultraviolet ray absorbent, 40-45 parts of white corundum powder, 3-5 parts of filler powder, 4-6 parts of a short glass fiber, 5 parts of a yellow color paste, and 1-2 parts of white carbon black; and the component B comprises 15-25 parts of an alicyclic amine, 10-15 parts of isophorone diamine, 6-9 parts of aminoethylpiperazine, 2-3 parts of a curing accelerator, 40-45 parts of the white corundum powder, 4-6 parts of the short glass fiber, 4-6 parts of the filler powder and 3-5 parts of the white carbon black. The preparation method comprises the steps of yellow color paste preparation, component A preparation and component B preparation. Compared with adhesives obtained through the prior art, the mechanical strength and the wear resistance of the adhesive of the invention are obviously improved.

Owner:YANTAI TIGHTSEN FINE CHEM

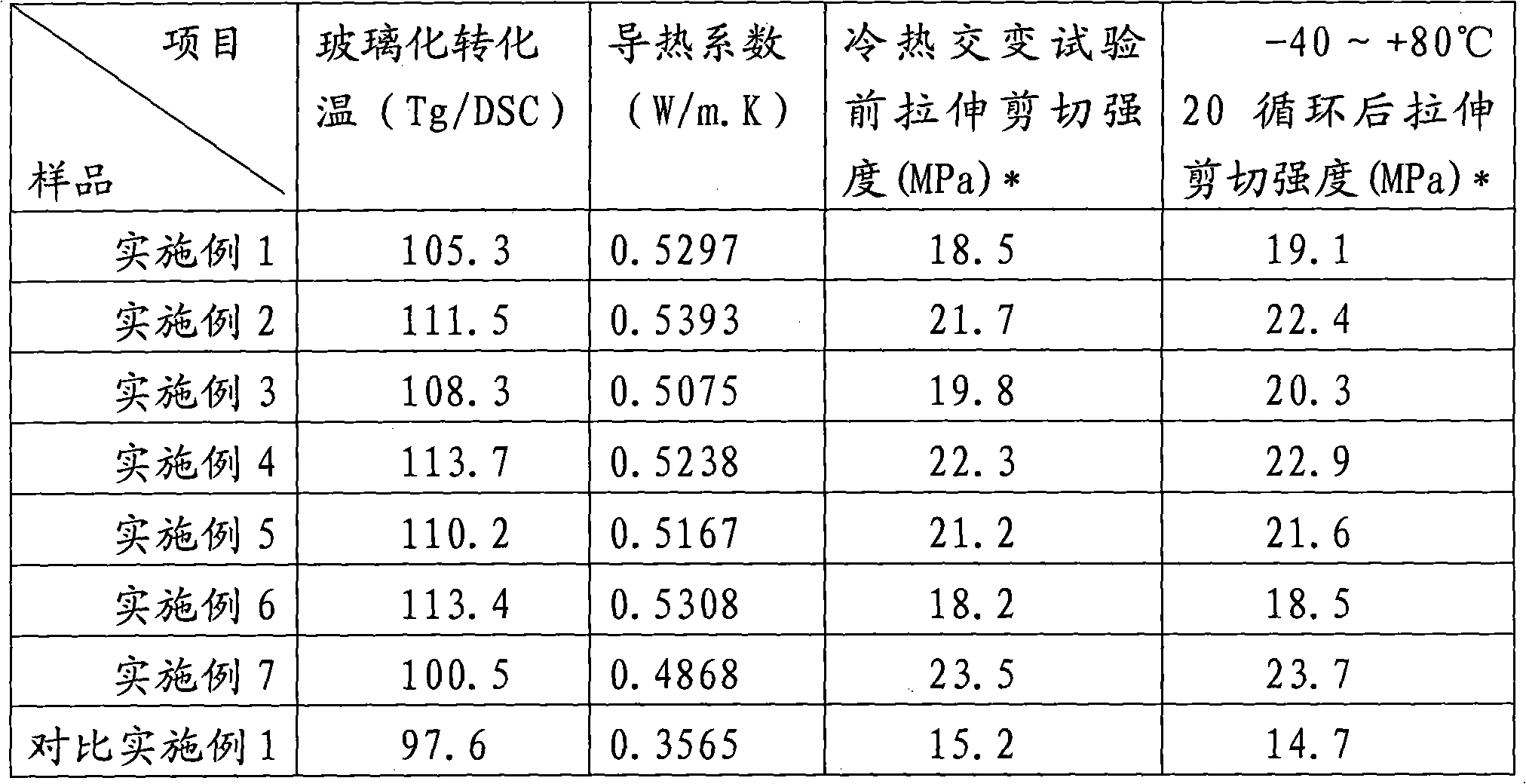

Heat-conducting electronic packaging composite and preparation method thereof

ActiveCN105754297AImprove thermal stabilityImprove thermal conductivityLithium chlorideHeat conducting

The invention provides a heat-conducting electronic packaging composite and a preparation method thereof. The preparation method comprises the following steps: mixing nano-alumina, nano-silica, a silane coupling agent KH-551, a gamma-aminopropyltriethoxysilane and water at first, and stirring; drying after filtering; mixing with N-methyl pyrrolidone, pyridine and triphenyl phosphate for reaction; adding lithium chloride and methyl alcohol for further reaction; filtering, flushing with N-dimethyl formamide and drying; re-adding acetone for ultrasonic dispersion; mixing bisphenol A epoxy resin, Neodymium(III) 2,4-pentanedionate and water, heating, and stirring for dissolution; mixing the two mixtures, and stirring while performing ultrasonic treatment; performing water bathing, adding 3,5-diaminobenzoic acid, N-aminoethylpiperazine and trimethyl hexamethylene diamine, stirring, and then conducting vacuum degassing; finally, pouring the mixture into a die for curing to obtain the heat-conducting electronic packaging composite. The heat-conducting electronic packaging composite has excellent heat stability, and meanwhile, has very good heat conductivity and a good heat dissipation effect.

Owner:深圳市锦昊辉实业发展有限公司

Synthesis method of triethylene diamine from piperazine by product

A process for synthesizing the trivinyldiamine from the by-product of piperazine, which is the mixture of N-beta-hydroxyethyl piperazine, N-beta-hydroxyethyl ethanediamine, N-beta-aminoethyl piperazine, and pinerazine, includes primary catalytic reaction, hydroxyethylating reaction, and secondary catalytic reaction. Its advantages are long service life of catalyst, high output rate, and high purity.

Owner:TIANJIN UNIV

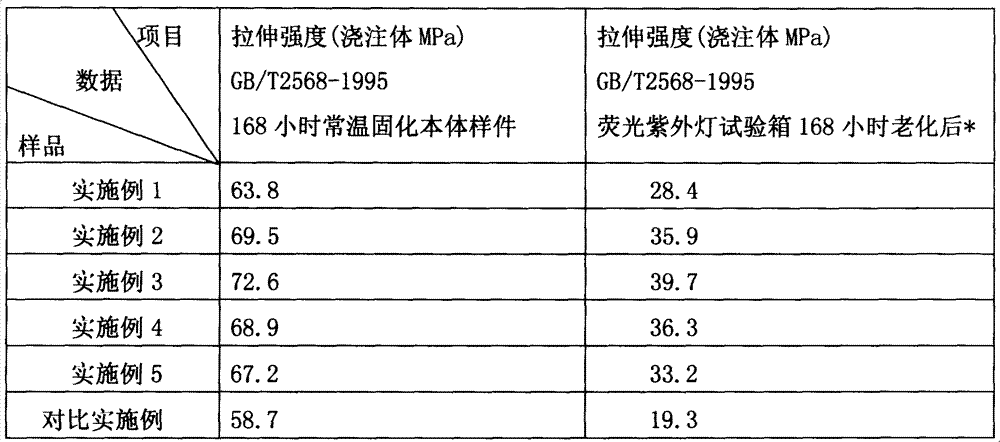

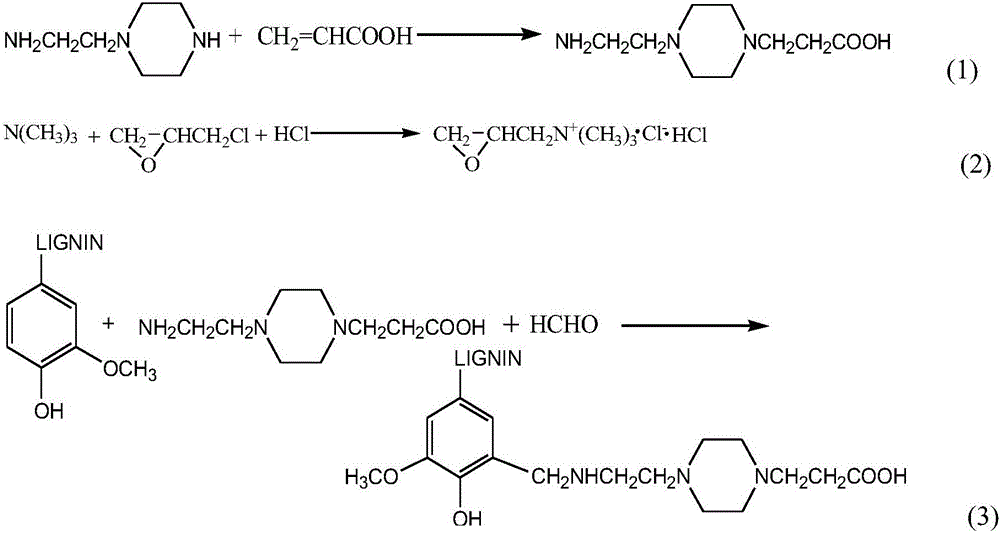

Lignin cyclamine cationic-type asphalt emulsifier and preparation method thereof

InactiveCN106084250AGood emulsifying effectImprove hydrophilicityBuilding insulationsCarbon numberEpoxy

The invention discloses a lignin cyclamine cationic-type asphalt emulsifier and a preparation method and application thereof. The molecular structure general formula of the emulsifier is as shown in the description, wherein R is a methyl group (-CH3) or an ethyl group (-C2H5) or a hydroxyethyl group (-C2H4OH), and LIGNIN represents a lignin molecular chain. The lignin cyclamine cationic-type asphalt emulsifier is prepared from, by mass, 100 parts of lignin, 159-230 parts of water, 19-27 parts of sodium hydroxide, 42-50 parts of N-aminoethylpiperazine, 23-29 parts of acrylic acid, 30-36 parts of formaldehyde (37%), 35-82 parts of tertiary amine with a low carbon number, 42-50 parts of industrial hydrochloric acid (30%) and 31-37 parts of epoxy chloropropane. According to the lignin cyclamine cationic-type asphalt emulsifier, the synthesis raw materials are easy to obtain, the production cost is low, the technology is simple, and high-temperature reacting is not needed; the emulsifier can emulsify different types of asphalt, the prepared emulsified asphalt is fine and uniform, the storage stability is good, and rapid-cracking cationic-type emulsified asphalt can be prepared.

Owner:SHANDONG UNIV

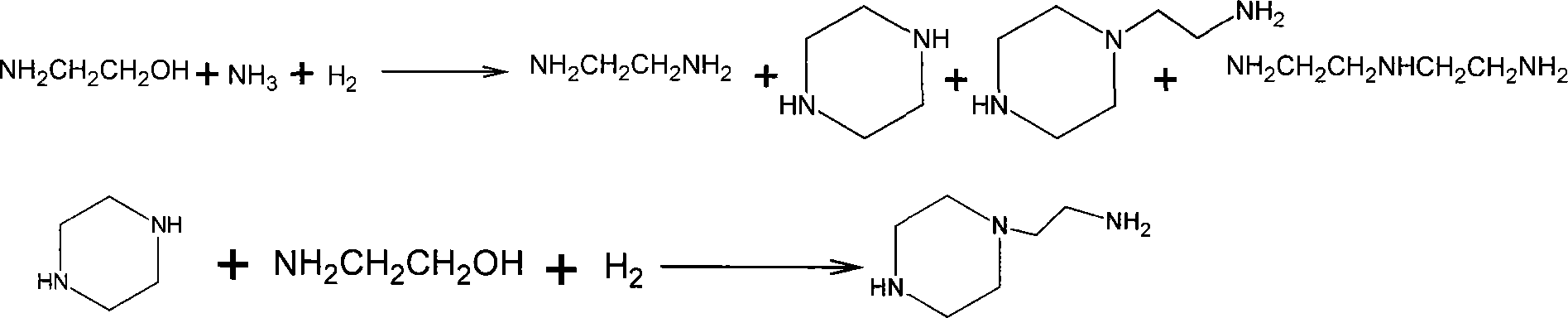

Combined preparation method for ethylene diamine and aminoethylpiperazine

InactiveCN101215239BHigh yieldMolecular sieve catalystsAmino compound preparation by condensation/addition reactionsEthylenediamineContact time

The invention discloses a combined preparation process of ethane diamine and aminoethyl piperazine, aiming to solve the problem low yield when prepared associated ethane diamine and aminoethyl piperazine. The invention comprises the steps as flowed that firstly mixing ethane diamine and ammonia to react under the conditions of the exist of mordenite of condensed amination catalyst phosphorous modification, 2.0MPa-5.0MPa pressure, 300-350 DEG C temperature, 6-12:1 of ammonia and aminoethyl alcohol weight ratio, 20-30 seconds of reaction contact time, distilling and separating product liquid toobtain aminoethyl alcohol product, secondly reacting piperazine which is obtained in first step and aminoethyl alcohol under the conditions of the exist of ZSM-5 zeolite of condensed amination catalyst silicon modification, 4.0MPa-8.0MPa pressure, 350-400 DEG C temperature, 0.5-1.5:1 of piperazine and aminoethyl alcohol weight ratio, and 10-20 seconds of reaction contact time, distilling and separating product liquid to obtain aminoethyl piperazine product. The invention is mainly combined to be used to prepare ethane diamine and aminoethyl piperazine.

Owner:山西玉龙化工有限公司

Polyester powder furniture coating and preparation method thereof

InactiveCN105969122AIncrease crosslink densityHigh tensile strengthPowdery paintsPolyester coatingsAluminatePolyester

The invention discloses a polyester powder furniture coating, which is composed of the following raw materials (by weight): 0.4-14 parts of lecithin, 0.1-0.2 part of 1,2-epoxy-4-vinylcyclohexane, 1-2 parts of polybenzimidazole, 0.7-1 part of triethanolamine oleate, 2-3 parts of diacetone alcohol, 10-12 parts of tung oil, 0.06-0.07 part of sodium hydroxide, 3-4 parts of methanol, 0.1-0.2 part of perfluorosulfonate resin, 6-8 parts of acetic acid, 10-15 parts of 26-30% hydrogen peroxide, 10-17 parts of tetraethyl orthosilicate, 0.1-0.2 parts of Y-chloropropyltrimethoxysilane, 70-80 parts of unsaturated polyester resin, 0.6-1 part of methylethyl ketone peroxide, 0.1-0.2 part of aminoethylpiperazine, 10-14 parts of calsite powder, 0.6-1 part of formamide, 2-4 parts of tetrabutyl titanate and 3-4 parts of calcium aluminate.

Owner:刘辉

Modified anti-crack concrete with excellent compressive and flexural strength

The invention discloses a modified anti-crack concrete with excellent compressive and flexural strength. The modified anti-crack concrete comprises, by weight, 100-120 parts of ordinary portland cement 42.5, 6-12 parts of epoxy resin, 4-8 parts of a styrene acrylic emulsion, 3-9 parts of a carboxylated styrene butadiene emulsion, 20-30 parts of modified polypropylene fibers, 4-9 parts of steel fibers, 2-8 parts of an acrylonitrile-butadiene-styrene copolymer, 0.5-1.5 parts of polydimethylsiloxane, 5-15 parts of aminoethylpiperazine, 2-5 parts of resorcinol, 1-3 parts of a silane coupling agent, 4-8 parts of fly ash, 60-80 parts of medium sands, 1-5 parts of expanded perlite, 2-6 parts of mineral slag, 1-4 parts of kaolin, 3-6 parts of silicon powder, 4-8 parts of emulsified asphalt, and 3-9 parts of an additive. The concrete has excellent compressive and flexural strength.

Owner:蚌埠市方阵商品混凝土有限公司

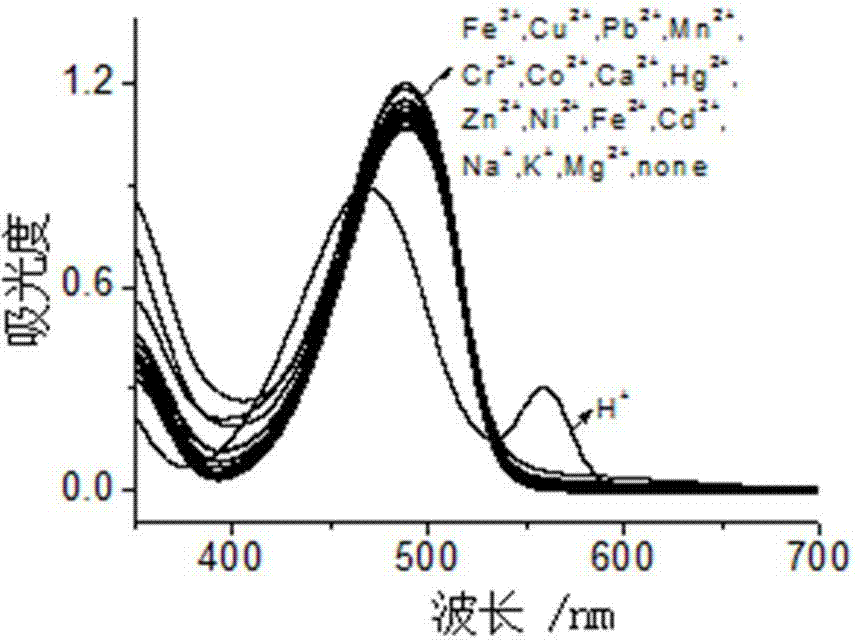

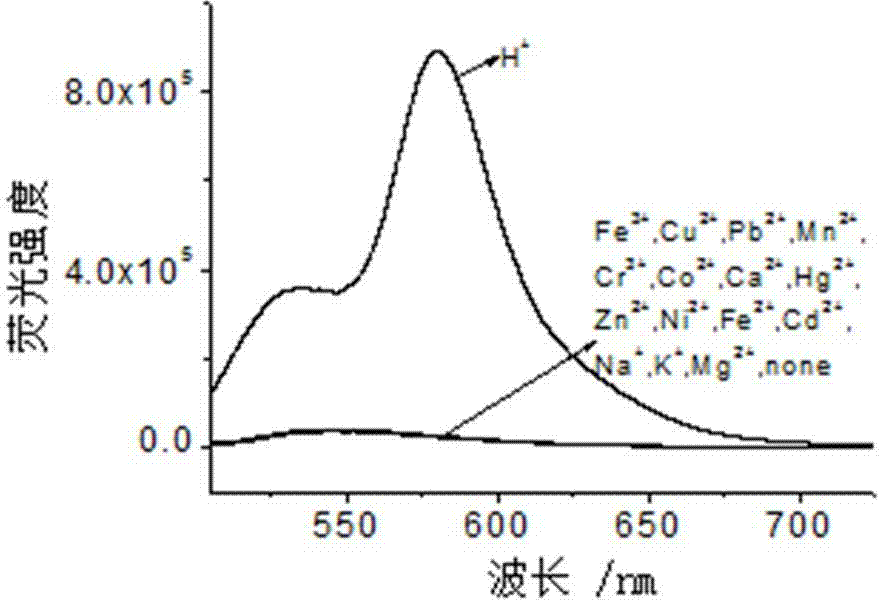

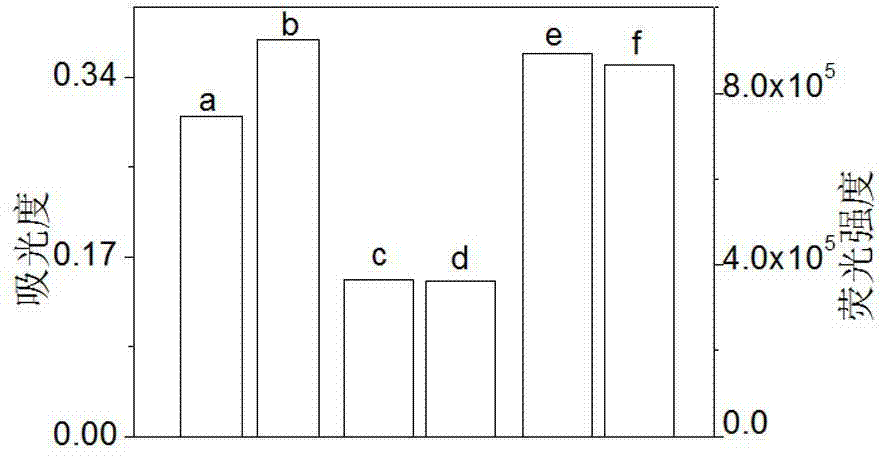

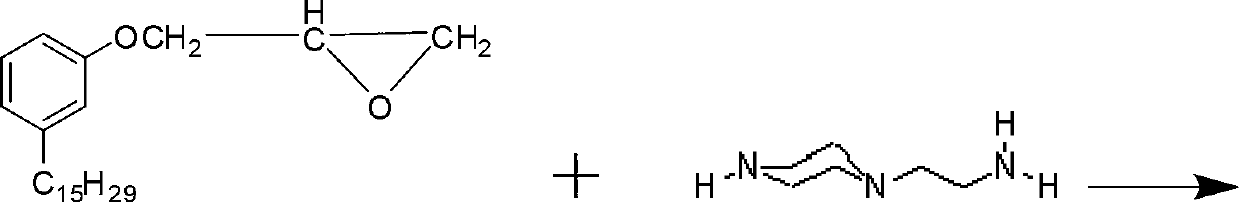

Rhodamine-oxadiazole derivative and preparation method and application thereof

InactiveCN103570736ARapid responseLess side effectsOrganic chemistryMaterial analysis by observing effect on chemical indicatorFluorophorePerylene derivatives

The invention discloses a rhodamine-oxadiazole derivative and a preparation method and an application thereof. The specific preparation method comprises the following step: with N-aminoethylpiperazine, rhodamine B, DIPEA (Diisopropyl Ethyl Amine), 4-chloro-7-nitro-2, 1, 3-benzoxepin oxadiazole and K2CO3 with a mol ratio of (1-10): 1: (1-20): (1-1.5): 1 as reactants, preparing a product by a two-step-one-pot method, wherein the product can be used for H<+> ion colorimetry and used as a fluorescent probe. The structure designed and synthesized by the invention is short in synthesis route and mild in reaction conditions, an intermediate is unnecessary to be separated to obtain a target probe with a high yield, and no obvious FRET (fluorescence resonance energy transfer) exists between the oxadiazole and rhodamine fluorophores with matched spectrums in the structure, so that the H<+> can be detected through three channels, and the rhodamine-oxadiazole derivative has high selectivity, high sensitivity and large application potential.

Owner:SUZHOU UNIV

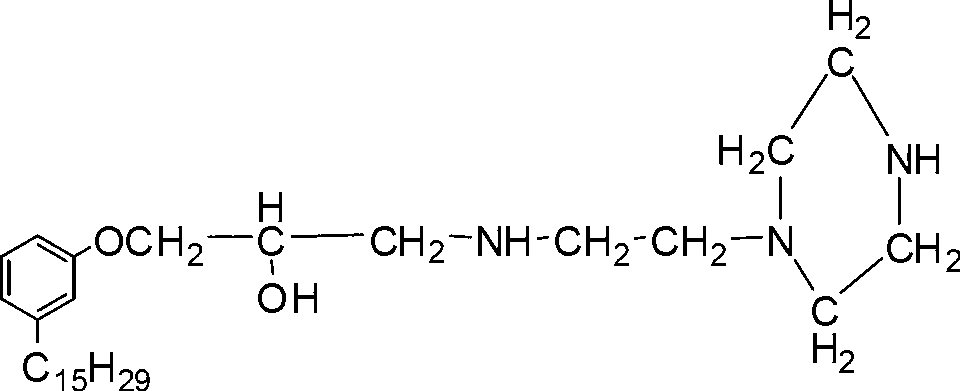

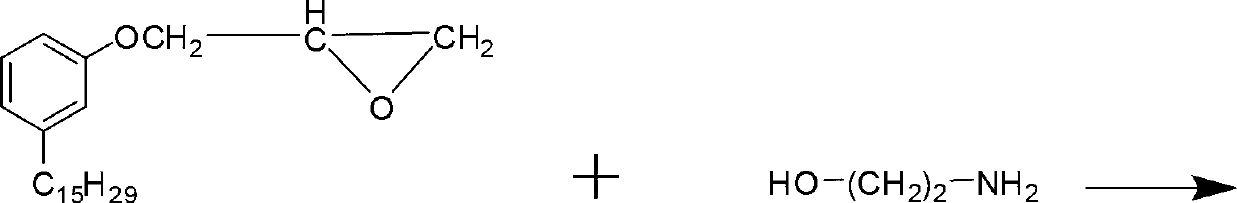

Anacardol glycidyl ether modified mixed amine hardener and preparation method thereof

InactiveCN103145953ALow toxicityReduce volatilityOrganic compound preparationAmino-hyroxy compound preparationTetramine2-Aminoethanol

The invention discloses anacardol glycidyl ether modified mixed amine hardener which is synthesized by anacardol glycidyl ether and mixed amine, wherein the weight ratio of the anacardol glycidyl ether to the mixed amine is 80:60-20:40. The mixed amine is composed of N-amino ethyl group piperazidine, 2-aminoethanol, polyethylene polyamine, and triethylene tetramine. The invention further provides a preparation method of the anacardol glycidyl ether modified mixed amine hardener. According to the preparation method of the anacardol glycidyl ether modified mixed amine hardener, the anacardol glycidyl ether and the mixed amine are obtained according to the weight percentage, and then the mixed amine is put into a reaction still, the reaction still is heated to the temperature of 50-70 DEG C, the anacardol glycidyl ether is added into the reaction still for 1-3 hours under the stirring condition of 600-800 circles / minute, and stirring and reaction are carried out for 3-4 hours, and finally the anacardol glycidyl ether modified mixed amine hardener is obtained. Due to the fact that the modified mixed amine hardener is hardener with middle and normal temperature, toxicity and volatility of the mixed amine can be effectively reduced, cost is reduced, and various film panting diseases which easily occur in a construction process can be avoided at the same time.

Owner:上海美东生物材料股份有限公司

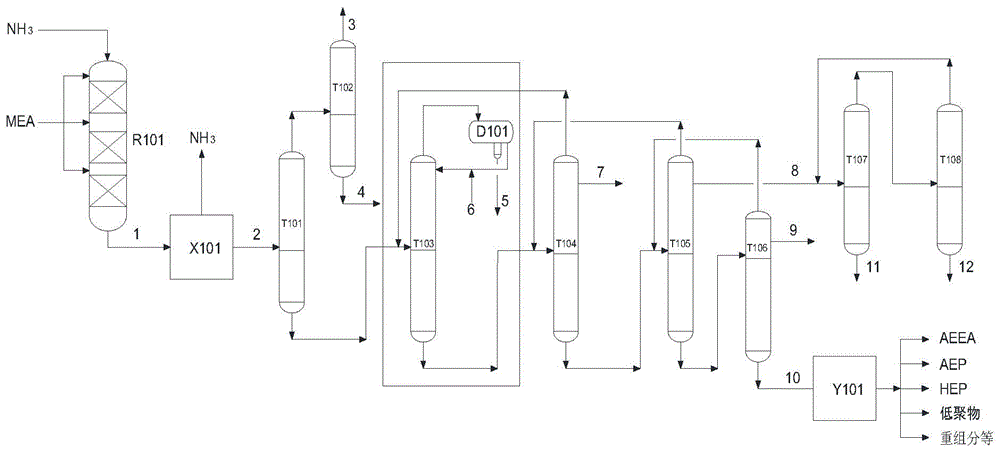

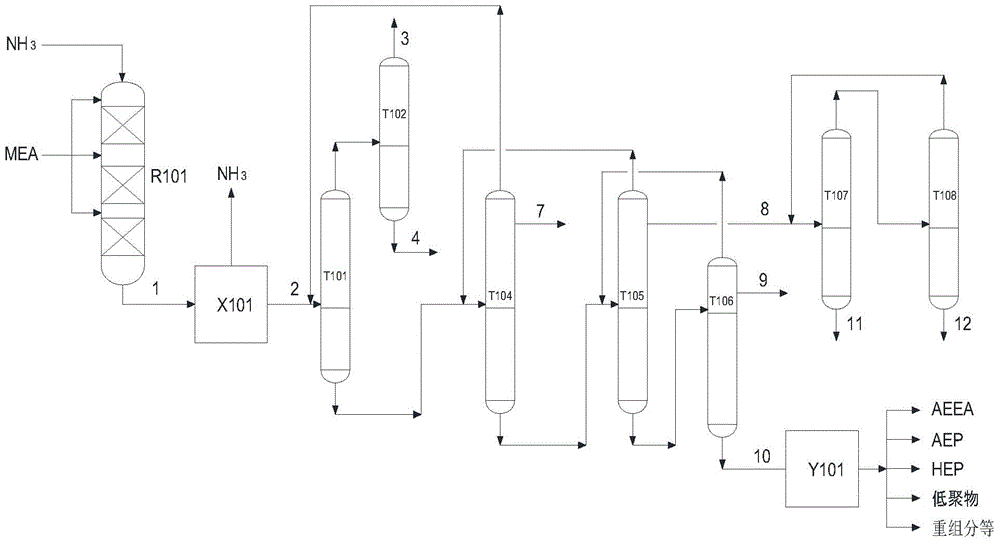

Production method for ethylenediamine through catalytic ammoniation process

ActiveCN105585502AAmino compound purification/separationOrganic compound preparationEthylenediamineDiethylenetriamine

The invention relates to a production method for ethylenediamine through a catalytic ammoniation process. The production method provided by the invention comprises the following steps: firstly recovering ammonia from catalytic amination reaction products, then separating free water and ethylenediamine (EDA) through rectification, and subjecting the free water and ethylenediamine (EDA) to azeotrope removal through pressurized rectification so as to obtain an ethylenediamine (EDA) product; and subjecting a monoethanolamine-contained mixture obtained from separation of the free water and ethylenediamine (EDA) to azeotropic rectification and separating crystal water so as to obtain anhydrous piperazine (PIP), then carrying out ordinary rectifying separation through a plurality of rectifying towers so as to obtain diethylenetriamine (DETA), separating a mixture of monoethanolamine (MEA) and triethylenediamine (TEDA) through pressure-swing rectification, recycling monoethanolamine (MEA) to an ammoniation reactor, and subjecting heavy components (aminoethyl ethanolamine (AEEA), aminoethylpiperazine (AEP), hydroxyethyl piperazine (HEP), oligomers and a heavy-component amine mixture) to stage-by-stage separation through a plurality of falling-film evaporators. Thus, the production method provided by the invention can be applied in industrial production of ethylenediamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

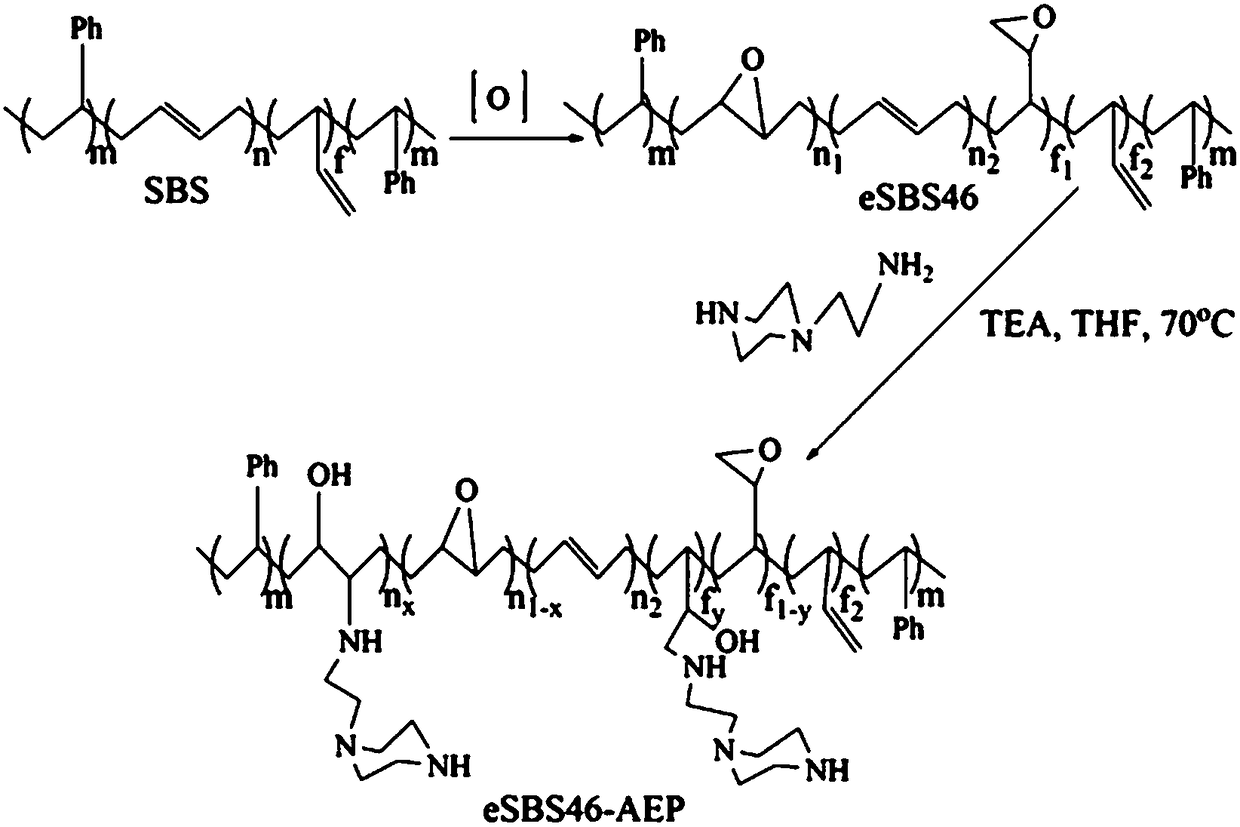

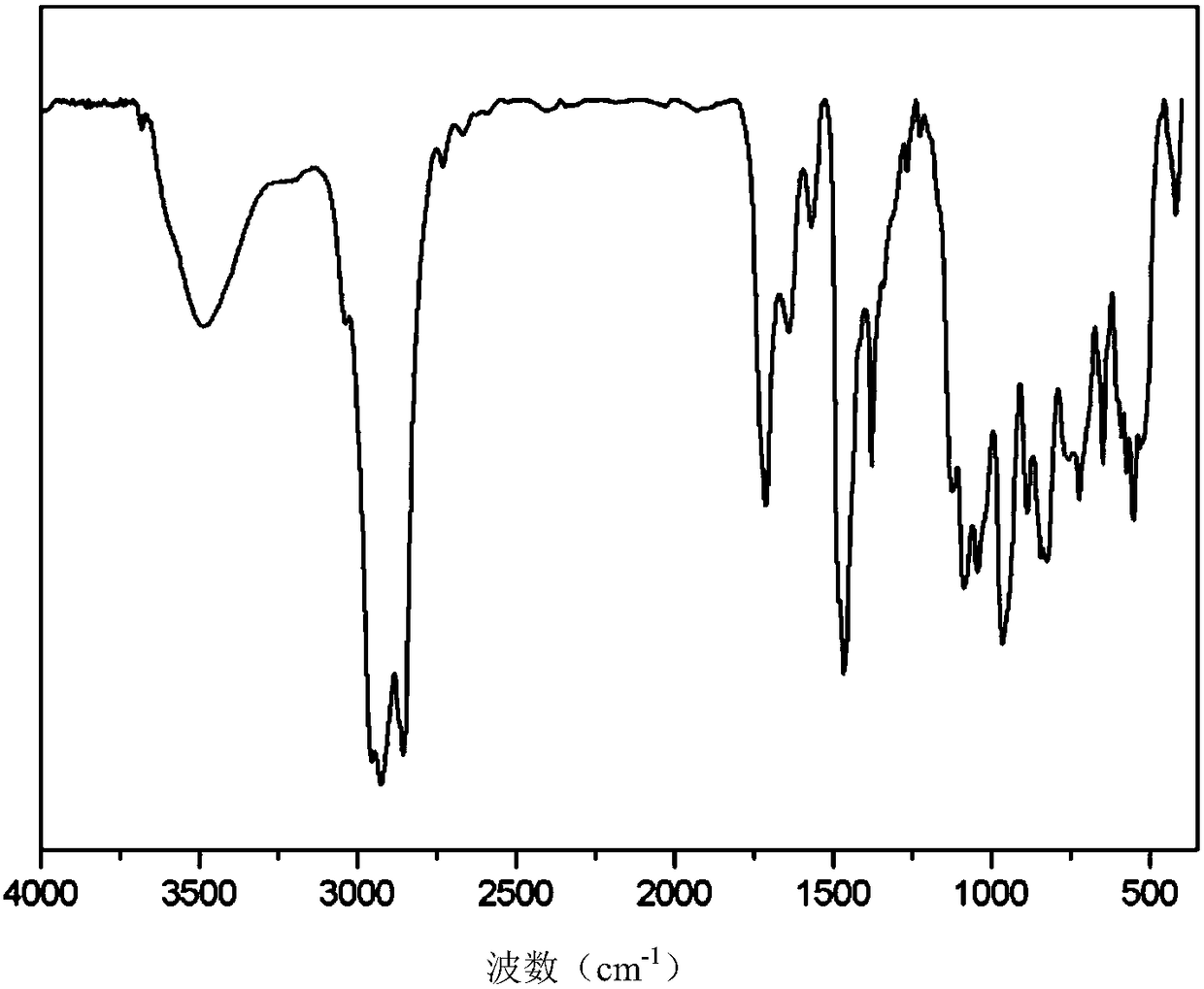

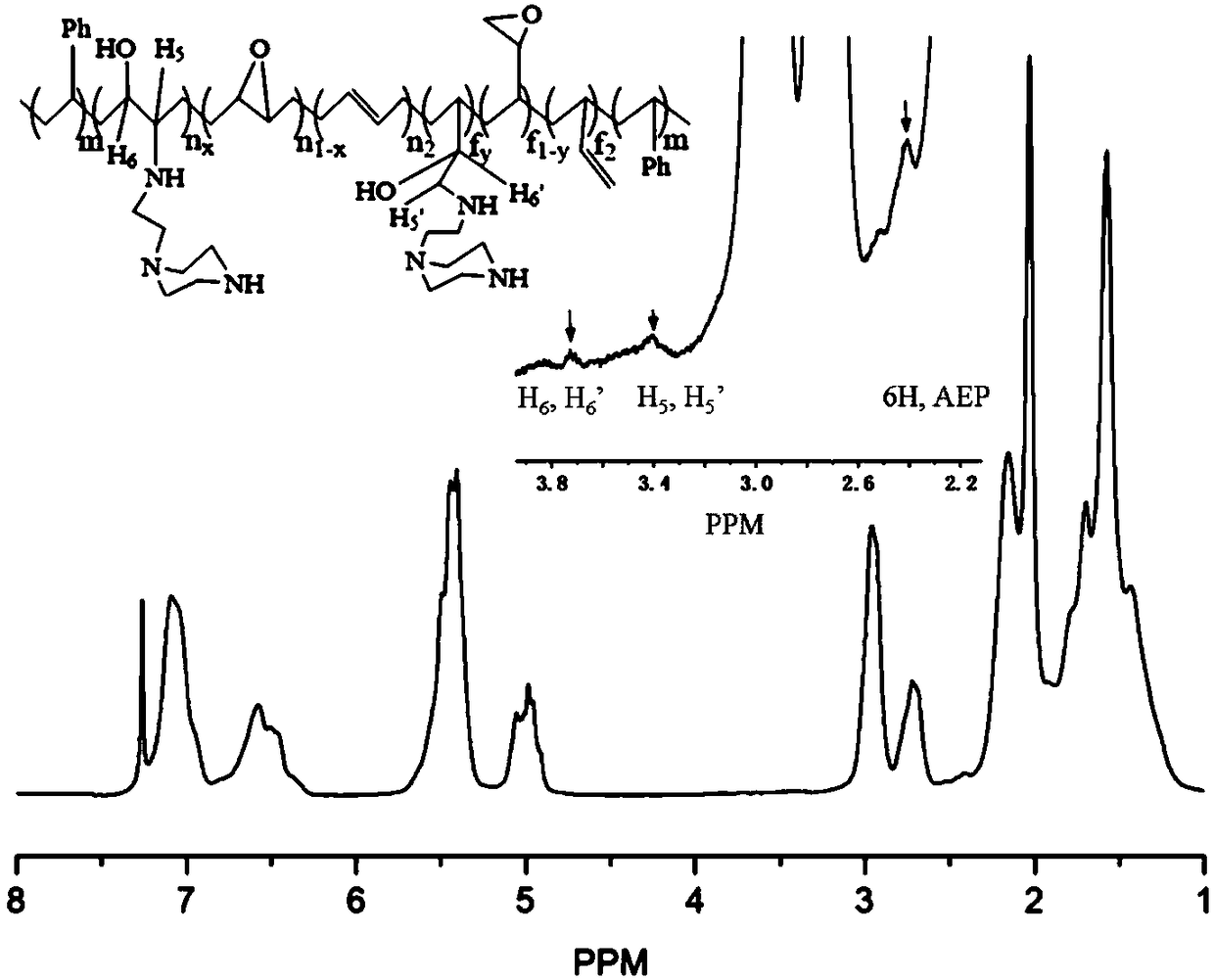

Epoxidized SBS, blocked macromolecular active amine toughening agent, preparation and application thereof to epoxy resin

The invention belongs to the technical field of an epoxy resin toughening agent, and discloses epoxidized SBS, a blocked macromolecular active amine toughening agent, preparation and application thereof to epoxy resin. A preparation method of the epoxidized SBS comprises the following steps of (1) performing heating reaction on hydrogen peroxide and tungstic acid; then, mixing the materials with phosphoric acid; dripping chloridized quaternary ammonium salt; obtaining a catalyst; (2) using hydrogen peroxide as an oxygen source; performing catalytic oxidation on the SBS under the catalyst effect to obtain the epoxidized SBS. The preparation method of the toughening agent comprises the step of performing ring opening reaction on the epoxidized SBS and aminoethylpiperazine under the catalysteffect in the organic solvent to obtain a product. The catalysis activity of the catalyst is high; no side reaction exists; during the SBS epoxidation, the method is simple; the conditions are mild; the control is easy; the yield is high; the epoxidation product cannot easily gel; the product can be easily purified; the catalyst can be easily recovered. The toughening agent has the obvious toughening effect on the epoxy resin; in addition, the transparency of the epoxy resin cannot be influenced.

Owner:中科广化(重庆)新材料研究院有限公司 +3

Modified epoxy resin coating

InactiveCN105400380AImprove mechanical propertiesAccelerated corrosionAnti-corrosive paintsPolyurea/polyurethane coatingsResin coatingPyrrole

The invention discloses a modified epoxy resin coating. The coating comprises a component A and a component B in a weight ratio of (80-100):(10-18), wherein the component A is prepared from the following raw materials in parts by weight: 30-46 parts of aliphatic glycidyl ether epoxy resin, 20-30 parts of acrylic acid emulsion, 10-16 parts of modified alkyd resin, 5-10 parts of polyurethane, 2-10 parts of allyl glycidyl ether, 10-30 parts of polypyrrole hollow spheres, 10-20 parts of titanium dioxide microspheres, 3-8 parts of quartz sands, 3-6 parts of mica iron oxide, 1-3 parts of cotton linter, 1-10 parts of macroporous type-II strong base anion resin, 5-10 parts of kaolin, 1-3 parts of zinc oxide, 2-6 parts of sodium polyacrylate, 20-30 parts of polyvinyl alcohol, 0.5-2.5 parts of polyorganosiloxane, 0.2-0.9 part of caster oil, 0.5-1.8 parts of a wetting agent and 20-60 parts of deionized water; and the component B is prepared from the following raw materials in parts by weight: 5-10 parts of propylene glycol monomethyl ether acetate, 15-30 parts of aminoethylpiperazine, 10-20 parts of m-xylylenediamine, 10-30 parts of propanediol butyl ether and 20-40 parts of deionized water. The modified epoxy resin coating has good adhesion and excellent corrosion resistance.

Owner:合肥市易远新材料有限公司

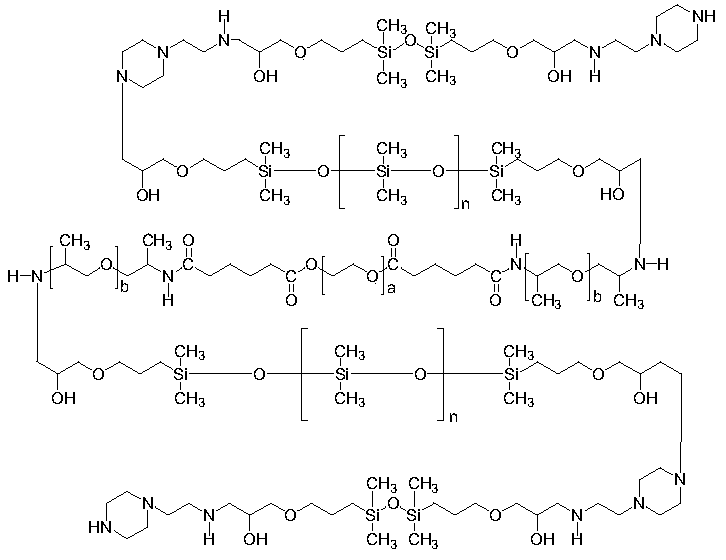

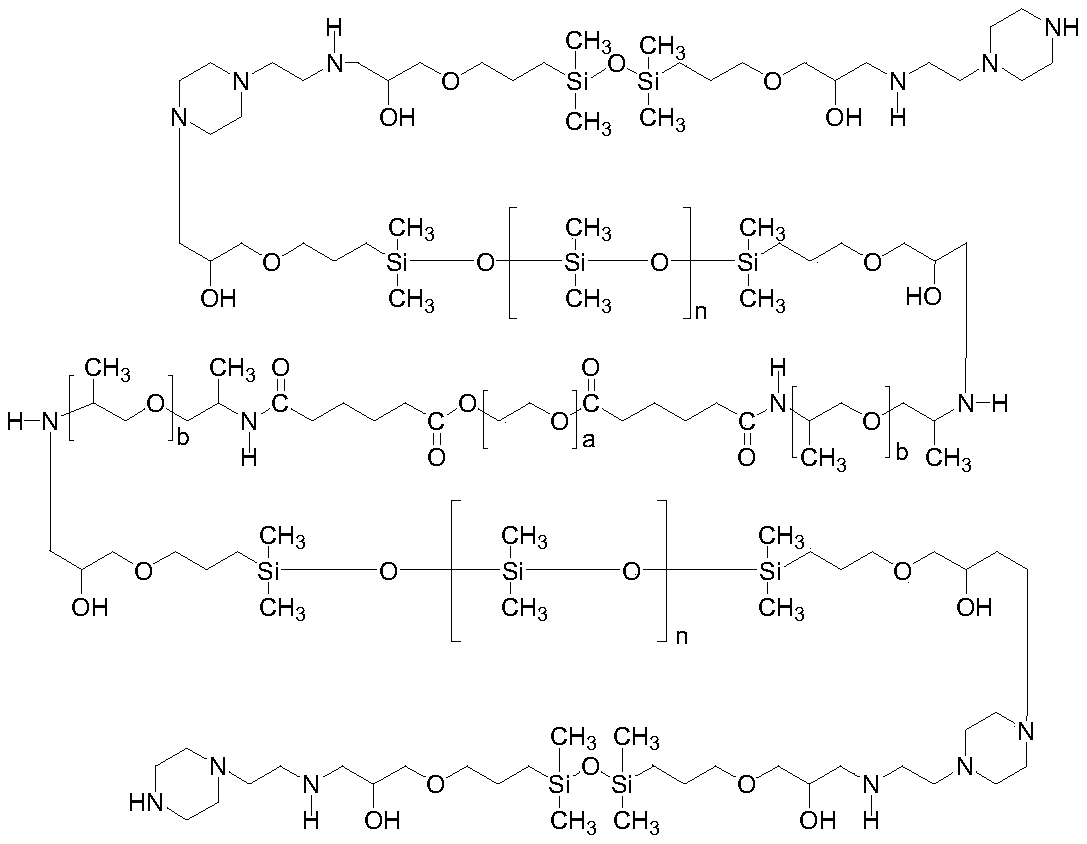

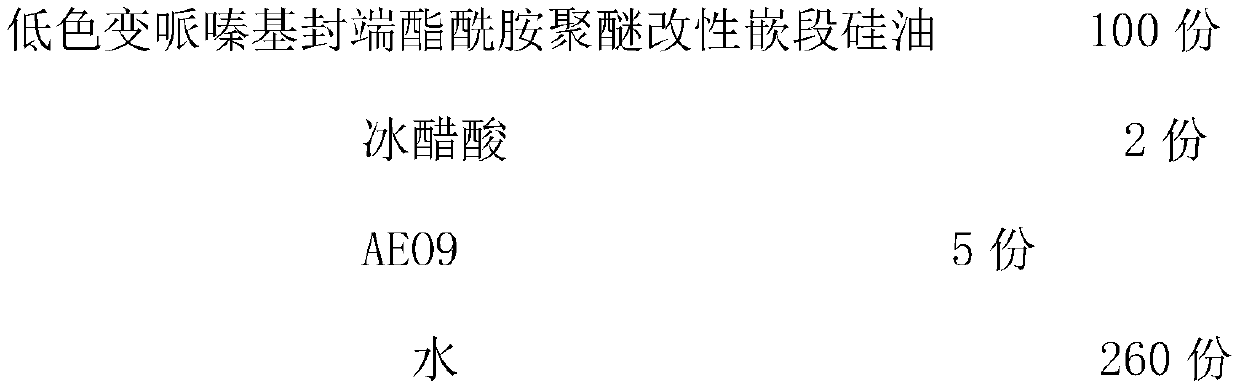

Preparation method of low-discoloration piperazinyl-terminated polyether ester amide modified block silicone oil

The invention relates to the field of textile additives, in particular to a preparation method of low-discoloration piperazinyl-terminated polyether ester amide modified block silicone oil. The low-discoloration piperazinyl-terminated polyether ester amide modified block silicone oil is prepared from the raw materials: N-aminoethylpiperazine, an epoxy terminating agent, polyether ester amide, epoxy-terminated silicone oil and isopropanol. The emulsified silicone oil is used for finishing of nylon fabric, and the processed fabric has good soft and smooth hand feeling, and is low in discoloration. Piperazinyl groups, polyether groups and amide groups are introduced into a main chain of the silicone oil, and thus the defects of low adsorption rate, large discoloration, poor hydrophilicity andnon-ideal hand feeling due to the fact that traditional block silicone oil is used for finishing of the nylon fabric are overcome.

Owner:HANGZHOU MEIGAO HUAYI CHEM

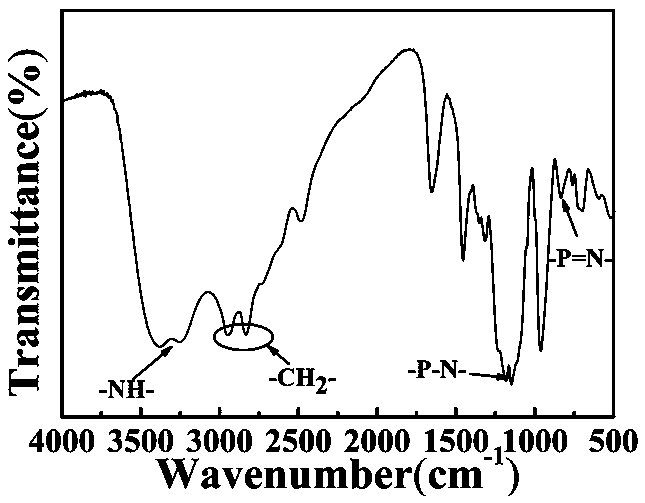

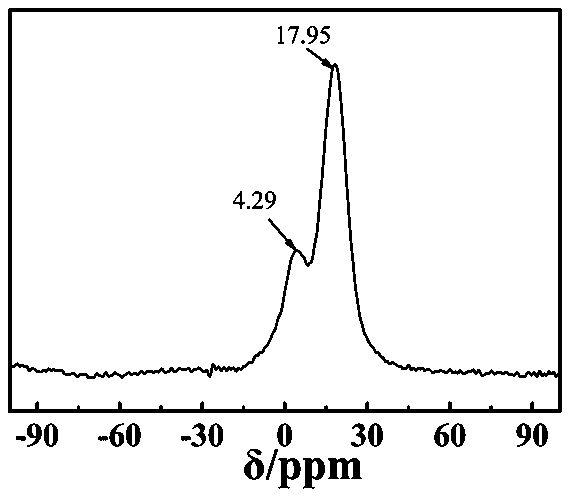

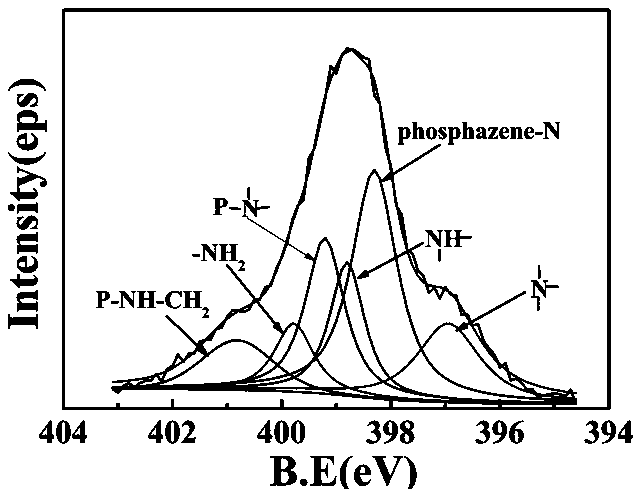

Active amino cross-linked phosphazene derivative and preparation method and application thereof, and flame-retardant epoxy resin

Owner:HEBEI UNIVERSITY

Concrete with excellent flexural property and tensile property and preparation method thereof

InactiveCN106220092AExcellent flexural and tensile propertiesImprove densification performanceEpoxySlag

The invention discloses concrete with the excellent flexural property and tensile property. The concrete is prepared from a component A, a component B and water, wherein the mass ratio of the component A to the component B to water is (2-4):(20-50):(3-6); the component A is prepared from epoxy resin, modified polypropylene fibers, acrylonitrile-butadiene-styrene copolymer, polydimethylsiloxane, N-aminoethylpiperazine, resorcinol and a silane coupling agent KH-560; the component B is prepared from ordinary Portland 42.5 cement, fly ash, medium sand, scoria, ceramsite, expanded perlite, mineral slag, kaolin and additives. The invention further provides a preparation method of the concrete with the excellent flexural property and tensile property. The prepared concrete has the excellent flexural property and tensile property.

Owner:蚌埠市方阵商品混凝土有限公司

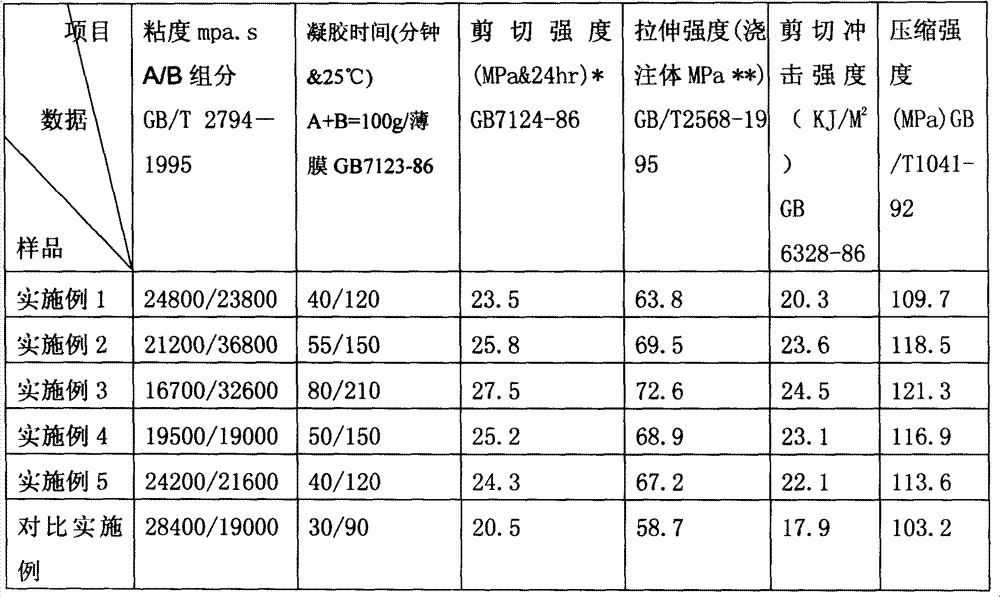

Novel two-component mold producing material and preparation method thereof

The invention relates to a novel two-component mold producing material and a preparation method thereof. The novel two-component mold producing material comprises a component A and a component B, wherein the component A is a resin component and comprises ingredients as follows: bisphenol A epoxy resin, aluminium hydroxide, silicon dioxide, polyethylene wax, ethylene bis stearamide and an organic silicon defoaming agent; the component B is a curing component and comprises ingredients as follows: polyamide resin, N-aminoethylpiperazine, nonyl phenol, the aluminium hydroxide, the silicon dioxide, the polyethylene wax, the ethylene bis stearamide and the organic silicon defoaming agent. The two-component mold producing material and the preparation method thereof have the benefits as follows: the two-component mold producing material has good plasticity, malleability and reactivity, when the material is used for producing a mold, the producing time is greatly shortened, and the producing flow is simplified; the material has good flame retardance and high safety; the prepared mold is high in mechanical strength, not easy to abrade and durable and has a smooth surface.

Owner:共享新材料(山东)有限公司

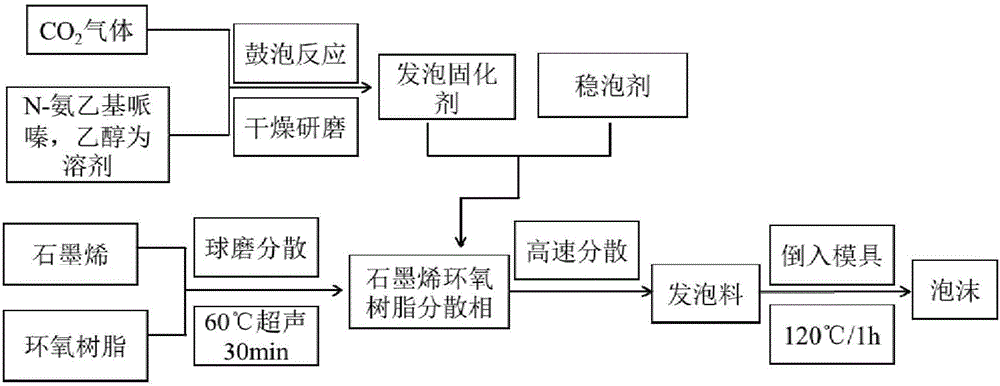

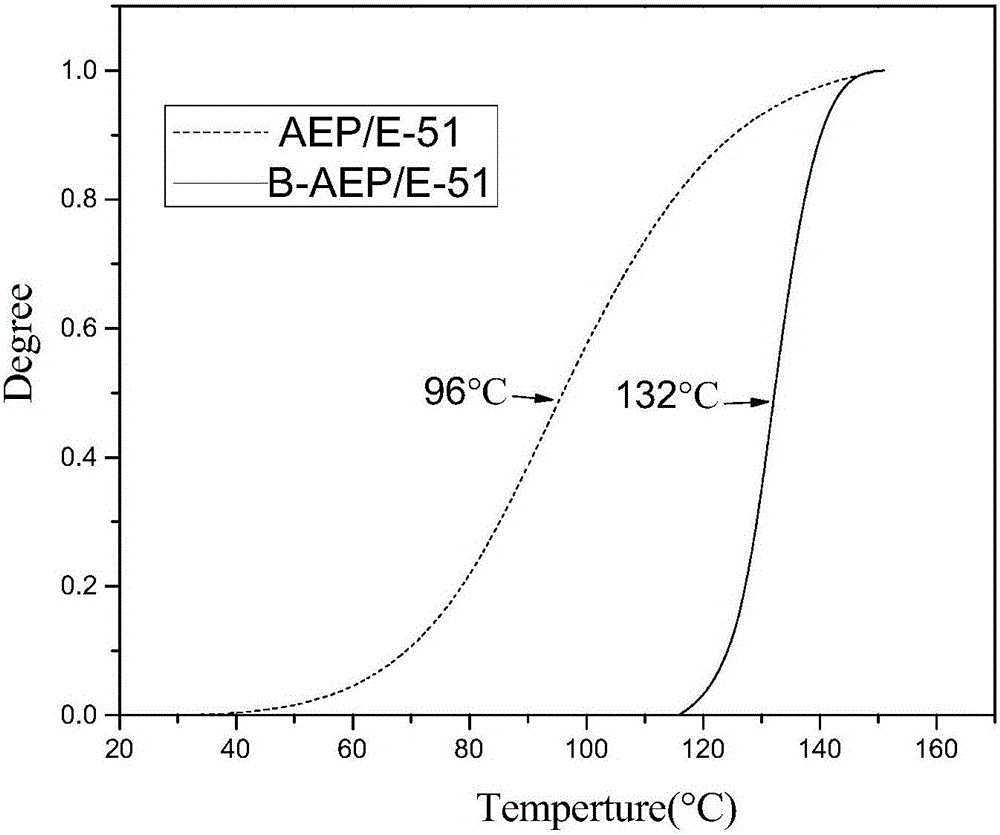

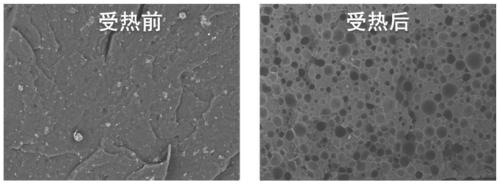

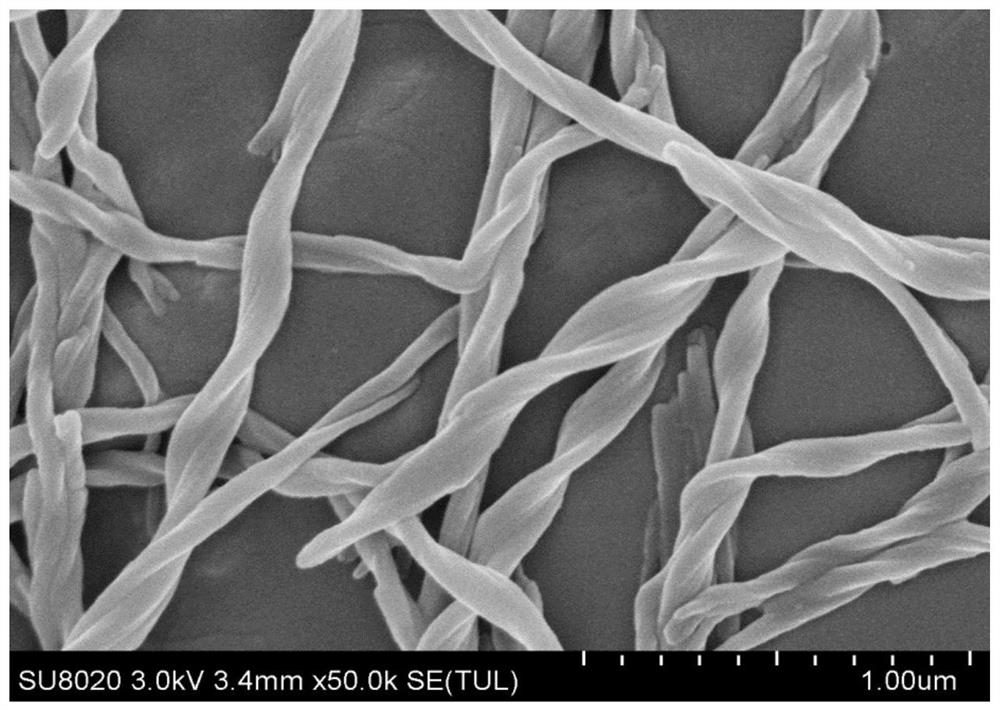

Graphene and epoxy resin composite foam material and preparation method thereof

The invention provides an environment-friendly and simple method for preparing graphene and epoxy resin composite foam material by single-component foaming, comprising: allowing N-aminoethylpiperazine (AEP) and CO2 to react to obtain a latent curing-foaming agent (B-AEP); ball-milling epoxy resin and graphene, ultrasonically dispersing at 55-60 DEG C for 30-35 min, cooling to room temperature, adding the curing-foaming agent and a foam stabilizer, stirring to obtain single-component foam, pouring into a preheated mold, and curing at 120-125 DEG C to obtain the graphene and epoxy resin composite foam material. The prepared foam material has excellent storage stability, good foam pore structure, excellent compressibility and good antistatic property.

Owner:滁州斯英铂聚合材料有限公司

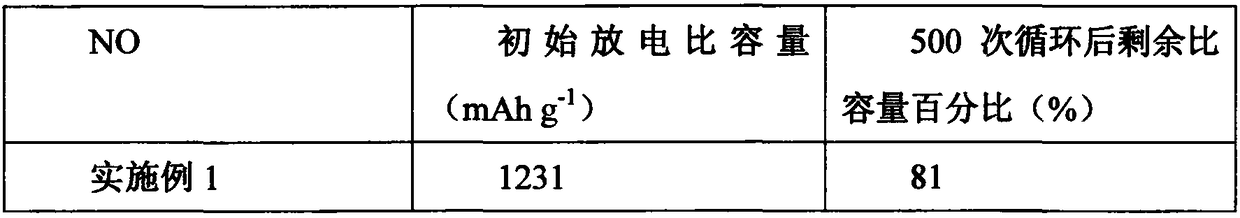

Lithium-sulfur battery positive electrode material and cationic lithium-sulfur battery binding agent

InactiveCN108493411AIncrease working voltageIncrease energy densityCell electrodesMetal foilElectric vehicle

The invention provides a lithium-sulfur battery positive electrode material and a cationic lithium-sulfur battery binding agent. The lithium-sulfur battery positive electrode material is characterizedby comprising a current collector metal foil and electrode paste, wherein the electrode paste is coated on a surface of the current collector metal foil and contains a carbon-sulfur compound and thelithium-sulfur battery binding agent, and the lithium-sulfur battery binding agent comprises a polymer obtained by polymerization reaction of N, N-methylene-bisacrylamide and aminoethyl piperazine. The lithium-sulfur battery assembled by taking the prepared cationic binding agent as the lithium-sulfur battery binding agent can be directly used in a hybrid electric vehicle.

Owner:DONGHUA UNIV

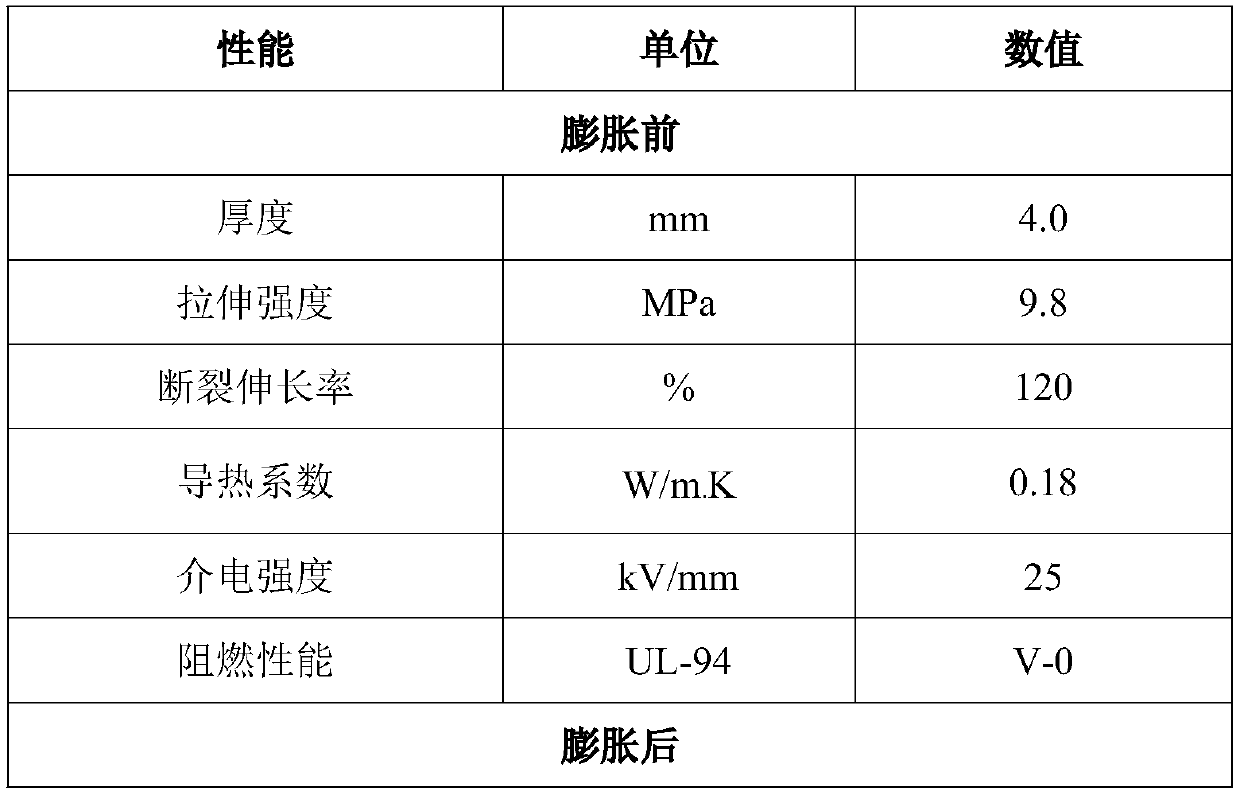

Silicone rubber based thermal failure protection material and preparation method and application thereof

ActiveCN110093037AProlong vulcanization induction periodIncreased scorch safetyPower batteryVulcanization

A silicone rubber based thermal failure protection material and a preparation method and application thereof are provided. The material includes 100 parts of epoxidized silicone rubber, 0.5-10 parts of a vulcanizing agent, 0.1-8 parts of a vulcanization regulator, 2-40 parts of a flame retardant, 5-80 parts of a plasticizer and 5-100 parts of a reinforcing agent. The epoxidized silicone rubber isprepared by epoxidizing silicone rubber containing unsaturated double bonds with an epoxidizing agent. The vulcanizing agent is passivated N-aminoethyl piperazine and is prepared by adding N-aminoethyl piperazine into a kneading machine, feeding carbon dioxide and performing mechanical mixing. The vulcanization regulator is dialkyldithiophosphate. The material has excellent fireproofness, flame retardance, heat insulation performance, electric breakdown resistance, and the like, and is controllable in volume expansion so that the material is a thermal failure protection material with excellentcomprehensive performance, can be used for power batteries, modules thereof and other fields, and has a good application prospect.

Owner:苏州沃尔兴电子科技有限公司 +1

Organic lithium soap composite urea-based lubricating grease and preparation method thereof

ActiveCN112080328AImprove extreme pressure and anti-wear performanceImprove mechanical propertiesThickenersLithium soapOrganic acid

The invention relates to organic lithium soap composite urea-based lubricating grease with excellent extreme-pressure wear resistance and a preparation method thereof, in particular to novel organic acid lithium soap composite urea-based lubricating grease containing an amino-containing saturated dinitrogen-containing heterocyclic compound and a preparation method of the novel organic acid lithiumsoap composite urea-based lubricating grease. The product is prepared from the following specific raw materials, by weight: 65-90% of base oil, 5-20% of organic lithium soap, and 3-12wt% of a thickening agent. According to the novel organic lithium soap composite urea-based lubricating grease, by introducing the N-aminoethyl piperazine and the organic lithium compound, the extreme-pressure wear resistance and the mechanical stability of the grease are improved on the basis of keeping the original properties of the urea-based lubricating grease unchanged, so that the service life of the lubricating grease under a bearing condition is prolonged. And the lubricating requirements of bearings and equipment under the conditions of frequent shearing and heavy load can be met.

Owner:长沙众城石油化工有限责任公司

Modified polyacrylonitrile

The invention discloses a modified polyacrylonitrile which comprises polyacrylonitrile, a filling agent, a curing agent, an accelerant, a coupling agent, a flexibilizer and a vulcanizing agent, wherein the filling agent is glass fiber, the curing agent is N-aminoethylpiperazine, the accelerant is zinc dimethyldithiocarbamate, the coupling agent is methacryloxy propyl trimethoxyl silane, the flexibilizer is an acrylonitrile-butadiene-styrene copolymer, and the vulcanizing agent is benzoyl peroxide. According to the modified polyacrylonitrile, the filling agent, the curing agent, the accelerant, the coupling agent, the flexibilizer and the vulcanizing agent are added into the polyacrylonitrile, so that the modified polyacrylonitrile has the characteristics of being high in strength, high in abrasion resistance, excellent in tear resistance, and good in fatigue resistance.

Owner:TAICANG CHENZHOU PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com