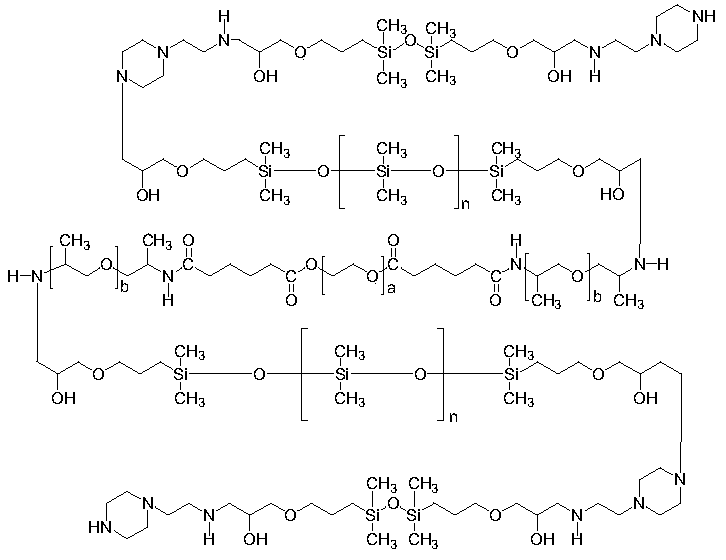

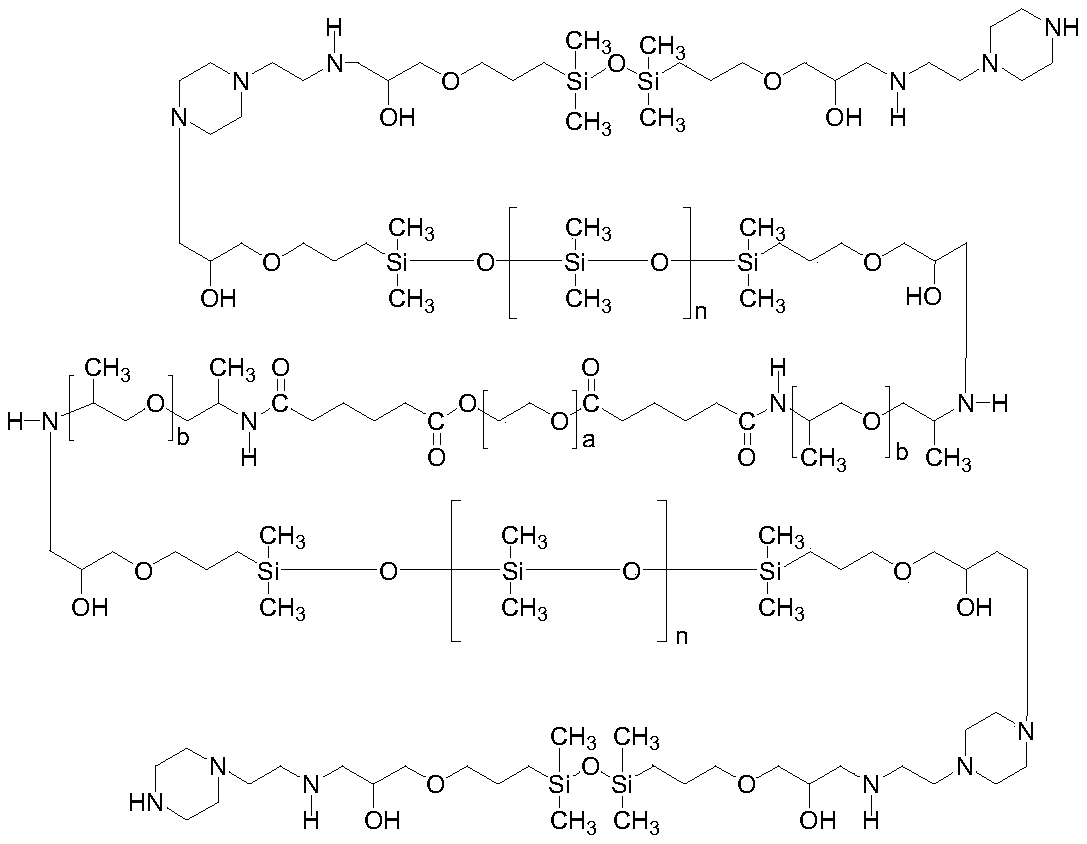

Preparation method of low-discoloration piperazinyl-terminated polyether ester amide modified block silicone oil

A modified technology of ester amide and polyether, which is applied in the direction of improved hand feeling fibers, fiber types, textiles and papermaking, etc., which can solve the problems of gray cloth stiffness, easy color change of fabrics, and reduced wearing performance, and achieve easy operation of the synthesis process , The synthesis process is simple, and the effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Add 55 grams of N-aminoethylpiperazine into the reaction vessel, pump 70 grams of epoxy capping agent into the high level tank, raise the temperature of the reaction vessel to 65°C, add the epoxy capping agent dropwise, and keep warm after the addition is completed Reacted for 2 hours to obtain a double-ended piperazine cap;

[0023] 2) Add 2,000 grams of epoxy silicone oil with a number average molecular weight of 10,000 terminals, 95 grams of esteramide polyether, and 900 grams of isopropanol into a reaction vessel, heat to 78° C., and keep warm for 8 hours, then add 1 ) obtained in all the double-ended piperazine end caps, at 78 ° C, heat preservation reaction for 5 hours, to prepare the required low color change piperazinyl end-capped esteramide polyether modified block silicone oil of the present invention.

Embodiment 2

[0025] 1) Add 70 grams of N-aminoethylpiperazine into the reaction vessel, pump 80 grams of epoxy capping agent into the high level tank, raise the temperature of the reaction vessel to 70°C, add epoxy capping agent dropwise, and keep warm after the addition is completed Reacted for 3 hours to obtain a double-ended piperazine cap;

[0026] 2) Add 3,000 grams of epoxy silicone oil with a number average molecular weight of 13,000, 105 grams of ester amide polyether, and 1,000 grams of isopropanol into a reaction vessel, heat to 80° C., and keep warm for 9 hours, then add 1 ) obtained in all the double-ended piperazine end caps, at 80 ° C, heat preservation reaction for 6 hours, to prepare the required low color change piperazinyl end-capped esteramide polyether modified block silicone oil of the present invention.

Embodiment 3

[0028] 1) Add 80 grams of N-aminoethylpiperazine to the reaction vessel, pump 90 grams of epoxy capping agent into the high level tank, raise the temperature of the reaction vessel to 85°C, add epoxy capping agent dropwise, and keep warm after the addition is completed Reacted for 4 hours to obtain a double-ended piperazine cap;

[0029] 2) Add 3,500 grams of epoxy silicone oil with a number average molecular weight of 15,000, 115 grams of ester amide polyether, and 1,100 grams of isopropanol into a reaction vessel, heat to 82°C, and keep warm for 10 hours, then add 1 ) obtained in all the double-ended piperazine end caps, at 82 ° C, heat preservation reaction for 8 hours, to prepare the required low color change piperazinyl end-capped esteramide polyether modified block silicone oil of the present invention.

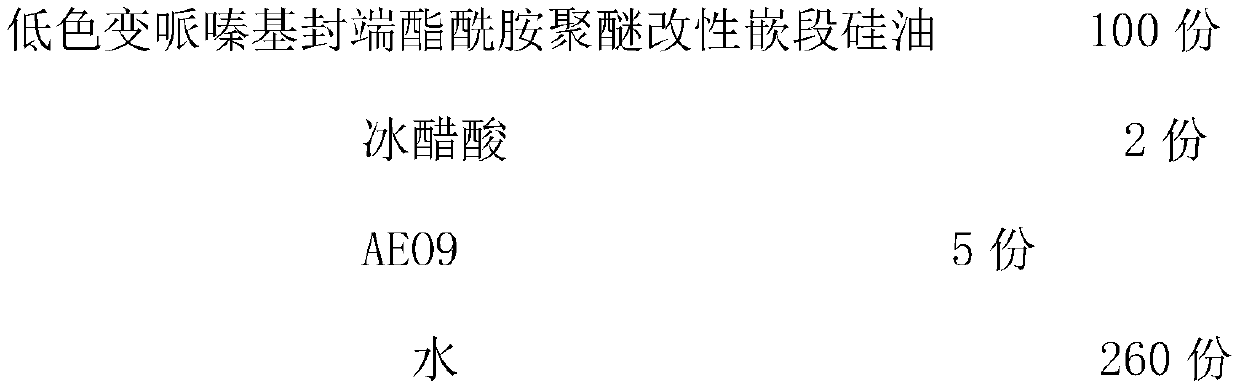

[0030] Low color change piperazinyl terminated ester amide polyether modified block silicone oil application finishing process:

[0031] 1. Preparation of low color ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com