Wear-resistant epoxy glue and preparation method thereof

An epoxy glue, wear-resistant technology, applied in the direction of epoxy glue, adhesive, adhesive type, etc., can solve the problems of glass transition temperature reduction, low impact strength and wear resistance, unstable fillers, etc. , achieve excellent elastic recovery rate, improve mechanical strength and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

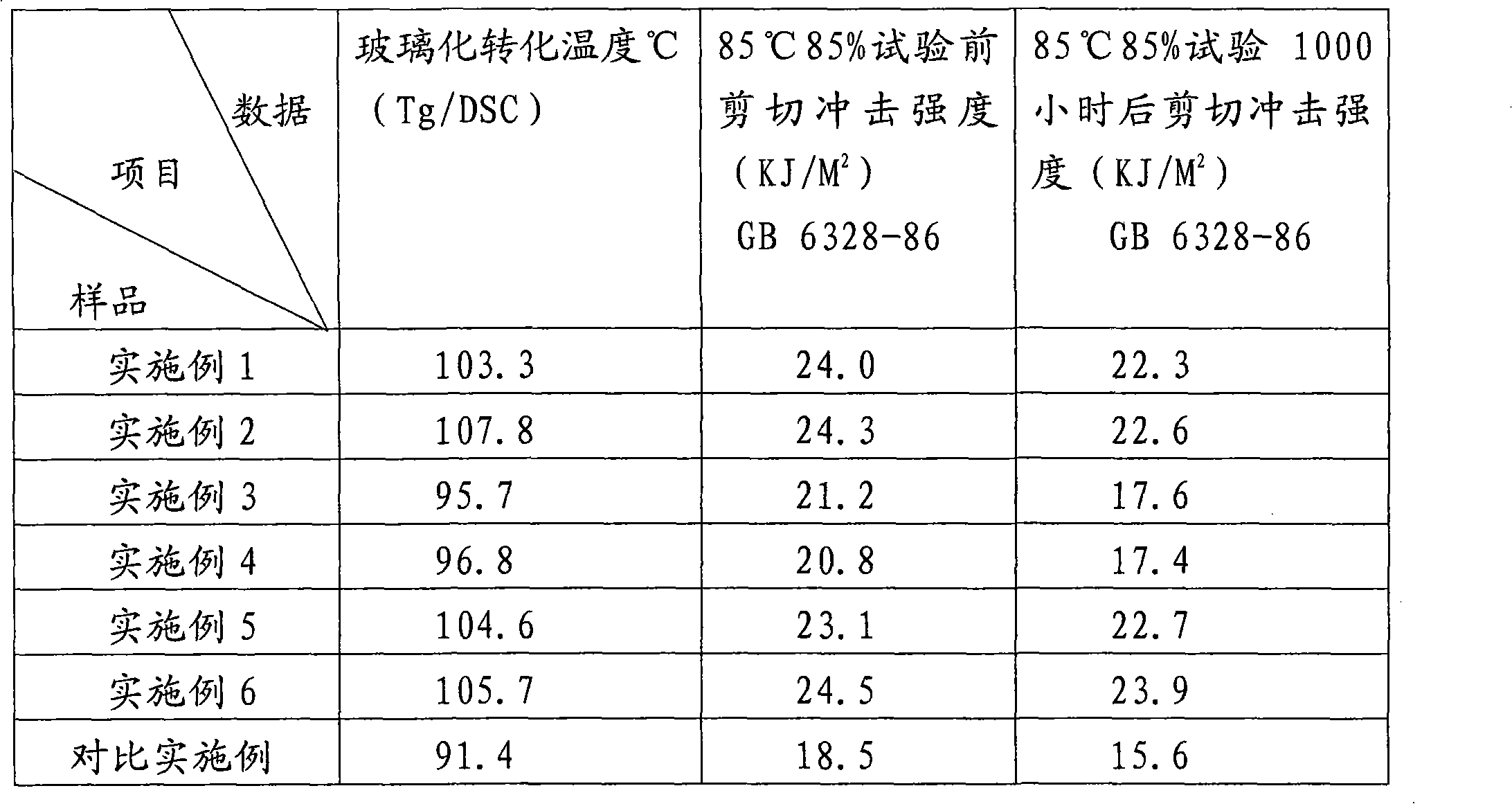

Examples

Embodiment 1

[0049] 1) Preparation of bisphenol F epoxy resin modified by nano-rubber particles: using a high-torque vertical agitating ball mill with a planetary gear reducer, a rod-type stirring paddle, a frequency converter and electric heating, with a speed of 0-150 rpm, The cylinder volume is 3L.

[0050] Weigh 590g of BFE170 bisphenol F epoxy resin and 250g of 1,4-butanediol diglycidyl ether, place them in a vertical stirring mill cylinder, heat the resin to 90°C, add 1.8L volume (about 3.8Kg) 2mm wear-resistant ceramic balls, adjust the speed to 100 rpm and stir for 15 minutes, then adjust the speed to 150 rpm, weigh 160g of nano-rubber particle powder, add it to the mixing mill cylinder in small quantities while stirring, and keep warm for 90~ 100°C, high-speed stirring ball mill for 2 hours, the discharge valve is set with 30-mesh stainless steel mesh, filtered, and discharged to obtain nano-rubber particle modified bisphenol F epoxy resin, which is ready for use;

[0051] 2) Pre...

Embodiment 2

[0058] 1) Preparation of bisphenol F epoxy resin modified by nano-rubber particles: use a high-torque vertical stirring ball mill with a planetary gear reducer, a rod-type stirring paddle, a frequency converter and electric heating, with a speed of 0-150 rpm, and a cylinder Volume 3L.

[0059] Weigh 590g of NY170 bisphenol F epoxy resin and 250g of 1,6-hexanediol diglycidyl ether, place them in a vertical stirring mill cylinder, heat the resin to 90°C, add 1.8L volume (about 3.8Kg) of 2mm wear-resistant ceramic balls, adjust the speed to 100 rpm and stir for 15 minutes, then adjust the speed to 150 rpm, weigh 160g of nano-rubber particle powder, add it to the mixing mill cylinder in small quantities while stirring, and keep warm for 90~ 100°C, high-speed stirring and ball milling for 2 hours, the discharge valve is set with a 30-mesh stainless steel mesh, and filtered to obtain nano-rubber particle modified bisphenol F epoxy resin, which is ready for use;

[0060] 2) Preparat...

Embodiment 3

[0066] 1) Bisphenol F epoxy resin modified by nano-rubber particles is the same as in Example 1.

[0067] 2) Preparation of component A:

[0068] Weigh 200g of BPE-170 epoxy resin and 100g of nano-rubber particle modified bisphenol F epoxy resin into a 3L vertical stirring mill cylinder, heat to 80°C and keep it warm, add 600g of alumina ceramic balls for grinding, and Stir and ball mill at 130 rpm for 30 minutes; add 5g of chopped nylon 6 fiber, stir and mill at 130 rpm for 30 minutes; stop heating, add 40g of 100# white corundum powder, 30g of 200 mesh glass fiber powder, and grind at 110 rpm Minute stirring and ball milling for 20 minutes; cool down to 50°C, add 5g of coupling agent KH560, stir at 50 rpm for 10 minutes, add gas phase method SiO 2 20g, stirred and ball milled at 50 rpm for 10 minutes, then stirred and ball milled at 110 rpm for 20 minutes, and discharged.

[0069] 3) Preparation of component B:

[0070] Weigh 650g of YD8140 polyamide, 150g of isophorone d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com