Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

981 results about "Bisphenol F" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

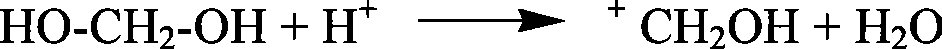

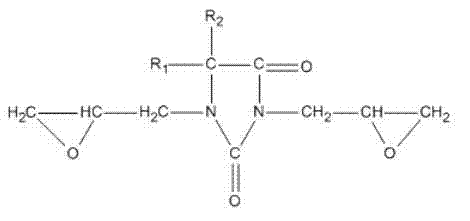

Bisphenol F (BPF; 4,4’-dihydroxydiphenylmethane) is a small aromatic organic compound with the chemical formula (HOC₆H₄)₂CH₂. It is related to bisphenol A through its basic structure, as both belong to the category of molecules known as bisphenols, which feature two phenol groups connected via a linking group. In BPF, the two aromatic rings are linked by a methylene connecting group.

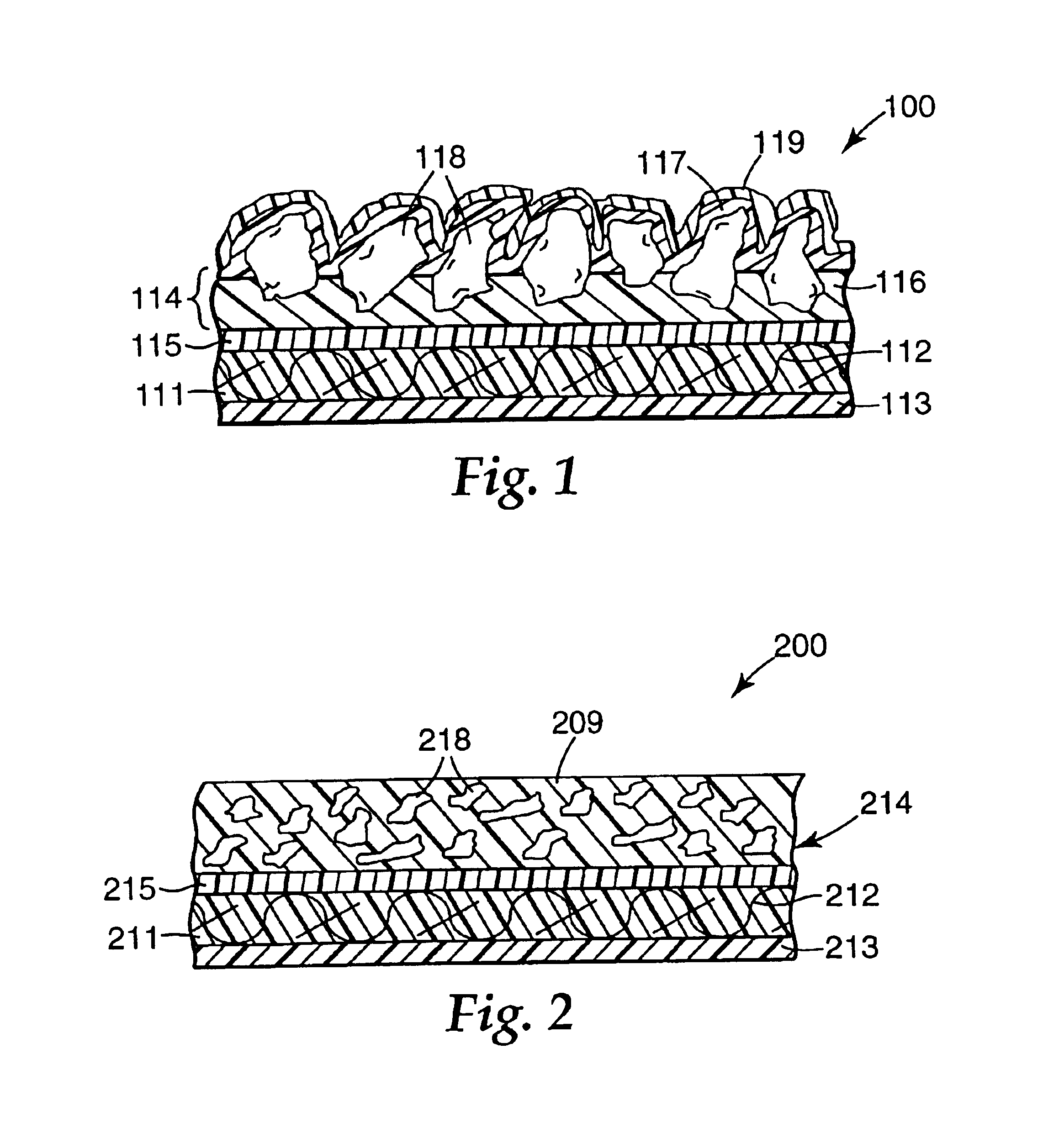

Coated abrasive articles and method of abrading

A curable composition comprises epoxy resin preparable by reaction of epichlorohydrin with at least one of bisphenol A or bisphenol F, polyfunctional (meth)acrylate, dicyandiamide and photoinitiator. The curable composition is useful for preparing treated backings and coated abrasive articles.

Owner:3M INNOVATIVE PROPERTIES CO

Bisphenol a and aromatic glycidyl ether-free coatings

ActiveUS20070036903A1Good metal substrateGood inter-coat adhesionLiquid surface applicatorsSynthetic resin layered productsPolyesterMeth-

Disclosed are Bisphenol A (BPA), Bisphenol F, Bisphenol A diglycidyl ether (BADGE), and Bisphenol F diglycidyl ether (BFDGE)-free coating compositions for metal substrates including an under-coat composition containing a polyester (co)polymer, and an under-coat cross-linker; and an over-coat composition containing a poly(vinyl chloride) (co)polymer dispersed in a substantially nonaqueous carrier liquid, an over-coat cross-linker, and a functional (meth)acrylic (co)polymer. Also provided is a method of coating a metal substrate using the BPA, BPF, BADGE and BFDGE-free coating system to produce a hardened protective coating useful in fabricating metal storage containers. The coated substrate is particularly useful in fabricating multi-part foodstuffs storage containers with “easy-open” end closures.

Owner:SWIMC LLC

Pre-coated film propping agent, preparation method of the pre-coated film propping agent and sand prevention method adopting the pre-coated film propping agent

ActiveCN102660245AImproves breakage resistanceEasy to divertFluid removalDrilling compositionBisphenol FPolyamine

The invention relates to a pre-coated film propping agent, a preparation method of the pre-coated film propping agent and a sand prevention method adopting the pre-coated film propping agent. The pre-coated film propping agent comprises propping agents, one or more pre-coated resins, one or more pre-coating curing agents, a coupling agent and a lubricating agent. The one or more pre-coated resins comprise bisphenol-A epoxy resin, bisphenol-F epoxy resin and / or novolac epoxy resin. The one or more pre-coating curing agents are selected from alicyclic polyamines, aromatic polyamines, modified alicyclic polyamines and / or modified aromatic polyamines. The coupling agent is an organosilane coupling agent.

Owner:BEIJING QISINTAL SCI & TECH +1

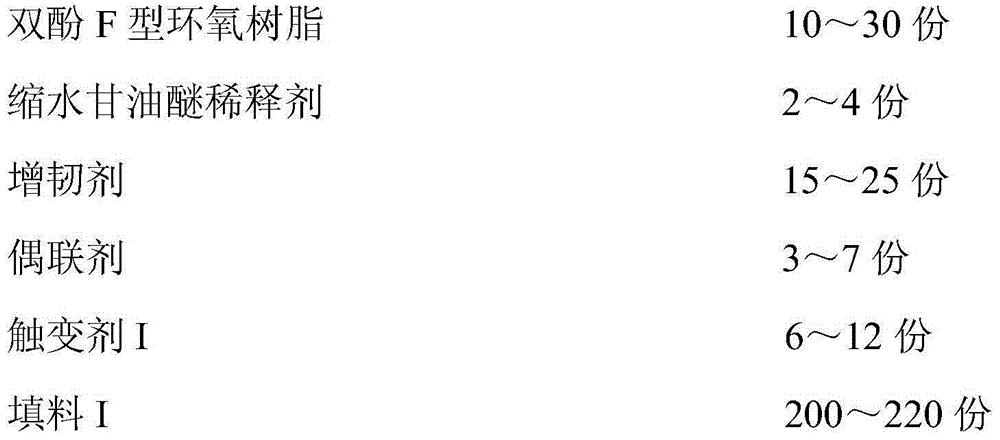

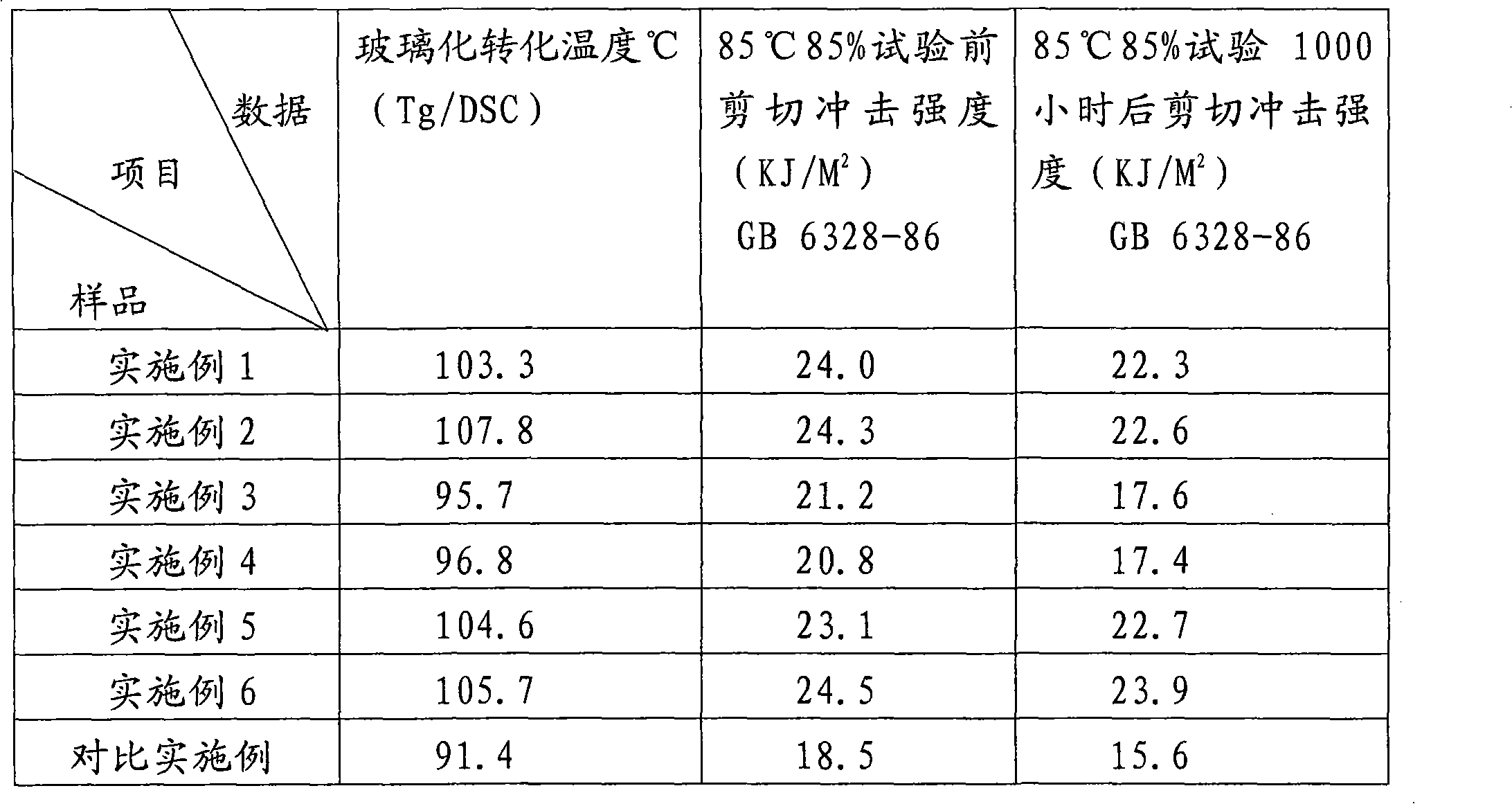

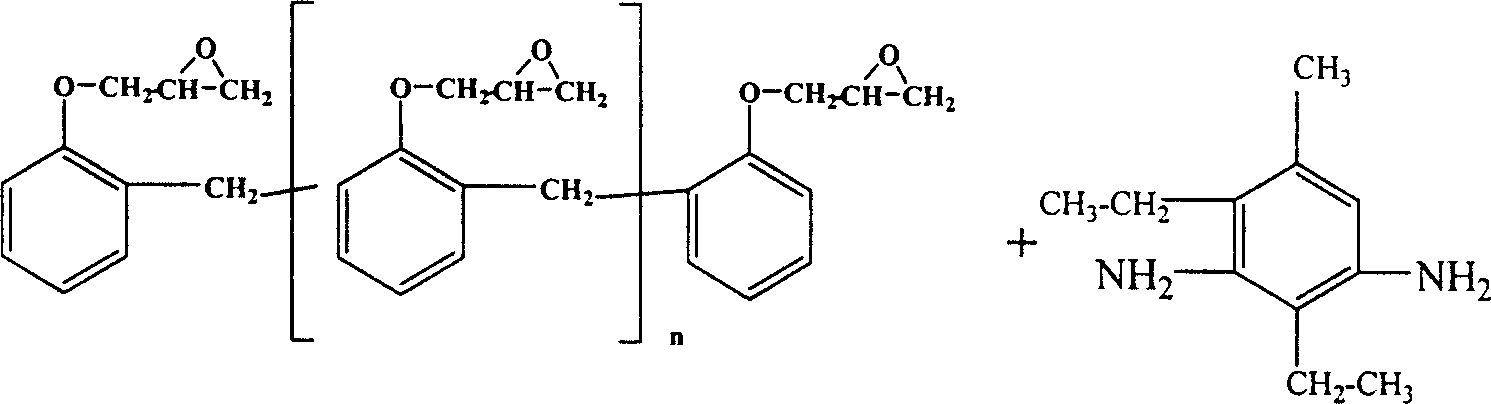

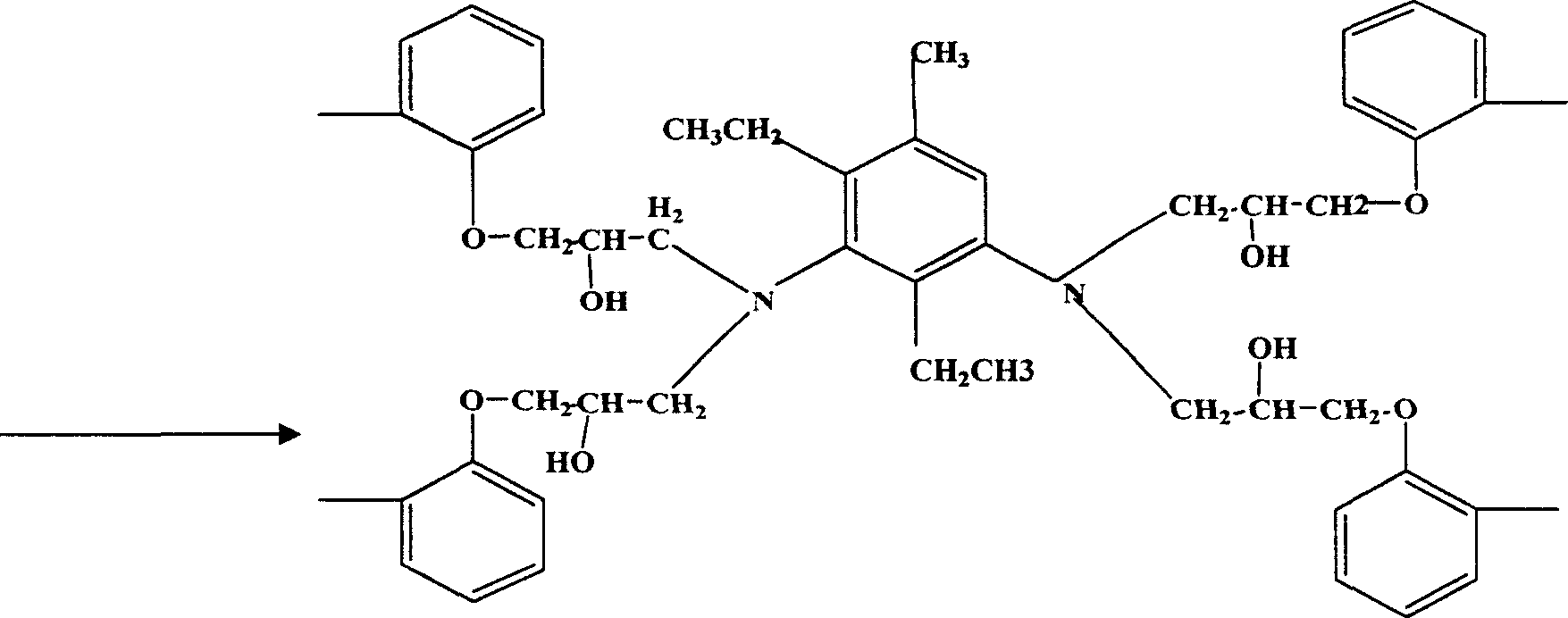

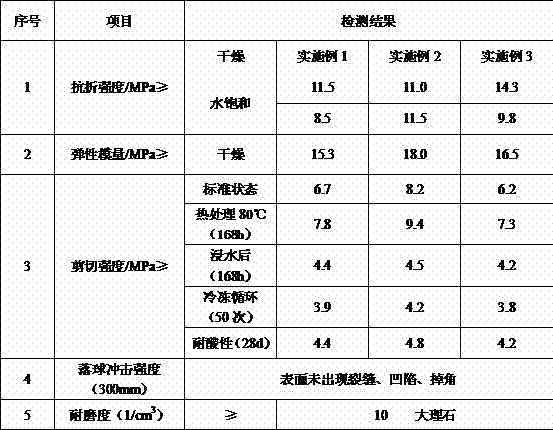

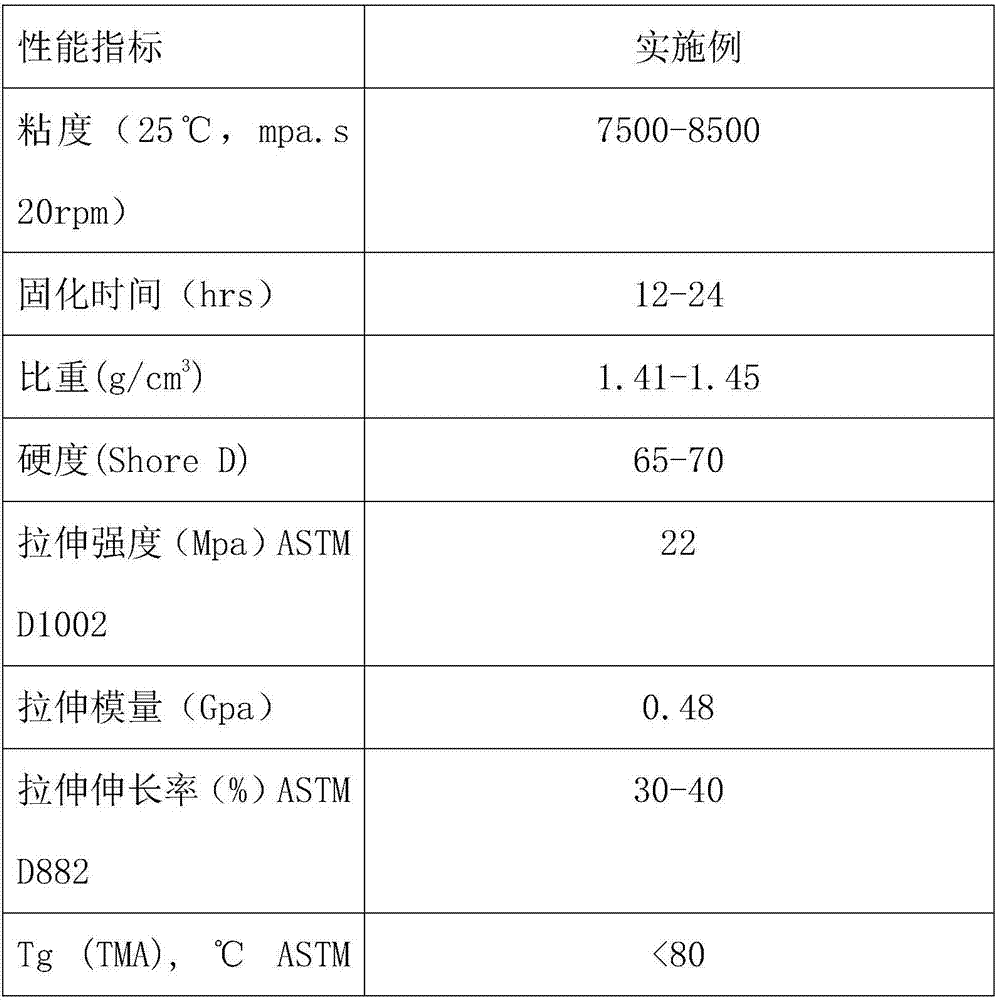

Double-component high-strength building epoxy structural adhesive and preparing method thereof

ActiveCN105062396AStir wellImprove toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberGlycidyl ethers

The invention provides double-component high-strength building epoxy structural adhesive and a preparing method thereof. The structural adhesive is mainly formed by mixing a component A and a component B at the weight ratio of 1.8-2.5:1. The component A is mainly composed of bisphenol A type epoxy resin, bisphenol F type epoxy resin, glycidyl ether diluent, a flexibilizer, a coupling agent, a thixotropic agent I and filler I. The component B is mainly composed of a complex-amine curing agent, an accelerator, hixotropic agent II and filler II. The epoxy structural adhesive is used for reinforcing construction of carbon fiber plates, and the carbon fiber plates are light in mass, convenient to bond in construction (the structural adhesive does not flow) and high in strength. Compared with a steel bonding construction method, the procedures of welding, polishing, pressurizing and the like are not needed in the method. The complex-amine curing agent is adopted in the developed component B, and the curing object is high in bonding strength, good in water resistance and good in toughness. The epoxy resin adhesive component A is free of crystallization, easy to smear and convenient to construct.

Owner:CARBON TECH CO LTD

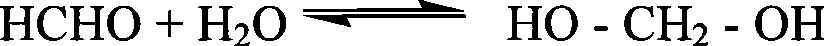

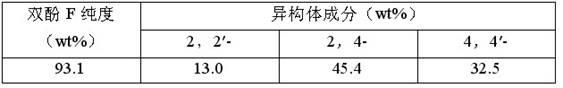

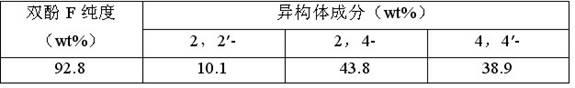

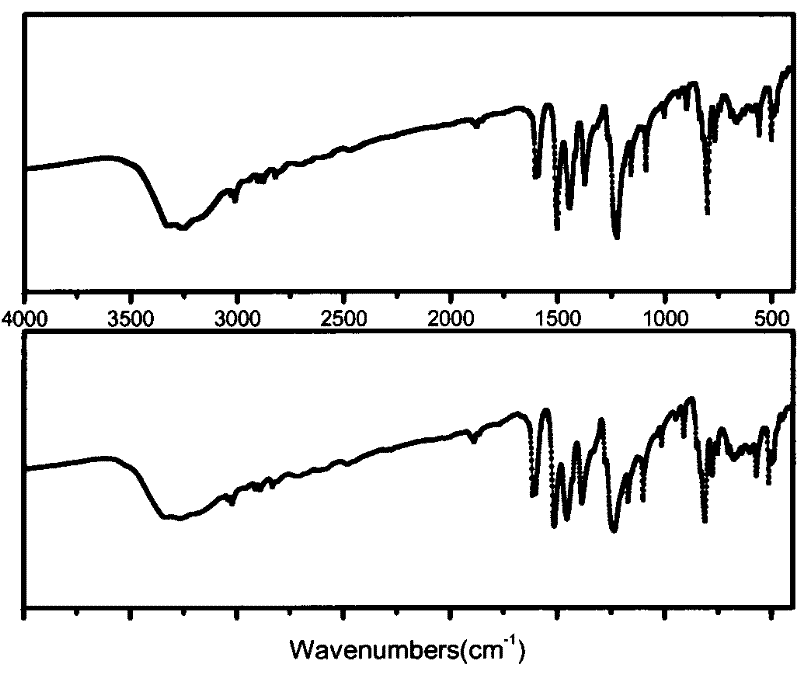

Method for synthesizing high content of 4,4'-dihydroxydiphenylmethane by one-step method

InactiveCN101440022AReduce the feed ratioReduce stepsOrganic chemistryOrganic compound preparationSodium bicarbonateWater baths

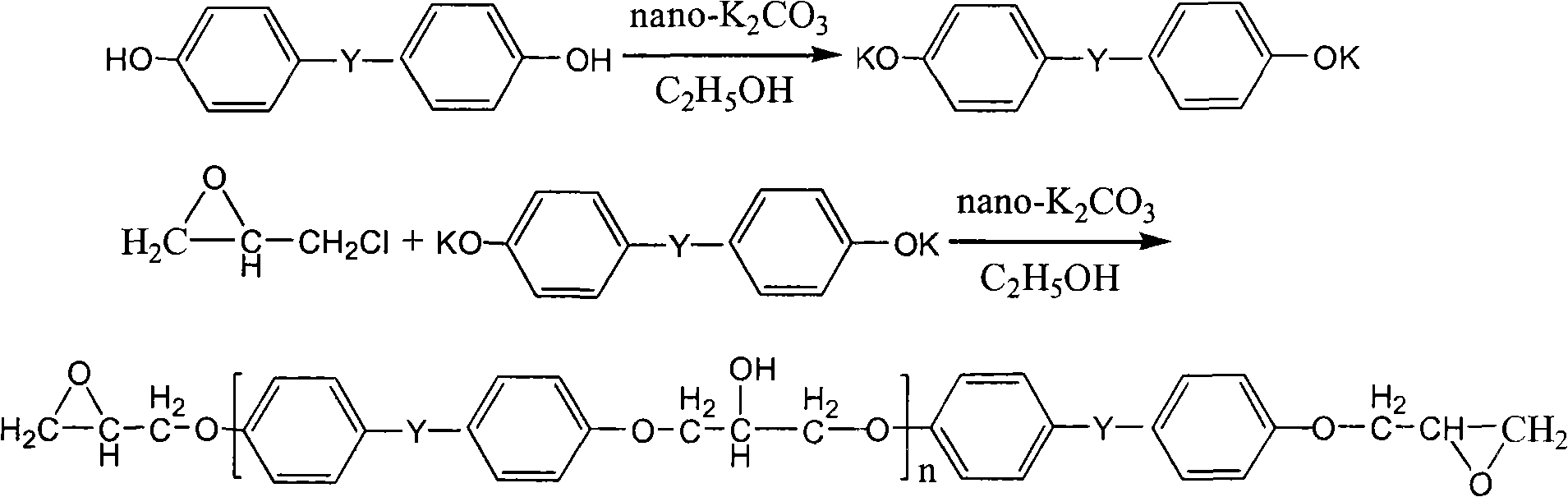

The invention discloses a method for synthesizing dihydroxy diphenyl methane with high 4, 4' site content by one stage process, relates to a method for synthesizing bisphenol F with high 4, 4' site content and provides a method for synthesizing dihydroxy diphenyl methane with high 4, 4' site content by one stage process, which reduces dosage of phenol and production cost and has yield of more than 60 percent. The method comprises the following steps: adding the phenol into a container provided with an electric stirrer, a thermometer and a reflux condensation tube, heating the phenol in water bath, adding phosphoric acid after the phenol is fully melted, stirring the mixture, and fully mixing the phenol and the phosphoric acid to obtain mixed solution; adding formaldehyde solution into the mixed solution, separating acid after reaction, neutralizing an oil phase by sodium bicarbonate, separating water and an organic phase, decompressing and distilling the mixed solution, removing the phenol and the water, and cooling, crystallizing and filtering the mixed solution to obtain products.

Owner:XIAMEN UNIV

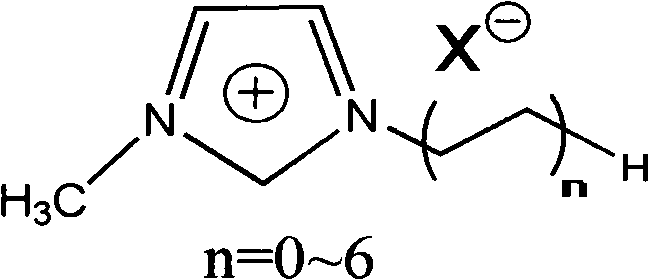

Chemical method for preparing organic silicon modified epoxy resin

InactiveCN102532556AGood compatibilitySimple preparation processAdhesivesBoiling pointCompound (substance)

The invention relates to a chemical method for preparing organic silicon modified epoxy resin, aiming to solve the technical problems that the compatibility is not good and the efficiency is low in a modification process of organic silicon epoxy resin. The chemical method comprises the following steps of: adding epoxy resin (one of bisphenol A epoxy resin and bisphenol F epoxy resin), hydroxyl-terminated methyl phenyl polysiloxane (with the use amount of 20-50% of the mass of the epoxy resin) and a catalyst (which is 1-5% of the total mass of two components including the epoxy resin and the hydroxyl-terminated methyl phenyl polysiloxane) into a reactor; uniformly agitating and gradually raising the temperature to 60-140 DEG C, and reacting for 4-6 hours; after the reaction, lasting under the condition of 120-130 DEG C / 5-10 mmHg for 0.5 hours; and desorbing low-boiling-point compounds, which are generated in the reaction, in vacuum to obtain the organic silicon modified epoxy resin.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method for bisphenol F

ActiveCN102491879AEasy to separate and recycleThe synthesis process is simpleOrganic chemistryOrganic compound preparationAluminium chlorideSynthesis methods

The invention discloses a synthesis method for bisphenol F, in which aluminium chloride, titanium tetrachloride and modified cation exchange resin are adopted as catalysts, and phenyl hydroxide and formaldehyde are adopted as raw materials. The invention has the technical effects as follows: the aluminium chloride, the titanium tetrachloride and the modified cation exchange resin are adopted for catalysis to synthesize the bisphenol F, and the resin catalyst is easy to separate and recover and can be used repeatedly; 2, a recrystallization and reduced pressure distillation combined separation technology is adopted for coproduction of high-purity bisphenol F and common bisphenol F products, the maximum yield of the bisphenol F reaches 90 percent, the content of 4, 4'-bisphenol F in a dimethyl benzene recrystallization product reaches 93.5 percent, reduced pressure distillation after-products are mainly other two isomers, and the separation of the 4, 4'-bisphenol F is realized effectively; 3, the requirement for the concentration of the formaldehyde raw material is not strict while the traditional one stage process require that the concentration of formaldehyde is above 40 percent; and 4, the synthesis technology is simple, the operation is convenient, and the realization of industrial production is easy.

Owner:湖南嘉盛德材料科技股份有限公司

Wear-resistant epoxy glue and preparation method thereof

InactiveCN102040933AIncrease elasticityImprove wear resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesGas phaseMicrosphere

The invention relates to wear-resistant epoxy glue and a preparation method thereof. The epoxy glue is prepared by mixing a component A and a component B based on a weight ratio of (100:11.1)-(100:13.3), wherein the component A comprises the following raw materials in parts by weight: 10-20 parts of liquid epoxy resin, 10-20 parts of bisphenol F epoxy resin with modified nano rubber particles, 2.5-5 parts of epoxy resin activity diluent, 0.5-1.0 part of coupling agent, 53-61 parts of aluminum oxide ceramic microsphere, 4-6 parts of white alundum powder, 3-5 parts of glass fiber powder, 0.5-1.2 parts of chopped nylon fiber and 1-2 parts of gas-phase silicon dioxide; and the component B comprises the following raw materials in percentage by weight: 55-65 parts of polyamide, 12-18 parts of isophorone diamine, 4-7.5 parts of AEPHP (N-Aminoethylpiperazine), 1-2 parts of solidification accelerating agent, 8-10 parts of kaolin, 3-6 parts of glass fiber powder and 3-5 parts of gas-phase silicon dioxide. The preparation method comprises the following steps: preparing the bisphenol F epoxy resin with modified nano rubber particles; respectively preparing the component A and the component B;and mixing the component A and the component B in proportion when the epoxy glue is used.

Owner:YANTAI DARBOND TECH

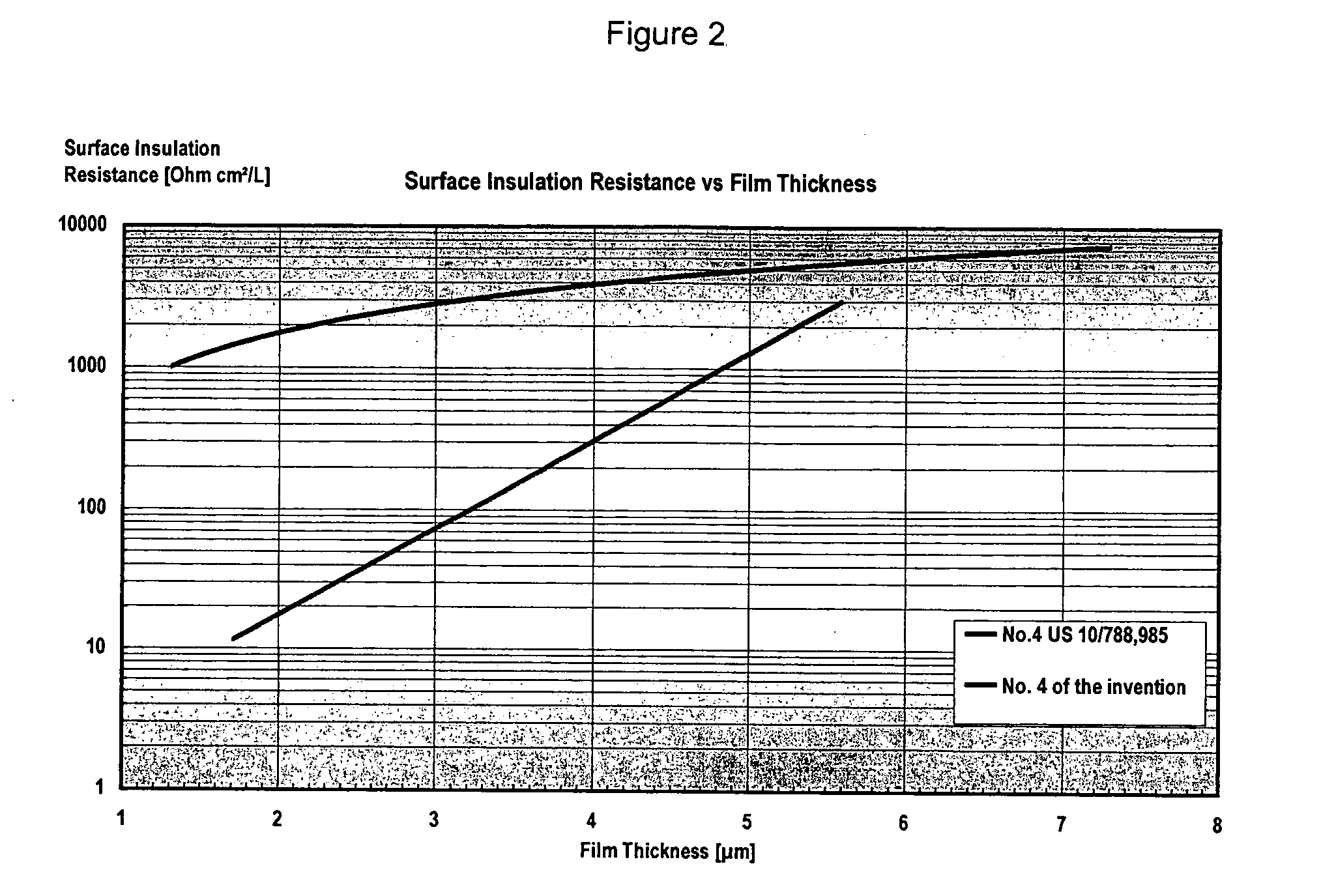

Self-bonding coating composition

InactiveUS20070087201A1Excellent bonding strength and corrosion resistanceIncrease temperatureMaterial nanotechnologySynthetic resin layered productsOrganic solventElectrical steel

A self-bonding coating composition for the production of electrical steel sheets cores comprising A) 100 parts per weight of at least one epoxy resin based on bisphenol-A-type and / or bisphenol-F-type, 100% of solids, B) 0.1 to 200 parts per weight of nano particles having an average radius ranging from 2 to 600 nm, C) 0 to 25 parts per weight of at least one curing agent selected from the group consisting of dicyandiamide, blocked isocyanate and Lewis acid or selected from the group consisting of phenolic resin, carboxylic acid, anhydride and Lewis acid, 100% of solids, D) 0.1 to 10 parts per weight of at least one additive, and E) 50 to 200 parts per weight of water or at least one organic solvent, ensuring increased re-softening temperatures as well as excellent bonding strength, corrosion resistance and electrical insulation of the coating.

Owner:EI DU PONT DE NEMOURS & CO

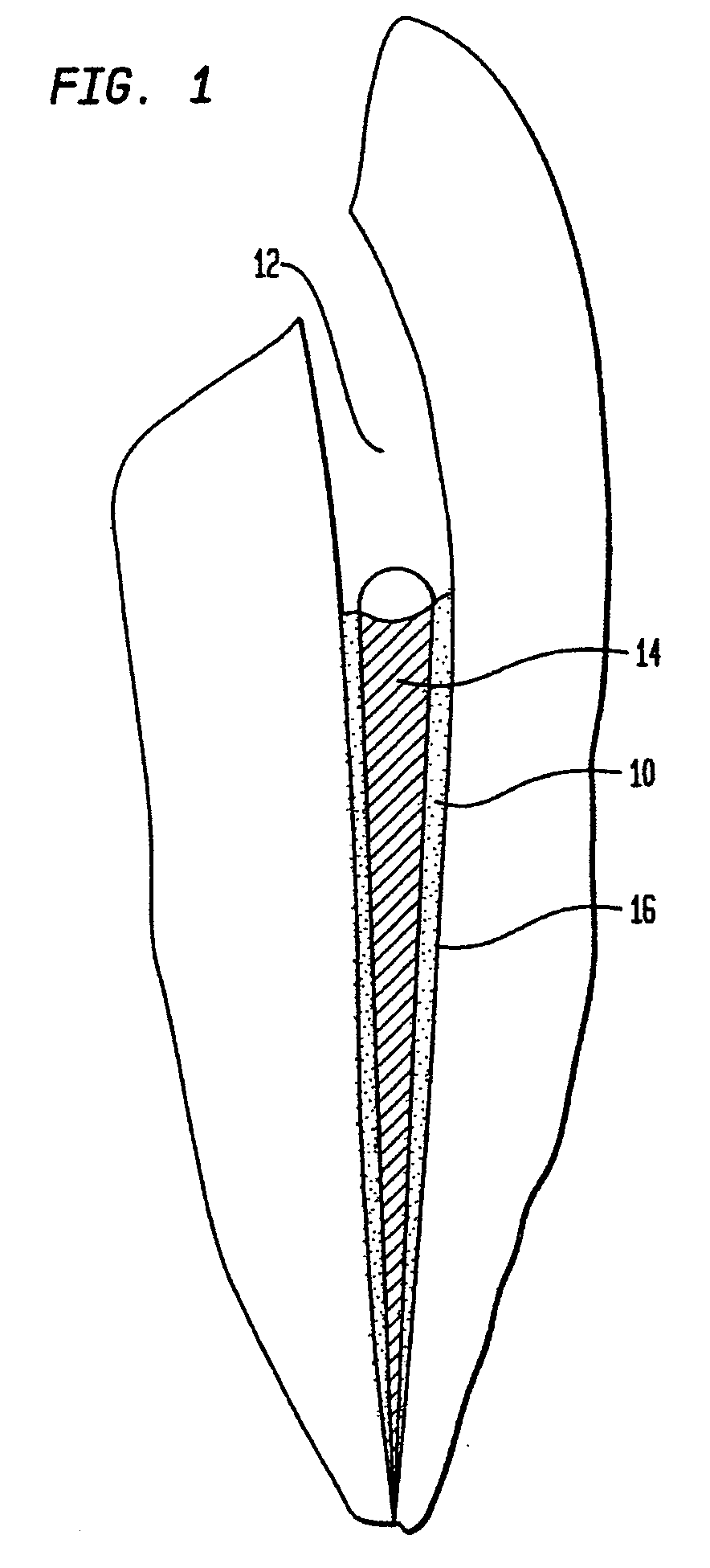

Epoxy based oil free root canal sealer

Epoxy polymers for dental use including the reaction product of a diepoxide oligomer and a bridged dipolyamine are described. The epoxy polymers include the reaction product of diepoxide oligomers comprised of bisphenol A diepoxide oligomers and / or bisphenol F diepoxide oligomers and bridged dipolyamine monomers having two polyamine regions and a hydrocarbon region of at least 28 carbon atoms.

Owner:ESSENTIAL DENTAL SYST

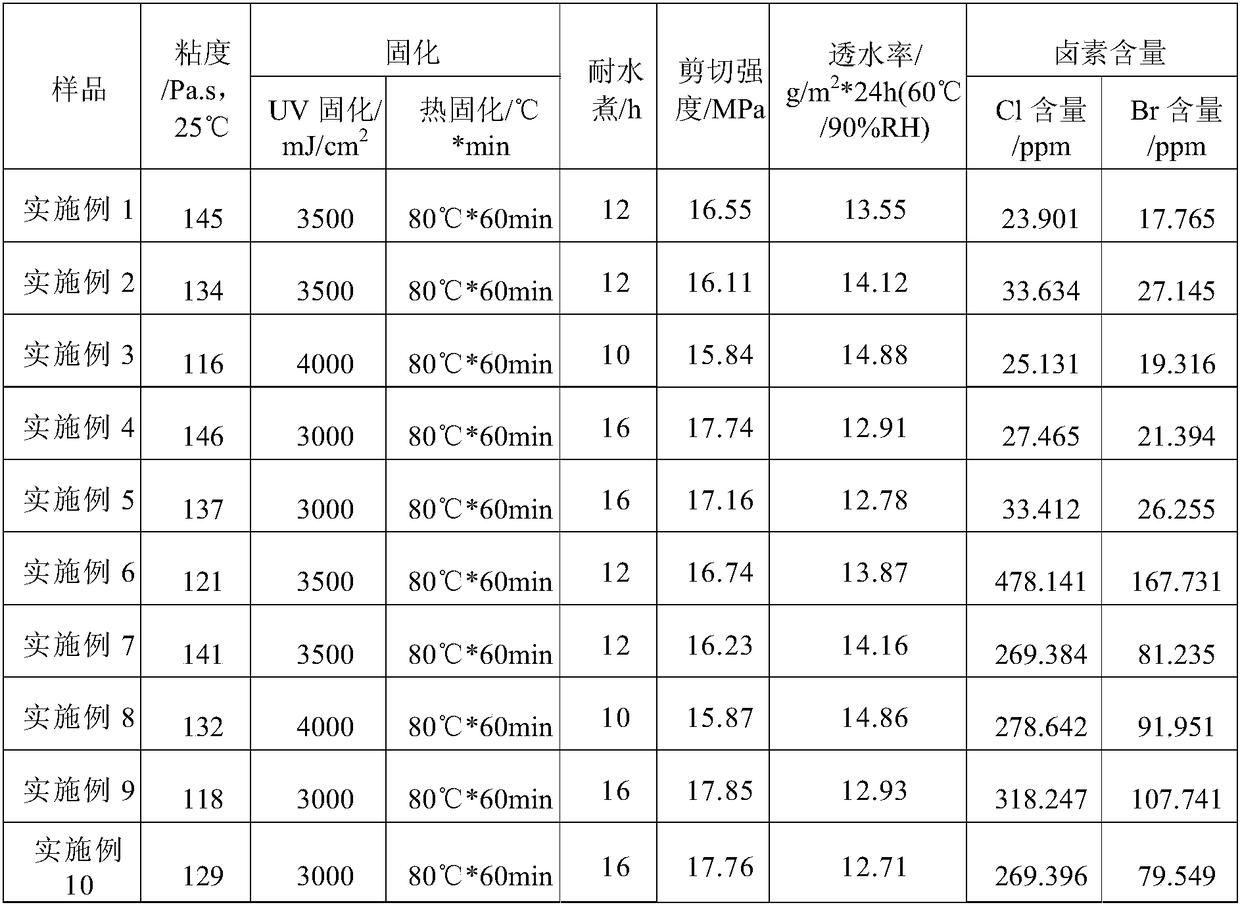

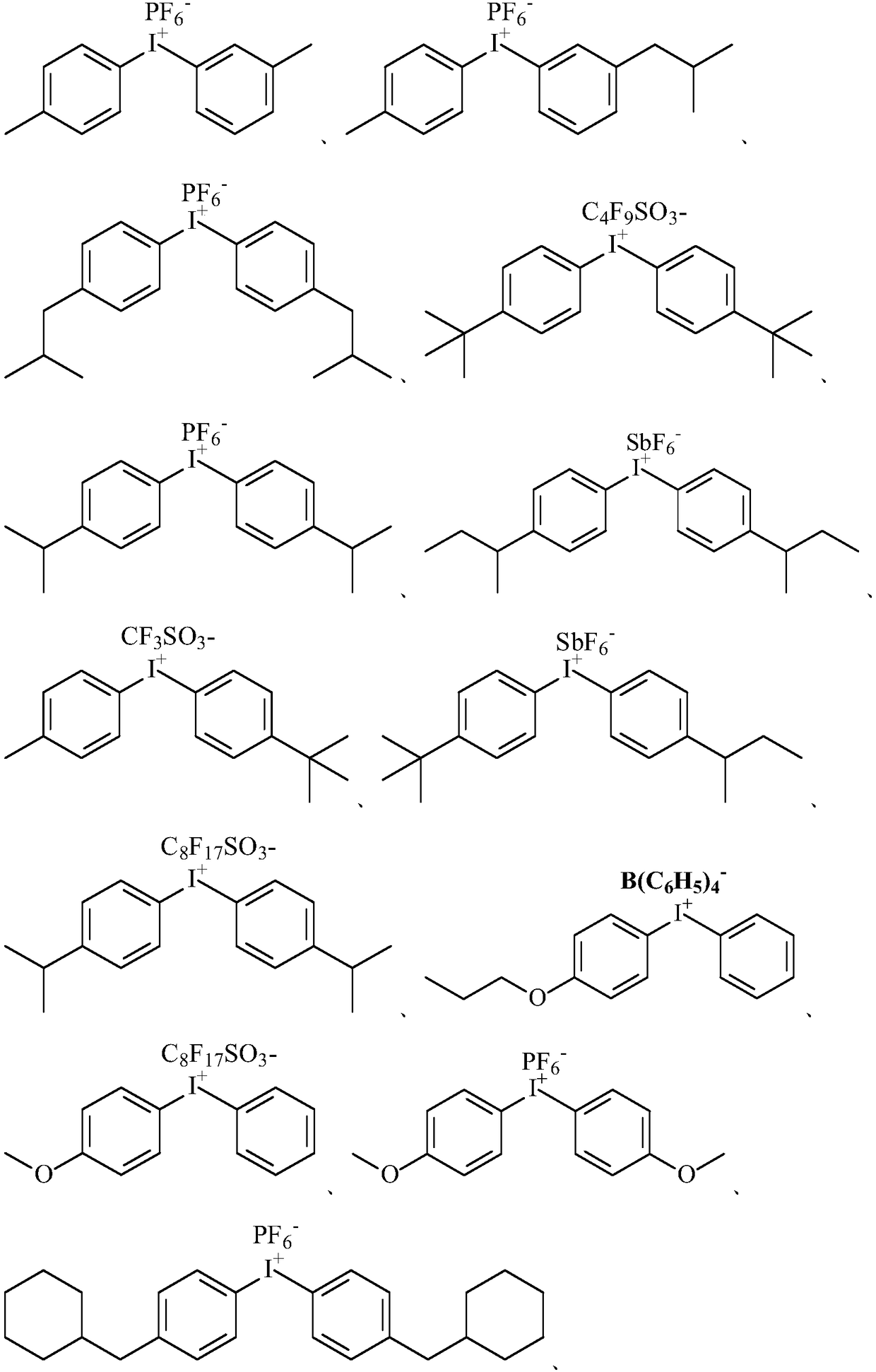

Epoxy adhesive for OLED frame encapsulation and preparation method of epoxy adhesive

InactiveCN108546536ACuring shrinkage is smallNot easy to terminateNon-macromolecular adhesive additivesMacromolecular adhesive additivesAntioxidantWater vapor

The invention discloses an epoxy adhesive for OLED frame encapsulation and a preparation method of the epoxy adhesive. The epoxy adhesive is prepared from the following components in parts by weight:50-80 parts of epoxy resin, 5-10 parts of epoxy diluents, 5-10 parts of flexibilizer, 20-40 parts of filler, 1-5 parts of photoinitiator, 0.1-1 part of antioxidant and 0.3-3 parts of additive. The epoxy resin is one or a mixture of more of cycloaliphatic epoxy resin and bisphenol F epoxy resin. The epoxy diluent is one or a mixture of more of oxetane and aliphatic glycidyl ether. The photoinitiator is a cationic photoinitiator which comprises an iron-arene photoinitiator and a hexafluorophosphate photoinitiator. The epoxy adhesive adopts a curing way that ultraviolet exposure and heating are conducted in sequence, has the advantages of less curing agent residue, less volatile component residue, low curing temperature, strong bonding force, boiling resistance, water vapor resistance, oxygenbarrier performance and the like, and reaches the halogen-free standard.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Electric-insulation epoxy resin castable for outdoor mutual inductor

ActiveCN103709608AExcellent physical and chemical propertiesHeat resistantPlastic/resin/waxes insulatorsPolymer scienceFirming agent

The invention relates to an electric-insulation epoxy resin castable for an outdoor mutual inductor. The epoxy resin castable comprises the following materials by weight percent: 21-26% of resin, 45-55% of filling, 15-25% of a curing agent and 2-6% of other auxiliary agents, wherein the resin is formed by mixing organic silicon modified epoxy resin, phenolic aldehyde epoxy resin, brominated epoxy resin and bisphenol F-type epoxy resin; the filling is silane-processed silica powder; the curing agent is modified methylhexahydrophthalic anhydride; the other auxiliary agents include a curing catalyst, a plasticizer, a reactive diluent, a silane coupling agent, a coloring agent and an antioxidant. The electric-insulation epoxy resin castable has excellent physical and chemical properties and has the performance of heat resistance, low temperature resistance, ultraviolet irradiation resistance, ageing resistance and the like. The electric-insulation epoxy resin castable is applicable to the electric insulation of the outdoor mutual inductor and other electrical equipment.

Owner:JIANGXI TENGDE IND

Weather-resistant epoxy polyurethane anticorrosive paint and preparation thereof

InactiveCN101298535AGood weather resistanceStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsGas phaseSiloxane

The invention relates to a weather resistant epoxy-polyurethane anti-corrosion coating and a manufacturing method thereof, which adds phenol-A epoxy resin, bisphenol-F epoxy resin, hydroxyl contained saturated polyester resin and fluorocarbon resin into the mixed solvent of dimethylbenzene, n-butyl acetate, methyl isobutyl ketone and butanone; then adds rutile type titanium pigment, saponite, sericite in powder, polyacrylate co-polymer, polymethyl alkyl siloxane, benzotriazole, gas phase silica and iso-caprylic acid znic to make the fluid A of the weather resistant epoxy-polyurethane anti-corrosion coating while adds fatty group polyisocyanate into the mixed liquor of anhydro-dimethylbenzene and the n-butyl acetate to make fluid B, and mix the two components during application. The invention can be applied to the preservation of the surfaces of outdoor steel structures, pipes and concrete requiring weather resistance, light aging resistance and acid, alkali and salt corrosion resistance.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

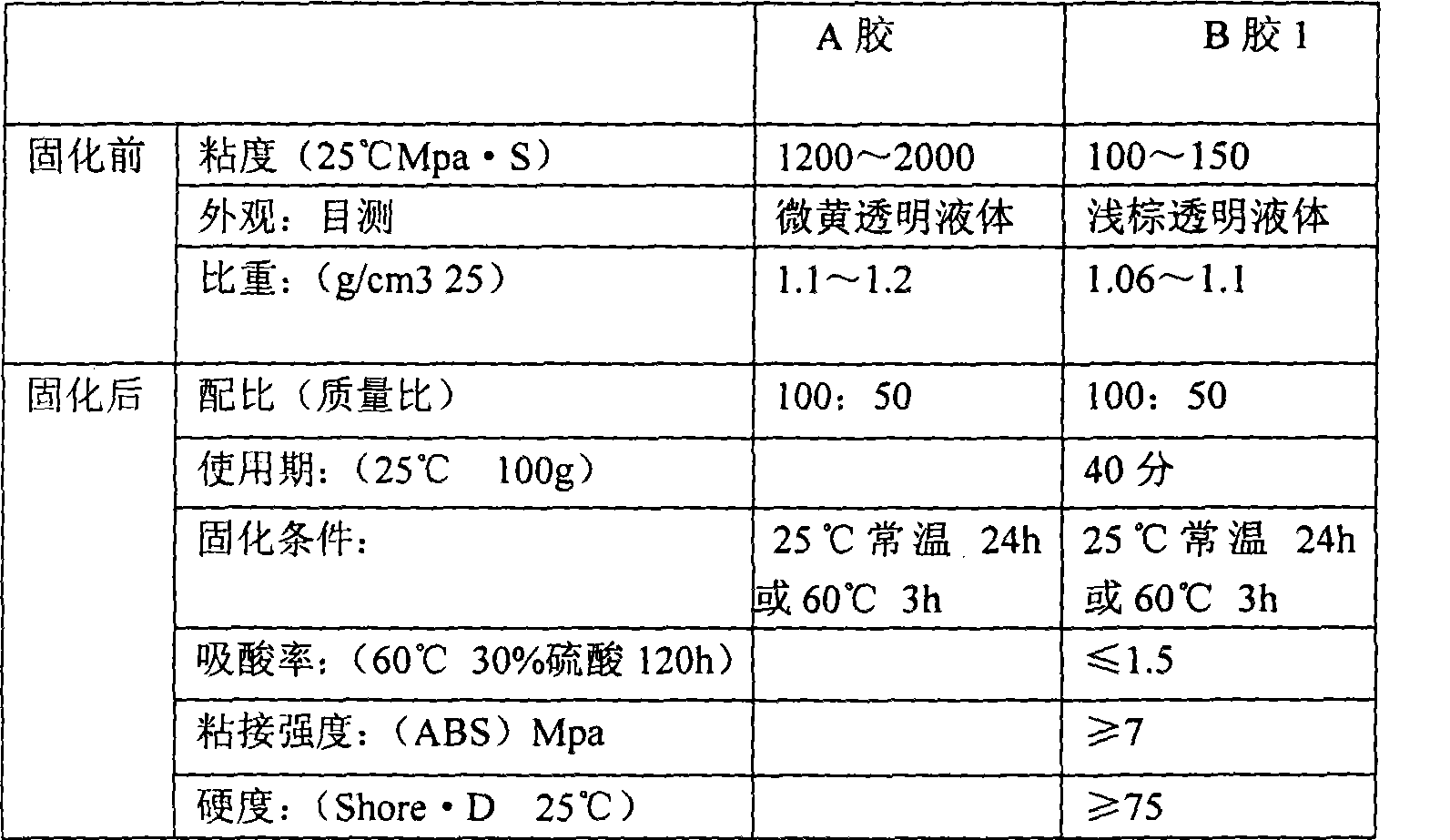

Lead accumulator epoxy resin sealant and preparation method thereof

ActiveCN101457133AEfficient responseReduce manufacturing costAldehyde/ketone condensation polymer adhesivesCell component detailsAnilineSealant

The present invention relates to a lead accumulator epoxy resins sealant and preparation method thereof, particularly a cementing compound used on lead acid batteries sealing and adhesive bonding. The lead accumulator epoxy resins sealant includes A component and B component, the mass portion proportioning between A component and B component is as following: A:B = 2:1, wherein the raw material mass proportioning of A component is as following: bisphenol A epoxy resins 70-80, bisphenol F epoxy resins 10-15, butyl glycidyl ether 3-5, 2-methylphenol glycidyl ether 8-12, polyurethane 5-8, resin acceptor 0.1; and the raw material mass portion proportioning of B component is as following: aniline 400, polyoxymethylene 70-76, aminic acid 30, water 100-300, benzenemethanol 300-500, anti-oxidant 2, cure accelerator 20-35, and nonyl phenol 60.

Owner:宜兴市普利泰电子材料有限公司

Epoxy resin composition, prepreg and fiber-reinforced composite materials

An epoxy resin composition containing an epoxy resin [A1], epoxy resin [B1], epoxy resin [C1] and curing agent [D] wherein [A1] is a bisphenol-type epoxy resin with a softening point of 90° C. or more, [B1] is a tri- or higher functional amine-type epoxy resin, [C1] is a bisphenol F-type epoxy resin with a number average molecular weight of 450 or less, and the epoxy resins [A1] to [C1] satisfy the following contents per 100 parts by mass of total epoxy resin content: [A1] 20 to 50 parts by mass, [B1] 30 to 50 parts by mass and [C1] 10 to 40 parts. The present invention provides low-viscosity epoxy resin compositions that are excellent in impregnating reinforcing fibers and capable of producing cured resins with excellent modulus and toughness, as well as prepregs and fiber-reinforced composite materials based on those epoxy resin compositions.

Owner:TORAY IND INC

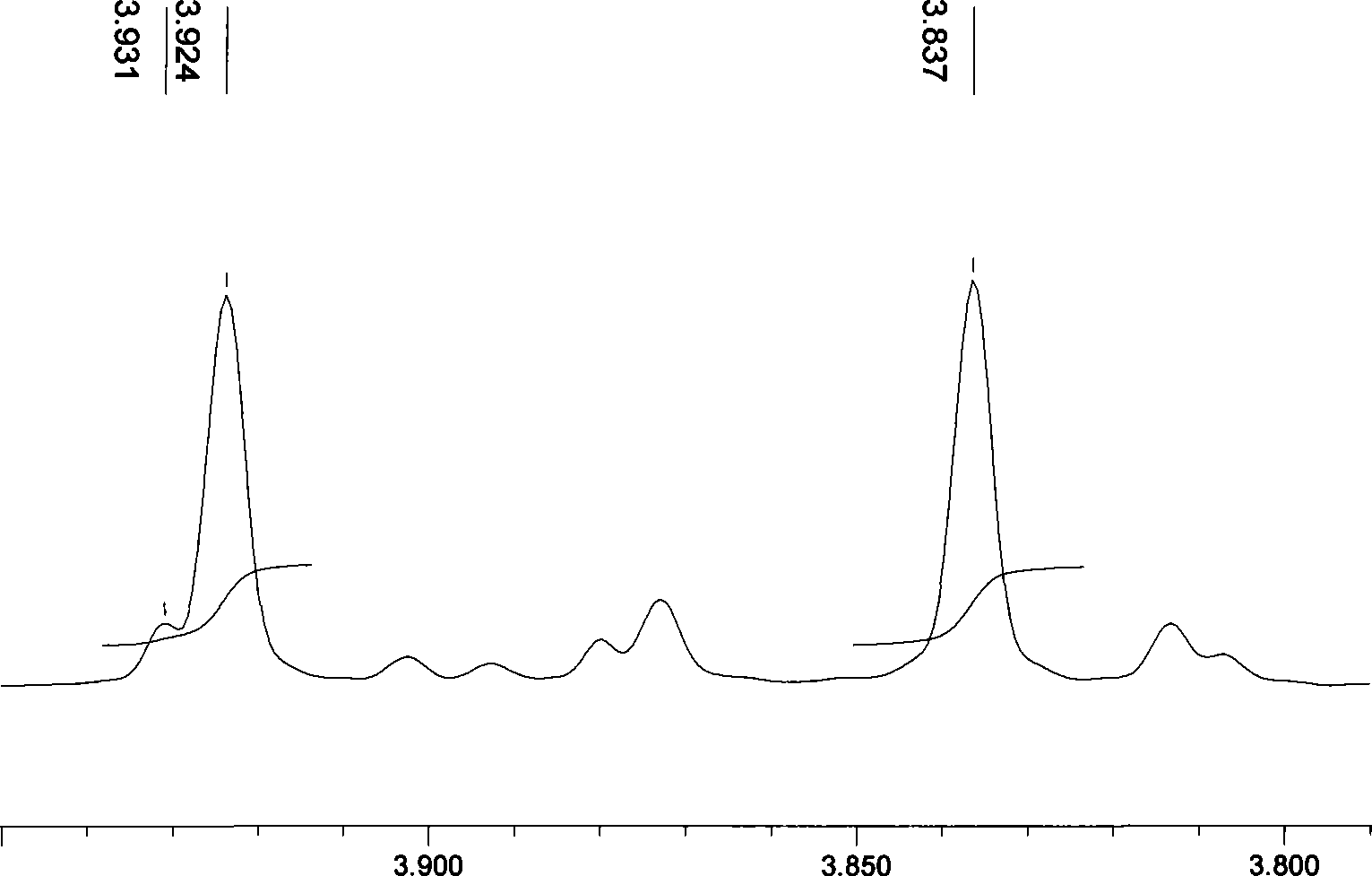

Preparation method of bisphenol F with high ortho-position isomer content

ActiveCN102070409ARaw materials are easy to getEasy to operateOrganic chemistryOrganic compound preparationOrtho positionSynthesis methods

The invention discloses a preparation method of bisphenol F with high ortho-position isomer content. The preparation method comprises the following steps: synthesizing the bisphenol F by adopting a two-step method, separating an organic phase and a phosphoric acid phase, neutralizing the organic phase and removing salt, and recovering phenol under the reduced pressure to obtain the bisphenol F product, wherein in the first step of the two-step synthesis method, the phenol reacts with formaldehyde under the weakly acidic condition; and in the second step, a large amount of catalyst phosphoric acid and formaldehyde are added into the reaction liquid obtained in the first step, and the formaldehyde completely reacts. The invention overcomes the defects that the content of the ortho-position isomer in the bisphenol F prepared by the existing bisphenol F preparation method is low, the curing speed of the synthesized bisphenol F epoxy resin is slow, the resin is easy to crystallize and the like.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

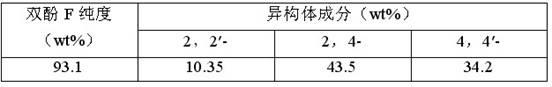

Method for preparing bisphenol F by using 1-alkyl-3-methylimidazole acidic ionic liquid

InactiveCN102584541AExtended service lifeNot corrosiveOrganic chemistryOrganic compound preparationOrganic solventSolvent

The invention relates to a method for preparing bisphenol F by using a 1-alkyl-3-methylimidazole acidic ionic liquid. According to the invention, phenol and formaldehyde are used as raw materials, and the 1-alkyl-3-methylimidazole acidic ionic liquid is used as a solvent and a catalyst, and bisphenol F can be prepared by condensation reaction. As for the method, other organic solvents easy to volatilize are not used, the defects that the reaction time is long, recovery is difficult, the service life is short, the corrosivity is strong and the like when the bisphenol F is subjected to catalytic synthesis by common bronsted acid can be solved, and the method provided by the invention is a novel bisphenol F preparing method which is efficient and environment-friendly.

Owner:XIANGTAN UNIV

Modified epoxy resin adhesive used under low temperature

InactiveCN1670105ASmall coefficient of linear expansionImprove mechanical propertiesEpoxy resin adhesivesEpoxyThermal expansion

The invention relates to a modified epoxide resin adhesive agent used in low temperature and comprises in the weight proportion of modified epoxide resin of 50-80 shares, toughening agent of 50-20 shears and curing agent of 18-24 shears. The said modified epoxide resin is produced using TEOS as a precursor and original position introducing inorganic earth silicon particles in the weight proportion of 2-4 wt% in the bisphenol F epoxide resin by a sol-gel processing. The said toughening agent is low molecular weight epoxide resin, and the said curing agent is liquid aromaticamine. When it is used, mixing the said components homogeneously, spreading on the adhered substance by a vacuum pressure impregnation technology or directly, holding the temperature of 70-80 Deg. C for 24 h, then heating to the temperature of 130-140 Deg. C and holding for 12 h to make the adhesive agent cure completely. The said adhesive agent can be used in the temperature of -269-50 Deg. C and has higher tensile strength in low temperature, better impact flexibility, higher glass transition temperature and lower thermal-expansion coefficient.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Solvent-free high-elasticity epoxy self-leveling coating and preparation method thereof

ActiveCN102876198AReduce brittlenessHigh impact strengthEpoxy resin coatingsSolvent freeReactive diluent

The invention discloses a solvent-free high-elasticity epoxy self-leveling coating and a preparation method thereof. The solvent-free high-elasticity epoxy self-leveling coating is characterized by comprising the following components in part by mass: 100 parts of bisphenol A epoxy resin, 0 to 40 parts of bisphenol F epoxy resin, 10 to 30 parts of single-functional group epoxy reactive diluent, 10 to 30 parts of multi-functional group epoxy reactive diluent, 10 to 40 parts of toughening agent, 5 to 70 parts of inorganic filler, 1 to 4 parts of wetting dispersant, 2 to 3 parts of leveling agent and 1 to 3 parts of defoaming agent. The solvent-free high-elasticity epoxy self-leveling coating is strong in dynamic load bearing capacity and scratch resistance capacity.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Lead-free environmental-friendly circuit board conductive silver paste and preparation method thereof

InactiveCN104036842AReduce dosageImprove printing effectMetal/alloy conductorsCable/conductor manufactureEnvironmental resistanceMicrosphere

The invention provides a kind of lead-free environmental-friendly circuit board conductive silver paste, which is prepared by the following raw material by weights: 60 to 70 of silver powder of 20 to 30mum, 5 to 8 of copper powder of 1 to 10nm, 8 to 10 of glass powder, 5 to 7 of SnO2 powder, 5 to 8 of silver powder of 40 to 60nm, 2 to 4 of pentaerythritol tristearate, 4 to 6 of isophorone, 3 to 5 of saturated polyester resin EK410, 4 to 7 of bisphenol F epoxy resin, 1 to 2 of salicylic acid, 3 to 5 of polyurethane resin, 1 to 2 of triallyl isocyanurate, 1 to 2 of microsphere starch, 1 to 2 of fumed silica, 4 to 6 of isobutyl ketone, 6 to 8 of ethanol , 2 to 4 of butanol, and 6 to 8 of butyl acetate. The lead-free environmental-friendly circuit board conductive silver paste and the preparation method thereof are characterized in that the use amount of the silver powder is small, the printing performance is good, the yield of the circuit board is high, the conductive performance is good, lead-free environmental-friendly performance is provided, the technology is simple, the operation is convenient and easy, and the product performance is convenient to control.

Owner:铜陵市超远精密电子科技有限公司

Modified epoxy adhesive for stone combination and preparation method thereof

ActiveCN102786903AHigh hardnessLow shrinkageNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFatty amine

The invention relates to a two-component modified epoxy adhesive for stone combination and a preparation method thereof, which is characterized in that an A component is prepared by bisphenol A epoxy resin, bisphenol F epoxy resin, an active diluent, a bisphenol A, an anti-yellowing additive, a wetting agent, and inorganic powder, and a B component is prepared by self-made ketoimine, nonyl phenolglycidyl ether modified aliphatic amine, alicyclic amine, a coupling agent, a wetting agent, and a curing accelerator; the A and B components are mixed and used according to a mass ratio of 10:2.5-5.In the ketoimine preparation, the mass ratio of butanone to diethylenetriamine is 70-90:100; in the modified aliphatic amine preparation, the mass ratio of nonyl phenol glycidyl ether to diethylenetriamine is 100:21-32; the two-component modified epoxy adhesive for stone combination has the characteristics of good curing performance, and low cost.

Owner:HUNAN KOSEN NEW MATERIAL

UVLED light-curing wood coating

InactiveCN108314911AGood storage stabilityFast curingEpoxy resin coatingsChemistryCycloaliphatic epoxy

The invention discloses an UVLED light-curing wood coating and application thereof, the coating comprises an oxetane compound, an epoxy compound selected from the group consisting of at least one of bisphenol A type epoxy resin, bisphenol F type epoxy resin or an alicyclic epoxy compound, a (methyl) acrylate compound, a cationic and a radical photoinitiator, and optionally a sensitizer. The coating has excellent response to an UVLED light source in the wavelength range of 200 to 450 nm, and the curing speed is fast. The cured coating is excellent in hardness, wear resistance, flexibility, adhesion, alcohol resistance and yellowing resistance and the like. The coating is odorless and has strong technical and market competitiveness.

Owner:CHANGZHOU GREEN PHOTOSENSITIVE MATERIALS CO LTD

Corrosion-resistant electric material and application thereof

InactiveCN104086888AImprove defectsImprove corrosion resistancePlastic/resin/waxes insulatorsEpoxyTriallyl isocyanurate

The invention discloses a corrosion-resistant electric material which is prepared from the following raw materials: graphite, borax, kieselguhr, kaolin, polypropylene resin, bisphenol F-type epoxy resin, polysiloxane, dicyclopentadiene, dimethylamino ethoxyethanol and triallyl isocyanurate. The invention further discloses an application of the electric material. The corrosion-resistant electric material disclosed by the invention is applicable to multiple different severe environments, and potential safety hazard of an ordinary electric material is avoided.

Owner:重庆浦盛机电工程有限公司

Synthesis method of low-molecular weight epoxy resin

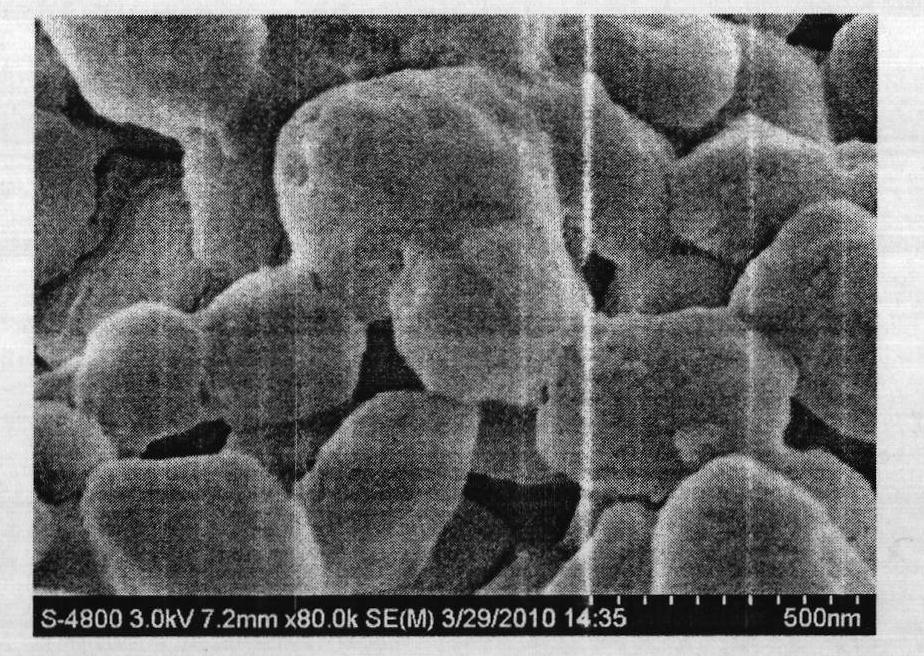

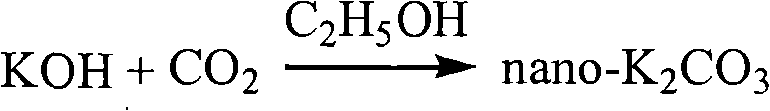

InactiveCN102040568ALong reaction stepsExtend life cycleOrganic chemistrySynthesis methodsReaction temperature

The invention provides a preparation method of low-molecular weight epoxy resin. The method comprises the following steps: adding bisphenol A, epoxy chloropropane, potassium carbonate having grain size of 100-300 nanometer and solvent into a reactor for reaction; and distilling or rectifying the reaction liquid, and recycling the solvent to obtain the low-molecular weight colorless liquid bisphenol A type epoxy resin. The same effect is obtained by replacing bisphenol A with bisphenol S, bisphenol F or bisphenol fluorene to synthesize corresponding bisphenol S, bisphenol F or bisphenol fluorene type low-molecular weight epoxyresin. The method for synthesizing the low-molecular weight epoxy resin has the advantages of low reaction temperature, short reaction time, simple operation, high epoxy value of product, no production of industrial wastewater and good industrial prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Synthesis method of bisphenol F in salt bath system

InactiveCN103319314AHigh yieldIncrease contentOrganic chemistryOrganic compound preparationOrganic solventSynthesis methods

The invention relates to a synthesis method of bisphenol F in a salt bath system. The bisphenol F, which is relatively high in yield, high in content of 4,4-dihydroxy diphenyl methane and good in selectivity, is prepared from a reaction of phenol and formaldehyde under a salt bath system and a catalyst through regulating and controlling technological parameters. And the preparation method is simple, and the synthesis process is free from an organic solvent, thus being light in environmental pollution.

Owner:SHAANXI NORMAL UNIV

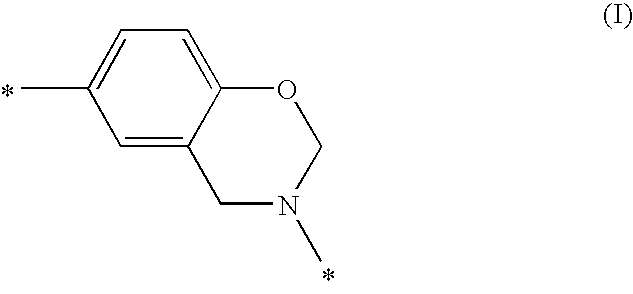

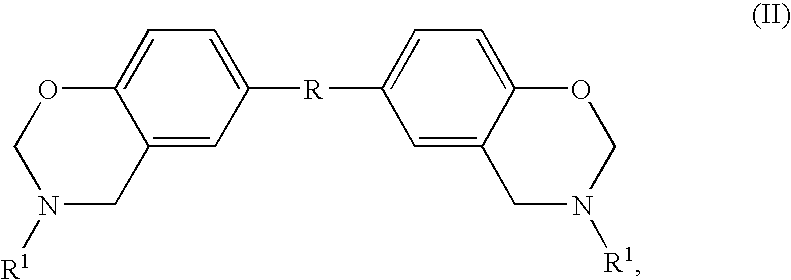

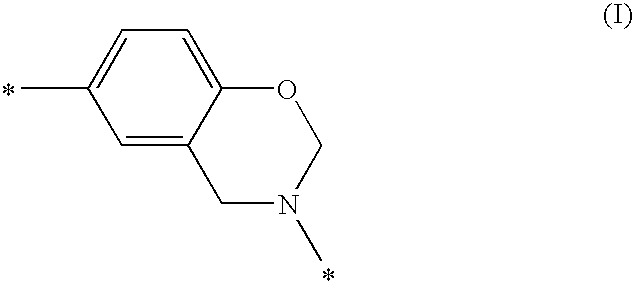

Composition Comprising Benzoxazine and Epoxy Resin

ActiveUS20080302471A1Reduce flammabilityFavorable curing conditionGroup 4/14 element organic compoundsSynthetic resin layered productsPolymer networkBisphenol AF

The instant invention relates to compositions comprising a benzoxazine resin and an advancement resin based on bisphenol A diglycidyl ether and bisphenol S and, optionally, ferrocene and aluminium trihydrate. Such compositions are, when cured to form polymeric networks, difficultly inflammable and resistant to high temperatures. Such compositions may especially be used in the production of printed wiring boards.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC +1

Epoxy resin pouring sealant and preparation method thereof

InactiveCN107163888AImprove crack resistanceImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAging resistance

The present invention relates to an epoxy resin pouring sealant and a preparation method thereof, the epoxy resin pouring sealant includes A and B components, the A component includes, by weight, 40-70 parts of bisphenol F epoxy resin, 20-50 parts of an active polyurethane toughening agent, 10-20 parts of an active diluent, 30-50 parts of an inorganic filler and 1-10 parts of an additive; the B component includes, by weight, 40-70 parts of modified alicyclic amine; 30-60 parts of polyetheramine and 3-10 parts of a promoter. The weight ratio of A to B is 2-4:1. The epoxy resin pouring sealant has better aging resistance and strong resistance to cold and hot impact, and meets the high temperature and cold impact requirement of electronic sealing.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

Insulation cable material and preparation method thereof

InactiveCN104119624AImprove insulation performanceImprove mechanical propertiesEpoxyAluminium hydroxide

The invention belongs to the field of new materials, and discloses an insulation cable material prepared from the following raw materials by weight: 30-40 parts of PVC (polyvinyl chloride), 20-30 parts of polypropylene resin, 16-20 parts of bisphenol F epoxy resin, 12-15 parts of gamma-aminopropyltriethoxysilane, 10-12 parts of phthalic anhydride, 5-6 parts of modified diatomite, 5-6 parts of modified kaolinite, 3-4 parts of dimethyaminoethoxyethanol, 2-3 parts of polyglycolic acid, 1-2 parts of triallyl isocyanurate, 1-2 parts of aluminium hydroxide, 1-2 parts of antimonous oxide and 1-2 parts of titanium carbide. The insulation cable material not only has good insulation properties, but also has the advantages of high mechanical strength, corrosion resistance, good flame retardant performance and low cost , and the like.

Owner:STATE GRID CORP OF CHINA +1

Epoxy resin composition for vacuum introduction formation of fibre reinforced composite material and preparation method of epoxy resin composition

InactiveCN102964780ALow viscosity requirementImprove high temperature resistanceResin matrixFiber-reinforced composite

The invention relates to an epoxy resin composition for vacuum introduction formation of a fibre reinforced composite material and a preparation method of the epoxy resin composition. The epoxy resin composition comprises a component A and a component B, wherein the component A comprises the following ingredients in parts by mass: 100 parts of epoxy resin, 5-20 parts of diluent, 0.5-5.0 parts of silane coupling agent, 0.5-5.0 parts of inorganic filler; and the component B comprises the following ingredients in parts by mass: 25-45 parts of amine curing agent and 0.5-5.0 parts of accelerant. According to the invention, blend type epoxy resins of hydantoin epoxy resins and low-viscosity epoxy resins (4,5-epoxy cyclohexane-1,2-dioctyl phthalate diglycidyl ester, bisphenol F type glycidyl ether epoxy resin or bisphenol A type glycidyl ether epoxy resin) are adopted as a resin matrix, so that the requirement of vacuum introduction formation of the fibre reinforced composite material for the resin low viscosity can be met, and a composite material product has excellent high temperature resistance property.

Owner:BLUESTAR BEIJING CHEM MACHINERY

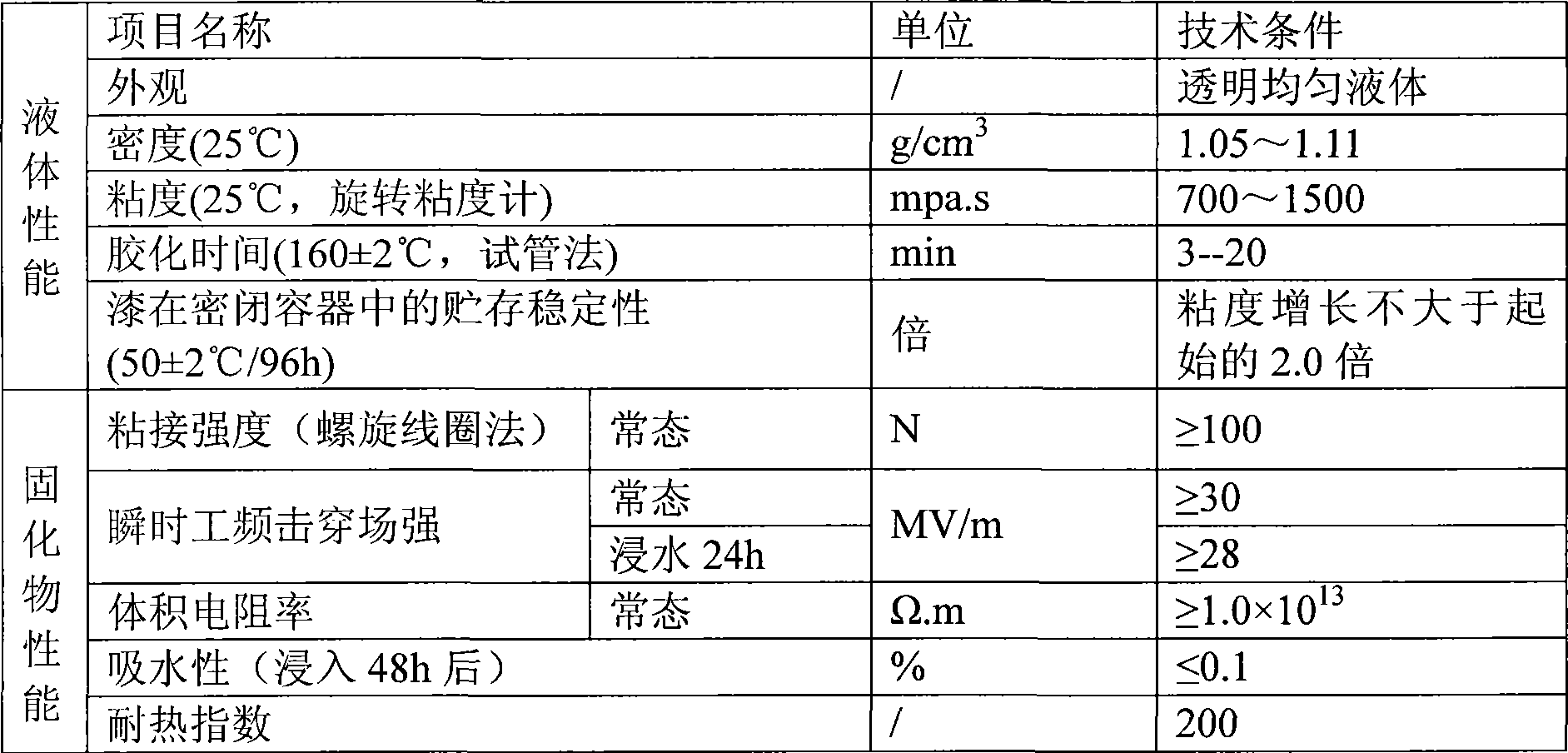

Epoxy solvent-free impregnating resin and preparation thereof

A 200-level epoxy solvent-free impregnated resin chooses bisphenol F epoxide resin, alicyclic epoxide resin and polyimide resin as main resin material. Pre-polymerization modification is carried out to the resin, and then epoxy anhydride solvent-free impregnated resin is made by adding modified thermostable anhydride as a curing agent; subsequently, by using the thermostable anhydride and metal salt to carry out complex reaction, the impregnated resin is passivated to form a relatively stable complex compound so as to ensure that the epoxy resin and the anhydride are stable at low temperature (normal condition) after mixing, and quickly react when the temperature reaches certain extent. As the bisphenol F epoxide resin, the alicyclic epoxide resin and the thermostable anhydride have small molecular weight and low viscosity, the viscosity is moderate and the permeability is good after the resins are mixed with the polyimide resin, therefore, the impregnated resin can satisfy the property and use technology requirements on impregnated resin in the insulated structure of a high-speed train motor with the speed per hour up to over 200km / h.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com