Method for synthesizing high content of 4,4'-dihydroxydiphenylmethane by one-step method

A technology of dihydroxydiphenyl and step method, which is applied in the field of synthetic compounds, can solve problems such as too long process routes, and achieve the effects of simple synthesis process, convenient operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 37.6g of phenol into a four-neck flask equipped with an electric stirrer, a thermometer and a reflux condenser, heat in a water bath, and after the phenol is fully melted, drop in 5.4ml of phosphoric acid, stir vigorously to fully mix the phenol and phosphoric acid, and then slowly drop Add 8.2 g of formaldehyde solution (according to mass percentage, the concentration of formaldehyde solution is 37%), make the molar ratio of phenol and formaldehyde 4: 1, and react at a constant temperature at 45°C for 4 hours, stop stirring, and separate the acid and oil phase with a separatory funnel Neutralize with sodium bicarbonate to pH 5.6, then separate the water from the organic phase, then use a rotary evaporator for vacuum distillation to remove phenol and water, cool, crystallize, and filter to obtain the product.

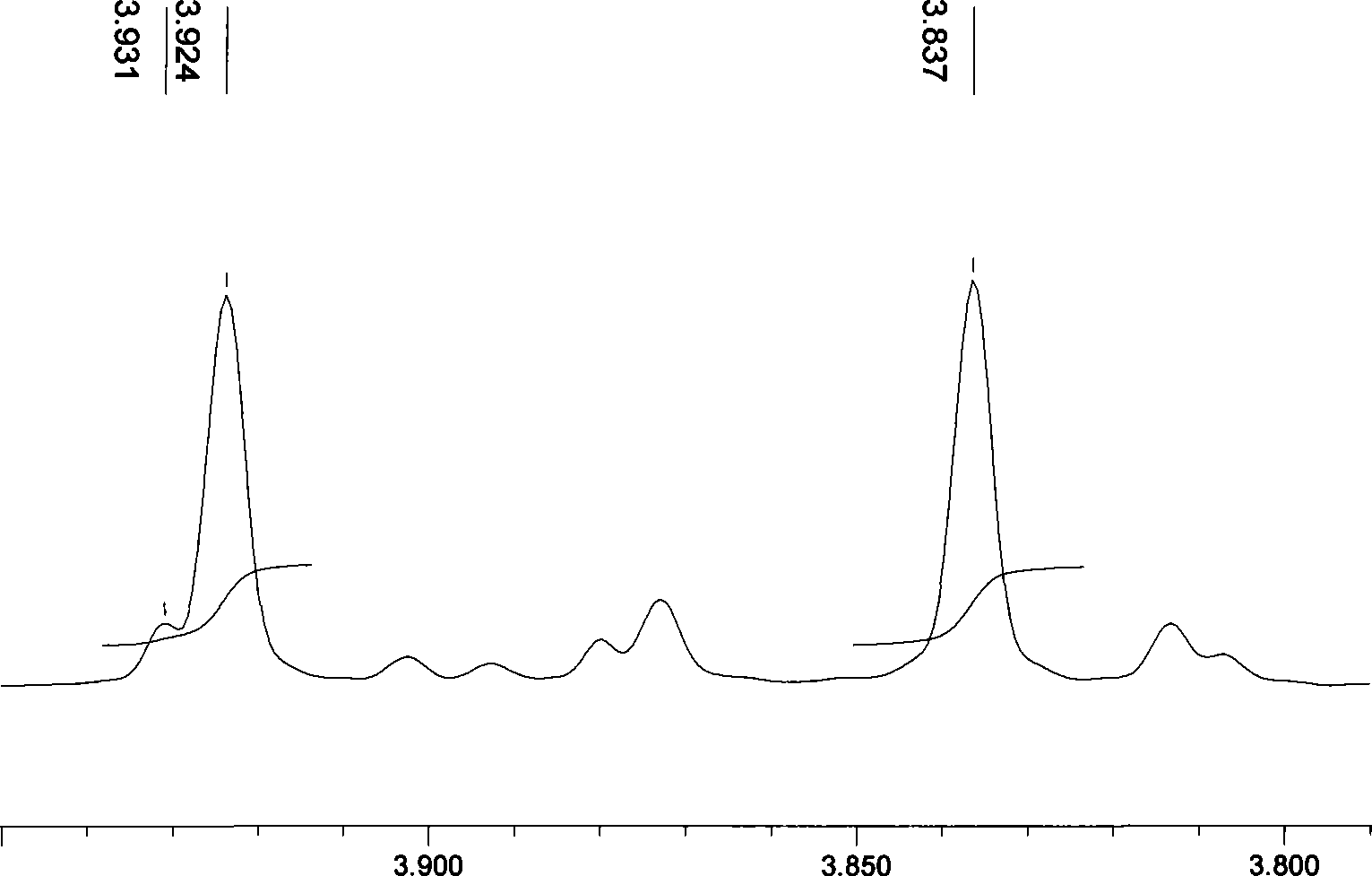

[0047] see figure 1 , the peaks of chemical shift 3.931 and 3.924 belong to the methylene nuclei of 2,2'-structure and 2,4'-structure respectively, and the p...

Embodiment 2

[0050] Similar to Example 1, the difference is that the concentration of formaldehyde solution is 40%, the molar ratio of phenol to formaldehyde is 5:1, and the oil phase is neutralized to pH 6 with sodium bicarbonate.

Embodiment 3

[0052] As described in Example 1, the amount of phenol was changed to 28.3g, so that the molar ratio of phenol to formaldehyde was 3:1, and the concentration of formaldehyde was 38% by mass percentage, and the oil phase was neutralized with sodium bicarbonate until the pH value was 5.5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com