Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Butyl vinyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

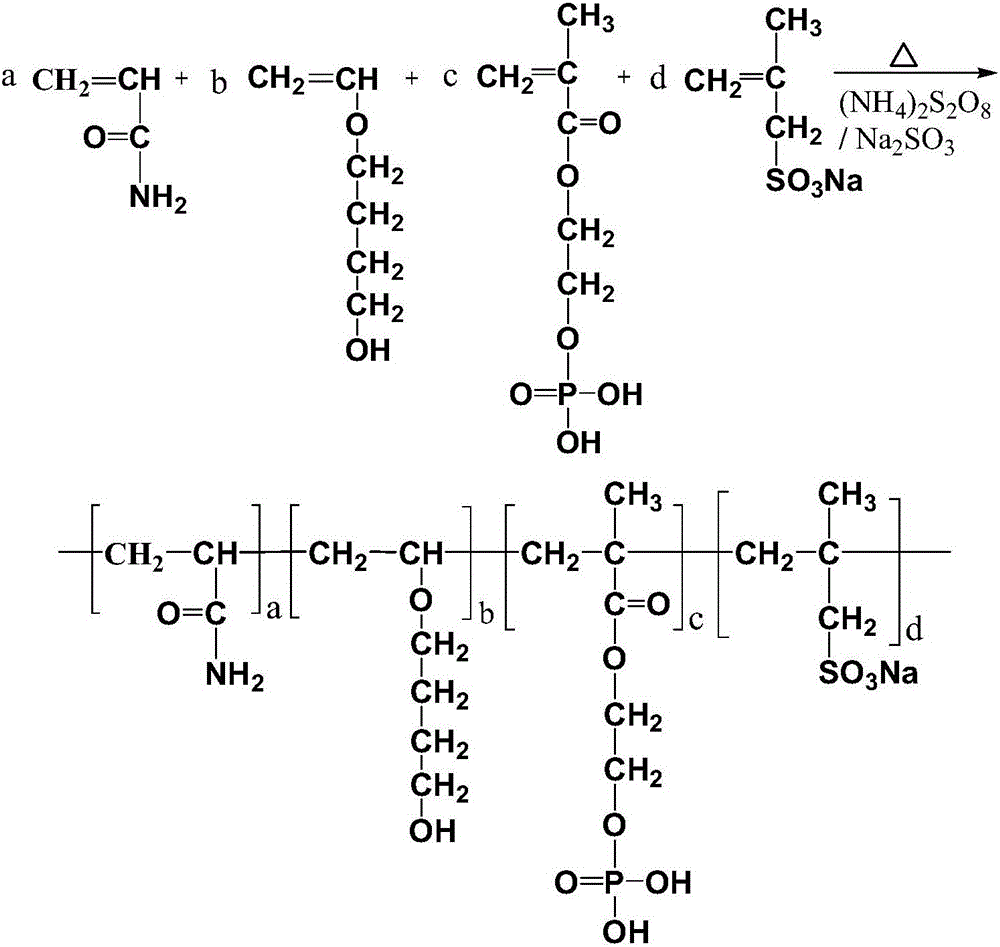

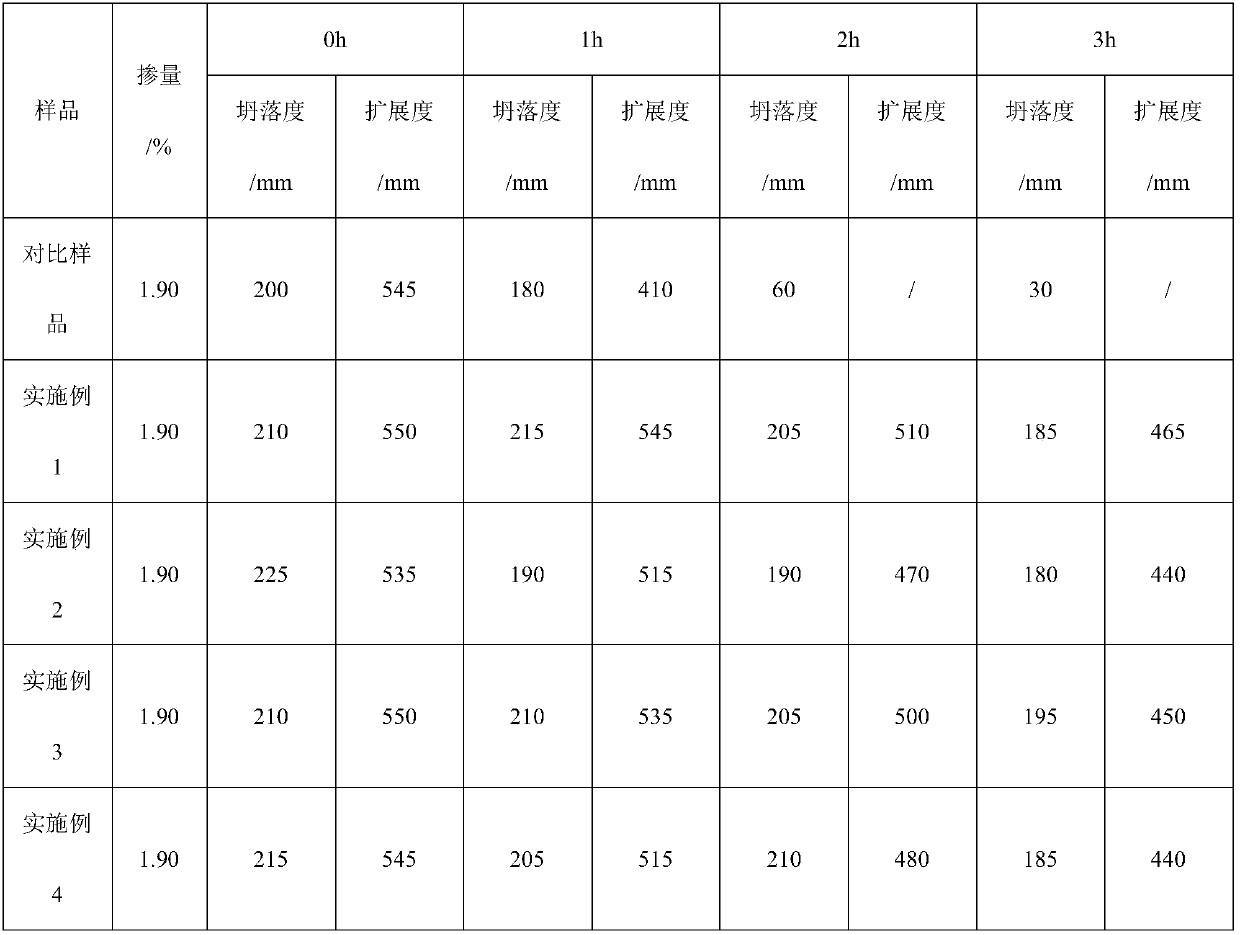

Concrete viscosity reducer and preparation method thereof

The invention discloses a concrete viscosity reducer and a preparation method thereof. The viscosity reducer is prepared from raw materials including 1,4-butanediol vinyl ether, unsaturated amide and unsaturated phosphate ester through polymerization. The production process of the prepared concrete viscosity reducer is simple, the concrete viscosity reducer has good adaptability with a polycarboxylate water reducer, the concrete viscosity reducer in the mass 0.01%-0.03% that of gel materials is mixed with concrete, the workability of the concrete can be remarkably improved, and the problems that the concrete viscosity is high and concrete is difficult to pump at a low water-gel ratio are effectively solved.

Owner:中建西部建设新材料科技有限公司 +2

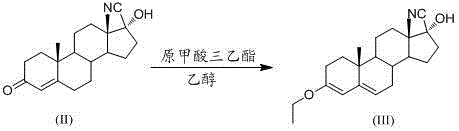

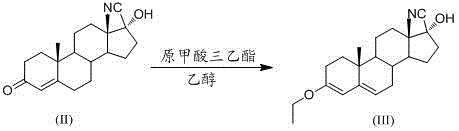

Synthesis method of 17alpha-hydroxyl progesterone

The invention discloses a synthesis method of 17alpha-hydroxyl progesterone, which comprises the steps of by taking 4-androstene-diketone as a starting raw material, carrying out vyanation via acetone cyanohydrin, protecting 3carbonyl by using triethyl orthoformate and ethyl alcohol, protecting 17hydroxy by using butyl vinyl ether, and carrying out hydrolysis after Grignard reaction to generate the 17alpha-hydroxyl progesterone. According to the synthesis method, the cost is reduced, the environment pollution is decreased, the reaction time is shortened, the aftertreatment process of the industrial production is simplified, the production time and cost are greatly saved, the productivity is improved and convenience is brought to the industrial implementation. Compared with the traditional process, the synthesis method has the characteristics of low raw material cost, simple and convenient method, high yield, good selectivity, mild reaction condition, small pollution and applicability to industrial production; and the method is stable and easy to realize.

Owner:ZHEJIANG PURUI PHARMA

Process for polymerization preparation of vinyl chloride/isobutyl vinyl ether copolyresin latex

The invention discloses a process for polymerization preparation of vinyl chloride / isobutyl vinyl ether copolyresin latex which consists of, subjecting 65-85 parts of chloroethylene and 15-35 parts of isobutylvinyl ether monomer to emulsifier-containing, water-soluble redox initiation system and aqueous phase of pH regulator for polymerization 2-12 hours, wherein the polymerization temperature being 35-65 deg. C.

Owner:HANGZHOU ELECTROCHEM GROUP +1

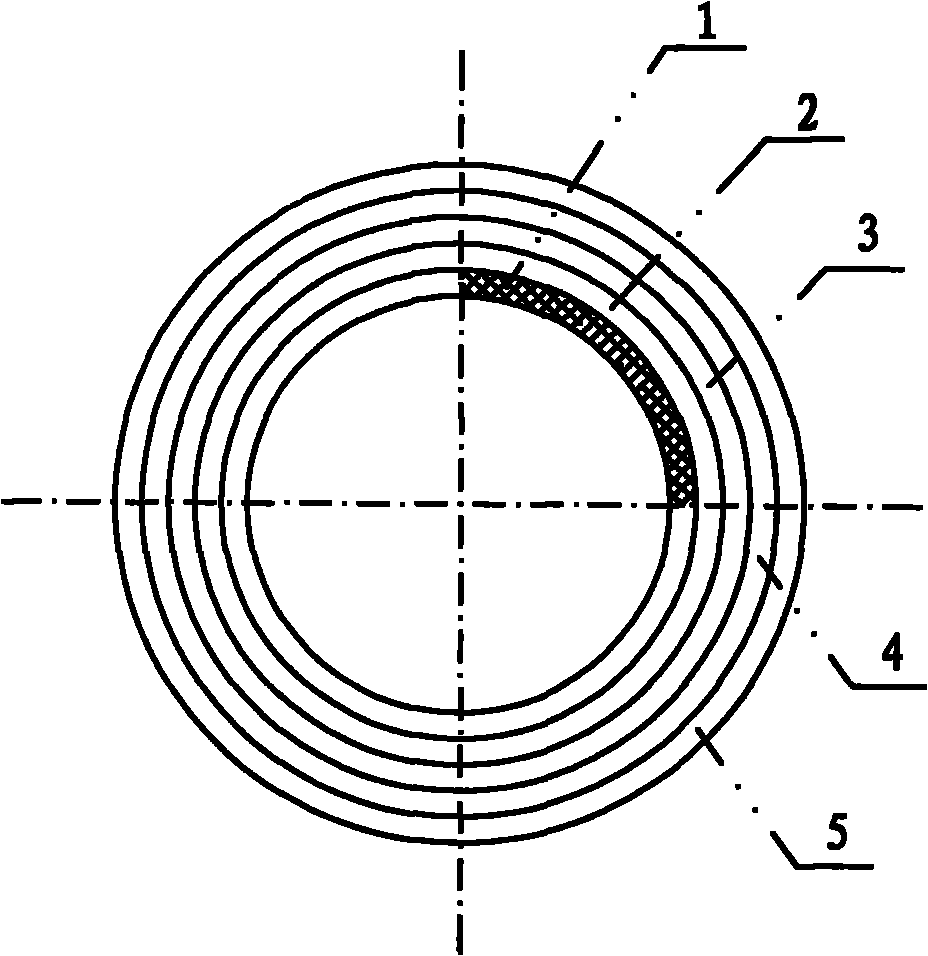

Perfluoroether composite air condition hose and preparation method thereof

InactiveCN102042446AMeet anti-seepage requirementsChemically resistantFlexible pipesRubber materialVulcanization

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

Copolymer resin of chloroethylene-isobutyl vinyl ether-glycidyl acrylate and preparation method thereof

The invention discloses a copolymer resin of chloroethylene-isobutyl vinyl ether-glycidyl acrylate and a preparation method thereof. The copolymer resin is obtained by copolymerization of 65-85 mass parts of chloroethylene, 15-30 mass parts of isobutyl vinyl ether and 0.5-5.0% (corresponding to the total mass of chloroethylene and isobutyl vinyl ether) of glycidyl acrylate. The preparation method comprises the following steps: adding the chloroethylene, isobutyl vinyl ether and glycidyl acrylate into aqueous phase containing emulsifier, a water-soluble redox initiation system and pH regulator, and carrying out emulsion polymerization for 3-10 hours at the temperature of 35-60 DEG C. The invention adds glycidyl acrylate into chloric ether resin to improve the heat stability of chloric ether resin and adhesion with metal; and meanwhile, copolymer has uniform composition and has high dissolving speed in solvent, such as sundex and the like.

Owner:HANGZHOU ELECTROCHEM GROUP +1

Cementing compositions

A cement composition is basically comprised of a hydraulic cement, water in an amount sufficient to form a pumpable slurry and a fluid loss control polymer additive comprised of 69 weight % of the calcium salt of 2-acrylamido-2-methyl propane sulfonic acid, 14 weight % of the calcium salt of maleic acid, 14 weight % of N-vinyl caprolactam and 3 weight % of 4-hydroxybutyl vinyl ether.

Owner:HALLIBURTON ENERGY SERVICES INC

Stain resistant environment-friendly color-coated sheet

ActiveCN105002495AImprove corrosion resistanceImprove adhesionSuperimposed coating processEpoxyEnvironmental resistance

The invention provides a stain resistant environment-friendly color-coated sheet, comprising a substrate, a chemical passivation layer, a low fluorine base coat, a high fluorine surface coat and a back coat, wherein the substrate is a steel plate and the surface of the steel plate is coated with a zinc layer; the high fluorine surface coat comprises 3-5wt% of 1,4-butanediol, 1-2wt% of silicon dioxide, 1-3wt% of aluminium oxide and 90-95wt% of polyvinylidene fluoride; the low fluorine base coat comprises 15-25wt% of 4-hydroxybutyl vinyl ether, 10-20wt% of polyvinyl alcohol and 55-75wt% of polyvinylidene fluoride; the chemical passivation layer comprises 25-30wt% of molybdate, 45-50wt% of organic fluorine modified epoxide resin, 5-7wt% of zirconium nitrate, 10-15wt% of phosphoric acid and 5-15wt% of silicon dioxide. The color-coated sheet prepared by the invention is high in stain resistance and weather fastness, and the surface coat is excellent in adhesion force.

Owner:扬子江新型材料(苏州)有限公司

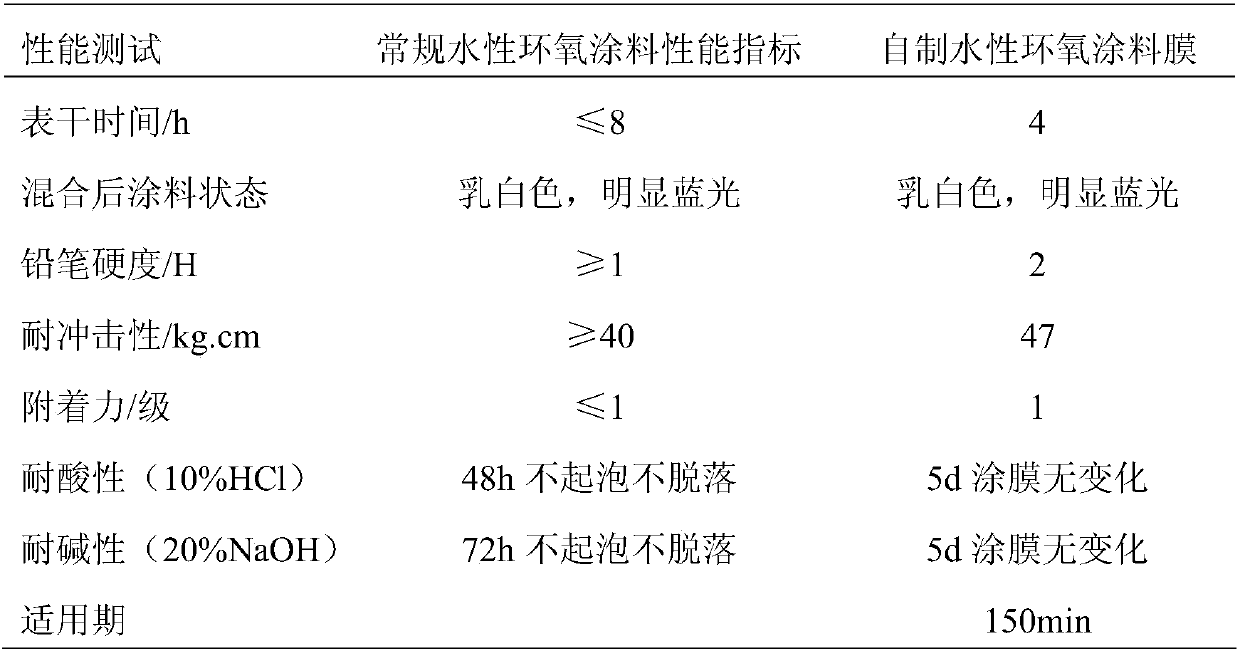

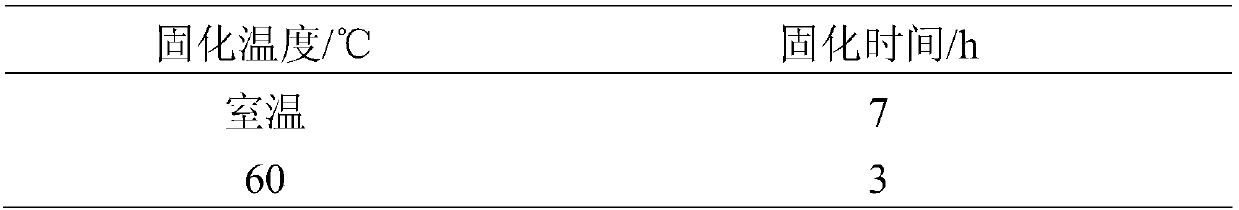

Waterborne epoxy emulsion, waterborne epoxy resin coating and preparation method thereof

InactiveCN108047431AImprove stabilitySolve problems that require high-temperature energy-consuming curingEpoxy resin coatingsEpoxyPolyethylene glycol

The invention belongs to the technical field of epoxy coatings, and discloses a waterborne epoxy emulsion, a waterborne epoxy resin coating and a preparation method thereof. The preparation method ofthe waterborne epoxy emulsion comprises the steps that 1, polyethylene glycol and maleic anhydride are subjected to a heating reaction, then, epoxy resin is added for a continuous heating reaction, and an epoxy resin emulgator is obtained; 2, the emulgator and the epoxy resin are mixed, and the waterborne epoxy emulsion is obtained through the phase inversion technology. The preparation method ofthe waterborne epoxy coating comprises the steps that 1, an amine compound and epoxy resin are subjected to a heating reaction, polyethylene glycol diglycidyl ether is added for a continuous heating reaction, butyl vinyl ether is added for a continuous reaction, and a waterborne curing agent is obtained; 2, the waterborne curing agent and the waterborne epoxy emulsion are mixed, and the waterborneepoxy coating is obtained. The waterborne epoxy emulsion is good in stability; the waterborne epoxy coating is cured at the room temperature, the application period is long, and the formed coating has the good mechanical property, hardness and acid and base resistance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +4

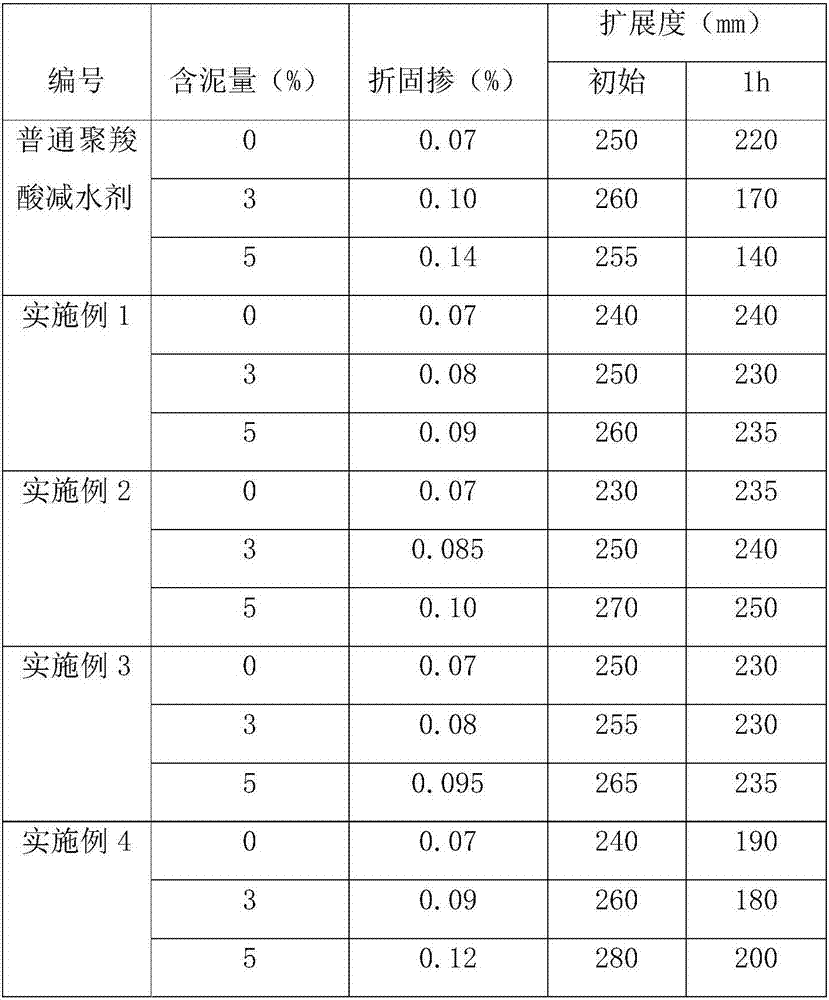

Soil insensitive polycarboxylic acid water reducer and preparation method thereof

The invention relates to a soil insensitive polycarboxylic acid water reducer and a preparation method of the reducer. The water reducer is prepared by taking a 4-hydroxybutyl vinyl ether macromonomer, unsaturated carboxylic acid, unsaturated sulfonate and an unsaturated ester micromonomer as a comonomer, and an initiator and a chain transfer agent as a molecular regulator for copolymerization reaction. A mass ratio of the 4-hydroxybutyl vinyl ether macromonomer to unsaturated carboxylic acid to unsaturated sulfonate to the unsaturated ester micromonomer to the initiator to the chain transfer agent to deionized water is (24-120):(4-8):(6-8):(10-20):(0.8-1.5):(0.4-2):(70-120). The invention further provides the preparation method of the water reducer. The water reducer is insensitive to a sand content of a sandstone material in concrete; when the water reducer is used for the concrete with the high sand content, the water reducer has higher water reducing capability and smaller slump loss than the traditional polycarboxylic acid water reducer; and the water reducer solves the problem that the traditional polycarboxylic acid water reducer is sensitive to soil, a raw material of sandstone, in the concrete application.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Preparation method and application of water-based fluoropolymer emulsion

The present invention relates to preparation process of water thinned fluoric polymer emulsion for paint. The preparation process is one emulsion copolymerization process with trifluorochloro ethylene, alkyl vinyl ether or vinyl acetate, hydroxyl butyl vinyl ether, undecylenic acid and polyoxyethylene acrylate as monomers, non-ionic emulsifier NP and anionic ammonium perfluoro octoate as composite emulsifier, and composition of ammonium persulfate or potassium persulfate and sodium bisulfite as redox initiation system. The polymerization may be completed in room temperature and is simple, and the product has excellent chemical stability, mechanical stability and mechanical performance. The emulsion has relatively high fluorine content, so that the prepared paint has excellent corrosion resistance, weather resistance and antifouling performance.

Owner:TONGJI UNIV

Method for preparing compound 4-hydroxy butyl vinyl ether

InactiveCN101898939AHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound additionSurface-active agentsButanediol

The invention belongs to a method for preparing a vinyl ether compound, in particular to the method for preparing 4-hydroxy butyl vinyl ether. In the reaction of 1,4-butanediol and acetylene, dimethyl sulfoxide is added so that beneficial effects are achieved for the reaction, wherein the content of a 4-hydroxy butyl vinyl ether crude product is improved to 81 percent from 72 percent before adding; and a cyclic acetal byproduct is reduced to about 4 percent from 6 percent before adding. The content of the crude product can be further improved by 1 to 2 percent by adding a cationic surface active agent, namely octadecyl trimethyl ammonium chloride.

Owner:焦作新景科技有限公司

Synthesis method of 4-hydroxybutyl vinyl ether polyoxyethylene ether

The invention relates to a synthesis method of 4- hydroxybutyl vinyl ether polyoxyethylene ether, and belongs to the technical field of polyether compound synthesis in organic chemistry. The synthesis method comprises two phases, namely a primary synthesis phase and a final synthesis phase, and specifically comprises the following steps: subjecting a part of 4-hydroxybutyl vinyl ether to a pre-reaction with a primary synthesis catalyst, adding the pre-reaction product into the rest part of 4-hydroxybutyl vinyl ether, introducing ethylene oxide to carry out primary synthesis so as to obtain a primary product, adding a final synthesis catalyst into a part of the primary product to carry out a secondary pre-reaction, and subjecting the secondary pre-reaction product to final synthesis reactions with the rest part of the primary product and ethylene oxide so as to obtain the final product. The product obtained by the technical scheme provided by the invention has the advantages of low by-product content, narrow molecular weight distribution, and high double-bond protection rate.

Owner:ZHEJIANG LYUKEAN CHEM

Synthesis method of isobutyl vinyl ether and device thereof

ActiveCN101555198AReduce riskWell mixedEther preparation by compound additionIsobutanolReaction temperature

The invention discloses a synthesis method of isobutyl vinyl ether and a synthesis device thereof. In the method, isobutanol and acetylene which are taken as raw materials are etherified in a kettle type reactor to synthesize the isobutyl vinyl ether with the existence of a catalyst and an additive, wherein the temperature of the etherification is 120-200 DEG C, the reaction pressure is 0.4-0.8 Mpa; a reaction product is distilled from the reactor after reaction; and the product is refined to obtain an isobutyl vinyl ether product with the purity of above 99 percent, and the catalyst and the additive in the reactor can be continuously reused. The conversion rate of the isobutanol and the acetylene can achieve above 90 percent, the yield of synthesis reaction is above 95 percent, and the synthesis reaction adopts a closed reactor without tail gas exhausted basically.

Owner:HANGZHOU ELECTROCHEM GROUP

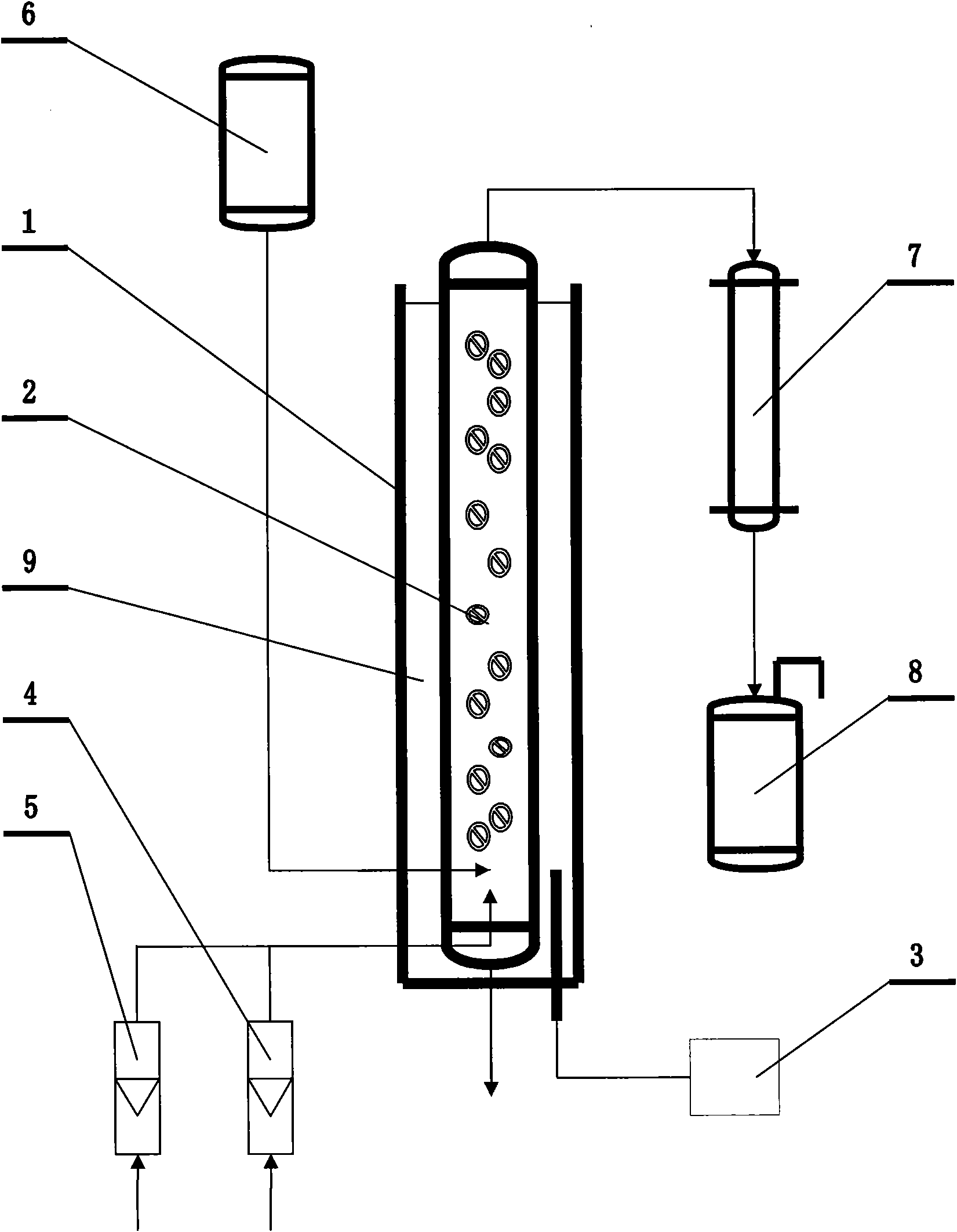

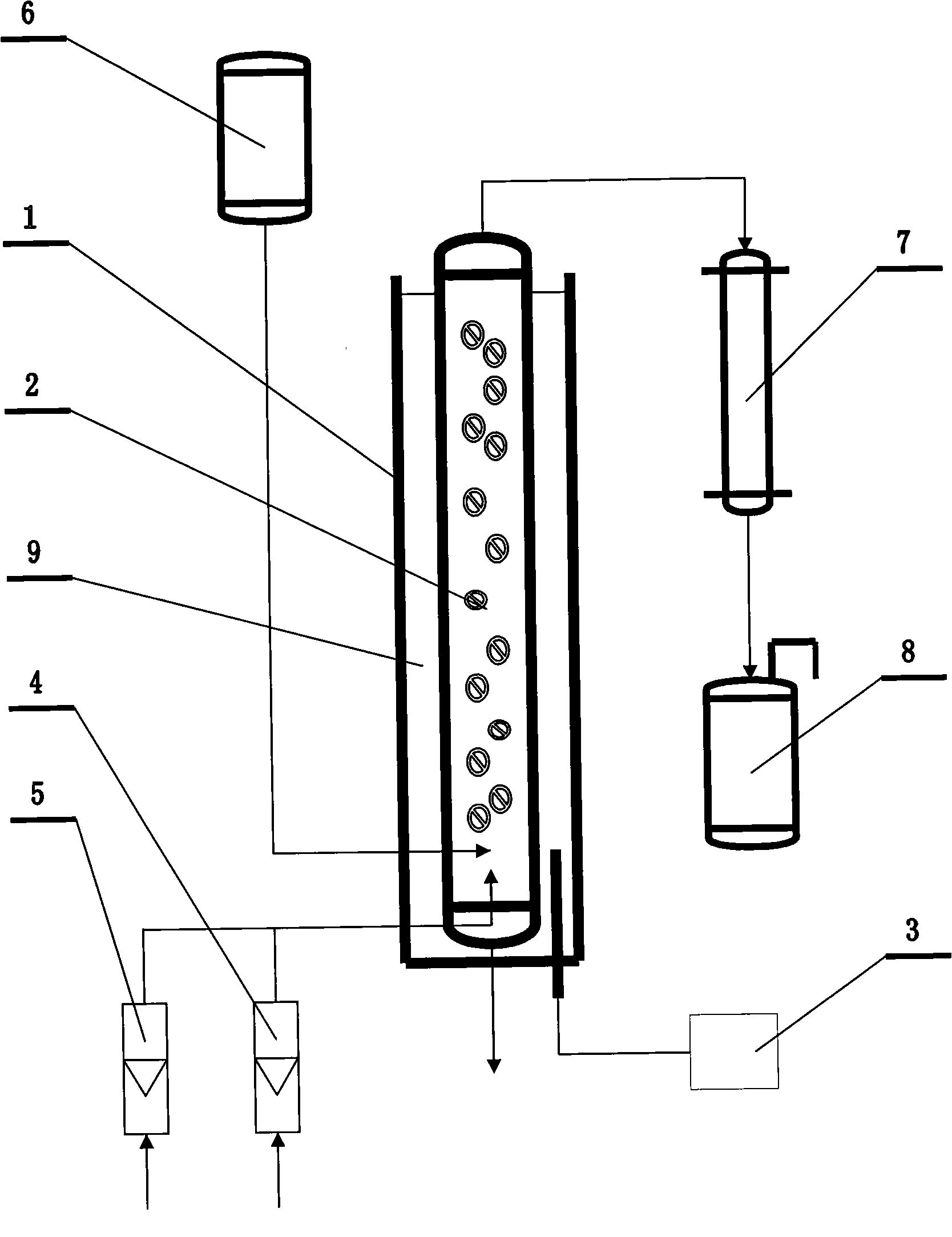

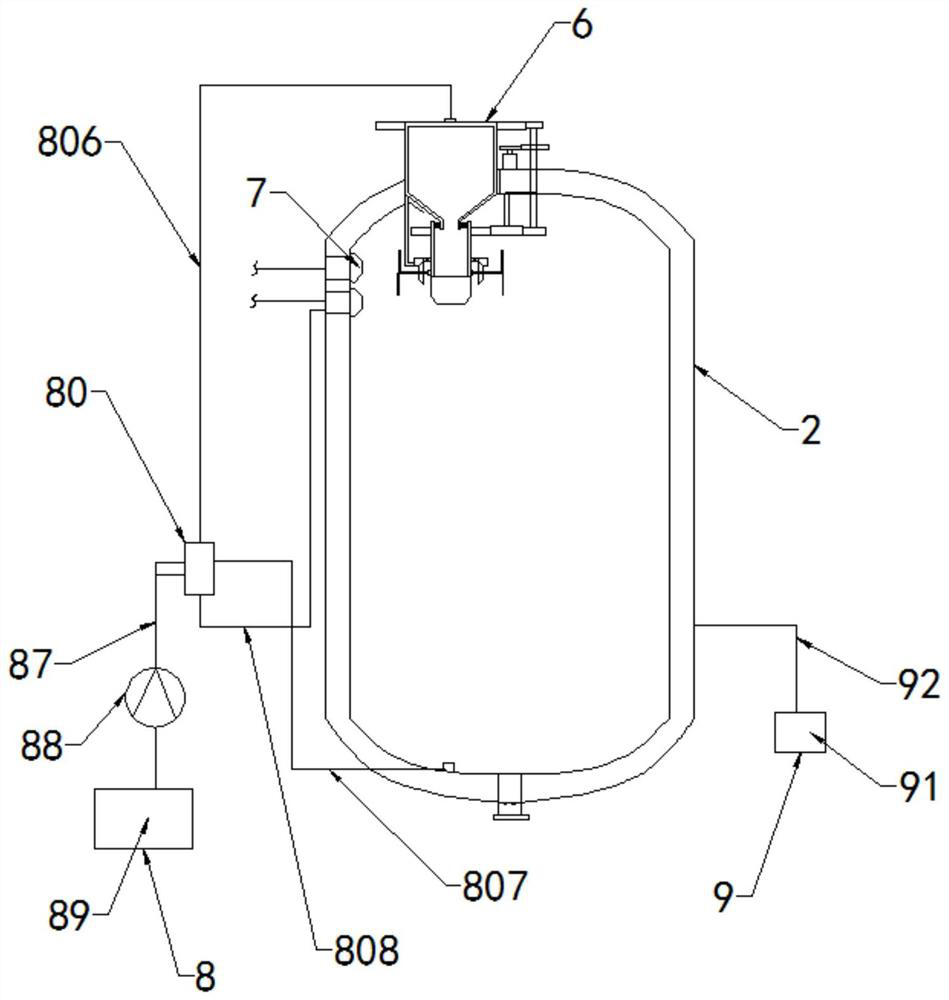

Preparation device of isobutyl vinyl ether and preparation method thereof

InactiveCN102976904AAvoid Explosion HazardsIncrease reaction rateEther preparation by compound additionIsobutanolVapor–liquid separator

The invention discloses a preparation device of isobutyl vinyl ether and a preparation method of isobutyl vinyl ether, which relates to isobutyl vinyl ether. The invention provides the preparation device of isobutyl vinyl ether and the preparation method of isobutyl vinyl ether. The preparation device of isobutyl vinyl ether is safe, efficient, low in energy consumption, low in cost and easy to industrialize. The device is provided with an absorber, a gas-liquid separator, a metering pump, a constant temperature oil bath, a tubular reactor, a condenser and a reducing valve. The preparation method comprises the following steps: 1) dissolving acetylene in a saturated solution formed by isobutanol and catalyst solutions; 2) pressurizing the saturated solution obtained in step 1) to 1-5MPa by the metering pump and introducing the saturated solution to the heated tubular reactor, wherein acetylene dissolved in the isobutanol and catalyst solutions react with isobutanol in the tubular reactor to generate isobutyl vinyl ether; and 3) cooling reactants sent from the tubular reactor, wherein part of the reactants is used as a coarse product of isobutyl vinyl ether and the rest of the reactants is circulated to step 1) and mixed with continuously fed isobutanol and catalyst solutions.

Owner:XIAMEN UNIV

Method for producing vinyl-4-hydroxybutyl ether through acetylene method, and catalyst thereof

InactiveCN103394371AInhibit side effectsHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound addition1,4-ButanediolReaction temperature

The present invention discloses a method for producing vinyl-4-hydroxybutyl ether through an acetylene method, and a catalyst thereof. According to the present invention, an catalysis amount of a 1,4-butylene glycol potassium salt and 1,4-butylene glycol are mixed, acetylene is introduced, a reaction temperature is controlled to 80-150 DEG C, acetylene pressure is controlled to 0.1-2 MPa, and the obtained material is transferred into a rectification tower to be subjected to rectification after the complete reaction to obtain vinyl-4-hydroxybutyl ether; and compared with the catalyst in the prior art, the catalyst of the present invention has the following characteristics that: generation of side reactions can be effectively prevented, catalysis activity is high, and a service life is long.

Owner:BOAI NKY PHARMA LTD

Preparation method of water-based chloroethylene/isobutyl vinyl ether copolymer dispersion

ActiveCN102181006AHas "self-emulsifying" propertiesReactiveVolatile organic compoundButyl vinyl ether

The invention discloses a preparation method of water-based chloroethylene / isobutyl vinyl ether copolymer dispersion. 60 to 75 mass percent of chloroethylene monomer, 25 to 40 mass percent of isobutyl vinyl ether monomer, acrylic hydroxyalkyl ester or the monomer of the same kind in an amount which is 5 to 15 percent of the total mass of the chloroethylene and the isobutyl vinyl ether, and unsaturated carboxylic acid monomer in an amount which is 10 to 25 percent of the total mass of the chloroethylene and the isobutyl vinyl ether are used as raw materials; and the water-based chloroethylene / isobutyl vinyl ether copolymer dispersion is obtained by polymerization reaction, neutralization reaction, aqueous phase dispersion treatment and organic solution removal in organic solvent, initiator and organic amine neutralizer. The dispersion has low volatile organic compound (VOC) content, environmental friendliness and good cohesiveness, and is particularly suitable for producing water-based coating, water-based adhesive and water-based ink.

Owner:江苏利思德新材料股份有限公司

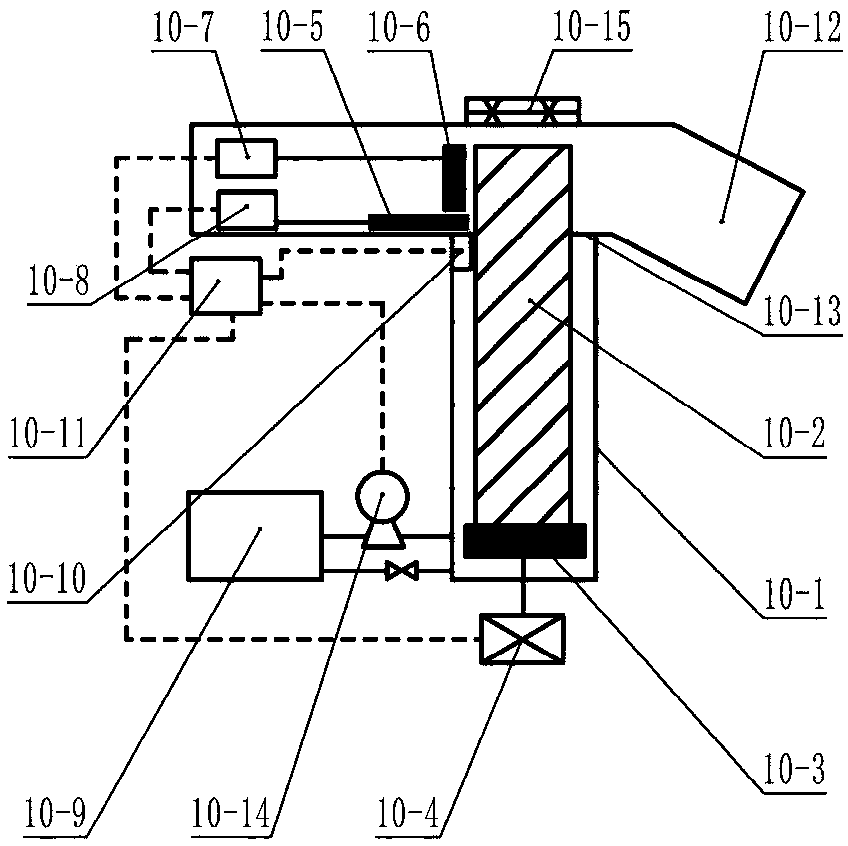

Damping polycarboxylic acid water reducing agent as well as preparation method and special production equipment thereof

The invention provides a damping polycarboxylic acid water reducing agent as well as a preparation method and special production equipment thereof. According to the method, firstly, 4-hydroxybutyl vinyl ether polyoxyethylene polyoxybutylene ether is synthesized; the partial 4-hydroxybutyl vinyl ether reactants are subjected to pre-reaction; products are fed into the rest reactant; ethylene oxide and epoxybutane are added for reaction to obtain 4-hydroxybutyl vinyl ether polyoxyethylene polyoxybutylene ether oligomers; then, partial oligomers are subjected to pre-reaction; the products are fedinto the rest oligomers; ethylene oxide and epoxybutane are added for reaction; the 4-hydroxybutyl vinyl ether polyoxyethylene polyoxybutylene ether is obtained; then, the 4-hydroxybutyl vinyl ether polyoxyethylene polyoxybutylene ether, the 4-hydroxybutyl vinyl ether and unsaturated monocarboxylic acid monomers are subjected to monomer polymerization reaction to generate the damping polycarboxylic acid water reducing agent. The equipment comprises a pre-reaction kettle and a reaction kettle; a polyether primary and secondary pre-reaction kettle is provided with a catalyst continuous feeding device. The damping polycarboxylic acid water reducing agent provided by the invention has a good damping effect.

Owner:武汉新绿博恩科技有限公司

Process for producing fluoropolymers

There is provided the process for effectively preparing the fluorine-containing polymer without using CFC and HCFC which have a high polymerization rate and a high ozone depletion potential and a coating film having excellent mechanical properties, solvent resistance and chemical resistance can be formed using the obtained fluorine-containing polymer. In preparing the fluorine-containing polymer by polymerizing a monomer containing a fluoroolefin in a polymerization medium, the fluorine-containing solvent having an ozone depletion potential of 0 and a solubility of hydroxybutyl vinyl ether of not less than 0.5% is used as the polymerization medium.

Owner:DAIKIN IND LTD

Antifouling paint for coating bottom of steel ship and preventing cracking

ActiveCN103788780AMeet environmental protection requirementsImprove crack resistanceAntifouling/underwater paintsRosin coatingsXylyleneSolvent

The invention discloses an antifouling paint for coating the bottom of a steel ship and preventing cracking, which is prepared from the following components in parts by weight: 10-25 parts of chloro-ether resin, 15-25 parts of epoxy-ester resin, 10-20 parts of rosin, 5-10 parts of pigment, 20-50 parts of antifouling agent, 1-3 parts of auxiliaries and 5-20 parts of mixed solvent, wherein the chloro-ether resin contains chloroethylene and isobutyl vinyl ether; the epoxy-ester resin contains fatty acid and bisphenol A epoxy resin; the antifouling agent contains cuprous oxide and thiram algicide; the auxiliaries include a wetting dispersant and an antifoaming agent; the mixed solvent contains xylene and 200# coke solvent. Without internally-forbidden toxic materials, the antifouling paint meets the state environmental protection requirements, and the antifouling period reaches 1-3 years; the antifouling paint has the characteristics of good anti-cracking property, rare falling and the like, can overcome the shortcomings that the existing antifouling paint easily gets crispy, is not environment-friendly and the like, and is mainly applied to the antifouling treatment of the bottom of a steel ship.

Owner:XIAMEN SUNRUI SHIP COATING

Highly-adaptive ultra-slow-release type polycarboxylate slump retaining admixture and preparation method thereof

A highly-adaptive ultra-slow-release type polycarboxylate slump retaining admixture and a preparation method thereof are disclosed. The method includes an esterification step, namely a step of reacting methacrylic acid, a saturated acid and 3-bis(2-hydroxyethyl)amino-2-hydroxy propanesulfonic acid under the existence of a catalyst to obtain an unsaturated esterified small monomer; (2) subjecting 4-butanediol vinyl ether polyoxyethylene ether as a macromonomer to copolymerization under the action of a composite photoinitiator; and (3) neutralizing the obtained copolymerization product with a sodium hydroxide solution to obtain the slump retaining admixture. The prepared slump retaining admixture has good slump retaining capability at high temperature for long time, has certain anti-mud effects and has good adaptability to mud-containing ground materials.

Owner:GUANGDONG KEZHIJIE NEW MATERIALS +1

Preparation method of isobutyl vinyl ether

InactiveCN105837407ASimple structureNo moving partsEther separation/purificationEther preparation by compound additionMicro bubbleVapor–liquid separator

The preparation method of isobutyl vinyl ether relates to isobutyl vinyl ether. The isobutanol solution containing the catalyst is pumped into the loop reactor from the bottom of the riser through the metering pump, and the mixed gas of acetylene and nitrogen enters the gas injector from the bottom of the riser after passing through the gas buffer tank, compressor and adsorption drying column; The driving material flows into the downcomer from the upper part of the riser, exchanges heat with the heat transfer oil through the heat exchanger, and then circulates back to the riser, and the ejected tiny bubbles are mixed and contacted with the isobutanol solution to react to obtain a reaction mixture; the reaction mixture It flows out from the outlet at the top of the riser, and enters the gas-liquid separator for gas-liquid separation after being cooled by the cooler. The liquid coming out of the bottom is isobutyl vinyl ether. The invention has good mass and heat transfer effect, simple device structure, safety and high efficiency, simple operation, low cost and easy industrialization.

Owner:XIAMEN UNIV

Preparation method and product of palbociclib

The invention discloses a preparation method of palbociclib. The preparation method comprises the following steps: 1) dissolving 4-(6-aminopyridine-3-yl)-piperazine-1-tertiary butyl carboxylate into asolvent A, adding an alkali reagent, activating at 0-20 DEG C, adding 6-bromine-2-chlorine-8-cyclopentyl-5-methyl-pyridino-[2,3-D]-pyrimidine-7(8H)-ketone, adjusting the solution to acid after a reaction is completed, cooling and filtering, taking filter cakes, and drying the filter cakes to obtain an intermediate I; 2) in the presence of an inert atmosphere, dissolving the intermediate I and butyl vinyl ether into a solvent B, catalyzing with a catalyst at 95-105 DEG C, cooling and separating a crystal after the reaction is completed, filtering, and taking the filter cakes, and drying the filter cakes to obtain an intermediate II; 3) dissolving the intermediate II into a solvent C, adding an acid, adjusting the solution to acid after the reaction is completed, filtering, and taking and centrifuging filtrate to obtain a target product, namely palbociclib. By adjusting reaction parameters and optimizing preparation process procedures, the preparation method is high in product yield, good in purity, simple and mild in process conditions and applicable to industrial large-scale production.

Owner:CHONGQING SANSHENG IND CO LTD

Sound-absorbing cotton for noise-reduction automobile exhaust pipe

InactiveCN106351722AEffective Noise Reduction ProcessingSimple structureExhaust apparatusSilencing apparatusFiberEpoxy

The invention provides sound-absorbing cotton for a noise-reduction automobile exhaust pipe. The sound-absorbing cotton is prepared from, in weight percentage, 40% of epoxy resin, 45% of polyether polyol DMN (dimethylnitrosamine)-3050, 5% of diethanol amine, 5% of 1,4-butanediol, 2% of isobutyl vinyl ether and 3% of N-tert-2-benzothiazyl sulfonamide. The sound-absorbing cotton for the noise-reduction automobile exhaust pipe is excellent in sound-absorbing performance and wide in sound-absorbing frequency range and can overcome the shortcomings of fiber materials, non-woven materials and plastic materials, weather resistance and strength are achieved, the sound-absorbing effect of the sound-absorbing cotton can reach 3 times or more as compared with that of a traditional sound-absorbing material.

Owner:WUHU EVERSHINE AUTOMOTIVE COMPONENT

Fully-degradable high-strength rope knot temporary plug

The invention discloses a fully-degradable high-strength rope knot temporary plug. The fully-degradable high-strength rope knot temporary plug is prepared by the following steps of blending a polymer A, a plasticizer and sodium dodecyl sulfate, and sequentially drying, melting, spinning, drying, weaving and cutting, wherein the preparation method of the polymer A comprises the following steps of S1, dissolving triethylene glycol divinyl ether, butanediol, 4-hydroxybutyl vinyl ether and 2-acrylamide-2-methylpropanesulfonic acid in distilled water to obtain a solution A; S2, dissolving ammonium persulfate in the other part of distilled water to obtain a solution B; and S3, adding the solution A into a reaction container, keeping the temperature at 50 DEG C in a water bath, stirring, then slowly dropwise adding the solution B into the solution A within 1 hour, and after dropwise adding, continuously keeping the temperature at 50 DEG C to react for 8-10 hours, so as to obtain a polymer A. The temporary plug can replace a horizontal well bridge plug and all temporary plugging agents, and the material of the temporary plug can be completely degraded into carbon dioxide and water.

Owner:SICHUAN JIEBEITONG ENERGY TECH CO LTD

A kind of antistatic ABS composite material and preparation method thereof

A novel antistatic ABS composite material provided by the invention consists of 150 to 250 parts of acrylonitrile, 200 to 400 parts of butadiene, 400 to 600 parts of α-methylstyrene, and 10 to 30 parts of hydroxybutyrate It is prepared from base vinyl ether, 10-30 parts of vinyl acetate and 15-30 parts of initiator. The invention also discloses a method for preparing the composite material by adopting a novel monomer with an antistatic effect. The method mainly includes: firstly preparing two different latexes respectively, and then mixing the two latexes for copolymerization. After the polymerization reaction is completed, , purifying and drying the obtained antistatic ABS composite material to finally prepare the composite material, which has good antistatic performance.

Owner:HEFEI GENIUS NEW MATERIALS

Preparation method of copolymer of hydroxybutyl vinyl ether and maleic anhydride

InactiveCN101659725ANo smellNo three-dimensional cross-linked structureAcetic acidMaterial consumption

The invention discloses a preparation method of copolymer of hydroxybutyl vinyl ether and maleic anhydride, which comprises the following steps of: adding the mixed solvent of ethyl acetate and cyclohexane into a reactor; after heating to 50 to 70 DEG C, adding hydroxybutyl vinyl ether and maleic anhydride in sequence, stirring and mixing; then adding cyclohexane liquid containing initiator at a uniform speed ratio in 20 to 40 minutes; and after reacting for 1 to 5 hours at constant temperature, filtering out the clear liquid to obtain crosslinking copolymer of hydroxybutyl vinyl ether and maleic anhydride. The copolymer of hydroxybutyl vinyl ether and maleic anhydride prepared by the preparation method has the advantages of no smell, less material consumption, simple process and low cost,and can expand in a water system to form a transparent gelled product with a netty three-dimensional crosslinking structure.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation method of organic tin-free chlorine ether resin

Owner:HANGZHOU ELECTROCHEM GROUP

Polypropylene-nano particle compound material and preparation method thereof

The invention discloses a composite material which consists of polypropylene, nanometer particles and polyisobutyl vinyl ether-maleic anhydride and a preparation method thereof. Through the synergic action of the polyisobutyl vinyl ether-maleic anhydride copolymer and the nanometer particles in the material, the acting force between the polypropylene and the nanometer particles is enhanced, and cluster effect caused by hydrogen bonds among the nanometer particles is weakened, thereby, the nanometer particles can be scattered in the polypropylene evenly in the nanometer scale, and the obtained polypropylene-nanoparticle composite material has the advantages of good flexibility, high shock resistant strength and excellent processing property. The invention has the advantages of simple processing technique, high production efficiency and low cost.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Stainless steel stamping tension lubricating oil

InactiveCN103756763AImprove the lubrication effectImprove cooling effectLubricant compositionPhosphorous acidTert butyl phenol

The invention discloses a stainless steel stamping tension lubricating oil which comprises the following components in parts by mass: 1-2 parts of glycerin monostearate, 55 parts of LN32 mechanical oil, 8 parts of chlorinated paraffin, 4 parts of dimethyl silicon oil, 19 parts of phosphorous acid di-n-butyl phosphate, 8 parts of lead naphthenate, 23 parts of triethanolamine oleate, 9 parts of poly(n-butyl) vinyl ether, 35 parts of transformer oil, 17 parts of vulcanized whale oil, 2 parts of 2.6-di-tert-butyl phenol and 1 part of hydroxypropyl methyl cellulose. The stainless steel stamping tension lubricating oil is good in lubrication and cooling property and easy to demold, and is capable of preventing a stamped surface from scratch or rusting, ensuring surface smoothness and cleanness, and meeting the direct assembling requirements.

Owner:CHANGSHU MEIERTE METAL PROD

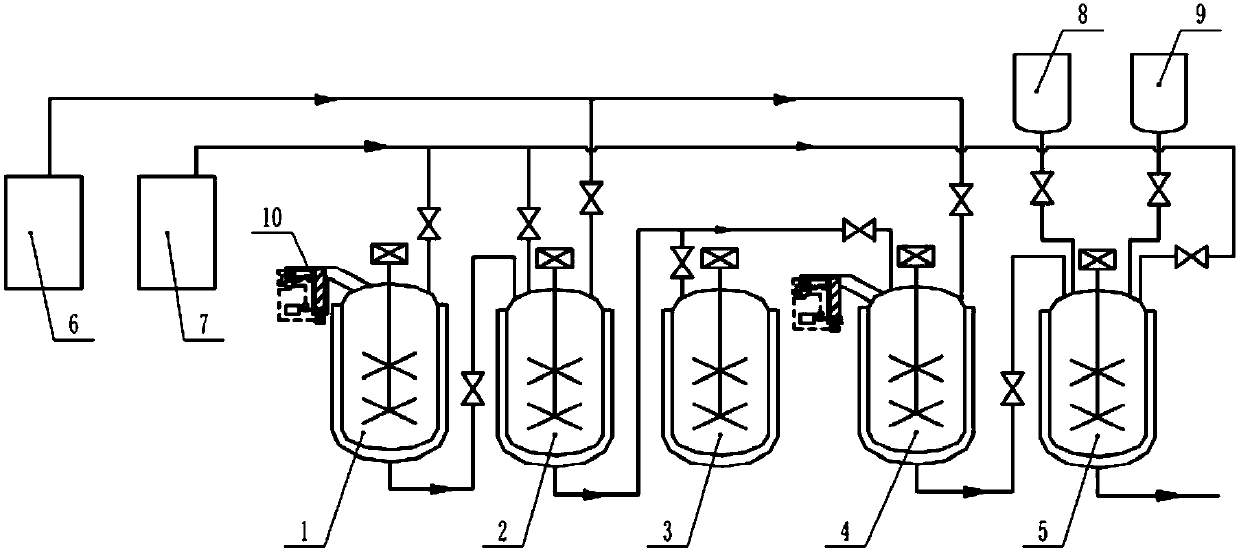

Polycarboxylic acid high-performance water reducing agent production and synthesis device and production process thereof

InactiveCN113058532AHigh polymerization activityGood mud resistanceChemical/physical/physico-chemical stationary reactorsFeed devicesPtru catalystEthylene oxide

According to the technical scheme, a polycarboxylic acid high-performance water reducing agent production and synthesis device is characterized by comprising a polyether primary pre-reaction kettle, a polyether primary reaction kettle, a polyether secondary pre-reaction kettle, a polyether secondary reaction kettle and a water reducing agent reaction kettle which are connected in sequence; the device further comprises a 4-hydroxybutyl vinyl ether storage tank and an ethylene oxide and epoxybutane storage tank; the water reducing agent reaction kettle is further provided with an unsaturated monocarboxylic acid monomer solution storage tank and an initiator and chain transfer agent solution storage tank, and the polyether primary pre-reaction kettle and the polyether secondary pre-reaction kettle are provided with continuous catalyst feeders; and a first feeding mechanism for dispersing and feeding materials and a second feeding mechanism for atomizing and feeding ethylene oxide, epoxybutane and 4-hydroxybutyl vinyl ether are arranged on a feeding hole of the polyether primary reaction kettle. The device has the beneficial effects that the efficiency of producing and synthesizing the polycarboxylate water reducing agent is high, the mixing is sufficient, and the quality of the produced polycarboxylate water reducing agent is good.

Owner:浙江衢州鼎盛建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com