Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1728results about "Ether separation/purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene

InactiveCN101693703ASuitable for industrial productionEther separation/purificationChemical industryThermal energyExtractive distillation

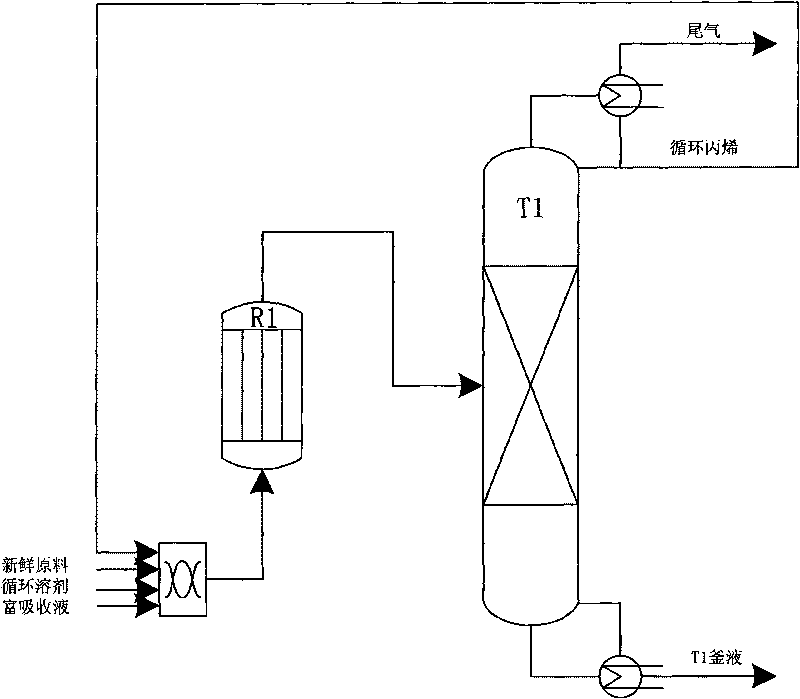

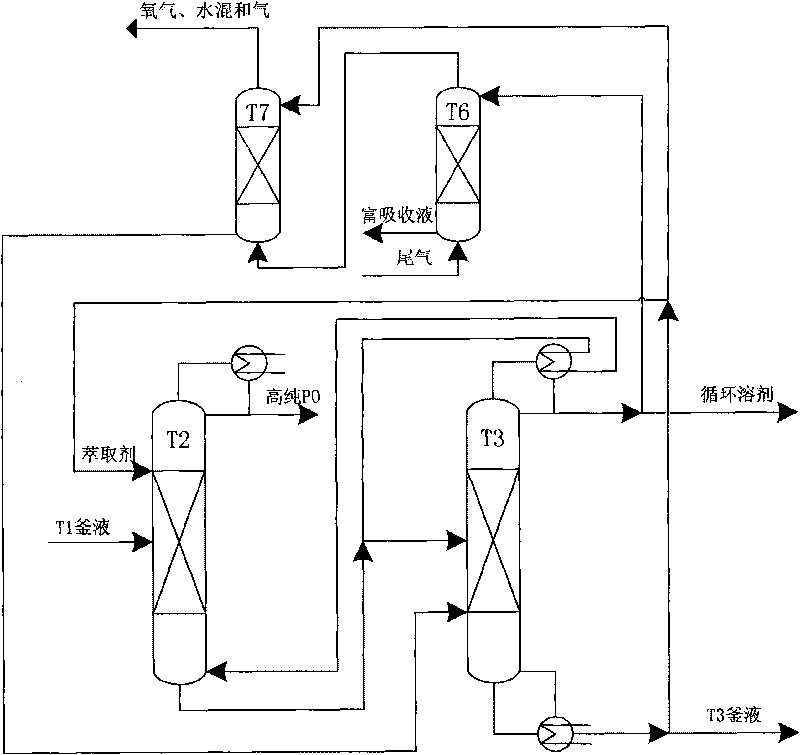

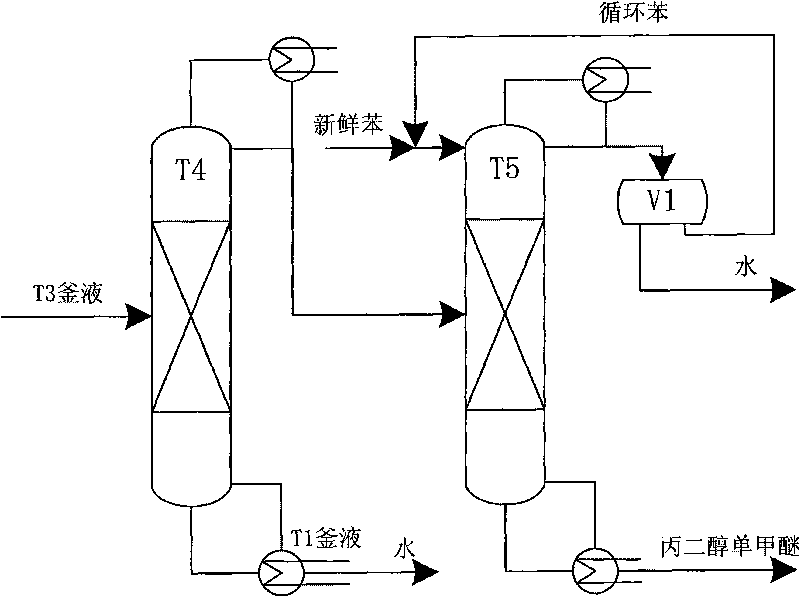

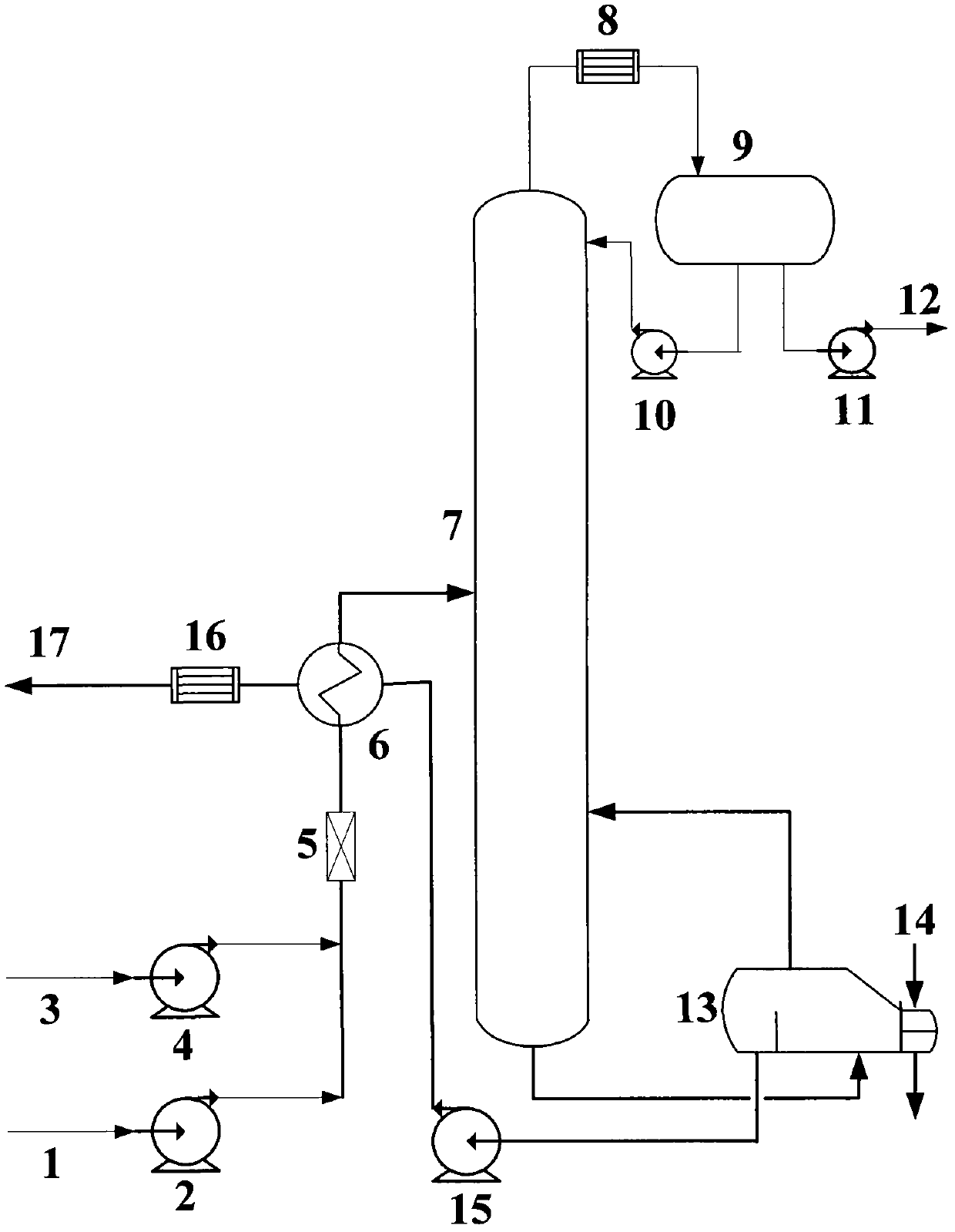

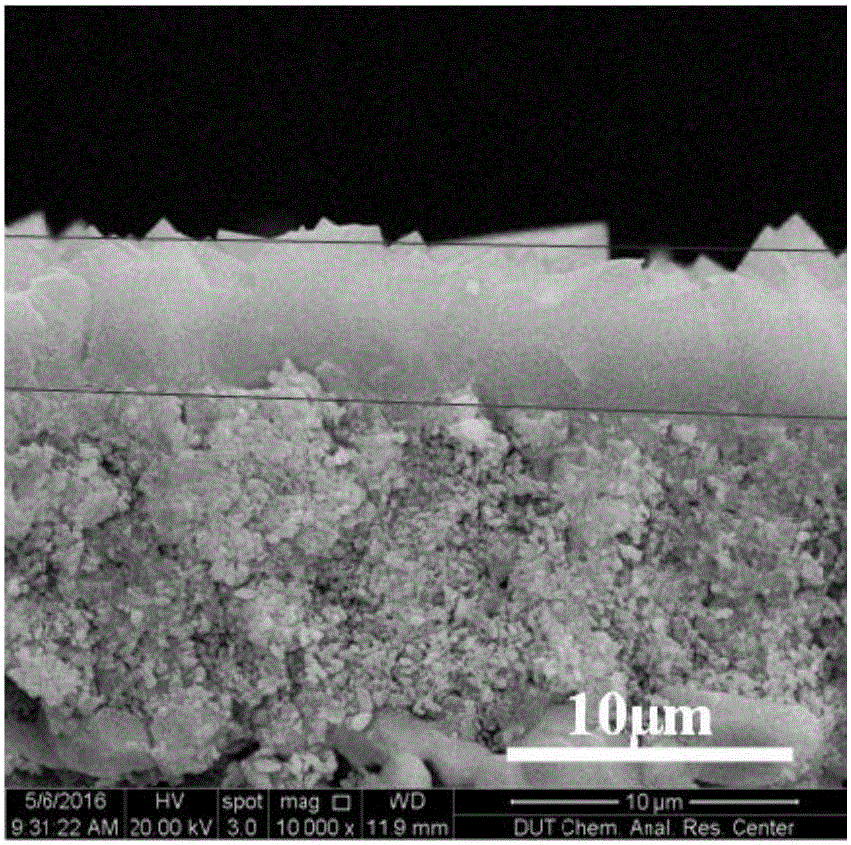

The invention relates to an energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene, belonging to the field of petrochemical technology. The technique comprises a reaction part, a separation part and a tail gas treatment part, and is characterized in that propylene and hydrogen peroxide have an epoxidation reaction through a Ti-Si molecular sieve at medium pressure and low temperature; the propylene and solvent have higher recovery rate, the propane epoxide meeting the requirement of commercial-grade purity can be obtained by extractive distillation, and the joint product of propylene glycol monomethyl ether can be prepared by azeotropic distillation and purification; after part of tail gas is condensed and absorbed and the propylene is recovered, the tail gas reaches the standard and is discharged; extracting agent, absorbing agent and entrainer which are needed by the technique are in closed cycle in the process flow; and medium-pressure operation is adopted by a propylene tower to ensure water-cooling on the top of the tower, and thermal energy can be recovered by multiple-effect rectification and matching of streams. The technique has the effect and the advantage that the new energy-saving and environment-friendly technique for producing the propane epoxide can generate remarkable economic and social benefits.

Owner:DALIAN UNIV OF TECH

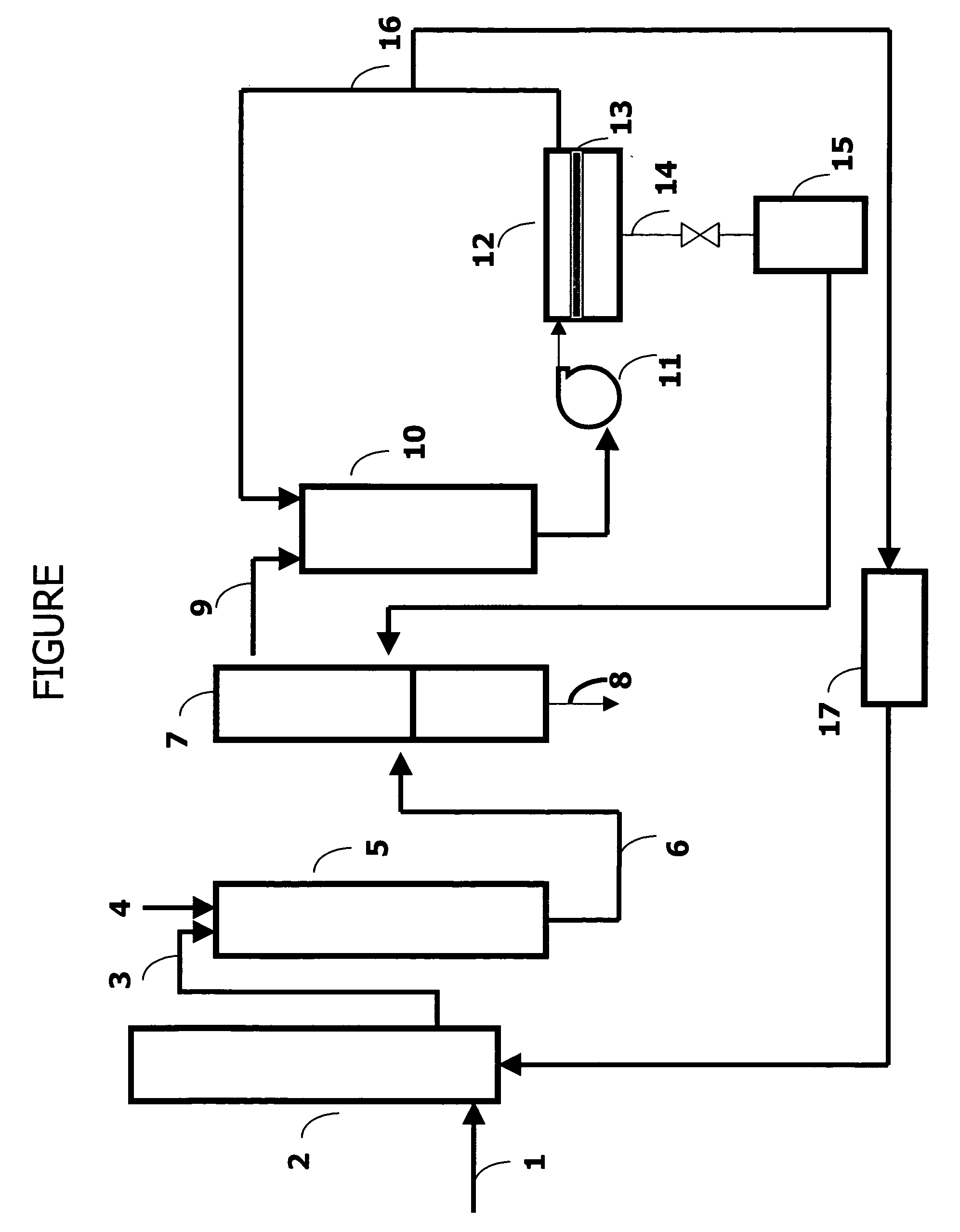

Processes for recovering oligomers of glycols and polymerization catalyst from waste streams

Processes for recovering and recycling oligomers and polymerization catalyst from aqueous waste streams generated during the production of polyalkylene ether glycols are provided. The processes utilize membranes; preferably reverse osmosis or nanofilter membranes. The processes can reduce waste and costs associated with the polymerization of polyalkylene ether glycols by recovery and recycling of glycols and catalysts

Owner:SUNKARA HARI BABU +2

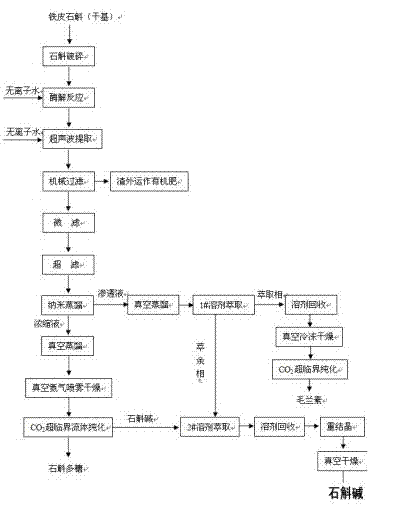

Method for one-time separation and extraction of dendrobe polysaccharide, dendrobine and erianin from dendrobium candidum

InactiveCN102786604AHigh purityAvoid lostEther separation/purificationEnzymatic hydrolysisDendrobium candidum

The invention discloses a method for one-time separation and extraction of dendrobe polysaccharide, dendrobine and erianin from dendrobium candidum. The method for extraction of dendrobe polysaccharide, dendrobine and erianin from dendrobium candidum comprises the steps of crushing of dendrobe, enzymatic hydrolysis, ultrasonic extraction, microfiltration, ultrafiltration and nano-membrane concentration, solid-liquid separation, vacuum cryogenic distillation, solvent extraction, solvent recovery, recrystallization, vacuum low-temperature drying and purification in the carbon dioxide supercritical fluid, thereby obtaining the dendrobe polysaccharide, dendrobine and erianin. The prepared product has good color, good solubility and high active ingredients.

Owner:HHUANGSHAN LVJIUYUAN BIOLOHICAL TECH

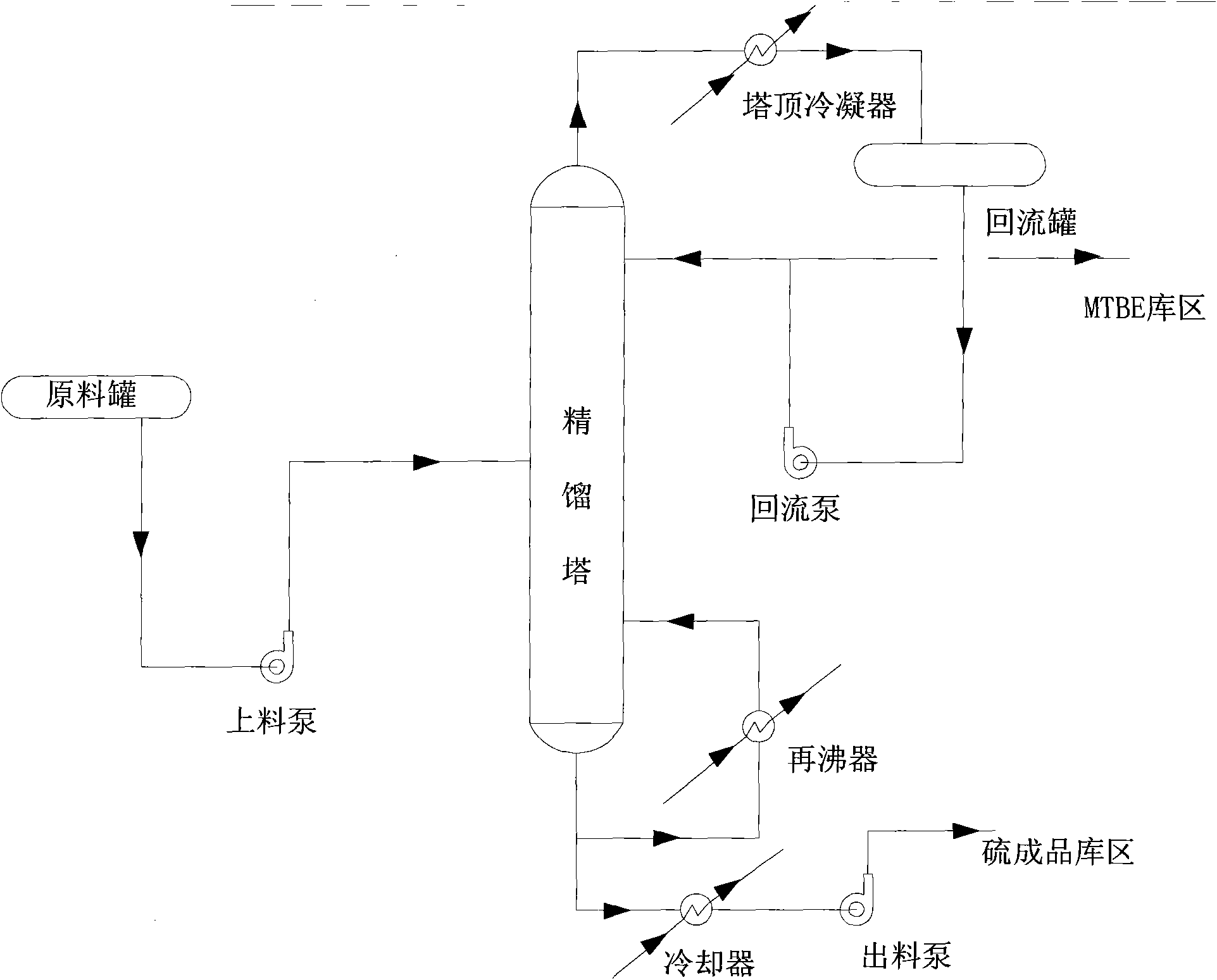

Method for desulphurizing methyl tertiary butyl ether with high sulphur content

InactiveCN101643392ASimple processAdvanced technologyEther separation/purificationPolymer scienceSulfur product

The invention relates to a method for desulphurizing MTBE with high sulphur content, belonging to the field of the refining of methyl tertiary butyl ether (MTBE). The methyl tertiary butyl ether (MTBE) with high sulphur content is placed into a distillation tower and heated by a reboiler, the temperature of a tower kettle is kept between 90 DEG C and 120 DEG C, the pressure of the tower kettle iskept at 0.08+ / -0.02 MPa, the temperature of a tower top is kept between 69 DEG C and 75 DEG C, and the pressure of the tower top is kept at 0.06+ / -0.02 MPa so that a finished product is distilled outof the tower top, a reflux ratio is kept from 1 to 10, and a sulfur product is recycled from a tower bottom. The invention has the advantages of simple process, advanced technology, easy and convenient control operation, little investment, low cost and no three-waste pollution.

Owner:SHANDONG YUHUANG CHEM CO LTD

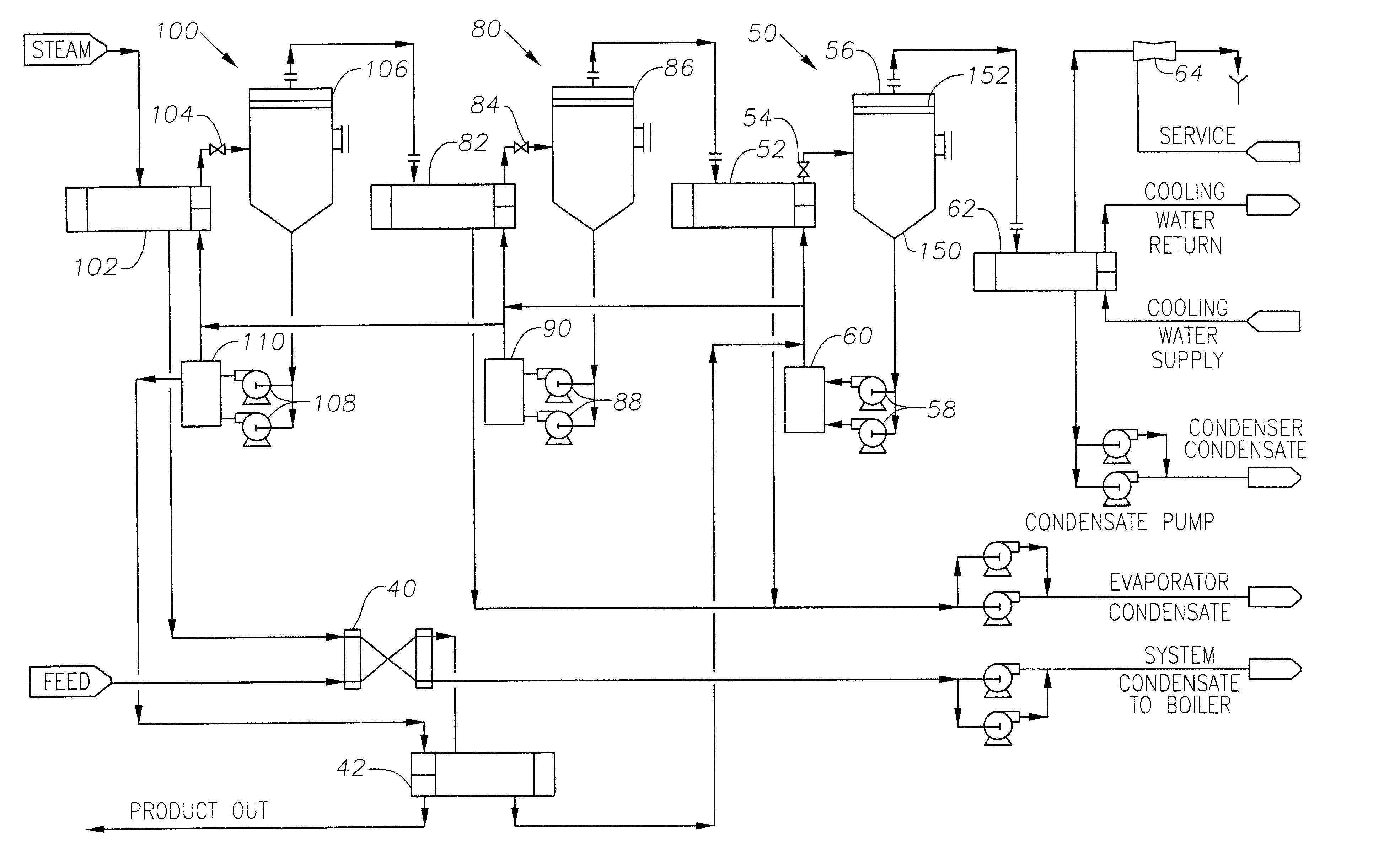

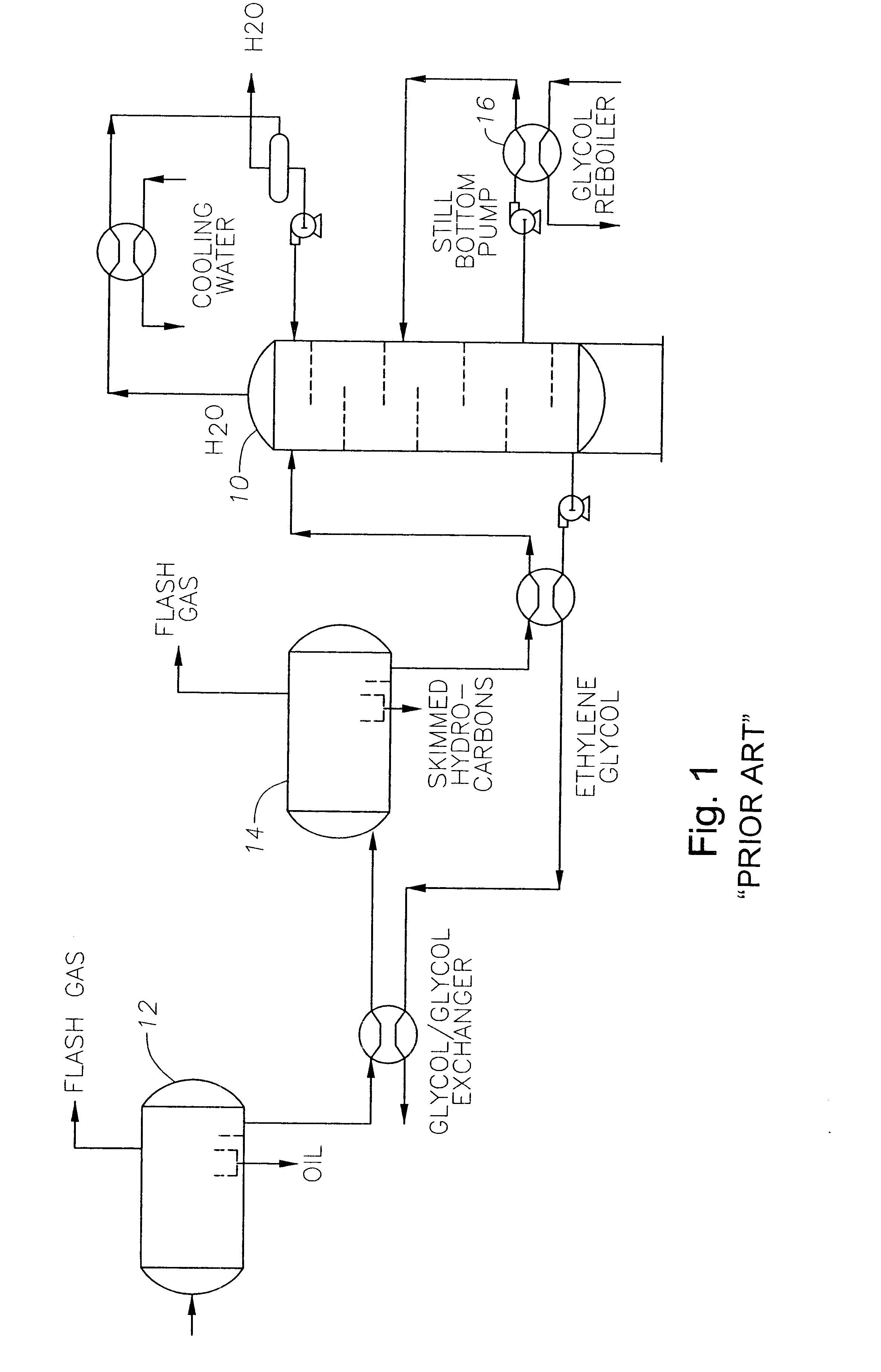

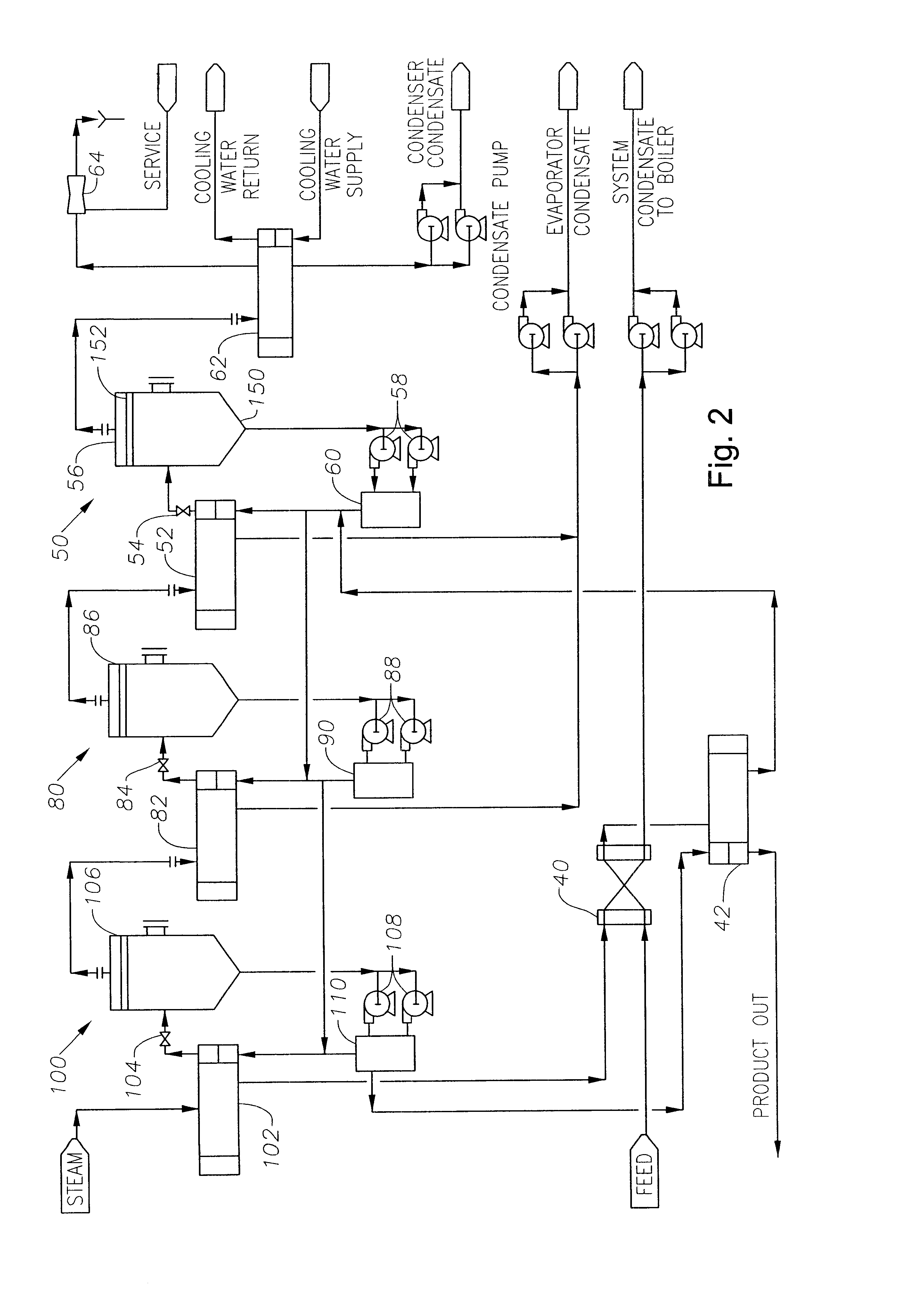

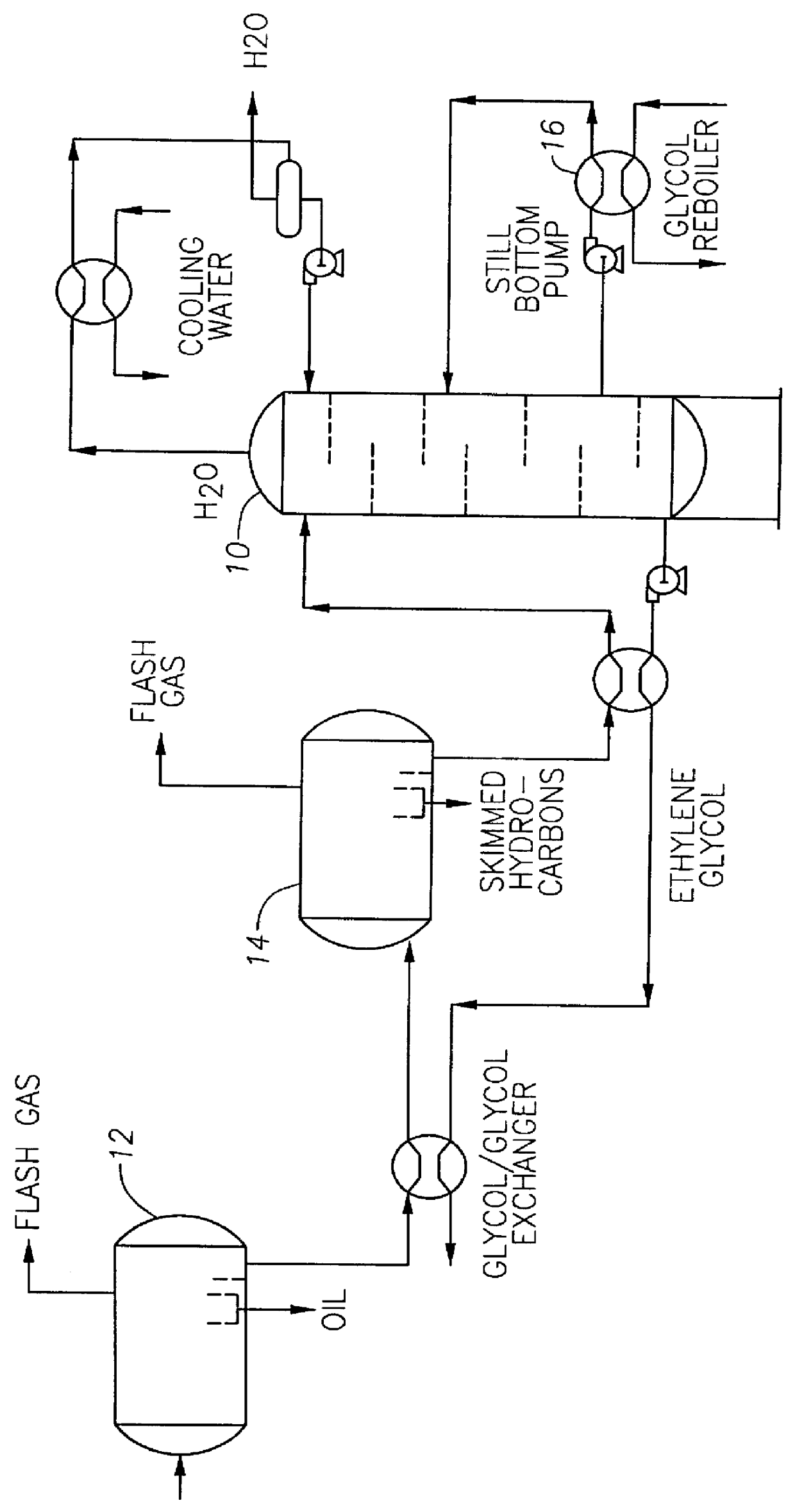

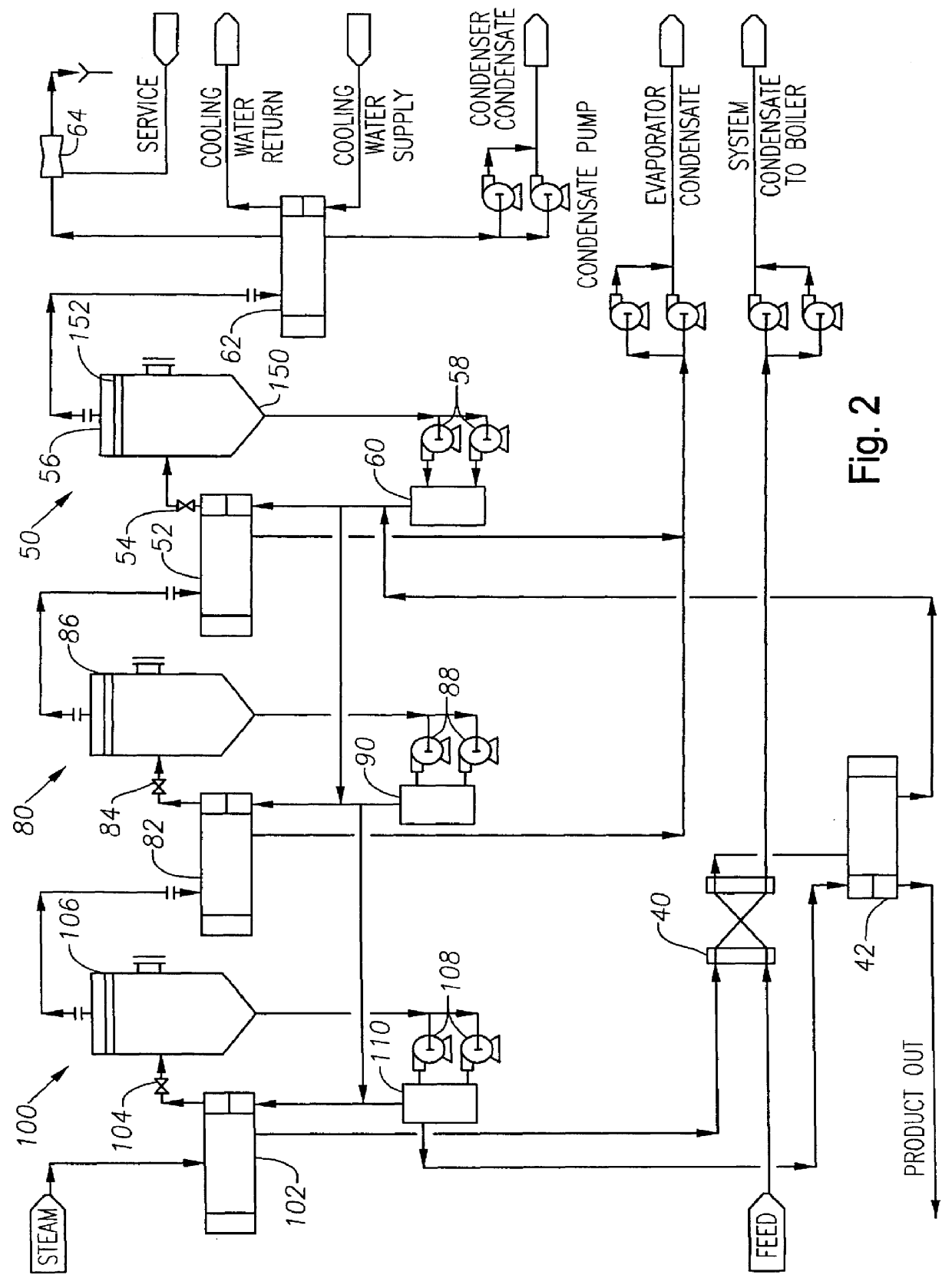

System for recovering glycol from glycol/brine streams

A system for recovering glycol from glycol and brine mixtures produced from oil or natural gas wells that combines energy efficiency with a capability for handling salt and other solids contained in the mixture. The system comprises three effect evaporator systems in series. Each effect evaporator system comprises an evaporator, a separator vessel, product pumps, and a solids removal system.The process utilizes the system to remove salt and other solids as well as excess water leaving a glycol stream that can be reused as a hydrate inhibitor. The process begins by preheating a glycol / brine stream comprising approximately fifty percent (50%) glycol. The stream is then subjected to three evaporation cycles. The first evaporation cycle comprises introducing the preheated stream into a suppressed boiling point evaporator where the stream is heated under a constant pressure. The stream pressure is then dropped to cause a portion of the water contained in the stream to vaporize or flash. The flashing stream is then introduced into a separator vessel where the water vapor is separated from the remaining liquid stream. The water vapor is removed from the separator and condensed. The remaining liquid glycol / brine stream is then pumped from the separator vessel through a solids removal system where precipitated salts and solids are removed. These steps are repeated two additional times. Each time the remaining liquid stream becomes more concentrated with glycol until the finished product is approximately ninety percent (90%) glycol.

Owner:TRANSOCEAN SEDCO FOREX VENTURES LTD

Process and system for recovering glycol from glycol/brine streams

A process and a system is disclosed for recovering glycol from glycol and brine mixtures produced from oil or natural gas wells that combines energy efficiency with a capability for handling salt and other solids contained in the mixture. The system comprises three effect evaporator systems in series. Each effect evaporator system comprises an evaporator, a separator vessel, product pumps, and a solids removal system. The process utilizes the system to remove salt and other solids as well as excess water leaving a glycol stream that can be reused as a hydrate inhibitor. The process begins by preheating a glycol / brine stream comprising approximately fifty percent (50%) glycol. The stream is then subjected to three evaporation cycles. The first evaporation cycle comprises introducing the preheated stream into a suppressed boiling point evaporator where the stream is heated under a constant pressure. The stream pressure is then dropped to cause a portion of the water contained in the stream to vaporize or flash. The flashing stream is then introduced into a separator vessel where the water vapor is separated from the remaining liquid stream. The water vapor is removed from the separator and condensed. The remaining liquid glycol / brine stream is then pumped from the separator vessel through a solids removal system where precipitated salts and solids are removed. These steps are repeated two additional times. Each time the remaining liquid stream becomes more concentrated with glycol until the finished product is approximately ninety percent (90%) glycol.

Owner:TRANSOCEAN SEDCO FOREX VENTURES LTD

Method for producing low-sulfur methyl tertiary butyl ether

ActiveCN102491882ASatisfy to reconcileFulfil requirementsEther separation/purificationSulfur contentRaw material

The invention provides a method for producing low-sulfur methyl tertiary butyl ether (MTBE), which is used for producing low-sulfur MTBE products by re-rectifying MTBE containing sulfur. The method can use the MTBE with 10-150 ppm of sulfur content as a raw material to produce the MTBE products with containing sulfur content less than 10 ppm or even less than 5 ppm, and can use the MTBE with sulfur content more than150 ppm to produce the MTBE products with sulfur content less than 150 ppm. Especially, produced MTBE with the sulfur content less than 10 ppm or even less than 5 ppm can not only meet blend requirements of state V clean gasoline, but also requirements of industrial chemical raw materials can be met.

Owner:HEBEI REFINING TECH CO LTD

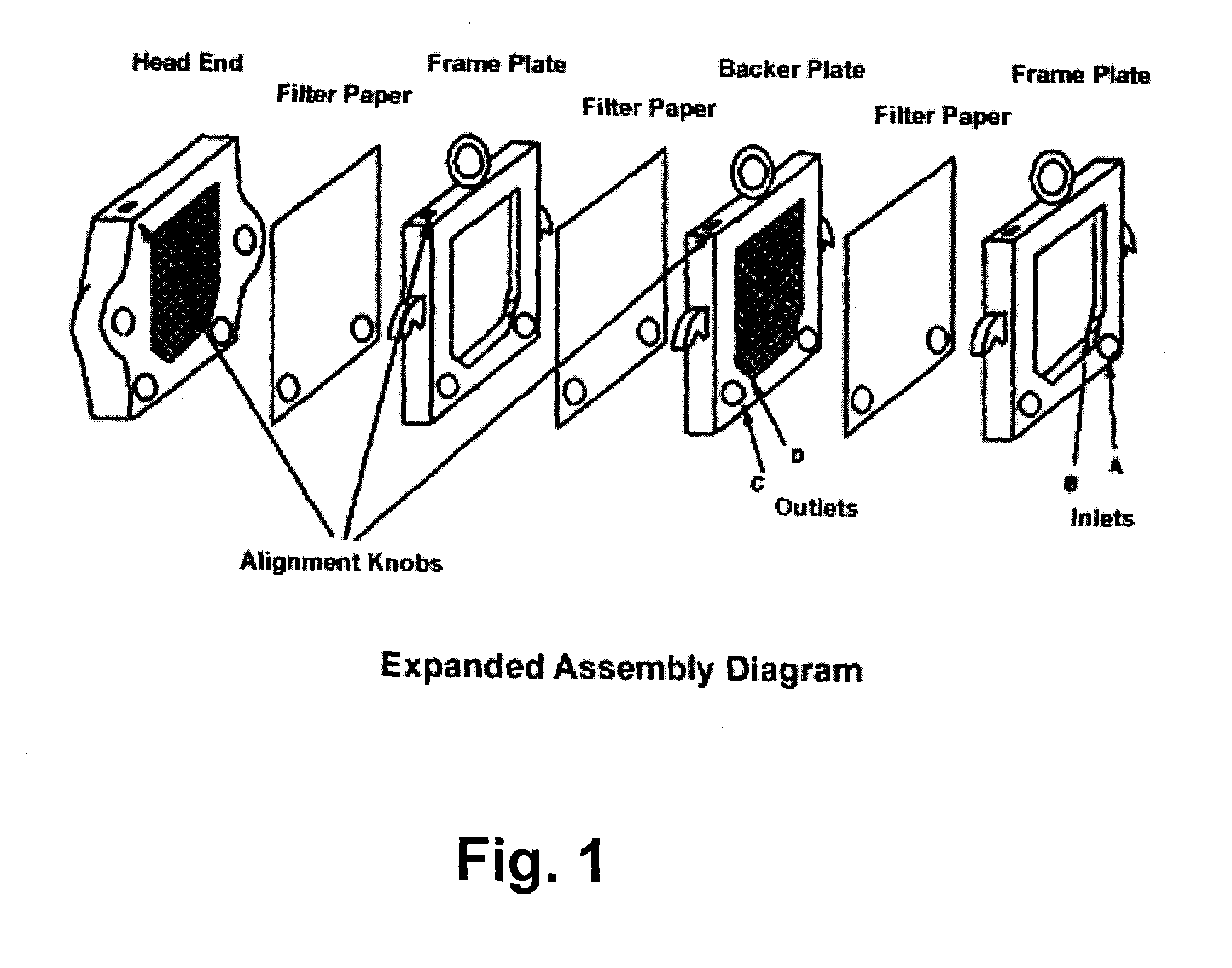

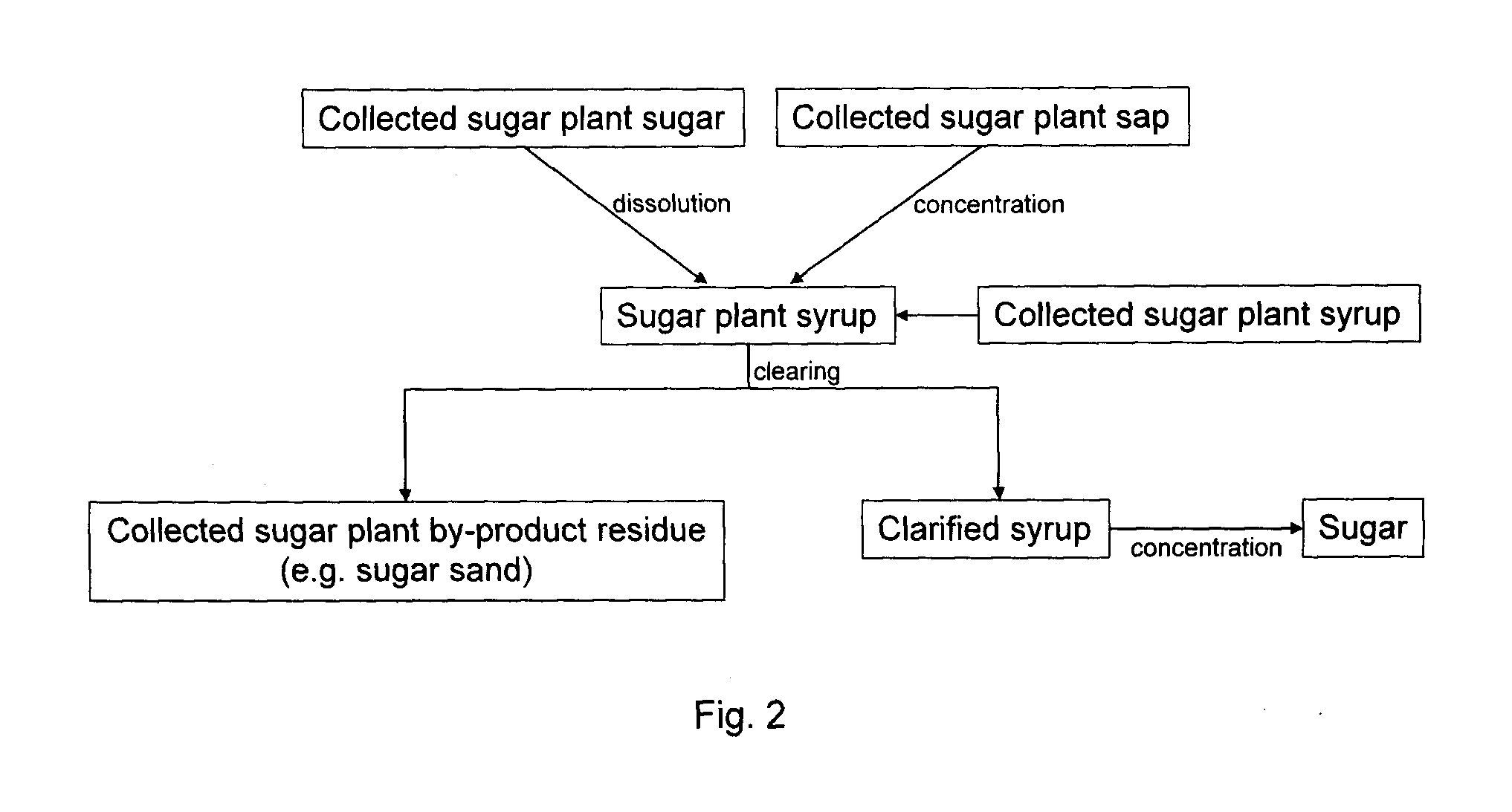

Sugar plant derived by-products and methods of production thereof

InactiveUS20130203688A1Good for healthBiocideEther/acetal active ingredientsFiltrationHealth condition

The present document describes a nutraceutical or cosmeceutical composition for the prophylaxis of an ailment comprising a therapeutically effective amount of a sugar plant syrup filtration residue in association with a pharmaceutically acceptable carrier. The present document also describes a nutraceutical or cosmeceutical composition for improving health condition of skin. The present document describes a method of producing a sugar plant syrup-derived product; wherein the improvement is characterized in the step of: collecting a sugar plant syrup residue during the production of sugar or syrup to produce a syrup-derived by-product.

Owner:FEDERATION DES PRODUCTEURS ACERICOLES DU QUEBEC

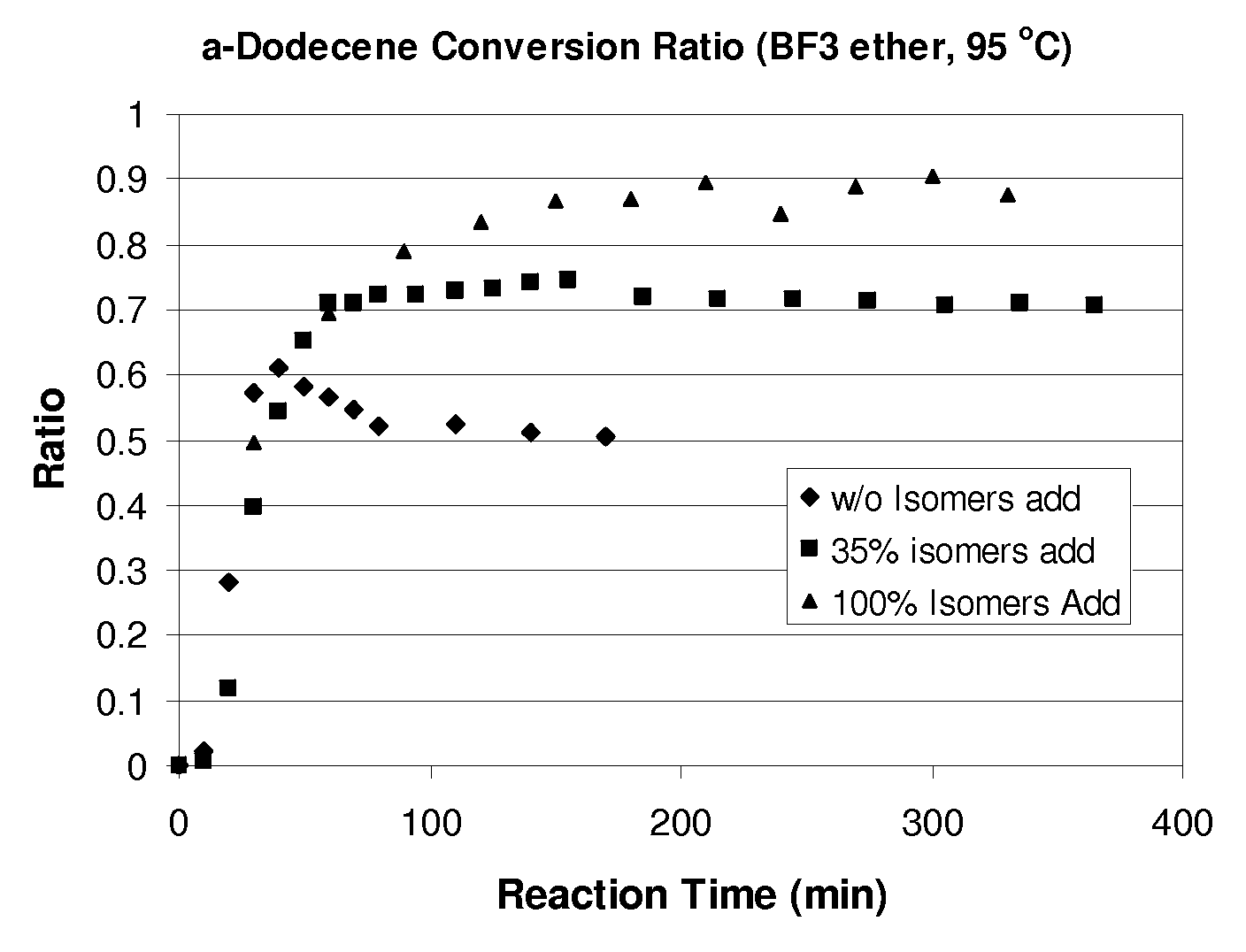

Process for olefin etherification

The invention relates to processes for the etherification of olefins with alcohols. According to one aspect, a heterogeneous etherification catalyst is used under conditions that permit limiting the contact time between the desired product and the catalyst, thereby mitigation reverse reactions. According to a second aspect, a recycling process is used that significantly increases the yield of desired product.

Owner:DOW GLOBAL TECH LLC

Process for preparation of polytrimethylene ether glycols

Owner:EI DU PONT DE NEMOURS & CO

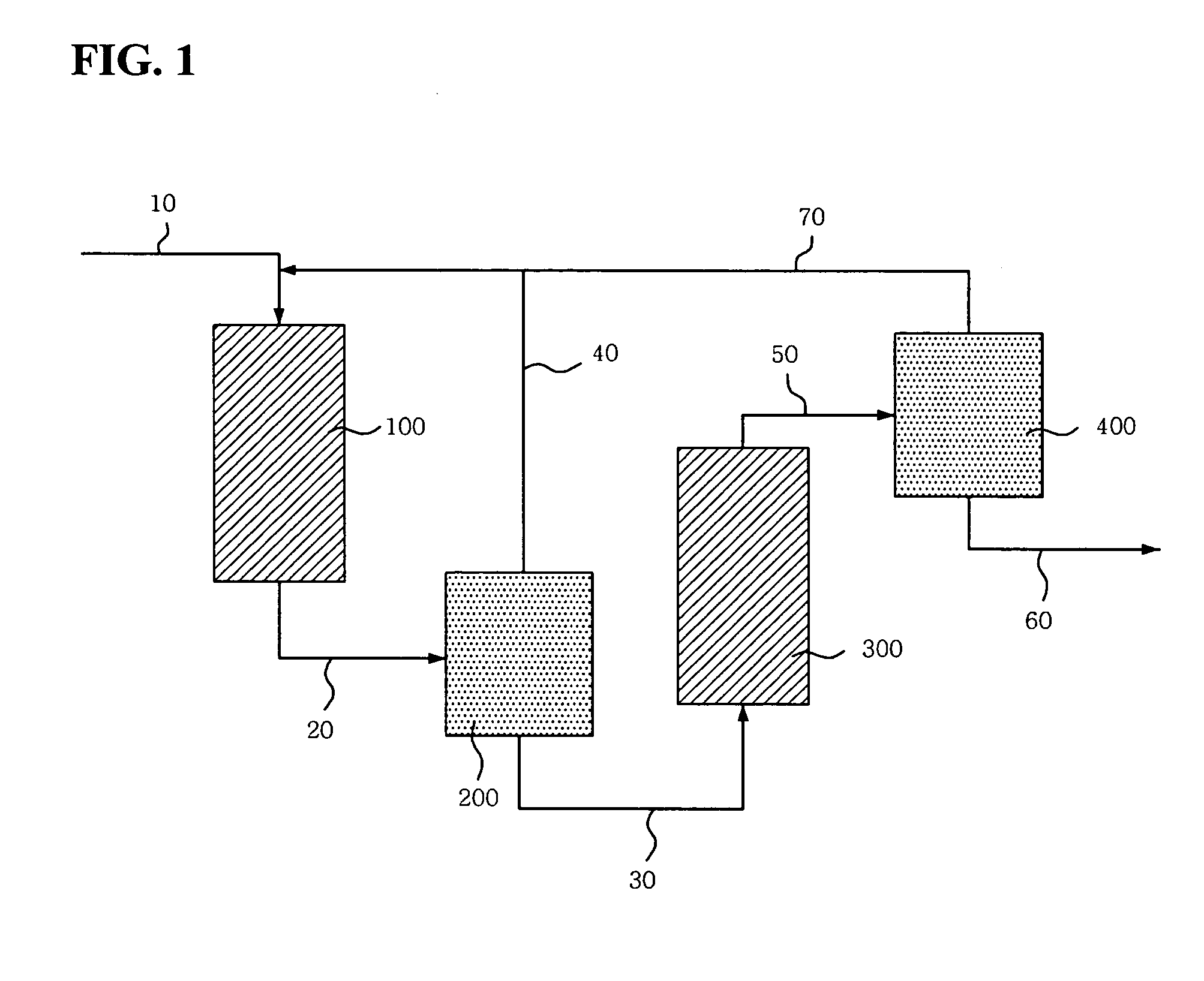

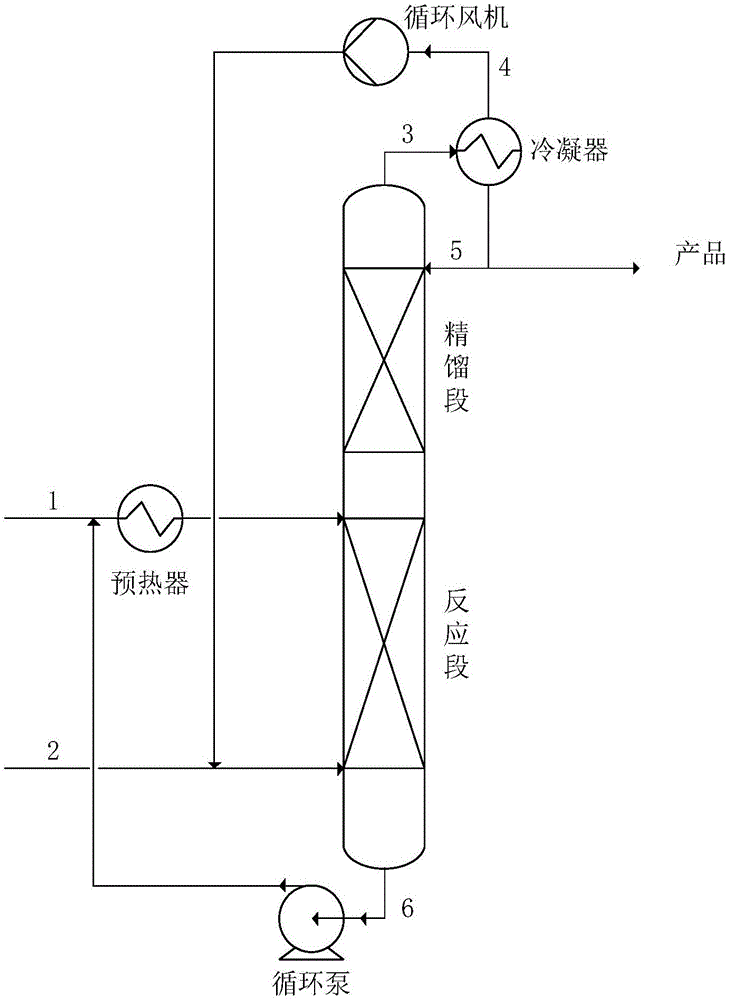

Method and device for removing organic sulfur in methyl tertiary butyl ether (MTBE)

InactiveCN102381945AHigh yieldHigh desulfurization rateEther separation/purificationTowerMethyl tert-butyl ether

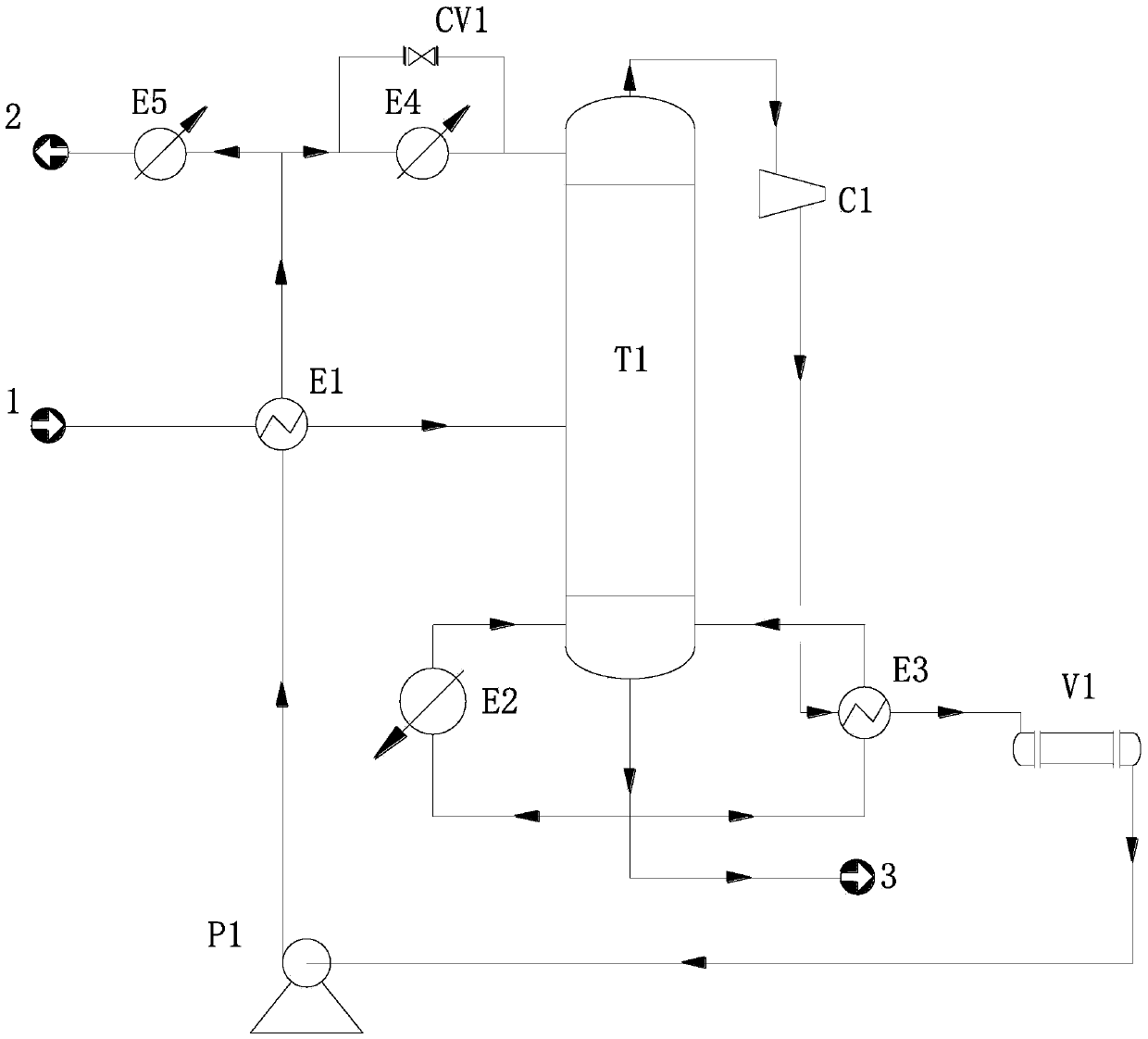

The invention relates to a method and a device for removing organic sulfur in methyl tertiary butyl ether (MTBE). The method and the device are utilized for high-sulfur content MTBE refinement. The method and the device realize normal-pressure low-temperature extraction rectification desulphurization of a high-sulfur content MTBE product. A technical scheme of the invention comprises the following steps that 1, a sulfur-containing MTBE product is heated by a heat exchanger and then is fed into a rectifying tower from a lower part of the rectifying tower; 2, an extractant is fed into the heat exchanger, is heated and then is fed into the rectifying tower from an upper part of the rectifying tower, wherein a rectifying tower temperature is in a range of 70 to 80 DEG C and the heated sulfur-containing MTBE product and the heated extractant countercurrently contact with each other so that countercurrent contact extraction desulphurization is realized; 3, the desulfurated MTBE product is output from the top of the rectifying tower, is subjected to cooling condensation to form liquid in the heat exchanger and then is output; and 4, the sulfur-containing extractant obtained by the step 2is output from the bottom of the rectifying tower, is heated by the heat exchanger, is fed into a flash tank, is distilled at a temperature of 80 to 85 DEG C so that the residual desulfurated MTBE product is distilled off, then is fed into an actifier column, and countercurrently contacts with dry air in the actifier column so that countercurrent contact gas stripping regeneration is realized. Through the method and the device, good desulphurization effects are realized; a high product yield is obtained; and an extractant can be regenerated for recycle. The method is convenient for operation,has low costs and low energy consumption, and can be utilized for high-sulfur content MTBE product refinement.

Owner:SOUTHWEST PETROLEUM UNIV

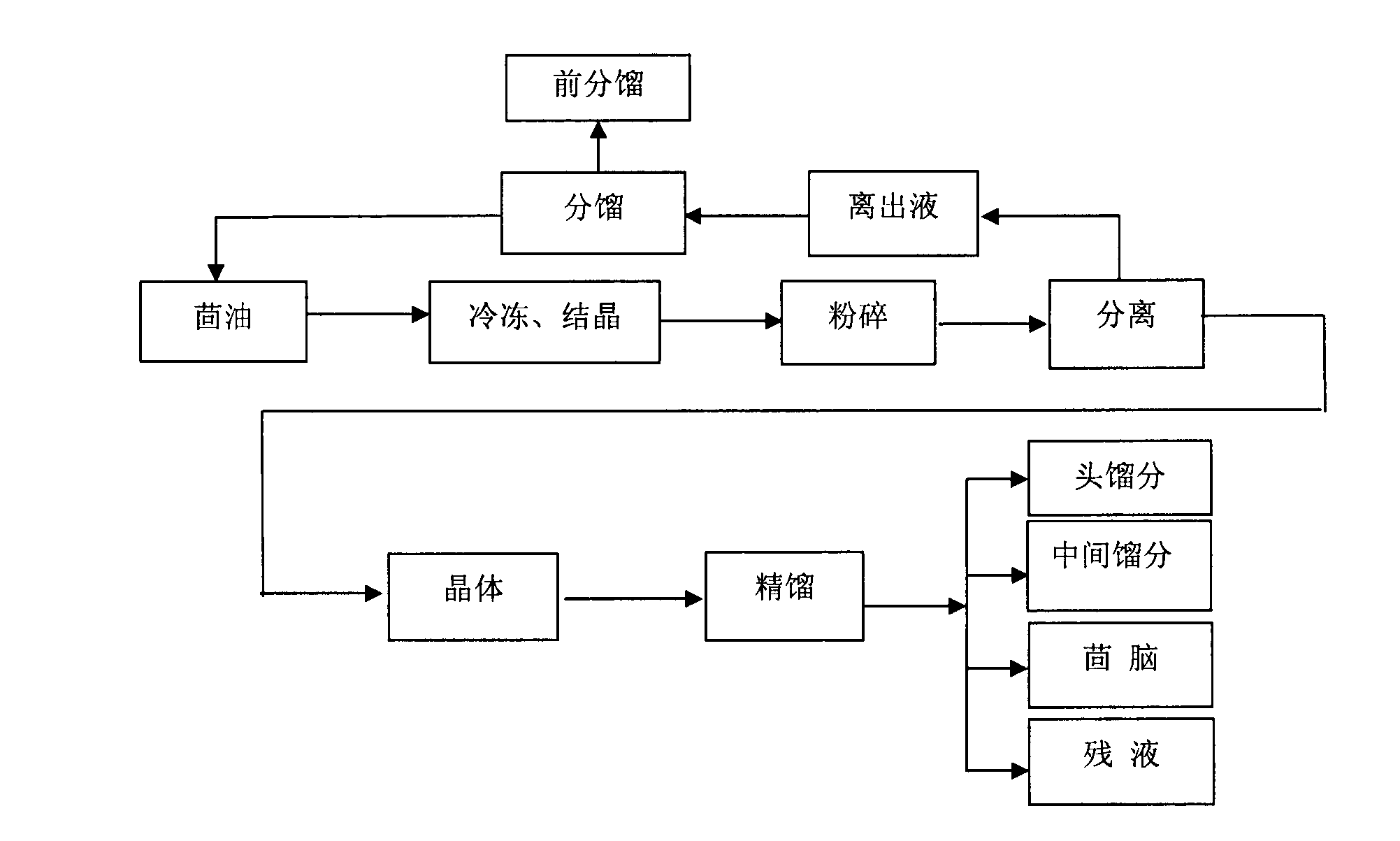

Isolation method for high purity anethole

InactiveCN102491884AAvoid residueReduce manufacturing costEther separation/purificationCentrifugationSolvent

The invention provides an isolation method for high purity anethole. Anise oil is used as a raw material, and a product of high purity anethole is produced after the steps of refrigeration, fragmentation, centrifugation and rectification are carried out. According to the invention, crystallization separating and rectification separating are combined, anethole with a high purity of no less than 99.6% is produced, and no solvent is needed for rinsing of crystals, which enables residual of solvents to be avoided, production procedures to be reduced and production cost to be lowered down.

Owner:GUANGXI FORESTRY RES INST

Process of separating 1-methoxy-2-propanol and 2-methoxy-1-propanol from aqueous compositions

InactiveUS20040000473A1Ether separation/purificationVacuum distillation separationPropanolDistillation

A process is disclosed of separating 1-methoxy-2-propanol and 2-methoxy-1-propanol from aqueous compositions, by dewatering of the aqueous composition containing 1-methoxy-2-propanol and 2-methoxy-1-propanol to a concentration of 1-methoxy-2-propanol and 2-methoxy-1-propanol of at least 90 percent by weight in total and isolation of 1-methoxy-2-propanol, 2-methoxy-1-propanol or mixtures thereof by distillation.

Owner:DEGUSSA AG +1

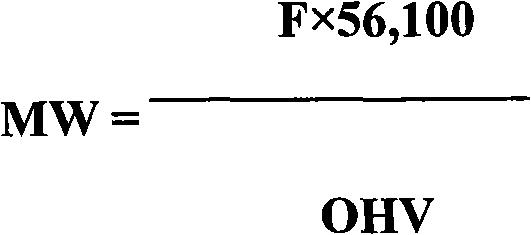

Method for refining low-odor polyether polyol

InactiveCN101775132AEfficient removalNo smellCosmetic preparationsEther separation/purificationPolyolSorbent

The invention relates to a method for refining low-odor polyether polyol. The polyether polyol is catalyzed and synthesized by using alkali metal. The method is characterized by comprising the following steps of: adsorbing, crystallizing and filtering for 1-5 times at 60-120 DEG C by using pure water which accounts for 0.1-10 percent of the total mass of rough polyether polyol and two adsorbents to obtain the low-odor polyether polyol, wherein the adsorbents are hydrated magnesium silicate and kieselguhr with the mass proportion of 1;1, and the total adding amount of the adsorbents accounts for 0.1-3 percent of the total mass of the rough polyether polyol. The invention can effectively remove the content of potassium and sodium ions in the polyether polyol, prevents the generation of a by-product generating odor to the greatest extent while effectively removing the potassium and sodium ions in polyether and enables the polyether polyols to hardly have odor, thereby fundamentally reducing the odor of the polyether.

Owner:SHANDONG BLUSR DONGDA CHEM

Process for the preparation of dimethylether from hydrocarbons

ActiveUS20060287405A1Reduce in quantityEconomical and efficientEther separation/purificationOrganic compound preparationSyngasPtru catalyst

Disclosed herein is a process for the preparation of dimethylether from hydrocarbons, including tri-reforming a feedstock mixture comprised of hydrocarbons, carbon dioxide and water vapor in the presence of a tri-reforming catalyst, to prepare a syngas, which then undergoes gas-phase direct synthesis into dimethylether in one step in the presence of a hybrid catalyst. According to the process of this invention, three main processes among typical syngas preparation processes are simultaneously performed, and then, the syngas thus obtained is prepared into dimethylether through a direct reaction in one step, thereby decreasing the apparatus cost and operation cost. In addition, all of the carbon dioxide separated and recovered from the unreacted material and by-products may be reused as reaction material, thus decreasing the generation of carbon dioxide and reducing the material cost.

Owner:KOREA GAS CORPORATION

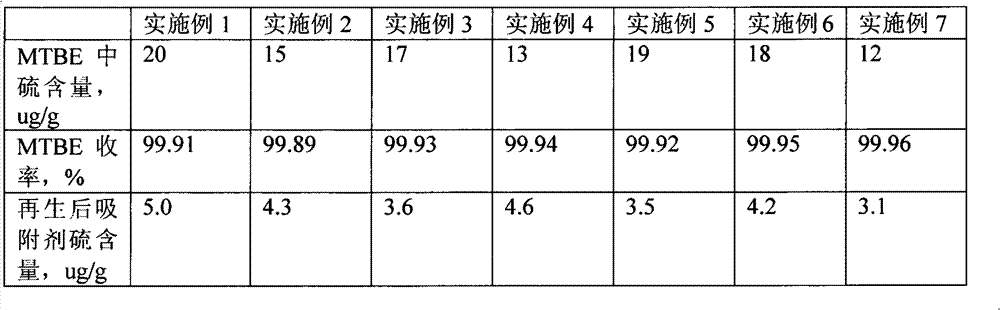

Method for removing sulfides in MTBE by adsorptive distillation

The invention provides a technology for removing sulfides in MTBE by adsorptive distillation. The technology is characterized in that a substance with a boiling point higher than that of MTBE and relatively high absorptive selectivity upon thioether, mercaptan, disulfide and thiophene is adopted as an adsorbent; under certain temperature and technologcial conditions, sulfides in MTBE are selectively absorbed by the adsorbent; and the sulfur-containing adsorbent is regenerated and recycled with a vacuum distillation method, and sulfides are recovered, such that sulfides in MTBE are removed and recycled. With the technology, the content of sulfides in MTBE can be reduced from 600-800ug / g to below 20ug / g, and MTBE target product yield is greater than 99.8%.

Owner:九江齐鑫化工有限公司 +2

Method for deeply desulfurizing methyl tertiary butyl ether

ActiveCN102557888AReduce sulfur contentMeet the requirements of motor gasolineEther separation/purificationDistillationAutomotive gasoline

The invention provides a method for deeply desulfurizing methyl tertiary butyl ether. The method is characterized in that the sulfur-containing methyl tertiary butyl ether is mixed with light oil to form a mixture; the mixture enters a distillation column for distillation, so as to remove sulfur compounds in the sulfur-containing methyl tertiary butyl ether; and the column reactor temperature of the distillation column is 70 DEG C to 120 DEG C, the column top temperature is 50 DEG C to 60 DEG C, the pressure is 0.01 MPa to 0.15 MPa, the theoretical column plate number is 3 to 20 and the reflux ratio is 0.25 to 10. By adopting the method, the total sulfur content of the methyl tertiary butyl ether can be reduced from more than 1000 Mug*g-1 to less than 1000 Mug*g-1, and the distilled methyl tertiary butyl ether can well satisfy the requirement of mixing automotive gasoline of a production country IV or a production country V.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

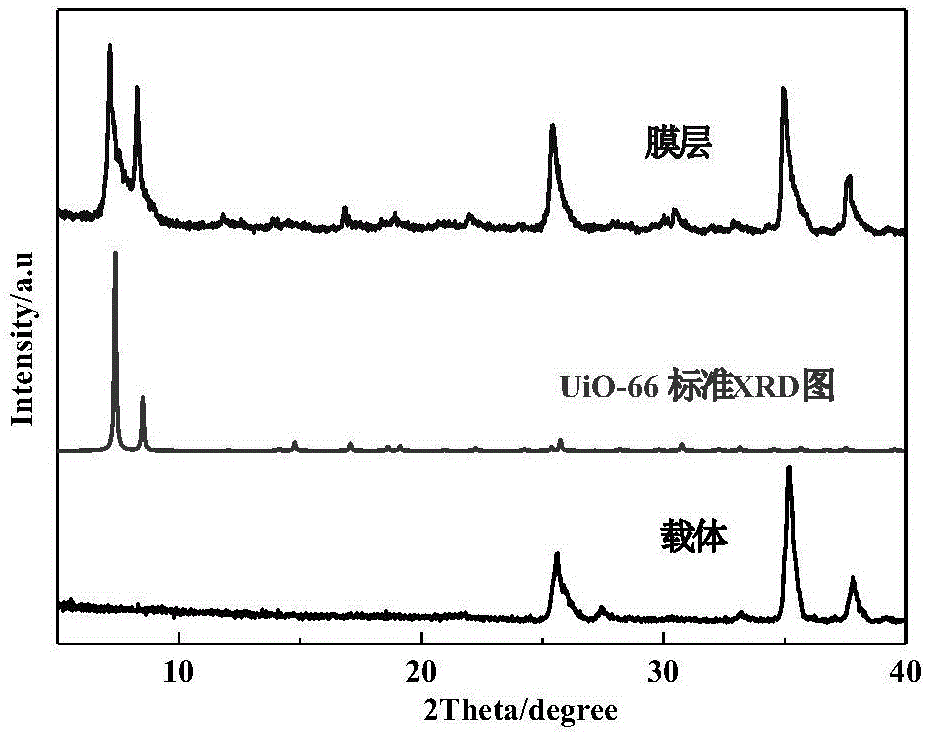

Method for preparing metal-organic framework UiO-66 series membranes and separating methanol/methyl tert-butyl ether mixture

ActiveCN106492651AHigh crystallinityStable separationMembranesEther separation/purificationChemistryMethanol

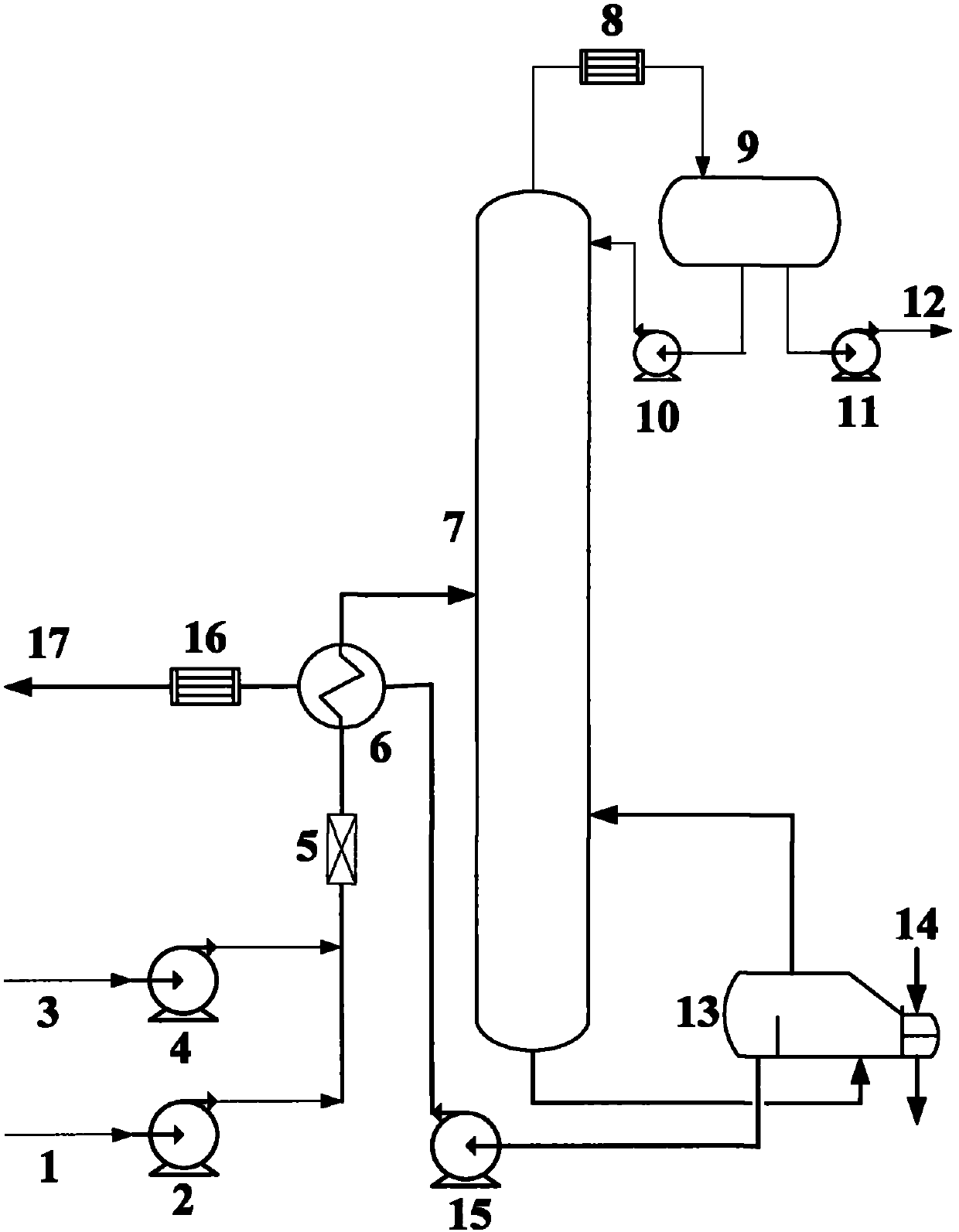

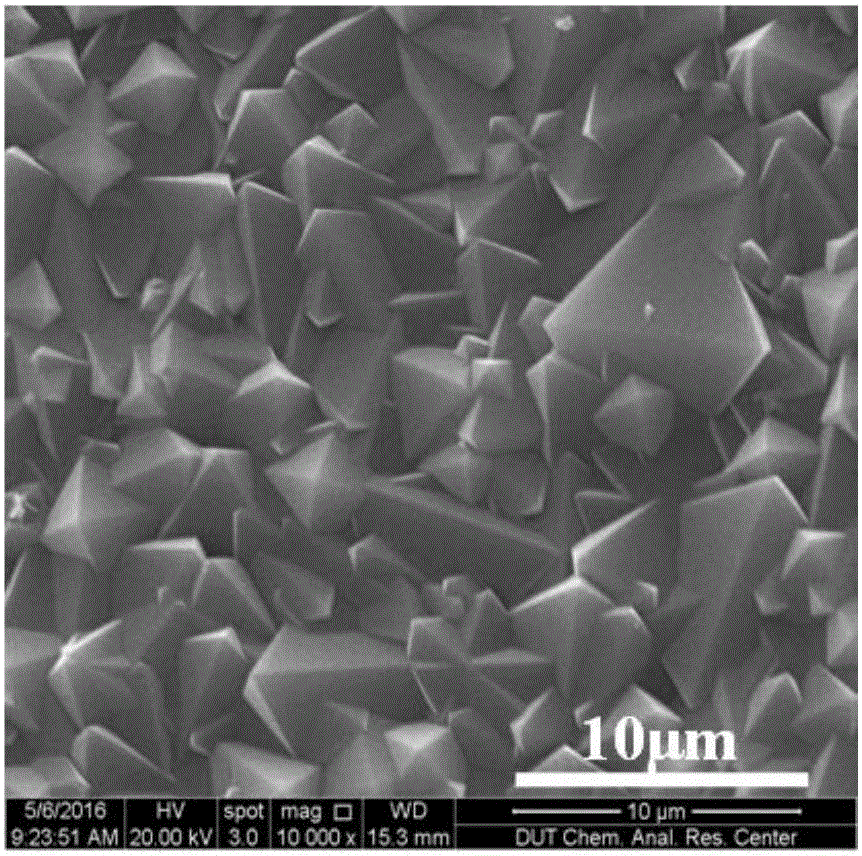

The invention provides a method for preparing metal-organic framework UiO-66 series membranes and separating a methanol / methyl tert-butyl ether mixture and belongs to the technical field of chemical separation. According to the method, the metal-organic framework UiO-66 series membranes are growth and synthesized through putting a porous ceramic tube carrier with a seed layer into a membrane forming solution; through adding a glacial acetic acid regulator, the forming of continuous and complete high-performance membranes is facilitated. The methanol / methyl tert-butyl ether mixture is effectively separated by using the screening performance and methanol preferential adsorbability of the UiO-66 series membranes, and the UiO-66 series membranes have good stability in a separation system. According to the method, by making full use of the screening performance and methanol preferential adsorption characteristic of the UiO-66 series membranes, the permeation flux is relatively high and is higher than 1.2kg / (m<2>h), the separation effect is good, the separating factor is greater than 200, and the permeation performance can be kept stable in long-term operation, so that the practical application value is potential.

Owner:DALIAN UNIV OF TECH

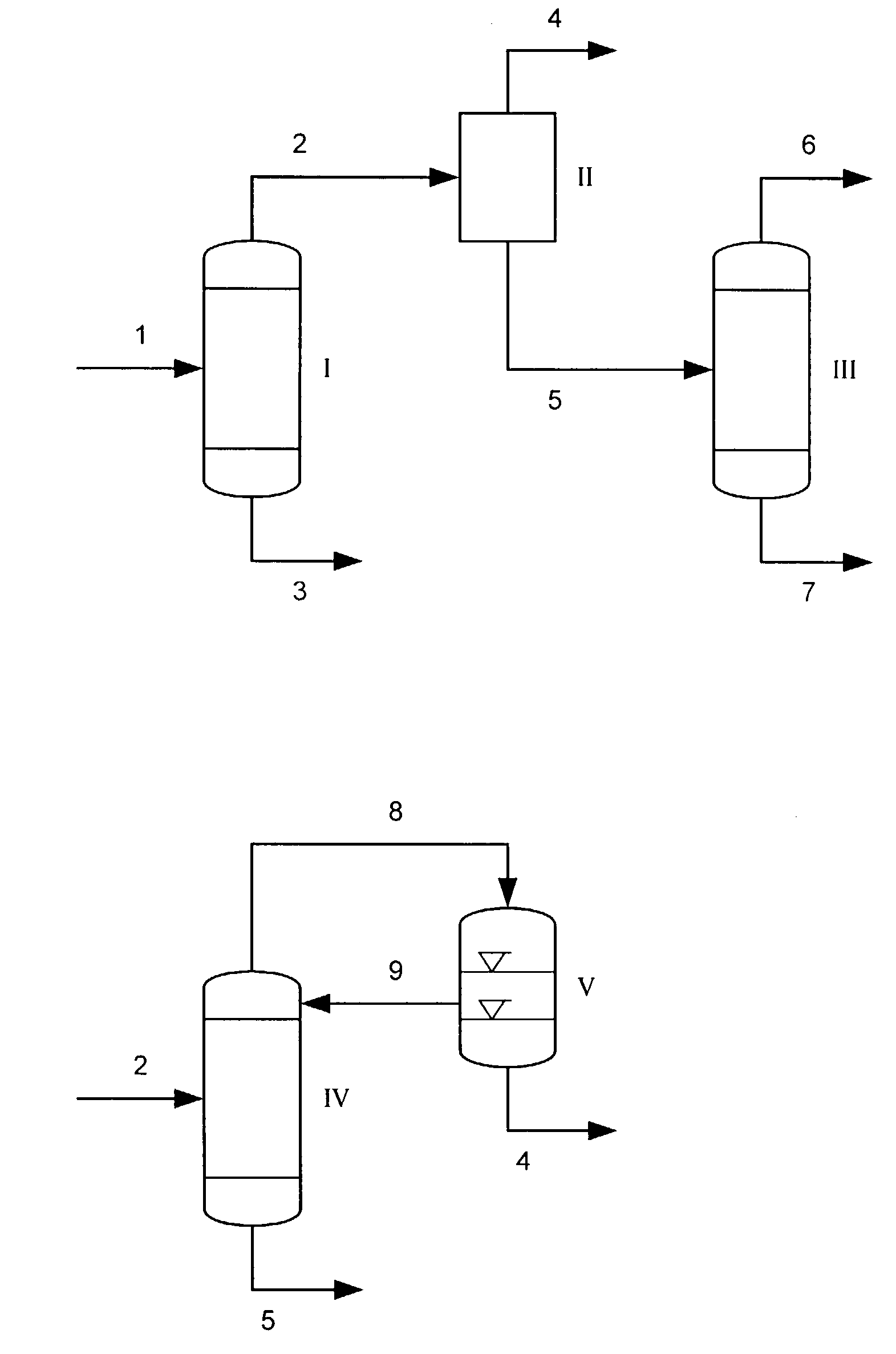

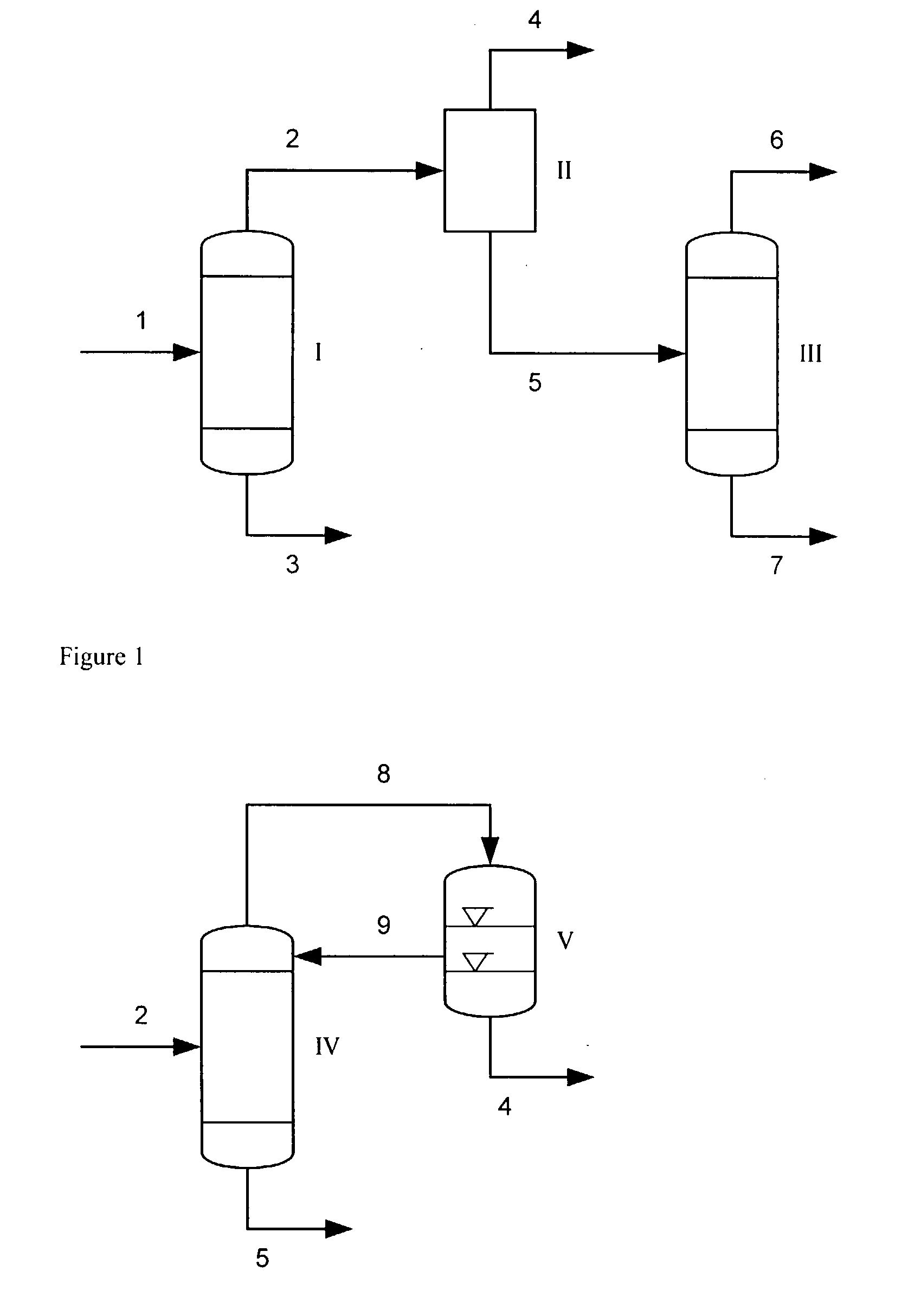

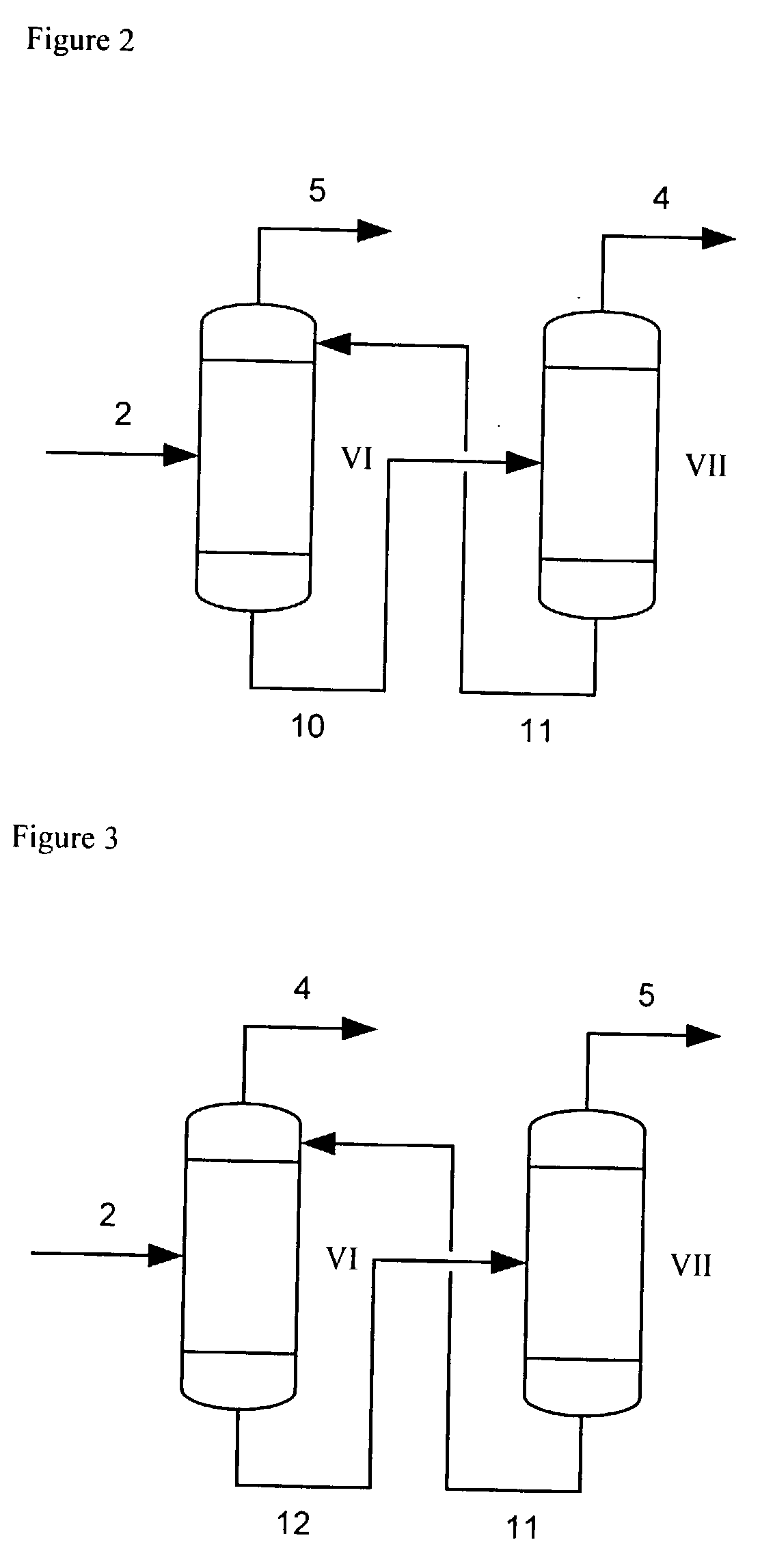

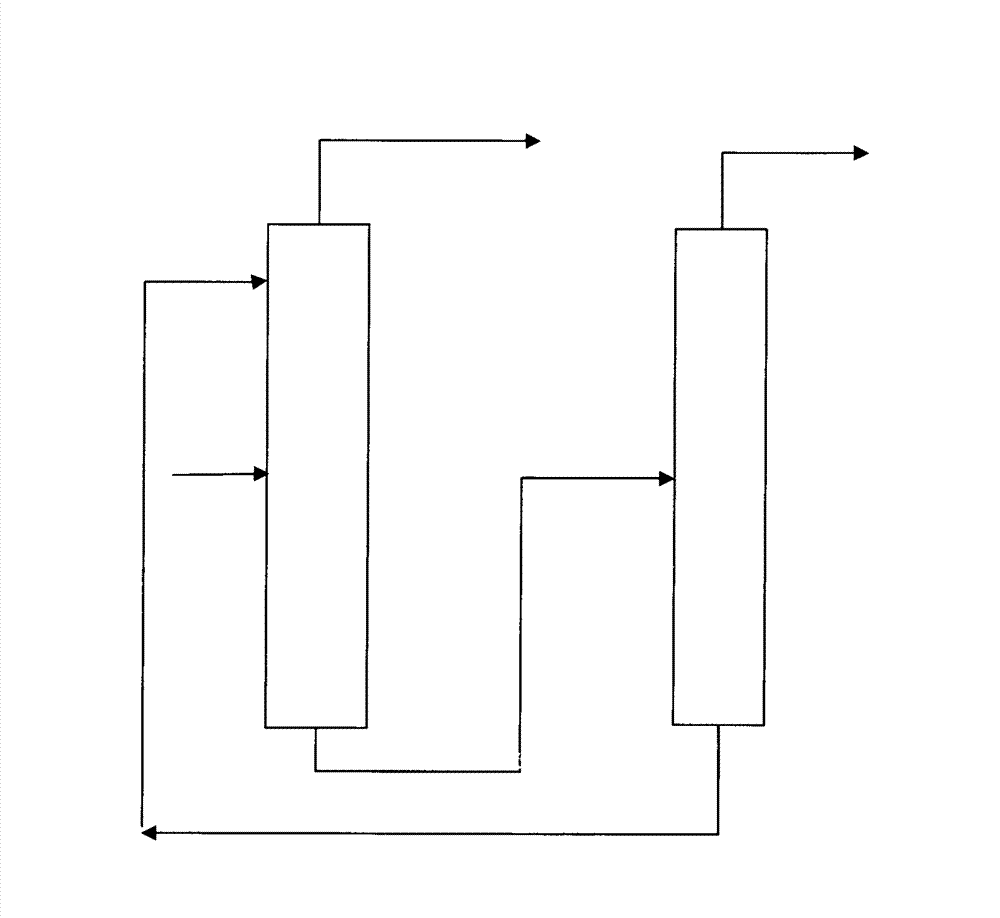

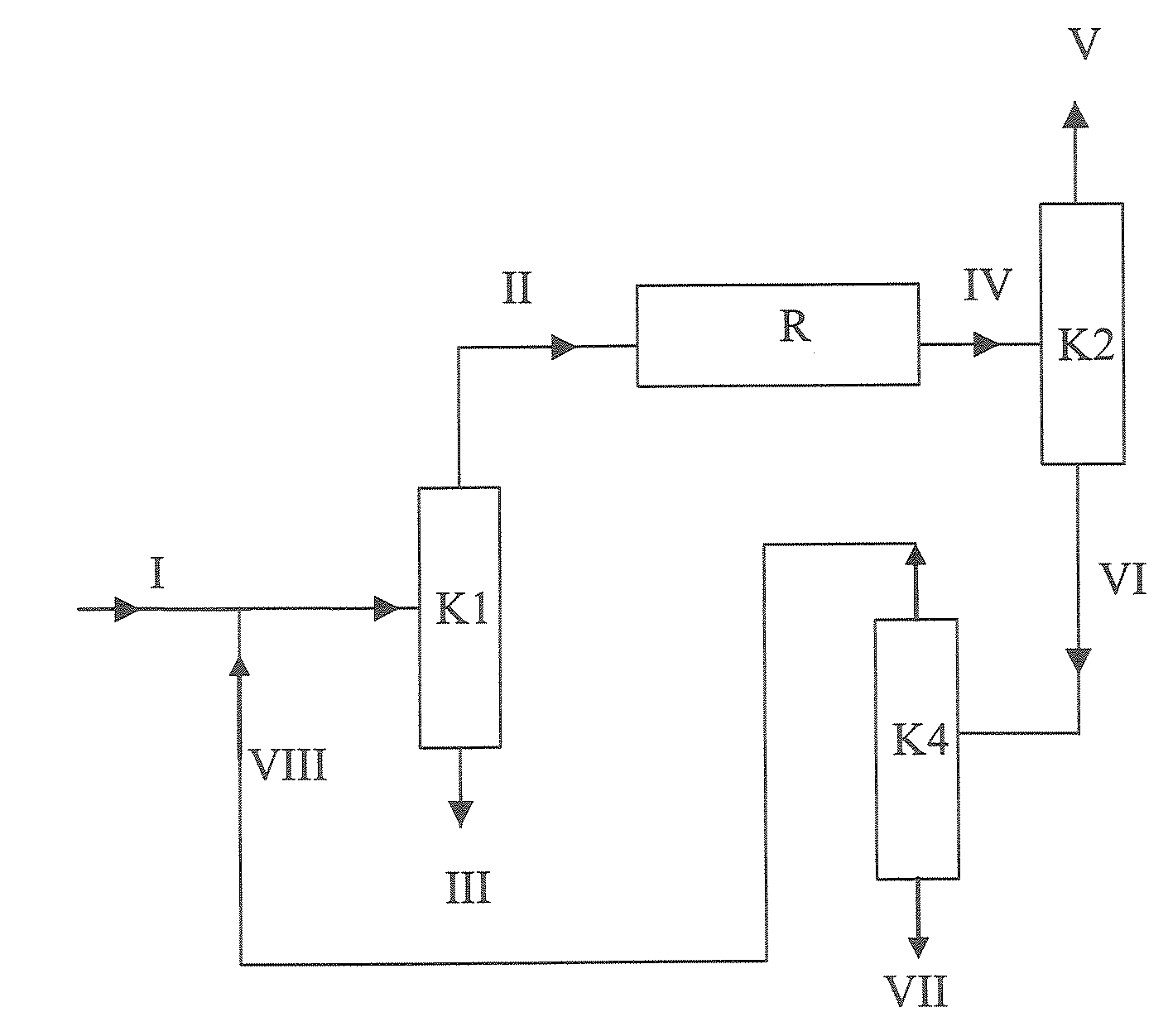

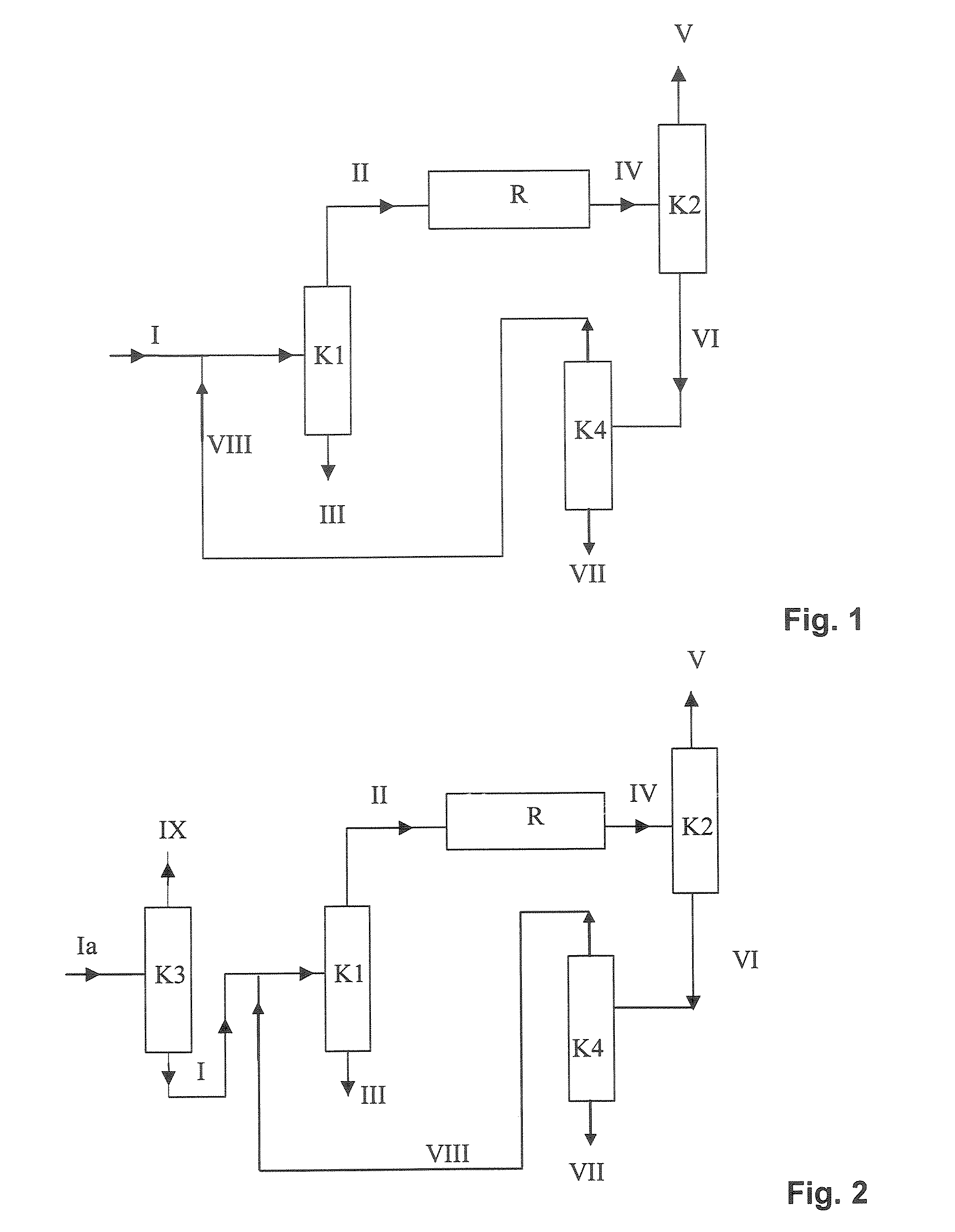

Process for the dissociation of mtbe

ActiveUS20080058575A1Improved and simplifiedWork-up of the bottom products obtainedEther separation/purificationOrganic compound preparationGas phaseBoiling point

Isobutene is prepared by dissociation of MTBE in the gas phase, by a) fractional distillation of an MTBE-containing stream comprising feed MTBE (I) and a recycle stream (VIII) to give an MTBE-containing overhead stream (II) and a bottom stream (III) having a boiling point higher than MTBE, b) catalytic dissociation of the overhead stream (II) obtained in step a) to give a dissociation product (IV), c) separation by distillation of the dissociation product (IV) obtained in step b) into an overhead stream (V) comprising more than 90% by mass of isobutene and a bottom stream (VI) comprising diisobutene, MTBE and more than 50% of the methanol present in the dissociation product (IV), d) fractional distillation of the bottom stream obtained in step c) under conditions under which the methanol is obtained as bottom product (VII) and more than 99% of the MTBE is obtained in the overhead product (VIII), and e) recirculation of the overhead product (VIII) to step a).

Owner:EVONIK OPERATIONS GMBH

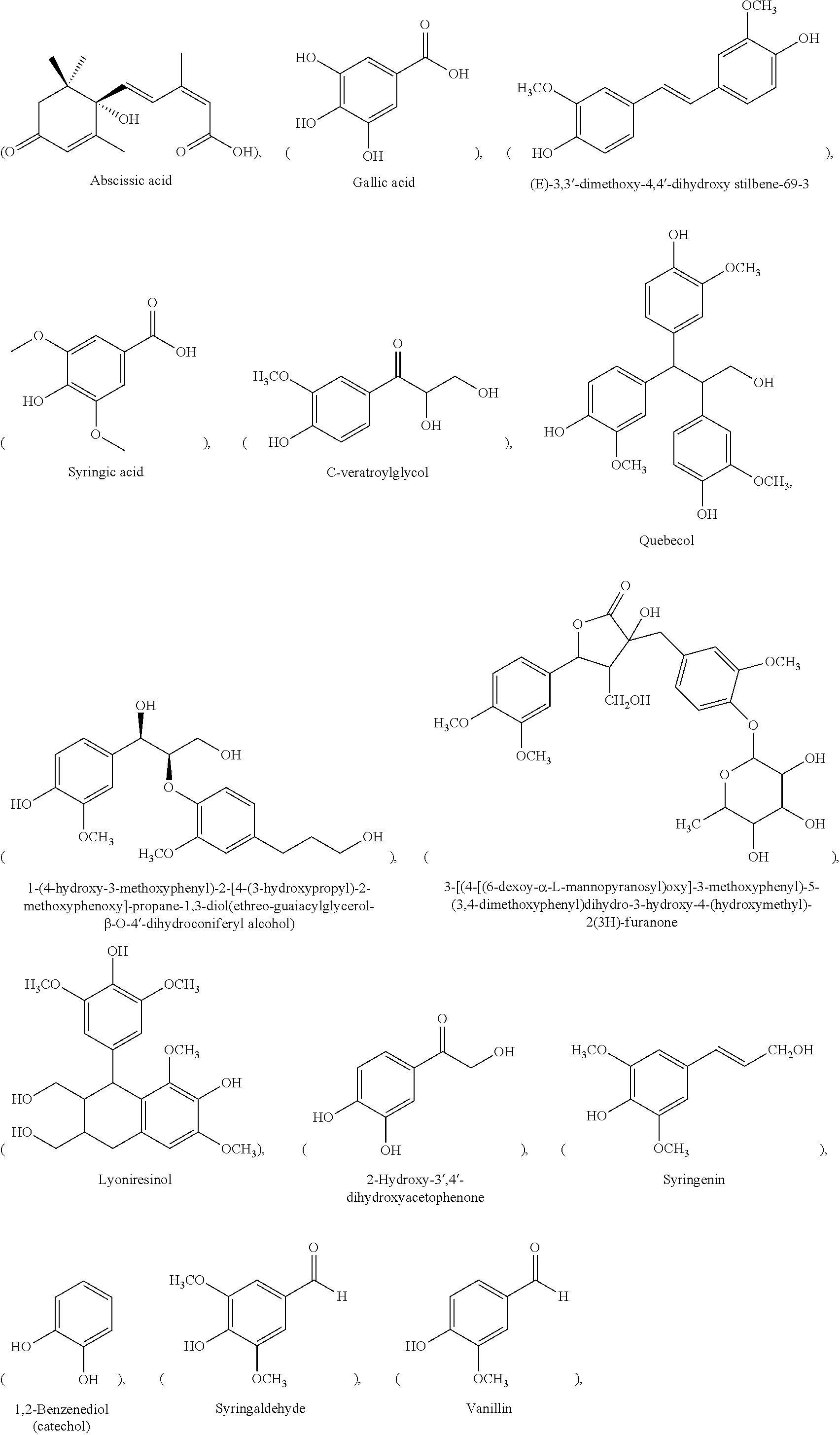

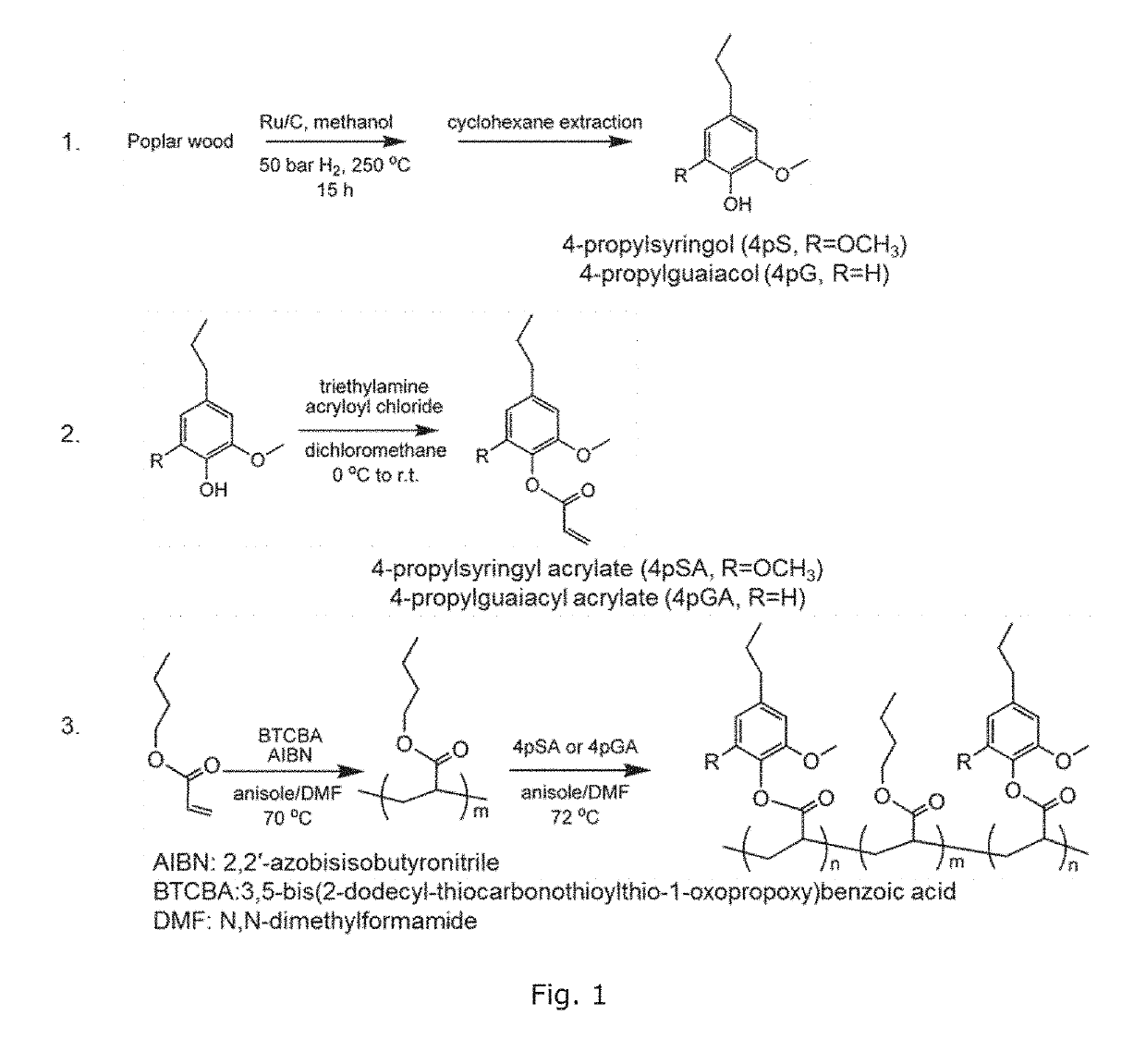

Bio-based polymers from raw lignocellulosic biomass

ActiveUS20190144590A1High yieldSolid electrolytesPreparation from carboxylic acid halidesCellulosePolymer electrolytes

Disclosed herein is a method of making polymerizable bio-based monomers containing one phenolic hydroxyl group which has been derivatized to provide at least one polymerizable functional group which is an ethylenically unsaturated functional group (such as a [meth]acrylate group), where the precursors of the polymerizable bio-based monomers are derived from raw lignin-containing biomass. Also disclosed herein are bio-based copolymers prepared from such bio-based monomers and a co-monomer, and methods of making and using such bio-based copolymers. In particular, the bio-based copolymers can be used as pressure sensitive adhesives, binders, and polymer electrolytes.

Owner:UNIVERSITY OF DELAWARE

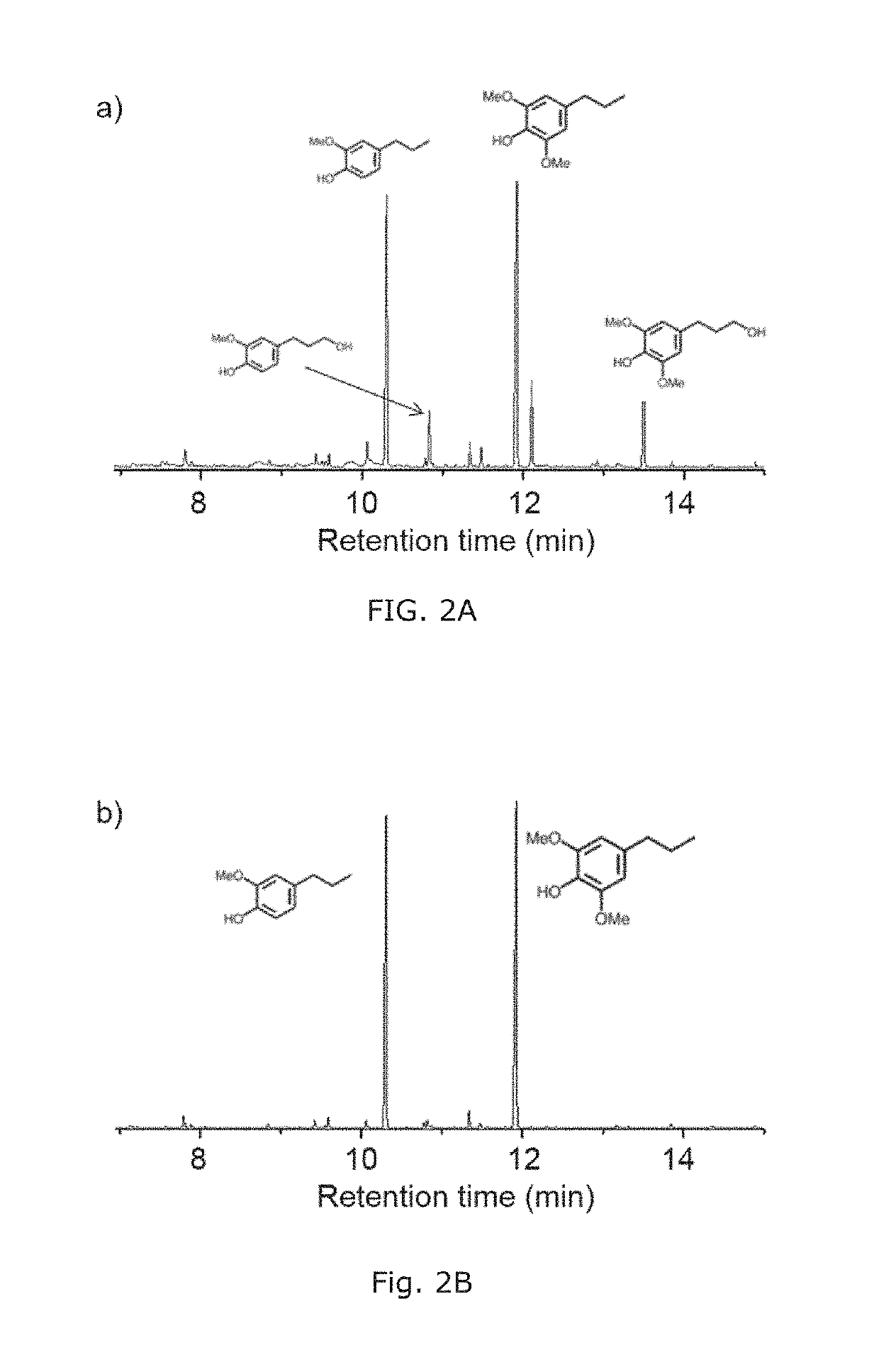

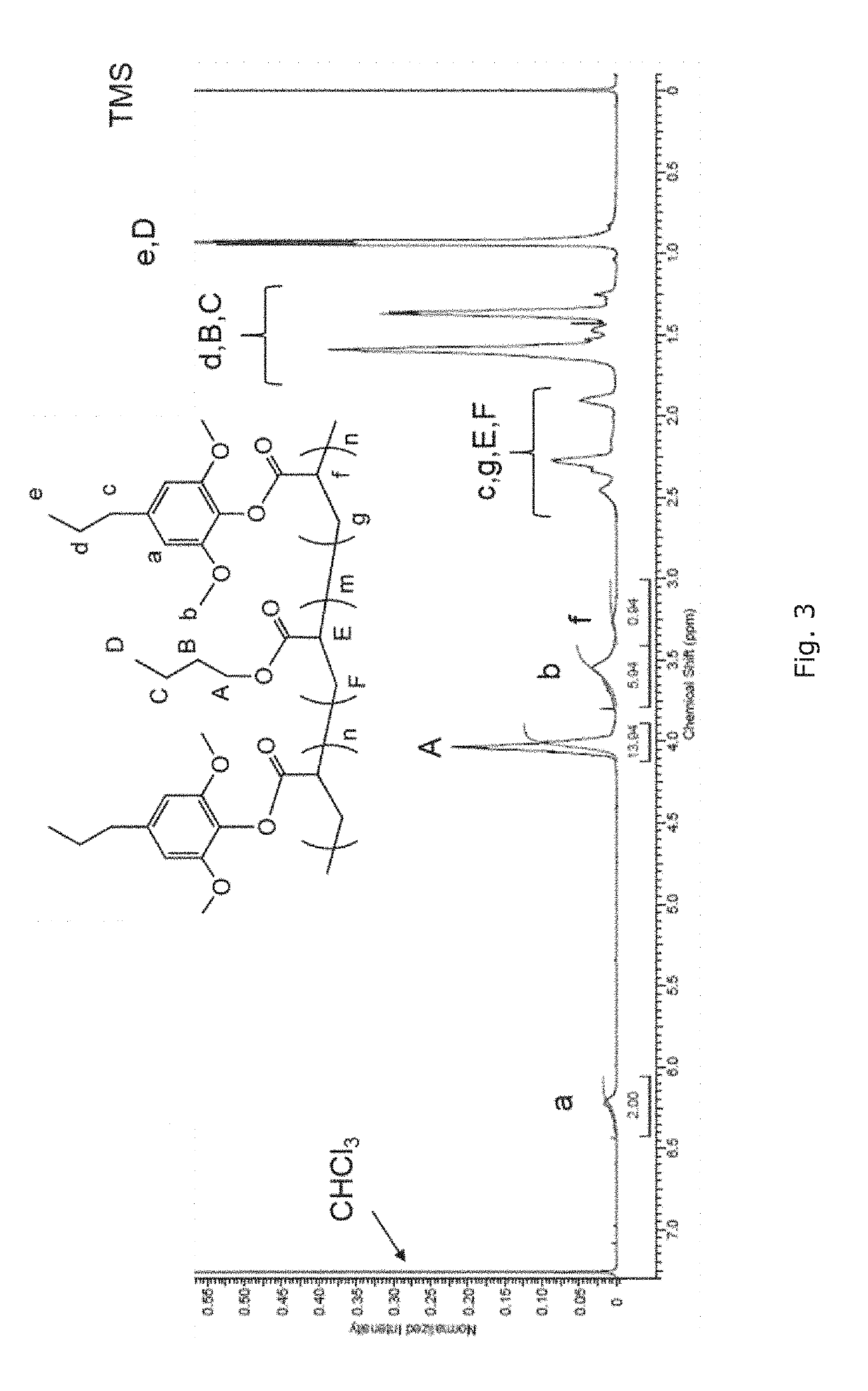

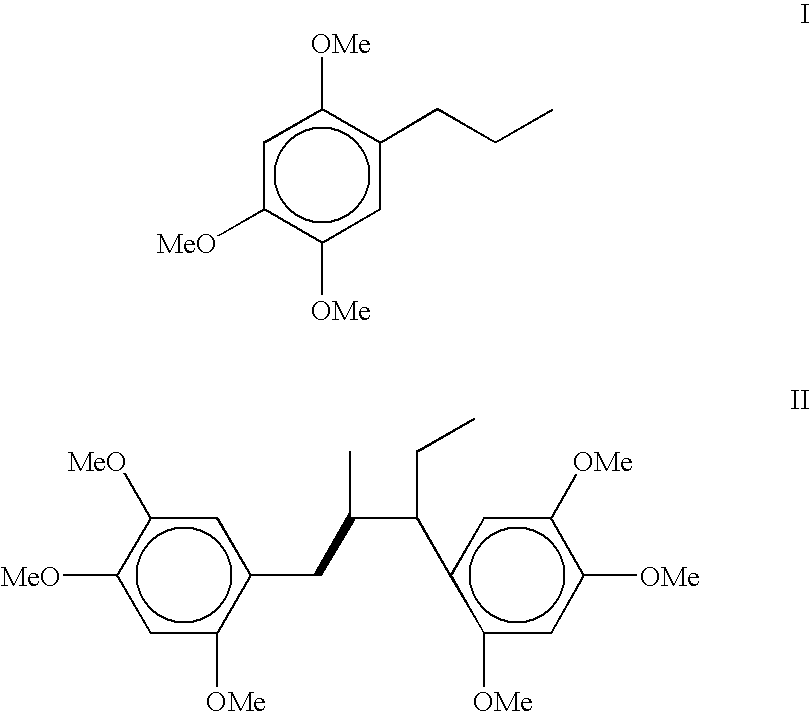

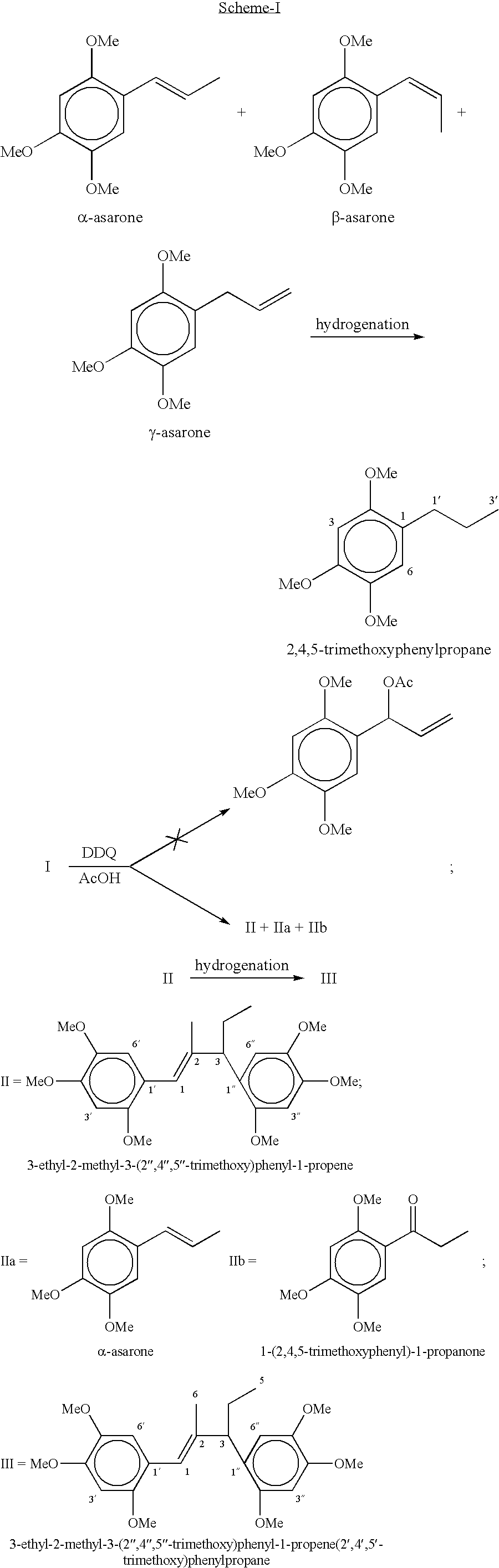

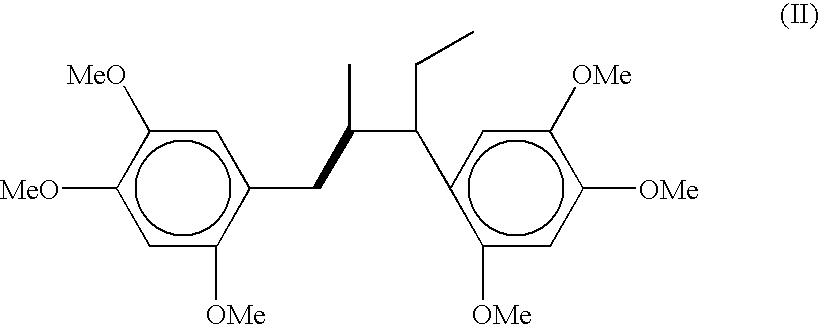

DDQ mediated one step dimerisation of beta-asarone or beta-asarone rich acorus calamus oil in the formation of novel neolignan

InactiveUS20030187306A1Easy to useEther separation/purificationOrganic compound preparationOrganic acidAsarone

The present invention relates to a novel neolignan (NEOLASA-I) 3-ethyl-2-methyl-3-(2'',4'',5''-trimethoxy-phenyl-1-(2',4',5'-trimethoxy)phenyl-1-(2',4',5'-trimethoxy)phenyl-1-propene and a process for the preparation of high purity, higher yield neolignan, alpha-asarone, 2,4,5-trimethoxy-phenyl propionone from beta-asarone or beta-asarone rich Acorus calamus oil containing alpha and gamma-asarone by hydrogenating and dimerizing by treatment with DDQ in presence of an organic acid.

Owner:COUNCIL OF SCI & IND RES

Process for separating solids from valuable or harmful liquids by vaporisation

ActiveUS8652304B2Prevent thermal degradationDrying using combination processesSolvent extractionOil and natural gasPetroleum

The present invention is directed to an enhanced process for separating dissolved and suspended solids from valuable or harmful liquids and more particularly to improving the operational aspects and separation efficiency of treating certain water miscible fluids including those used for oil and gas processing such as glycols, as well as automobile and aircraft fluids, that have become contaminated with dissolved and / or suspended solid matter.

Owner:PRIME SERVICES TRUSTEE

Method of stabilizing reduced coenzyme Q10 and method of acidic crystallization

InactiveUS7169590B2Favorably protected against oxidationHigh yieldBiocidePeptide/protein ingredientsStrong acidsSolvent

The present invention relates to a method of efficiently producing reduced coenzyme Q10 having excellent qualities which is useful as an ingredient in foods, functional nutritive foods, specific health foods, nutritional supplements, nutrients, animal drugs, drinks, feeds, cosmetics, medicines, remedies, preventive drugs, etc. This method is suitable for industrial production thereof.It is possible to handle reduced coenzyme Q10 in state of being protected from oxidation by molecular oxygen by bringing the reduced coenzyme Q10 in contact with a solvent containing a strong acid. Furthermore, when reduced coenzyme Q10 is crystallized in the presence of a strong acid, crystallization can be carried out while the formation of oxidized coenzyme Q10 as a by product is minimized, and, then high-quality crystals thereof can be produced.

Owner:KANEKA CORP

Method of stabilizing reduced coenzyme q10

ActiveUS20050008630A1Quality improvementMinimize formationOrganic active ingredientsEther separation/purificationCompound (substance)Coenzyme Q10

The present invention provides a stabilization method, a preservation method and the like method of reduced coenzyme Q10, which is useful as functional nutritive foods, specific health foods and the like. Furthermore, the present invention provides a method for efficiently obtaining reduced coenzyme Q10 of high quality and by a method suitable for a commercial production. It is possible to handle and stably preserve reduced coenzyme Q10 under a condition that oxidation by a molecular oxygen is inhibited by contacting reduced coenzyme Q10 with an ascorbic acid and citric acid or a related compound thereof, and thus a stabilized composition is obtained. Moreover, reduced coenzyme Q10 is converted into a crystalline state in such a condition that the formation of oxidized coenzyme Q10 as a byproduct is minimized by crystallizing reduced coenzyme Q10 in the presence of ascorbic acid or a related compound thereof, etc., and thus a reduced coenzyme Q10 crystal of high quality is produced. Furthermore, by successively crystallizing the generated reduced coenzyme Q10 in the presence of ascorbic acid or a related compound thereof after reducing oxidized coenzyme Q10 to reduced coenzyme Q10 using ascorbic acid or a related compound thereof, operations are simplified and minimized, and thus reduced coenzyme Q10 of high quality is produced.

Owner:KANEKA CORP

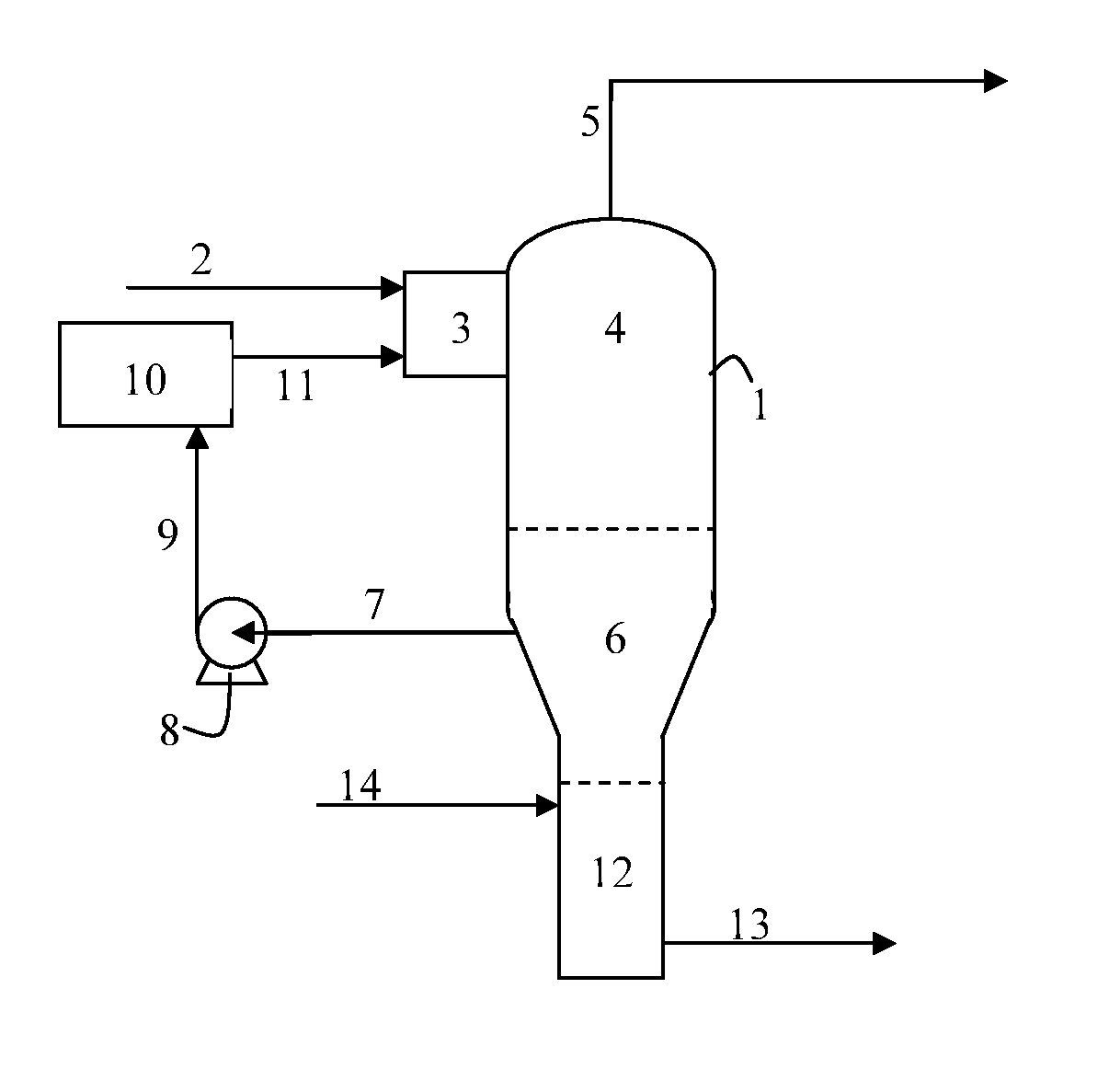

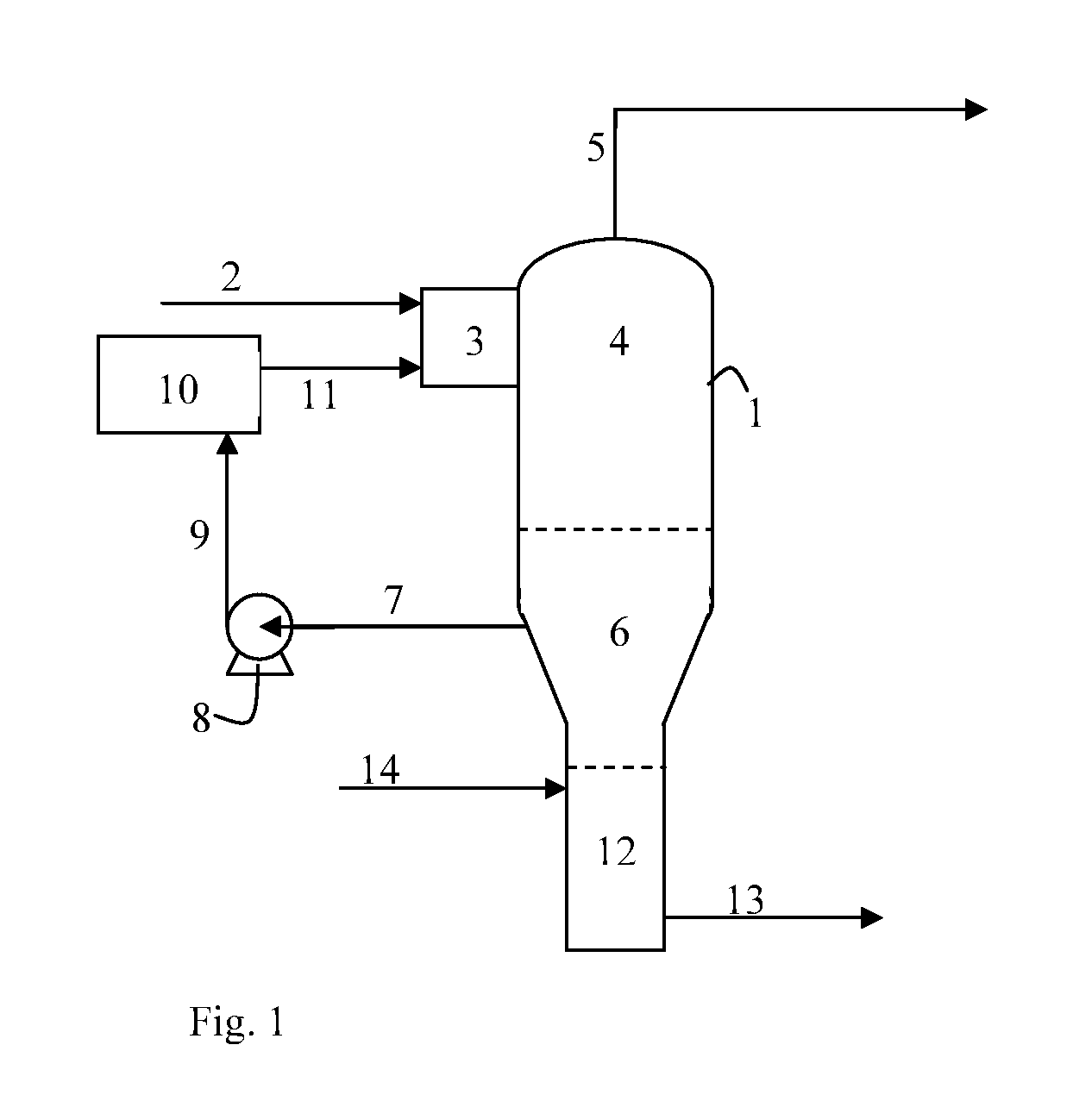

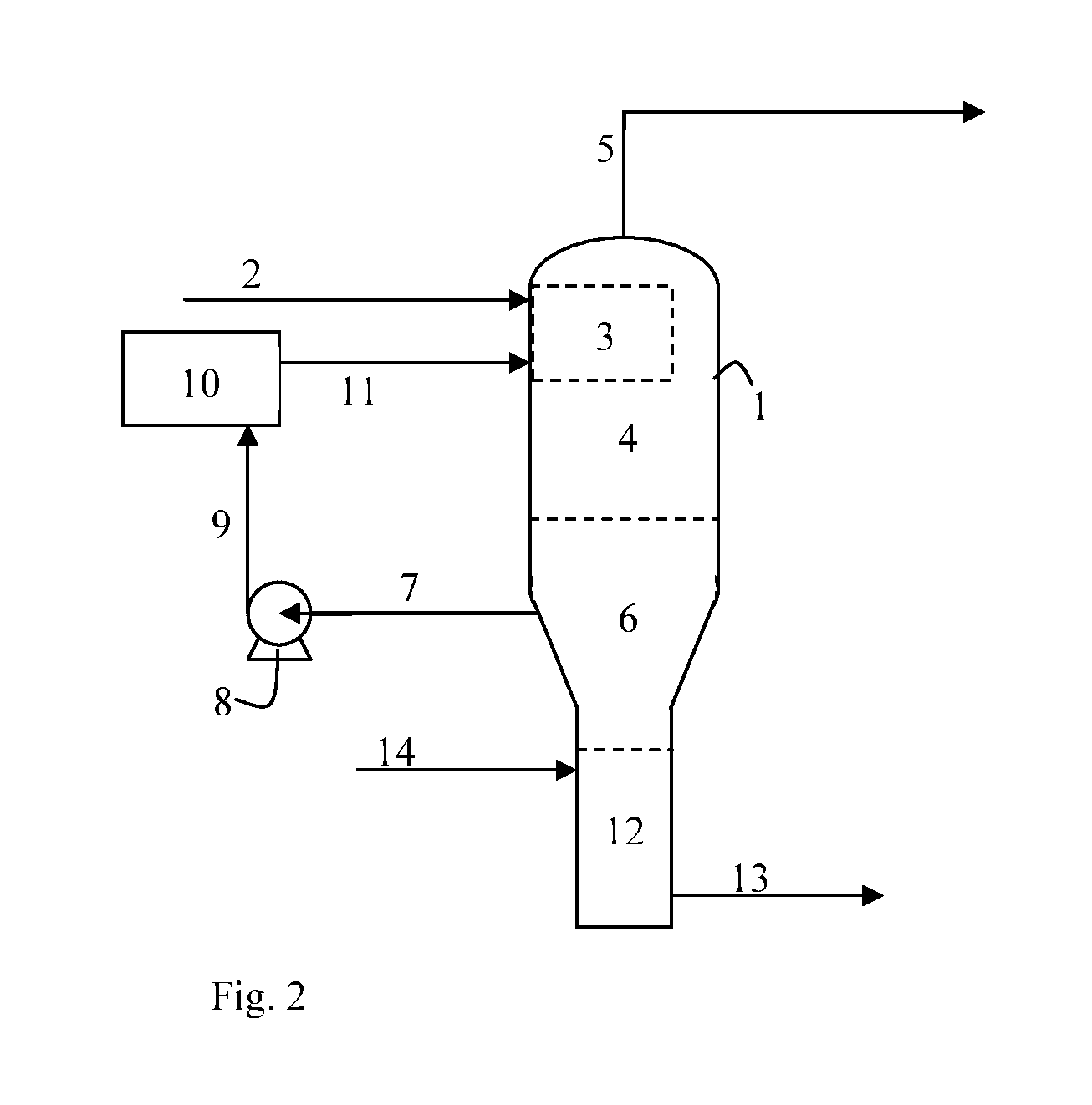

Method and device for recovering polyethylene glycol raffinate byproduct from ethylene glycol process

InactiveCN102010294AImprove film formationReduce corrosionEther separation/purificationMultistage water/sewage treatmentAlcoholPolyethylene glycol

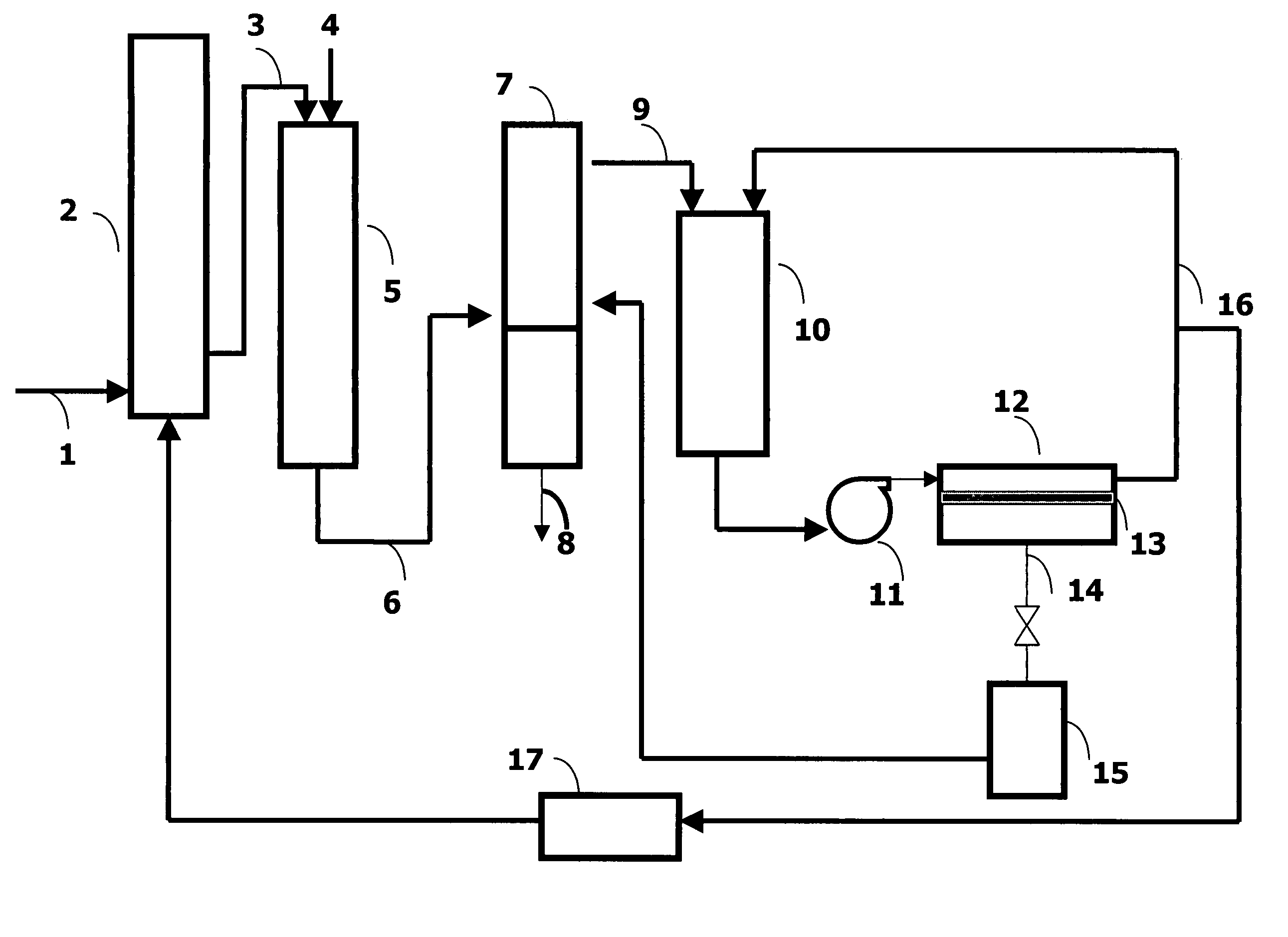

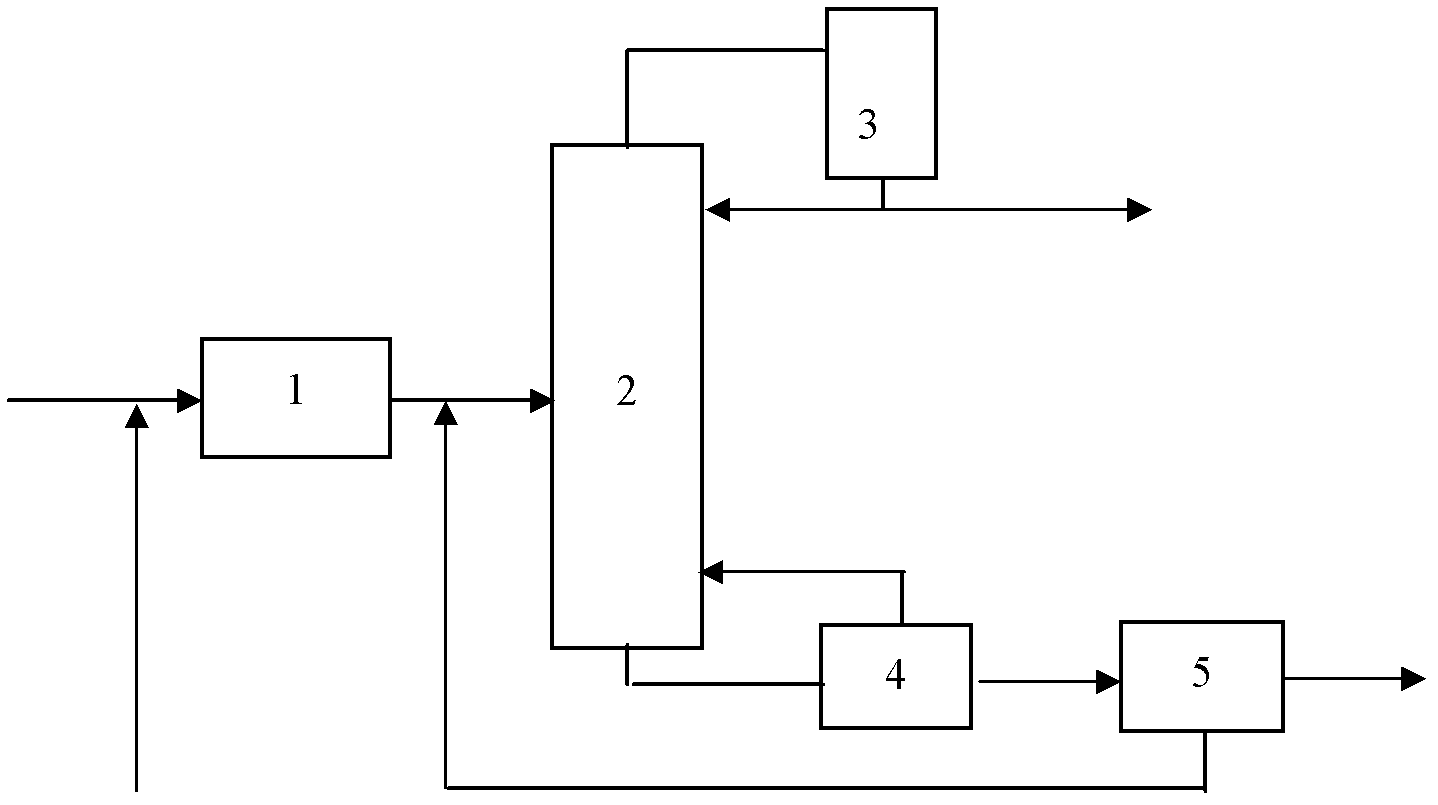

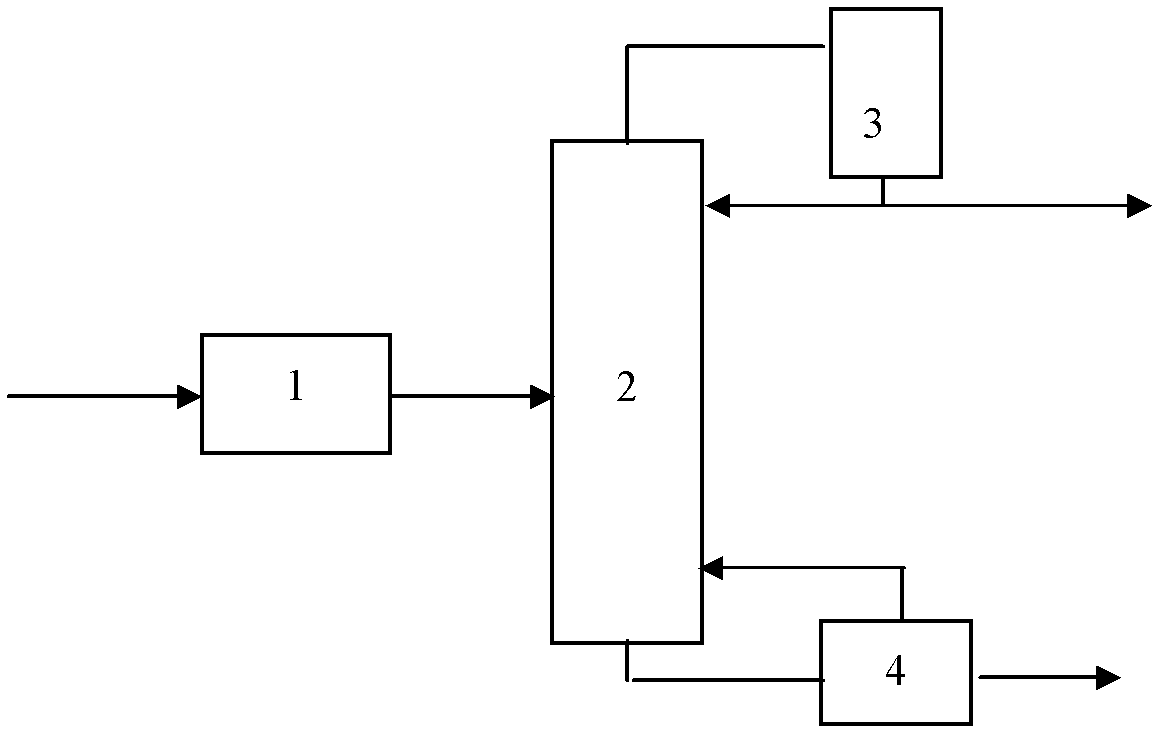

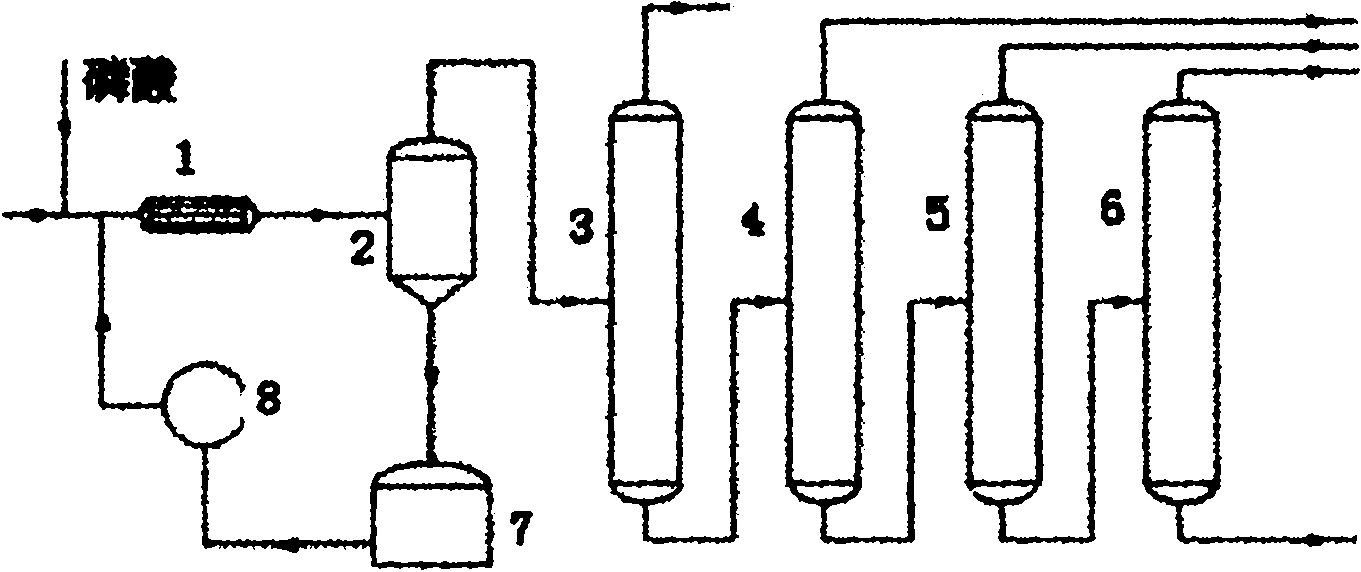

The invention relates to a method and a device for recovering a polyethylene glycol raffinate byproduct form an ethylene glycol process. The method comprises the following steps of: (1) adding phosphoric acid into the polyethylene glycol raffinate, controlling the pH value to be between 7 and 9, conveying the mixture to a preheater (1), and preheating; (2) allowing a preheated material to enter a scraper falling-film evaporator (2), discharging a material at the bottom of the evaporator into an intermediate tank (3), and allowing the material to enter the preheater (1) through a centrifugal separator (8); (3) conveying the mixture of water and alcohol on the top of the falling-film evaporator to a dehydration rectifying tower (3); (4) conveying a mixed alcohol material at the bottom of the tower to an ethylene glycol separating tower (4); (5) conveying the material at the bottom of the tower to a diethylene glycol separating tower (5); and (6) conveying the material at the bottom to a triethylene glycol separating tower (6), and collecting products on the top and bottom of the tower respectively. The method is simple, efficient and low in energy consumption, and is suitable for industrial application; and by the method, the utilization rate of the raffinate produced by ethylene glycol is improved.

Owner:NINGBO POLYTECHNIC +1

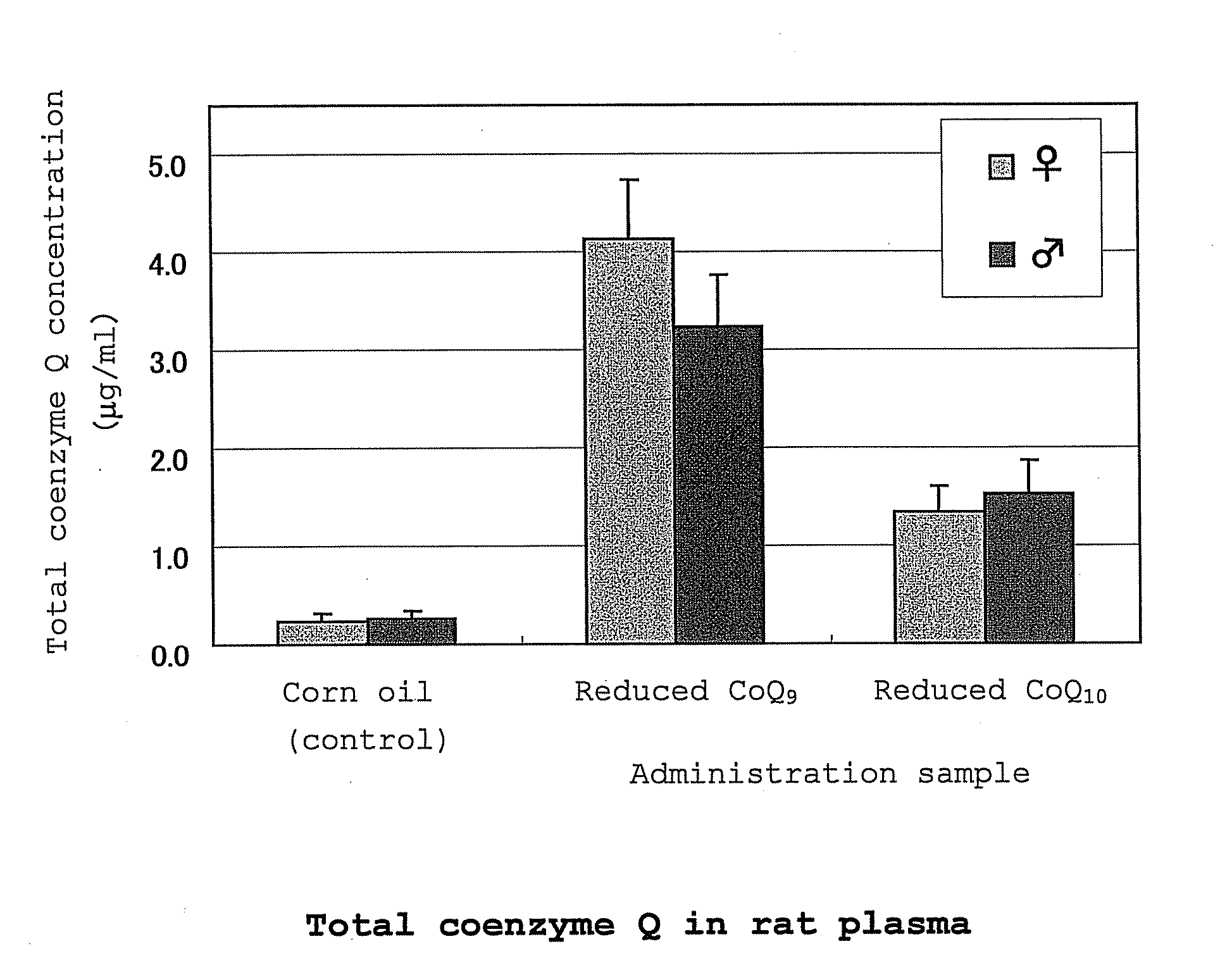

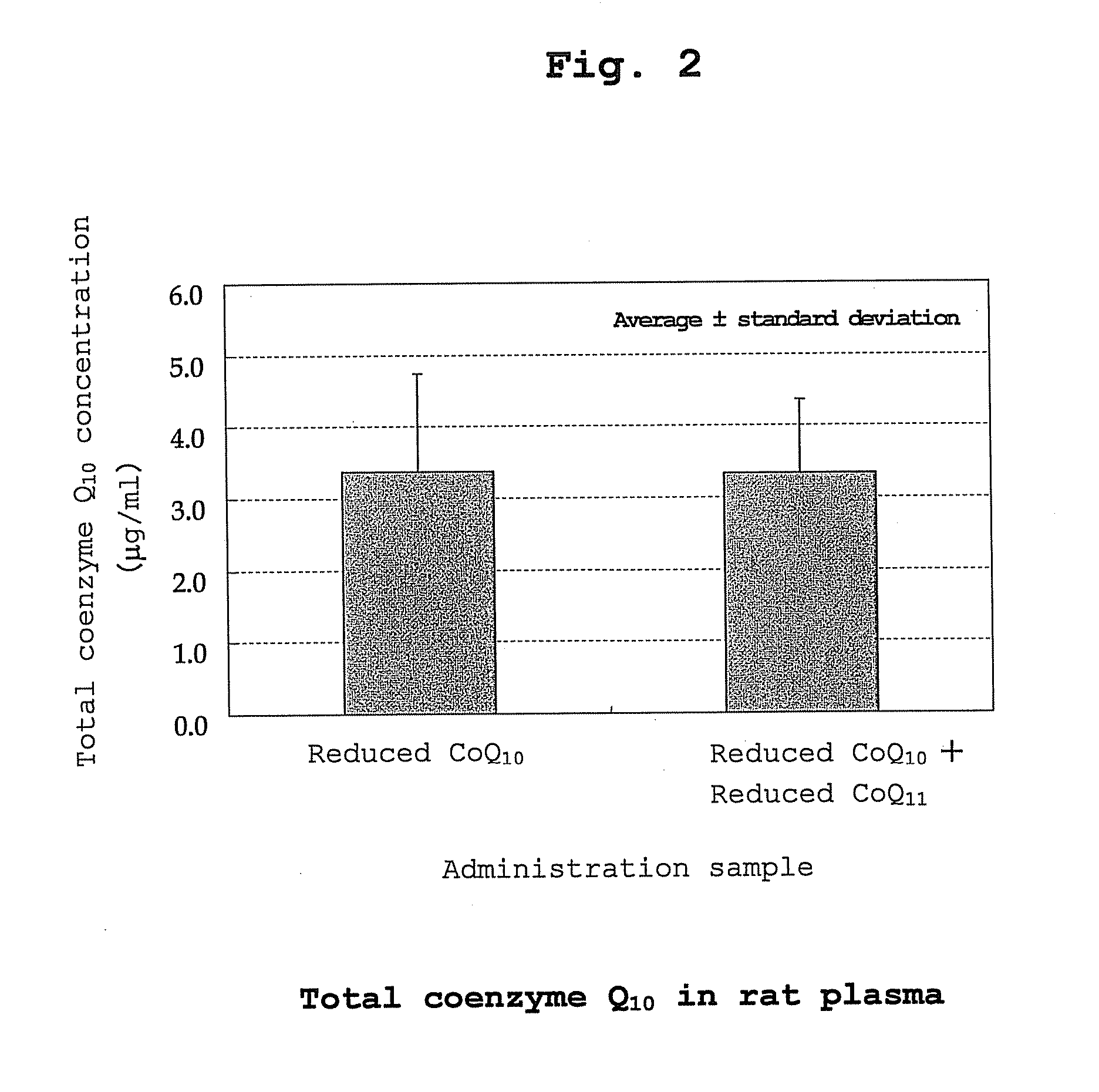

Stabilization method of reduced coenzyme q10

ActiveUS20070258966A1Improve stabilityPromote absorptionCosmetic preparationsHydroxy compound active ingredientsCoenzyme Q10Coenzyme A

The present invention provides a method for stabilizing reduced coenzyme Q10, which is useful as a food, nutritional product, nutritional supplement, animal drug, drink, feed, cosmetic, pharmaceutical product, therapeutic drug, prophylactic drug and the like. The present invention also provides a method of producing a reduced coenzyme Q10-containing composition which includes the co-presence of reduced coenzyme Q10 and reduced coenzyme Q9 and / or reduced coenzyme Q11.

Owner:KANEKA CORP

Method for preparing diol mono-tert-butyl ether

ActiveCN106397137APromote generationSuppress generationEther separation/purificationEther preparation by compound additionEtherDiol

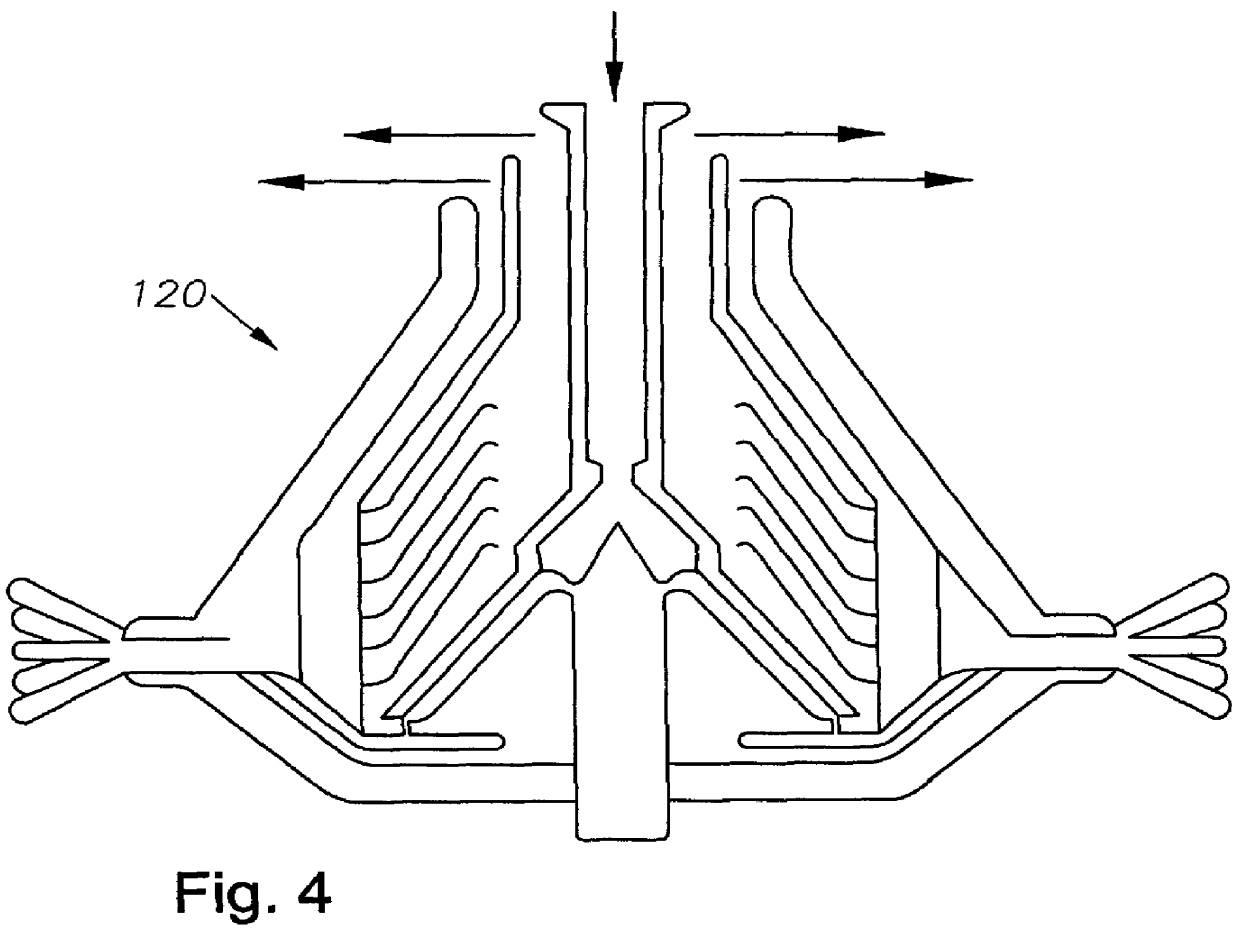

The present invention relates to a method for preparing diol mono-tert-butyl ether. According to the method, isobutene gas and liquid-phase diol are introduced into the catalyst bed layer in the middle portion of a reactor, the generated diol mono-tert-butyl ether is instantly distilled from the bed layer under the gas stripping effect of the isobutene gas so as to avoid the generation of ethylene glycol di-tert-butyl ether due to the continuous reaction between the diol mono-tert-butyl ether and the isobutene, the diol mono-tert-butyl ether is separated on the upper portion of the reactor, the separated diol mono-tert-butyl ether is condensed on the tower top, the condensed diol mono-tert-butyl ether is extracted from the tower top or the side line, and the unreacted isobutylene and the unreacted diol are respectively extracted from the tower top and the tower bottom and then are recycled to the inlet. With the process of the present invention, the generation of the diol di-tert-butyl ether can be inhibited, such that the problems that the azeotropy of the diol di-tert-butyl ether and the diol mono-tert-butyl ether causes high separation energy consumption, high investment, and the like can be avoided.

Owner:WANHUA CHEM GRP CO LTD

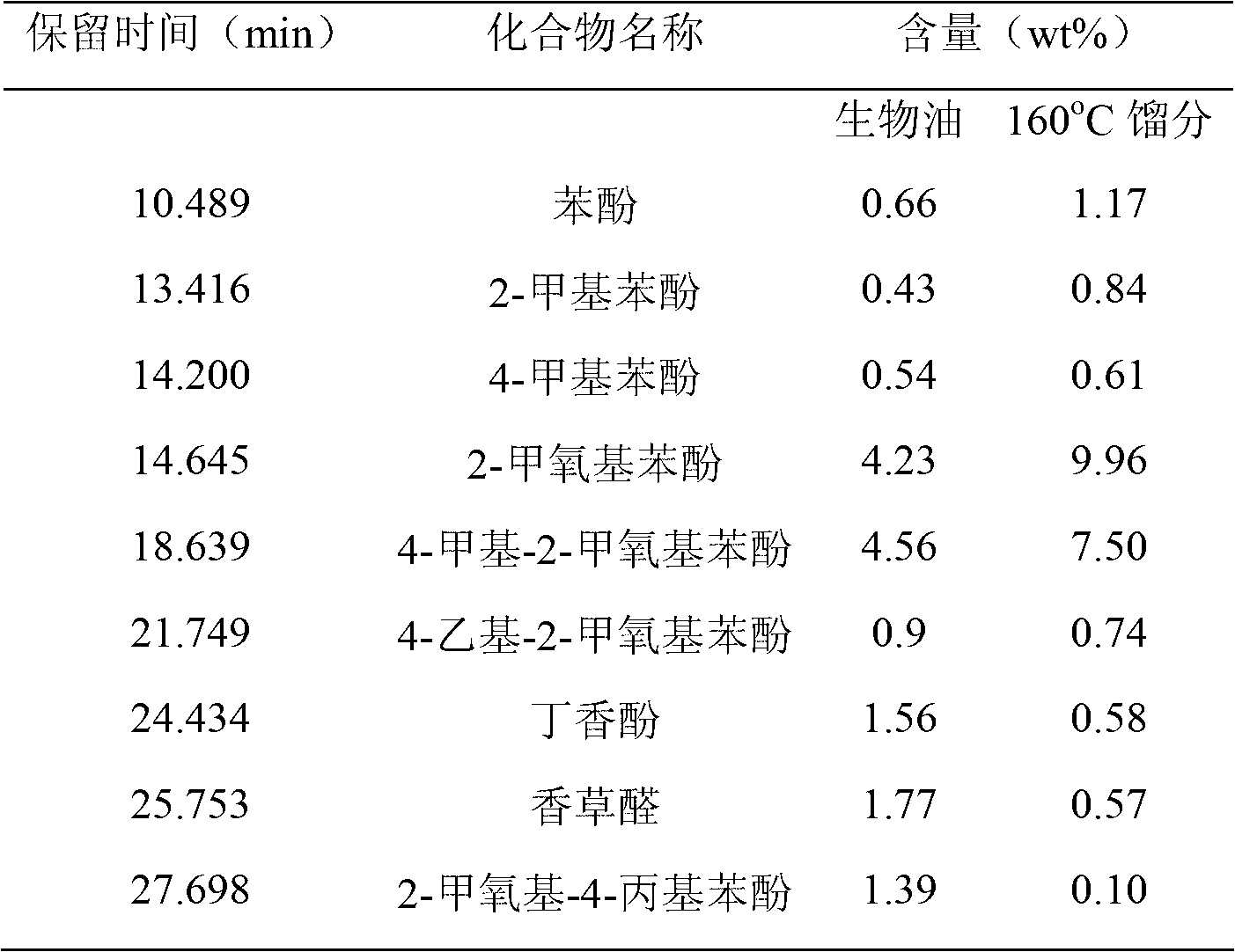

Method for separating phenols from bio-oil

InactiveCN102976906AIncrease useHigh economic valueEther separation/purificationOrganic compound preparationDistillationSaline solutions

The invention provides a method for separating phenols from bio-oil, which relates to a method for separating phenols from oil obtained through pyrolysis of biomass. The method comprises the following steps: distilling bio-oil, intercepting fractions obtained at a temperature below 160 DEG C and adding aqueous alkali for alkalization until the pH value of the fractions is greater than 10; and extracting an alkalized solution with an extractant, acidifying a water phase left after extraction with an acid, then adding a saline solution, carrying out extraction again by using a back-extractant and removing an organic phase through reduced pressure distillation so as to obtain a mixture of phenols. The method provided by the invention both broadens usage and improves the economic value of the bio-oil and opens up a wide prospect for separation and utilization of the bio-oil.

Owner:XIAMEN UNIV

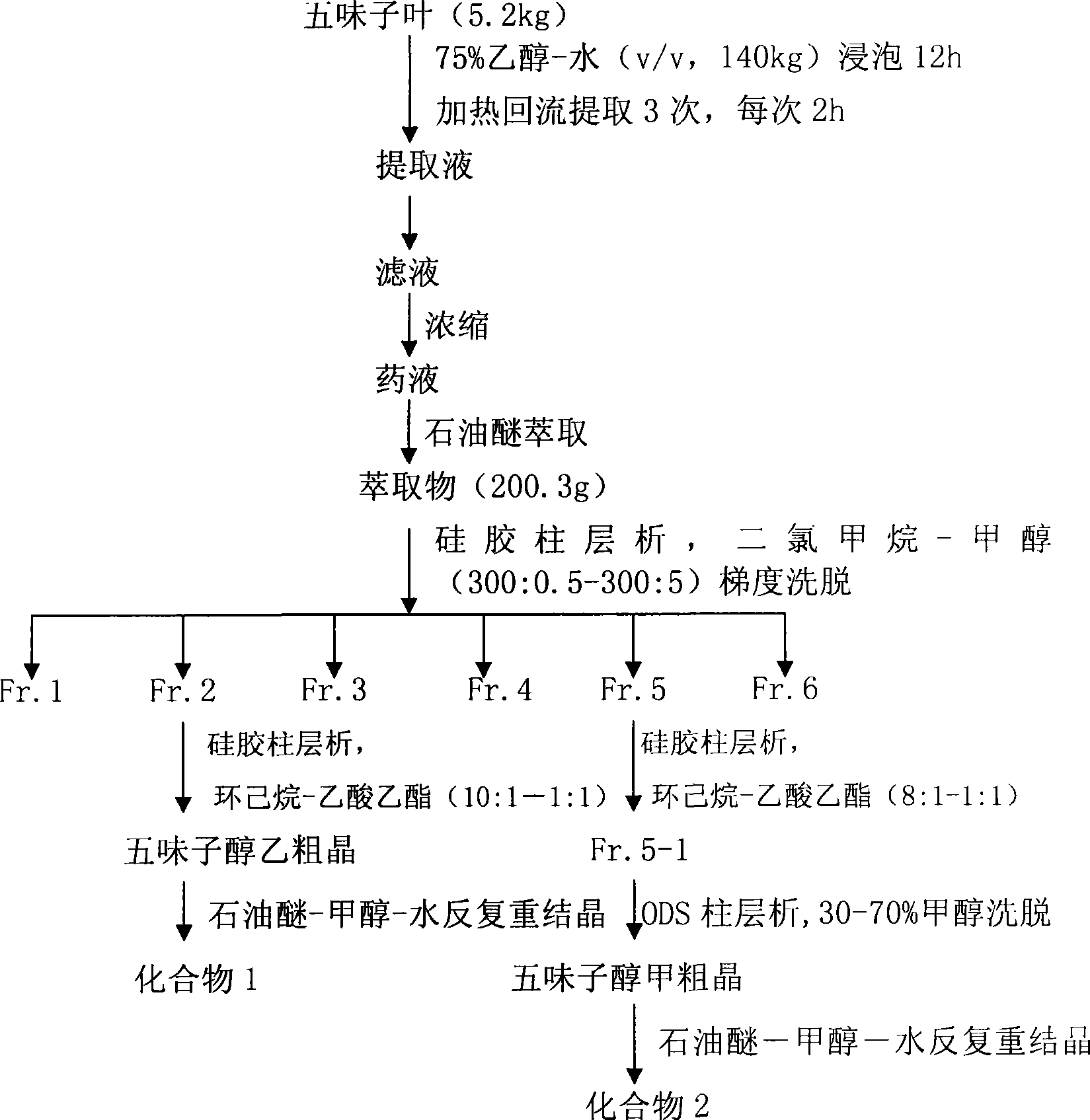

Novel technique for preparing schizandrol A and schizandrol B

ActiveCN101503341ASimple processEasy to operateNervous disorderEther separation/purificationBiotechnologyChromatographic separation

The invention belongs to the field of medical technology and discloses a new preparation technique of schizandrol B and schizandrol A in schisandra chinensis baill leaves. The technique comprises the steps: schisandra chinensis baill leaves are taken as raw material, ground and then processed by one or more technique(s) in solvent extraction method, organic solvent extraction method, resin adsorption method, normal phase column chromatography, reversed-phase column chromatography and the like, namely, the schisandra chinensis baill leaves are taken as raw material, extracting solution containing the schizandrol A and the schizandrol B is extracted by organic solvent; after extract is processed by repeated column chromatographic separation, the flowing parts containing the schizandrol A and the schizandrol B are collected, and the schizandrol A and the schizandrol B are obtained after repeated recrystallization of the condensate; the purities of the schizandrol A and the schizandrol B can be more than 98% by HPLC detection. The preparation method has simple technique, stable purity and good reproduction quality, can be used for replacing shizandra fruit to extract and prepare standard product, fully utilizes the resource of shizandra and relieve the situation that the supply of the shizandra fruit is not adequate to the demand.

Owner:SHENYANG PHARMA UNIVERSITY

Heat pump rectification device and method for removing sulfide in MTBE

ActiveCN105363235AImprove utilization efficiencyReduce consumptionEther separation/purificationChemical industryRefluxReboiler

The invention relates to a heat pump rectification device and method for removing sulfide in MTBE (Methyl Tertiary Butyl Ether). The device mainly comprises a feed preheater, a rectification tower, a compressor, an auxiliary reboiler, a main reboiler, an auxiliary cooler, a product cooler, a buffer tank and a reflux pump. The gas the distillation tower top is compressed by the compressor into superheated steam, which is used as a heat source and introduced through the reboiler for heat exchange at the tower bottom; and condensed liquid after heat exchange enters the buffer tank, passes through a reflux pump and is preheated with the raw materials by the feed preheater; and part of the cooled liquid is pumped back to the rectification tower for reflux, and the other part of the cooled liquid is recovered as a top product. By using the heat pump distillation, the transfer of the heat taken by the tower top condenser to the reboiler at the tower bottom is realized, which greatly reduces the energy consumption. Sulfur content of MTBE at the distillation tower top is 5-9ppm, and the recovery rate of MTBE is 99.6-99.8%. The device is simple for operation, safe, reliable, efficient and energy-saving.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com