Isolation method for high purity anethole

A high-purity, anethole technology, applied in ether separation/purification, ether preparation, organic chemistry, etc., can solve the problems of low product yield and purity, and achieve the effects of reducing production costs and avoiding solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

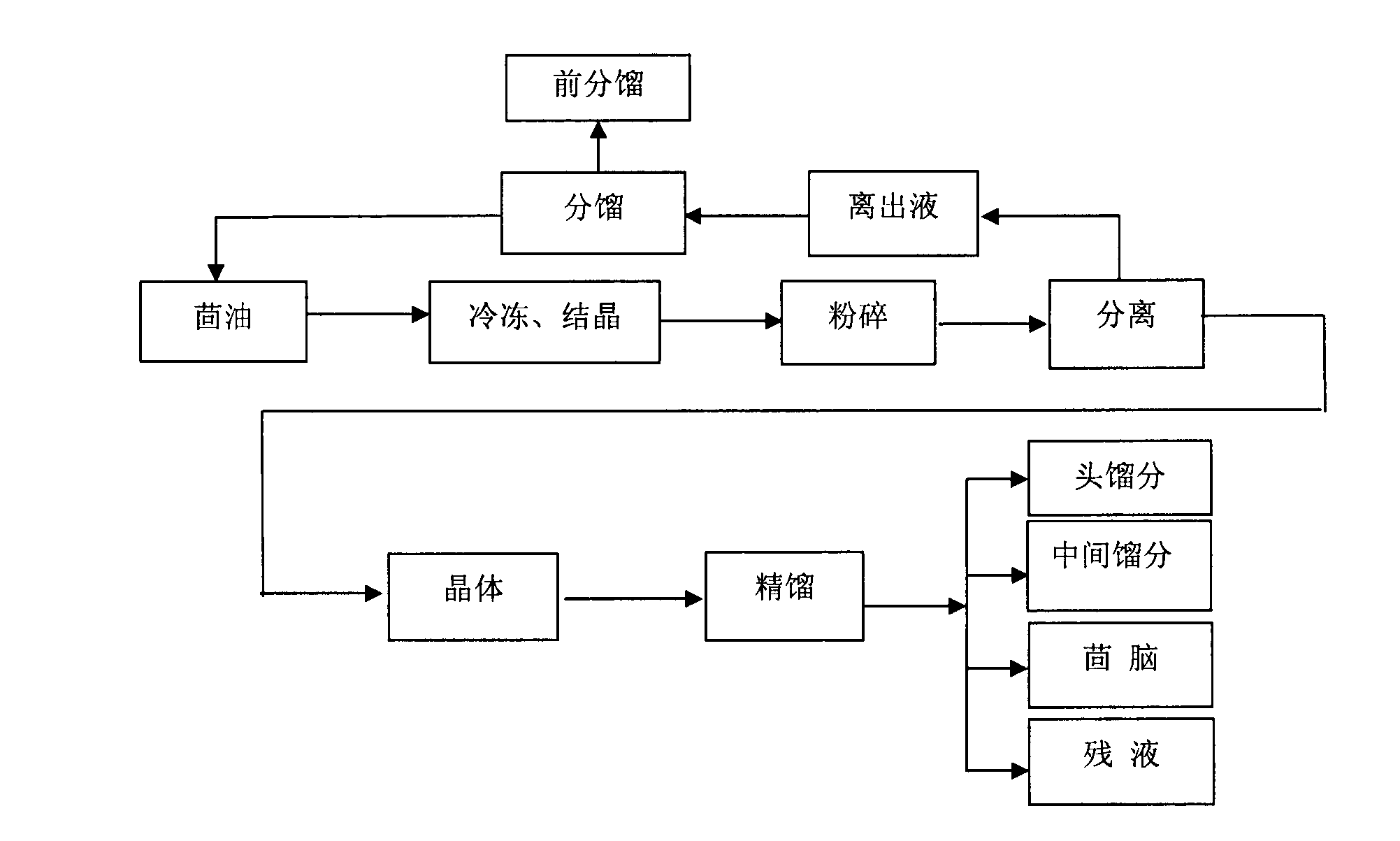

Image

Examples

Embodiment 1

[0016] A kind of high-purity anethole isolation method of the present invention comprises the following steps:

[0017] Pack 7000kg of fennel oil with anethole content of 88.5% into stainless steel trays, freeze at 4°C for 20 hours, crush the frozen blocky fennel crystals with a crusher, the particle size is 20 mesh, and then crush the fennel oil Put the crystals into a centrifuge with a cloth bag, centrifuge for 20 minutes at 1600r / min, thaw the centrifuged anethole crystals, and then put them into the rectification column. The reflux ratio at the beginning of the rectification is 10:3. The kettle temperature is 125°C, the vacuum degree is 5mmHg, and when the purity of anethole reaches 99.6%, the reflux ratio becomes 1:7. After rectification, a total of 5952 kg of anethole products with a content greater than 99.6% were obtained.

Embodiment 2

[0019] A kind of high-purity anethole isolation method of the present invention comprises the following steps:

[0020] Pack 6000kg of fennel oil with anethole content of 88.5% into stainless steel trays, freeze at 2°C for 15 hours, crush the frozen blocky fennel crystals with a crusher, the particle size is 40 mesh, and then crush the fennel oil Put the crystals into a centrifuge with a cloth bag, centrifuge for 15 minutes under the condition of 1800r / min, thaw the centrifuged anethole crystals, and then put them into the rectification column. The reflux ratio at the beginning of the rectification is 10:4, The temperature of the tower kettle is 129° C., the vacuum degree is 7 mmHg, and when the purity of anethole reaches 99.6%, the reflux ratio becomes 1:6. After rectification, a total of 5039 kg of anethole products with a content greater than 99.6% were obtained.

Embodiment 3

[0022] A kind of high-purity anethole isolation method of the present invention comprises the following steps:

[0023] Pack 6500kg of fennel oil with anethole content of 88.5% into stainless steel trays and freeze at 0°C for 18 hours, crush the frozen blocky fennel crystals with a crusher to a particle size of 30 mesh, and then crush the crushed fennel oil Put the crystals into a centrifuge with a cloth bag, centrifuge for 18 minutes under the condition of 2000r / min, thaw the centrifuged anethole crystals, and then put them into the rectification column. The reflux ratio at the beginning of the rectification is 10:3, The temperature of the tower kettle is 135° C., the vacuum degree is 10 mmHg, and when the purity of anethole reaches 99.6%, the reflux ratio becomes 1:5. After rectification, a total of 5520 kg of anethole products with a content greater than 99.6% were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com