Method for separating phenols from bio-oil

A technology for bio-oil and phenols, which is applied in the separation/purification of carbonyl compounds, ether separation/purification, chemical instruments and methods, etc. The effect of improving economic value and expanding use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

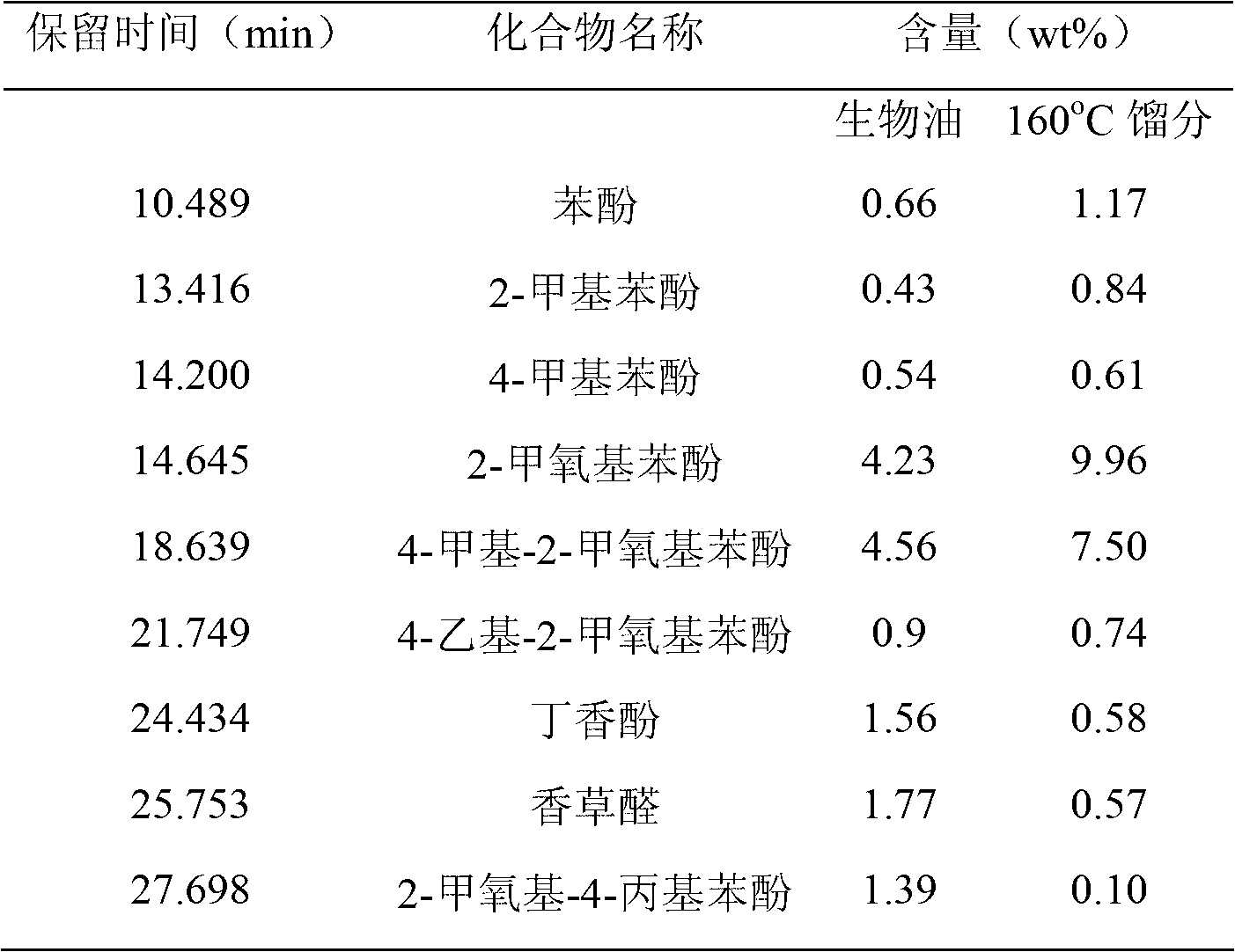

[0019] The bio-oil was subjected to atmospheric distillation at 160°C to obtain distillation fractions. The main phenolic substances and contents in the bio-oil and fractions are shown in Table 1. Take 5 mL of bio-oil distillation fraction and add 2.5 mol / L sodium hydroxide solution to alkalinize to pH 10.5. Take 2 mL of alkalized solution and extract 3 times with 2 mL of ethyl acetate, mix and shake and let stand for 1 h to form a distinct organic phase and aqueous phase. Take 2 mL of the aqueous phase solution and add 2.5 mol / L hydrochloric acid solution to acidify to pH about 6.0, and add 2 mL of 2.5 mol / L sodium chloride solution. Then extracted three times with 2 mL of ethyl acetate, mixed and oscillated, and after standing for 1 h, the organic phase containing phenols was collected, and the purity of phenols was measured to be 73.2 wt%.

[0020] Table 1

[0021]

Embodiment 2

[0023] Similar to Example 1, 5 mL of bio-oil distillation fraction was added into 2.5 mol / L sodium hydroxide solution for alkalinization to pH 12.0. Take 2 mL of alkalized solution and extract 3 times with 2 mL of ethyl acetate, mix and shake and let stand for 1 h to form a distinct organic phase and aqueous phase. Take 2 mL of the aqueous phase solution and add 2.5 mol / L hydrochloric acid solution to acidify to pH about 6.0, and add 2 mL of 2.5 mol / L sodium chloride solution. Then extracted three times with 2 mL of ethyl acetate, mixed and oscillated, and after standing for 1 h, the organic phase containing phenols was collected, and the purity of phenols was measured to be 74.7 wt%.

Embodiment 3

[0025]Similar to Example 1, 5 mL of bio-oil distillation fraction was added to 2.5 mol / L sodium hydroxide solution for alkalinization to pH 11.5. Take 2 mL of alkalized solution and extract 3 times with 2 mL of ethyl acetate, mix and shake and let stand for 1 h to form a distinct organic phase and aqueous phase. Take 2 mL of the aqueous phase solution and add 2.5 mol / L hydrochloric acid solution to acidify to pH about 6.0, and add 2 mL of 2.5 mol / L sodium chloride solution. Then extracted three times with 2 mL of butyl acetate, mixed and oscillated, and after standing for 1 h, the organic phase containing phenols was collected, and the purity of phenols was measured to be 78.1 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com