Perfluoroether composite air condition hose and preparation method thereof

A composite air conditioner and perfluoroether technology, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve problems such as failure to reach, and achieve the effects of good vibration absorption performance, strong anti-penetration ability, and low vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 1 example

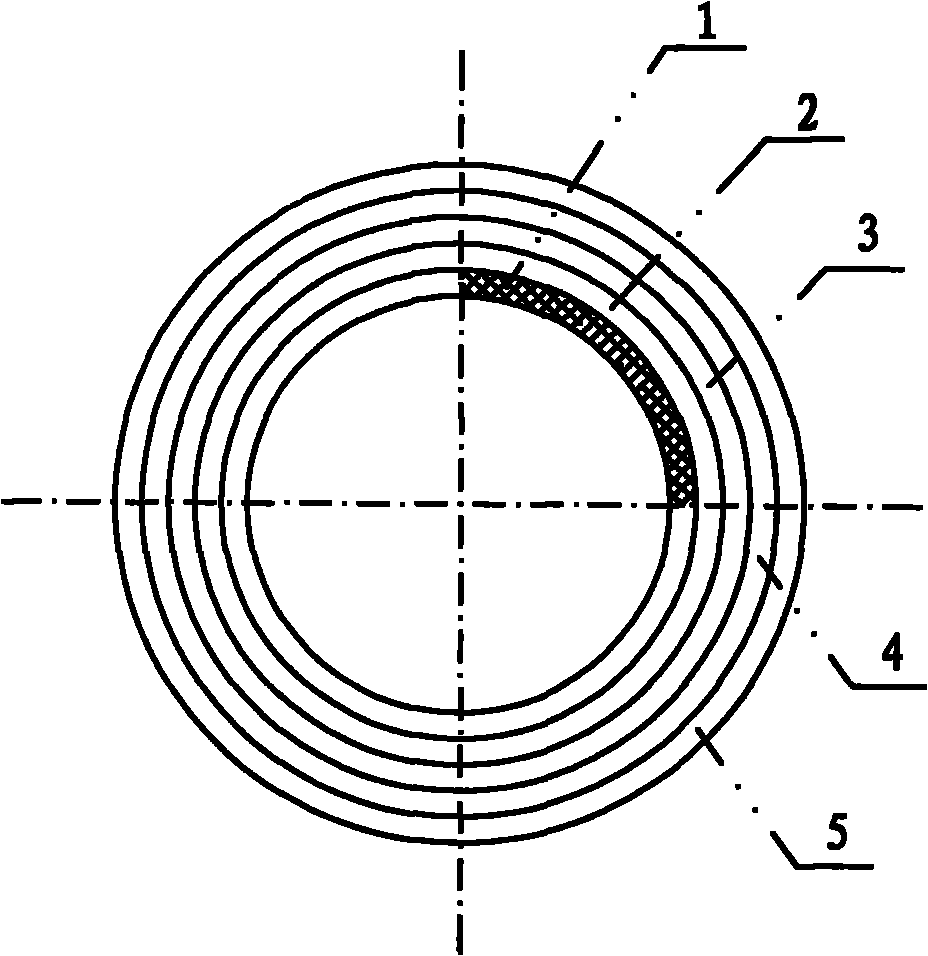

[0067] see Figure 1-Figure 2 , The perfluoroether composite air-conditioning hose has five layers from the inside to the outside, including an inner rubber layer 1, a shielding layer 2, a middle rubber layer 3, a reinforcing layer 4 and an outer rubber layer 5. The inner diameter of the entire perfluoroether composite air-conditioning hose is 2-800 mm, and the wall thickness of the tube is 0.5-30 mm.

[0068] The inner rubber layer 1 is mainly made of perfluoroether rubber material.

[0069] The inner rubber layer 1 is made of the following raw materials in weight percentage:

[0070] Perfluoroether raw rubber FFKM 48~52%,

[0071] Magnesium oxide 5-10%,

[0072] Thermal carbon black N990 25-30%,

[0073] Hydroxyfluorosilicone oil 0.7~3%,

[0074] Calcium carbonate 12~19%,

[0075] Triallyl isocyanurate 0.5~3%,

[0076] Bisphenol AF 0.5~3%,

[0077] Accelerator BPP 0.5-1.5%.

[0078] The perfluoroether rubber material is synthesized from tetrafluoroethylene, perfluor...

no. 2 example

[0111] The preparation process of producing perfluoroether compound air-conditioning hose with an inner diameter of 8mm and a wall thickness of 3.5-4.8mm.

[0112] The production process in this embodiment is basically the same as that in the first embodiment, except for the third and fourth steps in the preparation of inner rubber layer 1 .

[0113] The third step is to discharge the above-mentioned mixed rubber into the open mill, and sequentially add the accelerator BPP and bisphenol AF in the open mill for mixing, and undergo one-stage vulcanization and two-stage vulcanization, and finally extrude The rubber sheet of the inner rubber layer 1 was obtained; among them, the first-stage vulcanization was vulcanized by an electric heating oil pressure plate vulcanizer, the vulcanization temperature was 172°C, and the vulcanization time was 15 minutes; 230°C, the time is 11h.

[0114] The fourth step is to granulate the extruded rubber sheet, and then send it to the pipe extrud...

no. 3 example

[0117] The preparation process of producing perfluoroether air-conditioning composite hose with an inner diameter of 9.52mm and a wall thickness of 4.0-5.0mm.

[0118] The production process in this embodiment is basically the same as that in the first embodiment, except for the third and fourth steps in the preparation of inner rubber layer 1 .

[0119] The third step is to discharge the above-mentioned mixed rubber into the open mill, and sequentially add the accelerator BPP and bisphenol AF in the open mill for mixing, and undergo one-stage vulcanization and two-stage vulcanization, and finally extrude The rubber material sheet of the inner rubber layer 1 was obtained; among them, the first-stage vulcanization was vulcanized by an electric heating oil pressure plate vulcanizing machine, the vulcanization temperature was 172°C, and the vulcanization time was 18 minutes; ℃, the time is 12h.

[0120] The fourth step is to granulate the extruded rubber sheet, and then send it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com