Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

475results about How to "Chemically resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin composite, and preparation method thereof and using method thereof

This invention supply a epoxide resin combination and its preparation method, and its application as filling material of railway plate type orbit convex shape block platform. It takes ethoxyline resin, pigment, padding, curing agent and other accessory ingredient as main ingredient. This ethoxyline resin combination possess good construction usability, good cement bond property, appropriate elasticity and syntheses mechanical property, and has performance of ultraviolet radiation proof, moisture-proof.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Spray polyurea high-performance waterproof paint and preparation method thereof

InactiveCN101818019AFast curingHigh strengthPolyurea/polyurethane coatingsDiluentUltimate tensile strength

The invention relates to a spray polyurea high-performance waterproof paint which is characterized by comprising component A and component B, wherein the component A comprises semi-prepolymer formed by the reaction between 70-35 parts of polyisocyanate and 30-50 parts of polyether glycol, and 0-15 parts of diluent based on parts by weight; the component B comprises 50-70 parts of amine-terminated polyether, 20-40 parts of amine chain extender and 5-10 parts of filler; and the volume ratio between the component A and the component B is 1:1. Compared with the common spray polyurea high-performance waterproof paint, the spray polyurea high-performance waterproof paint has higher tensile strength, elongation at break, tearing strength and other physical properties, and not only is applicable to waterproof projects of common building projects, basic facilities and the like, but also is especially suitable for high-difficulty waterproof projects of large basic facility construction such as a high speed railway, a subway, a tunnel, water conservancy project and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

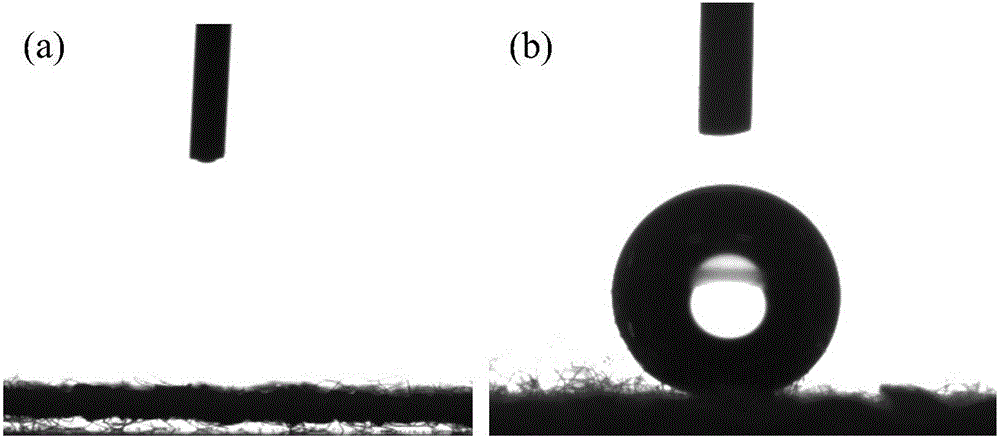

Method for preparing super-hydrophobic textile from thiol-ene click chemistry-modified fiber

InactiveCN105696306AWashableWear-resistantLiquid repellent fibresAbrasion resistant fibresFiberPolyester

The invention relates to a preparation method of a functional textile, and belongs to the field of textile surface grafting modification. The method for preparing a super-hydrophobic textile from a thiol-ene click chemistry-modified fiber is characterized by comprising the steps that alkali liquor steaming treatment is performed on a polyester fiber, then mercaptosilane is fixed to the surface of the polyester fiber, finally a methacrylate monomer is grafted to the surface of the polyester through a thiol-ene click chemistry reaction to reduce the surface tension of the fiber, and then the super-hydrophobic polyester textile is obtained. The contact angle between the polyester textile prepared through the method and water drops is larger than 150 degrees, and the polyester textile is stable to acid, alkali, salt and solvent and capable of resisting friction and washing and has the very good hydrophobic stability.

Owner:SHAANXI UNIV OF SCI & TECH

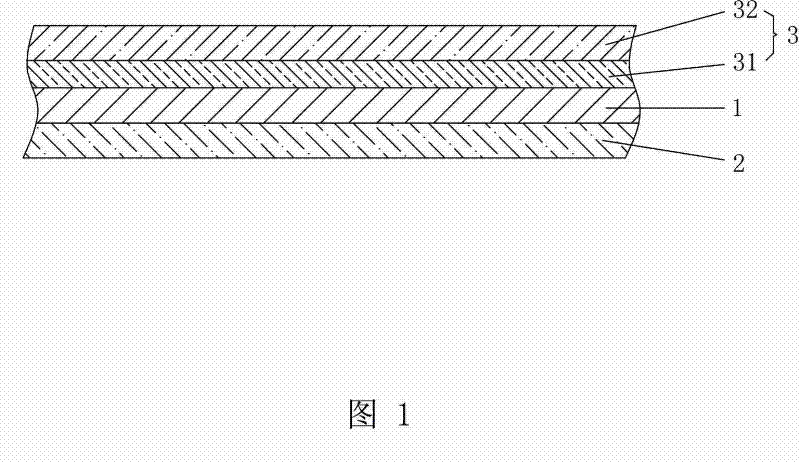

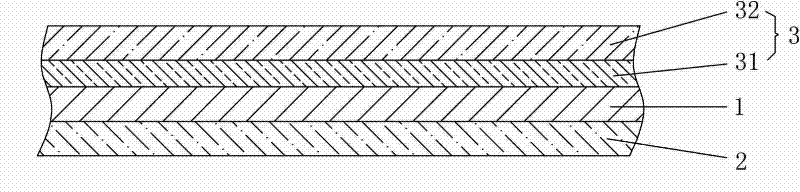

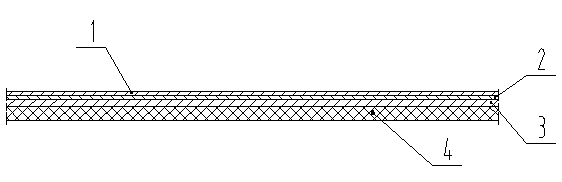

Multi-layer thermal transfer ribbon and manufacturing method thereof

The invention relates to a multi-layer thermal transfer ribbon and a manufacturing method thereof, and the multi-layer thermal transfer ribbon comprises a membranous base band, a heat-resistant printing ink layer and a heat transfer printing ink layer, wherein the heat-resistant printing ink layer is coated on one side of the base band, the heat transfer printing ink layer is coated on the other side of the base band, the heat transfer printing ink layer comprises a stripping printing ink layer and an adhesive printing ink layer, the stripping printing ink layer is directly coated on the surface of the base band, the adhesive printing ink layer is coated on the stripping printing ink layer, printing ink in the striping printing ink layer is hot-melting type printing ink, and the printing ink in the adhesive printing ink layer is the hot-melting type printing ink or solvent type printing ink. The heat transfer printing ink layer of the multi-layer mixed-based ribbon can be easily completely stripped off the base band, and the great adhesive ability is realized on a smooth medium; in addition, the multi-layer thermal transfer ribbon further has the advantages of high resolution, clear printing, anti-friction property, moisture resistance, chemical corrosion resistance, environment friendliness and the like.

Owner:泉州市山水电脑耗材有限公司

Long fiber reinforced polypropylene/PPE alloy material and its prepn and application

The long fiber reinforced polypropylene / PPE alloy material has oriented fibers in the length over 4 mm and in netted configuration, and thus greatly raised shock resistance, rigidity, creeping resistance and size stability. What is more important is that the material may be mixed with many kinds of other material and thus has wide application range. The material may be prepared through powder soaking process, smelting soaking process, etc. The long fiber reinforced polypropylene / PPE alloy material of the present invention has excellent tensile, bending and anti-shocking performance, and may be used in manufacturing automobile part, pipe, valve part, electric tool, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Concrete structure heavy-duty nano composite coating and protection method

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

Preparation method of aluminium oxide honeycomb ceramics

InactiveCN104072111ASimple production processLow equipment requirementsTemperature resistanceHoneycomb

The invention discloses a preparation method of aluminium oxide honeycomb ceramics. The preparation method comprises the following steps: 1) preparing aluminium oxide honeycomb blank bodies with parallel pore passages; 2) dumping or degreasing the aluminium oxide honeycomb blank bodies; and 3) calcining the aluminium oxide honeycomb blank bodies to obtain the aluminium oxide honeycomb ceramics with pore passage inner wall extending whisker structures. The ceramic matrix part particles prepared by the method are tightly bonded and whiskers grow on the honeycomb pore inner walls. The honeycomb ceramics have the excellent properties such as high temperature resistance and chemical corrosion resistance and are suitable for filtration and purification of various fluids. According to the used honeycomb ceramics, filtered matters are easily removed by adopting various methods and the honeycomb ceramics can be reused. The preparation method is simple in process, is low in equipment requirements, is convenient in operation control, has high production efficiency and is suitable for large-scale industrial production.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

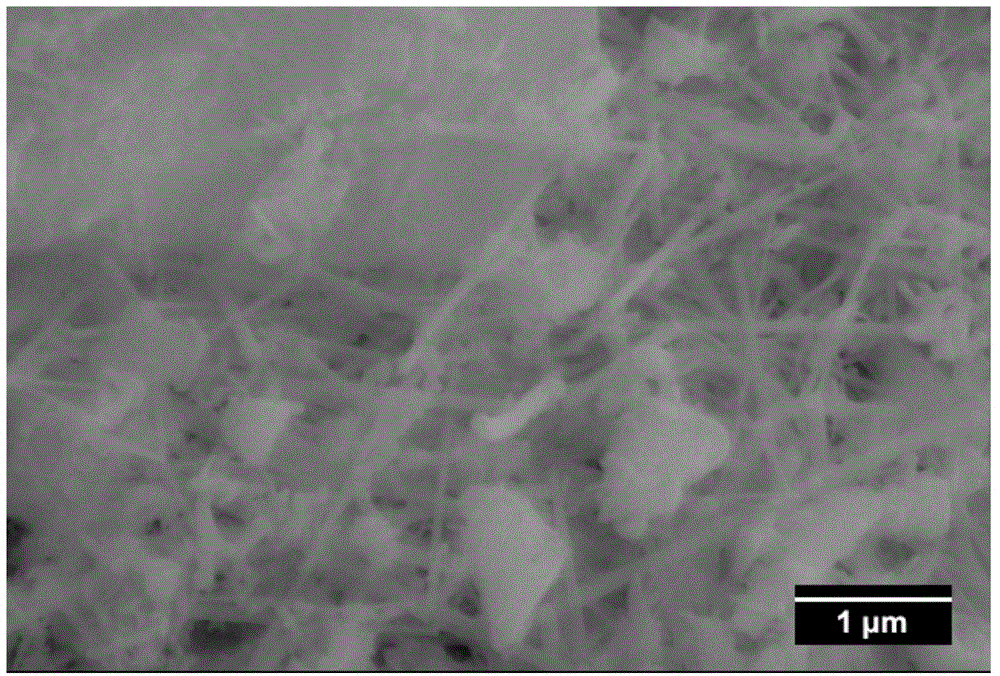

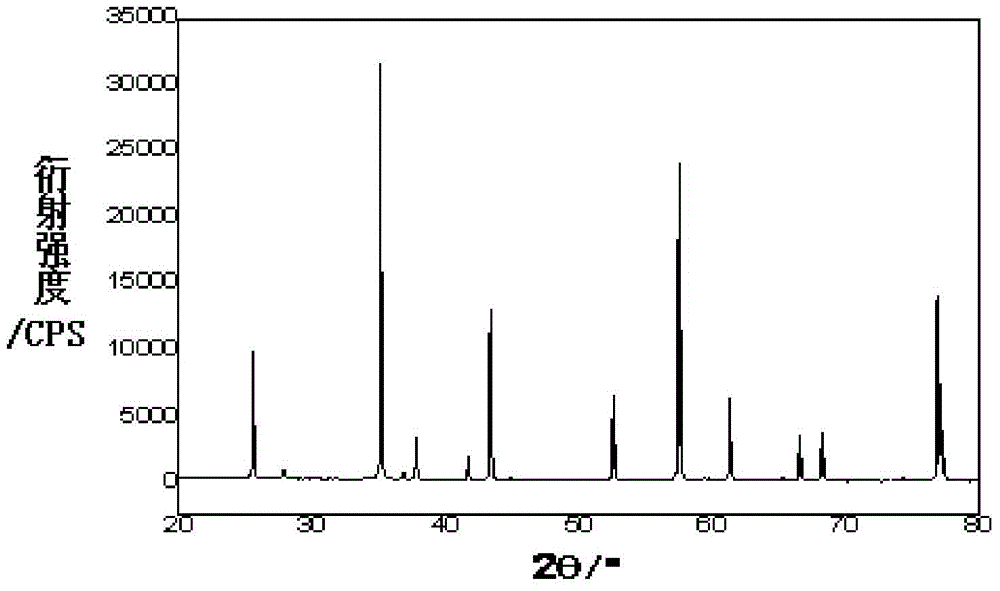

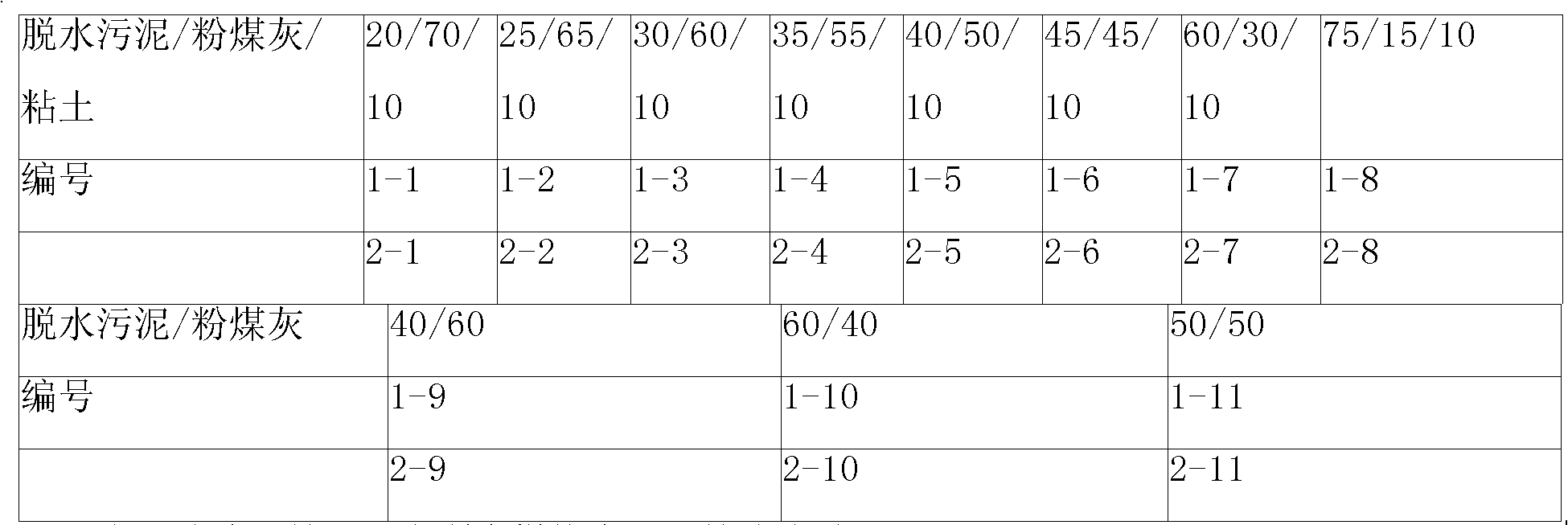

Ceramic aggregate biological filler and preparation method thereof

InactiveCN101514112ALight weightHave mechanical strengthSustainable biological treatmentCeramic materials productionSludgeExpanded clay aggregate

The invention discloses ceramic aggregate biological filler and a preparation method thereof. The filler uses coal ash and sludge as main raw materials, clay as binder, and aluminum sulfate octadeca hydrate or hydrogen peroxide solution as foaming agent, and is prepared by mixing the raw materials, the binder, the foaming agent and water, granulating and sintering at high temperature. Compared with the prior art, the main raw materials of the invention are solid waste materials, thereby reducing pollution of coal ash and sludge to environment and treating waste materials by waste materials; the coal ash can be directly used without complicated pretreatment; organic substance and inorganic substance in the sludge are used to reduce resource waste; hole structure of sludge ceramic aggregate is improved, the ceramic aggregate has loose and porous structure for enriching a great amount of microorganism in sewage, thereby being suitable for biological filler can realizing sewage treatment with high efficiency and low cost; the invention has simple manufacturing process, low cost, strong adaptability, and good economic benefit and social benefit.

Owner:ARCHITECTURAL DESIGN RES INST OF GUIZHOU

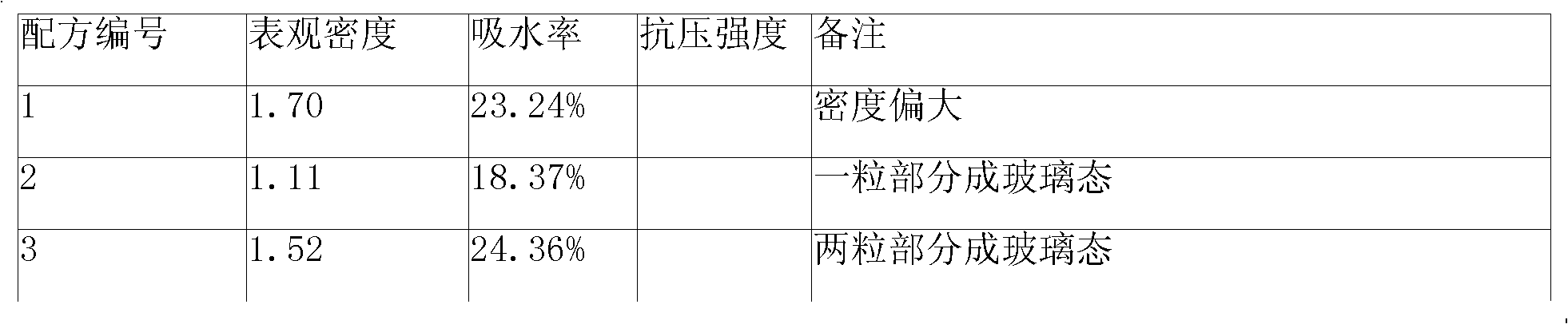

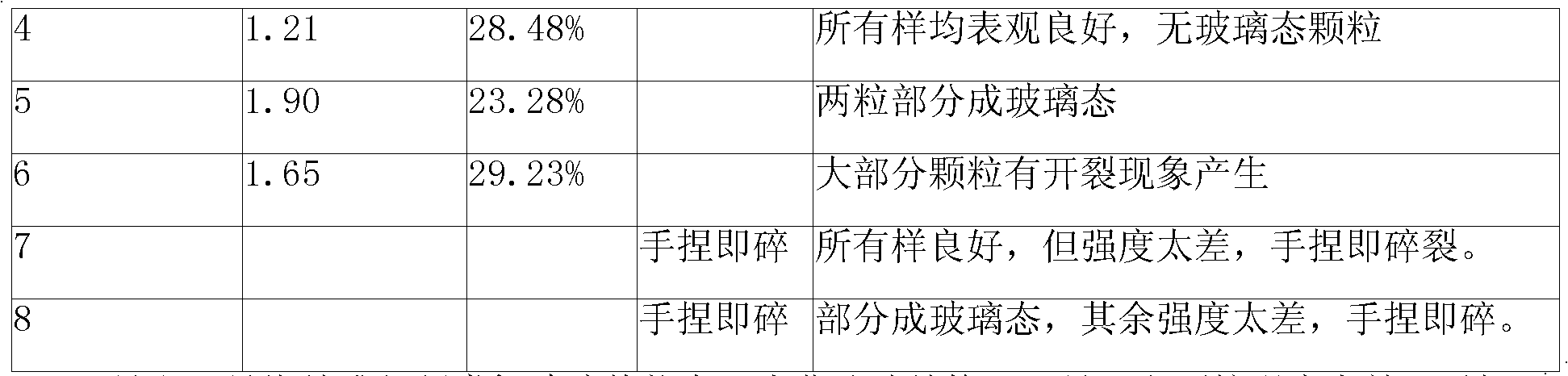

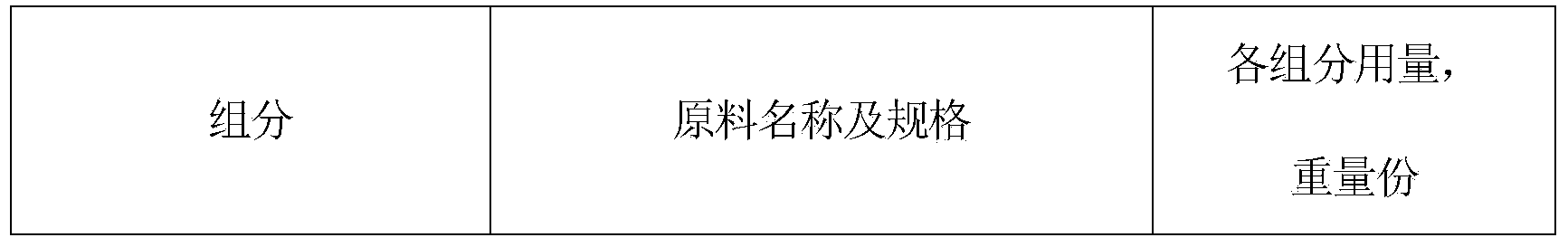

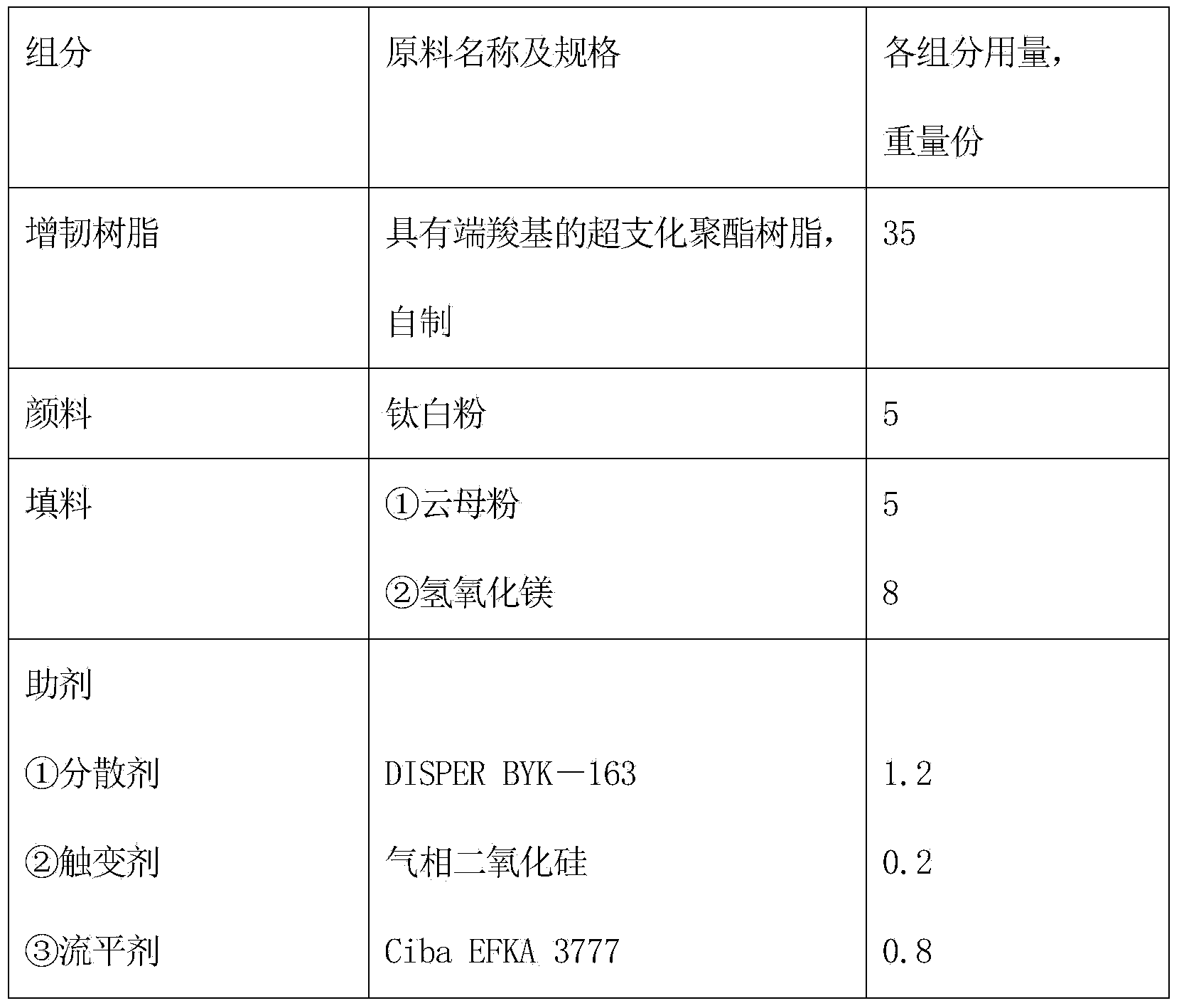

Fire retardant coating for steel structure surface of nuclear power plant

InactiveCN103709899AChemically resistantFlame retardantFireproof paintsEpoxy resin coatingsFoaming agentHyperbranched polyester

The invention relates to a fire retardant coating for a steel structure surface of a nuclear power plant. The fire retardant coating consists of components A, B and C at a weight ratio of (4-6): 1: 1, wherein the component A is a mixture composed of 15-35 parts of epoxy resin, 2-10 parts of reactive diluent, 5-15 parts of dehydration catalyst, 10-30 parts of carbonizing agent, 5-20 parts of foaming agent, 15-35 parts of fire retardant, 5-15 parts of smoke inhibitor, 10-30 parts of pigment and filler and 2-10 parts of auxiliaries; the component B is a mixture composed of 10-50 parts of toughened resin, 10-30 parts of pigment and filler and 2-10 parts of auxiliaries; the C component is an amine curing agent; and the toughened resin in the component B is hyper-branched polyester resin with a terminal carboxyl group. The fire retardant coating disclosed by the invention is more excellent than a normal intumescence fire retardant coating in binding strength, freezing and thawing cycle resistance, acid and base resistance, and fire retardant limit, and is specifically up to fire resistance requirements of the steel structure surface of the nuclear power plant.

Owner:CHINA NAT OFFSHORE OIL CORP +3

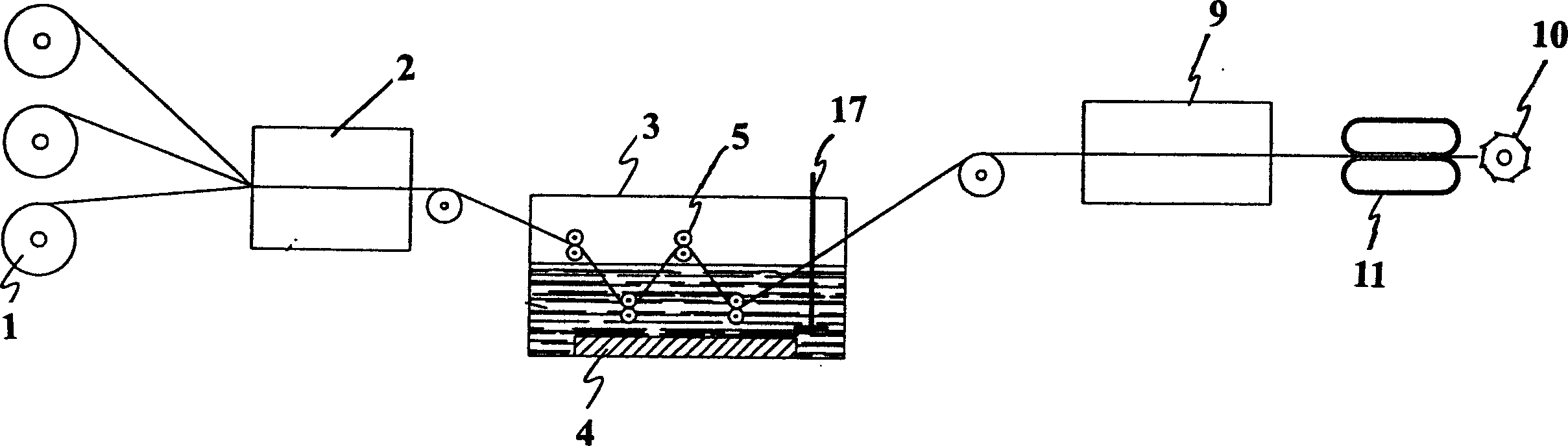

Synthetic fiber paper containing polyphenyl sulfide and aromid fiber and producing method thereof

InactiveCN1974925AHigher than strongHigher than the moldNon-fibrous pulp additionCalendersPolymer scienceThermal expansion

The present invention belongs to the field of synthetic fibre paper. In particular, it relates to a kind of synthetic fibre paper made up by using aramid fiber as structural fiber and utilizing polyphenylene sulfide fiber or granules through the processes of adhesive bonding and finalization. Said synthetic fiber paper possesses the excellent properties of light weight, high strength, resisting high temperature, resisting fatigue, resisting chemical corrosion, resisting radiation, high specific modulus, low thermal-expansion coefficient and good biological compatibility, and can be extensively used in the fields of electromechanical technology and aerospace industry. Besides, said invention also provides a wet preparation method for producing said synthetic fiber paper.

Owner:陶世毅 +3

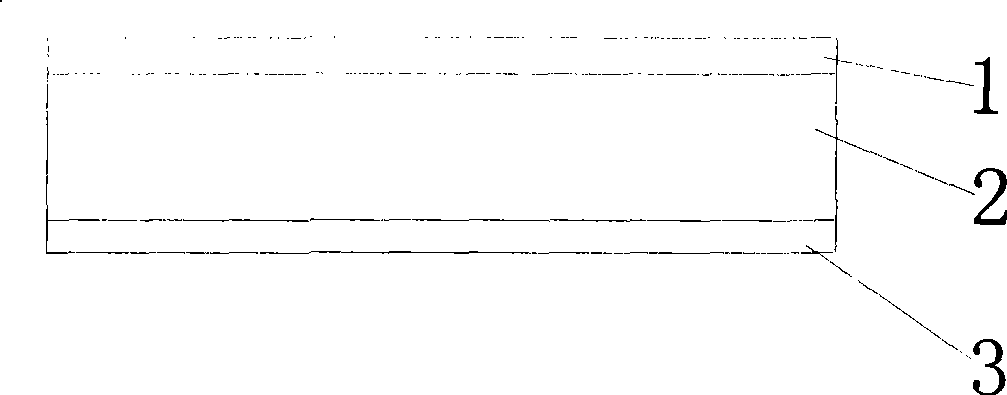

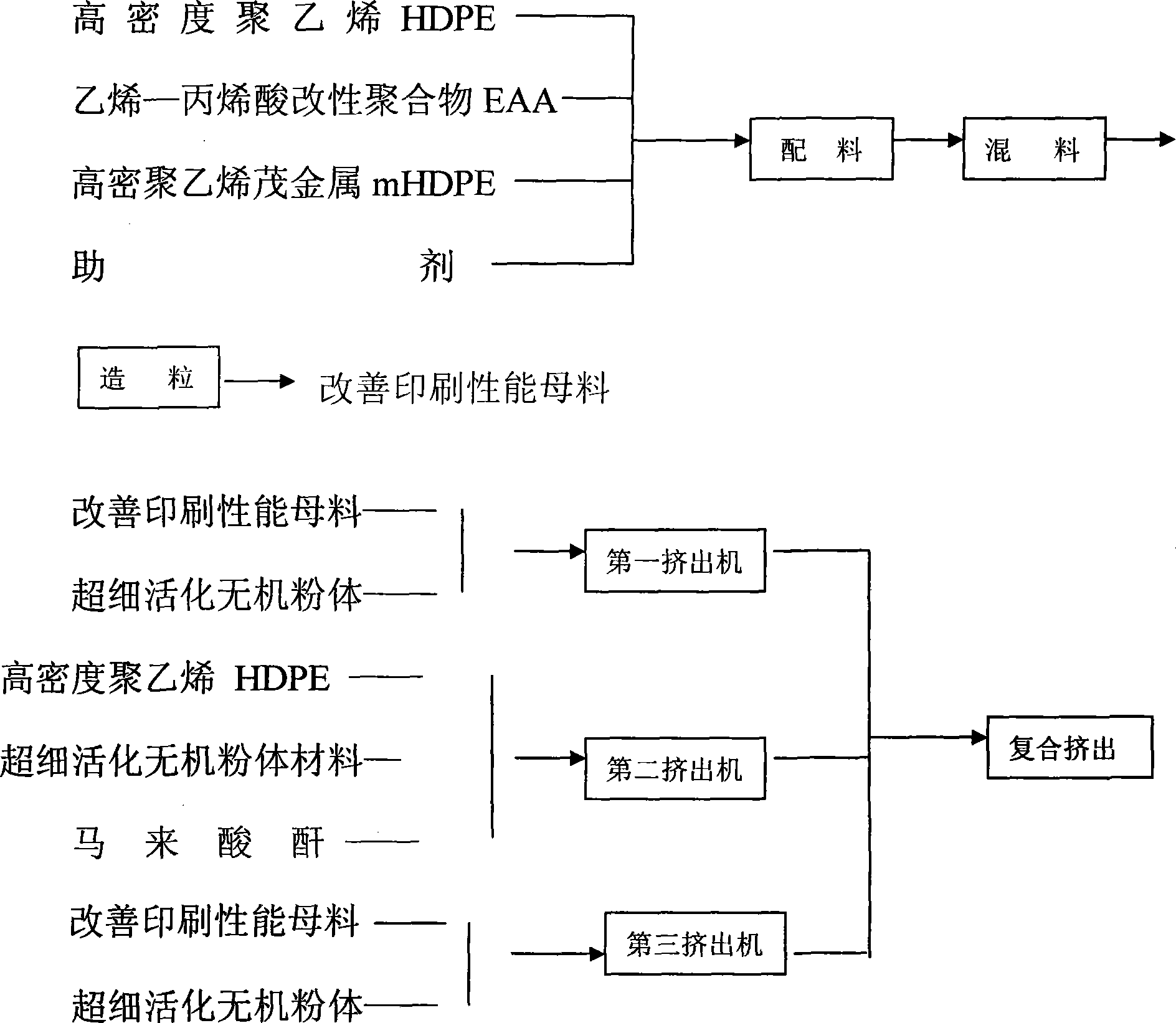

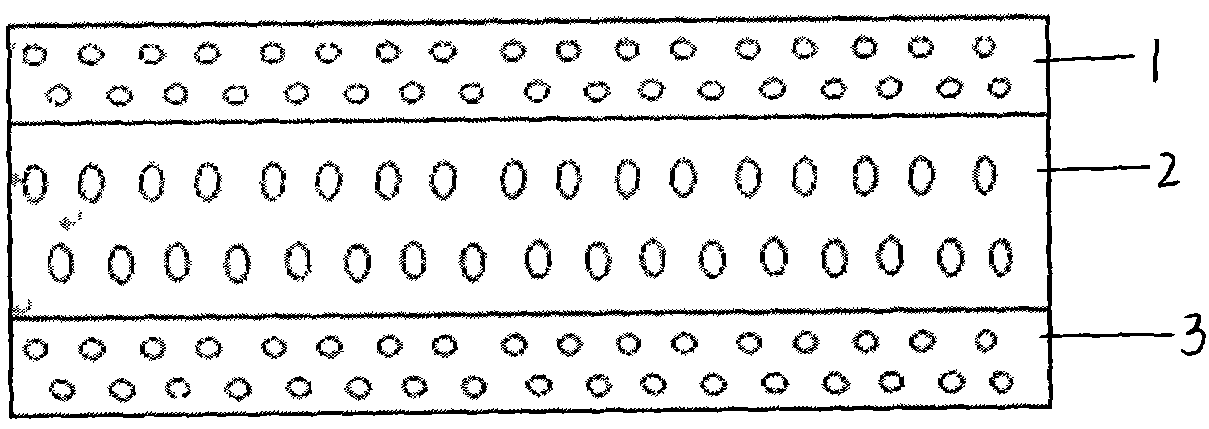

Modified polyolefins paper without plant fibre

InactiveCN101462387AImprove folding resistanceImprove rigiditySynthetic resin layered productsPolyolefinOrganic chloride compound

The invention discloses modified polyolefin paper without plant fiber. The modified polyolefin paper is formed by a matrix layer 1 without the plant fiber, a matrix layer 2 without the plant fiber and a matrix layer 3 without the plant fiber which are compounded into a whole, wherein the matrix layer 1 and the matrix layer 3 are prepared by 20 to 30 percent of ethylene-acrylic acid modified copolymer EAA, 45 to 60 percent of metallocene high-density polyethylene mHDPE, and 20 to 25 percent of activated ultrafine inorganic powder respectively, and the matrix layer 2 is prepared by 60 to 90 percent of activated ultrafine inorganic powder, 2 to 5 percent of maleic anhydride and 8 to 35 percent of high-density polyethylene. The modified polyolefin paper has the advantages of good ink receptivity and softness. Therefore, the modified polyolefin paper can be used as industrial paper, packing paper and household paper, can also be used as cultural paper, and enlarges the use range. The modified polyolefin paper has higher foldability and rigidity, has the longitudinal and transverse tearing strength which are superior to those of plant fiber paper, has good surface flattening, good handwriting, and clear printing performance, saves printing ink, has simple production technology, protects forest resources, saves energy sources and water, reduces the discharge of organic chlorides and harmful gas, has no waste, and protects the environment.

Owner:宋旭

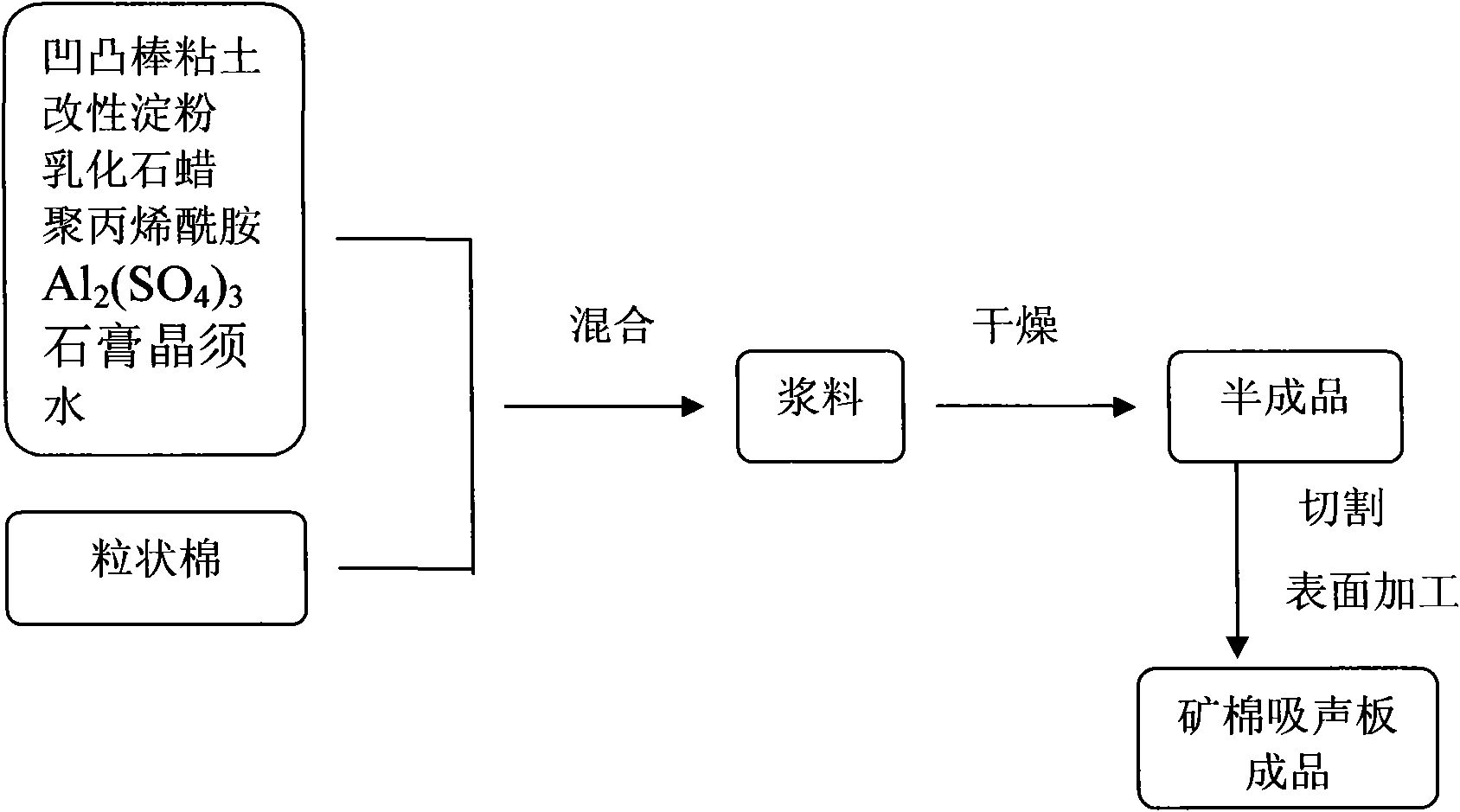

Novel enhanced mineral cotton acoustic board and preparation method thereof

ActiveCN102400498ATake advantage ofHigh strengthSolid waste managementSound proofingTemperature resistanceImpurity

The invention discloses a novel enhanced mineral cotton acoustic board, which comprises 100 weight parts of mineral cotton, 1.6 to 1.0 weight part of polyacrylamide, 5 to 9 weight parts of modified starch, 10 to 16 weight parts of attapulgite clay, 0.4 to 0.7 weight part of aluminum sulfate, 0.5 to 0.7 part of emulsified paraffin and 2 to 30 parts of gypsum crystal whisker. The invention also discloses a preparation method for the novel enhanced mineral cotton board. The method comprises the following steps of: preparing, forming, drying and performing surface finishing. In the method, the gypsum crystal whiskers are prepared from desulfurized gypsum with low purity, and the strength of the mineral cotton acoustic board is enhanced by adding the gypsum crystal whiskers. The gypsum crystal whiskers have the advantages of high strength, high toughness, temperature resistance, chemical corrosion resistance and the like; and the gypsum crystal whiskers which are used as fine monocrystals have complete internal structures, and due to highly-ordered atomic arrangement, the gypsum crystal whiskers do not almost have the defects of cavity, impurities, granular interfaces and the like of any ordinary material, and the strength of the gypsum crystal whiskers is close to a crystal theoretical value, namely the strength of an interatomic valence bond.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Polyurethane resin combination and preparation method and using method thereof

The invention provides a polyurethane resin composition, its preparation method, and using method of the same used as filling material of railway plate type dreg-free track convex block. The polyurethane resin composition is mainly used as filling material of railway plate type dreg-free track convex block, and mainly includes: polyether or polyester polyol, isocyanate or prepolymer of the same, pigment, filling and other auxiliary agent. Advantages of the prepared polyurethane resin are: construction manufacturability is better, bonding to cement of cured resin is good; the polyurethane resin is resistant of ultraviolet ray irradiation, moisture, heat, ageing and fatigue, and owns appropriate elasticity and integrated mechanical capability.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

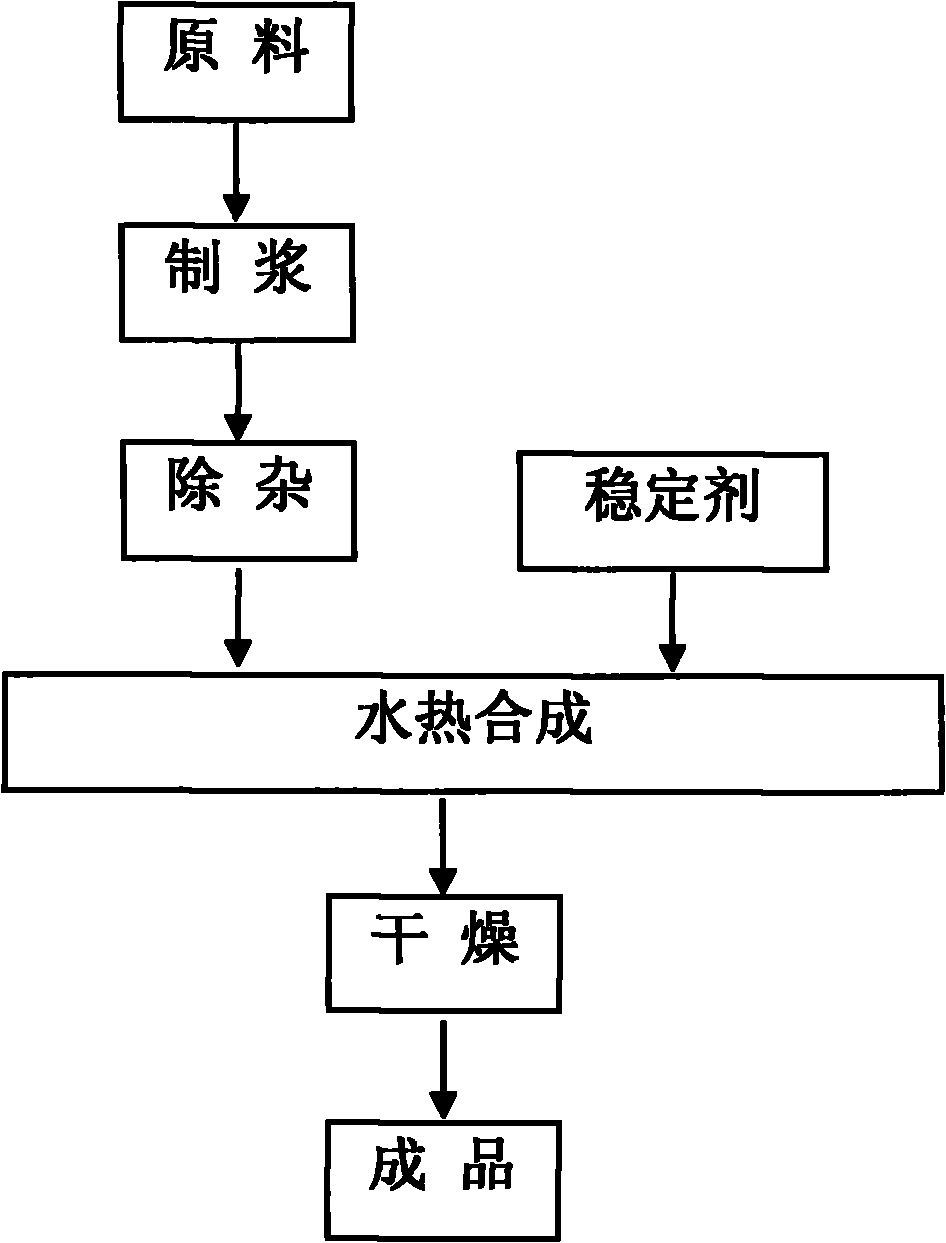

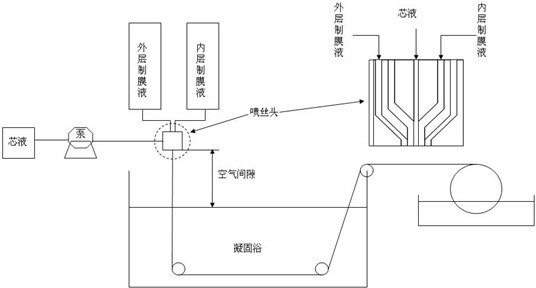

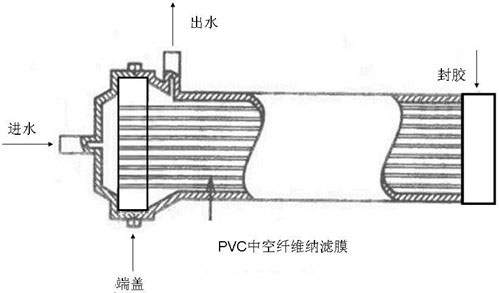

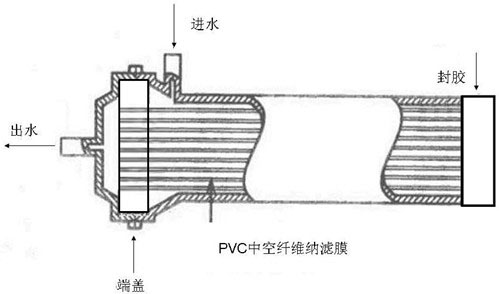

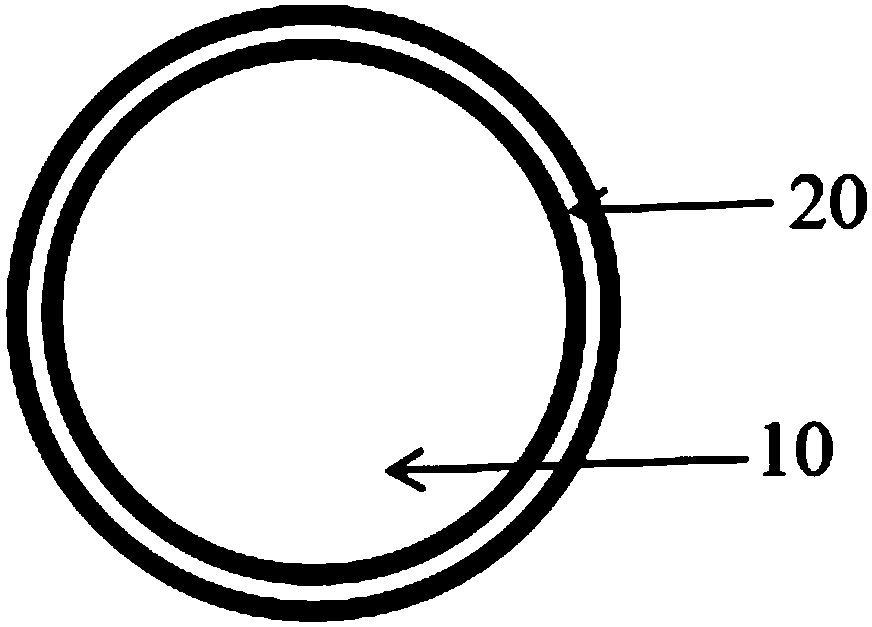

Positively charged polyvinyl chloride hollow fiber nanofiltration membrane and preparation method thereof

ActiveCN102210979ABacteria resistantWith acid and alkali resistanceSemi-permeable membranesFiberPolyvinyl chloride

The invention discloses a method for preparing a positively charged polyvinyl chloride (PVC) hollow fiber nanofiltration membrane. The positively charged PVC hollow fiber nanofiltration membrane has a two-layer structure consisting of a positively charged compact skin layer and an electrically neutral porous support layer; the pore diameter of micropores of the compact skin layer is 1-5nm, and the pore diameter of micropores of the porous support layer is 10-100nm; and the outer diameter of the membrane is 1.5-3.0mm, and the inner diameter of the membrane is 0.5-2mm, wherein the positively charged compact skin layer comprises main components of polyvinyl chloride and cationic copolymer; and the electrically neutral porous support layer comprises main components of polyvinyl chloride and an inorganic filler. The method for preparing the positively charged PVC hollow fiber nanofiltration membrane comprises the following steps of: co-extruding positively charged compact skin layer membrane preparing liquid and electrically neutral porous support layer membrane preparing liquid in a two-layer ring shape; and curing and forming hollow fibers by using a dry-wet spinning process. The prepared hollow fiber nanofiltration membrane has the advantages of easily controlled interception property, high strength, simple preparation process and the like, and is a high-performance, low-cost and long-life nanofiltration membrane material for water treatment.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

Composition of unsaturated resin, preparation method, and method of application

This invention provides an unsaturated resin composition, its preparation method, and its application as the filler of the slab-free track cam plate. The unsaturated resin composition is mainly composed of unsaturated resin, pigment, filler, peroxide initiator, and other additives. The unsaturated resin composition has such advantages as high processability, and high adhesiveness to cement after cured, appropriate elasticity, good comprehensive mechanical properties, and high UV, humidity, heat, aging and fatigue resistance.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Modified urea-formaldehyde powder adhesive

InactiveCN1542074AReduce sizing costsHigh bonding strengthAldehyde/ketone condensation polymer adhesivesStrong acidsToughening

The modified urea-formaldehyde powder adhesive for adhering wood product mainly is prepared by using spray dried pure urea-formaldehyde powder or melamine-urea-formaldehyde powder as base material; composite curing agent comprising amine salt of strong acid, organic acid and maleic anhydride; fine water soluble vinyl resin powder, tanning extract and coconut shell powder as toughening, antiageing and free aldehyde absorbing additive; and certain amount of corn powder, gypsum powder and flour as stuffing, and through mixing. The modified urea-formaldehyde powder adhesive has the advantages of high strength, high toughness, ageing resistance, water resistance, chemical corrosion resistance and environment friendship.

Owner:SHANGHAI UNIV

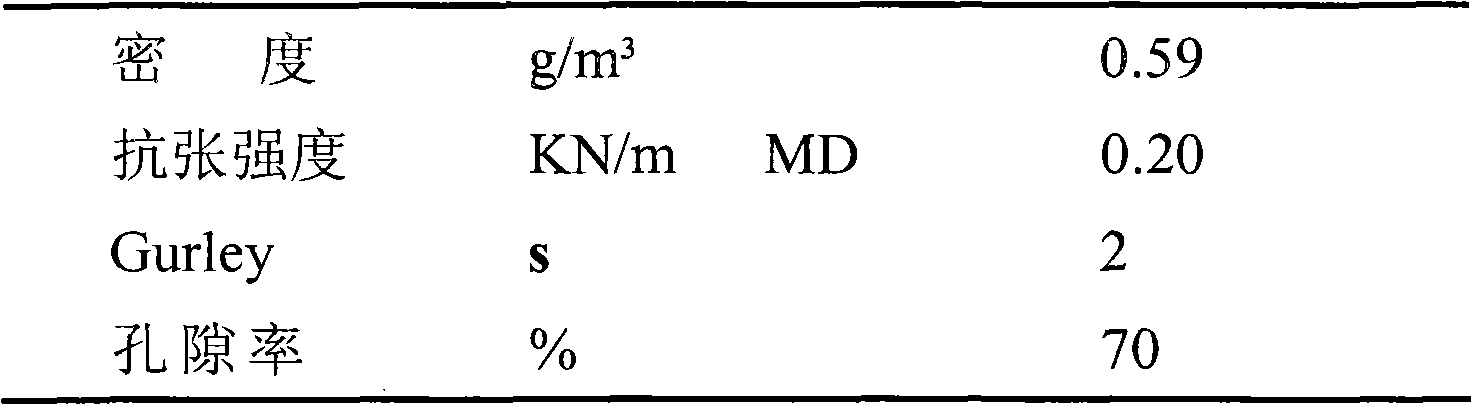

Battery diaphragm based on aramid fibre

InactiveCN101867030AOvercome the weakness of heat intoleranceProne to liquid-solid phase separationCell component detailsPorosityElectrical resistance and conductance

The invention discloses a battery diaphragm based on aramid fibre. The battery diaphragm is manufactured mainly from ultra-short aramid fibre in match with aramid fibre fibrid, and the specific requirements of air permeability and porosity of the battery diaphragm can be satisfied through adjusting fibre formula and molding process. The battery diaphragm can realize mechanical isolation function of the positive and negative poles of the battery, ensures low resistance and high ion electrical conductivity simultaneously, and has enough electrochemistry stability. Compared with traditional plastic diaphragm, the battery diaphragm in the invention has more excellent comprehensive properties, i.e. excellent heat resistance performance, high strength, fatigue resistance performance, low deformation, fire-resistant and flame retardant performance, chemical-corrosion resistance performance and the like. The battery diaphragm in the invention can be widely applied to the manufacturing of various ion batteries.

Owner:深圳昊天龙邦复合材料有限公司

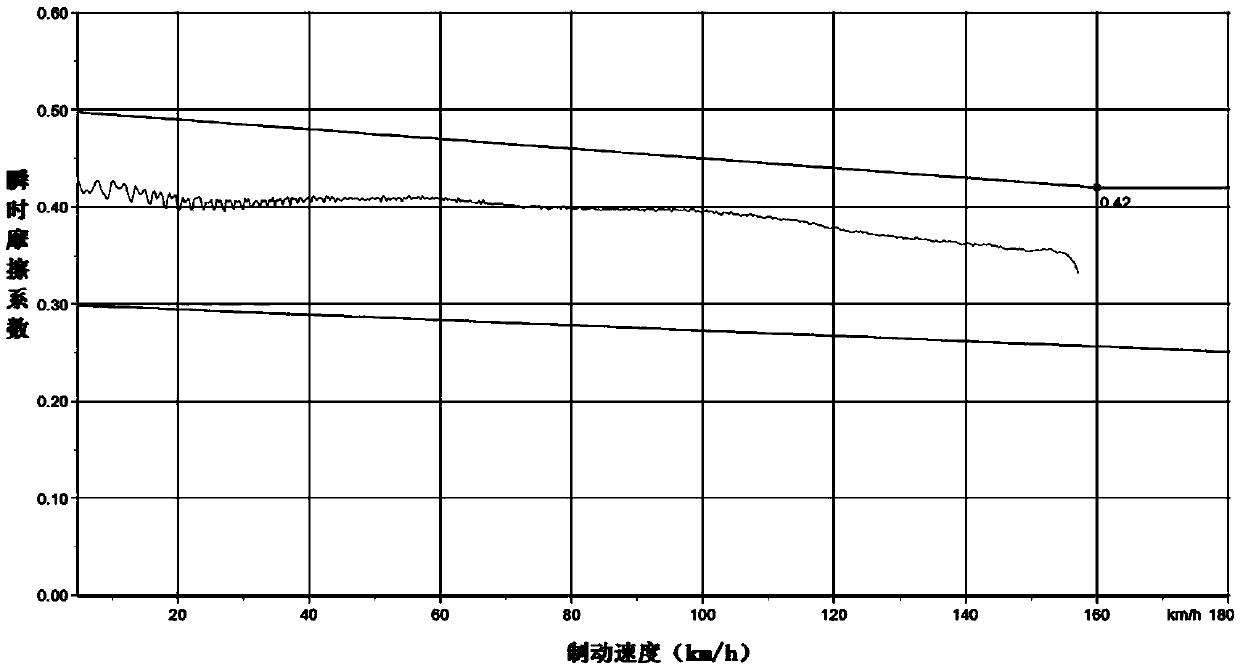

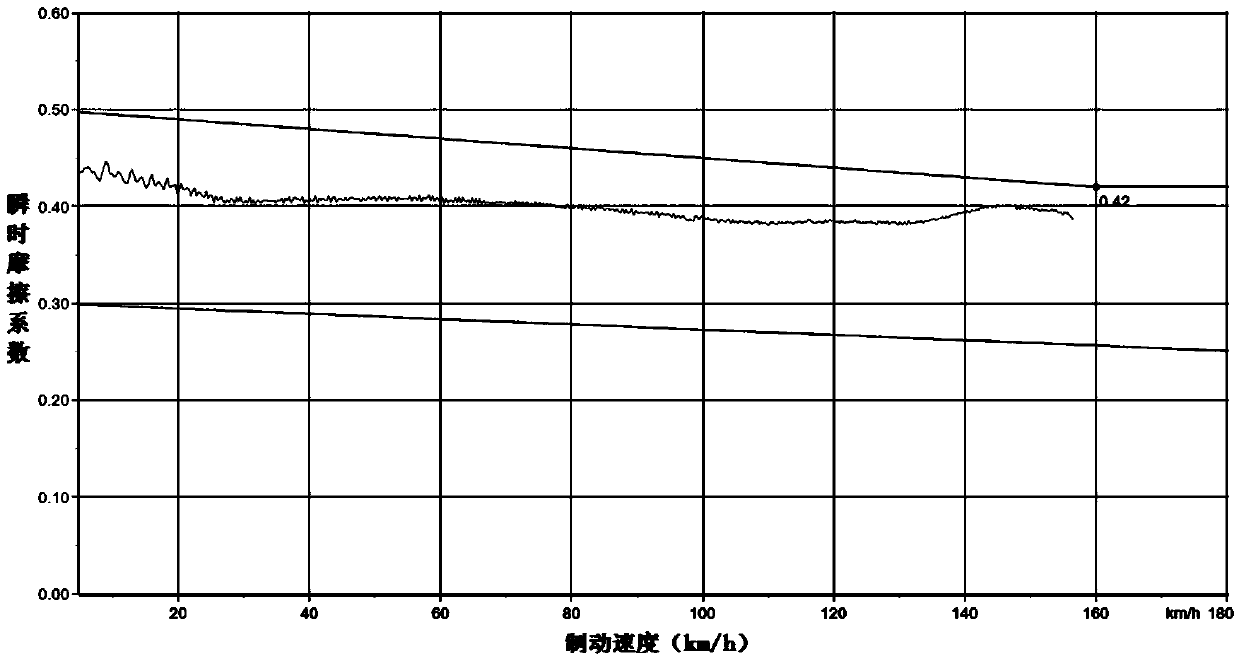

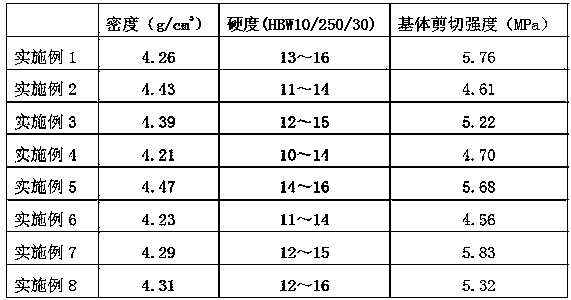

Powder metallurgy brake pad friction material and preparation method thereof

The invention relates to a powder metallurgy brake pad friction material and a preparation method thereof. The preparation method comprises the following specific steps: (A) raw materials are weighed, and include the following components in percentage by mass: 46-56% of copper, 25-35% of ferrochrome, 8-18% of graphite and 4-7% of silicon carbide; (B) the raw materials are fully mixed; (C) the raw materials are molded by pressing; and the pressing pressure is 15-20 MPa; and (D) the pressurization and the sintering are performed; the sintering temperature is 950-1050 DEG C; the sintering time is 7-15 h; and the sintering pressure is 0.5-3 MPa. The prepared powder metallurgy brake pad friction material is high in purity, excellent in friction performance and lower in cost.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

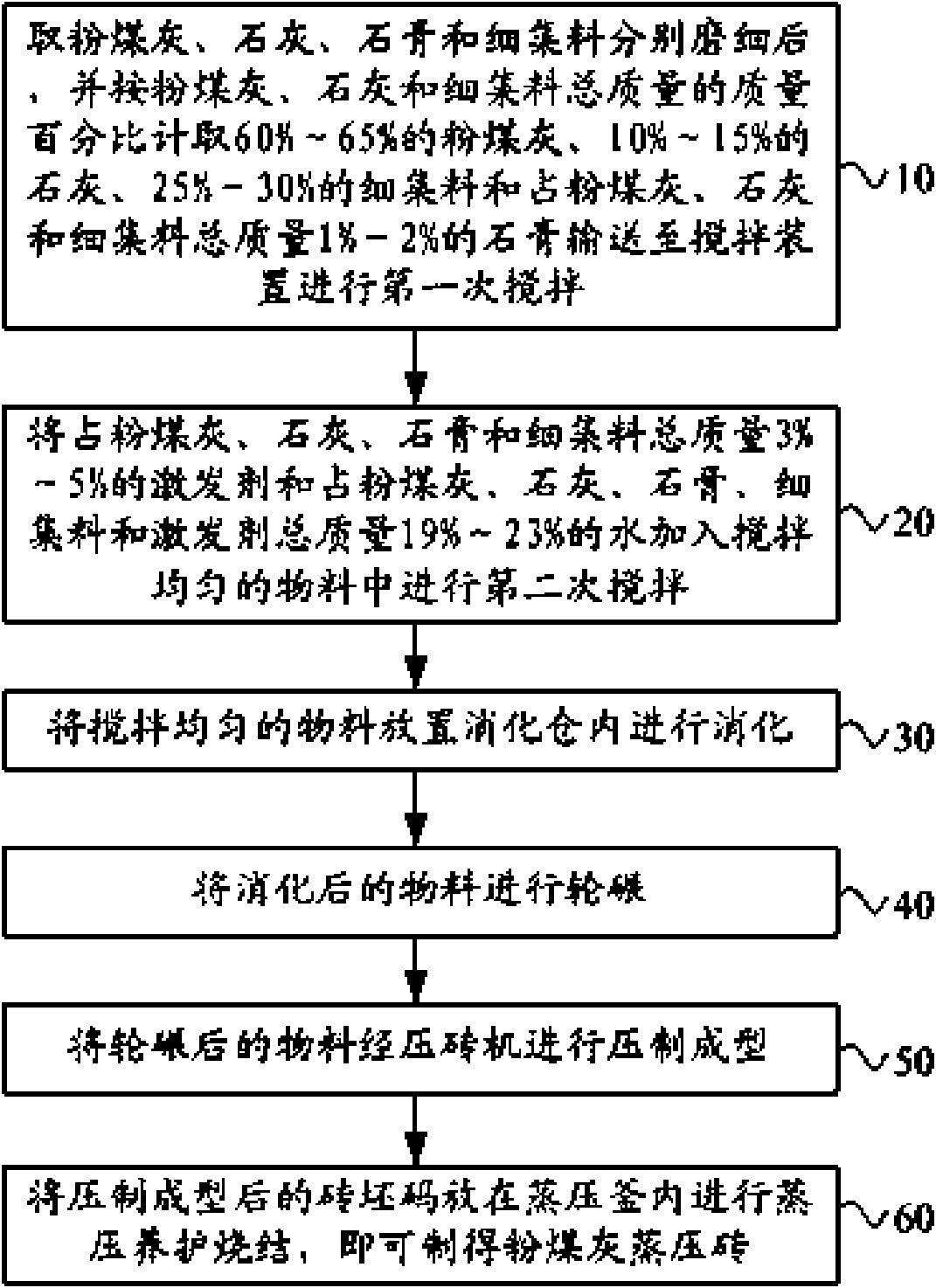

Fly ash stilled brick and preparation method thereof

InactiveCN101672084ALow densityHigh strengthMixing operation control apparatusCeramic shaping apparatusGypsumTemperature resistance

The invention relates to a preparation method of fly ash stilled bricks, which comprises the following steps: conveying 60% to 65% of fly ash, 10% to 15% of lime, 25% to 30% of fine aggregate in masspercent and 1% to 2% of gypsum in mass percent in the gross mass of the fly ash, the lime and the fine aggregate to a stirring device for first stirring; adding excitant and water to the uniformly stirred materials for second stirring; placing the uniformly stirred materials in a digestion chamber for digestion; rolling the digested materials; pressing and forming the rolled materials through a brick press; palletizing the pressed and formed brick blanks in a still kettle for stilling, maintenance and sintering, and thus obtaining fly ash stilled bricks. The fly ash stilled bricks prepared according to the reasonable matching proportion of the invention have the advantages of energy saving, waste recycling, small density, high strength, favorable water absorption, high temperature resistance, chemical corrosion resistance, good contraction performance, long service life and the like.

Owner:准格尔旗粉煤灰煤矸石研发中心

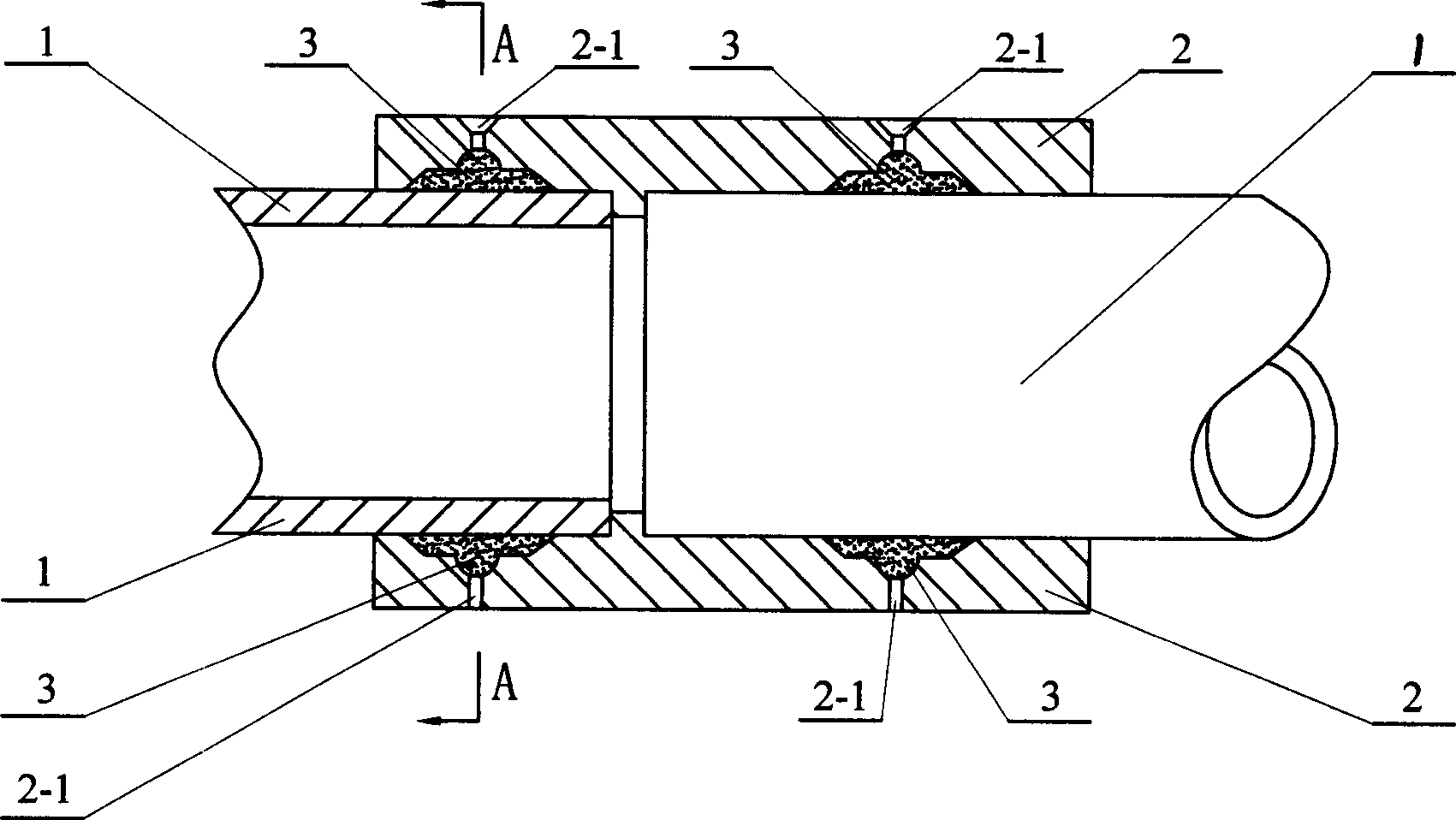

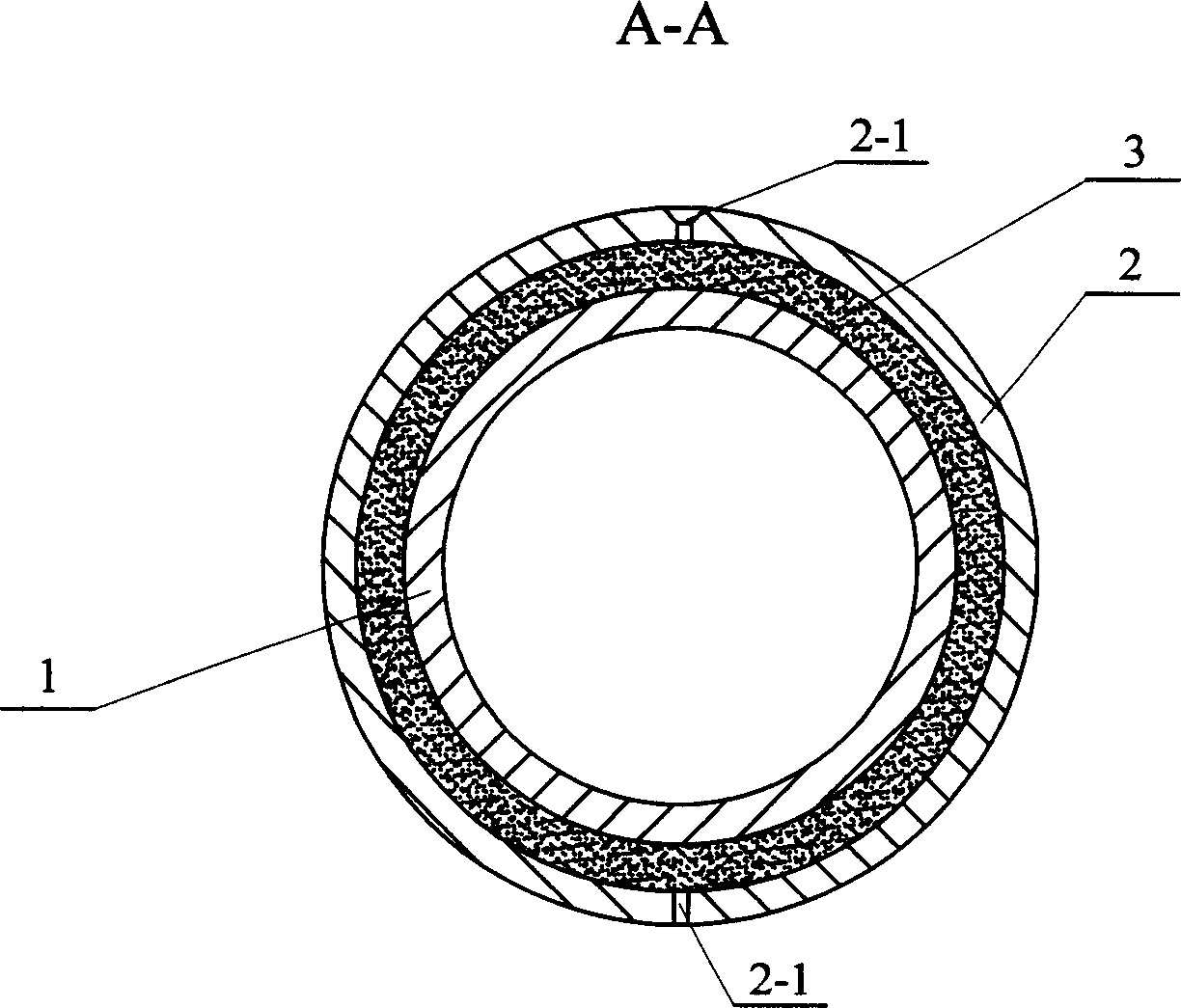

Pressure injection-moulded hot melt sealed pipe joint and sealing method thereof

InactiveCN1807958AImprove sealingIncrease elasticityNon-disconnectible pipe-jointsDual actionEngineering

The invention relates to a hot melt sealing tube interface of pressure injection and relative sealing method, which relates to the tube connection technique, and solves the problems of vulnerable connection sealing ring, worse sealing, leakage, high cost and complex operation in present installment and usage. The invention is formed by the connection tube (2) and the hot melt adhesive layer (3). Wherein, there are at least two couples of radial hot melt adhesive filling holes (2-1) at different parts of axial outer wall of said connection tube (2); and the hot melt adhesive layer (3) is solidified in the gap between the outer surface of tube connection end (1) and the inner surface of connection tube. The invention uses pressure injection to fill the melt hot melt adhesive into the tube and the connection tube to form an annular hot melt adhesive layer to seal and fix the tube.

Owner:李富春

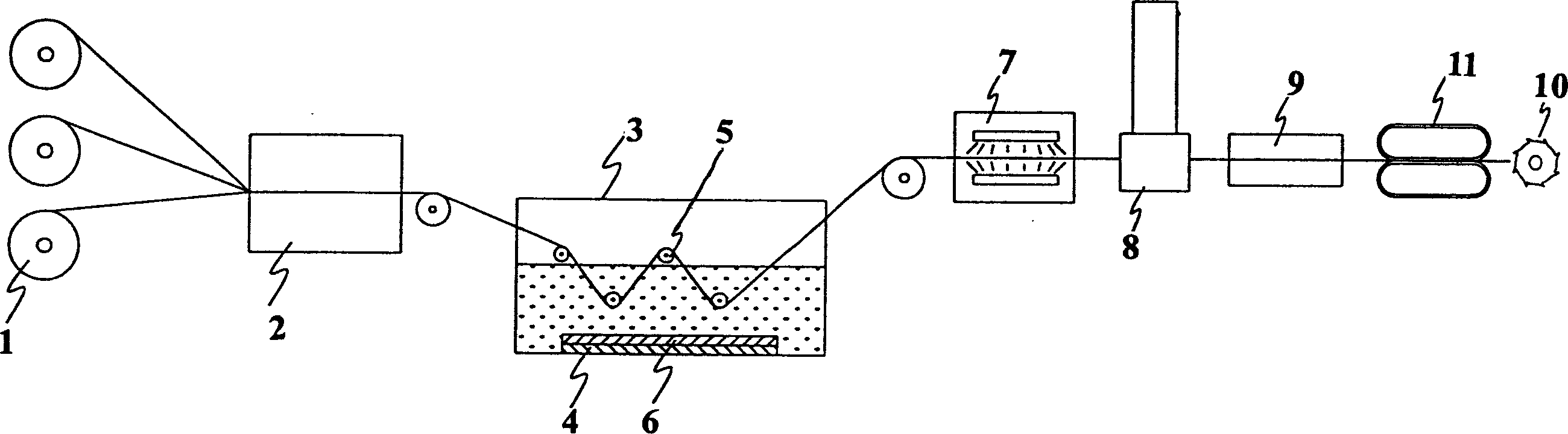

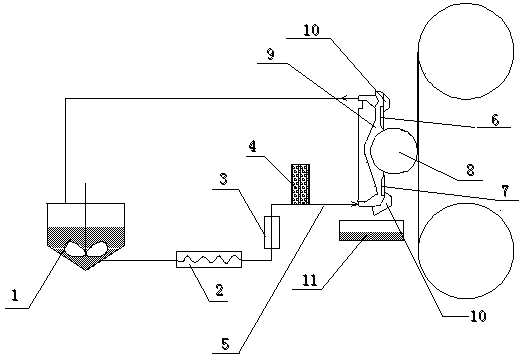

Surface coating device and method for lithium battery pole piece or diaphragm

InactiveCN104275268AChemically resistantHigh temperature resistantLiquid surface applicatorsCell electrodesRegular patternFiltration

The invention relates to a surface coating device and method for a lithium battery pole piece or diaphragm; a coating head is provided with an upper scraper which can be vertically and finely tuned, a lower scraper, an intaglio roller, a slurry cavity and a baffle plate for sealing the cavity; the upper scraper and the lower scraper are respectively positioned on the upper part and the lower part of the intaglio roller; the surface of an intaglio roller body is marked with regular patterns; the coating method comprises two steps: slurry preparation and surface coating. A ceramic slurry has the advantages of chemical corrosion resistance, high temperature resistance, good filtration and adsorption performance and higher stability, can prevent generation of diaphragm contraction due to heat emitting of a battery, and also can prevent a fire outbreak problem caused by crystal structure shifting and collapse due to unstable anode materials; and the influence of the cavity pressure fluctuation on the coating thickness can be avoided, the coating operation on an ultra-thin substrate material is facilitated, and the coating accuracy is ensured.

Owner:WANXIANG 123 CO LTD +2

Moisture-curing polyurethane epoxy coal-tar bitumastic

InactiveCN101760135AUniform thicknessNo effect on cure speedAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyCyclohexanone

The invention relates to a moisture-curing polyurethane epoxy coal-tar bitumastic. The invention adopts a technical scheme that: the bitumastic is formed by a component A and a component B in a weight ratio of 1:1-1:2; and the preparation method comprises the following steps of: placing 37 to 40 parts of polymethylene polyphenyl isocyanate, 11 to 13 parts of polyether 330 or 3,030, 2 to 3 parts of polyether 635 or 450, 8 to 9 parts of DOP or DBP, 3 to 4 parts of epoxy resin, 0.002 to 0.003 part of phosphoric acid and 33 to 37 parts of solvent No.S10,000 or industrial xylene in a reaction kettle at the temperature of between 81 and 86 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component A; and placing 62 to 66 parts of coal-tar, 9 to 10 parts of cyclohexanone, 10 to 11.5 parts of toluene, and 7 to 8 parts of solvent No.S1,000or industrial xylene in the reaction kettle at the temperature of between 115 and 120 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component B. The coating applied by the bitumastic is waterproof and long in life time and can further protect equipment and pipes.

Owner:孙锡宁

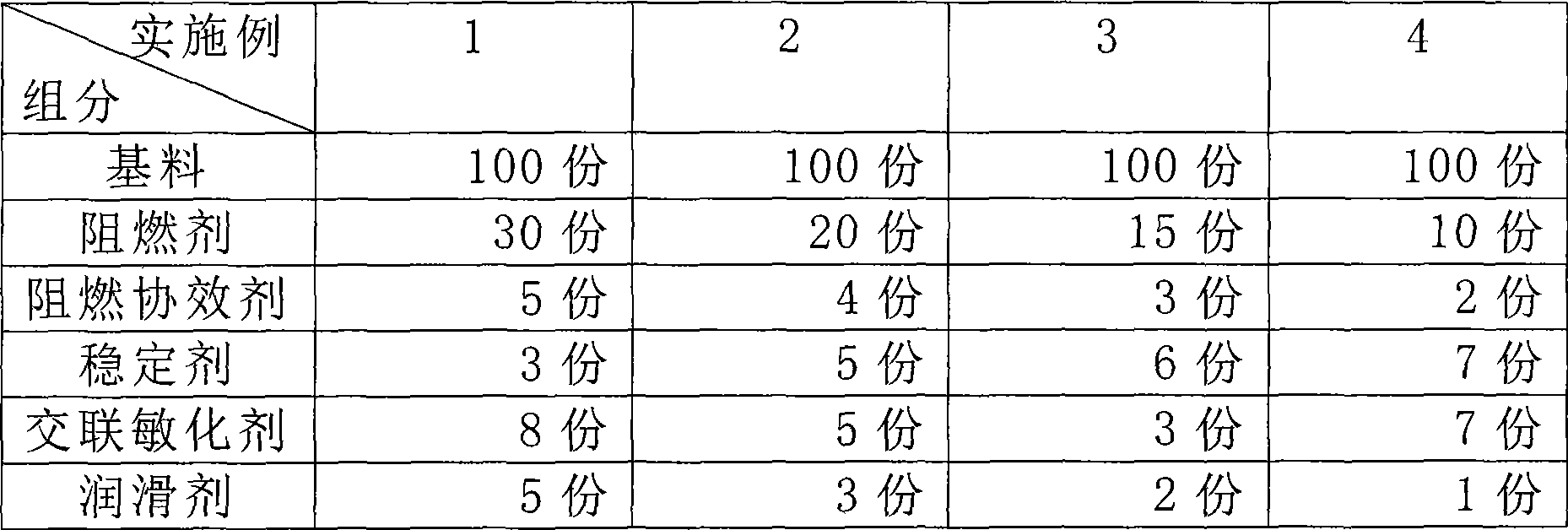

Halogen-free flame retardant insulation material for photovoltaic cable

ActiveCN101456987AImprove aging resistanceGood weather resistancePlastic/resin/waxes insulatorsWeather resistanceEngineering

The invention provides a halogen-free flame retardant insulation material used for a photovoltaic cable, which belongs to a novel cable material technical field and solves the problems exiting in the present halogen-free flame retardant insulation material used for the photovoltaic cable, that is, poor mechanical properties of tensile strength, elongation break and the like, poor heat aging property, shorter service life, and the like. The halogen-free flame retardant insulation material used for the photovoltaic cable comprises the following components according to a weight ratio: a 100 proportion of base material, 8-35 proportion of flame retardant, 2-8 proportion of stabilizer, and 1-10 proportion of crosslinking sensitizer. The halogen-free flame retardant insulation material used for the photovoltaic cable has the advantages of low production cost, good mechanical properties as heat aging property, tensile strength, elongation break and the like, long service life, low temperature tolerance, ozone resistance, weather resistance, direct current voltage resistance, and dynamic penetration resistance, etc.

Owner:临海市亚东特种电缆料厂

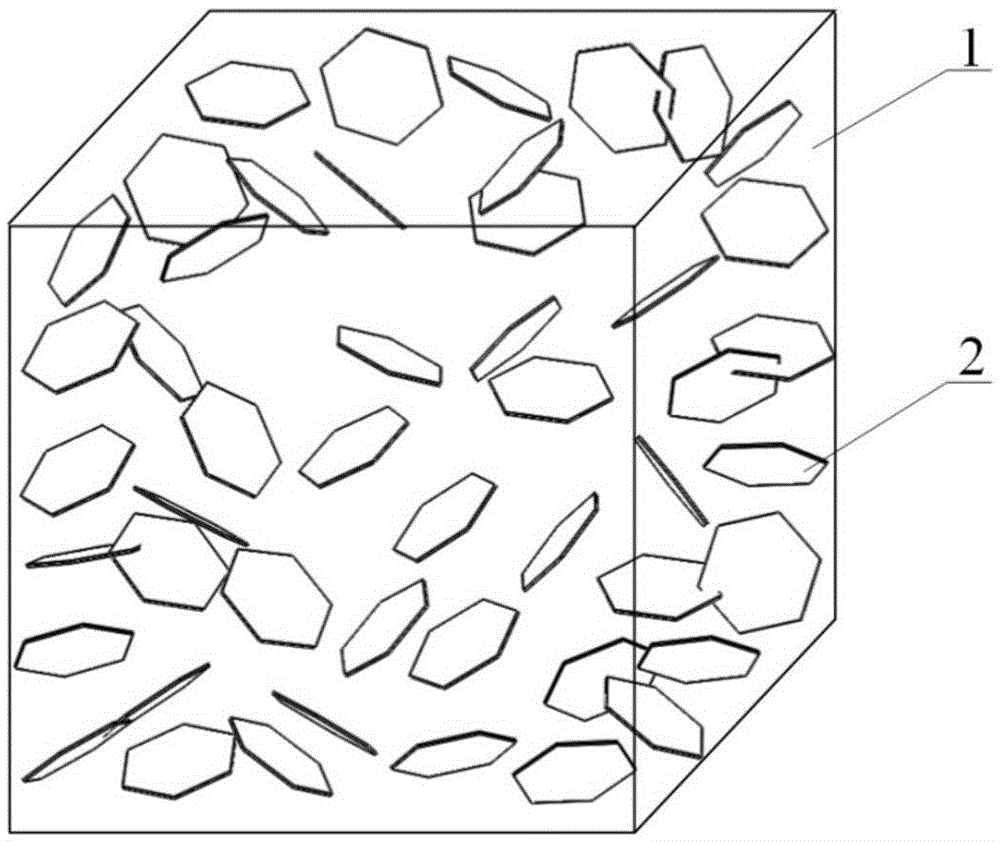

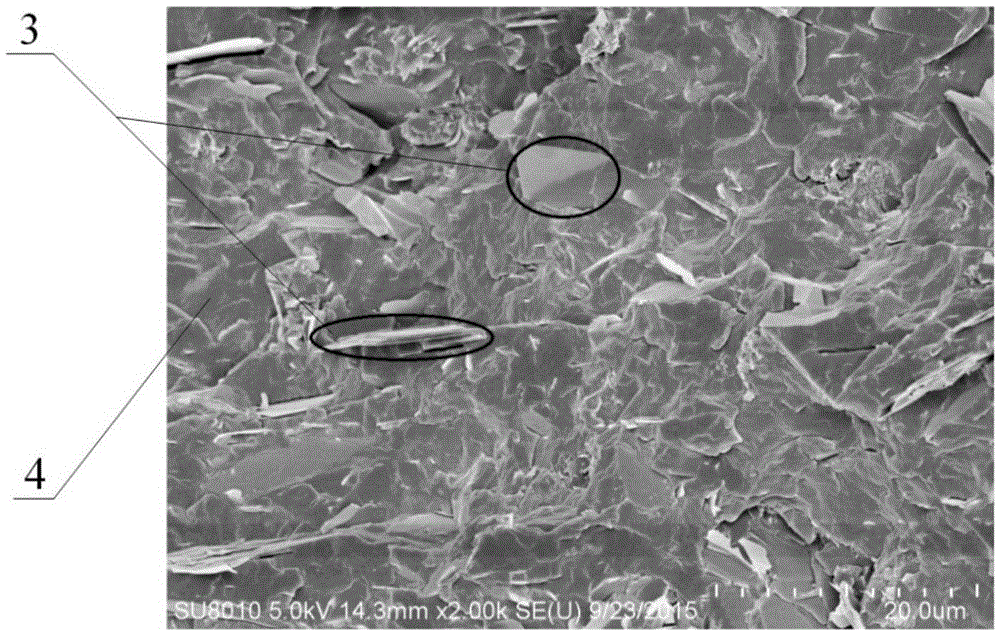

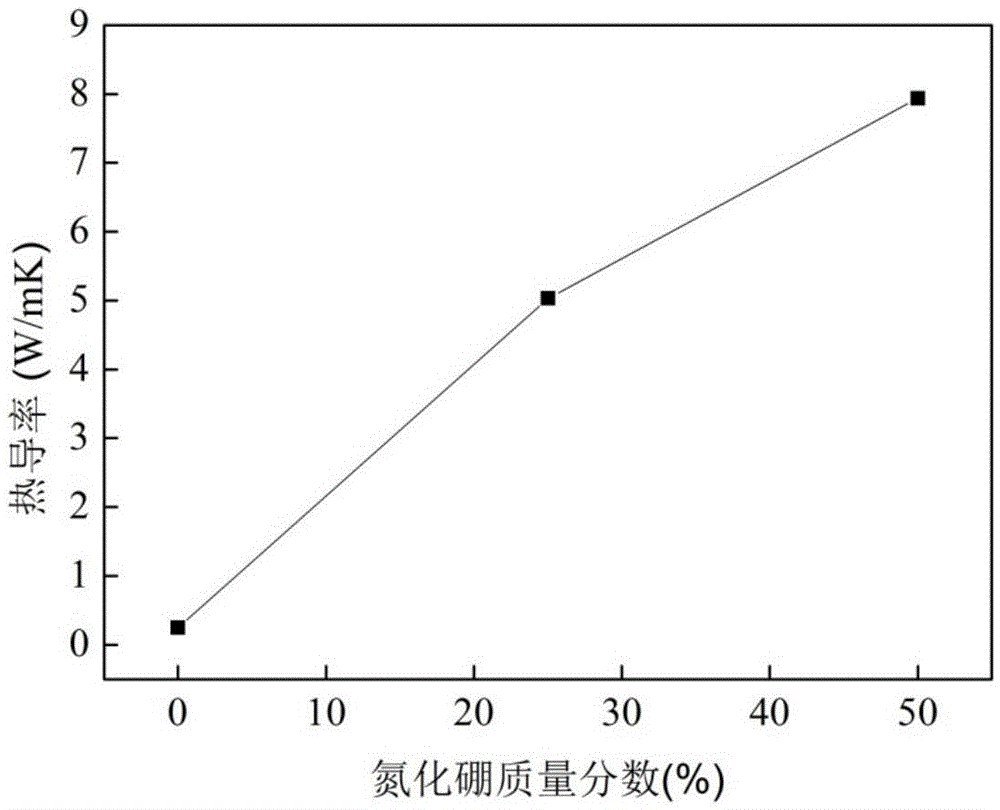

Polypropylene composite material with high thermal conductivity and preparation method thereof

InactiveCN105647015AGuaranteed mechanical propertiesHigh thermal conductivityMaleic anhydrideBoron nitride

The invention belongs to the technical field of thermally conductive composite materials, in particular relates to a polypropylene composite material with high thermal conductivity and a preparation method of the polypropylene composite material. The polypropylene composite material is prepared from polypropylene, a dopamine modified filler and maleic anhydride grafted polypropylene; the mass ratio of the polypropylene to the dopamine modified filler to the maleic anhydride grafted polypropylene is (47 percent to 74 percent):(25 percent to 50 percent):(1 percent to 3 percent); the filler is boron nitride, alumina or aluminum nitride. The preparation method is a melt-blending method; the obtained composite material has the advantages of light weight, chemical corrosion resistance, high thermal conductivity and the like; compared with the thermal conductivity (0.24 W / mK) of the conventional polypropylene, the thermal conductivity of the composite material with 25 weight percent of the filler is 4.94 W / mK which is 20.6 times that of the conventional polypropylene, and the thermal conductivity of the composite material with 50 weight percent of the filler is 7.92 W / mK which is 33 times that of the conventional polypropylene; the polypropylene composite material can be synthesized into the thermally conductive composite material with industrial application value, and is applicable to the fields requiring heat transfer and heat management, such as electronic packaging field, LED (light emitting diode) system field, heat exchanger field and motor field.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

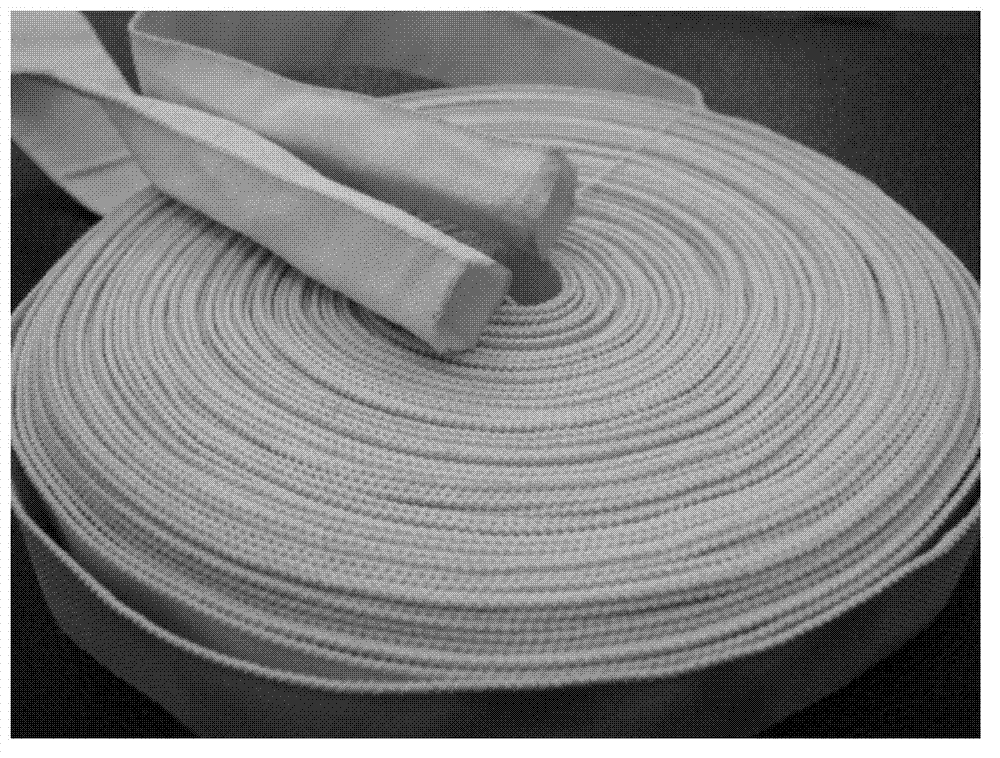

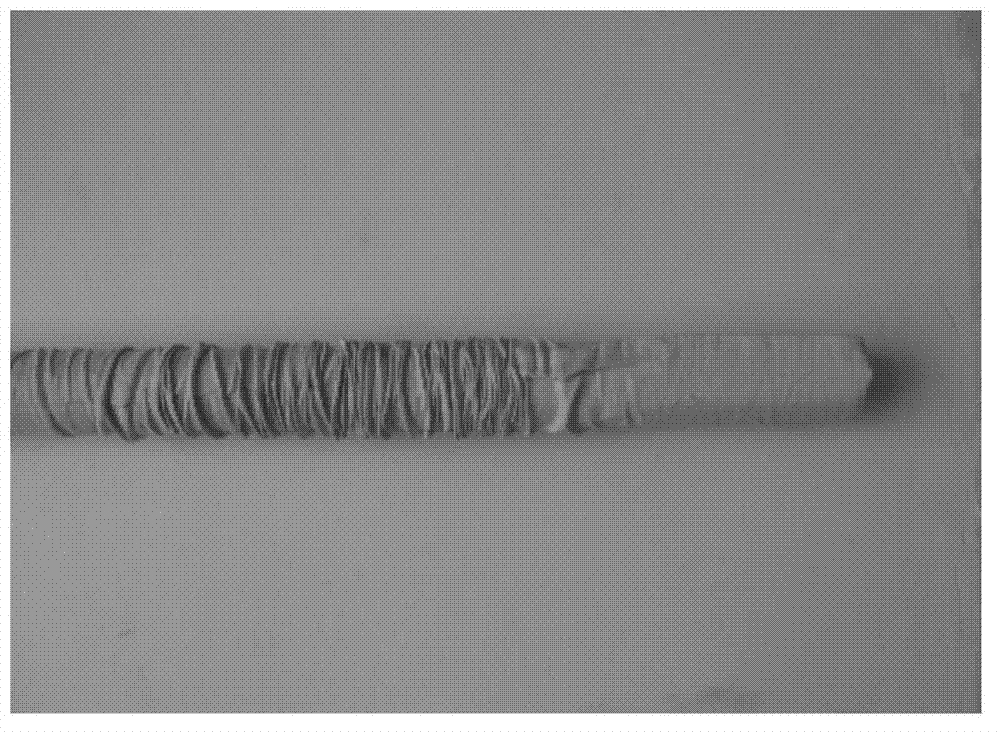

Preparation method of high-strength fine-diameter ultra-thin tubular fabric

ActiveCN102767028AAchieve normalizationAchieve Dimensional StabilizationWoven fabricsSmall caliberMaterials science

The invention relates to a preparation mehtod of a tubular fabric, in particular to a preparation method of a high-strength fine-diameter ultra-thin tubular fabric. The preparation method solves the problem that the existing preparation method of the tubular fabric cannot achieve the tubular fabric with a small caliber and a thin wall and cannot meet requirements for light weight and super-strong tensile force resistance of the fabric in special application. The preparation method particularly comprises steps of: selecting poly-p-phenylenebenzobisthiazole (PBO) fibers with fiber density of 100-300D to serve as warp yarns and weft yarns; conducting twisting treatment on filament yarns of the PBO fibers with twisting of 230 twist / meter; enabling the weft yarns to be free from being twisted, and winding the weft yarns into a appropriate pirn with a shuttle size of a shuttle loom; and adopting yarns of a transverse system and a longitudinal system which are mutually and vertically arranged, interweaving on a weaving machine according to certain rules to form the fabric, i.e. adopting a plain weave structure. The preparation method is used for preparing the fine-diameter ultra-thin tubular fabric.

Owner:HARBIN INST OF TECH

PVC composite shingle

InactiveCN103362274AImprove wear resistanceExtended service lifeCovering/liningsSynthetic resin layered productsManufacturing technologyChlorinated polyvinyl chloride

The invention discloses a PVC (polyvinyl chloride) composite shingle which is provided with a multilayer composite structure and comprises an abrasion-resistant layer, a color film layer, a substrate and a base material from the top down, wherein the base material is a crusted foaming board; the abrasion-resistant layer is a transparent film with a colorless UV (ultraviolet) coating on the external surface of the film; the substrate is a PVC sheet about 0.2-1mm thick; the base material is the PVC crusted foaming board, or a PVC / CPVC (chlorinated polyvinyl chloride) crusted foaming board; and the color film layer is a color film with decorative board patterns such as a woody pattern and a stone imitation pattern. The composite shingle is simple in manufacturing technology and has better decoration performance; the abrasion resistance of the external surface of the composite shingle and the structural strength of the composite shingle can be improved significantly; and the service life of the composite shingle can be prolonged.

Owner:TAIZHOU HUALI PLASTIC

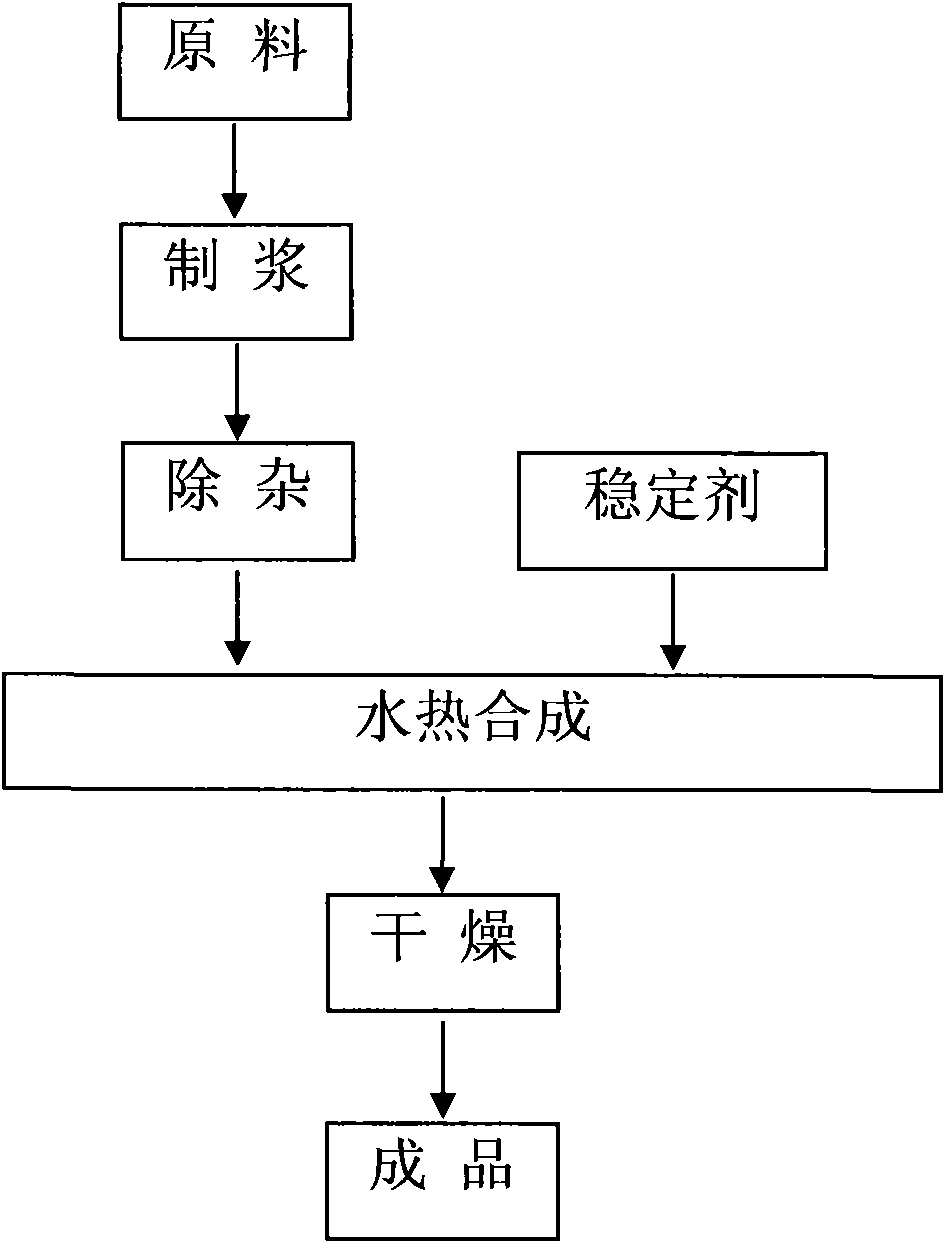

Calcium silicate high-filling polymer modified paper

InactiveCN102011347ALow lateral shrinkageWith whitenessSpecial paperPaper/cardboardLinear low-density polyethyleneCalcium silicate

The invention relates to calcium silicate high-filling polymer modified paper, which is compounded and formed by three layers of non-plant fiber calcium silicate substrates, wherein the first layer and the third layer are prepared from 2 to 6 percent of ethylene bis stearamide, 8 to 23 percent of high-density polyethylene, 3 to 9 percent of metallocene polyethylene, 0 to 1 percent of low-molecular polyethylene, 50 to 60 percent of activated calcium silicate, 10 to 25 percent of calcium silicate inorganic powder and 0 to 3 percent of addition agents, the first layer and the third layer accounts for 25 percent of the weight of the paper, the second layer is prepared from 50 to 60 percent of activated calcium silicate powder, 10 to 25 percent of calcium silicate, 2 to 9 percent of styrene-butadiene block copolymer, 7 to 21 percent of high-intensity polyethylene materials, 4 to 8 percent of linear low-intensity polyethylene and 0 to 3 percent of addition agents, and the second layer accounts for 50 percent of the weight of the paper. The modified paper has the same appearance, whiteness, sizing degree, opacity, strength, toughness and rigidity as plant fiber paper and has simple production processes, no bacteria and poison; and because the product is used for packing paper and can replace the traditional plastic packing paper, a great amount of petroleum can be saved.

Owner:宋旭

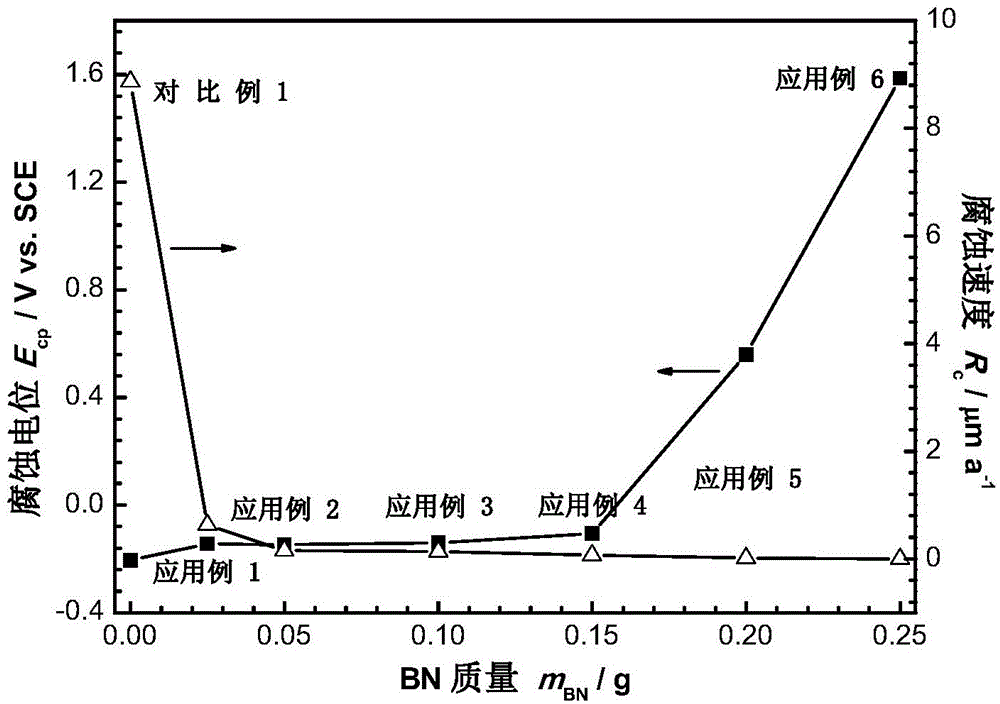

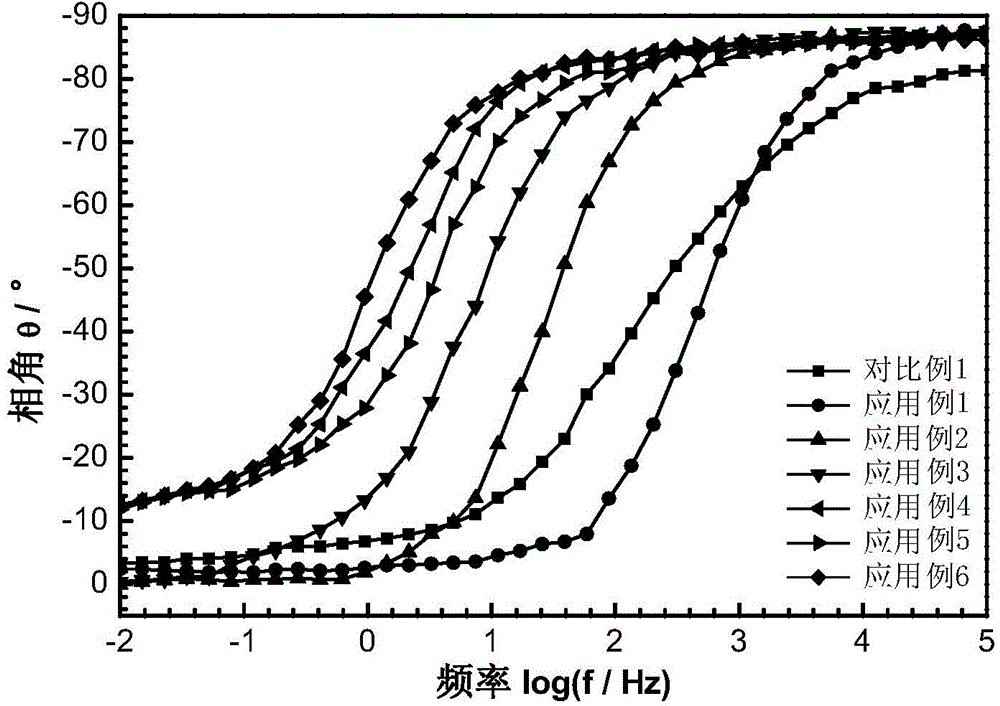

Preparation method of stripping boron nitride anticorrosive coating, coating obtained by preparation method and application of coating

InactiveCN104629510AIncrease thermal conductivity and heat resistanceGood mechanical propertiesAnti-corrosive paintsSolventCorrosion

The invention discloses a preparation method of a stripping boron nitride anticorrosive coating. The preparation method specifically comprises the following steps: 1, performing ultrasonic stripping on hexagonal boron nitride in a solvent, washing, and performing freeze-drying to prepare stripping boron nitride; 2, removing stains, iron rusts and other impurities from the surface of a base material; 3, mixing the stripping boron nitride with an organic coating by virtue of ultrasonic or mechanical stirring to prepare the stripping boron nitride anticorrosive coating; and 4, coating the stripping boron nitride anticorrosive coating to the surface of a metal matrix to obtain a stripping boron nitride anticorrosive coating layer. The preparation method disclosed by the invention can be used for effectively solving the problems in the prior art and preparing an ultrathin anticorrosive coating layer which is superior in corrosion resistance.

Owner:DALIAN UNIV OF TECH

Antibacterial PVC wood plastic plate and preparation method thereof

InactiveCN105038010AImprove impact resistanceImprove tensile propertiesSodium bicarbonateMicrocrystalline wax

The invention discloses an antibacterial PVC wood plastic plate. The antibacterial PVC wood plastic plate is prepared from, by weight, 100 parts of PVC-1300, 20-30 parts of PVC-1000, 10-20 parts of C 9 petroleum resin, 40-50 parts of modified nano calcium carbonate, 6-8 parts of corn straw powder, 0.5-1 part of AC foaming agents, 0.3-0.6 part of sodium bicarbonate, 1-3 parts of calcium and zinc stabilizers, 2-3 parts of silane coupling agents KH550, 2-3 parts of ACR, 0.2-0.5 part of microcrystalline wax, 0.2-0.5 part of stearic acid, 3-4 parts of PVC foaming regulators ZB-530, 4-5 parts of molybdenum oxide, 0.5-1.0 part of ammonium polyphosphate, 1-1.5 parts of zinc borate, 0.2-0.4 part of nanometer titanium dioxide and 3-4 parts of polyhexamethyleneguanidine phosphate. Extrusion shaping is performed through a conventional extruding machine. The PVC plate has good antibacterial performance, meanwhile has good impact resistance and tensile strength and has the advantages of being resistant to chemical corrosion and low in cost.

Owner:滁州远方车船装备工程有限公司

Composite cathode material, preparation method and lithium ion battery

ActiveCN108832093AImprove thermal stabilityGuaranteed thermal stabilityCell electrodesSecondary cellsManganeseSodium-ion battery

The invention relates to a composite cathode material, comprising a base cathode material and a magnesium aluminate material MgAl2O4 coating the surface of the base cathode material. Preferably, the base cathode material is a nickel-cobalt-manganese ternary cathode material LiNixCoyMnzO2 or a nickel-cobalt-aluminum ternary cathode material LiNixCoyAlzO2, wherein x+y+z=1, 0 (x, y, z (1. The invention also relates to a preparation method of the composite cathode material and a lithium ion battery. The MgAl2O4 on the surface of the cathode material can protect the cathode material in the inner layer, improve the thermal stability of the cathode material, and thus improve the cycle stability and safety of the battery.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com