Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

293results about How to "Moisture resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant synthetic paper

Owner:CHANGZHOU JINKA CARD BASE SHEET

3D (three dimensional) wood printing supply and preparation method thereof

The invention provides a 3D (three dimensional) wood printing supply which comprises components in percentage by mass as follows: 60%-90% of wood meal, 3%-15% of ABS (acrylonitrile butadiene styrene) plastics, 4%-15% of PLA (poly lactic acid), 2%-10% of PHA (polyhydroxyalkanoate), 1%-2% of PP (polypropylene) and 1%-2% of a compatilizer. The 3D wood printing supply has the characteristics such as water proofing, corrosion resistance, moisture resistance, freeness of worm damage, mildew and toxicity, acid and alkali resistance, environment protection and the like, the real flavor of wood is diffused; the wood printing supply is fused and deposited by a 3D printer at the temperature of 190-230 GDE C to form various different 3D models, the 3D models have the hand feel, the impression and the fragrance of natural wood and have an effect approaching to a solid wood effect and wood properties, and the printing supply can be nailed, drilled, planed, carved, adhered and painted as wood; and the comprehensive physical properties and chemical properties can be well improved and optimized, the performance requirement of the 3D printer can be effectively reduced, and accordingly, the printing supply is suitable for both high-end printers and low and medium-end 3D printers and has a wider application range.

Owner:广东傲趣三维科技有限公司

Multi-layer thermal transfer ribbon and manufacturing method thereof

The invention relates to a multi-layer thermal transfer ribbon and a manufacturing method thereof, and the multi-layer thermal transfer ribbon comprises a membranous base band, a heat-resistant printing ink layer and a heat transfer printing ink layer, wherein the heat-resistant printing ink layer is coated on one side of the base band, the heat transfer printing ink layer is coated on the other side of the base band, the heat transfer printing ink layer comprises a stripping printing ink layer and an adhesive printing ink layer, the stripping printing ink layer is directly coated on the surface of the base band, the adhesive printing ink layer is coated on the stripping printing ink layer, printing ink in the striping printing ink layer is hot-melting type printing ink, and the printing ink in the adhesive printing ink layer is the hot-melting type printing ink or solvent type printing ink. The heat transfer printing ink layer of the multi-layer mixed-based ribbon can be easily completely stripped off the base band, and the great adhesive ability is realized on a smooth medium; in addition, the multi-layer thermal transfer ribbon further has the advantages of high resolution, clear printing, anti-friction property, moisture resistance, chemical corrosion resistance, environment friendliness and the like.

Owner:泉州市山水电脑耗材有限公司

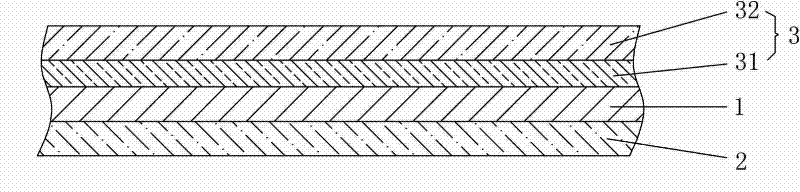

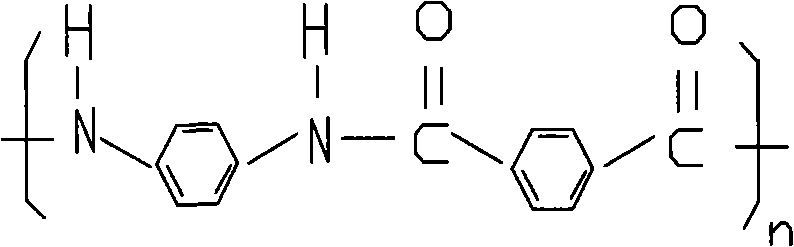

Multifunctional macromolecule filter material and preparation method thereof

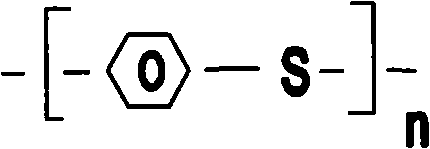

InactiveCN101314091ALow costMoisture resistantSynthetic fibresFiltration separationGlass fiberPrice ratio

The invention relates to a multifunctional polymer filtering material which comprises 70 to 85 percent of glass fiber, the balance being one or a plurality of aramid, polytetrafluoroethylene (PTFE) fiber, polyphenylene sulfide fiber, poly (p-phenylene-benzobisoxazole) (PBO) fiber, p-aramid, ceramic fiber, stainless steel fiber and copper fiber. The invention also discloses a method for preparing the multifunctional polymer filtering material. The method comprises the following steps: mixing the 70 to 85 percent of glass fiber and at least one of aramid, polytetrafluoroethylene (PTFE) fiber, polyphenylene sulfide fiber, poly (p-phenylene-benzobisoxazole) (PBO) fiber, para-aramid, ceramic fiber, stainless steel fiber, copper fiber into a synthetic fabric; and puncturing and shaping the synthetic fabric and a base fabric to obtain a finished product. The filtrating material produced by the method has the advantages of low cost, water proofing, temperature resistance, corrosion resistance and high performance to price ratio.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Hickory nut shell ecologic wood composite material and preparation method thereof

The invention relates to a plastic-wood composite material and provides a hickory nut shell ecologic wood composite material and a preparation method thereof. The hickory nut shell ecologic wood composite material is prepared from following components including, by weight, 50-60 parts of a thermoplastic high-molecular resin, 40-50 parts, or 30-40 parts, of hickory nut shell powder, 10-20 parts of wood powder, 8-10 parts of light calcium carbonate, 10-14 parts of a compatilizer, 2-4 parts of a thermal stabilizer, 2-4 parts of a lubricant, 2-3 parts of a plasticizer, and 1-3 parts of an antioxidant and an ultraviolet stabilizer. A comprehensive technology comprising deep process of raw materials and extrusion moulding and the like is employed. Deep process waste of wild hickories and waste plastic resources are employed. The composite material in the invention has dual-characteristics, which exist in common plastic-wood, of wood and plastic, is better in mechanical performances and is more rigid, durable, wear-resistant and weather-resistant. The method is simple and convenient, is low in manufacturing cost, can be recovered and recycled, can save energy resources and can protects environment.

Owner:LIAONING CHANGBAIXIANZI BIOTECH

Thermal sublimation digital image ribbon and method for making same

The invention relates to a thermal sublimation digital image color band and a manufacturing method thereof, wherein the thermal sublimation digital image color band has a base band, a film covering layer and a thermal sublimation ink layer are coated on one side of the base band, and a heatproof lubricating layer is coated on the other side of the base band. The method comprises the following steps: a polyester film is used as the base band; after being dispersed in high speed, a polymeric dispersant, a solvent, an accessory ingredient, a resin cementing agent and a coloring agent are ground, and then ink sizing agent is obtained; thermoplastic resin, the ink sizing agent and heat-resistant silicon resin are coated on the both surface of the base band through a gravure coating machine to form the film covering layer, the ink layer and the heatproof lubricating layer, and at last the required size is obtained by cutting. The color band of the invention has the advantages that the production and application costs are low, and the combination properties of the color band, such as rigidity, heat resisting property, wearing resistance, adhesive rate, printing definition and so on are excellent.

Owner:深圳市墨库图文技术有限公司

Method for preparing sea cucumber collagen small peptide freeze drying powder extracted from sea cucumber decoction liquor

InactiveCN101532044AEasy to processHigh in nutrientsPeptide preparation methodsFermentationSmall peptideEnzymatic hydrolysis

The invention relates to deep processing of sea cucumbers, in particular to a method for preparing sea cucumber collagen small peptide freeze drying powder extracted from sea cucumber decoction liquor. The method adopts the sea cucumber decoction liquor as the raw material and comprises the steps of A. obtaining the sea cucumber decoction liquor; B. enzymatic hydrolysis; C. purification of sea cucumber collagen small peptide; and D. freeze-drying, drying and product packaging. The method can increase the processing rate and nutritional value of sea cucumbers, and by adopting FD space biological freezing and drying technology, the activity, oxidation resistance, re-polymerization resistance and moisture binding resistance of the sea cucumber collagen small peptide can be kept, and the sea cucumber collagen small peptide can be stored easily due to less moisture.

Owner:DALJANSKOE OOO PO KHIMICHESKOMU MATERIALU TVERDOGO TELA KEHSYTEH

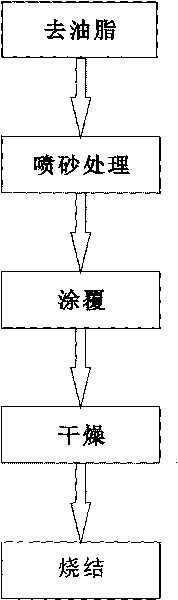

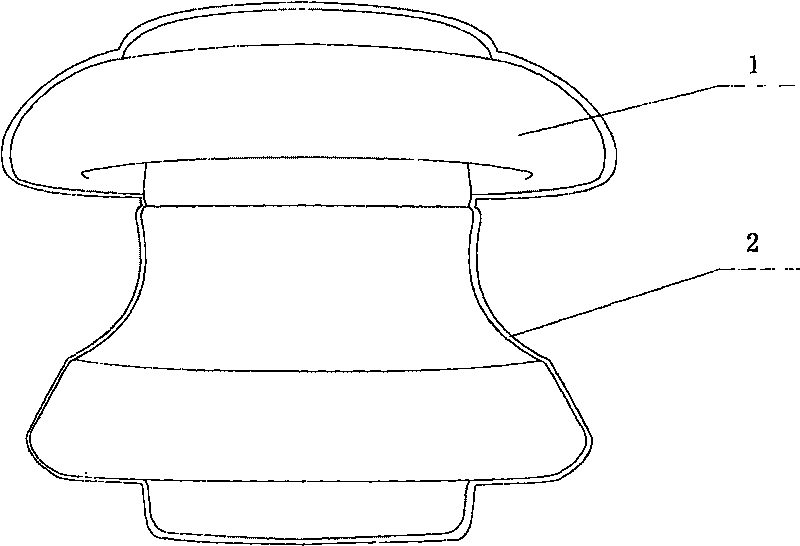

Coating method for wire or electrical insulator with teflon coating

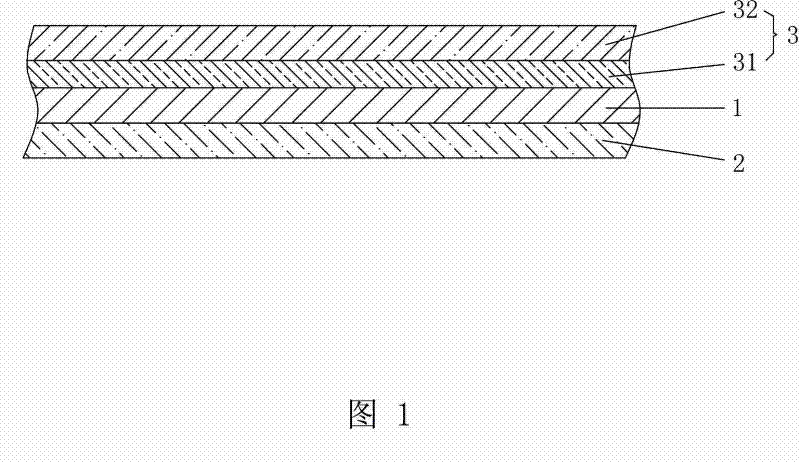

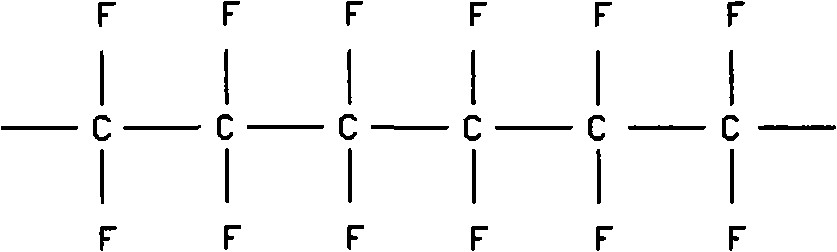

InactiveCN101707103AExcellent heat and low temperature resistanceReduce permeabilityInsulatorsInsulating conductors/cablesTemperature resistanceTransmission line

The invention relates to a coating method for a wire or an electrical insulator with a teflon coating, which relates to the technical field of transmission lines. The coating method for the electrical insulator (3) comprises the steps of degreasing, sand-blasting treatment, coating, drying and sintering. The coating method for the wire (1) comprises the steps of degreasing, coating adhesives and spraying the coatings. As the teflon has inadhesion property and moisture resistance, the aim of preventing serious icing can be fulfilled by spraying the teflon on the outsides of the wire and the electrical insulator, and the aim of preventing the pollution flashover can be fulfilled by spraying the teflon on the outside of the electrical insulator. As the teflon coating film has excellent heat resistance and low temperature resistance, the wire or electrical insulator sprayed with the teflon can work normally in a high-temperature environment in summer or a low-temperature environment in winter.

Owner:河南省电力公司洛阳供电公司输电公司

Reflective marking belt base material, base material and method for manufacturing reflective marking belt

The invention discloses a reflective marking belt base material which comprises the following components: 8-15 parts of SBS, 2-6 parts of EVA, 5-10 parts of quartz sand 7-12 parts of rosin, 3-6 parts of a petroleum resin, 30-50 parts of wollastonite powder, 20-40 parts of calcium carbonate, 1-8 pats of pigments, 2-5 parts of a plasticizer, 1-2 parts of paraffin and 8-15 parts of glass beads. In addition, the invention also discloses a base material and a method for manufacturing a reflective marking belt. The reflective marking belt base material disclosed by the invention has the advantages of high compatibility with the ground and asphalt and high strength and toughness.

Owner:SICHUAN JIANGYOU YUSHU YESHILI REFLECTIVE MATERIAL

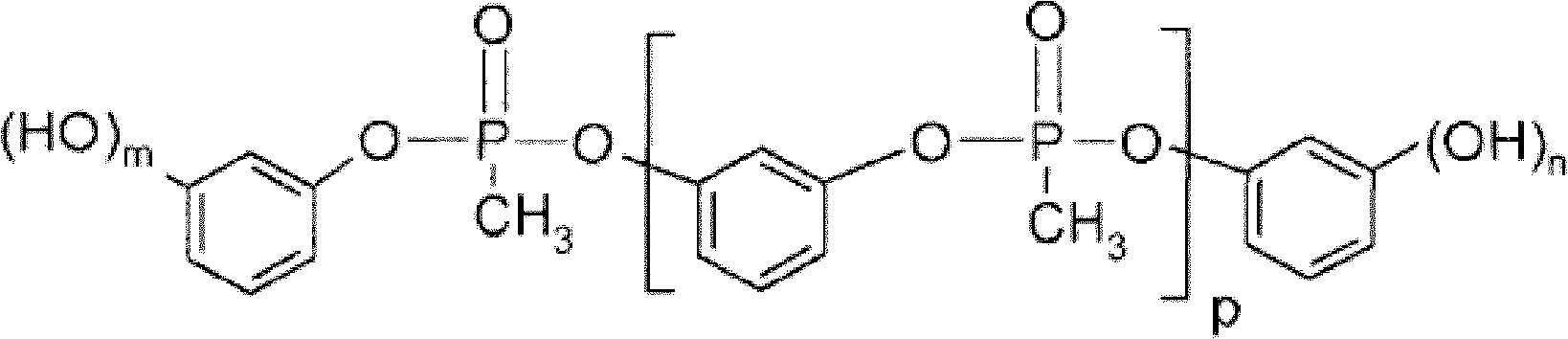

Halogen-free fire resistance resin composite and application thereof

InactiveCN102020830AGood heat resistanceSmall water absorptionPrinted circuit aspectsPrinted circuit manufactureMetal foilFlame resistance

The invention relates to a halogen-free fire resistance resin composite and application thereof. The halogen-free fire resistance resin composite comprises the following components: bifunctional or multifunctional halogen-free epoxy resin, reactive polyphosphonate and cyanate resin. The halogen-free fire resistance resin is applied to a prepreg; the prepreg comprises a base material and the halogen-free fire resistance resin composite attached to the base material after being impregnated and dried. The halogen-free fire resistance resin composite is applied to a plyboard for a printing circuit; the plyboard for the printing circuit comprises a plurality of stacked prepregs and single-surface or double-surface metal foil arranged on the stacked prepregs; each prepreg comprises the base material and the halogen-free fire resistance resin composite attached to the base material after being impregnated and dried. The halogen-free fire resistance resin composite has high heat resistance, fire resistance and dip soldering resistance, and thereby, the halogen-free fire resistance resin composite can be used for manufacturing the resin sheet, the resin composition metal foil, the prepreg, the plyboard and the printed wiring board.

Owner:GUANGDONG SHENGYI SCI TECH

Steel pipeline corrosion proof reinforcing method

The invention relates to a method for reinforcing and antisepticising steel pipeline, comprising the following steps of: processing the surface of steel pipeline to be reinforced and antisepticised, preparing epoxy ethylene resin and resin mortar, using the mortar to fill and block the crack and perforation part of the pipeline, sticking bidirectional carbon fiber cloth on the patching part, finally winding and sticking the unidirectional carbon fiber cloth on the pipeline in circularity when the surface of the pipeline is being coating by the prepared resin, the direction of the carbon filament should be right angle of 90 degrees with the axes of the pipeline, and then winding and brushing, recoating a layer of resin surface layer after the surface of the resin gel is dry. The invention has the advantages that the adopted carbon fiber epoxy ethylene resin composite material system has the excellent performances of high strength, light weight, corrosion resistance and humidity resistant, evident dual effect of reinforcing and antisepticising, and practical and reliable method for patching crack and perforation, which can greatly prolong the service life of the pipeline.

Owner:上海华夏化工材料有限公司

Moisture absorption resisting aluminum alloy slit flux-cored wire and manufacturing method thereof

ActiveCN101920403AMoisture resistantWelding/cutting media/materialsSoldering mediaAl powderMoisture absorption

The invention relates to a moisture absorption resisting aluminum alloy slit flux-cored wire and a manufacturing method thereof. An alloy belt is used as the outer skin of the flux-cored wire, wherein the component of the flux-cored wire contains 5 to 90 wt.% of CsAlF4, 5 to 90 wt.% of Cs3AlF6, 1 to 45 wt.% of KALF4, 1 to 45 wt.% of K3AlF6, 0.001 to 2.0 wt.% of aluminum powder, 0.001 to 2.0 wt.% of silicon powder and 0.001 to 2.0 wt.% of Al-Mg alloy. By using the aluminum alloy belt sold on the market, based on the optimized proportion of the flux-cored wire component, the slit flux-cored wire is sewn as the slit having a stair so as to match with the edge of the flux-cored wire, thereby efficiently preventing water and other chemical materials from entering into the flux-cored wire through the slit and ensuring excellent moisture absorption resisting property. The flux-cored wire adopts torch soldering, induction brazing and furnace brazing to solder aluminum-aluminum alloy, aluminum-copper alloy and aluminum alloy-copper alloy. The slit metal not only has higher strength and air impermeability but also has excellent spreading property and permeating property.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

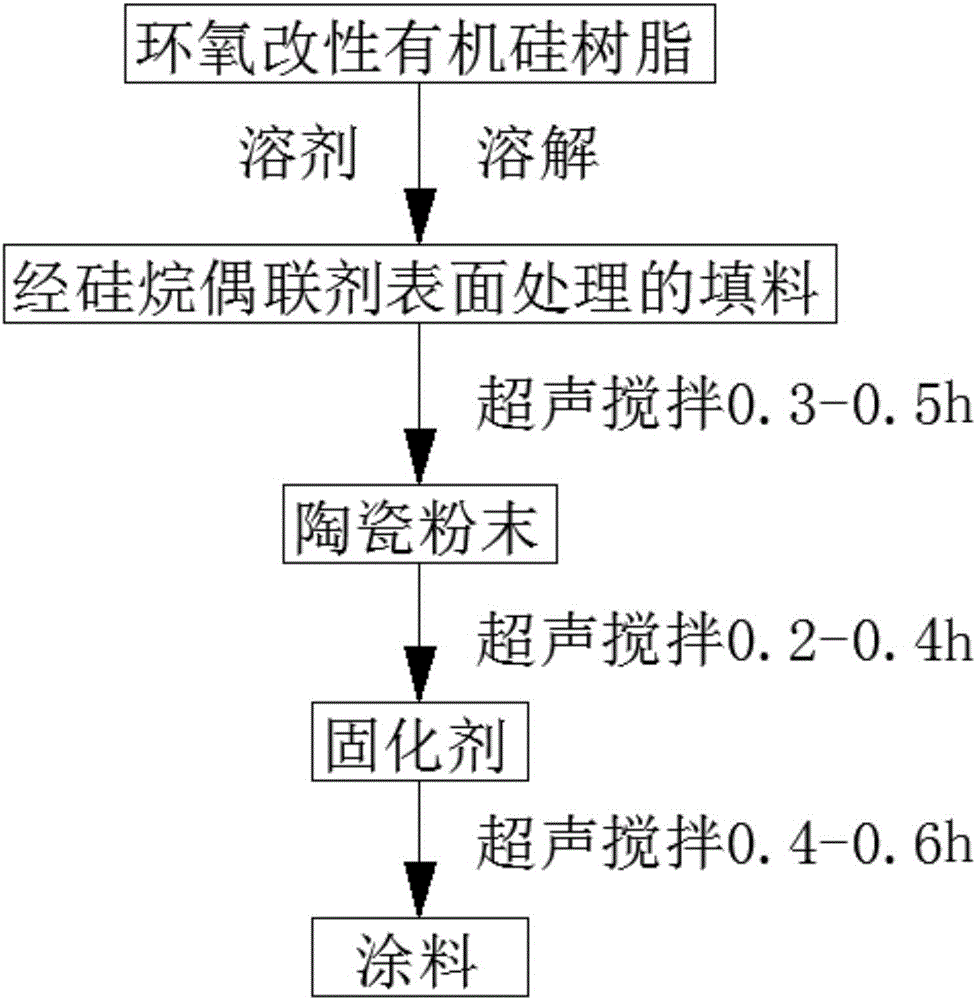

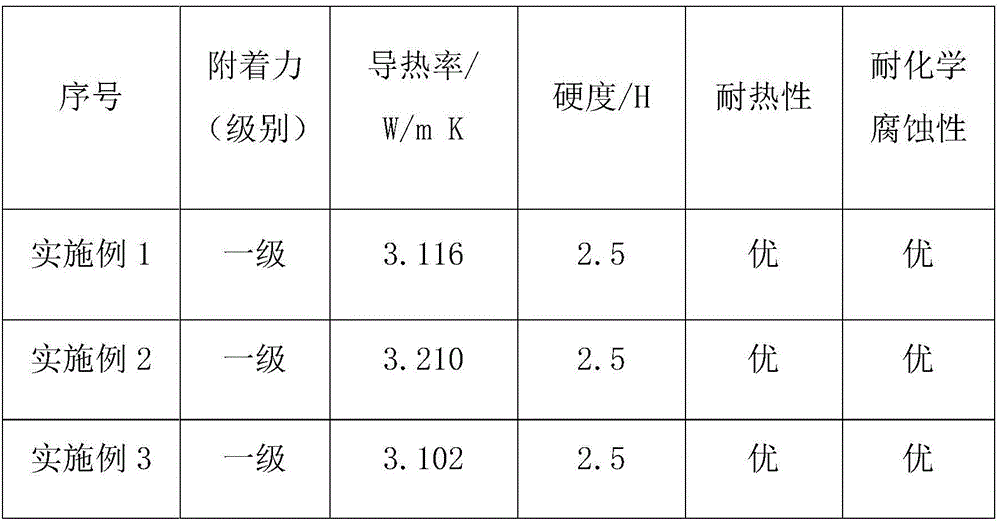

Preparation process for high-temperature-resistant high-thermal-conductivity insulating paint

ActiveCN106497412AImprove adhesionSimple preparation processFireproof paintsPlastic/resin/waxes insulatorsOperabilitySolvent

The invention discloses a preparation process for a high-temperature-resistant high-thermal-conductivity insulating paint, belonging to the technical field of paints. The paint comprises the following raw materials by mass: 12 to 23% of epoxy modified organosilicone resin, 33 to 48% of a solvent, 0.7 to 0.9% of a silane coupling agent, 36 to 42% of a filling material, 0.1 to 0.3% of a curing agent, 0.03 to 0.08% of ceramic powder and 0.02 to 0.07% of nanometer diamond. The paint prepared in the invention can be used for a long time at a high temperature and has good stability, insulating properties, wear resistance and good corrosion resistance; and the preparation process is simple and has good operability.

Owner:WUHU CITY SIHAN POWDER COATINGS CO LTD

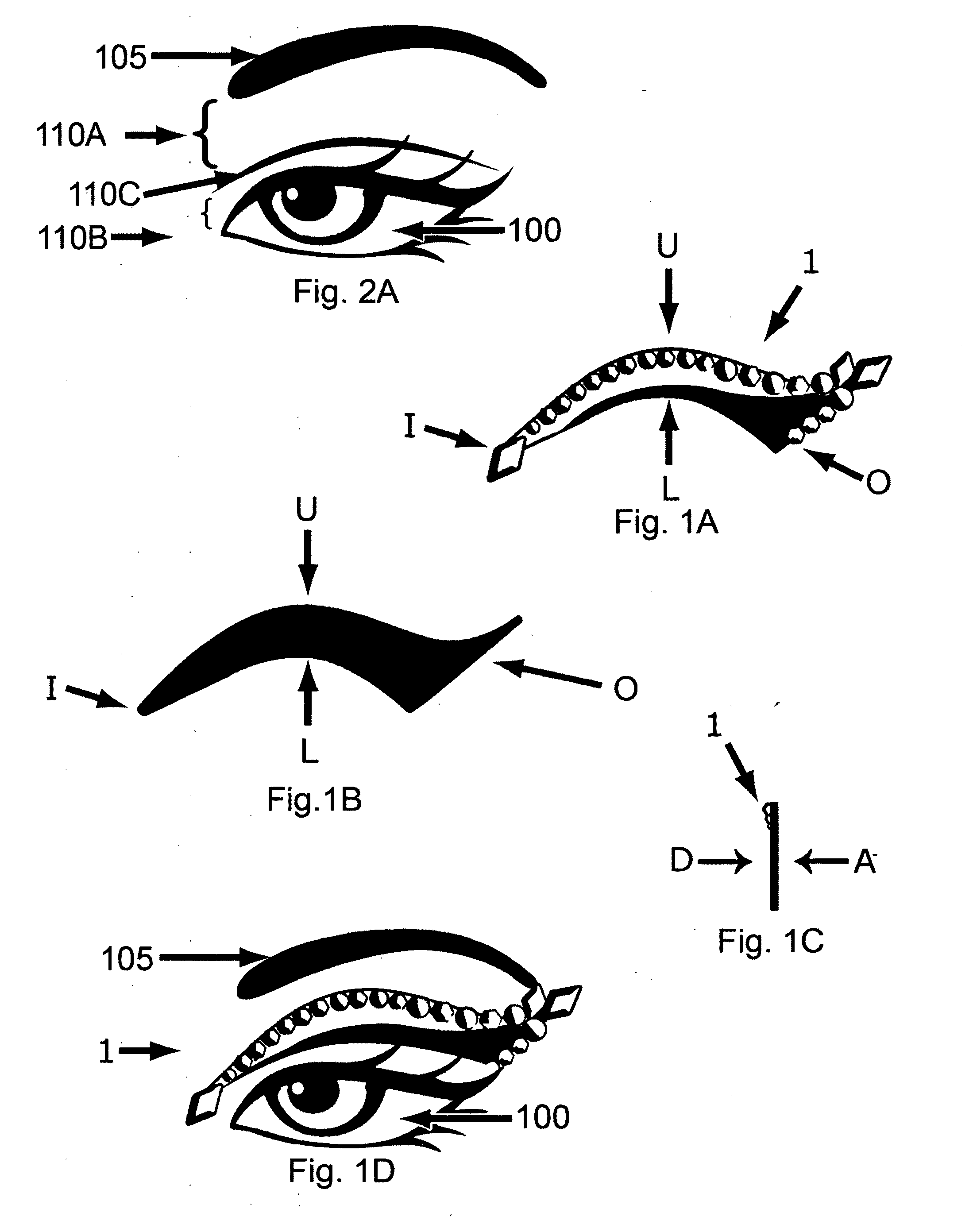

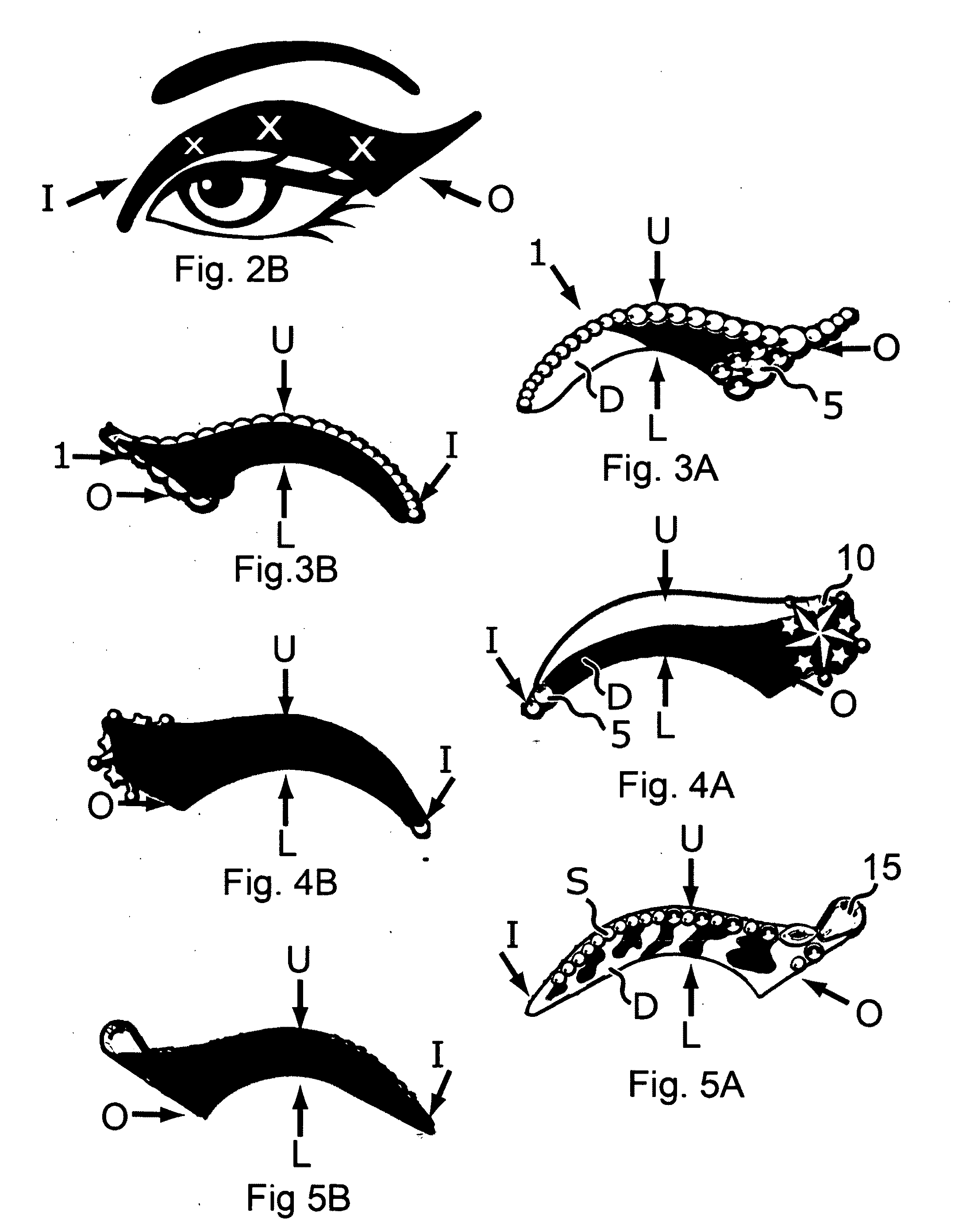

Decorative eyelid covering and process

InactiveUS20100242539A1Moisture resistantSuitable for useLamination ancillary operationsLaminationEyelidEngineering

A flexible eyelid cover includes an adhesive having a decorative design arranged opposite an inner surface of the flexible eyelid cover. The cover is formed from wig adhesive and adheres to an upper eyelid of a wearer. An upper edge of the cover is convex in shape. A lower edge of the cover includes a first curved surface and a second curved surface. The second curved surface is concave in shape and arranged on a region of the upper eyelid distal from the nose. Various designs and ornaments may be adhered to outer surface of the cover.

Owner:MAXEY SHANNON

Health food for protecting liver and adjusting blood fat and method for preparing the same

InactiveCN1466990AHigh activityReduce cholesterolDigestive systemUnknown materialsCordycepsActive component

A health-care food for protecting liver and regulating blood fat is prepared through extracting active components from red sage root, peach kernel and gynostemma pentaphyllum in sub-boiling water, adding chitosan, flocculating setting, filter, mixing with fermented cordyceps powder, spray drying, adding starch and dextrin, mixing, granulating, drying, tabletting and coating.

Owner:SHANGHAI MODERN CHINESE TRADITIONAL MEDICINE TECH DEV

Environment self-adaptation modularized intelligent building system suitable for field

InactiveCN104947795ATo achieve the purpose of dry and wet separationHigh tensile strengthRoof covering using slabs/sheetsRoof improvementIntelligent lightingFiber

The invention discloses an environment self-adaptation modularized intelligent building system suitable for the field. The environment self-adaptation modularized intelligent building system comprises a modularized-assembled building body structure, an assembled house unit bathroom, an assembled house integrated kitchen, an assembled house carbon fiber electric heating floor heating plate, a solar photovoltaic power generation system, a wind power generation system, a wind-solar complementary power system, a roof rainwater collecting system, an FRP digestion tank, a soilless cultivation sunshine vegetable greenhouse, a cooling water curtain and the like, wherein the wind-solar complementary power system is composed of the solar photovoltaic power generation system and the wind power generation system. Solar photovoltaic power generation can be achieved through the building system, energy of power generation can be used for cooling in summer and heating in winter, water resources of the nature can be recycled, and the modularized movable building system can reduce the environment pollution and material waste and can also reduce power supply cost and the like.

Owner:镇江绿材谷新材料科技有限公司

Health food capable of increasing bone density and delaying senility and its production process

InactiveCN1416728AEnsure reliabilityGuarantee stabilityAntinoxious agentsSkeletal disorderIncreased Bone DensityIsoflavones

The health food capable of increasing bone density and delaying senility consists of the effective components of soybean, epimedium, astragalus root, angelica and mulberry as well as supplementary material including calcium gluconate, carboxymethyl starch sodium and avicel. The preparation process of the health food includes supercritical CO2 extraction to obtain angelica oil; ethanol extraction to obtain soybean isoflavone; water extraction of epimedium, astragalus root, mulberry and angelica after extracting oil, spray drying and other steps to prepare powder; mixing soybean isoflavone and the powder as well as calcium gluconate, carboxymethyl starch sodium and avicel; pelletizing, tableting and coating to obtain the health food product.

Owner:SHANGHAI MODERN CHINESE TRADITIONAL MEDICINE TECH DEV

Titaniferous stainless steel electroslag remelting casting powder

The invention discloses titaniferous stainless steel electroslag remelting casting powder which is prepared from the raw materials in parts by weight as follows: 46.0-50.0 parts of fluorite, 20.0-24.0 parts of alumina powder, 18.5-22.5 parts of lime, 3.5-5.5 parts of fused magnesite, 2.0-4.0 parts of titanium dioxide as well as other components: 0.0-0.6 part of SiO2, 18.0-22.0 parts of CaO, 20.0-24.0 parts of Al2O3, 4.2-5.8 parts of MgO, 2.0-4.0 parts of TiO2, 45.0-51.0 parts of CaF2, less than 0.03 part of S and less than 0.03 part of C. Slag is formed by the casting powder according to strict quality control standard so as to ensure that the impurity content is low, the purity is high and the slag is dry and free from moisture. In the electroslag remelting process, desulfuration and deoxygenation effects are enhanced, the resistivity is improved, and the casting powder is free from cutoff in arcing, good in lubrication and relatively easy to popularize and apply.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Preparation method of ultraviolet cured adhesive for flat panel display

The invention relates the method for preparation of ultra-violet light curing adhesive, which is made by main body rubber, reinforced rubber, deflocculating agent, organosilicon coupling agent, stabilizing agent and photo-initiation agent. The ultra-violet light curing adhesive comprises following characteristics: 1 not needing mix; 2 rapid curing at indoor temperature, and controlling the curing speed; 3 suiting for supermatic flow operation; 4 excellent moisture-proof, low and high temperature impact property resistance, and long life; 5 100% solid coating, no environmental contamination. The UV curing adhesive possesses the advantages of short curing adhesive, strong adhesive force, heat resistance and moisture-proof, so it is used in LCD rim.

Owner:XIAN RUILIAN NEW MATERIAL CO LTD

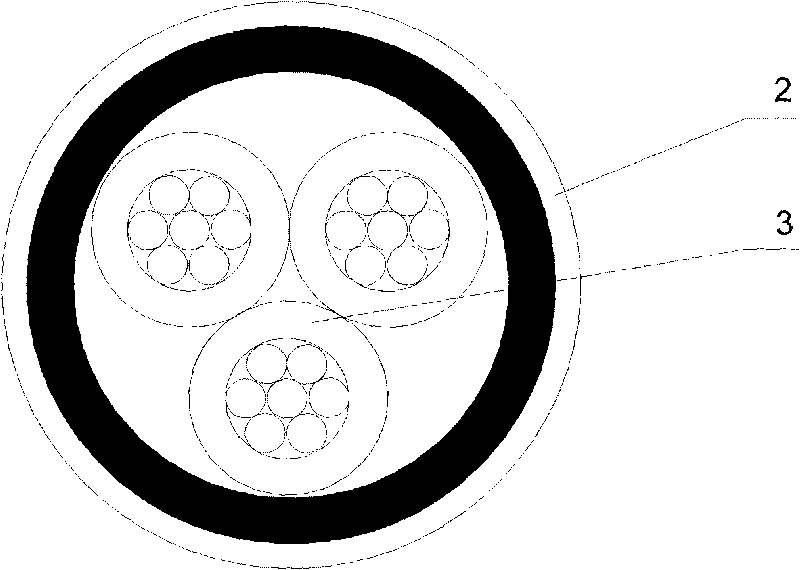

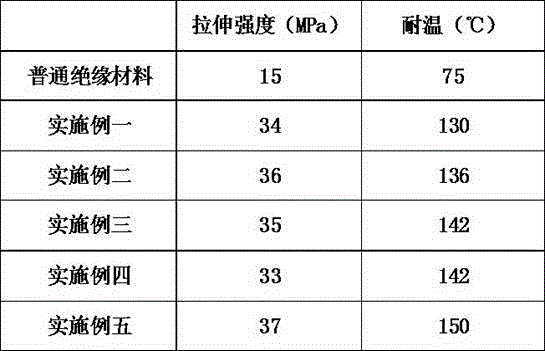

High-heat-resistance insulating composite and preparation method thereof

The invention discloses high-heat-resistance insulating composite and a preparation method thereof. The insulating composite comprises according to parts by weight: 30-40 parts of epoxy resin, 10-20 parts of polytetrafluoroethylene, 10-20 parts of polypropylene enhanced fiber 4-10 parts of silica powder, 10-25 parts of nano zinc oxide, 10-15 parts of nano calcium carbonate, 3-8 parts of silane coupling agent, 10-20 parts of nano aluminum oxide, 5-10 parts of dibenzoyl peroxide, and 7-12 parts of a plasticizer. The insulating composite is simple to manufacture, a manufacturing process is environment-friendly and pollution-free, the manufactured insulating composite is anticorrosive, damp-proof and high-temperature-resistant and flame-retardant, has good mechanical and electrical properties and is suitable for the preparation of power cables.

Owner:HENAN YAAN ELECTRICAL INSULATION MATERIAL PLANT CO LTD

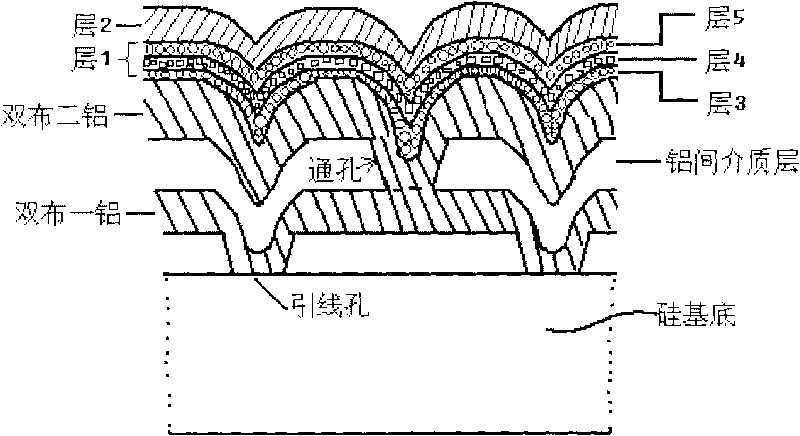

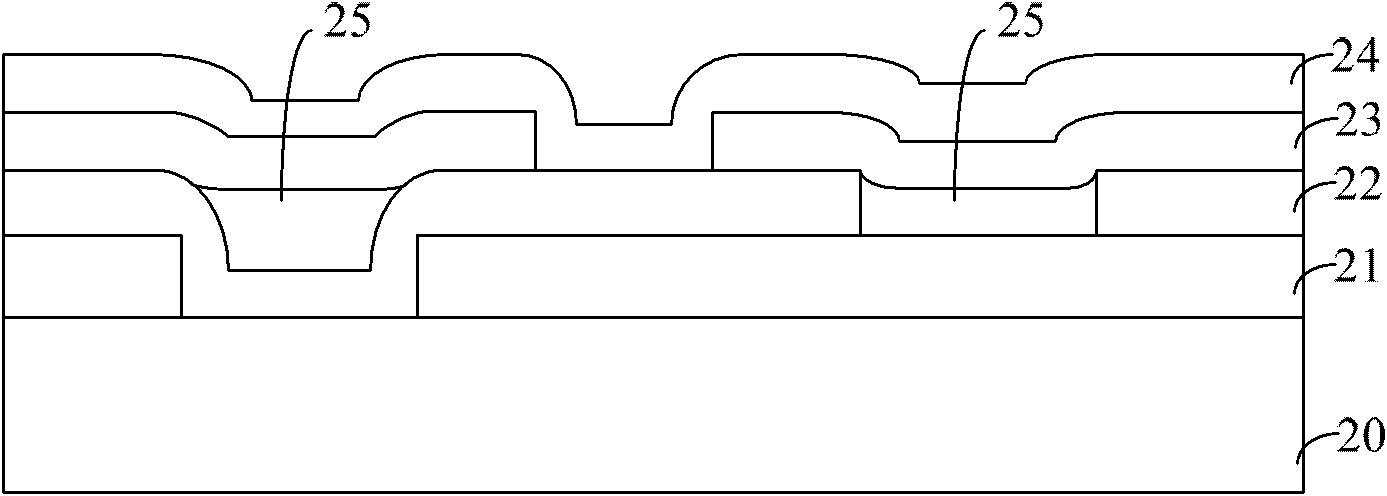

Multi-layer compound passivation layer structure of Bipolar circuit and manufacturing process thereof

InactiveCN101710580AReduce stressImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesHigh densitySilicon oxide

The invention provides a multi-layer compound passivation film structure of a Bipolar circuit, which comprises a bottom silicon oxide film layer and a silicon nitride film layer, wherein the silicon oxide film layer is deposited on the surface of a silicon substrate, and the silicon nitride film layer is deposited on the silicon oxide film layer; a certain proportion of phosphine is doped in the silicon oxide film layer; and the silicon oxide film layer sequentially comprises an undoped silicon oxide layer, a doped phosphorosilicate glass layer and an undoped silicon oxide layer. Meanwhile, the invention also provides a manufacturing process of the multi-layer compound passivation film of the Bipolar circuit. The multi-layer compound passivation film structure of the Bipolar circuit has scratch resistance, moisture resistance, high density, low film stress, higher impurity absorbing ability, better step covering ability and excellent photoelectric properties, electrical characteristics and heat stability, reduces the soft breakdown, and solves the problems of poor reliability, and the like.

Owner:HANGZHOU SILAN INTEGRATED CIRCUIT

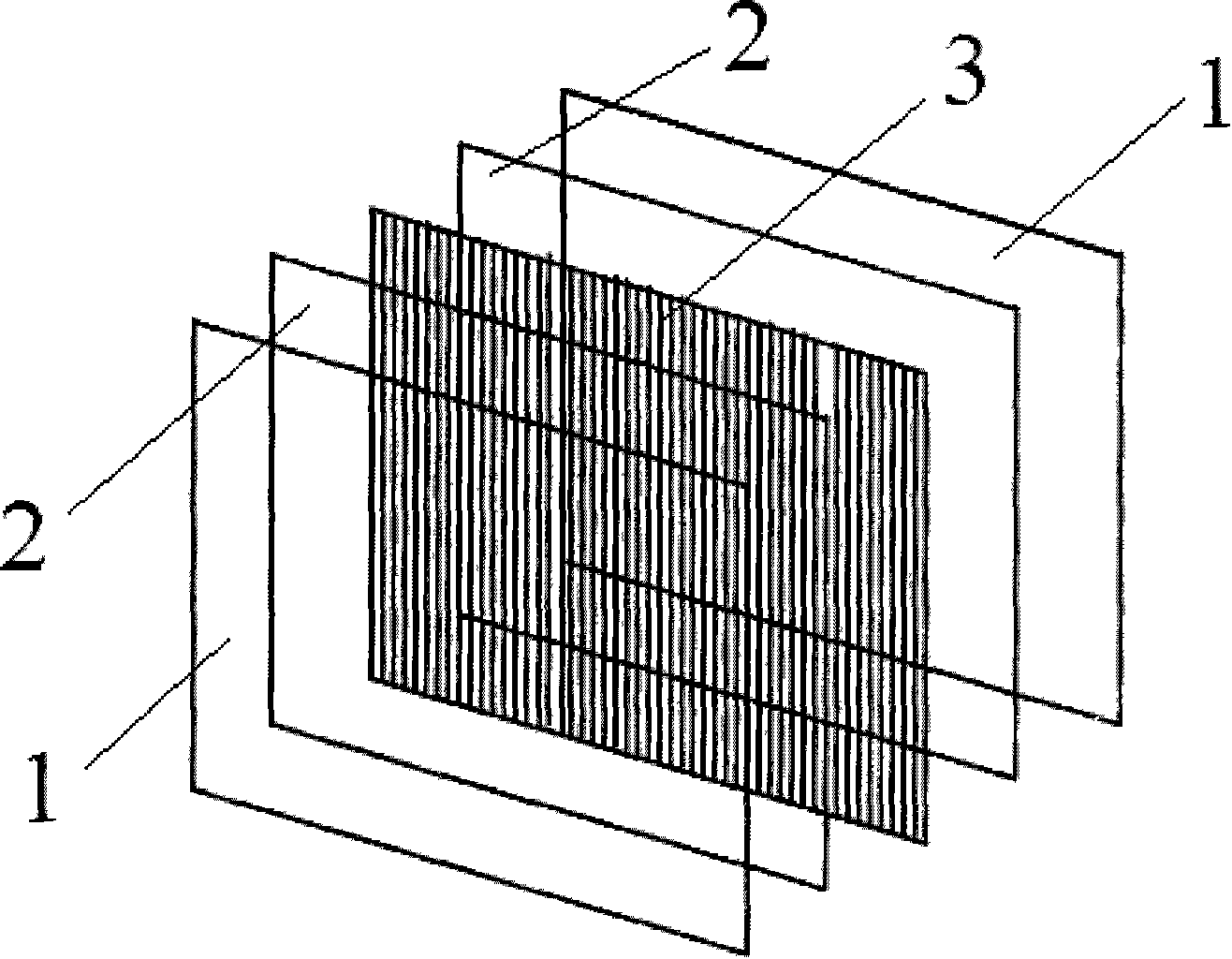

Solar photovoltaic curtain wall

InactiveCN101629435AHeat resistantCold-resistantWallsSemiconductor devicesHeat resistanceEngineering

The invention discloses a solar photovoltaic curtain wall, comprising an inner layer glass substrate, an outer layer glass substrate, a photovoltaic interlayer between the inner layer glass substrate and the outer layer glass substrate. PVB sealing adhesive films are respectively arranged between the photovoltaic interlayer and the inner layer glass substrate as well as the outer layer glass substrate. The solar photovoltaic curtain wall has the characteristics of heat resistance, cold resistance and wetness resistance, increases the mechanical property of a curtain wall glass, and prolongs service life; and the transparent PVB adhesive films are also good for the beauty of the curtain wall glass and the buildings.

Owner:BEIJING TIME VALIANT TECH DEV

Phenolic aldehyde modified amine curing agent and preparation method thereof

InactiveCN103113544AResilientWater resistantEpoxy resin adhesivesHexamethylenediamineMannich reaction

The invention discloses a phenolic aldehyde modified amine curing agent which is prepared by polycondensing mixed phenol, polyformaldehyde and mixed amine through Mannich reaction. The preparation method comprises the following steps: adding phenol, nonylphenol and m-cresol at 35-45 DEG C, and evenly mixing; sequentially adding hexamethylene diamine and triethylene tetramine, and adding polyformaldehyde for reaction in batches in the process of gradually heating to 70-80 DEG C; and after the addition of the polyformaldehyde is finished, further reacting at 70-80 DEG C to obtain the product after the reaction is finished. The curing agent can be directly cured in water, has certain toughness and is favorable in curing effect; an epoxy resin cured by the curing agent has high dry shear bonding strength and in-water cured shear bonding strength; and the preparation method of the curing agent is simple to operate and mild in reaction conditions, and industrial production can be realized.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Aqueous paint capable of generating chromatic pattern and preparation method thereof

The invention provides a water paint which can produce colorful patterns, and is made from color gel granules, protecting glue, and water. The constituents by weight proportions are 25-35 portions of gel granules, 45-55 portions of protecting glue; the rest is water. The constituents making up the color gel granules are 11-22 portions of pigment slurry, 45-70 portions of cellulose ether solution, 1-5 portions of film forming addition agent, and 0.5-1.5 portions of fungicides, and 1-7 portions of antifreeze. The preparing method includes 1, obtaining color gel granules, 2, obtaining protecting glue, and 3, obtaining the paint with color patterns. The invention has the advantages that the color gel granules is in a relatively stable state in the protecting glue; the paint can be sprayed on the surface of an object to form various separate three-dimensional color patterns, has excellent anti-aging performance, is innoxious and harmless, can replace wallpaper, can be sprayed on wooden furniture, metal, plastic and other objects, has excellent wear resistance and long service life.

Owner:LUOYANG DAYU IND

Technique for synthesizing air-dry type oxirene ester resin

This invention relates to a process for synthesizing air-drying epoxy vinyl ester resin. The process comprises: reacting bisphenol A type epoxy resins with low and high epoxy equivalent, and organic unsaturated monocarboxylic acid at 120-160 deg.C in the presence of catalyst and polymerization inhibitor, and then diluting with crosslinkable monomer. The resin has good air-drying performance, with surface drying time less than or equal to 0.5 h, and inner drying time less than or equal to 4 h. Besides, the resin has appropriate viscosity, good wettability with glass fibers and glass mats, good physical and mechanical performance, and good chemical corrosion resistance, and is suitable for various molding processes of fiber reinforced plastics such as manual pasting, coiling, drawing and spraying. The method has such advantages as simple process, low energy consumption, and stable product quality.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

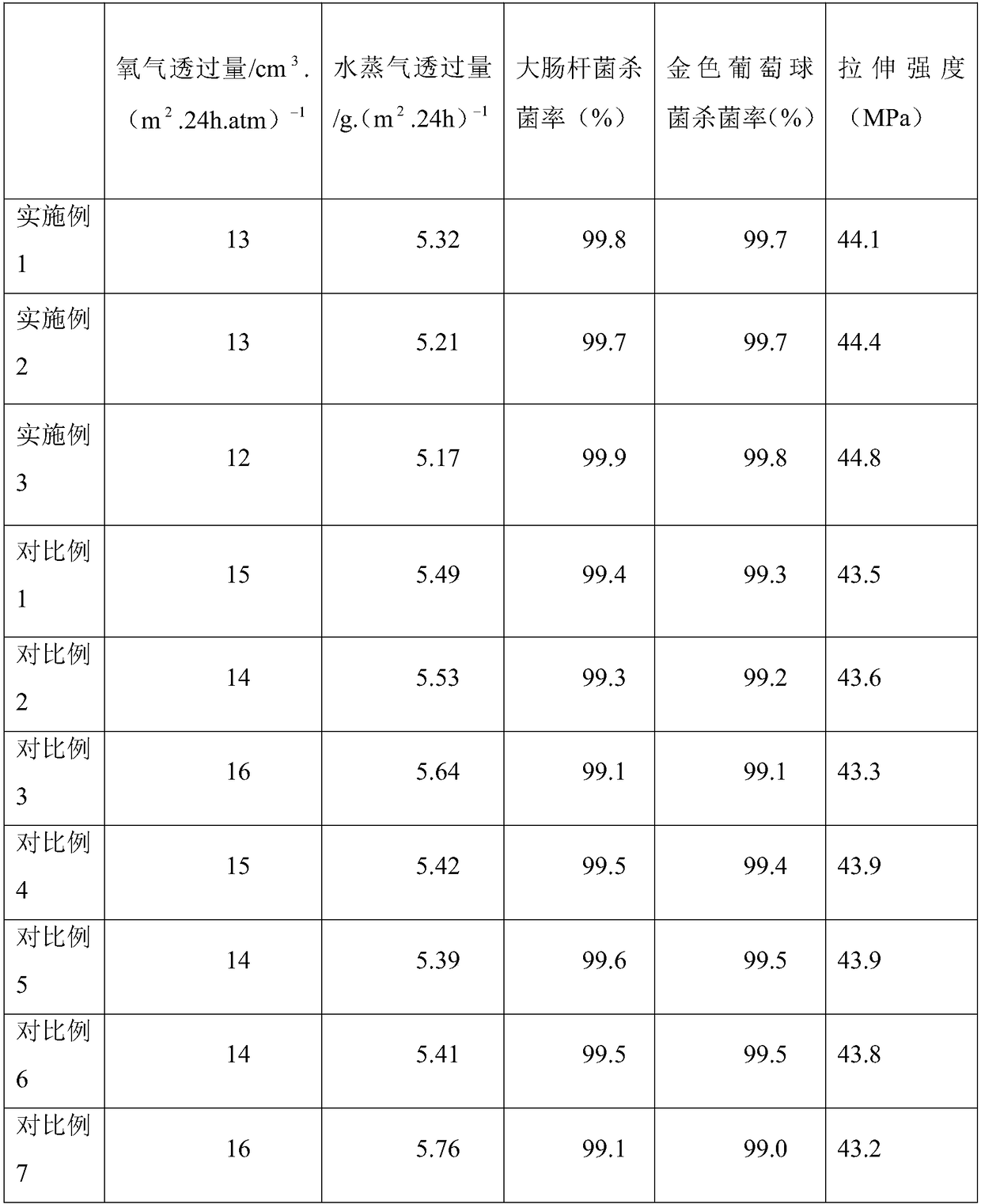

Antibacterial high barrier food wrapping film and preparation method thereof

The invention discloses antibacterial high barrier food wrapping film and a preparation method thereof. The film is prepared from ethylene vinyl alcohol copolymer, polyurethane, polyvinyl acetal, a compound silicate mineral additive and a silane coupling agent KH-550. The antibacterial high barrier food wrapping film takes the ethylene vinyl alcohol copolymer, the polyurethane, the polyvinyl acetal and the compound silicate mineral additive as materials of the wrapping film, based on the ethylene vinyl alcohol copolymer, the polyurethane, the polyvinyl acetal, the compound silicate mineral additive and other materials are added, the blending technology is adopted, and the wrapping film is obtained through an extrusion mechanism, so that the antibacterial performance, barrier performance and other performance of the wrapping film are greatly improved.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Method for processing polyurethane mold surface through Teflon coating

The invention discloses a method for processing a polyurethane mold surface through a Teflon coating. The method comprises the steps that the polyurethane mold surface is degreased; sand blasting is carried out on the degreased polyurethane mold surface, and then the Teflon coating is sprayed on the polyurethane mold surface; the Teflon coating sprayed on the polyurethane mold surface is heated; 5, the Teflon coating is sprayed on the polyurethane mold surface for the second time on which melting processing is carried out; and 6, the Teflon coating on the polyurethane mold surface processed in the step 5 is molten. The Teflon coating has the advantages of inadhesion, heat resistance, sliding performance, moisture resistance, abrasion resistance and corrosion resistance. The polyurethane mold surface coated with the Teflon coating which can be used repeatedly after coating is performed one time. The trouble that coating of a mold release agent needs to be carried out every time molds are released is saved; the production process is simplified, production efficiency is improved, production cost is reduced, and no harm is produced to the human body and environment.

Owner:ZHEJIANG ZHENYANG COLD INSULATION TECH CO LTD

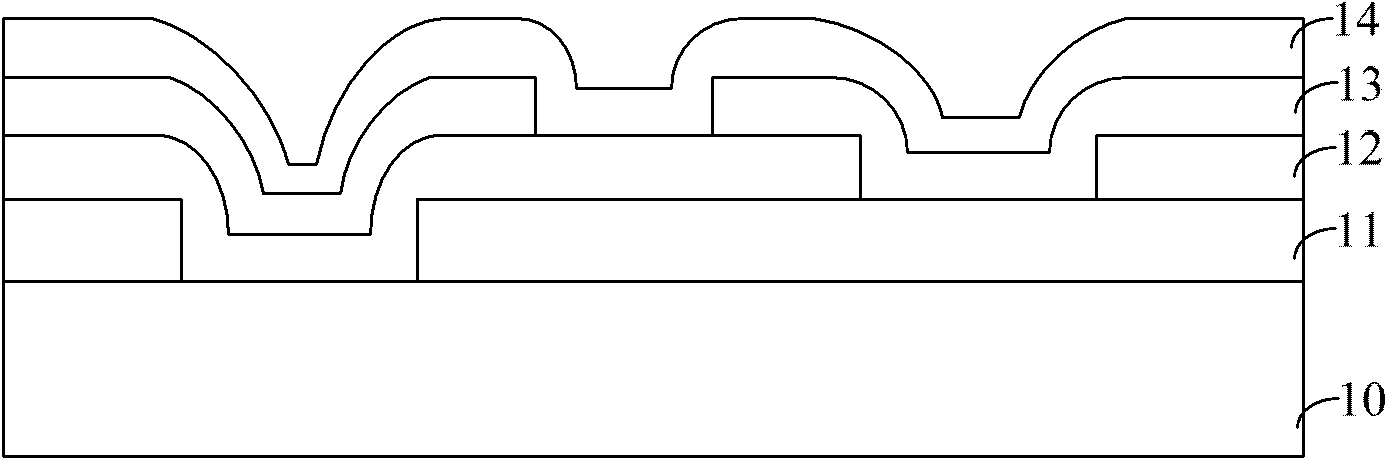

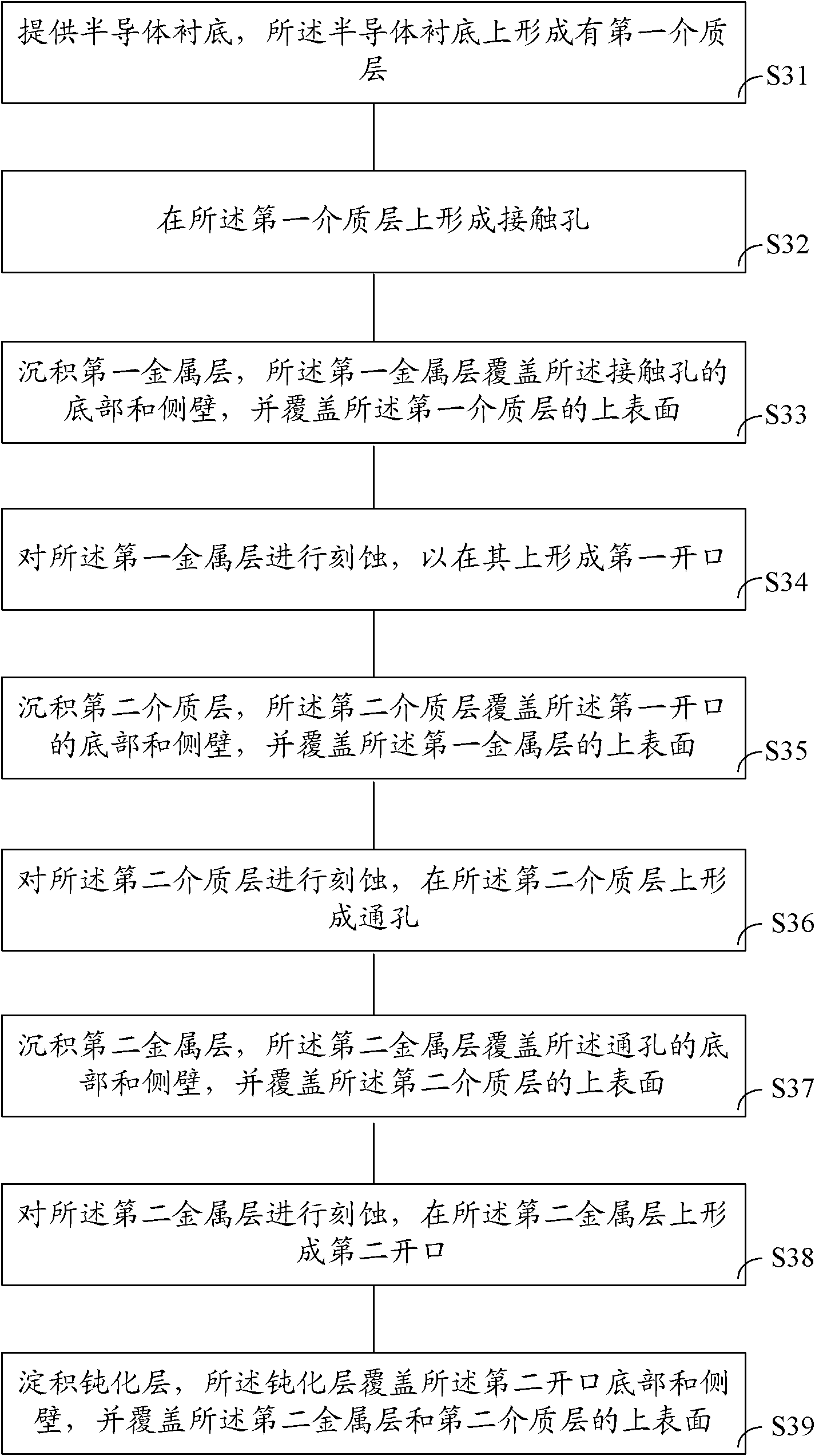

Wiring structure forming method

InactiveCN102354684AImprove the shape of the stepsPromote formationSemiconductor/solid-state device manufacturingEngineeringMedia layer

The invention provides a wiring structure forming method which comprises the following steps of: providing a semiconductor substrate, and forming a first medium layer thereon; forming a contact hole on the first medium layer; depositing a first metal layer, covering the bottom and side wall of the contact hole and covering the upper surface of the first medium layer; etching the first metal layer with a wet method, and etching with a dry method to form a bowl-mouth first opening; depositing a second medium layer, covering the bottom and side wall of the first opening and covering the upper surface of the first metal layer; etching the second medium layer to form an inverted trapezoidal through hole; depositing a second metal layer, covering the bottom and side wall of the through hole and covering the upper surface of the second medium layer; and etching the second metal layer with a wet method, and etching with a dry method to form a bowl-mouth second opening. Through the invention, the requirement on planarization of a process platform of near or below 1.5 microns is met without adopting SOG planarization, glue back-etching SOG planarization and the like.

Owner:HANGZHOU SILAN INTEGRATED CIRCUIT

Composite fire-proof paint

InactiveCN1621463AHigh mechanical strengthStrong adhesionFireproof paintsPolymer scienceWater soluble

The present invention is one kind of water soluble fireproof composite inorganic / organic polymer filming paint. The present invention has excellent fireproof performance, can bear the effect of flame, and has fireproof foamed layer with high heat isolating performance, high mechanical strength, less chap and falling out, good decoration property, low cost and other advantages.

Owner:长春百乐施建筑装饰设计院

Preparation method of heat preservation and insulation high polymer material

The invention belongs to the field of preparation and modification of natural high polymer materials, and aims to solve the technical problems of high cost, poor heat resistance, flammability and toxic fume generation in case of combustion in the prior art. The invention provides a preparation method of a heat preservation and insulation high polymer material. The method comprises the following steps: A, pulverizing plant biomass waste; B, activating the plant biomass waste; C, obtaining surface grafting modified plant biomass waste powder; D, granulating to obtain modified plant biomass waste dry powder; and E, uniformly mixing the modified plant biomass waste dry powder, polyvinyl chloride, processing aids and fillers according to a certain mass ratio to obtain the heat preservation and insulation high polymer material. A heat preservation and insulation material product prepared by using the heat preservation and insulation high polymer material as a raw material has the advantages of hard texture, light weight, favorable heat preservation effect, environment friendliness and the like.

Owner:四川梅塞尔科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com