Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

221results about How to "With stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant synthetic paper

Owner:CHANGZHOU JINKA CARD BASE SHEET

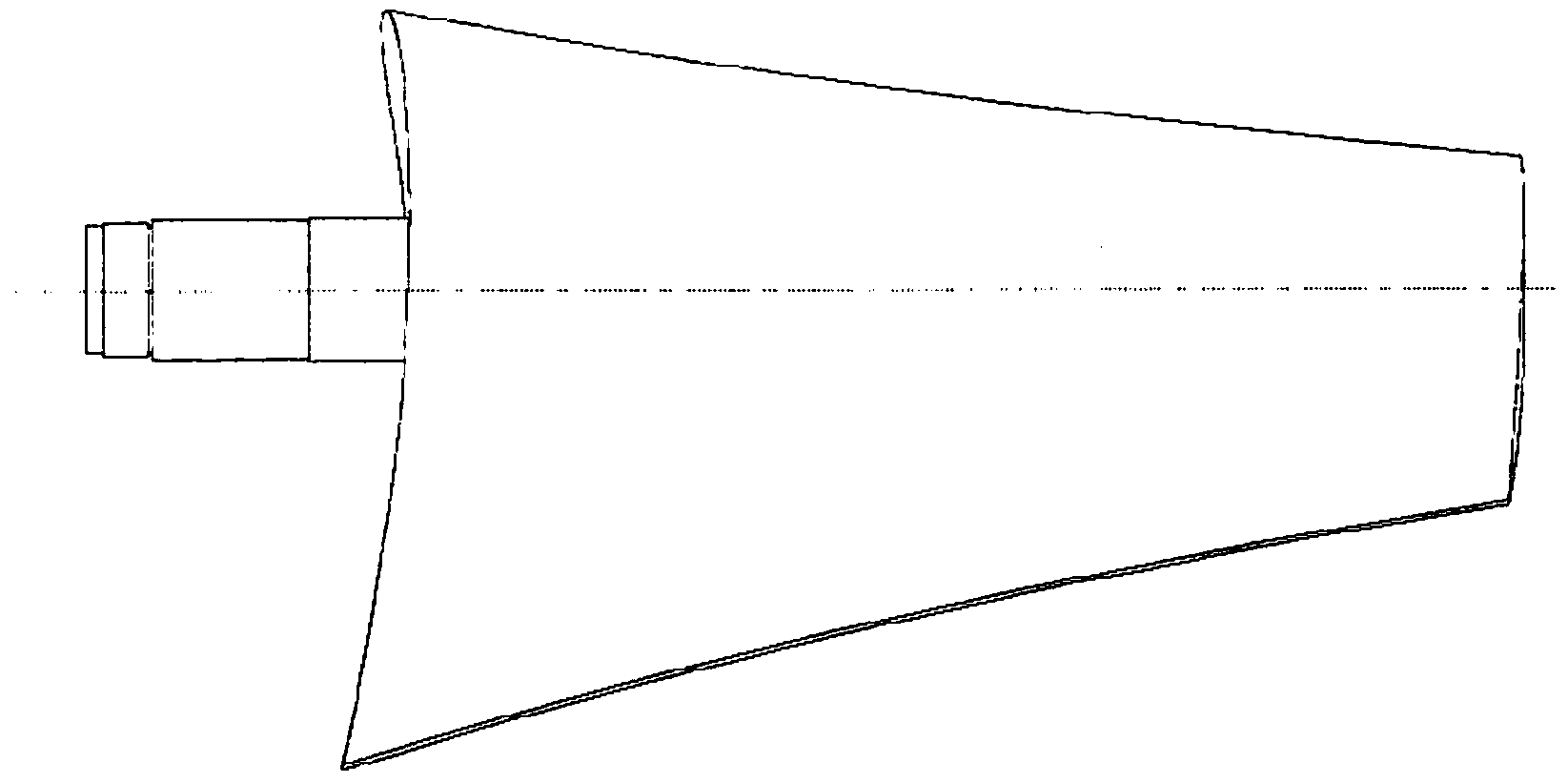

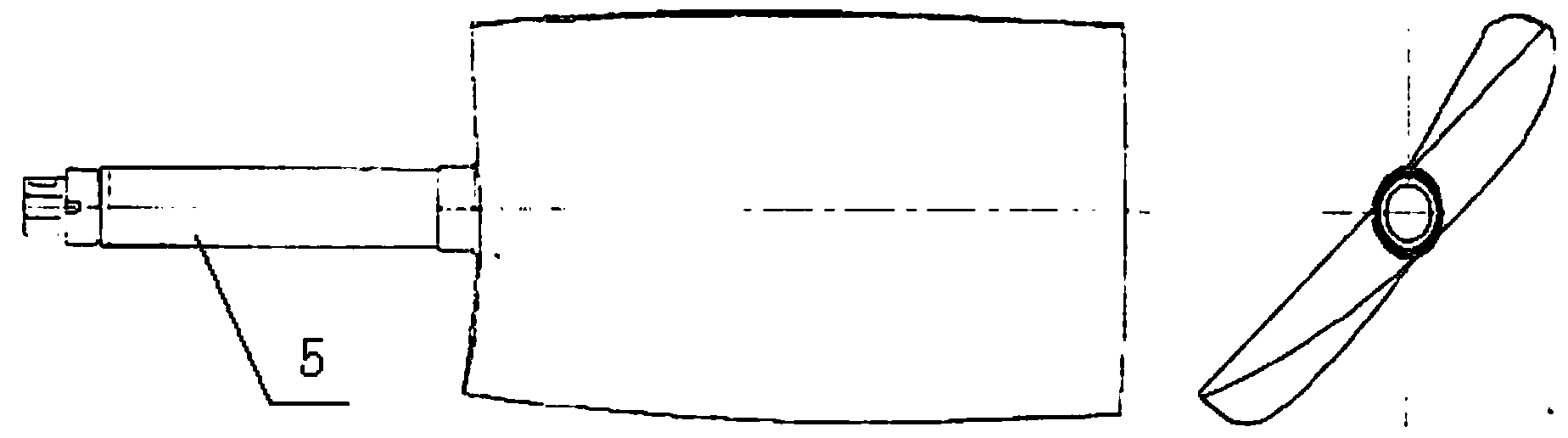

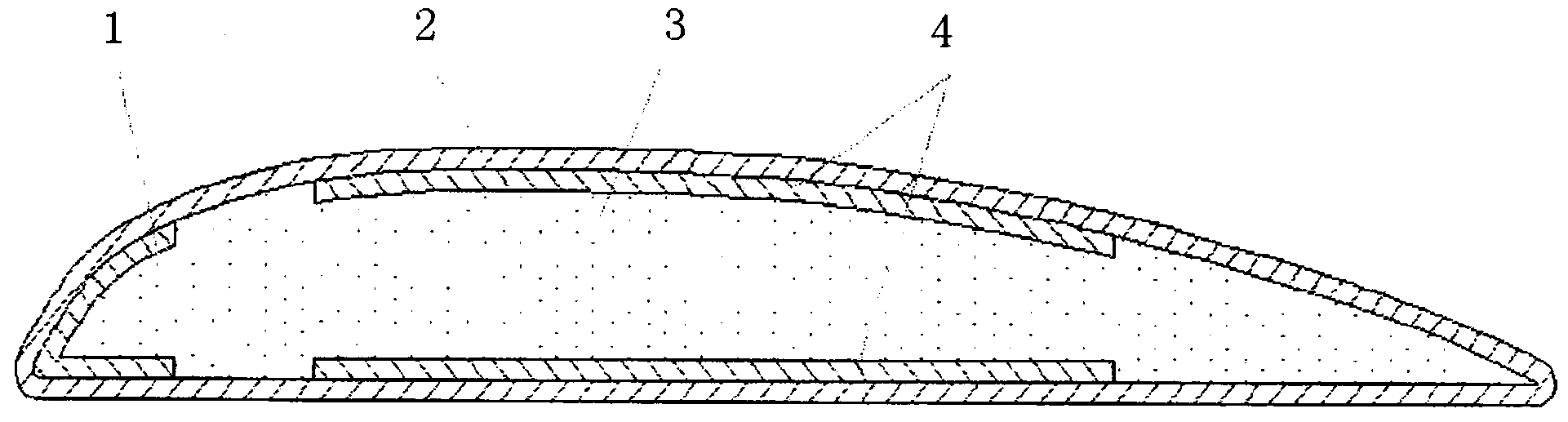

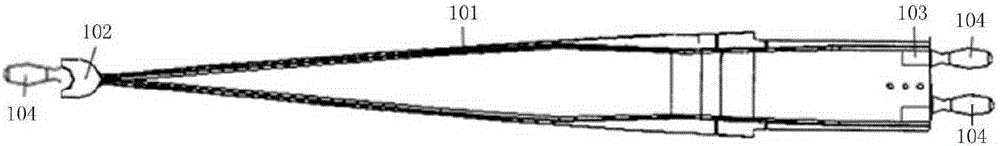

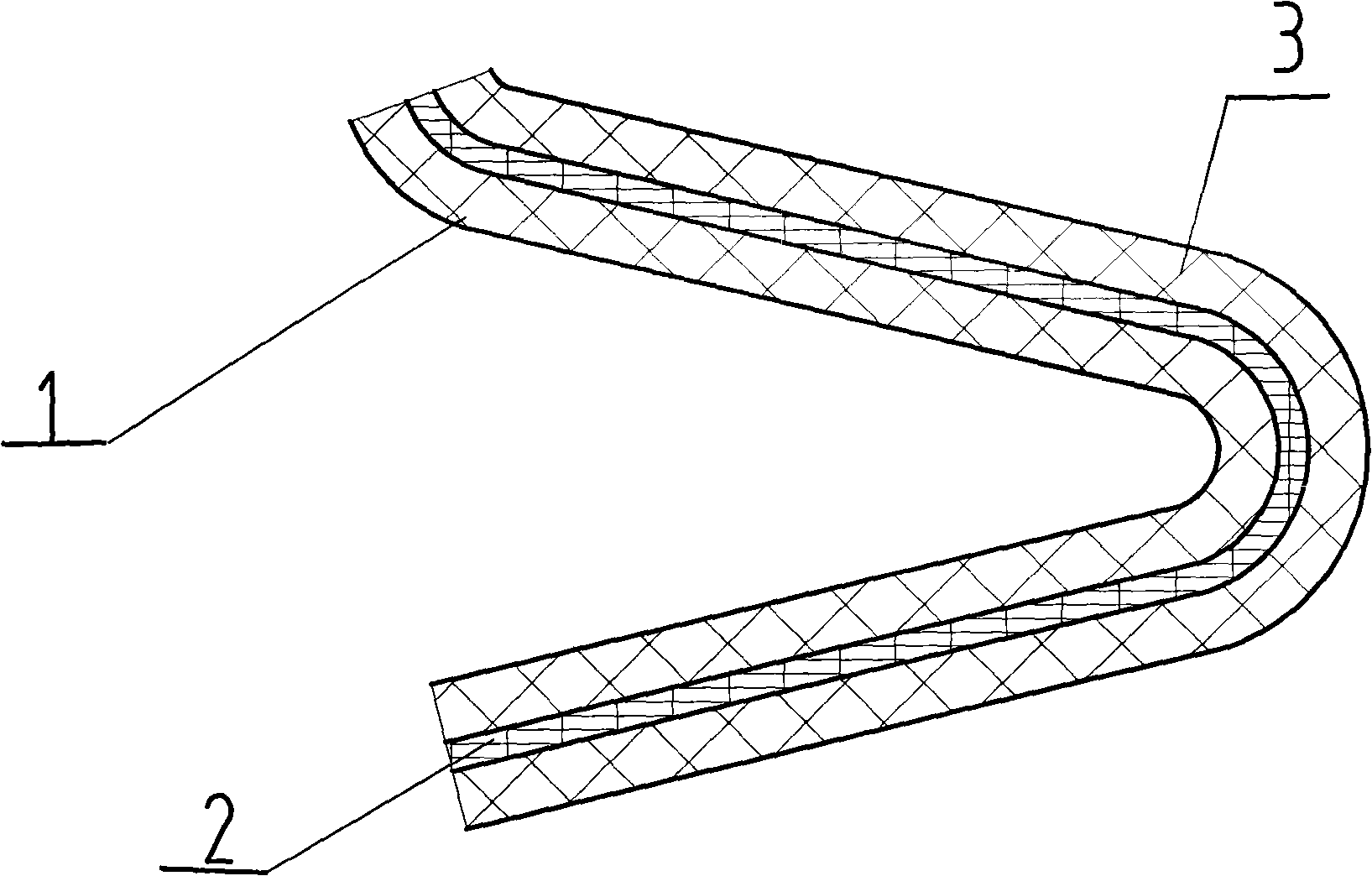

Carbon fiber composite foam core sandwich structure wind tunnel fan blade and molding method

ActiveCN104358708AEasy to controlGuarantee molding qualityPump componentsPumpsInterior spaceHigh humidity

The invention provides a carbon fiber composite foam core sandwich structure wind tunnel fan blade. The wind tunnel fan blade is characterized in that a skin is arranged at the outer part; the internal front end of the skin is connected to a front edge reinforcing area; the internal middle part of the skin is connected with a main bearing beam; an internal space defined by the skin, the front edge reinforcing area and the main bearing beam is filled with a foam core material; the skin comprises an inner skin and an outer skin; the outer skin is laid and adhered to the surface of the inner skin; the thickness of the main bearing beam is changed from 8-10 mm at the root part of the blade to 2-4 mm at the tip of the blade; the thickness of the front edge reinforcing area is 2-5 mm, the thickness of the inner skin is 2-5 mm, and the thickness of the outer skin is 1-3 mm. A molding method comprises the following steps: (a), pasting a blade handle with the foam core material; (b), feeding prepreg; (c), performing paving and glue suction compaction on the front edge reinforcing area and the main bearing beam; (d), performing paving and glue suction compaction on the inner skin; (e), solidifying; (f), molding the outer skin. According to the invention, the high-performance wind tunnel fan blade can be produced, and the use requirements under low-temperature, high-pressure, high-humidity and normal-temperature vacuum simulated climate environments can be met.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

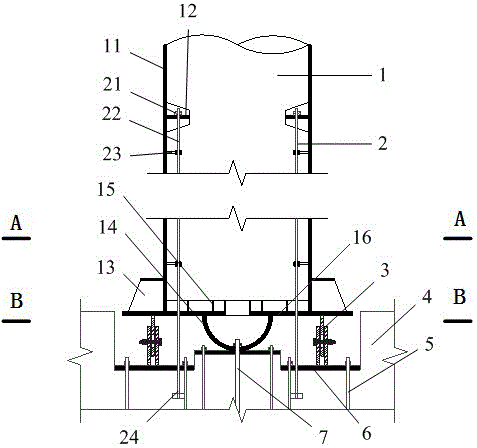

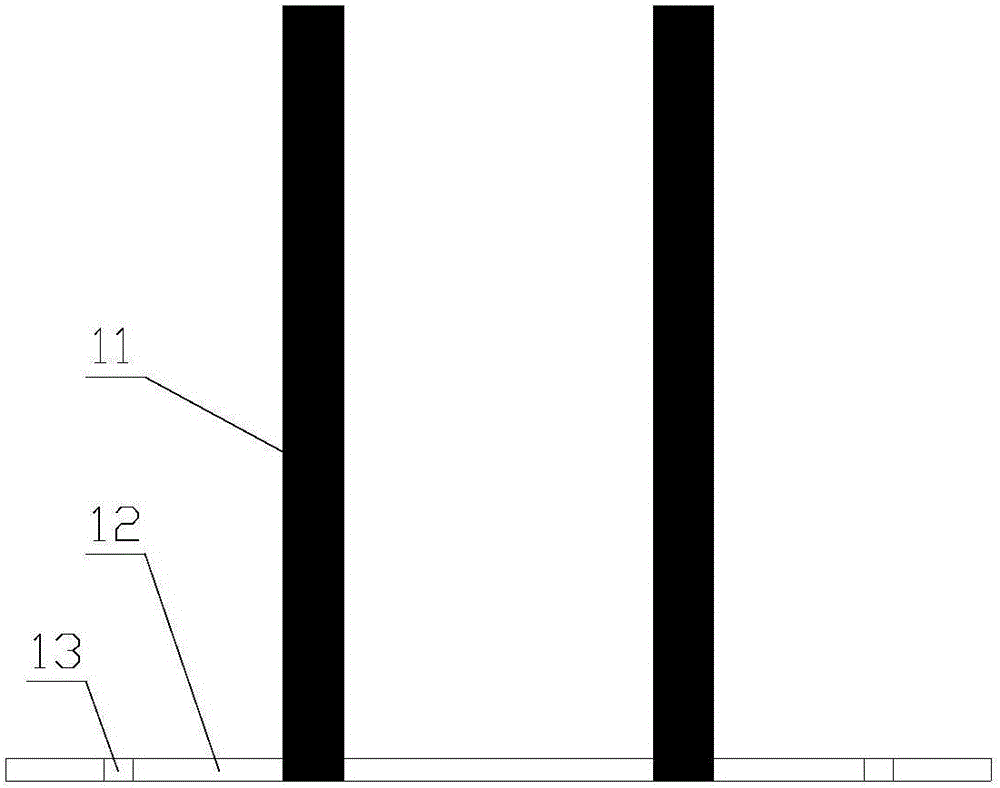

Swing self-reset and self-standing type high-rise structure

ActiveCN105672517AGood self-resetting performanceEasy maintenanceShock proofingPre stressEngineering

The invention relates to a swing self-reset and self-standing type high-rise structure.The structure mainly comprises an upper portion structure, stay rope systems, a friction damping device, a cast-in-place foundation, a common ground anchor, a pre-buried steel plate and a shearing-resisting ground anchor.The section of the upper portion structure is identical with the section of a common self-standing type high-rise structure while the stay rope systems are evenly distributed along the inner side of the cylinder wall of the upper portion structure, a swing hemisphere is arranged between the upper portion structure and the cast-in-place foundation, and meanwhile the friction damping device is installed at the proper position of the bottom plate.When the structure system bears a large dynamic load, the upper portion structure swings around the contact point of the swing hemisphere and the pre-buried steel plate, energy is dissipated through the friction damping device, shearing force is resisted through the shear-resisting ground anchor, and reset is achieved through prestresss stay ropes after vibration.The swing self-reset and self-standing type high-rise structure has the advantages that the steel using amount of the upper portion structure is small, the structure is simple, cost is low, automatic resetting can be achieved, and maintenance is convenient.

Owner:SUZHOU UNIV OF SCI & TECH

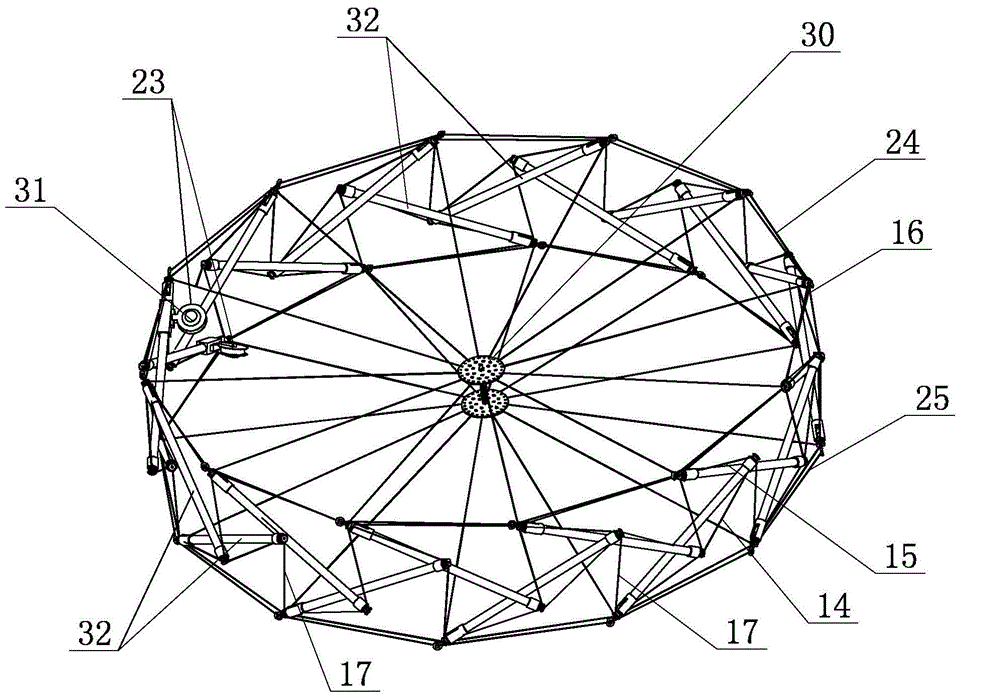

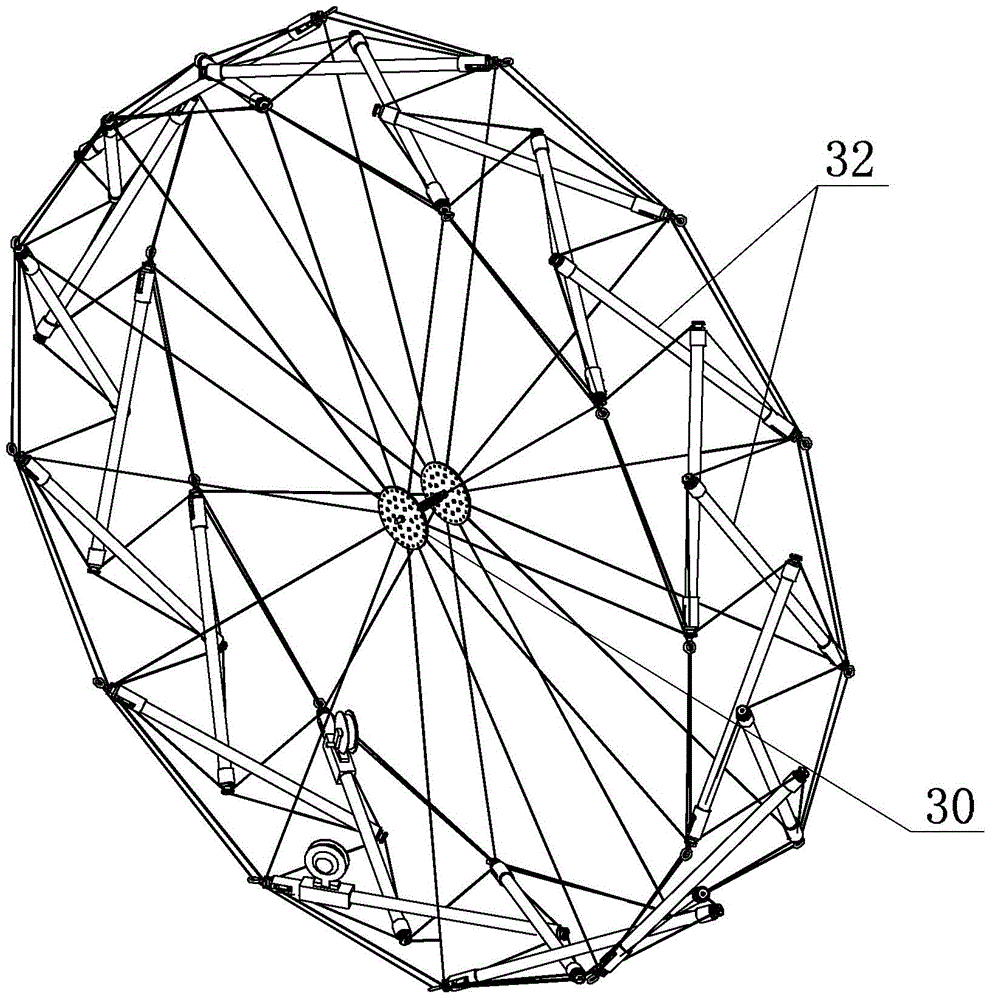

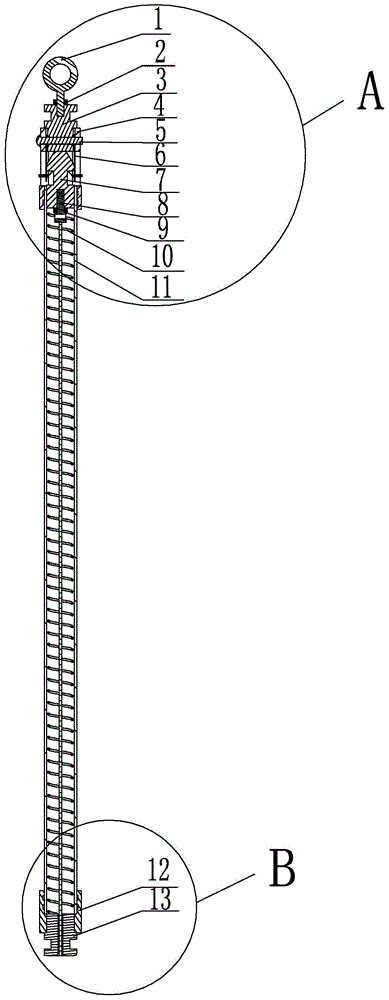

Spatially extendible annular tensioning integrated antenna mechanism

ActiveCN105071012ALight in massLightweight advantage is obviousCollapsable antennas meansFiberEngineering

The invention provides a spatially extendible annular tensioning integrated antenna mechanism, relates to antenna mechanisms, and solves the problems that a present extendible annular antenna needs lots of mechanical connection in the folding and unfolding process and further causes high total weight and low unfolding reliability. A main-end fixation member is fixedly connected with one end of a main-end connecting tube via a pin, the other end of the main-end connecting tube is fixedly connected with one end of a carbon fiber tube, two bar-shaped openings are formed in the sidewall of the main-end connecting tube along the length direction, two locking flat springs are arranged correspondingly at the positions of the bar-shaped openings, a drive spring is placed in the carbon fiber tube, an annular groove is formed in the middle portion of a guiding slide block circumferentially, when the antenna mechanism is unfolded, the lower portion of the locking flat springs are clamped in the annular groove of the guiding slide block, the lower end of the guiding slide block is connected with a slide block screw, the guiding slide block is placed at the upper end of the driving spring, an auxiliary-end fixation piece is fixedly connected with the other end of the carbon fiber tube via an auxiliary-end connecting piece, and the amount of tensioning integrated rods is an even number. The antenna mechanism is used in the field of wireless communication.

Owner:HARBIN INST OF TECH

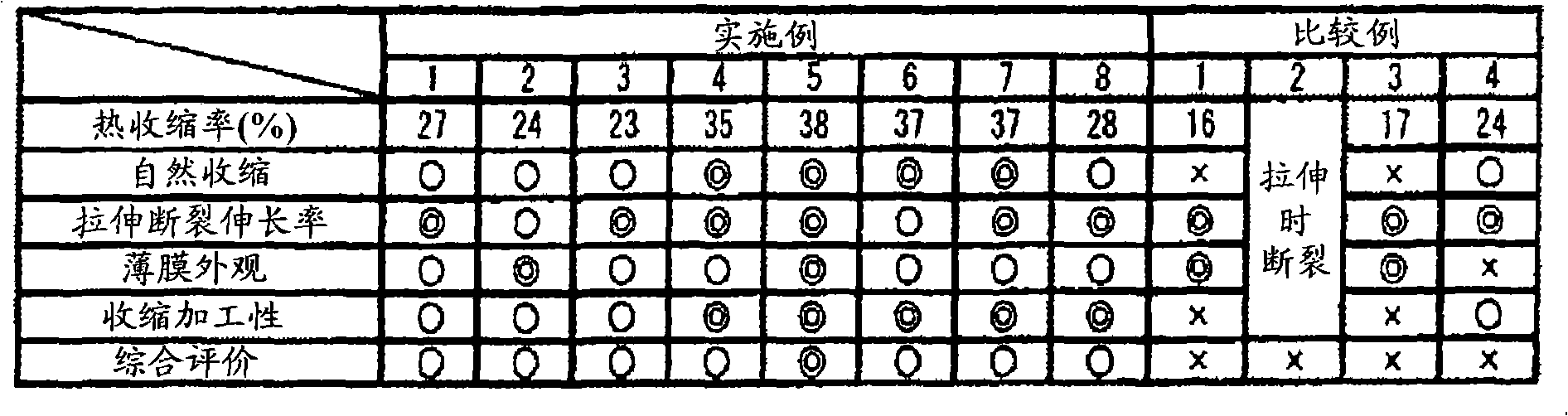

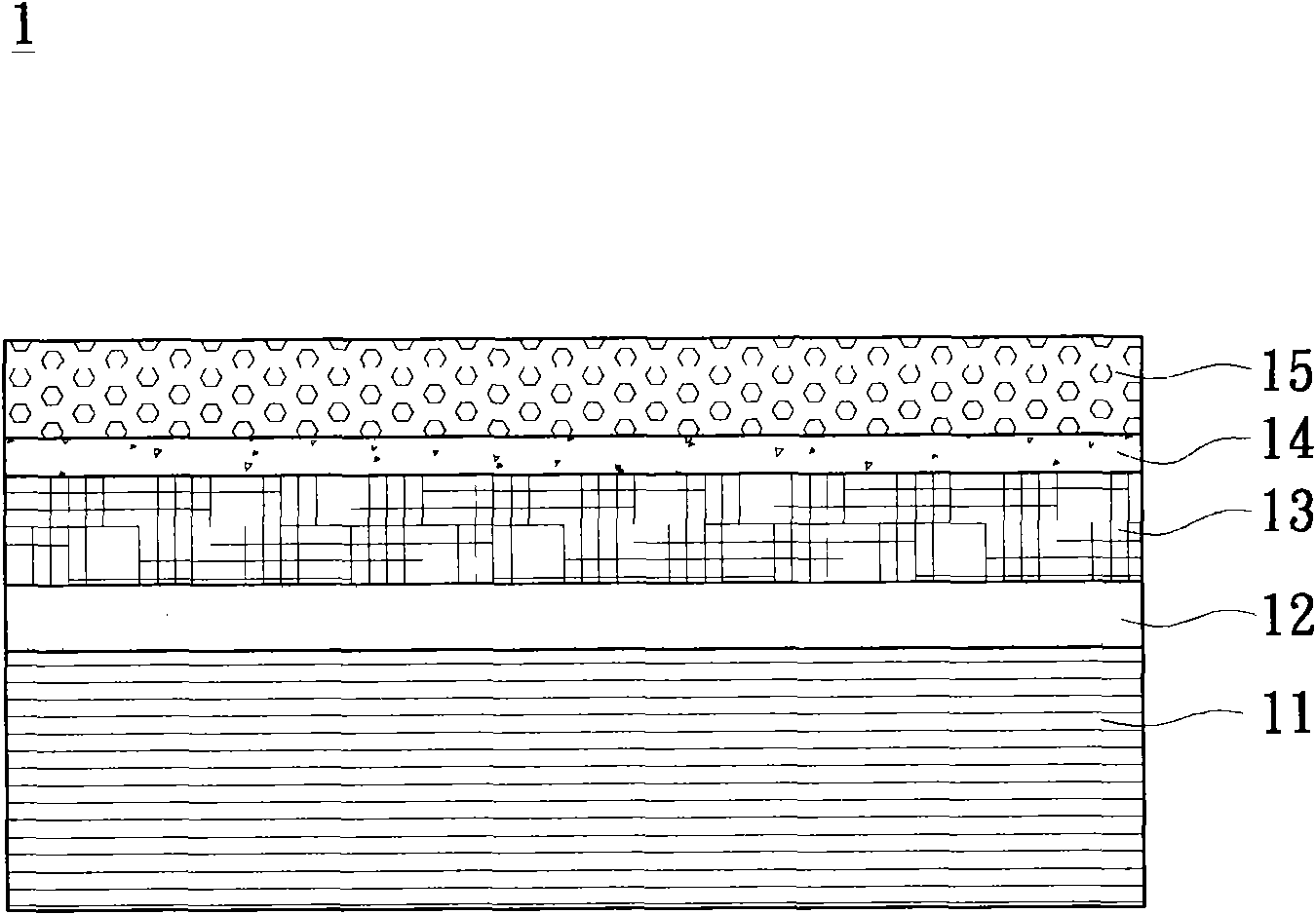

Thermally shrinkable polyolefin film, molded article using the film, thermally shrinkable label, and container

ActiveCN101316708AImprove featuresEasy to processStampsSynthetic resin layered productsPolyolefinPolyresin

Disclosed is a thermally shrinkable polyolefin film which comprises a mixed resin mainly composed of a polyolefin resin (A), a polylactic acid resin (B) and a resin (C) capable of improving the compatibility between the resin (A) and the resin (B) or has at least one layer comprising the mixed resin, wherein the ratio of the resin (A) to the resin (B) ((A) / (B)) is 99 / 1 to 70 / 30 by mass. The film has a thermal shrinkage ratio in at least one direction of 20% or higher as determined after immersing the film in hot water of 80 DEG C for 10 seconds, has a natural shrinkage ratio of less than 10% as determined after storing the film for 7 days under environment of 40 DEG C and 50% RH, is excellent in thermal shrinking properties and shrinkage finishing, and is reduced in natural shrinking. Also disclosed is a thermally shrinkable polyolefin label. Further disclosed is a container having the label thereon.

Owner:MITSUBISHI CHEM CORP

Manufacturing method of macrofiber porous metal material

The invention discloses a manufacturing method of a macrofiber porous metal material. The method comprises the following steps: firstly, metal macrofiber filaments are woven into a weaving body, the minimal feature size of the shape of the weaving body is 5 times larger than the maximum feature size of the cross sections of the metal macrofiber filaments, and when the cross sections of the metal macrofiber filaments are round, the minimal feature size of the shape of the weaving body is larger than 5 times of filament diameter; secondly, a metallurgical bonding process is performed on the weaving body, so as to enable the contact parts of the filaments to achieve metallurgical bonding and the non-contact parts of the wires to form pores, and the pores are distributed in the filament track direction; finally, the required macrofiber porous metal material can be manufactured and obtained. The macrofiber porous metal material manufactured by adopting the manufacturing method provided by the invention has continuous macrofiber, high wire mechanical property, high fatigue strength and anti-impact property, has the rigidity which is the same as that of a conventional volume material, and can be machined, as a common metal material, to be mechanical parts with bearing force and in constitutive structure shapes.

Owner:SOUTH CHINA UNIV OF TECH

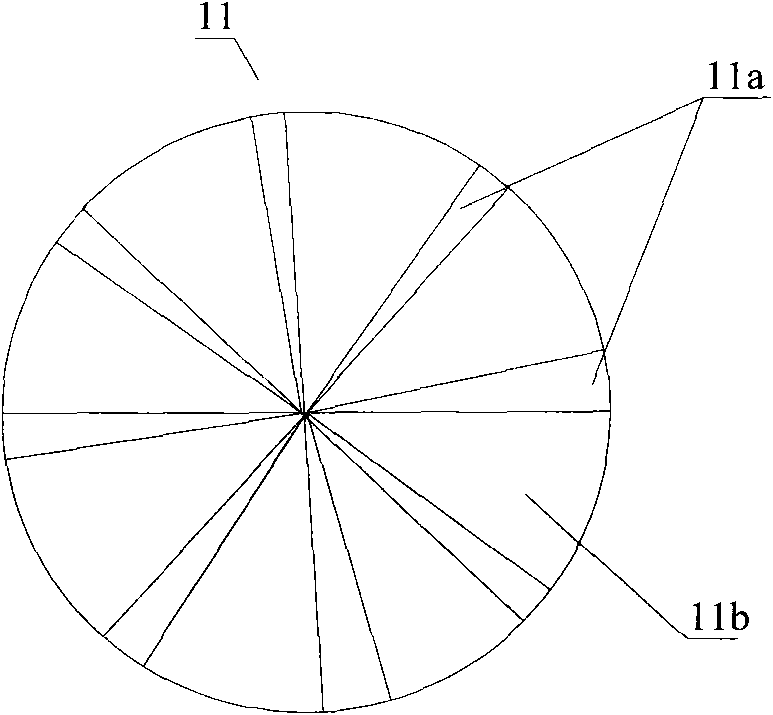

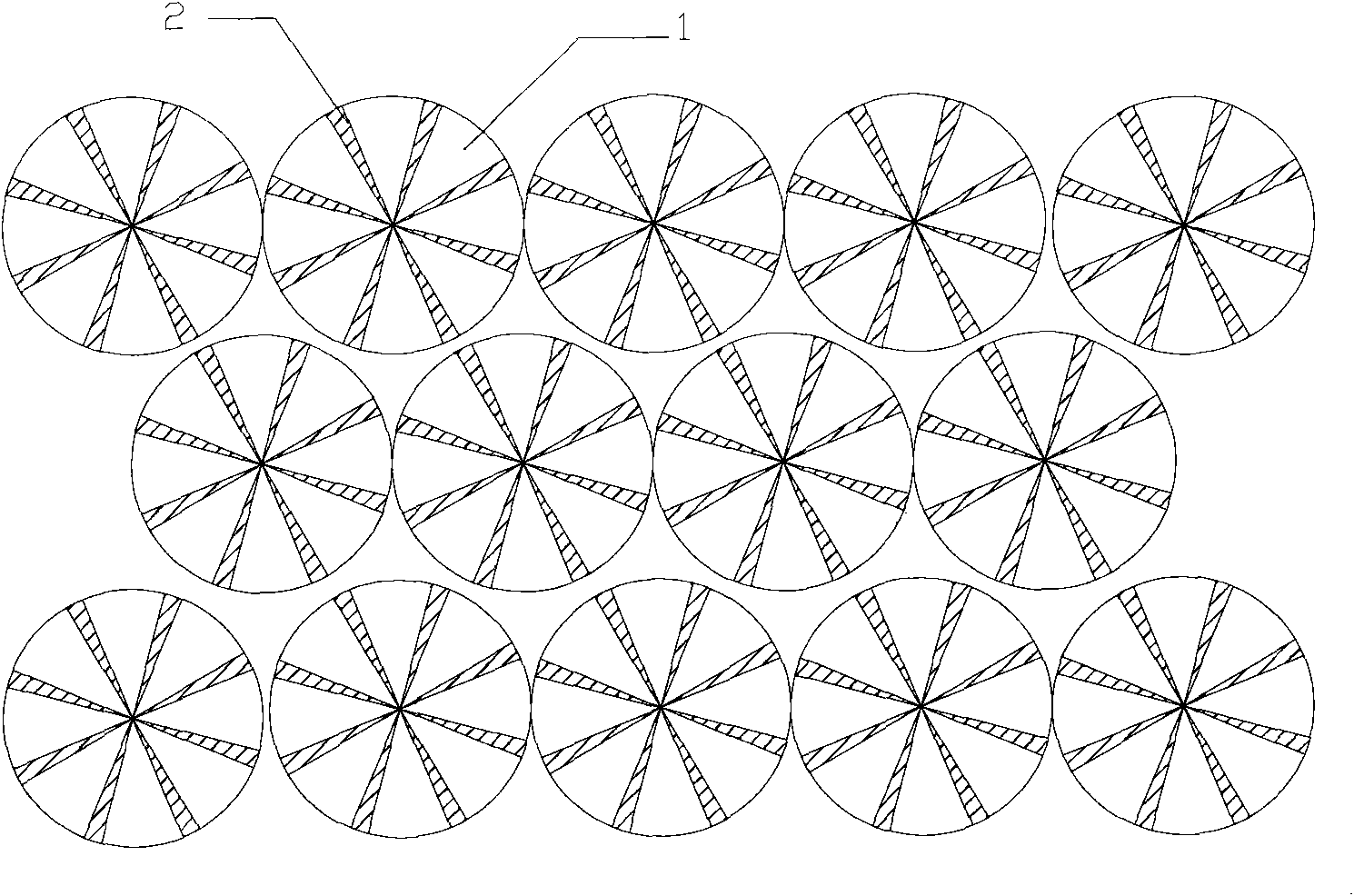

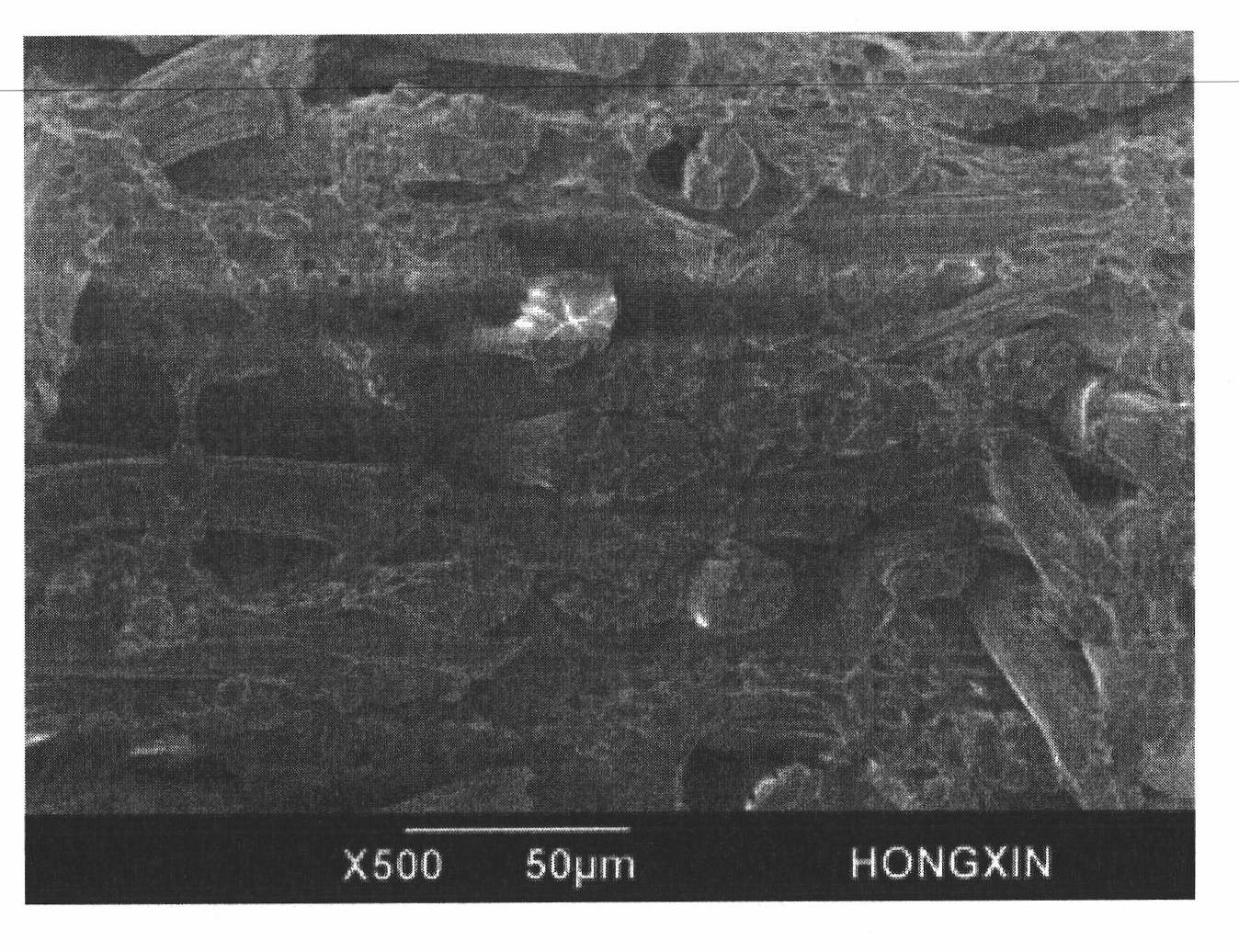

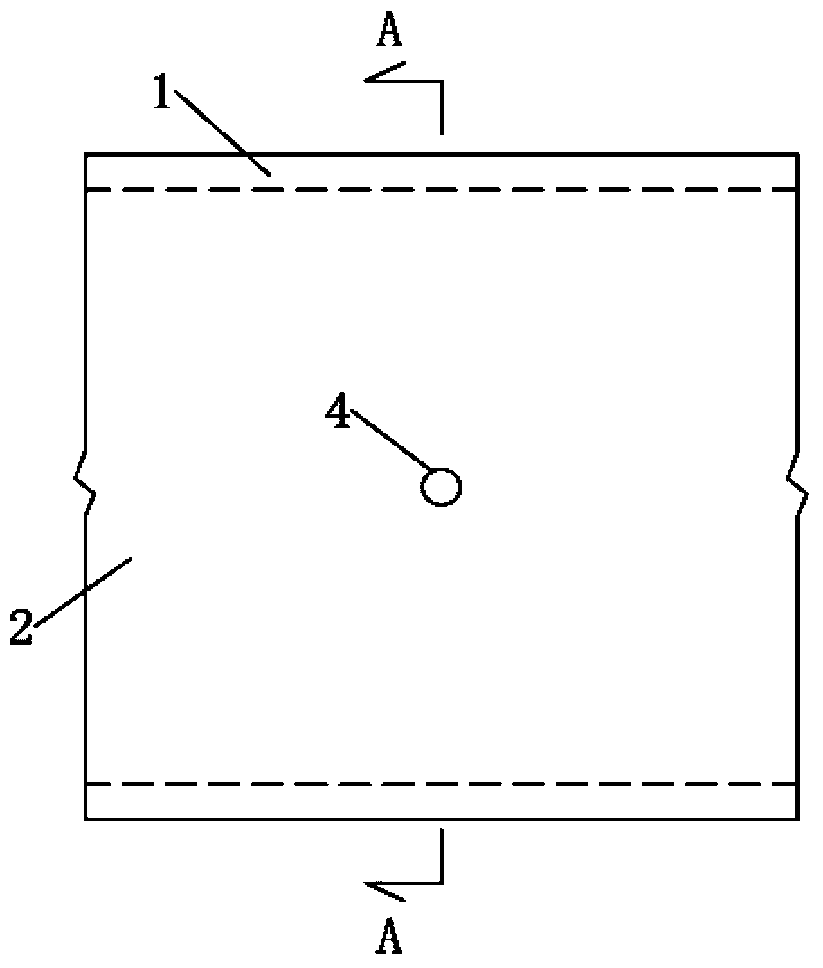

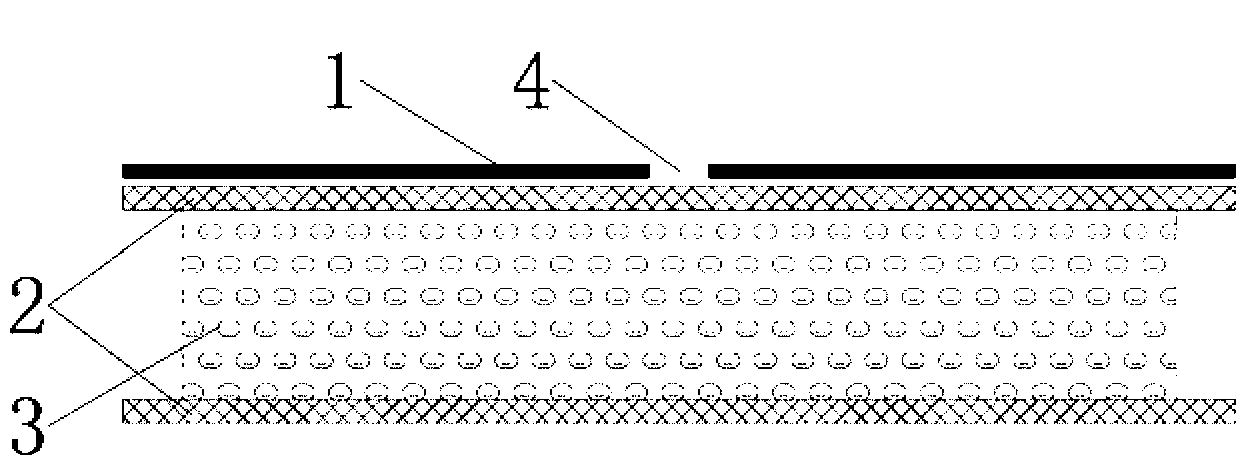

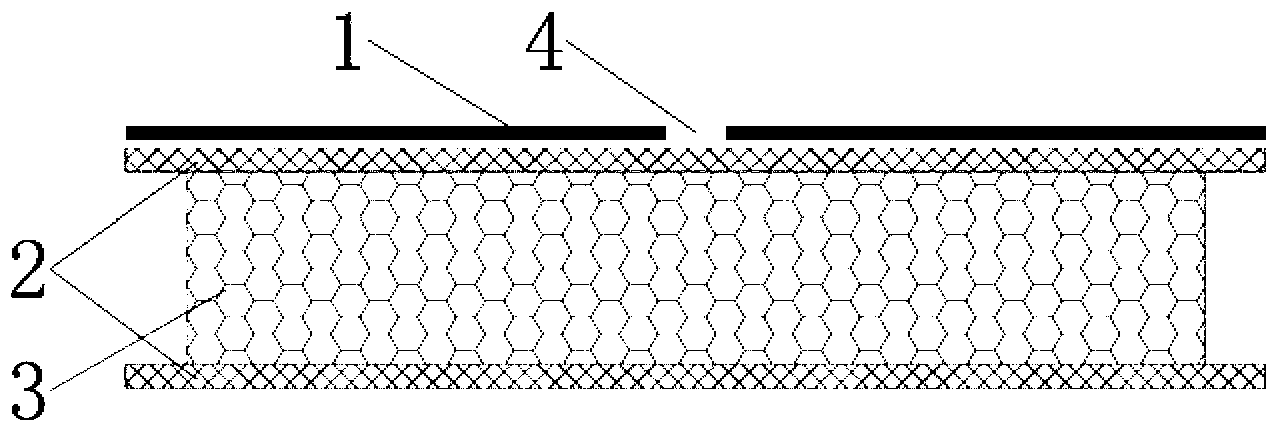

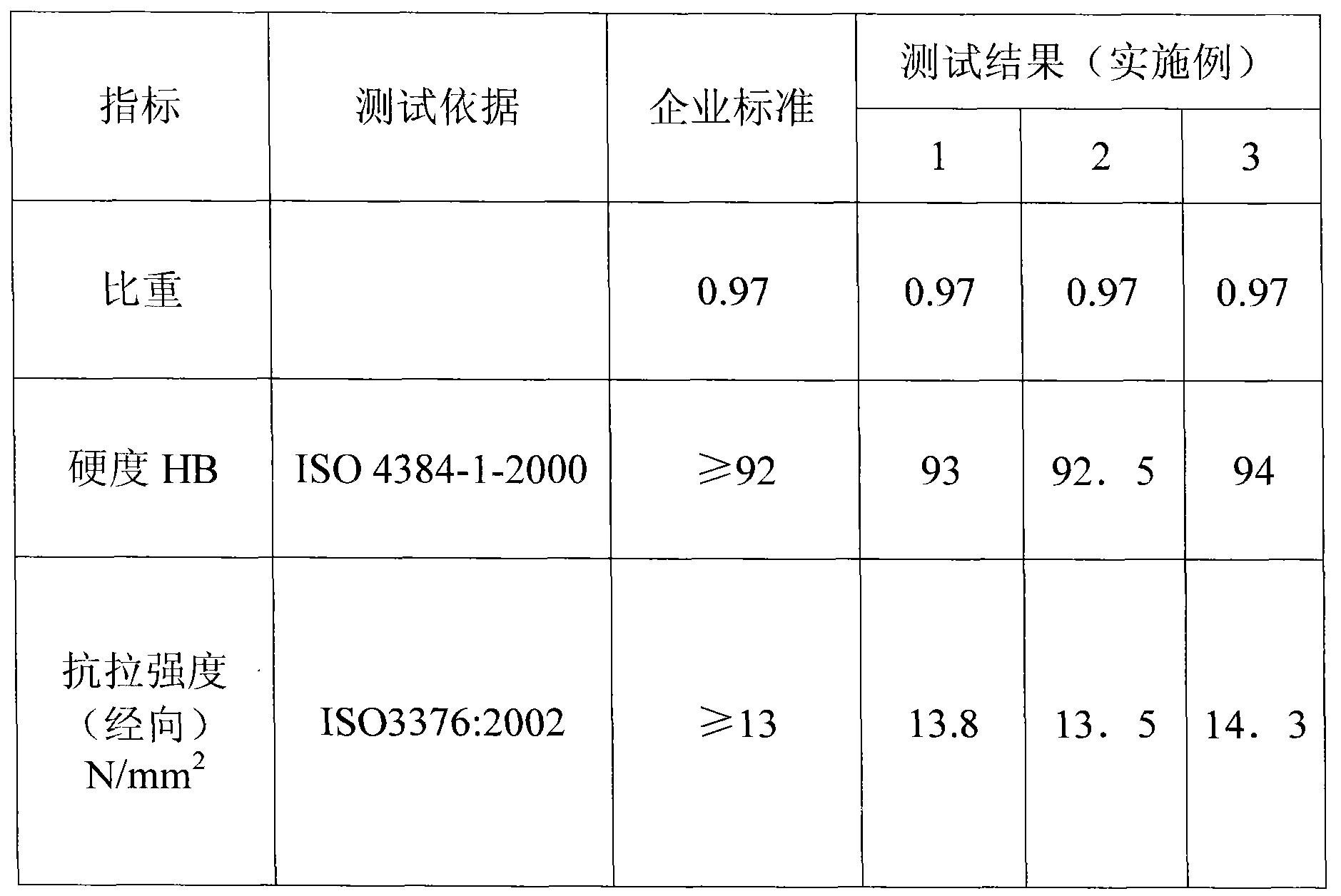

Superfine fiber polyurethane synthesis leather and preparation method thereof

InactiveCN101798763AWith stiffnessConsider softnessSynthetic resin layered productsFilament/thread formingPolyesterPolymer science

The invention provides superfine fiber polyurethane synthesis leather, comprising non-woven fabric and polyurethane dipped in the non-woven fabric. The non-woven fabric is prepared from double-component superfine fibers, and the double components in the double-component superfine fibers are polyamide superfine fibers and polyester superfine fibers. The double-component superfine fibers comprise framework fibers in radial arrangement and ceasma fibers filled among the framework fibers, and the double components respectively form the framework fibers and the ceasma fibers. The superfine fiber polyurethane synthesis leather provided by the invention contains the polyester superfine fibers and the polyamide superfine fibers, thereby the synthesis leather retains the performances of the two superfine fibers, and has both the stiffness of terylene and the plasticity of nylon.

Owner:厦门象屿兴泓超细材料有限公司

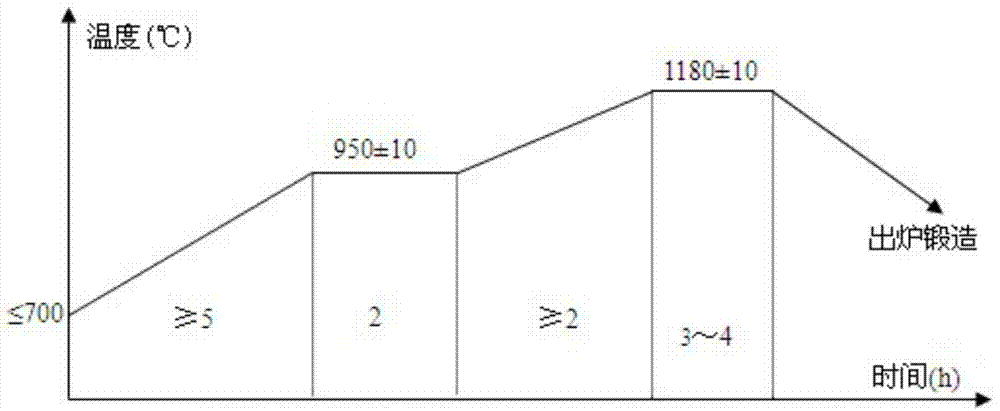

Driving rod of driving mechanism of nuclear power station control rod and preparation method thereof

InactiveCN103789684AReach mechanicalMeet the requirementsNuclear energy generationReactors manufactureElectricityNuclear power

The invention discloses a driving rod of a driving mechanism of a nuclear power station control rod and a preparation method of the driving rod. The preparation method comprises the following steps: 1) selecting raw materials, smelting by using an electric furnace, refining in AOD (Argon Oxygen Decarburization) and refining by using an LF (Low Frequency) furnace so as to obtain molten iron; 2) casting the molten iron into an electrode; 3) remelting the electroslag of the electrode to obtain a steel ingot, wherein the steel ingot comprises the following components in percentage by weight: less than or equal to 0.150% of C, less than or equal to 1.00% of Mn, less than or equal to 1.00% of Si, less than or equal to 0.030% of S, less than or equal to 0.030% of P, less than or equal to 0.50% of Ni, 11.50-13.50% of Cr, less than or equal to 0.06% of Co, less than or equal to 0.001% of B and the balance of Fe; 4) fogging the steel ingot into a tube blank, hot-rolling and hot-drilling the tube blank so as to obtain a pierced billet; and 5) processing the pierced billet into the driving rod of the driving mechanism of the nuclear power station control rod. When being used in a CRDM (Control Rod Drive Mechanism), the CRDM driving rod prepared according to the method disclosed by the invention is ideal in wear-resistance and free of deflection or deformation and has certain rigidity when being meshed with a hook claw and can be safely operated under the condition of load, the service life meets the CRDM design provision and the national standard requirements, the quality also meets the advanced level of similar products in other countries, and domestication of the CRDM driving rod is achieved.

Owner:中广核工程有限公司 +1

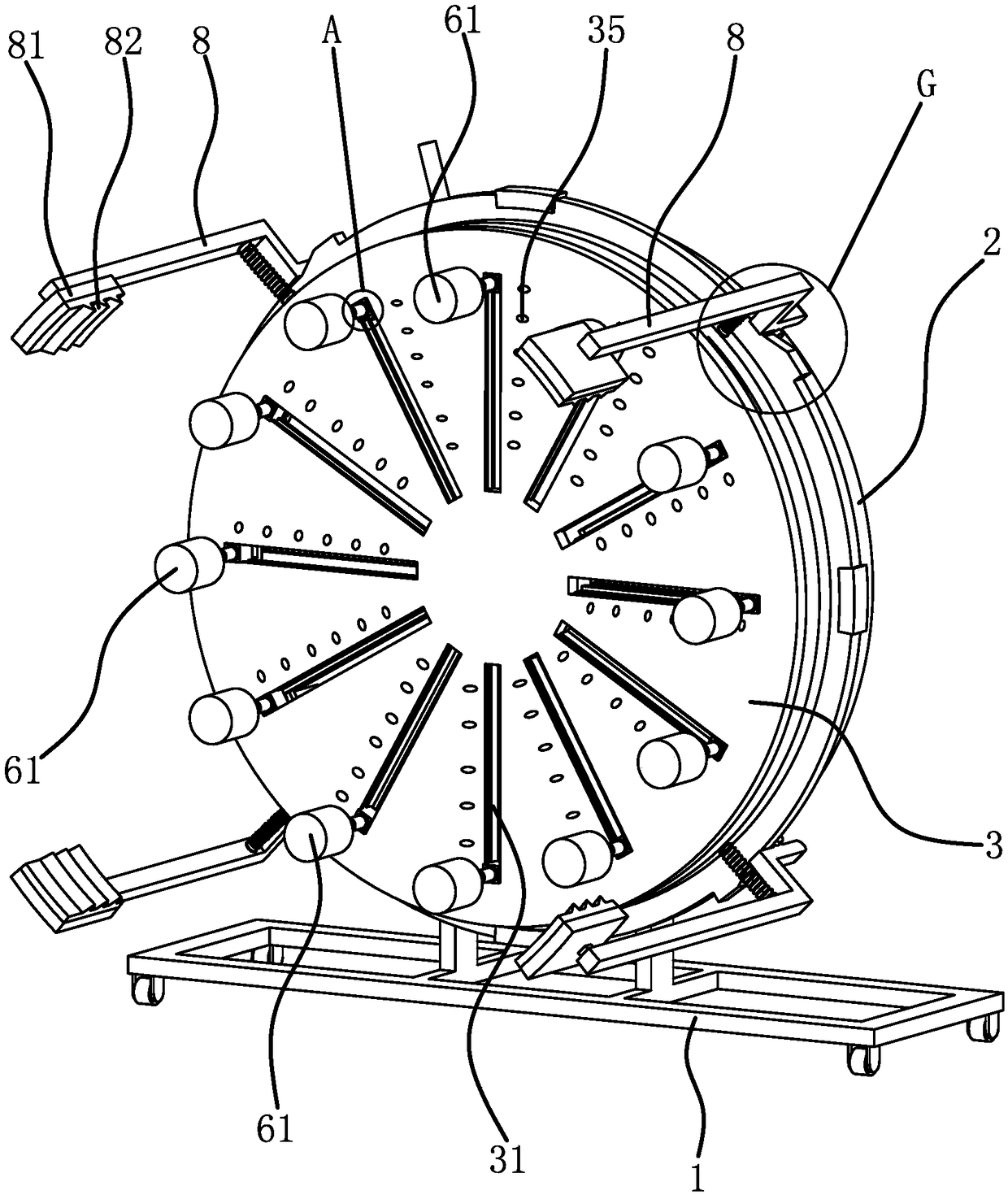

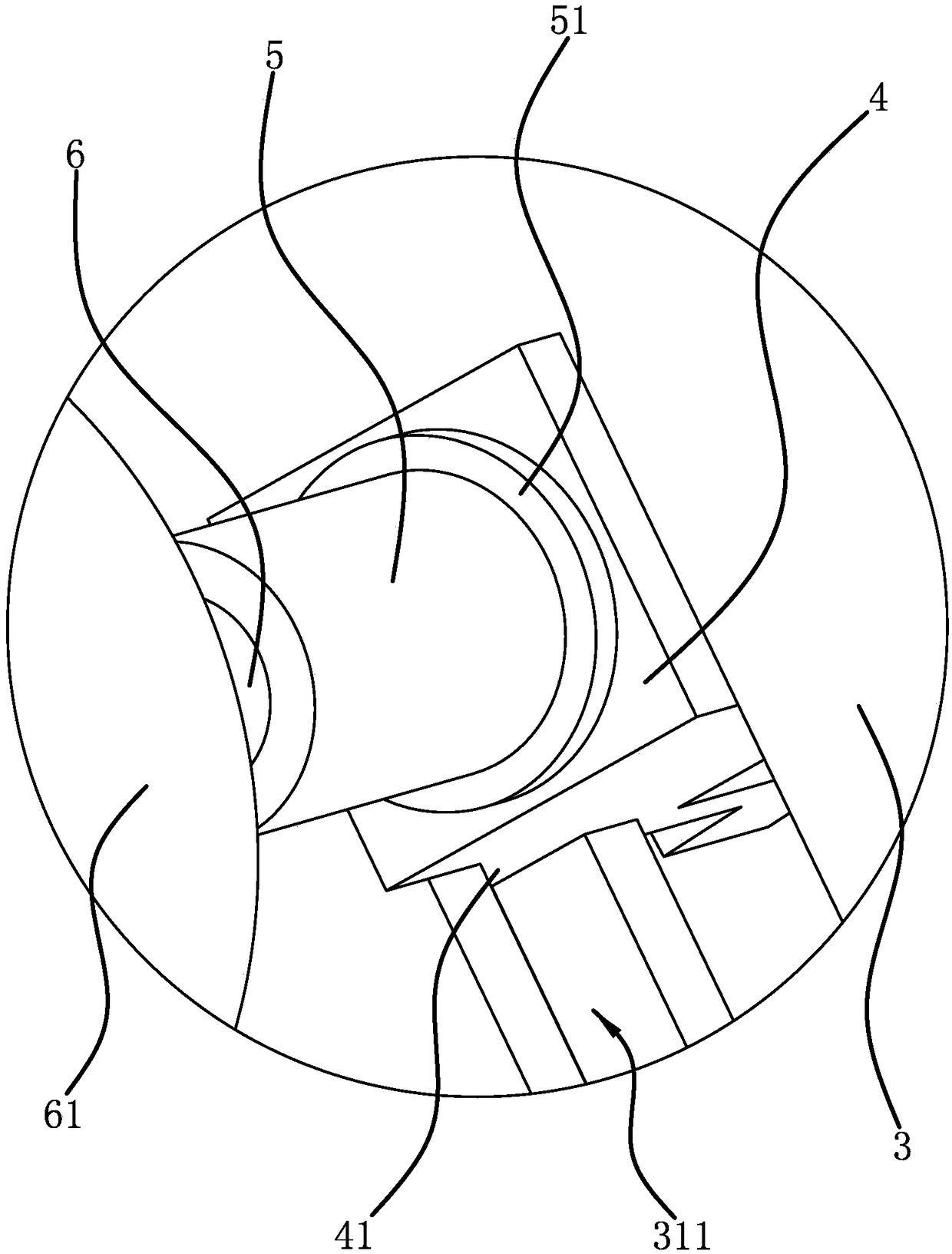

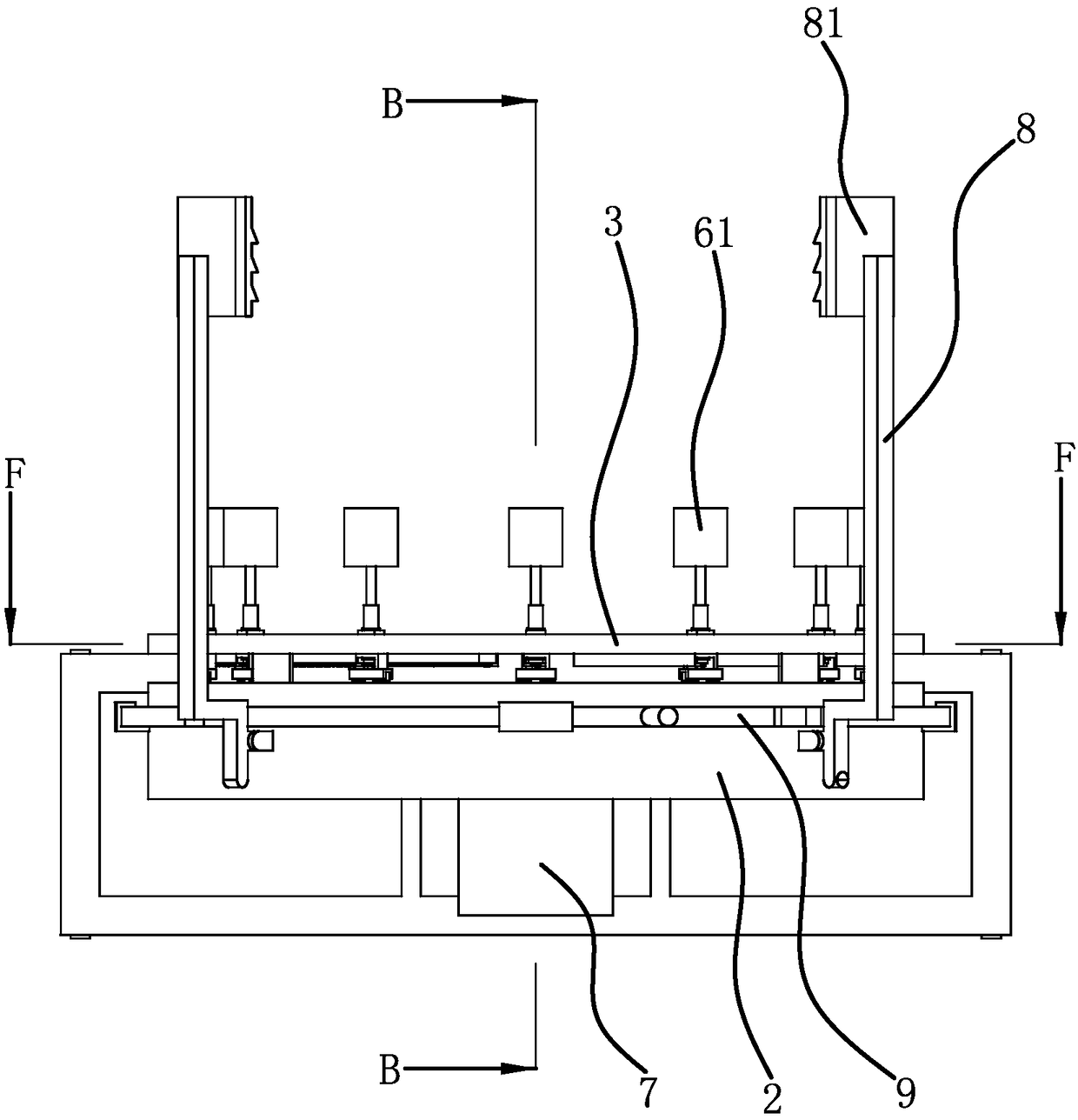

Automobile hub cleaning device

ActiveCN108909685AEasy to useSave effortCleaning apparatus for vehicle exteriorsDrive motorEngineering

The invention provides an automobile hub cleaning device, belonging to the technical field of automobile cleaning and solving the problem of costing a lot of time and labor for cleaning existing automobile hubs. The automobile hub cleaning device comprises a base, wherein the base is fixedly connected to a shell, a mounting plate is detachably connected to the shell and connected with a pluralityof sliders in a slidable manner, rotating columns are rotatably connected to the sliders, cleaning heads are connected to the front ends of the rotating columns in the slidable manner, cleaning sponges fixedly sleeve the front ends of the cleaning heads, the rear side of the shell is fixedly connected with a driving motor, a coupling member is further arranged in the shell, the plurality of sliders can synchronously move under the action of the coupling member, and a transmission member capable of driving the rotating columns to rotate synchronously when the sliders move is further arranged between the rotating columns and the mounting plate. The automobile hub cleaning device is more convenient and labor-saving in use and has higher efficiency.

Owner:SHANDONG LIANGSHAN TONGYA AUTOMOBILE MFG CO LTD

Stiffness/damping adjustable double-cantilever beam sealed passive damper

InactiveCN102418769AChange the coefficient of frictionWith stiffnessNon-rotating vibration suppressionNumerical controlCantilevered beam

The invention relates to a numerical control machine tool and workpiece passive vibration damping device which can be applied to the field of machining and has the obvious single-degree-of-freedom vibration characteristic. The device comprises a shell, a base, cantilever beams, a mass block, a screw, a nut, a gasket, a friction plate, a threaded hole and the like and is of a box-like sealed structure. The device is characterized in that main mode motion which is strictly vertical to the direction of the cantilever beams is realized, and the vibration characteristic is derived from first-orderbending vibration of the two cantilever beams. The stiffness and damping of the device are adjustable, and the adjustment can be realized by adjusting the position of the mass block in the device andthe pretightening force of the friction plate, thereby having a wider vibration suppression frequency range. The device is suitable for the characteristics that the dynamic property of a workpiece ora machine tool changes during the machining and a damper is required to be capable of adjusting parameters. The device can be mounted on a numerical control lathe, a milling machine or the workpiece for vibration damping. The device is simple in structure, convenient to implement and lower in cost, has no environmental pollution, and can be used for effectively reducing the vibration during cutting machining and realizing high-efficient and high-quality machining of parts.

Owner:BEIHANG UNIV

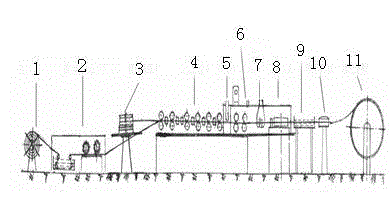

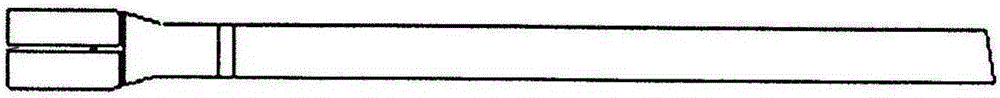

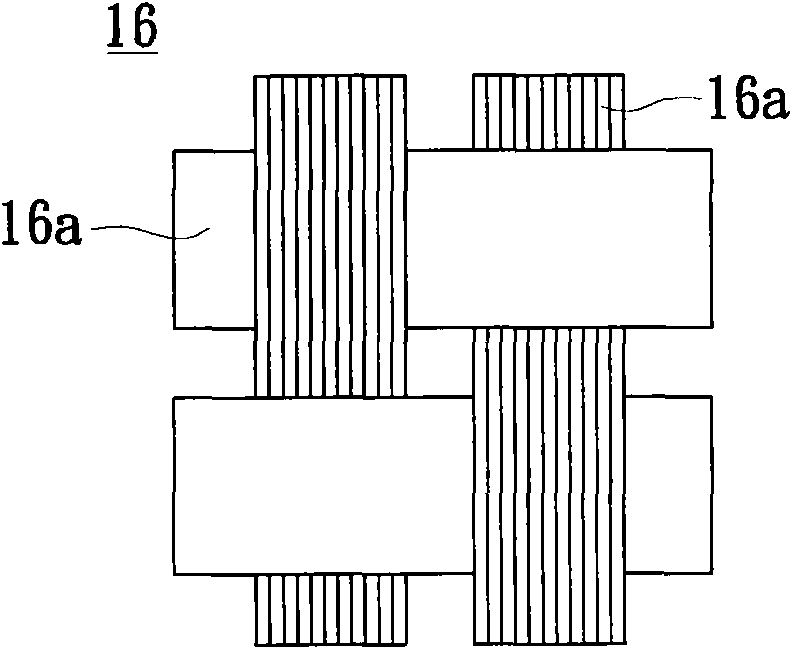

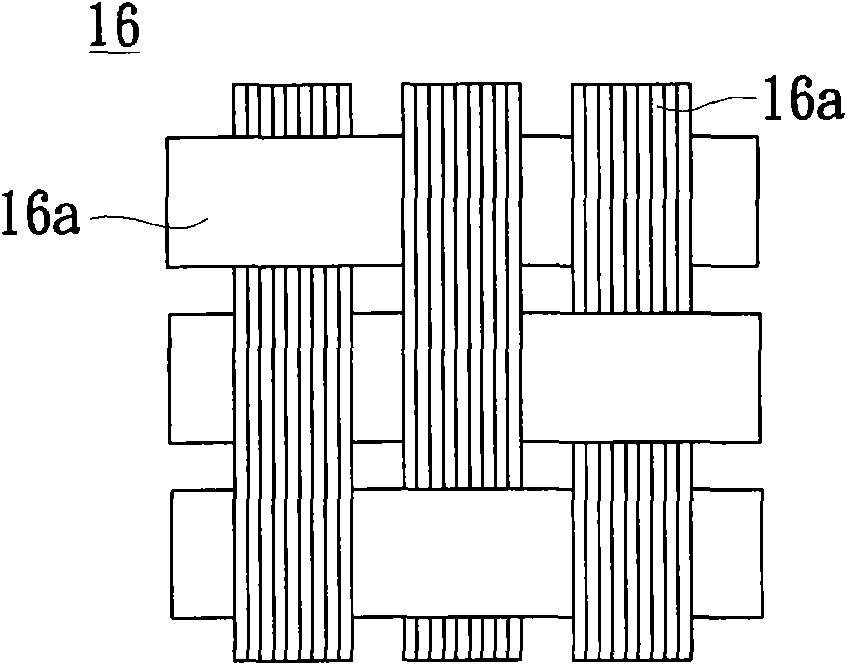

Copper-coated plastic wire production process and copper-coated plastic wire production line

ActiveCN102982907AReduce weightReduce loadCoaxial cables/analogue cablesWaveguidesCoaxial cableShielding gas

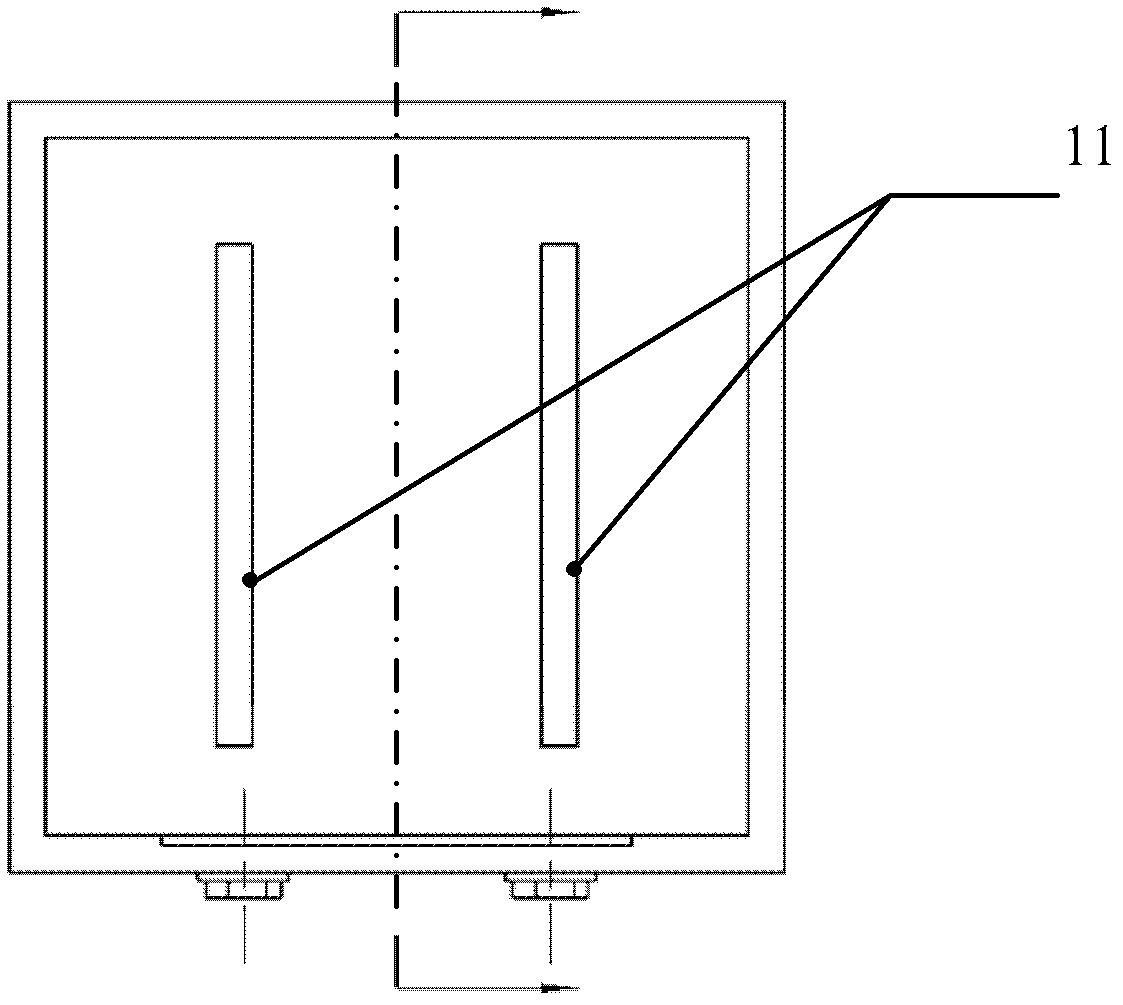

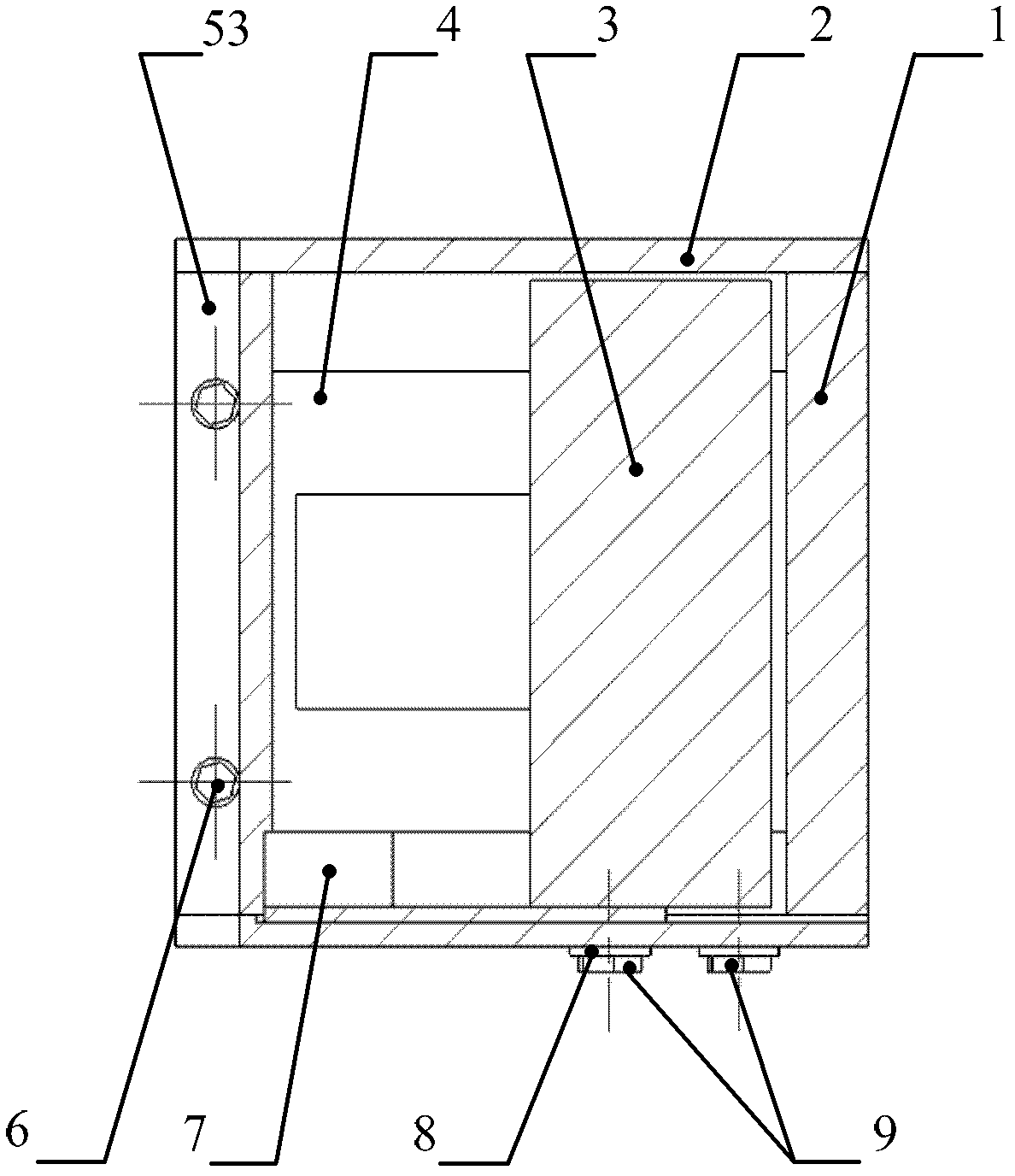

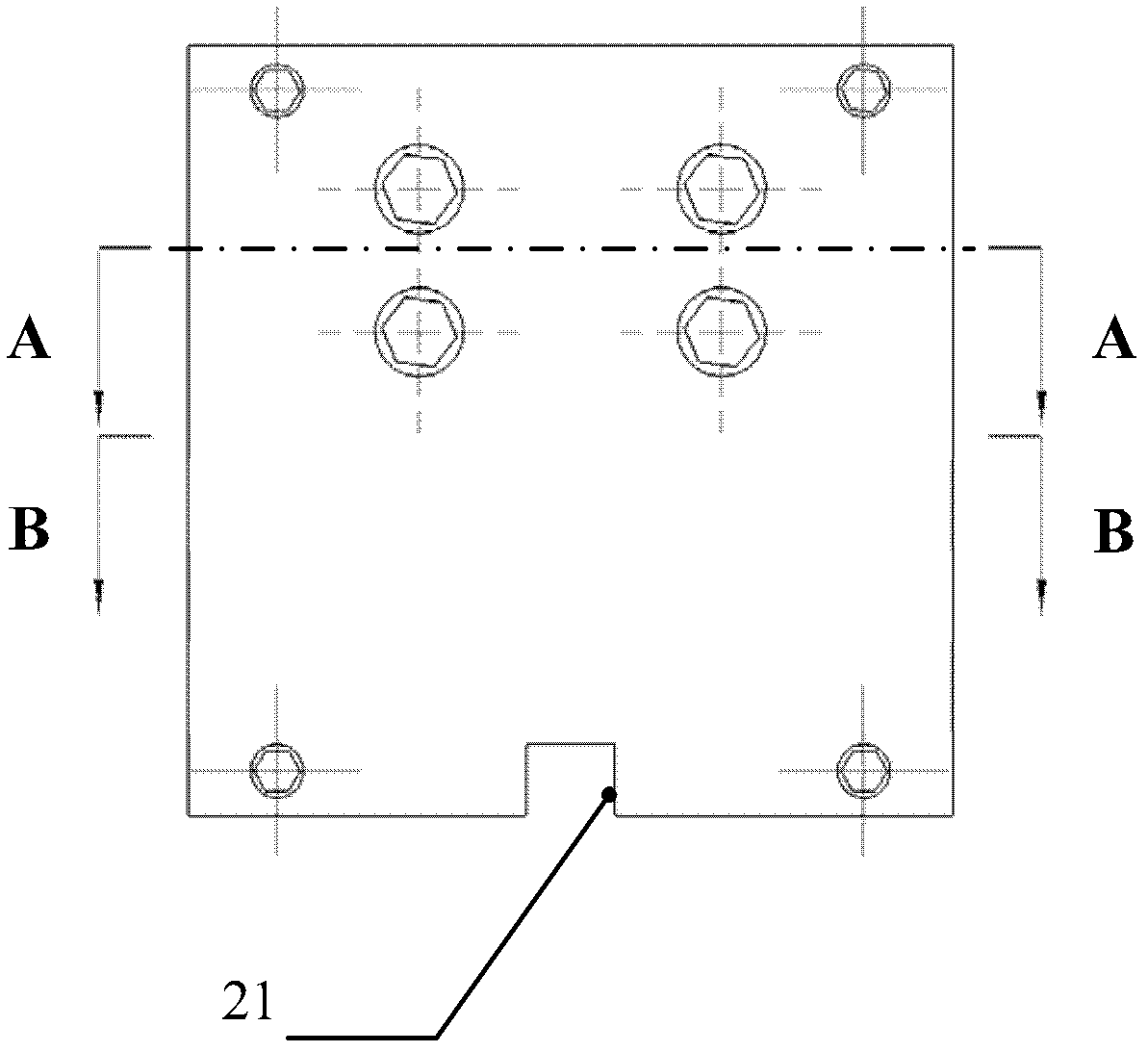

The invention discloses a structure of a copper-coated plastic wire which is used for transmitting radio frequency signals and serves as a coaxial cable inner conductor and a copper-coated plastic wire production process. The structure of the copper-coated plastic wire is a copper layer coated plastic wire. A copper layer and a plastic wire are bonded though hot melting glue. A production line designed according to the structure of the copper-coated plastic line comprises a copper belt material disk (1), a copper belt cleaning and brushing device (2), a plastic wire coil (3) for wrapping hot melting glue films, a wrapping device (4) for enabling copper belts to wrap plastic wires, an argon arc welding gun (5) for welding copper belt longitudinal seams, an induction heating coil (7) for heating wire bases, a wire drawing machine (8), a cooling groove (9), a blowing-drying machine (10) and a copper-coated plastic wire finished product winding rotary drum (11). The argon arc welding gun, the induction heating coil and a large disk of the wire drawing machine are sealed in a protection gas box. Argon is led into a protection gas inlet (6) to prevent high temperature copper layers from being oxidized. Power for transmitting all devices of the production line is driven by the wire drawing machine so as to enable motion speed of all portions of the whole production line to be identical.

Owner:大连通发诚信科技有限公司

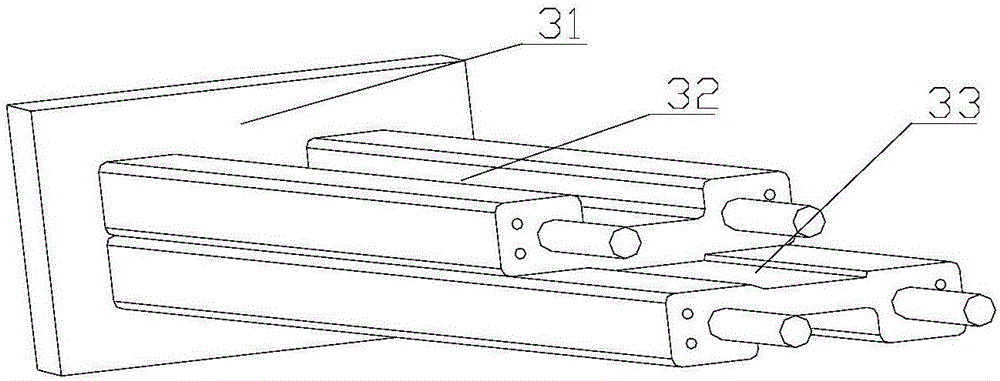

Tool and production method for producing variable cross-section type I-shaped composite part

The invention relate to a tool and production method for producing a variable cross-section type I-shaped composite part. According to the technical scheme, the tool is composed of an upper male die, a lower male die, a middle spacer plate and composite even pressing plates on the two sides. The production method comprises the steps that firstly, the composite even pressing plates are made; then, carbon fiber prepregs cut into fixed sizes are laid on a forming tool; finally all parts of the carbon fiber prepregs laid well are transferred from the forming tool to an assembly solidification tool for integral assembly, and packaged in a vacuum bag; the fully sealed prepreg blank is subjected to solidification forming under the conditions of 120-180 DEG C and 0.3-0.8 mpa for 1-3 hours; and after cooling, the composite even pressing plates, the middle spacer plate, the upper male die and the lower male die are detached to obtain the variable cross-section type I-shaped composite part. According to the production process, the pressure transmission efficiency of the part in the solidification process can be improved; generation of the structure defect of the part is reduced; the shape and the internal quality of the part are ensured.

Owner:SHENYANG AIRCRAFT CORP

Production process of digital photo paper synthesized by multiple fibers

InactiveCN102220724AImprove stiffnessGood surface absorptionVegetable material additionPaper/cardboardFiberUltrafiltration

The invention discloses a production process of digital photo paper synthesized by multiple fibers. The production process comprises the following procedures: internal sizing liquid preparing, surface sizing liquid preparing, pulp breaking, pulp mixing, net forming, surface sizing, drying and reeling, blending, prime coating and cast coating, wherein in the pulp breaking procedure, bamboo pulp and reed pulp are added to the original wood pulp and sodium silicate is added to the breaking solution; in the surface sizing procedure, the surface sizing liquid is prepared by decocting modified starch and cassava starch and a rheology modifier is added; in the blending procedure, the membrane ultrafiltration deionized water is used; and in the prime coating procedure, a soft calender and four dryers are added. The produced high gloss photo paper has a fine and smooth surface and the characteristics of high gloss and density, wide color gamut, high ink absorbency and water resistance, good stiffness and the like.

Owner:HUANGSHAN HUABANG DIGITAL TECH

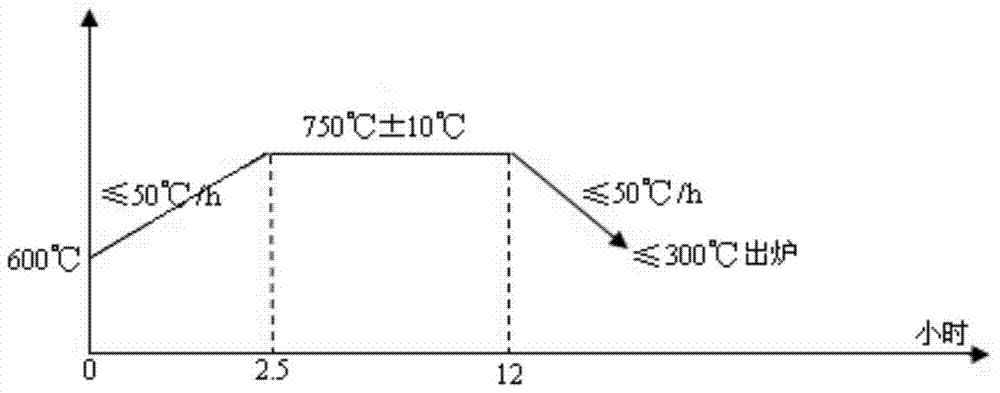

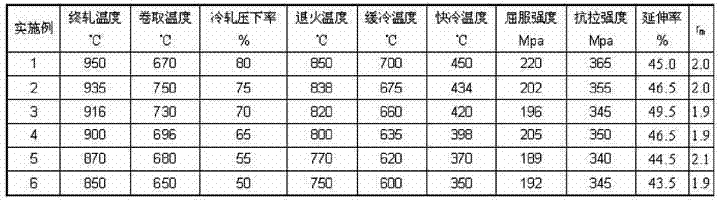

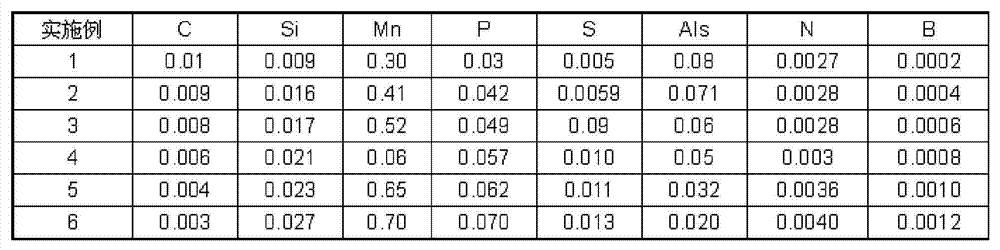

340MPa-grade high-strength cold-rolled steel plate used for deep-drawing, and production method thereof

The invention relates to a 340MPa-grade high-strength cold-rolled steel plate used for deep-drawing, and a production method thereof. The steel plate comprises the components of, by mass: no more than 0.010% of C, no more than 0.060% of Si, 0.30%-0.70% of Mn, 0.030%-0.070% of P, no more than 0.015% of S, 0.020%-0.080% of Als, no more than 0.0050% of N, 0.0002%-0.0012% of B, and balance of Fe and inevitable impurities. A production method of the steel plate is that: a middle-ladle temperature is controlled at a value 20-60 DEG C higher than a liquidus temperature; a furnace discharging temperature is 1150-1250 DEG C; a final rolling temperature is 850-950 DEG C; a coiling temperature is 650-750 DEG C; and a cold rolling total reduction rate is controlled at 50-80%. In a continuous annealing process, a soaking temperature is 750-850 DEG C; an annealing temperature is 600-700 DEG C; and a flash cooling temperature is 350-450 DEG C.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

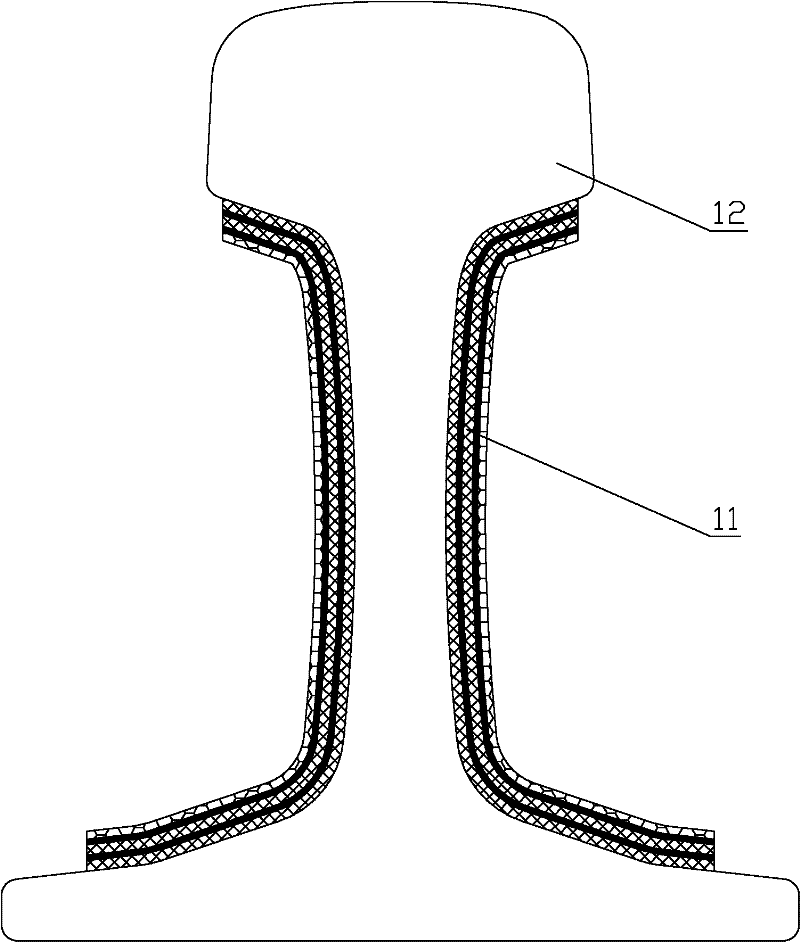

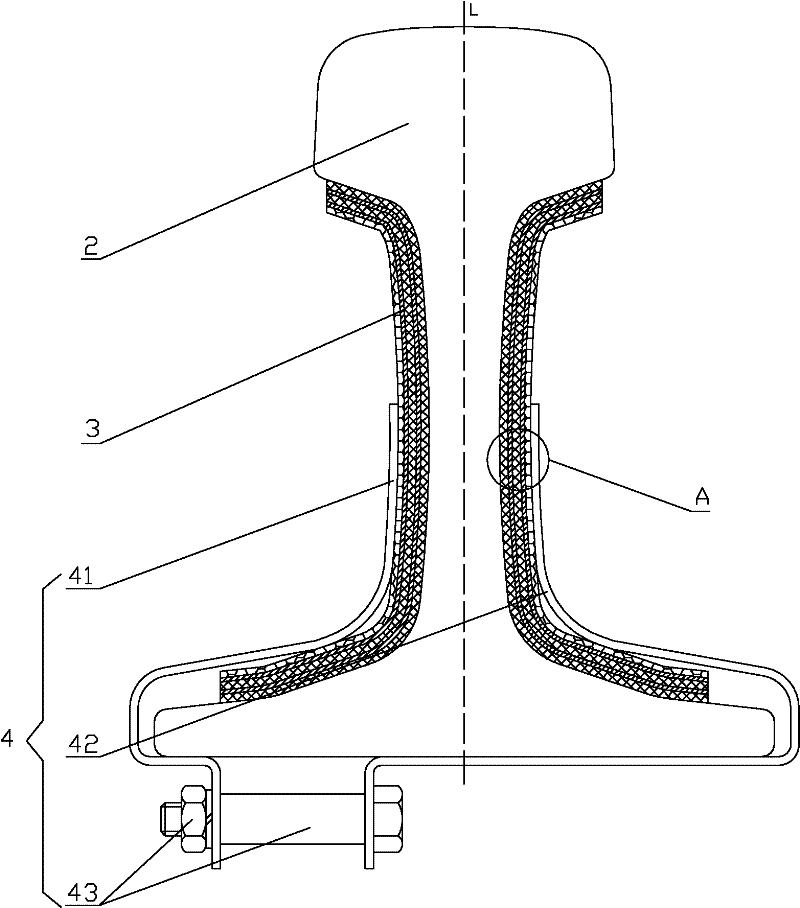

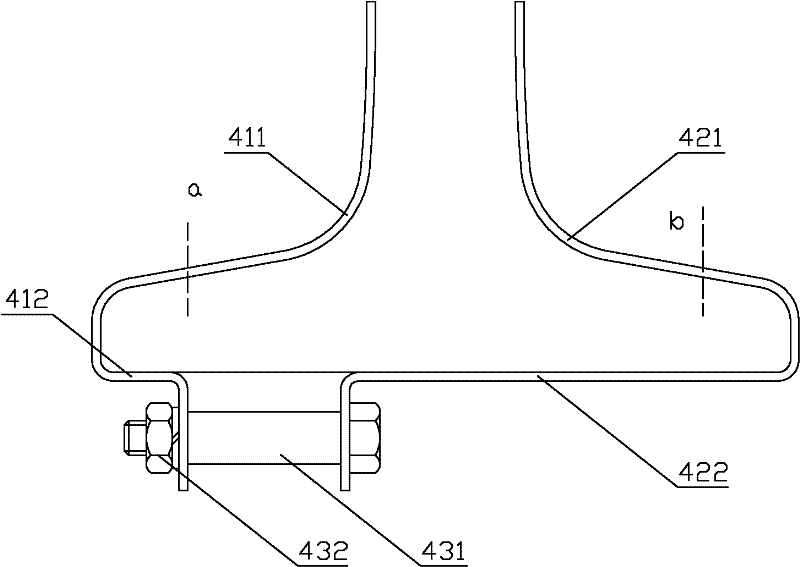

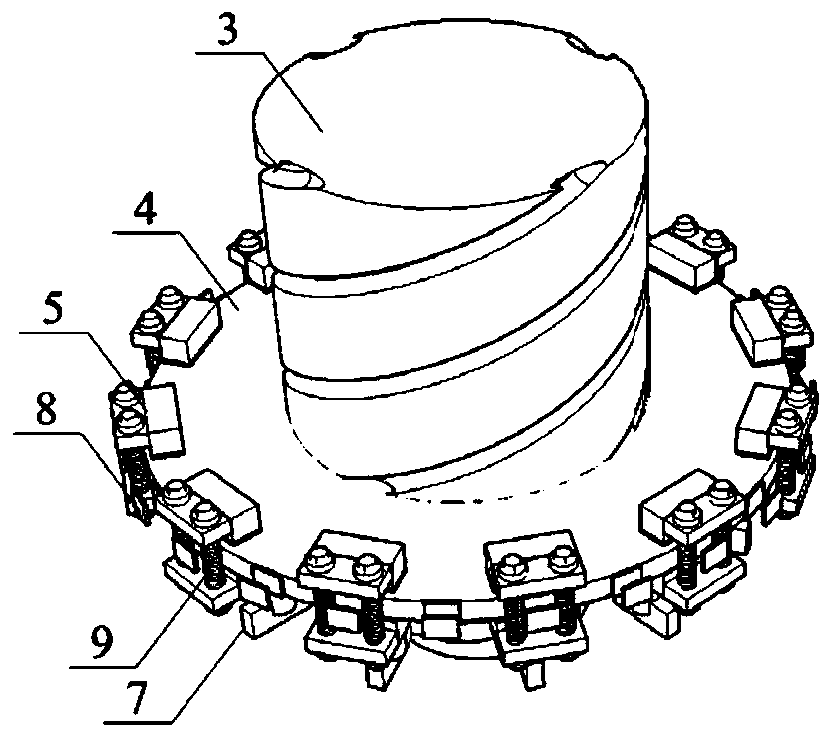

Track damping shock absorber

The invention discloses a rail damping shock absorber, which comprises a damping structure laid on the rail waist of the rail, and also includes a clamping assembly clamping the damping structure close to the rail waist, and the clamping assembly includes a left clamping part and the right clamping part, and a connecting part detachably connecting the left clamping part and the right clamping part. Compared with the rail body of the track, the damping structure has a higher damping loss factor, which can fully play the role of energy conversion and ensure the noise reduction performance of the damping shock absorber. At the same time, since the clamping component can clamp the damping structure closely to the rail waist, the damping structure and the rail waist do not need to be fixedly connected together; when the track or the damping structure needs to be replaced, the connection between the left clamping part and the right clamping part The locking relationship between the track and the damping structure can be replaced separately, and the usable structure can still be used to reduce the waste of track maintenance, avoid unnecessary economic losses, and improve the cost performance of the damping shock absorber.

Owner:BEIJING HUANTIE UNITED NOISE CONTROL TECH

Explosive welding manufacturing method of high-purity niobium-oxygen-free copper composite plate

InactiveCN109604806AGuaranteed SuperconductivityReduce oxygen contentNon-electric welding apparatusNiobiumMechanical stability

The invention discloses an explosive welding manufacturing method of a high-purity niobium-oxygen-free copper composite plate. The method comprises the following steps that a high-purity niobium plateserves as a composite plate, an oxygen-free copper plate is used as a substrate, and high-purity niobium is manufactured in an explosive welding mode; and the quality purity of the high-purity niobium plate is not less than 99%, the thickness of the high-purity niobium plate is not larger than 2 mm, the oxygen content in the oxygen-free copper plate is less than 2 ppm, and the thickness of the oxygen-free copper plate is larger than 10 mm. According to the method, the composite surface of the high-purity niobium plate and the oxygen-free copper plate are subjected to high-speed collision through explosion welding to form a solid-phase metallurgical bonding to be combined, the defect that the oxidation of the high-purity niobium plate and oxygen absorption of the oxygen-free copper plate in the heating rolling process are avoided, the problem that the high-purity plates with relatively large elongation rates are difficult to cold rolling and rolling is solved, and the excellent superconducting performance of the high-purity niobium material is kept, and meanwhile, the thickness of a superconducting cavity is increased by the oxygen-free copper plate, and thus the mechanical stability of the superconducting cavity is enhanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

PFF integral composite reversed filtering layer and construction method thereof

ActiveCN103321258AGuarantee the construction qualitySimplify the construction processArtificial islandsProtective foundationWater layerMaterials science

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

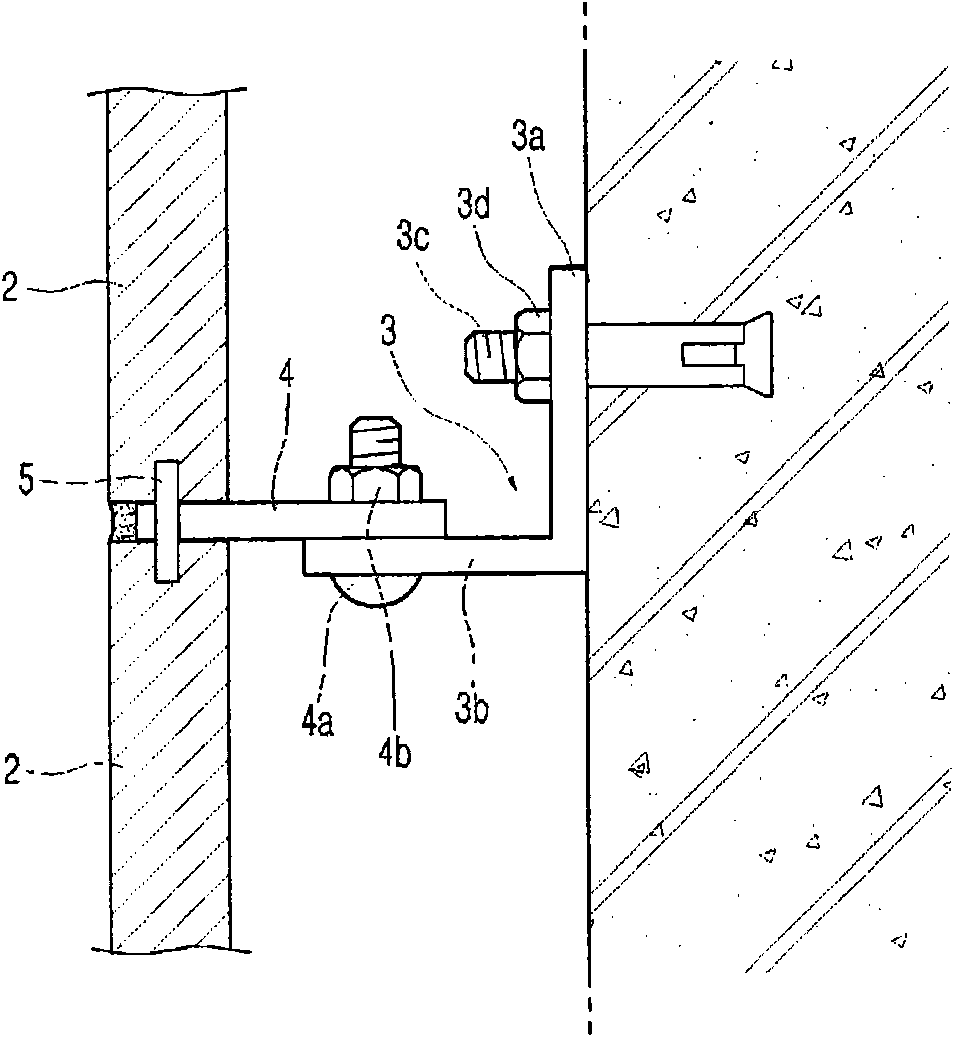

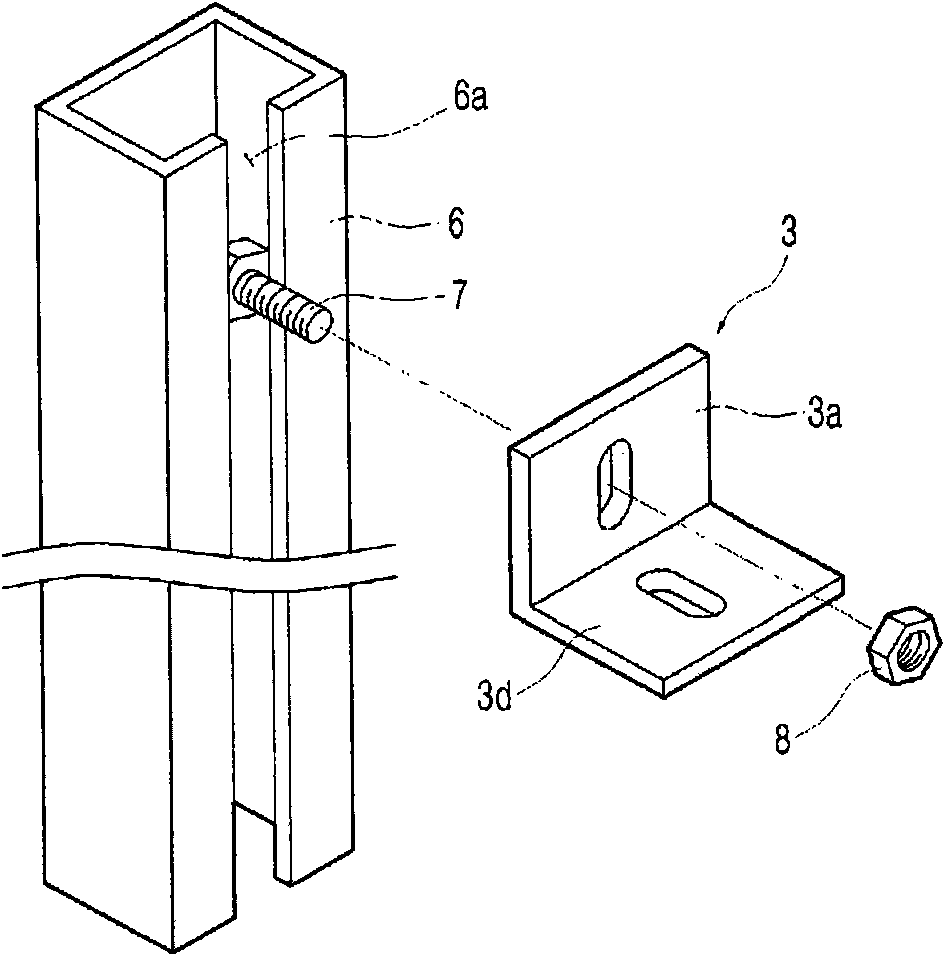

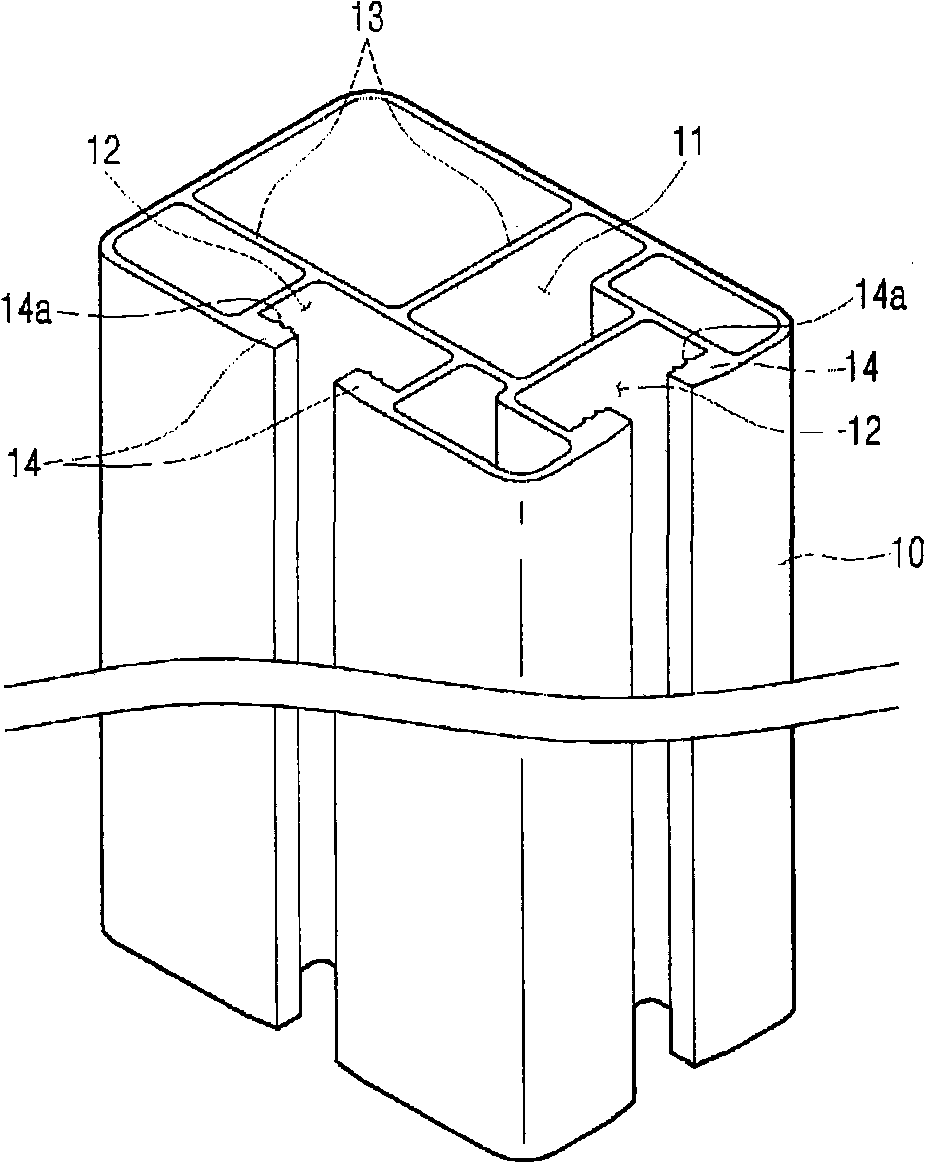

Frame structure for installation of wall panel of building, and wall panel installation device and wall panel installation method using same

The present invention relates to a frame structure for installation of heavy interior and exterior wall panels such as stone panels, which can be freely adjusted in height and horizontal position through the use of a light weight structure, and to a wall panel installation device and method using the same. The frame structure for installation of building wall panels according to the present invention includes: a frame body having a square cross section; a reinforcement portion extended integral from an inner side surface of the frame body to define a frame body interior; a groove portion formed along an outer surface of the frame body in a lengthwise direction; a stopper portion curved inward from an end of the groove portion; and a flange portion extended from both ends of the outer surface of the frame body facing the outer surface of the frame body where the groove portion is formed. The frame structure of the present invention is made of light, nonferrous metals such as aluminium and has sufficient strength for installation of heavy metallic panels. Accordingly, the frame structure is lightweight, produced at low costs compared to steel products, and enables easy transportation and construction.

Owner:金光贤

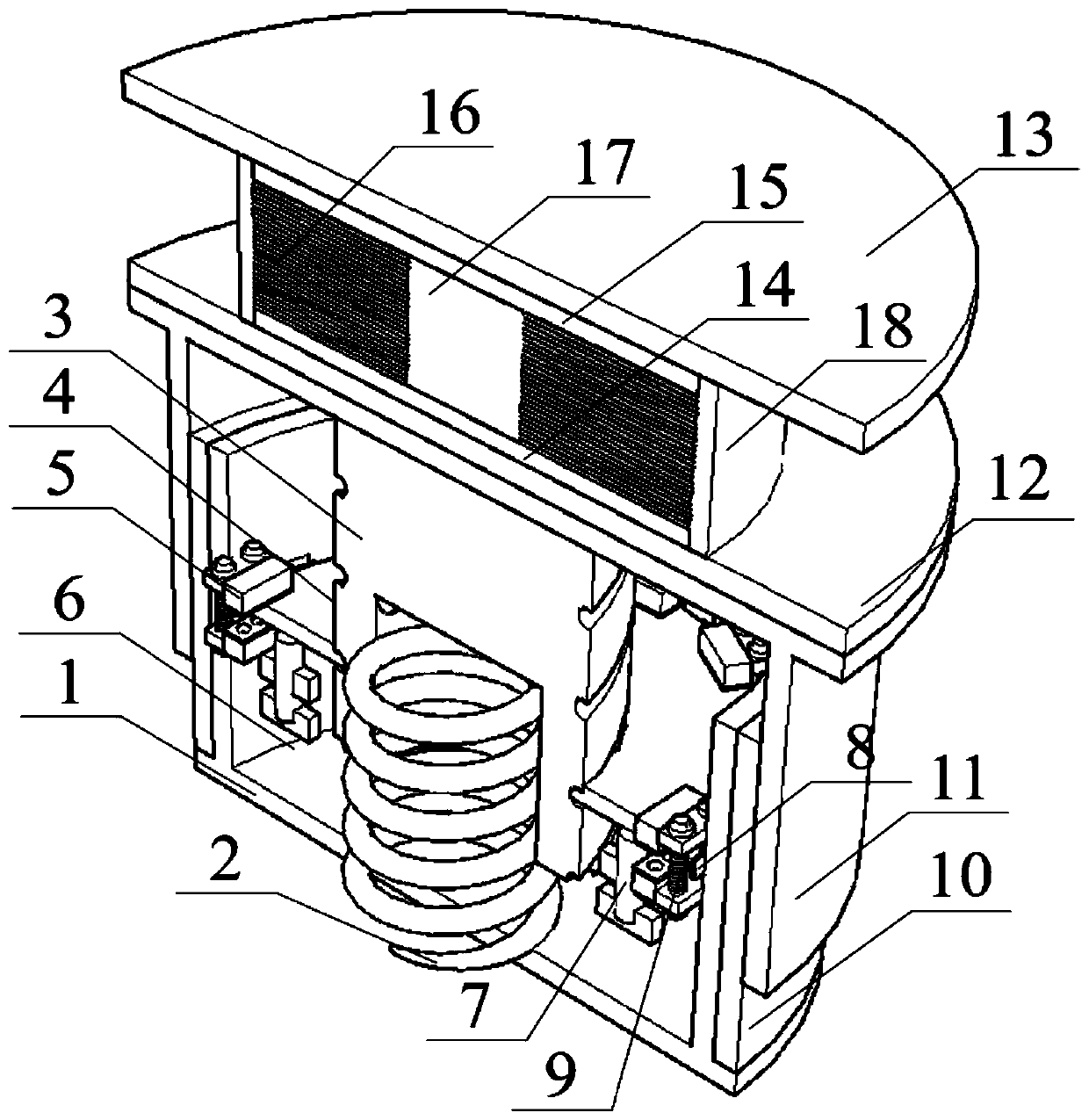

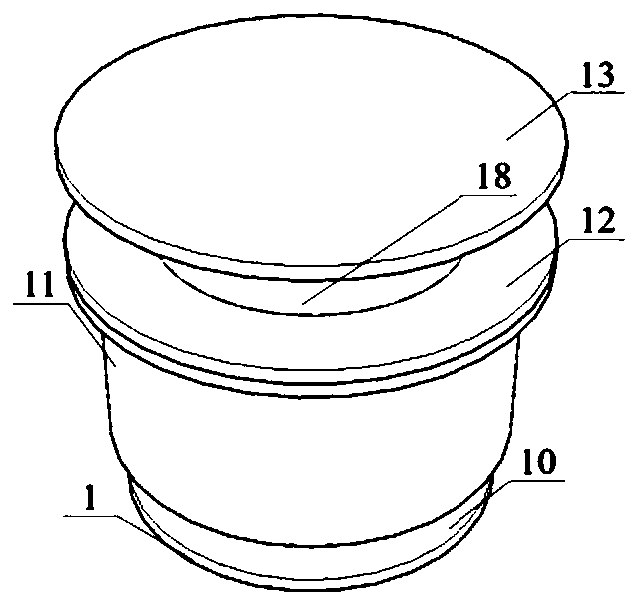

Three-dimensional vibration isolation device combining inerter and rubber support

ActiveCN111305631AImprove bearing capacityAchieve isolationNon-rotating vibration suppressionProtective buildings/sheltersVertical vibrationNoise control

The invention belongs to the field of vibration and noise control, and relates to a three-dimensional vibration isolation device combining an inerter and a rubber support. The three-dimensional vibration isolation device combining the inerter and the rubber support comprises a spiral spring, a rotary shaft, a rotary disc, rotary disc constraint parts, coils, neodymium magnets, damping liquid, damping rods, an upper sleeve, a lower sleeve, a Teflon sleeve, laminated rubber, a lead core, a rubber protective sleeve, an upper connecting plate, a lower connecting plate, a rubber support upper protection plate and a rubber support lower protection plate. According to the three-dimensional vibration isolation device combining the inerter and the rubber support, three-dimensional vibration isolation is achieved by connecting an inerter vibration isolation system and the rubber support in a decoupling mode; and effective vertical vibration isolation can be achieved by connecting the spiral spring and the inerter system in parallel, horizontal vibration isolation can be achieved by the rubber support, and a decoupling system is arranged, so that horizontal vibration isolation and vertical vibration isolation function respectively to achieve three-dimensional vibration isolation. The three-dimensional vibration isolation device combining the inerter and the rubber support is widely applicable to buildings built over a subway and important instruments and equipment with three-dimensional vibration isolation requirements, and the three-dimensional vibration isolation effect is better than that of an existing steel spring vibration isolator.

Owner:TONGJI UNIV

Shoe-heel regenerated leather

The invention relates to shoe-heel regenerated leather which is characterized in that the composition comprises the following components in percentage by weight: 17-27 natural latex, 5-10 fish oil, 10-13 white glue, 40-50 crushed leather and 2-4 tannin extract. A manufacturing method of the shoe-heel regenerated leather comprises the following steps of: primarily crushing and intermediately crushing the crushed leather to manufacture pulp after the two steps of fine crushing, then refining through a refiner to separate impurities with large grain diameters, tanning the pulp through the tannin extract, carrying out leather auxiliary-agent processing , such as greasing by adding the fish oil, hardness increasing by using the white glue, dye toning and the like, simultaneously combining the processed pulp together with the natural latex and aluminum sulfate (used for drying and controlling a pH value) to be manufactured into a regular shape through dewatering and drying, and finally dewatering and drying. The product has the advantages of low price, high production efficiency, high drying speed and energy saving.

Owner:ZHEJIANG SUNNYESINA REGENERATED LEATHER

Low-noise centrifugal ventilator casing

The invention discloses a low-noise centrifugal ventilator casing belonging to the technical field of noise reduction for ventilators. The ventilator casing is formed by sequentially compositing a carbon structural steel inner layer, an inner-layer sound absorption plaster material, a porous foam metal plate, an outer-layer sound absorption plaster material and a carbon structural steel outer layer. The invention provides the low-noise casing which is simple in structure, light in weigh and good in noise reduction effect, and has certain stiffness. The amount of used metal materials is reduced, the cost is lowered, and the noise is reduced to about 10dB.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

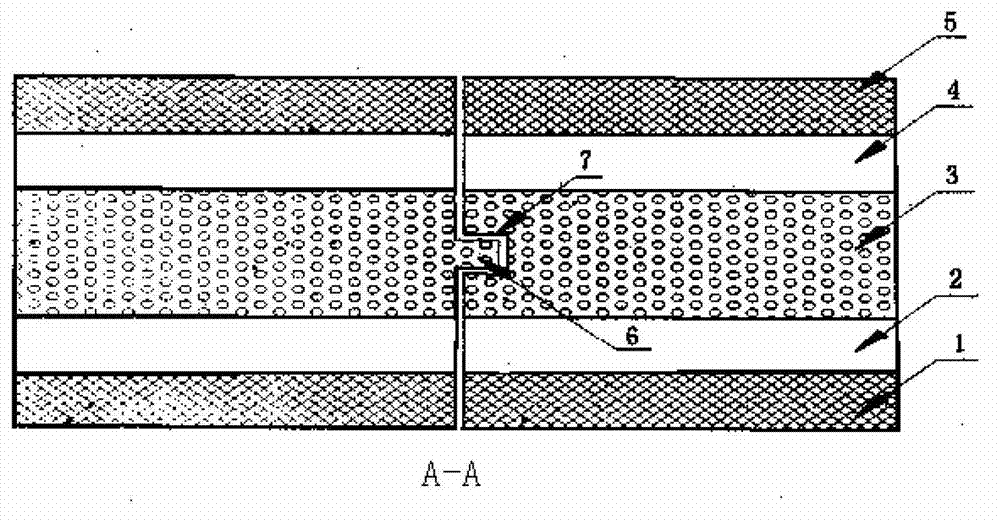

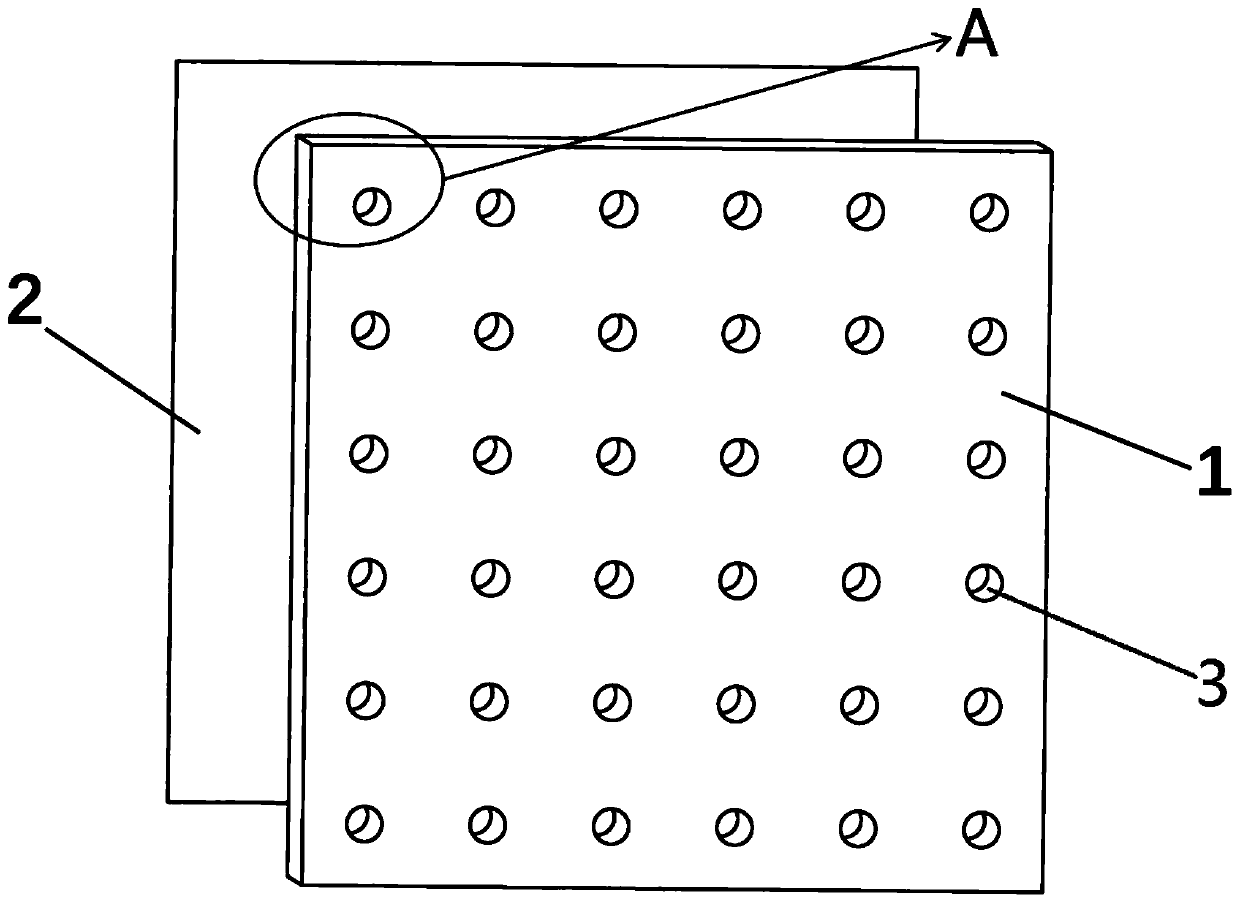

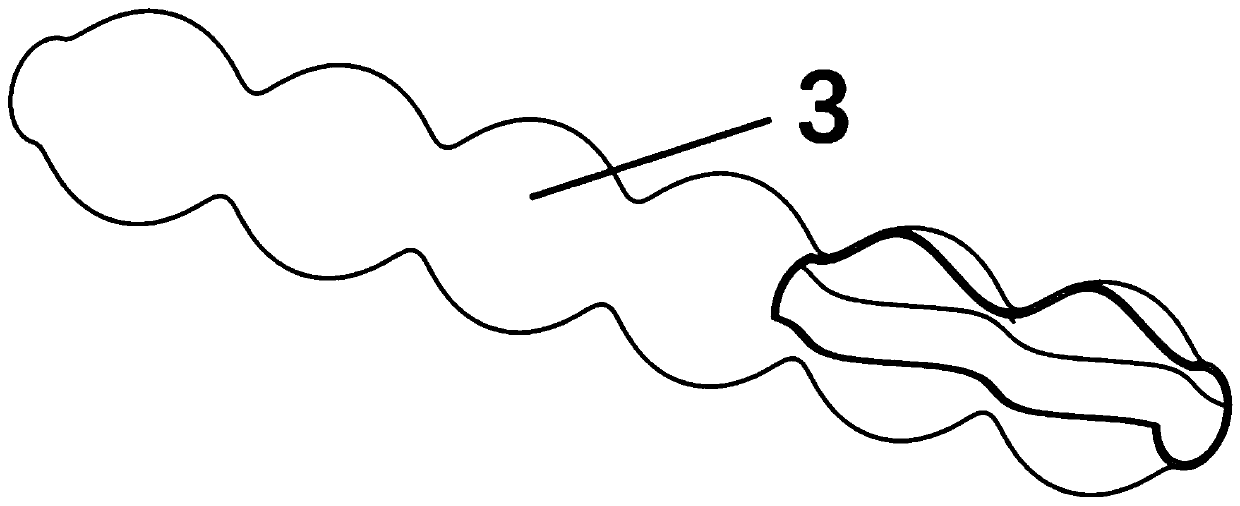

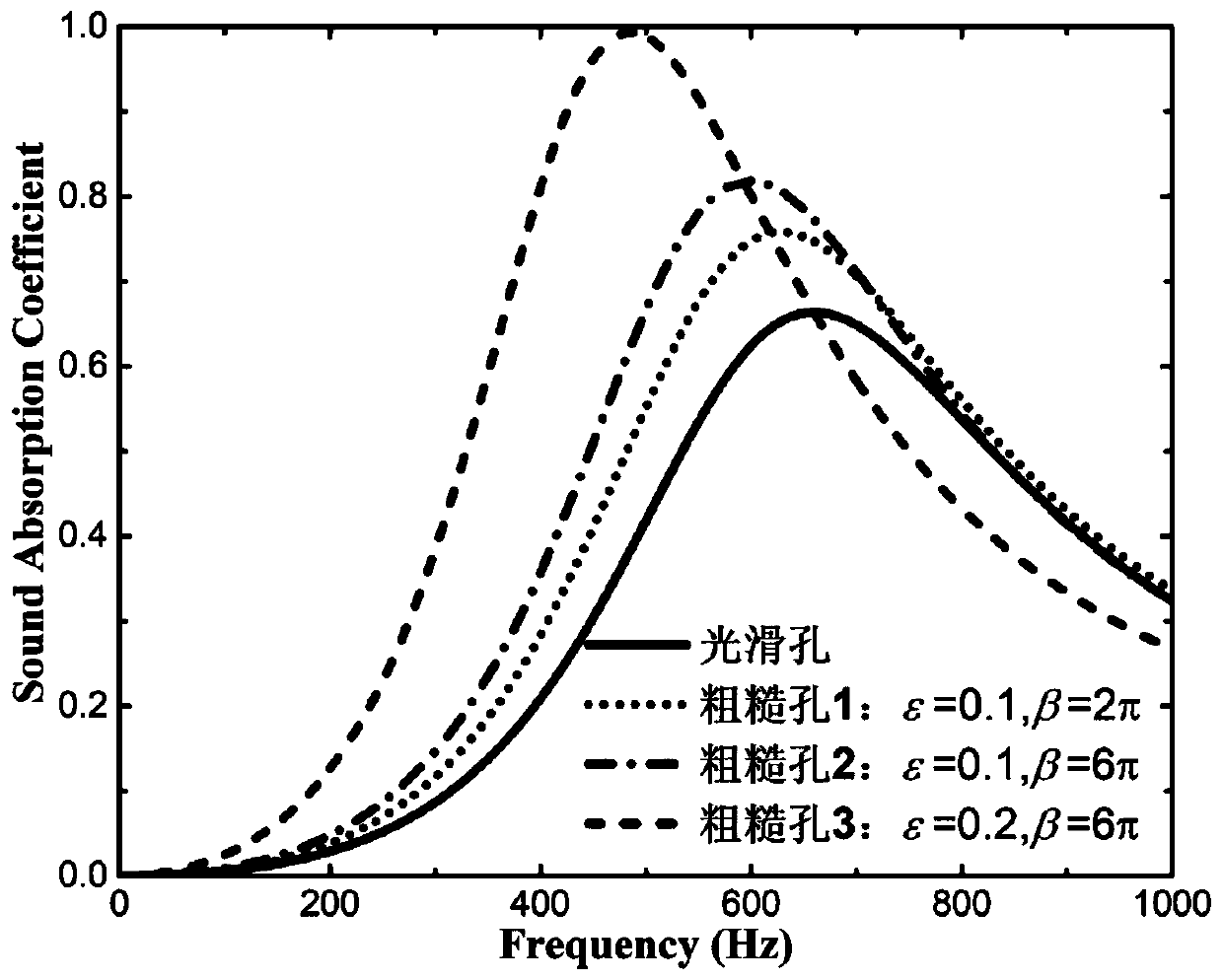

Micro-perforated panel sound absorbing body with rough surface modified micro-pores

InactiveCN109763577AWide frequency rangeSimple control functionSound proofingFlooring insulationsLow frequency bandEngineering

The invention discloses a micro-perforated panel sound absorbing body with rough surface modified micro-pores. The micro-perforated panel sound absorbing body with the rough surface modified micro-pores comprises a perforated panel and a rigid back lining; a cavity is formed between the perforated panel and the rigid back lining; rough sound absorbing pores are formed in the perforated panel; thedirections of the pores are all perpendicular to an upper panel; the rough pore shapes of the sound absorbing pores which are formed in the perforated panel are controlled by using a function. The micro-perforated panel sound absorbing body with the rough surface modified micro-pores is simple and practical in structure, has good medium and low frequency band sound absorption performance and flexible sound absorbing adjusting function, has the characteristic of light weight, and has good and broad application prospects.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

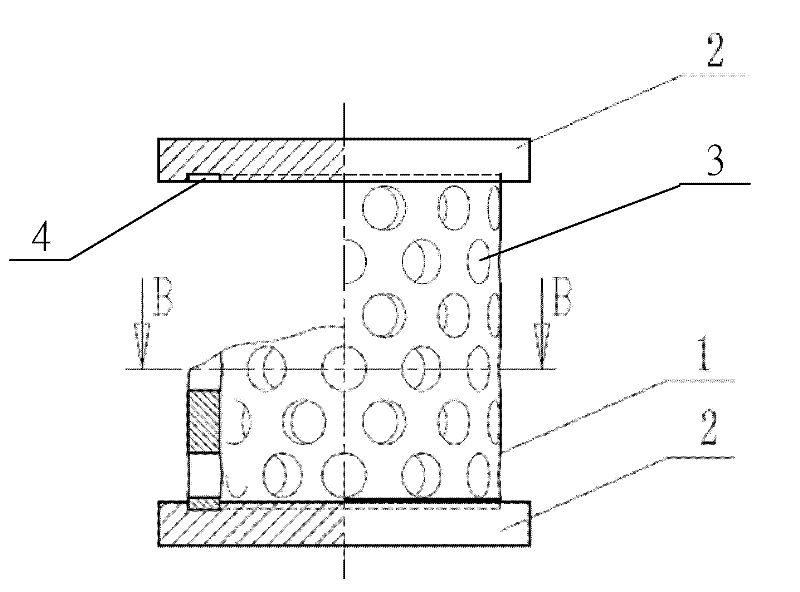

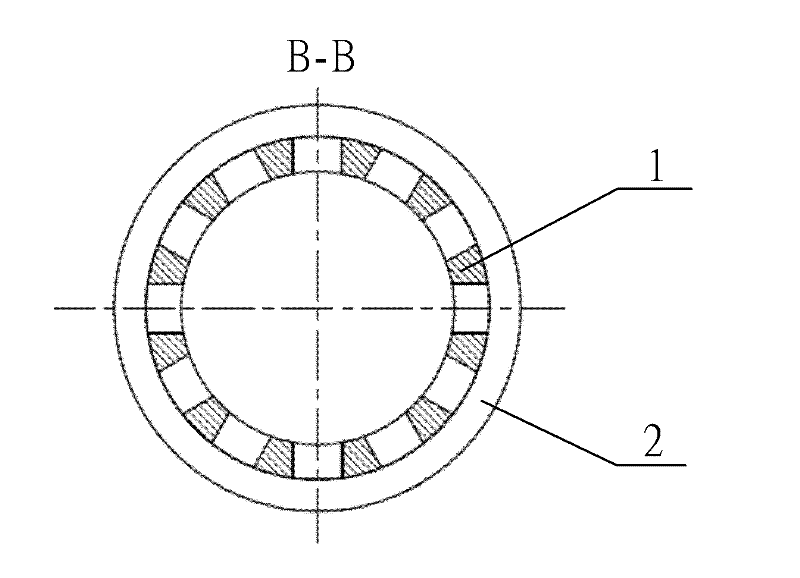

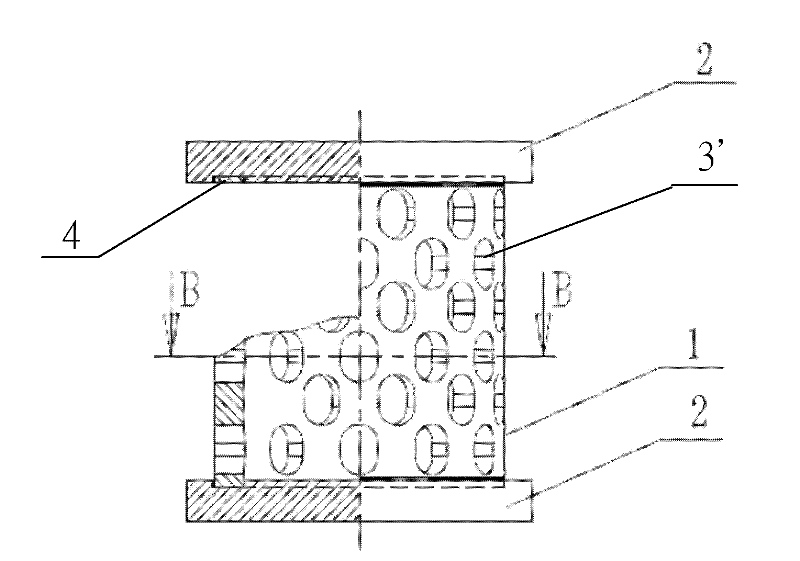

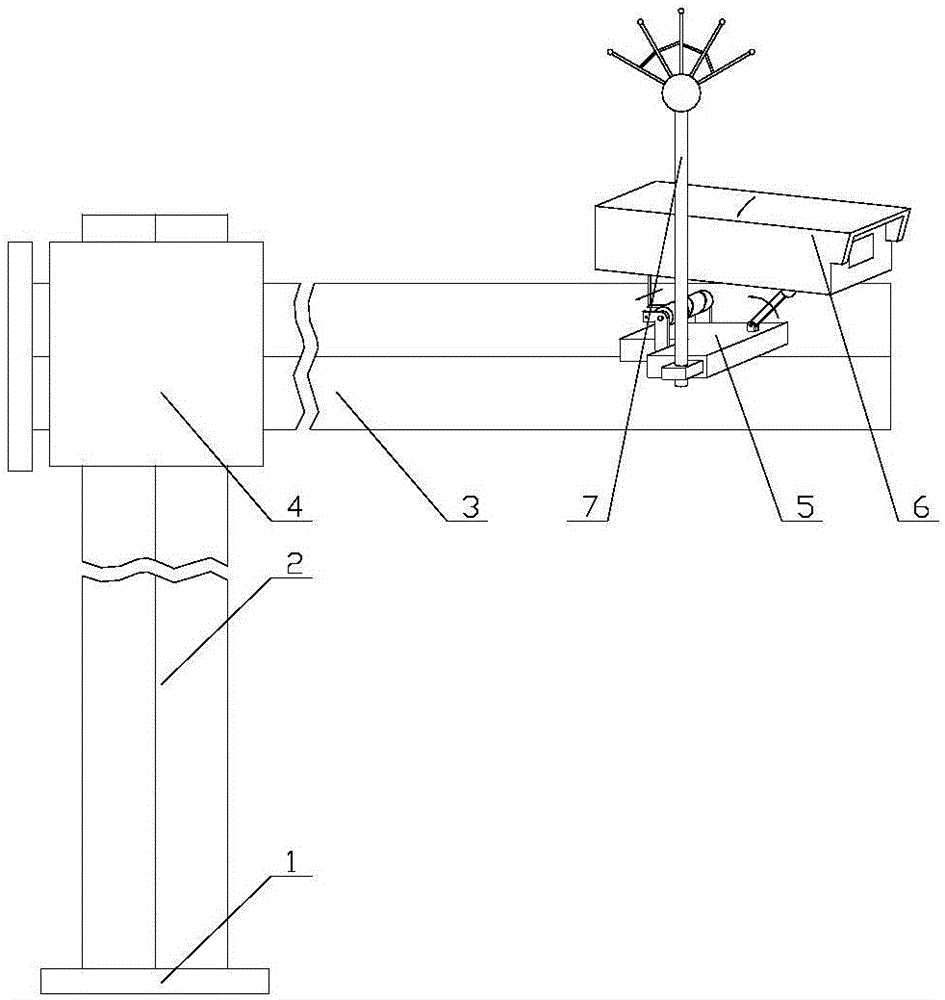

Porous cylindrical energy absorbing devices and anti-whipping limiting part adopting same

InactiveCN102226489AWith stiffnessPrevent sudden bucklingNuclear energy generationPipe elementsEngineeringEngineering structures

The invention relates to the field of energy absorbing devices, in particular to porous cylindrical energy absorbing devices and an anti-whipping limiting part adopting the same. Each energy absorbing device comprises a cylindrical pipe body and plate bodies fixed at the two ends of the cylindrical pipe body, wherein the cylindrical pipe body is provided with a plurality of pores. The anti-whipping limiting part comprises a bottom plate arranged on a civil engineering structure, wherein the bottom plate is provided with at least an energy absorbing device; and a connection plate is arranged at the other ends of the energy absorbing devices and is provided with at least an adjusting base plate. The energy absorbing devices have the following beneficial effects: the well-arranged pores are arranged on the cylindrical pipe bodies of the energy absorbing devices, so shearing surfaces are produced on the sections of the cylindrical pipe bodies, when forces in the axial directions of the pipe bodies act on the energy absorbing devices, a plurality of shearing surfaces ensure that the pipe bodies are easy to deform due to local shearing force bearing, thus absorbing the energy.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Intelligent anti-lightening traffic condition monitoring device with splicing cross rod

InactiveCN106192803AIncrease profitRealize acquisitionStands/trestlesTraffic signalsClamp connectionAgricultural engineering

The invention discloses an intelligent anti-lightening traffic condition monitoring device with a splicing cross rod, belongs to intelligent anti-lightening traffic condition monitoring devices in the technical field of intelligent traffic, and aims to provide the intelligent anti-lightening traffic condition monitoring device with the splicing cross rod. The intelligent anti-lightening traffic condition monitoring device comprises a base, a stand column, a cross rod, wherein the stand column and the cross rod are connected through a fixed mounting frame; a breaching camera and a mounting bracket are mounted on the cross rod through the mounting bracket; the mounting bracket comprises the base; a supporting rod is arranged on the top surface of the front end of the base; a connecting ball joint is connected to the free end of the supporting rod; fixing seats are connected to two sides of the rear end of the base; a rotating roller and a connecting rod are arranged between the fixing seats side by side; spiral grooves are formed in the rotating roller; a sliding block is connected to the connecting rod; a moving block is connected to the sliding block, and is in clamping connection to the spiral grooves; and a L-shaped swinging rod is connected to the sliding block, and the other end of the L-shaped swinging rod is connected with the bottom of the breaching camera.

Owner:CHENGDU KECHUANGGU TECH CO LTD

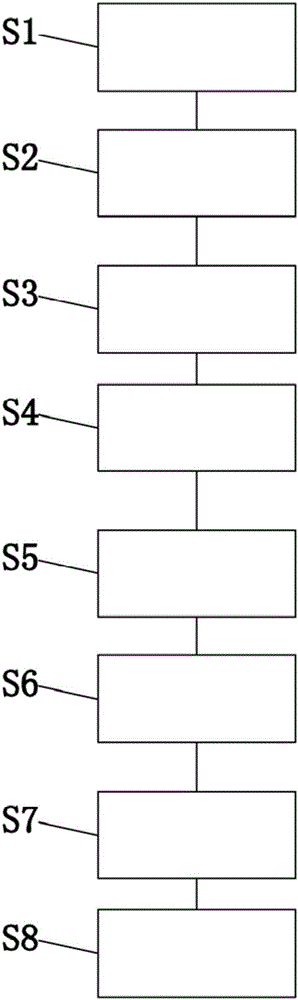

Mounting method for sill anchor combined support frame for steel structure shear wall and outer frame column base of super high-rise building

ActiveCN105926958AEasy docking installationEasy to adjustBuilding material handlingSteel columnsHigh rise

The invention discloses a mounting method for a sill anchor combined support frame for a steel structure shear wall and an outer frame column base of a super high-rise building. The method comprises the following steps of: S1, paying off at the position of the sill anchor combined support frame after civil foundation bed construction is finished; S2, mounting a transition rack at a proper position; S3, assembling an anchor bolt stock, an anchor bolt and an anchor bolt penetrating rack into an anchor bolt component, and placing the anchor bolt component on the transition rack; S4, preserving slot templates on a steel plate wall or a steel column foot base anti-shear component; S5, performing a primary calibration on the perpendicularity, the planimetric position and the anchor bolt top elevation of the overall anchor bolt component; S6, performing a secondary calibration on the perpendicularity and the elevation of the anchor bolt in the anchor bolt component before pouring concretes; and S8, pouring building foundation concretes. The mounting method has the advantages of assembling the sill anchor combined support off site so as to reduce in-site cross operation, flexibly adjusting the sill anchor combined support according the practical situation on site, greatly improving the construction efficiency and the like.

Owner:北京市机械施工集团有限公司 +1

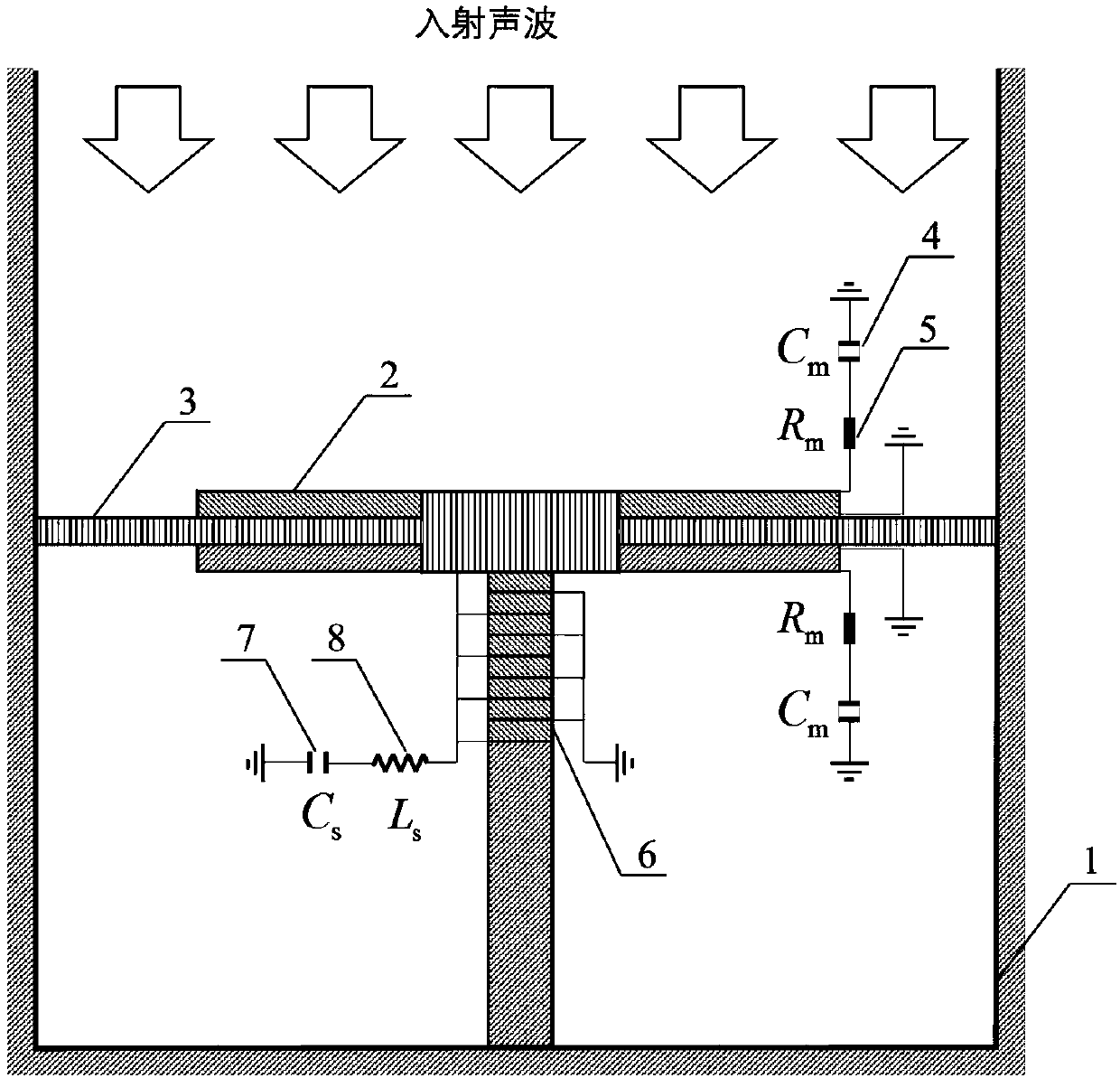

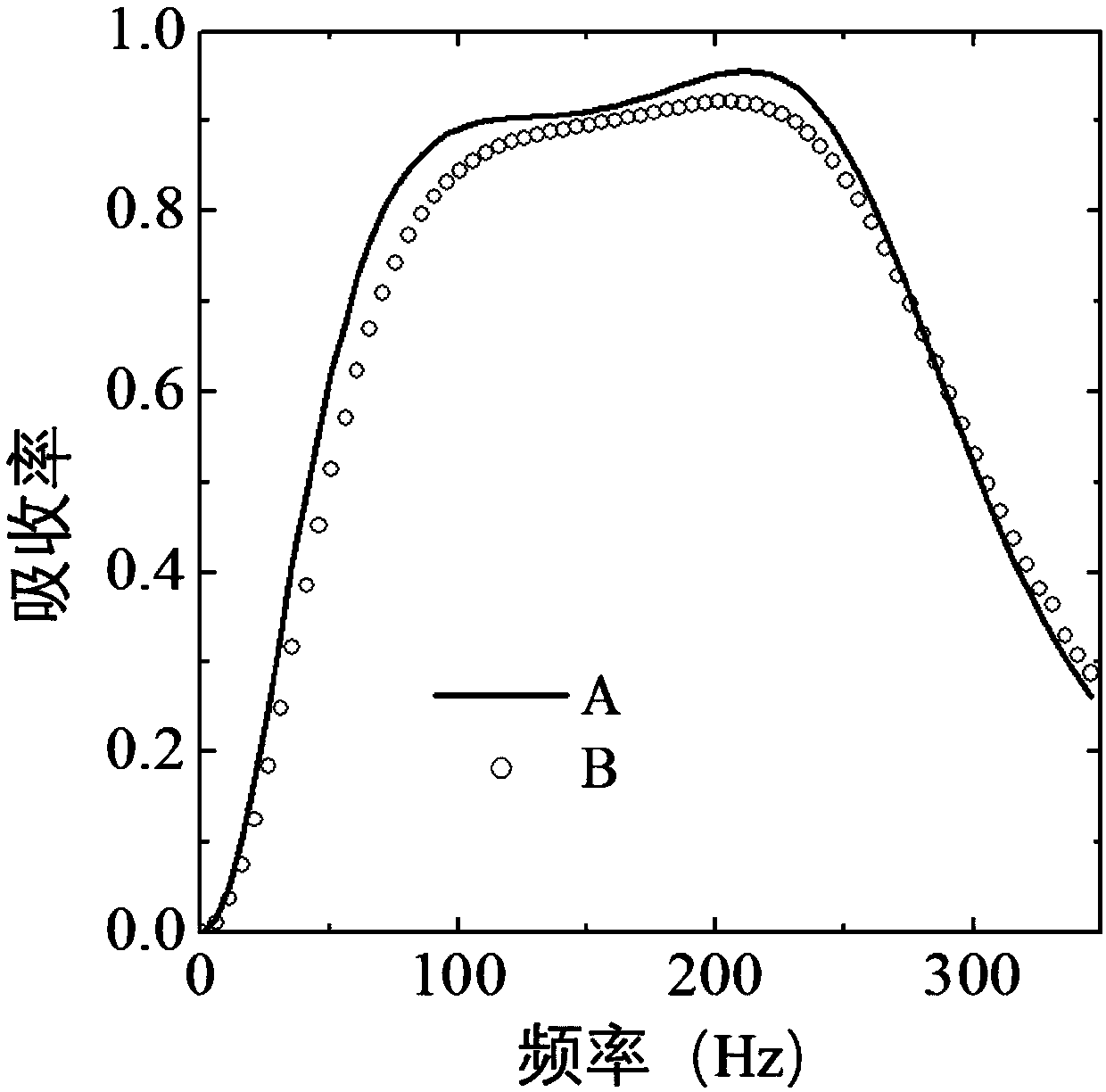

Low-frequency sound absorption metamaterial

ActiveCN110277083AImprove sound absorption strengthReduce the thickness of the structureLayered productsSound producing devicesElectricityAcoustic absorption

The invention relates to a low-frequency sound absorption metamaterial, and belongs to the technical field of sound absorption metamaterials. The sound absorption metamaterial disclosed by the invention is mainly based on a circuit control theory of a piezoelectric material, a piezoelectric film and a piezoelectric stack are independently regulated and controlled through a piezoelectric film circuit and a piezoelectric stack circuit, and the matching condition of the acoustic resistance and the acoustic reactance can be greatly improved without changes of the geometric configuration and the size. The sound absorption strength, the sound absorption frequency and the sound absorption bandwidth of the sound absorption metamaterial are regulated and controlled, a wide sound absorption frequency range is achieved for sound waves below 300 Hz, and the sound absorption frequency can be regulated within the wide range. The sound absorption metamaterial is small in structural thickness, small in size and high in sound absorption efficiency, and the limitation of a traditional method and a common metamaterial in low-frequency (smaller than or equal to 300 Hz) sound absorption is broken through.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

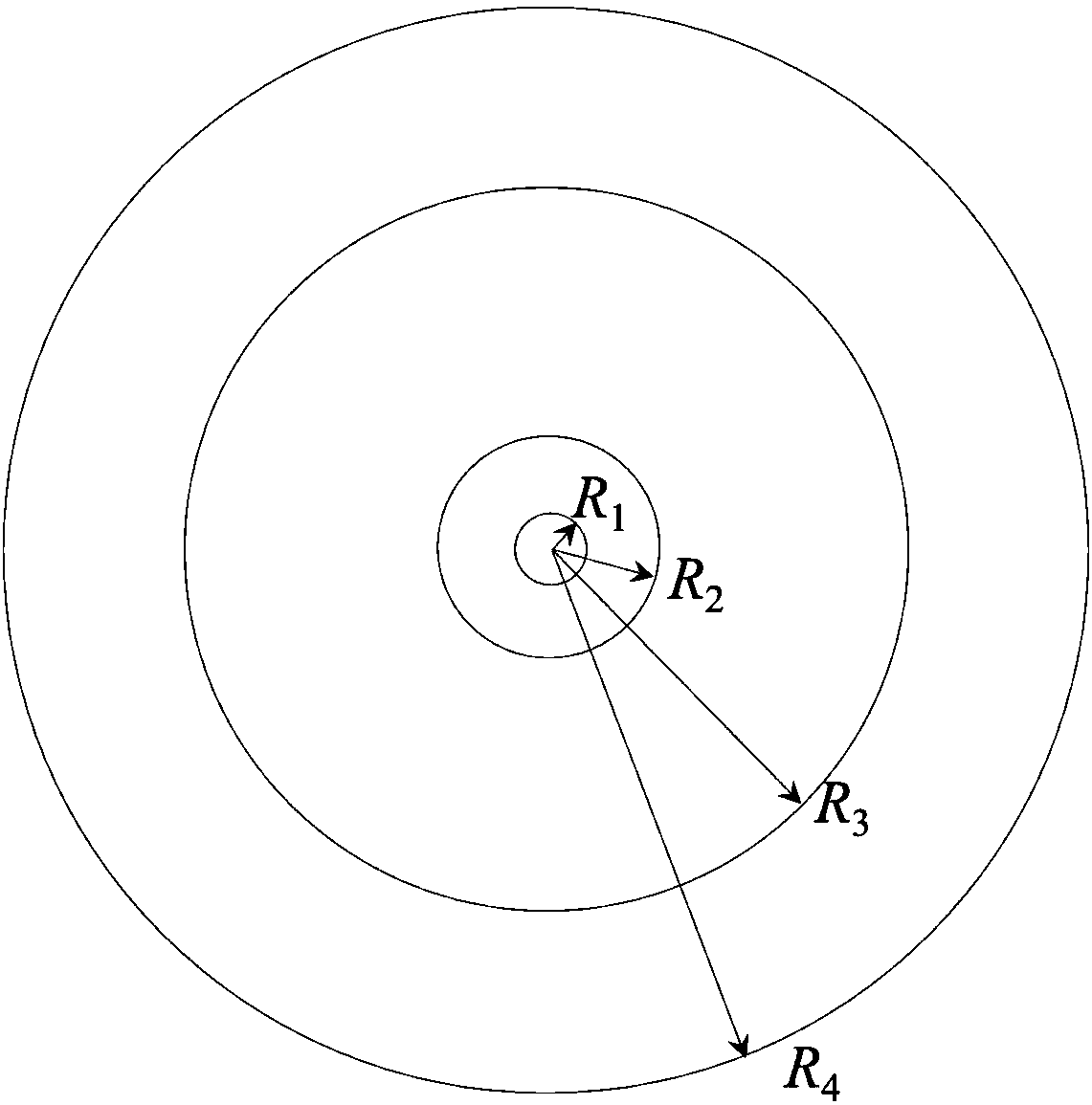

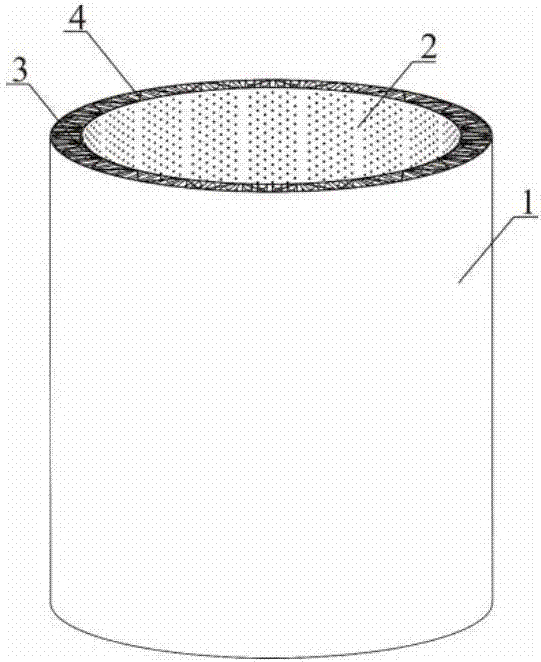

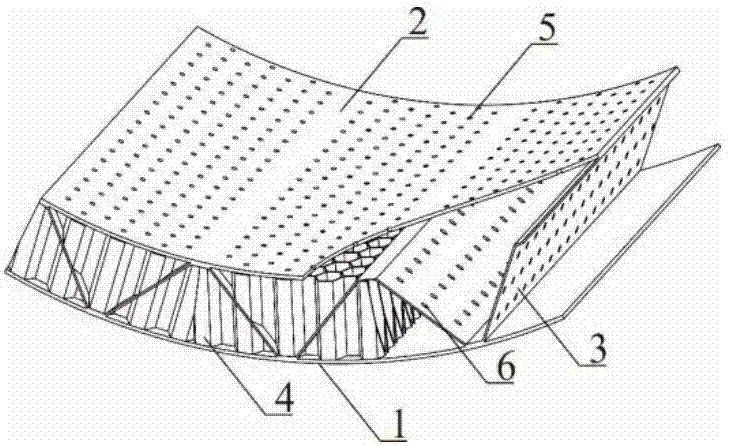

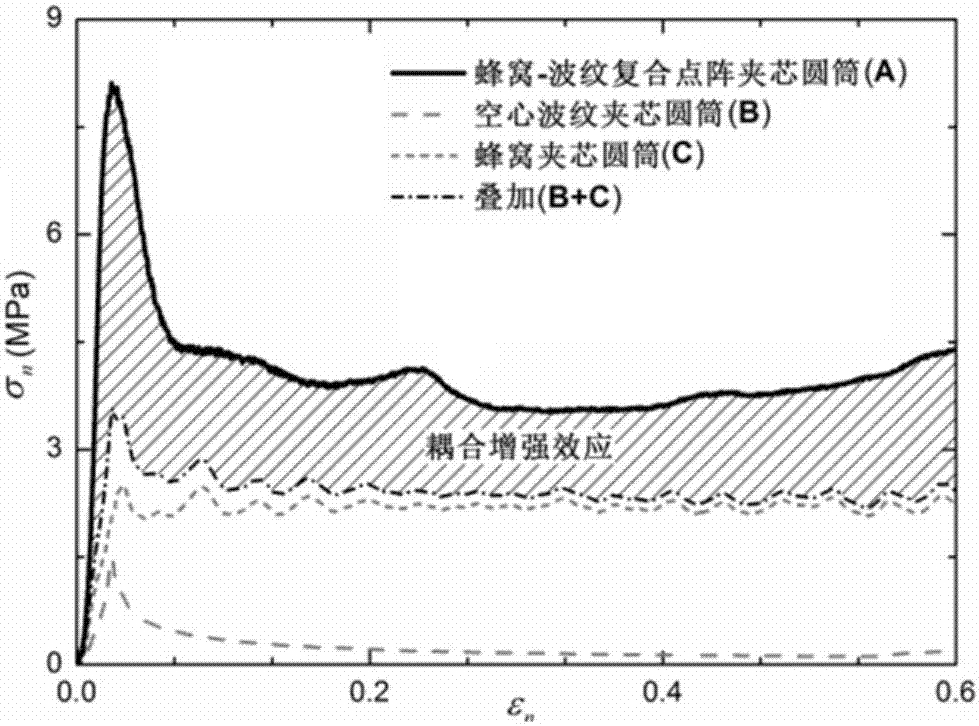

Honeycomb-corrugated composite lattice sandwich cylindrical shell and preparation method thereof

InactiveCN107344431AIncreased sound absorption frequency rangeGood sound absorptionLamination ancillary operationsLaminationEngineeringEnergy absorption

The invention discloses a honeycomb-corrugated composite lattice sandwich cylindrical shell and a preparation method thereof. The method comprises the following steps: cutting an aluminum honeycomb into a rectangular structure by adopting wire-electrode cutting; preparing a micro-punched corrugated plate by adopting mold-pressing, bending and laser boring technologies; fixedly forming the micro-punched corrugated plate on an annular corrugated mould, thereby acquiring a micro-punched annular metal corrugated core; respectively preparing an outer drum and a micro-punched inner drum on a metallic drum mould; connecting the micro-punched core with the micro-punched inner drum and outer drum in the manner of gluing or welding; and filling a corrugated channel with the aluminum honeycomb for gluing, thereby acquiring a multifunctional micro-punched honeycomb-corrugated composite lattice sandwich cylindrical shell. The structure integrates light weight, load bearing, energy absorption and sound wave absorption; the preparation technology is mature; and the honeycomb-corrugated composite lattice sandwich cylindrical shell has wide market prospect in the fields of civil use and military use with active demand on load bearing, sound absorption and noise lowering.

Owner:XI AN JIAOTONG UNIV

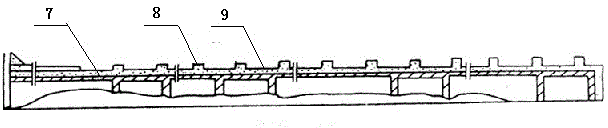

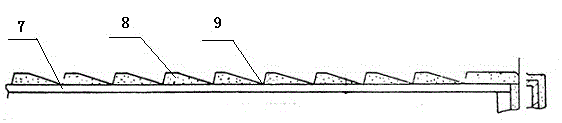

Bed-top of concentrating table

The invention relates to parts for gravity concentration equipment, in particular to a bed-top of a concentrating table. The bed-top is of novel material. By modifying the structure and material of the bed-top, the grade of finished ores is greatly increased, and the service life of the bed-top is greatly prolonged. The bed-top comprises a face plate, an ore feeding trough and a water feeding rough; the bed-top is characterized in that the face plate is provided with rifle strips, at least two deep and shallow grooves are provided between every two rifle strips, the section of the deep and shallow grooves is trapezoidal, and the ore feeding trough and the water feeding trough are made of environmental material. The bed-top is applicable to concentration of fine materials and is widely applicable to concentration of tin, tungsten, gold and silver, lead, zinc, titanium, iron, manganese, ferrotitanium, coal and the like.

Owner:江西省浩燃冶金设备有限责任公司

Tear-resistant packing material structure manufacture method and tear-resistant product

The invention provides a tear-resistant packing material structure manufacture method and a tear-resistant product. The tear-resistant packing material structure manufacture method comprises a first material preparing step, wherein the first material preparing step comprises a warp and weft direction fiber bundle weaving step and a first press fit step; a second material preparing step, wherein the second material preparing step comprises a second press fit step and a first coating step; a third press fit step; a second coating step; a fourth press fit step; a third coating step and a drying step; and therefore, the tear-resistant packing material structure which is provided with a heat-sealing layer, a transition layer, a film-similar tear-resistant layer, a junction layer and a paper layer in sequence from bottom to top. The tear-resistant packing material structure manufacture method can be realized by automated mechanical equipment, so that the production efficiency can be improved, and the manpower cost is lowered. The tear-resistant packing material structure provided by the invention has printability and deflection owned by the paper layer and also has the effects of bearing capacity, high strength, high toughness and the like of the tear-resistant layer.

Owner:FOMSON DEV ENTERPRISES

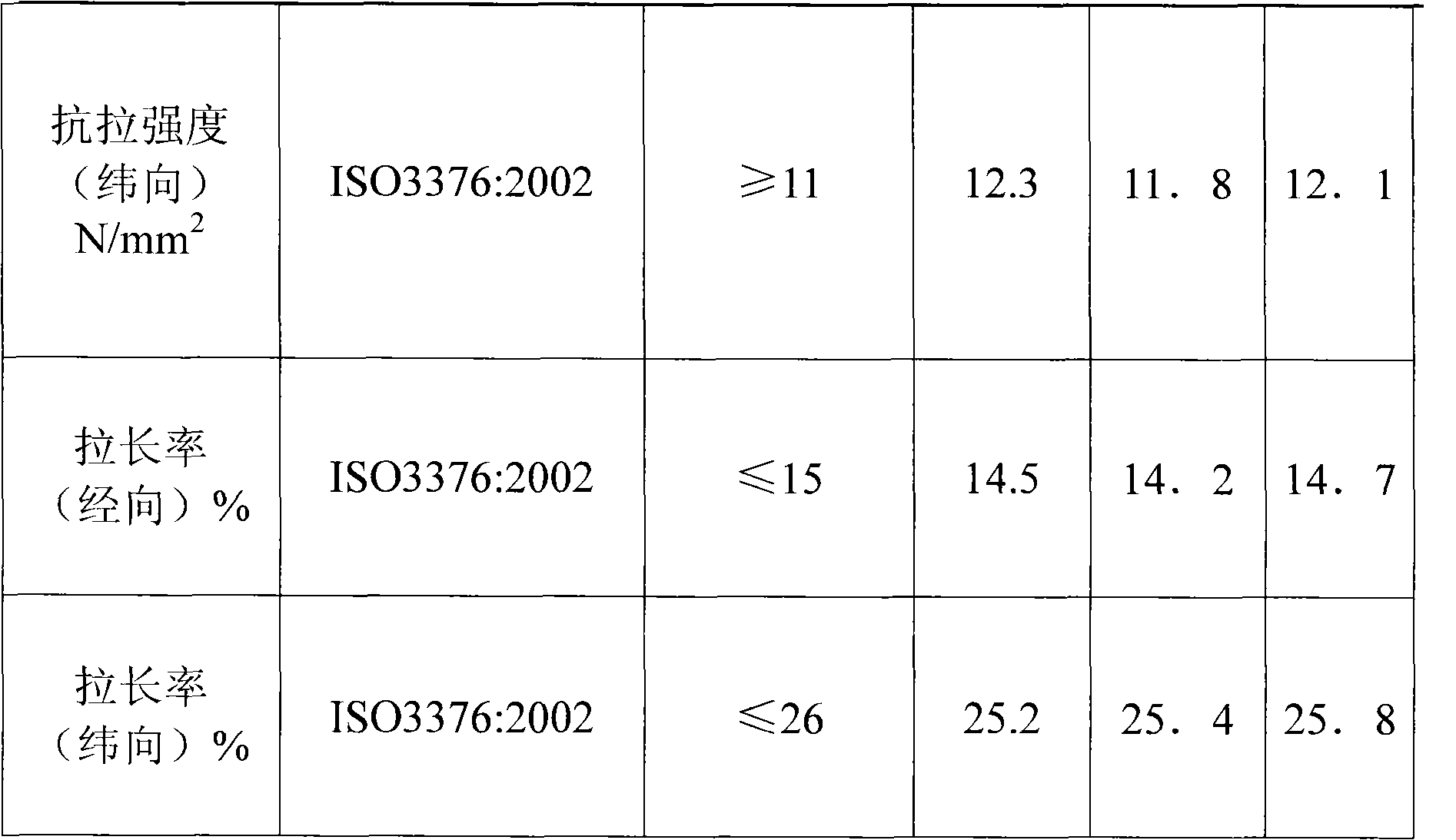

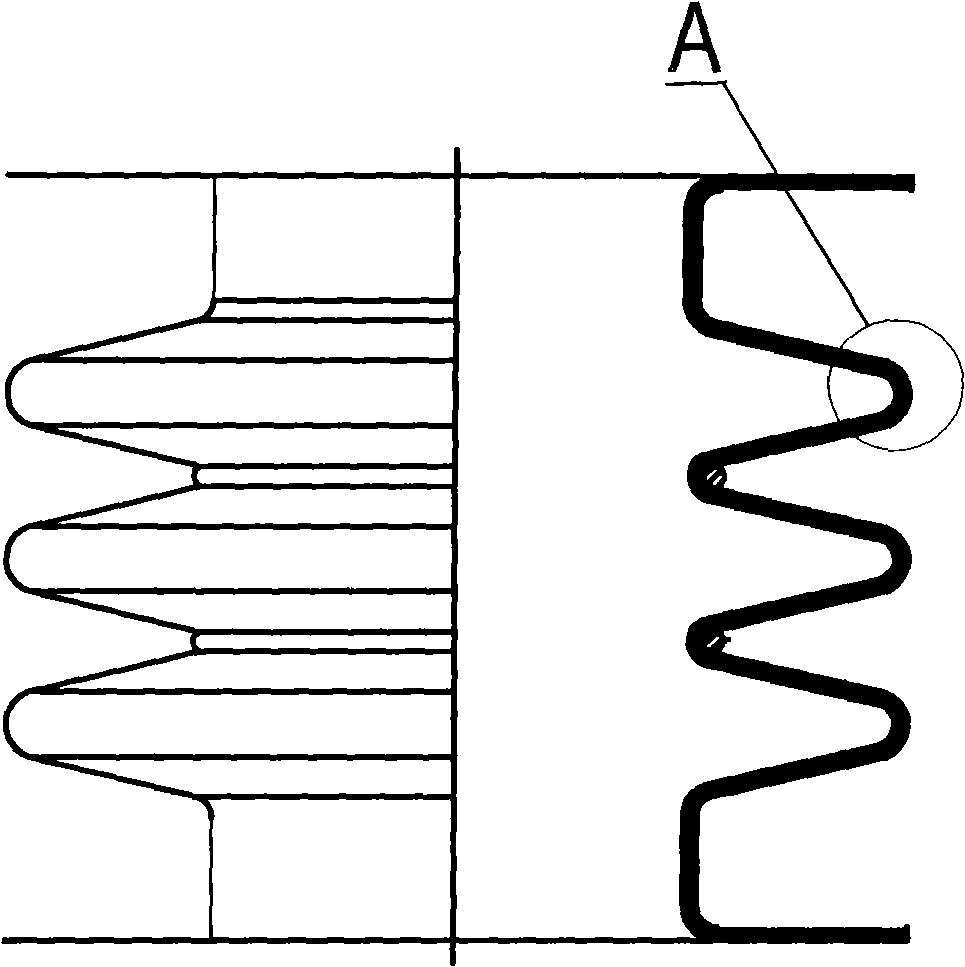

Bellows used for polytetrafluoroethylene compensator and manufacturing method thereof

InactiveCN101319740AWith stiffnessImproved resistance to positive pressurePipeline expansion-compensationFlexible pipesMetal gridMesh grid

The invention relates to a bellows manufacturing technique, particularly relates to a bellows applied to a polytetrafluor ethylene compensator and a manufacturing method thereof. An inner polytetrafluor ethylene corrugated layer, a metal corrugated layer and an outer polytetrafluor ethylene corrugated layer are successively melted into an integrated body; the two diagonals of the unit grid in the metal corrugated layer are identical with the axial direction and radial direction of the bellows respectively; during the manufacturing process, the two diagonals of the quadrangular unit grid in the metal grid are laid around the polytetrafluor ethylene film in the directions identical with the axial direction and radial direction of the cylindrical mould. The technique is aimed at providing a bellows with strong capability to bear positive and negative pressures for a polytetrafluor ethylene compensator and as well as the manufacturing method. Compared with the prior art, the bellows has certain rigidity, the service life is long, small-bore bellows capable of bearing positive and negative pressures can be manufactured more easily, and the capability of the polytetrafluor ethylene compensator is improved, and so on.

Owner:温州市氟塑设备制造厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com