Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Good sound absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

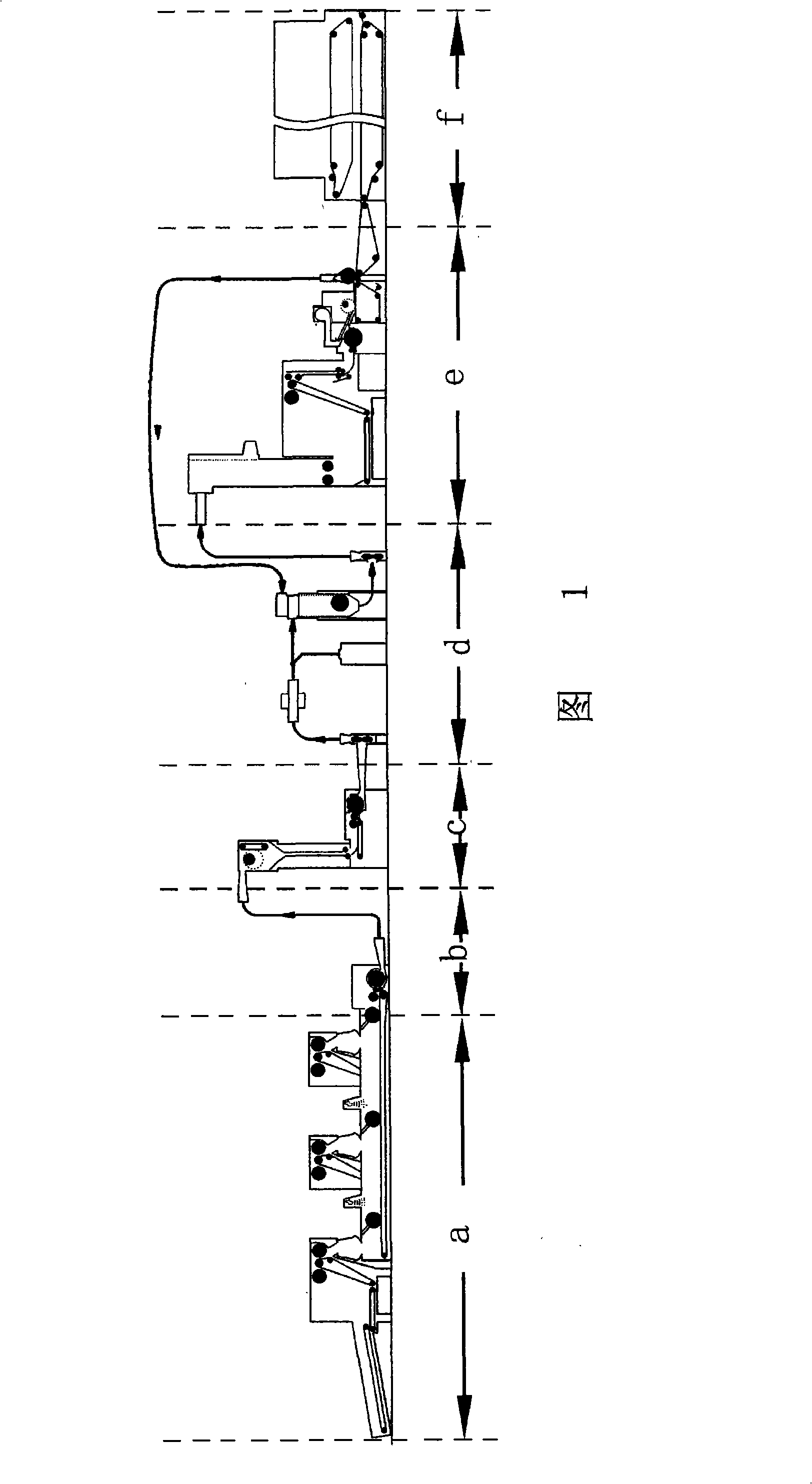

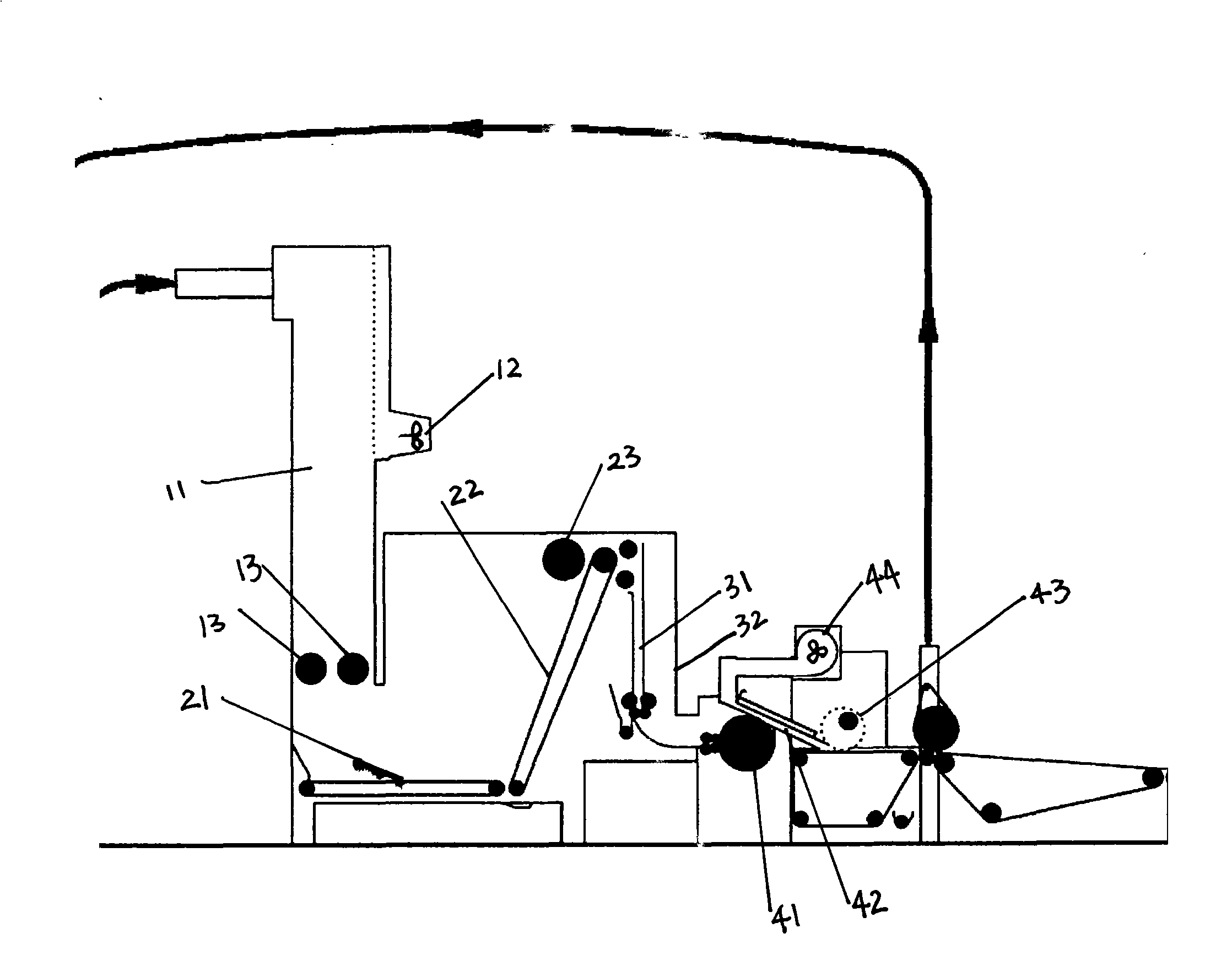

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

Montmorillonite/isotactic polypropylene/polylactic acid composite sound absorbing cotton and preparation method thereof

InactiveCN103696127ASimple production processRaw materials are cheap and easy to getSynthetic resin layered productsNon-woven fabricsAdditive ingredientPolypropylene

The invention discloses montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton, which consists of a top surface layer, a back surface layer and a fiber cotton layer, wherein the fiber cotton layer is clamped and arranged between the top surface layer and the back surface layer, and the top surface layer and the back surface layer are made of non-woven fabric materials. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton is characterized in that the non-woven fabric is prepared form the following ingredients in parts by weight by a melt blowing method: 100 parts of isotactic polypropylene, 10 to 12 parts of polylactic acid, 10 to 12 parts of montmorillonite powder, 5 to 7 parts of dilauryl thiodipropionate, 2 to 3 parts of zinc oxide, 12 to 15 parts of diethylene glycol dibenzoate, 4 to 6 parts of triethyl citrate, 2 to 3 parts of zinc chloride, 5 to 7 parts of chitosan, 2 to 3 parts of molecular sieves, 12 to 15 parts of yellow cinnamon leaf, 2 to 3 parts of rhizoma gastrodiae, 2 to 3 parts of mint, 2 to 3 parts of radix angelicae pubescentis and 4 to 5 parts of auxiliary agents. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton has the advantages that the montmorillonite, the isotactic polypropylene and the polylactic acid are compounded for preparing the sound absorbing cotton by the melt blowing method, the production process is simple, the raw materials are easy to obtain, the cost is low, and the prepared product has the advantages that the air permeability and the oxygen permeability are good, the tensile strength and the extension degree are high, the sound absorbing effect is obvious, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

PET (polyethylene glycol terephthalate) fiber/polyacrylonitrile fiber composite sound absorbing cotton and preparation method of PET fiber/polyacrylonitrile fiber composite sound absorbing cotton

InactiveCN102965847AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesPolymer scienceAntioxidant

The invention discloses PET (polyethylene glycol terephthalate) fiber / polyacrylonitrile fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of polyacrylonitrile fibers, 10 to 15 parts of emulsifying agents OP-20, 5 to 10 parts of peregal O-15, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SEBS (styrene ethylene butylene styrene), 15 to 20 parts of calcined clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of diisooctyl phthalate, 4 to 6 parts of tricresyl phosphate, 2 to 3 parts of polyethylene wax, 1 to 2 parts of vinyl (beta-methoxyethoxy) trisilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of dimethyl dimercapto isooctyl acetate tin, 0.5 to 1.5 parts of anti-aging agents ODA (octyl decyl adipate) and 1 to 2 parts of antioxidants 1035. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

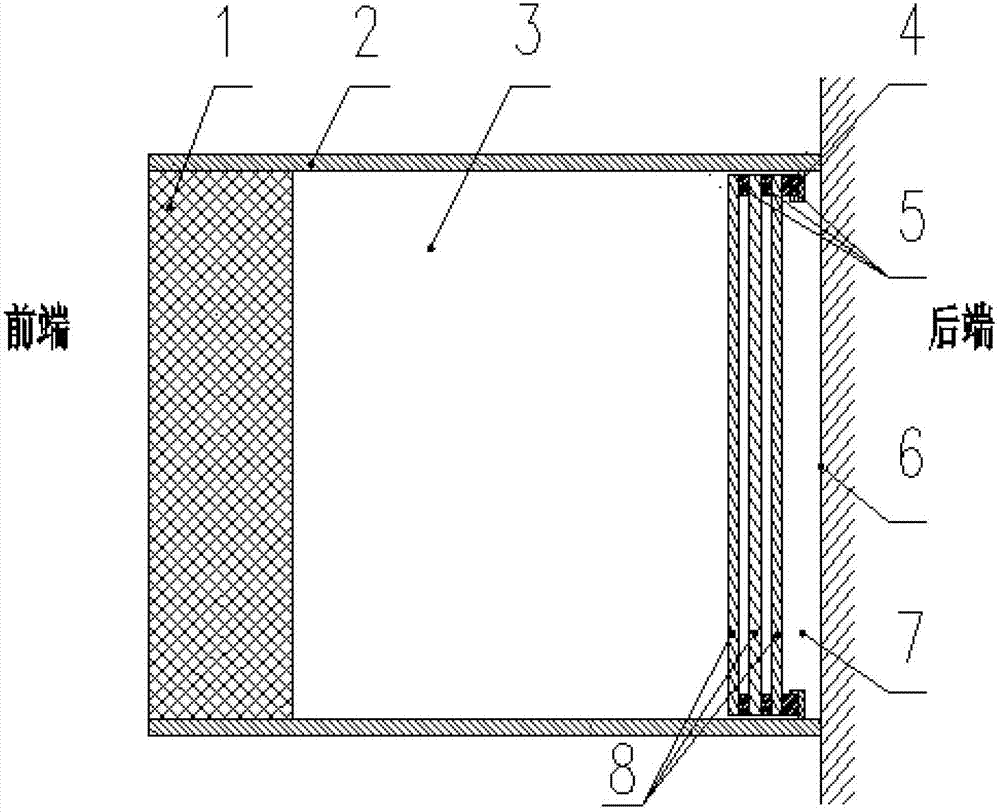

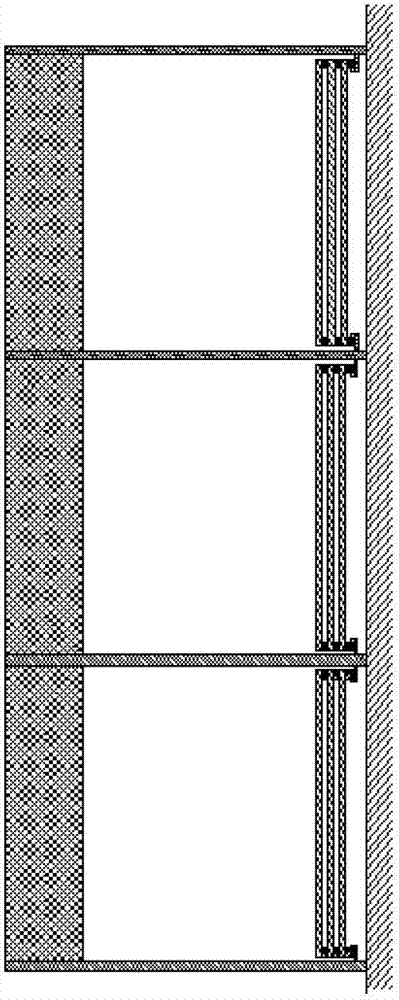

Thin broadband sound-absorbing structure of composite multi-layer mechanical impedance plates

InactiveCN102968985AIncreasing the thicknessSound absorption frequency bandwidthSound producing devicesWater-setting substance layered productAdhesiveCavity resonance

The invention provides a thin broadband sound-absorbing structure. The structure comprises a sound-absorbing material, a support and at least two layers of mechanical impedance plates, wherein the sound-absorbing material is installed on the inner side of one end of the support, a supporting plate is arranged on the inner wall of the other end of the support, each of the mechanical impedance plates consists of a back plate and sticky elastic rings at two ends of the back plate, adjacent back plates are not in contact, sticky elastic rings are stuck to the supporting plate through an adhesive, the sticky elastic rings, the support inner wall and the back plates are attached tightly, a hollow is formed among the sound-absorbing material and the mechanical impedance plates, and the back plate on the outermost side is recessed towards the support end face by certain distance. Mechanical impedance is coupled to a traditional sound-absorbing material and a cavity resonance absorption mechanism, a novel thin broadband sound-absorbing mechanism is formed, the structure thickness is not increased basically based on the acoustic performance, the middle / high-frequency sound absorption performance is good, the low-frequency sound absorption effect is improved greatly and the sound-absorbing structure of which the thickness is thin and the sound-absorbing frequency band is wide is produced.

Owner:JIANGSU UNIV

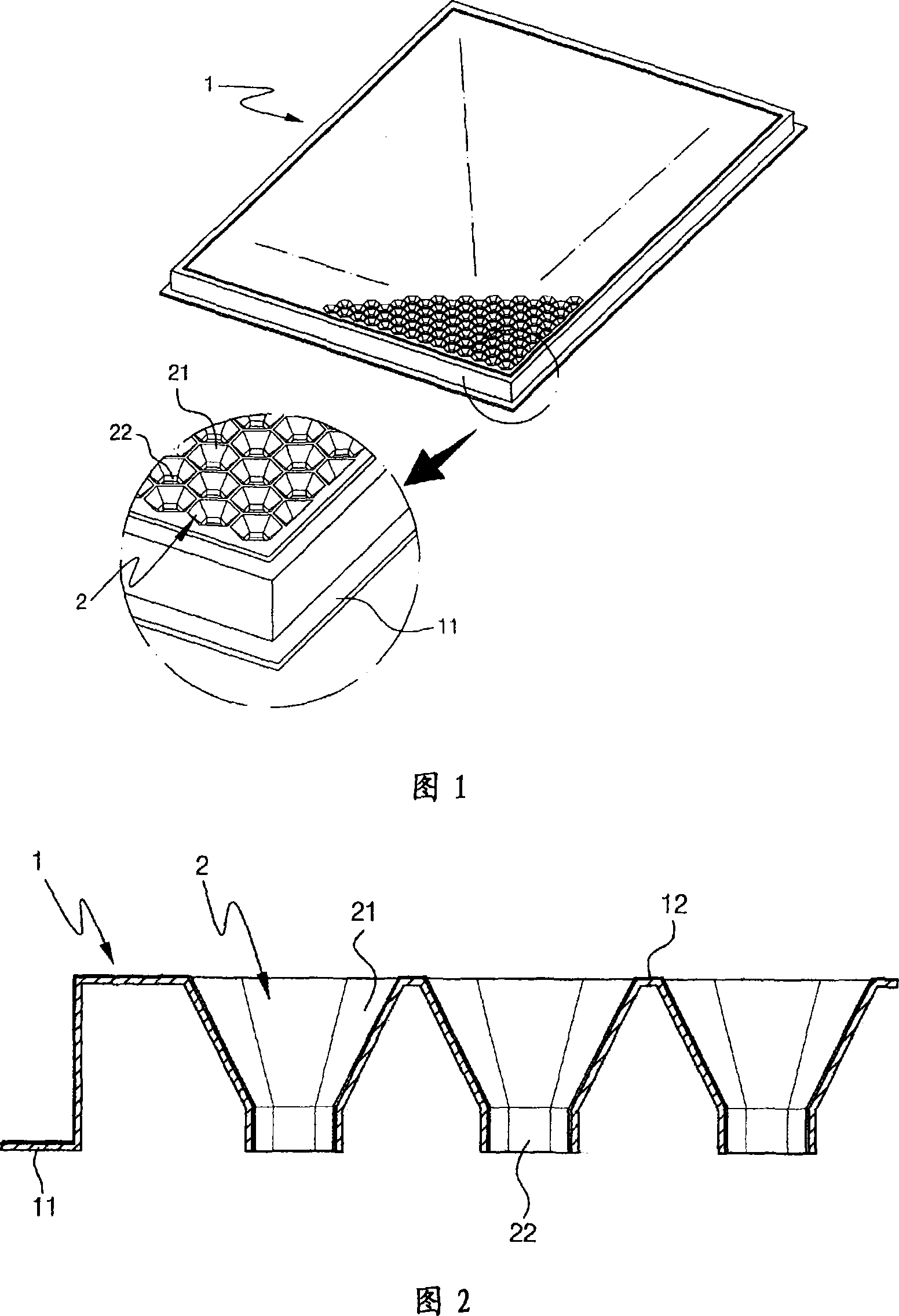

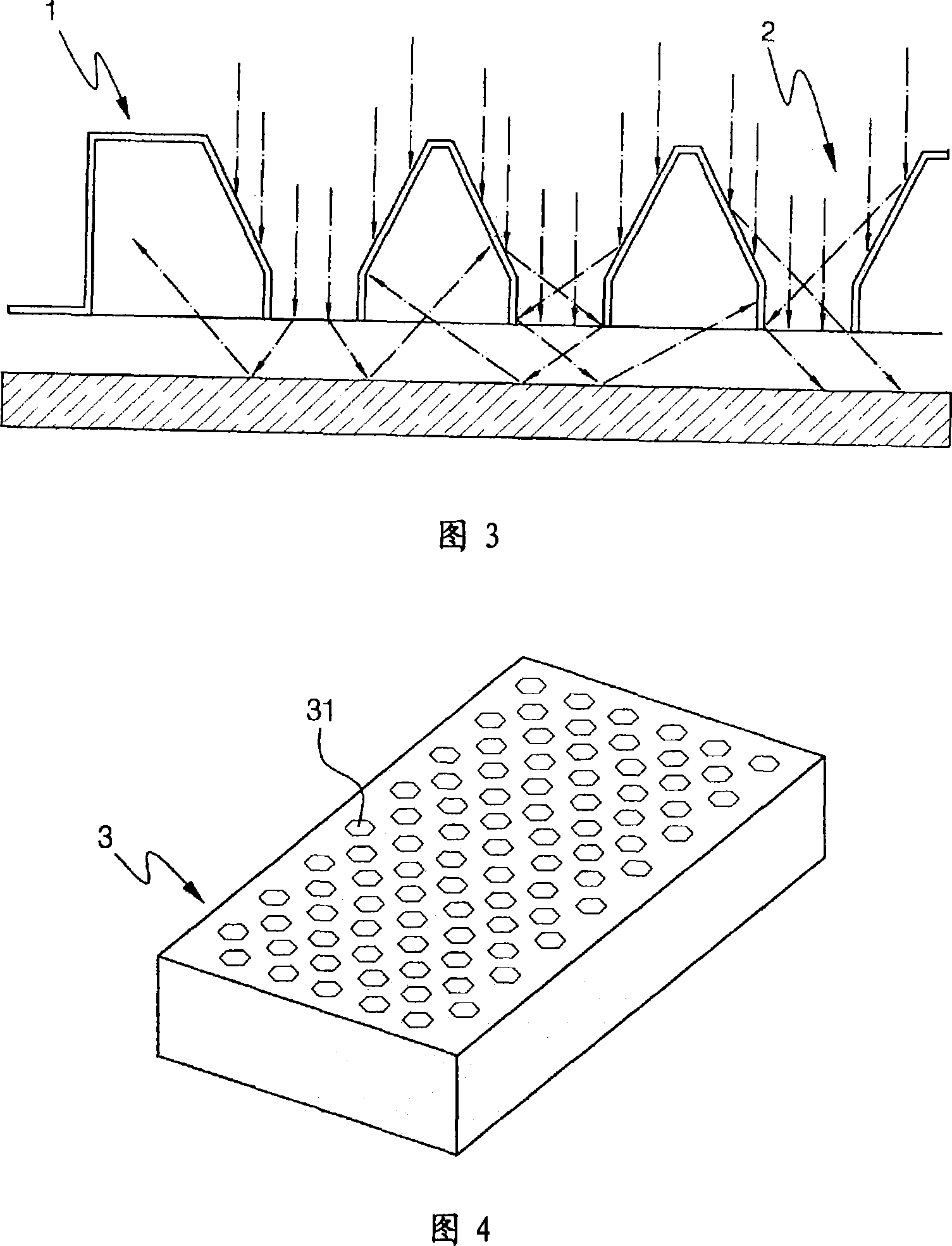

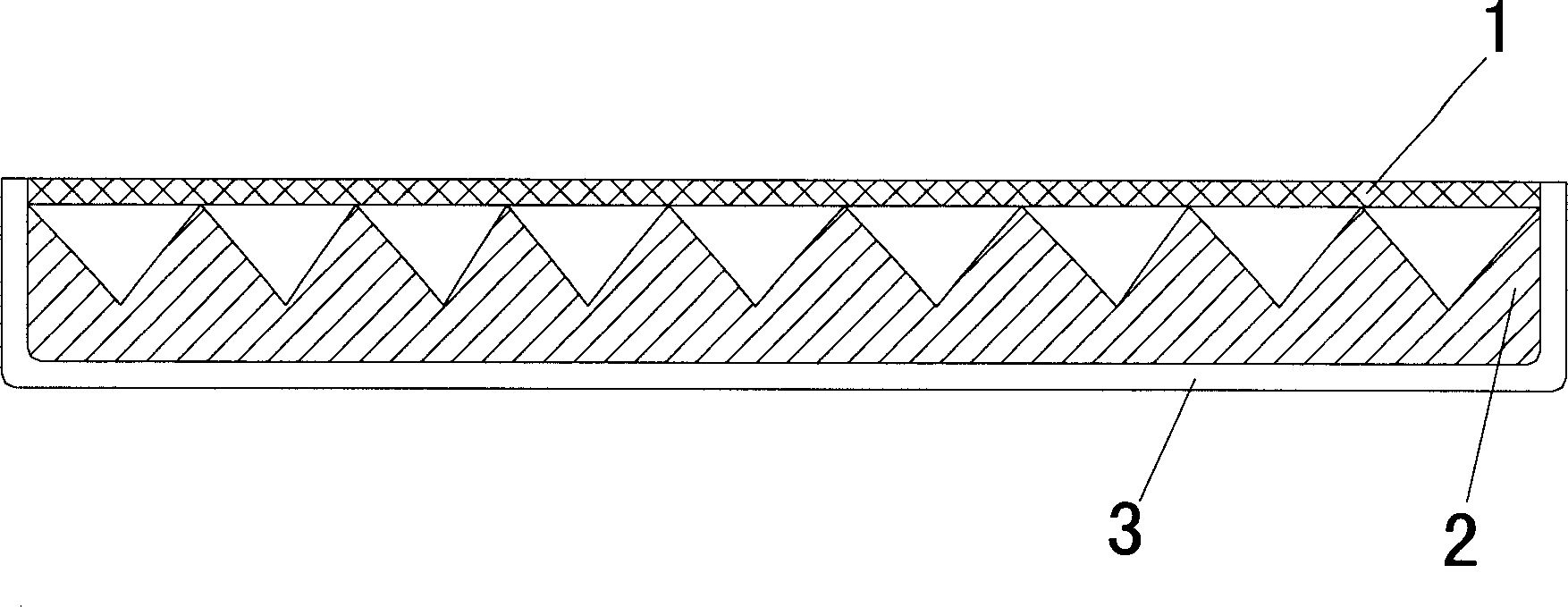

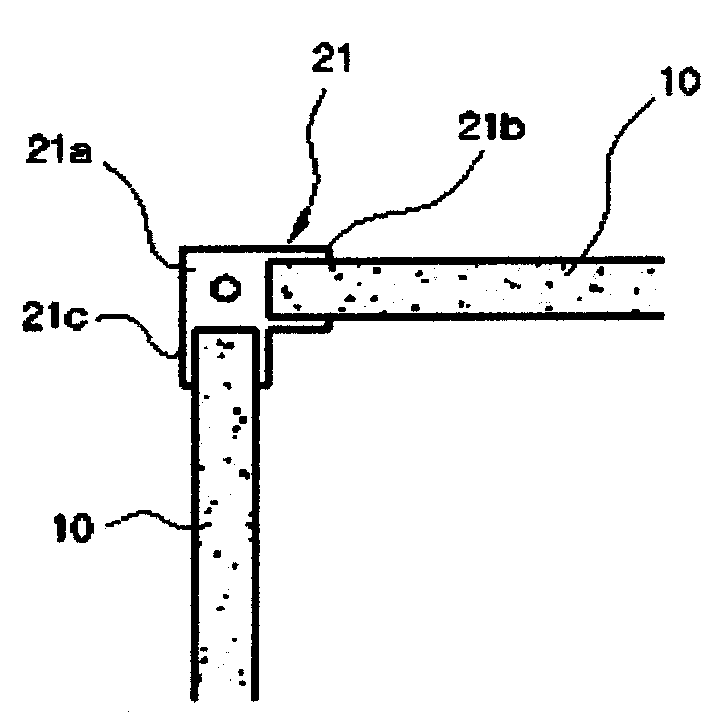

The sound-absorbing panel

InactiveCN101194077AGood sound absorptionEffective absorptionCovering/liningsSound proofingInterior spaceSection plane

Owner:金永玉

Cellulose-reinforced polyurethane/epoxy resin interpenetrating polymer network hard composite foam material and preparation method thereof

InactiveCN105348473AHigh compressive strengthGood sound absorptionInterpenetrating polymer networkIsocyanate compound

The invention discloses a cellulose-reinforced polyurethane / epoxy resin interpenetrating polymer network hard composite foam material and a preparation method thereof, relates to a foam material and a preparation method thereof and aims at solving the problems that existing polymer formed through mutual interpenetrating of two types of polymer, namely polyurethane and epoxy resin, is poor in sound absorption property and low in mechanical property. The sound absorption property of the composite foam material ranges from 80% to 92%, and the composite foam material is prepared from polyether polyol, isocyanate, water, a foaming agent, foam stabilizer, initiator, hydrosol of nano-crystalline cellulose with the mass percentage being 1%, chain extender, a cross-linking agent and epoxy resin. The preparation method comprises the steps of firstly, mixing the polyether polyol, the foam stabilizer, the initiator, the foaming agent, the chain extender and the water with cellulose obtained after pretreatment, then adding the epoxy resin and the cross-linking agent, and obtaining a mixture; then mixing the isocyanate with the mixture, conducting stirring till bubbles are generated, leaving the mixture standing still, obtaining a foamed mixture, finally, conducting curing on the foamed mixture at the room temperature, and then conducting curing at the high temperature.

Owner:NORTHEAST FORESTRY UNIVERSITY

Mute environment-friendly paint and preparation method thereof

The invention relates to mute environment-friendly paint and a preparation method thereof. The mute environment-friendly paint consists of filler, an odor-eliminating latex, an assistant, pigment, a flame retardant and water, wherein the filler comprises a wood fiber, diatomite, expanded perlite and hollow glass microspheres; the expanded perlite is open pore expanded perlite with 14-120 meshes; and the average grain diameter of the odor-eliminating latex is 0.15-0.5mu m. The preparation method of the mute environment-friendly paint comprises three steps of premixing, dispersing and grinding and adjusting paint. The prepared mute environment-friendly paint has the advantages of favorable mute effect, safety, environmental protection, capability of adjusting the indoor air temperature, simple and convenient construction, favorable decorative effect and the like as well as favorable market prospect.

Owner:中科力川(北京)建设工程有限公司

Polyurethane semi-rigid foam composition and preparation method thereof

The invention provides a polyurethane semi-rigid foam composition which is formed by the following components in parts by weight: 100 parts of premixed polyether A and 120-170 parts of isocyanate B. The invention also provides a preparation method of the polyurethane semi-rigid foam composition. The polyurethane semi-rigid foam composition provided by the invention has excellent sound absorption effect and low VOC (Volatile Organic Compounds) content and is especially suitable for automobile roofs.

Owner:上海井上高分子制品有限公司

Acoustic board of glass fibre composite

InactiveCN101000763AGood sound absorptionImprove corrosion resistanceSound producing devicesEpoxyGlass fiber

A sound absorption board of glass fiber composite material is prepared as setting external frame to be basin form, placing sound absorption felt in said frame with base surface and peripheral wall, arranging surface grille above said felt, firm-jointing edge of said grill with edge of said frame, forming both said grille and said frame by glass fiber composite material, distributing conical structure at surface of said felt, sticking said felt on internal surface of said frame by epoxy and preparing said frame by extruding process.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

Elevator traction belt and elevator

InactiveCN105672009AHigh tensile strengthReduce weightRope making machinesElevatorsResin matrixEngineering

The invention discloses an elevator traction belt and an elevator with the traction belt. The traction belt comprises a wrapping layer and at least one bearing body sleeved with the wrapping layer. Each bearing boy comprises basalt fibers and a resin matrix which are compounded together. The basalt fibers comprise multiple parallel basalt fiber filaments. Due to the fact that density of the basalt fibers and the density of the resin are both smaller than that of a steel wire, the weight of the traction belt is effectively reduced, the traction belt can be easily used on the elevator with superlarge lifting height, and the range of an existing maximum elevator lifting height can be widened. Meanwhile, the basalt fibers have a good sound absorption effect, the traction belt is made from the basalt fibers, noise generated during operation of the traction belt can be effectively lowered, and elevator taking comfort is improved. The basalt fiber filaments are arranged in the resin matrix in parallel, friction force among the fiber mono-filaments is reduced, the traction belt has the advantages of being free of twisting, resistant to abrasion, resistant to fatigue and the like, the traction performance of the traction belt is improved, and the service life of the traction belt is prolonged.

Owner:HITACHI ELEVATOR CHINA

PET (polyethylene glycol terephthalate) fiber/ceramic fiber composite sound absorbing cotton and preparation method of PET fiber/ceramic fiber composite sound absorbing cotton

InactiveCN102965840AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / ceramic fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of ceramic fibers, 10 to 15 parts of emulsifying agents OP-4, 5 to 10 parts of peregal O-15, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SBR (styrene butadiene rubber), 15 to 20 parts of nanometer bauxite, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of glycerol triglycerin acid ester, 4 to 6 parts of triphenyl phosphate, 2 to 3 parts of microcrystalline wax, 1 to 2 parts of vinyl (beta-methoxyethoxy) trisilane, 2 to 3 parts of zinc stearate, 1 to 2 parts of lead sulfate tribasic, 0.5 to 1.5 parts of anti-aging agents ODA (octyl decyl adipate) and 1 to 2 parts of antioxidants 168. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Glass wool ceiling board and preparation method thereof

ActiveCN104652745AGood sound absorptionGood thermal insulationGlass making apparatusCovering/liningsGypsumWool

The invention discloses a glass wool ceiling board. The glass wool ceiling board comprises a glass wool board layer, a glass fiber felt layer and a plaster coating material layer, wherein the glass wool board layer is prepared from centrifugal glass wool fibers with an environment-friendly resin binder, and the mass ratio of the centrifugal glass wool fibers, the environment-friendly resin binder and a plaster coating material is (85-93): (7-15): (2-3). A preparation method of the glass wool ceiling board comprises the steps of uniformly spraying the environment-friendly resin binder to the surfaces of the centrifugal glass wool fibers in an atomization state, carrying out wool collection by a wool collector, compressing and conveying collected wool into a curing oven for curing so as to obtain a glass wool board, then, carrying out glass fiber felt facing on the glass wool board, and carrying out compressed plaster coating material spraying according to different decorative patterns. Compared with the prior art, the glass wool ceiling board and the preparation method thereof have the advantages that glass wool ceiling boards of rich and diverse forms can be prepared according to customer requirements, and the ceiling board has heat preservation, heat insulation, sound absorption and fire prevention effects, does not fall dust, is free from formaldehyde release, is harmless to the health of users and is light in weight, so that the requirements on the load of a building can be lowered, and transporting and mounting are more convenient.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL

Novel sound-proof building material and preparation method thereof

The invention discloses a novel sound-proof building material and a preparation method thereof and relates to the technical field of novel building materials. The novel sound-proof building material is prepared from raw materials in parts by weight as follows: 30-45 parts of polyethylene, 28-36 parts of polybutadiene rubber, 15-24 parts of kaolin, 10-18 parts of asbestos, 8-17 parts of plant fiber, 12-20 parts of volcanic mud, 8-16 parts of hollow glass beads, 7-15 parts of glass fibers, 5-9 parts of montmorillonite, 4-8 parts of nanometer oxide, 8-13 parts of silica particles, 10-16 parts ofpolyurethane resin particles, 4-9 parts of diatom ooze, 8-14 parts of calcium silicate, 4-7 parts of a foaming agent, 3-8 parts of an antioxidant, 4-7 parts of a flame retardant and 2-5 parts of a plasticizer. The novel sound-proof building material is light and easy to mount, has the advantages of stable chemical property, good sound absorbing effect and good flame retardance, can effectively weaken noise outside space, is low in raw material cost and has good market prospect.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

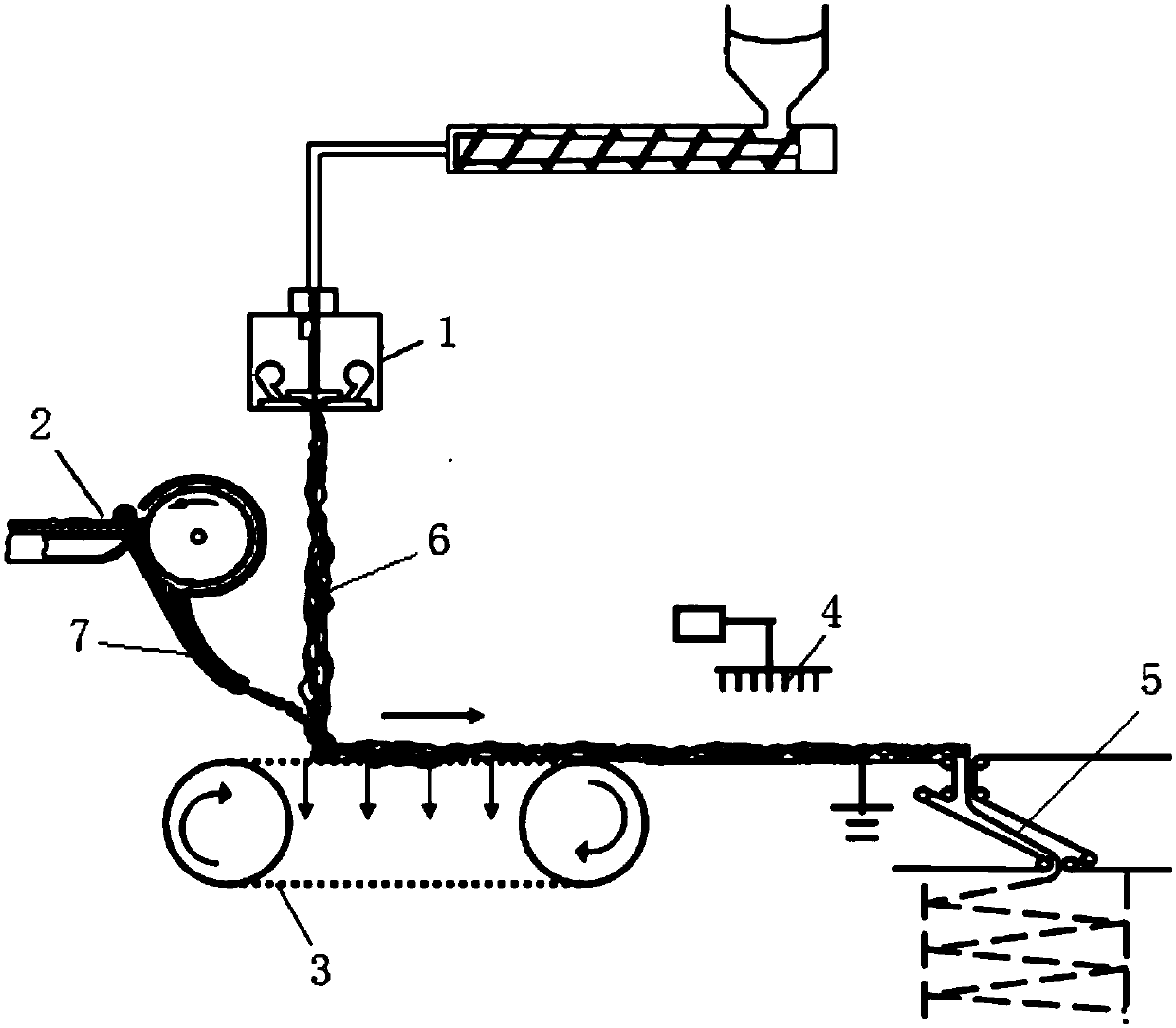

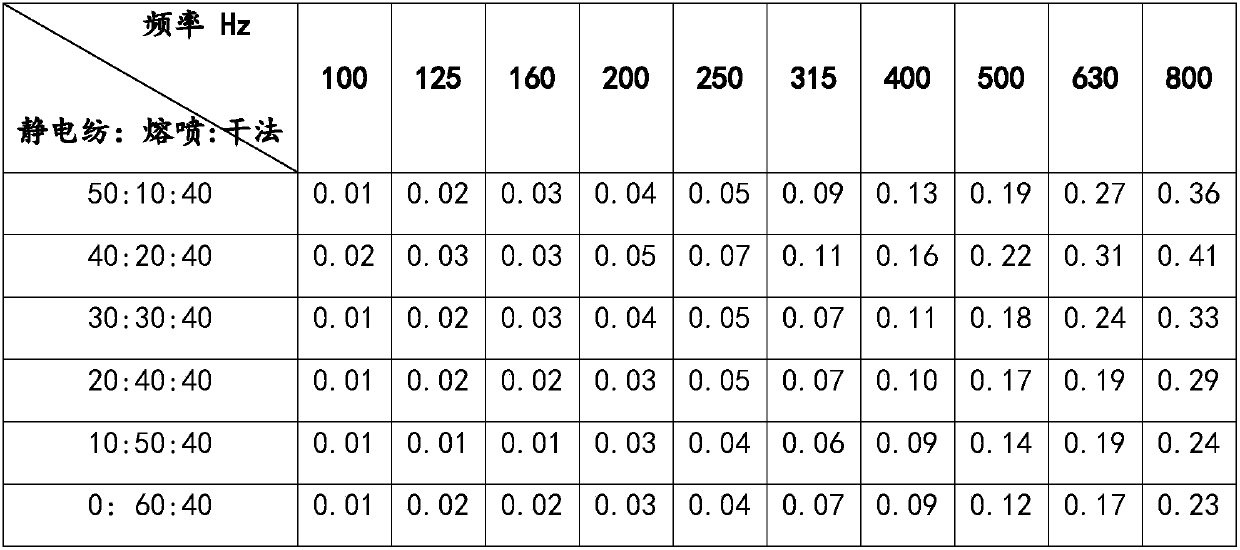

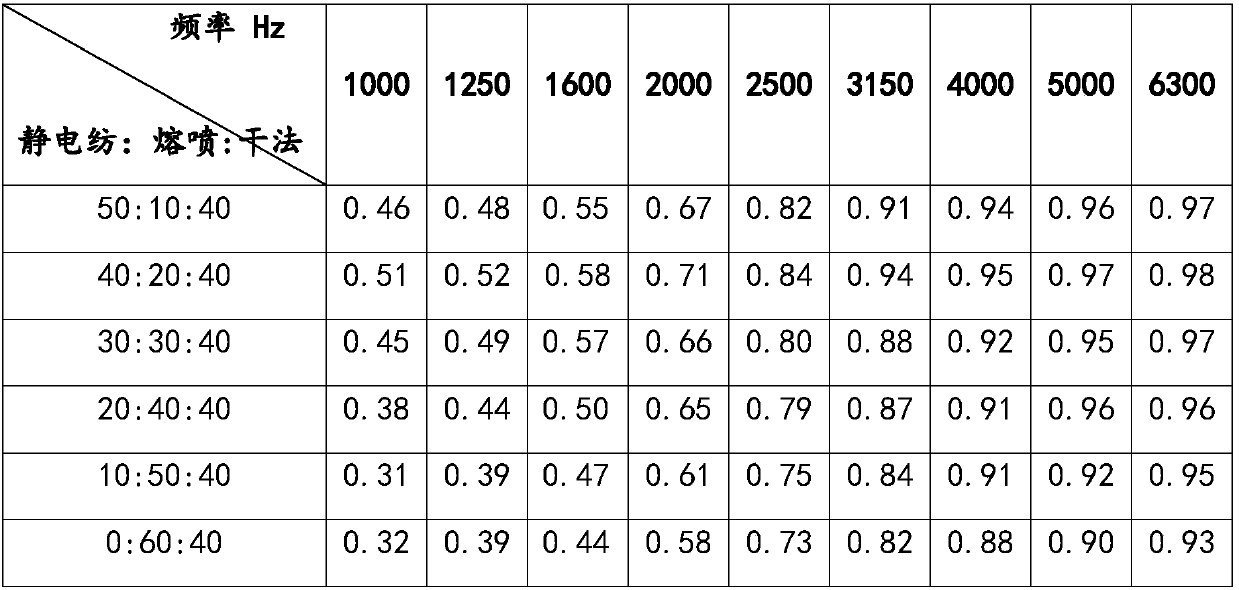

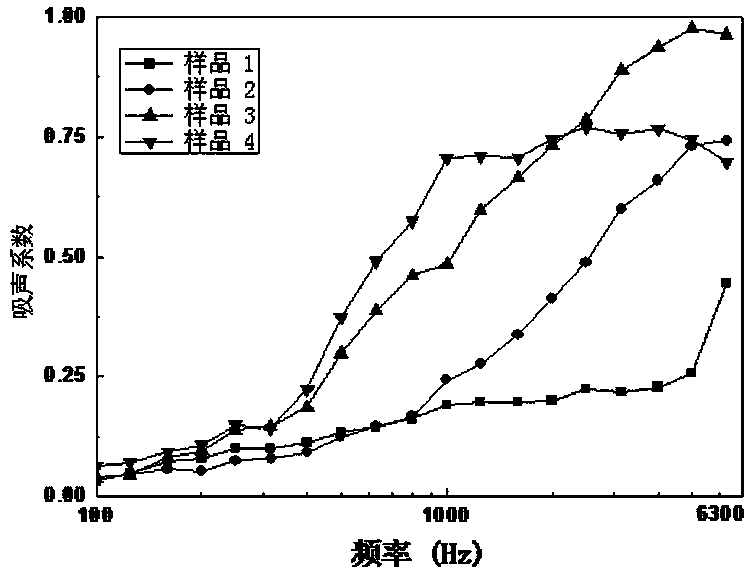

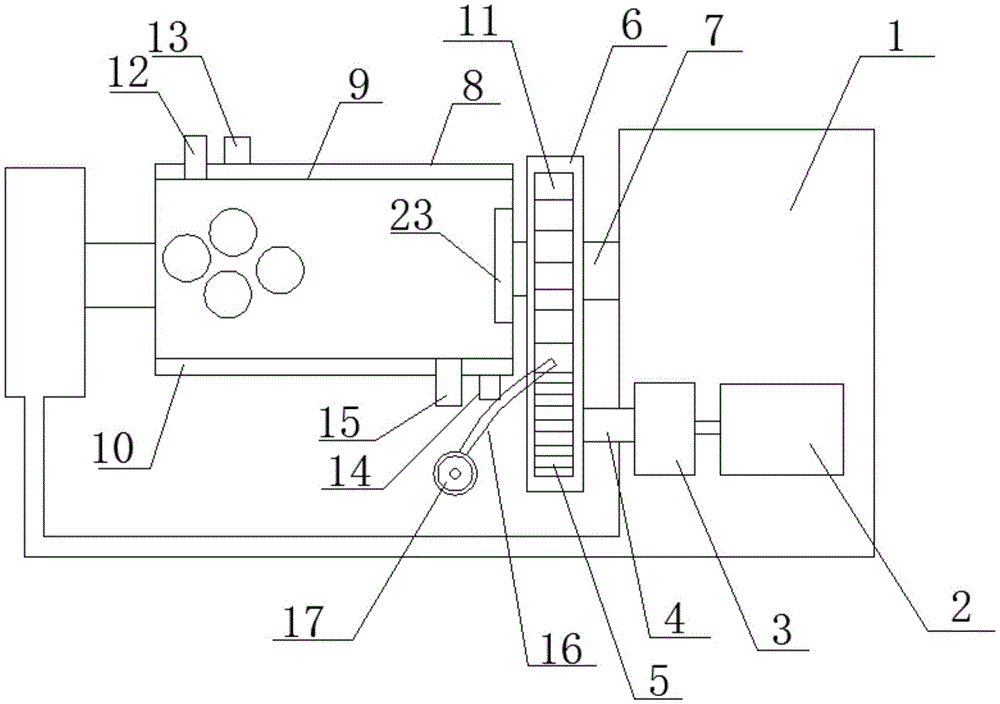

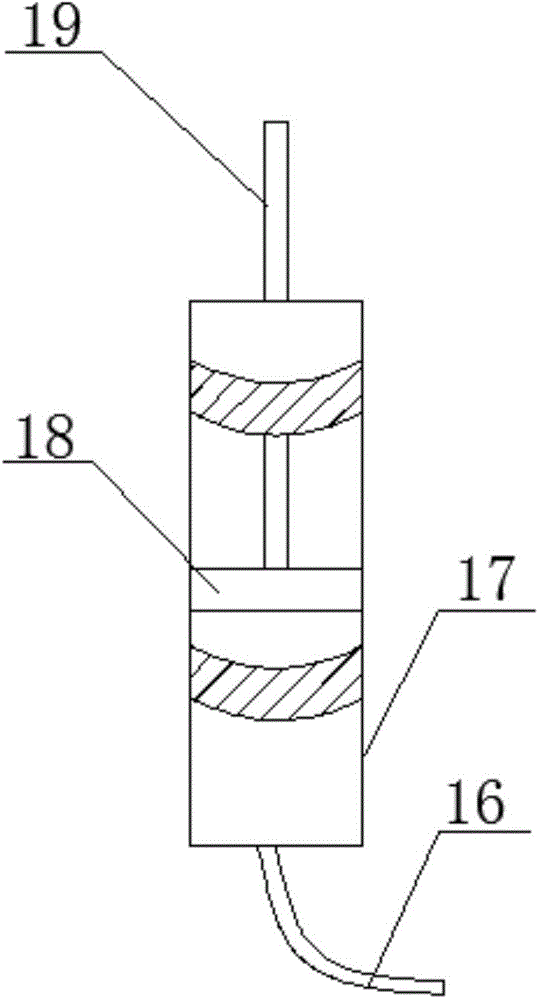

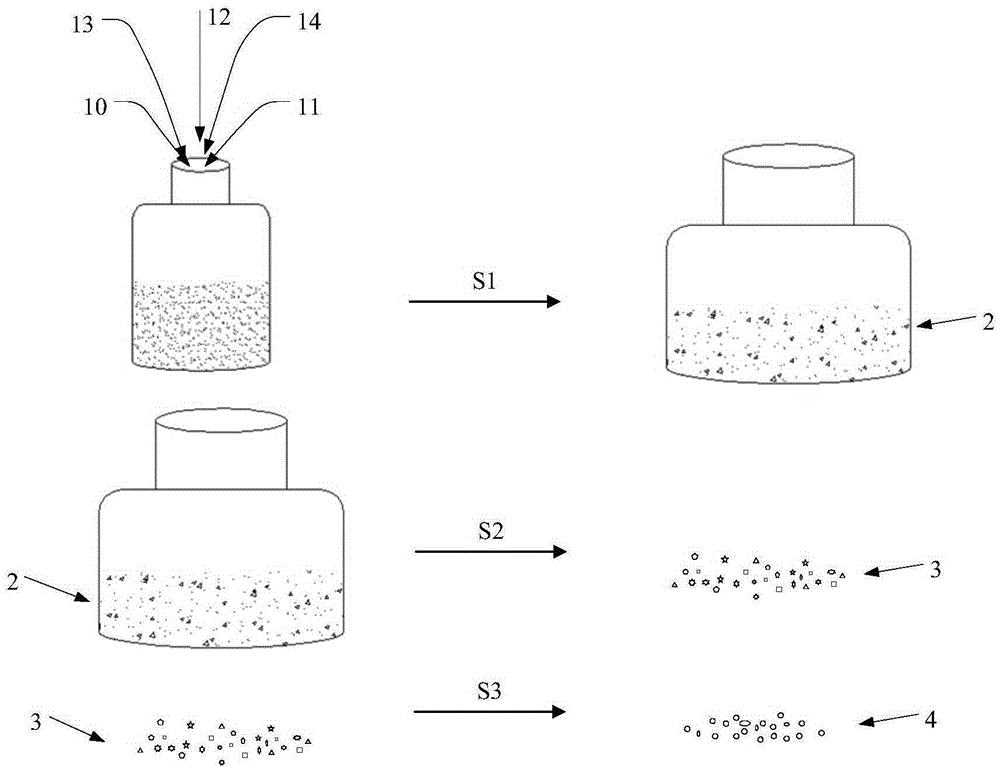

Method and device for preparing three-component sound-absorption cotton through electrostatic spinning-melt blowing-dry laying

The invention relates to a method and device for preparing three-component sound-absorption cotton through electrostatic spinning-melt blowing-dry laying. The method includes the following steps of firstly, mixing 10-65 parts by weight of electrostatic spinning nanofiber, 10-65 parts by weight of melt blowing superfine fiber and 10-40 parts by weight of dry fiber to obtain an electrostatic spinning-melt blowing-dry laying three-component fiber net; secondly, conducting processing after required grams per square meter of net is laid in a crossed mode to obtain the finished sound-absorption cotton product. The electrostatic spinning nanofiber, melt blowing superfine fiber and dry fiber are combined to prepare the three-component sound-absorption cotton, the obtained sound-absorption cotton has nano-scale electrostatic spinning fiber, micron-scale melt blowing fiber and thick dry staple fiber of different fineness degrees, the porosity of the sound-absorption cotton is larger due to the electrostatic spinning fiber of a nanometer structure, the fiber close to nanoscale can resonate with sound waves so as to attenuate energy, and the all-frequency sound absorption effect can be enhanced by reasonably configuring through three types of fibers of different fineness degrees.

Owner:武汉每时工业发展有限公司 +1

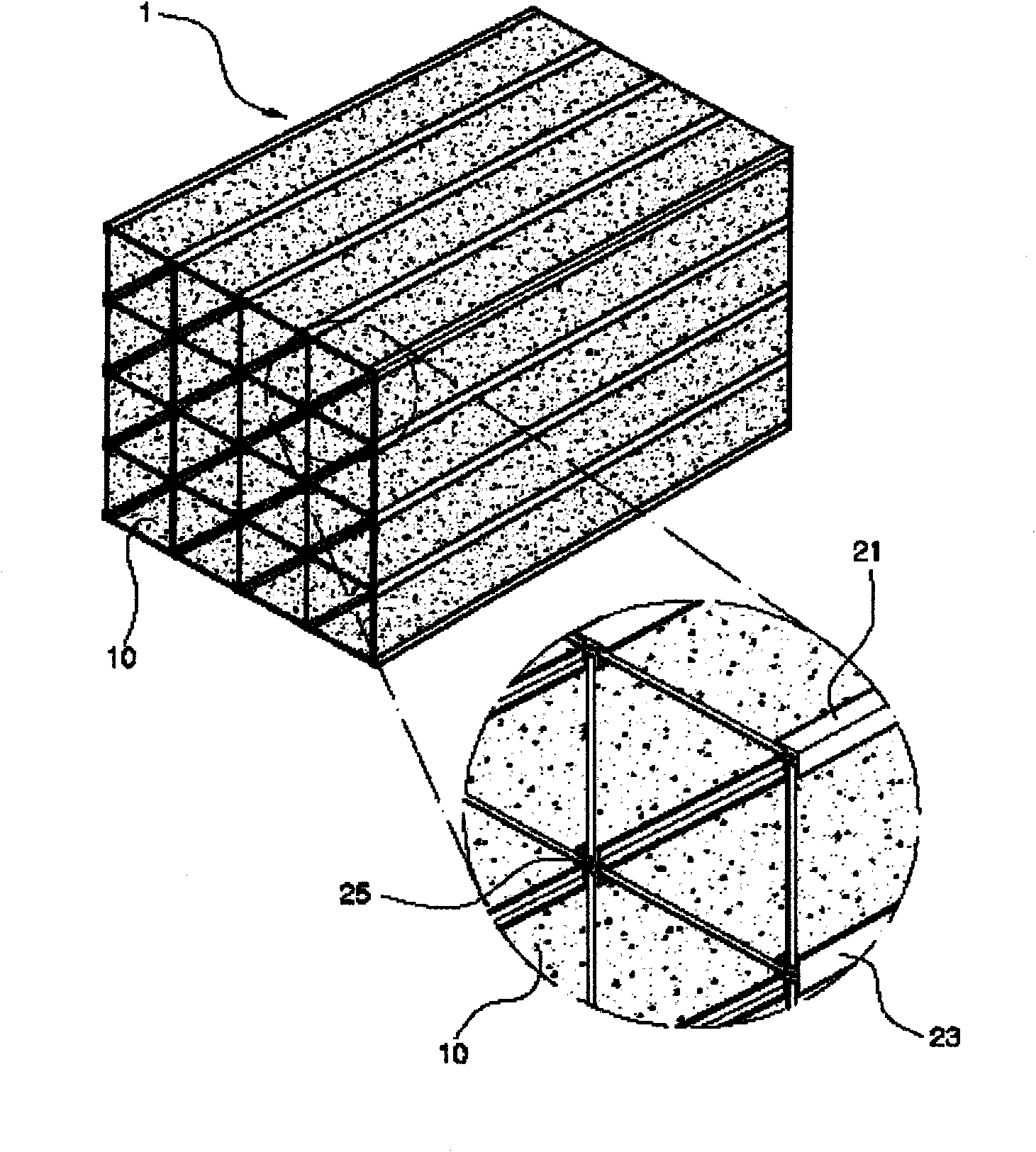

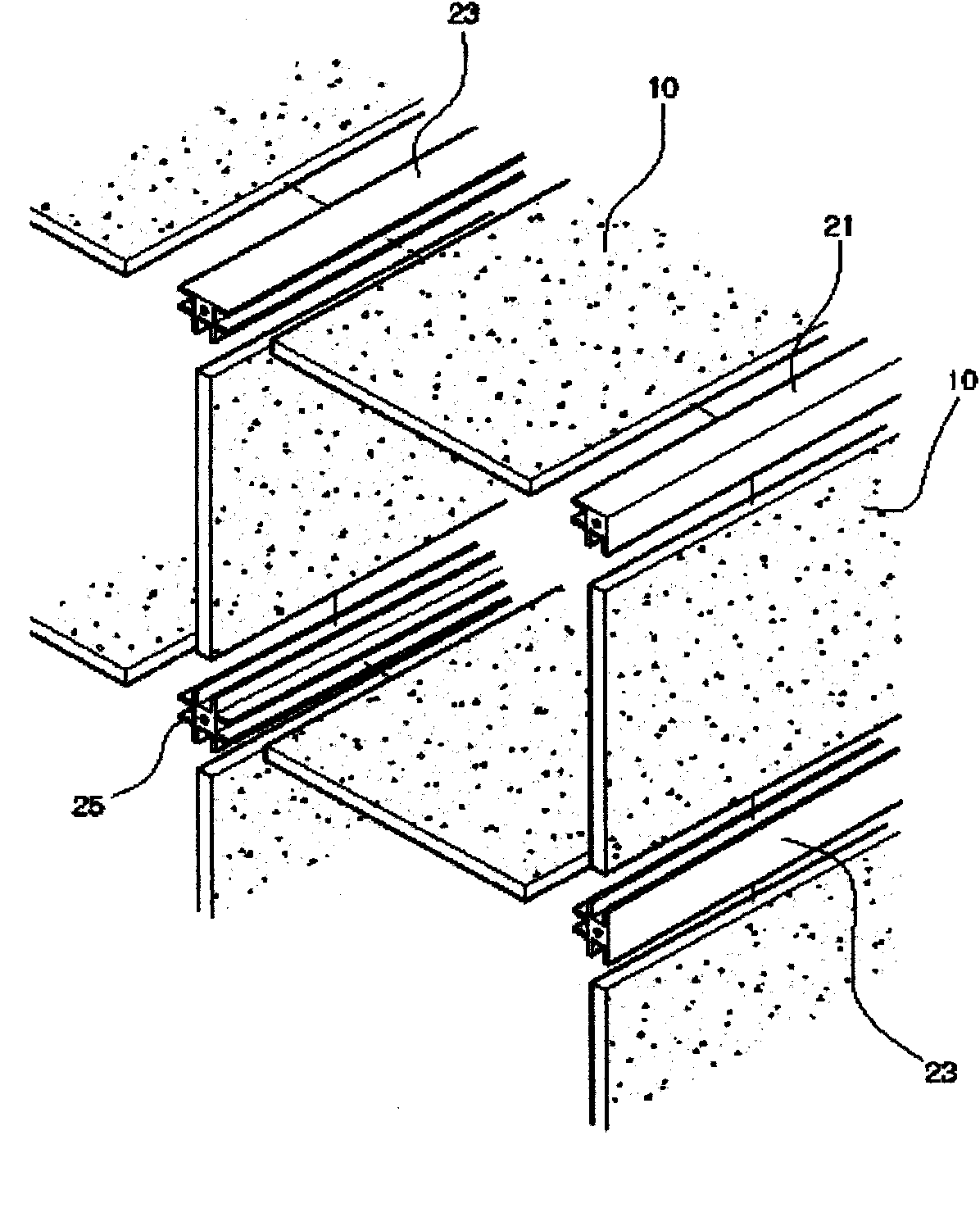

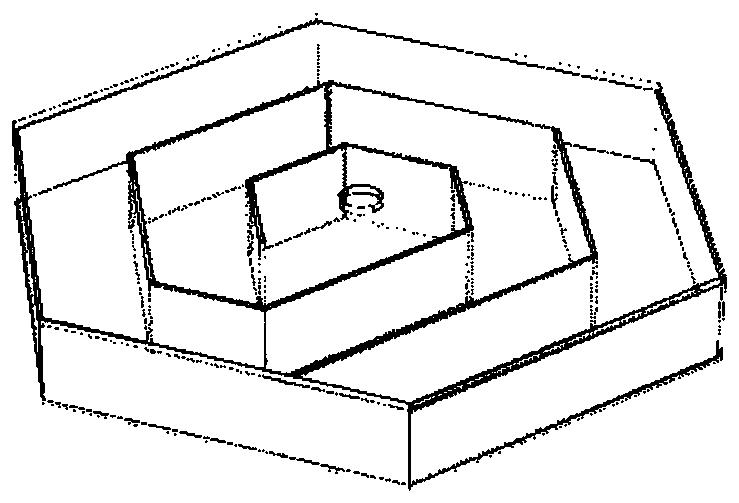

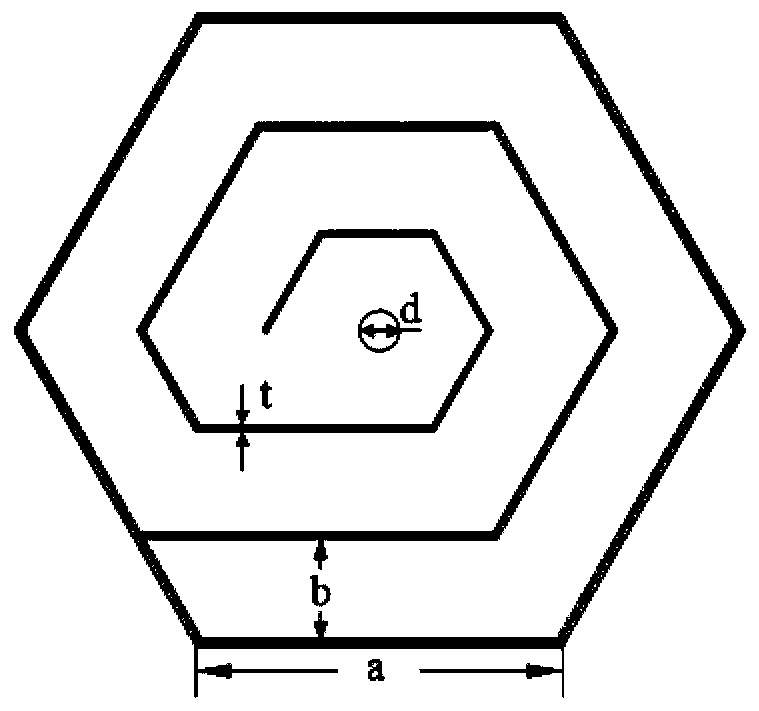

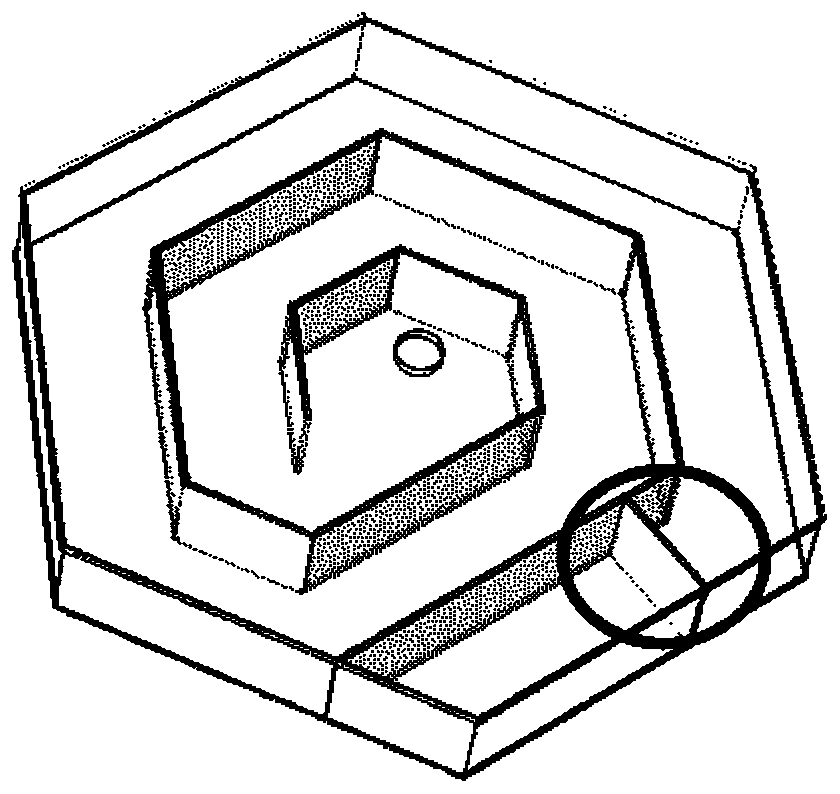

Sound absorption unit, sound absorption structure and sound absorption method

ActiveCN110047458AGood sound absorptionEasily adjust the center frequencySound producing devicesCouplingResonance

The invention discloses a sound absorption unit, a sound absorption structure and a sound absorption method. The sound absorption unit comprises cells, partition plates and a cover plate, wherein thecells are of the regular hexagon structures. The partition plates are arranged inside the cells, the cells are partitioned by the partition plates so that continuous labyrinth channels inside the regular hexagon structures, the cover plate covers the cells, the sound absorption structure comprises a plurality of the sound absorption units, the sound absorption units are subjected to resonance coupling, and noise of different frequencies can be absorbed by adjusting geometric parameters of the sound absorption units; the sound absorption method comprises the following steps that on the basis ofone or more noise frequencies to be absorbed, the geometric dimension of at least one sound absorption unit is determined, three-dimensional printing or mold opening machining is performed on the sound absorption units of the geometric dimension, the multiple sound absorption units are subjected to resonance coupling to form the sound absorption structure, and the opening of the sound absorptionstructure faces a noise source to absorb sound.

Owner:XI AN JIAOTONG UNIV

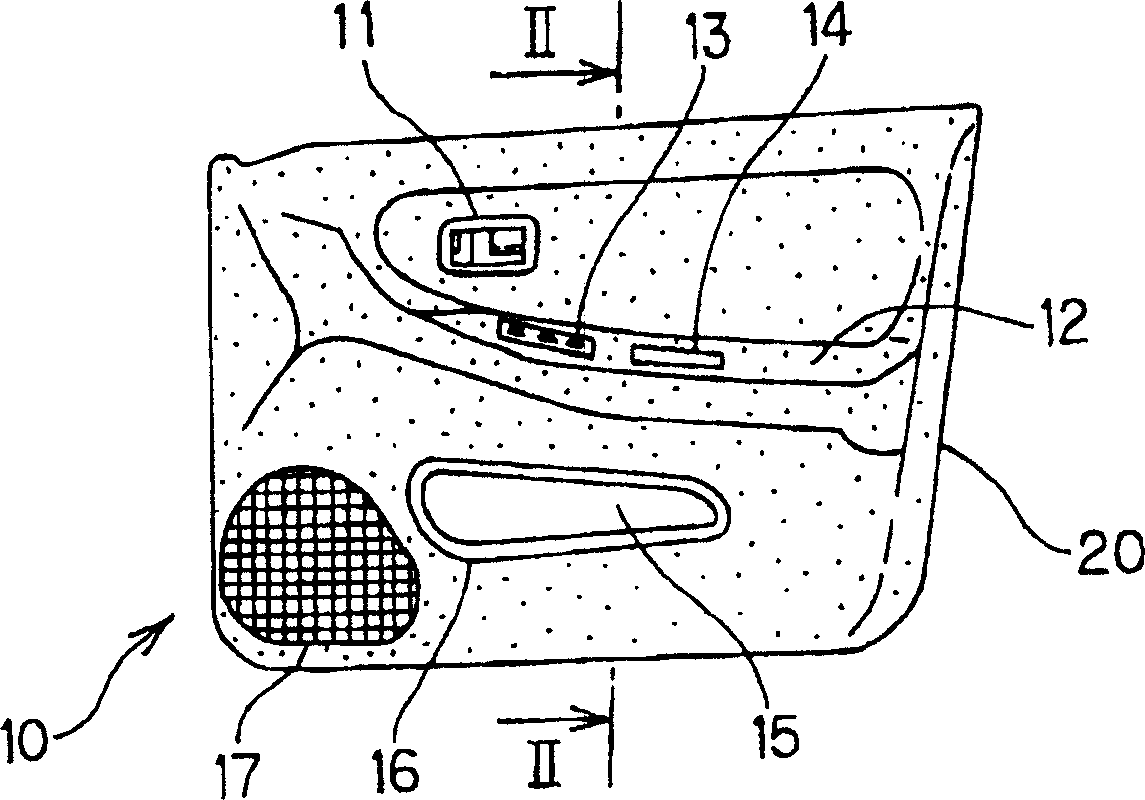

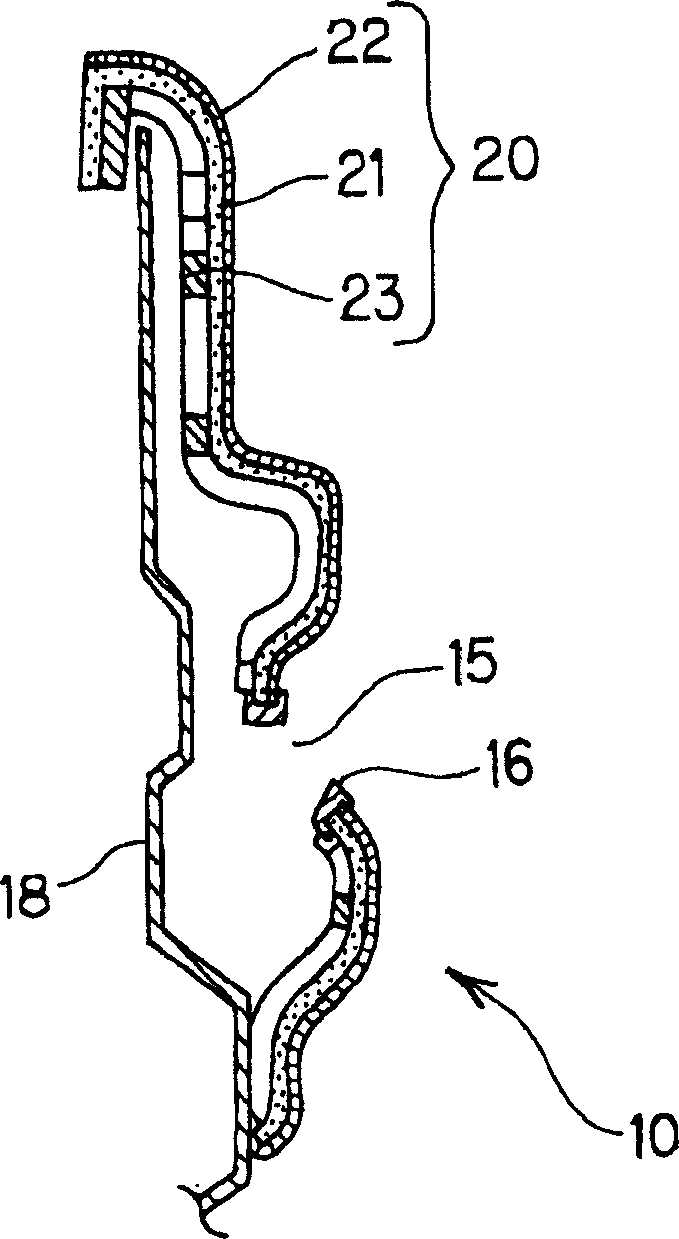

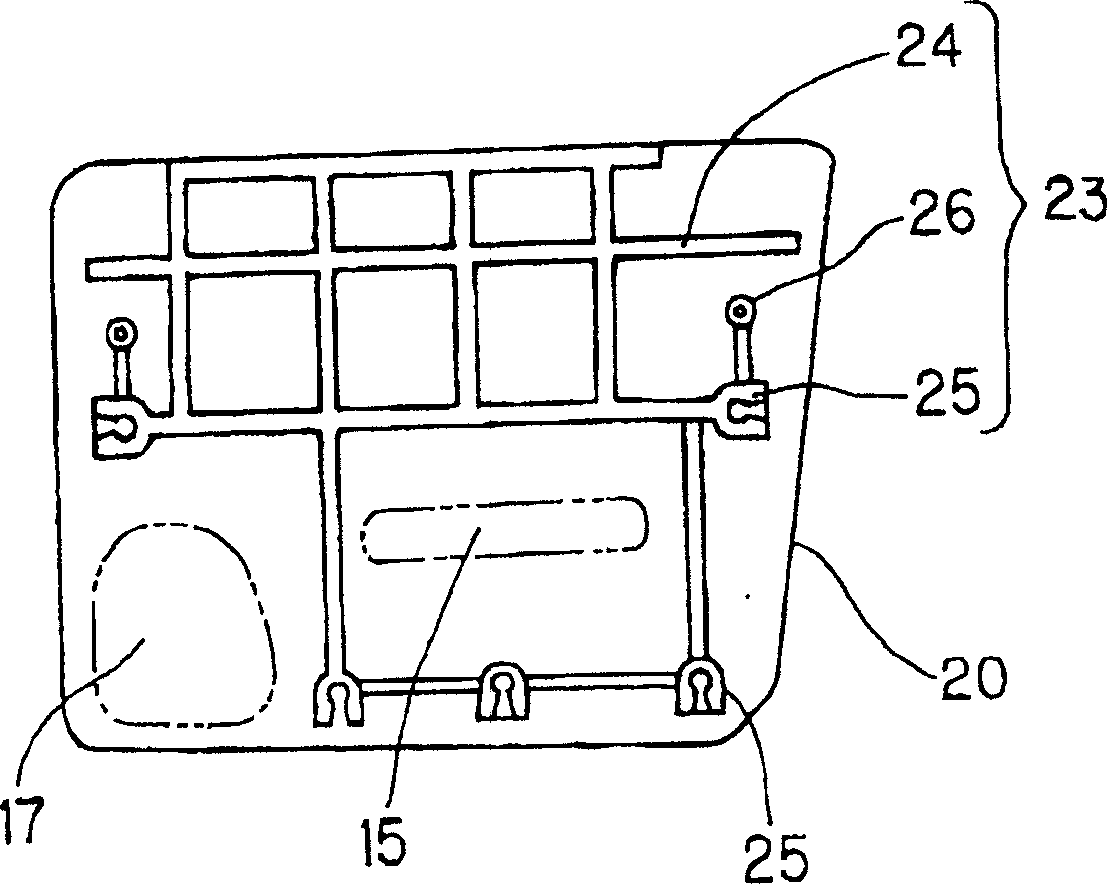

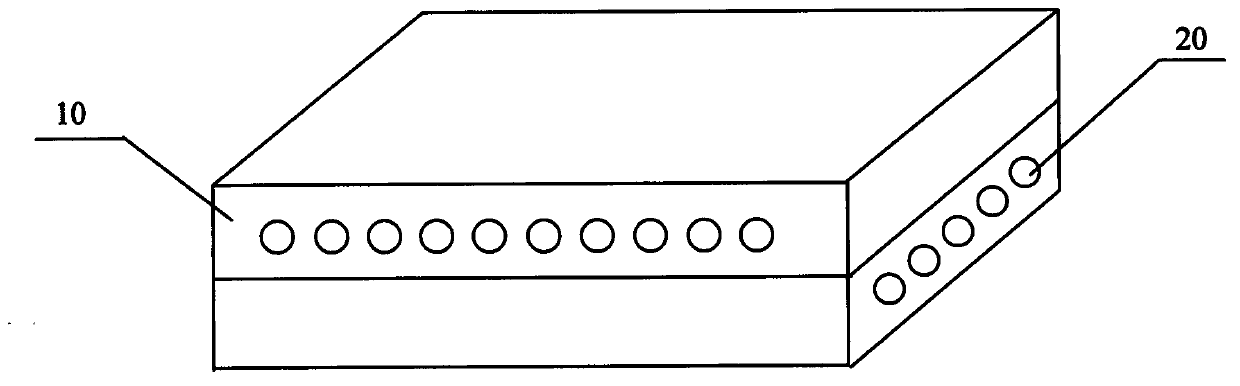

Interior decoration part for automobile and method for manufacturing the same

Owner:KASAI KOGYO CO LTD

Preparation method of porous sound absorption structure composite material

The invention discloses a preparation method of a porous sound absorption structure composite material. The method comprises the following steps: stacking 3-5 layers of pre-woven high-performance fiber cloth, printing 10-40 parallel three-dimensional straight pipelines on the high-performance fiber cloth by wax materials, PLA (polylactic acid) environment-friendly materials and the like through a 3D printer respectively in the middle of each layer, wherein the pipelines between the two adjacent layers are spatially orthogonal, the diameter of each pipeline is 1 mm to 3 mm, and the distance between the central lines of the two adjacent layers of prefabricated pipelines is 2 mm to 4 mm; injecting epoxy resin, forming by a molding process, and heating in a drying oven at 40-200 DEG C until the 3D pipeline printing materials are fully volatilized or molten to obtain the porous sound absorption structure composite material. The 3D printer used in the preparation process of the porous sound absorption structure composite material is high in printing speed and precision and stable in performance, the printing materials easily volatilized or molten when being heated are used, a preparation process of through holes is greatly simplified, and the price of the printing materials is low; the prepared porous sound absorption structure composite material integrates structural material and sound absorption performances, and is simple in construction process, low in cost and excellent in performances such as good sound absorption effect, corrosion resistance, environmental protection, light weight, high strength and high product size stability.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

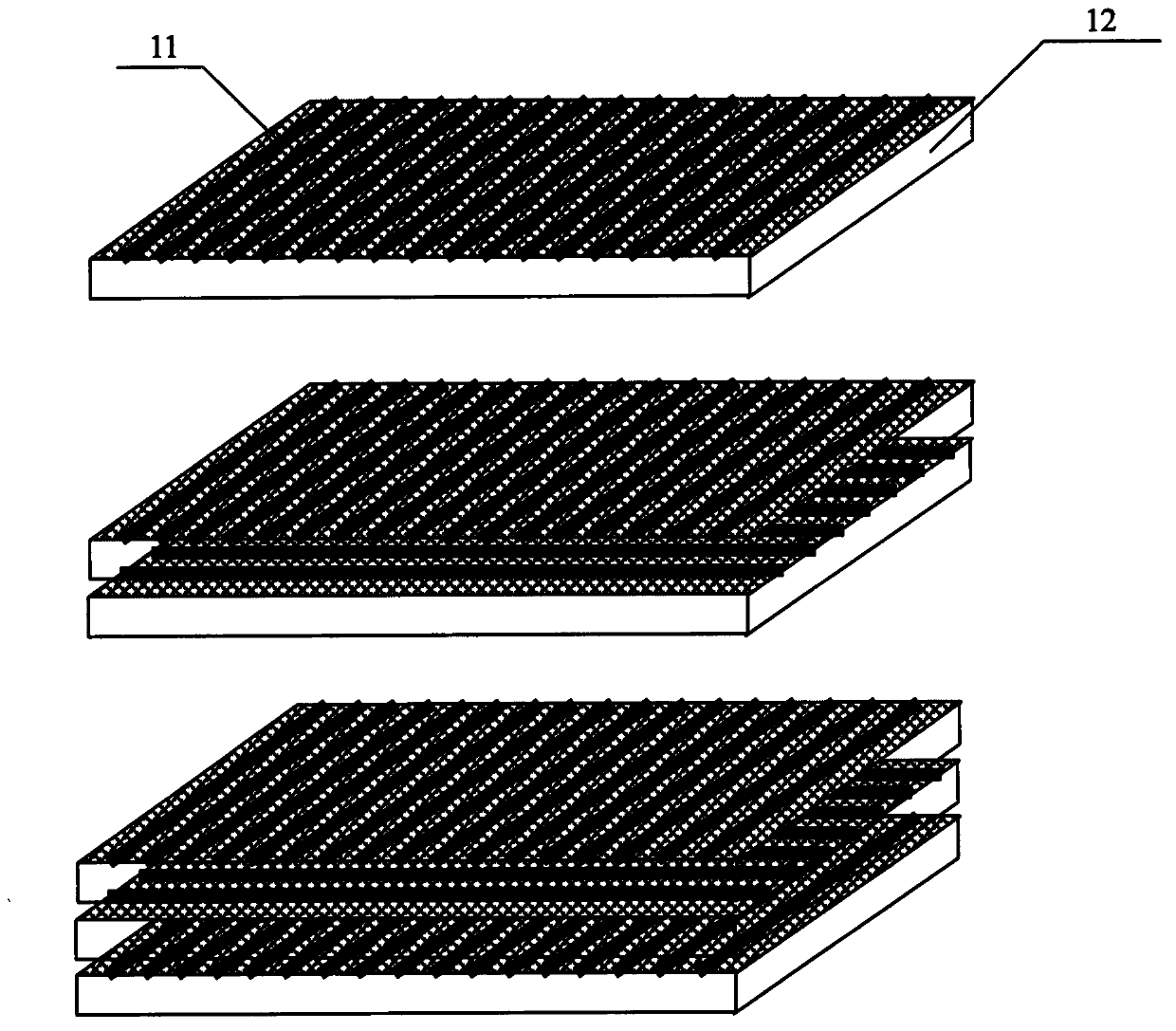

Sound-absorption needled non-woven composite and preparation method thereof

ActiveCN103818084AImprove sound absorptionGood sound absorptionSynthetic resin layered productsLaminationPolyesterHot pressing

The invention discloses a preparation method for a sound-absorption needled non-woven composite. The preparation method comprises the following steps: A, opening porous polyester fibers, carding and netting; B, inputting the fiber net into a needling machine for reinforcing by needling, winding, cutting, and preparing fabric, wherein the thickness of the fabric is 4-40 mm and the surface density of the fabric is 40-500 g / m<2>; C, laminating 2-6 layers of the fabric, conducing hot pressing for combining, and then cooling, wherein the temperature for the hot pressing is 100-120 DEG C. The invention further discloses the sound-absorption needled non-woven composite. After hot pressing for combining, the sound-absorption performance of the sound-absorption needled non-woven composite is significantly improved; besides, the sound-absorption needled non-woven composite is light, thin, high in strength and low in production cost.

Owner:DANYANG YUSHENG TEXTILE NEW MATERIAL

Ball grinding mill

InactiveCN106140403AShorten the timeRun fastGear lubrication/coolingGrain treatmentsDrive shaftEngineering

The invention discloses a ball grinding mill. The ball grinding mill comprises a machine frame and a ball grinding barrel. A motor is installed on the lower portion of the right end of the machine frame. The output end of the motor is connected with a speed reducer. The output end of the speed reducer is connected with a transmission shaft. The transmission shaft is provided with a drive gear. The left end and the right end of the ball grinding barrel are connected to the machine frame through rotating shafts. The rotating shaft at the right end is provided with a gear, and a protection cover is arranged outside the gear and the drive gear. The protection cover is provided with a hose stretching into the protection cover. The other end of the hose is connected with a piston barrel. The ball grinding barrel comprises an inner barrel body and an outer barrel body. A cooling cavity is formed between the inner barrel body and the outer barrel body. The cooling cavity is provided with a cooling liquid inlet and a cooling liquid outlet. A sound absorption material lining layer is arranged on the inner side of the inner barrel body. A lining plate is arranged on the inner side of the sound absorption material lining layer. A lifting groove is formed in the inner wall of the lining plate. The lifting groove and the inner wall of the lining plate are both provided with wear-resisting layers. A static elimination device is further arranged at the right end of the inside of the inner barrel body. The ball grinding mill is simple in structure, convenient to use, capable of achieving sound insulation and abrasion resistance, high in stability and long in service life.

Owner:苏州旋特自动化科技有限公司

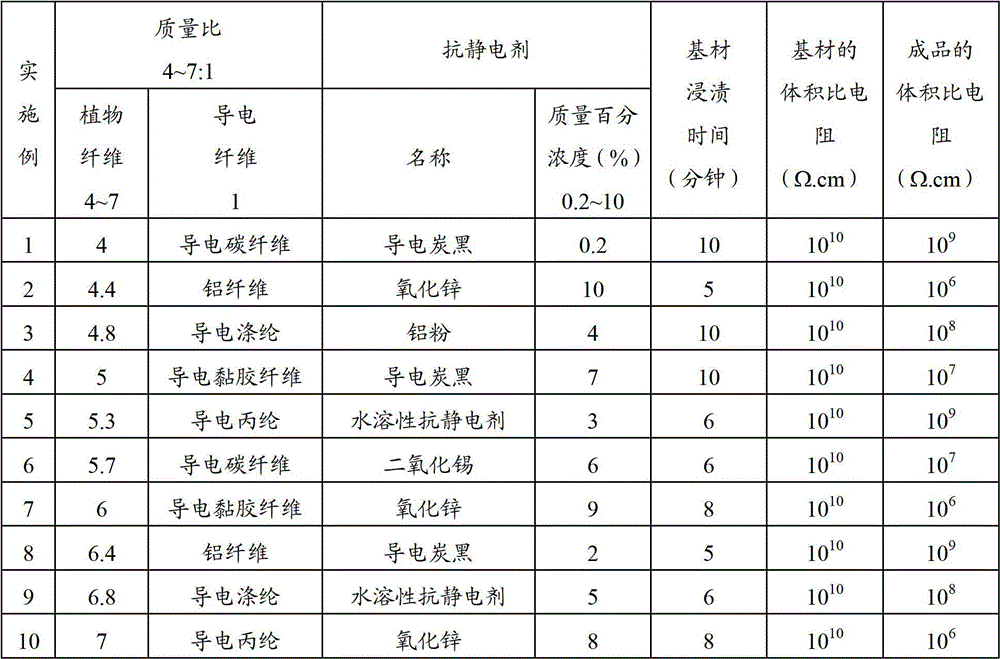

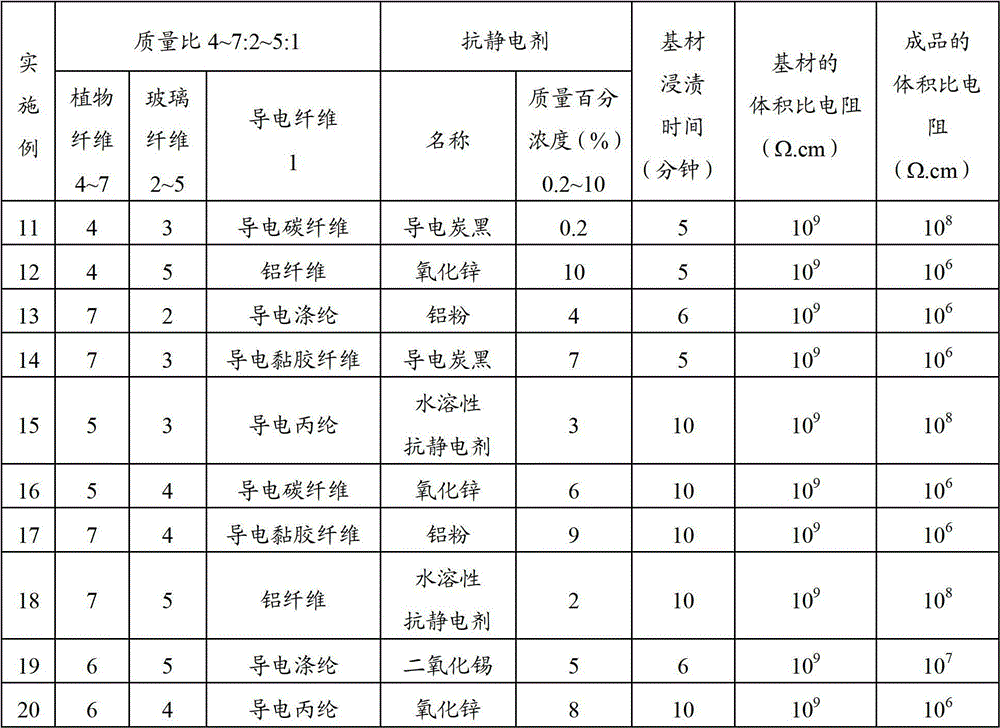

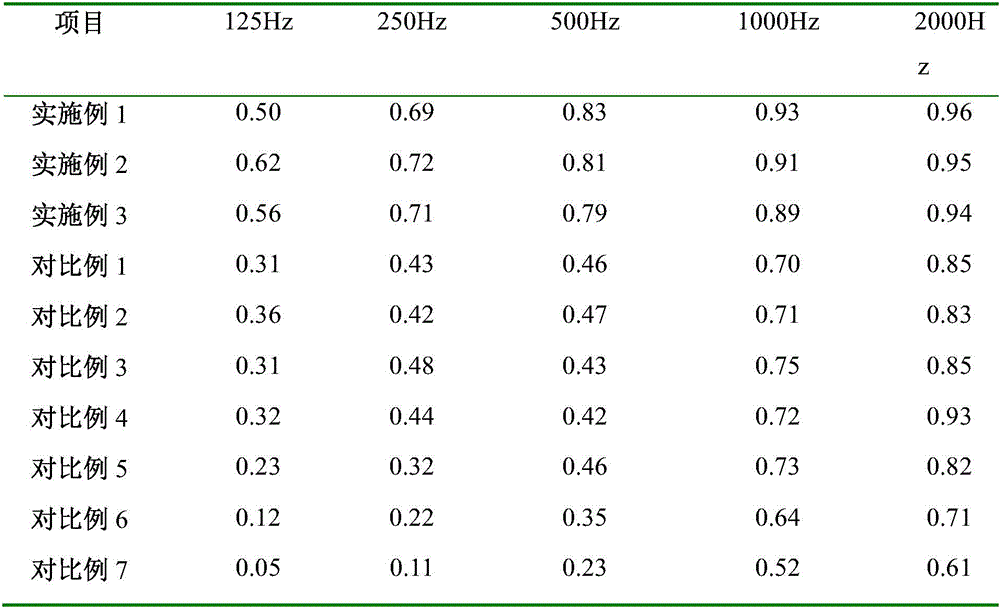

Antistatic sound absorption paper and preparation method thereof

InactiveCN102747646AGood sound absorptionAvoid fireNon-fibrous pulp additionSynthetic cellulose/non-cellulose material pulp/paperFire hazardChemistry

The invention discloses an antistatic sound absorption paper and a preparation method thereof. The antistatic sound absorption paper contains plant fibers, conductive fibers and an antistatic agent. The preparation method of the antistatic sound absorption paper comprises the following steps of: (1) making a base material by utilizing the plant fibers and the conductive fibers; (2) preparing an antistatic impregnation liquid by adding the antistatic agent in water; (3) impregnating the base material in the antistatic impregnation liquid; and (4) drying impregnated products. The antistatic sound absorption paper has the advantages of sound absorption, flame retardance and antistatic performance, is applied to places such as movie theaters, music halls, lecture halls and conference rooms and, has excellent sound absorption effect, and can be also used for avoiding potential safety hazards caused by fire hazards and the like due to static electricity. The antistatic agent is added in the impregnation liquid, and the antistatic sound absorption paper is manufactured by an impregnation treatment method, thus the preparation process is simple and easy to operate.

Owner:陈吉轩

Hollow microspheres-enhanced polyimide matrix foamed composite material and preparation method thereof

ActiveCN104086995AHigh glass transition temperatureExcellent and density controllable densityFoaming agentMicrosphere

The invention provides a hollow microspheres-enhanced polyimide matrix foamed composite material and a preparation method thereof. The apparent density of the foamed composite material is 0.023-0.035g / cm<3>, the foam shrinkage rate is -35.0% to -20.0%, the compressive strength is 0.05-0.35MPa, the impact strength is 20-60KJ / m<2>, and the average sound absorption coefficient within the frequency range of 125-4,000Hz is 0.40-0.51. The preparation method comprises the following steps: mixing aromatic dianhydride with aromatic diamine and a surfactant to obtain a foaming precursor after esterifying the aromatic dianhydride; adding hollow microspheres and a foaming agent to a precursor solution, and heating the solution to obtain a foaming block; finally carrying out thermal imidization on the foaming block to obtain the foamed composite material. According to the method, the foamed composite material with good mechanical property, and excellent sound absorption and sound insulation can be prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of sound-absorbing rubber

The invention relates to a preparation method of sound-absorbing rubber, wherein the preparation method comprises the steps: according to the formula comprising 100-150 parts by weight of butadiene-acrylonitrile rubber, 5-15 parts by weight of hollow glass micro-beads, 3-8 parts by weight of nano molybdenum disulfide, 1-6 parts by weight of lanthanum oxide, 3-15 parts by weight of azodicarbonamide, 1-5 parts by weight of urea, 2-8 parts by weight of carbon nanotubes and 5-15 parts by weight of ethylene propylene diene monomer, adding the raw materials of the sound-absorbing rubber into an open mill, mixing, placing the product obtained from the mixing for 12-48 h, re-mixing, sending the product obtained from the re-mixing into a plate vulcanizing machine, and successively carrying out press vulcanization and press shaping. The sound-absorbing rubber has the advantages of good sound-absorbing performance, and large tensile strength.

Owner:昆明云垦橡胶有限公司

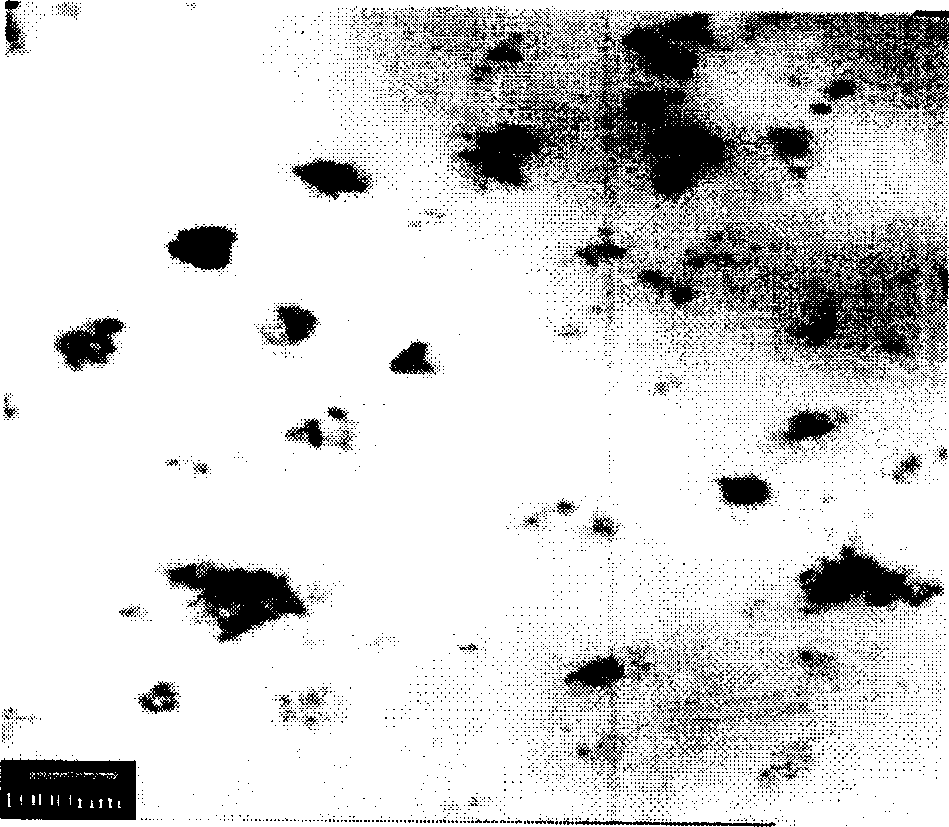

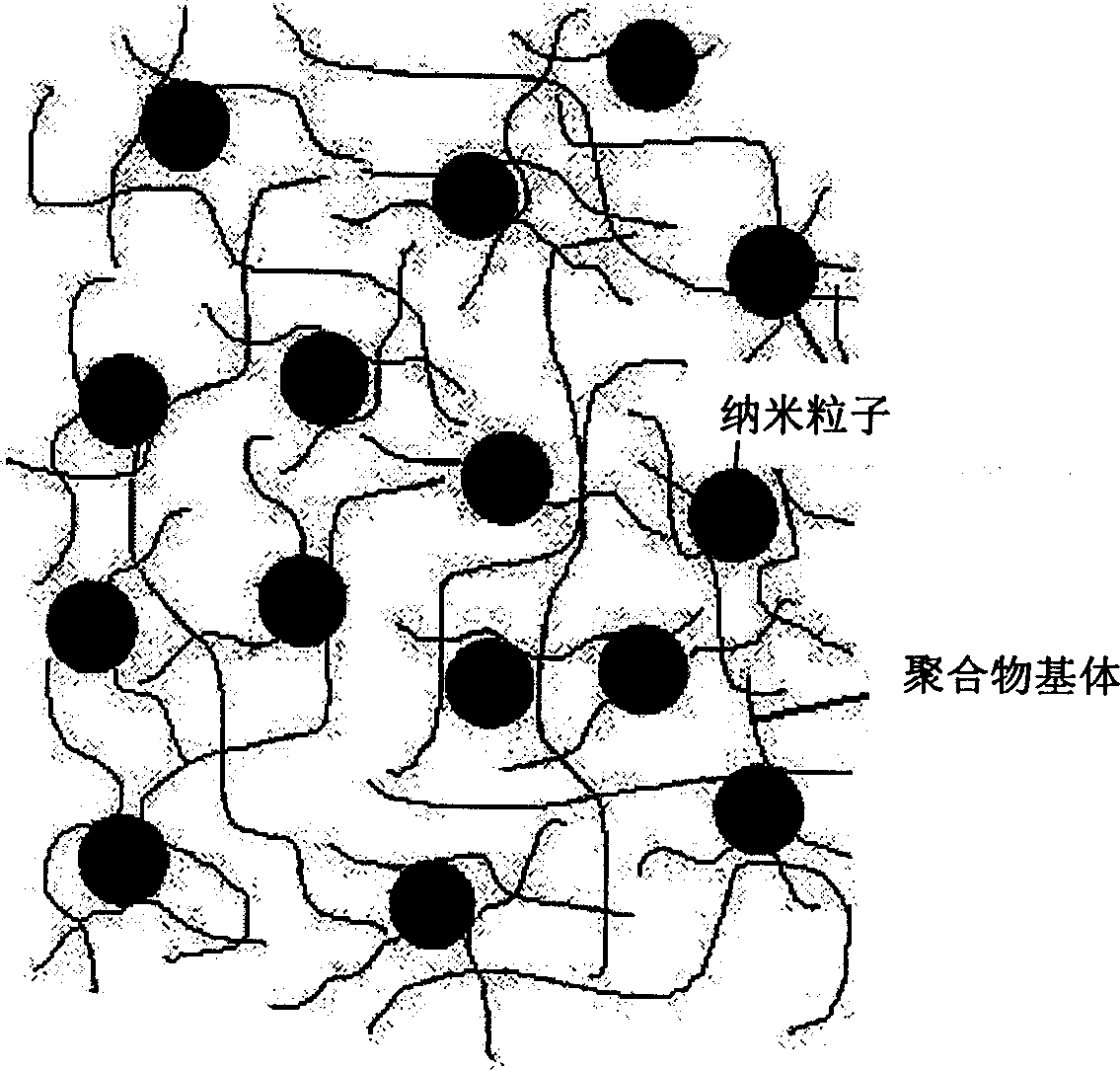

Method for preparing multifunctional building engineering paint

InactiveCN1632012AHigh tensile strengthExtended service lifeCoatingsUltravioletUltimate tensile strength

The invention relates to a method for preparing a multi-functional building coating. The flexible coating is the one with extension and retracting corresponding to stress,and suitable modulus and tensile strength when be extended, has protective and deconative effects of the usual coating as well as functions of water resistance and covering slot. It makes use of absorption and shielding of some nm particle to the ultraviolet ray,uses ball milling or high speed shearing and supersonic dispersion and self-crosslinking flexible latex to prepare nm compound self-crosslinking flexible latex,meanwhile,add the usual assistant to raise its flexibility and resistance to aging. In the productive course,use nm compound self-crosslinking flexible latex and new sound absorption material to produce the multi-functional building coating with outstanding sound absorption effect as well as high flexibility and resistance to aging,can be applied in other building,like decoration and protection of building on two sides of the high way,house and ground.

Owner:FUDAN UNIV

Thermosetting resin bonded shaped elements

InactiveUS6187698B1Good propertyImprove mechanical propertiesWoven fabricsNon-woven fabricsFiber layerEpoxy

Fibrous shaped elements bonded with thermosetting resins comprising a plurality of fiber layers with at least two different thermosetting resins, preferably with inner fiber layers comprising phenolic resins as the bonding agent and the upper and lower outer layers comprising epoxide resins as the bonding agent.

Owner:MOMENTIVE SPECIALTY CHEMICALS

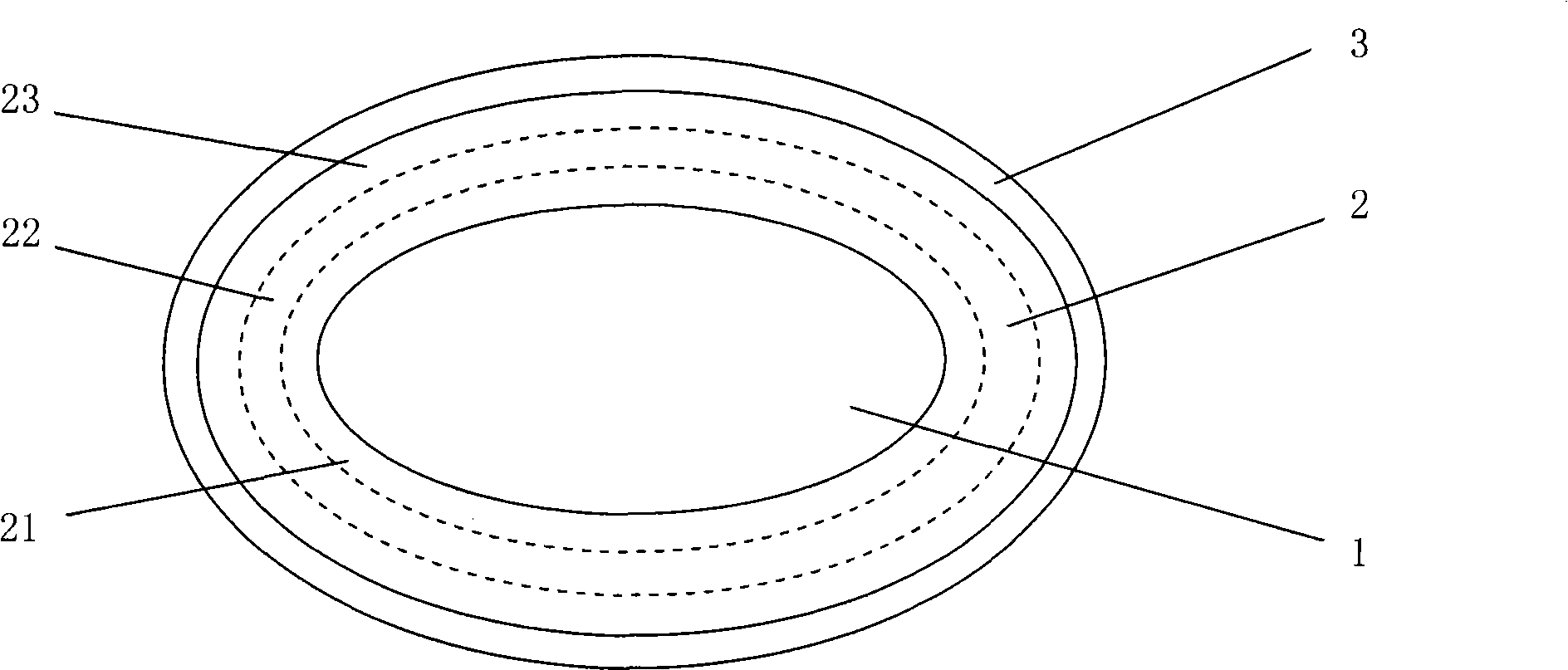

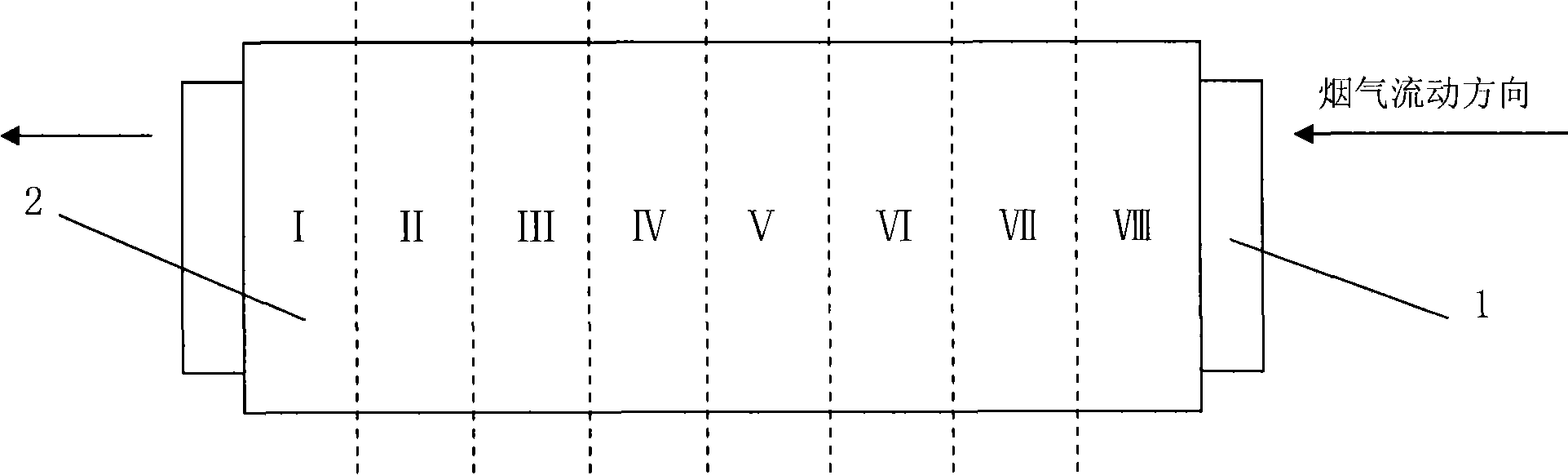

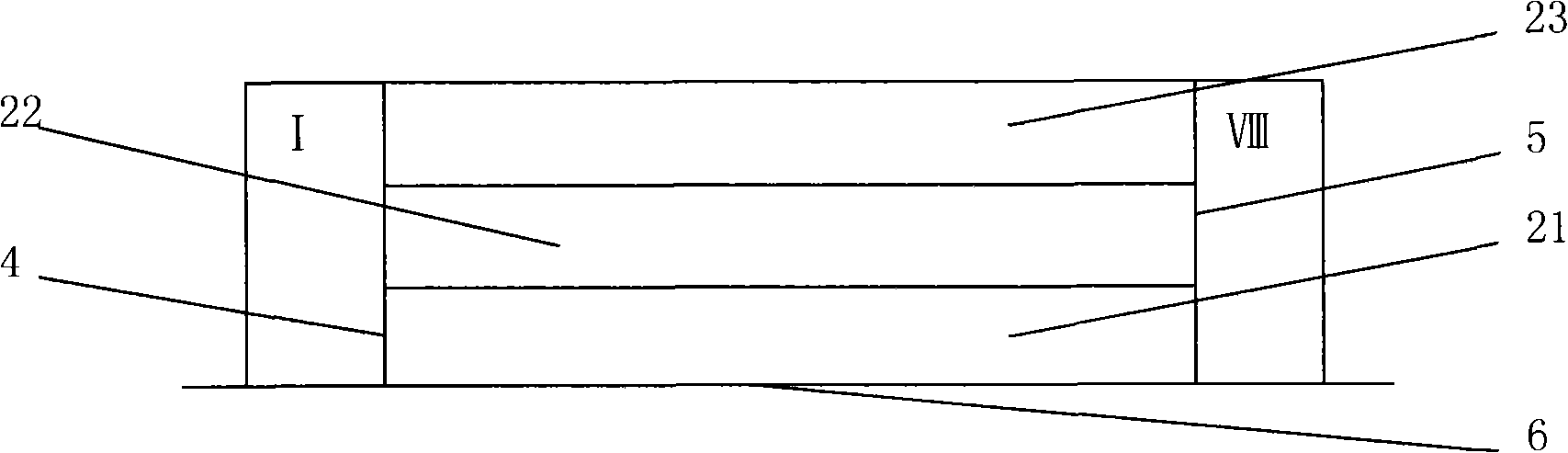

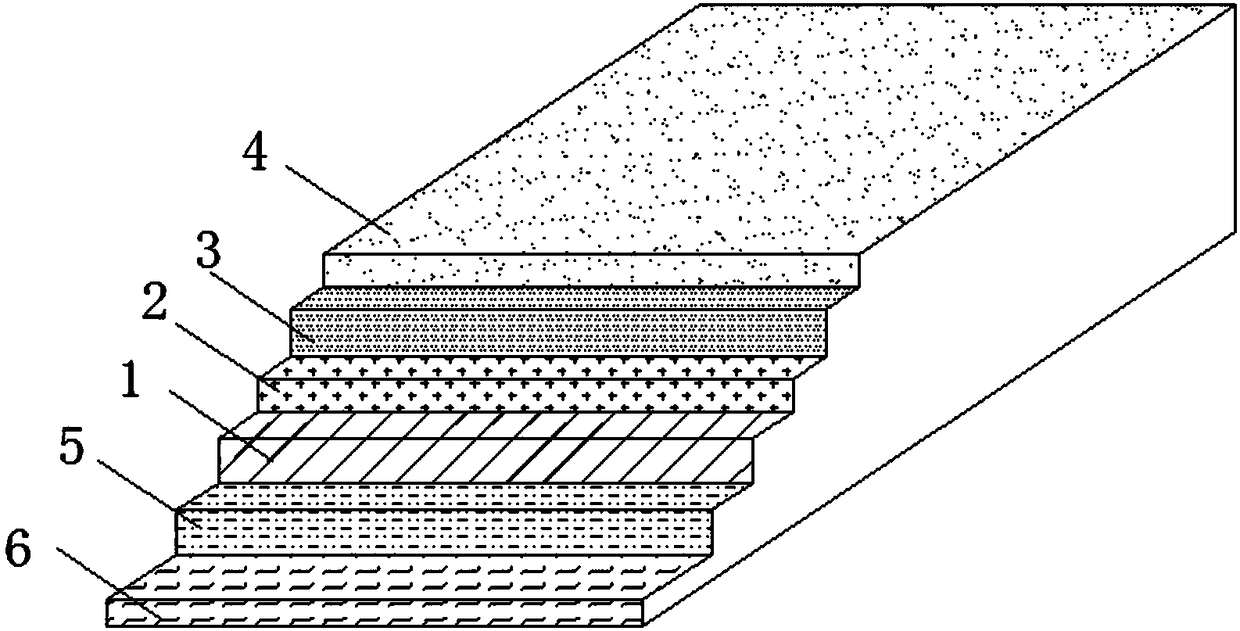

Inorganic combined seal spacer and method for making same

ActiveCN101260822AFixedGood heat insulationExhaust apparatusDispersed particle separationMetal fibersMaterials science

The invention provides an inorganic composite gasket and a preparation method thereof. The inorganic composite gasket comprises a compound which consists of an inorganic non-metallic fiber, an expansile material and bond, wherein, the inorganic composite gasket is divided into eight width sections in the width direction and is divided into three thickness layers from inside to outside; components of gaskets materials in each thickness layer and width section are the same or different, wherein, the expansile material in the three thickness layers have different contents, wherein, the inner layer occupies 33.3 to 50 percent of the total content, the intermediate layer occupies 30 to 40 percent of the total content, and the outer layer occupies 20 to 33.3 percent of the total content. The inorganic composite gasket has the advantages of breaking through the prior uniform gasket according to the requirement of the gasket in practical application to enable the components of the gasket to form asymmetrical distribution in the thickness direction and the width direction and meet the practical application requirement, and adopting a novel vacuum suction filtering technology to prepare the inorganic composite gasket with the method of composite molding, so that a product can achieve the excellent functions of fixing, sealing, heat insulating and sound-absorbing. The inorganic composite gasket can be applied to a catalytic converter of a motor vehicle.

Owner:上海伊索热能技术股份有限公司

Palygorskite-containing nonwoven material for sound absorbing cotton

InactiveCN103710860AImprove sound absorptionLoose structureNon-woven fabricsMedicinal herbsPalygorskite

The invention relates to a nonwoven material, in particular to a palygorskite-containing nonwoven material for sound absorbing cotton. The nonwoven material is made from, by weight, 100 parts of isotatic polypropylene, 1-2 parts of nano-graphite powder, 2-3 parts of corundum, 1-2 parts of molybdenum disulfide, 10-12 parts of dimethyl isophthalate, 1-2 parts of methylhydroquinone, 10-12 parts of palygorskite, 8-19 parts of bentonite, 2-3 parts of forsythia, 1-2 parts of sophora flavescens, 2-3 parts of cortex lycii and 4-5 parts of auxiliaries. The nonwoven material contains the palygorskite good in sound absorption effect and is added with the corundum, the bentonite, the nano-graphite powder, Chinese medicinal herbs and the like, so that the prepared nonwoven material is flat in structure, good in breathability, firm in bonding, flame retardant and heat resistant and good in sound absorption effect; after being subjected to multi-layer superposition, the nonwoven material can be made into the sound absorbing cotton, thereby having broad application prospect.

Owner:芜湖跃飞新型吸音材料股份有限公司

PVC (polyvinyl chloride) composite board

InactiveCN108527984AGood sound absorptionImprove sound absorptionSynthetic resin layered productsBuilding componentsAbsorption effectSurface finishing

The invention discloses a PVC (polyvinyl chloride) composite board. The PVC composite board comprises a base board. A noise-proof and moisture-proof layer is compressed at the upper end of the base board. A high-strength layer is adhered to the top end of the noise-proof and moisture-proof layer. A surface treatment layer is laid on the upper surface of the high-strength layer. A PVC foaming boardis compressed on the lower surface of the base board. A wearing layer is compressed on the lower surface of the PVC foaming board. The PVC composite board has the advantages that the PVC composite board is provided with the noise-proof and moisture-proof layer, a sound-absorbing cotton layer and a deadening felt in the noise-proof and moisture-proof layer have good sound absorption effect, and the effect is remarkable due to sound absorption by two layers of sound-absorbing materials; water-absorbing balls added into the deadening felt can absorb water to prevent moisture; the high-strength layer is arranged on the upper surface of the noise-proof and moisture-proof layer, so that the PVC composite board has high strength and harness, the strength is improved, and service life is prolonged.

Owner:SUZHOU HEJI RONGDA NEW MATERIALS CO LTD

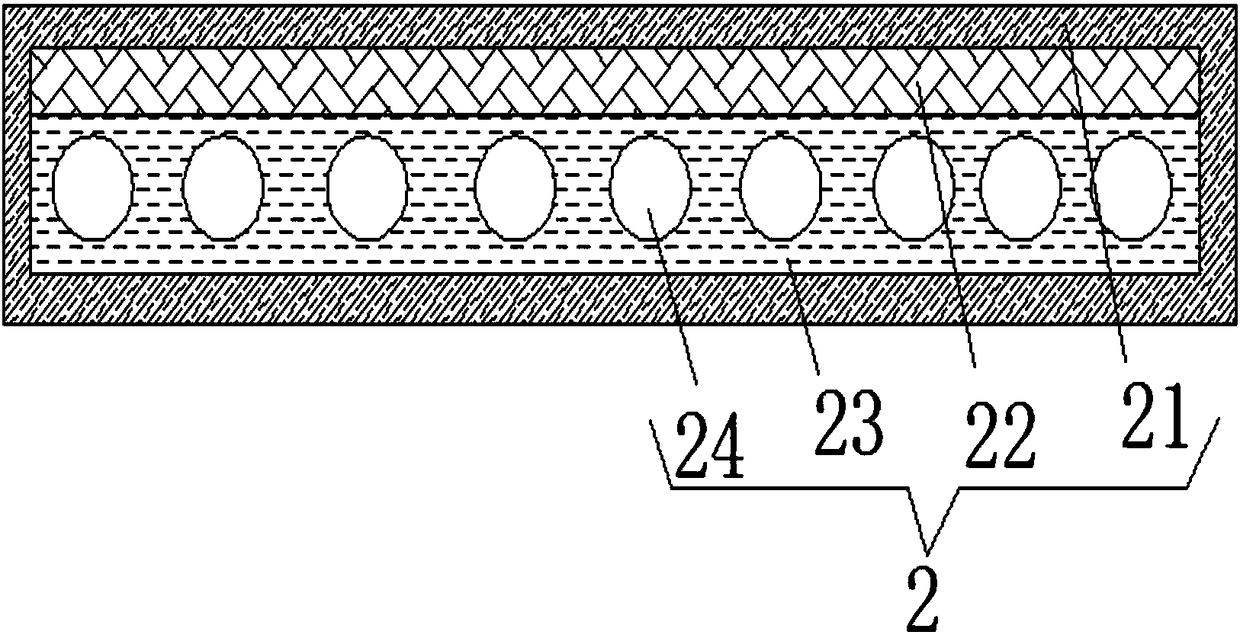

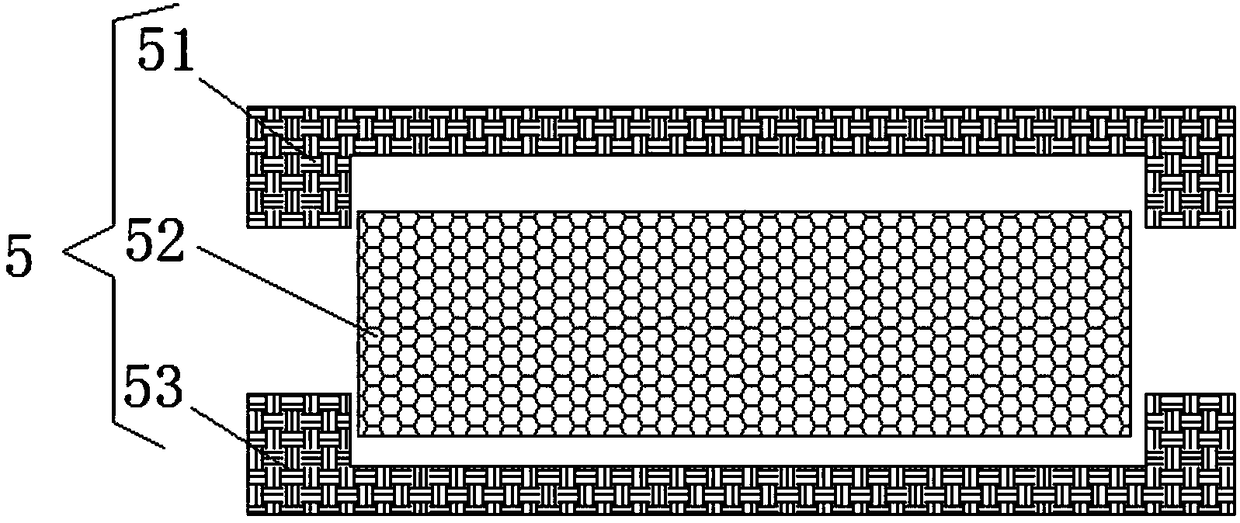

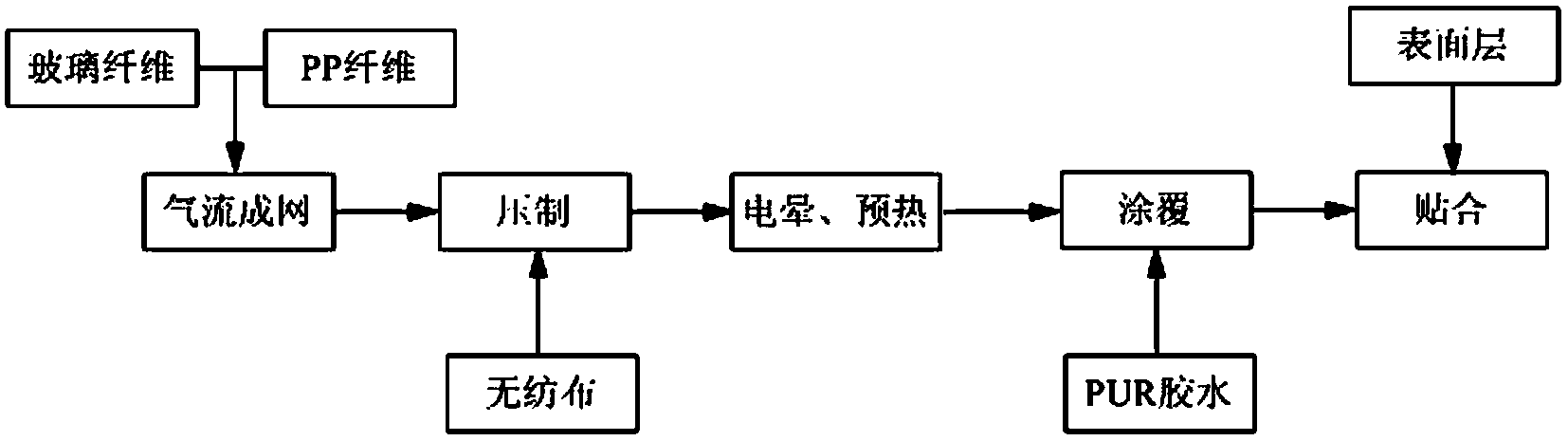

Insulation sound-absorbing decorative plate and preparation method thereof

ActiveCN103818080AReduce pollutionProduction process is environmentally friendlySynthetic resin layered productsLaminationBuilding materialWoven fabric

The invention relates to an insulation sound-absorbing decorative plate and a preparation method, which belongs to the technical field of building material. The insulation sound-absorbing decorative plate comprises a substrate, a superficial layer and a bottom layer; the substrate is spliced with the superficial layer through PUR glue, the other surface of the substrate is spliced to the bottom layer; the materials of the substrate are PP fiber and glass fiber; the material of the superficial layer is a PP membrane, or a PVC membrane, or a PETG membrane; and the material of the bottom layer is non-woven fabrics. The preparation method comprises the following steps: 1)mixing the PP fiber and glass fiber, using an air laying method to prepare an original substrate; 2)taking the non-woven fabrics as the bottom layer, compacting one side of the original substrate and the bottom layer by a veneer press under the temperature of 180-220 DEG C to prepare a double-layer plate; 3)performing corona treatment and preheating the substrate surface of the double-layer plate, then coating the PUR glue; and 4)applying the superficial layer and the substrate of the double-layer plate together. The insulation sound-absorbing decorative plate does not contain asbestos, benzene and formaldehyde which are harmful to human body, light pollution of a matte series product can be avoided, and the production technology enables environmental protection.

Owner:LIAOYANG YIMENG CARPET MFG

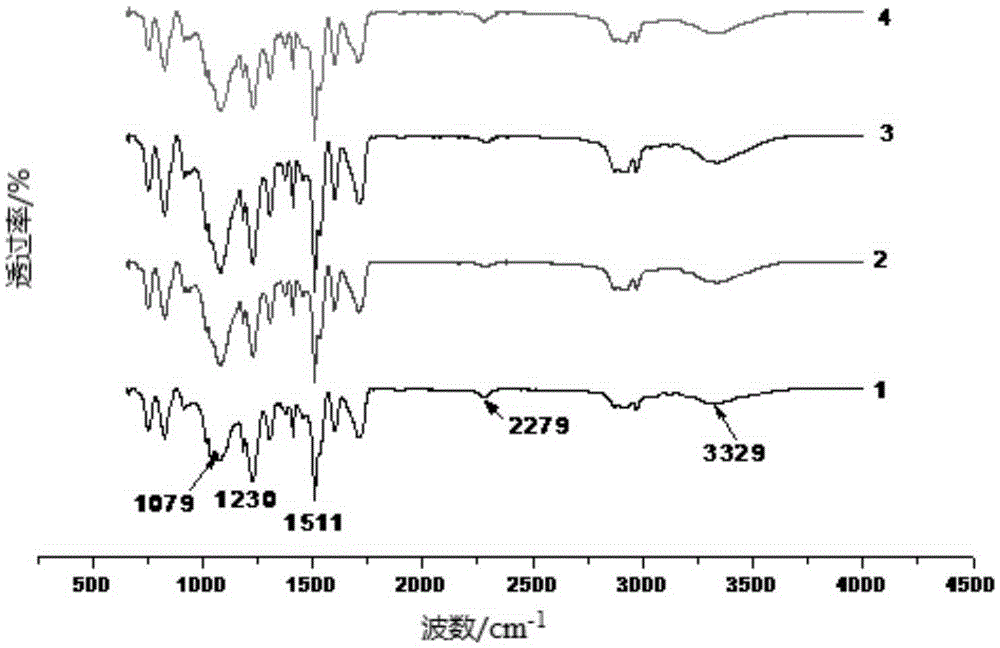

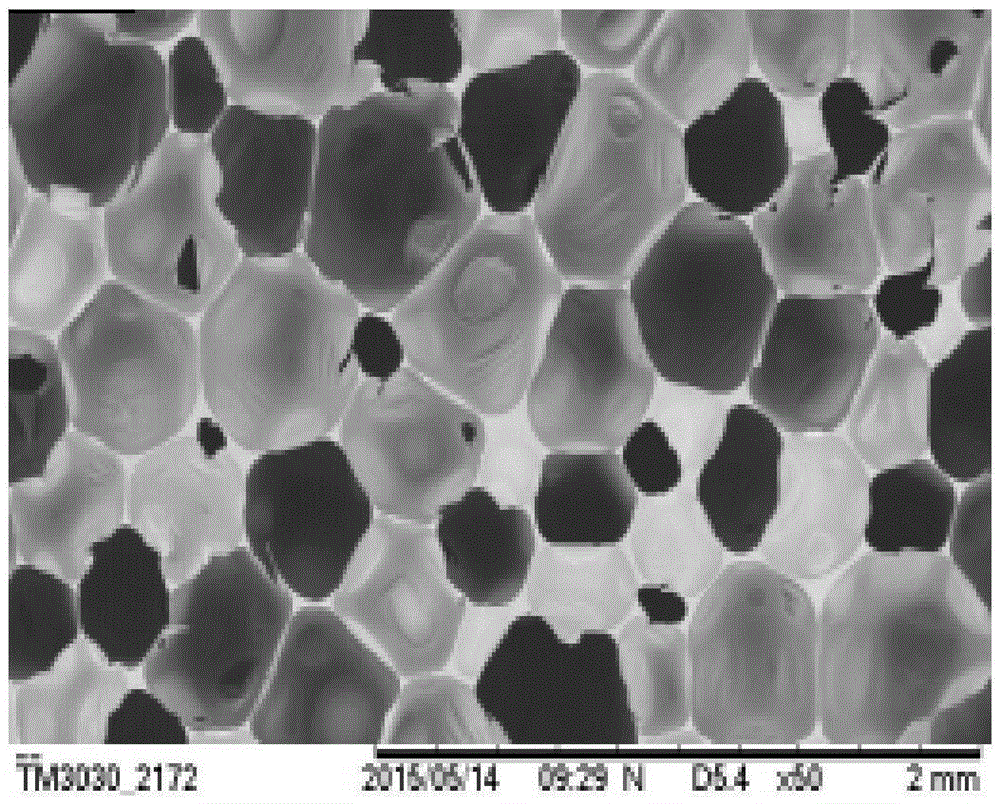

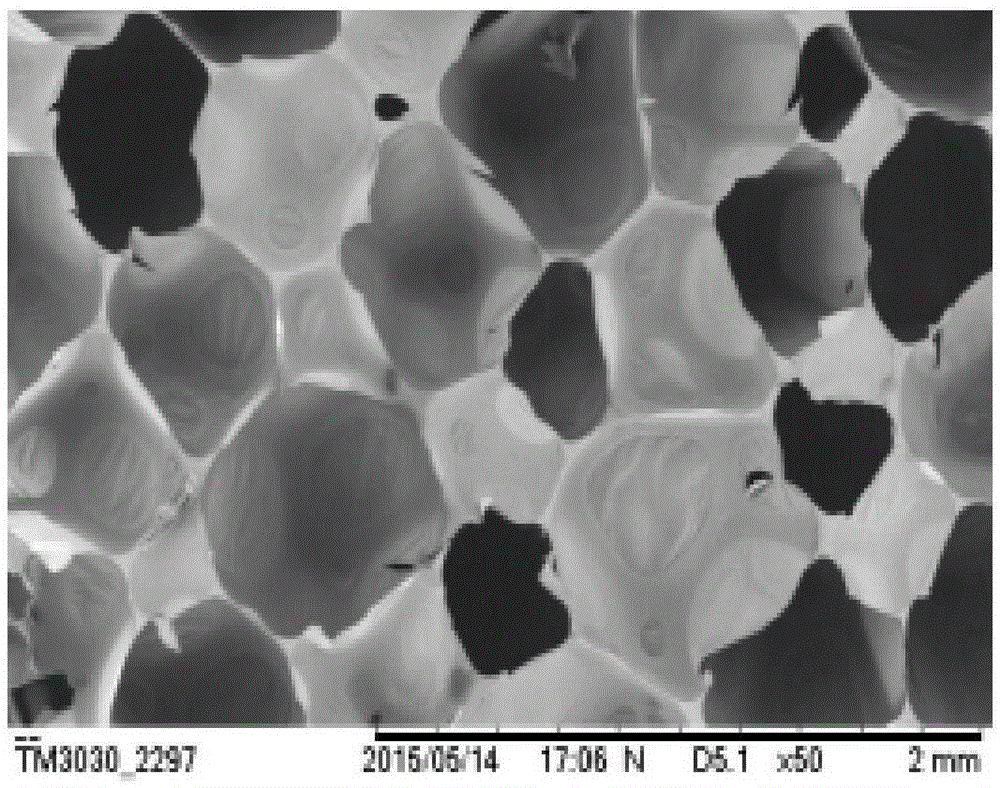

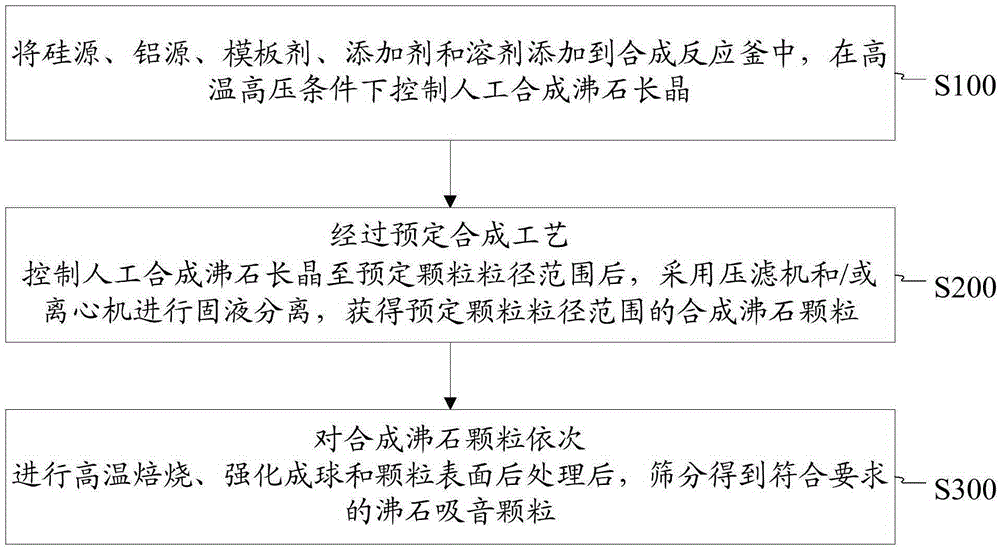

Sound absorption zeolite particle and synthesis and preparation method thereof

ActiveCN105347357AGood mass transfer efficiencyGood sound absorptionCrystalline aluminosilicate zeolitesSolventLoudspeaker

The invention discloses a sound absorption zeolite particle and a synthesis and preparation method thereof. The method comprises the following steps: adding a silicon source, an aluminum source, a template, an additive and a solvent into a synthesis reaction kettle, and controlling artificially synthesized zeolite crystal growth under high temperature and high pressure conditions for a predetermined synthesis time to reach a predetermined particle size range; carrying out solid-liquid separation by using a filter press and / or a centrifuge to obtain molded synthesized zeolite particles; and sequentially carrying out high temperature roasting, reinforcing balling and particle surface post-treatment on the molded synthesized zeolite particles, and screening to obtain the satisfactory sound absorption zeolite particle. The method adopting the above technical scheme does not need secondary molding, so influences of a bonding agent on the zeolite particles are avoided, thereby the sound absorption zeolite particle has good mass transfer and sound absorption effects when being applied in loudspeaker products; and the required zeolite particle is obtained through the high temperature roasting, reinforcing balling and particle surface post-treatment of the molded synthesized zeolite particles.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com