Sound absorption zeolite particle and synthesis and preparation method thereof

A zeolite and particle technology, which is applied to the field of zeolite sound-absorbing particles and their synthesis and preparation, can solve the problems of reducing the mass transfer efficiency and sound-absorbing effect of zeolite sound-absorbing materials, and achieve the advantages of eliminating polarity defects, improving particle strength and improving mass transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

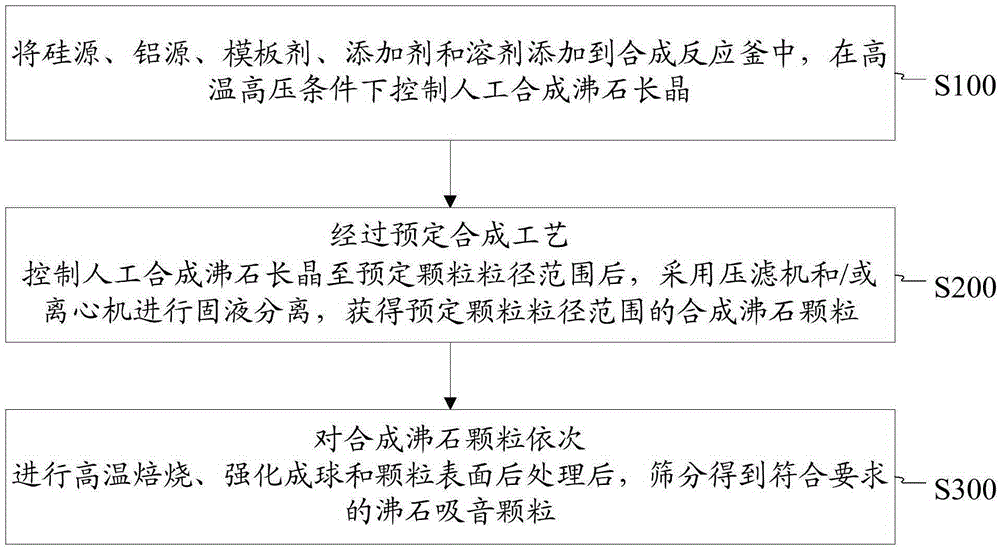

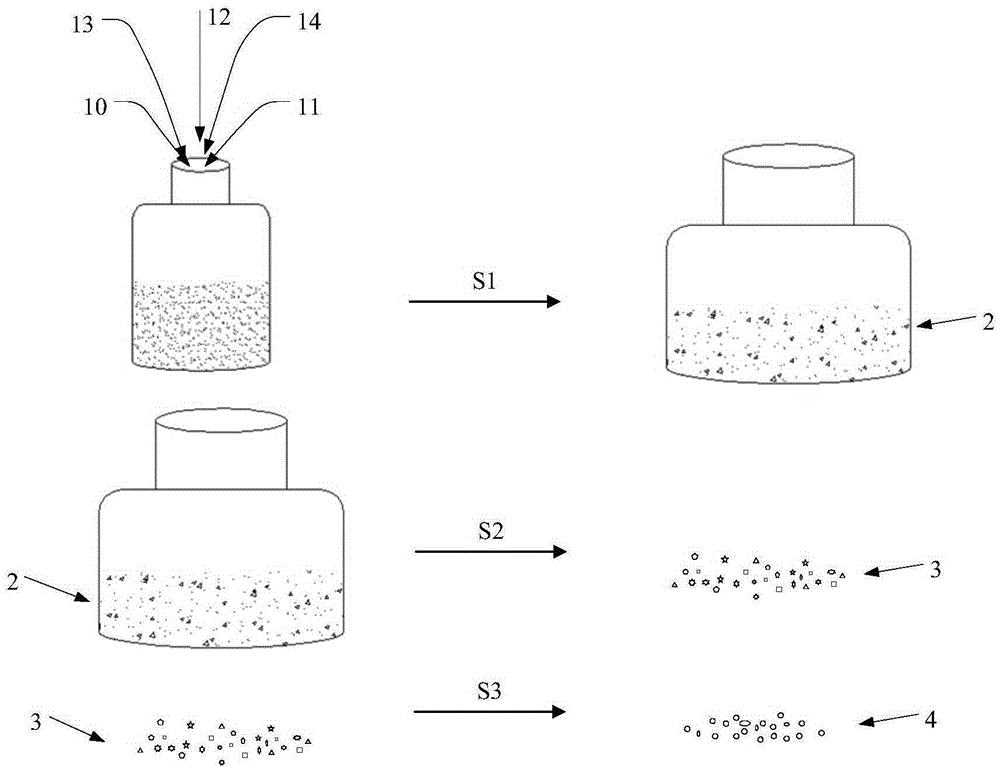

[0027] figure 1 The flow chart of the synthesis and preparation method of zeolite sound-absorbing particles provided in this example, figure 2 The process flow chart for the synthesis and preparation of zeolite sound-absorbing particles provided in this example, it should be understood that this example figure 2 The labels 10-14 in do not limit the execution order.

[0028] like figure 1 and figure 2 Collectively, the method includes:

[0029] S100, add silicon source, aluminum source, template agent, additives and solvents into the synthesis reaction kettle, and control the growth of artificially synthesized zeolite crystals under specific synthesis process conditions such as high temperature and high pressure.

[0030] Among them, the silicon source, aluminum source and template are all preferably chemically pure grade raw materials to ensure the purity of the prepared materials, minimize the defects in the microscopic crystal structure of the zeolite material, and ma...

Embodiment 2

[0044] Based on the synthesis and preparation method of the zeolite sound-absorbing particles provided in the first embodiment, the embodiment of the present invention also provides a zeolite sound-absorbing particle.

[0045] The zeolite sound-absorbing particles are synthesized from silicon sources, aluminum sources, templates, additives and solvents, and have a specific surface area of 220-750m 2 / g, the pore volume is 0.15-1.9ml / g, the macropore diameter is 0.1-50μm, the density is 0.3-0.9g / ml, and the particle size is 0.10-1.0mm.

[0046] The silicon source, the aluminum source and the template agent in this embodiment are all made of chemically pure grade raw materials, and the purity of the template agent is higher than 90%, and the addition ratio is 1% to 35%.

[0047] In summary, the present invention discloses a zeolite sound-absorbing particle and its synthesis and preparation method. By adding the raw materials required for the preparation of zeolite particles in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com