Insulation sound-absorbing decorative plate and preparation method thereof

A decorative board and substrate technology, applied in the field of thermal insulation and sound-absorbing decorative boards and their preparation, can solve problems such as lack of thermal insulation and sound absorption, cement sand is not environmentally friendly, and unfavorable to human health, and achieve good thermal insulation effects, eliminate light pollution, and easily The effect of cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

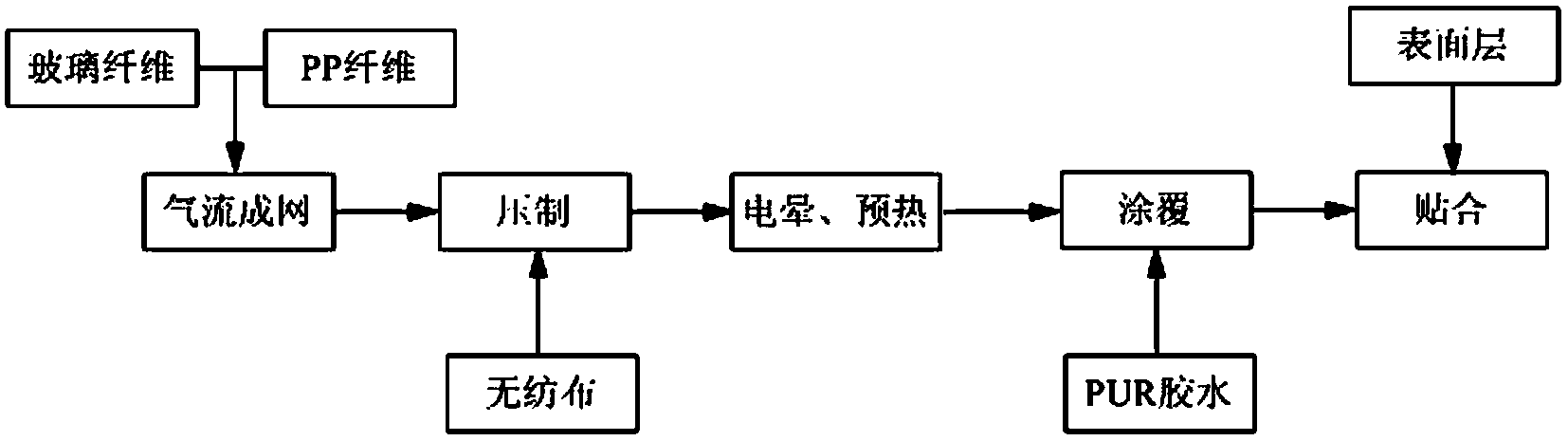

[0042] Mix PP fiber and glass fiber, the mixing ratio is 30% by weight of PP fiber, and the rest is glass fiber; use air-laid method, under the condition of 150~180°C, make PP fiber and glass fiber into a sheet, Constitute the original substrate, the thickness is 10mm; the production speed when air-laid is 3m / min;

[0043] Use PET non-woven fabric as the bottom layer, press one side of the original substrate and the bottom layer together with a press machine at a temperature of 180~220°C to make a double-layer board composed of the substrate and the bottom layer; the pressing pressure is 8Bar;

[0044] Corona treatment is carried out on the substrate surface of the double-layer board until the surface tension of the substrate surface of the double-layer board is 38 dynes, and then preheated to 40°C, and then a layer of PUR glue is coated on the substrate surface of the double-layer board;

[0045] Using PVC film as the surface layer, the surface layer and the substrate surface...

Embodiment 2

[0050] Method is with embodiment 1, and difference is:

[0051] (1) The mixing ratio of PP fiber and glass fiber is 40% by weight of PP fiber, and the rest is glass fiber; the original substrate is a coil with a thickness of 9mm; the production speed when air-laid is 2m / min;

[0052] (2) Use PP non-woven fabric as the bottom layer; the pressing pressure of the plate press is 5Bar;

[0053] (3) Corona treatment is performed on the substrate surface of the double-layer board until the surface tension of the substrate surface of the double-layer board is 39 dynes, and then preheated to 50°C;

[0054] The weight of the bottom layer of the prepared thermal insulation and sound-absorbing decorative board is 60g / ㎡, and the thickness is 0.28mm; the weight of the substrate is 1000g / ㎡, and the thickness is 3.5mm; the weight of the PP surface layer is 170g / ㎡, and the thickness is 0.18mm;

[0055] The thermal conductivity of the thermal insulation and sound-absorbing decorative panels is...

Embodiment 3

[0057] Method is with embodiment 1, and difference is:

[0058] (1) The mixing ratio of PP fiber and glass fiber is 50% by weight of PP fiber, and the rest is glass fiber; the thickness of the original substrate is 8mm; the production speed when air-laid is 3m / min;

[0059] (2) The pressing pressure of the pressing machine is 1Bar;

[0060] (3) Corona treatment is performed on the substrate surface of the double-layer board until the surface tension of the substrate surface of the double-layer board is 40 dynes, and then preheated to 20~60°C;

[0061] The weight of the bottom layer of the prepared thermal insulation and sound-absorbing decorative board is 70g / ㎡, and the thickness is 0.31mm; the weight of the substrate is 1500g / ㎡, and the thickness is 5mm; the weight of the surface layer is 120g / ㎡, and the thickness is 0.13mm;

[0062] The thermal conductivity of the thermal insulation and sound-absorbing decorative panels is 0.057W / (m k); the sound-absorbing and sound-insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com