Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

391results about "Lap forming devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for forming controlled density fibrous pads for diapers and the other absorbent products

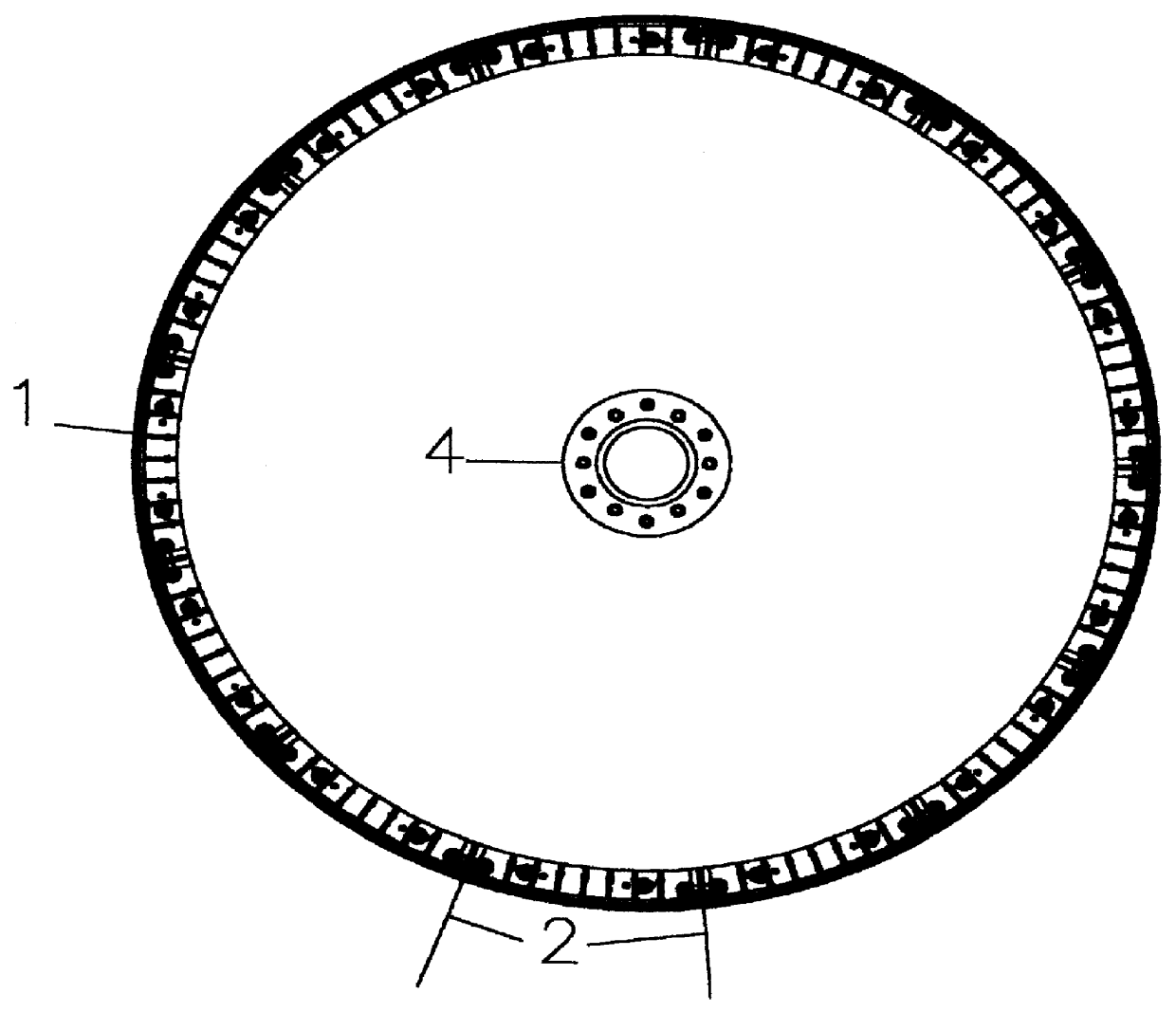

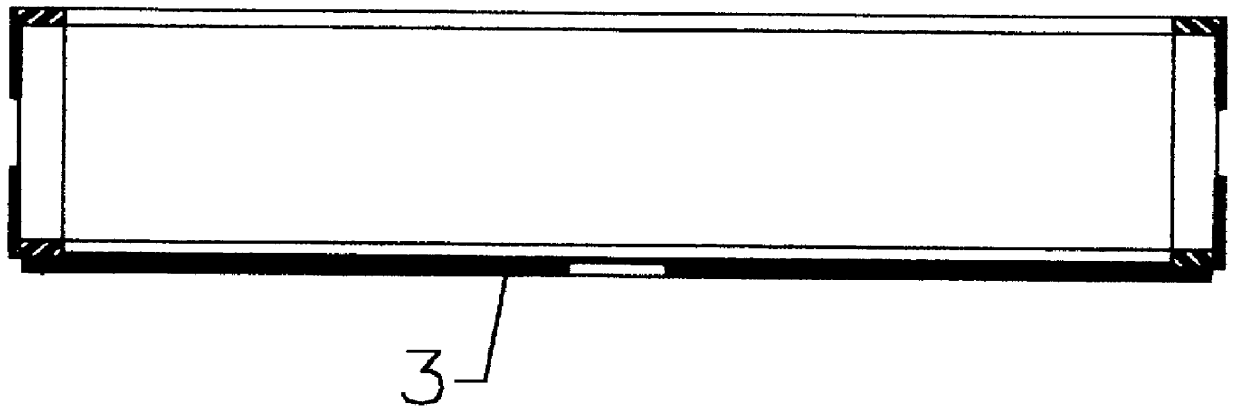

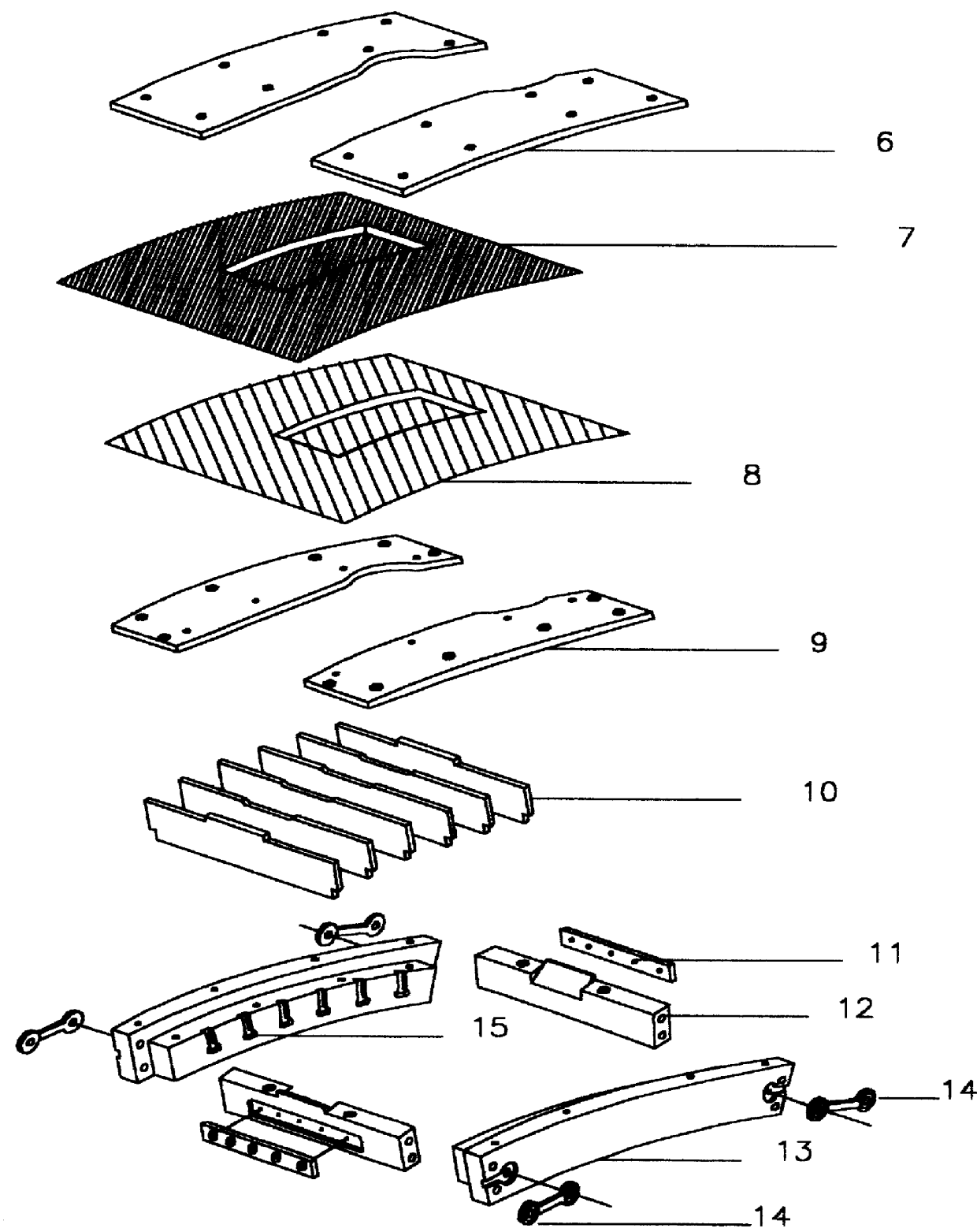

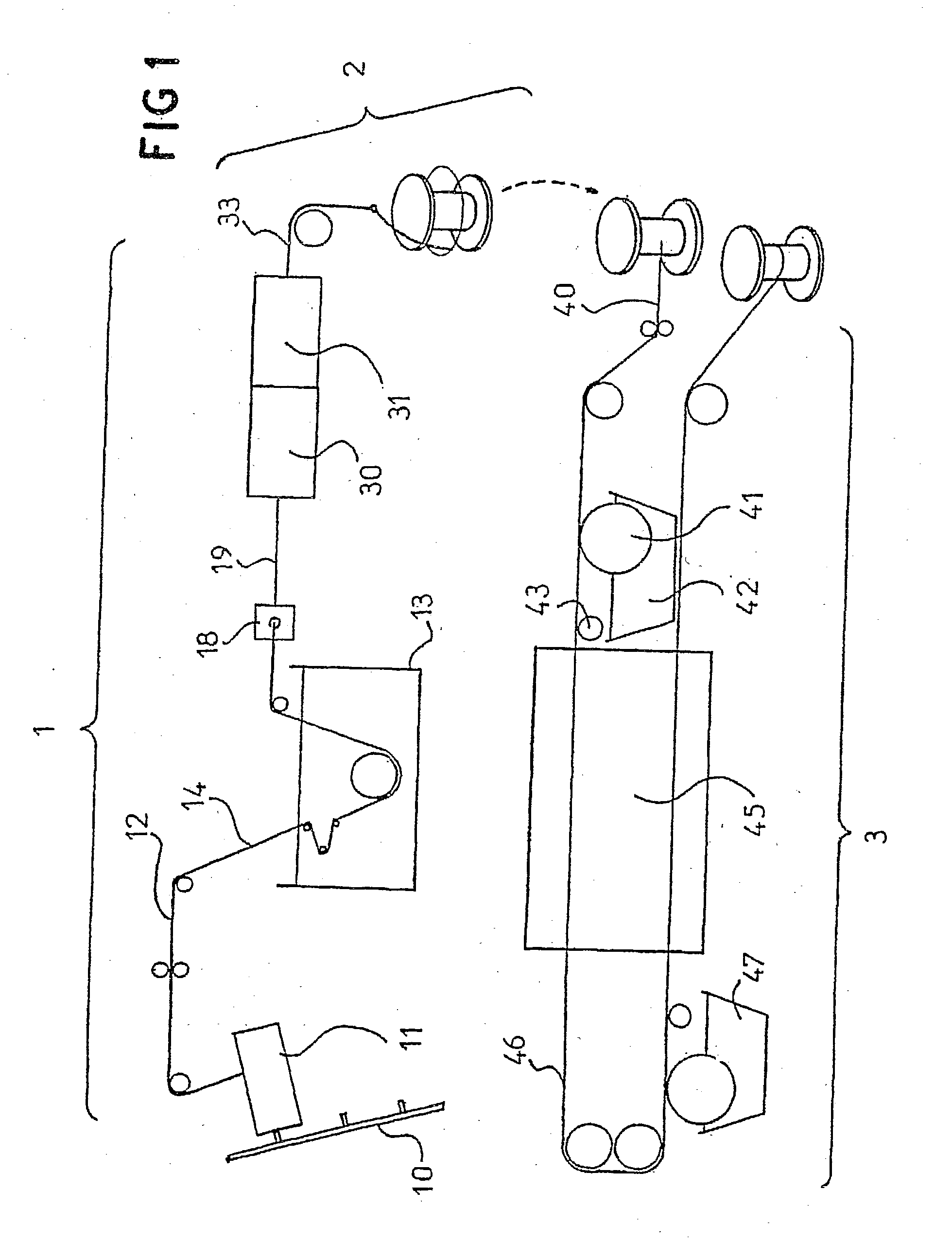

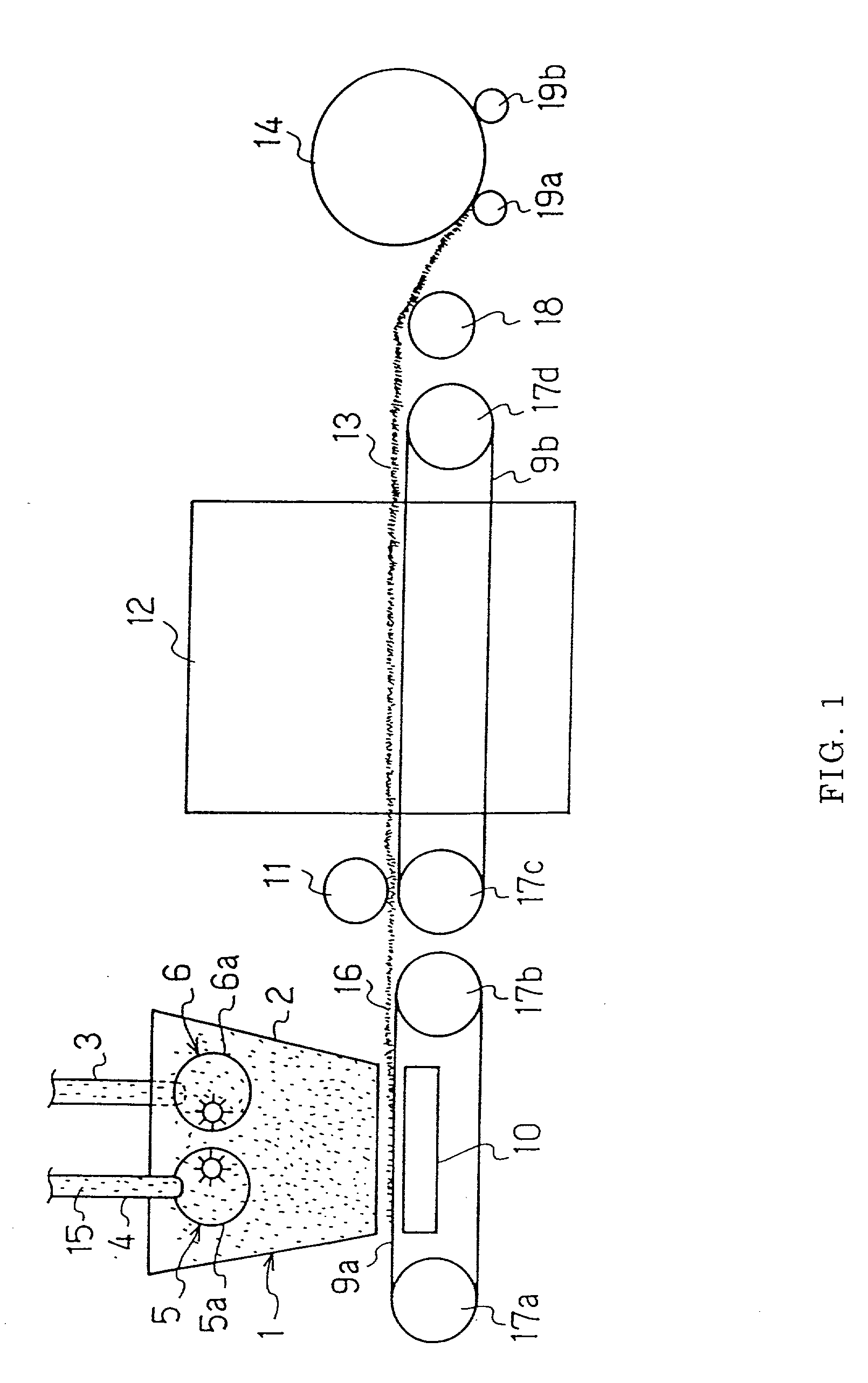

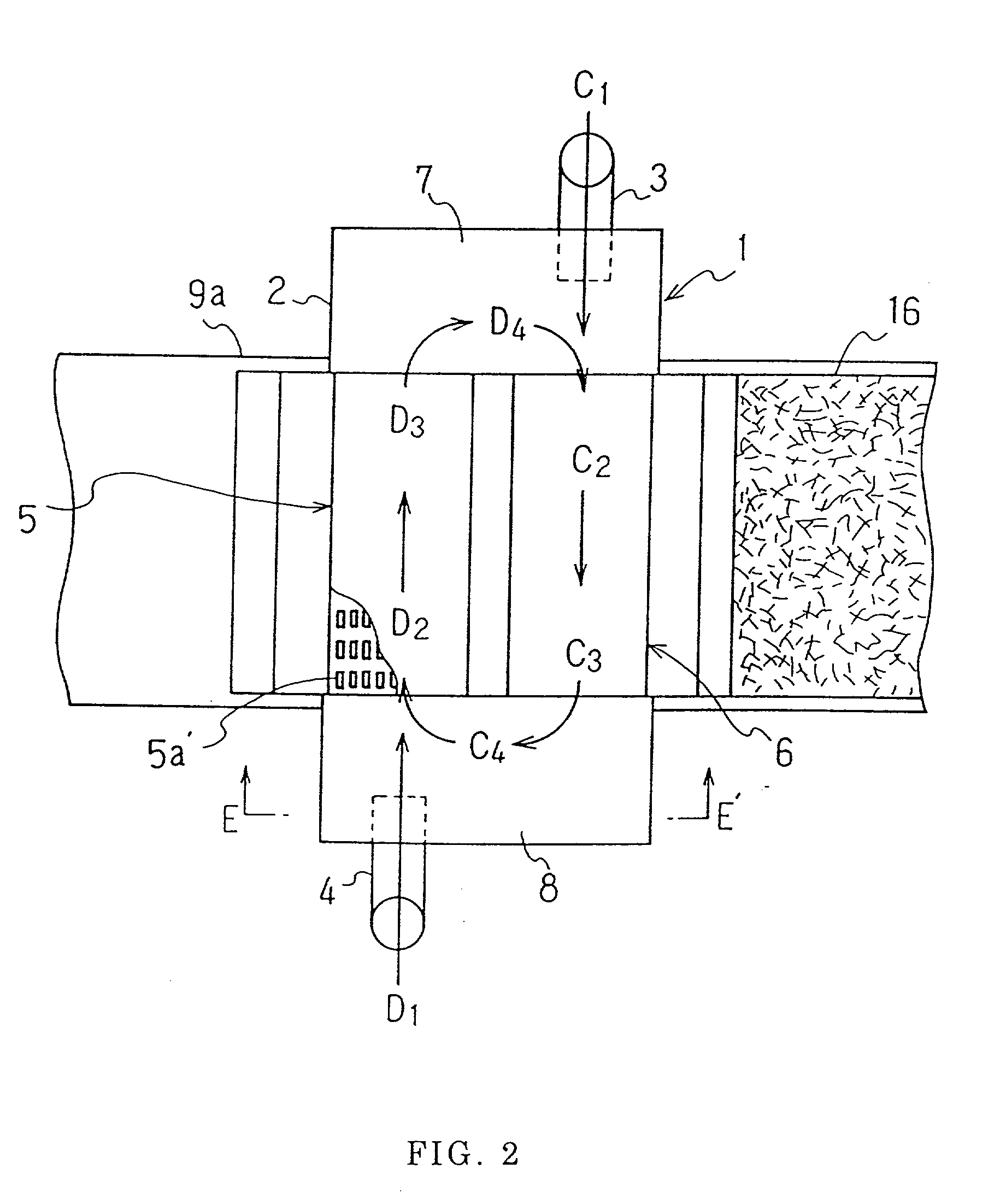

The present invention provides an improved apparatus for forming a fibrous pad for absorbent products with improved density control. Fibers entrained in a high speed air flow are deposited onto the foraminous surface of a spaced, three-dimensional pad-forming pocket. The fine foraminous pad forming screen is supported on its periphery by two top plates, a coarse forming screen, two subplates and end rails which incorporate a device to hold the pad forming screen. A gas flow regulating system consisting of precisely placed cross directional fixed and adjustable airflow control louvers controls the air flow direction and reduces spill over and turbulence during the pad formation and especially during the transition of the forming pocket into and out of the air stream as the rotary former shell rotates through the filling position. Additional control of density and fiber placement is gained through the use of additional gas control innovations including a tapering the pocket ends such that the airflow is streamlined especially during pocket transition through forming sections.

Owner:TONEY JERRY L +3

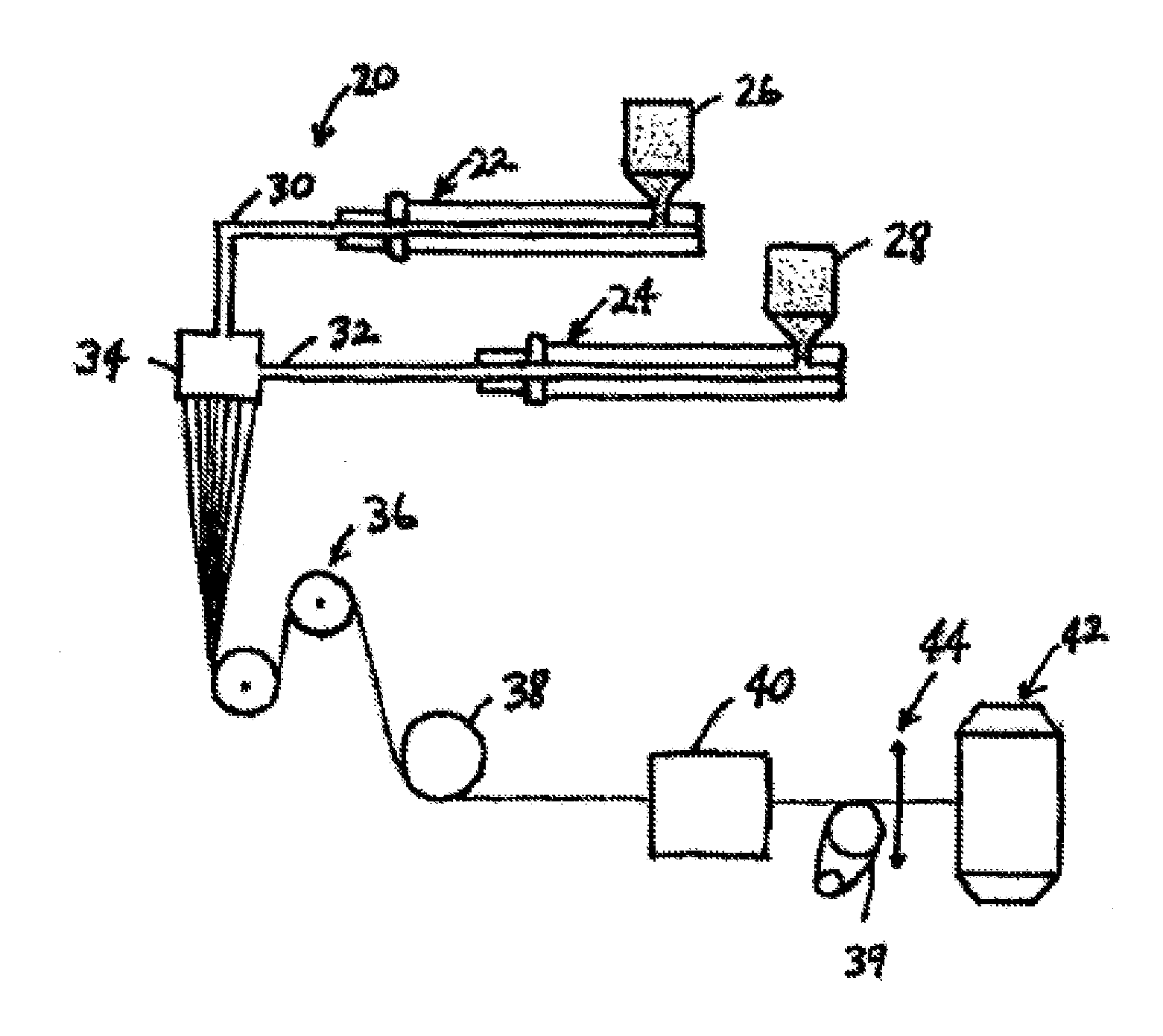

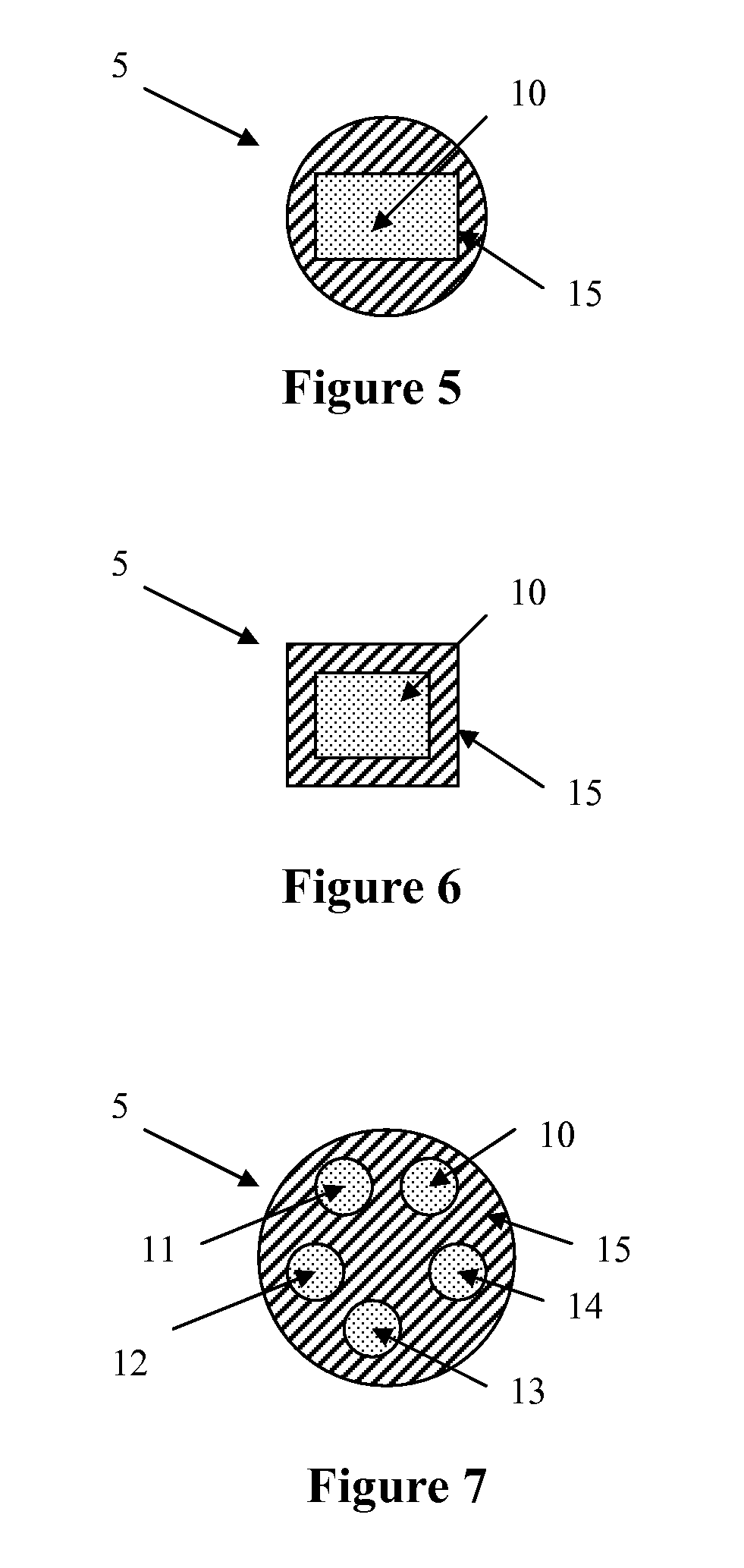

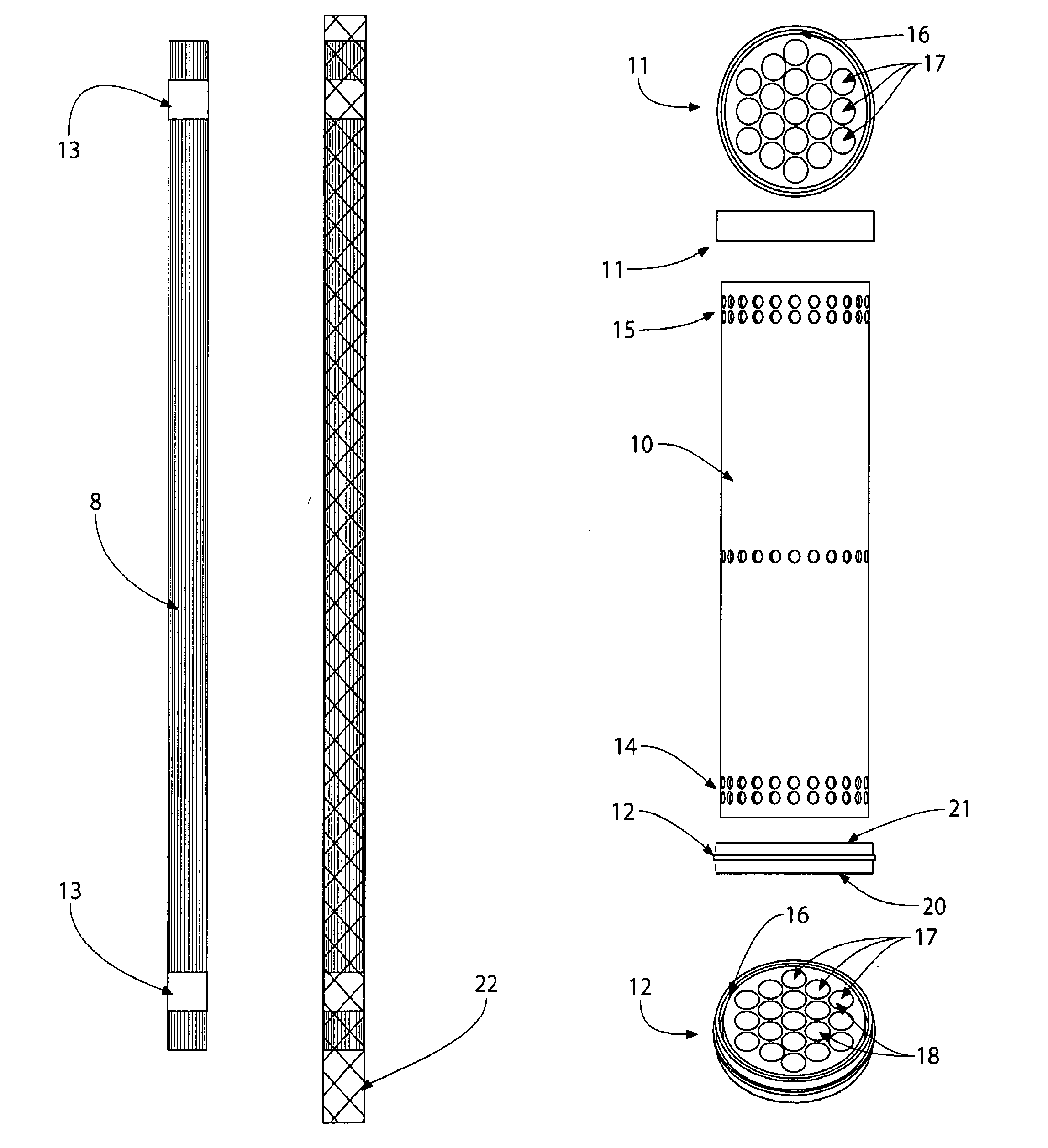

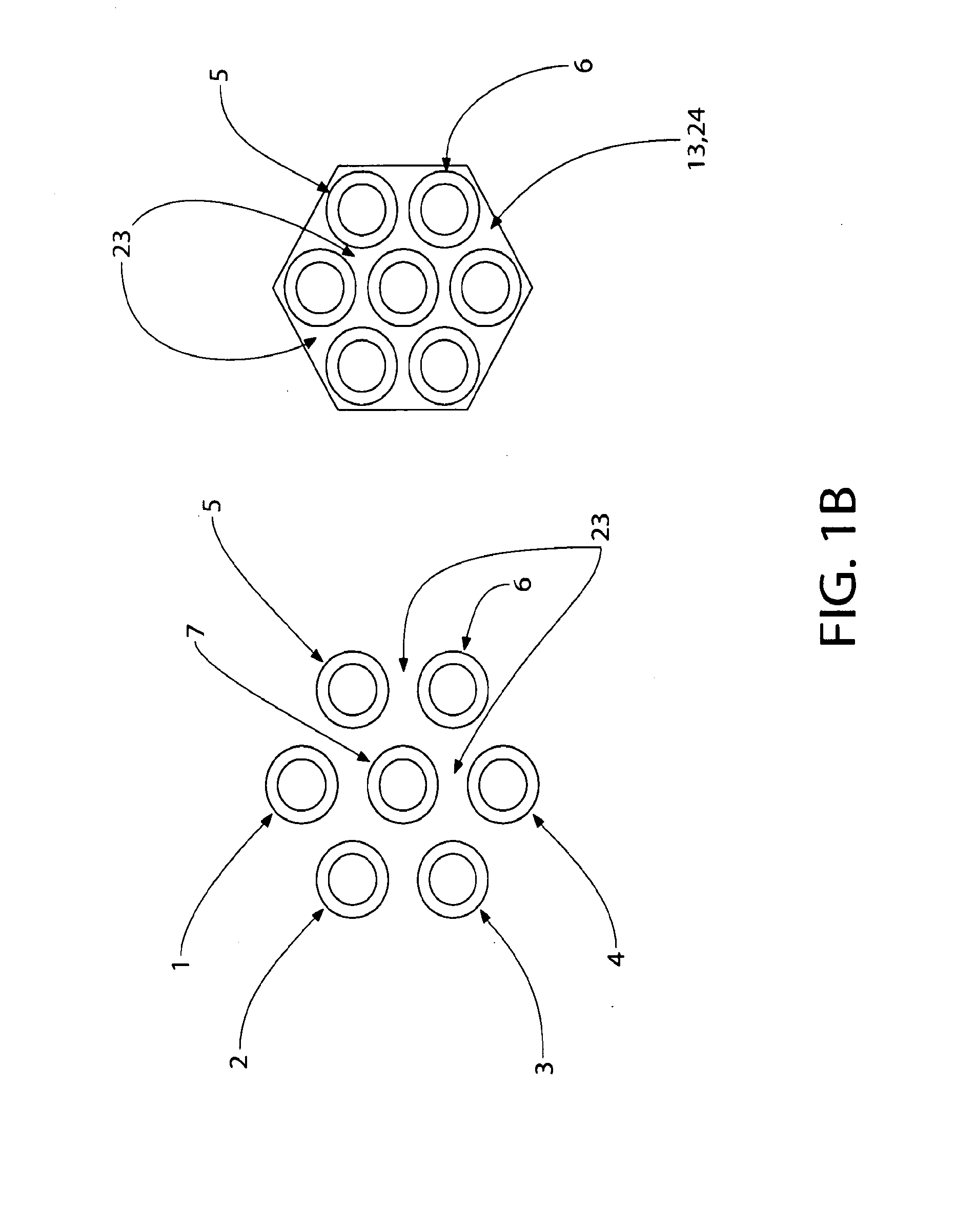

Non-woven fiber assemblies

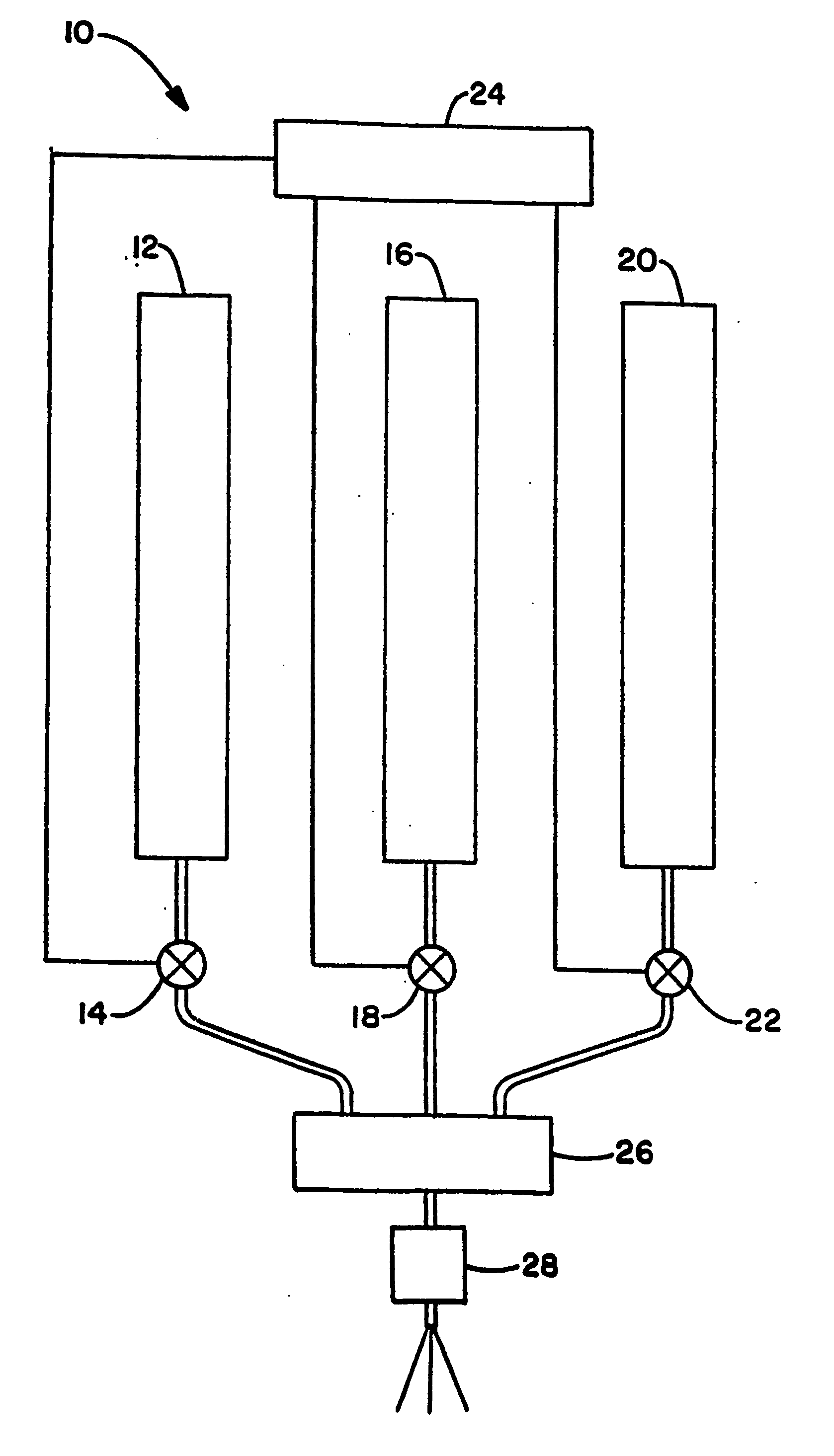

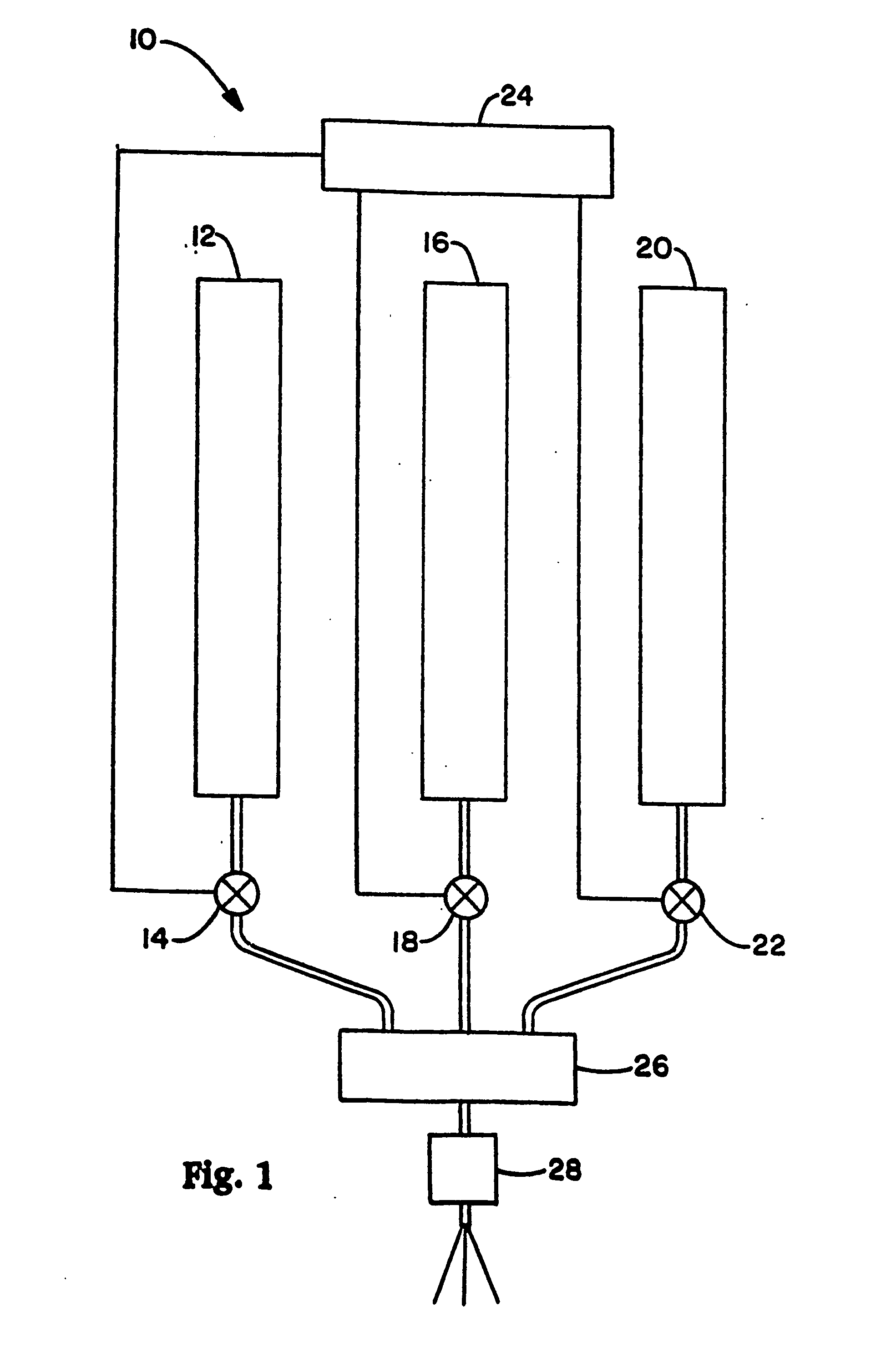

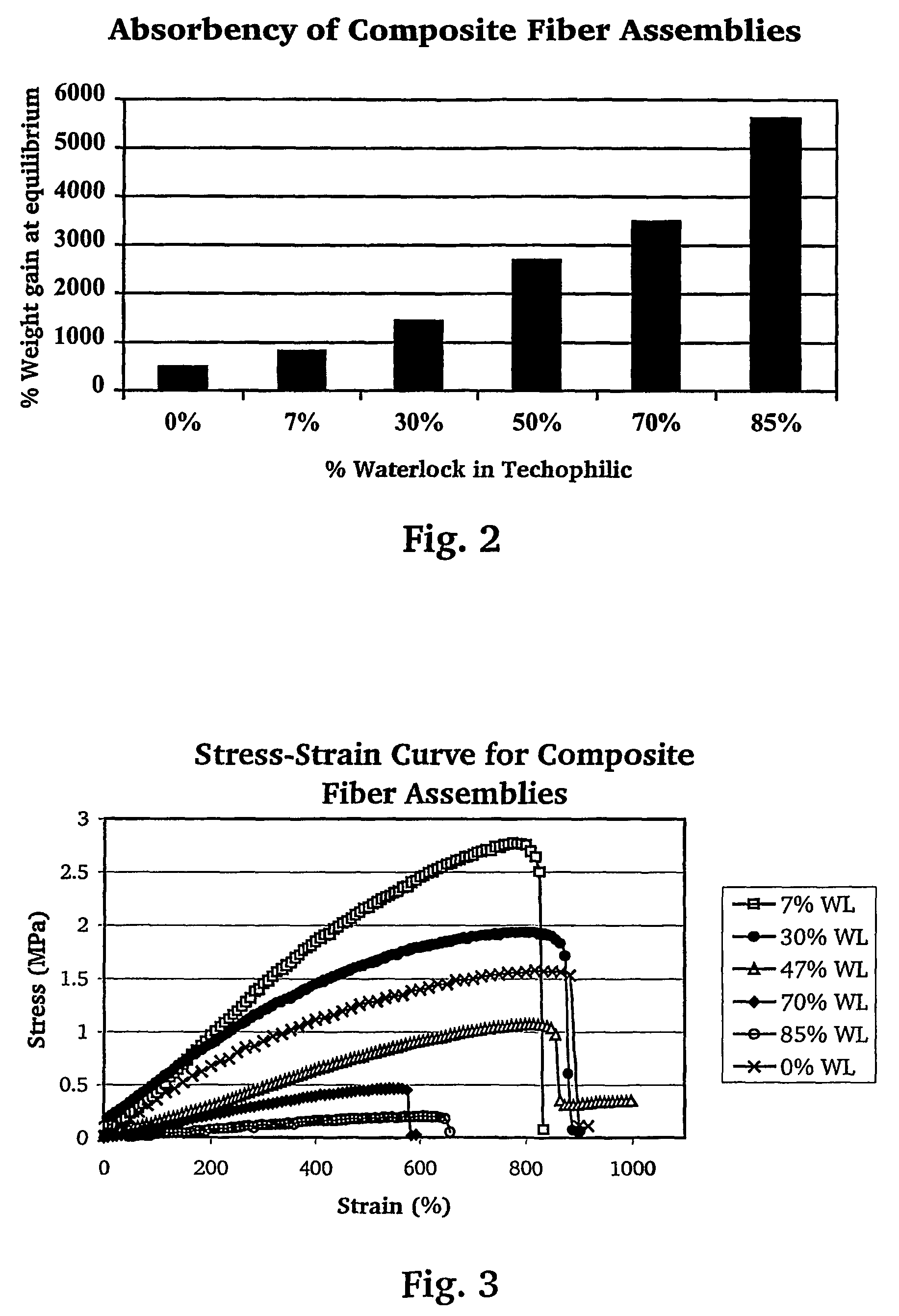

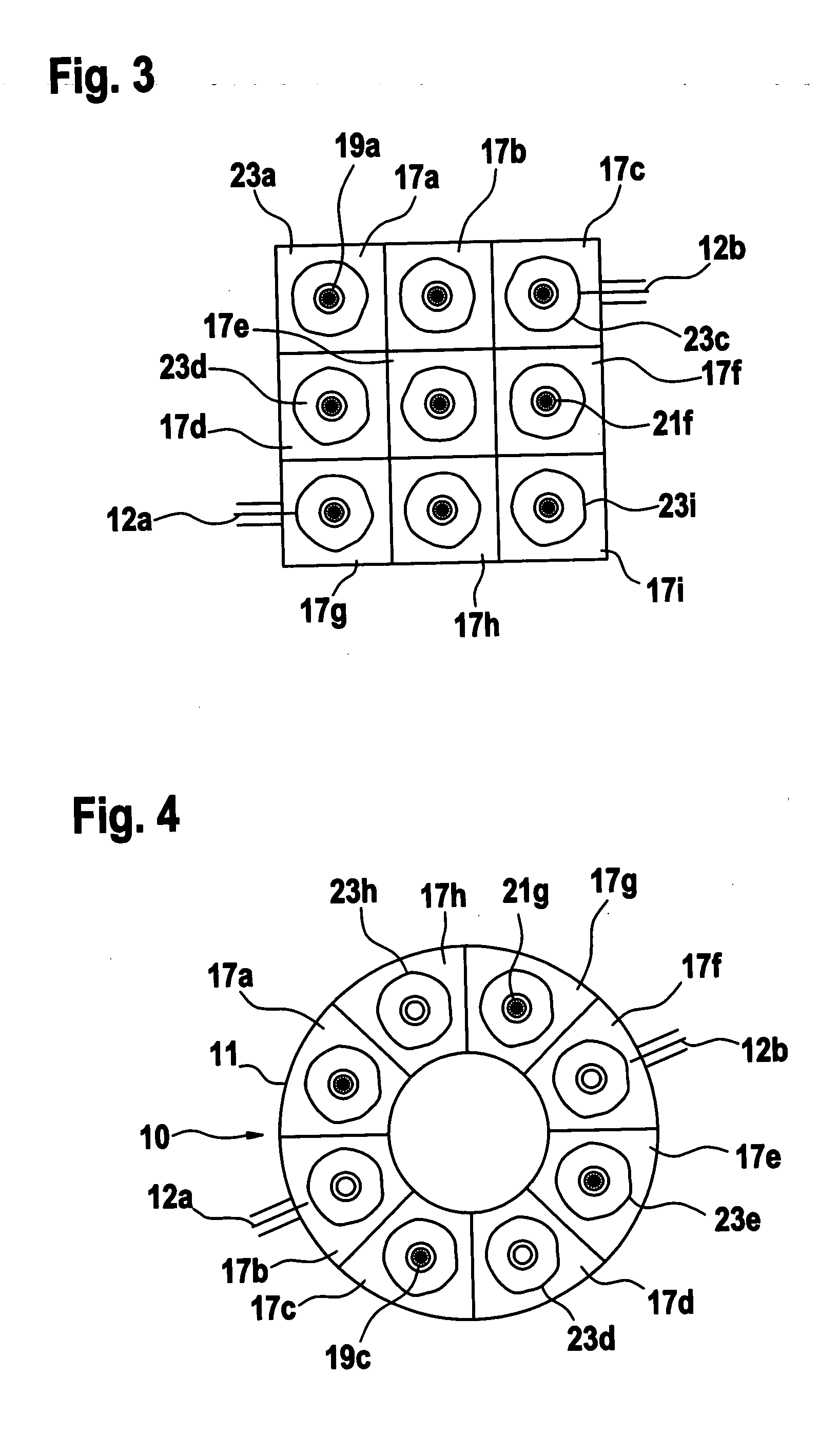

A non-woven fiber assembly comprises one or more fibers containing an adhesive component, an elastomeric component, and a hydrophilic component. A method of making a non-woven fiber assembly comprises the steps of providing one or more fiber-forming materials comprising an adhesive component, an elastomeric component, and a hydrophilic component, and forming said one or more fiber-forming materials into at least one fiber. A method of treating a patient comprises applying a medical dressing comprising the fiber assembly of the present invention to a patient. An apparatus (10) for forming a non-woven fiber assembly comprises a plurality of reservoirs (12, 16, 20) for containing more than one type of fiber-forming material, a plurality of valves (14, 18, 22), each independently in communication with a reservoir, and a fiber-forming device (28) selected from the group consisting of a spinnerette, a NGJ nozzle, and an electrospinning device, in communication with the valves.

Owner:THE UNIVERSITY OF AKRON

Non-woven fiber assemblies

In one embodiment, the present invention relates to a non-woven fiber assembly comprising one or more fibers wherein each fiber contains: a hydrophilic component; and an elastomeric component, and wherein the non-woven fiber assembly further comprises an adhesive component. In still another embodiment, the present invention relates to a non-woven fiber assembly comprising one or more fibers wherein each fiber contains: a hydrophilic component; an elastomeric component; and an adhesive component, wherein the hydrophilic component, the elastomeric component and the adhesive component are all contained within each fiber. Also disclosed is a method of making the afore-mentioned non-woven fiber assemblies. Additionally, a medical dressing made from the non-woven fiber assemblies of the present invention is disclosed.

Owner:THE UNIVERSITY OF AKRON

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

High ratio blended spinning technique for ultrashort low-density fibre based on cotton spinning device

InactiveCN101148797ARaise the ratioReasonable workmanshipFibre cleaning and opening machine combinationsCarding machinesYarnPolymer science

The present invention discloses the process of producing blended cheese yarn with high content of ultra short low density fiber in cotton spinning apparatus. A punching with high homogeneity and great cohesion is first produced through mixing ultra short low density fiber and other fiber in an opening and picking step much loosening and less beating; and then produced into cheese through the steps of combing, drawing, roving, spinning and coning. The blended cheese yarn consists of ultra short low density fiber 51-95 wt%, natural fiber 5-49 wt% and chemical fiber 5-49 wt%. The blended cheese yarn with high content of ultra short low density fiber is light, soft, lofty and high in strength, and its produced fabric has high color fastness.

Owner:DONGHUA UNIV +1

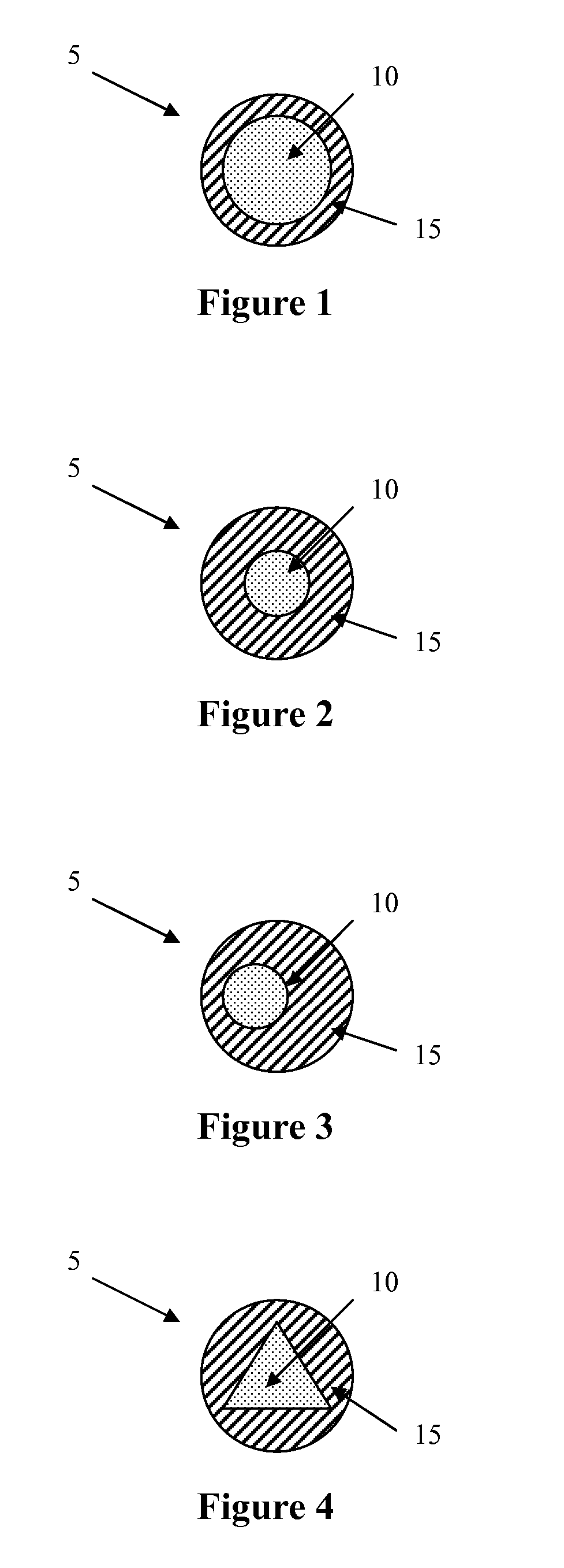

Multicomponent fiber comprising a phase change material

InactiveUS20070089276A1Avoid contactImprove thermal performanceFibre mixingLap-winding devicesFiberPhase-change material

The present invention is a multicomponent fiber comprising a temperature-regulating inner fiber component encapsulated by an outer fiber component. The invention further provides methods of preparing the inventive multicomponent fiber and methods of preparing a temperature-regulating fiber component incorporating at least one phase change material.

Owner:FIBER INNOVATION TECH

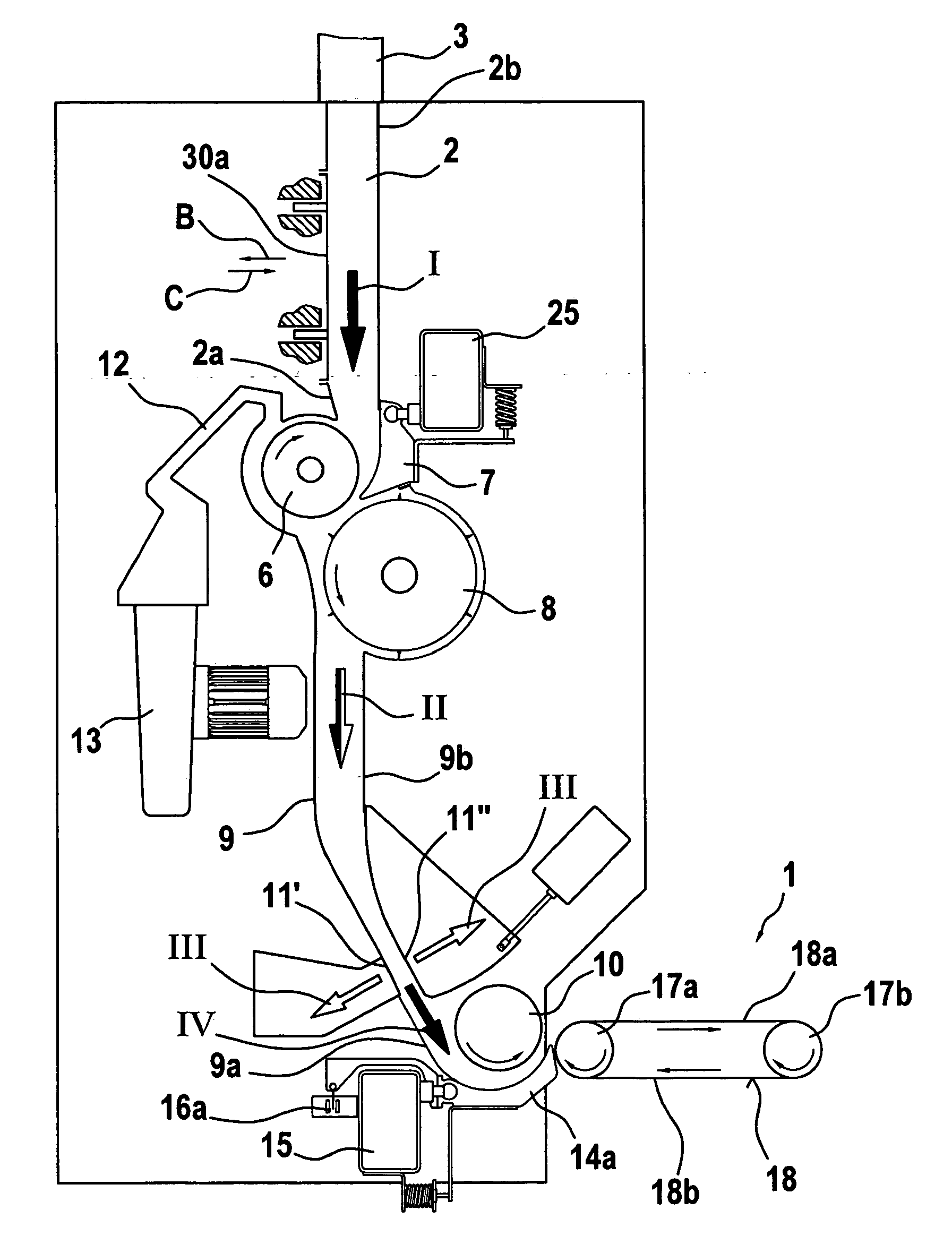

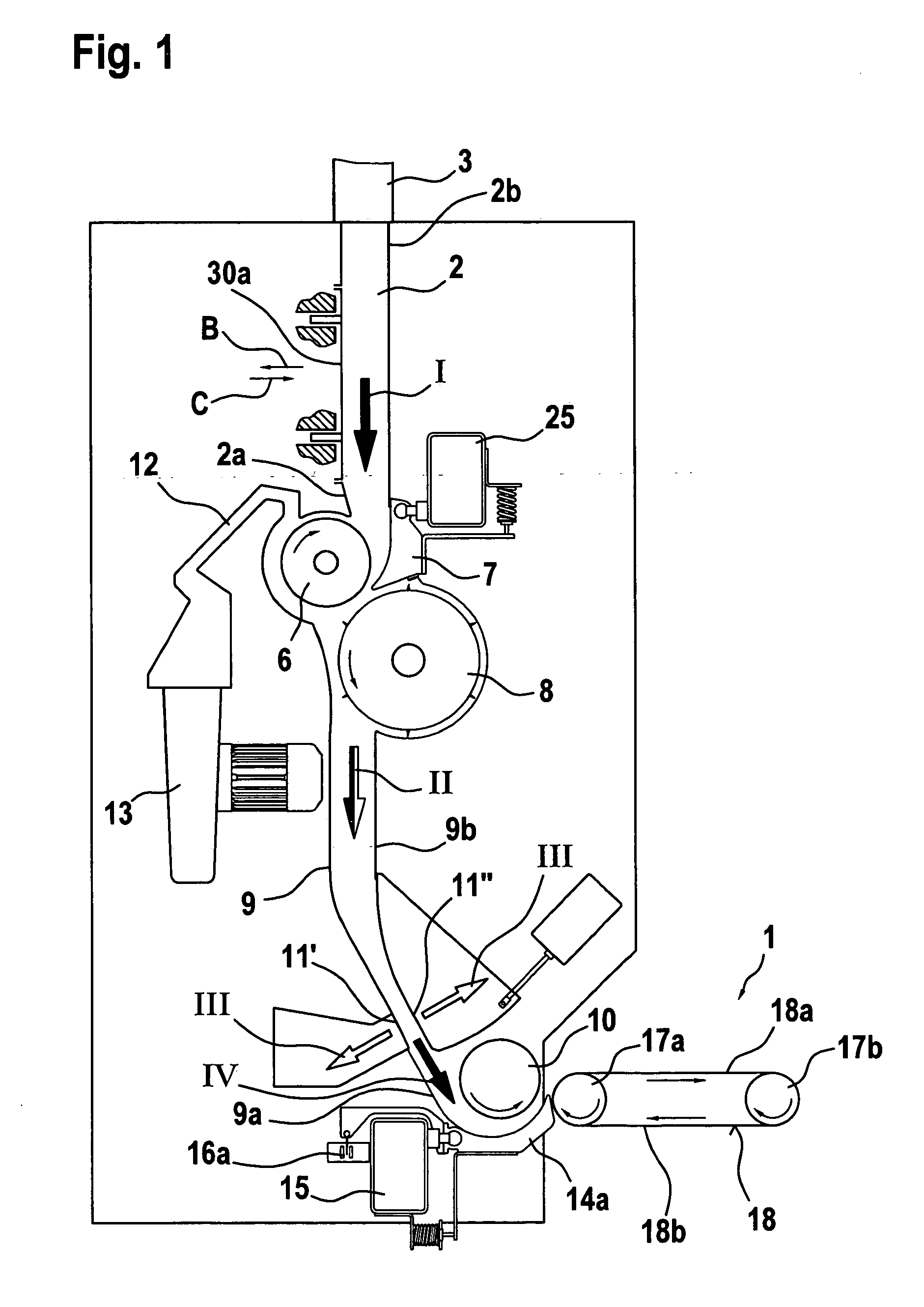

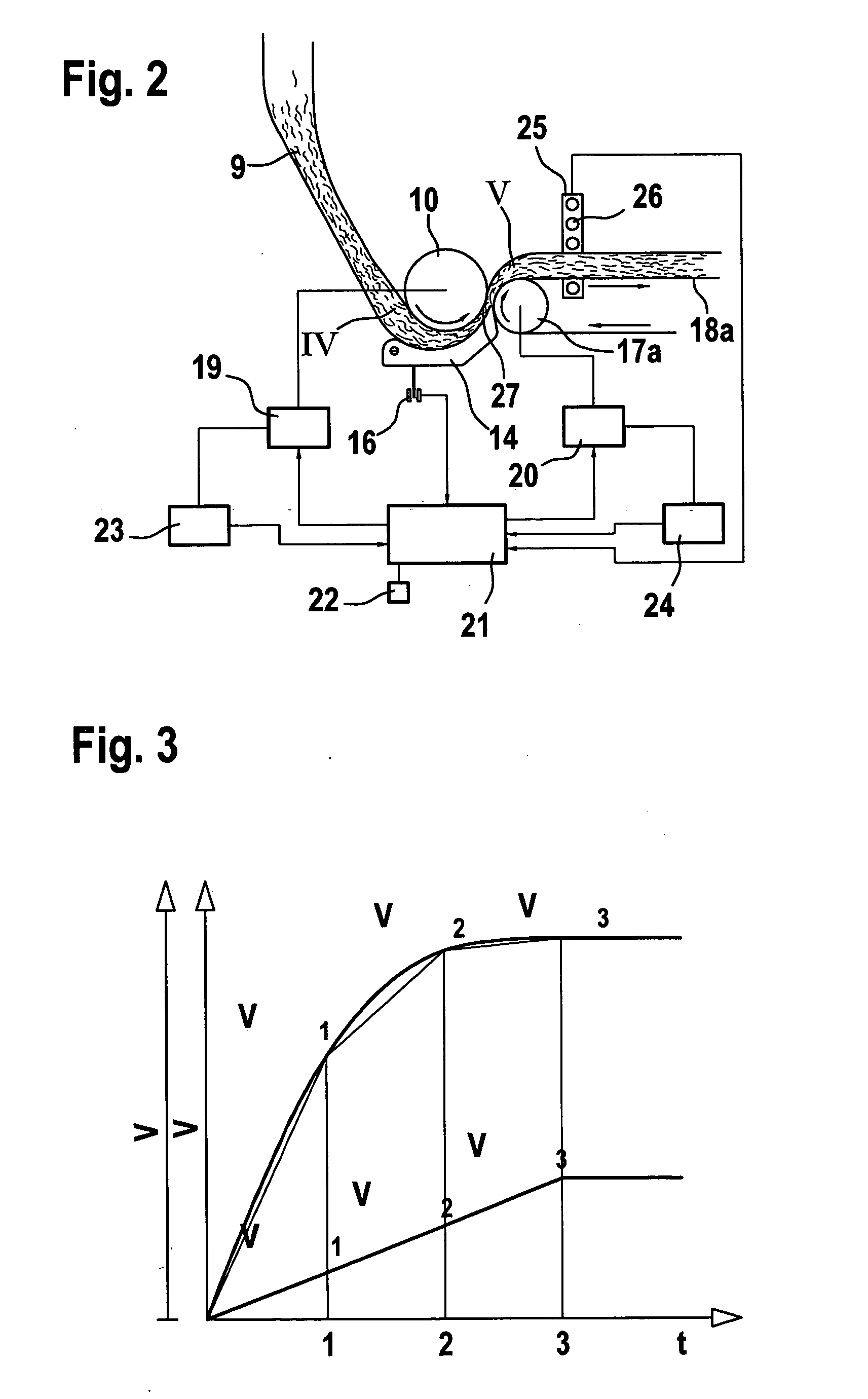

Device on a spinning preparation machine, for example a tuft feeder, having a feed device

A device on a spinning preparation machine, for example a tuft feeder, having a feed device comprising at least one slow-speed feed roller and a counter-element, for example a feed tray, with which fibre material can be supplied to a downstream transport device, has a driven transport element, for example a conveyor belt. In order to provide improved delivery from the feed device, or improved takeover by the downstream transport device, and to allow troublefree operation, for the purpose of determining setting values for the optimum speed of the transport element, a function between the measured values of the feed roller speed and the measured values of the transport speed is so determined that the fibre material lies on the moving surface of the transport element.

Owner:TRUETZSCHLER GMBH & CO KG

Method for the production of a carbon fiber-based reinforcing element for tires

InactiveUS20040043213A1Reduce riskImprove the lubrication effectCarbon fibresFilament handlingFiberCarbon fibers

A method for the production of a multifilament carbon fibre-based longitudinal reinforcing element, designed to be incorporated in a rubber-based item. Said method comprises the following steps, whereby untwisted carbon fibres are plunged into an impregnating bath contained a solution of resorcinol-formaldehyde resin and rubber latex, the impregnated fibres are then dried and the dried fibres are subsequently twisted. The inventive method is characterised by the fact that it also comprises a step, during the impregnation step, consisting in opening out the carbon fibres by spreading out the constituent filaments thereof in such a way that each fibre has an increased surface area on which the impregnation can be performed.

Owner:SOVOUTRI SOC VOULTAINE DE TRANSFORMES INDS

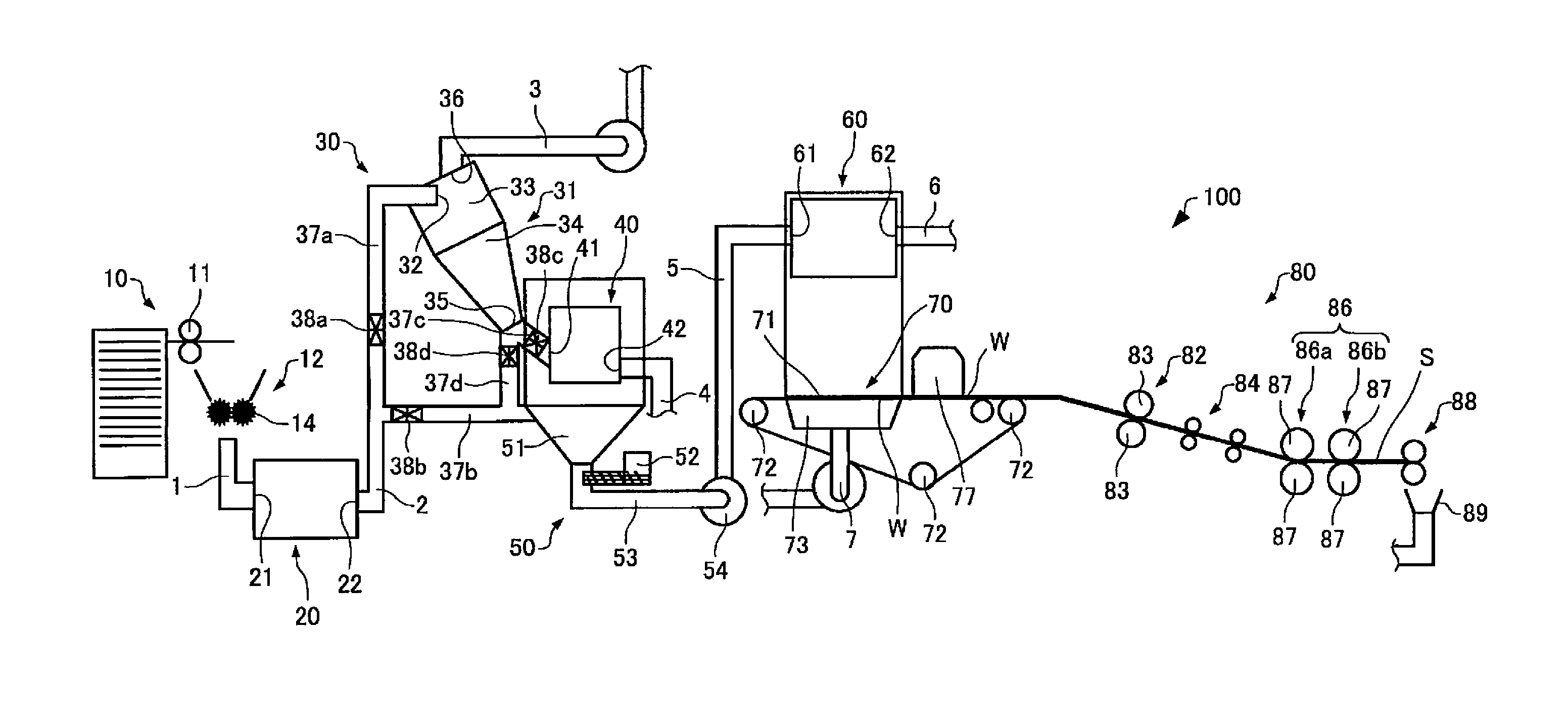

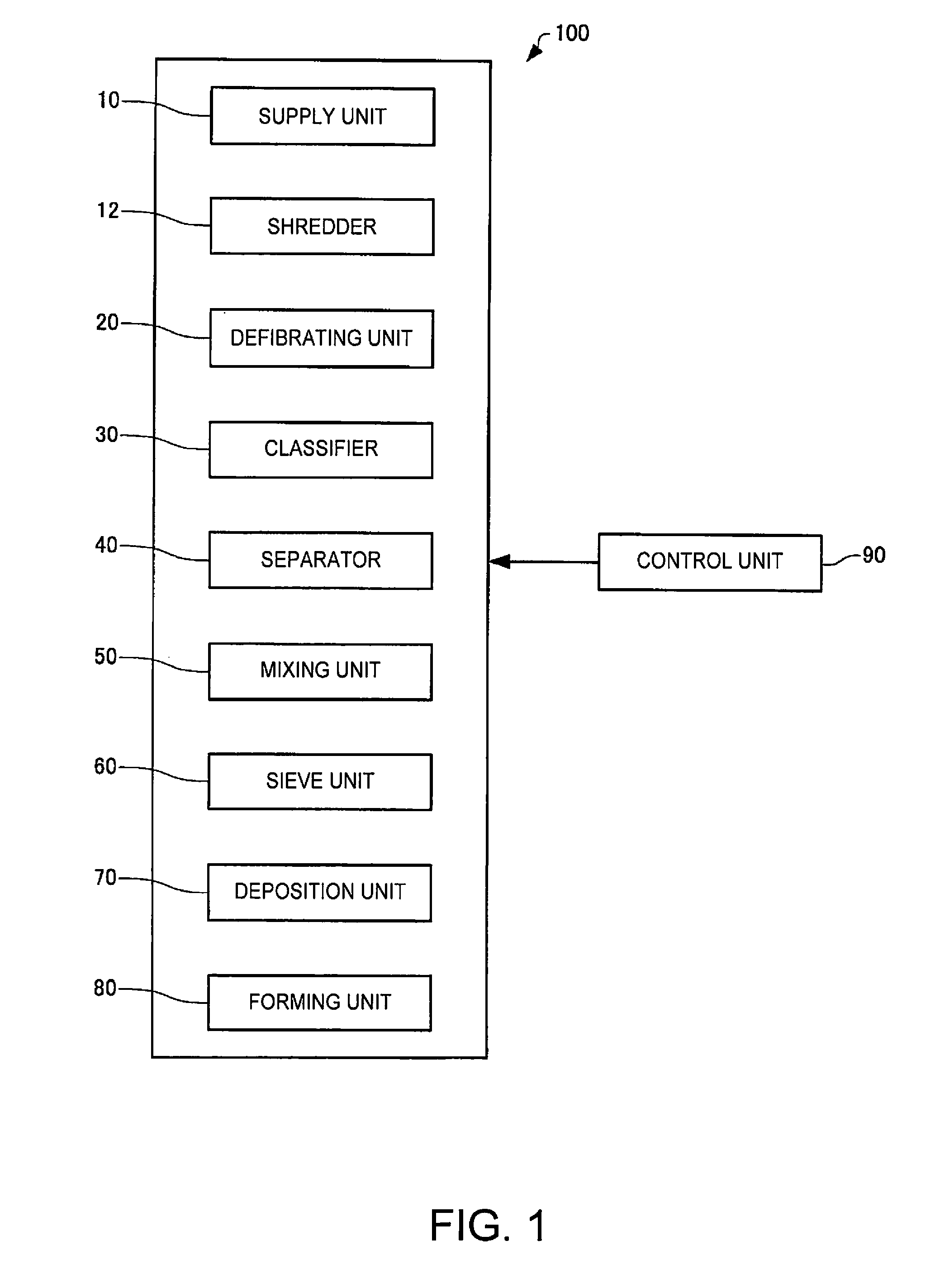

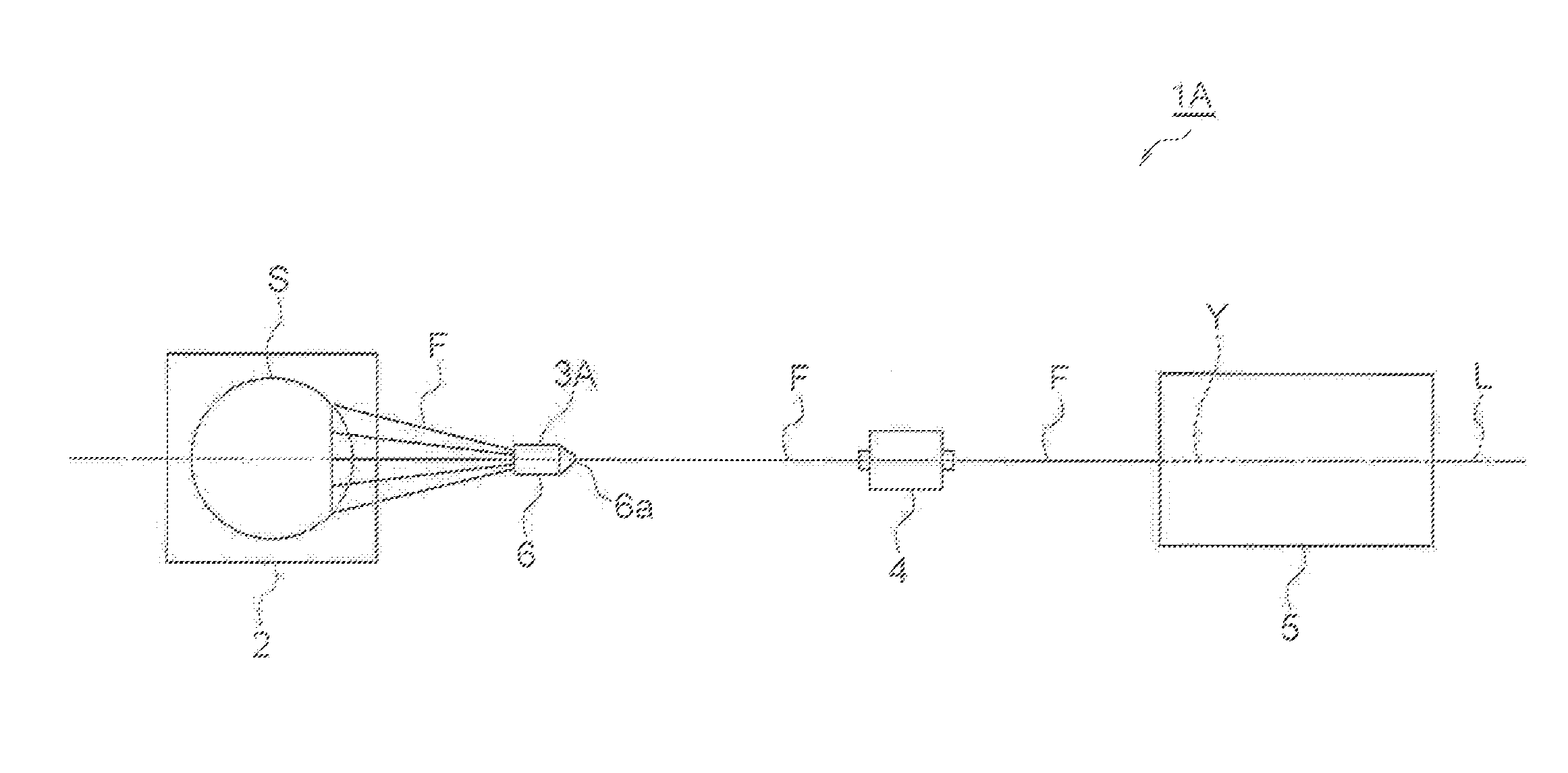

Sheet manufacturing apparatus

ActiveUS20160332325A1Change densityStrength be changedPaper recyclingLap forming devicesFiberControl unit

A sheet manufacturing apparatus can process various materials and manufacture a variety of sheets by changing conditions for making the sheets. A sheet manufacturing apparatus according to the invention has a supply unit that supplies feedstock; a defibrating unit that defibrates the feedstock; a classifier that classifies defibrated material that past the defibrating unit; a mixing unit that mixes an additive containing resin with the classified material that past the classifier; a sieve unit that passes the mixture that past the mixing unit through many openings; a deposition unit that deposits precipitate that past many openings in the sieve unit; a forming unit that applies pressure and heat to the web deposited on the deposition unit, forming a sheet; and a control unit that changes a condition of at least one of the classifier, mixing unit, sieve unit, deposition unit, and forming unit.

Owner:SEIKO EPSON CORP

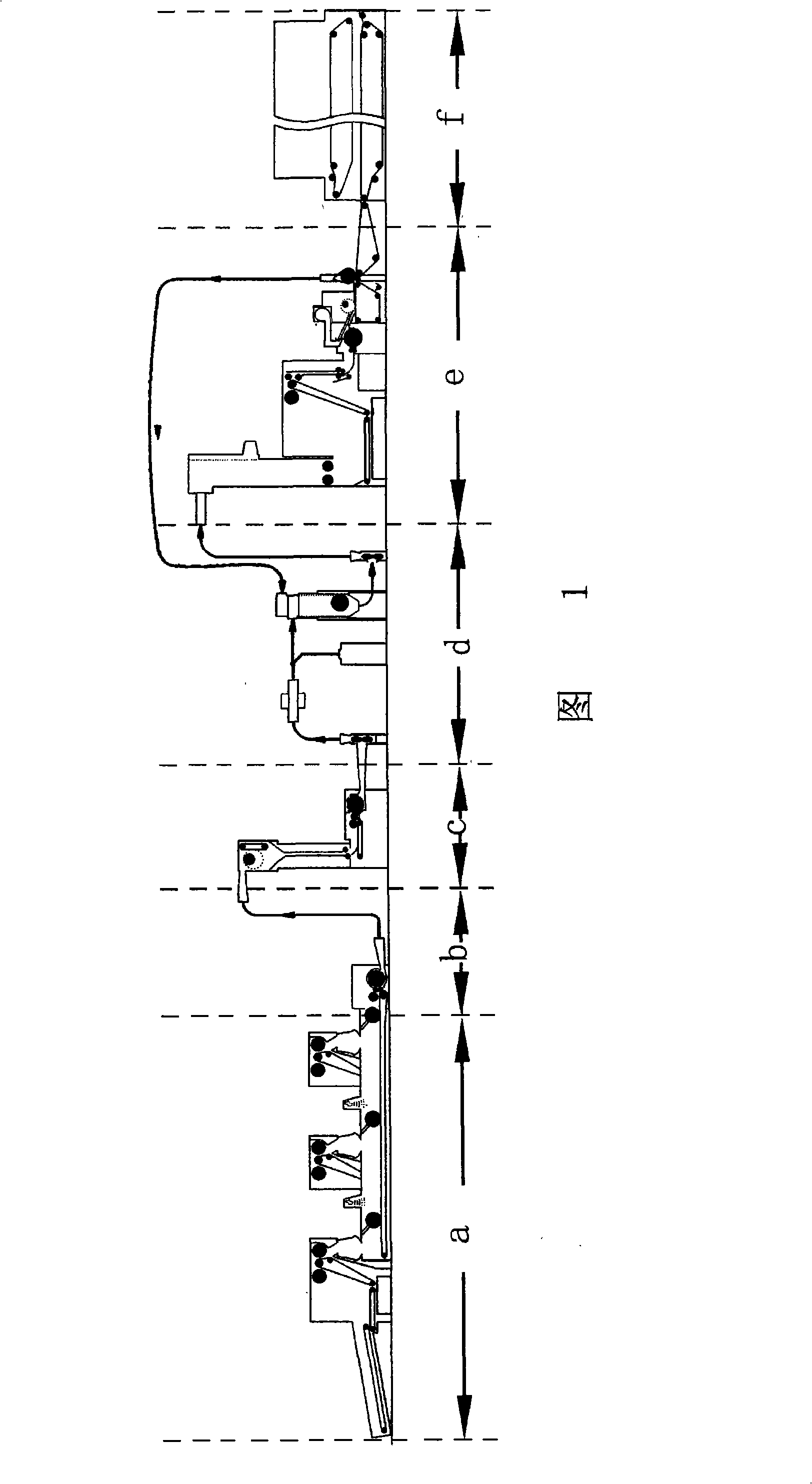

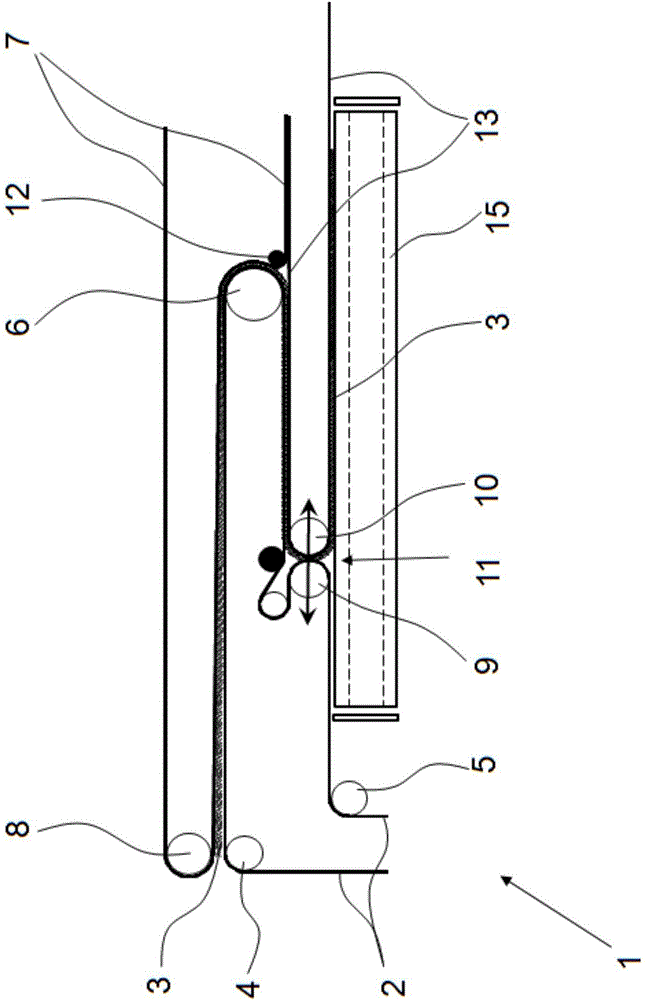

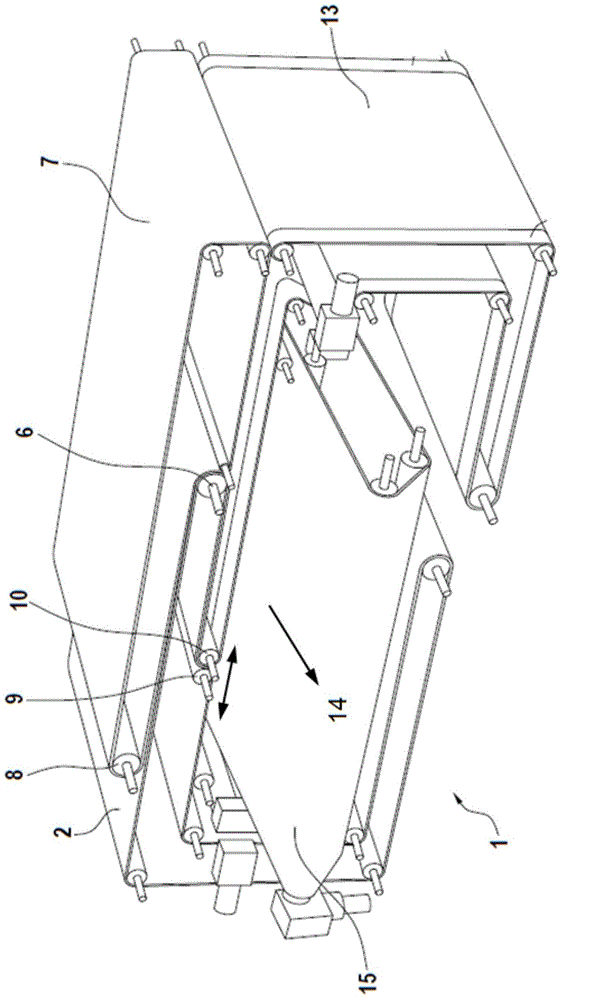

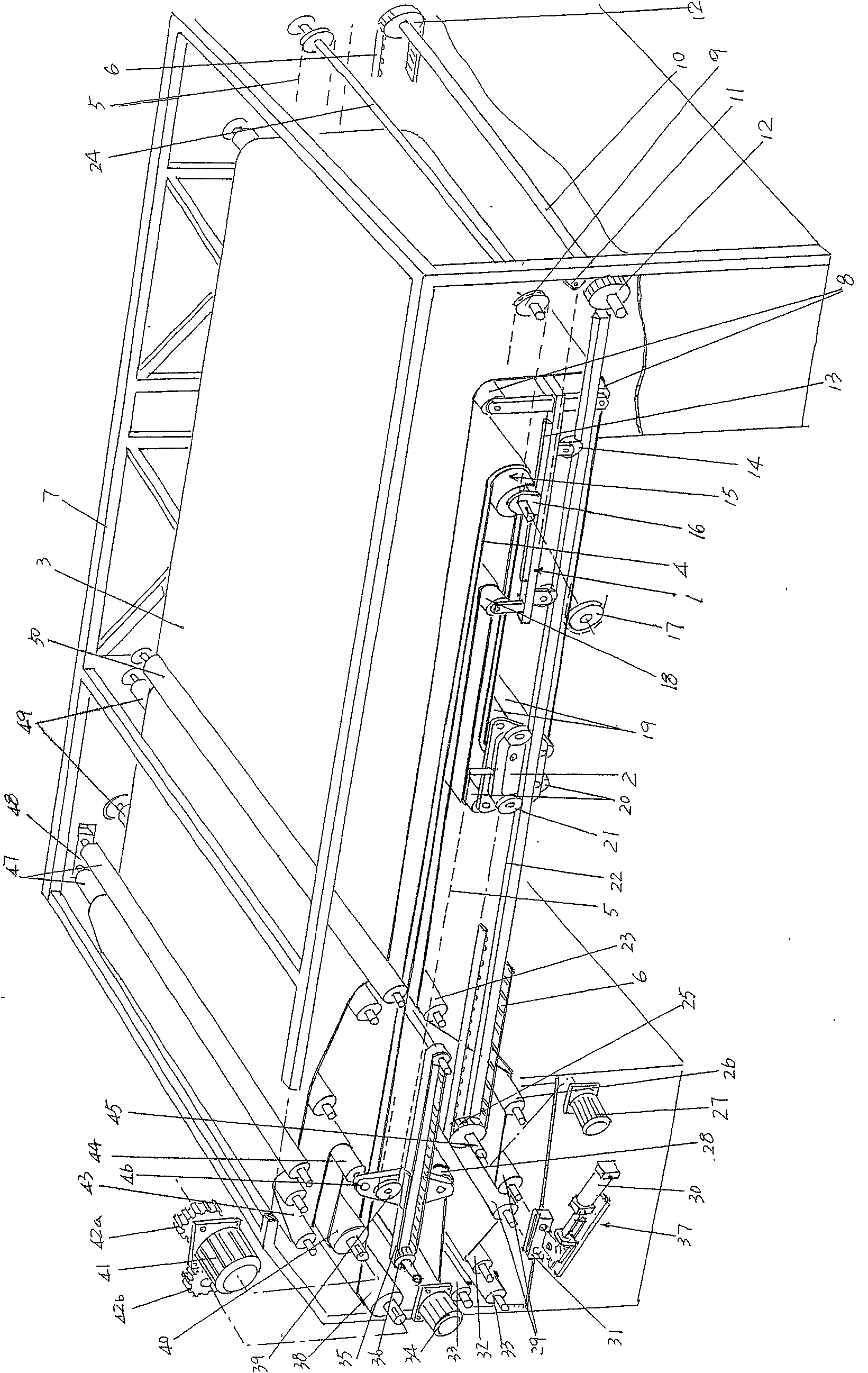

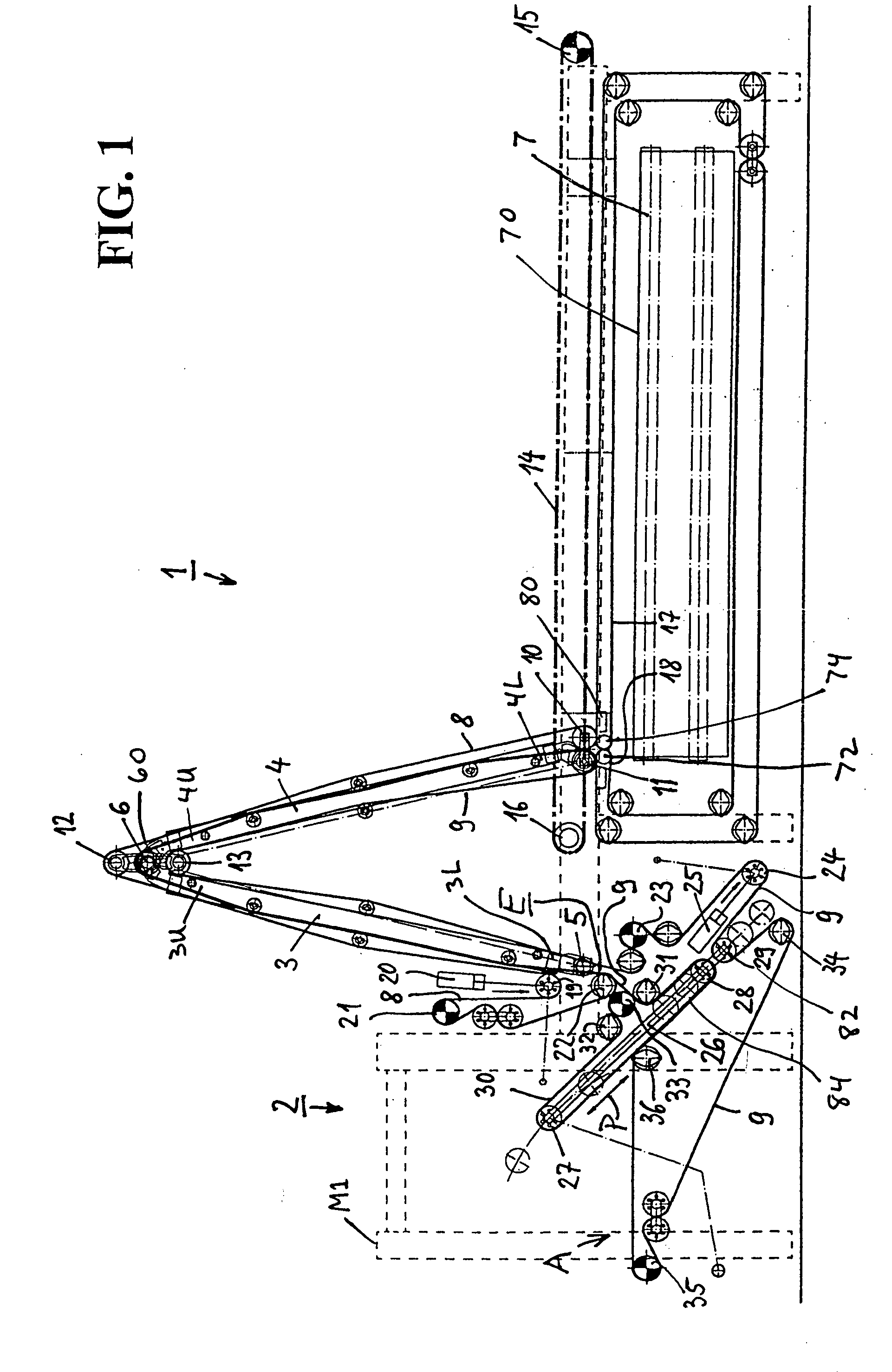

Crosslapper

The invention relates to a crosslapper used for a multi-layer fibre web to form non-woven fabrics.The crosslapper comprises at least one belt used for conveying the fibre web (3) from an input area of the crosslapper (1) to a lapping gap (11) of a lapping pulley. During the process, the lapping pulley enables the fibre web to be laid on an output belt (15). The crosslapper is characterized in that the output belt (15) is provided with a mechanism used for forming a horizontal segment (15a) in an area at a laying position of the output belt (15) of the fibre web (3).

Owner:TRUETZSCHLER GMBH & CO KG

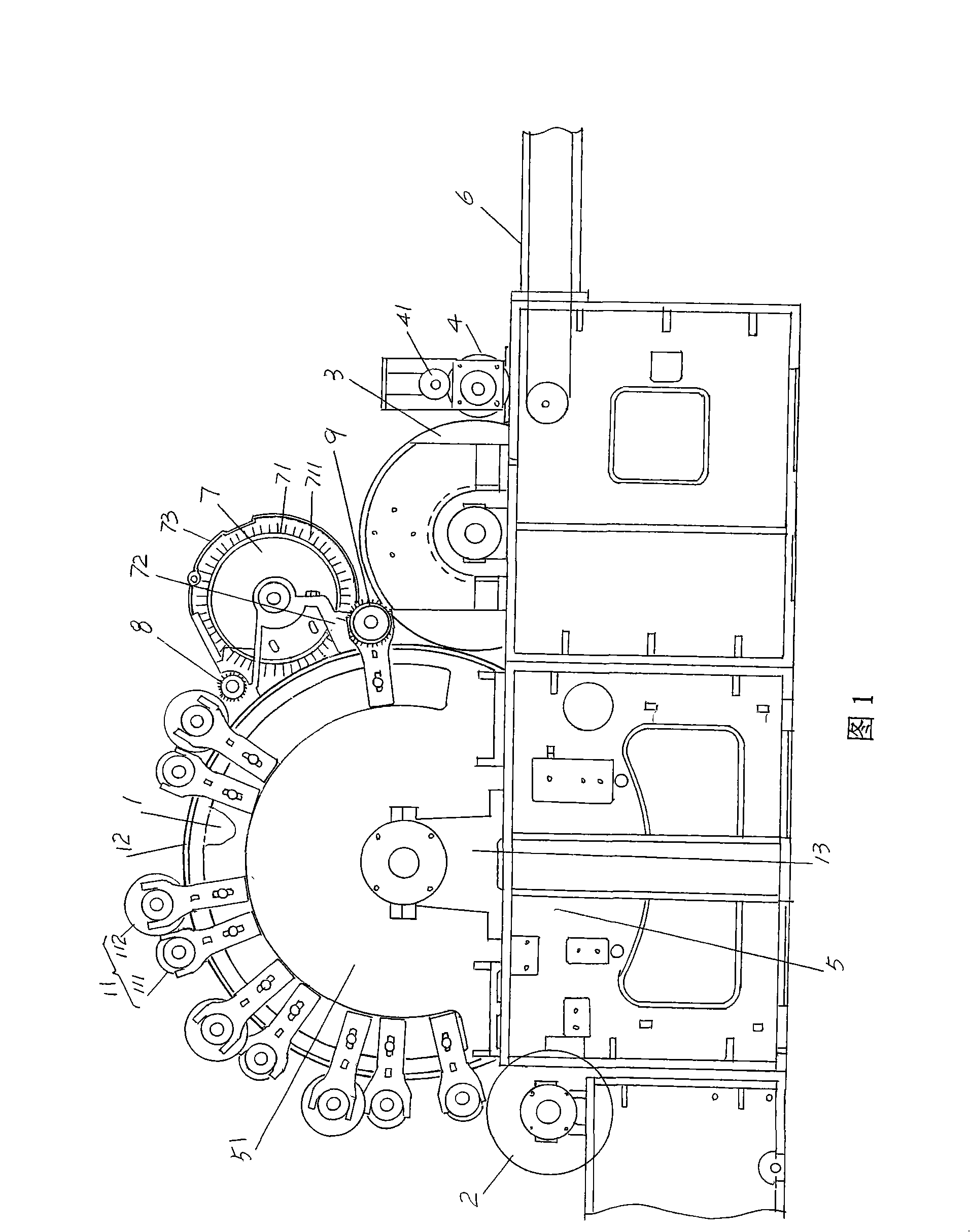

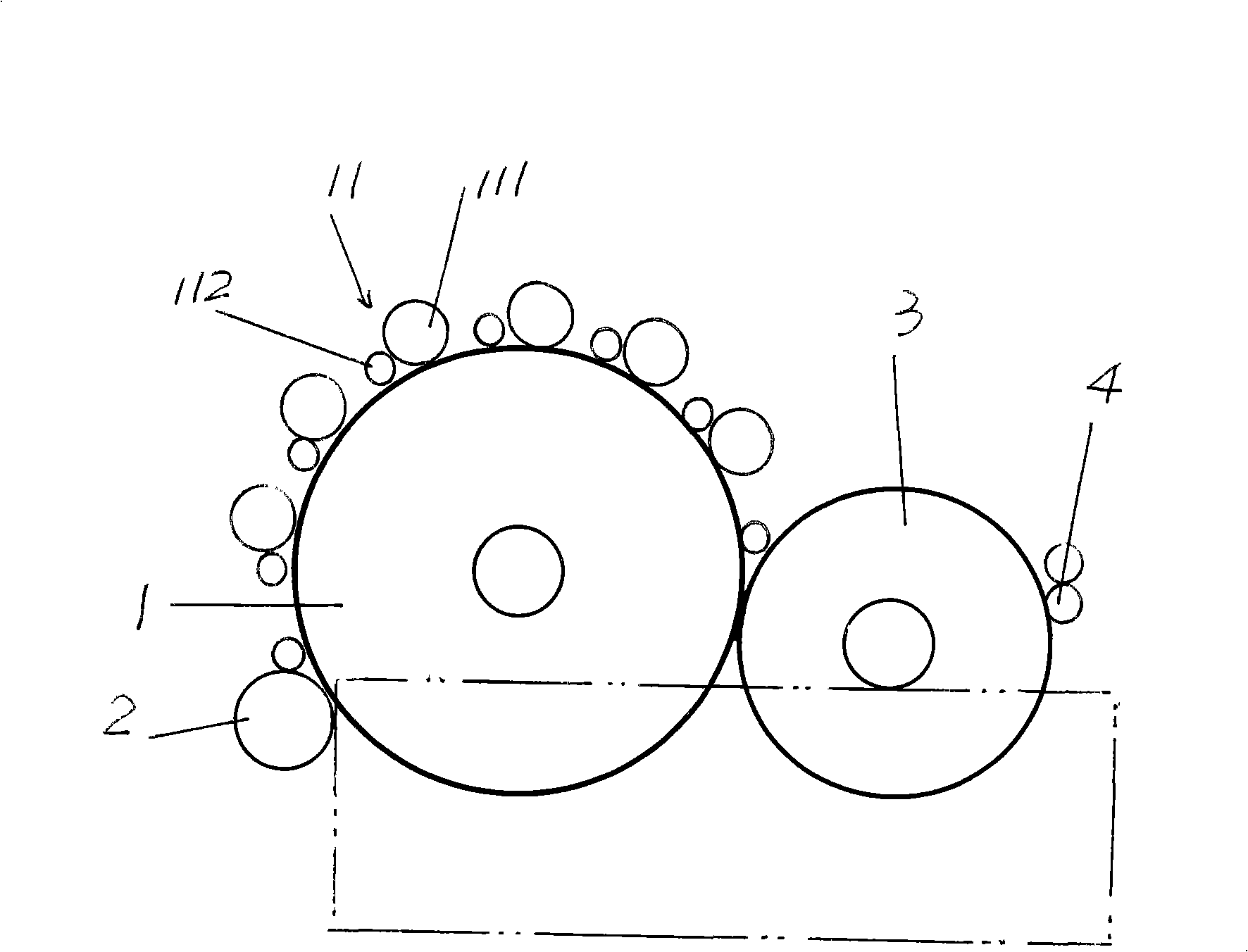

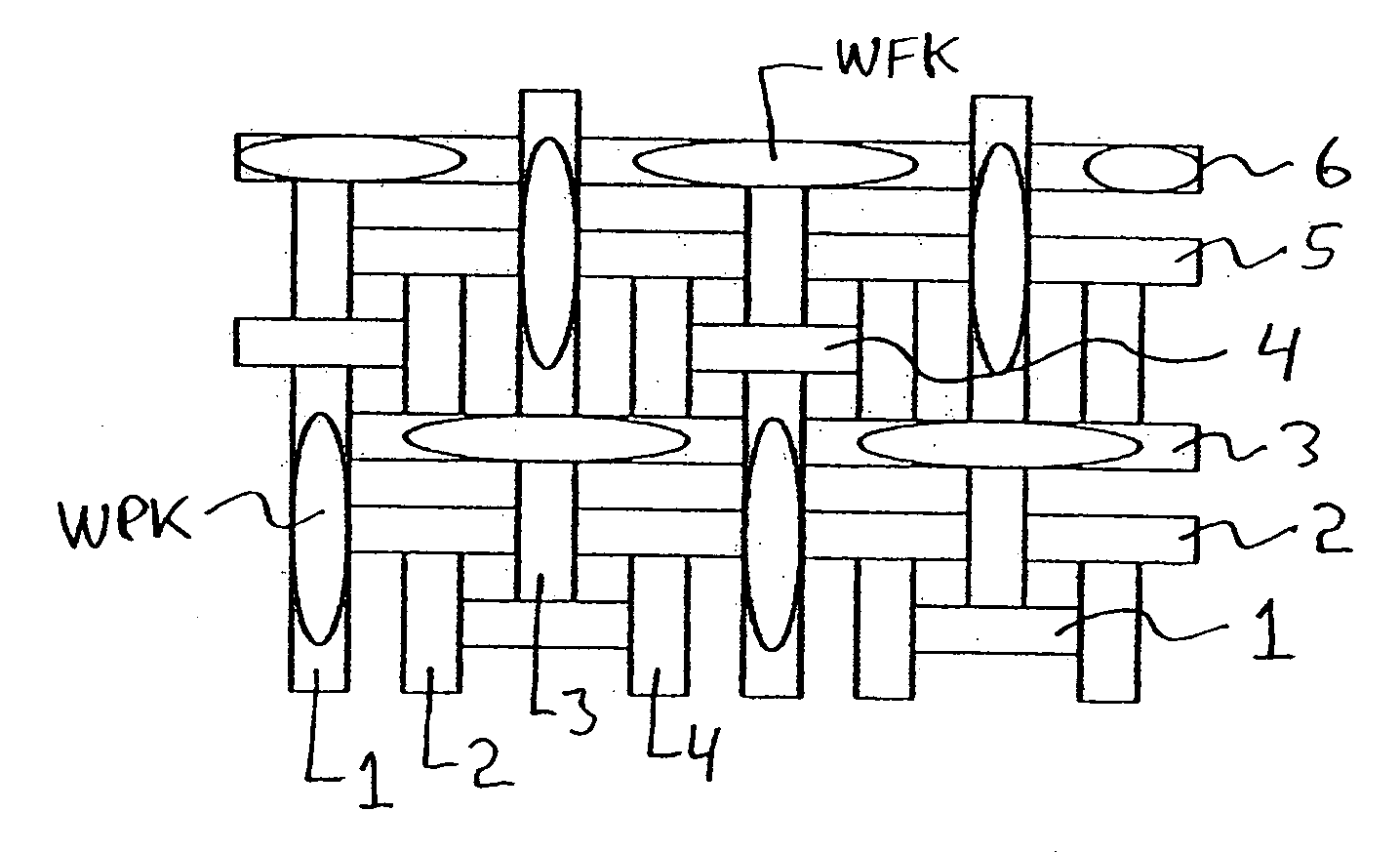

Main carding mechanism of interlaced fabric carding machine

InactiveCN101294317AMeet the requirements of cardingNo build-up in the clothing of the main carding cylinderCarding machinesLap forming devicesWall plateFiber

A main carding mechanism of non-woven cloth carding machine, which belongs to the field of non-woven machinery technology, comprises main cotton carding drums arranged on wall plates on two corresponding sides of a frame, a plurality of carding unit groups consisting of a working roller and a cotton stripping roller and similarly arranged on the wall plates of the two corresponding sides of the frame, and a web making roller and a stripping roller arranged on two corresponding sides of the frame rotatablely at both ends, wherein a transfer roller and the stripping roller are independently rotatablely arranged on the frame. The main carding mechanism is characterized in that a high-speed cotton stripping roller matched with the main cotton carding drums is arranged on the frame at a position substantially above the space between the main cotton carding drums and the web making roller and corresponds to the length directions of the main cotton carding drums and the web making roller. The main carding mechanism has the advantages that the fiber on the main cotton carding drums are completely transferred to the web making roller to make the weights of thin cotton webs reaching a transfer curtain consistent with each other, so that the production can be carried out continuously without periodically stopping machine to clean the main cotton carding drums.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

High performance laminated tapes and related products for ballistic applications

Highly uniform woven fibrous structures formed from fibrous tapes, wherein the tapes constitute the warp and weft tapes of a woven fabric. The individual fibrous tapes may be woven or non-woven, and may be formed as narrow tapes or may be cut from a wider fabric web.

Owner:HONEYWELL INT INC

Non-woven fabric comprising staple fibers and an absorbent article using the same

InactiveUS20020016120A1High densityHigh strengthLap-winding devicesLap forming devicesPolymer scienceSingle fiber

A non-woven fabric comprising staple fibers, having a fiber length of 3 to 25 mm and a single fiber fineness of 1 to 100 denier, and is produced by the fibers being dropped while being dispersed to be accumulated and adhered at the intersection point of the staple fibers. The non-woven fabric has a specific volume of 40 to 200 cm3 / g, and the number of fiber lumps having a volume of not less than 1 mm3 is not more than 5 lumps per 20 g of the non-woven fabric. The bulky non-woven fabric of the present invention in which the sufficient contribution to bulkiness by fibers is exhibited is suitable for sanitary materials, such as disposable diapers, sanitary napkins, incontinence pads, nursing pads or the like, or wipes etc.

Owner:CHISSO CORP

Net laying mechanism with compensation function

Owner:常熟市伟成非织造成套设备有限公司

Hollow fiber cartridges and components and methods of their construction

ActiveUS20140319045A1Reduce thermal stressHigh bulk densityMechanical working/deformationFibre mixingHollow fibreFiber

Owner:REFINE TECHNOLOGY LLC

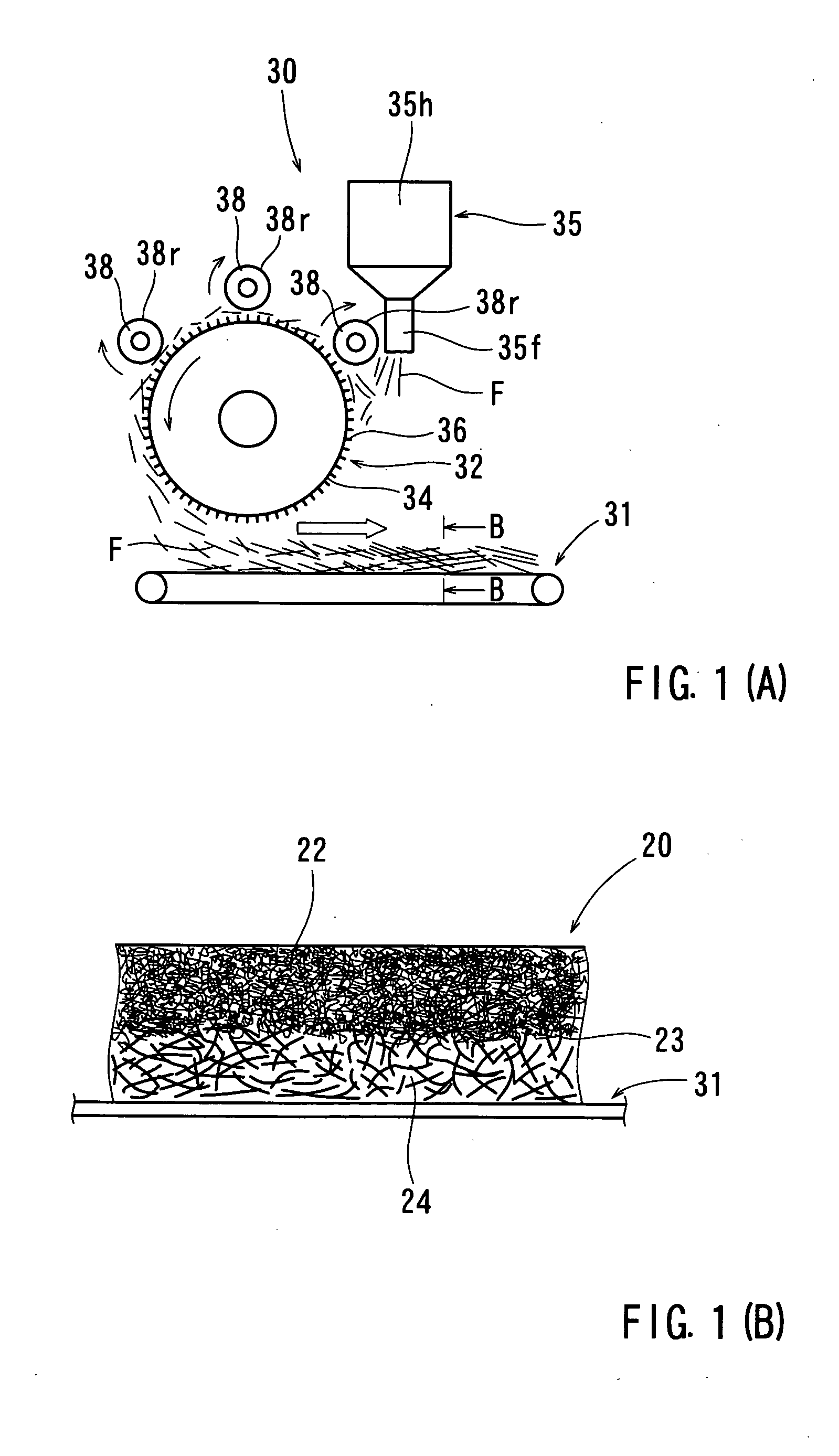

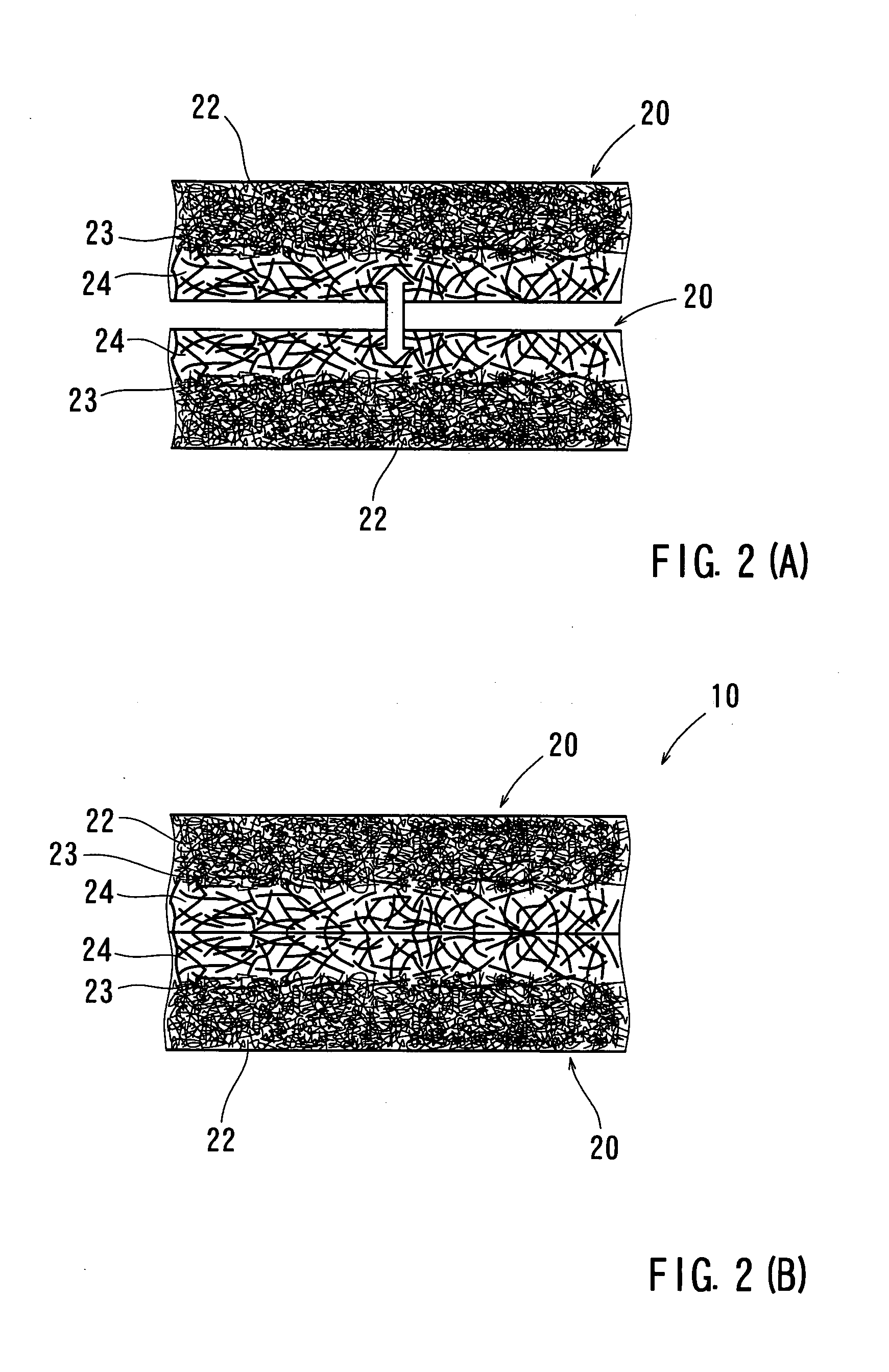

Fibrous formed products and methods for manufacturing such fibrous formed products

InactiveUS20050020164A1Reduce the cost of the whole machineImprove production efficiencyLap-winding devicesPile-fabric loomsFiberHigh density

In a method of manufacturing a fibrous formed product, a mixture of fibers, including thick fibers and thin fibers, is prepared in order to form fibrous mats. The mixed fibers are supplied onto an outer peripheral surface of a roller. As the roller rotates, the mixed fibers are released from the roller and are thrown toward a fiber receiving surface. A fibrous mat is formed on the fiber receiving surface with a low-density layer next to the fiber receiving surface and a high-density layer on top of the low-density layer. Thick fibers mainly form the low-density layer and thin fibers mainly form the high-density layer. First and second fibrous mats are overlaid with one another such that their low-density layers oppose each other.

Owner:TOYOTA BOSHOKU KK +2

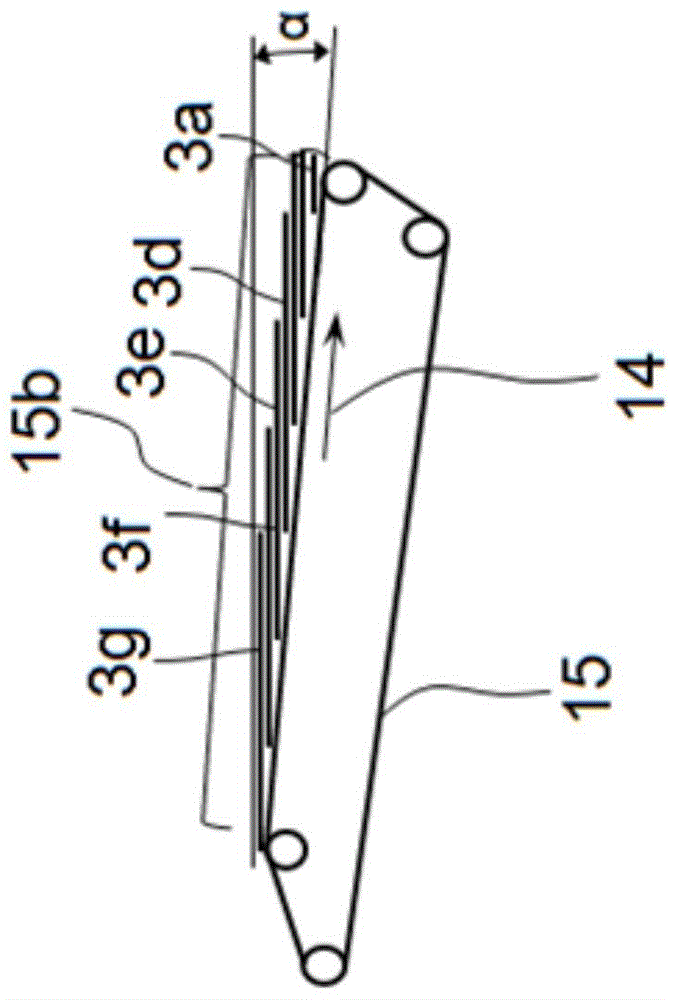

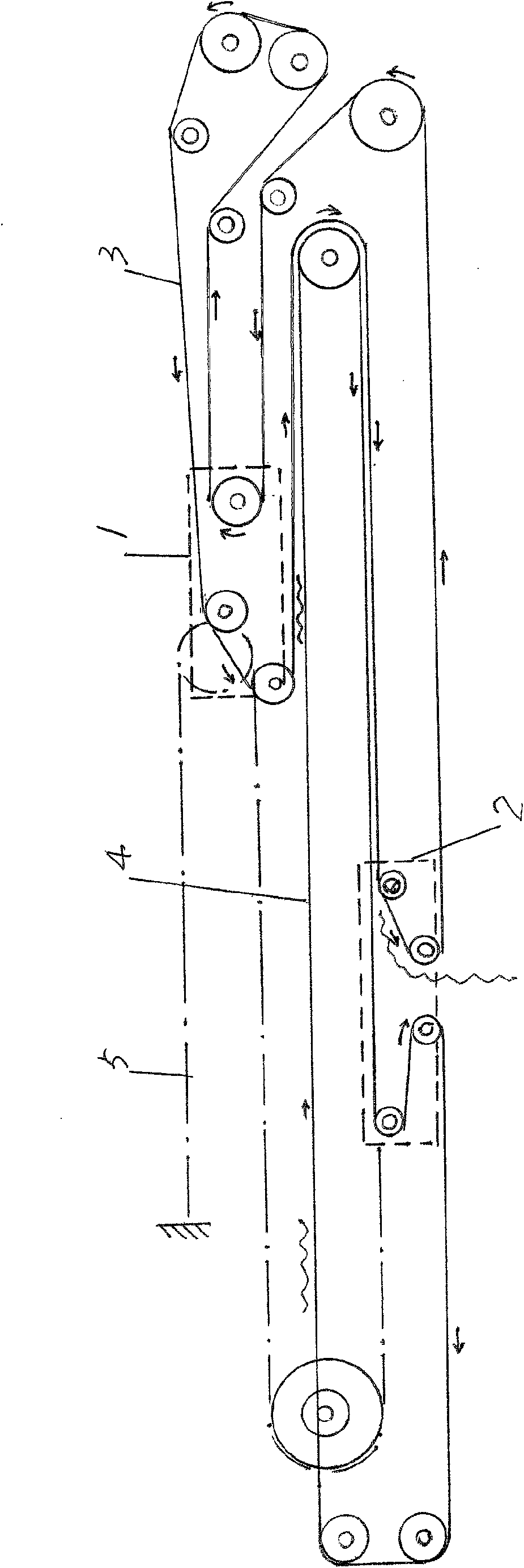

Fleece laying device

InactiveUS20050193525A1Reduce distortion problemsQuality improvementVegetable fibre separation from seedsLap-winding devicesFiberEngineering

A non-woven fiber web laying apparatus including (1) a camel back cross lapper having a supply arm, a layering arm connected thereto, and two delivery transport belts guided in juxtaposed fashion from an infeed zone to a lower end of the layering arm and (2) an upstream web buffering apparatus adapted to hold a web between two take-up transport belts at least one of which is one of the two delivery transport belts, the apparatus sandwiching the web substantially the entire path from the take-up site to the layering-arm lower end. While at least one of the two take-up transport belts of the web buffering apparatus is one of the delivery transport belts of the cross lapper, in one embodiment both of the take-up transport belts are the delivery transport belts. In another embodiment, only one of the take-up transport belts is a delivery transport belt, the other being a pressure belt operating only within the web buffering apparatus.

Owner:DILO MASCHF OSKAR

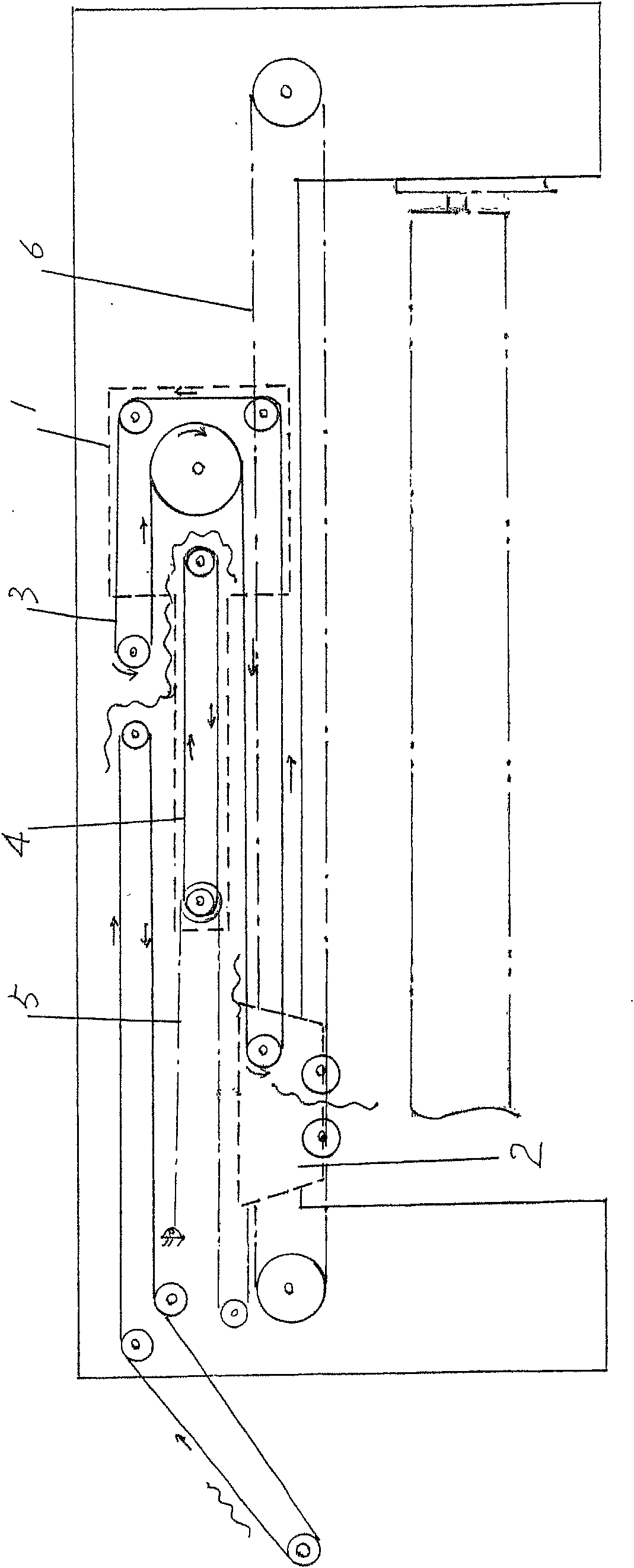

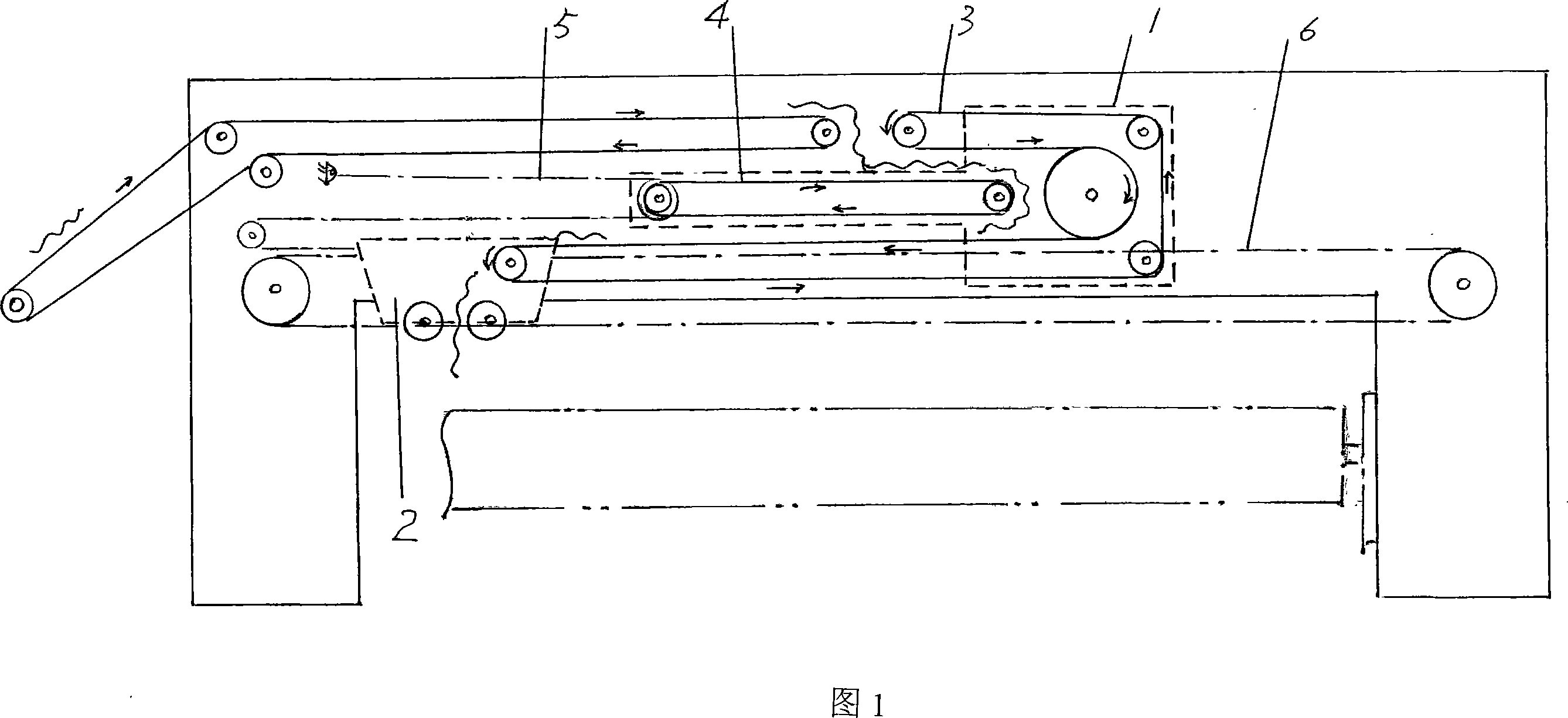

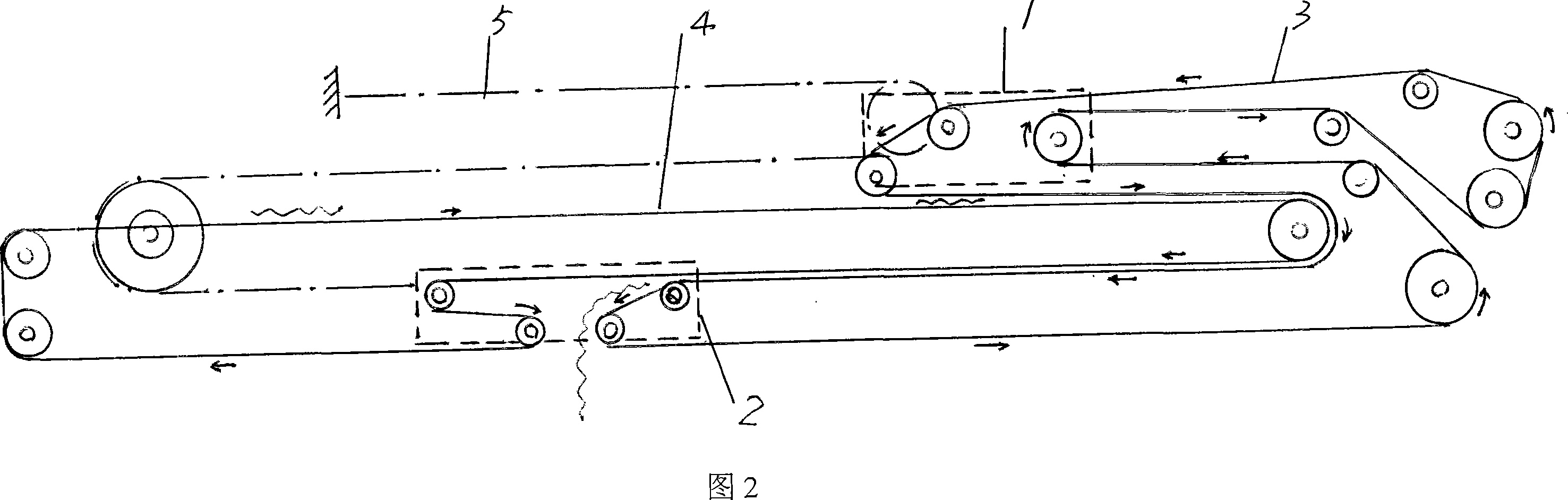

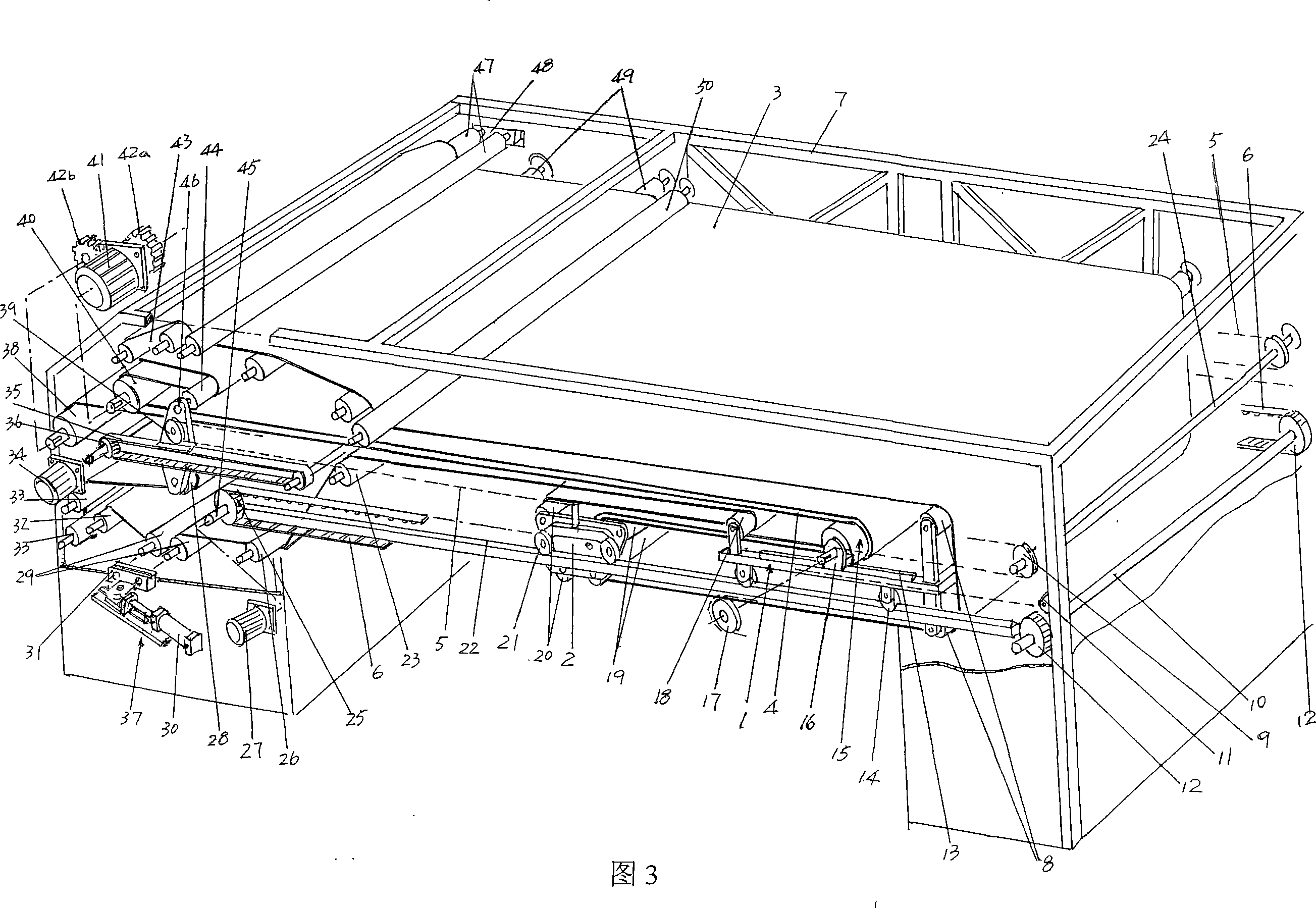

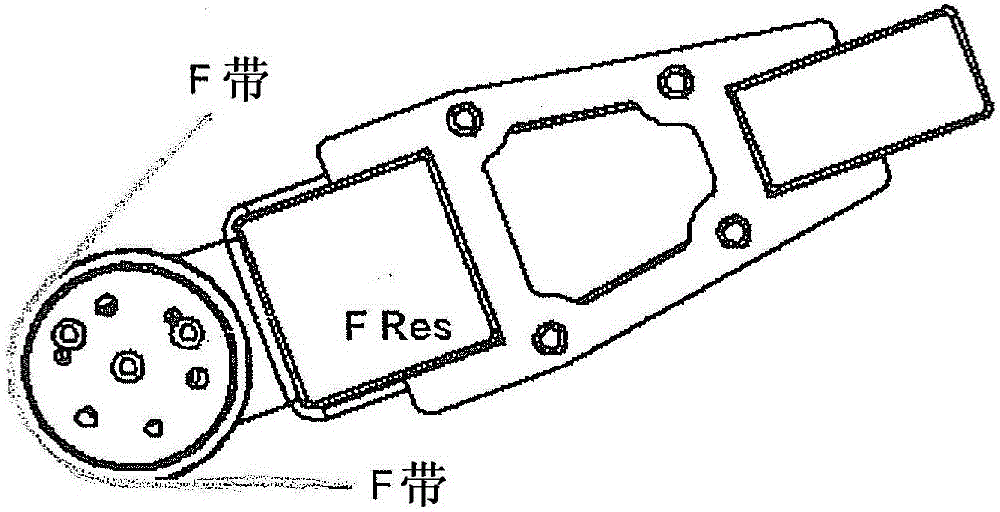

Net laying mechanism with compensation function

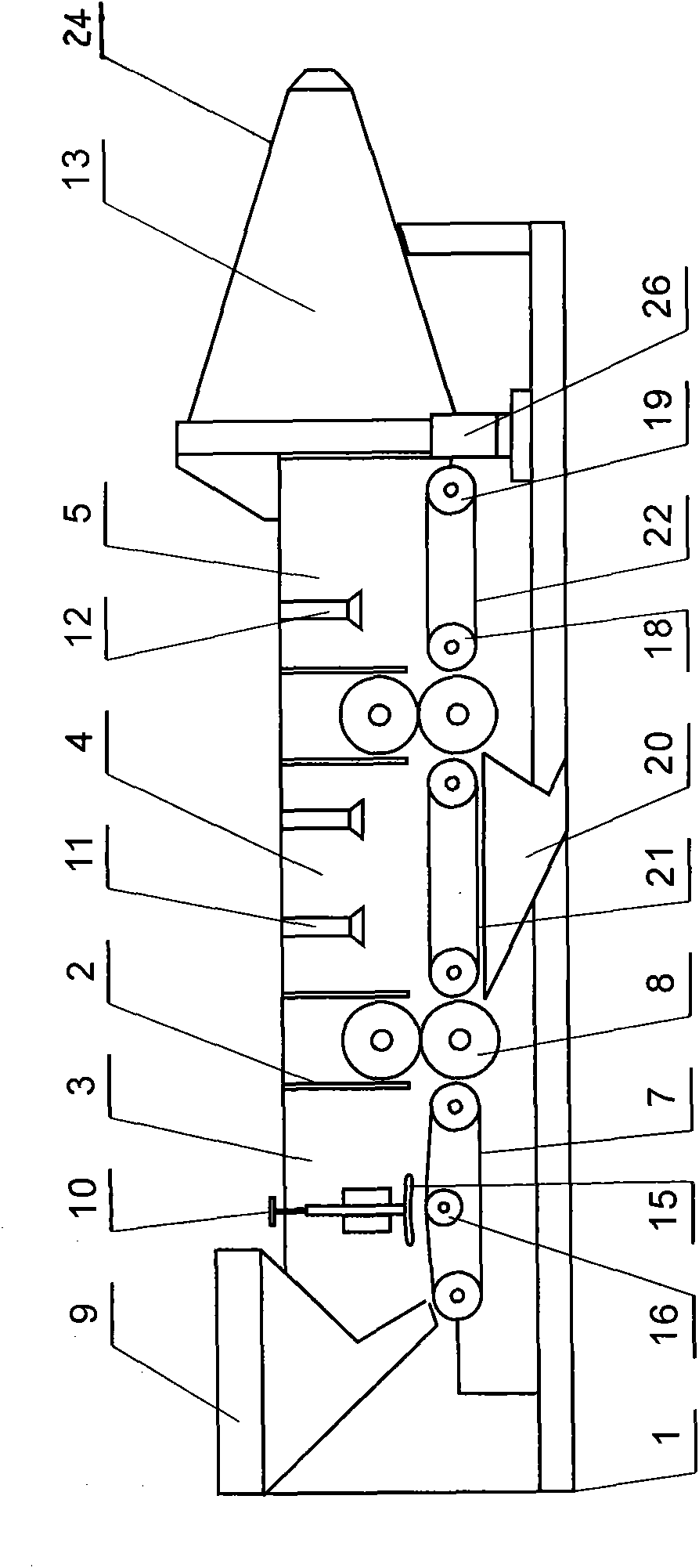

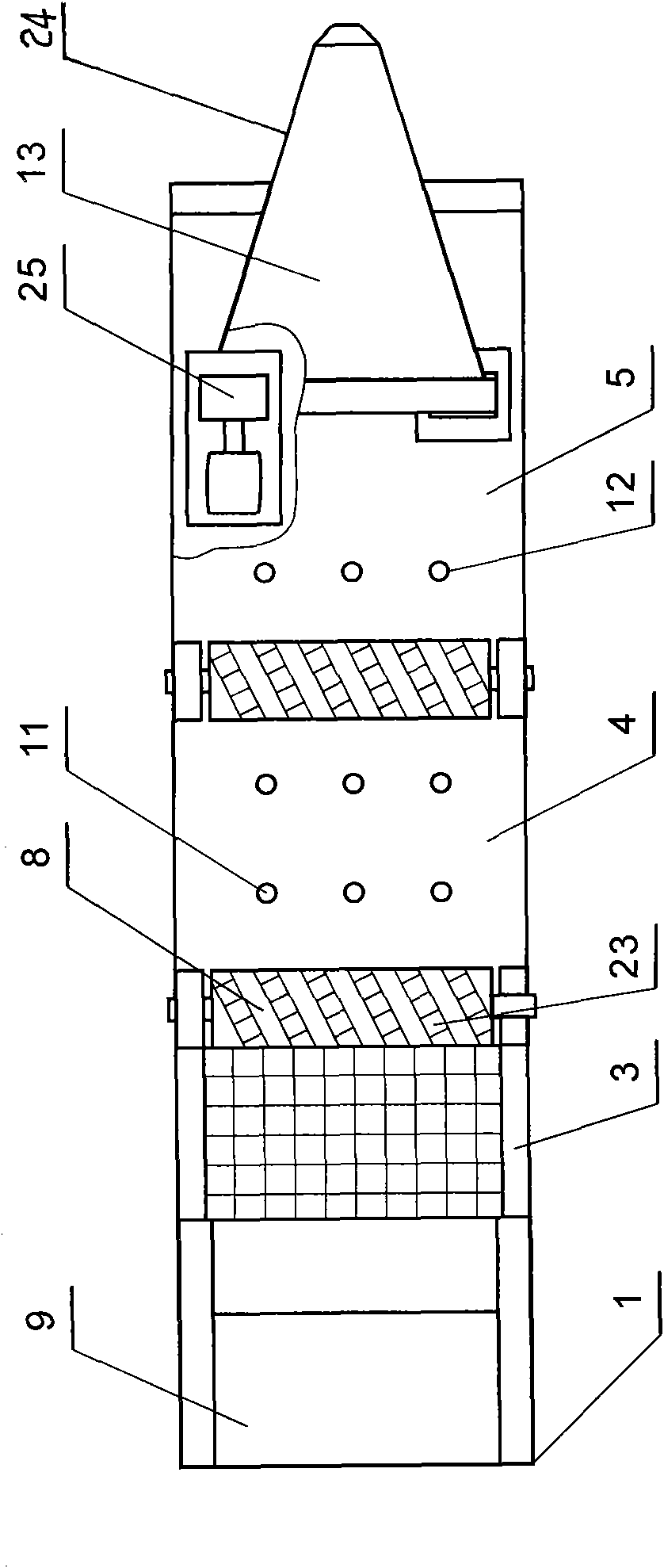

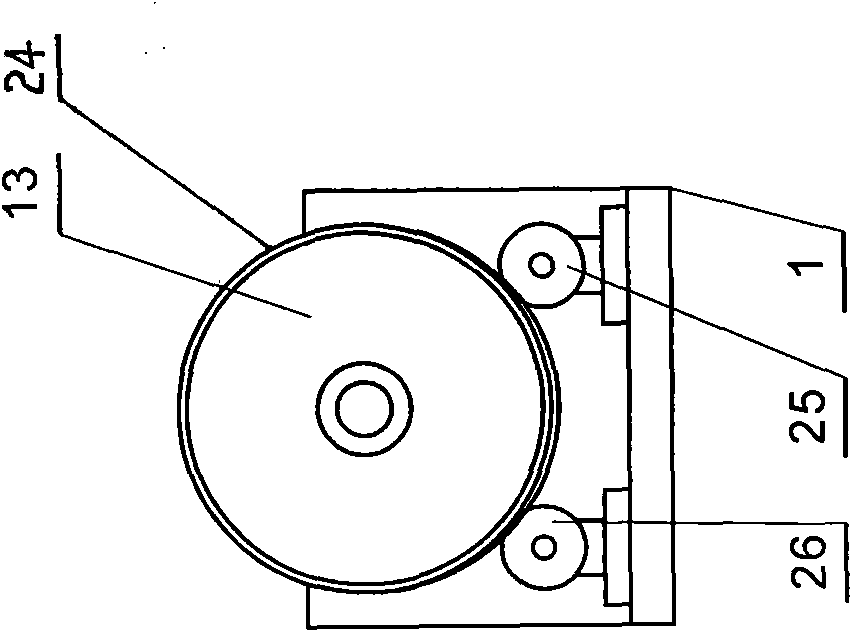

The invention relates to a lapping mechanism having a compensation function, and lapping the mechanism belongs to the technical field of a cotton web lay-up device in complete set non-woven mechanical equipment. The lapping mechanism comprises a lapping cart, a lapping trolley, a pair of first drive roll and second drive roll, a first conveying curtain, a second conveying curtain, and a pair of hauling wire ropes with the both ends fixed on a machine frame and the lapping trolley and the middle part mutually implicated with the lapping cart, and also comprises a first fiber web compensation device. The position of the first fiber web compensation device on the machine frame is arranged at the identical end provided with the first drive roll and the second drive roll machine frame, the first fiber web compensation device is connected with the first conveying curtain, the second conveying curtain, and a pair of hauling wire ropes, a second fiber web compensation device, the motion direction of which is opposite to the motion direction of the first fiber web compensation device is arranged on the lapping cart, and the second fiber web compensation device is mutually connected with the first conveying curtain, the second conveying curtain, and a pair of hauling wire ropes. The lapping mechanism has the advantages that a lay-up cotton web body presents the bread-shaped effect of the thick middle and the both thin sides, and has perfect improvement function to the quality of downstream non-woven products.

Owner:常熟市伟成非织造成套设备有限公司

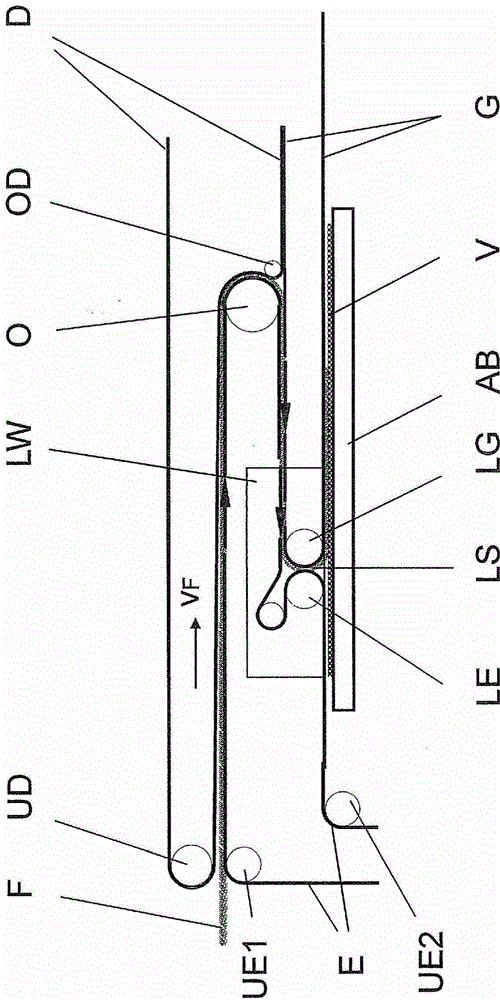

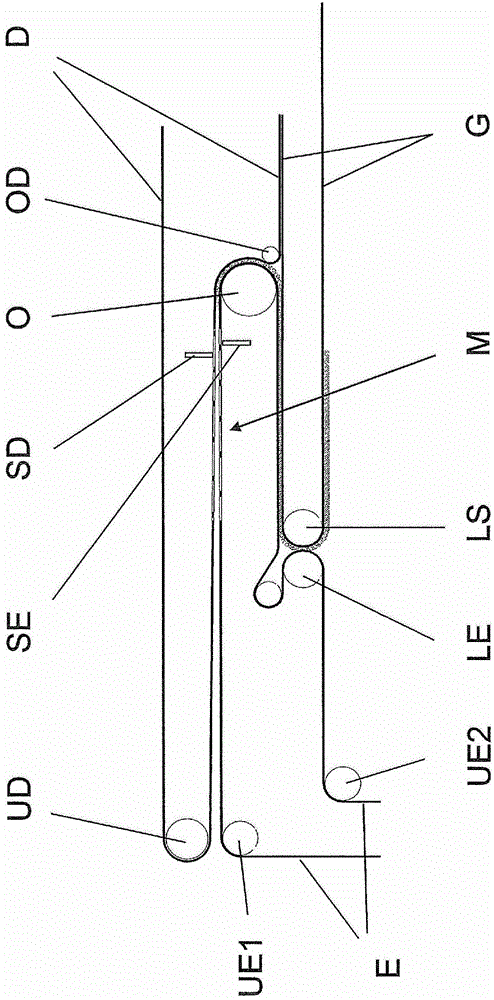

Cross Lapper

ActiveCN103221591BAvoid interferenceLow bending stiffnessLap forming devicesEngineeringNonwoven fabric

The invention relates to a cross-lapper and to a method for forming a nonwoven fabric made of a plurality of pile layers, consisting of an continuously revolving feed belt (E), a counter belt (D) continuously revolving at the same speed in the opposite direction, as well as an additional counter belt (G), wherein the pile (F) to be laid is first conveyed between a feed belt and cover belt (E, D) to a movable upper carriage (OW), which comprises a first deflection roller (O) for the feed belt (E), and is transferred there to the counter belt (G), wherein the feed and counter belts (E,G) are guided around two adjacent laying rollers (LE, LG) of a laying carriage (LW) which form a laying gap, and the laying carriage (LW) is movably mounted transversely to and above a discharge belt (AB) receiving the nonwoven fabric to be laid and moves back and forth periodically. According to the invention, the cover belt (D) is guided jointly with the feed belt (E) around a partial circumference of the first deflection roller (O).

Owner:TRUTZSCHLER NONWOVENS

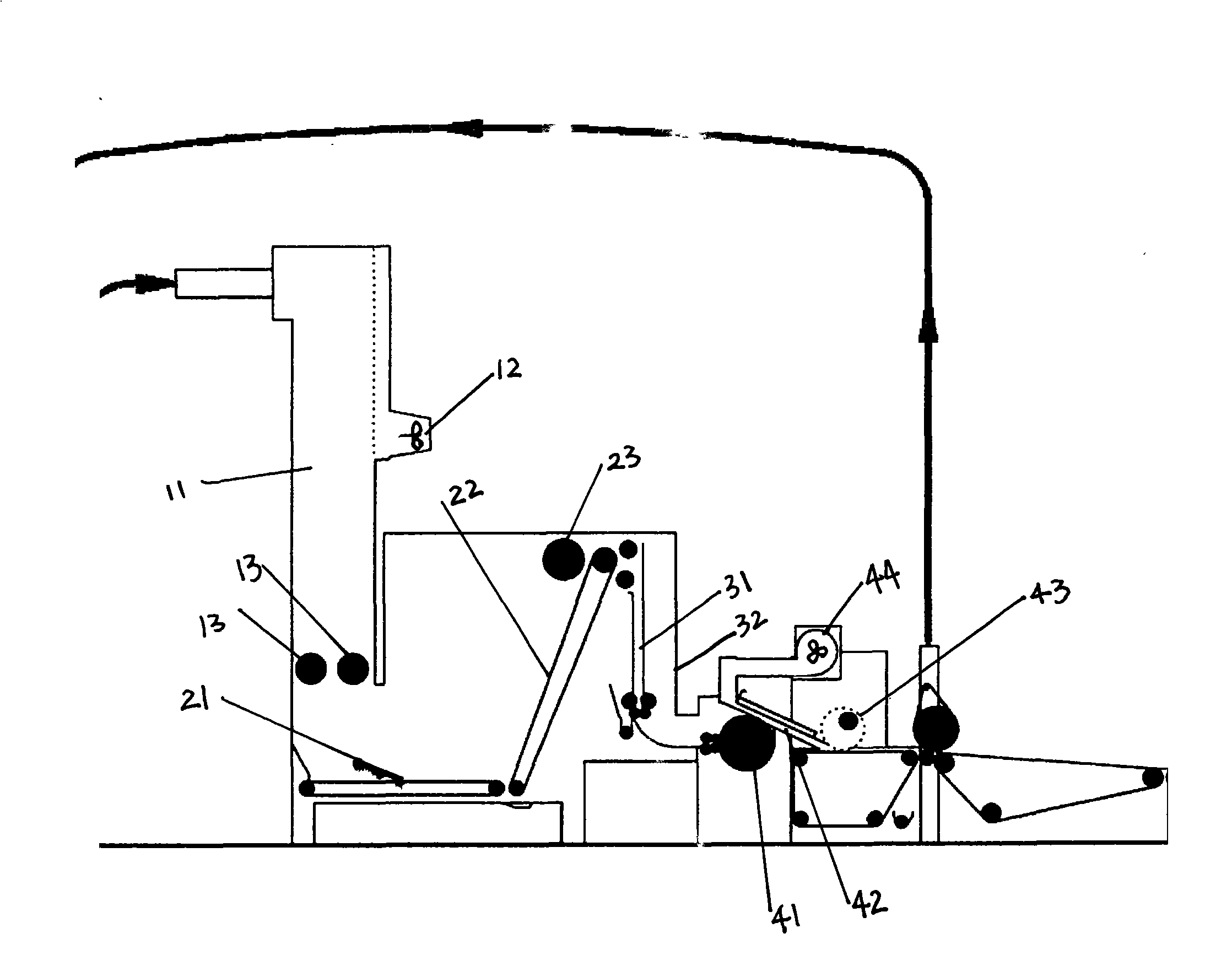

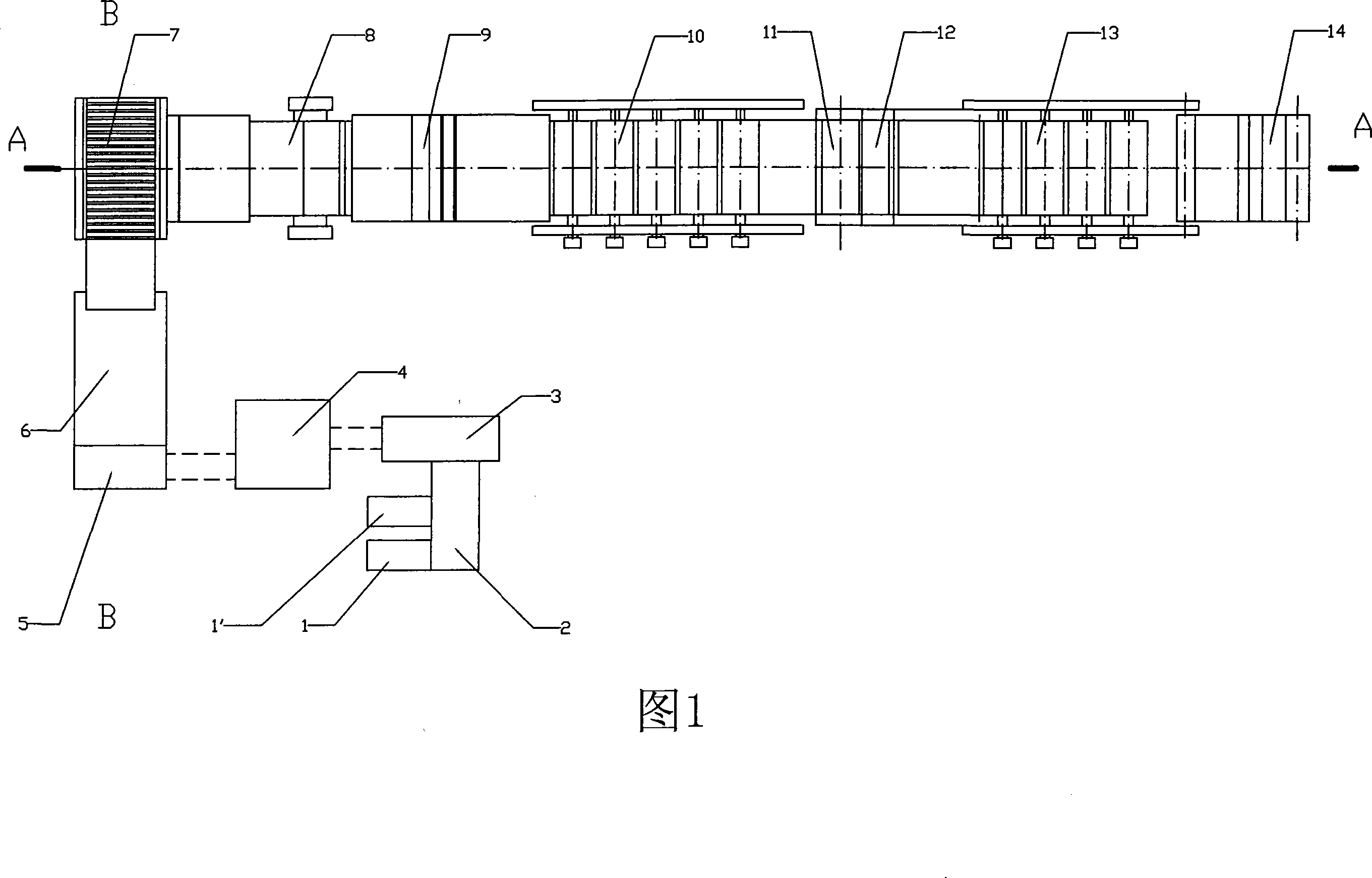

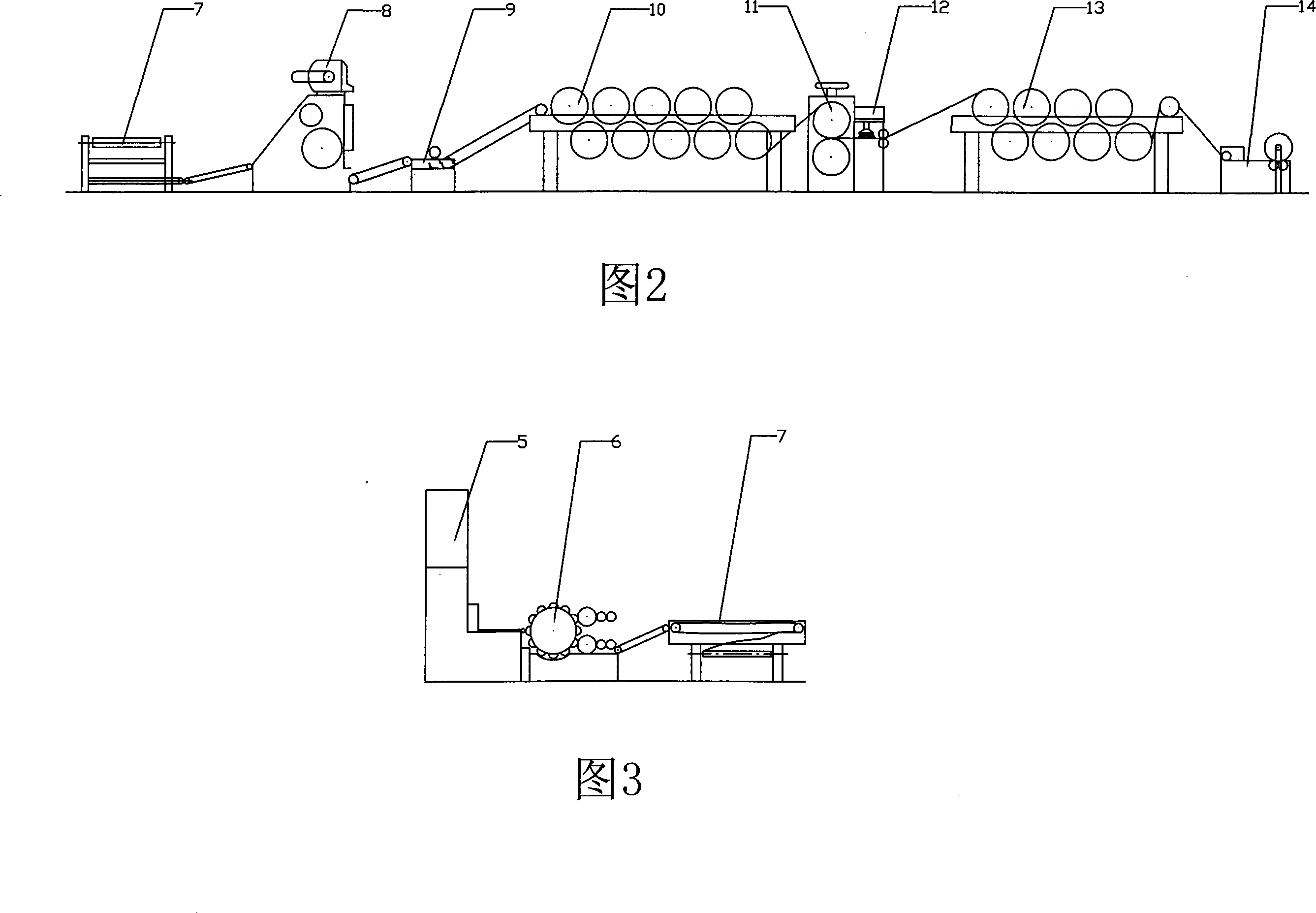

Device for preparing environment-friendly type bast fiber film

ActiveCN101215786ARun at high speedEasy to debugLap forming devicesPlant protective coveringsSpray coatingVolumetric Mass Density

The invention discloses an environment-friendly type bast fiber film preparation device, which comprises two feeding machines, a feed mixer, a crude opening machine, a fine opening machine, a vibrating air pressure bast feeding box, a carding machine, a mechanical cross lapper, an air-lay machine, an impregnator, a drying can type pre-drying pit, an air-pressure double-roller planishing mill, a surface spraying coating machine, a drying can type dying setting machine, a drafting side cut lap former and the other operation unit machines. Each unit-air conditioning adopts variable-frequency control and a synchronizer to control electric appliances, and each unit-air conditioning can be singly operated in high speed, and can be interlocked to operate with complete equipment. The invention has the advantages that fibrilia is delivered by an airflow pipeline on the crude opening machine, and between the crude opening machine and the carding machine, and the supply of raw material is continuous, net is combined in two times through a machine to pave net and airflow to form net, bast fiber film net has little density, even strength and stable quality, even coating layers are coated and sprayed on double faces of bast fiber film, and bast fiber film with different functions and usages can be made, continuous and stable full-automatic production of bast fiber film can be achieved.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Structured forming fabric and method

InactiveUS20090068909A1Improve system performanceIncreased caliper bulk absorbencyNon-fibrous pulp additionNatural cellulose pulp/paperMechanical engineeringWeft yarn

Forming fabric for making a bulky web. The fabric includes a machine facing side and a web facing side having pockets formed by warp and weft yarns. A bottom of the pockets is formed an exchange of a different number of the warp and the weft yarns. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

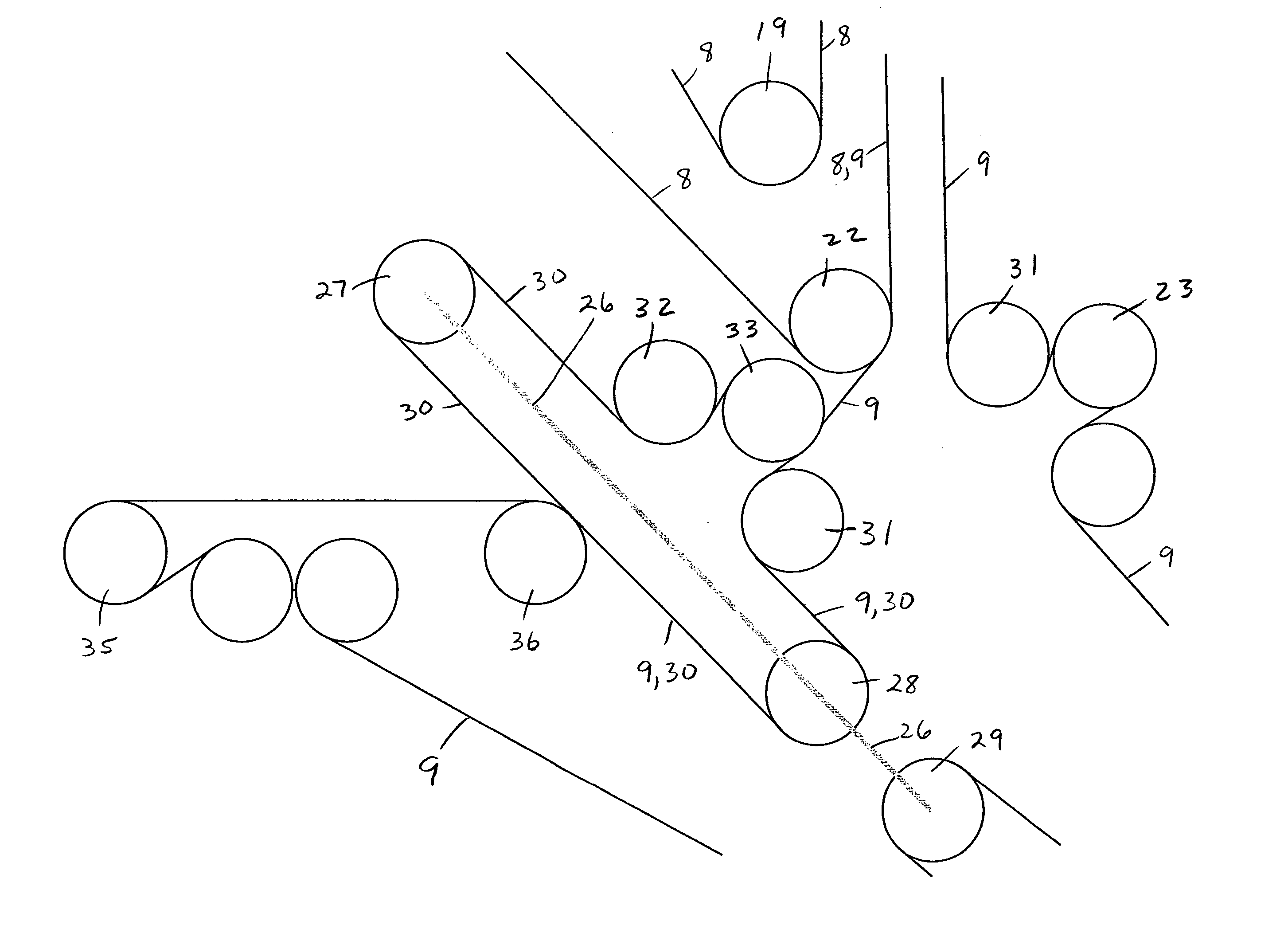

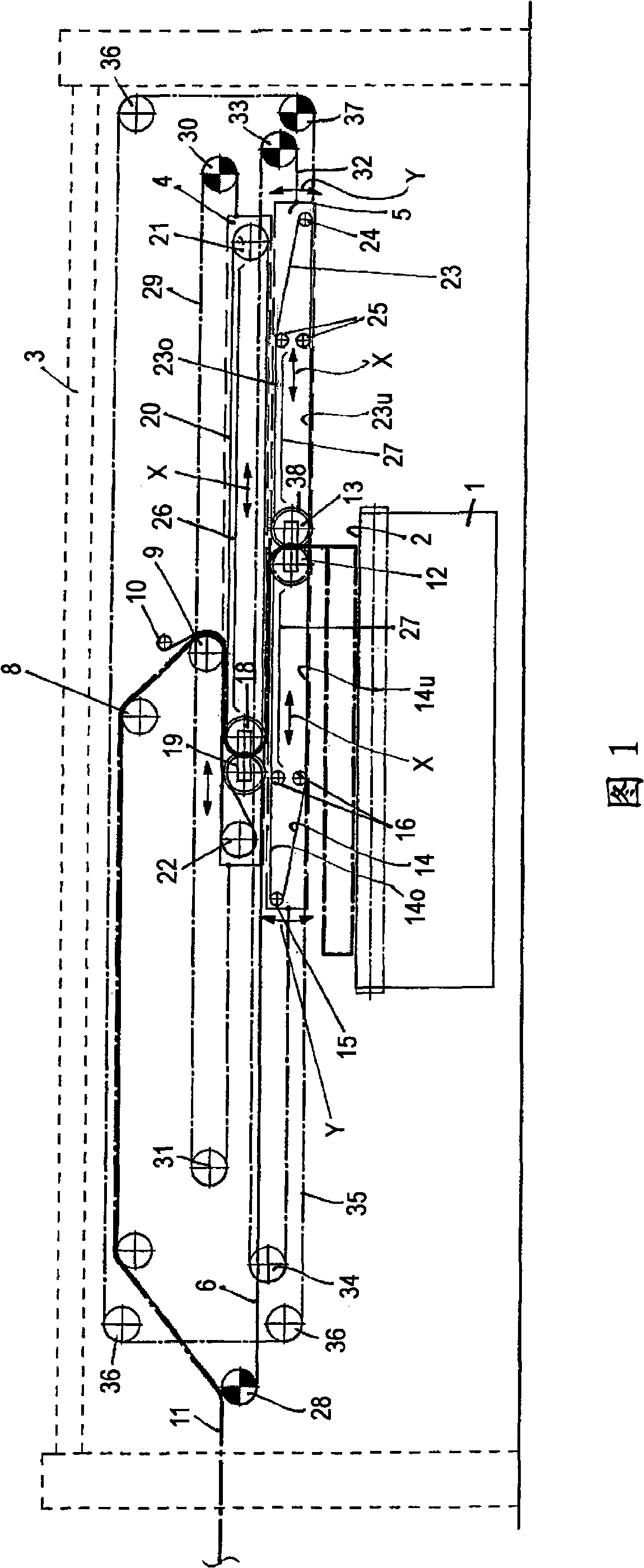

Fleece-laying apparatus

InactiveCN101275313AAvoid aerodynamic effectsAvoid damageLap forming devicesFibre feedersSandwich likeEngineering

In a fleece layer of the carriage cross-lapper type, the laying carriage conveyor belt ( 14 ) wraps around the first laying roller ( 12 ), the upper and lower strands ( 14 o, 14 u) of the belt being parallel to each other as they proceed from the first laying roller ( 12 ). An endless cover belt ( 23 ), which travels around in the laying carriage ( 5 ), wraps around the second laying roller ( 13 ), the cover belt having upper and lower strands ( 23 o, 23 u), which are parallel to each other as they proceed from the second laying roller ( 13 ) in the direction opposite that of the laying carriage conveyor belt ( 14 ). The mutual distances between the web entrance ( 8, 9 ), the upper carriage ( 4 ), the laying carriage ( 5 ), and the output conveyor belt ( 2 ) perpendicular to the transport directions of same are so small that the card web ( 11 ) to be laid is enclosed in a sandwich-like manner between the adjacent strands of the web entrance conveyor belt ( 6 ), of the upper carriage conveyor belt ( 20 ), and of the laying carriage conveyor belt ( 14 ), where the laid fleece on the output conveyor belt ( 2 ) is contacted by the laying carriage conveyor belt ( 14 ) and by the cover belt ( 23 ).

Owner:DILO MASCHF OSKAR

Fiber air-laying process for fibrous structures suitable for use in absorbent articles

The present invention refers to a process of making a fibrous structure, wherein roughly graded material is provided to rotating, apertured drums. The drums have at least one needle roll in their inside. The roughly graded material is agitated inside the drums, whereby fibers or small fiber clusters are separated from each other. These fibers and small fiber clusters are flung through the apertures to the outside of the drum, where they are directed onto a foraminous carrier to form a fibrous structure. The fibrous structures are especially useful in absorbent articles.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatus and method for dry forming a uniform non-woven fibrous web

Owner:BIAX FIBERFILM CORP

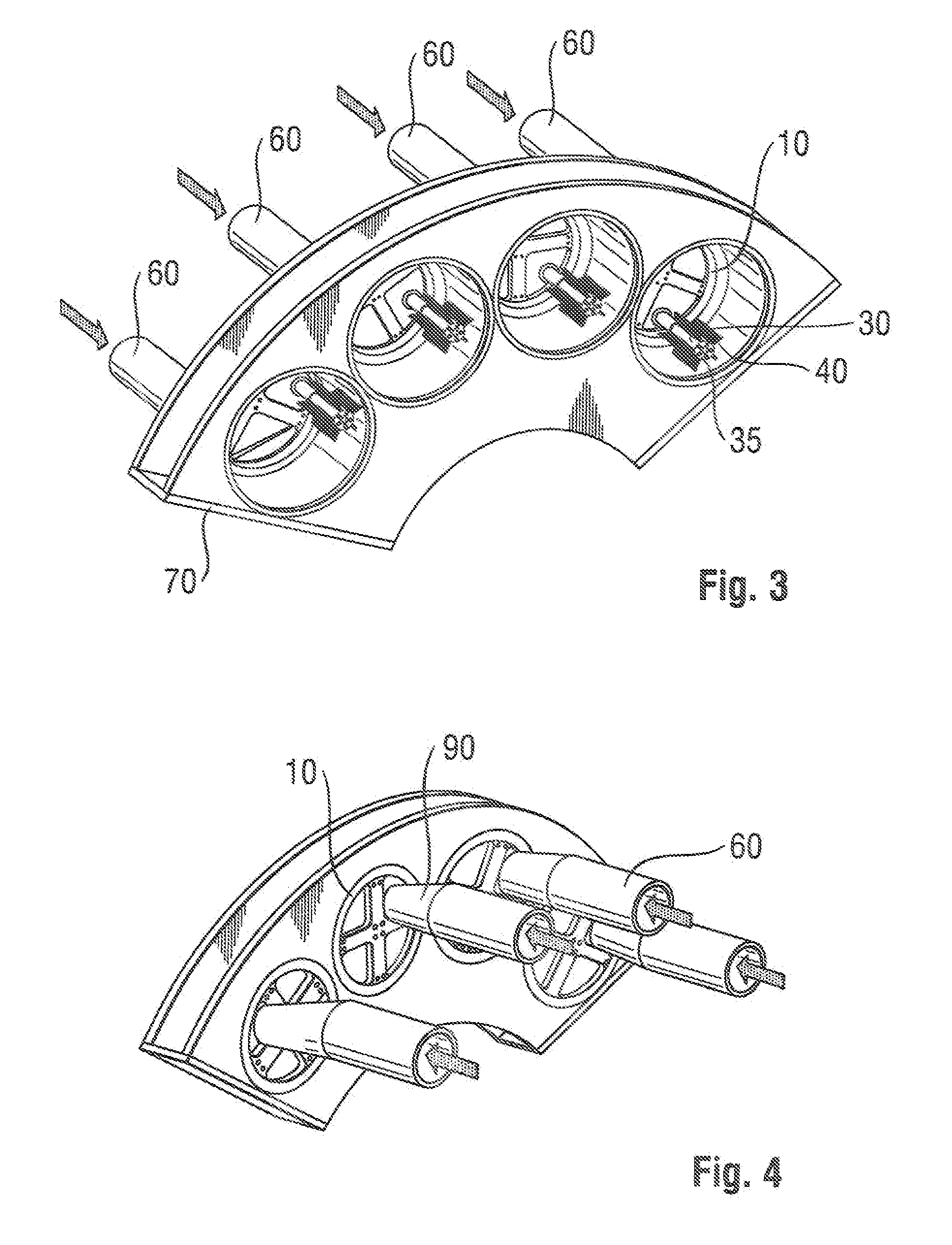

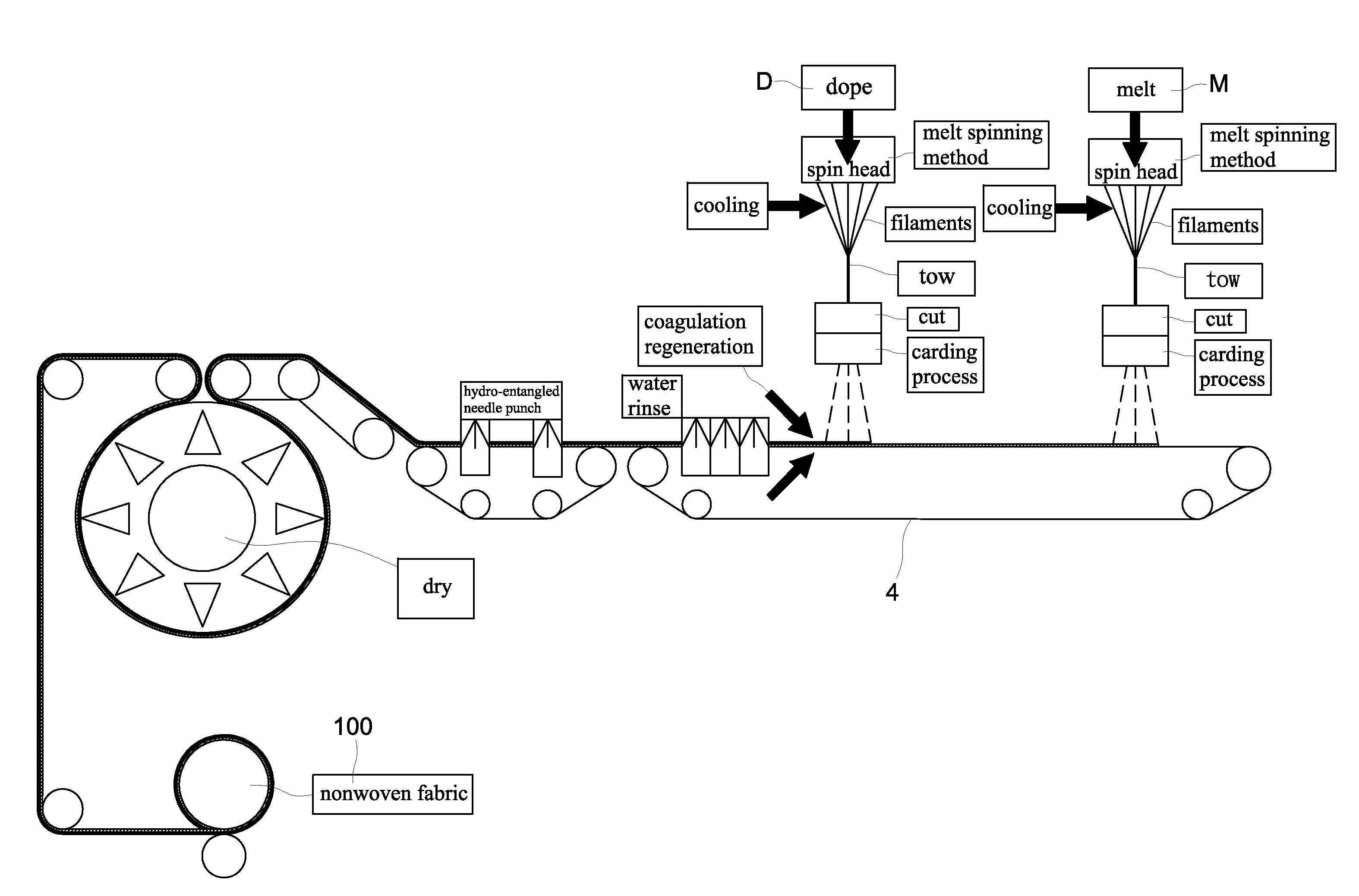

Stapled melt spinning method for producing non-woven fabrics with hygroscopic metastatic feature

ActiveUS20160145781A1Improve water absorptionReduce water contentPattern makingMonocomponent cellulose artificial filamentPunchingPolyamide

A stapled melt spinning method for producing nonwoven fabrics with hygroscopic metastatic feature. Firstly, fuse bio-polyamide 6,10 into melt, extrude and spin it out spin heads of extruder into filaments, cool, draw and collect filaments into tow, then extend, cut and card the filaments into the staples, and spread the staples on a conveyer to form fibrous web. Next, blend and dissolve pulp by N-methylmorpholine N-oxide (NMMO) dissolving solvent, dehydrate it to form dope, and extrude and spin it out spin heads of extruder into filaments, then cool, draw and collect filaments into tow, and extend, cut and card filaments into staples, then overlay the staples over existing fibrous web to form a composite fibrous web of bio-polyamide 6,10 and cellulose filaments. Finally, coagulate, regenerate and convert fibrous composite of bio-polyamide 6,10 and natural cellulose into nonwoven fabric with hygroscopic metastatic feature by hydro-entangled needle punching, drying, winding-up processes.

Owner:LIN CHIH HSIN

Mudar floss silver used for spinning, processing method and equipment thereof

InactiveCN101565860AEasy plantingLow costVegetable fibre separation from seedsLap forming devicesYarnFiber

The invention discloses a mudar floss silver used for spinning, a processing method and an equipment thereof, and is characterized in that the fruit of the mudar is adopted; after removing the seeds, the pappus fiber of the seed is taken and softened so that the fiber is softened and coiled as the silver; the processing equipment is characterized in that a cotton wadding chamber, a cleaning cotton chamber and a humidifying chamber are internally provided with a conveyor belt respectively and integrated in a long bar-shaped box; and engaged rollers connected with the three conveyor belts are arranged among the cotton wadding chamber, the cleaning cotton chamber and the humidifying chamber respectively. Compared with the prior art, the invention has the advantages that the mudar floss of the new spinning material is easily obtained, can compare the beauty with cotton and replace the cotton to be used for spinning yarns; and the weaved fabrics has the smooth sensing same as silk and the air-permeability and comfortableness similar to full cotton, supplements the shortages of cottons and petrochemical products, greatly improves the local entironment simultaneously, and is a spinning new fiber material which is ecologically environment-protective.

Owner:上海善道生物科技有限公司

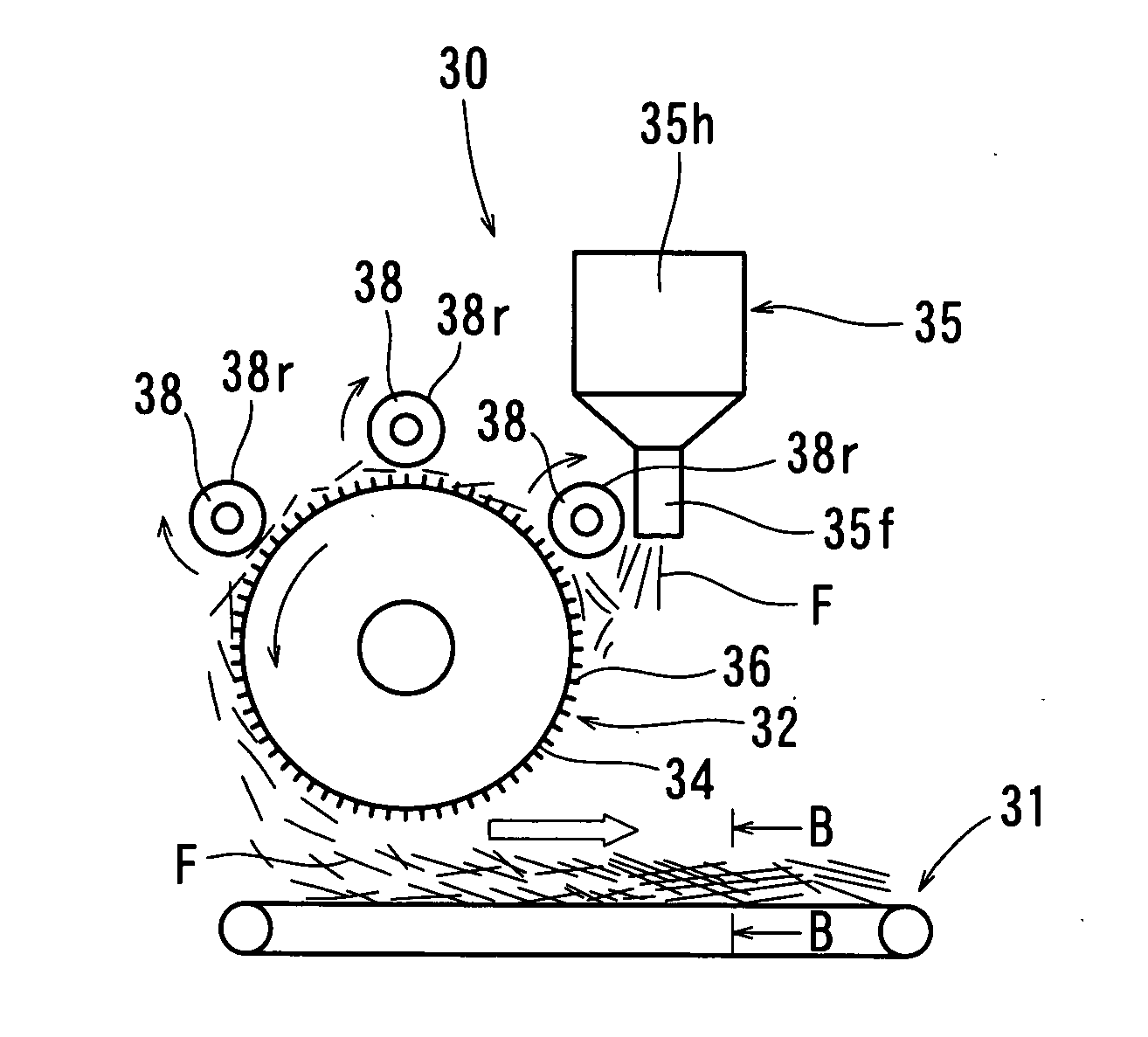

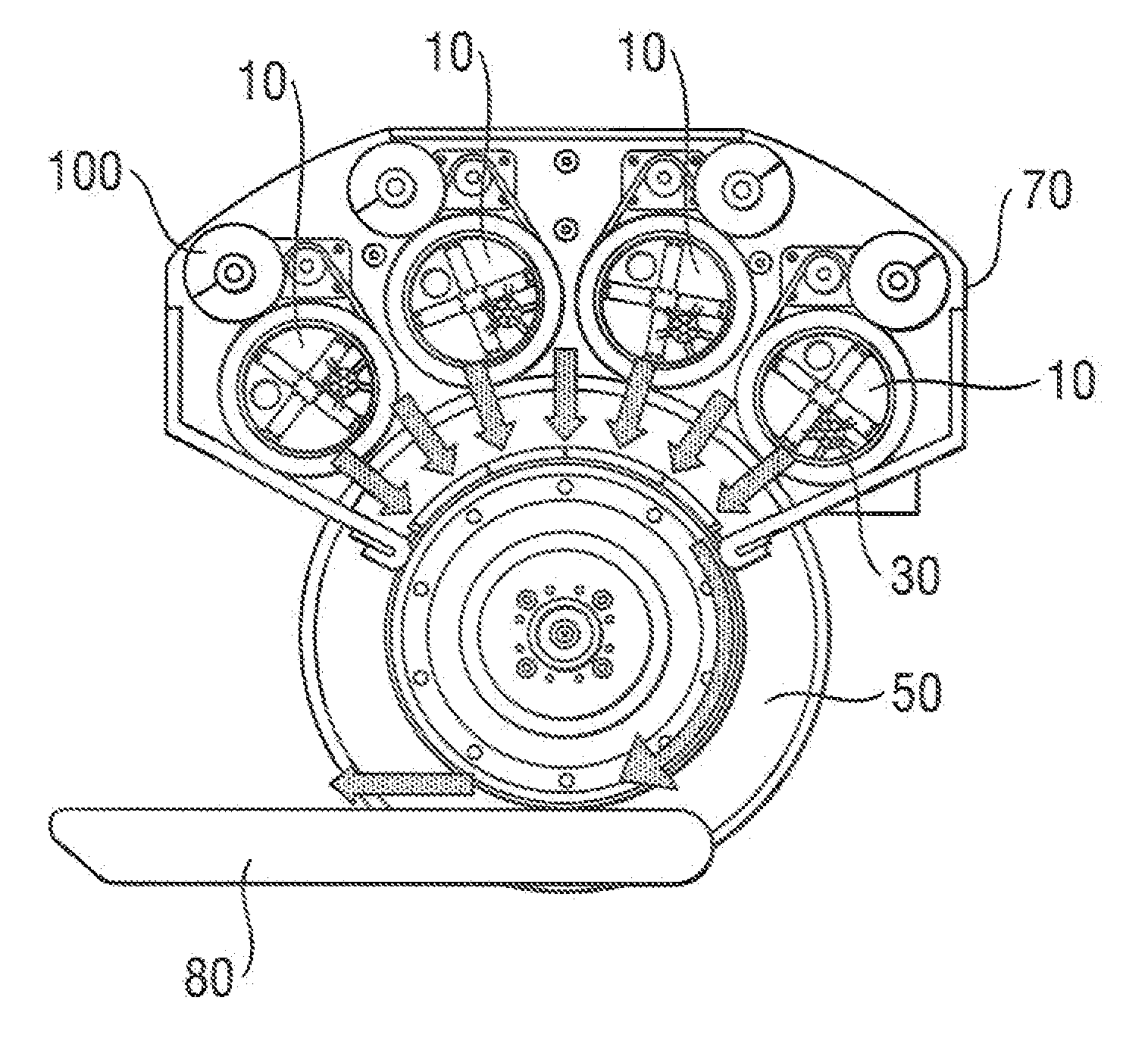

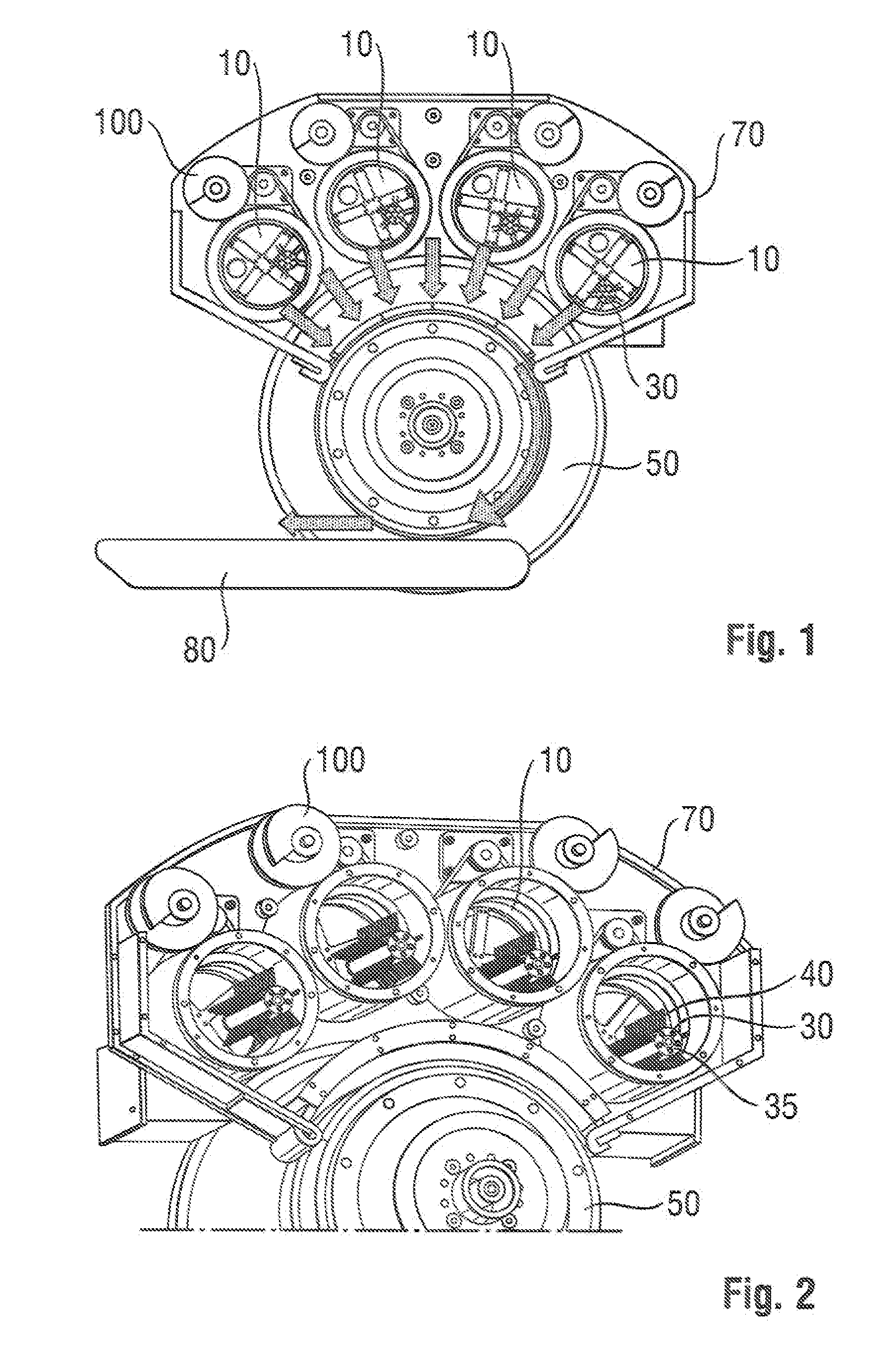

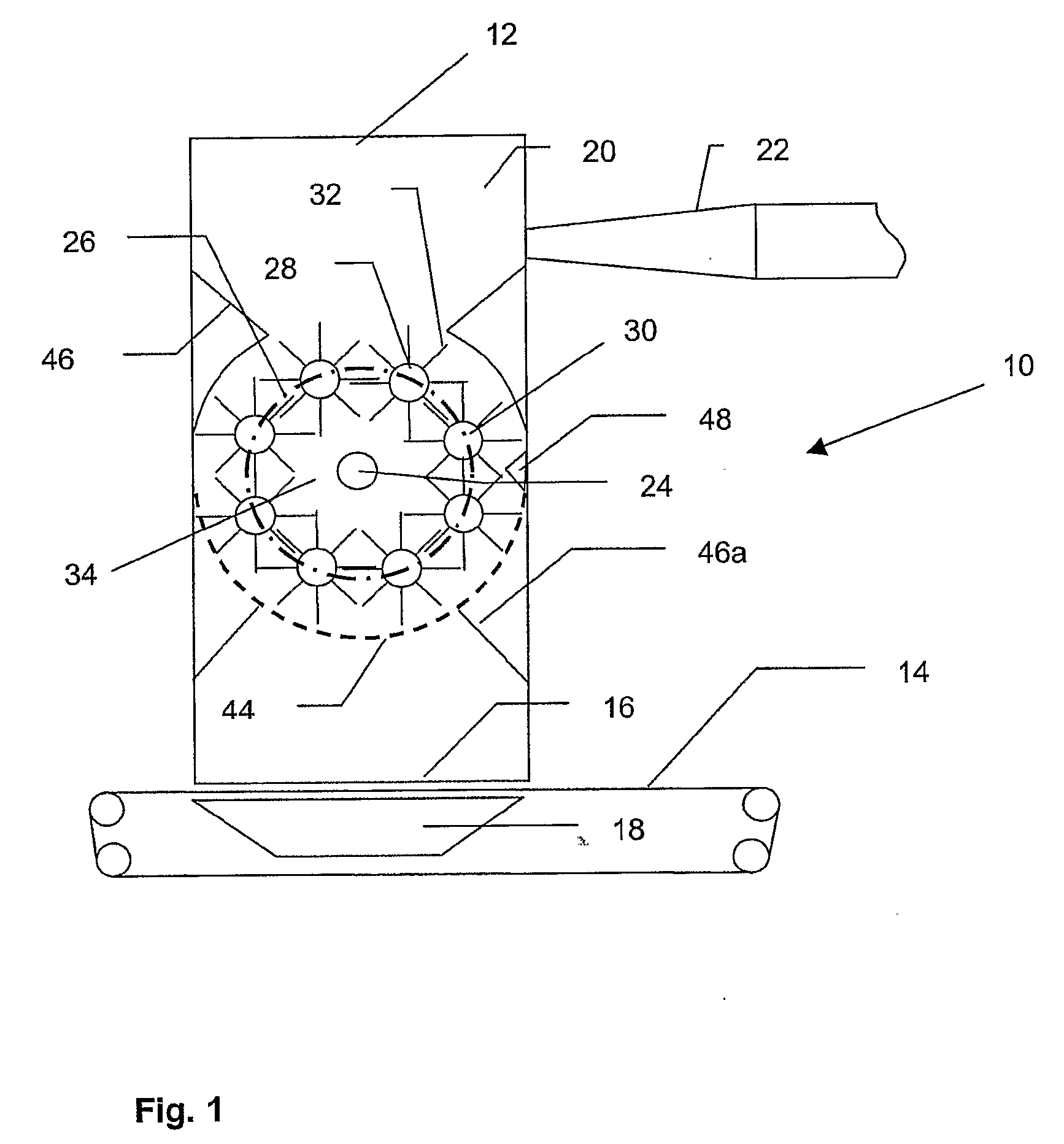

Forming Head and Process for the Production of a Non-Woven Fabric

InactiveUS20080241301A1Great fibre opening capacityEvenly distributedWood working apparatusLap forming devicesNonwoven fabricConveyor belt

The invention concerns a forming head for an apparatus for the production of a non-woven fabric by depositing fibres on a conveyor belt, comprising a fibre feeder which opens into a fibre processing chamber and which has a lower deposit opening for the delivery of fibres, wherein arranged in the fibre processing chamber are interengaging needle rollers with longitudinal axes oriented in mutually parallel relationship, which can rotate about their respective longitudinal axis, and the interengaging needle rollers enclose an inner chamber and are arranged with respect to the fibre feeder and the deposit opening in such a way that fibres fed to the forming head in operation enter the inner chamber by passing through between interengaging needle rollers and leave the inner chamber also by passing through between interengaging needle rollers.

Owner:GLATFELTER FALKENHAGEN GMBH

Core spun yarn taking collagenous fibers as main material and as leather layer and processing method of core spun yarn

InactiveCN105671723AHigh tensile strengthTensile strength does not affectCarding machinesLap forming devicesYarnTextile fiber

The invention discloses a core spun yarn taking collagenous fibers as a main material and as a leather layer and a processing method of the core spun yarn. The core spun yarn comprises a core yarn, wherein a leather layer formed by collagenous fiber bundles or a collagenous fiber bundle and other textiles covers or cover the core yarn; a collagenous fiber bundle and a branch thereof and an adjacent collagenous fiber bundle and a branch thereof form three-dimensional meshed structures which are mutually staggered, twisted and combined and axially arrayed. The processing method of the core spun yarn taking the collagenous fibers as the main material and as the surface layer comprises the following steps: (1) extracting collagenous fibers; (2) carding and striping the fibers; (3) drawing the fibers; and (4) performing spinning. According to the core spun yarn and the processing method thereof, the problem that the basic tensile strength cannot be achieved by extracting the collagenous fibers from leather and directly spinning the fibers in the prior art is solved, and the shortcoming that fine yarns are very hard to process or cannot be processed and the shortcoming that a product cannot fully exert the characteristic of the collagenous fibers as a large number of other textile fibers must be blended for spinning are overcome.

Owner:张立文

Thread production device

A yarn producing apparatus is an apparatus for producing CNT (carbon nanotube) yarn from CNT fibers while causing the CNT fibers to run. The yarn producing apparatus includes an aggregating unit that aggregates the CNT fibers, and a twisting and winding device that twists the CNT fibers aggregated by the aggregating unit.

Owner:MURATA MASCH LTD

Microwave sensor for measuring a dielectric property of a product

InactiveUS20050179443A1Prevent crashReduce the total massSafety devices for fibre treatmentResistance/reactance/impedenceVolumetric Mass DensityHigh field

The application relates to a microwave sensor for measuring a dielectric property, especially the density and / or moisture content of a product, having a microwave resonator, wherein a product introduced into the resonator interacts with a resonant microwave field generated in the resonator in order to determine suitable measured quantities, and is characterised in that at least two half-waves of the electric field are formed in the resonator in one direction, the product feed being effected in at least one region of high field intensity of one of the half-waves of the electric field.

Owner:TRUETZSCHLER GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com