Fleece-laying apparatus

A fiber web and web laying machine technology, which is applied to the fiber web laying machine, can solve problems such as complex routes, and achieve the effect that is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

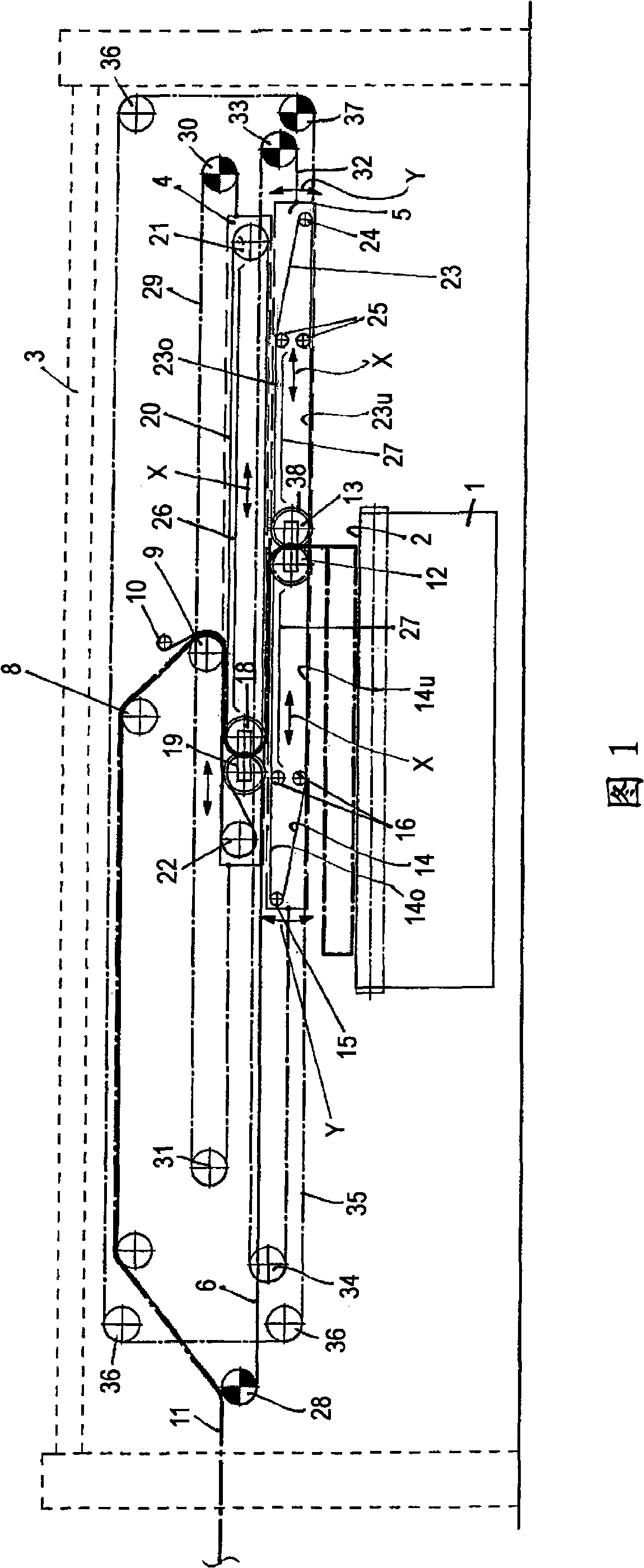

[0021] Accompanying drawing represents the schematic diagram of fiber web lapper, and shown lapper comprises:

[0022] - the output conveyor belt 2 , which is supported on the lower table 1 , is schematically represented by its deflection guide rollers and is designed, for example, as a slatted belt;

[0023]- an upper carriage 4 which is movable within the (schematically represented) frame 3 transversely to the conveying direction of the output conveyor belt 2; and

[0024] - The laying carriage 5 , which is movable below the upper carriage transversely to the output conveyor belt 2 .

[0025] In the example shown, the conveyor belt carrying the card web (hereinafter referred to as the card web inlet conveyor belt 6 ) passes the upper carriage 4 , which conveyor belt runs past a plurality of deflection guide rollers supported in the frame 3 . The card web inlet conveyor belt 6 does not pass through the laying carriage 5, but passes over it. Optionally, the upper carriage 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com