Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98 results about "Wood wool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood wool, known primarily as excelsior in North America, is a product made of wood slivers cut from logs. It is mainly used in packaging, for cooling pads in home evaporative cooling systems known as swamp coolers, for erosion control mats, and as a raw material for the production of other products such as bonded wood wool boards. In the past it was used to fill stuffed toys. It is also sometimes used by taxidermists to construct the armatures of taxidermy mounts.

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

Bamboo wood filigree recombination board and its production method

ActiveCN100999095AReduce manufacturing costSuitable for secondary processingWood working apparatusFlat articlesVolumetric Mass DensityEngineering

The present invention relates to a bamboo wood wool recombinant plate material, it can be made into square plate body or square column body. Said plate body is formed from bamboo wool and / or wood wool, its glue content is 2%-5% and its density is 500-800 kg / cu.m or 900-1100 kg / cu.m. Its production method includes the following steps: sawing bamboo and / or wood, slicing and / or shredding, drying, applying glue, secondary drying, selecting material, making blank, hot-pressing, solidifying and aftertreatment.

Owner:ZHEJIANG JIUCHUAN BAMBOO & WOOD

Cement flakeboard and production process thereof

InactiveCN101117005AEasy to useLow costSolid waste managementCeramic shaping apparatusWood shavingsChloride

The present invention provides a cement particle board and the manufacturing method thereof; the cement particle board comprises the weight percentage compositions of raw materials: 15 to 35 percent of wood wool (absolute dry wood wool), 15 to 45 percent of high-calcium fly ash, 30 to 55 percent of cement, 1 to 3 percent of sodium silicate, 0.3 to 1.8 percent of calcium chloride and 0.1 to 2 percent of addition agent. The method of the present invention uses high-calcium fly ash of industrial wastes, frutex or lops wood shavings for manufacture of hard board, thereby reaching the 'Cement Xylolite Slab (JC / T411-1991)' standard and saving production cost, reducing environmental pollution, expanding, at the same time, the range of wood raw materials for particle board production and creating higher economic value.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Production method of modified wood, bamboo glued mould

InactiveCN101450493ASimplify and save the secondary veneer lamination processSave resourcesOther plywood/veneer working apparatusWood treatment detailsMoistureMaterials science

The invention discloses a method for manufacturing modified plywood formwork of wood or bamboo wood. The method is implemented by the following steps: small-diameter cotton-wood, China fir or small-diameter mixed bamboo instead of large-diameter high-quality wood and large-diameter moso bamboo are taken as raw materials to process into wood wool and bamboo filaments; soluble phenolic resin with a solid content of 20 to 30 percent is used as a modifier of the material; the phenolic resin is impregnated in the fiber cell lumens of the material by a pressure impregnation method to change the moisture expansion property of the material; the wood wool or the bamboo filaments containing less than or equal to 15 percent of water is used as assembly materials; modified and dried wood wool or bamboo filaments and paper impregnated with phenolic resin are used as assembly materials for plywood, and an assembly structure is a three-layer composite structure; main parameters of thermo-compression and bonding include: a unit pressure of 40 to 50 kg / cm<2>, a bonding temperature of 150 + / -10 DEG C, thermo-compression time of one minute for each millimeter of the thickness of board; the board is unloaded when cooled to less than or equal to 50 DEG C after thermo-compression and bonding and is subjected to edge cutting to be processed to the plywood; and after the worn surface finish of the plywood is restored through recoating by a secondary veneering method, the plywood is reused.

Owner:李茂林

Method for using modified soy protein tackiness agent to prepare shaving board

InactiveCN101186048AWide variety of sourcesSource renewableDomestic articlesFlat articlesParaffin waxSulfite salt

The invention discloses a flakeboard manufacturing method adopting a modified soy protein bond. The method includes the following steps: 1) glue mixing: 10 parts of soy separated protein are gradually added into 87.7 parts of modified reagent solution, then the solution is stirred for 2 to 3 hours; 1 part of sodium sulfite and 1.3 parts of paraffin emulsion are added, then an even stirring is carried out; 2) wood wool production: natural air-dried castoffs of woods processing are crushed by a hammer grinder and selected so as to get the wood wool after impurities and dusts are removed; 3) gluing: the wood wool and the modified soy protein bond are evenly mixed; 4) hot-pressing: a ventilation process is carried out for drying and the water-content of the acquisition of the step 3) is regulated to 17 to 22 percent to get a plate blank; then the plate blank is hot-pressed for shaping so as to get the flakeboard. The flakeboard produced by the method of the invention has no poison and smell and no formaldehyde releasing.

Owner:ZHEJIANG UNIV

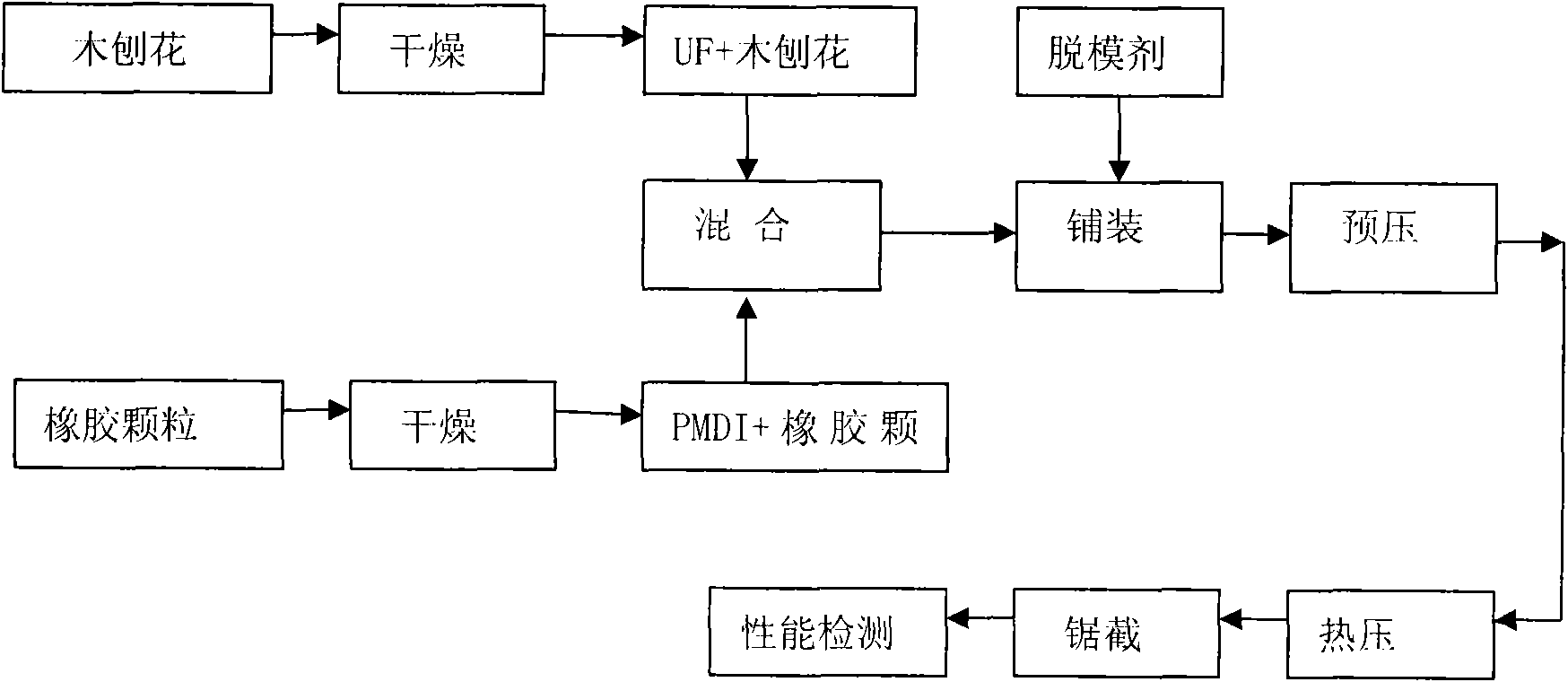

Preparation process of wood-rubber functional environment-friendly composite material

InactiveCN101549516AReduce releaseCan not cause pollutionWood working apparatusFlat articlesWood shavingsVolumetric Mass Density

The invention relates to a preparation process of a wood-rubber functional environment-friendly composite material, belonging to the technical field of wood composite material production. The preparation process of the wood-rubber functional environment-friendly composite material comprises the following steps: preparing and drying wood wool, mixing the wood wool with urea-formaldehyde glue (UF), preparing and drying rubber grains, mixing the rubber grains with isocyanate (PMDI), mixing the wood wool with the rubber grains, adding parting agent for pavement, pre-pressing, hot pressing, and the like. The preparation process of the invention also include the following parameters: the wood wool has a length of 3-25 mm, a width of 1.0-2.5 mm and a thickness of 0.2-0.8 mm; the water content of the dried wood wool is 6-9 percent; the isocyanate (PMDI) is 6 percent; the urea-formaldehyde glue (UF) is 10 percent; the ratio of the wood wool and the rubber grains (W / R) is 60 / 40; the rubber grain size is 5mm; the hot pressing temperature is 170 DEG C; the hot pressing time is 300s; and the density of a plate bland is 1000g cm.

Owner:赵君 +5

Phase-changing temperature-adjusting energy storage floor

InactiveCN1864957AHigh quality raw materialFormulation ScienceWood working apparatusFlat articlesFiberSolvent

The invention relates to a phase-change temperature-adjust energy-storage floor and relative production. Wherein, the inventive floor extracts wood from broken wood, wood wool, and chip, to be added with fiber extracted from waste paper; the wood cell wall is formed by the cellulose and hemicellulose of amylase and the wood with aromaticity. It uses the polymerization process and special extruder to make the temperature-adjust energy-storage floor at 180-280Deg. C, which will not be corrupted by general solvent, acid and alkali. The inventive production will not discharge waste and harmful gas, and it only uses wood powder, macromolecule synthetic material and agent, to save the energy and resource.

Owner:王方怡雪

Process for imparting water resistance to wood-based products

A process for preparing water resistant wood-based panels is disclosed. The process comprises the application of a latex-free wax emulsion to a mat of wood strands and adhesive before the application of heat and pressure to form said wood-based panel, or the application of said latex-free wax emulsion to a wood-based panel and allowing said composition to dry.

Owner:WALKER INDS HLDG

Producing method of wood plastic hard material

InactiveCN101693382AImprove the situation of extremely scarce resourcesDesignableDomestic articlesFlat articlesVolumetric Mass DensityMaterials science

The invention belongs to the field of man-made board production, particularly to a producing method of a wood plastic hard material. The wood plastic hard material comprises 90% of fast-growing wood wools and the producing method of the wood plastic hard material comprises the following steps: impregnating modified phenolic resin water-soluble plastic solution into wood wool fiber and wood wool fiber cell cavities by a press injection method to compound the two high polymer materials; and then carrying out hyperpressure compression and high temperature solidification to obtain the wood plastic hard material of a certain specifications. The wood wools are all arranged vertically along the fiber for keeping the natural grains of wood and the wood plastic hard material has attractive appearance and good processability, and the physical-mechanical characteristic and the use function of the wood plastic hard material has designability, and the density, the strength, the compact resistance, the rotproofness and the water resistance, the nail-holding ability and other indexes of the wood plastic hard material are all higher than that of high-quality natural wood. The invention provides a novel wood plastic hard material to woodware industry and construction industry for improving the condition that large-diameter high-quality wood and hard wood resources are extremely rare and has the advantages of simple, practical and reliable producing process, higher yield and additional value.

Owner:李一 +1

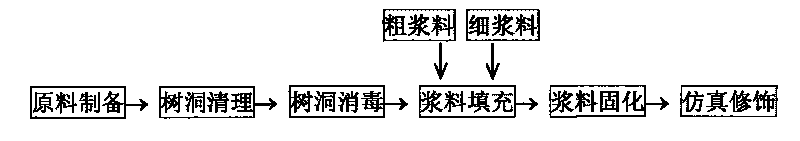

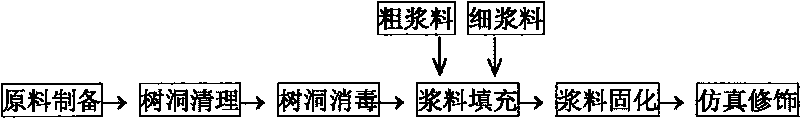

Bionic filling method of gradient of tree body hole

The invention relates to a bionic filling method of the gradient of a tree body hole, which comprises the following steps: tree hole clearing: removing impurities in the tree hole; tree hole sterilizing: spraying or smearing the water solution of copper sulfate; slurry preparing: mixing an inorganic adhesive and a wood unit formed by mixing wood fiber and wood wool to prepare coarse slurry, and mixing the inorganic adhesive and a wood unit of wood powder to prepare fine slurry; slurry filling: respectively filling the coarse slurry and the fine slurry to the inner layer and the outer layer of the tree hole by using the central axis of the tree body as a symmetric line, and under the action of gravity, the slurry is in gradient distribution in the vertical direction of the tree hole; slurry solidifying: after the slurry is filled layer by layer, bonding the slurry with the hole wall into a whole; and simulation decorating: bonding a layer of real tree bark on the solidified filling material. Thus, the solidified filling material and the tree body filled with the filling material have the same gradient distribution rules of density and strength, thereby being more close to the flexibility of the tree body.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

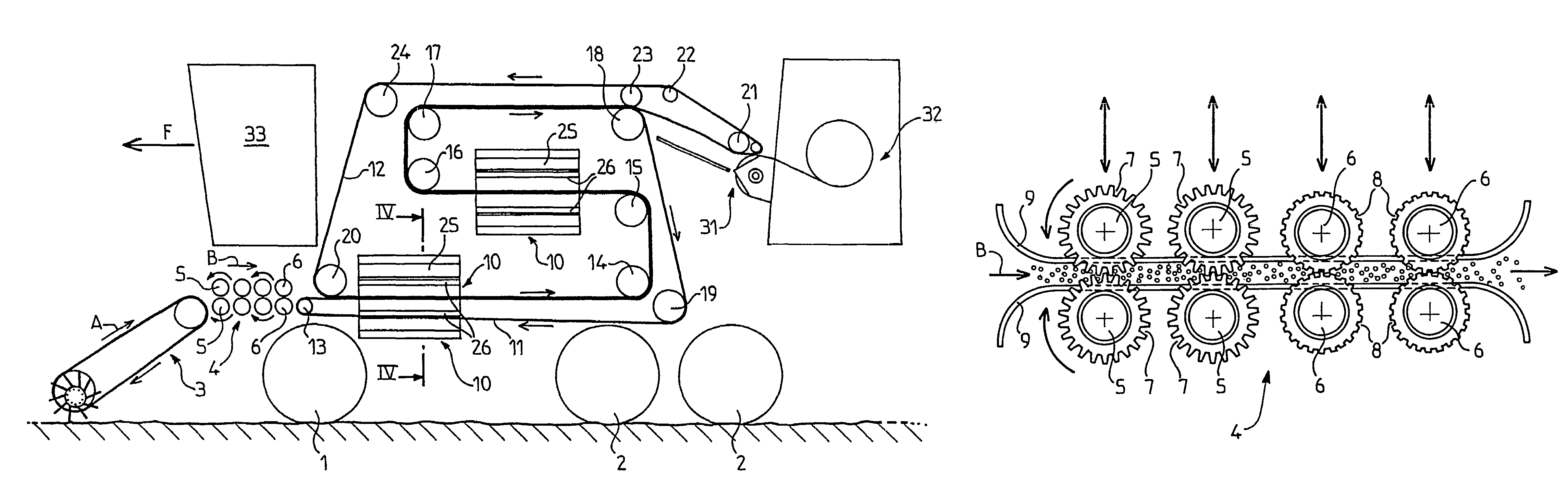

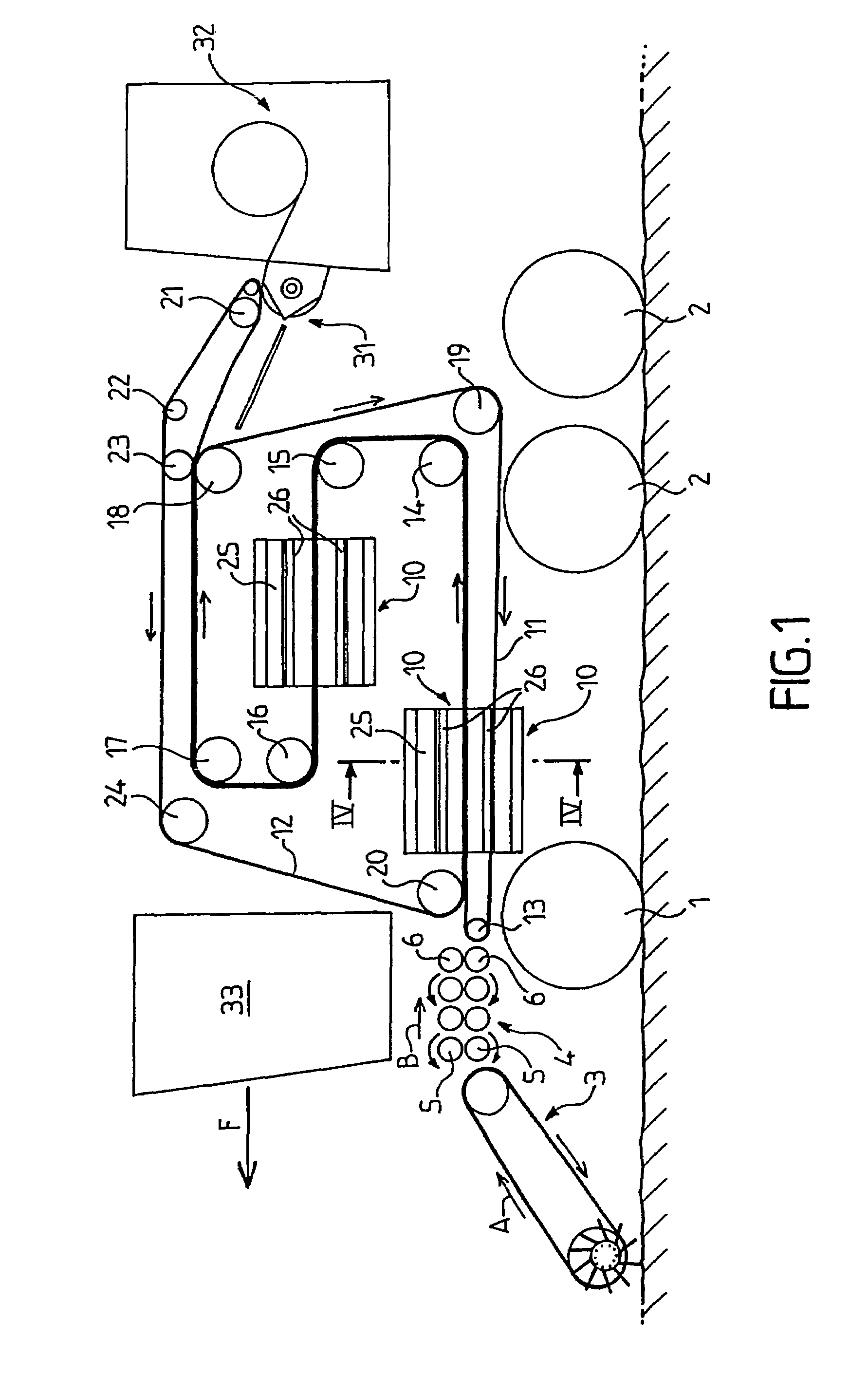

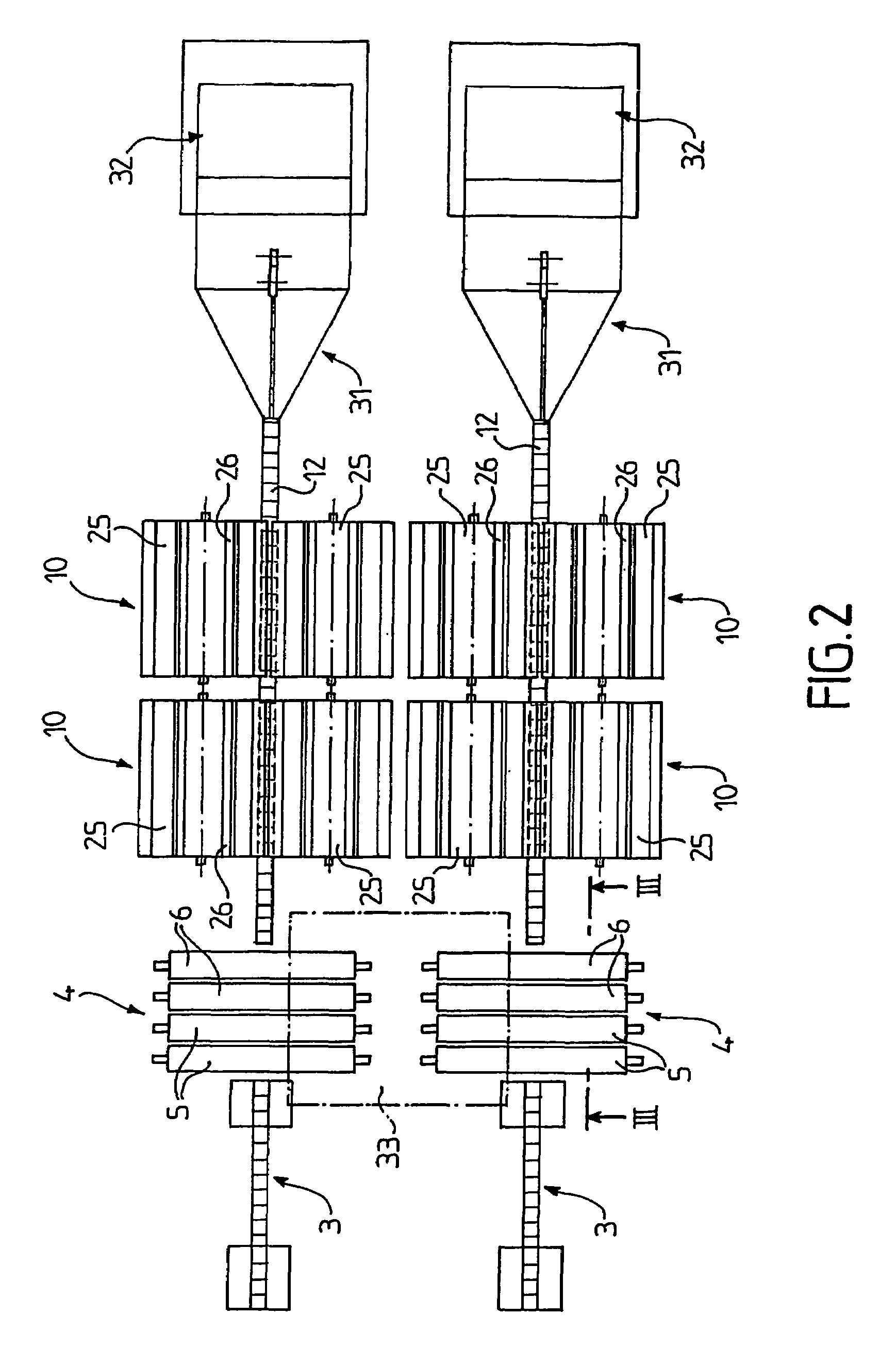

Method and machine for packing fibrous plants into balls especially common flax, hemp plant and sisal

InactiveUS7520214B2Combed more easily and more quicklyLess expensivelyMowersCuttersHemp plantPulp and paper industry

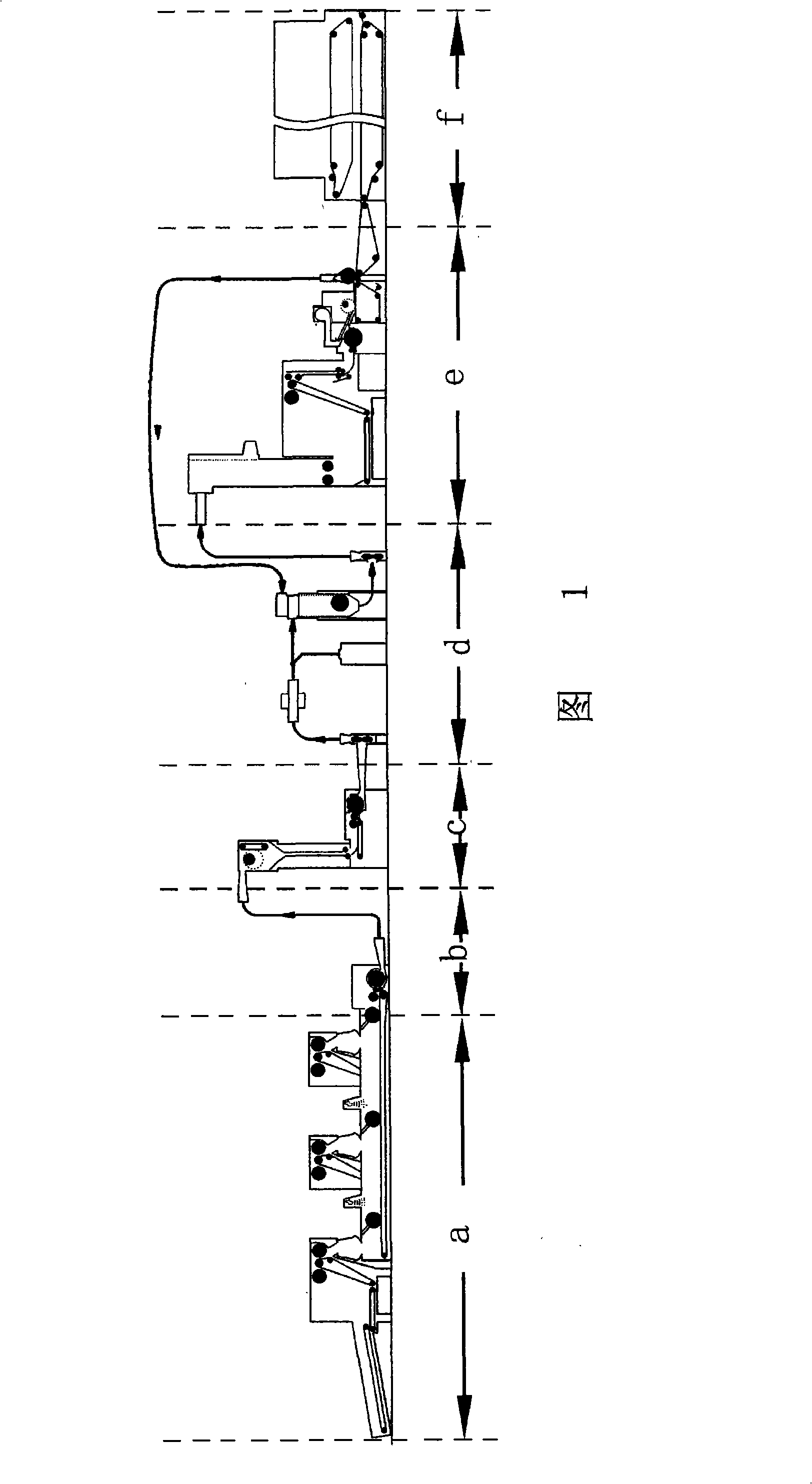

A method is provided for collecting at least partially retted plants and winding them into bales. The method is characterised in that the collected and wound plants are fibrous plants with previously cut tops and bottoms. A machine to perform the method has a gatherer (3) for collecting at least partially retted plants with previously cut tops and bottoms, a crusher (4) for grinding the stems of the plants without tops and bottoms to break the wood filaments therein, a decorticator (10) for scarifying the ground stems to release the wood filaments and shives, a unit (31) for laying flat the fibres scutched in this way, and a baler (32) for winding the same into bales.

Owner:DEHONDT GUY

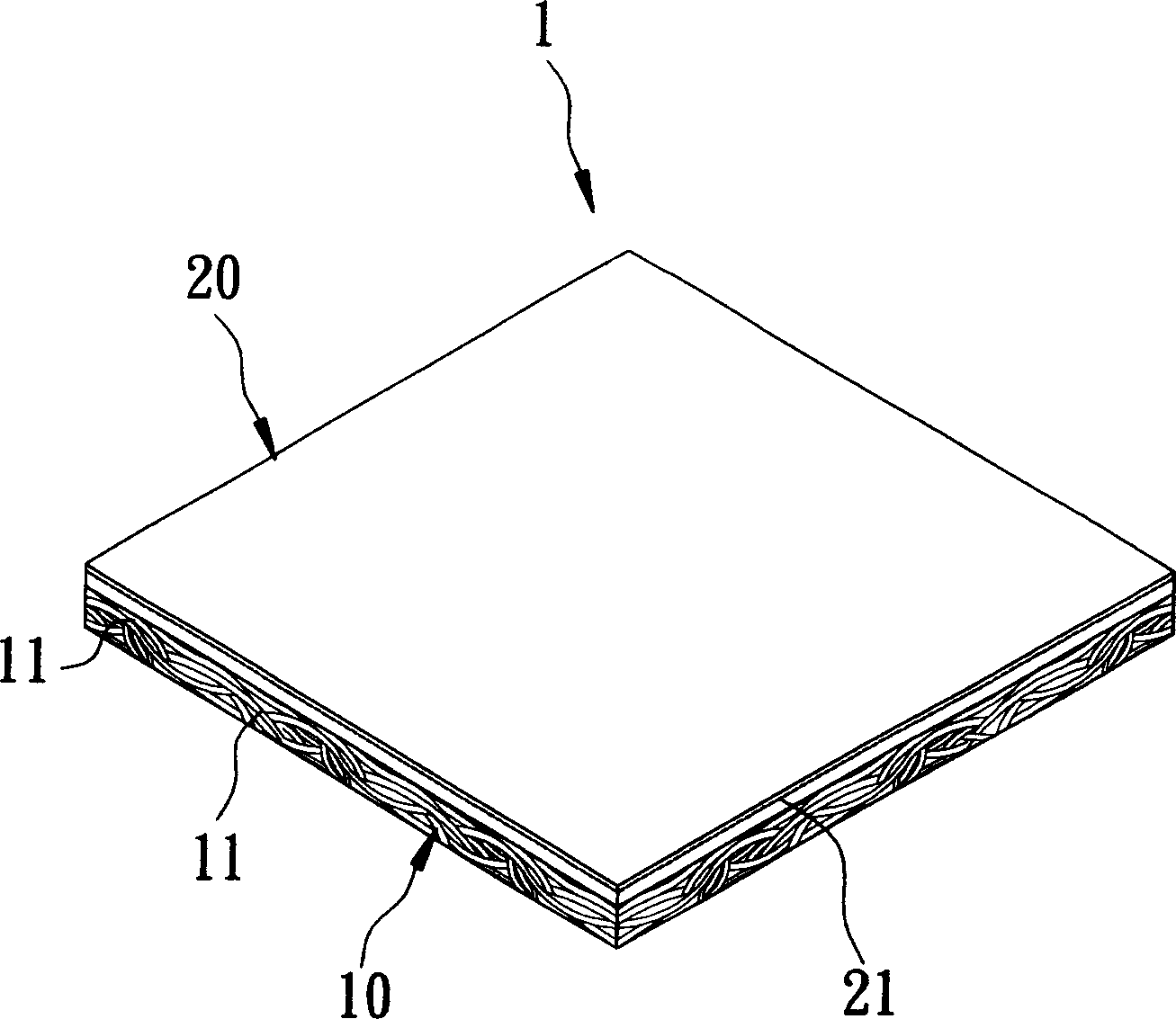

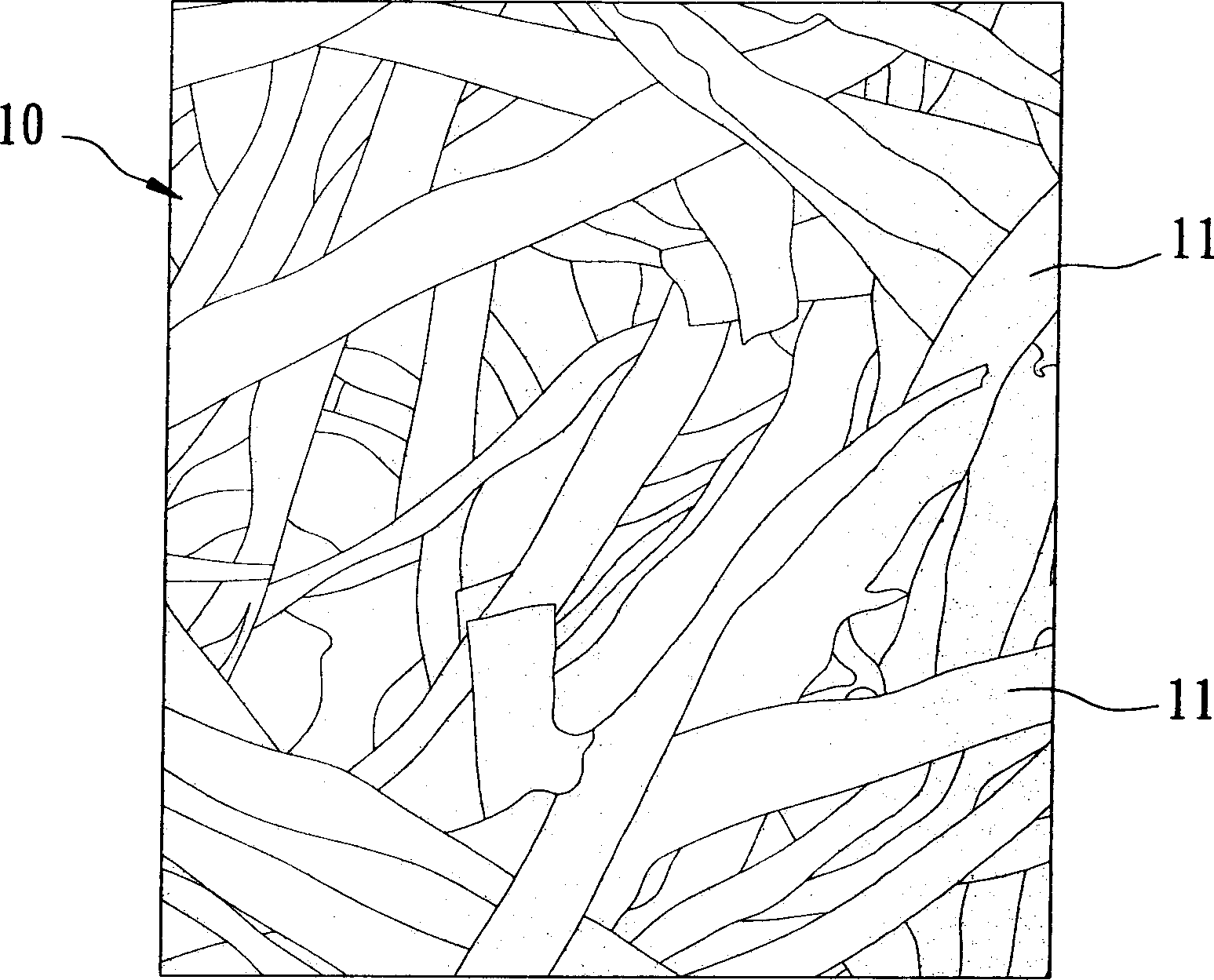

Bionic log processing method

ActiveCN105082270AHigh strengthImprove performanceLaminationLamination apparatusPreservativeWood wool

The invention discloses a bionic log processing method. The bionic log processing method is characterized by comprising the step one of raw material preparing and preprocessing; the step two of raw material preparation; the step three of high-temperature boiling dyeing; the step four of drying; the step five of sorting and storage; the step six of gluing and glue mixing by adding waterproof agents, fireproof agents and preservatives; the step seven of gradual change of wood flour of a veneer slab and directed pavement of wood wool; the step eight of premoulding of the veneer slab to form a veneer; the step nine of powdery gluing of the veneer; the step ten of overlaying of bionic log slabs in a multilayer tapered overlaid structure manner and cold pressing of the bionic log slabs; the step eleven of partial impregnation; the step twelve of hot pressing of the bionic log slabs in a multilayer tapered overlaid structure manner; and the step thirteen of trimming of finished bionic log products and storage of the finished bionic log products.

Owner:孙建民

Manufacture of low density panels

Low density composite wood panels are manufactured from a feedstock comprising wood wool strands of high average slenderness ratio and high average aspect ratio, and low bulk density. The feedstock wool strands are blended with a resin binder typically in the range of 3 to 5 percent by weight and a hot wax in the range 1 to 2 percent by weight and formed into a mat. The mat is hot pressed with steam injection to effect curing of the resin. The low density panels may include on one or both of their major faces a wood veneer layer. The wood wool strands typically comprise wood of the aspen or jack pine species.

Owner:FPINNOVATIONS INC

Mixed soil basement simulation wall picture and technological process

ActiveCN104057763AIncrease the sense of historical vicissitudesSpecial ornamental structuresBasementAdhesive

The invention provides a mixed soil basement simulation wall picture and a technological process. The technological process is composed of the five steps of manufacturing base layer formworks, a mixed soil basement, a UV imaging layer and a picture manufacturing layer, and carrying out antique processing. Each formwork is made of a smooth slab material like a cement wood-wool plate which is five to twenty five millimeters thick and not prone to deforming. The surface of each formwork is uniformly coated with acrylate, polyving akohol and adhesive. An argillaceous coating is four to nine millimeters thick, an outline is printed on the argillaceous coating through a UV imaging technology, then professionals paint and color the argillaceous coating manually, and the integral argillaceous basement simulation wall picture is obtained after antique processing is carried out, and can be formed by assembling and installing a plurality of printed formworks according to an original drawing. The mixed soil basement simulation wall picture has the advantages that the manufacturing speed is greatly increased, the manufacturing efficiency is greatly improved, the production and manufacture speed is high, the picture can be produced in a mass mode in a short time, installing and constructing are convenient and fast, the simulation degree is high, and the adaptability is high.

Owner:昝晓晖

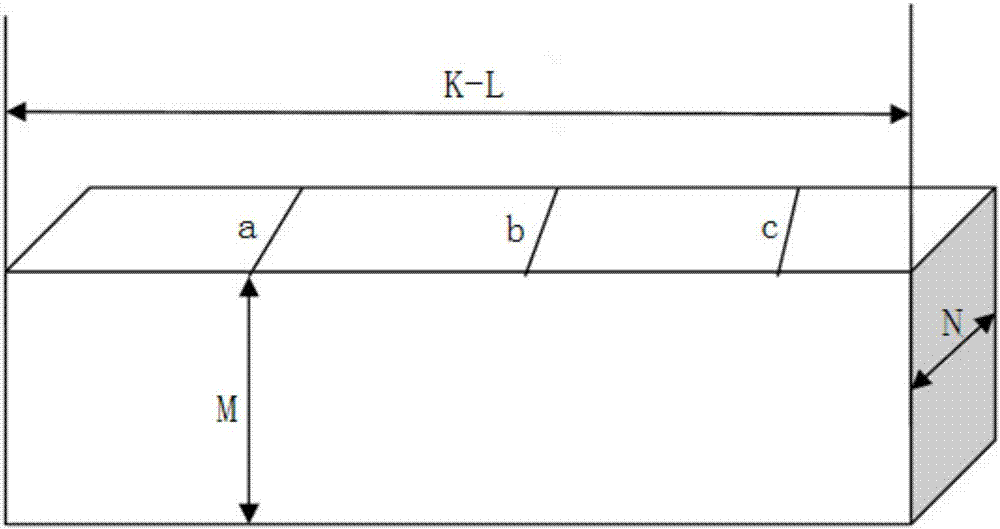

Clubbed composite material of wood-wool and plastics, and method of producing the same

A rod-type wood wire plastic composite material and the preparation method relates to a composite material and the preparation method. The present invention solves the problems of low intensity and high cost of the current wood-plastic composite material. The rod-type wood wire plastic composite material of the present invention is prepared through hot mixing, cool mixing, one-step extrusion and molding of 55 weight portion to 75 weight portion of rod-type wood wire, 20 weight portion to 45 weight portion of plastic and 0.5 weight portion to 4 weight portion of lubricant. The rod-type wood wire of the present invention is a wood-wire with a length of 1mm to 8mm and a length-diameter of 5 to 25. Though the rod-type wood wire of unit mass has a smaller specific surface area, the surface of each wood wire is far higher than wood powder particles; and the rod-type wood produces tropism in the extrusion and molding process. Therefore, the performances of the composite material are not lowered because of the reduction of the specific surface area of fiber material. Instead, the performances of the composite material are strengthened because of the large surface area and the tropism effects of each wood-wire. The present invention has the advantages of high strength of product, high production efficiency and low cost. And the present invention has the advantages of simple process and convenient operation.

Owner:NORTHEAST FORESTRY UNIVERSITY

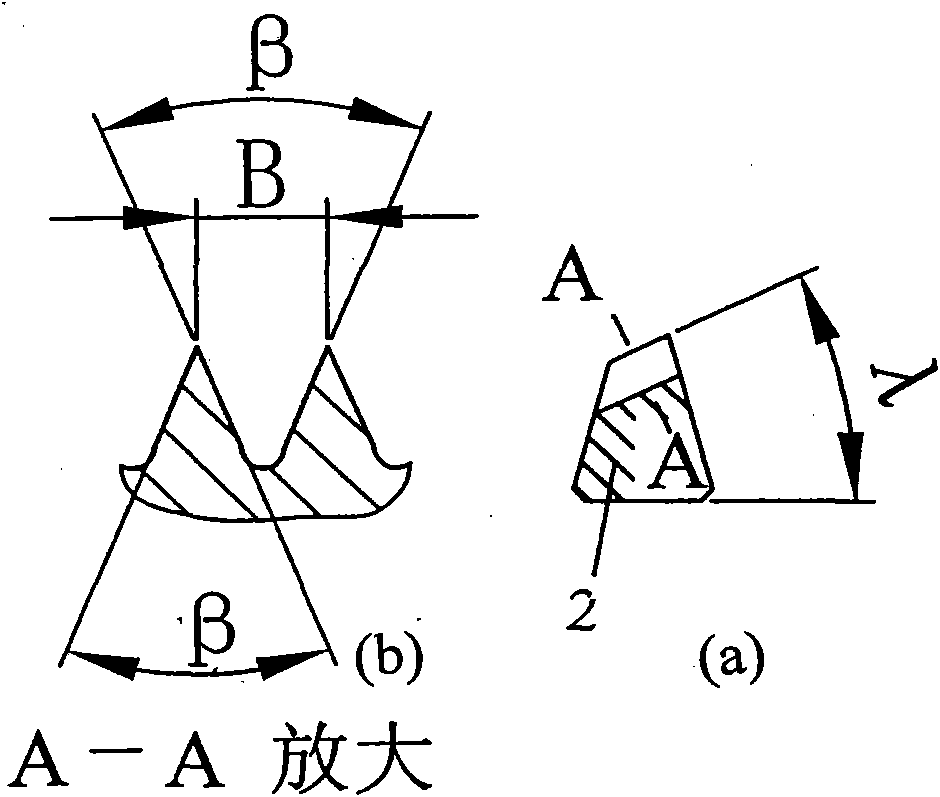

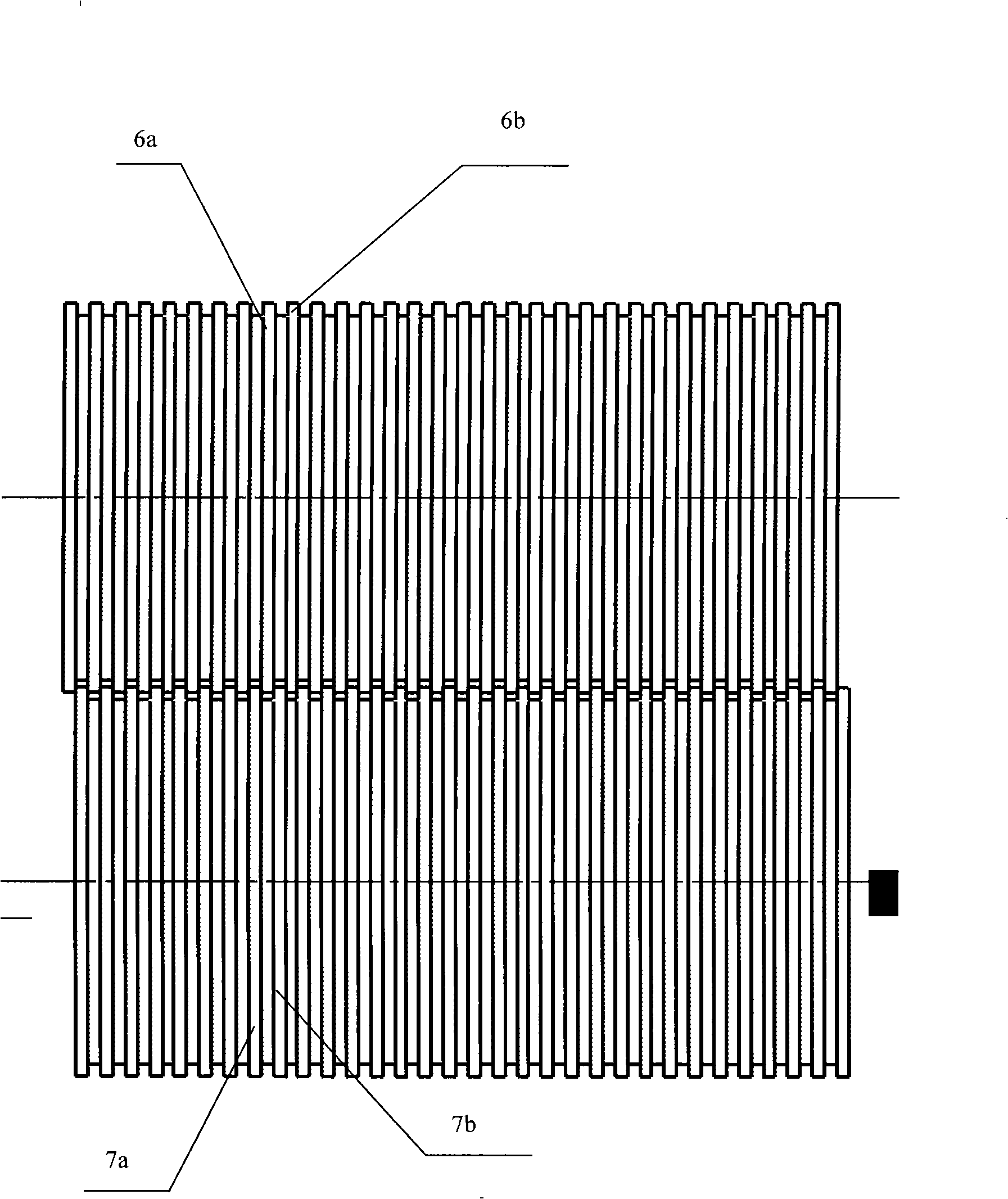

Method and tool for machining rod-shaped reconstructed wood unit

ActiveCN102085681ANo pollution in the processReduce noiseFlat surfacing machinesFiber orientationKnife blades

The invention discloses a method and a tool for machining a rod-shaped reconstructed wood unit. The method comprises the following steps of: cutting wood along the longitudinal direction of the fiber of the wood according to the set depth by using a scratching knife with more than two blades without sawdust; generating lateral separation and generating a scratching knife mark by the wood tissue with the set depth; cutting along the longitudinal direction of the wood by using the scratching knife blade in the direction vertical to the depth of the scratching knife mark; and cutting the wood toform a wood-wool rod. The middle boss of the base of a cutter is provided with dovetail grooves; one side surface of each dovetail groove is provided with a rectangular path; a plane cutter is arranged in the dovetail groove on the side, and the scratching knife is installed in the dovetail groove on the other side; the scratching knife and the plane cutter are fixed on two sides of the dovetail groove by press cakes; the scratching knife and the plane cutter are higher than the top surface of the boss; and a gap is formed between the inclined bottom surface of each press cake and the blade of the plane cutter. The wood-wool rod is easy to realize directional pavement when a wood assembly is reconstructed. The wood is cut longitudinally along the vertical grain without sawdust. The tool has the advantages of small noise, small cutting resistance, no dust pollution and high processing efficiency.

Owner:ZHEJIANG FORESTRY UNIVERSITY

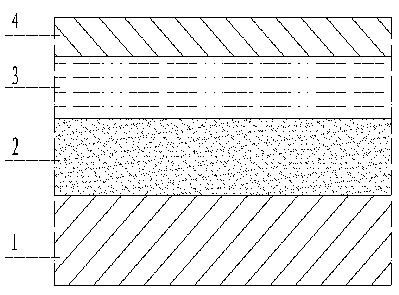

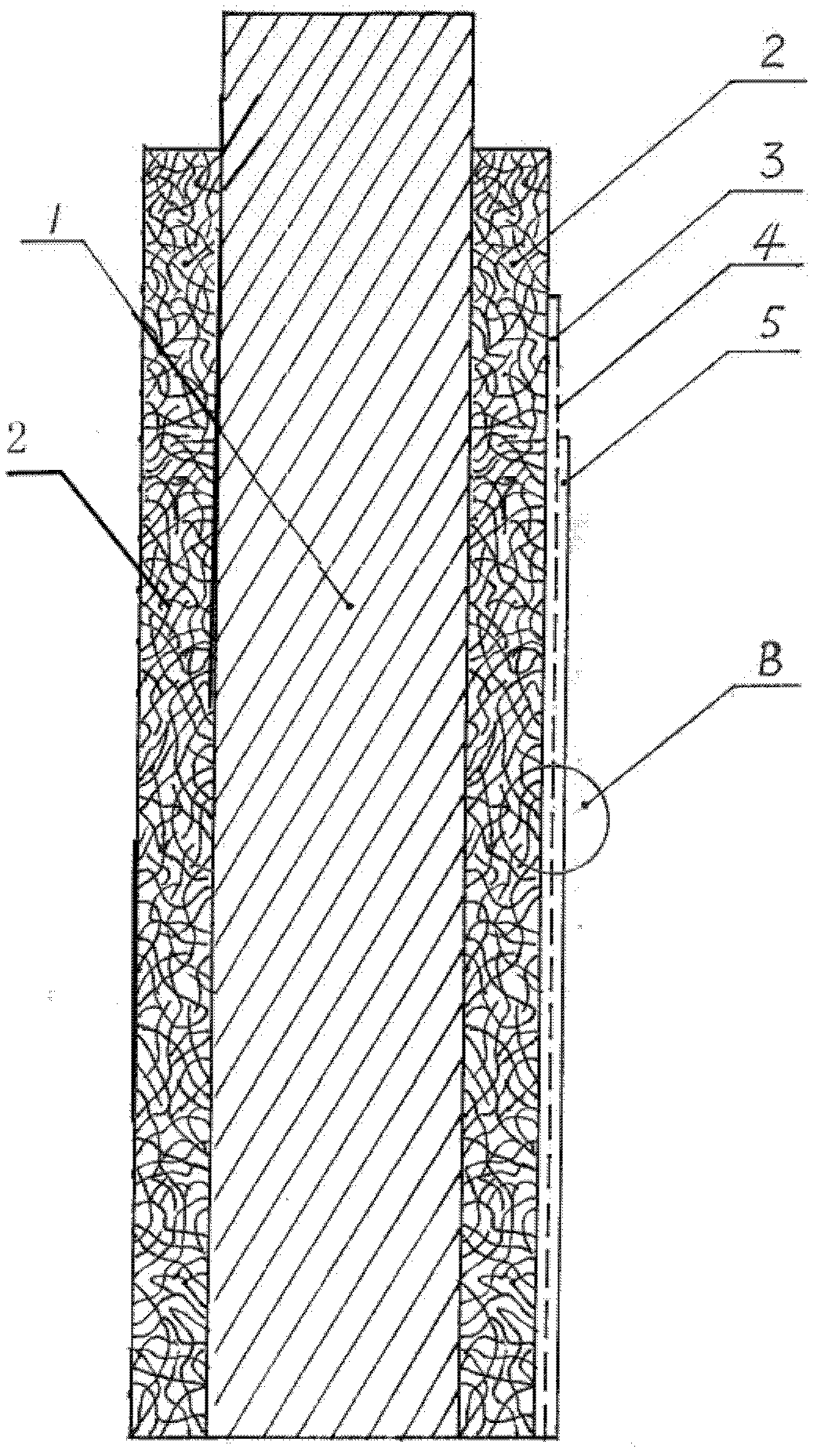

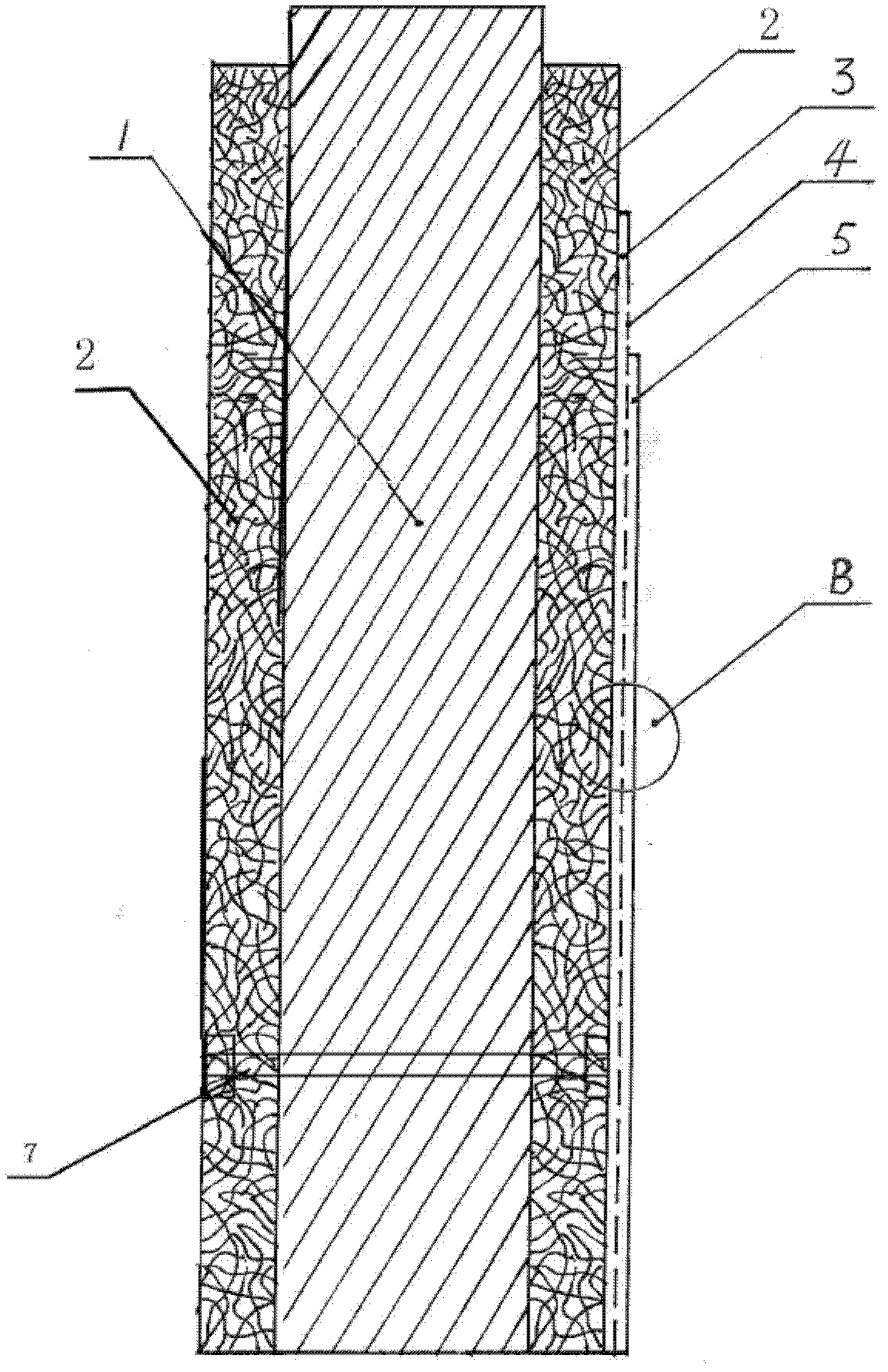

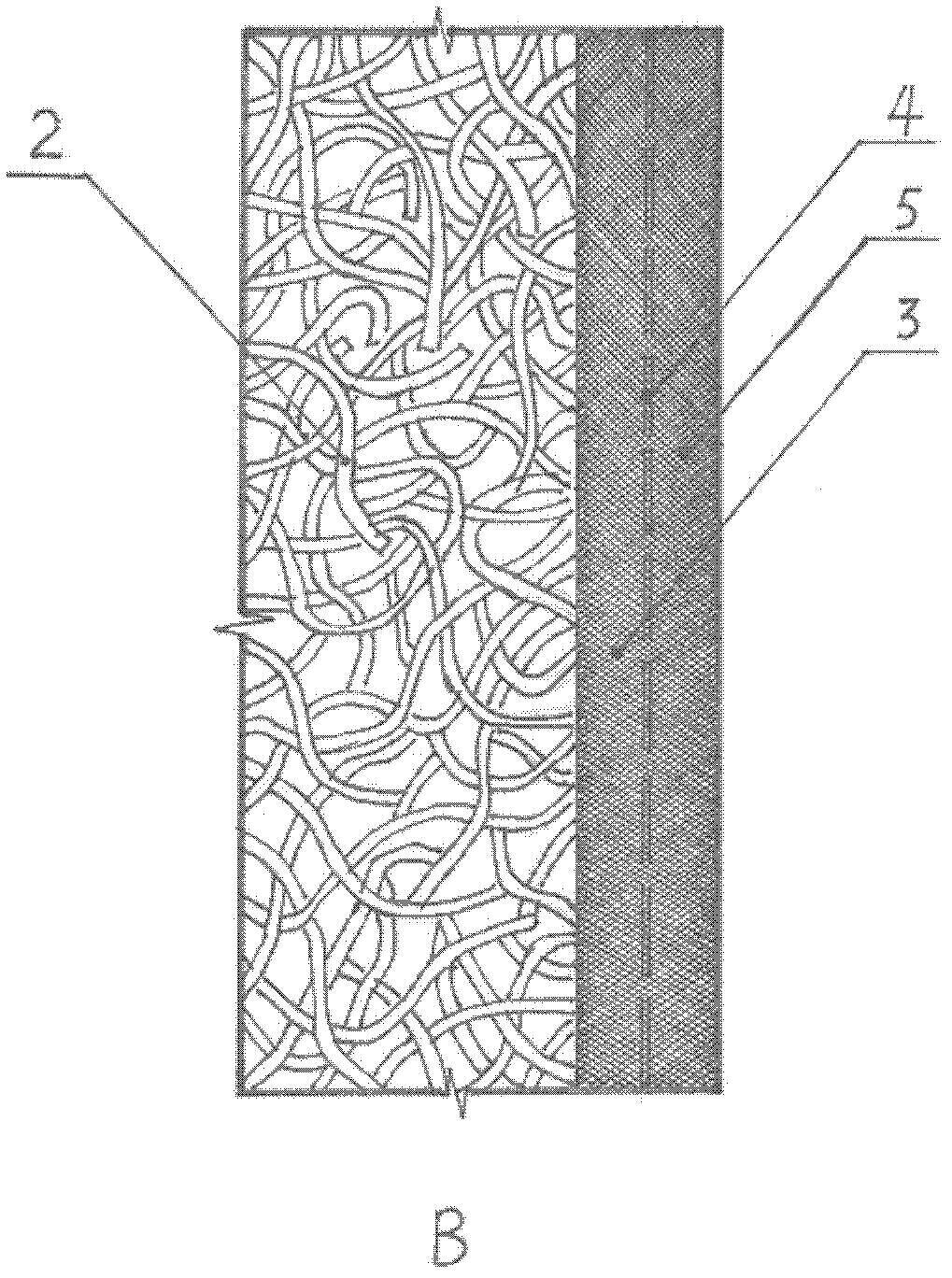

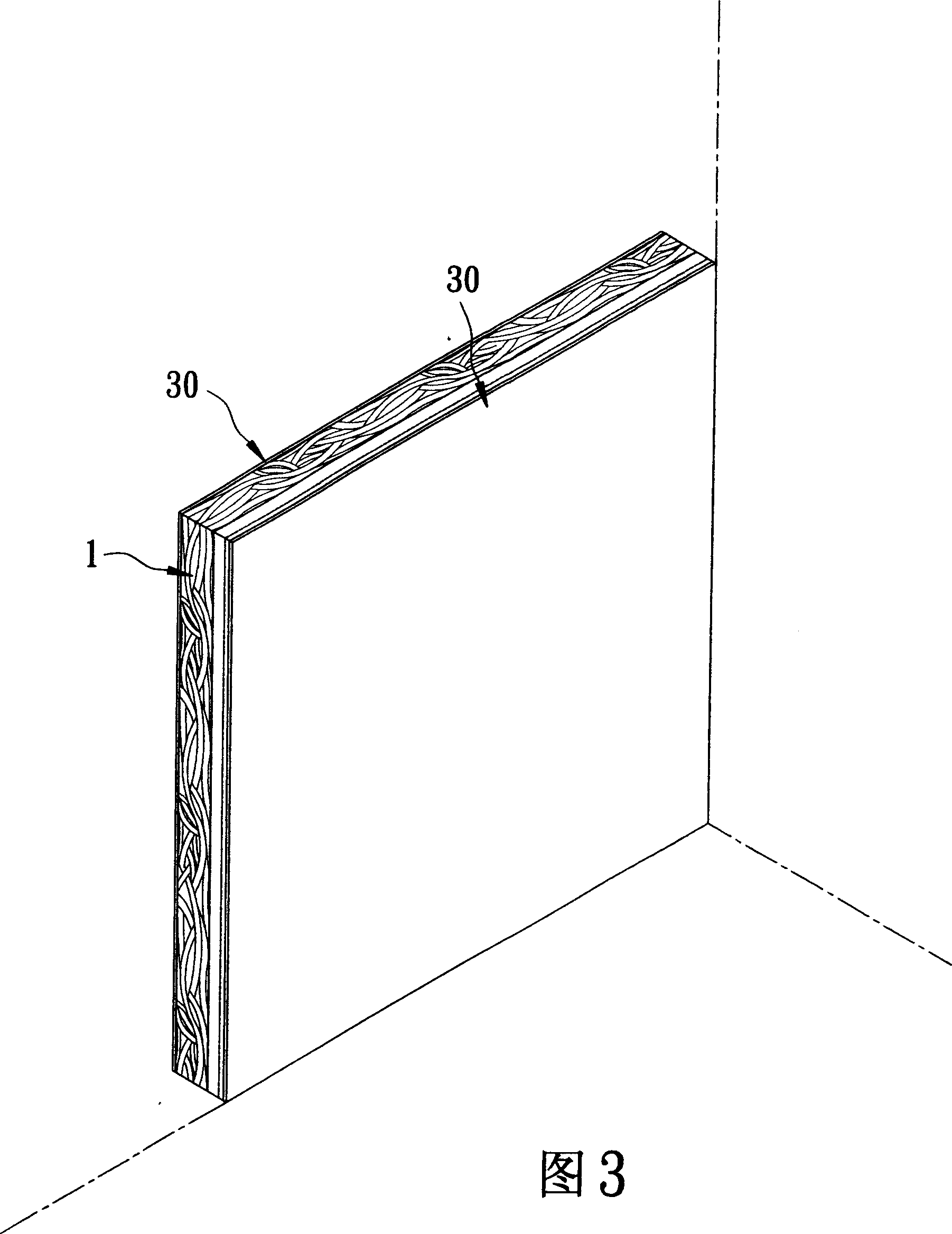

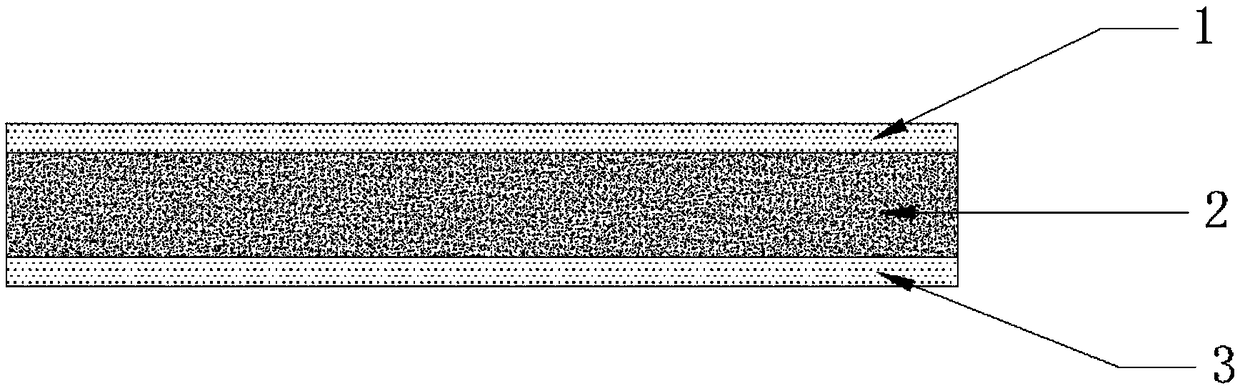

Self-heat preservation system of wood-wool cement board (WWCB) demoulding-free template

InactiveCN102535689AEasy constructionImprove insulation effectWallsHeat proofingFiberglass meshGlass fiber

The invention discloses a self-heat preservation system of a wood-wool cement board (WWCB) demoulding-free template, which comprises a concrete wall body, a heat insulation layer and a decorative surface coating arranged on the heat insulation layer, wherein the heat insulation layer is a WWCB which is internally poured with concrete so as to form the concrete wall body; and the decorative surface coating comprises primer of a decorative surface, glass fiber gridding cloth and surface coating of the decorative surface which are adhered on the WWCB from inside to outside. The self-heat preservation system not only is simple in construction and cost-saving, but also is environment-friendly and energy-saving, and is capable of guarantying the service life of the wall body to reach hundreds of years and the fire protection level of an external heat insulation wall to reach A-level standard; and furthermore, when being coated with the decorative surface coating, the self-heat preservation system is simple and convenient in technology, and beneficial to popularization and application.

Owner:泛亚环保(中国)有限公司 +5

Production process for manufacturing cement fibre board from fast growth aspen

InactiveCN101306557AOccupy not muchSimple production processCeramic shaping plantsWood working apparatusComing outWood wool

The invention relates to a processing technique of manufacturing a cemented excelsior board by using fast growing poplar, which is characterized in that the method comprises the following steps: cutting a piece of poplar wood into wood wool by using a wood wool making machine; weighing wood wool and cement required by a single excelsior board; dipping the wood wool into water; fully mixing with the cement in an agitator; uniformly spreading the agitated mixture of the wood wool and the cement in to a mould; sending each finished mould into a cooling press; starting the cooling press to press the loose mixture into solid mixture; placing concrete blocks above mould piles which come out from the cooling press for maintaining the mould piles; detaching board blanks from the mould and drying the same in natural condition; and sizing, trimming and sanding the board blanks, spraying color on the same, and processing corners of the same. The processing technique has the advantages of simple processing technique, small equipment investment, small occupied field and controllable output.

Owner:SHANGHAI XUNKUAI ENTERPRISE DEV

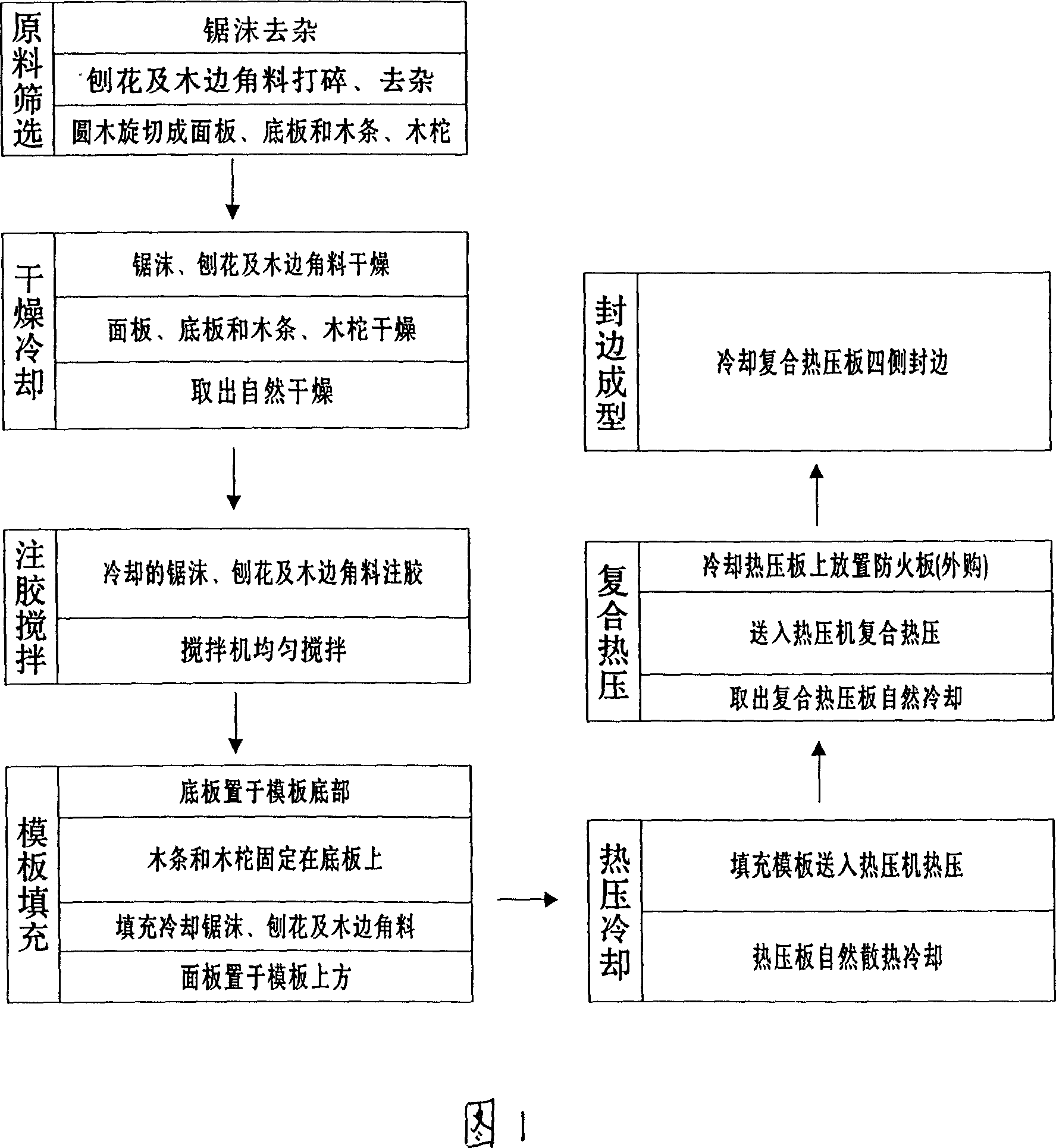

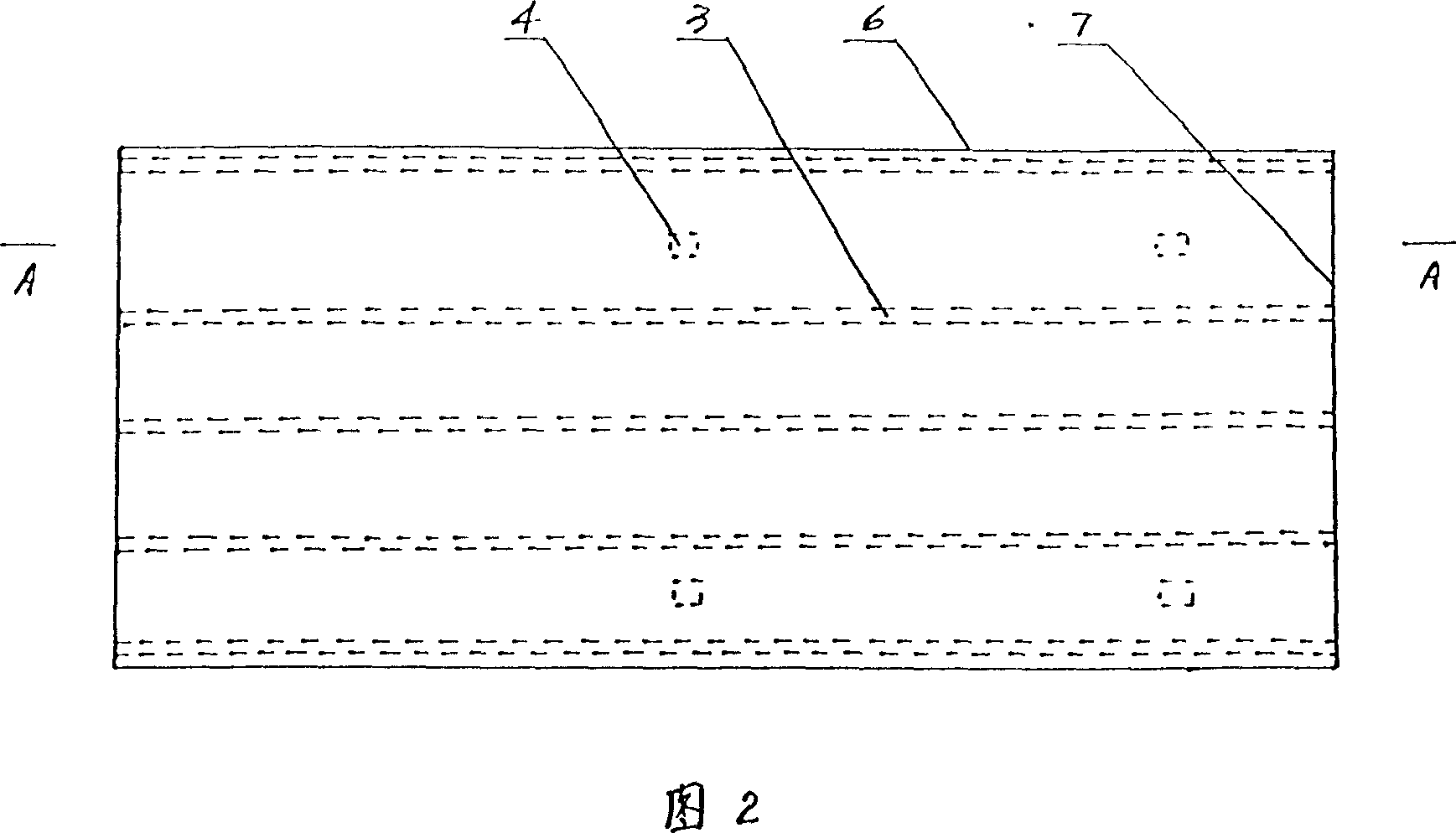

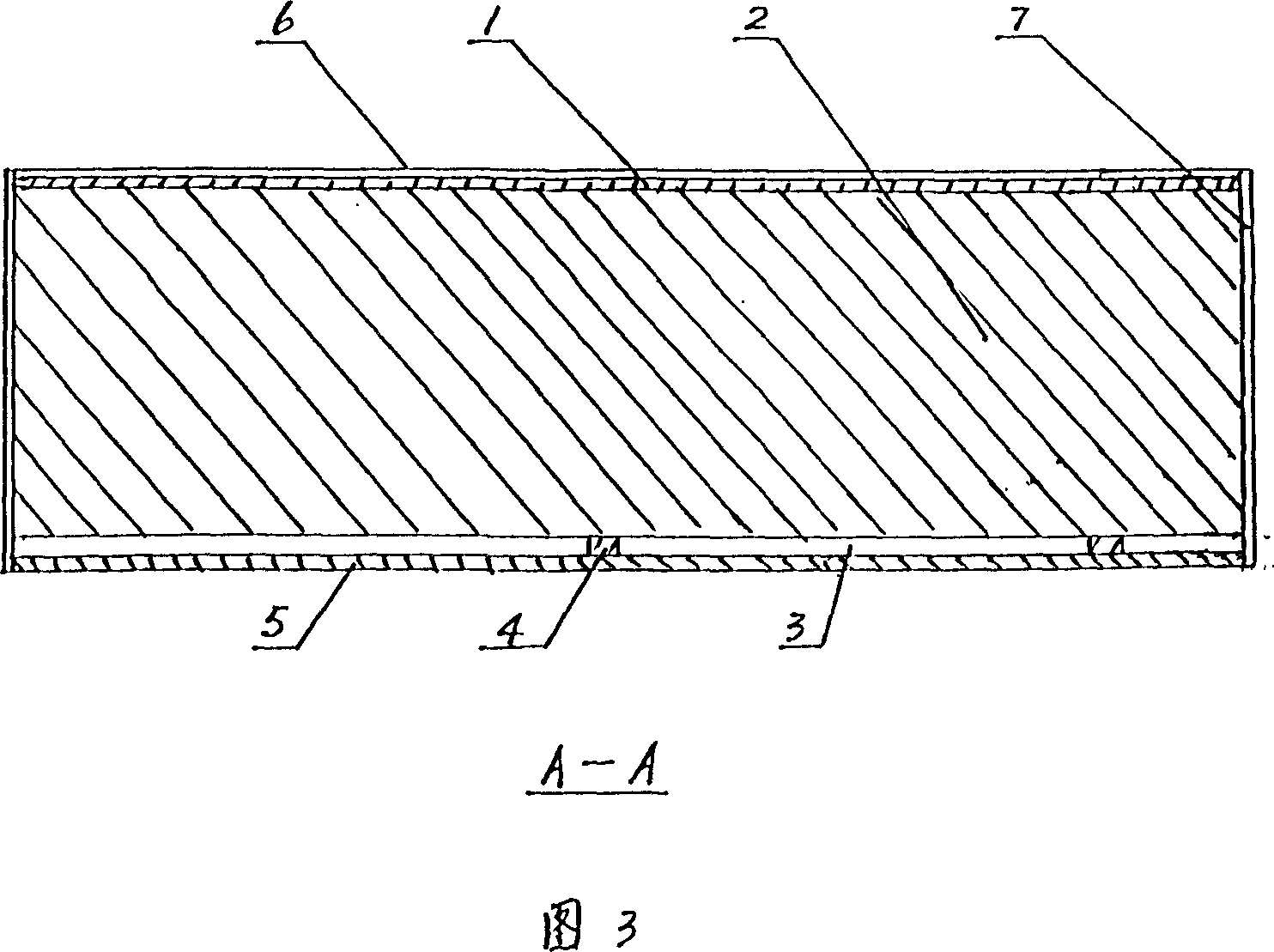

Bedplate of industrial sewing machine fabricated by mixing sawdust, wood wool, and wood

InactiveCN1958918ASave dataReduce adverse effectsSewing-machine elementsWood working apparatusWood shavingsWood wool

The present invention relates to a kind of industrial sewing machine table made up by using sawdust, wood shavings and waste wood material as main raw material through a certain production process. Said production process includes the following steps: screening raw materials, drying and cooling, injecting glue and stirring, filling mould, hot-pressing and forming.

Owner:曾昭富

Method for producing high strength wood-filament board

A high-strength wooden shred board with high mechanical properties and high heat and sound insulating performance is prepared from wooden shreds (60-300 mm *0.3-4mm*0.2-1.5 mm) through producing wood ply, slitting to obtain said wooden shreds, applying organic adhesive, stirring in drum, spreading, pressing, curing and trimming.

Owner:ZHEJIANG JIUCHUAN BAMBOO & WOOD

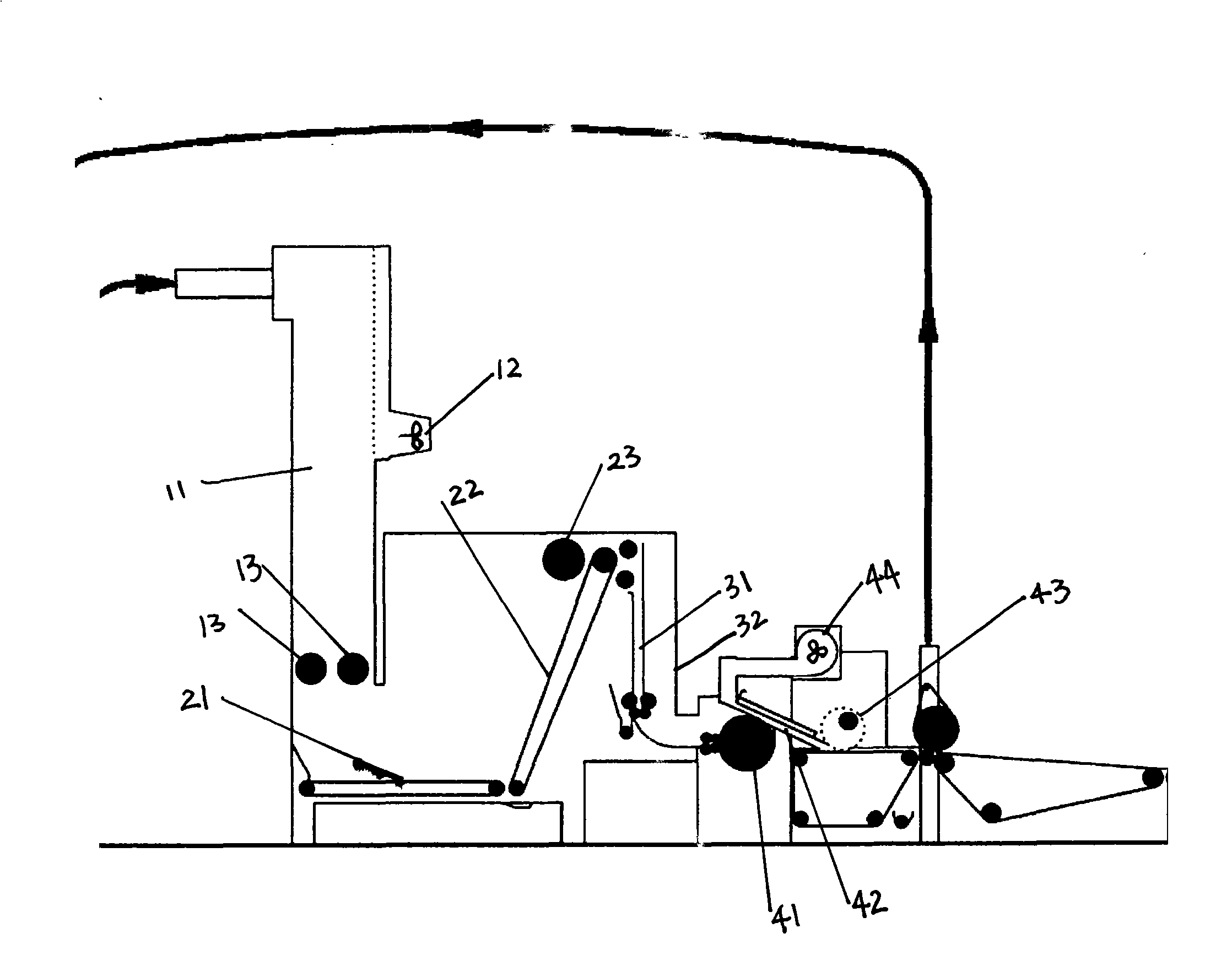

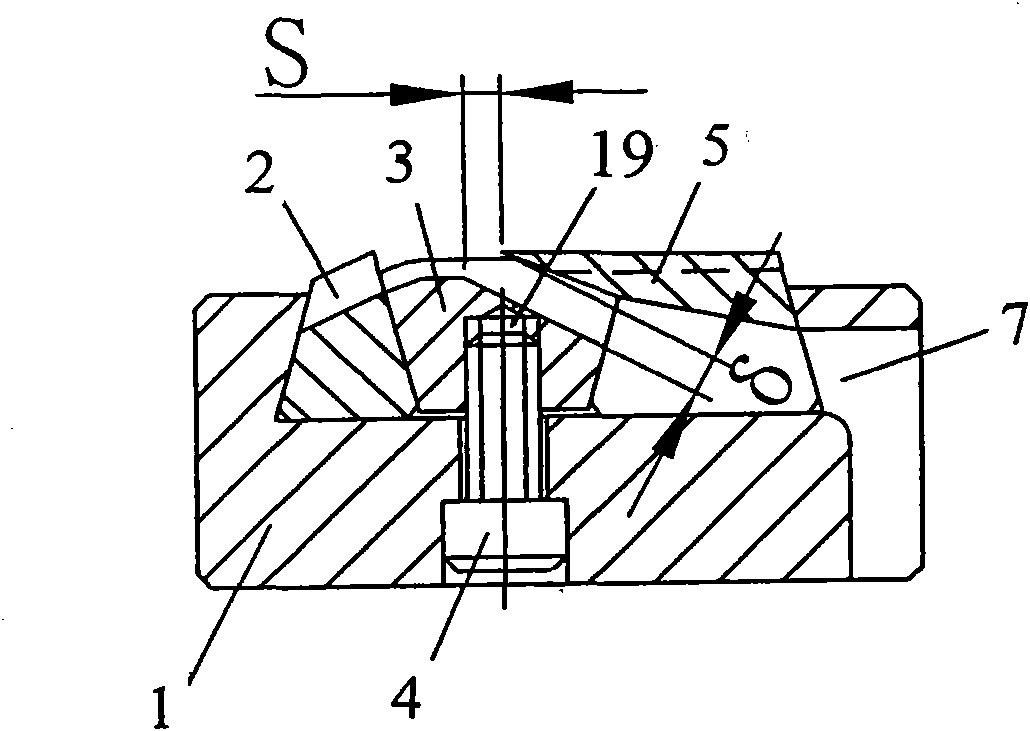

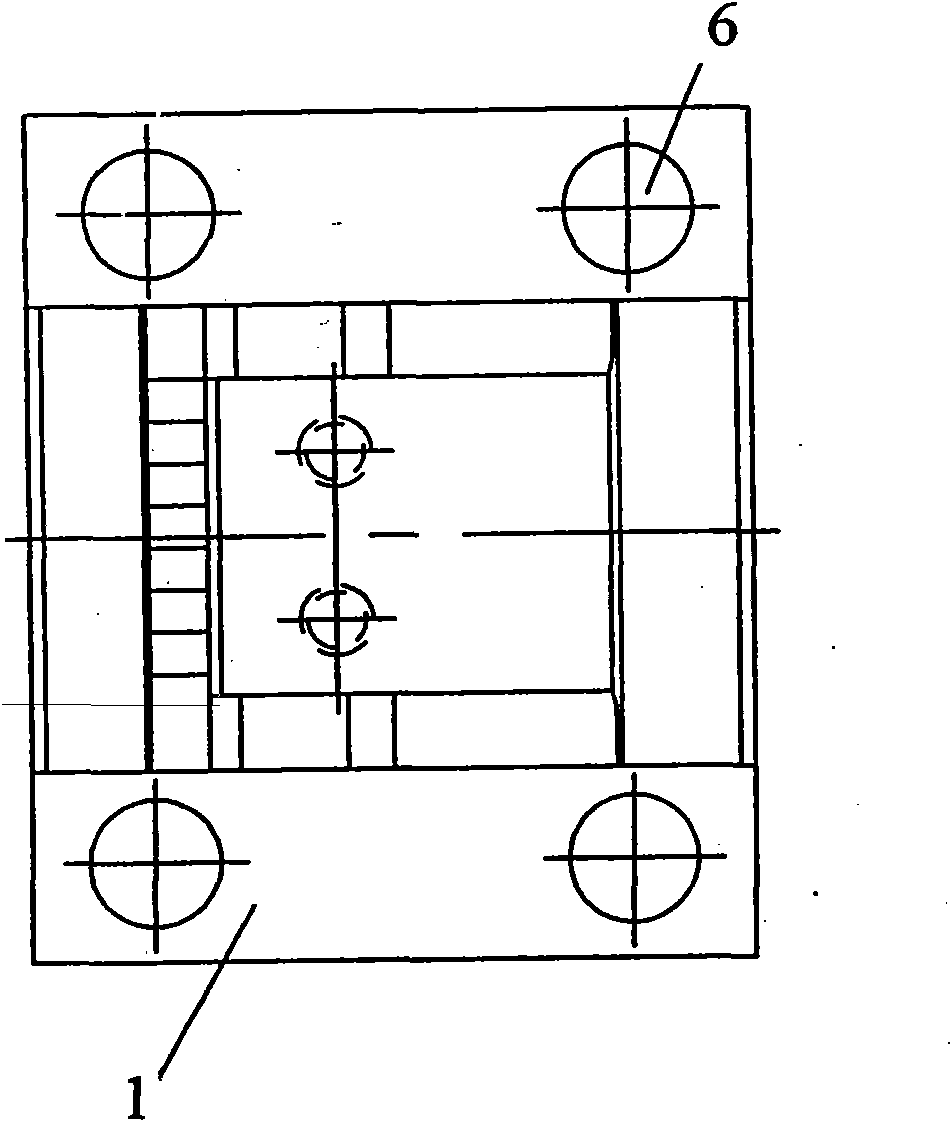

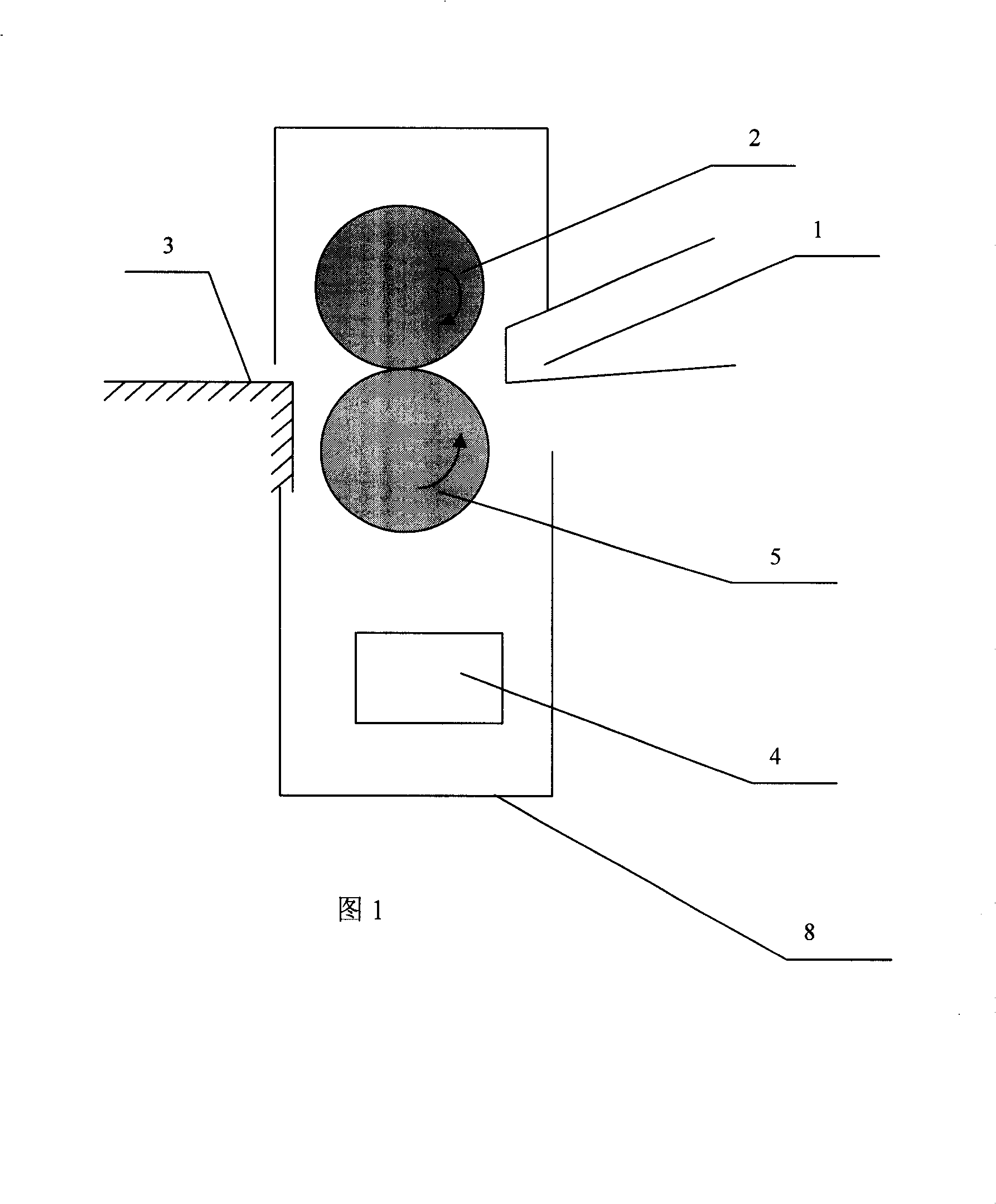

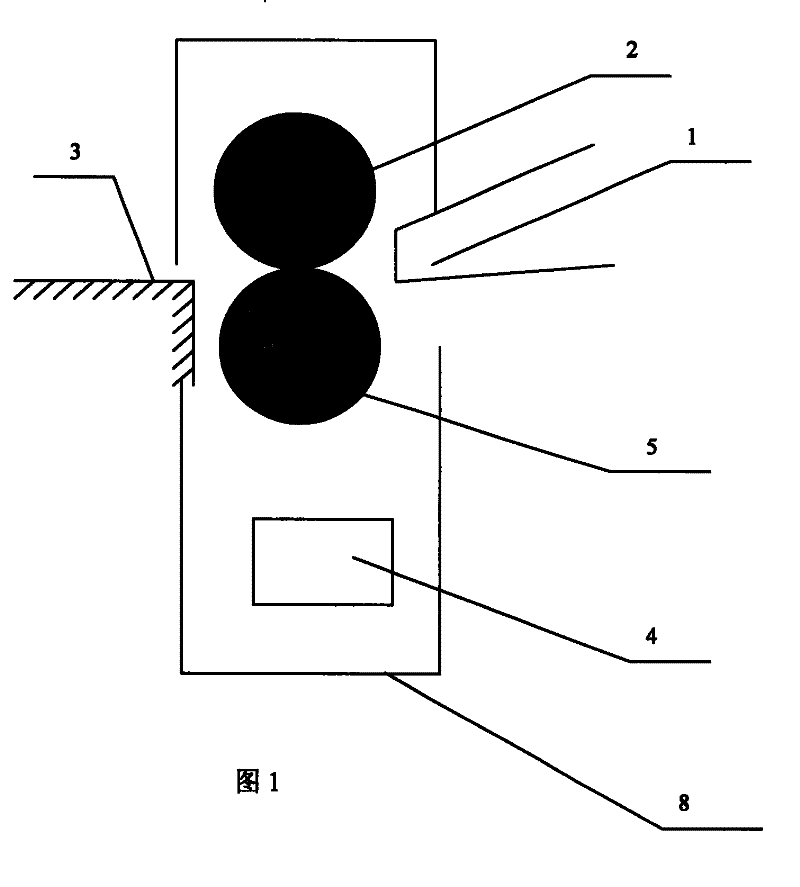

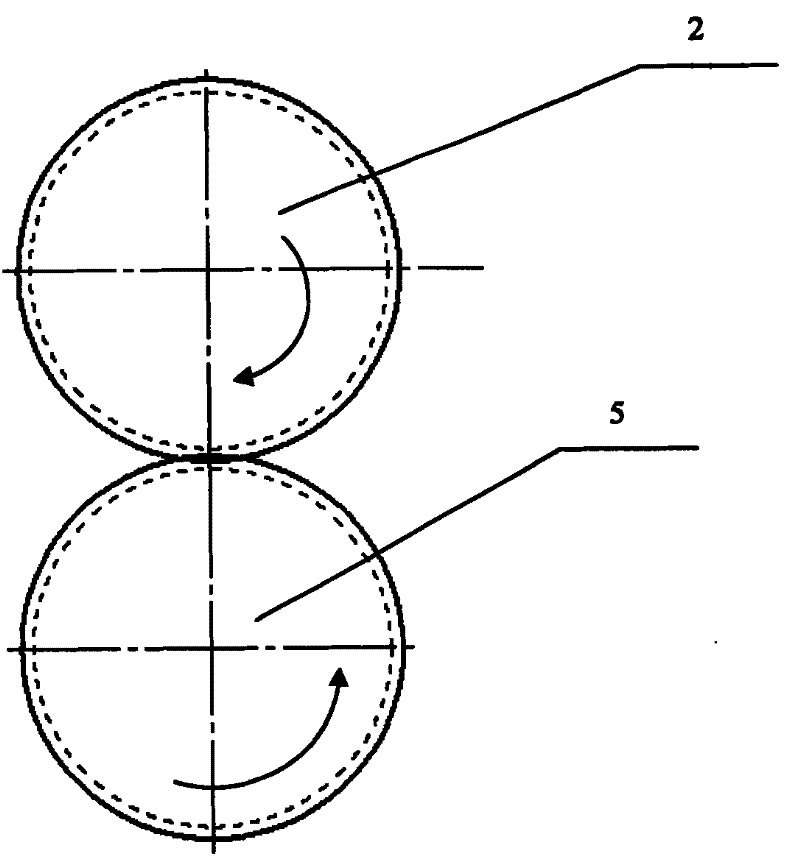

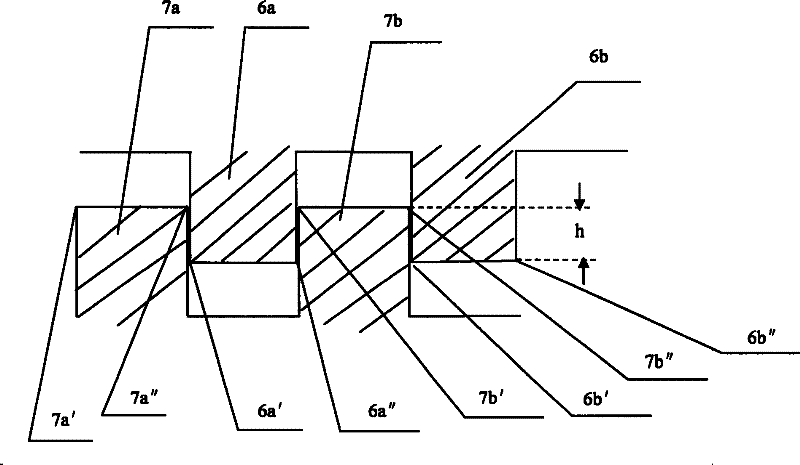

Apparatus for producing wood-wool and equipment thereof

The invention discloses a device for preparing wood wools and equipment thereof; the device includes a feed device, a discharge device and a breaking device arranged between the feed device and the discharge device; the breaking device is driven by a motor; the invention is characterized in that the breaking device is provided with breaking rollers that are arranged in pairs; the breaking rollers are arranged in that crushed aggregates of a single board are fed between the breaking rollers along the fiber direction and are sheared into the wood wools when passing through the breaking rollers; the equipment or device of the invention shears the crushed aggregates of the single board into the wood wools by shearing action by the breaking rollers with cylinderknives in pairs, which not only effectively utilizes high grade logs with good quality and greatly reduces the cost of wood wool plates, but also improves the property of the wood wool plates. The property of the wood wool plates manufactured by the wood wools produced by the invention can meet the requirement of 'Standard for a Flakeboard with an Oriented Structure LY / T1580-2000'.

Owner:BEIJING FORESTRY UNIVERSITY

Novel manufacturing method for fish taxidermy prosthesis specimens

The invention relates to the technical field of manufacturing of fish taxidermy prosthesis specimens, in particular to a novel manufacturing method for the fish taxidermy prosthesis specimens. Compared with the mode that in the prior art, straw, wood bits and wood wool are used as filling materials for manufacturing prostheses, polystyrene is used as a manufacturing material for the prostheses, and the novel manufacturing method has the advantages of being light and convenient to use and preventing mildewing, rotting and worm damage. Compared with the mode that in the prior art, a polyurethanefoaming agent is used for manufacturing the prostheses, the novel manufacturing method using the polystyrene as the manufacturing material for the prostheses has higher bearing capacity, can adapt tolarge fish specimens which are thick in hide and skin and heavy, and avoids that sinking occurs in the surfaces of the specimens; the method is not limited to manufacturing of rod-shaped or fusiform-shaped fish specimens, and can adapt to manufacturing of flat type (sea purse and stingray types) fish specimens.

Owner:SHANGHAI OCEAN UNIV

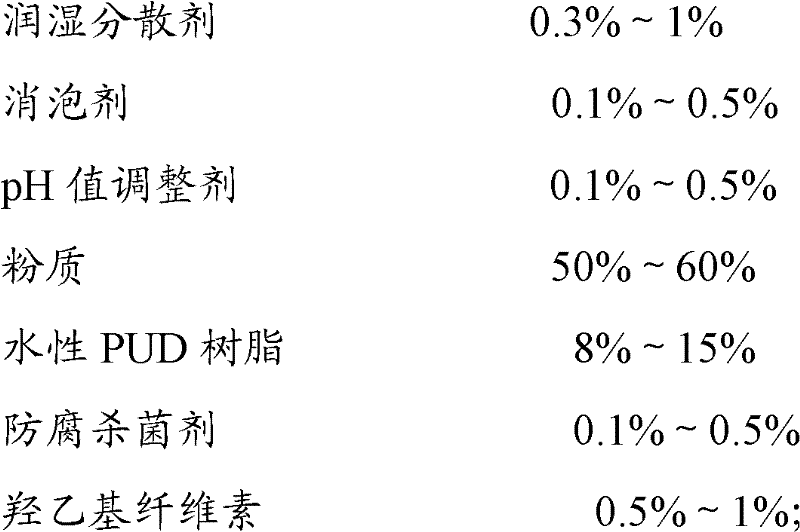

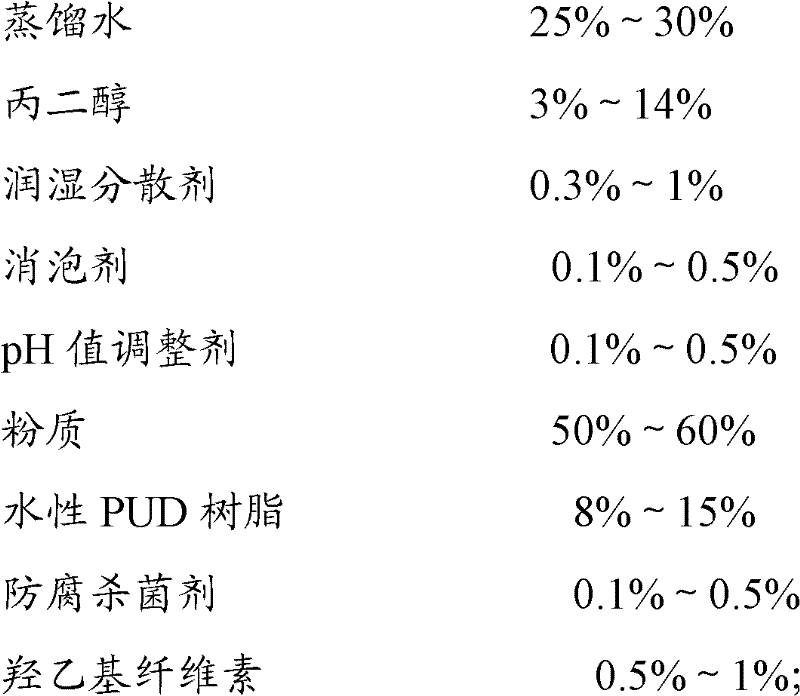

Aqueous wood-wool filling agent coated onto woodware and preparation method thereof

The invention relates to the technical field of woodware coatings, in particular to an aqueous wood-wool filling agent coated onto a woodware, and a preparation method thereof. The aqueous wood-wool filling agent coated onto the woodware comprises distilled water, propylene glycol, a wetting dispersant reagent, a defoaming agent, a pH value regulating agent, powdery matter, aqueous polyurethane dispersoid (PUD) resin, antiseptic bacteriacide and droxyethylcellulose. The aqueous wood-wool filling agent coated onto the woodware is prepared through adding the materials at different time at different stirring speed. The aqueous wood-wool filling agent coated onto the woodware not only can be directly used without being diluted by a solvent, has short drying time and can be directly coated with primer without polish, but also can be manually operated and is environmentally friendly, and especially, the adhesion of the primer can be enhanced after the aqueous wood-wool filling agent coated onto the woodware is wiped and dried.

Owner:东莞大宝化工制品有限公司 +1

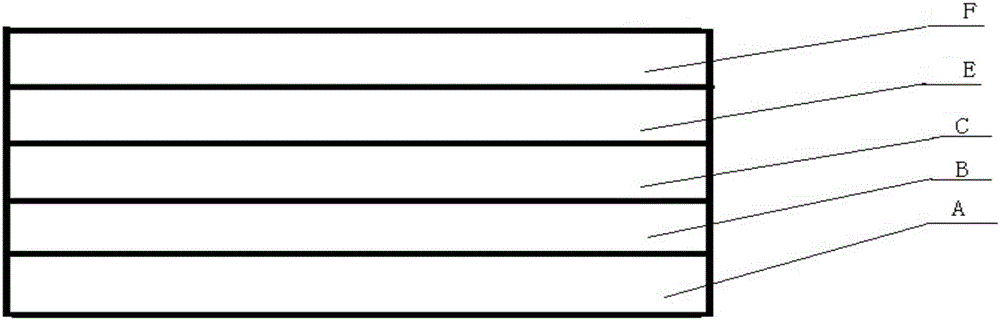

Radiation curable coating decorative board

InactiveCN106013672ALow costRaw materials are easy to getAntifouling/underwater paintsCovering/liningsWater basedHardness

The invention discloses a radiation curable coating decorative board. The radiation curable coating decorative board comprises a decorative board base body A. The surface of the decorative board base body A is coated with a radiation curable color primer layer B and a radiation curable color coating or printing ink layer C in sequence. Preferably, the surface of the radiation curable color coating or printing ink layer C is also coated with a transparent varnish layer D, a water-based inorganic gel layer E and a water-based photocatalyst sterilizing and anti-staining layer F. Compared with the prior art, an oriented strand board or an oriented stalk board or a wood-wool board or a straw board or a bamboo wool board is adopted as the base body of the decorative board, raw materials are easy to get, the cost is low, and the radiation curable coating decorative board has the advantages of being good in wear-resisting property and environmental protection property, rich in color and pattern, strong in three-dimensional sense, high in hardness, resistant to scratches, contamination and bacteria, easy to clean, capable of killing bacteria and the like and can be widely used in the fields such as partition walls, partitions, ceilings, walls, furniture and office table tops.

Owner:ZHUHAI JIAWEILI ENVIRONMENTAL PROTECTION SCI & TECH

Fire-proof sound insulation shock-proof plate and its producing method

InactiveCN1900440AImprove insulation performanceImprove sound absorptionConstruction materialSolid waste managementChlorideFire retardant

The disclosed board includes a wood-fiber layer and a cement layer. Pressing majority of wood-fiber with mixed calcium chloride, fire retardant, and a little cement produces wood-fiber layer. Mixing cement with resin produces the said cement layer. The inner side of cement layer is bonded to one side of the wood-fiber layer. The method includes following fabricating steps: first, cutting wood to fiber; next, pressing mixed calcium chloride, fire retardant, and cement produces tabular wood-fiber layer; then placing wood-fiber layer into die with cement and resin being filled to; finally, drying and molding.

Owner:官易泽

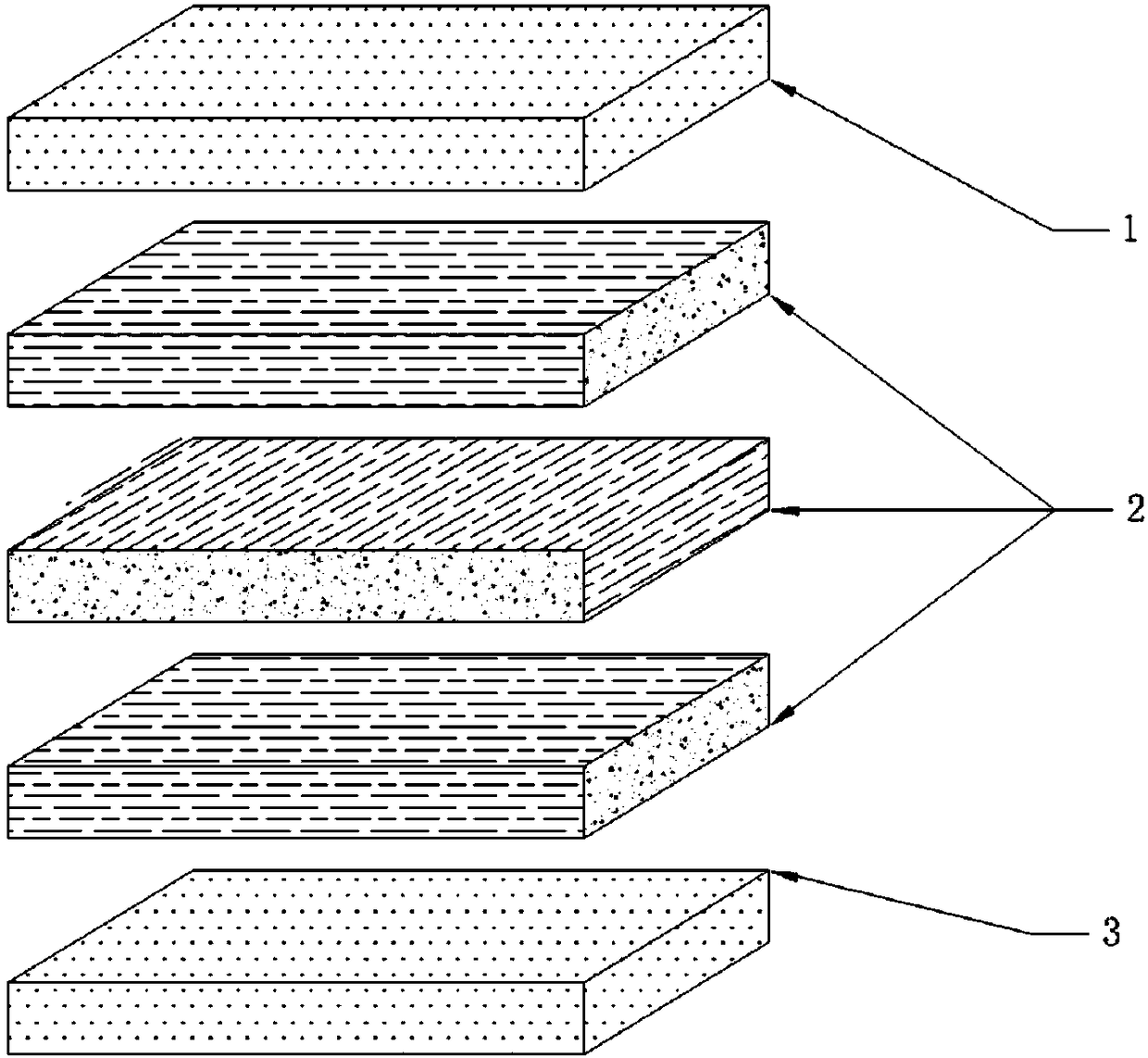

Wood-wool reinforced straw stalk board and preparation method thereof

PendingCN108544628AAct as a skeleton supportLow densityLaminationWood working apparatusSurface layerWood wool

The invention discloses a wood-wool reinforced straw stalk board and a preparation method thereof, and belongs to the technical field of artificial boards. The board comprises a surface layer, a corelayer and a bottom layer which are sequentially arranged from top to bottom, wherein the surface layer and the bottom layer are straw stalk layers, the core layer is formed by stacking and placing a plurality of layers of wood-wool straw stalk layers together, wherein each wood-wool straw stalk layer is composed of wood wool and straw stalks, the wood wool are arranged in a directional mode in thewood-wool straw stalk layers, and the wood wool in every two adjacent wood-wool straw stalk layers are perpendicular to each other; and the straw stalks in the wood-wool straw stalk layers are arranged in a gap of the wood wool to play a role in filling. According to the board and the method, a three-layer directional space structure of the wood wool and the straw stalks is constructed to serve as the core layer of the straw board, the wood wool can play a framework supporting role in the plates, a structure with a stable size is formed between the wood wool and the straw stalks, so that thedensity of the straw stalk board is reduced, the consumption of raw materials is reduced, and the light weight of the straw stalk board is realized.

Owner:HUNAN ACAD OF FORESTRY

Production process for wooden door

The invention discloses a production process for a wooden door, and relates to the field of furniture fitting production methods. The production process includes the steps of board drying, board pressing, cutting, sanding, framing, wood wool removing, paint spraying, drying and package molding. According to the step of wood wool removing, a primer material layer, a secondary slurry layer and an upper-layer polyurethane external photocurable varnish material surface layer with the thicknesses being 0.2-0.4mm are sequentially coated on the surface of the wooden door to serve as a bottom layer, a middle layer and an upper layer of a wooden door surface protective layer in sequence, and then standing lasts for 10-12 minutes; after the upper layer of the protective layer is cured, wood wool exposed out of the surface is swelled and erected, and fiber zymolase is sprayed onto the upper layer and can dissolve the wood wool; and the upper layer is cleaned with clear water and then is dried. By the adoption of the production process for the wooden door, the wood wool can be well removed, and the smoothness of a paint film is improved.

Owner:CHONGQING KUNXIU DOOR & WINDOW

Cement wood-wool acoustic board and preparation method thereof

The invention relates to a cement wood-wool acoustic board. The cement wood-wool acoustic board comprises the following components in parts by mass: 100 parts of magnesia, 60-100 parts of water, 30-50 parts of magnesium chloride, 50-80 parts of wood-wool, 20-70 parts of ferrous sulfate, 1-25 parts of a reinforcing agent, 1-10 parts of a heat enhancer, 5-8 parts of a filling agent, 0.1-5 parts of titanium pigment and 1-10 parts of a foaming agent. The cement wood-wool acoustic board is excellent in water resistance, corrosion-free and acid-alkali-resistant, cannot generate shrinkage cracks, has a good heat preservation effect, is resistant to ultraviolet irradiation, and cannot deform easily after moisture absorption; the heat conductivity of the product is 0.1-0.15, the compressive strength is 0.2-0.4Mpa, the acoustic absorption coefficient is up to 0.5, the water absorptivity is 0.8-0.9, the density is 0.9-1.5, and the cement wood-wool acoustic board can be self-distinguished in 5 seconds, so that the cement wood-wool acoustic board can be widely used and continuously replace the existing materials.

Owner:NANJING FORESTRY UNIV

Apparatus for producing wood-wool and equipment thereof

The invention discloses a device for preparing wood wools and equipment thereof; the device includes a feed device, a discharge device and a breaking device arranged between the feed device and the discharge device; the breaking device is driven by a motor; the invention is characterized in that the breaking device is provided with breaking rollers that are arranged in pairs; the breaking rollersare arranged in that crushed aggregates of a single board are fed between the breaking rollers along the fiber direction and are sheared into the wood wools when passing through the breaking rollers;the equipment or device of the invention shears the crushed aggregates of the single board into the wood wools by shearing action by the breaking rollers with cylinderknives in pairs, which not only effectively utilizes high grade logs with good quality and greatly reduces the cost of wood wool plates, but also improves the property of the wood wool plates. The property of the wood wool plates manufactured by the wood wools produced by the invention can meet the requirement of 'Standard for a Flakeboard with an Oriented Structure LY / T1580-2000'.

Owner:BEIJING FORESTRY UNIVERSITY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com