Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Act as a skeleton support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piezoelectric ultrasonic transducer

InactiveCN101121165AIncrease powerImprove efficiencyMechanical vibrations separationSound producing devicesAuditory radiationUltrasonic sensor

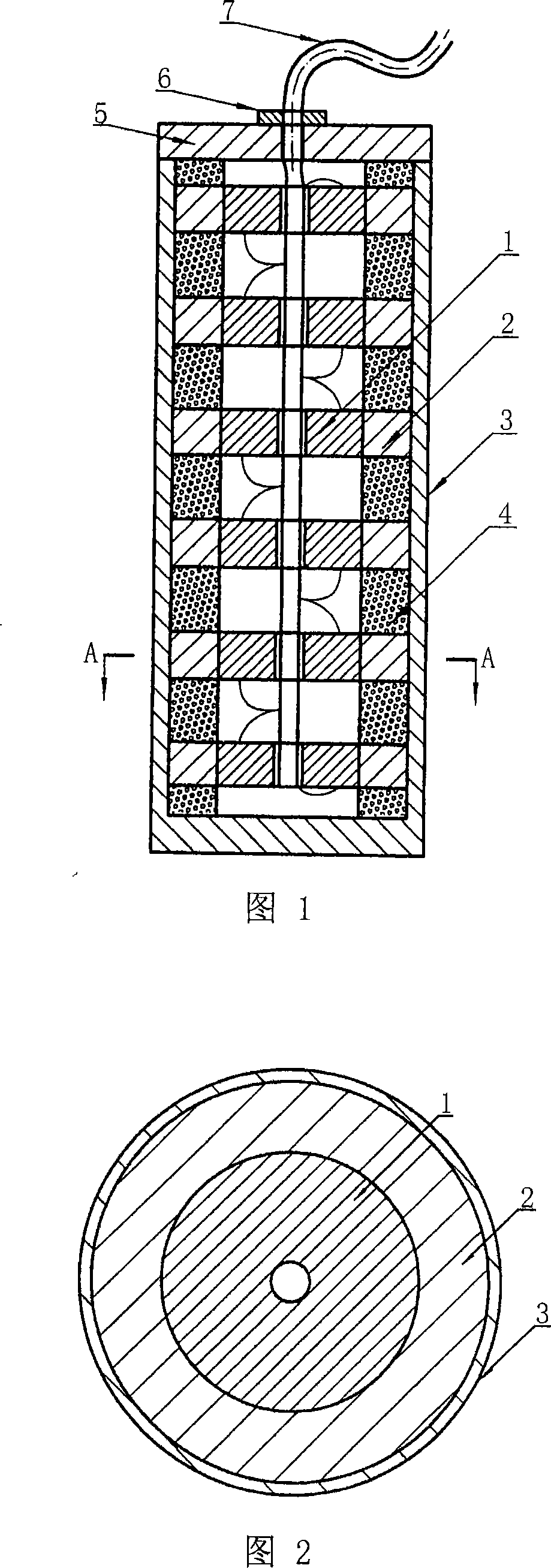

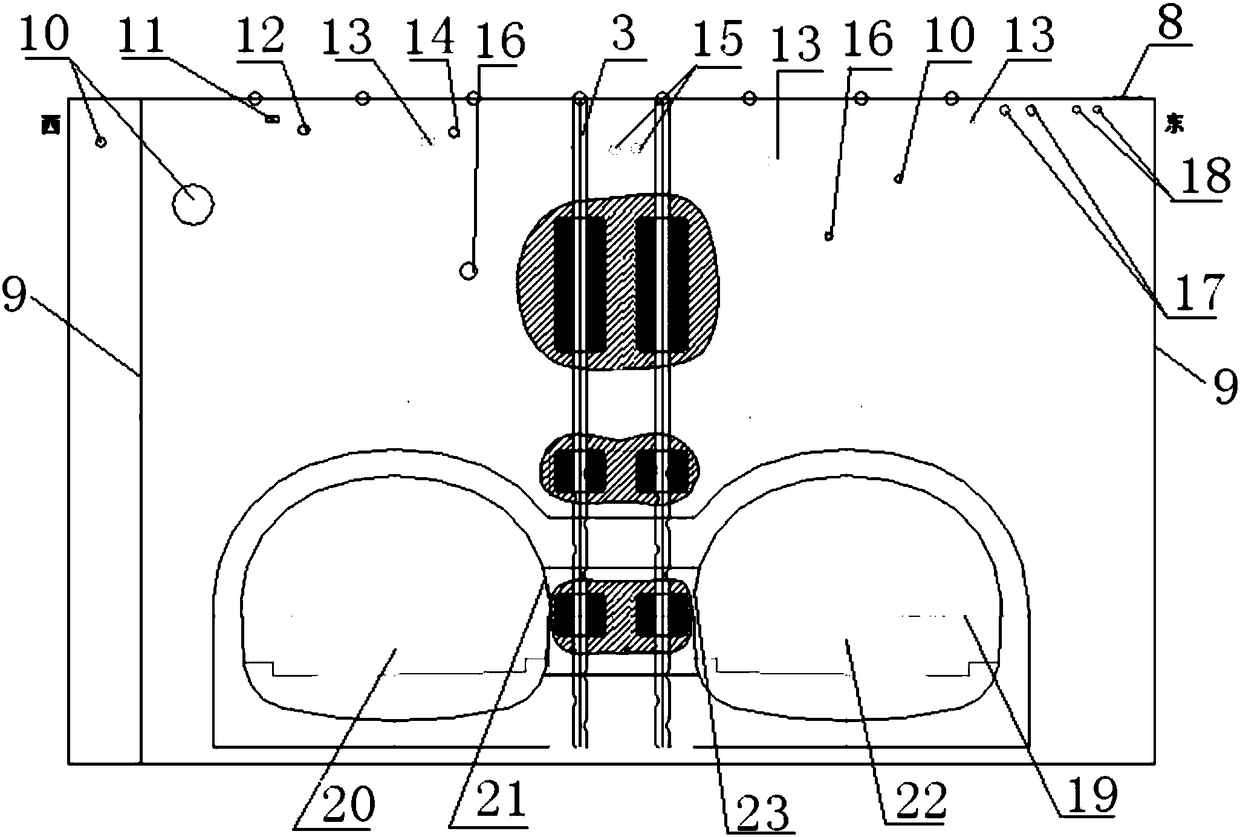

The invention relates to a high-power radial vibration piezoelectric ultrasonic transducer suitable for liquid ultrasonic treatment under normal pressure and high pressure. The purpose of the present invention is to provide a high structural strength, high power density, which can generate uniform sound radiation in the radial direction of 360°, aiming at the defects of low structural strength and low power density of existing ultrasonic transducers, It is a high-power radial vibration piezoelectric ultrasonic transducer especially suitable for liquid ultrasonic treatment under normal pressure and high pressure. The invention comprises a piezoelectric ceramic disc, a prestressed annular cover plate, a cylinder body, an insulating vibration-isolating ring pad and an end cover, wherein a through hole is arranged on the piezoelectric ceramic disc, and the side of the piezoelectric ceramic disc and the prestressed annular cover plate The composite disk piezoelectric transducer is formed by radial compounding. Several composite disk piezoelectric transducer units whose geometric parameters are consistent with the radial resonance frequency are connected in electrical parallel, and are closely fixed on the inner wall of the cylinder at equal intervals. An insulating vibration-isolating ring pad is arranged between two adjacent composite disc piezoelectric transducer units.

Owner:ZHEJIANG NORMAL UNIVERSITY

Low-density and high-strength ceramic proppant and production method thereof

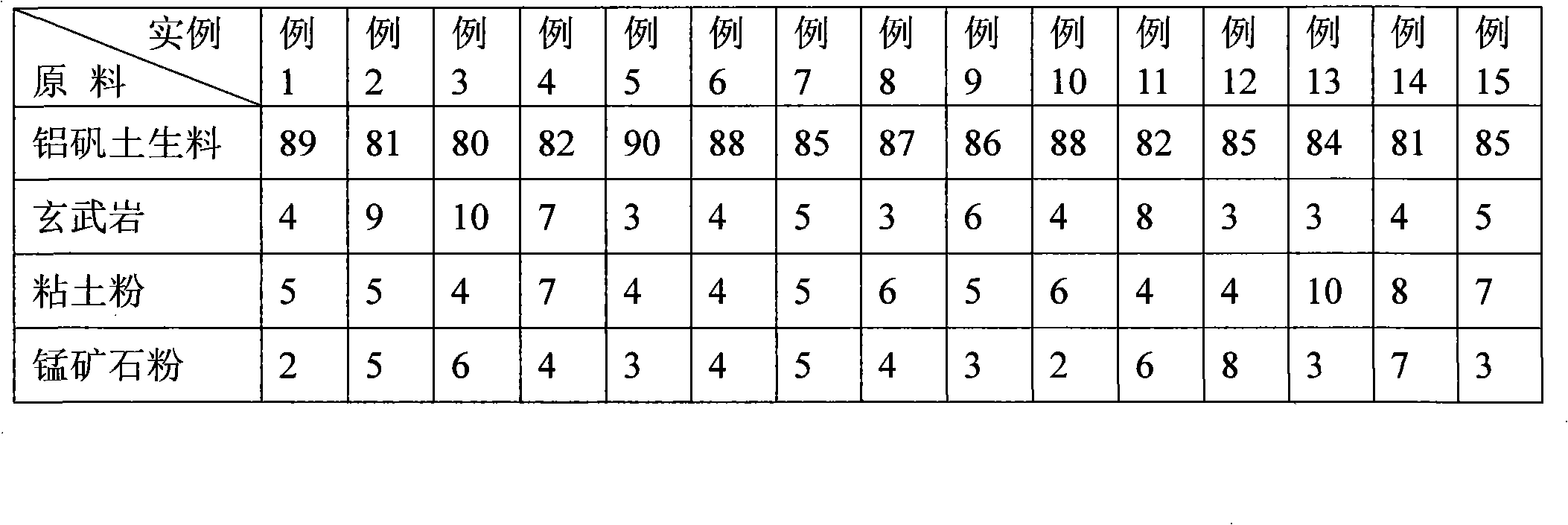

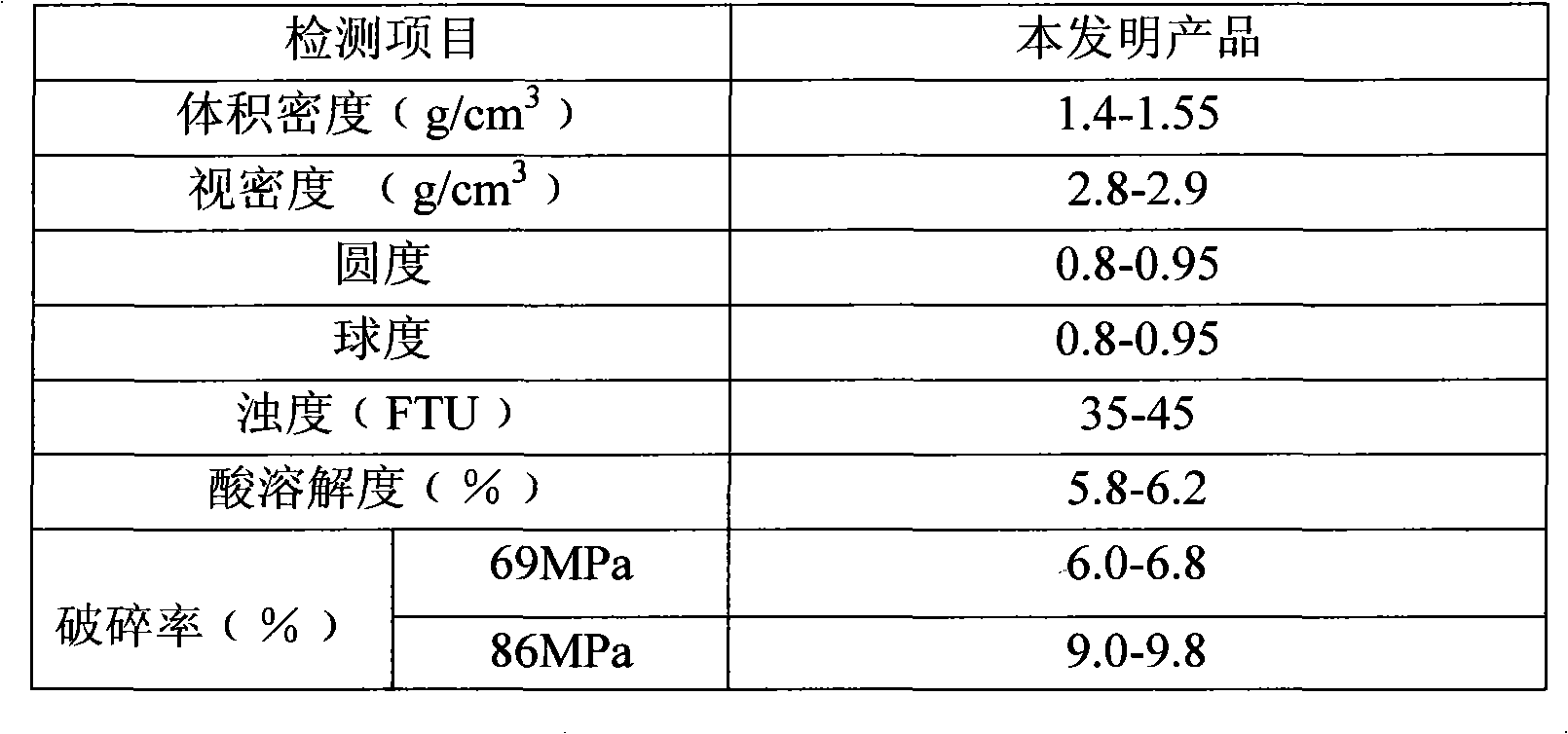

InactiveCN101831286AHigh surface finishGuaranteed StrengthFluid removalClaywaresExpanded clay aggregateMixed materials

The invention relates to a low-density and high-strength ceramic proppant and a production method thereof. The raw material comprises 80 to 90% of raw bauxite, 3 to 10% of basalt, 4 to 10% of clay silt, 4 to 10% of clay powder and 2 to 8% of manganese ore powder. The production method comprises the following steps of: firstly, weighing the raw materials in production, grinding the raw materials into fine powder, filtering the fine powder by a sieve of 320 meshes, uniformly mixing and stirring the powder and pelletizing the mixed material, and adding the atomizing steam till the mixed materialform semi-finished pellets; secondly, baking the semi-finished pellets in a rotary kiln for 6-8h, to obtain the finished product, wherein the temperature of the kiln head is 1280 to 1310 DEG C and the temperature of the kiln tail is 290 to 320 DEG C. The damage rate of the product of the invention at the pressure of 69 MPa and 86 MPa are respectively lower than 6.8% and 9.8%; the volume densityis only 1.45 to 1.55 g / sq.cm and obviously lower than the like products; and the product has higher strength. The invention has the advantages of less and easily obtained needed raw materials in the formulation, simplification of the production process, little investment, low cost and easy popularization and application.

Owner:郑州德赛尔陶粒有限公司

Rigidity enhanced, modified dedicated material of plastic pipe material

This invention relates to a specific modification material for increasing the rigidity of plastic pipes. The specific modification material is composed of: ultra-fine talcum powder 20-30 parts, toughening agent 10-15 parts, coupling agent 1-2 parts, plasticizer 5-8 parts, dispersant 3-5 parts, and high density polyethylene (HDPE) 50-55 parts. Plastic pipes modified with the specific modification material have rigidity 5-6% higher than that of neat HDPE pipes, thus can solve the problems of easy deformation, large influence to ground smoothness and easy breakage of HDPE pipes. Besides, plastic pipes modified with the specific modification material have improved impact strength and physical properties. Talcum powder can partly replace synthetic resin to reduce the cost.

Owner:辽宁艾海滑石有限公司

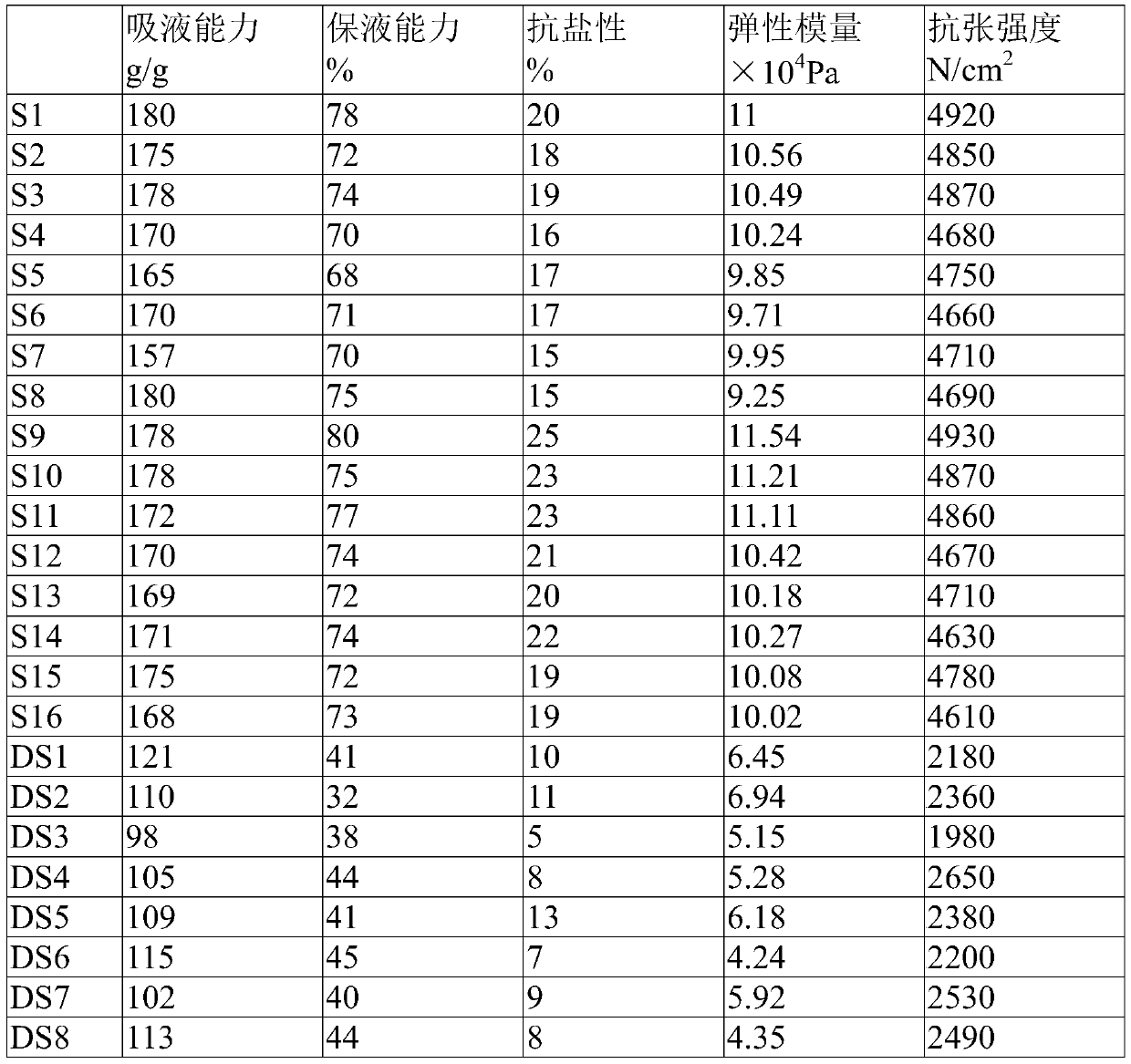

Expansion lost circulation additive, preparation method of expansion lost circulation additive, microcapsule-type lost circulation additive, water-based drilling fluid and application of lost circulation additives

ActiveCN109796941APromote degradationHigh strengthSolid waste managementDrilling compositionLost circulationPetroleum engineering

The invention relates to the field of drilling fluid treatment agents and discloses an expansion lost circulation additive, a preparation method of the expansion lost circulation additive, a microcapsule-type lost circulation additive, a water-based drilling fluid and application of the lost circulation additives. The expansion lost circulation additive is prepared in the mode that acrylamide, a strength improvement material, acrylate and gelatinization colloid are subjected to a polymerization reaction, acrylate is prepared in the mode that an acidity neutralizer and acrylic acid are subjected to a neutralization reaction, and the gelatinization colloid is prepared in the mode that starch is added to deionized water for a gelatinization reaction. The expansion lost circulation additive for the drilling fluid is stable in structure, high in strength, good in viscoelasticity, does not easily deform under the high-temperature and high-pressure environment of a well bottom and has a lostcirculation stopping effect.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of high-volume silicon-carbon negative electrode material

The invention relates to a method for preparing a modified graphite negative electrode material of a lithium ion power battery. The method particularly comprises the following steps: adding asphalt and resin into a kneading kettle with heating and stirring devices, heating until the asphalt and the resin are melted into liquid, continuously stirring, stopping heating after mixing uniformly and cooling to obtain a composite coating material block; performing coarse crushing on the composite coating material block and performing ultrafine crushing by using an airflow crushing machine or a cryogenic crushing machine to obtain composite coating material ultrafine powder; completely mixing the composite coating material ultrafine powder and graphite to obtain uniform powder; and performing heating, heat preservation and natural cooling on the uniform powder under the protection of inert gas, and sieving after cooling to obtain the modified graphite negative electrode material of the lithium ion power battery. The most outstanding innovation points are that the coating material precursor is subjected to compound treatment and coated by the graphite; the mixing uniformity of various coating material precursors is guaranteed, any solvents are not required, and environmental friendliness is realized; in addition, the process is simple, low in cost and easy in industrialized production.

Owner:SHENZHEN SINUO INDAL DEV

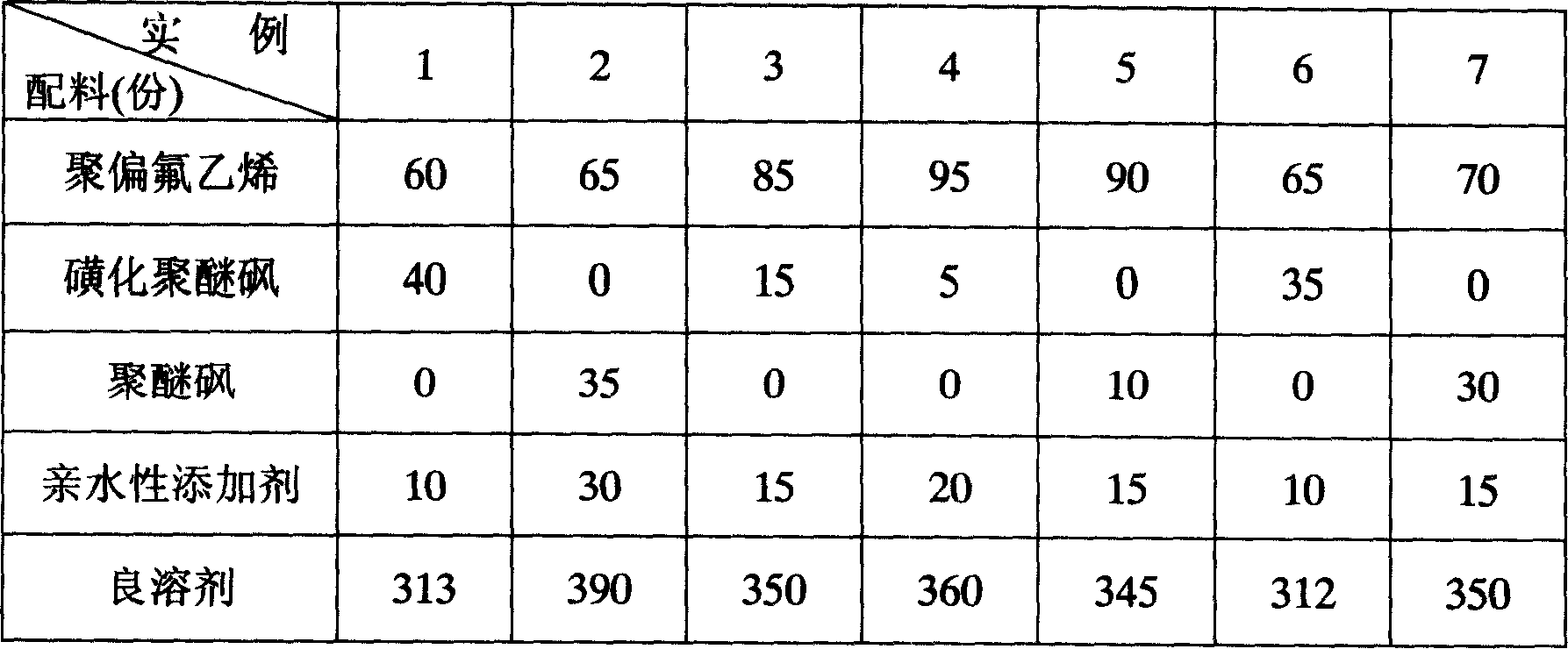

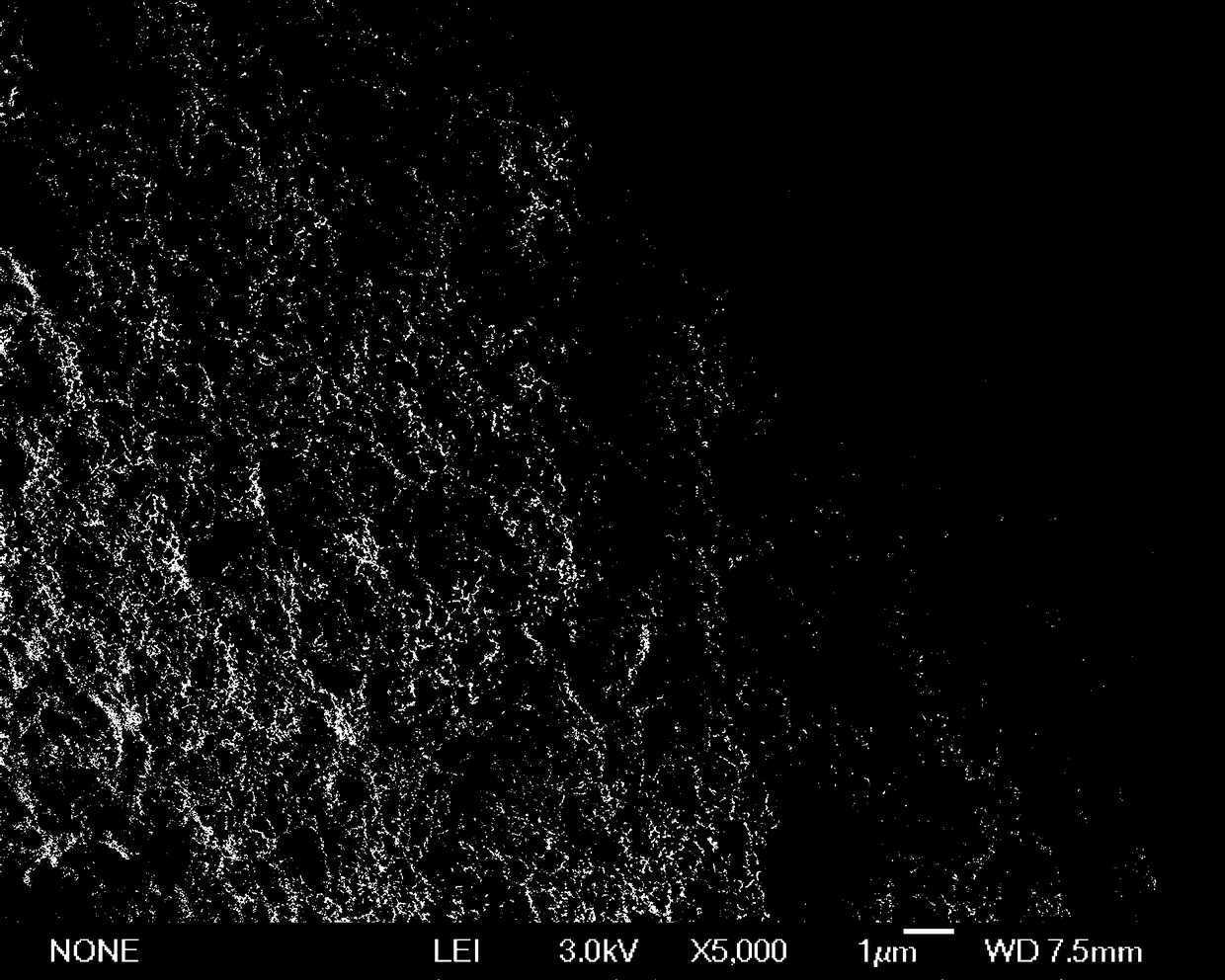

Formula of preparation liquid for hollow-fibre membrane and products thereof

InactiveCN1593734AMaintain stabilityReasonable ingredientsSemi-permeable membranesPolymer sciencePolyvinyl alcohol

The invention relates to a kind of hollow fiber membrane, especially a hollow fiber membrane formula with mixing hydrophilic poly-biasfluorine ethylene and its products. Raw material of this membrane is the mixture of poly-biasfluorine ethylene and sulfonated poly-ethersulphone or the mixture of bias fluorine polyethylene and poly-ethersulphone. Then the mixture reacts with hydrophilic additive that is polyethylene pyrrolidone or polyvinyl alcohol, then forms the hydrophilic hollow fiber membrane by the way of chemical grafting. Poly-biasfluorine ethylene has nice flexibility and poly-ethersulphone or sulfonated poly-ethersulphone has high intensity, so mixing them can make advantages for them of their abilities. In the result, it can make the resulting hollow fiber membrane have the high water flux and the temperate intensity, can improve hydrophilicity and stability of it, and can make it have longer service life. This membrane can be used extensively in the fields such as Medicine, Sanitation, Foodstuff, Industry and so on.

Owner:ZHEJIANG OMEX ENVIRONMENTAL ENG CO LTD

Phosphorus-accumulating bacteria immobilized small balls and application thereof

ActiveCN108359663AHigh activityLarge adsorption capacityWater contaminantsOn/in organic carrierSorbentBiocompatibility Testing

The invention discloses phosphorus-accumulating bacteria immobilized small balls prepared by the following steps: preparation of a bacterial suspension; adsorption with activated carbon; preparation of a gamma-polyglutamic acid / chitosan oligosaccharide hydrogel; preparation of a composite embedded carrier aqueous solution; and preparation of the phosphorus-accumulating bacteria immobilized small balls. The invention also discloses an application of the phosphorus-accumulating bacteria immobilized small balls in treatment of phosphorus-rich waste water. The prepared phosphorus-accumulating bacteria immobilized small balls have the advantages of high activity, large adsorption capacity and good mechanical strength. With activated carbon as an adsorbent, the biosorption capacity of the phosphorus-accumulating bacteria immobilized small balls is significantly increased, the skeleton supporting role can also be played, and the mechanical strength of the phosphorus-accumulating bacteria immobilized small balls is enhanced; the gamma-polyglutamic acid / chitosan oligosaccharide hydrogel has the advantages of good biocompatibility, high viscosity, no toxicity, and good environmental friendliness, and significantly promotes the activity and adsorption capacity of the phosphorus-accumulating bacteria immobilized small balls, can also improve the mechanical strength and water content of thesmall balls, and enlarges the pore size of scaffolds in the phosphorus-accumulating bacteria immobilized small balls.

Owner:QUFU NORMAL UNIV

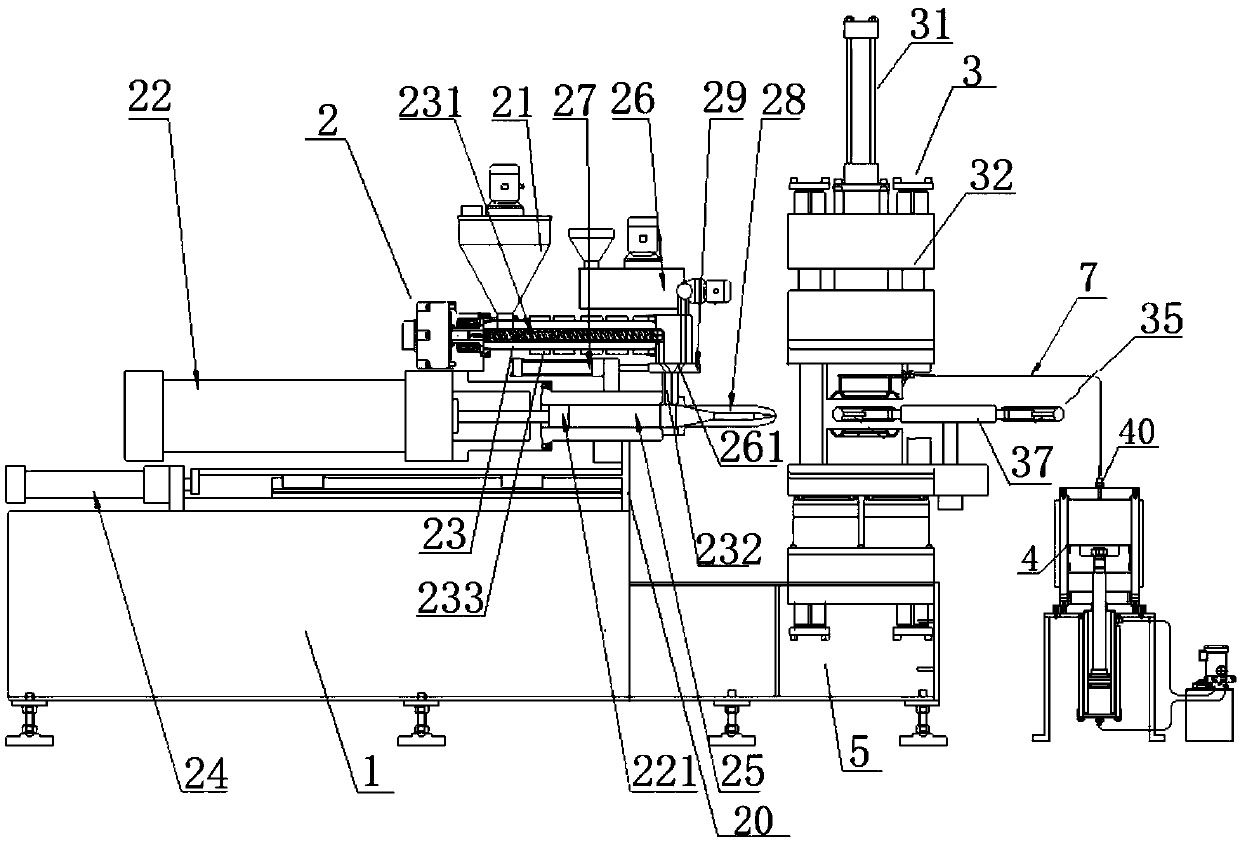

Vacuum plastic-absorbing molding process and device for reclaimed leather skin of automobile column plaque

The invention provides a vacuum plastic-absorbing molding process and device for reclaimed leather skin of an automobile column plaque. Thermoplastic synthetic fibers of a skin-core structure are evenly mixed with animal skin fibers to form a net, and through the spunlace or needle-punching non-weaving process, reclaimed leather mixed with the skin-core type thermoplastic synthetic fibers for the automobile column plaque is obtained; and in the vacuum plastic-absorbing molding procedure, by means of the vacuum plastic-absorbing molding device provided by the invention, multi-station integrated molding of the reclaimed leather skin of the automobile column plaque is achieved through the stations of reclaimed leather roll spreading, precise-temperature-control heating, fixing and vacuum plastic absorbing of the molded skin, recovery of reclaimed leather waste and the like, and the column plaque skin which is excellent in usability and formability is obtained. The vacuum plastic-absorbing molding process is simple, operation is convenient, and practicability is high.

Owner:SHANDONG UNIV +1

Method for preparing multilevel structure copper nitrate anode material

ActiveCN104993147AUniform particle sizeAct as a skeleton supportCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a method for preparing a multilevel structure copper nitrate anode material. The method comprises the steps of dissolving 100-200 g copper nitrate powder in 500 ml distilled water, adding 1-5 g carbon fiber after complete dissolution, stirring for 30 min at a high speed, then heating to 60-80 DEG C, adding 50-100 ml ethyl alcohol and 5 ml 1 mol / L glacial acetic acid, stirring for 3 min, then adding 1-2 g carbon black, and continuing to stir till complete volatilization; then, placing the obtained head product in an oven to be baked for 24 h at 60 DEG C, taking out the product, and grinding the product into powder, so that the multilevel structure copper nitrate anode material is obtained. The method has the advantage that the obtained copper nitrate anode material is of a stable multilevel composite structure, and the multilevel composite structure enables the copper nitrate anode material to have high capacity and long service life.

Owner:NINGBO UNIV

Preparation method for tin-carbon composite negative material

InactiveCN105161671AGuaranteed uniformitySimple processElectrode thermal treatmentSecondary cellsCarbon compositesGraphite

The invention provides a preparation method for a tin-carbon composite negative material. An outer layer of the tin-carbon composite negative material is a composite cladding layer jointly formed by asphalt, resin and tin powder, and an inner layer is the tin-carbon composite negative material which is composed of graphite and has a core-shell structure. In the tin-carbon composite material prepared according to the method, high specific capacity characteristic of tin is maintained, meanwhile, a modification effect on the graphite is played, the overall cyclic stability of the material is improved, the energy density of the negative material of a lithium ion battery is improved, thus, the negative material has higher specific capacity than the carbon negative material commonly used in the lithium ion battery in the current market, and the increasing energy density requirement of various portable electric devices on the battery is met.

Owner:田东

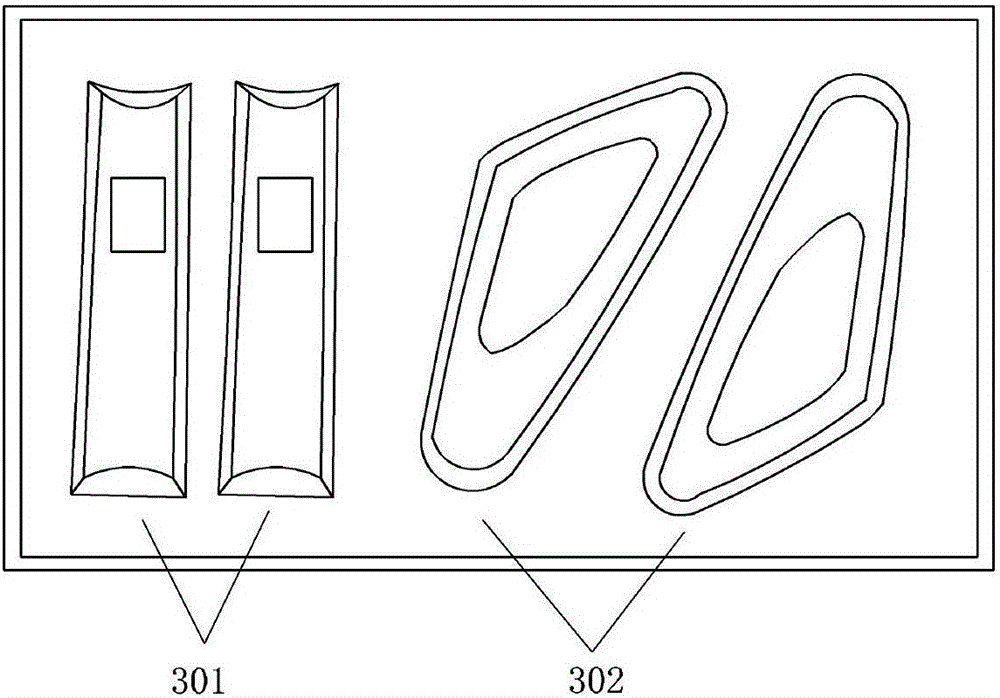

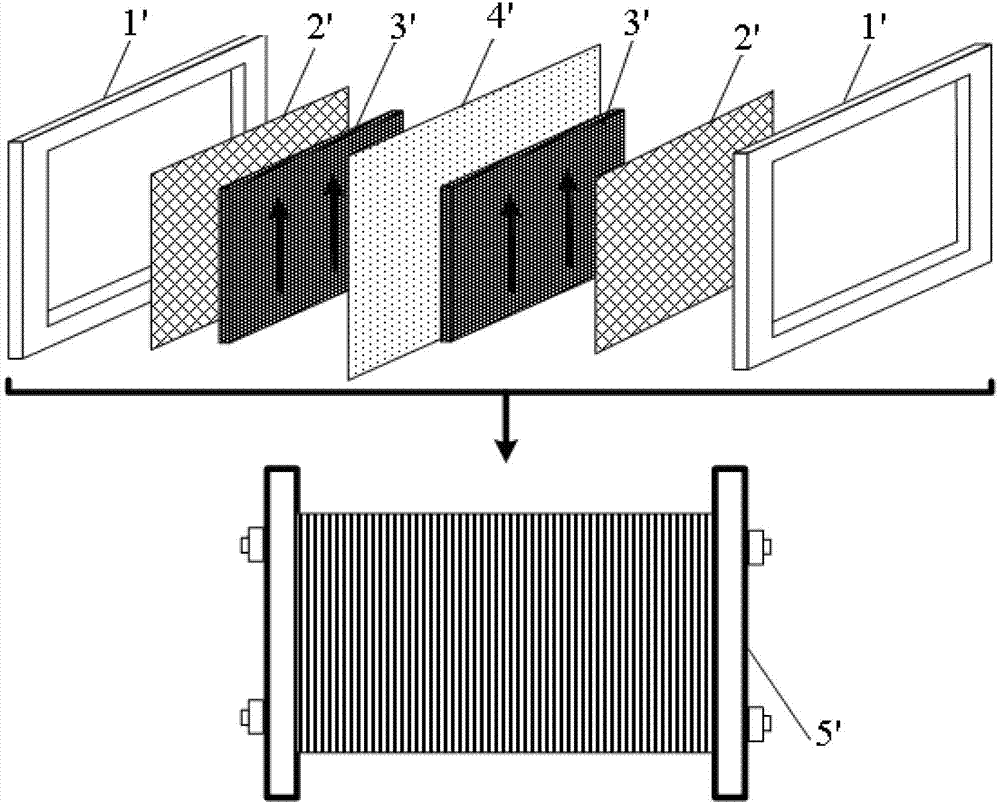

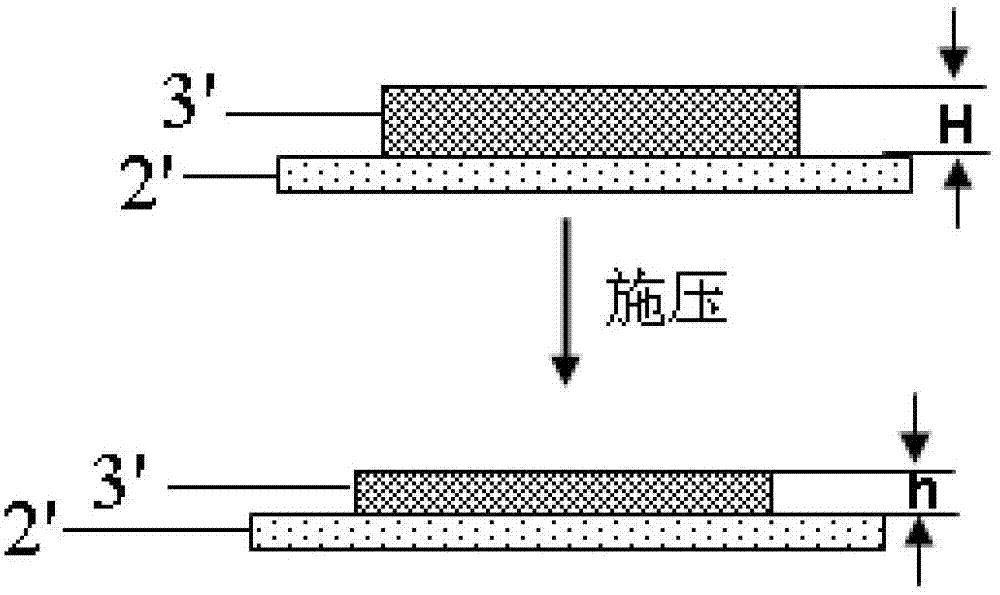

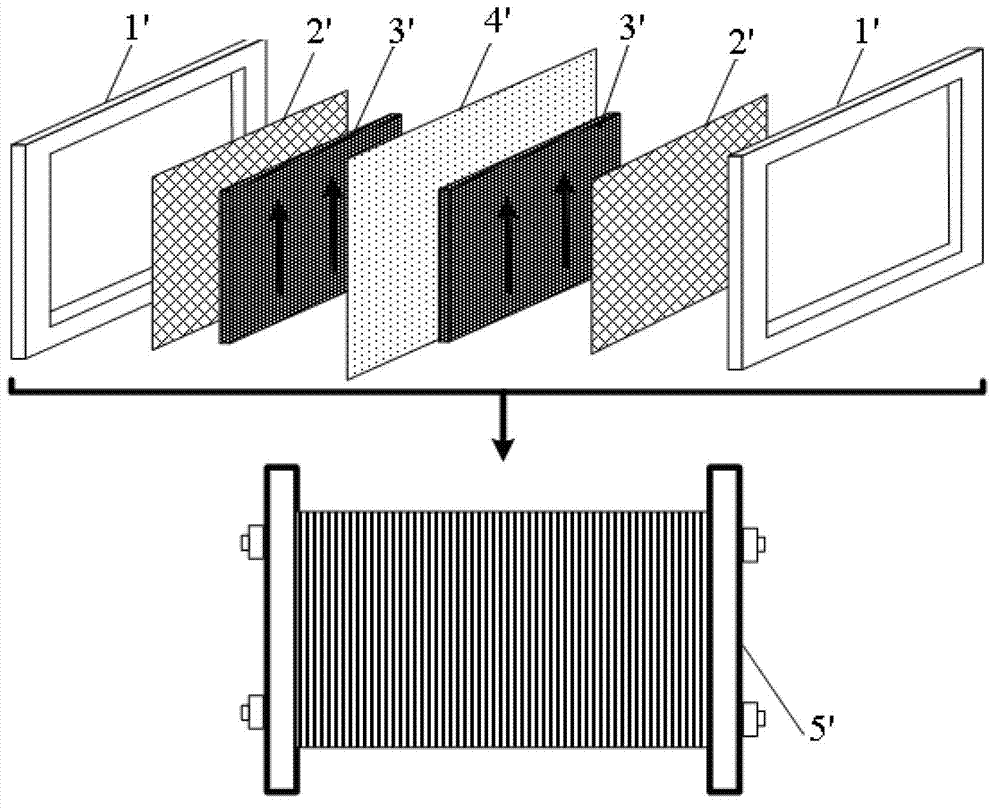

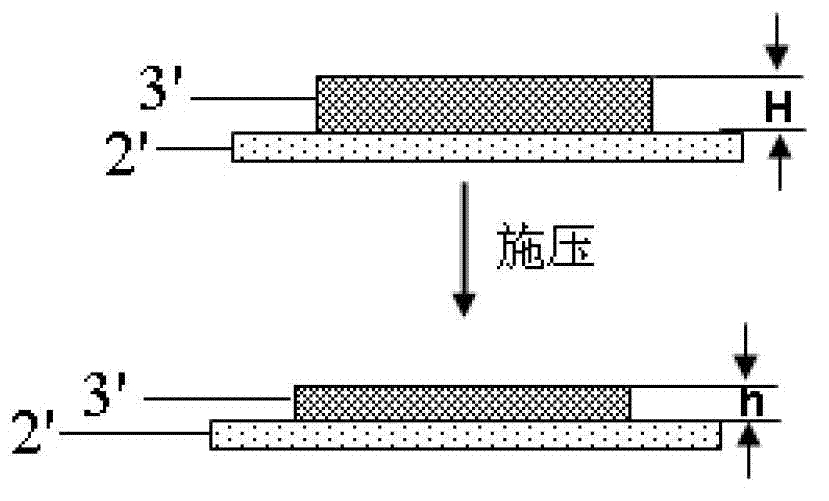

Composite porous electrode, single cell comprising composite porous electrode, cell stack and preparation method of composite porous electrode

ActiveCN102738473AConductiveAct as a skeleton supportFuel cells groupingFinal product manufactureRedoxHardness

The invention discloses a composite porous electrode, a single cell comprising the composite porous electrode, a cell stack and a preparation method of the composite porous electrode. The composite porous electrode comprises a porous electrode body and resin layers formed on the inner walls of pores of the porous electrode body; and through holes which can be used for ensuring electrolyte to flow are arranged in at least part of pores of the porous electrode body. After the resin layers are formed on the inner walls of the pores of the porous electrode body, when the composite porous electrode has electrical conductivity and porous structure, the resin layers take a skeleton supporting effect on the composite porous electrode, the hardness and the modulus of the porous electrode are improved, the composite porous electrode can be controlled to have well interface bonding with a collector plate or a pole plate under the condition of generating a small compression amount when being combined with the collector plate or the pole plate, and a contact resistance between the composite porous electrode and the collector plate or the pole plate is reduced, so that the effects of not only not influencing the process of smoothly carrying out penetration diffusion and oxidation-reduction reaction of electrolyte in the composite porous electrode, but also ensuring the low contact resistance between the composite porous electrode and the collector plate or the pole plate are achieved.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

Anti-spill breast pad and its manufacturing method

InactiveCN107440838AHigh water absorption characteristicsPrevent random walkingBreast bandagesBrassieresWater layerMaterials science

The invention discloses an anti-spill breast pad. A water absorbing layer comprises a water absorbing material and a coating layer located at an upper surface or a lower surface or upper and lower surfaces of the water absorbing material; the water absorbing material is in the shape of a shell and comprises an upper shell and a lower shell; the coating layer is a circular flaky structure and covers on the water absorbing material; the coating layer and the water absorbing layer are commonly formed to be a circular water absorbing layer; a water permeable layer, a waterproof layer and the water absorbing layer can be folded up along with a folding trace; under a folding state, the overlapped water permeable layers at both ends of the folding trace are jointed so that the breast pad is arched. The invention further discloses a manufacturing method of the anti-spill breast pad, which includes steps of manufacturing the water absorbing layer, and covering one layer or several layers of water permeable materials at the upper surface or the lower surface or upper and lower surfaces of the shell type water absorbing material as the coating layer; covering the water permeable layer and the waterproof layer at both sides of the water absorbing layer; crimping to form a jointing side; folding up; jointing the overlapped water permeable layers at both ends of the folding trace. The manufactured anti-spill breast pad can prevent the water absorbing material from leaking from the edge of the breast pad; meanwhile, the water absorbing property is enhanced.

Owner:CHANGZHOU DAILYS CARE PROD

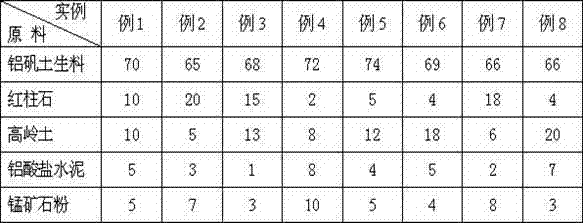

Low-density high-strength andalusite fracturing proppant and production method thereof

ActiveCN102268248ACompatibility is reasonableHigh compressive strengthFluid removalKaolin clayEngineering

The invention relates to a low-density high-strength andalusite fracturing propping agent and a production method thereof. The raw materials comprise: 65-75% of bauxite raw meal, 2-20% of andalusite, 5-20% of kaolinite, 1-8% of calcium aluminate cement, 3-10% of manganese ore powder. The production method comprises the following steps: weighing raw materials, grinding into fine powder, sieving, well mixing, adding into a rotating granulator for granulation, adding atomized aqueous vapor till the mixture becomes a spherical semifinished product, drying; sintering the semifinished product in a rotary kiln for 6-10 h with a kiln head temperature of 1300-1400 DEG C and a kiln tail temperature of 280-320 DEG C, taking the product out of the kiln to obtain a finished product. The product of theinvention has broken rates of 4.8% and 6.9% under pressures of 52 MPa and 69 MPa respectively, and has strength higher than that of other products of the same kind; the product has bulk density of 1.40-1.60 g / cm3, and apparent density of 2.60-2.85 g / cm3, and the density is lower than industrial standard; the product has high surface fineness, and can effectively reduce cost of petroleum fracturing.

Owner:郑州德赛尔陶粒有限公司

Composite porous electrode, single cell and cell stack containing same and preparation method thereof

ActiveCN102738474AAct as a skeleton supportHigh hardnessCell electrodesRegenerative fuel cellsRedoxHardness

The invention discloses a composite porous electrode, a single cell and cell stack containing the same and a preparation method thereof. The composite porous electrode comprises a porous electrode body and an intensified part distributed in the porous electrode body, wherein the bending resistance of the intensified part is superior to that of the porous electrode body, and the intensified part is penetrated through the porous electrode body along the thickness direction of the porous electrode body. After assembling the porous electrode body and the intensified part having better bending resistance than the porous electrode body to form the composite porous electrode, the composite porous electrode has conductivity and a porous structure, and simultaneously, the rigidity and modulus thereof are also increased. In case of the combination with a collection plate or pole plate, a favorable interfacial combination with the collection plate or pole plate can be achieved by controlling the composite porous electrode to produce a small compression amount, so that the contact resistance in between can be reduced, thereby not affecting the penetration and diffusion of the electrolyte in the composite porous electrode and the smooth implementation of the redox reaction, and ensuring lower contact resistance between the composite porous electrode and the collection plate or pole plate.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

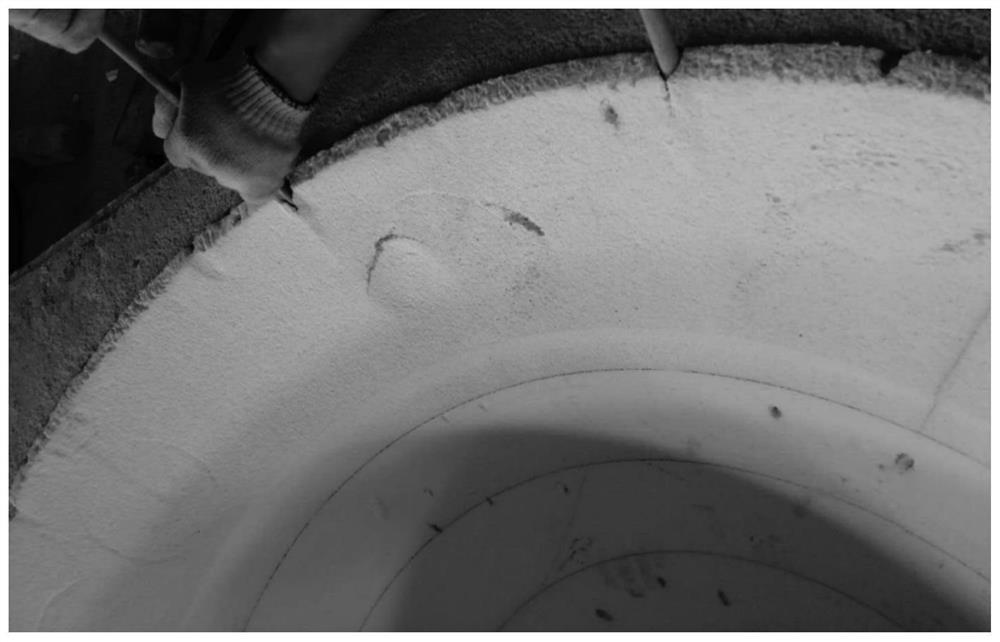

High-elasticity wear-resistant dual-density in-mold foaming rubber tire and manufacturing process thereof

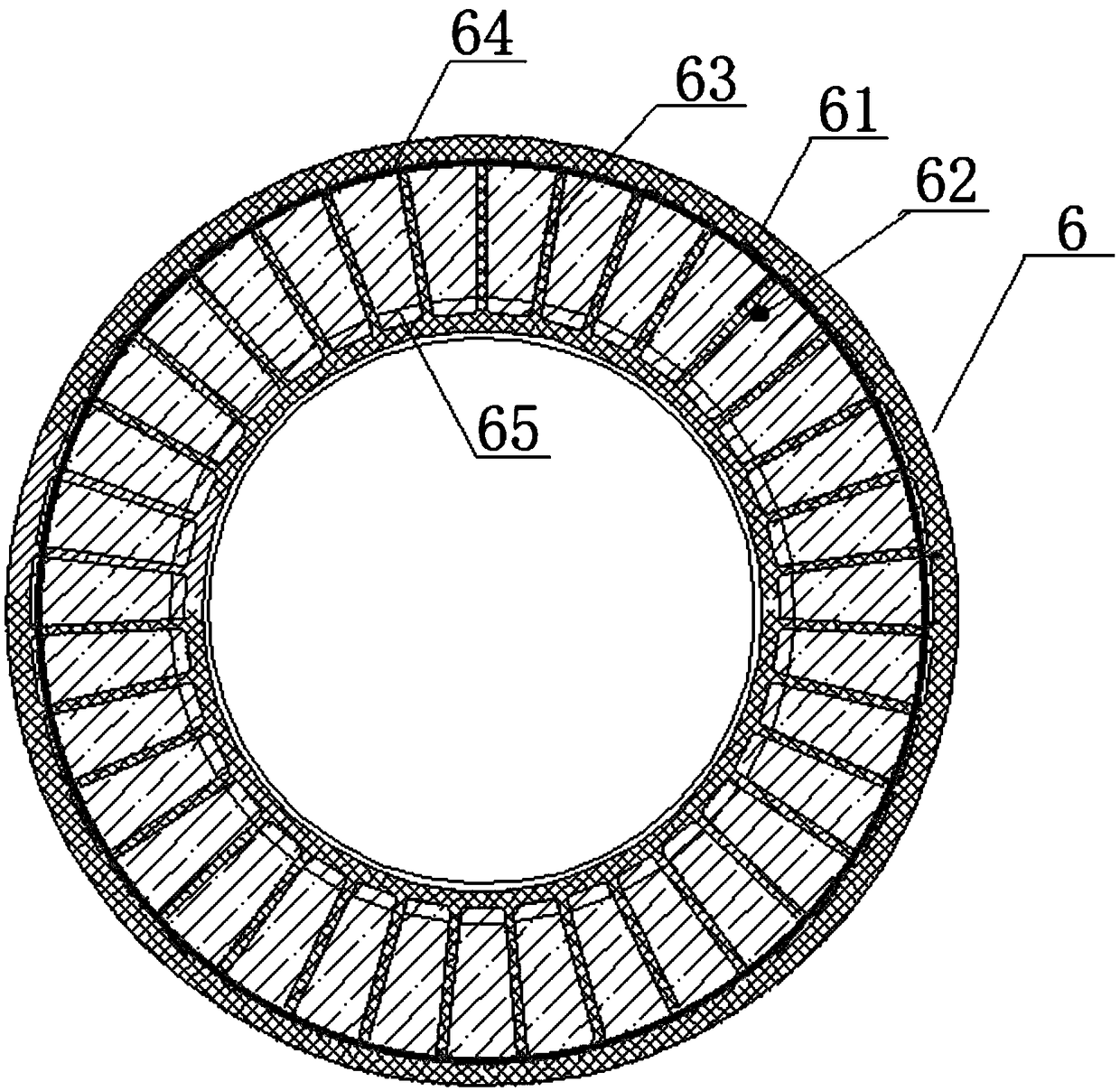

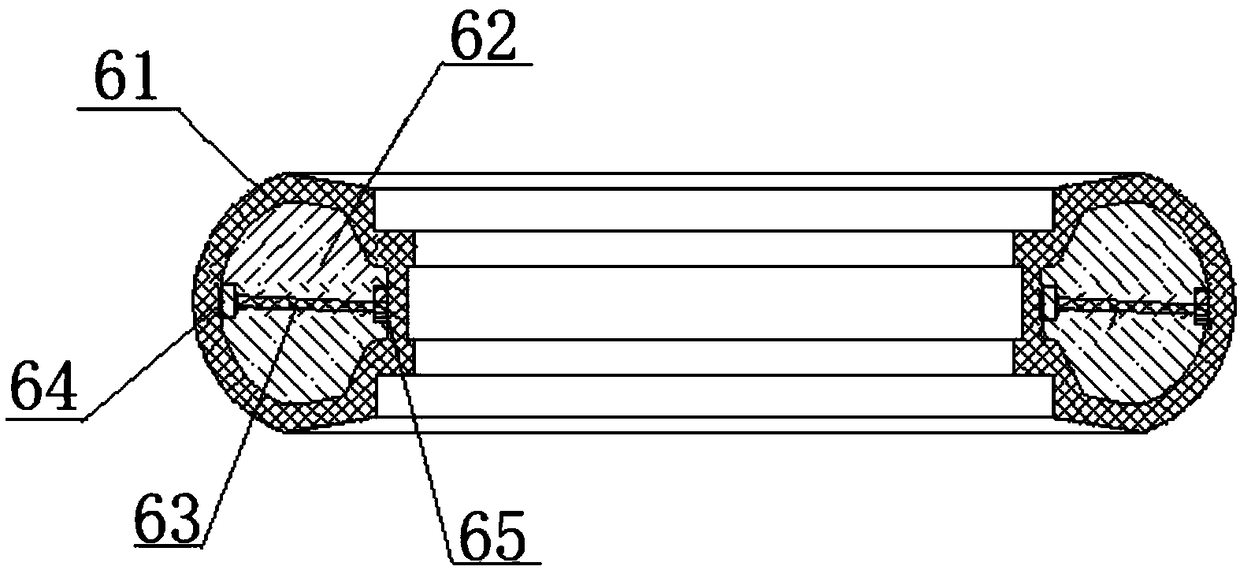

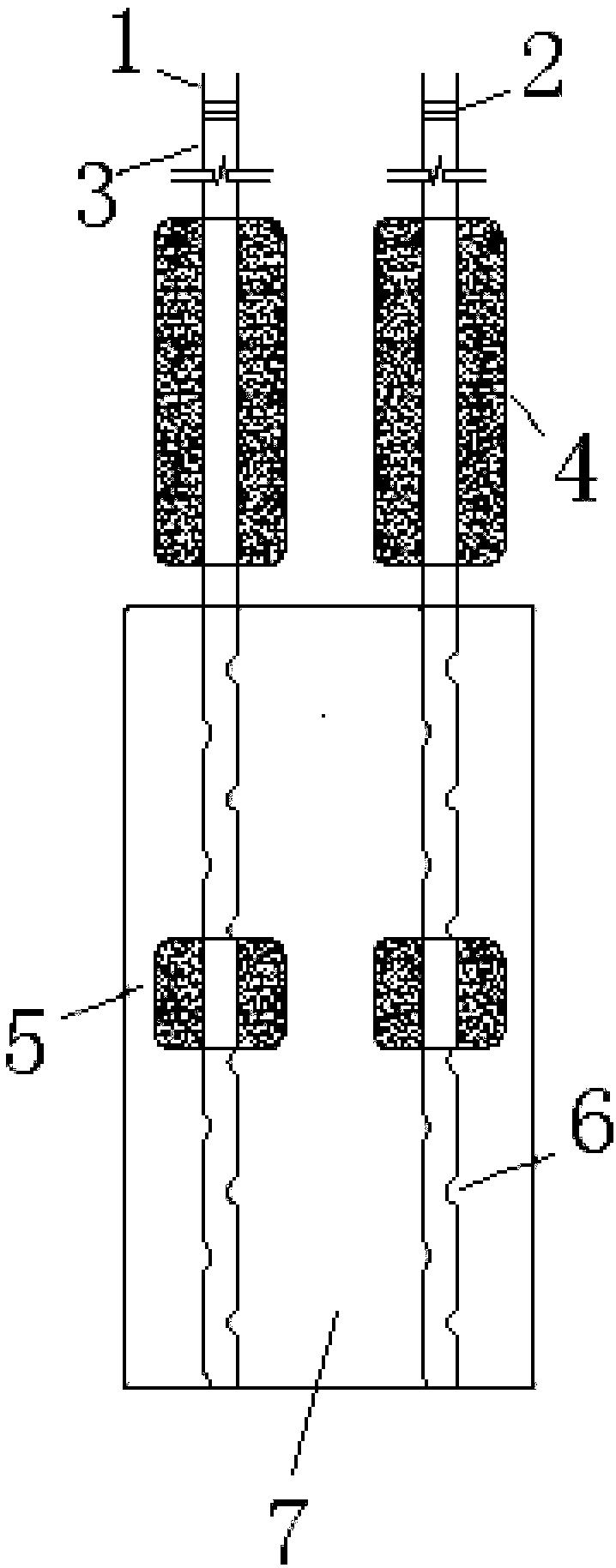

ActiveCN109318445AIncrease elasticitySlow down elastic fatigue decayWith separate inflatable insertsWith multiple inflatable chambersRubber materialHigh density

The invention discloses a high-elasticity wear-resistant dual-density in-mold foaming rubber tire and a manufacturing process of the high-elasticity wear-resistant dual-density in-mold foaming rubbertire, and belongs to the technical field of rubber product processes. The high-elasticity wear-resistant dual-density in-mold foaming rubber tire comprises a high-density outer layer and a low-densityinner layer, and is of an integrated structure with the same mold for discharging. The high-density outer layer and the low-density inner layer are made of high-density rubber materials and low-density rubber materials correspondingly. Spring supports in a radial state are uniformly embedded in the low-density inner layer so as to play the role of framework support, and the elasticity of springscan be selected to be consistent with the elasticity of low-density rubber so as to enhance the supporting strength of the low-density inner layer. In addition, a dual-density bi-directional injectionin-mold forming-vulcanizing tire production system is applied to complete dual-density glue bi-directional injection, foaming and vulcanizing processes in one mold and obtain the manufactured tire. The problems of the insufficient elasticity of a rubber tire, the separate operation of injection, foaming and vulcanizing of a dual-density tire, energy consumption, time consumption and the high costare solved.

Owner:东营睿港招商服务有限责任公司

Method for reinforcing rock pillar in shallow buried tunnel with small spacing in city

InactiveCN108194104AImproves strength and stabilityImprove reinforcement effectUnderground chambersTunnel liningTunnel constructionPetrology

The invention relates to a method for a reinforcing rock pillar in a shallow buried tunnel with small spacing in a city, and belongs to the technical field of tunnel construction. The methods comprisethe step that by the arrangement of one or more rows of grouting holes, seamless steel pipes are used as grouting pipes according to the construction sequence of jumping holes at intervals, through the hole grouting to reinforce septum rock pillars, the grouting pipes is used as a supporting skeleton to effectively improve the stability of the septum rock pillars; by the binding of the multi-stage pressure separating expansion mold bag on the grouting pipes, slurry is controlled to spread in the target area, and at the same time, the effects that the uplift and settlement of ground can be controlled and the impact on the ground and the surrounding area of the ground can be reduced are achieved; grouting material based on the rapid solidification type slurry can adjust the slurry gel timeaccording to the real time feedback of the grouting process in the field, the over diffusion of the slurry is prevented, the cost is saved, and the segmented and localized reinforcement of the septumrock pillars can be achieved by the matching with the pressure separating expansion mold bag.

Owner:SHANDONG UNIV

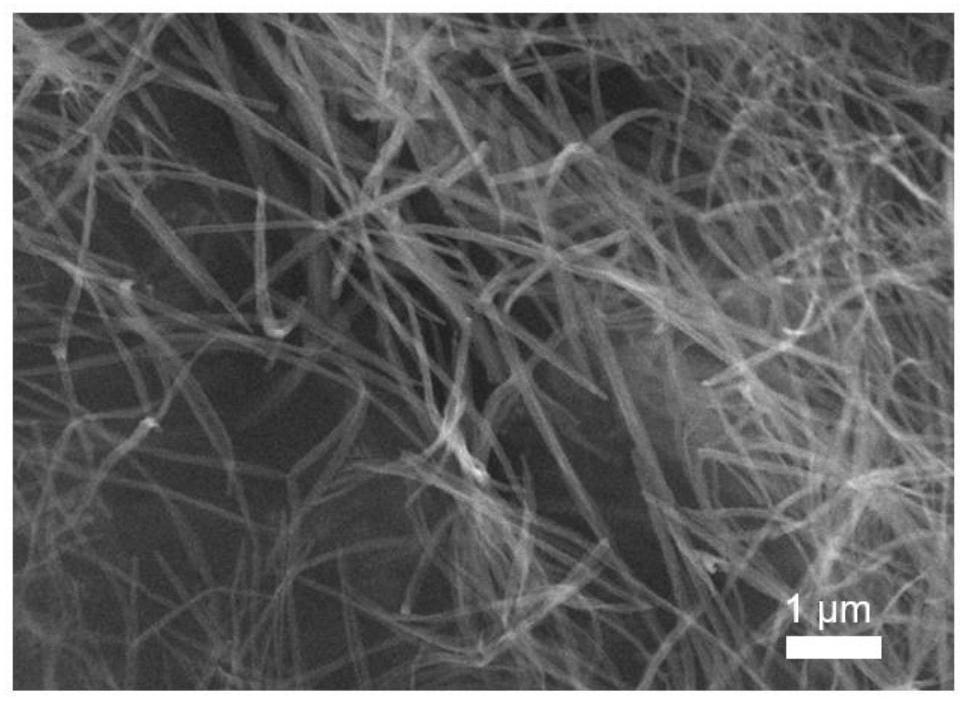

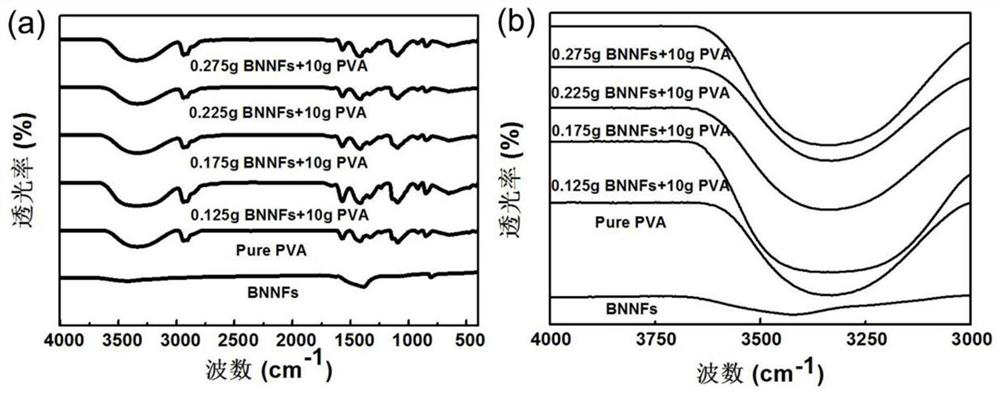

Preparation and application methods of porous boron nitride nanofiber/polyvinyl alcohol composite hydrogel

ActiveCN111909397ALow costEasy to getMaterial nanotechnologyNitrogen compoundsFlexible electronicsBiomedicine

The invention relates to a preparation method and an application method of porous boron nitride nanofiber / polyvinyl alcohol composite hydrogel. The preparation method comprises the following steps: adding porous BNNFs into deionized water to obtain a dispersion liquid; and adding PVA into the dispersion liquid, conducting heating and stirring in a water bath at 90-100 DEG C for 2-4 hours, and naturally cooling the sol obtained after heat preservation to room temperature, thereby obtaining the porous boron nitride nanofiber / polyvinyl alcohol composite hydrogel with favorable self-healing property. The hydrogel obtained by the invention can be retreated by a short-time freeze thawing method, so the mechanical properties of the hydrogel are enhanced, and the hydrogel can be used in the fieldsof biomedicine, wearable flexible electronic devices and the like, and has higher safety usability compared with hydrogel prepared by polymerizing monomolecules via a chemical cross-linking agent.

Owner:HEBEI UNIV OF TECH

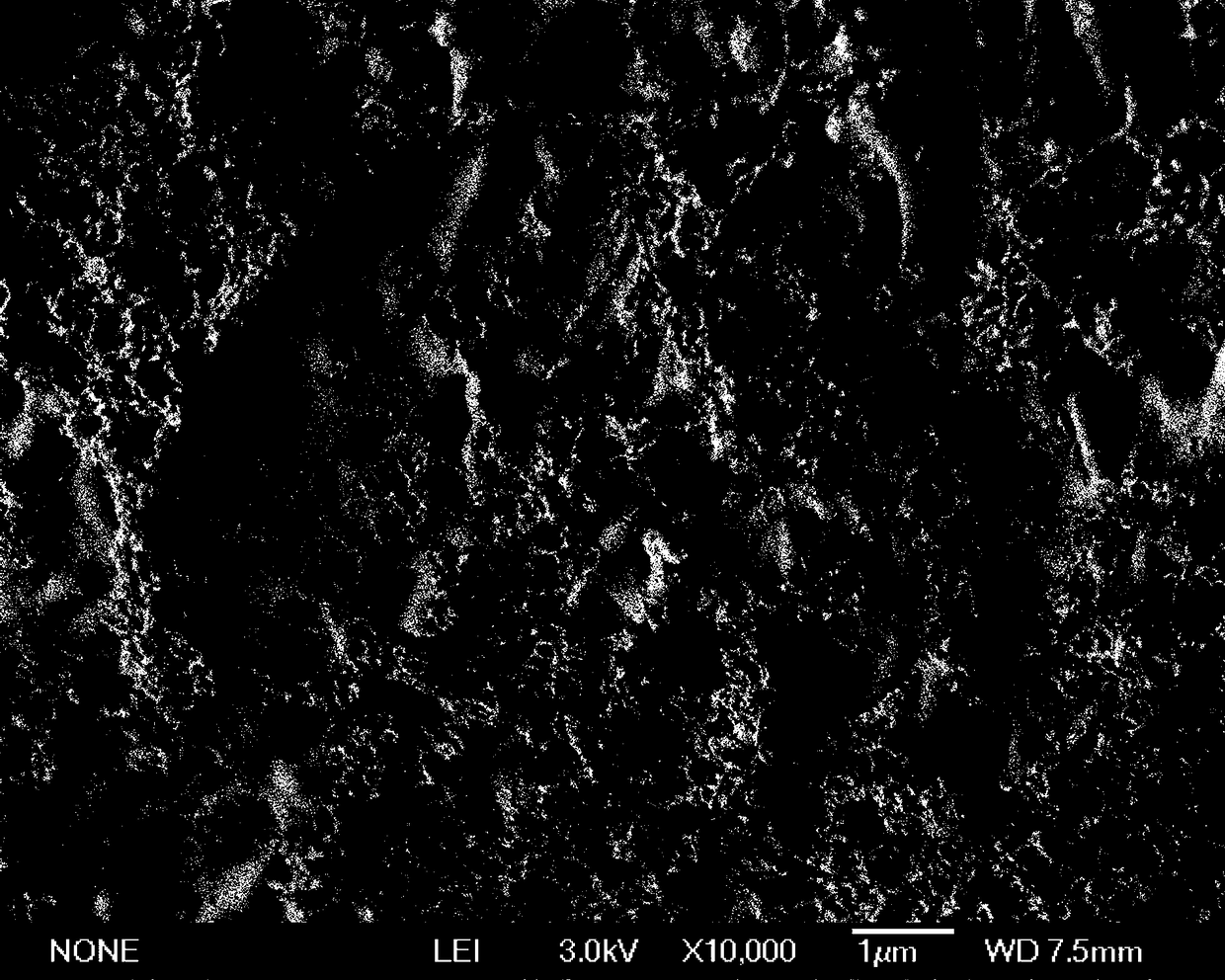

Preparation method of anticorrosion coating and application of anticorrosion coating to metal component of cable-stayed bridge

InactiveCN108047859AAct as a skeleton supportImprove bindingCable-stayed bridgeAnti-corrosive paintsIsolation effectThermal insulation

The invention discloses a preparation method of an anticorrosion coating. According to main points of the technical scheme, the method comprises: S1, pouring absolute ethanol to an Erlenmeyer flask, adding tetraethoxysilane, and performing uniform stirring; S2, weighing ammonia water, the mass of which is 0.05-0.1 time of that of tetraethoxysilane, and performing continuous stirring; S3, after thestirring is over, performing heating and drying to obtain nanometer SiO2 particles; S4, performing modification treatment; S5, sealing the container, and performing thermal insulation in a drying oven for 48 h; S6, performing centrifugation and repeated flushing to obtain SiO2, and grinding SiO2; S7, making a spraying suspending liquid; S8, performing spraying; and S9, after spraying is over, performing drying for 4 h, taking the product out, and performing natural cooling. The anticorrosion coating can closely adhere to a substrate, has a good water-isolation effect, and reduces corrosion that appears on the surface.

Owner:中能建路桥工程有限公司

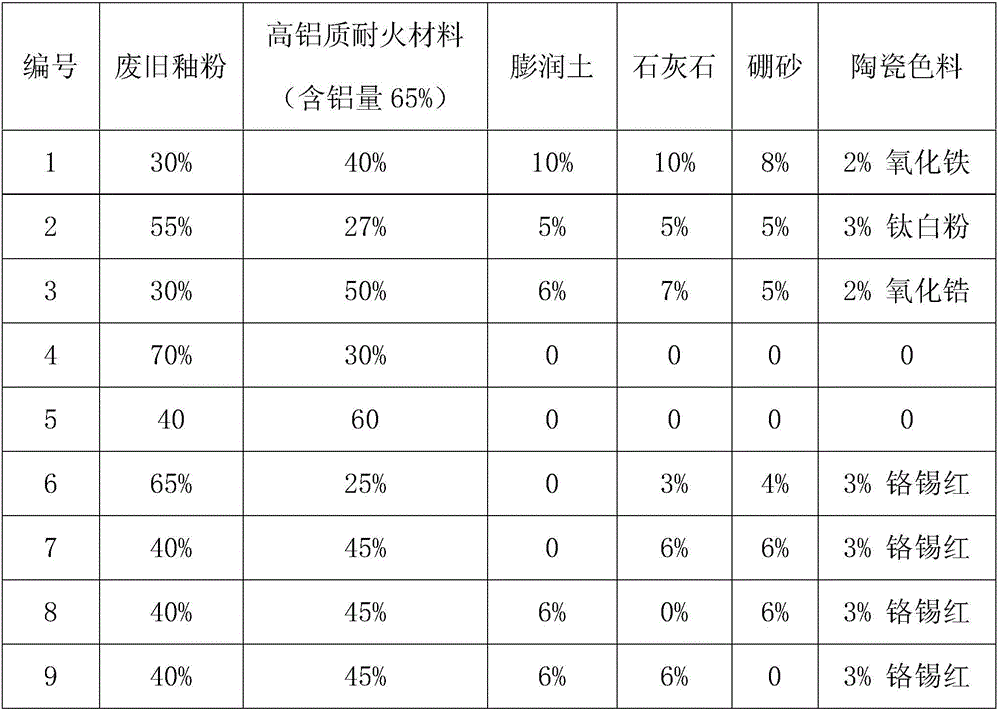

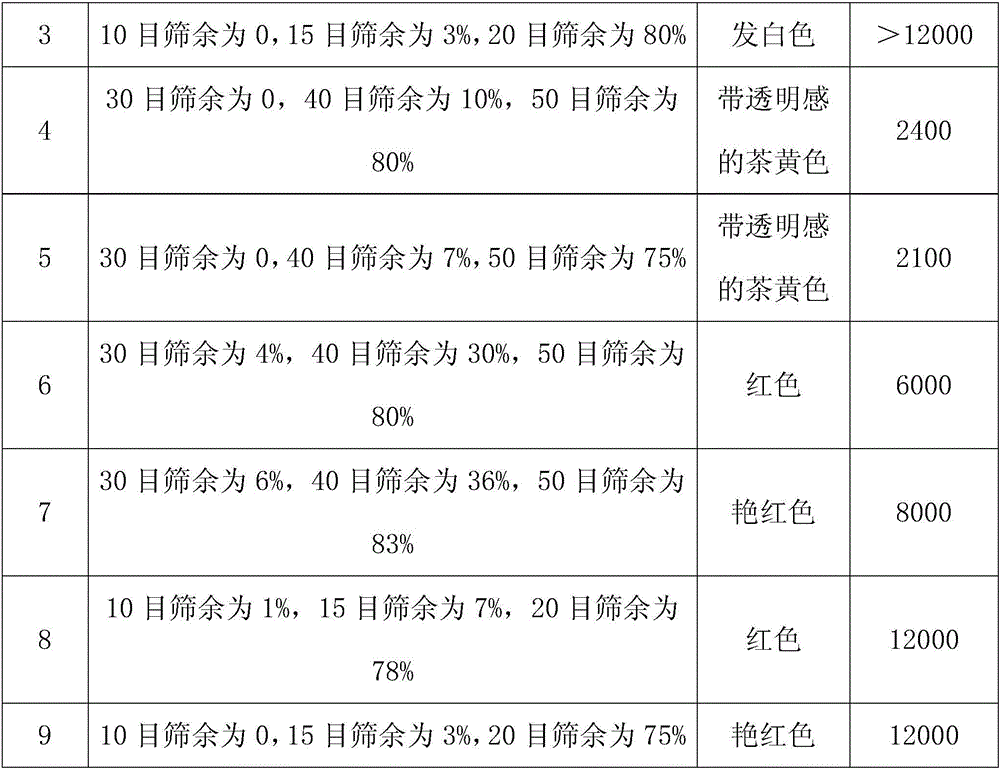

Fusion cake dry granule mainly prepared from waste glaze and preparation method thereof

The invention relates to a fusion cake dry granule mainly prepared from waste glaze and a preparation method thereof. The fusion cake dry granule is prepared from waste glaze powder and a high-aluminum refractory material in a ratio of (0.6-2.5)to1. The fusion cake dry granule mainly prepared from waste glaze is suitable for application for surface decoration of ceramic brick billets; and the decorative layer has the effects of wear resistance and skid resistance. The invention also provides a preparation method of the fusion cake dry granule mainly prepared from waste glaze. By converting the waste glaze into the production raw material, the preparation method is simple, and is low in cost.

Owner:LIXIAN XINPENG CERAMIC +3

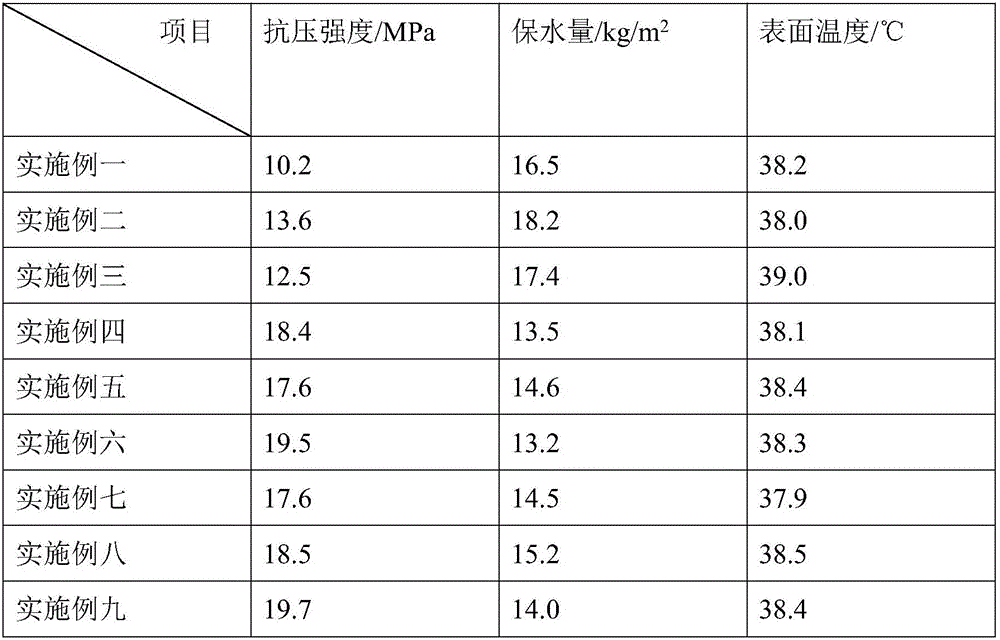

Porous sponge concrete and preparation process thereof

The invention provides porous sponge concrete which is characterized by comprising cement, coarse aggregate, water, a dispersing agent, a foaming agent, rubber powder and a porous sponge, wherein the weight ratio of the cement, the aggregate and the water is 1:(4-10):(0.2-0.5). The porous sponge concrete is prepared by the following steps: S1, weighing the cement, the coarse aggregate, the water, the dispersing agent, the foaming agent, the rubber powder and the porous sponge at a matching ratio for later use; S2, adding the cement, the coarse aggregate, the rubber powder and the foaming agent into a stirrer, performing dry mixing on the mixture for 10-20 s, then adding water into the mixture, continuously stirring for 20-30 s, adding the dispersing agent, continuously stirring for 60-120 s, adding the porous sponge into the mixture, stirring the mixture for 30-40 s and stopping stirring; S3, pouring slurry formed by uniform mixing in S2 into a forming mould, tamping the mixture in an insertion tamping manner and sending the forming mould into a maintenance room for maintenance, wherein the temperature of the maintenance environment is 17-23 DEG C, and the relative humidity of the maintenance environment is equal to or more than 90%; and S4, demoulding to obtain the porous sponge concrete. The prepared porous sponge concrete has the advantages that the using requirement can be met; and in addition, the temperature of the surface of a road can be effectively decreased, so that the porous sponge concrete has a positive effect of relieving a heat island effect.

Owner:达州天创新材料有限公司

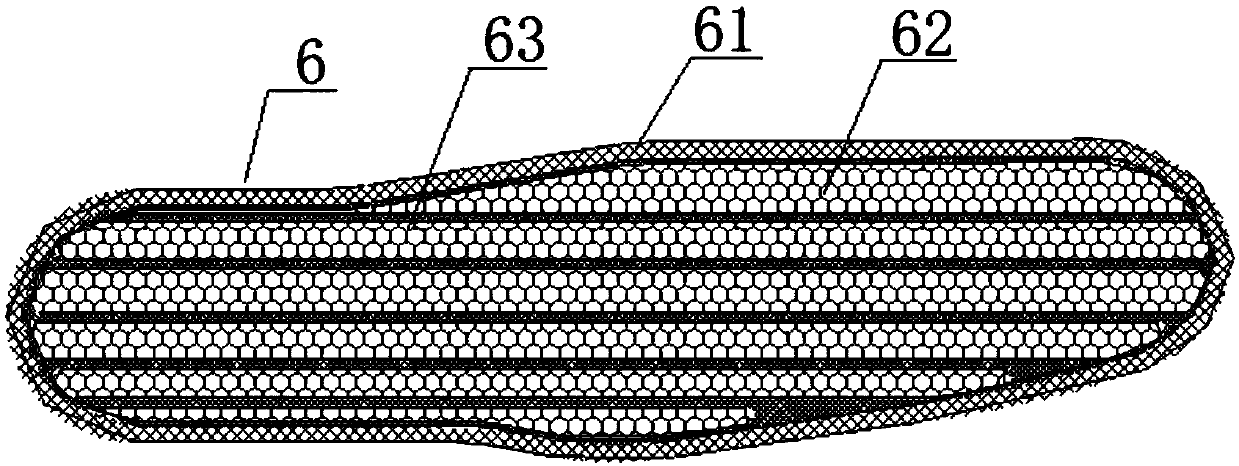

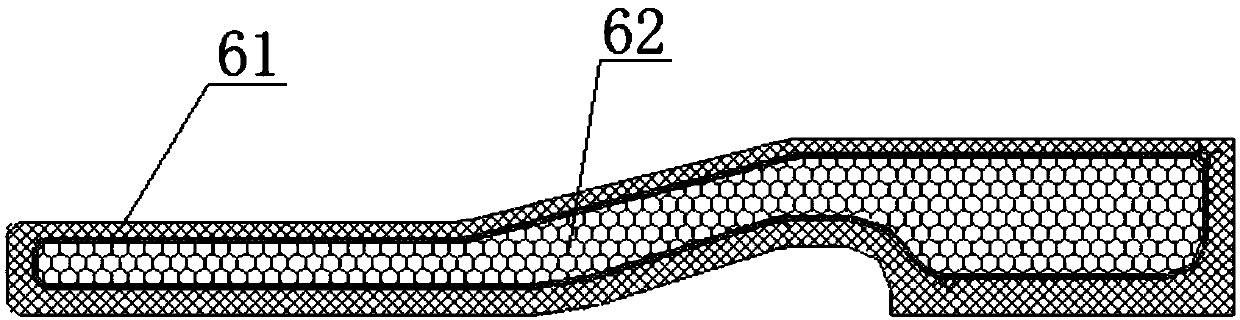

Double-density molding in-mold foaming vulcanization molding rubber health sole and production technology thereof

ActiveCN109572022AIncrease elasticitySlow down elastic fatigue decaySolesDomestic footwearFoaming agentVulcanization

The invention discloses a double-density molding in-mold foaming vulcanization molding rubber health sole and a production technology thereof, and belongs to the technical field of rubber sole products. The molded rubber sole comprises a high-density outer layer and a low-density inner layer, and is of an integrated structure removed from the same mold; materials of the high-density outer layer and the low-density inner layer are high-density rubber and low-density rubber correspondingly, and the low-density rubber is prepared by adding foaming agents into the high-density rubber and foaming;spring supports are further embedded into the low-density inner layer to play roles of skeleton support and massage health care, and the elasticity of the springs can be selected to be consistent withthe elasticity of the low-density rubber to strengthen the support strength of the low-density inner layer; and the double-density molding in-mold foaming vulcanization molding rubber health sole isprepared by adopting a double-density injection mold in-mold foaming production system to finish the double-density rubber injection, foaming and vulcanization processes in a mold, so that the circulation of products in each process can be effectively avoided. According to the double-density molding in-mold foaming vulcanization molding rubber health sole and the production technology thereof, theproblems of insufficient elasticity of rubber soles, separate processes of injection, foaming and vulcanization of double-density soles, energy consumption, time consumption and high cost are solved.

Owner:东营睿港招商服务有限责任公司

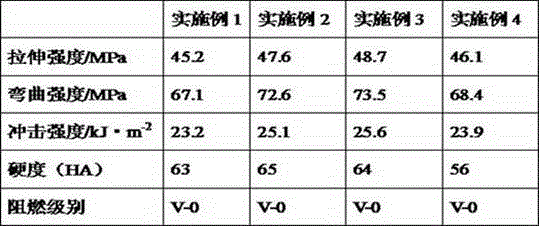

Halogen-free flame-retardant reinforced type ABS (acrylonitrile-butadiene-styrene) composite material and preparation method thereof

The invention relates to a halogen-free flame-retardant reinforced type ABS (acrylonitrile-butadiene-styrene) composite material and a preparation method thereof, and relates to the technical field of plastics. The halogen-free flame-retardant reinforced type ABS composite material adopts the technical scheme that the halogen-free flame-retardant reinforced type ABS composite material consists of an ABS matrix, a main flame-retardant matrix, a synergic matrix, a reinforced matrix, an anti-dripping agent, an antioxidant, a charring agent, paraffin and a color master batch. The halogen-free flame-retardant reinforced type ABS composite material and the preparation method have the advantages that by utilizing the compounding synergic function of the main flame-retardant matrix, the synergic matrix and the reinforced matrix, the flame-retardant property and mechanical property are good; by compounding inorganic components and organic components, the synergic function is formed, the flame-retardant efficiency and mechanical property of the composite material are improved, and the cost of material is reduced; by using the technology to produce, the technology is simple, the operation is convenient, the production efficiency is improved, and the production cost is reduced; while the property of the composite material is reached, the comprehensive cost is lower than the cost of the traditional ABS composite material.

Owner:DONGGUAN POLYTECHNIC

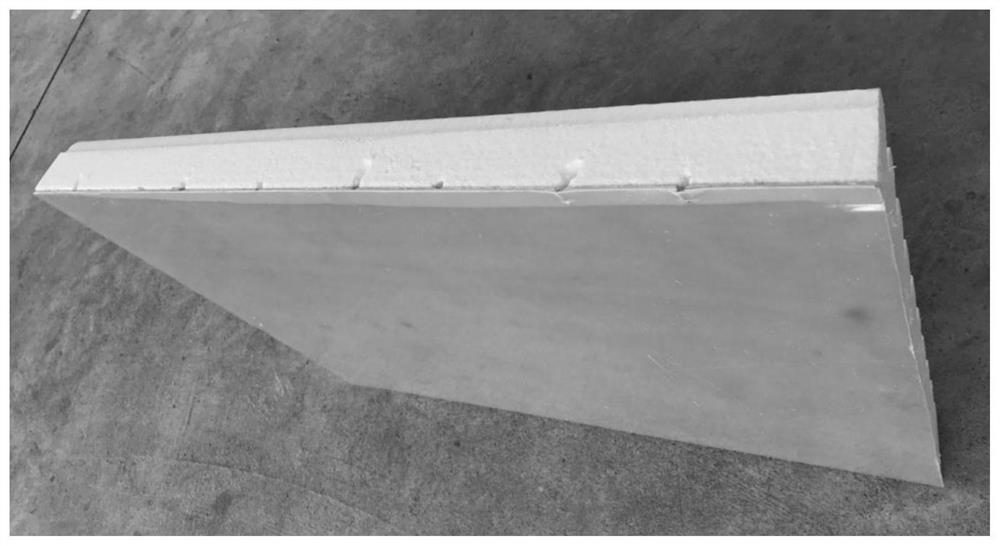

EPS foam-epoxy resin composite die and preparation method thereof

ActiveCN112126088AHigh strengthOptimized areaNon-macromolecular adhesive additivesFoundry mouldsOXALIC ACID DIHYDRATEFiber

The invention discloses an EPS (Expandable Polystyrene) foam-epoxy resin composite die, which is formed by adhering an epoxy resin reinforcing plate with the thickness of 1-5mm to the profile of a drawing part of an EPS foam die and compounding. The epoxy resin reinforcing plate is prepared from the following raw materials in parts by weight: 3-8 parts of bisphenol F epoxy resin, 10-20 parts of bisphenol A epoxy resin, 5-10 parts of E-51 epoxy resin, 10-15 parts of m-benzene unsaturated polyester resin, 1-5 parts of juncus effusus fiber powder, 1-3 parts of chitosan, 1-3 parts of oxalic acid,0.5-1.4 parts of wheat straw powder, 0.01-0.05 parts of a catalyst, 10-20 parts of an organic solvent, 5-10 parts of stone powder and 5-10 parts of a curing agent. The composite die is formed by compounding the EPS foam plate and the epoxy resin reinforcing plate, drawing can be balanced, stress points can be reinforced, the overall strength of the die is improved, and the problems that the EPS die is prone to deformation and difficult to draw during drawing are solved.

Owner:广西长城机械股份有限公司

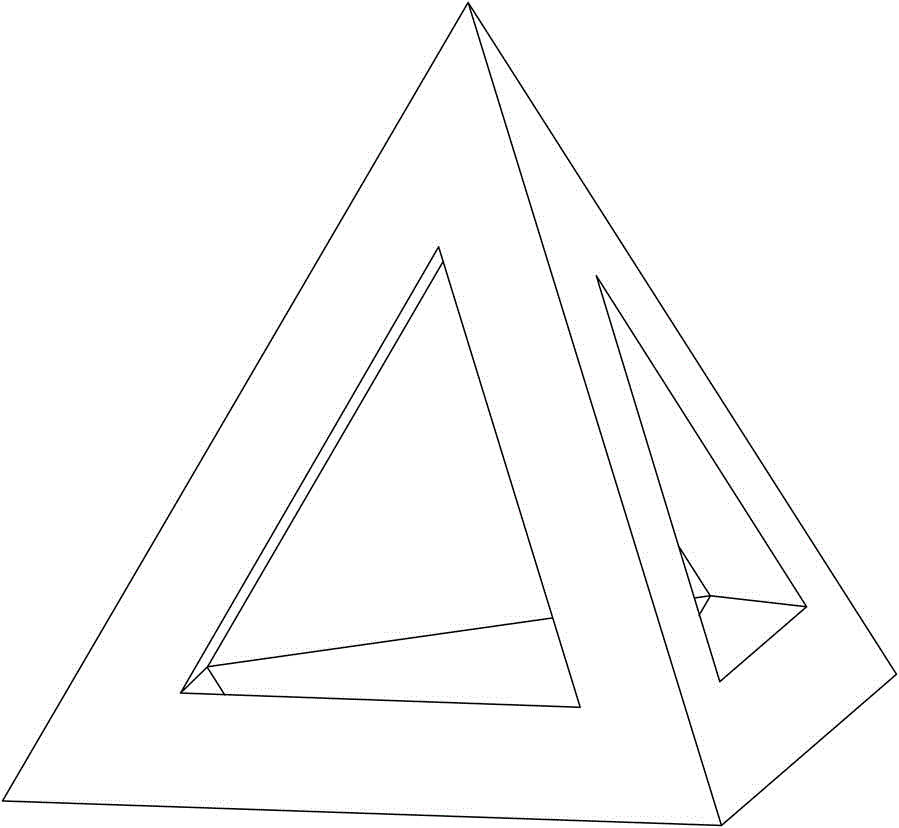

Pouring slurry for light board

The invention relates to pouring slurry for a light board. The pouring slurry is prepared from the following raw materials in parts by weight: 60-120 parts of cement, 70-120 parts of light materials, 2-6 parts of emulsion powder, 5-25 parts of coal ash, 30-50 parts of gypsum powder, 10-25 parts of triangular pyramid cage type glass fiber reinforced plastic particles, 0.05-3.5 parts of sodium carboxymethylcellulose, 0.8-3.0 parts of lignocelluloses, 0.6-2.0 parts of carbon fiber, 0.1-0.5 part of cellulose ether, 2.7-7.8 parts of beta-cyclodextrin, 0.01-10 parts of an early strength agent, 0.1-5 parts of a water reducer and 0.05-4 parts of an air entraining agent. The pouring slurry has the characteristics of light weight, high strength, heat resistance and shock resistance.

Owner:安徽东材材料科技有限公司

Plugging agent for plugging cracks, and plugging method thereof

ActiveCN110628399AHigh plugging strength and erosion resistanceGood plugging performanceDrilling compositionHigh polymerPolymer solution

The invention provides a plugging agent for plugging cracks, and a plugging method thereof, wherein the plugging agent comprises a first component and a second component, the first component comprisesa first reactive high polymer, a polymerization monomer, a cross-linking agent and an initiator, and the second component comprises insoluble solid particles and a polymer solution. According to theinvention, by using the plugging agent, oil reservoir cracks can be effectively plugged; the plugging agent has high plugging strength and scouring resistance based on the formation of an organic gel-particle three-dimensional network plugging system; and the first component and the second component have good injectivity before injection, so that the plugging agent of the invention has advantagesof good plugging performance and excellent injectivity.

Owner:PETROCHINA CO LTD

Titanium-doped ternary metal organic framework material and preparation method thereof

ActiveCN109174185APromote degradationPromote decompositionWater/sewage treatment by irradiationWater treatment compoundsTitanium metalMetal-organic framework

The invention discloses a titanium-doped ternary metal organic framework material and a preparation method thereof. The preparation method comprises the following steps: (S1) preparing 5,5',5''-(((1,3,5-triazine-2,4,6-triyl)tris(phenyl-4,1-diyl))tris(acetylene-2,1-diyl))triisodecanoic acid from 5-diethyl iodophthalate and 2,4,6-tris(4-ethynylphenyl)-1,3,5-triazine; (S2) adding a first metal sourceprecursor, a second metal source precursor and 5,5',5''-(((1,3,5-triazine-2,4,6-triyl)tris(phenyl-4,1-diyl))tris(acetylene-2,1-diyl))triisodecanoic acid into a reactor, and reacting at 25-75 DEG C for 4-90 hours, so as to obtain a binary metal organic framework material mixed solution; and (S3) adding a titanium metal source precursor into the mixed solution prepared in the step (S2) in a molar ratio of (1-10) to (1-10), and carrying out ion exchange, so as to obtain the titanium-doped ternary metal organic framework material. The prepared titanium-doped ternary metal organic framework material is high in catalytic activity and good in hydrothermal stability and can be repeated used.

Owner:苏州安仕泊环保科技有限公司

Embossment powder for outer wall, and preparation method thereof

The invention discloses embossment powder for an outer wall, and a preparation method thereof, and relates to the field of coating. The embossment powder for the outer wall comprises the following components in parts by mass: 20 to 25 parts of white cement, 50 to 65 parts of quartz powder, 10 to 20 parts of quartz sand, 0.1 to 0.15 part of a water repellent, 0.2 to 0.5 part of a thixotropic agent, 0.2 to 0.3 part of wood fiber, 1 to 1.5 parts of PVA and 0.3 to 0.5 part of methyl hydroxyethyl cellulose. The embossment powder provided by the invention belongs to a layer material in inorganic embossment, and has the characteristics of environmental friendliness, high whiteness, low alkalinity, high adhesive strength, small drying shrinkage, high water-proof and air-permeable properties and the like. Compared with the coating in the traditional embossment, the embossment powder is high in cost performance, uniform in spot, plump and high in stereoscopic sensation, and has development prospect in the field of outer wall texture effect decoration.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

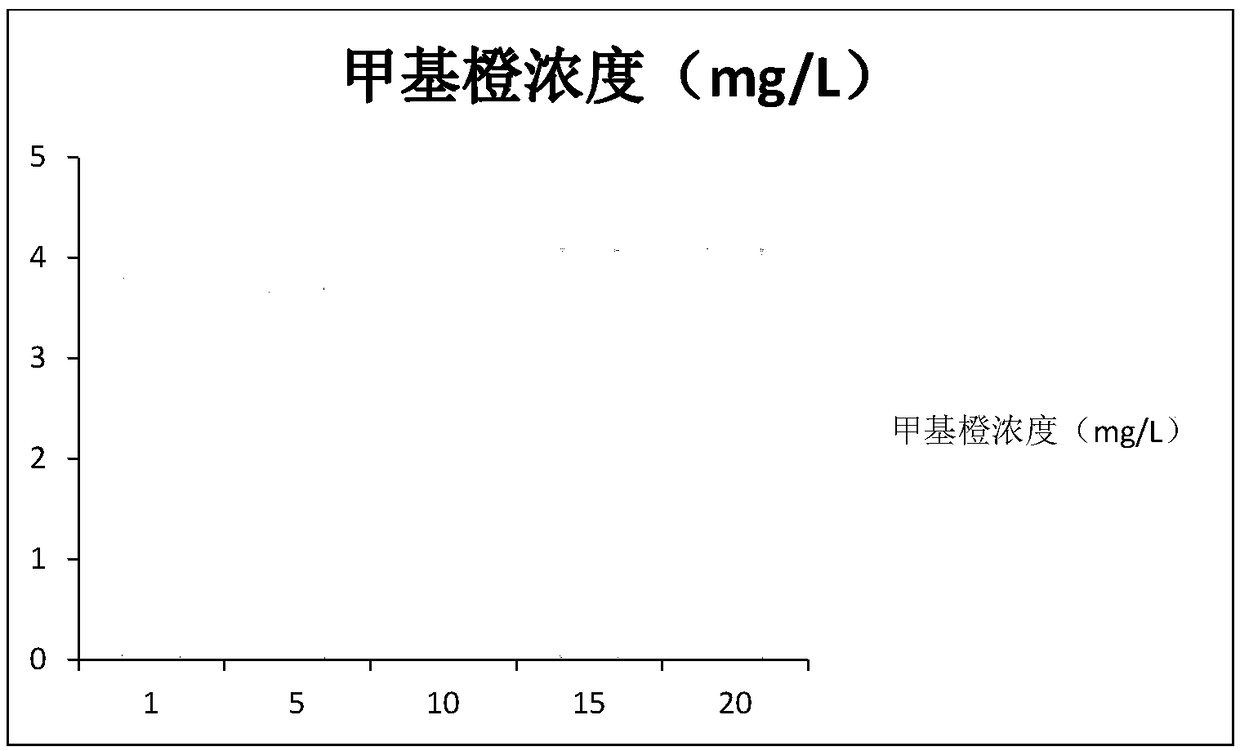

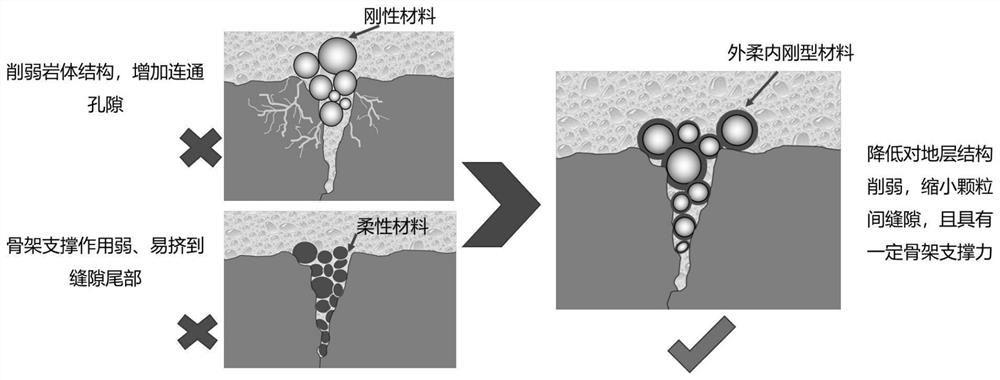

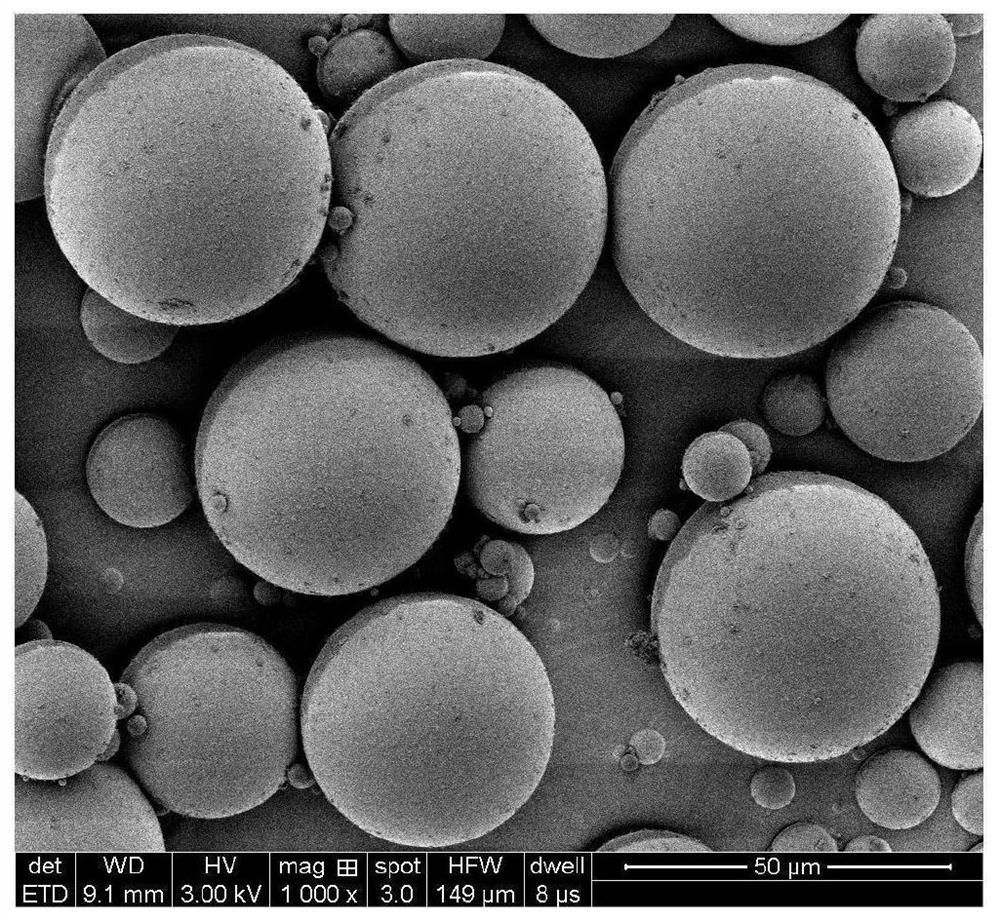

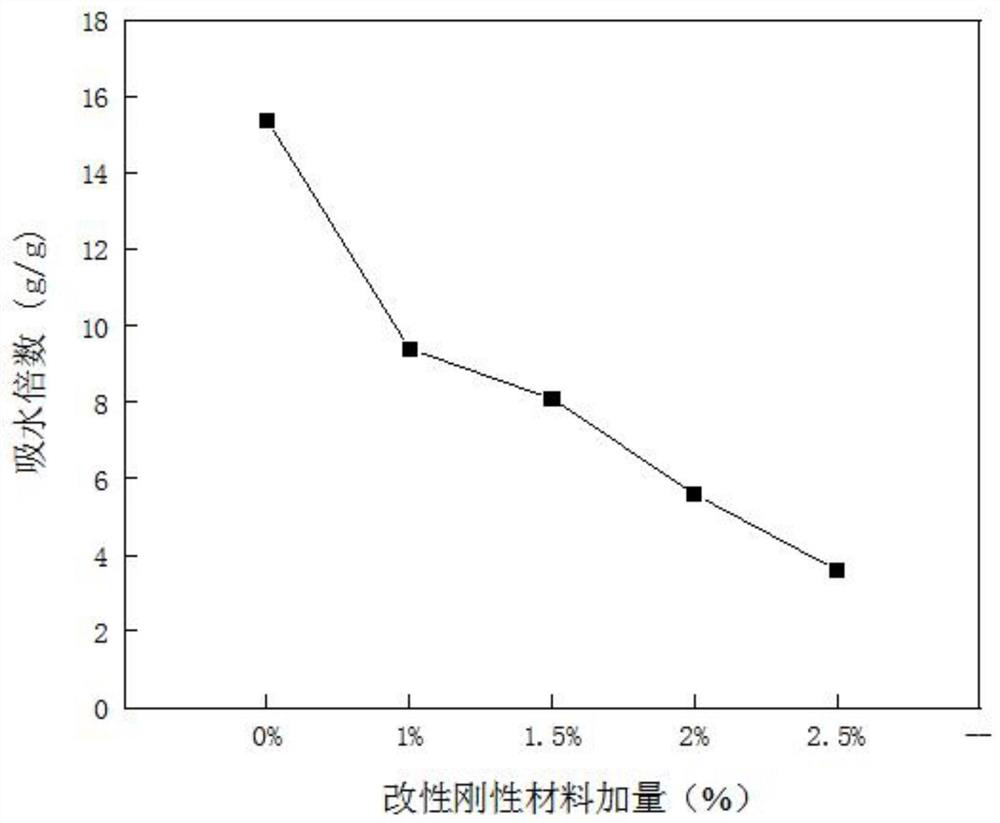

Lost circulation material with soft outside and rigid inside and preparation method thereof

PendingCN113528101ASimple preparation processImprove adaptabilityDrilling compositionWell cementingMeth-

The invention belongs to the field of oil and gas well cementation and oilfield chemistry, and particularly relates to a lost circulation material with soft outside and rigid inside and a preparation method thereof. The lost circulation material is a complex microsphere material which is prepared by taking acrylamide, 2-acrylamido-2-methylpropanesulfonic acid and N-vinyl pyrrolidone as comonomers as a flexible material and taking modified silicon dioxide and / or modified quartz sand as a modified rigid material through a reversed-phase suspension method, and the mass ratio of the acrylamide to the 2-acrylamido-2-methylpropanesulfonic acid to the N-vinyl pyrrolidone is (14-16):(3-2):(3-2). The lost circulation material with soft outside and rigid inside not only has variability, but also has a certain skeleton supporting effect. Along with the increase of the polymer concentration, the water absorption multiple of the material is increased, the deformability is enhanced, gaps with different sizes can be adaptively selected, and effective plugging is formed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Fracturing propping agent and preparation method thereof

InactiveCN106967409AReduce procurement costsAct as a skeleton supportFluid removalDrilling compositionPotassiumPotassium feldspar

The invention provides a fracturing propping agent and a preparation method thereof, and relates to the field of petroleum and gas exploration materials. The fracturing propping agent is mainly prepared from the following raw materials in percentage by mass: 60-75% of shale, 10-25% of bauxite propping agent wastes and 5-15% of potassium feldspar. By adopting the fracturing propping agent, the technical problems that in the prior art a fracturing propping agent is high in price of raw materials, high in production cost and low in cost performance are solved, and technical effects that the raw material cost is lowered, the production cost is lowered and the cost performance is improved are achieved.

Owner:ZHENGZHOU RUNBAO REFRACTORY MATERIAL CO LTD

Gypsum board with composite glass fiber veneering felts on surfaces

InactiveCN108166695AAct as a skeleton supportHigh tensile strengthCovering/liningsGlass/slag layered productsPolyesterGlass fiber

The invention discloses a gypsum board with composite glass fiber veneering felts on surfaces, and relates to decorative boards for buildings. The gypsum board is mainly composed of a gypsum board core layer and the composite glass fiber veneering felts which are attached to the outer sides of the gypsum board core layer, and the composite glass fiber veneering felts comprise following raw materials of, by weight, 35-50 parts of glass fiber chopped wires, 30-45 parts of polyester fibers, and 10-25 parts of wood fibers; and the glass fiber chopped wires have a diameter of 30-35 mu and a lengthof 30-35 mm, the polyester fibers have a diameter of 20-30 mu and a length of 30-35 mm, and the wood fibers have a diameter of 14-20 mu and a length of 20-30 mm. According to the gypsum board with thecomposite glass fiber veneering felts on the surfaces, various fiber materials such as glass fibers, the polyester fibers and the wood fibers to form the composite glass fiber veneering felts with the effects of fire retardant, sound proofing and noise reduction and water proofing and mould proofing; and the composite glass fiber veneering felts are combined with a gypsum board core, or special materials are added into the gypsum board core, so that the effects of the fire retardant, the sound proofing and noise reduction and the water proofing and mould proofing are improved, and the servicelife is prolonged.

Owner:TAISHAN GYPSUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com