Composite porous electrode, single cell and cell stack containing same and preparation method thereof

A technology of porous electrodes and monomers, which is applied in battery electrodes, regenerative fuel cells, fuel cell parts, etc., can solve the problem of difficult balance between the porosity and hardness of porous electrodes, and achieve the purpose of improving hardness and modulus, reducing Effect of contact resistance and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

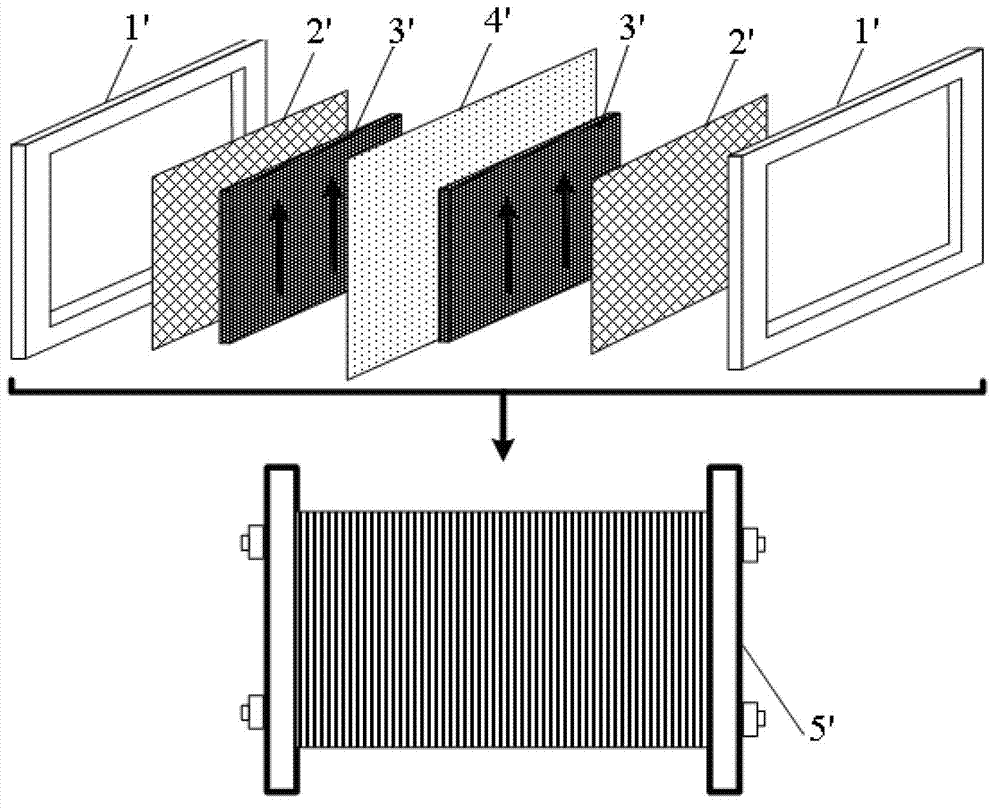

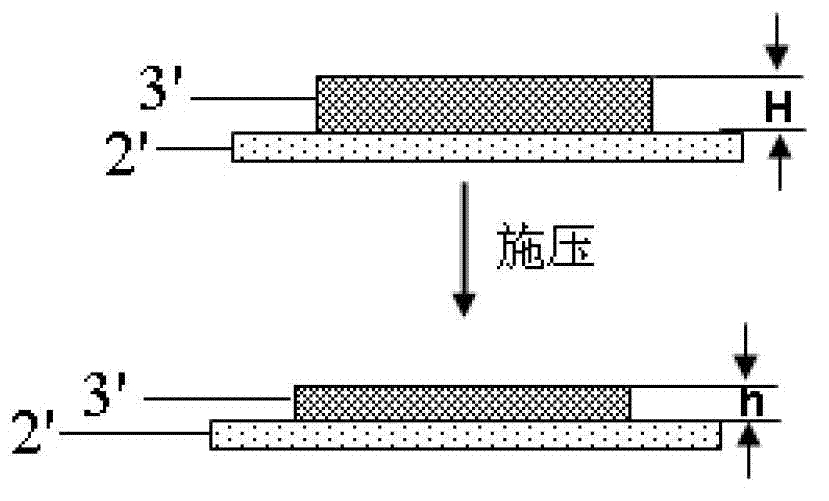

[0039] In another typical embodiment of the present invention, a method for preparing the composite porous electrode of the present invention is also provided. When the composite porous electrode includes an integrally formed porous electrode body 31 and a reinforcement part 33, the preparation method includes the following Steps: A1. Divide the area where the reinforced part 33 is to be formed in the porous electrode body 31 as the reinforced part matrix; and A2. Impregnate the resin material into the internal pores of the reinforced part matrix, and adhere the resin layer on the inner wall of the pore of the reinforced part matrix , form the reinforcing part 33, obtain the composite porous electrode 3; or when the composite porous electrode 3 includes the porous electrode body 31 and the reinforcing part 33 that are separately arranged, the preparation method includes the following steps: B1, dividing the porous electrode body 31 into multiple A region to be formed with the r...

Embodiment 1

[0059] Raw materials: Graphite felt is selected as the material of the porous electrode body, the porosity is 85%, and the external dimensions are 36mm*36mm*8mm. Polystyrene is selected as the impregnating resin, and the solvent is dimethylformamide.

[0060] making process

[0061] Preparation of reinforcement matrix: Divide two groups of cylindrical regions parallel to each other on the graphite felt. There are three cylindrical regions in each group of regions. Adjacent cylindrical regions between groups are arranged correspondingly. The total of all cylindrical regions The volume is 20% of the total volume of the composite porous electrode. The graphite felt in this area is cut out as the reinforcement matrix, and the remaining graphite felt with cylindrical through holes is used as the porous electrode body;

[0062] Preparation of reinforcement: Dissolve polystyrene resin in dimethylformamide to form a solution with a mass concentration of 18%, then immerse the matrix o...

Embodiment 2

[0066] Raw materials: Graphite felt is selected as the porous electrode body material, with a porosity of 85% and an overall size of 36mm*36mm*8mm. High-density polyethylene is selected as the impregnating resin.

[0067] making process

[0068] Preparation of reinforcement matrix: Divide two groups of regions parallel to each other on the graphite felt, each group of regions has three mutually isolated cylindrical regions, adjacent cylindrical regions between groups are arranged correspondingly, all cylindrical regions The total volume is 15% of the total volume of the composite porous electrode;

[0069] Prepare the reinforced part: Melt the high-density polyethylene into a melt at 180 °C; then place the melt on the upper end of the reinforced part matrix, immerse the melt into the reinforced part matrix, and wait until the melt is uniformly impregnated to the reinforced part In the matrix of the part, slowly cool to 25 °C to precipitate and solidify the polyethylene resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com