Formula of preparation liquid for hollow-fibre membrane and products thereof

A fiber membrane and membrane-making liquid technology, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of low water flux of hollow fiber membranes, reduced membrane water flux, and insufficient hydrophilicity. , to achieve the effect of simple film forming process, reasonable proportion and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

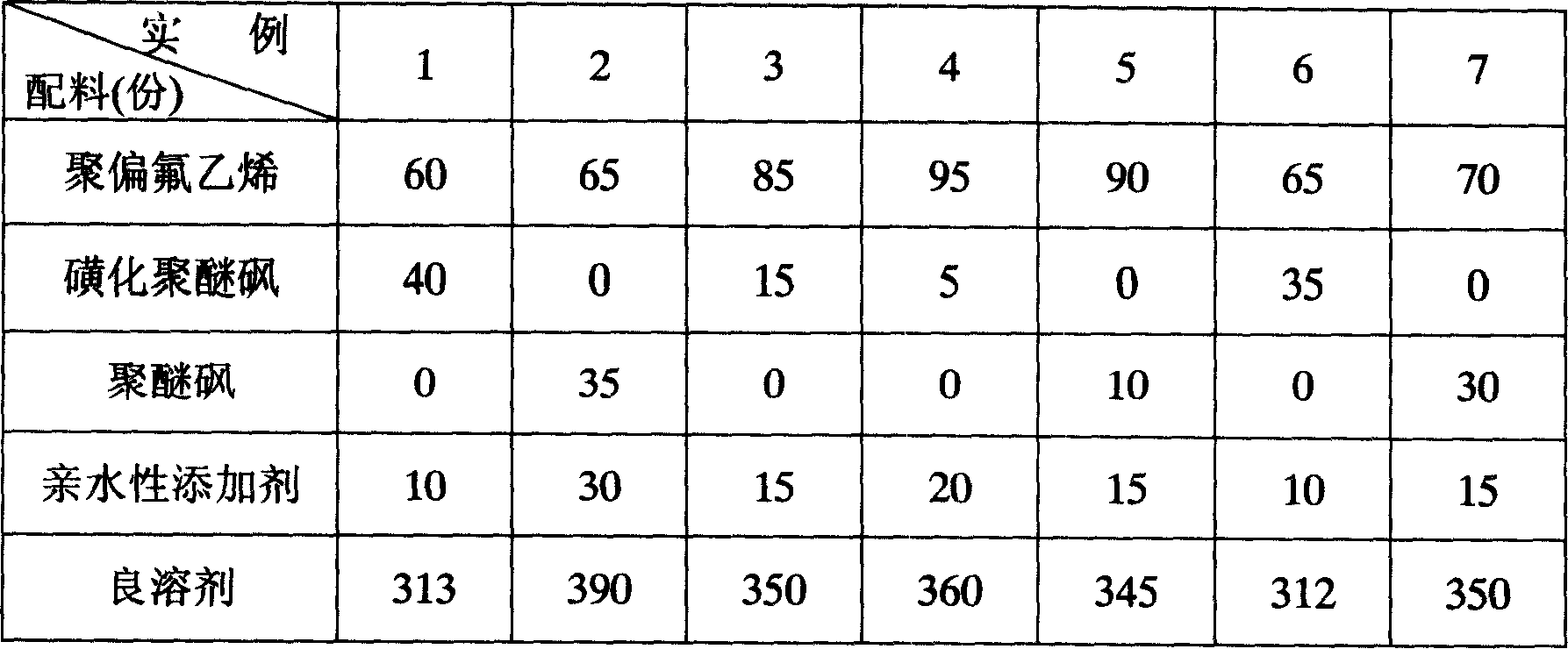

[0019] Take column 1 in Table 1 as an example to illustrate its specific implementation.

[0020] Step 1, after taking 60 parts of PVDF solid powder and 40 parts of solid SPES particles in the container and vigorously mechanically stirring them evenly, gradually add 313 parts of N, N'-dimethylacetamide (DMAc) to the feed liquid tank, adding while adding Stir to dissolve evenly. After stirring for 4 hours, 10 parts of PVP in DMAc solution was added to the mixture, and the stirring was continued until it was uniformly dissolved, which allowed the grafting of the hydrophilic additive into the blend through a chemical reaction.

[0021] Step 2, when the above mixed solution is stable, let stand or centrifuge to remove air bubbles. After defoaming, it is extruded into the annular space of the spinneret by a metering pump under a pressure of about 4 atmospheres. At the same time, the internal coagulation solidification bath quantitatively enters the insertion tube of the spinneret...

Embodiment 2

[0023] The hollow fiber membrane was prepared according to the same method and steps as in Example 1, except that the blend was PES. Taking column 2 in the table as an example, take 65 parts of PVDF solid powder and 35 parts of solid PES particles and stir vigorously in the container, and then gradually add 390 parts of solvent N,N'-dimethylformamide to the feed liquid tank , Stir while adding to make it dissolve evenly. After stirring for 4 hours, add N,N'-dimethylformamide solution containing 30 parts of PVP to the mixed solution, and continue to stir until it is uniformly dissolved. The outer diameter of the prepared hollow fiber membrane is 1.0mm, the inner diameter is 0.5mm, the porosity is 70%, the average pore diameter is 0.08μm, and the pure water flux is 530L / m at room temperature and 150kPa 2 h.

Embodiment 3

[0025]The hollow fiber membrane was prepared according to the same method and steps as in Example 1, except that the blend was PES. Take the third column in the table as an example, take 85 parts of PVDF solid powder and 15 parts of solid sulfonated PES particles in the container and stir them vigorously mechanically, then gradually add to the feed liquid tank containing 350 parts of solvent N-methyl-2-pyrrolidone , Stir while adding to make it dissolve evenly. After stirring for 4 hours, 15 parts of PVP was added to the mixture, and the stirring was continued until the mixture was uniformly dissolved. The outer diameter of the prepared hollow fiber membrane is 1.2mm, the inner diameter is 0.6mm, the porosity is 40%, the average pore diameter is 0.08μm, and the pure water flux is 400L / m at room temperature and 150kPa 2 h.

[0026] The ingredients of Embodiment 4 to Embodiment 7 are shown in Table 1 below, and the specific production process and other contents refer to the kn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com