Fusion cake dry granule mainly prepared from waste glaze and preparation method thereof

A main raw material, waste technology, used in the field of dry frit and its preparation, can solve the problems of human body and biological hazards, foaming, impurities, etc., to improve wear resistance and slip resistance, reduce environmental pollution, and high economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Further explanation, a kind of preparation method of the frit dry granule that takes waste and old glaze as main raw material, comprises the following steps:

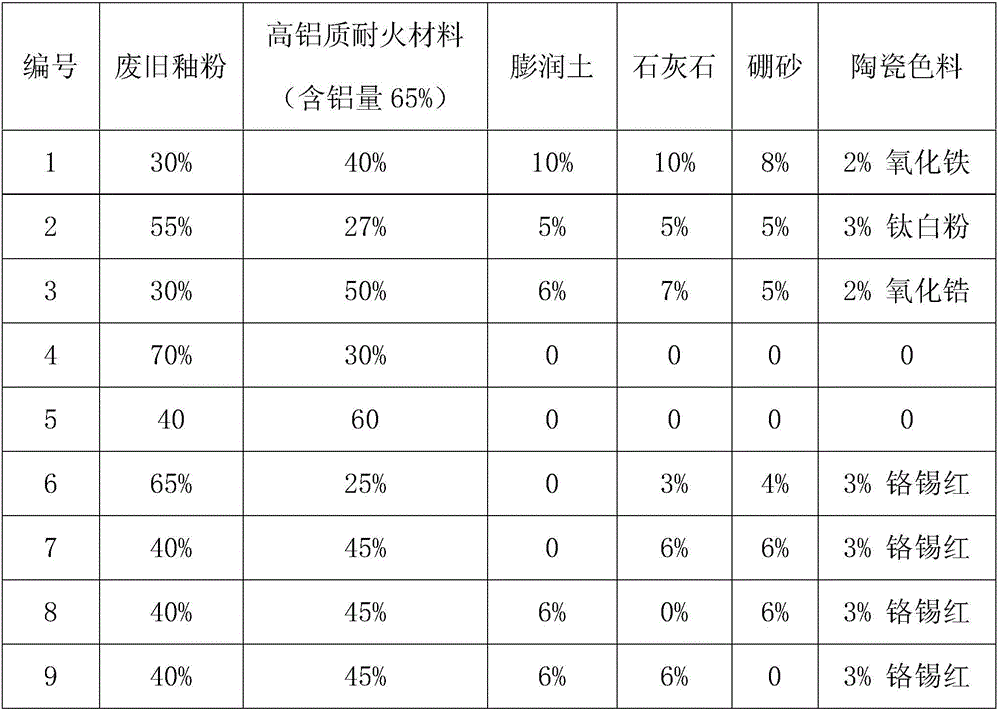

[0039] A. Weigh waste glaze powder, high alumina refractory material, bentonite, limestone, borax and ceramic pigment according to the proportion, and mix evenly;

[0040] B. Melt at 1250-1450°C and keep warm for 1-2 hours;

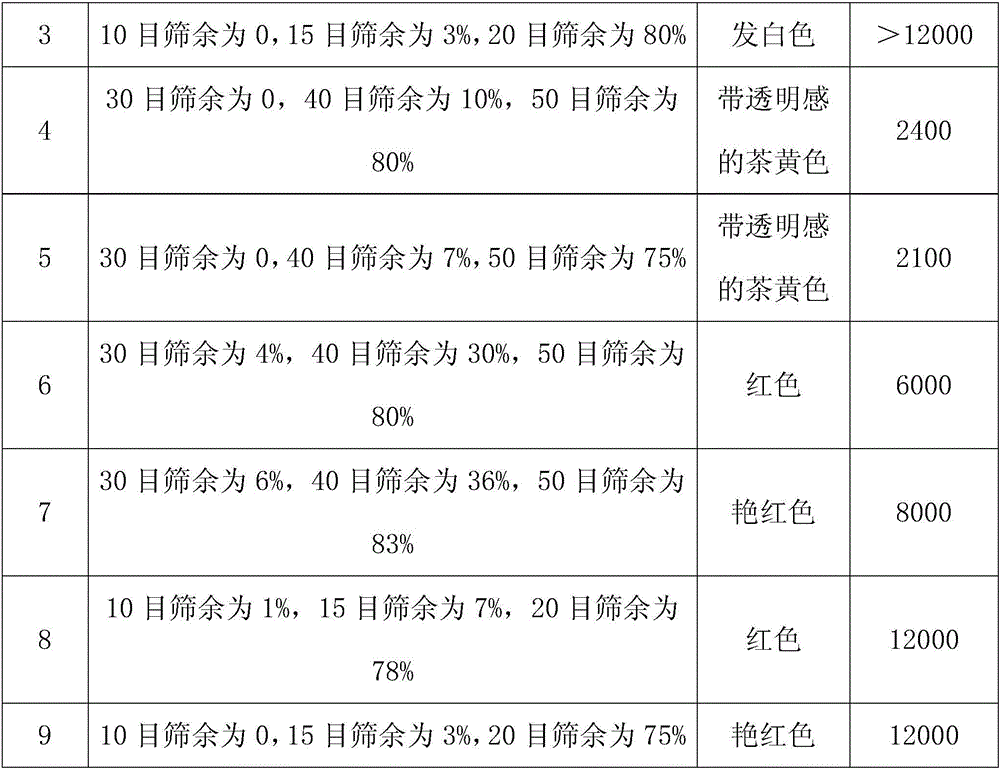

[0041] C. The material is quenched in water, dried, pulverized and granulated to obtain frit dry granules with a particle size of 10-50 mesh.

[0042]Further explanation, the preparation method of described waste glaze powder is as follows:

[0043] (1) Homogenization and precipitation: Pour the waste glaze slurry recovered from each process into a glaze vat with a mixer to mix evenly, and add 1% sedimentation agent when mixing;

[0044] (2) After the glaze slurry is precipitated, the water on the upper layer of the glaze slurry is taken out to obtain a glaze slurry with a water content of...

Embodiment

[0048] A preparation method of wear-resistant and non-slip frit dry granules for ceramic surface decoration with waste glaze as main raw material, which comprises the following steps:

[0049] Step 1) Preparation of waste glaze powder:

[0050] (1) Homogenization and precipitation: Pour the waste glaze slurry produced in the ball glaze workshop, glaze line and other processes into a glaze vat equipped with a mixer to mix evenly, and add 1% settling agent (polymerized chlorine) during the mixing process. Al2) allows the glaze slurry to settle quickly;

[0051] (2) After the glaze slurry is precipitated, the water on the upper layer of the precipitated glaze slurry is taken out to obtain a glaze slurry with a water content of about 30%;

[0052] (3) Extrusion: the glaze slurry with a water content of about 30% is pumped to the press machine for pressing by a slurry pump to obtain a glaze slurry with a water content of about 20%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com