Fibrous formed products and methods for manufacturing such fibrous formed products

a technology fibrous materials, which is applied in the field can solve the problems of increasing the overall machine cost, and achieve the effect of reducing the machine cost for manufacturing and increasing the relative manufacturing efficiency of fibrous formed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first representative embodiment

[0053] (First Representative Embodiment)

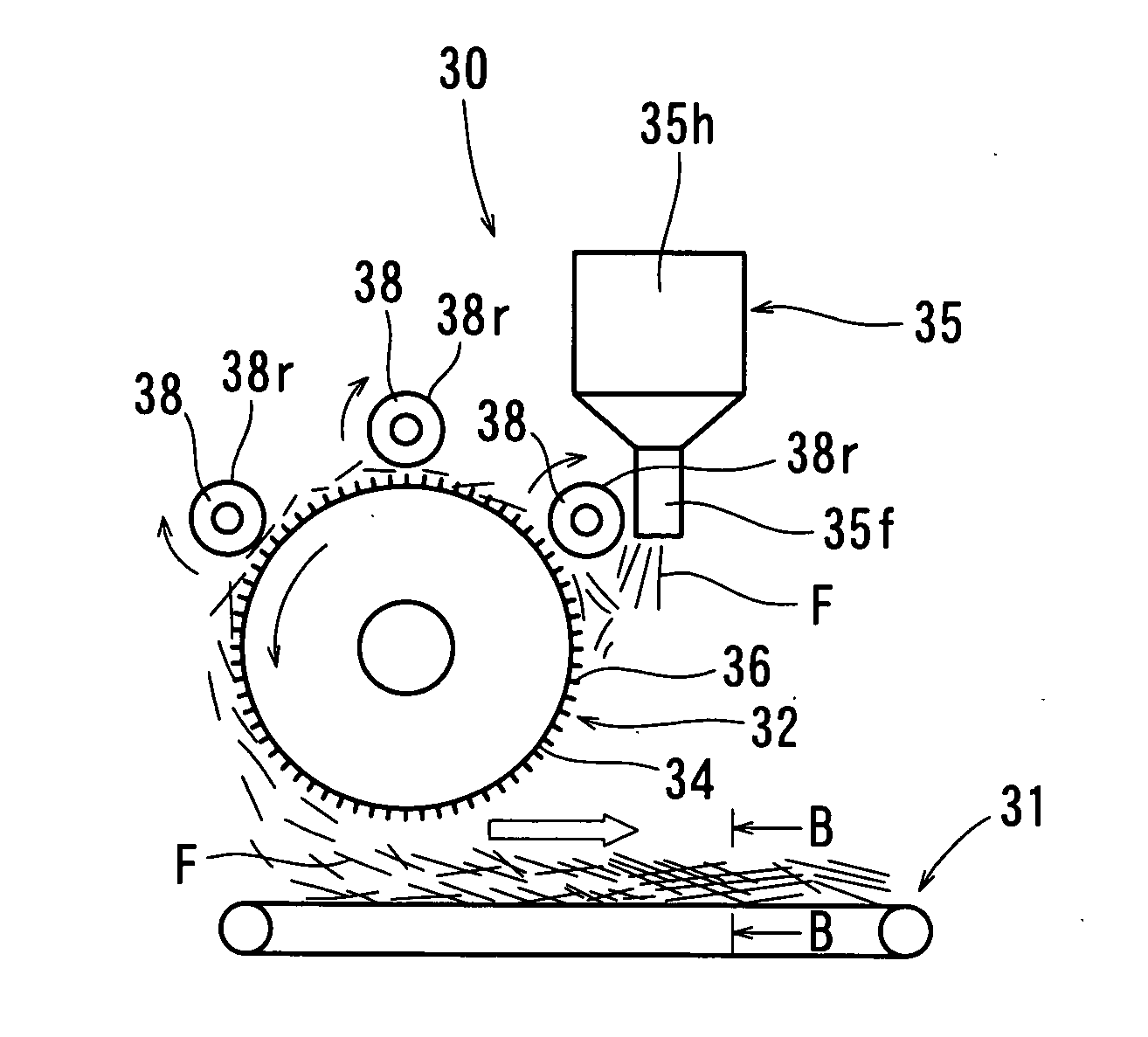

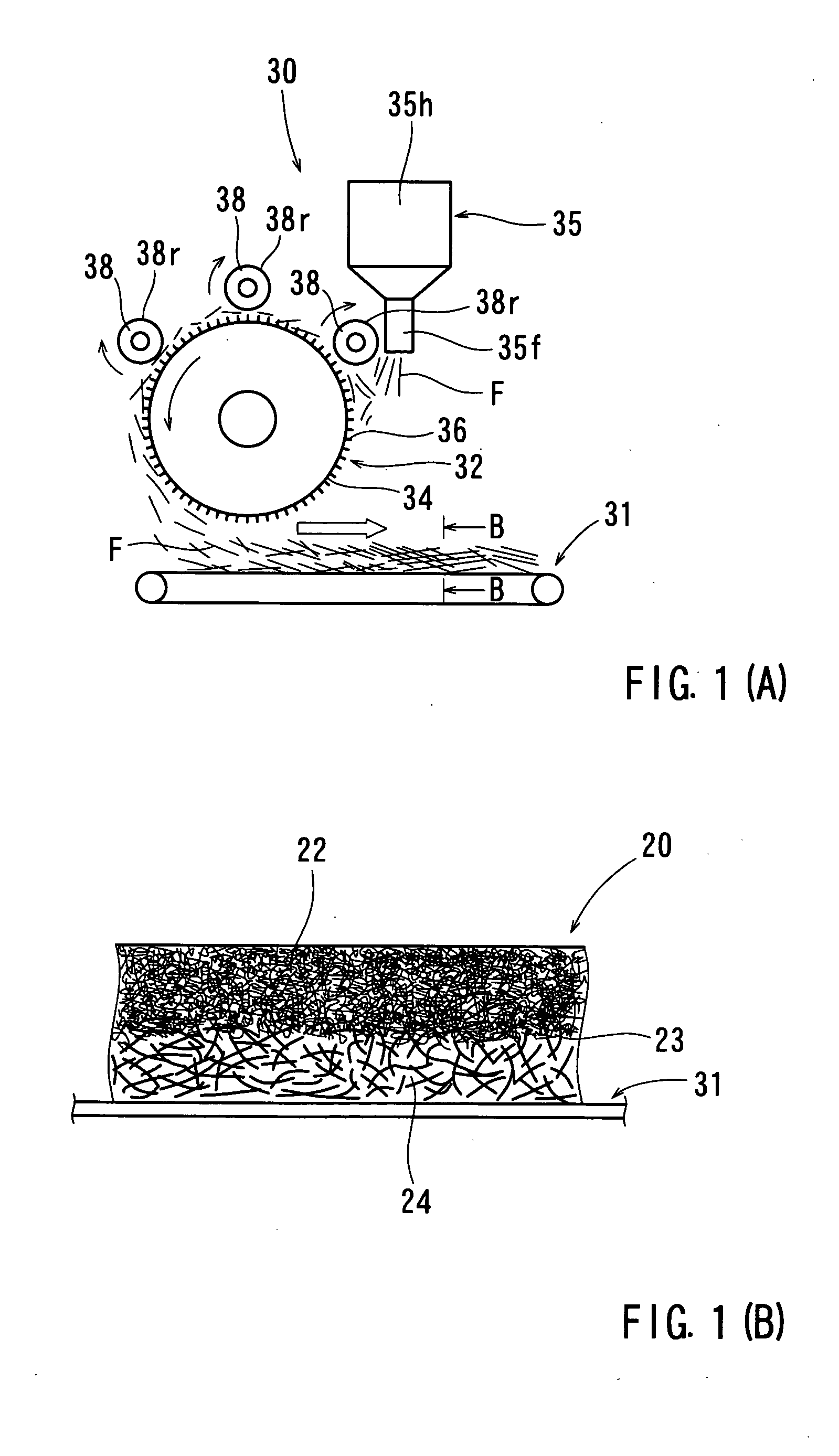

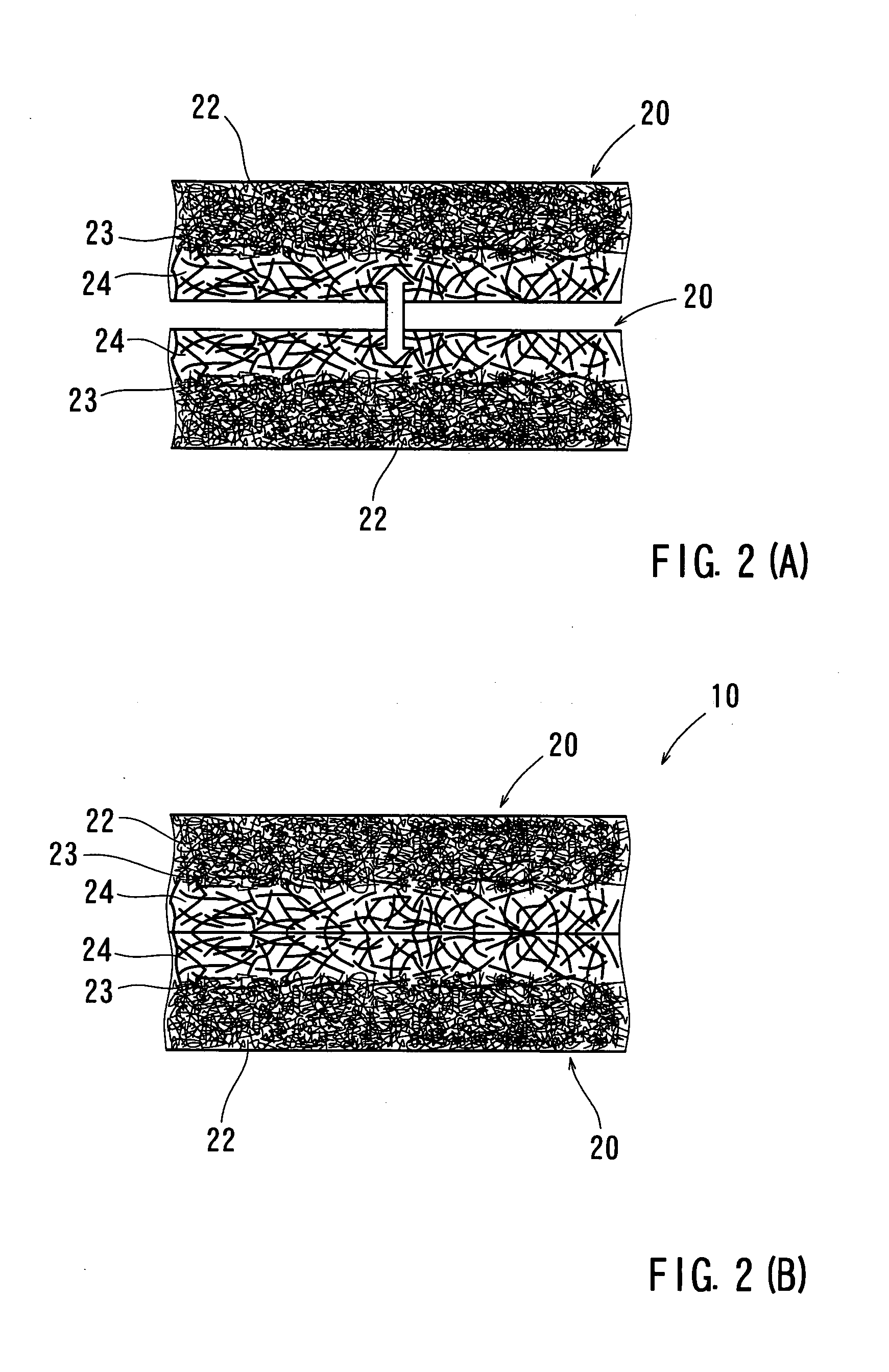

[0054] A first representative fibrous formed product and a first representative method of manufacturing such a fibrous formed product will now be described with reference to FIGS. 1 through 4. The first representative fibrous formed product is embodied as a panel that may be used as the base material of a ceiling member in an automobile. FIG. 1(A) shows a first representative machine 30 for manufacturing a fibrous mat. FIGS. 2(A) and 2(B) show steps of manufacturing a fibrous mat that becomes the material of a fibrous formed product. FIGS. 3(A) through 3(D) show the steps of manufacturing a ceiling member of an automobile.

[0055] Referring to FIG. 2(B), a fibrous formed product 10 is made of two sheets of fibrous mats 20. Each of the fibrous mats 20 are formed by approximately 25% by weight of natural fibers, approximately 25% by weight of inorganic fibers, and approximately 50% by weight of thermoplastic fibers. The natural fibers preferably ...

second representative embodiment

[0079] (Second Representative Embodiment)

[0080]FIG. 4(A) is a schematic view of a second representative fibrous mat manufacturing machine 1 that can continuously form two fibrous mats 20 so that they are automatically overlaid in the correct orientations with one another.

[0081] The machine 1 includes a first machine section 30a, for manufacturing one of the two fibrous mats 20 (hereinafter called “first fibrous mat 20”) and a second machine section 30b, for manufacturing the other of the two fibrous mats (hereinafter called “second fibrous mat 20”). The basic construction of the first machine section 30a and the construction of the second machine section 30b are substantially the same as with the first representative machine 30, described previously. Therefore, in FIG. 4(A), the parts of the first and second machine sections that are the same as parts of the first representative machine 30 are labeled with the same reference numerals. A repeated description of these parts will not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com