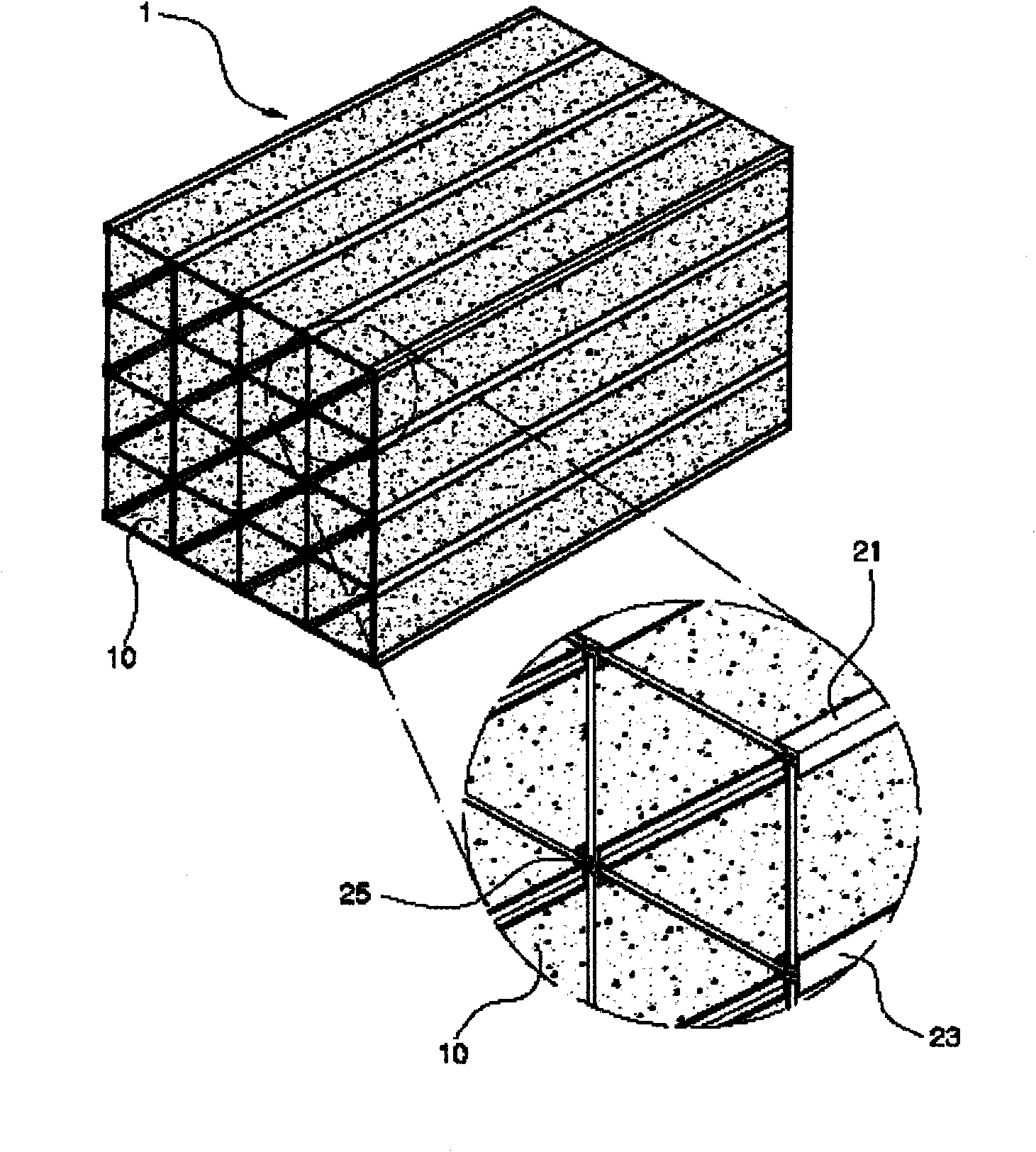

Grate muffler and preparation method thereof

A muffler and lattice technology, applied in the direction of sound insulation, building components, etc., can solve the problems of fine dust and other harmful substances, short service life, non-waterproof, etc., and achieve good sound absorption effect, no dust pollution, and easy service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0047] In another embodiment of the present invention, a method for preparing a lattice-type muffler is provided, which is characterized in that it includes the following steps:

[0048] Prepare foamed aluminum plate;

[0049]Cutting the foamed aluminum plate according to the set size and thickness;

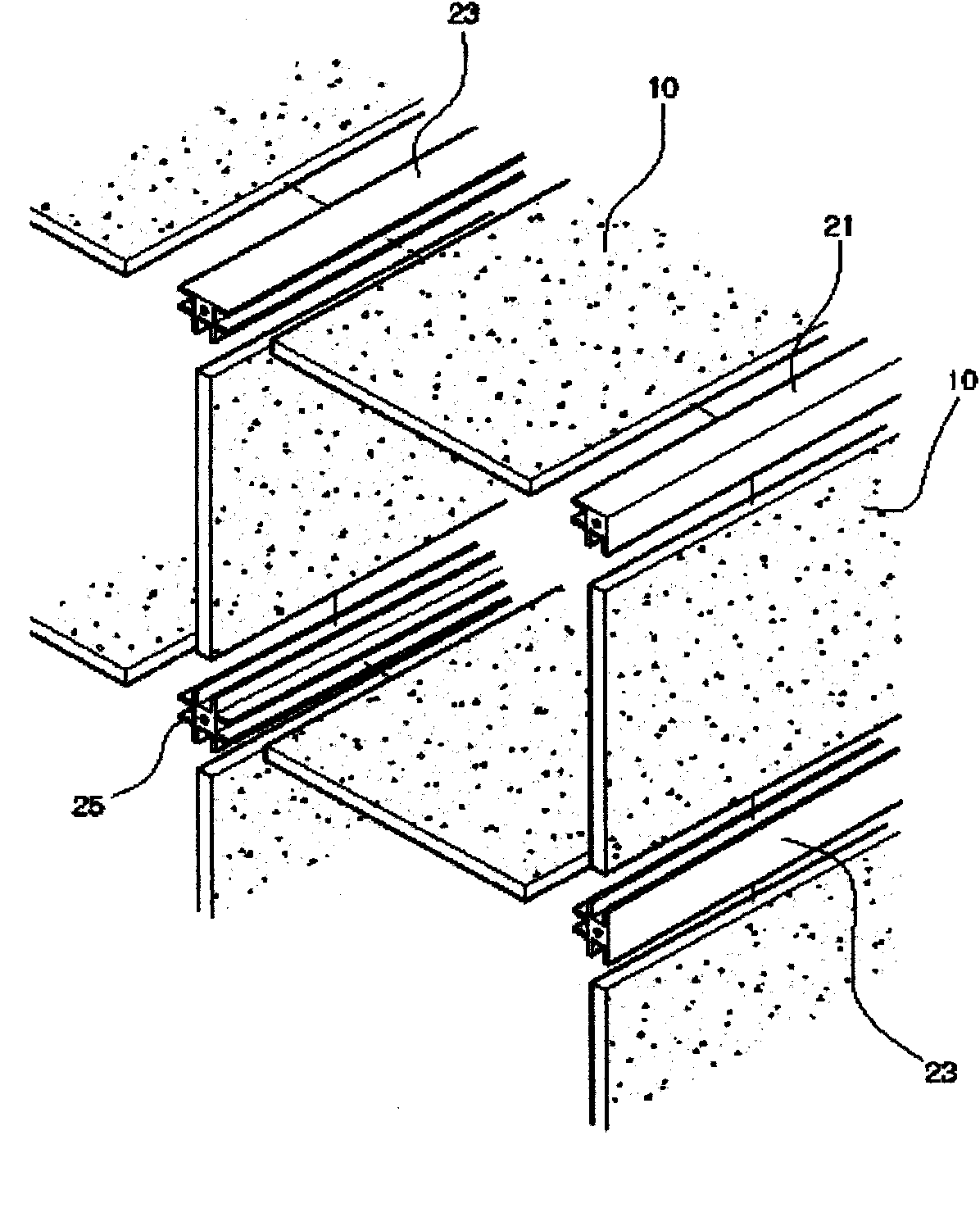

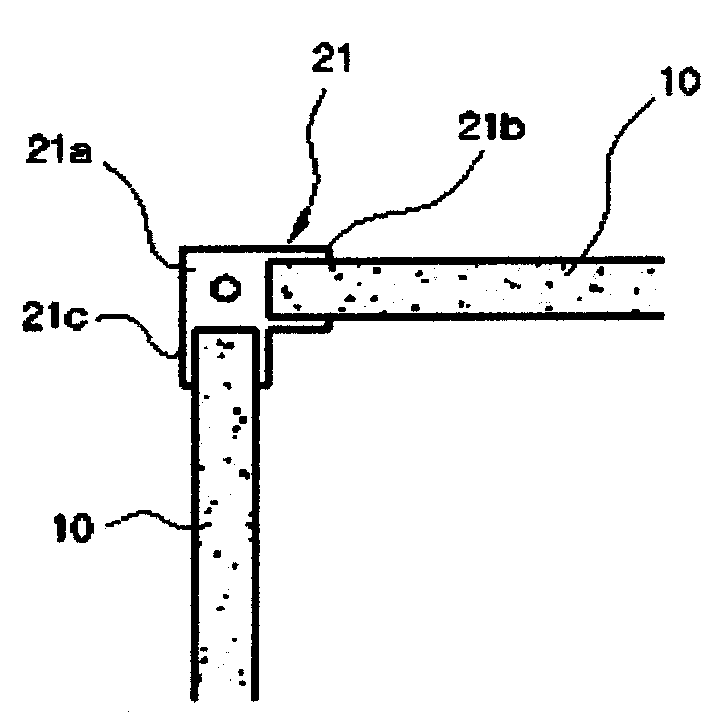

[0050] The cut foamed aluminum plates are respectively embedded in the fixed parts of the first frame, the second frame and the third frame, and assembled into a lattice type muffler.

[0051] The step of inlaying the cut foamed aluminum plates into the fixed parts of the first frame, the second frame, and the third frame respectively to form a grid-type muffler may further include: firstly put the first frame in place, and place the foamed The aluminum plates are respectively embedded in the two fixed parts of the first frame, and the upper, lower, left and right parts are respectively connected to the second frame; the foamed aluminum plates are respectively embedded in the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com