Interior decoration part for automobile and method for manufacturing the same

A technology for automotive interior parts and components, applied in the field of automotive interior parts and its manufacturing, can solve the problems of increased manufacturing costs of metal molds, long molding cycles, high material costs, etc., to reduce the amount of resin and simplify reprocessing. Utilize the effect of excellent operation and sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

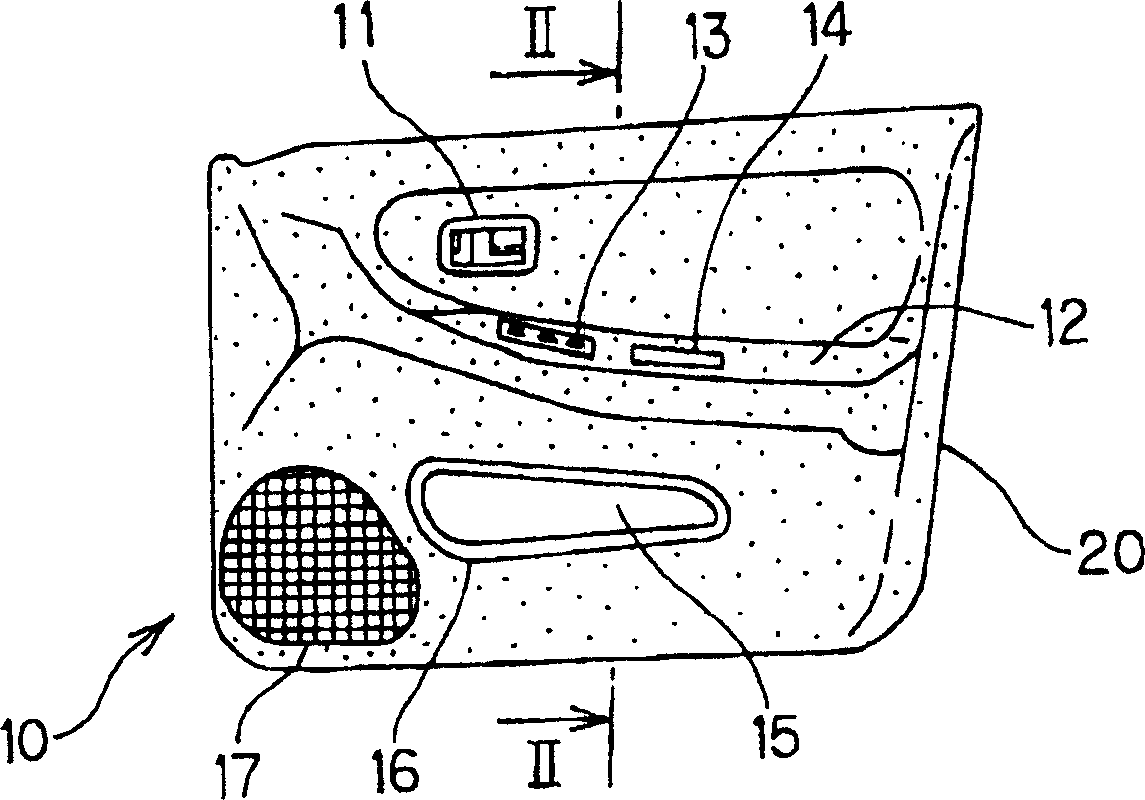

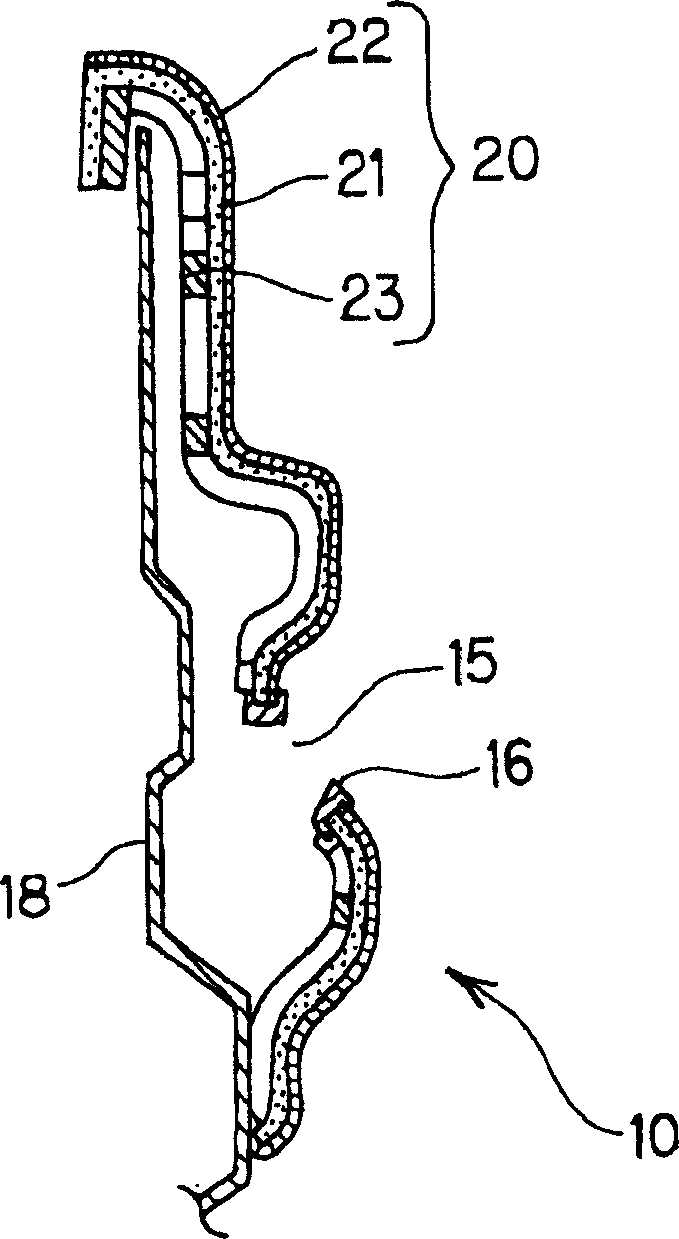

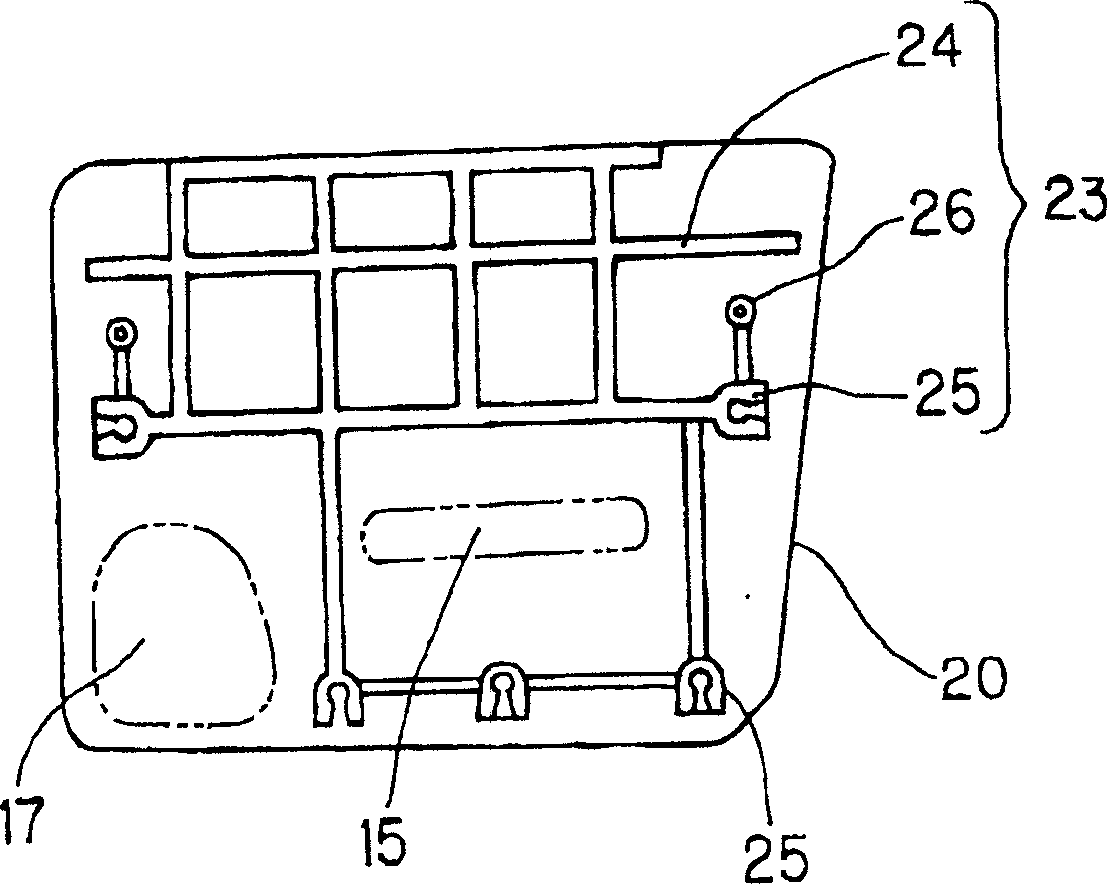

[0070] Figure 1 to Figure 10 Representing the first embodiment of the present invention, figure 1 To show a front view of an automotive interior part, figure 2 is a sectional view showing the structure of the automotive door trim, image 3 It is an explanatory drawing showing the arrangement pattern of the resin rib plate of the door trim for this automobile, Figure 4 It is an explanatory view showing a hook mounting seat of the door trim for an automobile and a reinforcing flash portion formed around a resin molded portion such as a protrusion, Figure 5 is a cross-sectional view showing the structure of the main part of the door trim for the automobile, Figure 6 , Figure 7 An overall view and a sectional view of main parts showing the molding die used for molding the automotive door trim, Figure 8 to Figure 10 It is an explanatory drawing showing each process of the manufacturing method of the door trim for an automobile.

[0071] First, in Figure 1 to Figure 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com