Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Shorten the forming cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

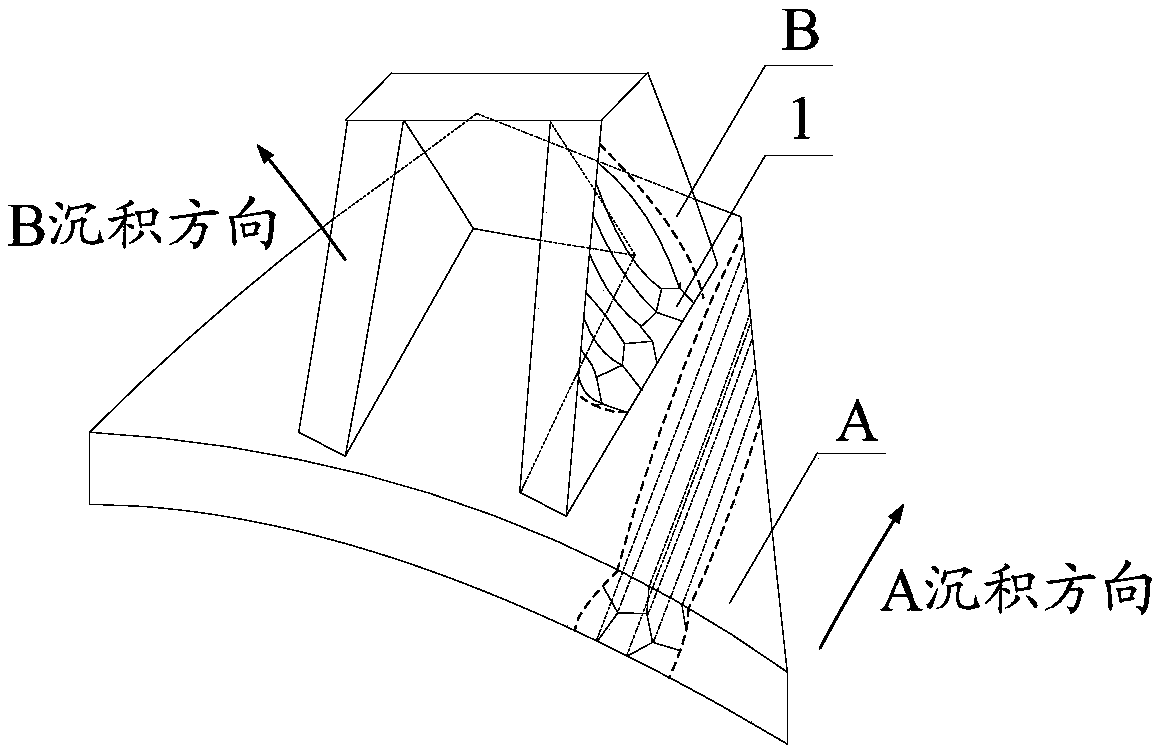

Method for forming large complex thin-wall shell with circumferential inner ribs

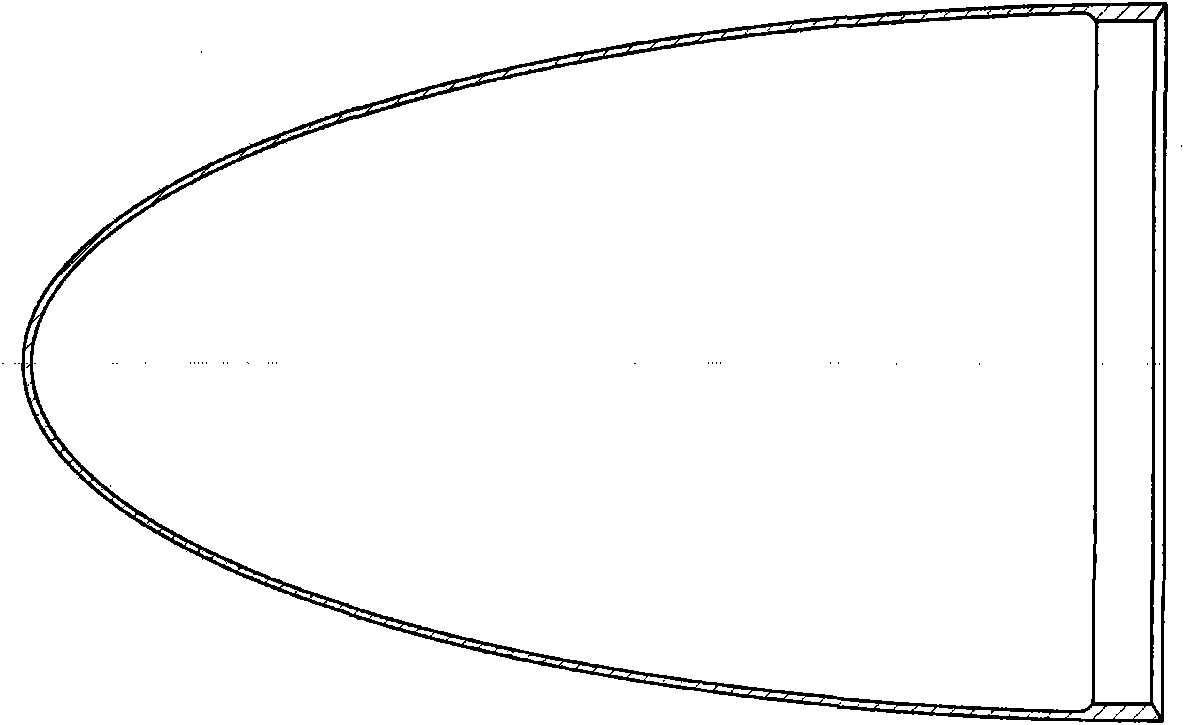

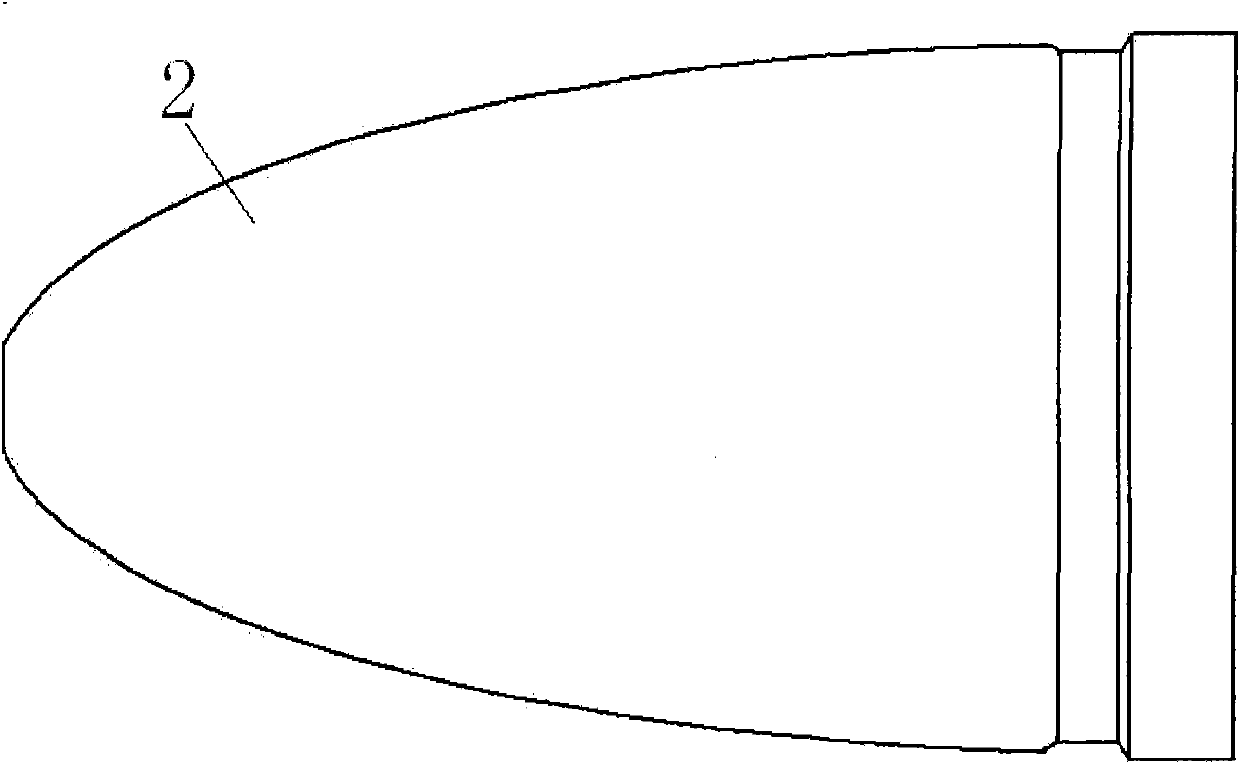

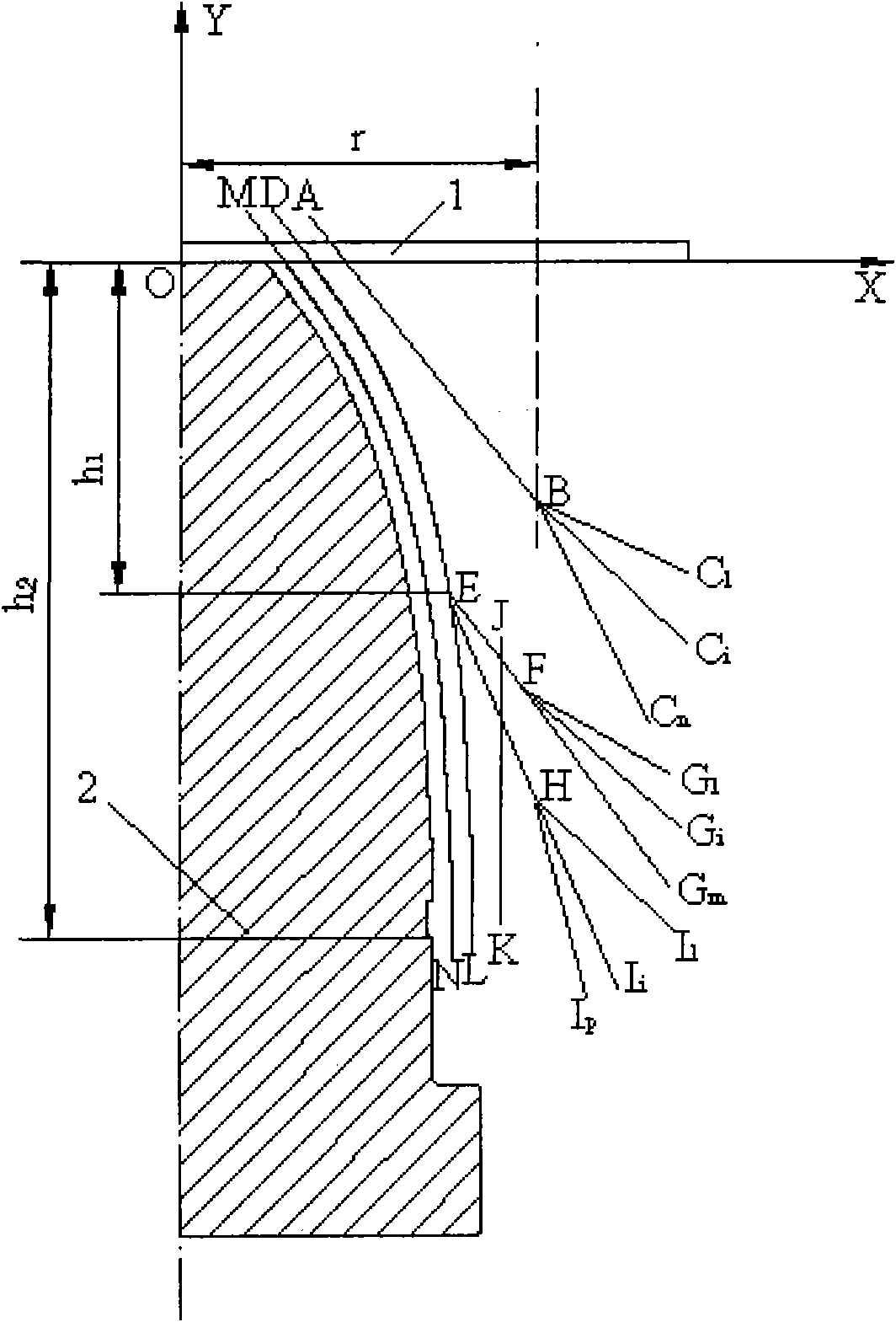

The invention relates to a method for forming a large complex thin-wall shell with circumferential inner ribs. The large complex thin-wall shell with the circumferential inner ribs is formed by adopting a composite spinning method combining strong spinning and general spinning. The method comprises the steps of: in forming, firstly determining the radius of an initial position to be ribbed on a plate blank, the height of the head of a filmed spin-forming part and the axial distance between a final ribbed position of a spinning piece and the top end of the spinning piece, and then forming by composite spinning in multiple rounds. In the method, under the conditions that only one core die and one set of rotary wheels are adopted, a prefabricated blank is not needed, intermediate annealing phase does not need to be adopted and no subsequent machining is needed, due to adoption of a reasonable composite spinning process, the flat plate blank is spun to form the large complex thin-wall shell with the circumferential inner ribs, so that the forming period is shortened, the cost is reduced, and large amount of manpower resources, material resources and financial resources are saved. The invention provides scientific basis for the spin-forming process scheme of the large complex thin-wall shell with the circumferential inner ribs and the determination of tracks of the rotary wheels, which is beneficial to promotion of further development of the advanced theory and technology of spinning.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Titanium alloy structural part and laser melting deposition forming method thereof

ActiveCN109261964AAvoid and eliminate the risk of severe crackingFast preparationAdditive manufacturing apparatusIncreasing energy efficiencyInterconnectionTitanium alloy

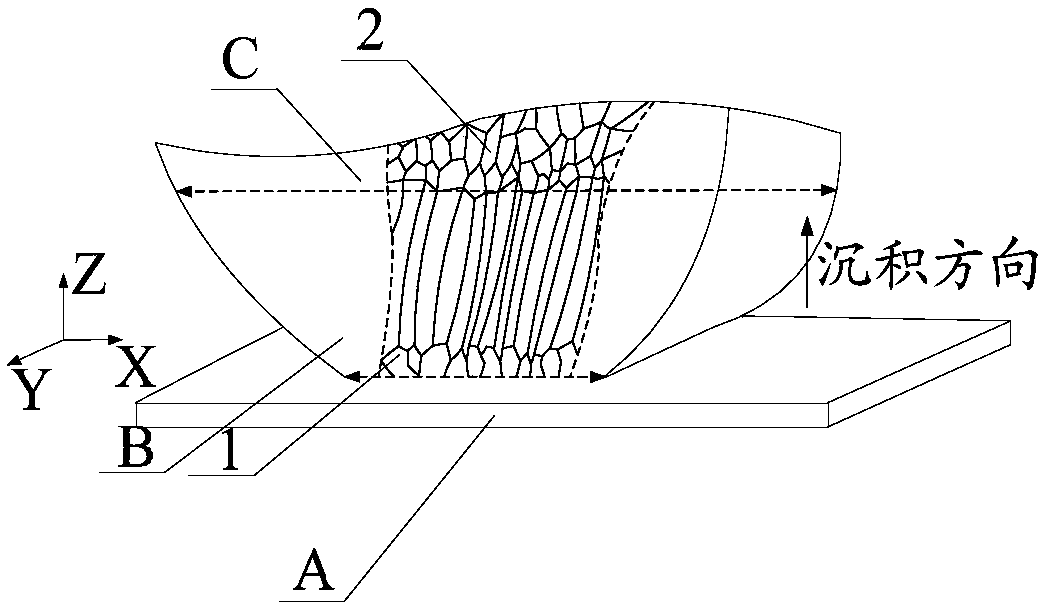

The invention belongs to the technical field of additive manufacturing and relates to a titanium alloy structural part and a laser melting deposition forming method thereof. The method includes steps:determining prone-to-crack areas of the titanium alloy structural part according to the size and structure of the titanium alloy structural part; adopting the laser melting deposition forming methodfor acquiring the titanium alloy structural part, wherein the grain morphology is controlled to be isometric crystal in forming of the prone-to-crack areas, and the grain morphology is controlled to be columnar crystal in forming of other areas. Deposited plasticity and ductility of the prone-to-crack areas are improved, serious cracking risks in a forming process of the titanium alloy structuralpart are effectively avoided and eliminated, and high forming efficiency is guaranteed. Compared with the prior art, the titanium alloy structural part and the laser melting deposition forming methodthereof have advantages that an interconnection process is avoided, special fixtures for clamping, positioning and the like are avoided, repeated machining before interconnection of small-size structures is avoided, once integral quick manufacturing of the titanium alloy structural part can be realized, and a forming period is remarkably shortened.

Owner:CAPITAL AEROSPACE MACHINERY +1

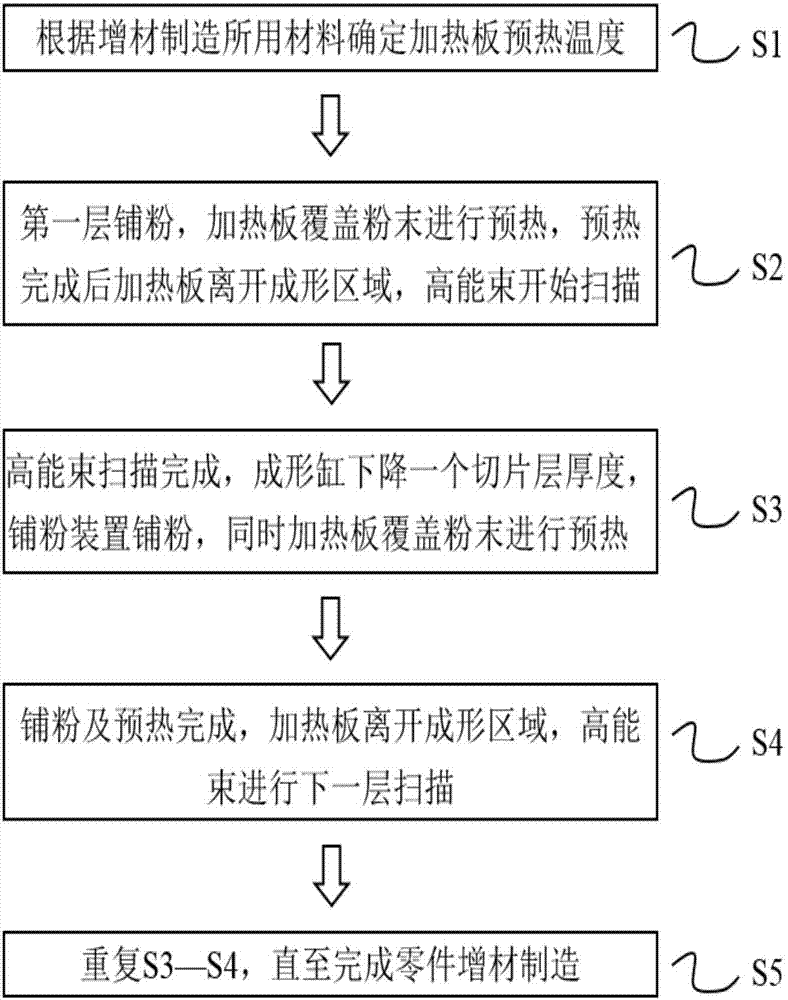

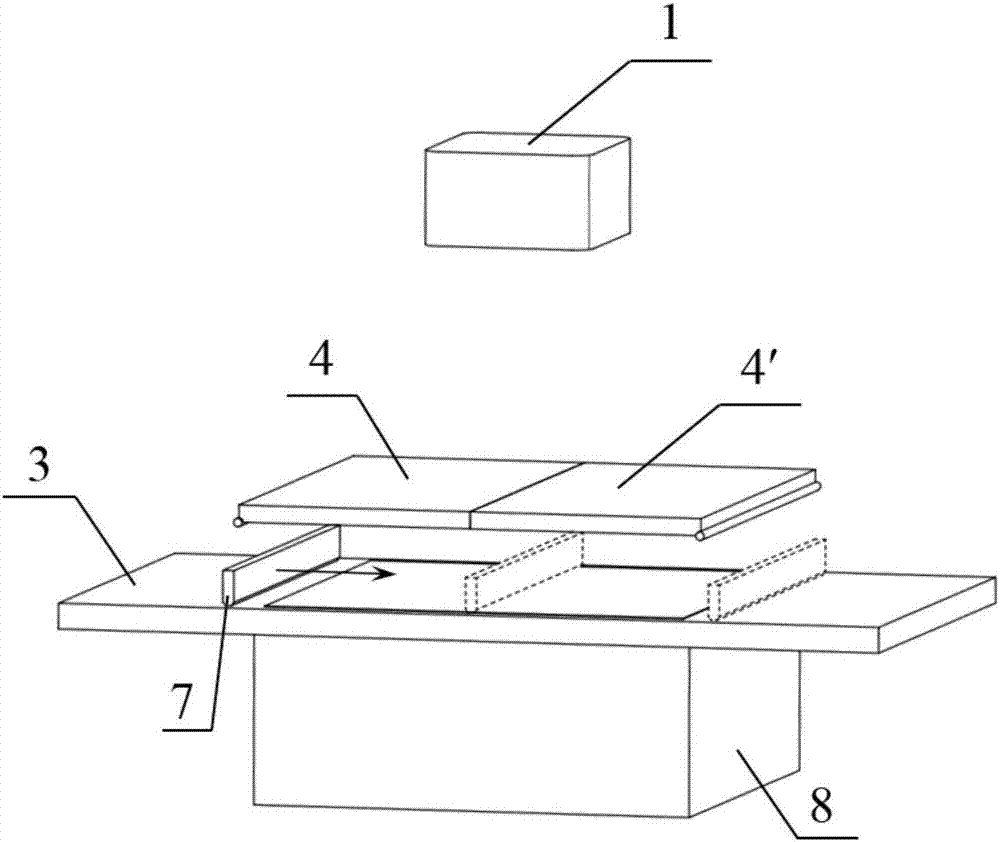

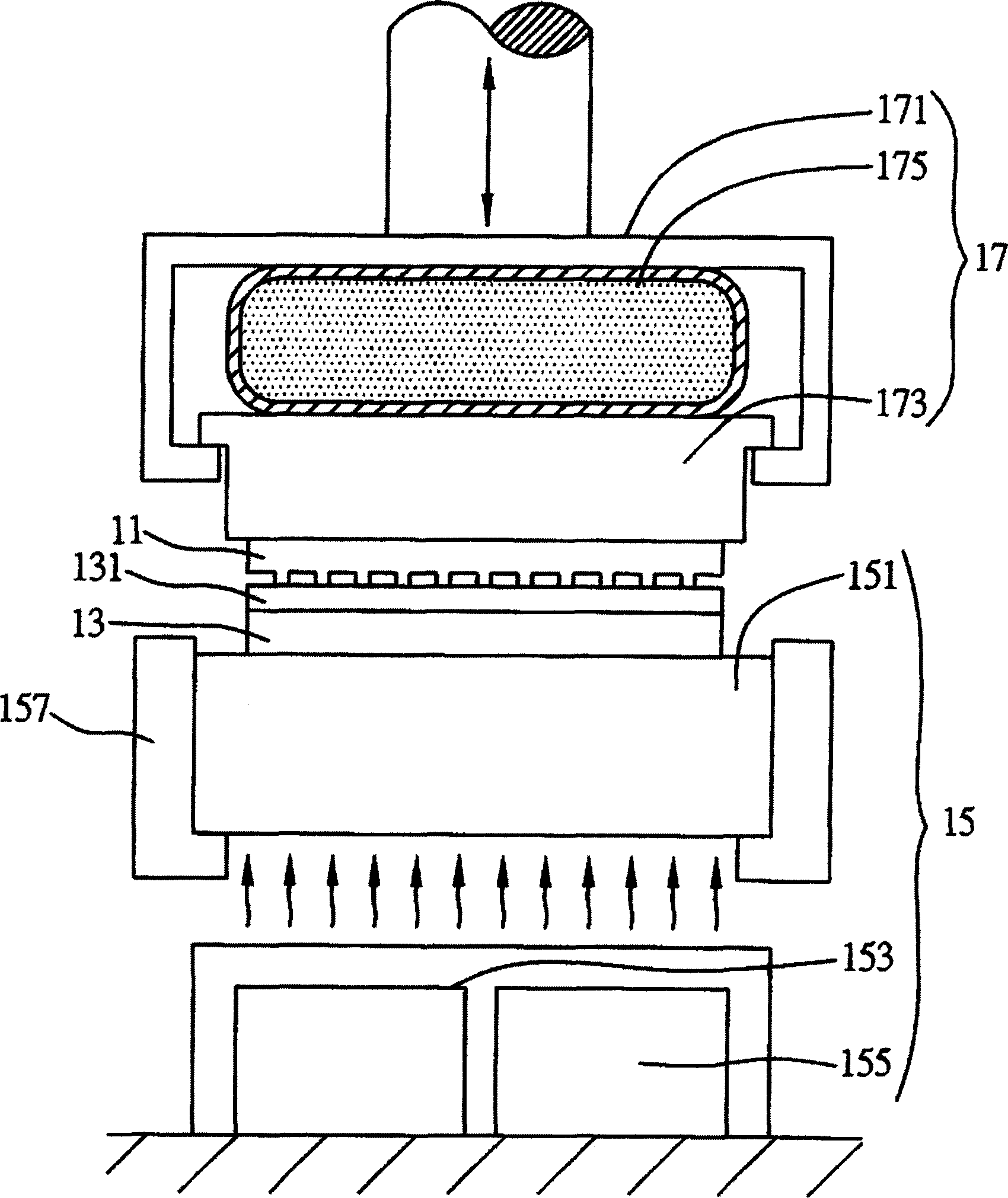

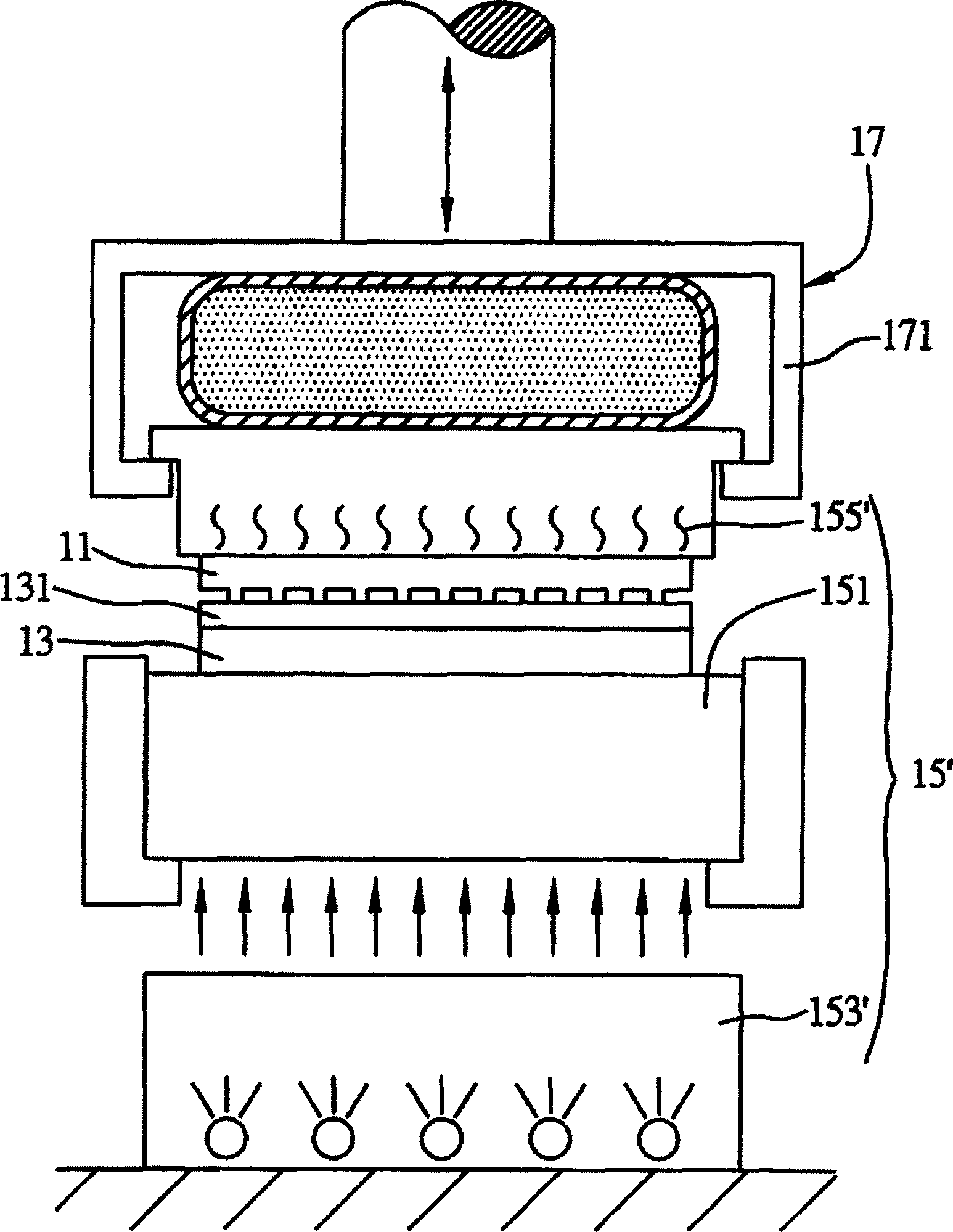

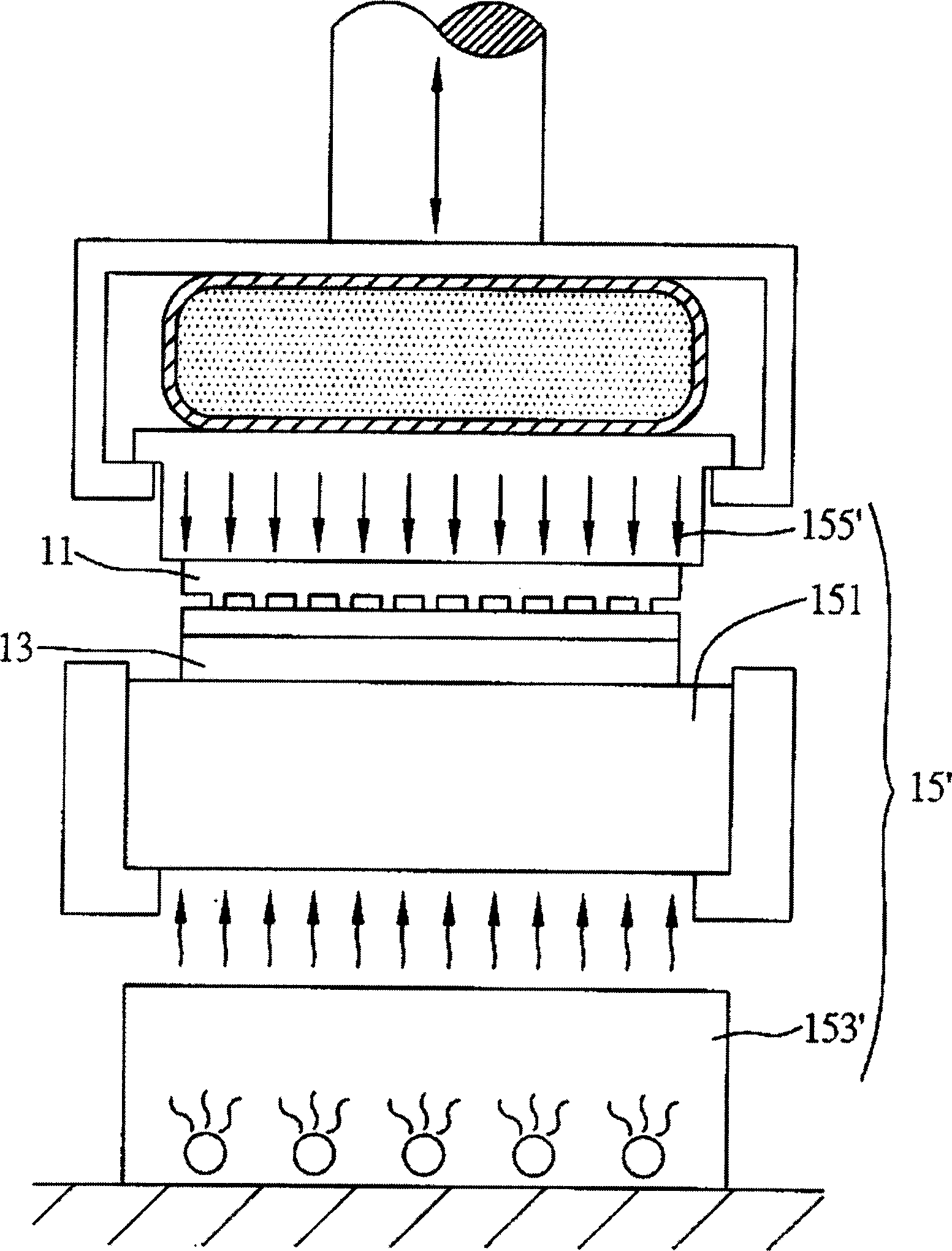

Preheating method and device suitable for powder laying type additive manufacturing

ActiveCN107379527AMonitor temperature in real timeHeating high temperatureManufacturing heating elementsIncreasing energy efficiencyControl systemMetallurgy

The invention provides a preheating method and device suitable for powder laying type additive manufacturing, and belongs to the technical field of additive manufacturing. A movable type plane heating plate capable of covering a whole powder bed is arranged over the powder bed, the mounting height of the plane heating plate is slightly larger than a powder laying device, in the powder laying process, the powder bed and parts are preheated, after powder laying is finished, a plane light source is closed and put away, and the phenomenon that in the machining process, the plane heating plate blocks a high-energy beam is avoided. In the heating process, a temperature measuring sensor is used for monitoring the temperature of the powder bed in real time, a control system is adopted to implement feedback control over preheating of the powder bed according to the temperature monitoring result, full-breadth covering type heating is adopted, and the powder bed and formed parts are subject to high-temperature, efficient and unifier preheating. The invention further provides the device achieving the above method. The method is wide in application material and high in expansibility and is particularly suitable for powder laying type additive manufacturing of multiple large-breadth high-energy beams.

Owner:HUAZHONG UNIV OF SCI & TECH

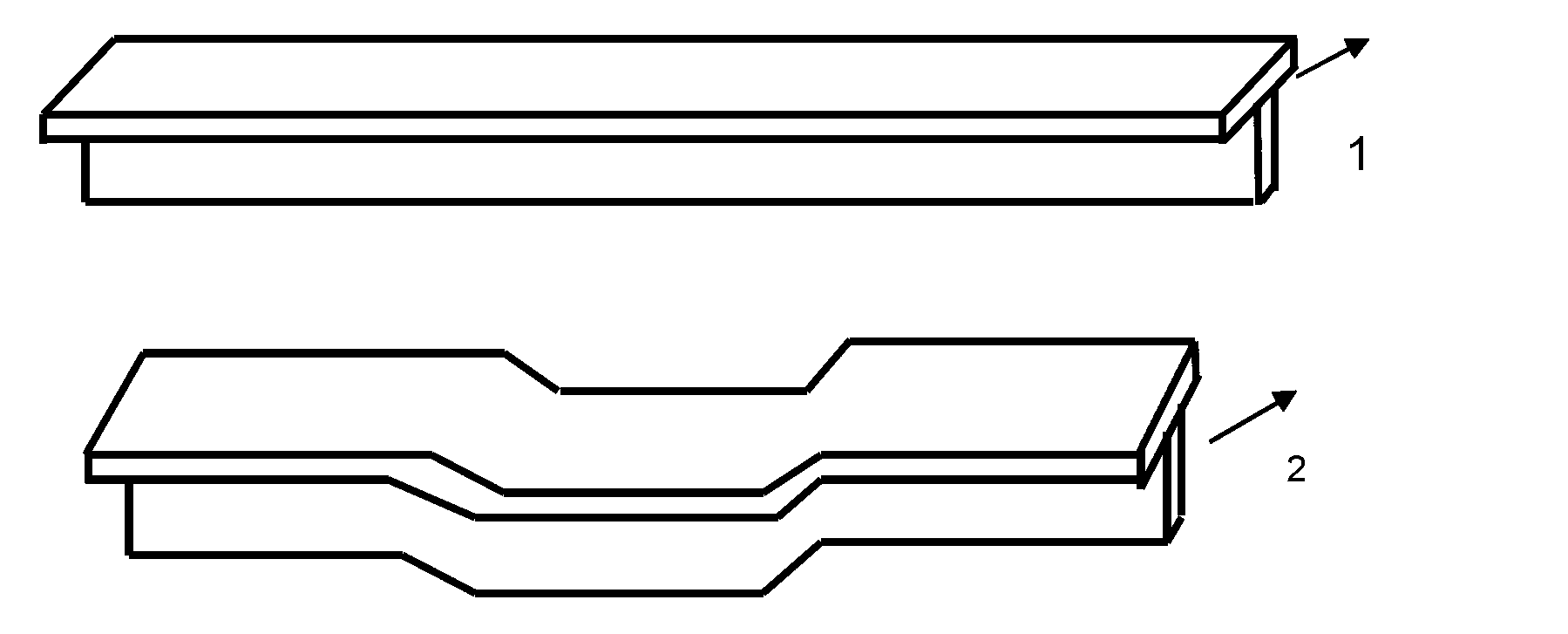

Rapid subsidence thermoforming mold and thermoforming method of aluminum alloy sections

The invention relates to a rapid subsidence thermoforming mold and a thermoforming method of an aluminum alloy section and in particular relates to the thermoforming mold and the thermoforming method of the aluminum alloy section. The invention aims at solving the problems that the heating efficiency of the existing subsidence thermoforming of the aluminum alloy sections is low, the entire production process is low in efficiency and not suitable for mass production due to the fact that local heating of the large aluminum alloy section is difficult. The rapid subsidence thermoforming mold comprises a male mold, a female mold, a contact-type electrode, a contract-type thermocouple, a pulsed power supply, a PID control system and a section blank. The rapid subsidence thermoforming method comprises the following steps of: placing the aluminum alloy section on the mold, carrying out rapid local heating on the section by virtue of pulse current assisted with self-block heating, and carrying out subsidence thermoforming to form a product with a desired shape by virtue of pressure. By utilizing the rapid subsidence thermoforming method, the heating efficiency can be improved by 300%-500%, the thermoforming cycle is shortened to 10-50 seconds, and the energy utilization rate can be improved by 200%-400%. The rapid subsidence thermoforming mold and the rapid subsidence thermoforming method are applied to the aerospace field.

Owner:HARBIN INST OF TECH

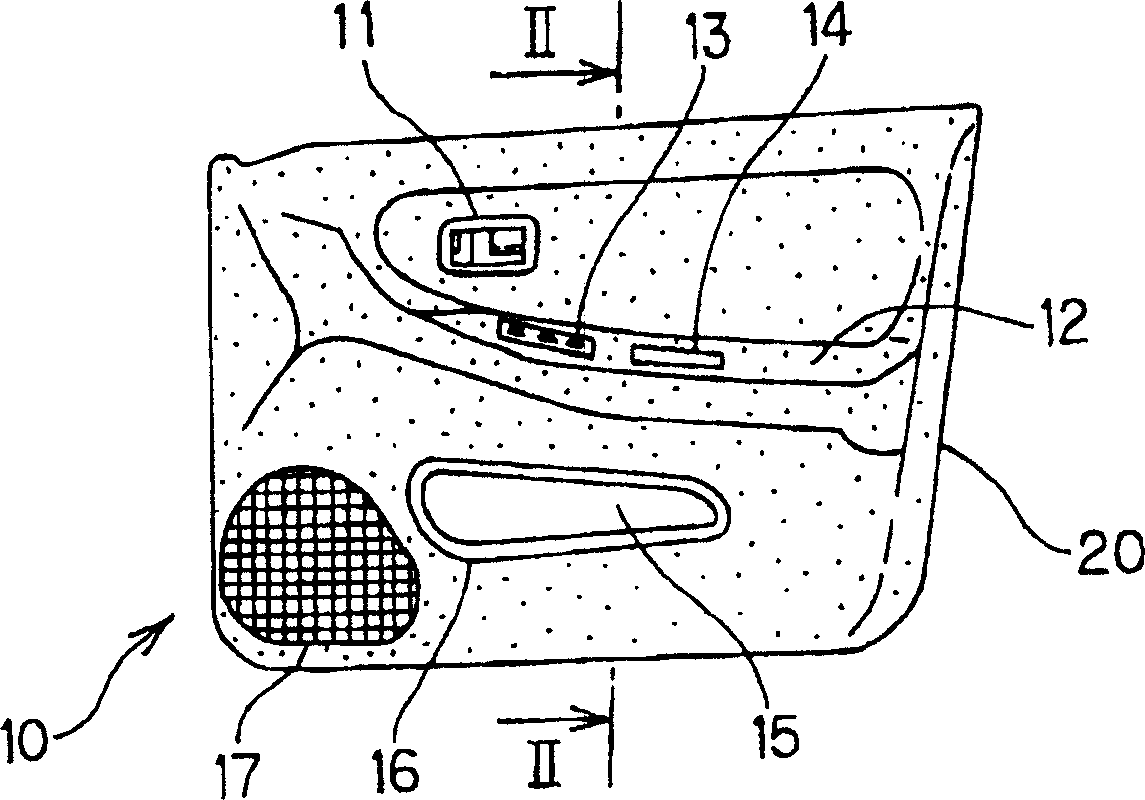

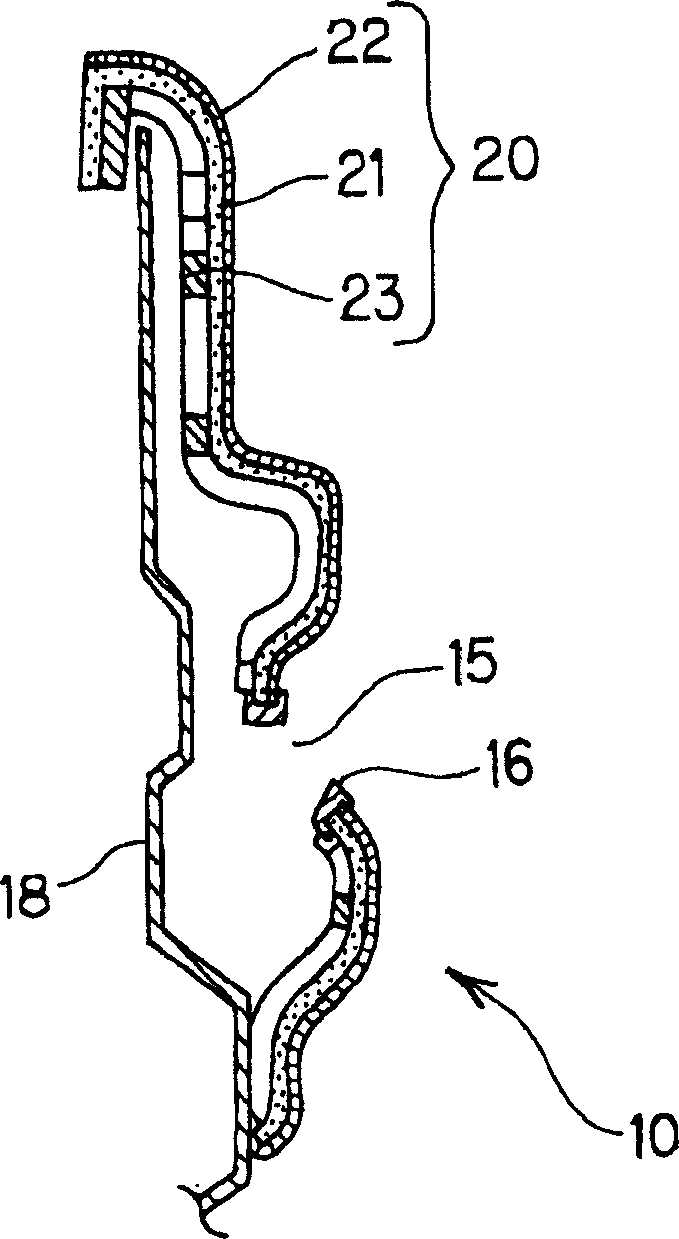

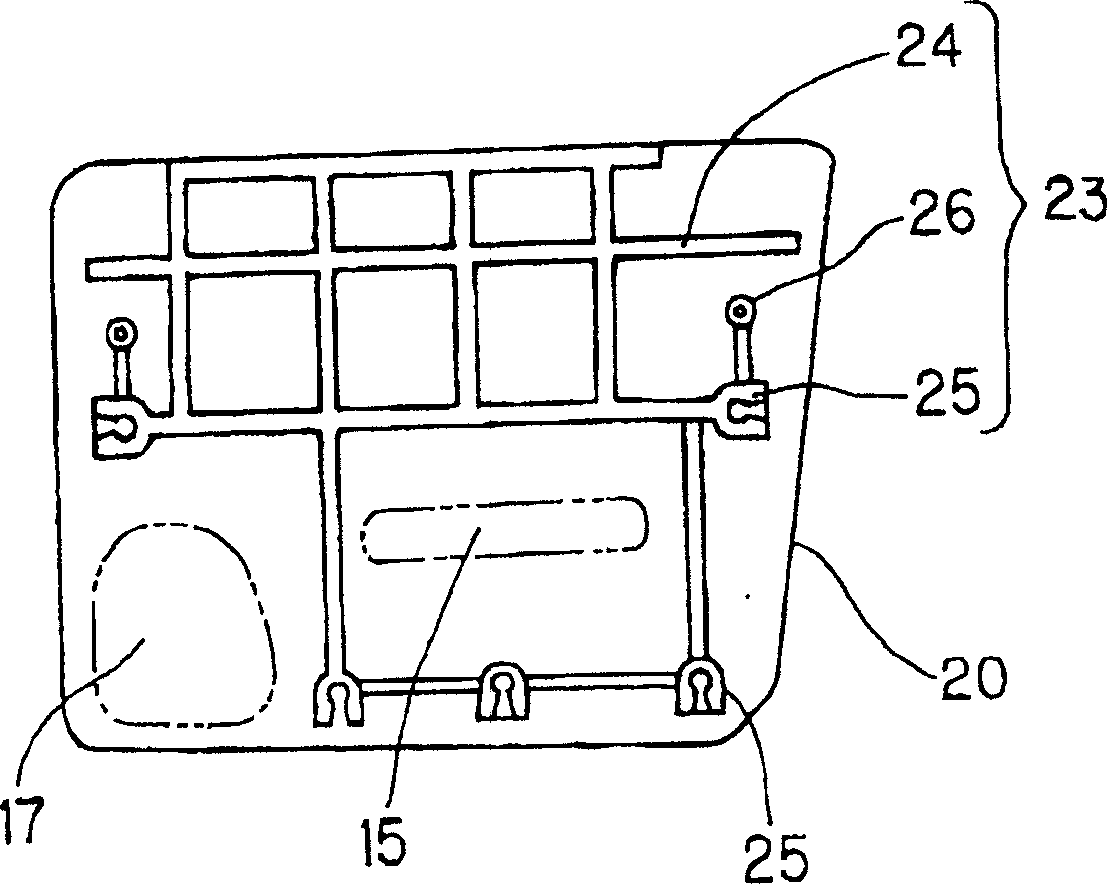

Interior decoration part for automobile and method for manufacturing the same

Owner:KASAI KOGYO CO LTD

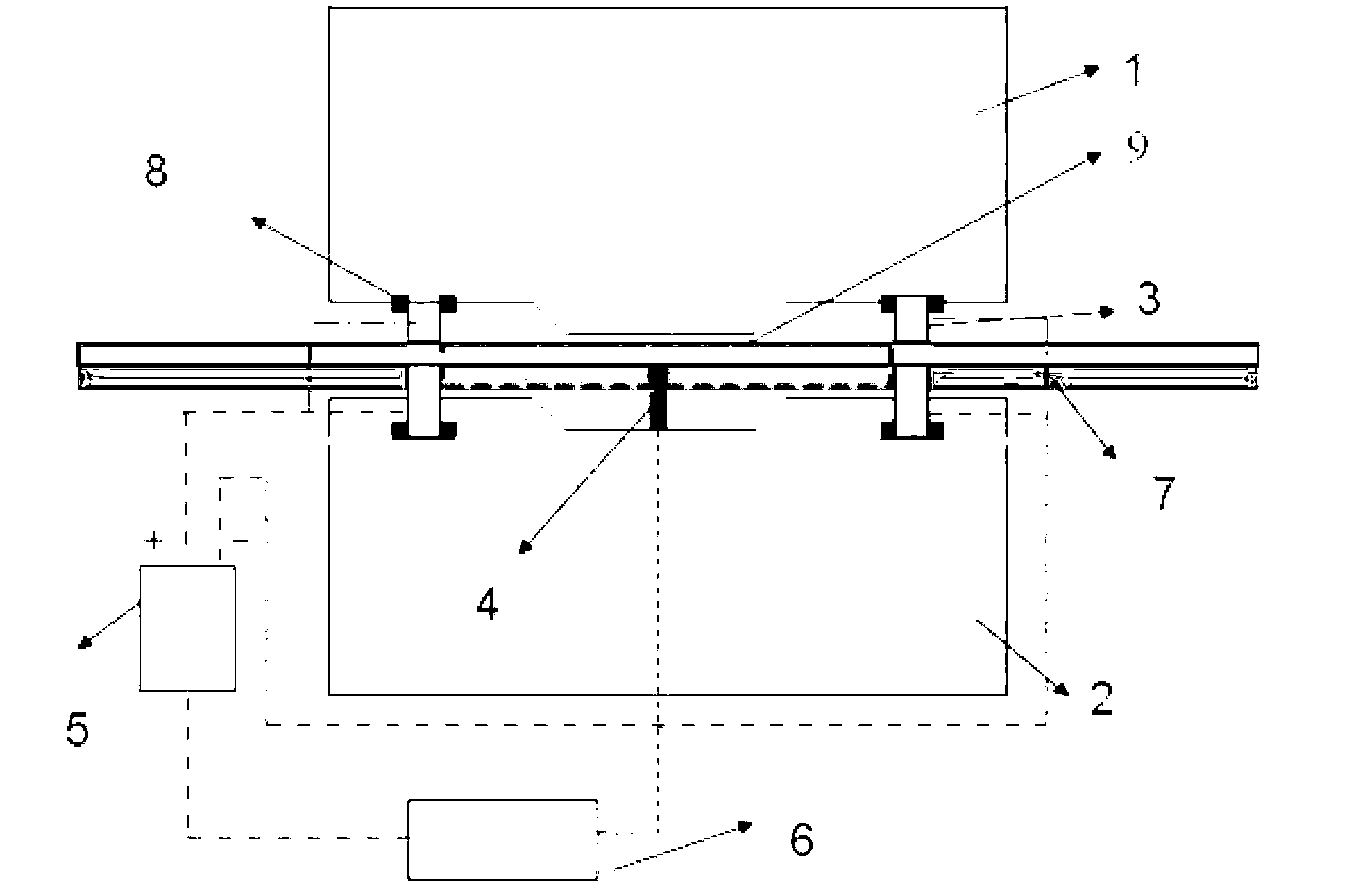

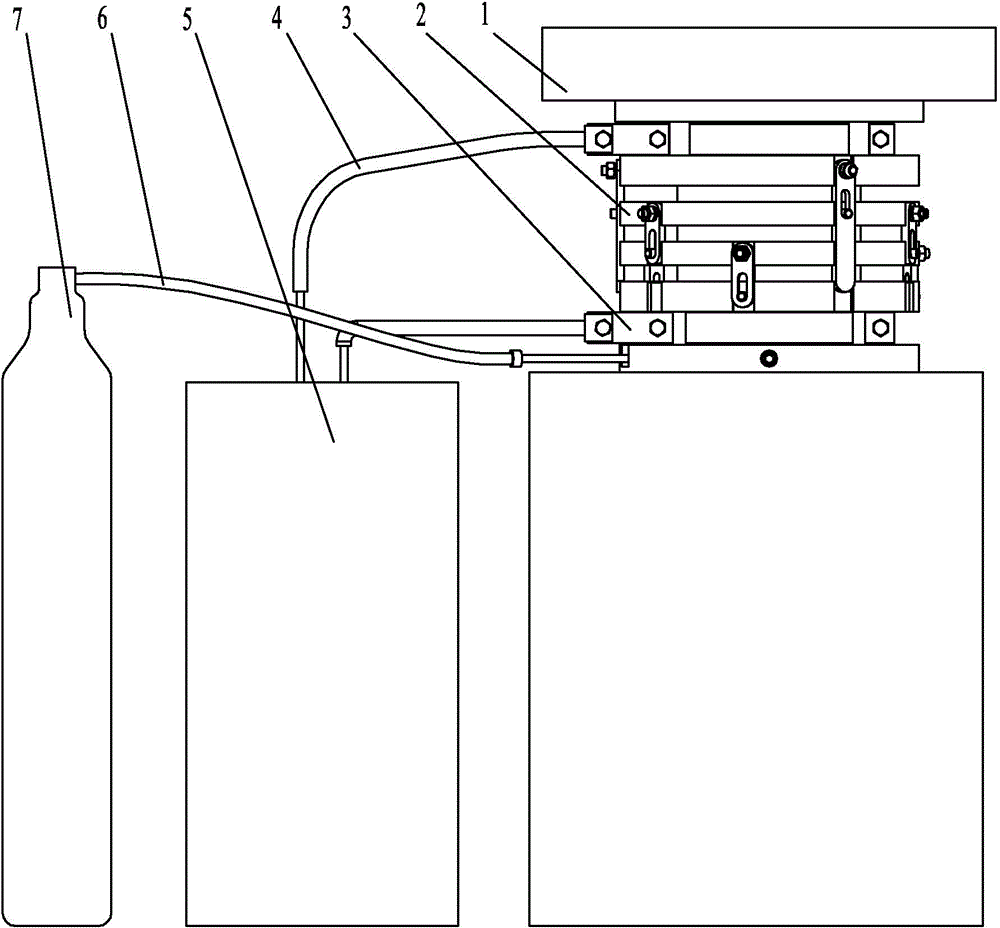

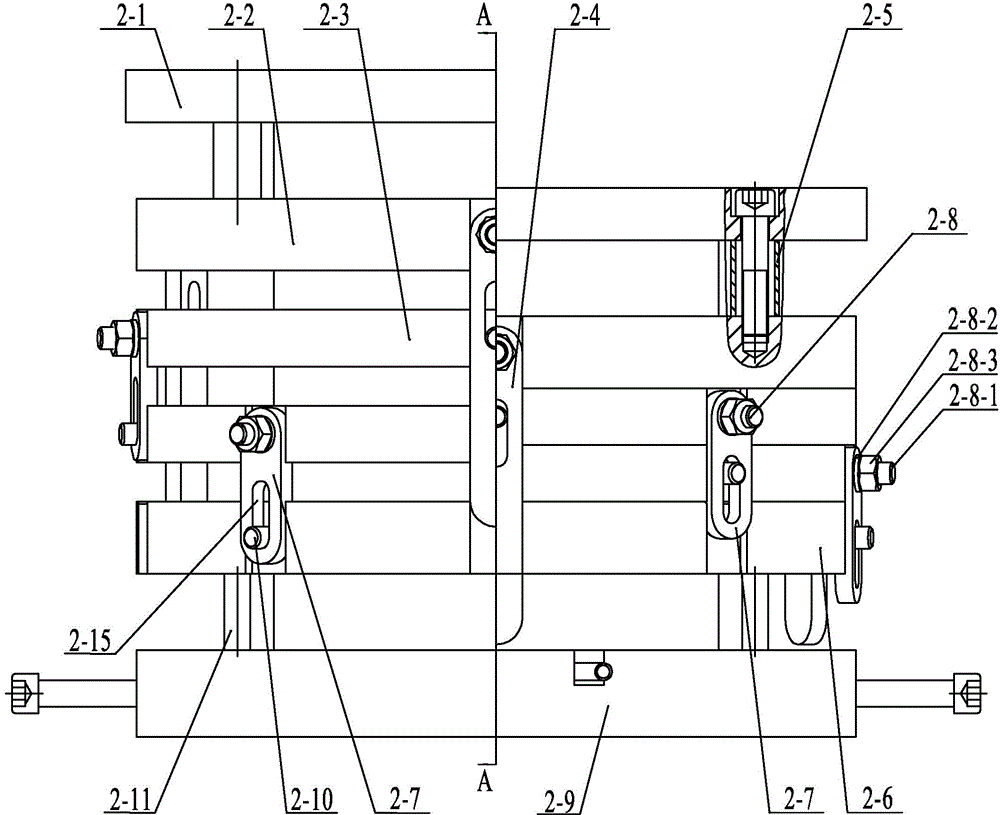

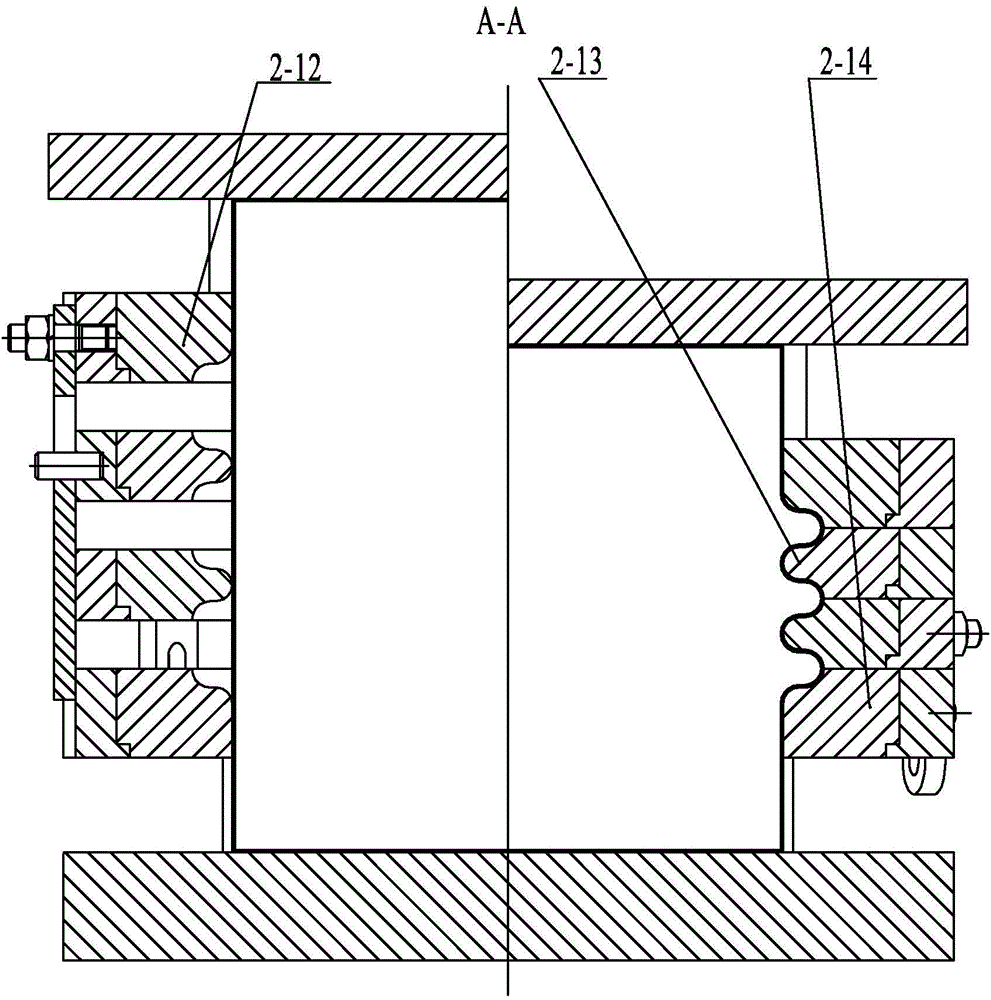

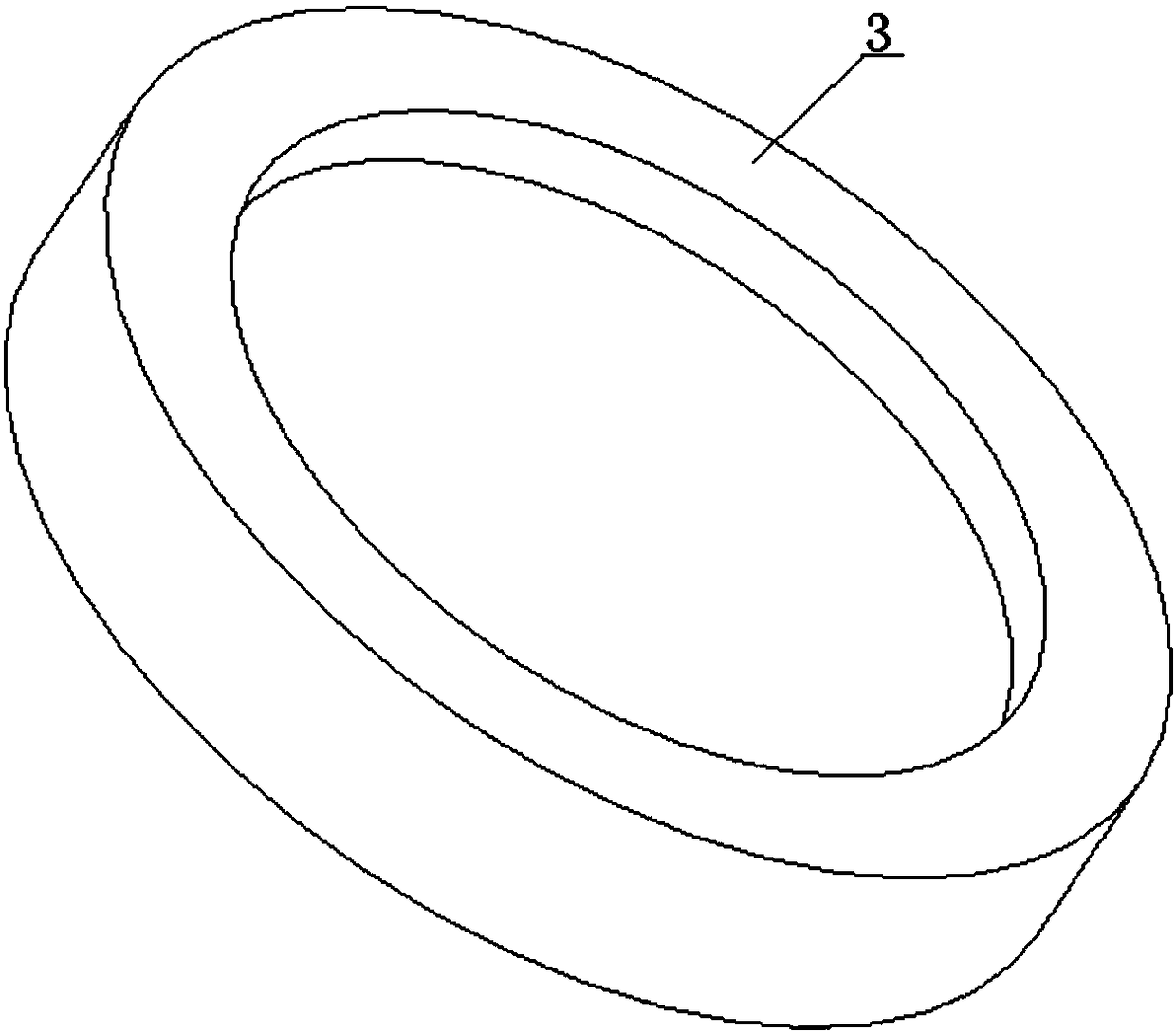

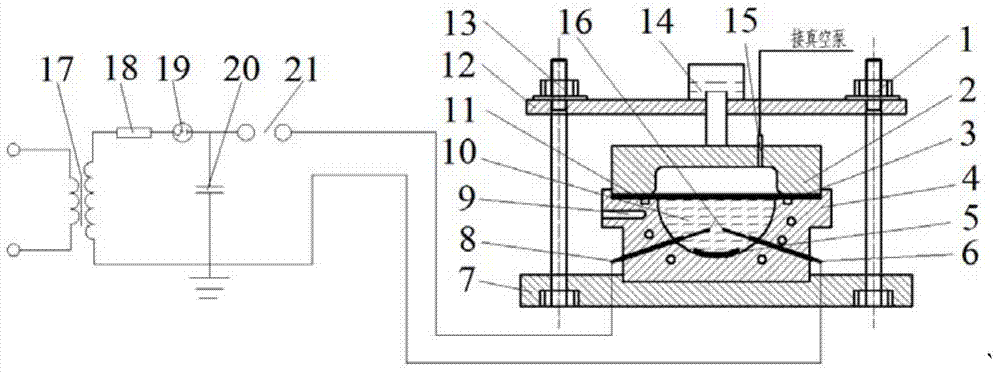

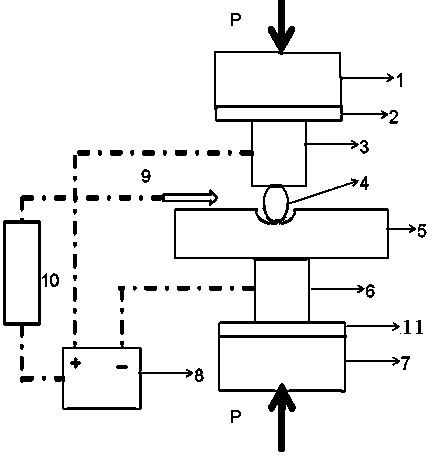

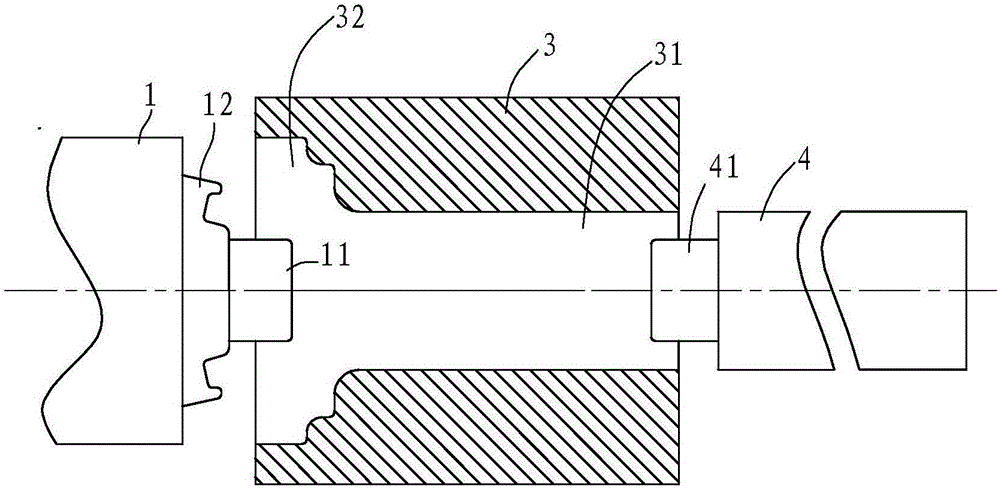

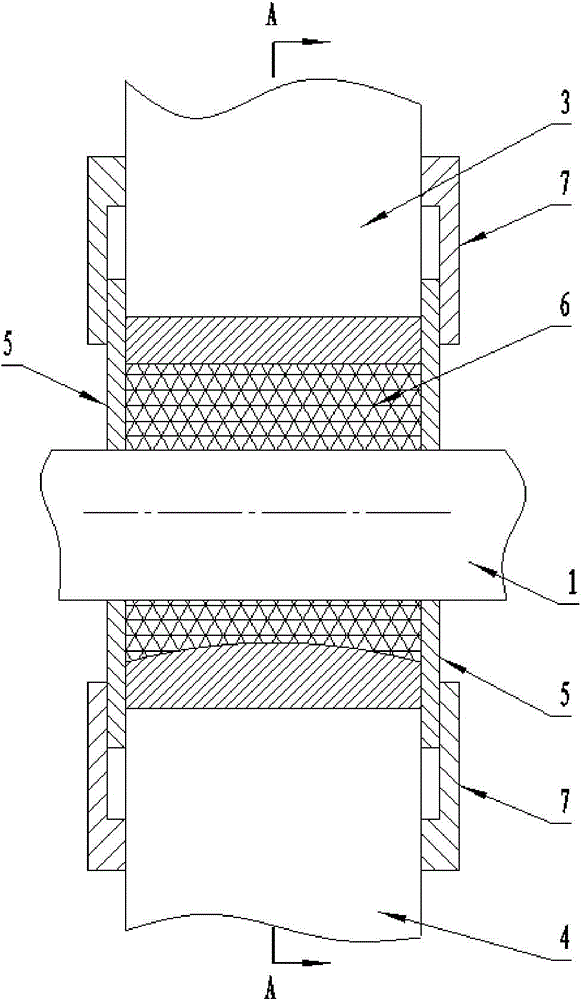

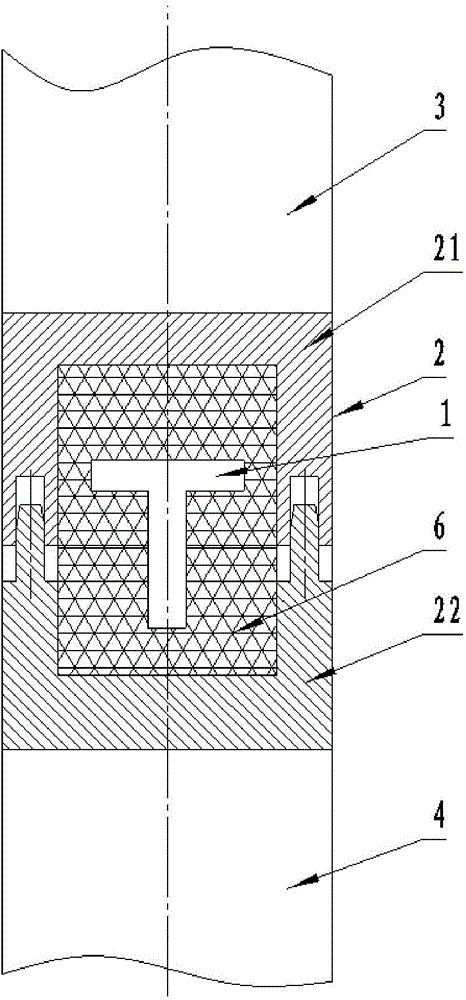

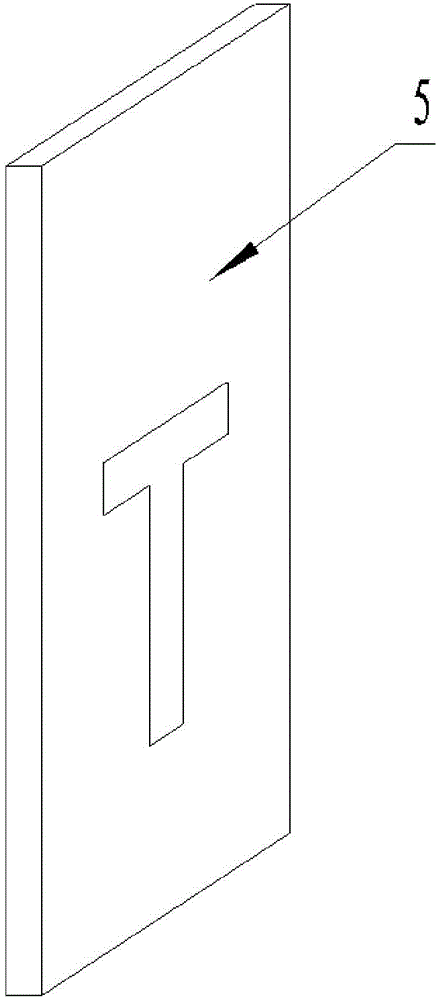

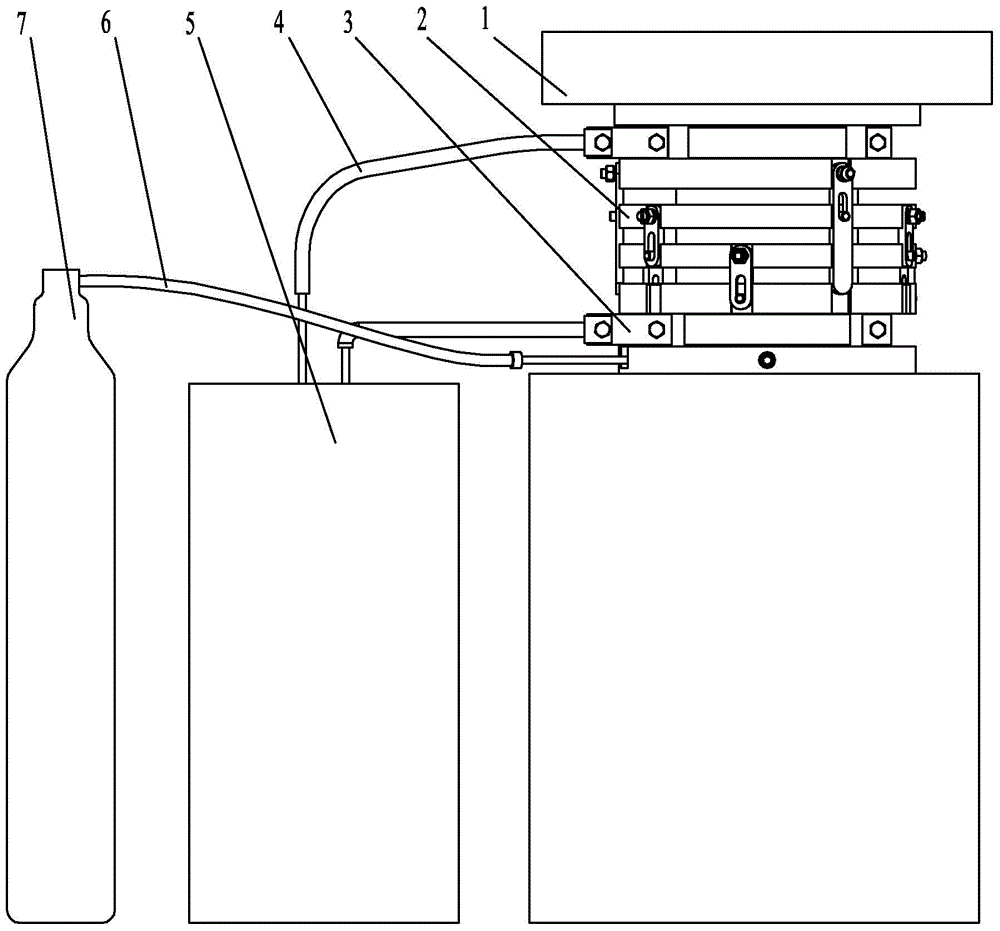

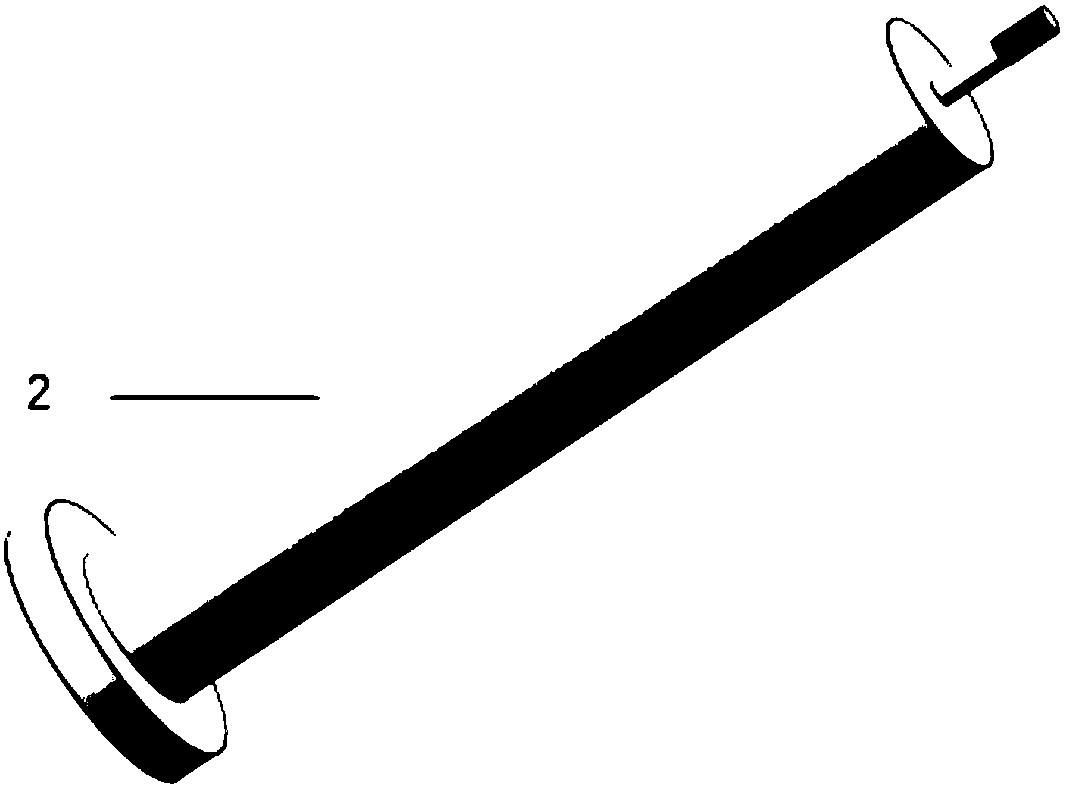

Device and method for hot forming of titanium alloy corrugated pipe through current assistance

ActiveCN104525660AImprove plastic deformation abilityUniform wall thickness distributionShaping toolsGas cylinderLow voltage

The invention discloses a device and method for hot forming of a titanium alloy corrugated pipe through current assistance, and relates to a device and method for hot forming of a corrugated pipe. The device and method for hot forming of the titanium alloy corrugated pipe through current assistance solve the problem that an existing titanium alloy corrugated pipe is difficult to manufacture, and high in cost and low in production efficiency. According to the device, the positive pole and the negative pole of an electrode (3) tightly sleeve the upper end and the lower end of a tube blank (10), a low-voltage high-current power source (5) is connected with the positive pole and the negative pole of the electrode (3) through a wire (4), a gas cylinder (7) is connected with a gas guide pipe (11) on the tube blank (10) through a gas pipe (6), and a forming die (2) is placed on a working platform of a press machine (1). The method comprises the steps that the first step, the tube blank (10) is manufactured; the second step, die setting is conducted; the third step, device installation is conducted; the fourth step, the corrugated pipe is formed; the fifth step, discharging is conducted; the sixth step, post-processing is conducted. The device and method are used for manufacturing the titanium alloy corrugated pipe.

Owner:HARBIN INST OF TECH

Thermal creep plastic forming method for special-shaped aluminum alloy wall plate with variable thicknesses

InactiveCN108856500AHigh dimensional accuracyHigh profile precisionShaping toolsVariable thicknessThermal creep

A thermal creep plastic forming method for special-shaped aluminum alloy wall plate with variable thicknesses and is suitable for the special-shaped aluminum alloy wall plate, high in size and moldedsurface precision requirement and good in surface quality, with the variable thicknesses. The method includes the following steps that firstly, a thermal creep plastic forming mold of the special-shaped aluminum alloy wall plate with the variable thicknesses is designed and machined; secondly, the special-shaped aluminum alloy wall plate with the variable thicknesses is subjected to plane unfolding; thirdly, according to the positions of reinforcing ribs in the plane unfolded drawing, corresponding reinforcing ribs are prepared on the plate, and positioning convex lugs are machined; fourthly,the special-shaped aluminum alloy wall plate with the variable thicknesses is bent in advance; fifthly, thermal creep plastic deforming is performed on the special-shaped aluminum alloy wall plate with the variable thicknesses; and sixthly, lineation is performed to cut off the positioning convex lugs. The wall plate formed through the method is short in machining period and low in cost, a formedpart is high in size and molded surface precision, and the surface quality is also remarkably improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Electromagnetic pulse forming device and method for aluminum-based carbon fiber reinforced composite material

The invention discloses an electromagnetic pulse forming device and method for an aluminum-based carbon fiber reinforced composite material. The electromagnetic pulse forming device comprises a crucible container, a crucible fixing device and carbon fiber cloth. The crucible container is fixedly arranged on the crucible fixing device. The carbon fiber cloth is arranged in the middle of the crucible container. Coils are arranged on both sides of the crucible container. An inner cavity of the crucible container is filled with metal aluminum or aluminum alloy melt. The two coils are distributed on the two sides of the carbon fiber cloth. By the adoption of the electromagnetic pulse forming device and method, the formation of the interfacial brittle phase is effectively retarded, the performance of the composite material is improved, the fiber is not easily damaged by pressure, the forming quality of the composite material is improved, the forming period is greatly shortened, the production efficiency is improved, and the composite material is more suitable for mass production.

Owner:WUHAN UNIV OF TECH

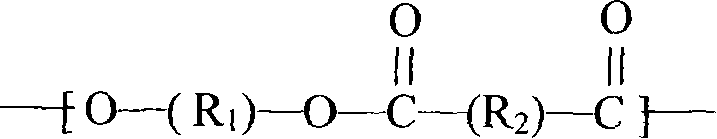

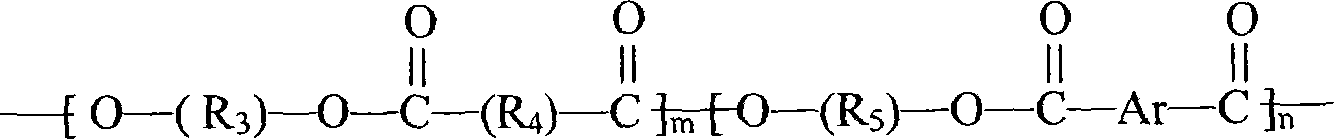

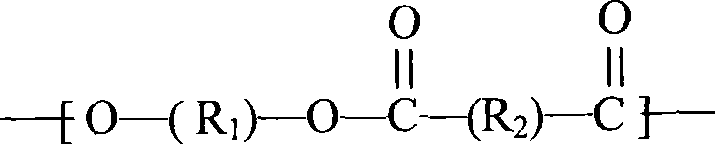

Poly-lactic-acid composition and formed body thereby and method for making said formed body

InactiveCN101070423AWith transparencyNo deformationCellulosic plastic layered productsPolyesterPolymer science

The invention discloses a combination of polylactic acid, it can be used to produce a heat-resistant, transparent and health decomposition of the body-forming and can significantly shorten the cycle. The combination of polylactic acid was added to the total weight of the combination of 0.1 to 10 percent and selected at least one from aliphatic polyester, aliphatic - a total of aromatic polyester and polyethylene glycol decomposition of Health polymer, it can use as the crystallization of the nucleating agent.

Owner:FAR EASTERN NEW CENTURY COPRRATION

Axial differential-pressure heat-state internal-pressure forming method of special-shaped variable-cross-section pipe fitting

The invention relates to an axial differential-pressure heat-state internal-pressure forming method of a special-shaped variable-cross-section pipe fitting, and relates to a forming method of the pipefitting. In order to solve the problems that during the process of an existing heat-state internal-pressure forming method of the special-shaped variable-cross-section pipe fitting, the pressure on the pipe fitting cannot be controlled in a zoning way, so that the deformation of zones and the wall thickness distribution cannot be effectively and reasonably controlled, the method comprises the following steps of (1) heating a mold; (2) placing an original pipe blank into the heat-state mold; (3) moving a punch to contact the pipe blank, sealing, and then filling a heat-state fluid medium intothe pipe blank through an internal pipeline; (4) starting a supercharger for controlling the internal pressure of the pipe blank so as to separate and seal the zones in the axial direction; (5) starting a supercharger for controlling the external pressure of the pipe blank, and filling pressure media with different sizes into the axial zones of the pipe blank; and (6) controlling the internal pressure and the external pressure of the pipe blank, enabling the pipe blank to deform, and obtaining the required special-shaped variable-cross-section pipe fitting. The axial differential-pressure heat-state internal-pressure forming method of the special-shaped variable-cross-section pipe fitting provided by the invention is used for forming the special-shaped variable-cross-section pipe fitting.

Owner:HARBIN INST OF TECH

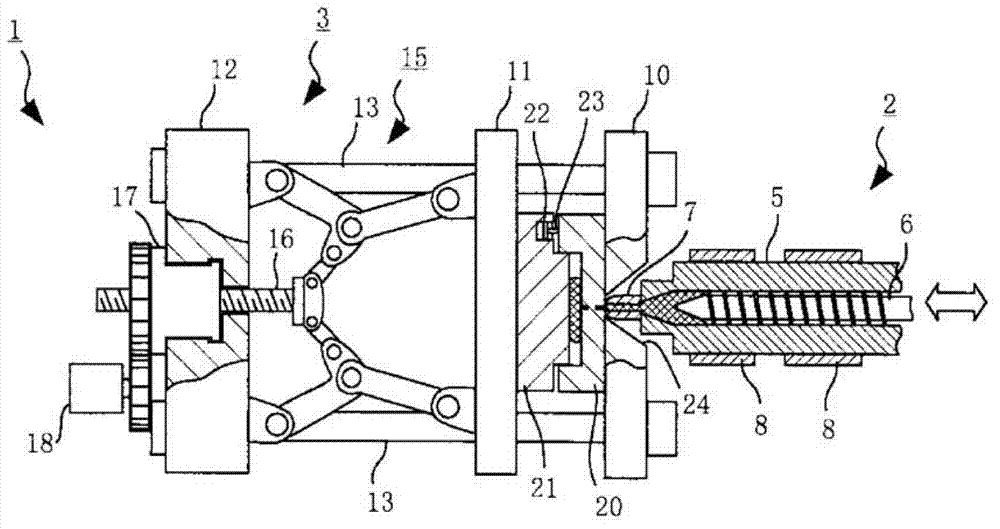

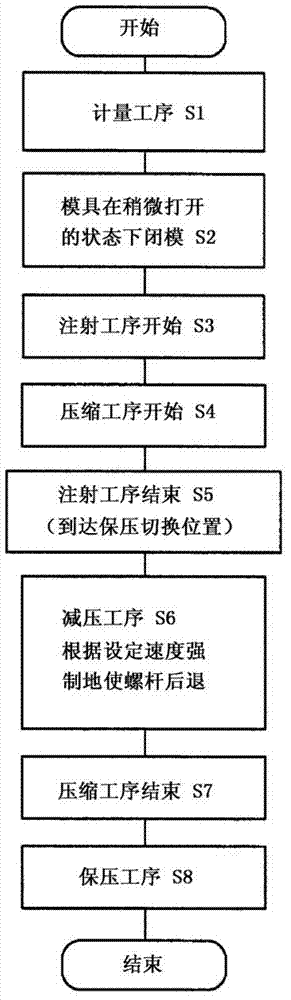

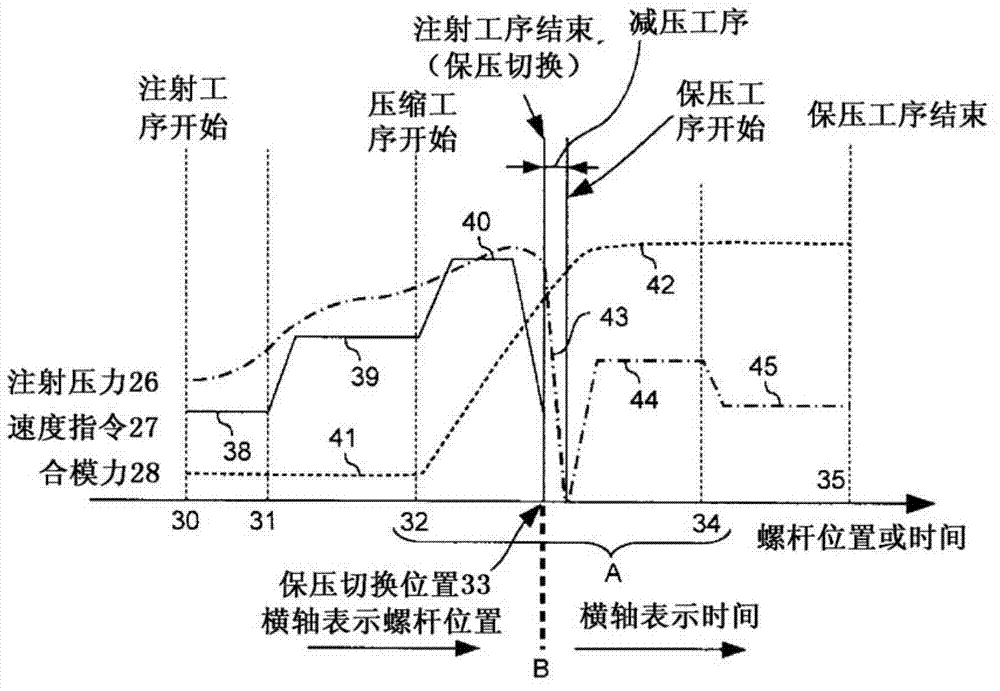

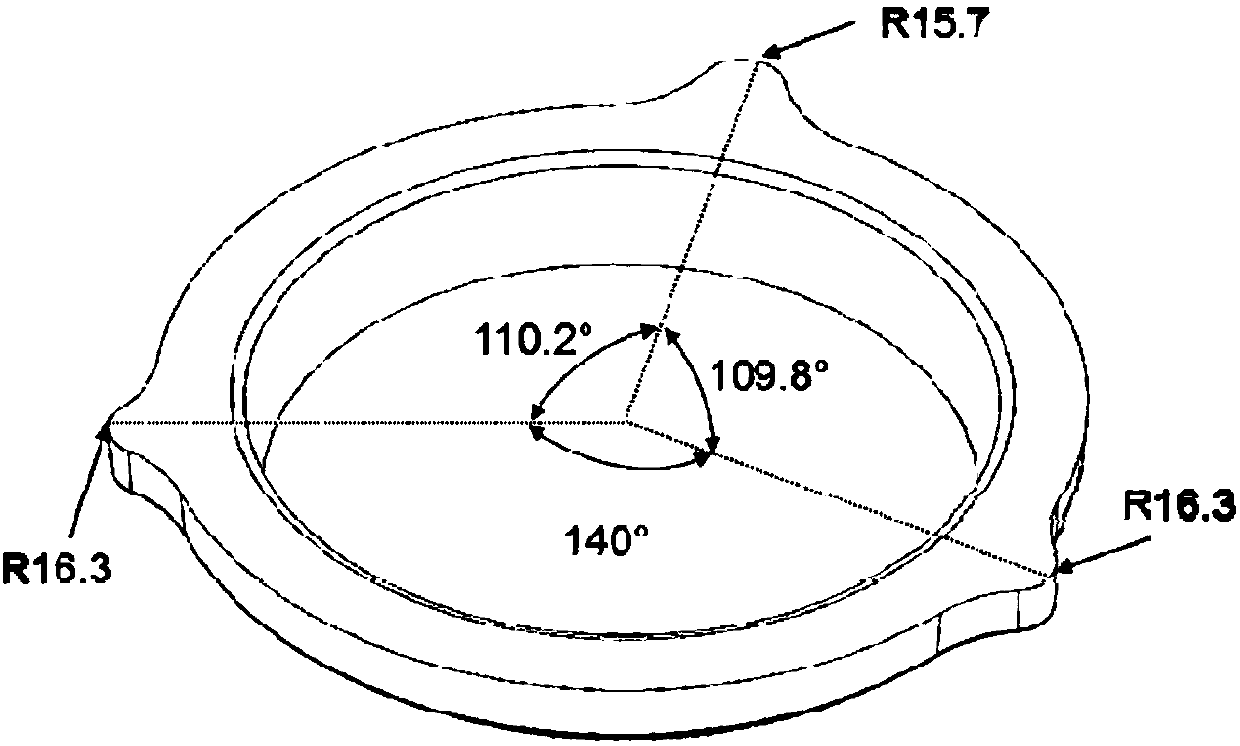

Method for forming thin-walled molded product

ActiveCN103158236AModerate deviations in pressure distributionPrevent residual residual stressFlat articlesLight guidePressure.drive

The invention provides a method for forming thin-walled molded product for thin and middle-large sized liquid crystal light panel. An injection device comprising a heating cylinder (5) and a screw (6) is used for shaping. Dies (20, 21) are opened to a preset state, and the screw (6) is driven axially to inject melting resin into die chambers. The dies (20, 21) are closed to compress the injected melting resin. In the compression process, the screw (6) withdraws preset time to lower the pressure of the melting resin in the die chambers. An axial driving force is applied to the screw (6) to retain preset resin pressure for melting resin. The screw (6) for retaining pressure drives to control speed and can be switched to pressure control.

Owner:JAPAN STEEL WORKS LTD

Hot extrusion and near net forming method of asymmetric aluminum alloy flange plate with convex lug

ActiveCN108526238ASimple structural designReduce difficultyExtrusion diesWheelsPunchingMechanical property

The invention provides a hot extrusion and near net forming method of an asymmetric aluminum alloy flange plate with a convex lug, which is applicable to aluminum alloy disc-shaped members with relatively high mechanical properties and complicated shapes and belongs to the field of precision plastic formation. The method provided by the invention comprises the following steps: (1) transforming into a basic extrusion part according to a flange plate part drawing; (2) determining the size of an extrusion blank; (3) designing and processing a hot extrusion die of the asymmetric aluminum alloy flange plate with the convex lug; (4) carrying out free forging on the blank; (5) carrying out reaming; (6) removing punching recess; (7) carrying out hot extrusion; (8) carrying out fine processing. Themethod provided by the invention is simple and feasible; the formed flange plate has high size precision and excellent mechanical properties; near net forming of parts can be realized; a non-matchingsurface does not need to be mechanically processed again, so that the subsequent processing amount is effectively reduced, the forming period is shortened and the efficiency is improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

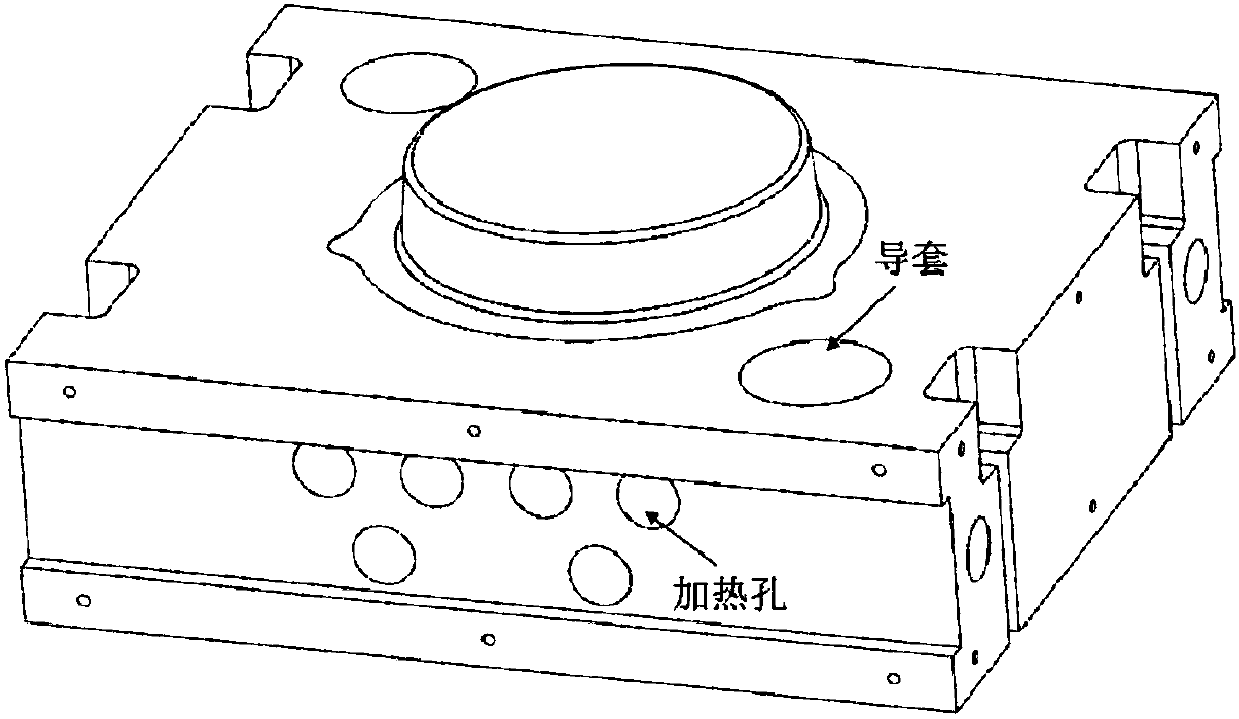

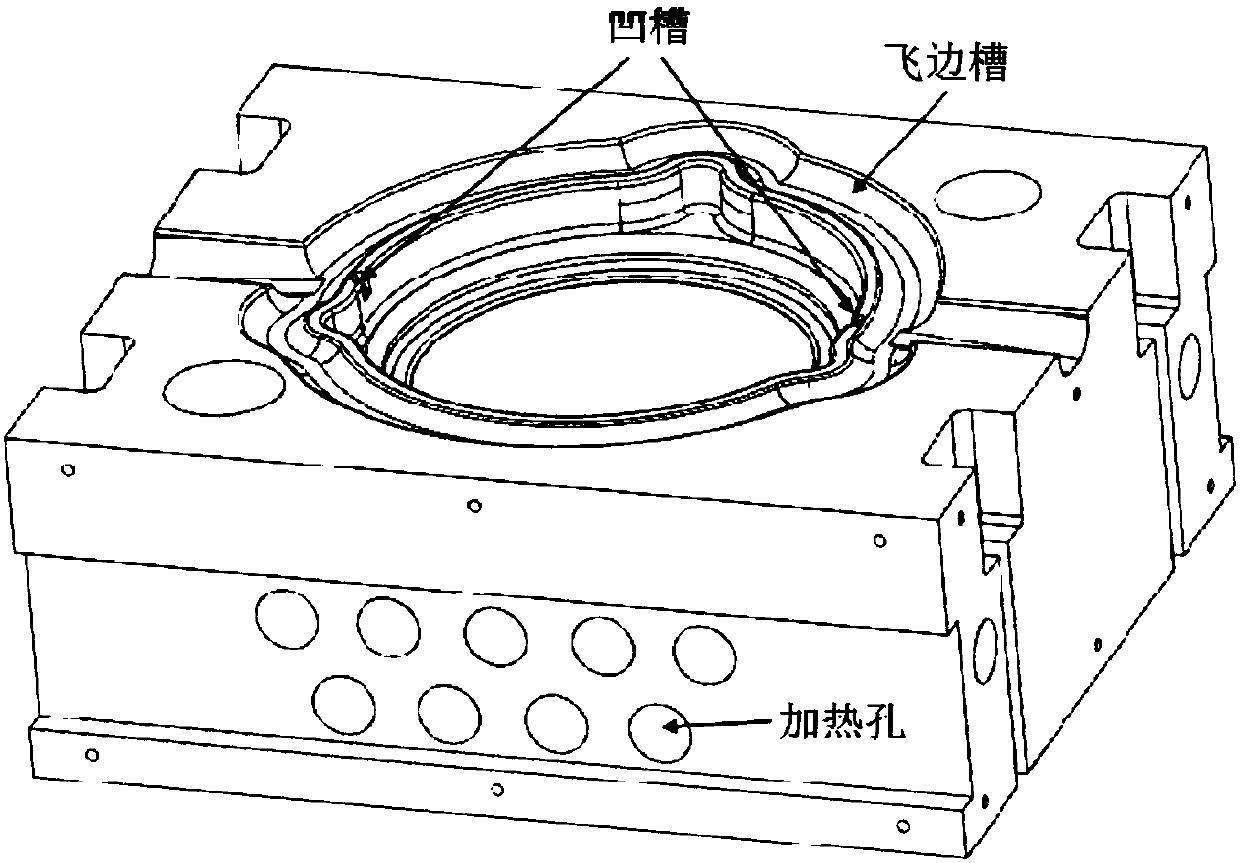

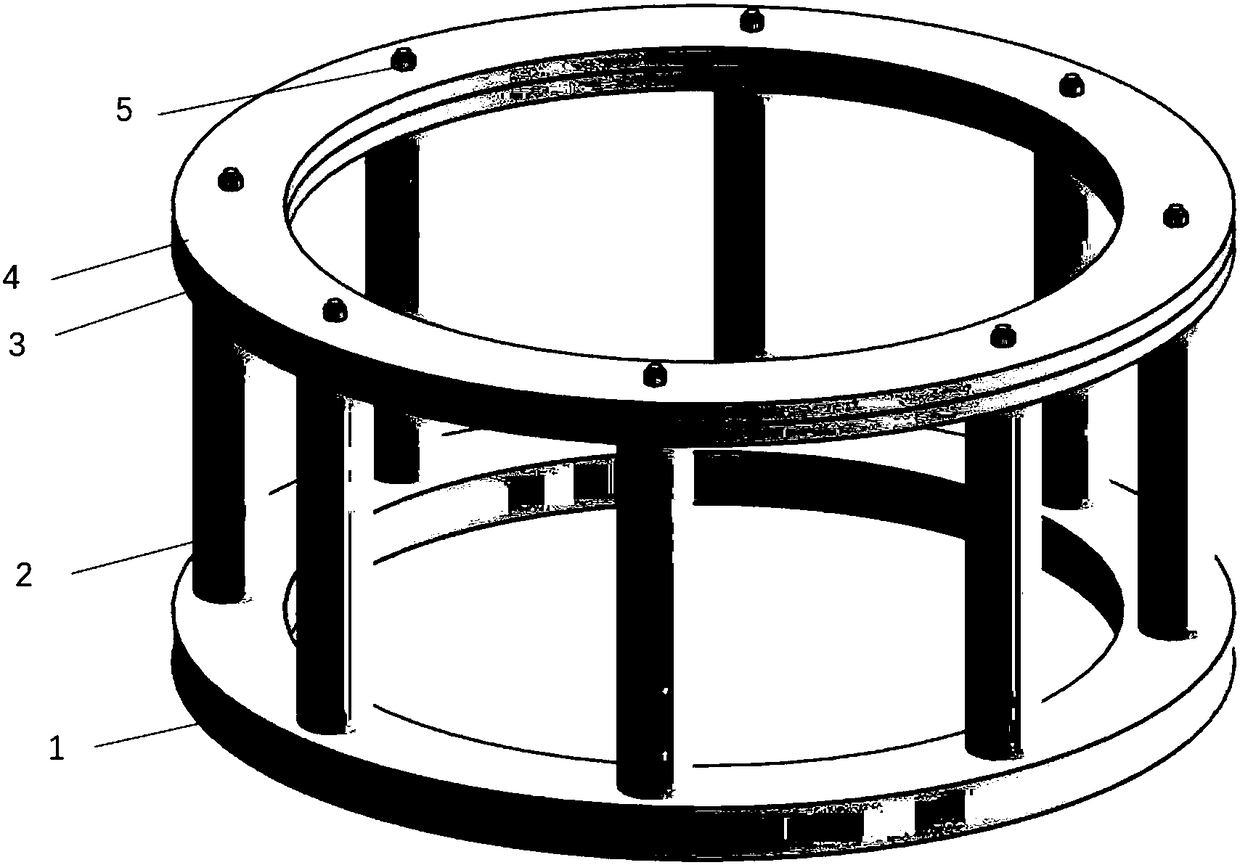

Laminated plate forming device and method based on electro-hydraulic forming

The invention provides an electro-hydraulic forming device for a thermal-plastic glass fiber enhanced aluminum alloy laminated plate. The device comprises a power supply device, a mold and a fixed heating device, and is characterized in that the mold is a graphite female mold (2); an exhaust hole (15) is formed in the bottom of the graphite female mold (2), and a vacuum pump can be used for emptying gas in the graphite female mold (2); during forming, the graphite female mold (2) is positioned through a circular groove in a graphite base (4), and a hydraulic cylinder (14) applies pressure to the graphite female mold (2) so as to fix the graphite female mold (2). According to the forming device, by the full use of a high-rate forming characteristic of electro-hydraulic forming, interlamination shearing force in the forming process can be reduced, so that the interlamination cracking is reduced, and the transverse rigidity of a laminated plate can be improved; furthermore, due to the high-rate forming characteristic of the electro-hydraulic forming, the problem of large recurrent magnitude caused by preheating punching can be solved, and the shape and orientation precision higher than that by adopting punching forming is achieved.

Owner:HUNAN UNIV

Pulse current auxiliary increment repair device and method

InactiveCN103350312ASolve technical problems that cannot achieve incremental repairEnsure consistencyExtrusion control devicesAutomatic controlMechanical property

The invention relates to a pulse current auxiliary increment repair device and a pulse current auxiliary increment repair method. The method comprises the following steps: introducing high-frequency pulse current into a filler and the deletion position of a product to be repaired by using an upper electrode and a lower electrode; quickly fusing the filler by an autonomous heating mode; realizing temperature measurement and control by using an infrared temperature measuring device and a proportion integration differentiation (PID) control system; applying a certain pressure to the filter by using an upper pressing head and a lower pressing head; and realizing diffusion connection of the filler and the deletion position of the mother material under the action of pressure so as to fulfill the aim of increment repair. The pulse current auxiliary increment repair device and the pulse current auxiliary increment repair method have the benefits that the method is different from the traditional welding repair method and can realize automatic control of the temperature of the filler area, so that the consistency of the microstructures and the mechanical properties of the mother material and the repair area is effectively guaranteed, and the service life of an aluminum alloy tyre die is greatly prolonged. By adoption of the method provided by the invention, the heating efficiency can be increased by 300 to 500 percent, the forming period is shortened to 10 to 50 s, and the repair period of single defect is only 20 to 30 s.

Owner:SHANDONG HUACHEN HEAVY MACHINE

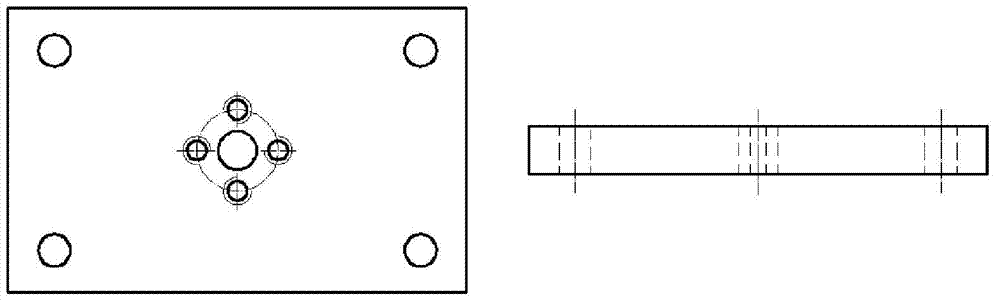

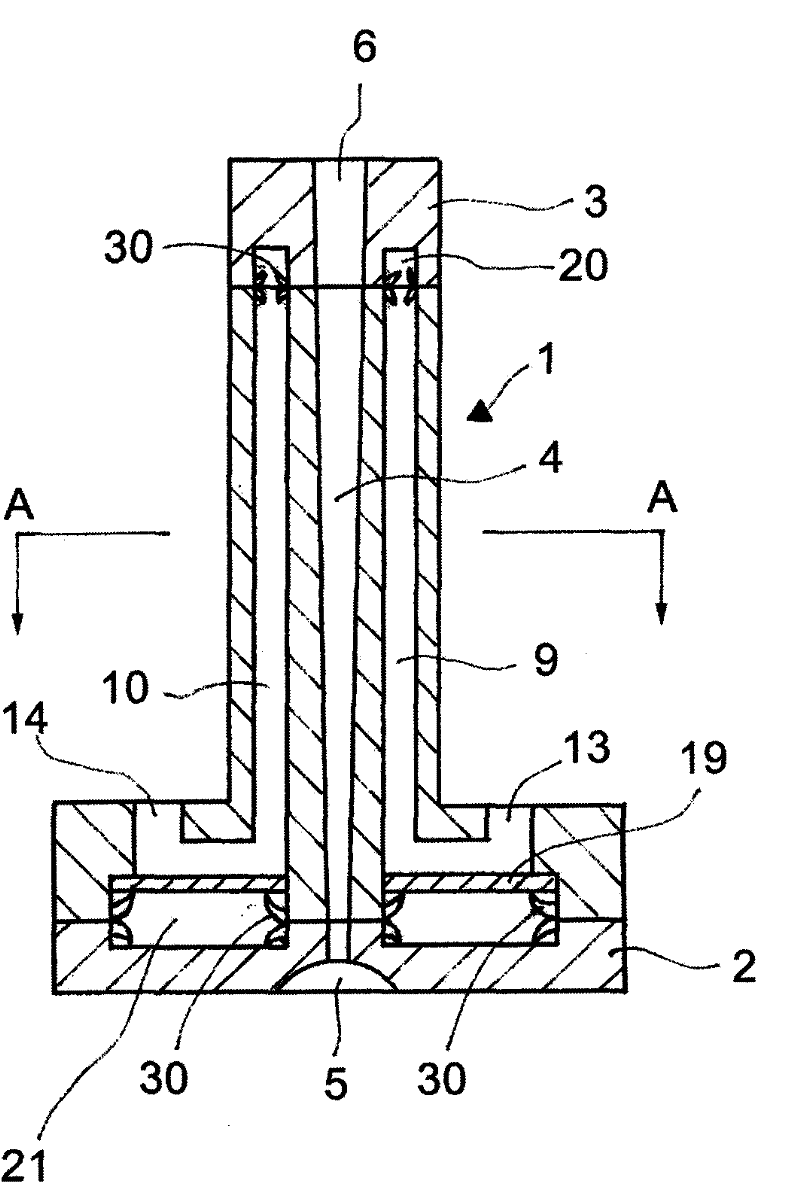

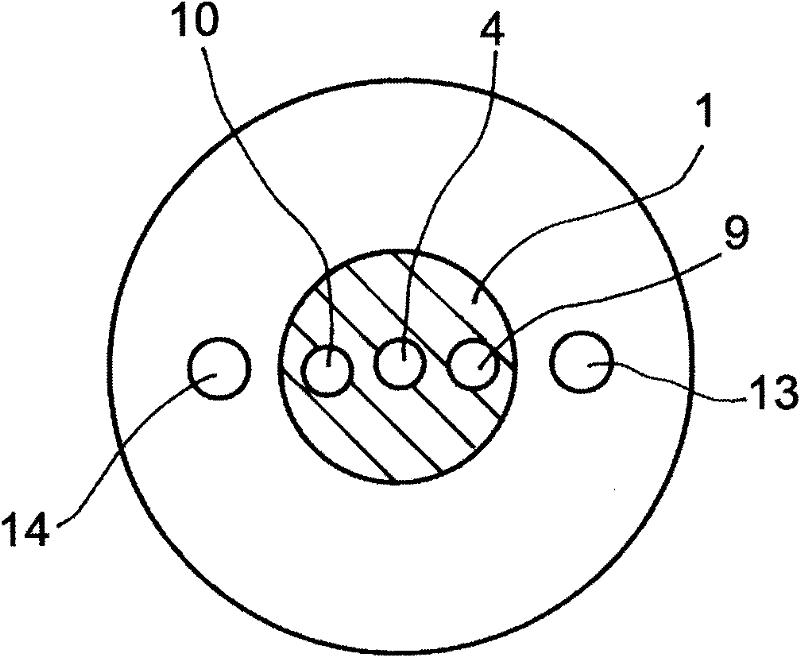

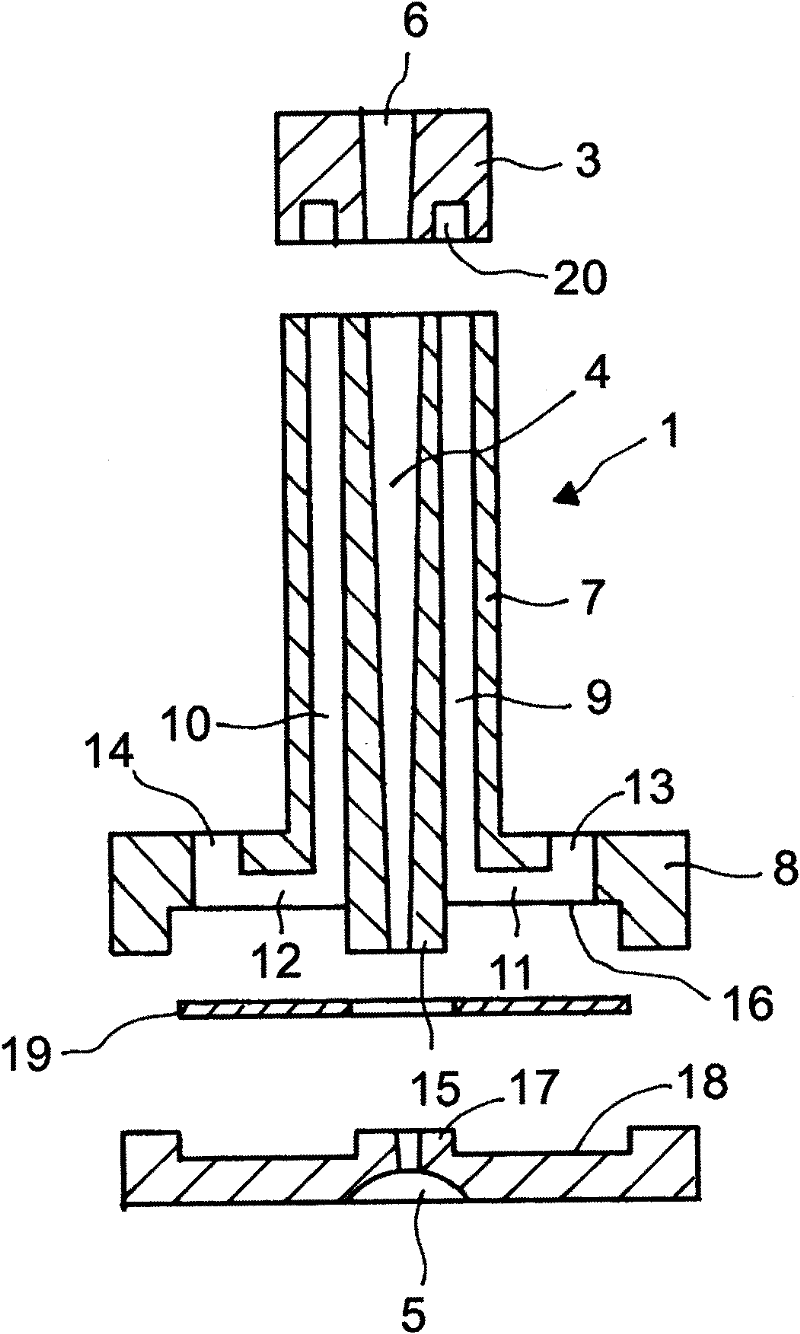

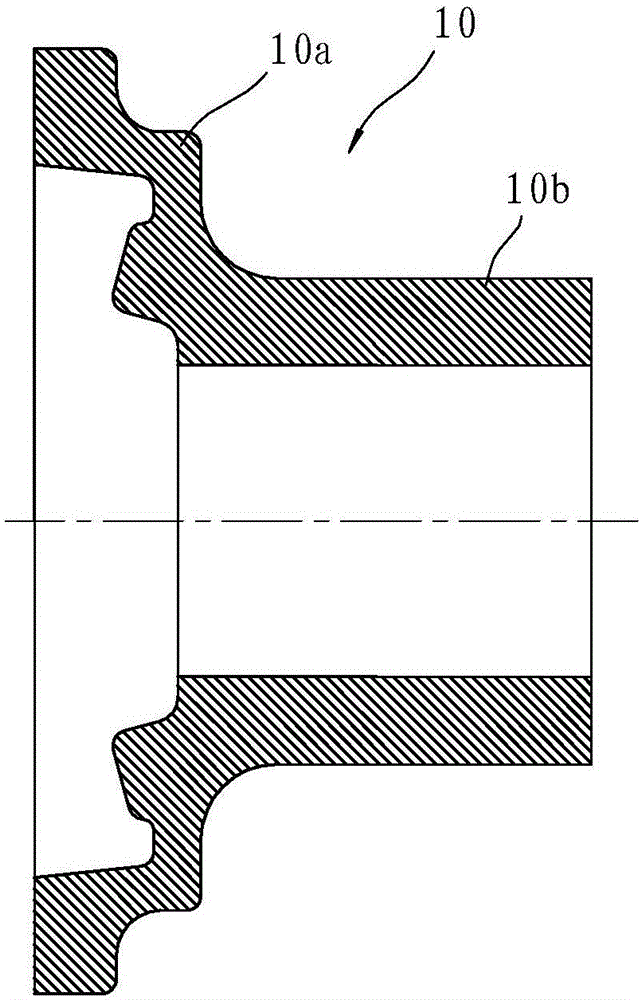

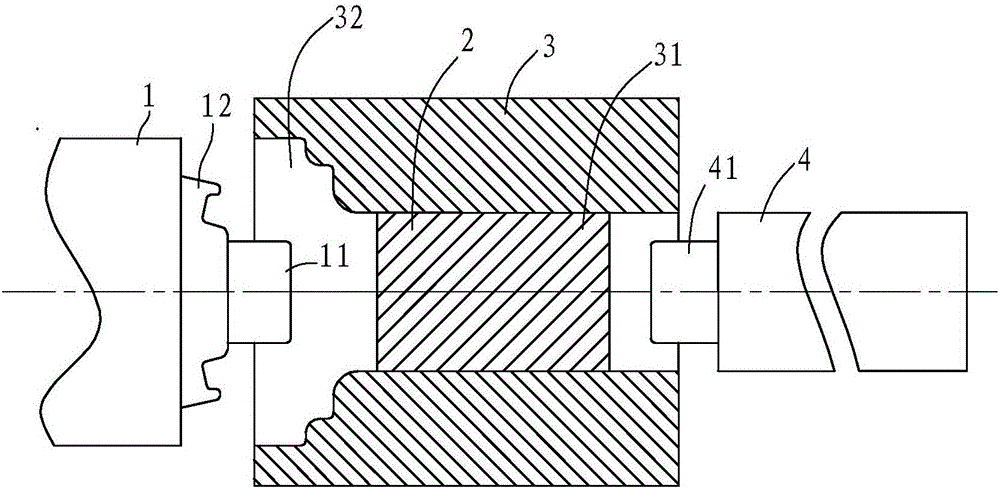

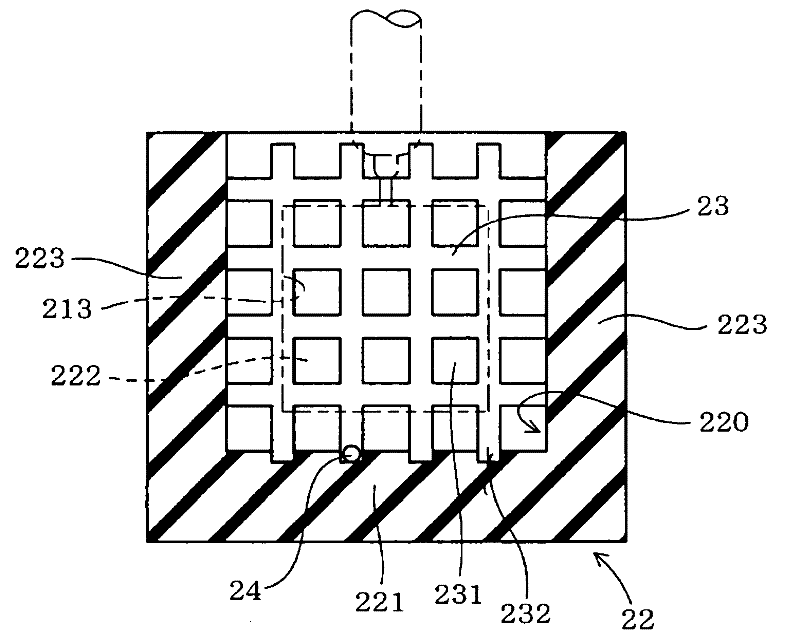

Sprue bush and its production method

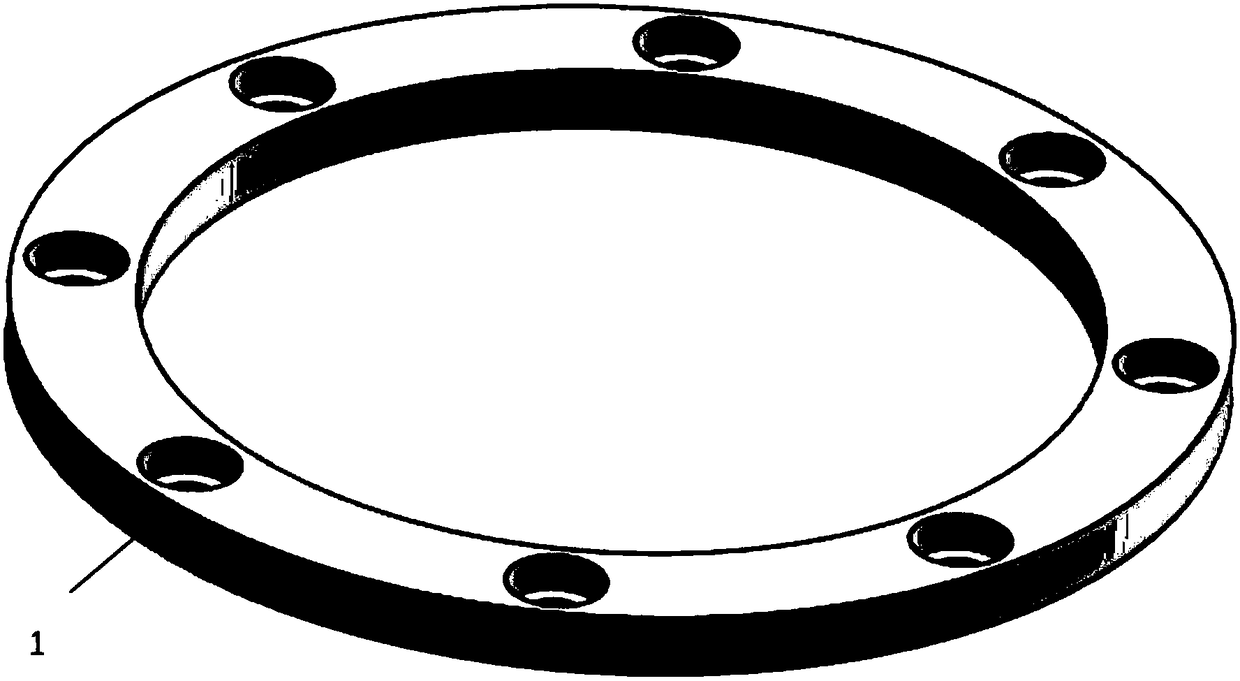

ActiveCN102336002AAvoid defects such as deformationShorten the forming cycleNon-electric welding apparatusWater leakageWater channel

The invention provides a sprue bush advantaged by shortening of forming period via effectively cooling a molten resin filled in a sprue and excellent durability. The sprue bush is characterized by comprising: a sprue bush main body (1) cooling water channels (9, 10) at the periphery of a sprue (4) at the center; and a protruding flange plate (2) disposed at the back surface side of the sprue bush main body (1), the components are welded to be an integration via friction press force. The sprue bush can be made from hard metal materials and no danger of water leakage is provided.

Owner:NGK INSULATORS LTD +1

Extruding-expanding molding method for rim provided with flange

An extruding-expanding molding method for a rim provided with a flange is characterized by comprising the following steps: (1) blanking; (2) heating: rods subjected to blanking and an extrusion mold are heated to an extrusion start temperature respectively; and (3) two-way extruding-expanding molding. Compared with the prior art, the extruding-expanding molding method has the advantages that fewer procedures are included, the whole set of molding tool and equipment investment is small, and the method is suitable for industrial batch production; the molding cycle is shortened, and the molding efficiency is increased; and the manufacture cost is reduced.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

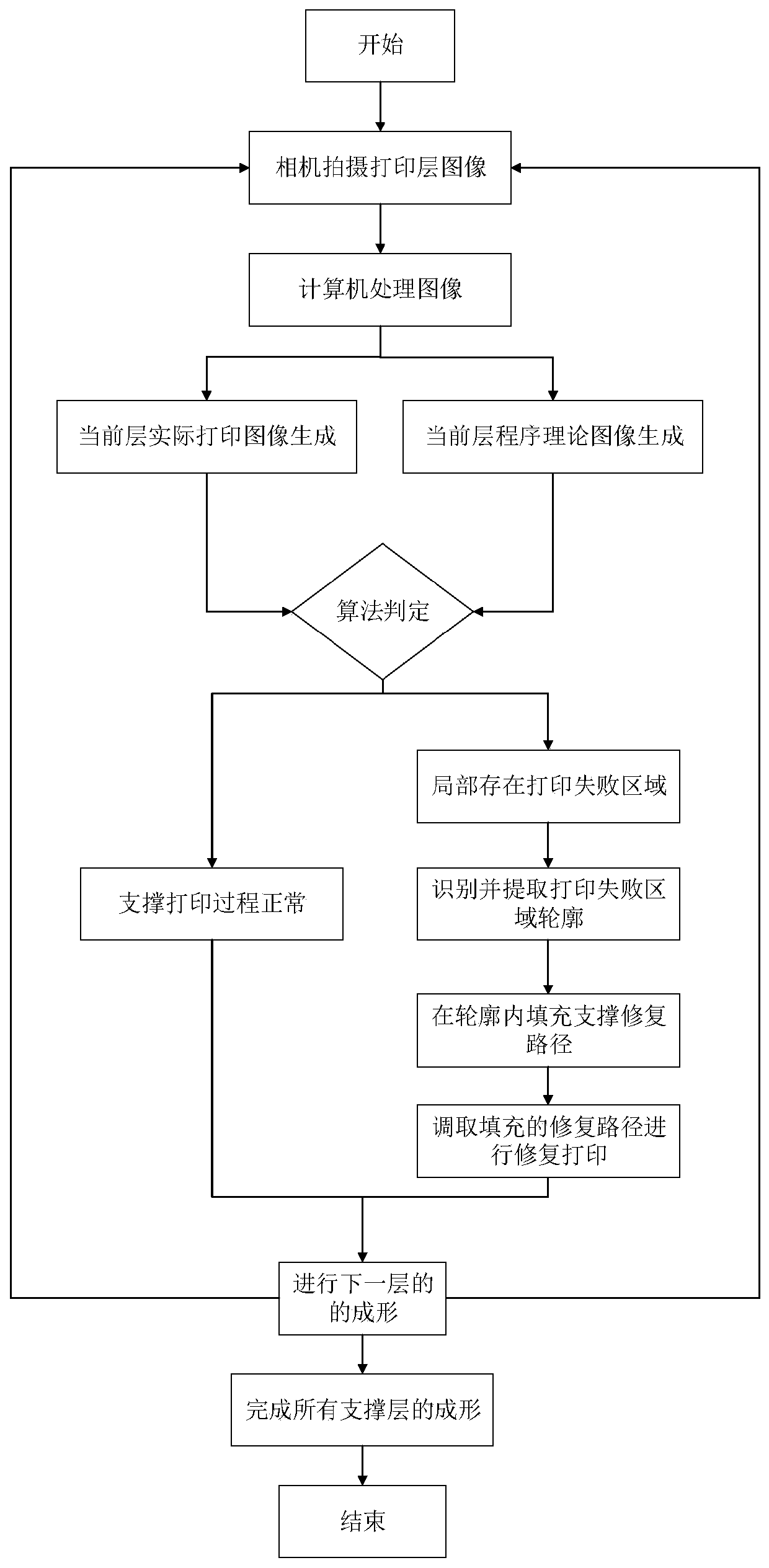

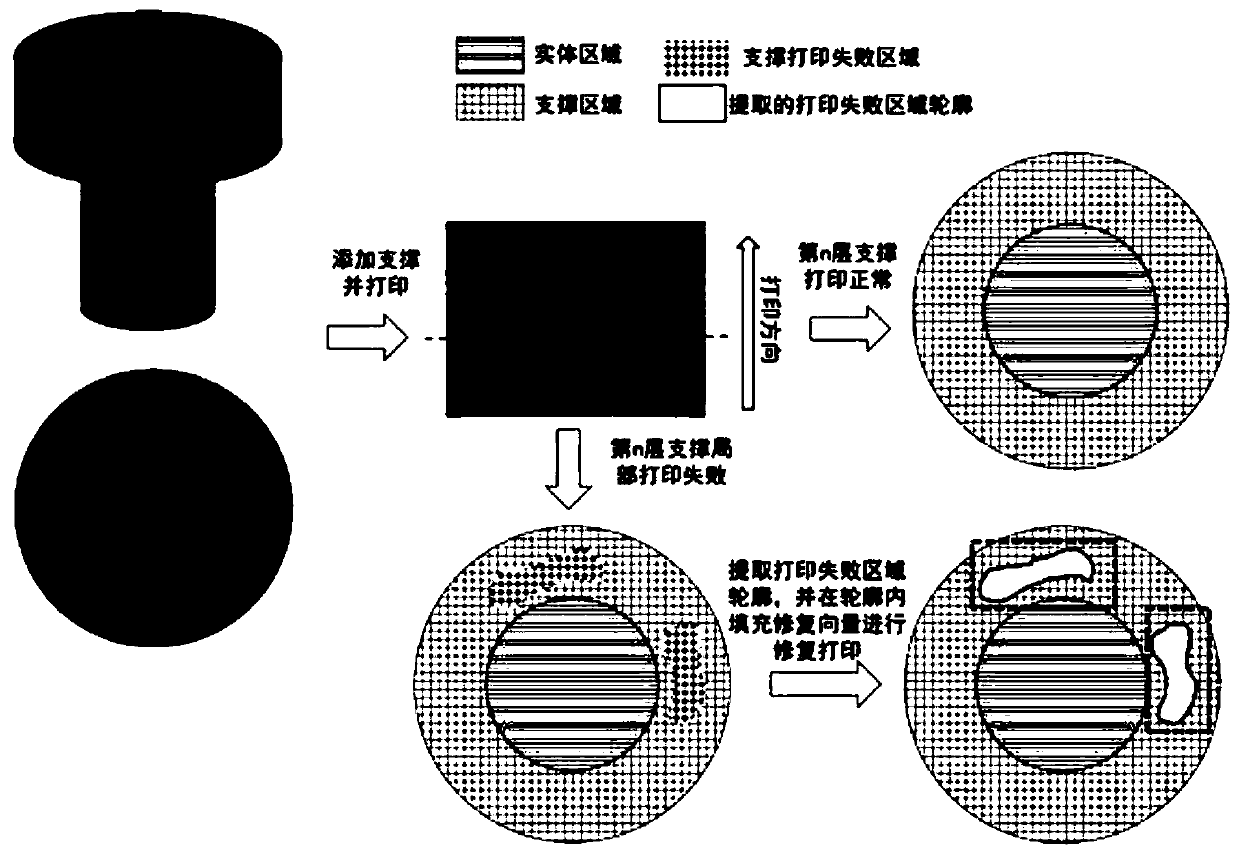

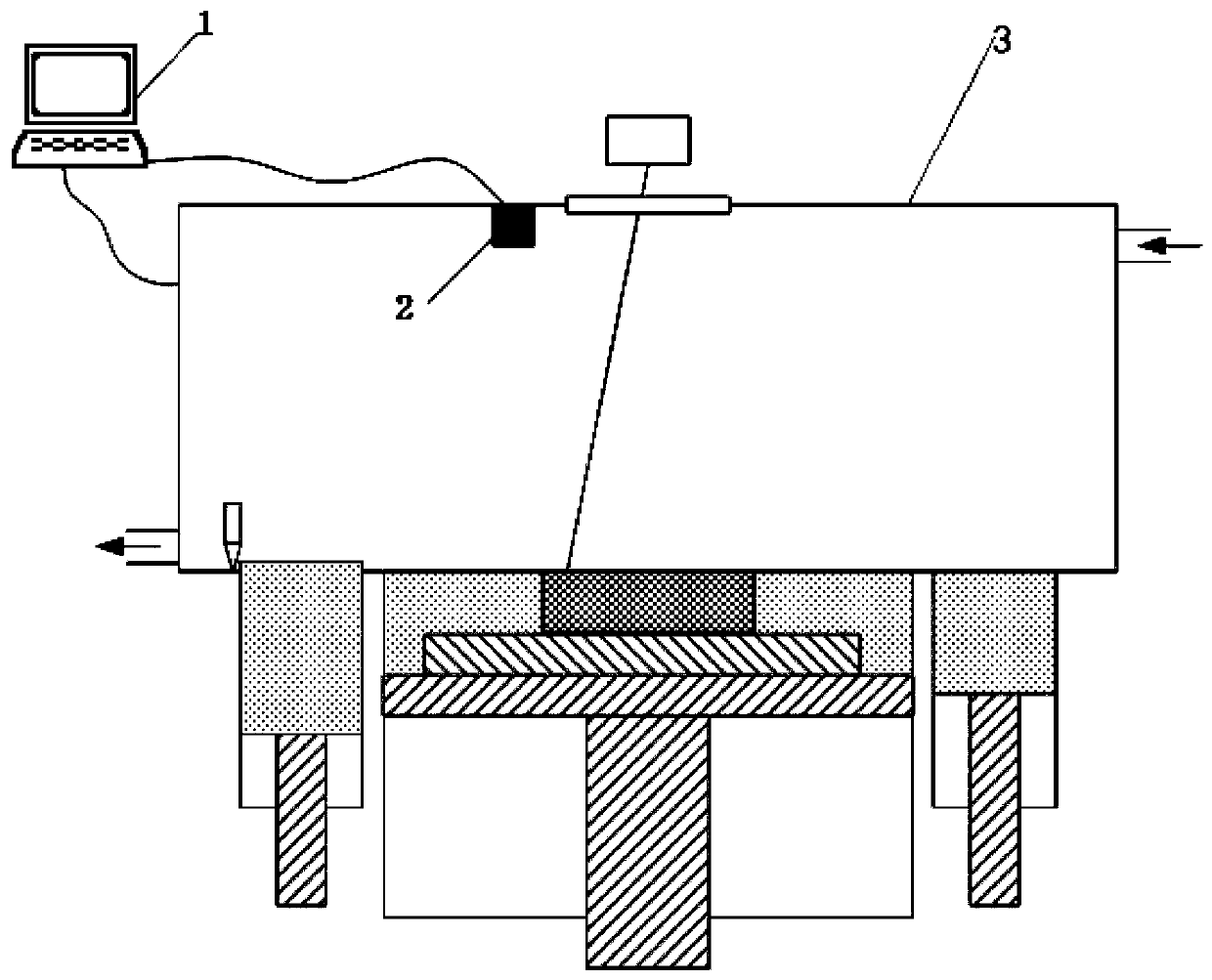

Support automatic repairing method based on additive manufacturing

ActiveCN111168064AAddress Printing RisksImprove forming qualityAdditive manufacturing apparatusIncreasing energy efficiencyComputer control systemAdditive layer manufacturing

The invention discloses a support automatic repairing method based on additive manufacturing. The method specifically comprises the following steps that 1, printed image information of each layer of support is collected by a camera in the forming process, and the printed image information is fed back to a computer control system; 2, whether the printing condition of the current layer of support isnormal or not is identified through the computer control system, contour features of a printing failure area are extracted if a support printing failure area exists, and a repair path is generated inthe contour; and 3, the repair path is called for repairing printing of the printing failure area. According to the support automatic repairing method based on additive manufacturing, when local support printing fails, detection and recognition are carried out in time, repairing is performed, the forming period is shortened, the printing efficiency is improved, the risk of part forming failures can be reduced, and the labor cost in the production process can be further reduced.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

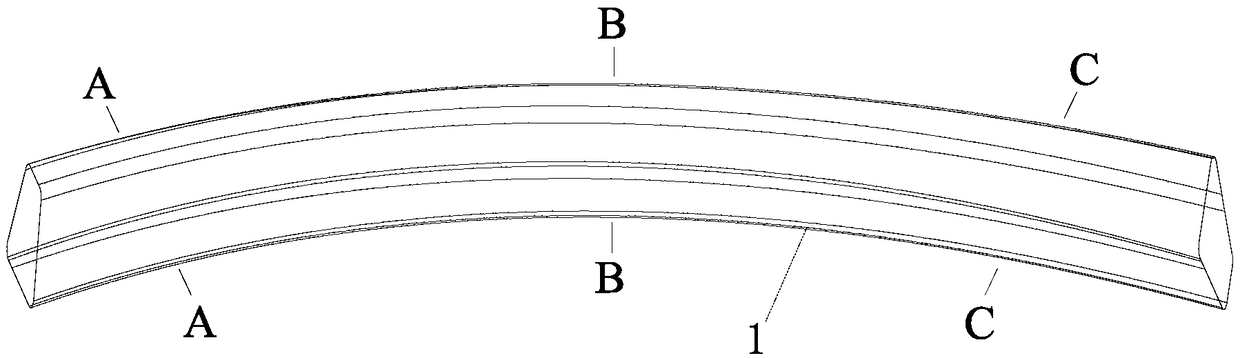

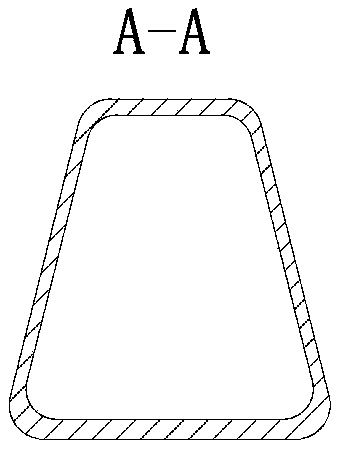

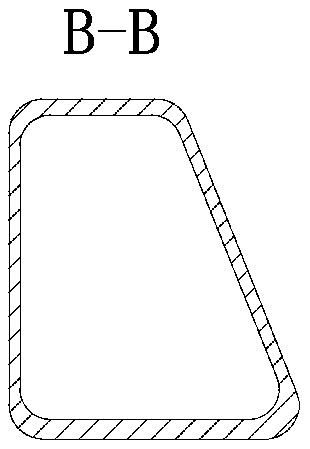

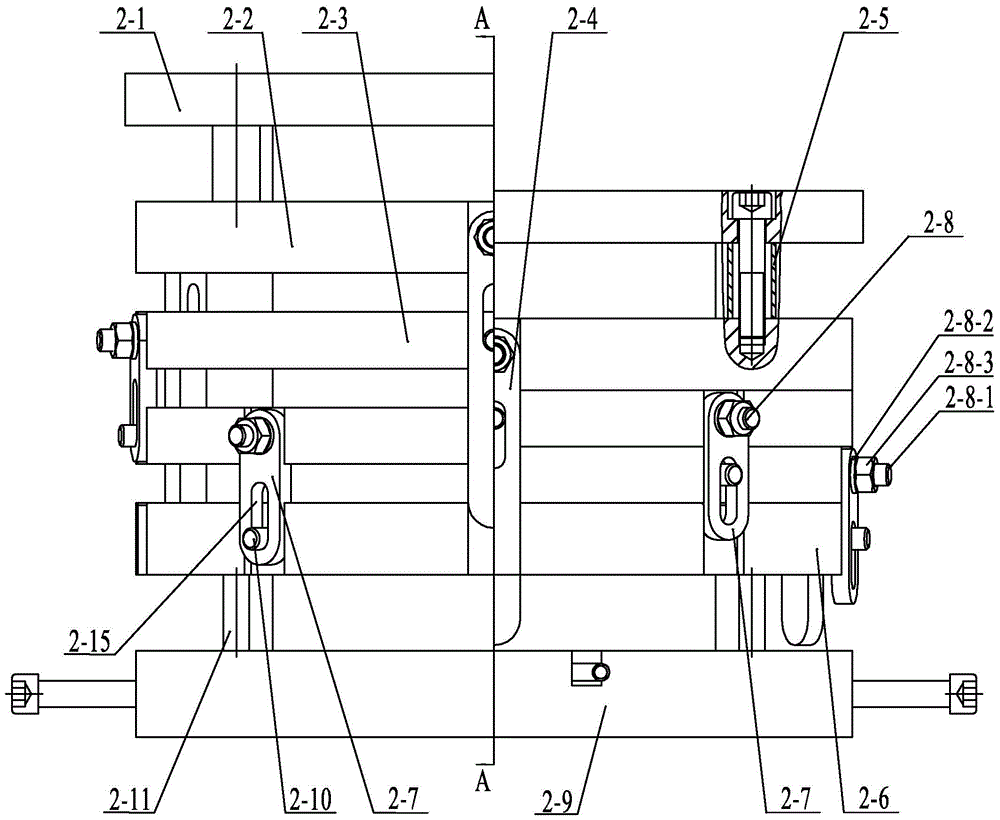

Flexible accommodating structure, multi-point profile stretch bending mold and stretch bending molding method

The invention provides a flexible accommodating structure, a multi-point profile stretch bending mold and a stretch bending molding method. A sealing space is formed inside the flexible accommodating structure, and a flexible medium filled in the sealing space is flexible filler. According to the profile section characteristics, the flexible filler is designed and replaced, so that the flexible filler adapts to the variety of the profile section. The flexible filler is arranged in the closed accommodating structure to bear 3D (three-dimensional) compressive stress, so that the profile section can be supported to avoid distortion. The stretch bending molding method adopts the multi-point profile stretch bending mold containing the flexible accommodating structure, so that the molding production period is shortened, the cost is reduced, and an efficient and digital production mode is provided for novel lightweight high-strength aluminum alloy frame parts.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

A current-assisted titanium alloy bellows hot forming device and method

ActiveCN104525660BImprove plastic deformation abilityUniform wall thickness distributionShaping toolsLow voltageGas cylinder

Owner:HARBIN INST OF TECH

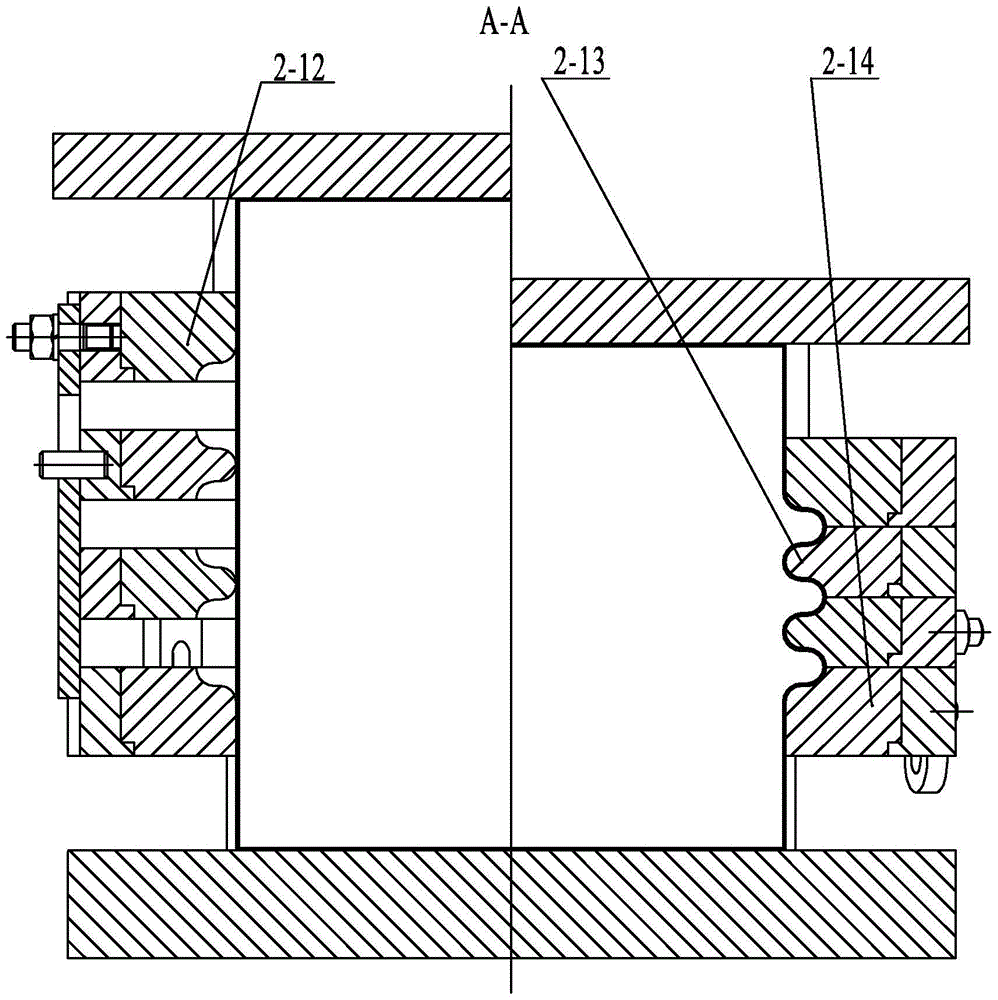

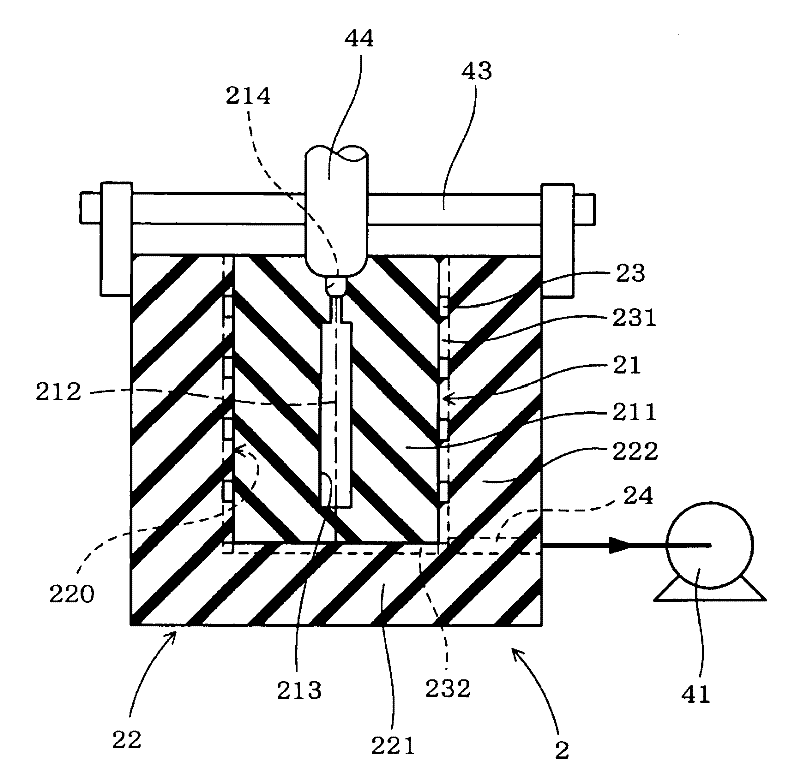

Resin molding rubber mold, resin molding device, and resin molding method

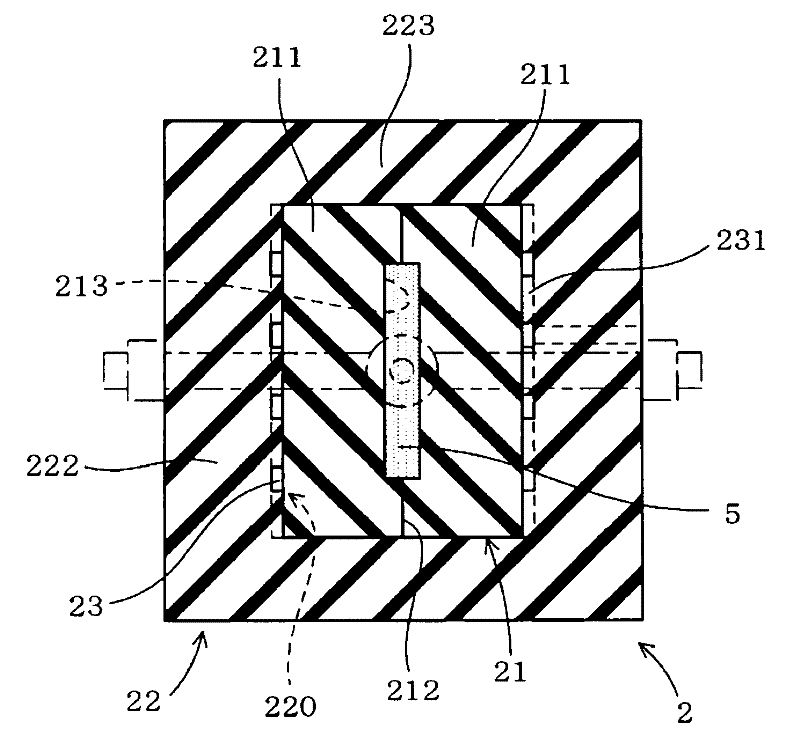

A resin molding rubber mold (2) comprises a cavity (213) into which a pressurized molten thermoplastic resin is placed. The rubber mold (2) comprises a core mold (21) consisting of a rubber material and having the cavity (213) formed therein, and also comprises a base mold (22) consisting of a rubber material and having a shape for allowing the core mold (21) to be placed in the base mold. The core mold (21) is formed by combining together a pair of split molds (211) along split surfaces (212) for opening the cavity (213). The base mold (22) has a lower surface section (221) and a pair of first side surface sections (222) which are formed on both sides of the direction in which the pair of split molds (211) is combined together.

Owner:TECHNO POLYMER CO LTD

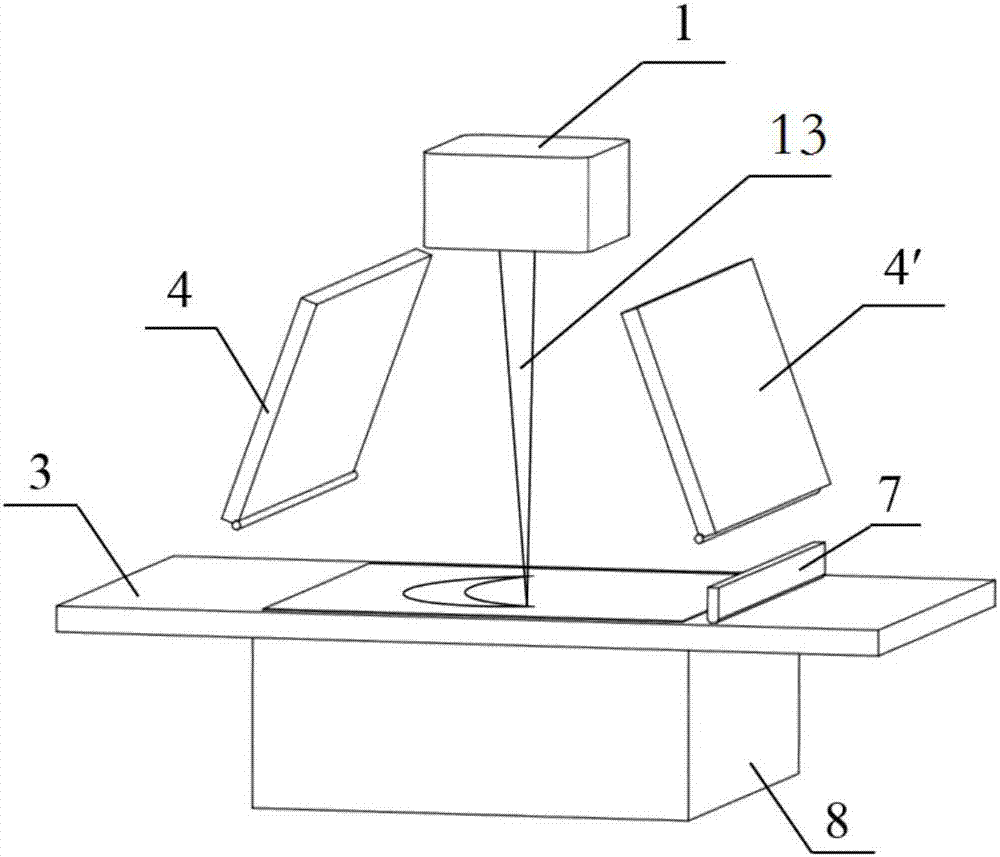

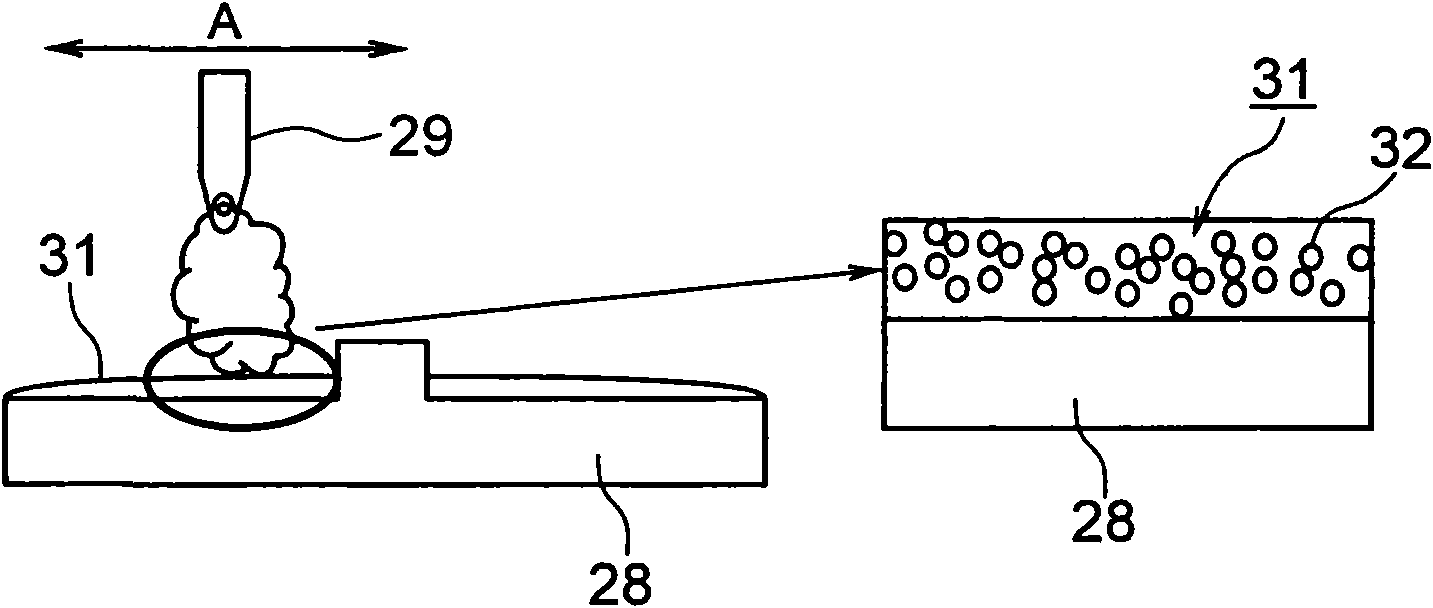

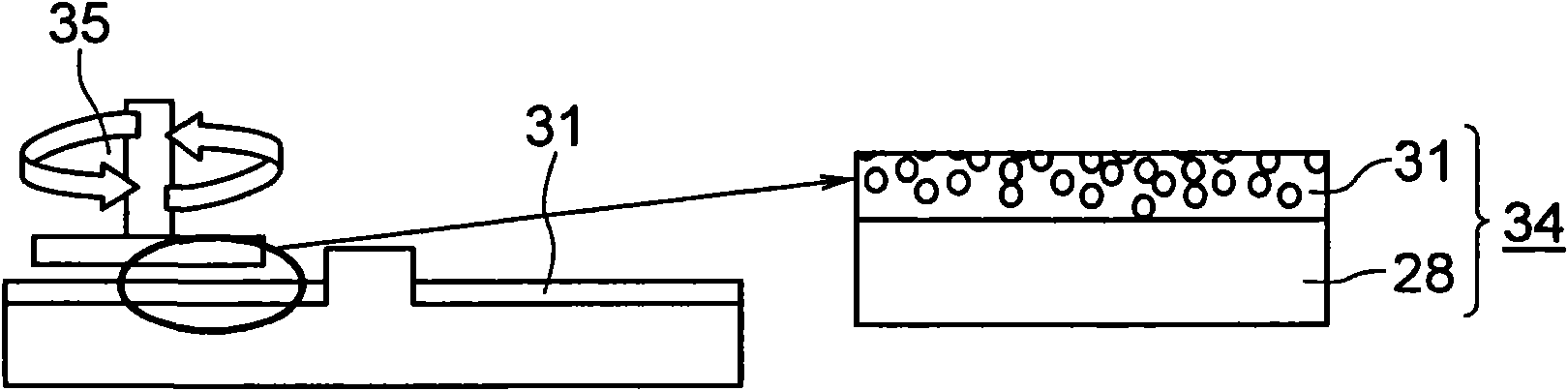

Electromagnetic progressive mold-free integral compound forming method and device for metal sheets

The invention discloses an electromagnetic progressive mold-free integral compound forming method and device for metal sheets and belongs to the related technical field of part shaping and manufacturing. The method comprises the following steps: designing an edge pressing assembly according to the dimension of a target shaping part; establishing a finite element model and carrying out simulated forming analysis; providing a forming device, setting discharge parameters and discharge paths according to the simulated result for electromagnetic progressive mold-free integral forming to obtain a preformed part; and clamping the preformed part on core mold-free spinning equipment to be shaped to obtain the final shape meeting the processing demands. The method and device disclosed by the invention achieve mold-free integral forming of large shell parts, so that the defect that the surface of the part is uneven is avoided effectively, and the forming precision and the surface quality of the formed part are improved greatly. In addition, the method is high in universality. One set of edge pressing assembly is only needed if different products are processed, so that the production period isshortened greatly, and the production cost of the large metal sheet is lowered remarkably.

Owner:HUAZHONG UNIV OF SCI & TECH

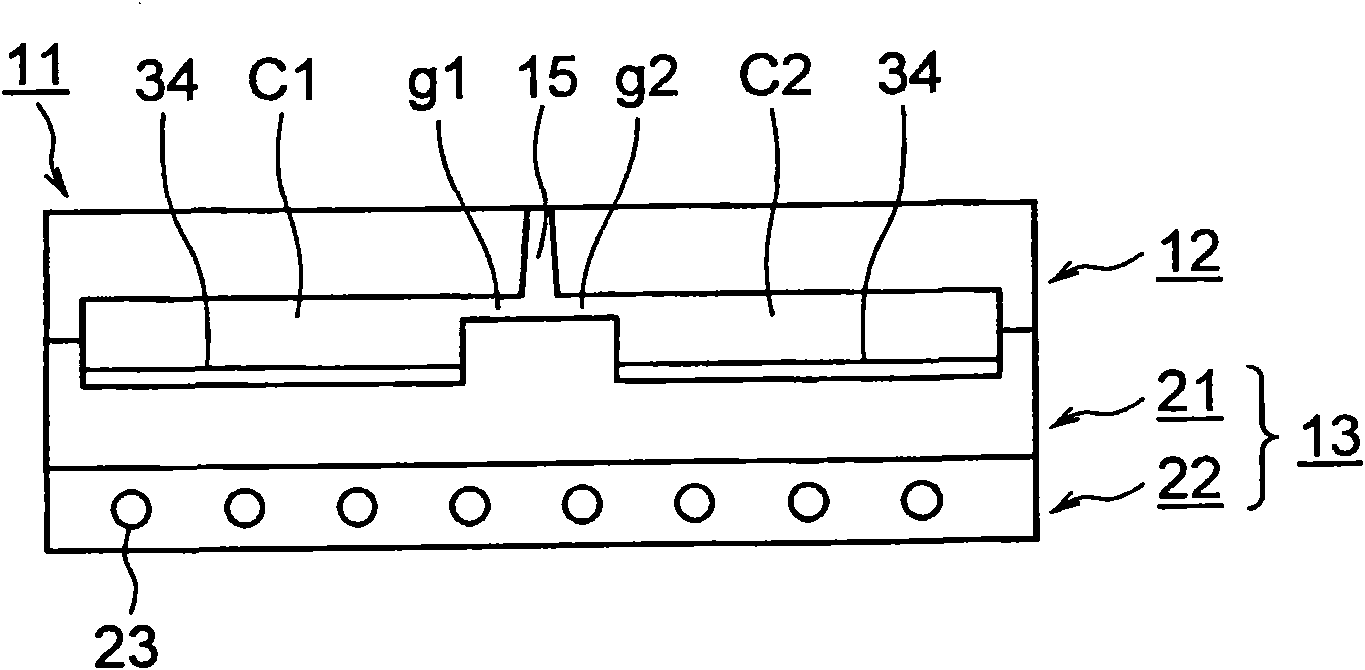

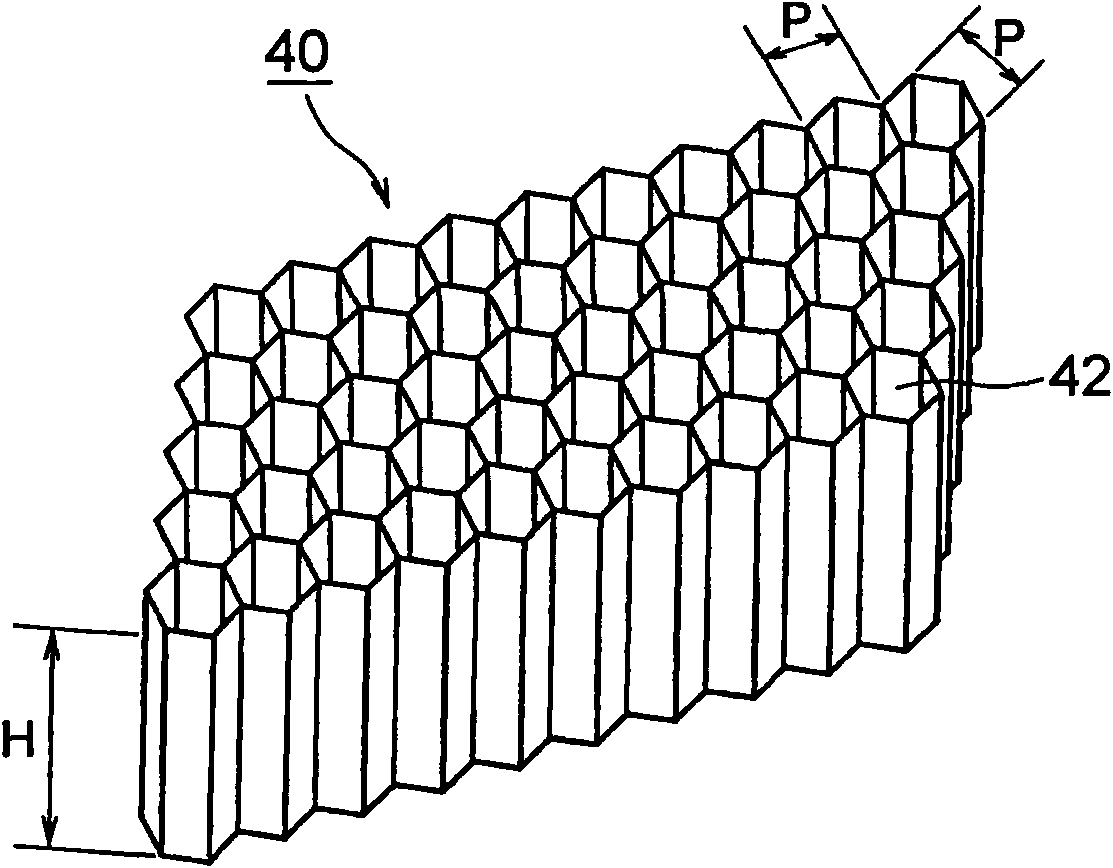

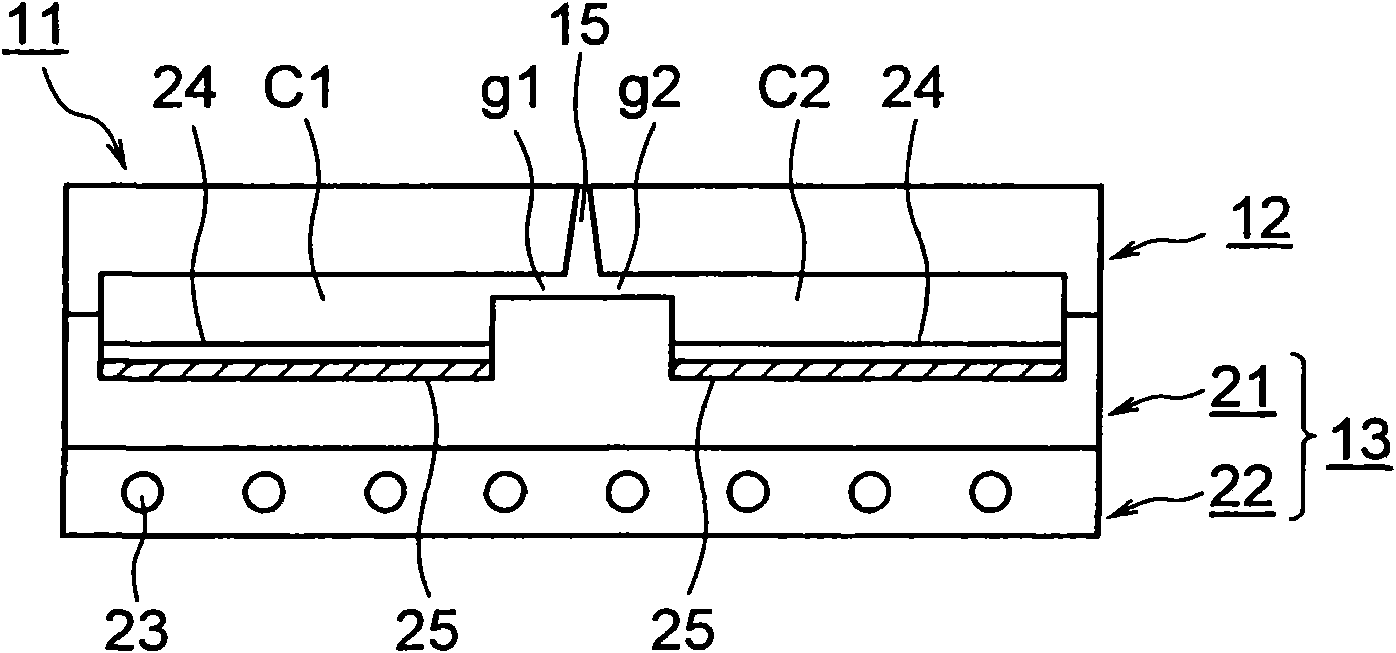

Resin molding apparatus

InactiveCN101618578AInhibit dissipationHigh transfer accuracyRecord carriersOptical articlesThermal energyThermal insulation

Disclosed is a resin molding apparatus capable of enhancing transfer accuracy, reducing the cost of a molding apparatus, and shortening a molding cycle. The resin molding apparatus includes a first mold; a second mold disposed in opposition to the first mold; a transfer plate (34) attached to one of the first and second molds and comprising a transfer surface bearing a pattern of pits and projections and oriented toward a cavity (C1, C2); and a thermal insulation layer (40) disposed between the transfer plate (34) and the one of the first and second molds and formed through growth from the transfer plate (34) side or from the one of the first and second mold sides. Being disposed between the transfer plate (34) and the one of the first and second molds, the thermal insulation layer (40) can restrain dissipation of thermal energy of a molding material toward the mold. This can restrain formation of a skin layer, which would otherwise result from a sharp drop in temperature of the molding material, whereby transfer accuracy can be enhanced.

Owner:SUMITOMO HEAVY IND LTD

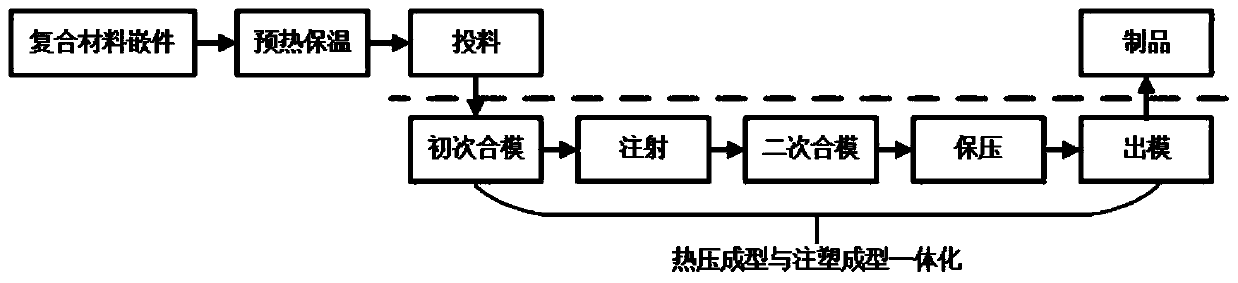

A method for integrally forming a thermoplastic composite structure on a resin plastic part

ActiveCN109278242BImprove performanceHigh specific strengthCoatingsInjection molding machineThermoplastic composites

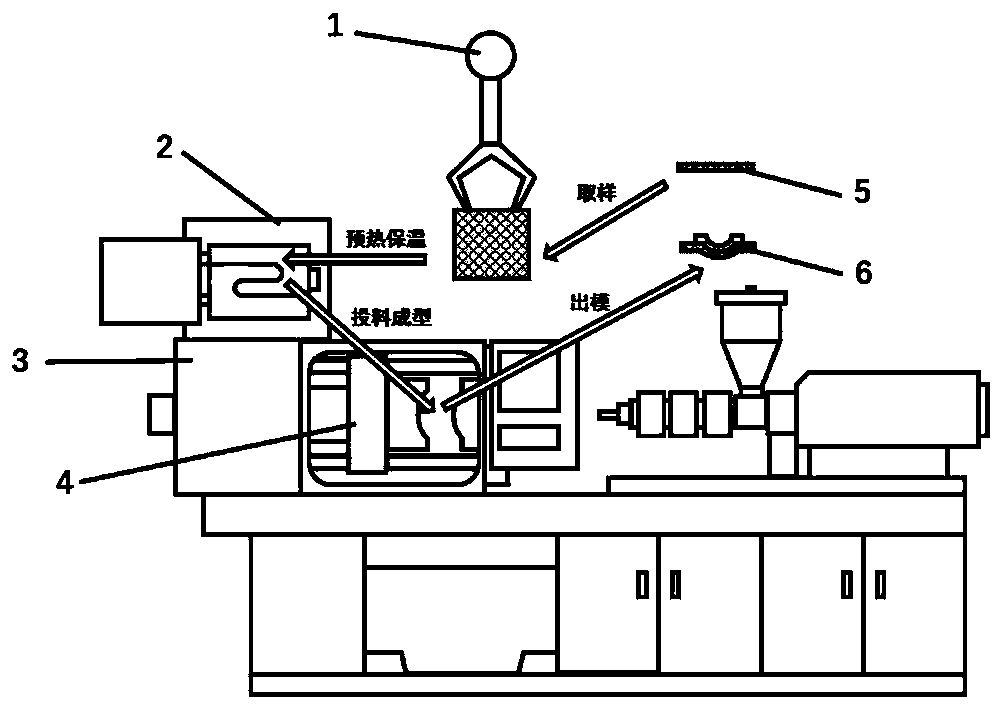

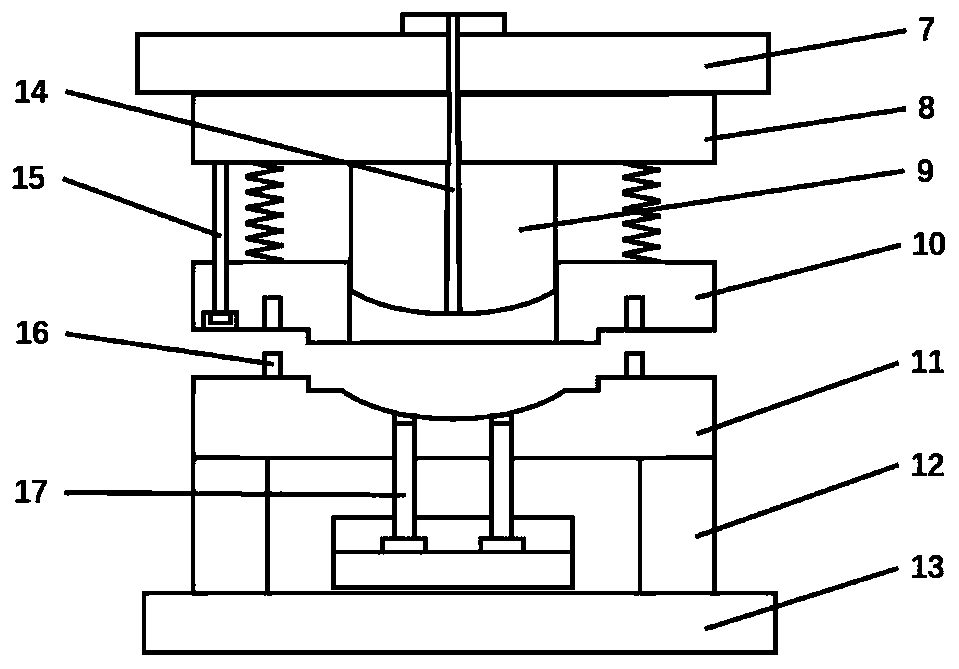

The invention belongs to the field of composite material forming, and particularly relates to a thermoplasticity composite material and surface resin plastic part integrated forming method. The methodcomprises the following steps that a, a thermoplasticity composite material insert is selected; and b, after being preheated, the insert is arranged in a die to be subjected to hot pressing and injection molding integrated forming,wherein after the die is closed for the first time and a closed cavityin the assigned size is formed, resin melt is injected into the cavity through an injection molding machine, then, the die is compressed to be completely closed, the resin melt transmits pressure to the insert to form the insert, meanwhile, under the action of the melt temperature, the resin meltmelts on the surface of the insert, and the insert and the resin plastic part form surface bonding. The thermoplasticity composite material and surface resin plastic part integrated forming method combines the advantages of hot pressing forming and injection molding compression forming, and is suitable for producing high-strength, high-size-precision and complex-structure composite material products; and due to the die pressing and injection molding compression integration character, the production efficiency can be improved, and the production period is shortened.

Owner:HUAZHONG UNIV OF SCI & TECH

Disc molding die, mirror-surface plate and molded object

InactiveCN1938141AImprove cooling effectCool evenlyRecord carriersRecord information storageCircular discEngineering

Owner:SUMITOMO HEAVY IND LTD +1

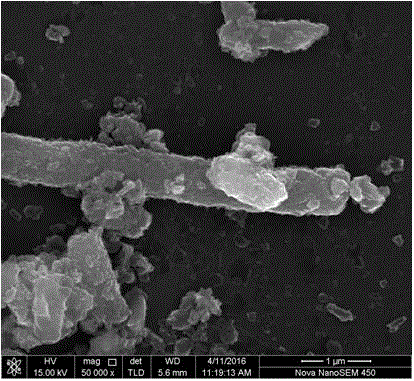

Preparation method for multi-wall carbon nano tube reinforced magnesium-based composite material coated with elemental copper

The invention discloses a preparation method for a multi-wall carbon nano tube reinforced magnesium-based composite material coated with elemental copper. The preparation method comprises the following steps of: firstly, preparing a multi-wall carbon nano tube coated with elemental copper; then, introducing multi-wall carbon nano tube magnesium alloy powder into material suspension coated with elemental copper to mix to obtain a mixture, vacuum-drying the mixture at a temperature being 50-100 DEG C, introducing the mixture into a ball-milling crucible, and ball-milling the mixture under protection of argon gas; cold-pressing the mixture into a prefabricated block under pressure of 50-150 MPa, putting the prefabricated block into a mould, heating the mould to a temperature being 10-30 DEG C lower than a solid phase line at a heating rate being 10-15 DEG C / min, continuously heating at a heating rate being 3-6 DEG C / min, and controlling a solidification phase rate of the mould to be within a range of 70-90%, thereby obtaining the multi-wall carbon nano tube reinforced magnesium-based composite material coated with elemental copper. The preparation method has the advantages of being simple, safe, low in cost, easy to operate, controllable, and the like.

Owner:NANCHANG UNIV

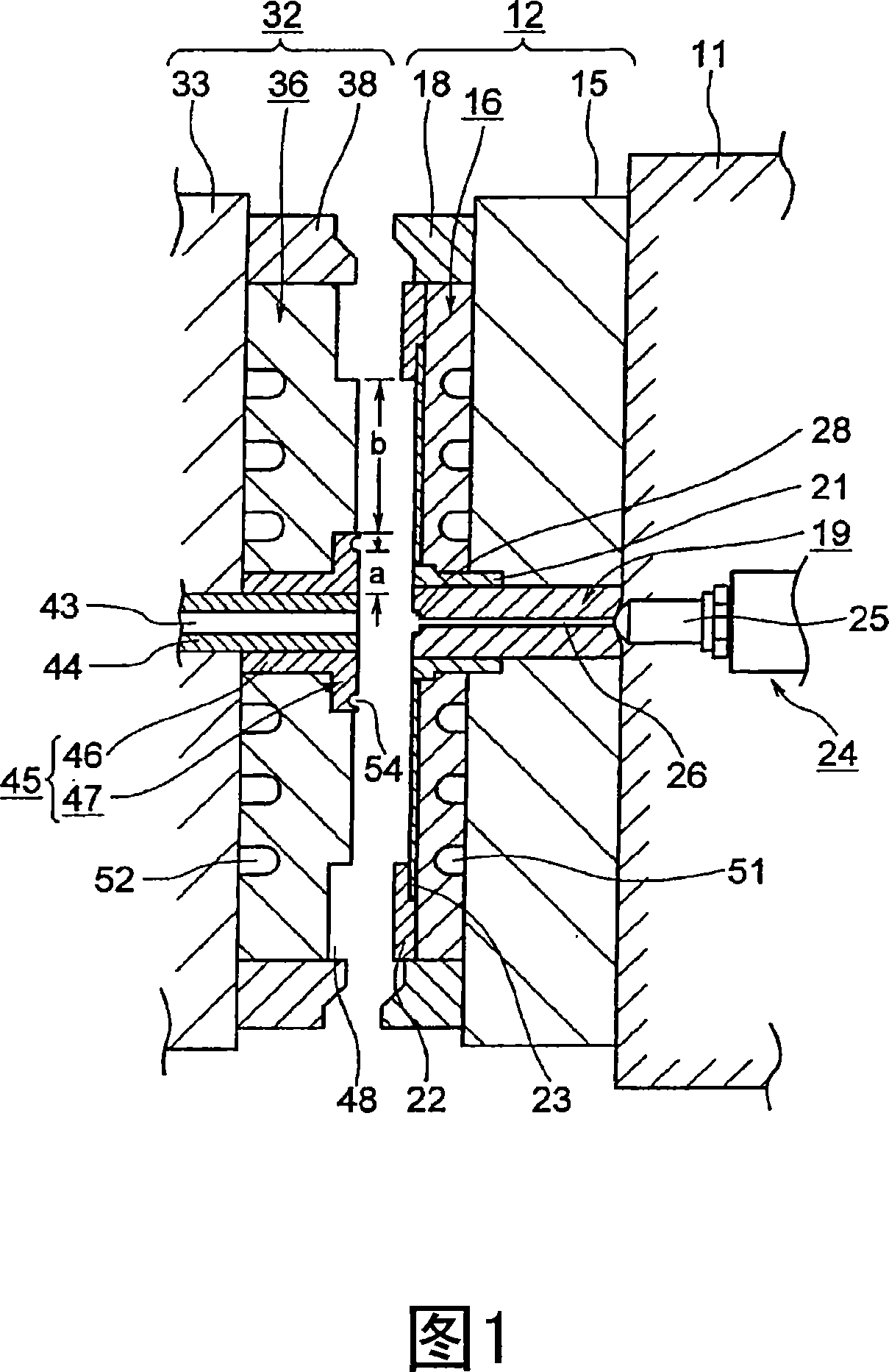

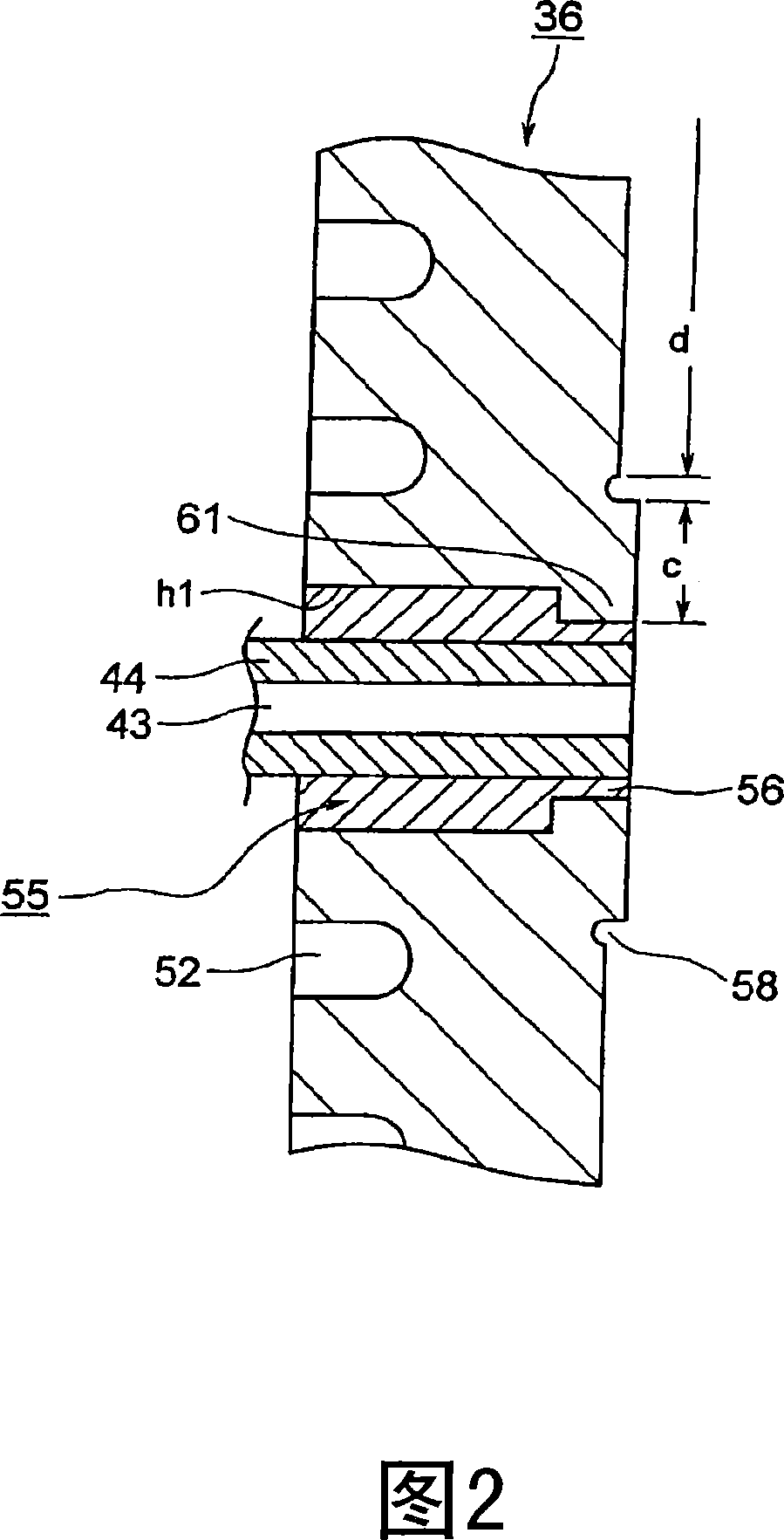

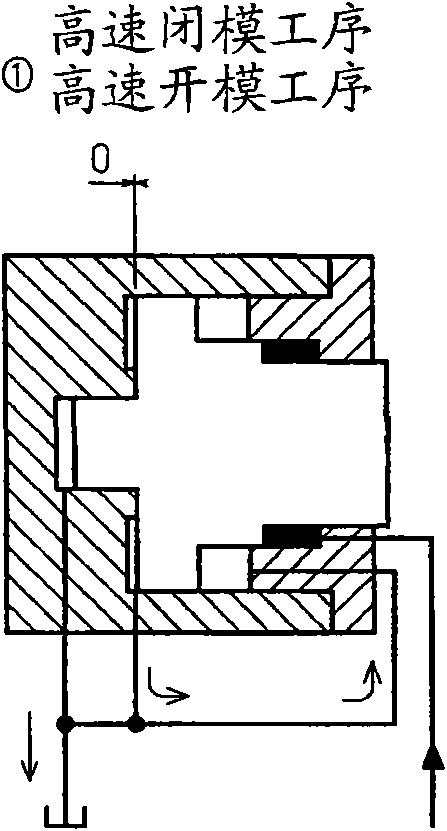

A mold clamping device and an operating method of the mold clamping device

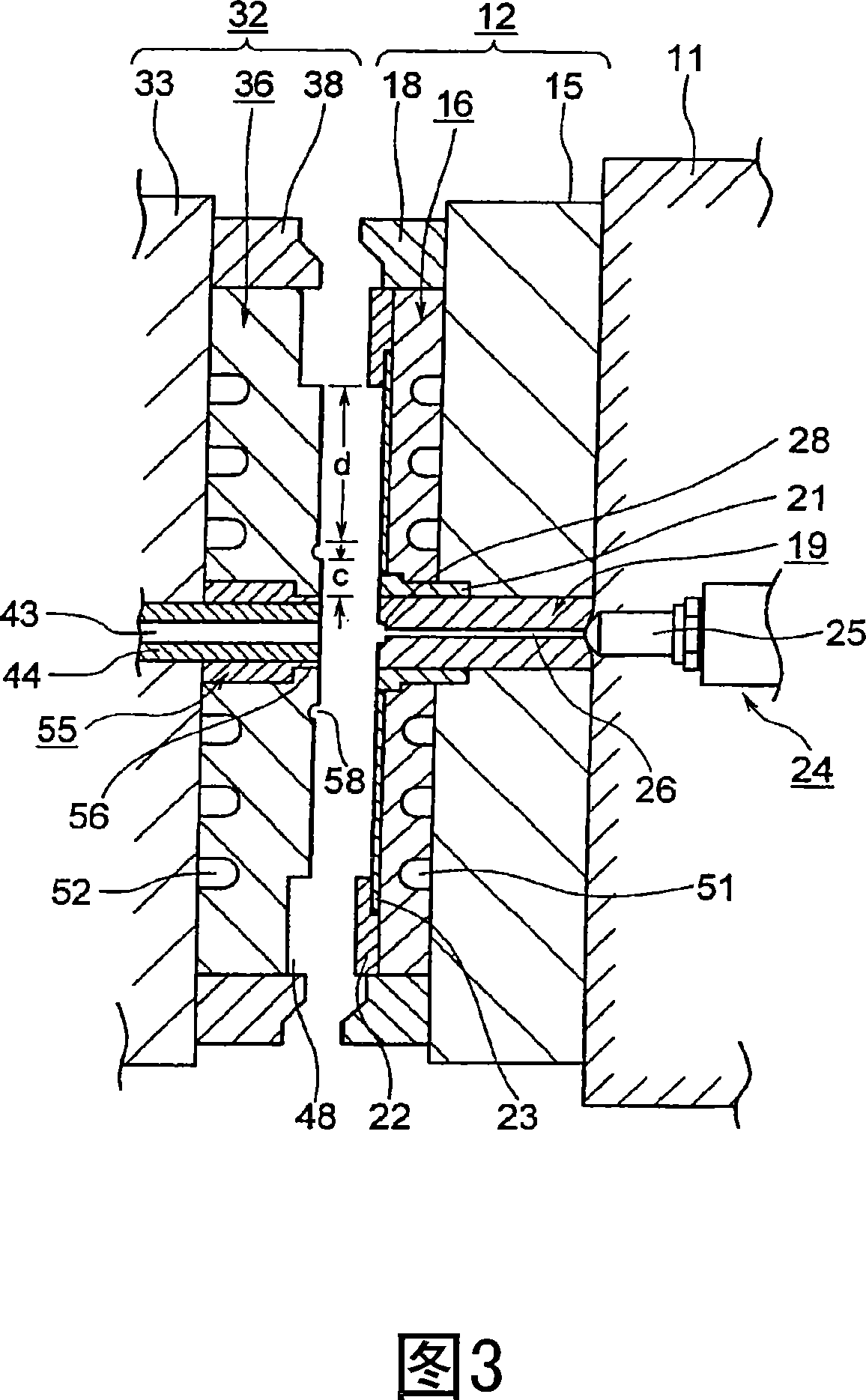

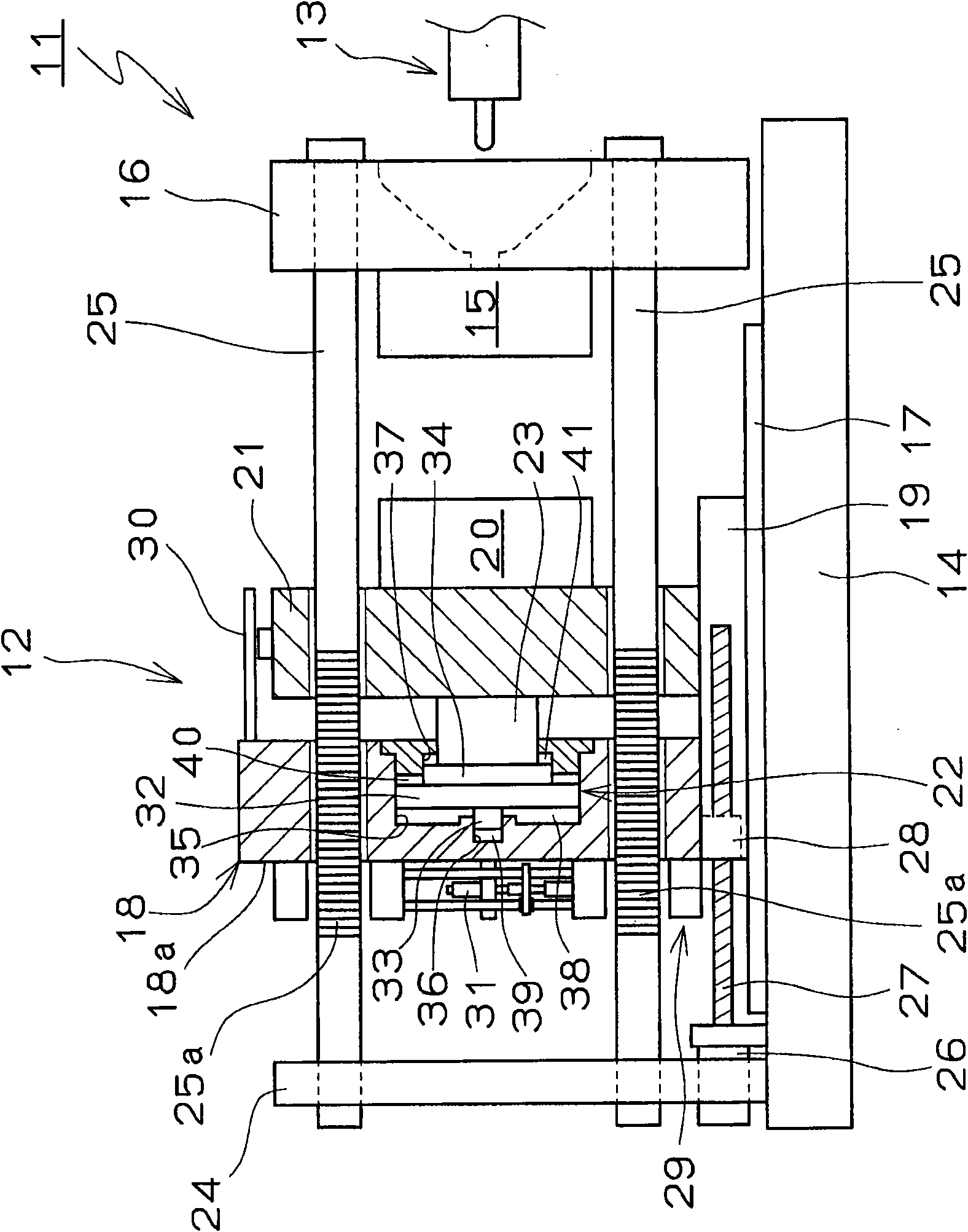

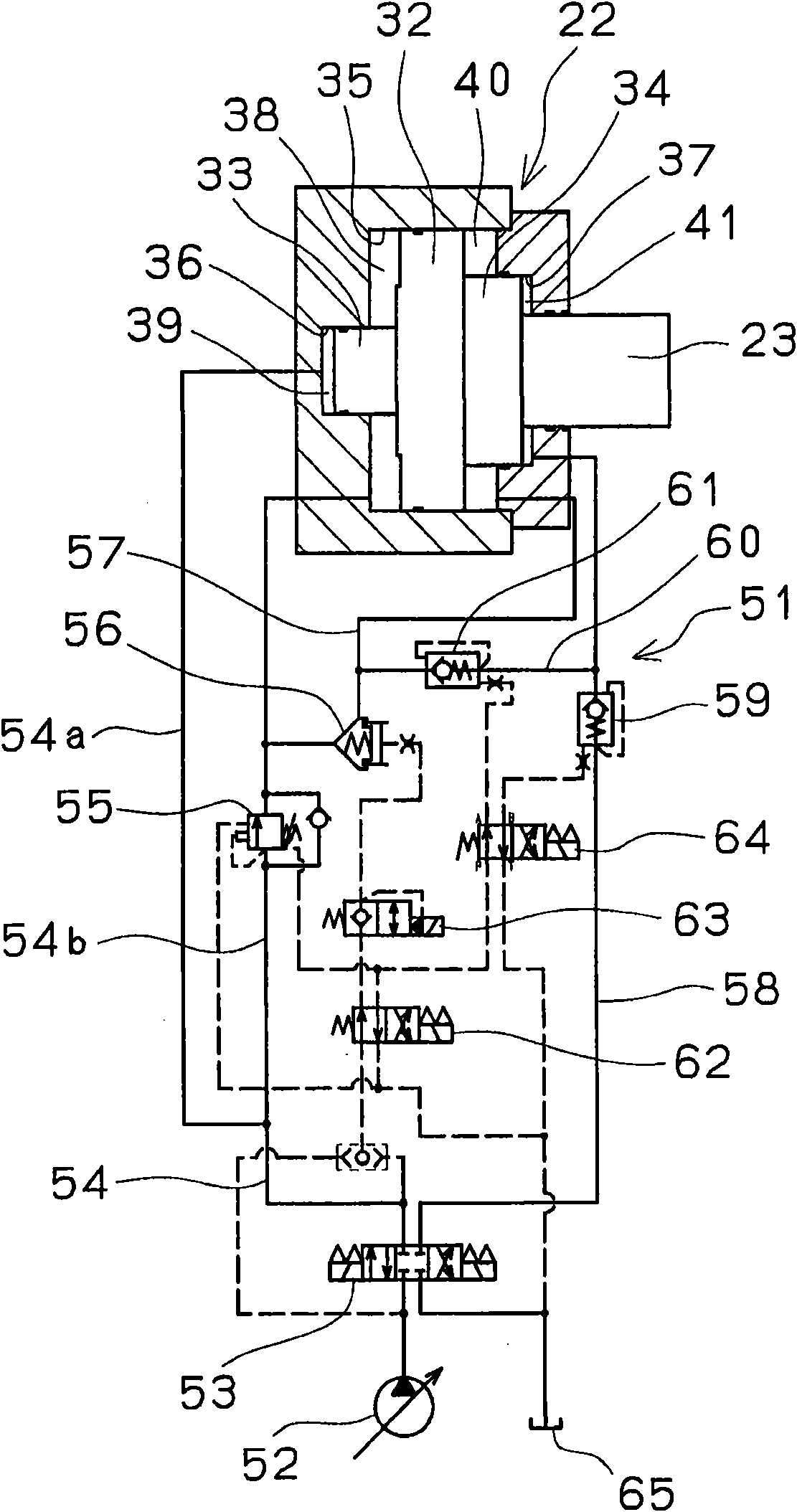

Provided is a mold clamping device by using a mold clamping pressure cylinder, capable of rapidly moving the mold clamping pressure cylinder toward two directions without size maximization of pumps or valves in a liquid pressure loop so as to shorten a period after clamping a locknut and a locking part. The mold clamping device (12), in which a movable metal mold (20) is close to or conjoined to a fixed metal mold (15) by a mold switching mechanism (26) and the mold is clamped by the mold clamping pressure cylinder (22) after clamping the locknut (29) and the locking part (25), is provided with a first pressure cylinder chamber (38) for mold clamping, a second pressure cylinder chamber (39) and a third pressure cylinder chamber (41) which pressure-receiving areas are less than that of a first pressure cylinder chamber (38), by using a mold clamping piston (32) of a mold clamping pressure cylinder (22) as a boundary.

Owner:JAPAN STEEL WORKS LTD

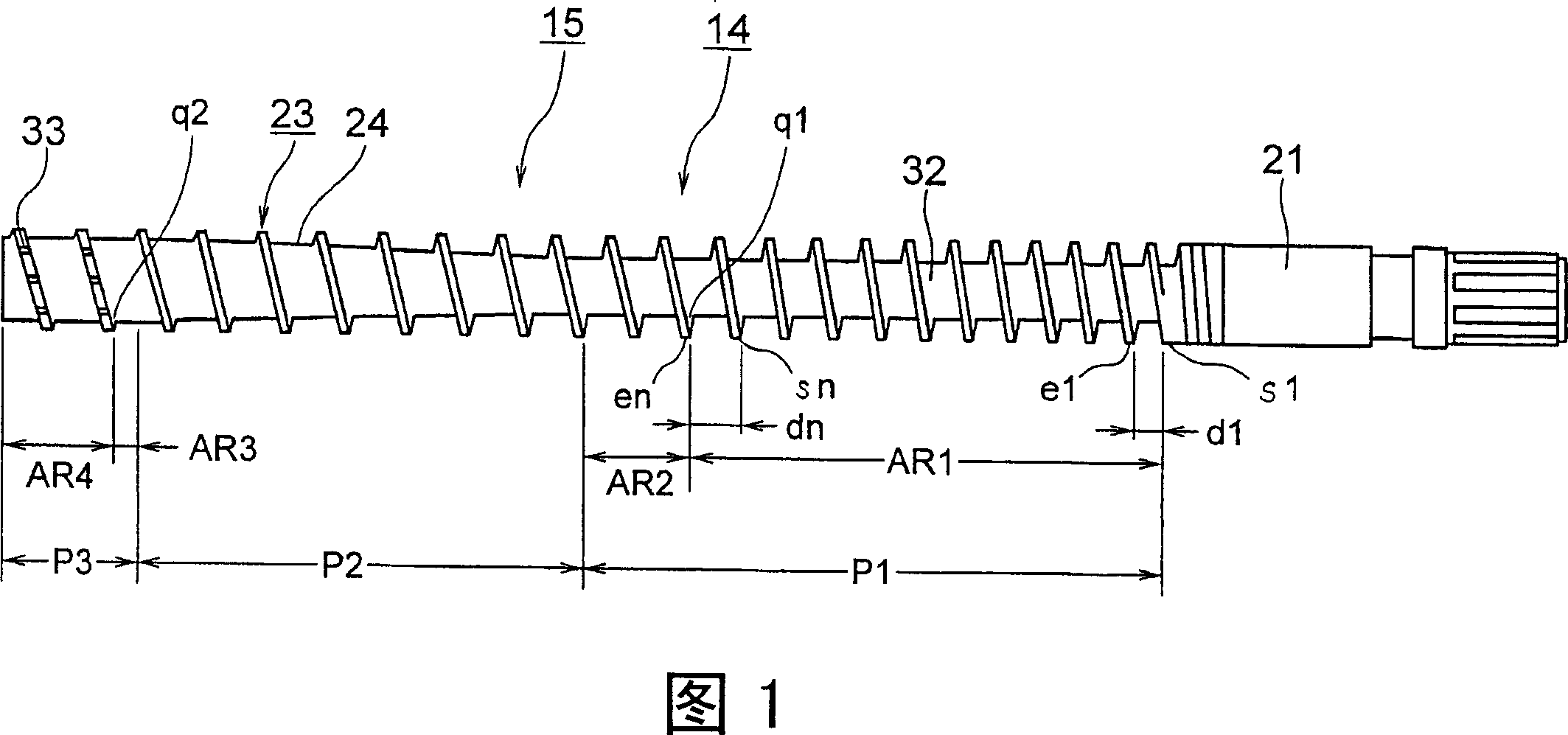

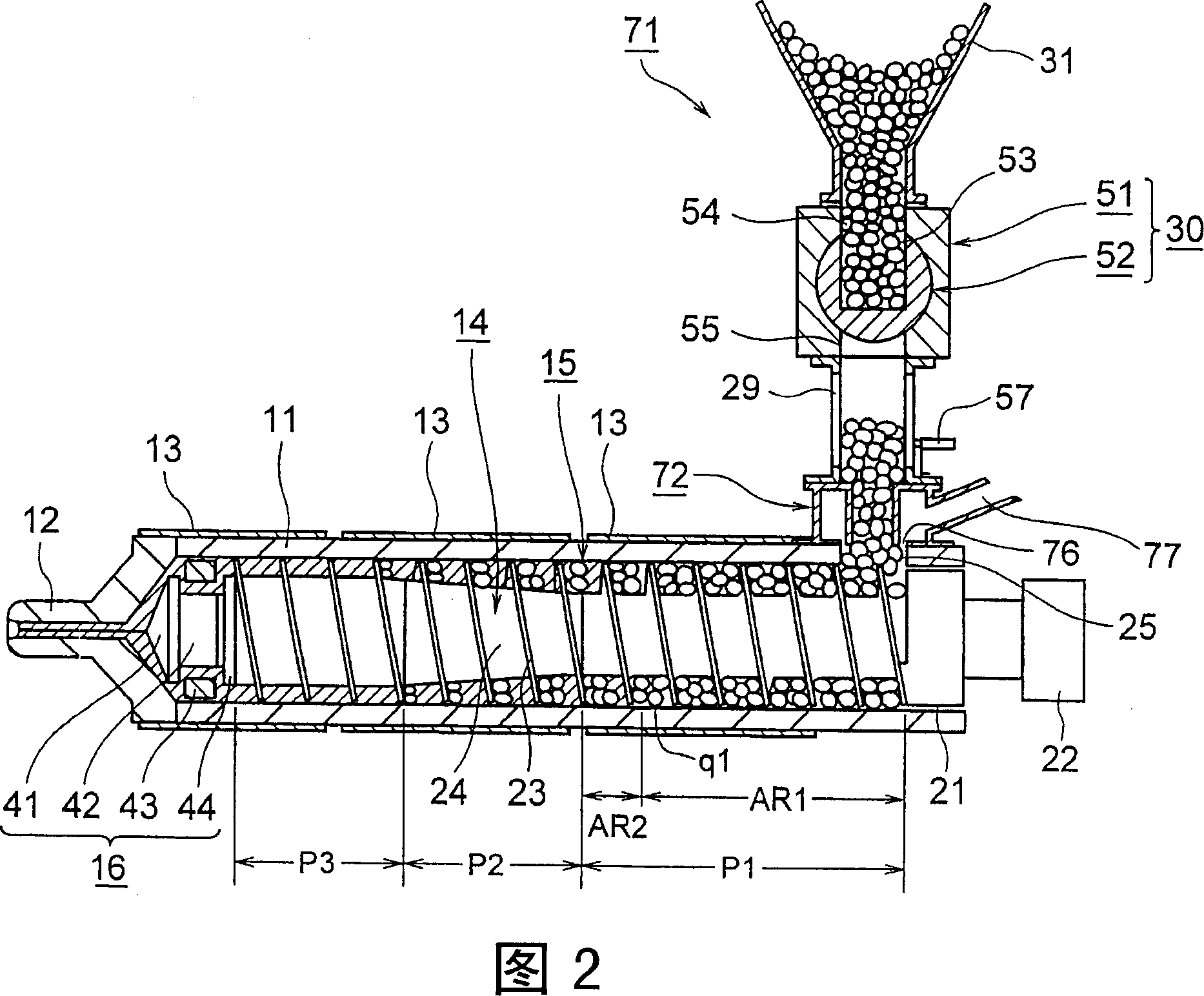

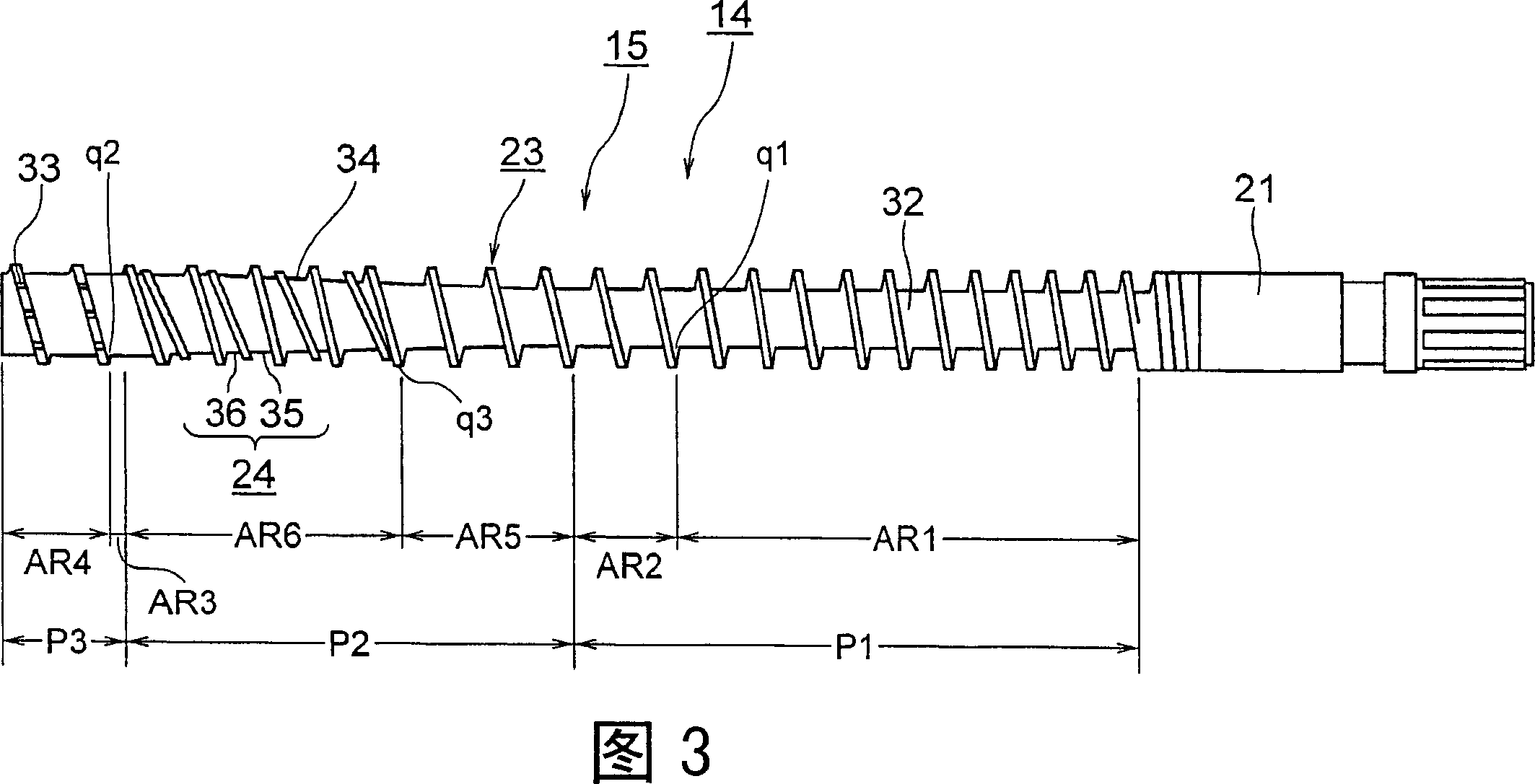

Injection member of molding machine and molding method

An injection member of a molding machine capable of reducing a molding cycle and a maintenance time and preventing galling from occurring between a cylinder member and the injection member and a molding method. The injection member of the molding machine comprises a supply part (P1) to which a molding material is supplied through the molding material supply port of the cylinder member, a compression part (P2) melting and compressing the molding material supplied from the supply part (P1) thereto, and a weighing part (P3) weighing the molding material supplied from the compression part (P2) thereto. The supply part (P1) comprises a pressure regulating and switching point (q1) at a position apart a specified distance from the front end rearward and is divided into two parts through the pressure regulating and switching point (q1). The pressure of the molding material is gradually reduced in a pressure gradually reducing area (AR1) starting at the rear end of the supply part (P1) to the pressure regulating and switching point (q1). The pressure of the molding material is regulated in a pressure regulating area (AR2) starting at the pressure regulating and switching point (q1) to the front end of the supply part (P1).

Owner:SUMITOMO HEAVY IND LTD

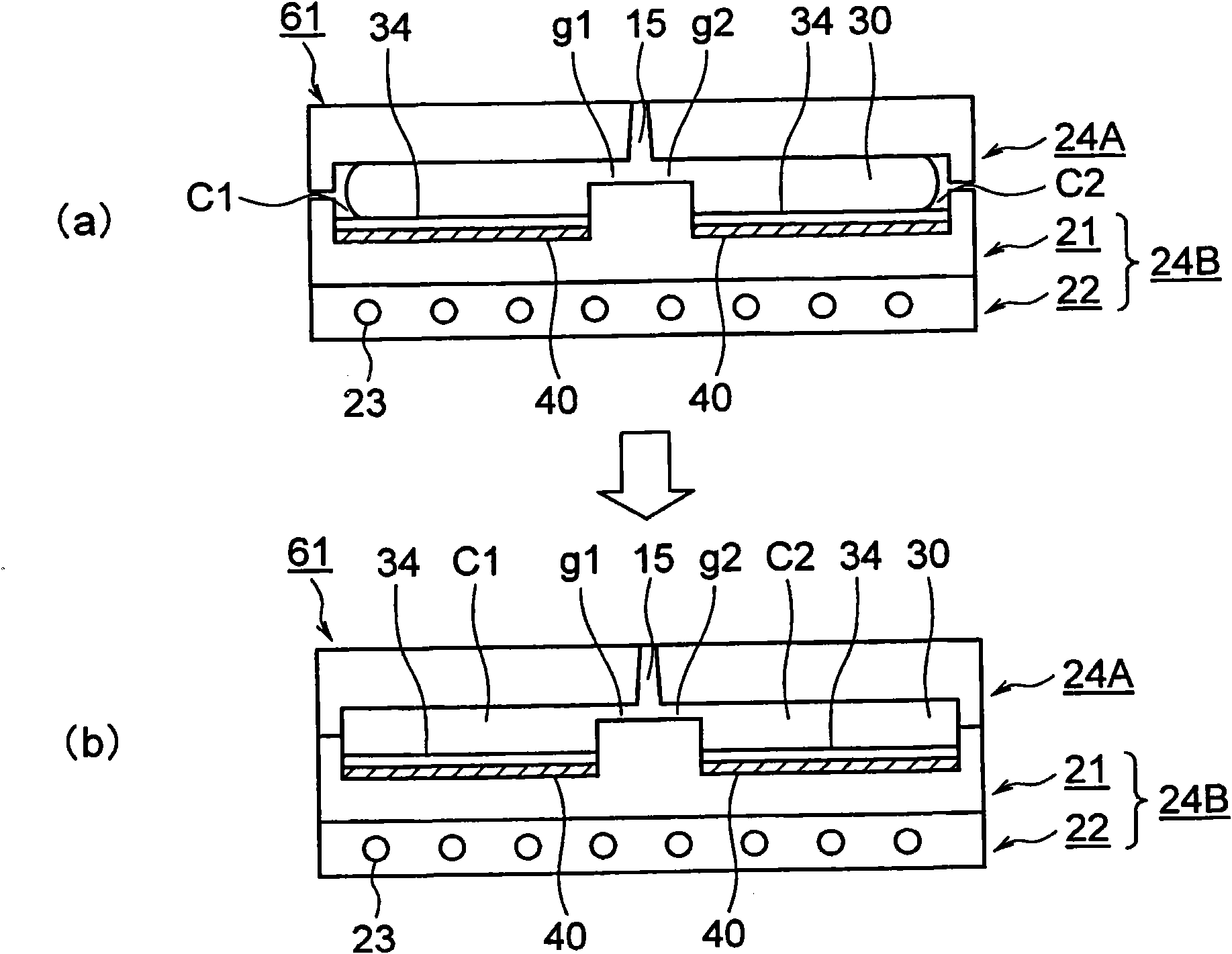

Heat insulating mold, mold component, molding machine, and method for manufacturing the heat insulating mold

This invention provides a heat insulating mold, a mold component, a molding machine and a method for manufacturing the heat insulating mold, which can realize shortened molding cycles and improved durability of heat insulating layer (25). The heat insulating mold comprises a mold plate and a transfer member mounted on the mold plate provided with a transfer face having a fine concavoconvex pattern on a face opposite to cavity spaces (C1, C2). The heat insulating layer (25) having a densified surface is formed on the mold plate in its face abutted against the transfer member. Since the heat insulating layer (25) is formed on the mold plate in its face abutted against the transfer member, the temperature of the molding material filled into the cavity spaces (C1, C2) is temporarily held by the heat insulating layer (25). As a result, the growth and development of the surface hardening layer is delayed, and the pattern transfer of the transfer face can be finished in the delayed period. Since the surface of the insulating layer (25) is densified, the surface of the heat insulating layer (25) can be smoothened to a very high level. Further, the durability of the heat insulating layer (25) can be improved.

Owner:SUMITOMO HEAVY IND LTD

Automatic clamping device for automotive connector

InactiveCN107020719AHigh degree of automationImprove work efficiencyDomestic articlesEngineeringAutomaticity

The invention relates to an automatic clamping device for an automotive connector. The automatic clamping device comprises a fixed support, and a metal disk, an automatic lifting mechanism and a delivery mechanism which are installed on the fixed support respectively. The metal disk is connected to the automatic lifting mechanism and the delivery mechanism respectively; and a metal part to be clamped is placed in the metal disk, lifted to the set height through the automatic lifting mechanism, and then conveyed to the set position through the delivery mechanism. Compared with the prior art, the automatic clamping device provided by the invention has the advantages that the automaticity is high, and the product quality is improved; the production cost is reduced; the molding cycle is shortened, etc.

Owner:SHANGHAI CHIEF LAND ELECTRONICS CO LTD

Micronano transfer device

InactiveCN1831644AAvoid interferenceSimple structurePhotomechanical apparatusSemiconductor/solid-state device manufacturingEnergy transferMicro nano

A micro-nano reprinting device consists of mould, base plate with a forming material layer and energy transfer module with energy transfer piece as well as an energy source. It is featured as connecting energy transfer piece to base plate for providing reprint energy to base plate by energy source to let partial reprint energy penetrate energy transfer piece up to base plate for carrying out reprint - formation of said forming material layer.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com