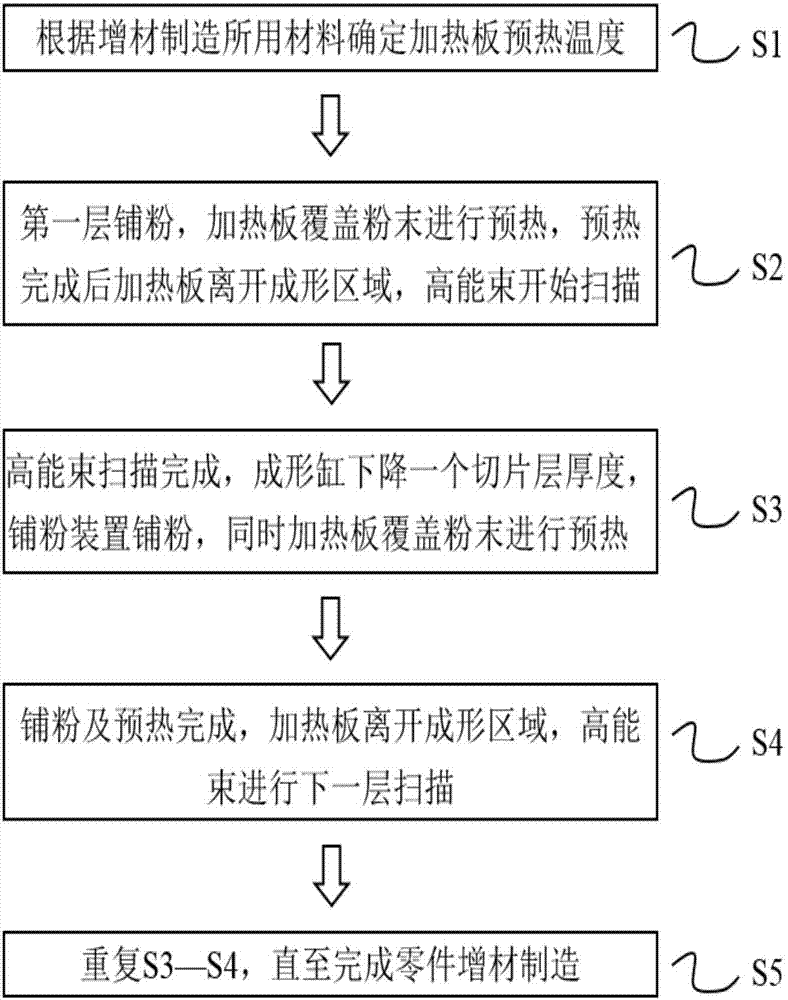

Preheating method and device suitable for powder laying type additive manufacturing

A technology of additive manufacturing and powder spreading device, which is applied in the field of additive manufacturing, can solve problems such as waste, difficulty in repair, and failure of part forming, and achieve the effects of efficient and uniform preheating, reduced heat dissipation, and high preheating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

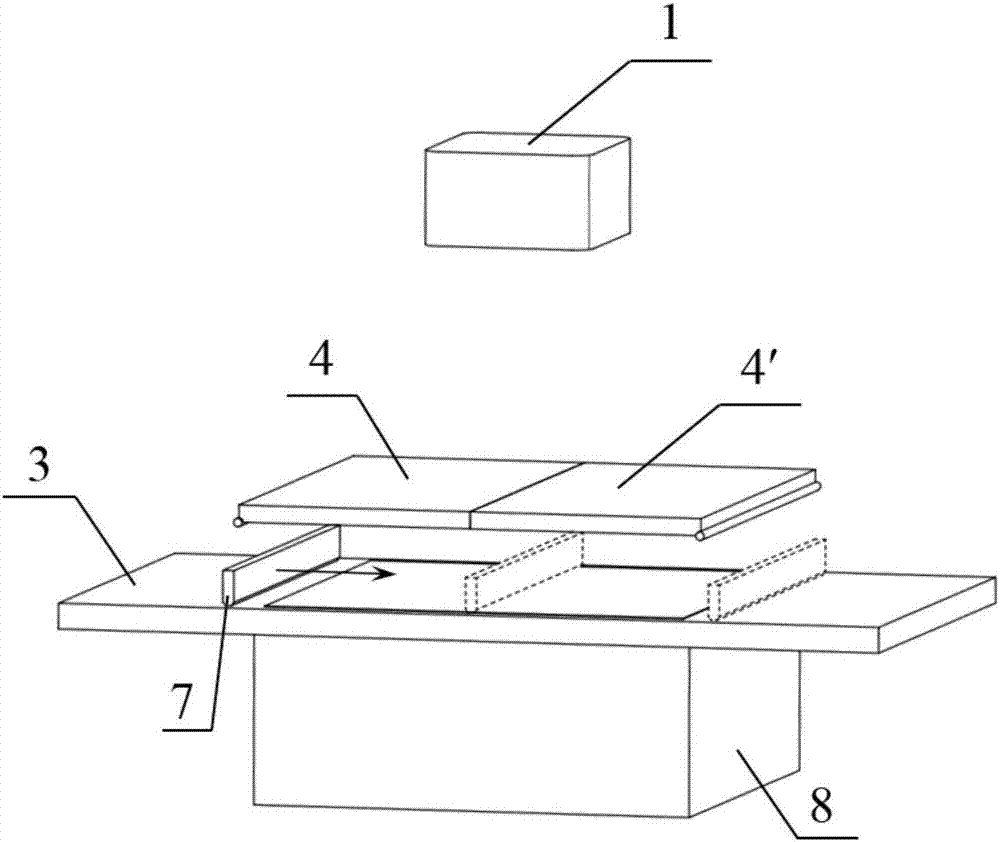

[0059] Embodiment 1: rail type preheating device

[0060] The device that embodiment 1 adopts is as Figure 4 As shown, the device includes a high-energy beam generation and control module 1, a forming cavity 2, a forming table 3, a powder spreading device 7, a forming cylinder 8, first and second powder feeding devices 9, 9', first and second The powder recovery device 10, 10' and the control system 11 also include the first and second plane heating plates 4, 4', the first and second heating plate motion guide rails 5, 5' and the first and second temperature measuring sensors 6 , 6'.

[0061] Among them, the high-energy beam generation and control module 1 is located at the top of the equipment, and the first and second powder feeding devices 9 and 9' and the first and second powder recovery devices 10 and 10' are respectively located on both sides of the equipment to realize two-way powder feeding and powder Recycle. The first and second flat heating plates 4, 4' are plac...

Embodiment 2

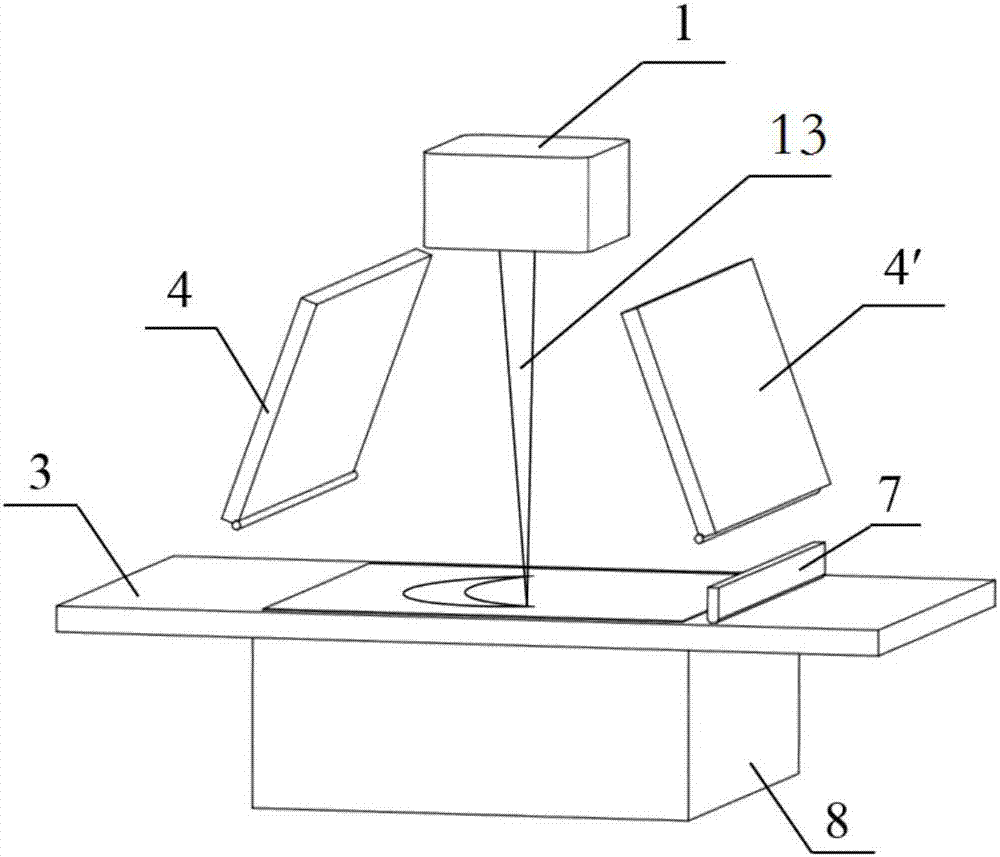

[0072] Embodiment 2: Foldable preheating device (two-way powder spreading)

[0073] The device that embodiment 2 adopts is as Figure 5 As shown, the device includes a high-energy beam generation and control module 1, a forming cavity 2, a forming table 3, a powder spreading device 7, a forming cylinder 8, first and second powder feeding devices 9, 9', first and second The powder recovery device 10, 10' and the control system 11 also include the first and second planar heating plates 4, 4', the first heating plate moving guide rail 5 (the first heating plate moving guide rail 5 is a pair of linear guide rails here) And the first and second temperature measuring sensors 6, 6'.

[0074] Figure 5 The device shown is Figure 4 The difference of the shown devices is that the first and second planar heating plates 4, 4' and the first and second heating plate moving rail pairs 5, 5' are set differently. specific, Figure 4 The first and second heating plate movement guide rail ...

Embodiment 3

[0086] Embodiment 3: Foldable preheating device (one-way powder spreading)

[0087] The device used in this embodiment is as Figure 8 As shown, it includes a high-energy beam generation and control module 1, a forming cavity 2, a forming table 3, a powder spreading device 7, a forming cylinder 8, a first powder feeding device 9, a first powder recovery device 10, a control system 11 and a first One, the second sensor placement table 12,12' also includes the first and second plane heating plate groups 4,4', the first heating plate moving guide rail 5 (the first heating plate moving guide rail 5 is a pair of linear guide rails here ) and the first and second temperature measuring sensors 6, 6'. The first and second sensor placement platforms 12, 12' are arranged on both sides of the forming cylinder 8, and are respectively used for installing the first and second temperature measuring sensors 6, 6'.

[0088] Among them, the high-energy beam generation and control module 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com