DC charging machine with charging gun temperature monitoring module and temperature control method of the DC charging machine

A monitoring module and charging gun technology, applied in temperature control, charging station, non-electric variable control, etc., can solve the problems of low safety performance, lack of intelligence, no temperature control function, etc., achieve low cost, simple internal circuit, and guarantee safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following is a description of a DC charger with a charging gun temperature monitoring module and temperature control according to the present invention in conjunction with the accompanying drawings and preferred embodiments. The specific implementation, structure, features and effects of the method are described in detail below.

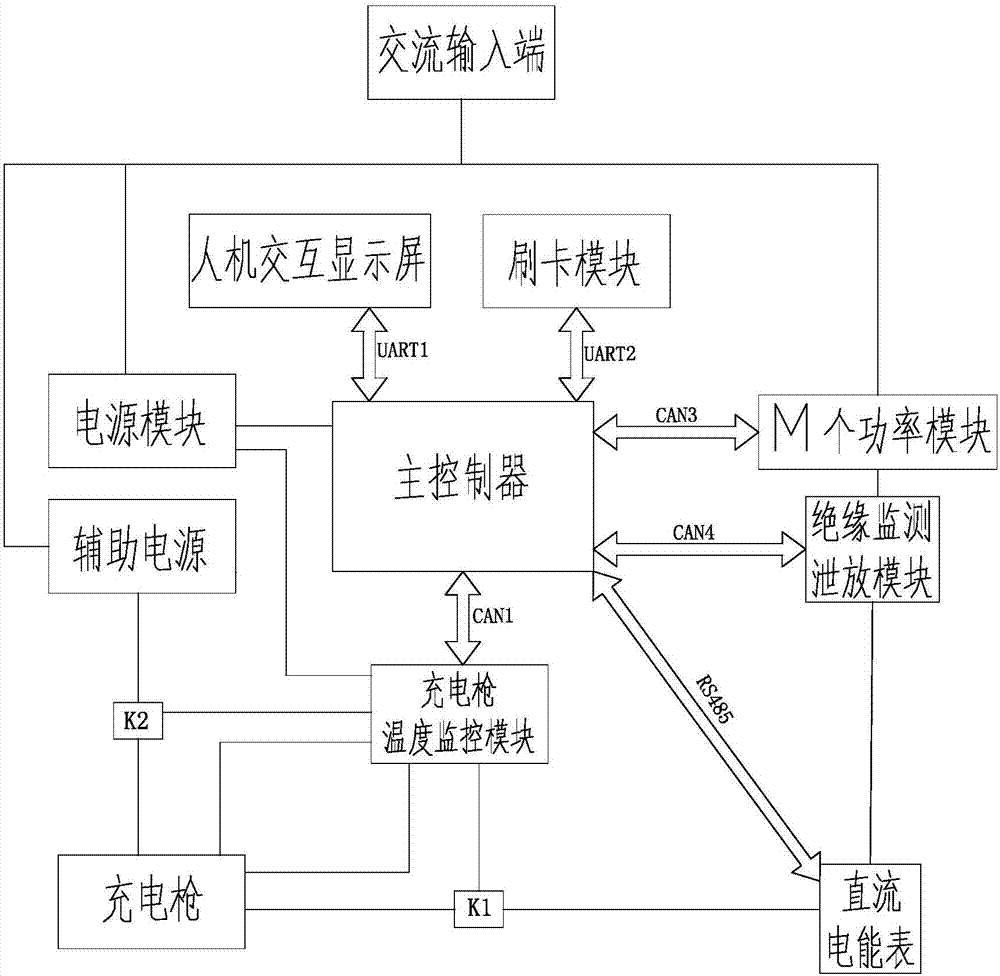

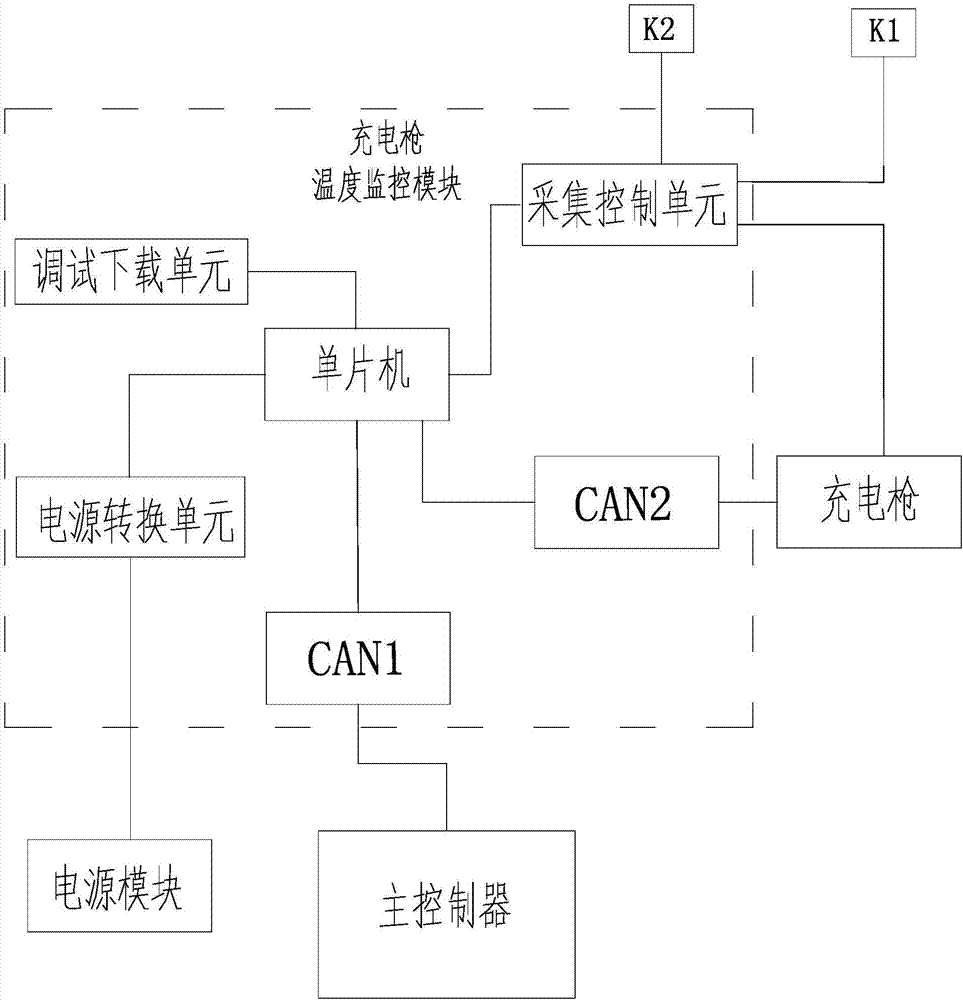

[0033] like Figures 1 to 2As shown, a DC charger with a charging gun temperature monitoring module includes a main controller and a human-computer interaction display connected to the main controller, a card swiping module, a power supply module, a charging gun temperature monitoring module, a power module group, The insulation detection and discharge module, the DC watt-hour meter, and an AC input terminal connected with the power module, the auxiliary power supply, and the power module to supply power to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com