Injection member of molding machine and molding method

A molding machine and component technology, which is applied to the injection parts of the molding machine and the molding field, can solve the problems of longer cooling time, shorter molding cycle, and foreign matter mixed in molded products, so as to shorten the molding cycle and prevent the temperature from becoming excessively high. , the effect of shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in this case, a molding machine, such as an injection molding machine, will be described.

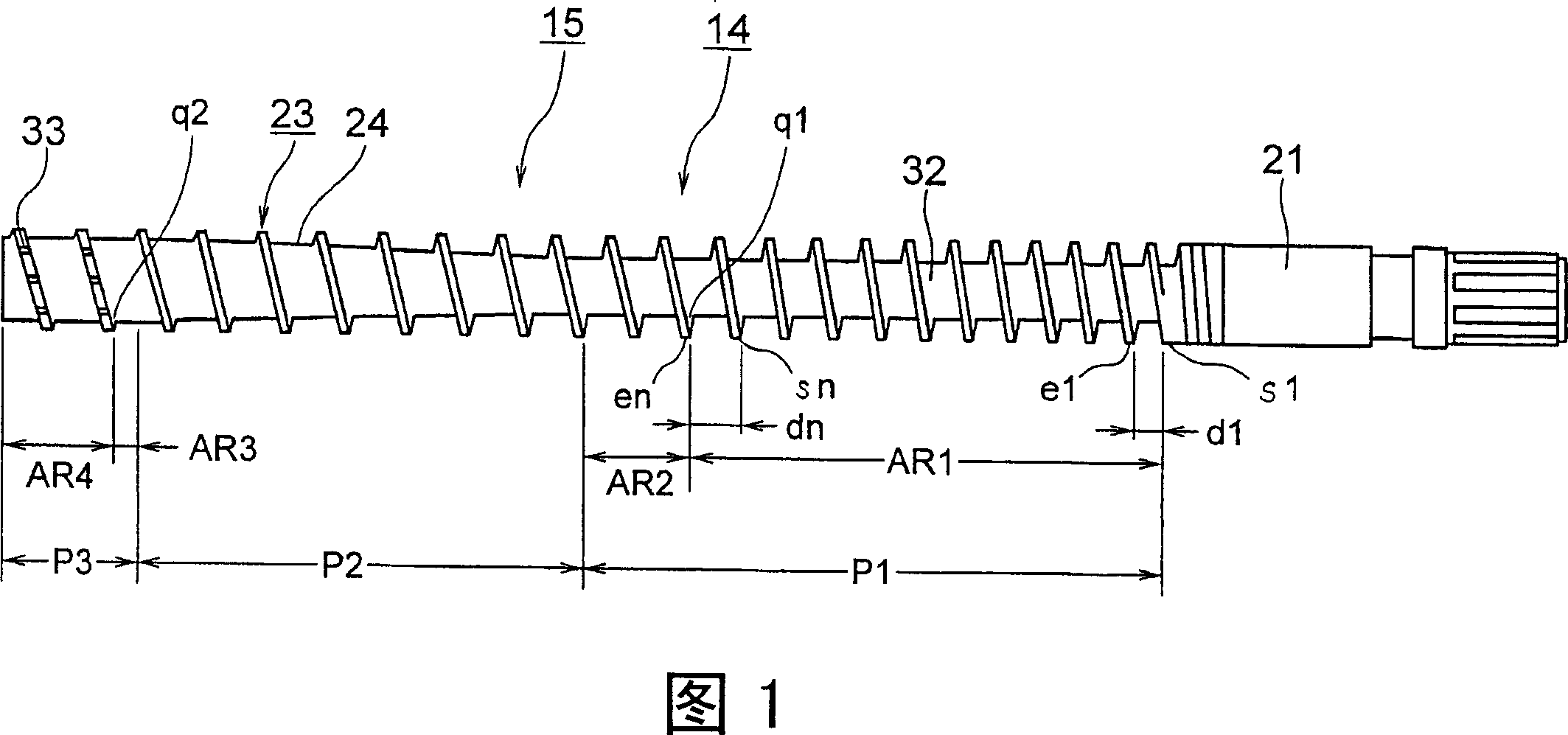

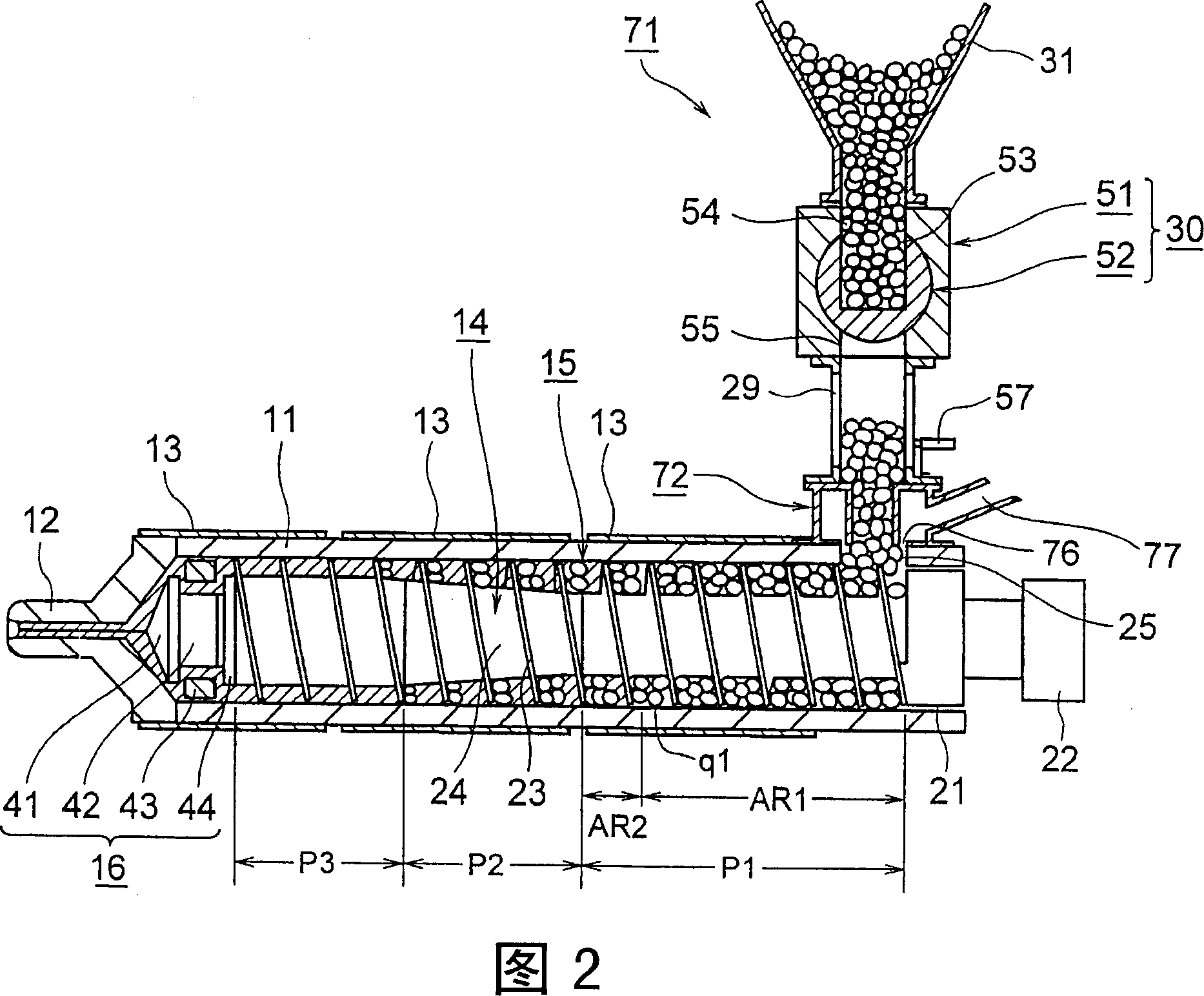

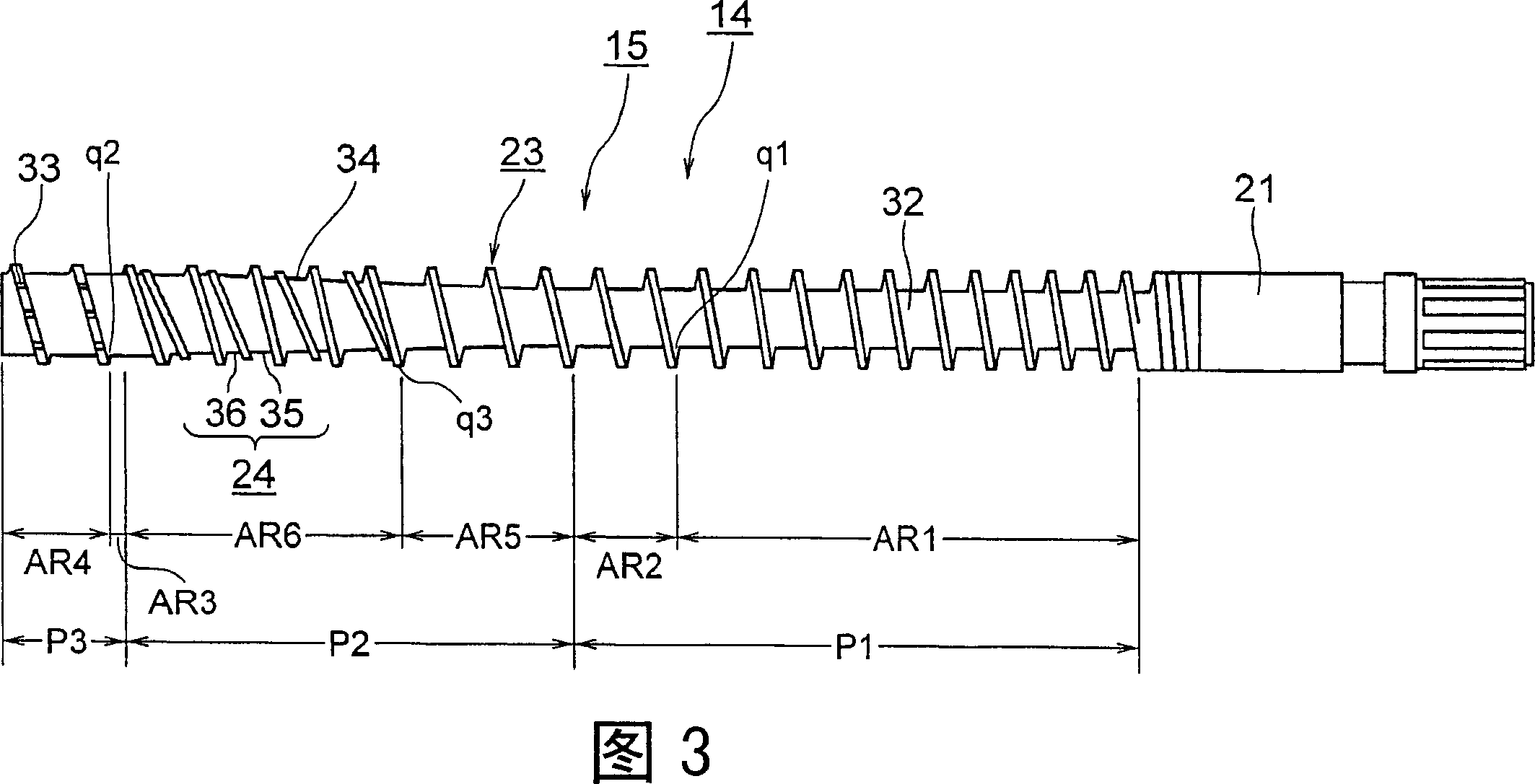

[0040] FIG. 1 is a schematic view of a main body portion of a screw according to a first embodiment of the present invention. Fig. 2 is a conceptual diagram of the injection device according to the first embodiment of the present invention.

[0041] In the figure, 11 is a heating cylinder as a cylinder member, an injection nozzle 12 is installed on the front end (left end in the figure) of the heating cylinder 11, and a plurality of heating cylinders are arranged on the outer periphery of the heating cylinder 11. Ring heater 13. In addition, in the heating cylinder 11, a screw 14 as an injection member is disposed rotatably and freely advancing and retreating (moving in the horizontal direction in the figure). And this screw 14 is comprised by the main-bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com