Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4241results about How to "Shorten maintenance time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

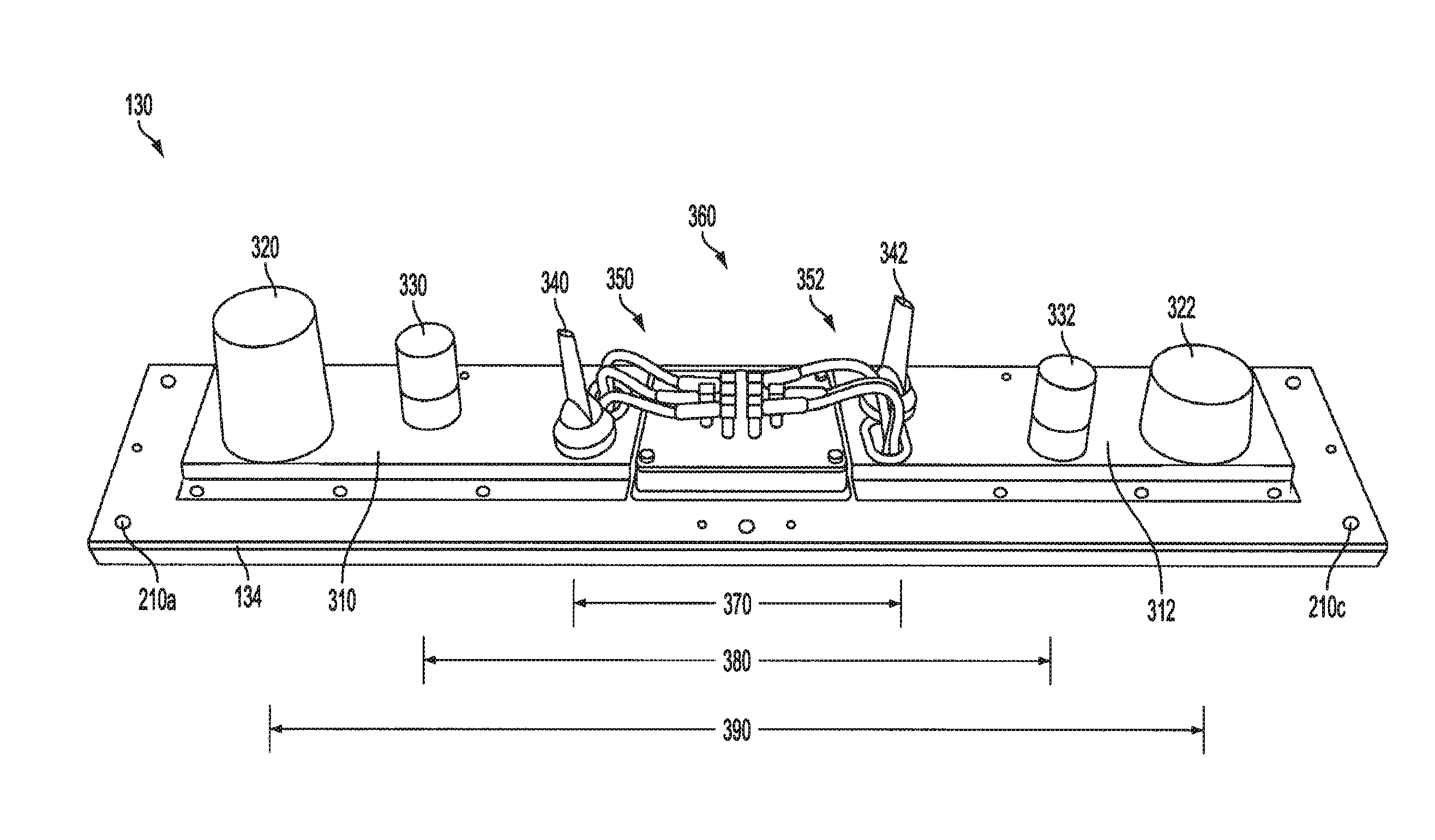

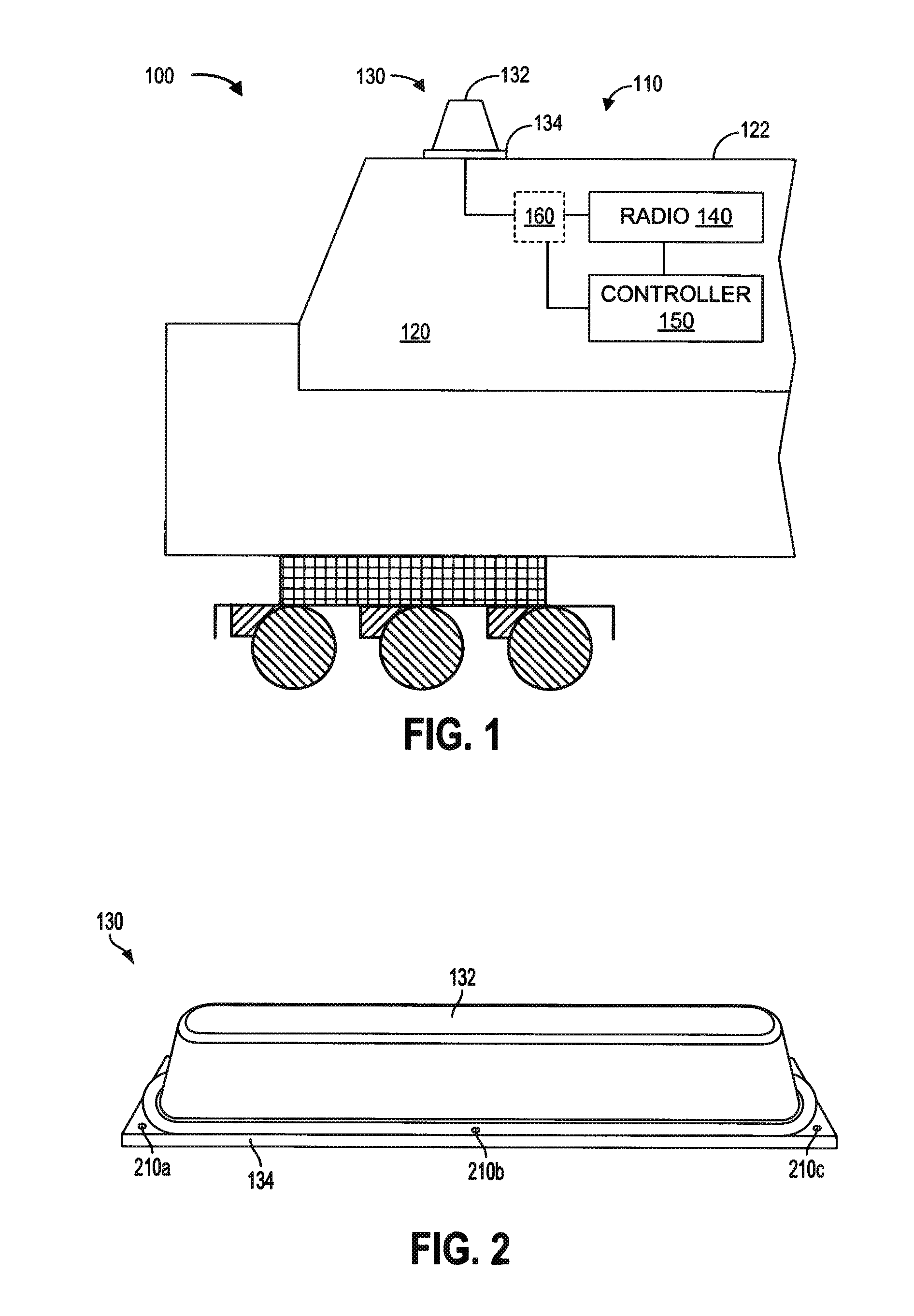

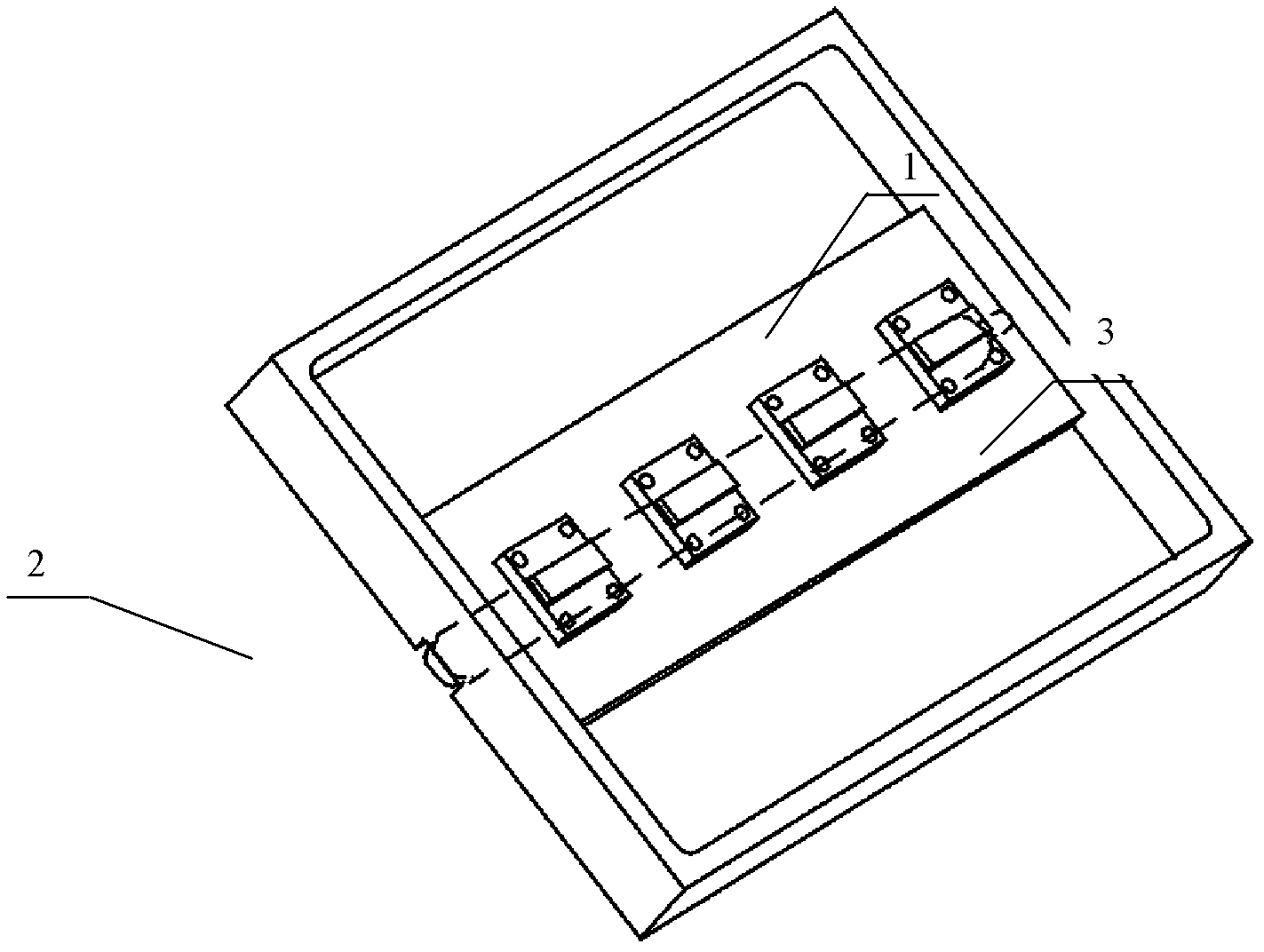

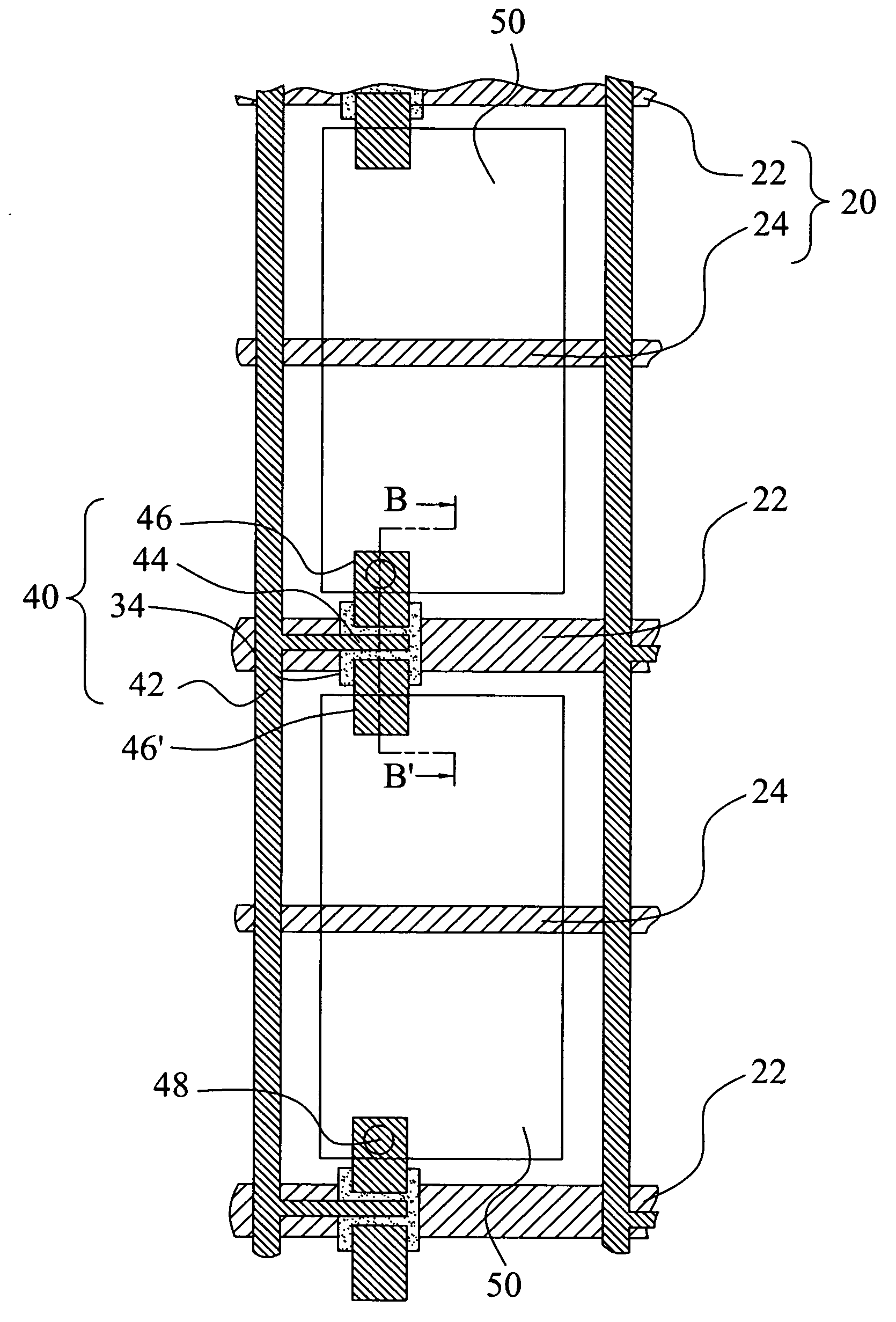

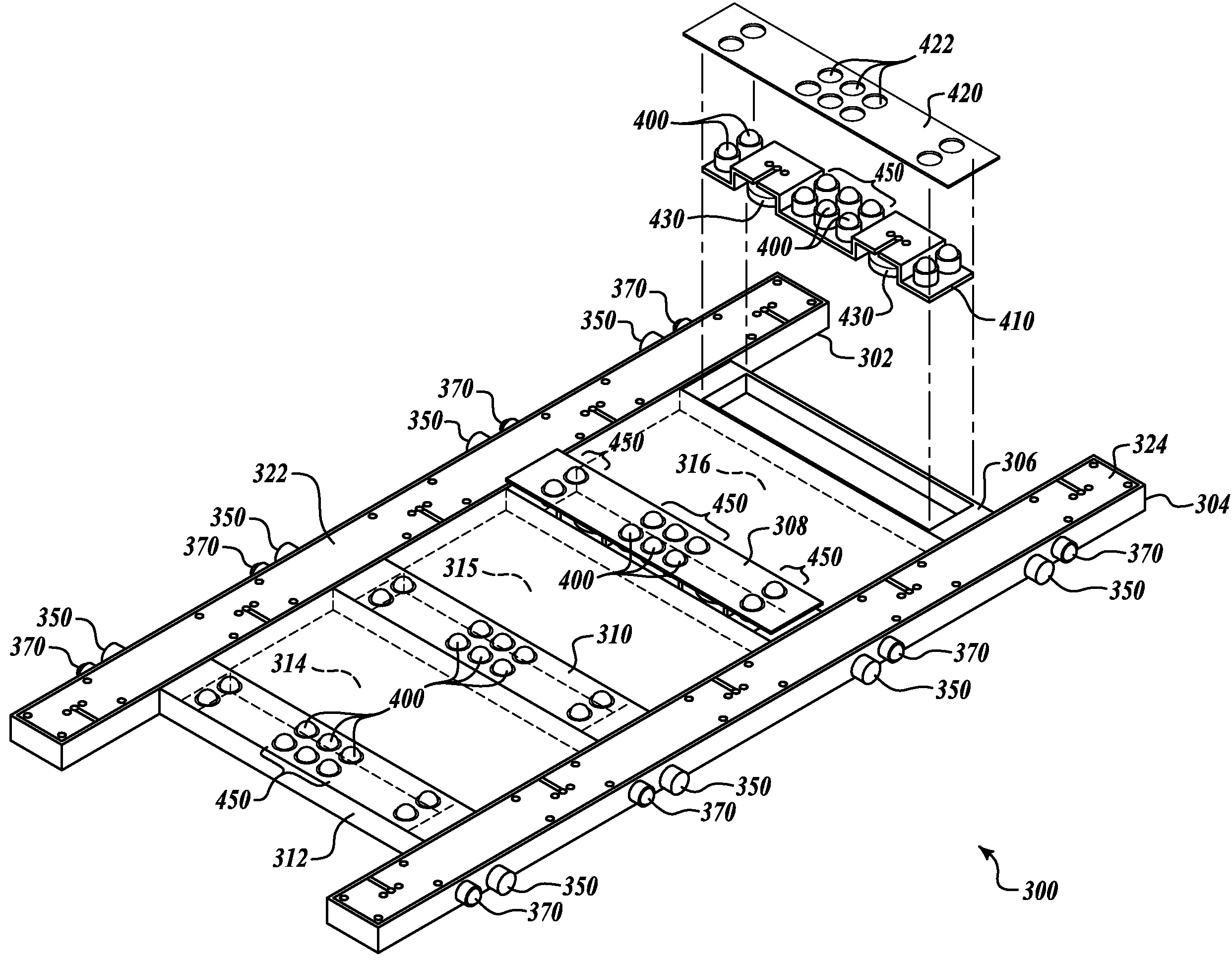

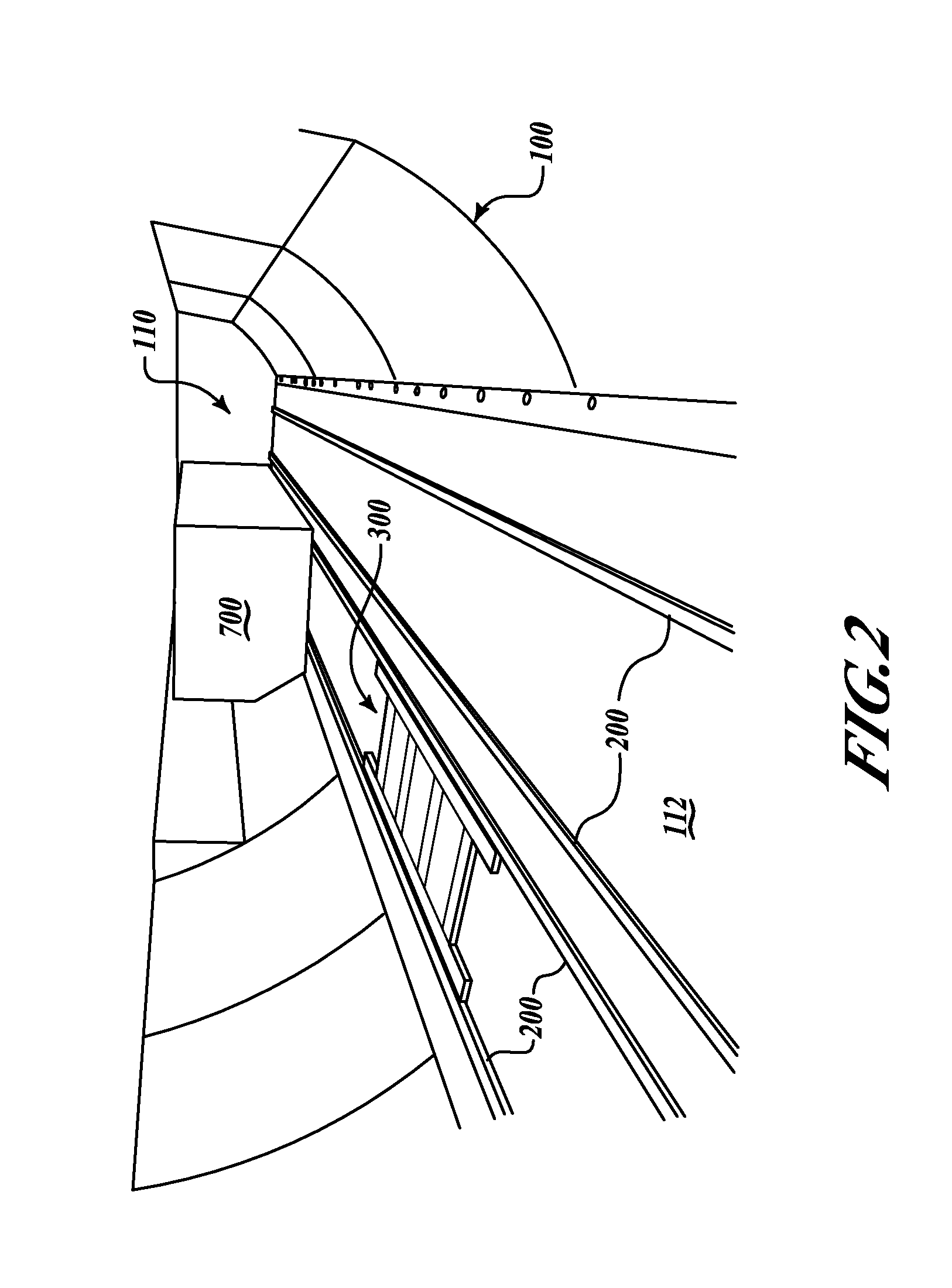

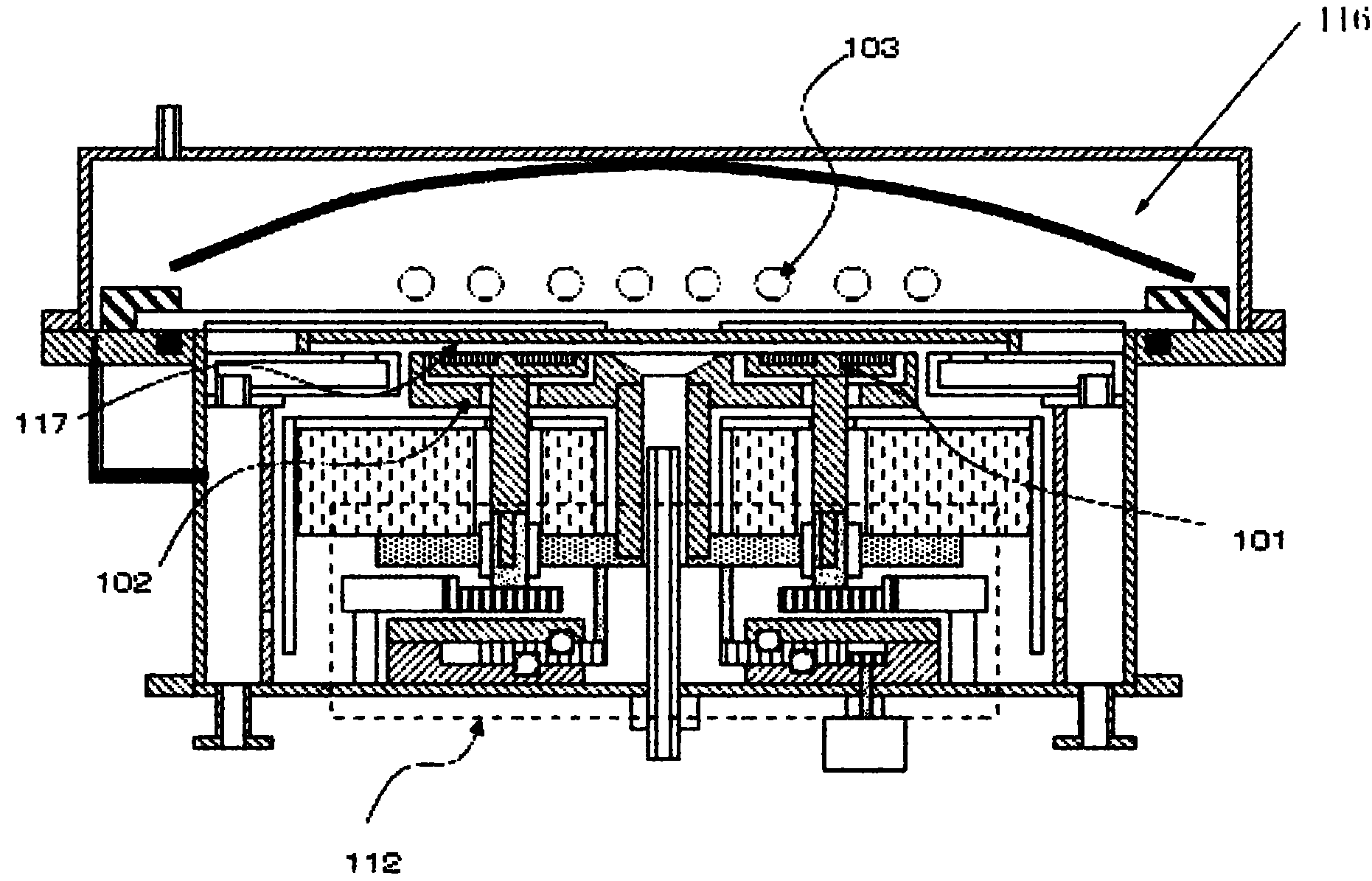

System and apparatus for locomotive radio communications

ActiveUS20110279337A1Shorten maintenance timeReduces intrusion of waterAntenna adaptation in movable bodiesAntennas earthing switches associationCommunications systemEngineering

In one embodiment, a radio communication system comprises a removable antenna platform and an antenna interface bulkhead connected to a roof of a locomotive. The antenna platform includes a blind mate connector connected to an antenna mount. The antenna mount is connected to a ground plane. The antenna interface bulkhead includes a blind mate connector configured to mate with the blind mate connector of the antenna platform when the antenna platform is attached to the antenna interface bulkhead. The antenna interface bulkhead is configured to attach to the antenna platform in one orientation. Thus, one or more antennas may be quickly attached to or removed from the roof of the locomotive reducing maintenance time for the locomotive when an antenna upgrade may be desired.

Owner:GE GLOBAL SOURCING LLC

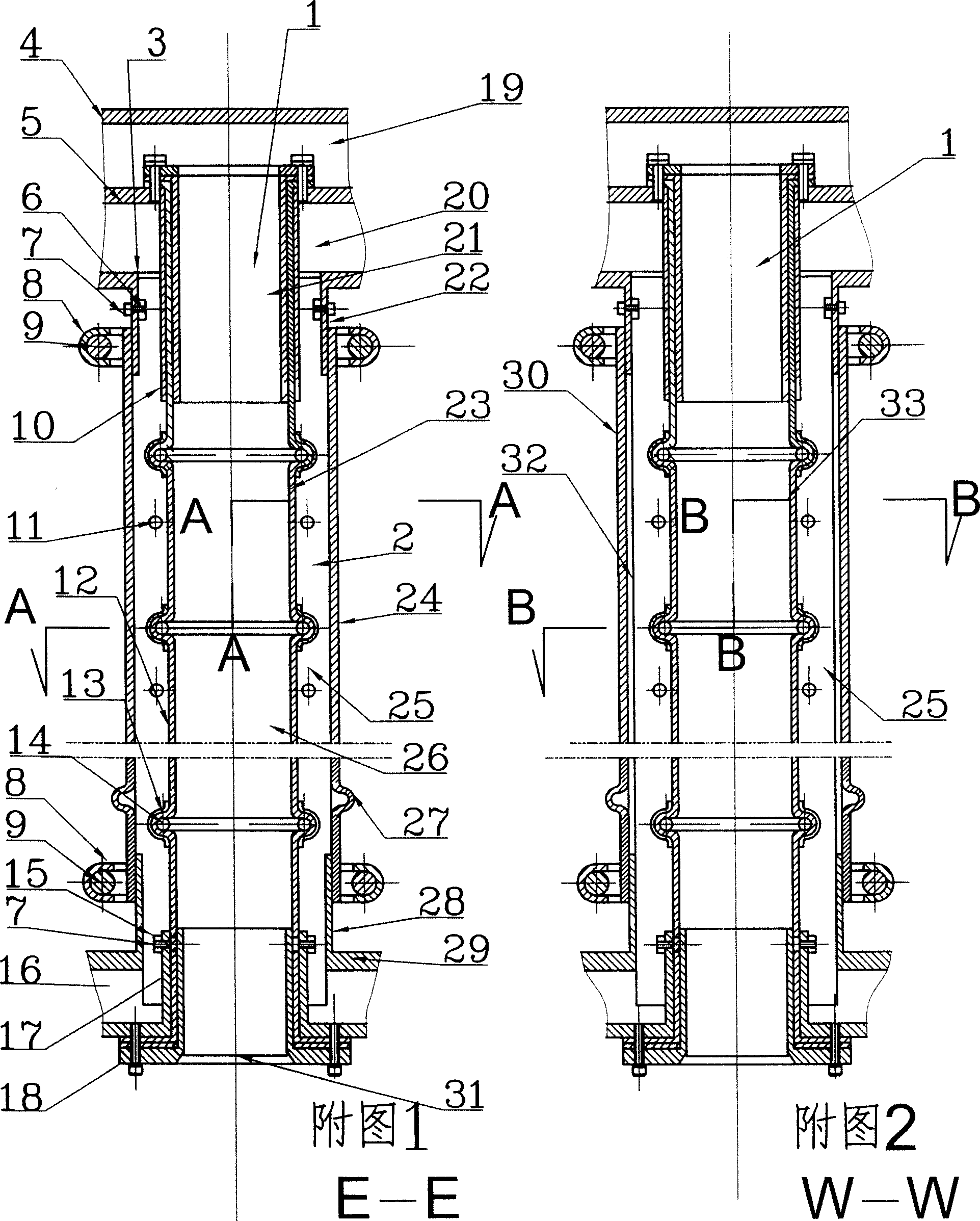

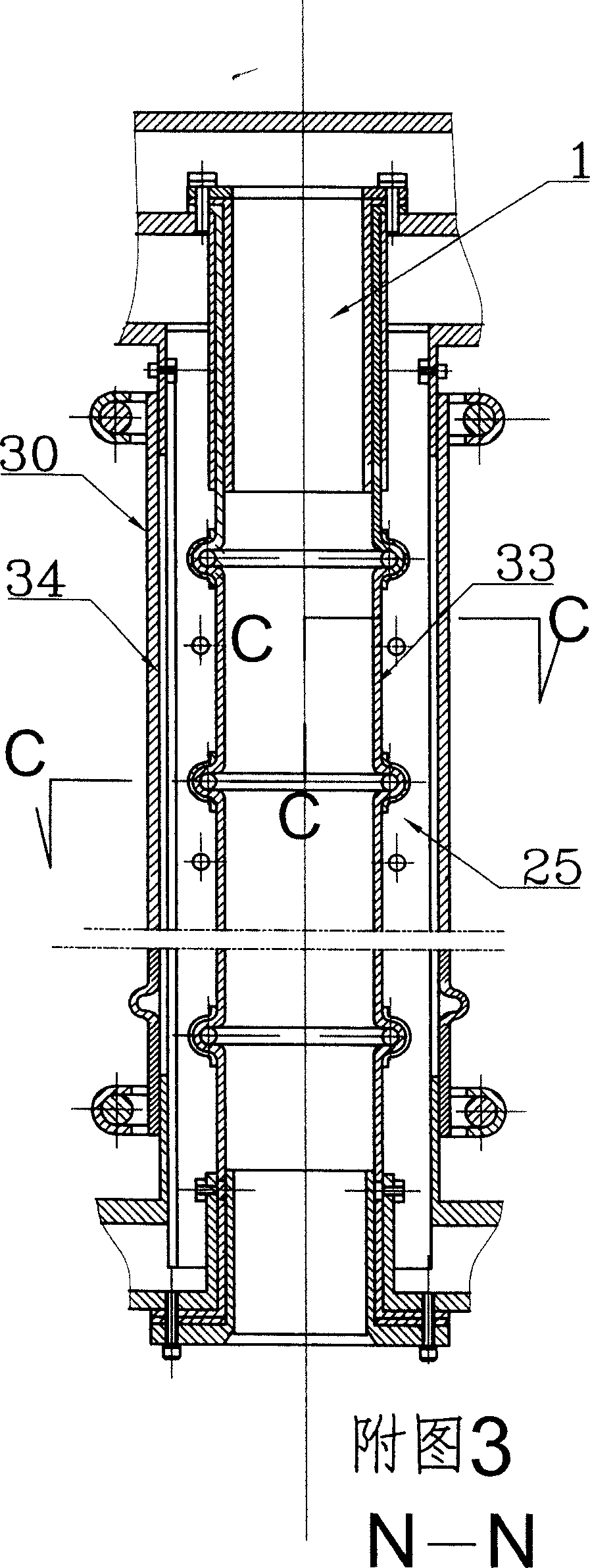

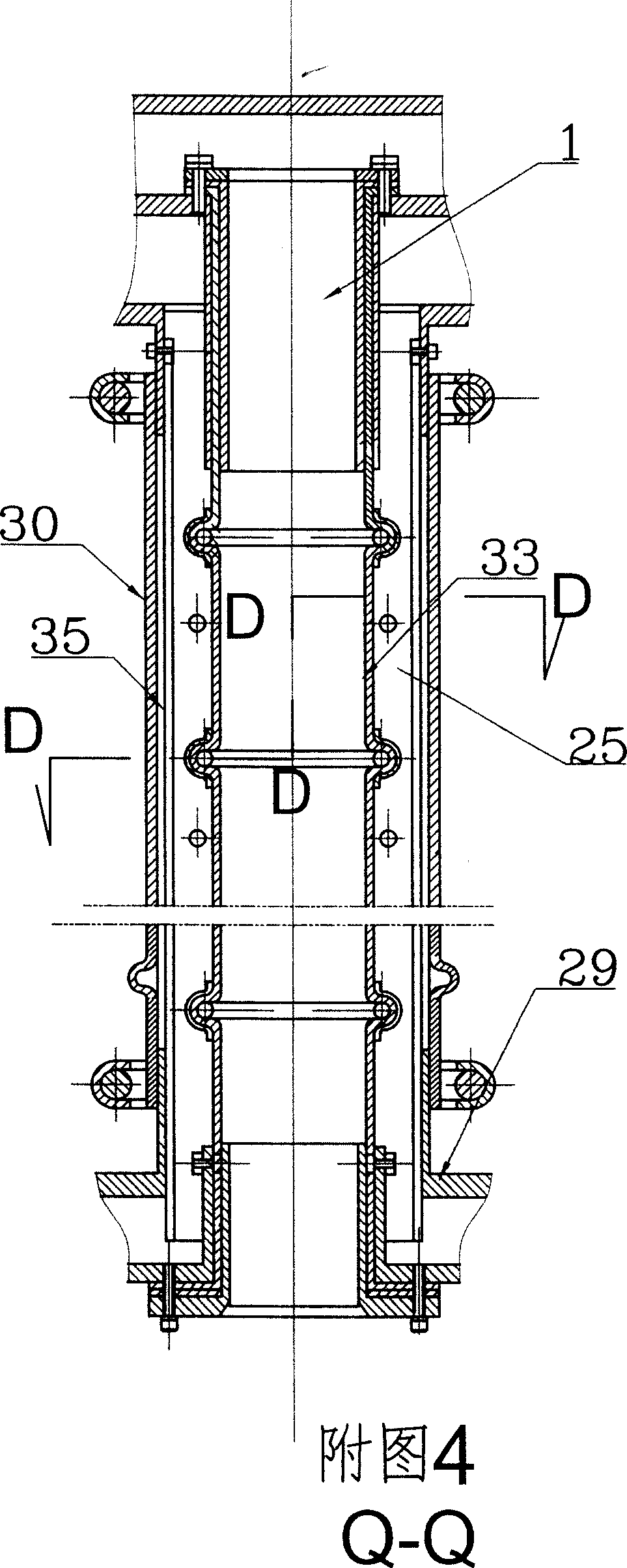

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

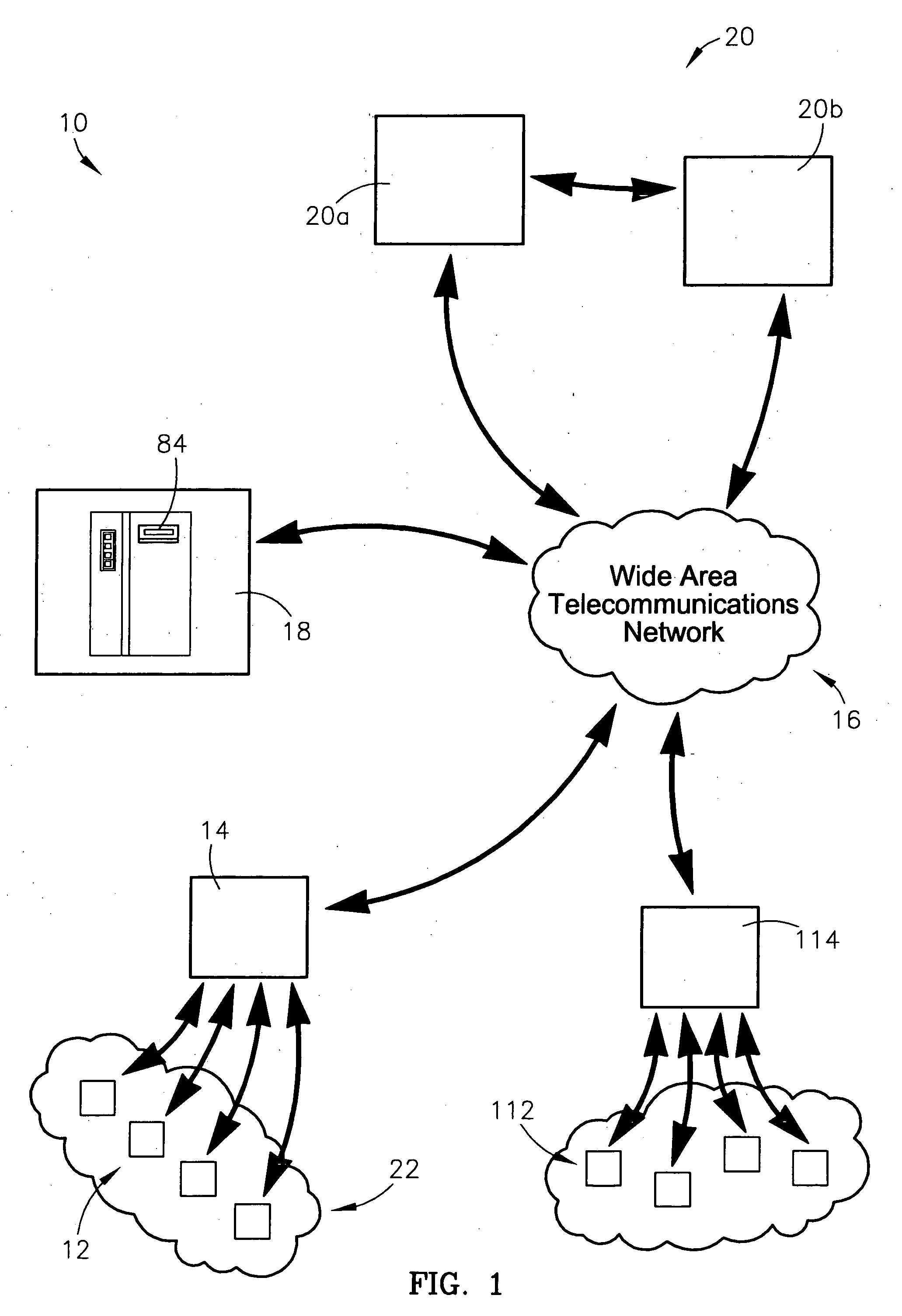

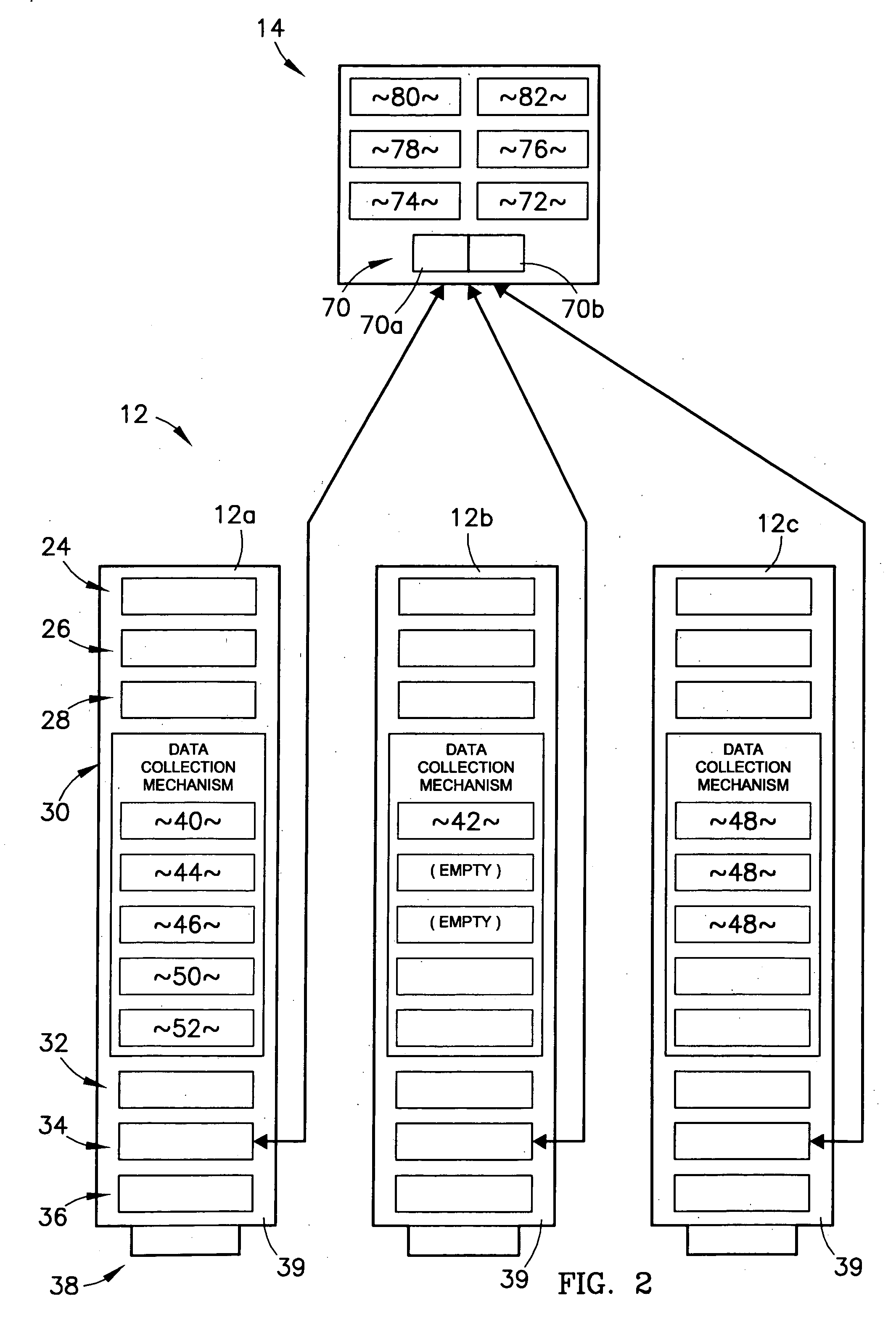

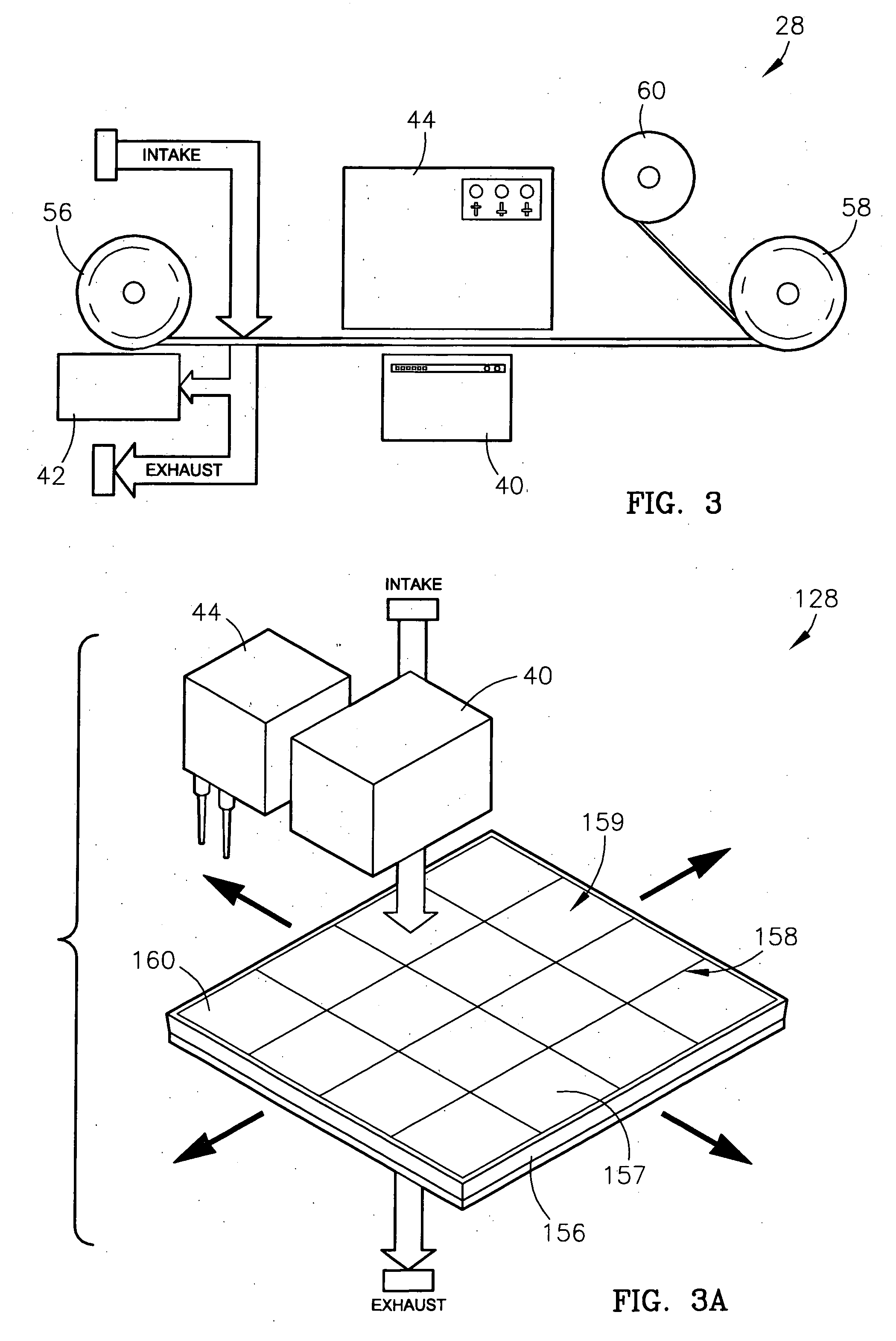

System and method for identifying, reporting, and evaluating presence of substance

ActiveUS20040120857A1Easy to removeEasy to replaceSolid-state devicesInvestigating moving sheetsRadioactive agentComputer science

A system and method for identifying, reporting, and evaluating a presence of a solid, liquid, gas, or other substance of interest, particularly a dangerous, hazardous, or otherwise threatening chemical, biological, or radioactive substance. The system comprises one or more substantially automated, location self-aware remote sensing units; a control unit; and one or more data processing and storage servers. Data is collected by the remote sensing units and transmitted to the control unit; the control unit generates and uploads a report incorporating the data to the servers; and thereafter the report is available for review by a hierarchy of responsive and evaluative authorities via a wide area network. The evaluative authorities include a group of relevant experts who may be widely or even globally distributed.

Owner:HONEYWELL FED MFG & TECHNOLOGI

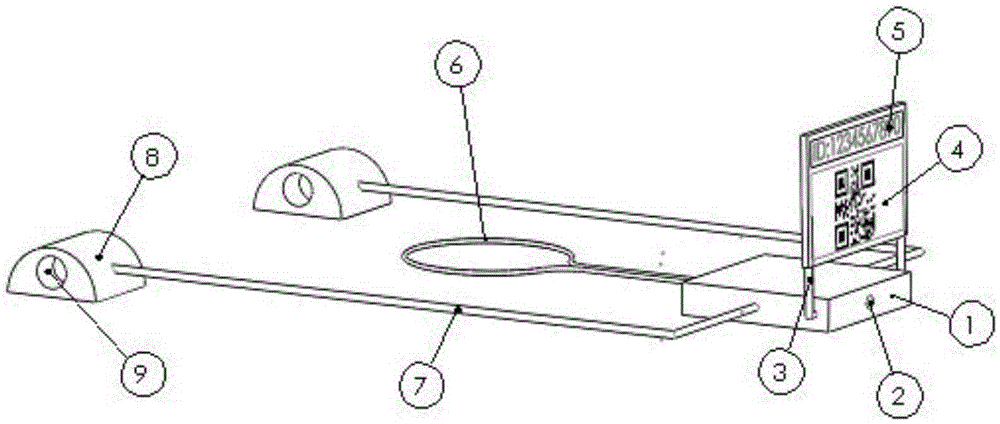

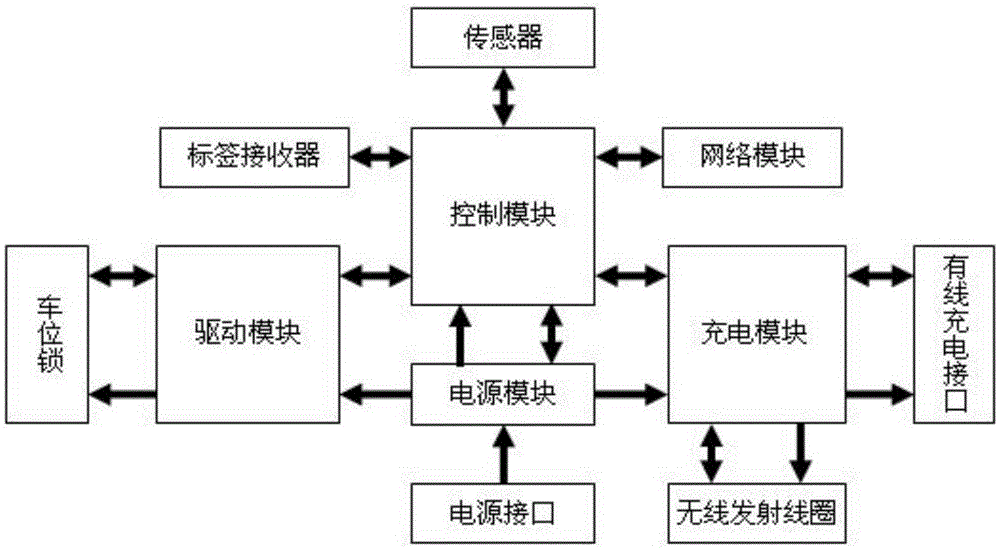

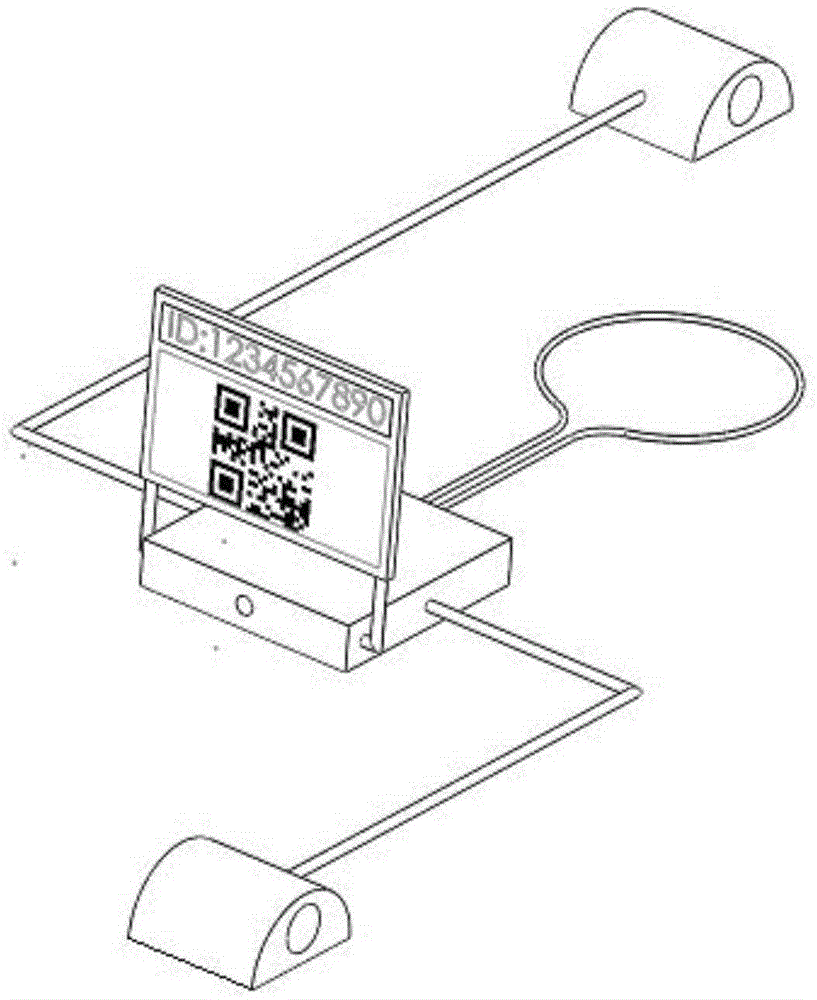

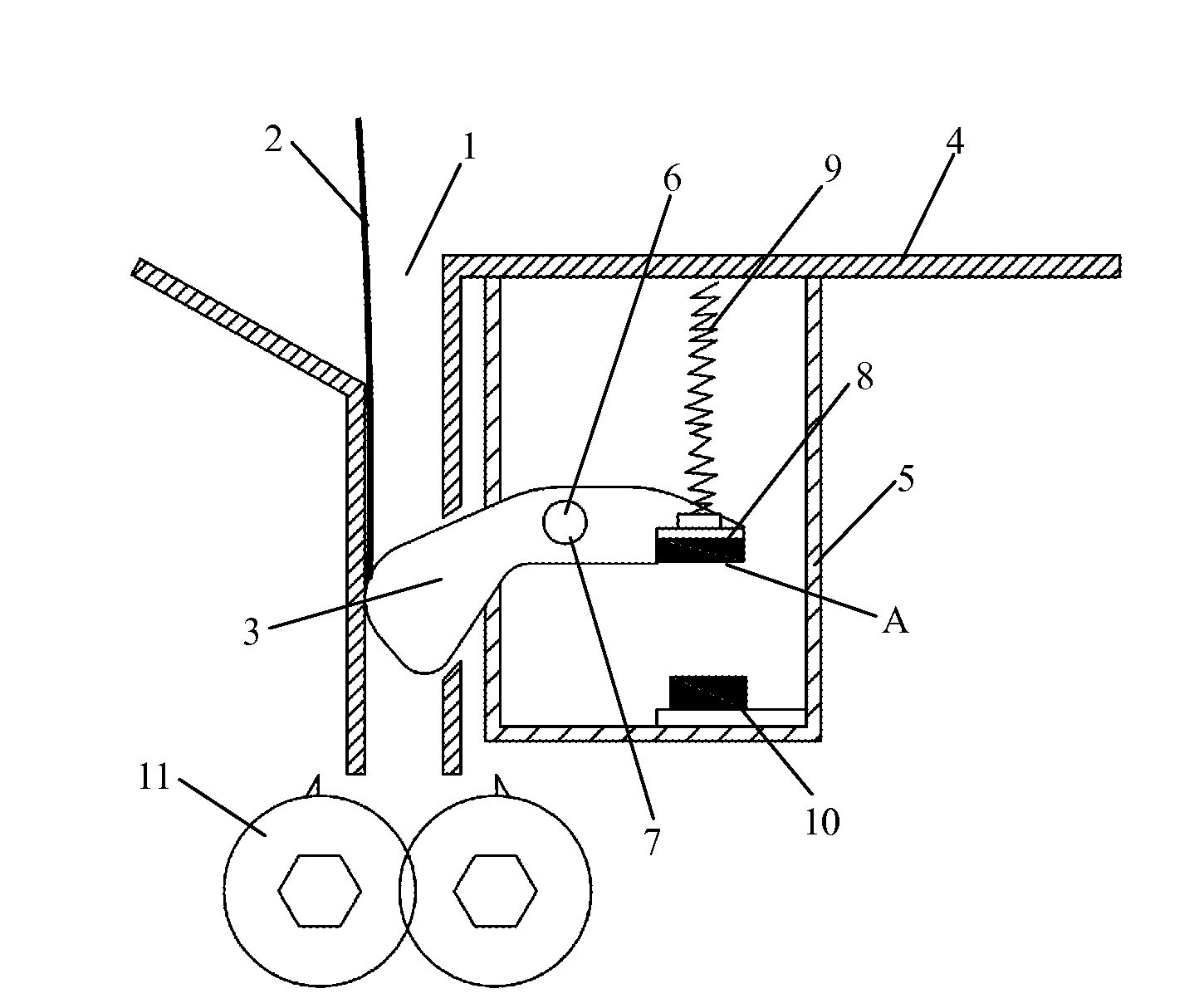

Charging device with parking lock function

InactiveCN105429254AConvenient charging operationAvoid accidentsBatteries circuit arrangementsCharging stationsTransmitted powerCharge control

The invention relates to a charging device with a parking lock function. A control box is internally provided with a charging module, a driving module, a power module and a control module; the charging module, the driving module and the power module are all connected with the control module; the control box is provided with an AC power interface; power is provided for the power module via the AC power interface; the power module transmits power to the driving module, the control module and the charging module respectively for providing charging power and working power; the driving module is connected with the control module and the parking lock for receiving a parking lock control command sent by the control module and driving the parking lock to be locked or unlocked according to the parking lock control command; and a charging interface is arranged on a stop block, the charging interface is connected with an electric vehicle via a power line, the charging module receives a charging control command sent by the control module, and the charging module realizes wired charging on the electric vehicle according to the charging control command and / or realizes wireless charging on the electric vehicle via a wireless charging coil.

Owner:焦力波

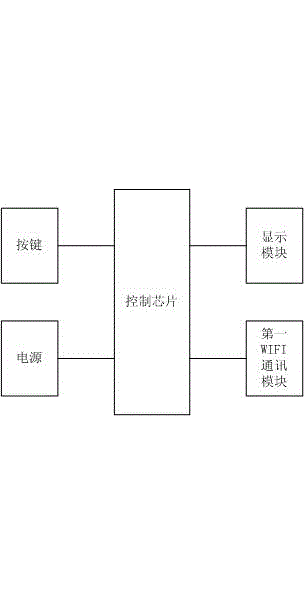

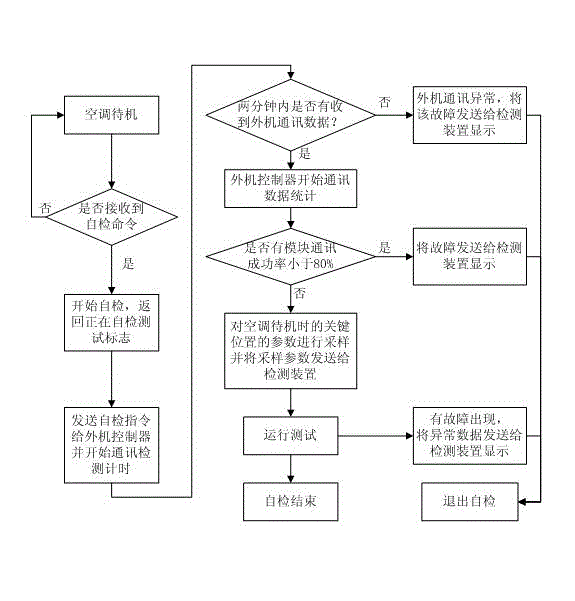

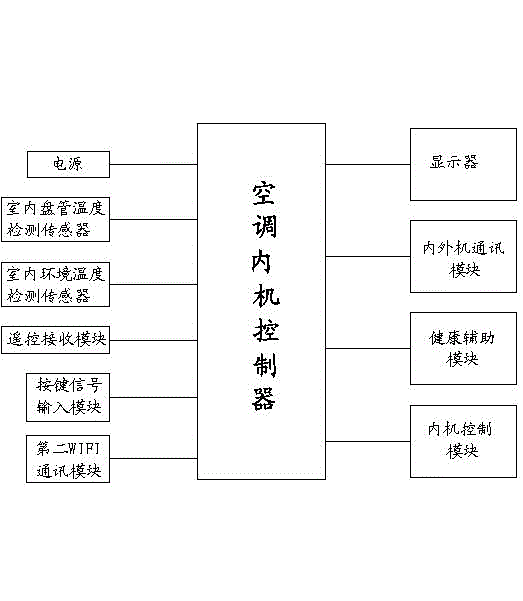

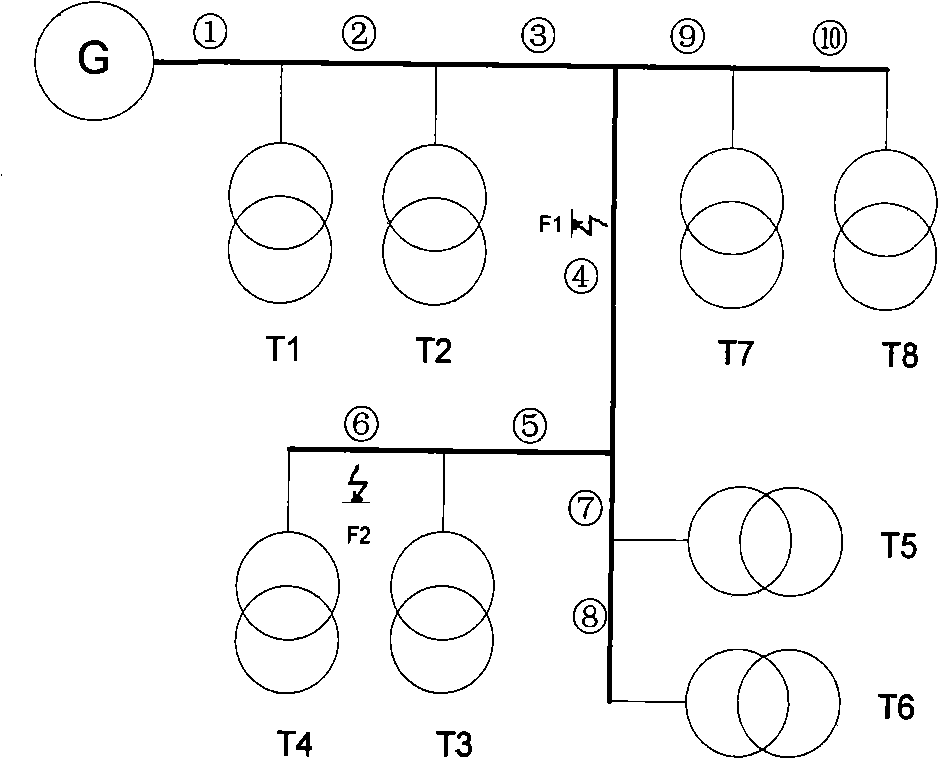

Air conditioning fault detection method

ActiveCN102748832AShorten maintenance timeEasy to determineSpace heating and ventilation safety systemsLighting and heating apparatusWifi networkAir conditioning

The invention discloses an air conditioning fault detection method. In the detection method, a detection device is communicated with an air conditioner through a wireless fidelity (WIFI) network and then controls an air conditioning controller to perform self-checking on the air conditioner. The air conditioning fault detection method can determine fault points of the air conditioner conveniently and rapidly, confirms fault positions and types, and reduces maintenance time of the air conditioner.

Owner:NINGBO AUX ELECTRIC

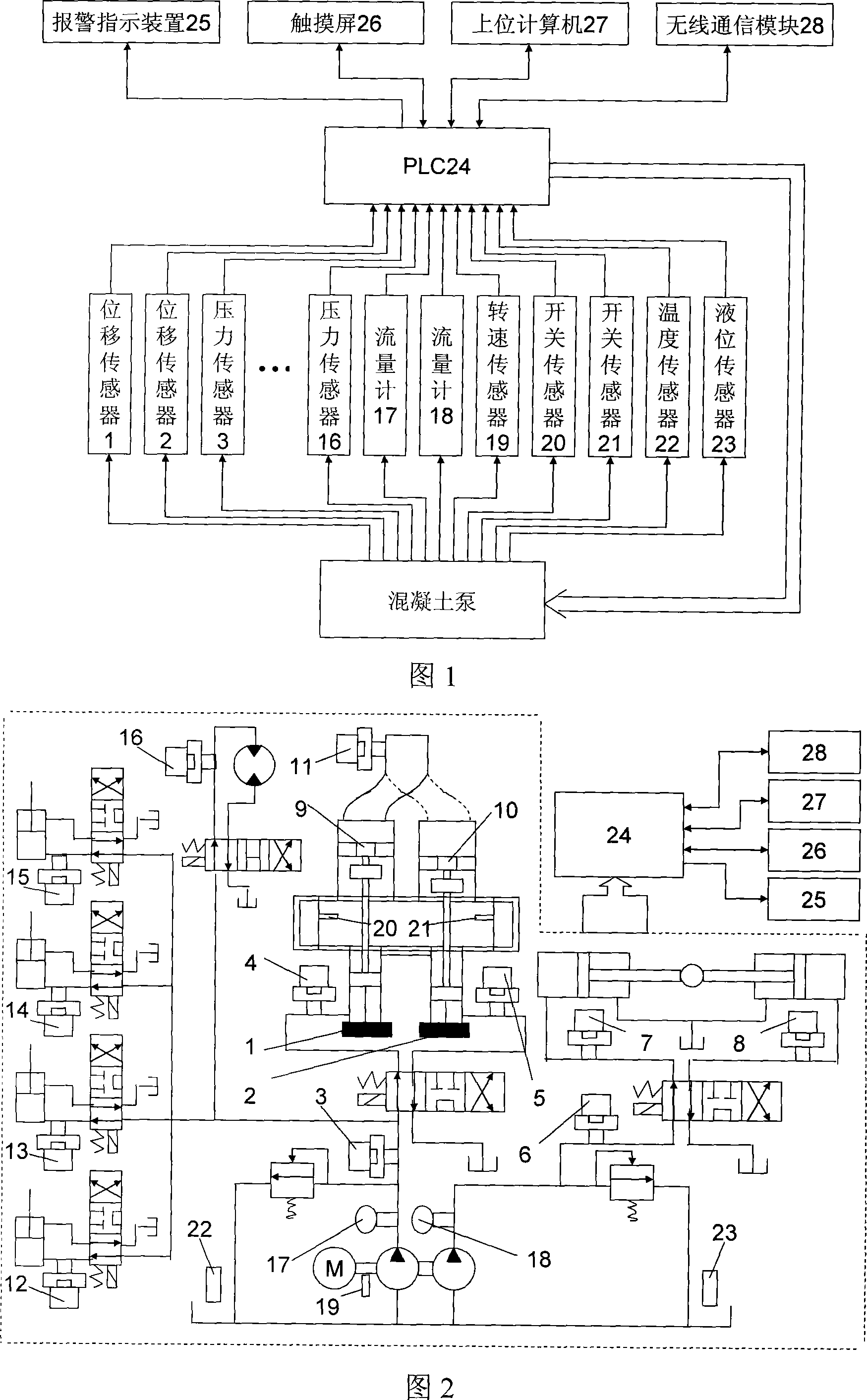

Concrete pump intelligent monitoring and control system

InactiveCN101178061AImprove performanceRealize intelligencePump controlBuilding material handlingElectric machineControl system

The invention discloses a concrete pump intelligent monitoring and control system. A magnetic telescopic displacement sensor is respectively arranged on the piston rod of the main cylinder of a concrete pump; pressure sensors are respectively arranged on a main pump hydraulic system, a concrete pump main cylinder, a swing hydraulic system, a swing cylinder, a concrete conveying cylinder piston, a concrete pump outlet, a concrete pump supporting leg hydraulic system, and a mixed hydraulic system; the outlet of the main cylinder and the outlet of an auxiliary pump are respectively provided with flowmeters; a rotation speed sensor is arranged on a motor mainshaft; a switch sensor is respectively arranged at the position of a concrete water tank; a temperature sensor and a liquid level sensor are arranged at the position of a concrete pump oil tank; all parts are respectively connected with the concrete pump and a PLC; the PLC is respectively connected with an alarm indicator device, a contact screen, an upper bit computer, and a wireless communication module. The invention can implement timely, online and remote state monitoring, malfunction diagnosing and intelligent control, so as to improve the integration performance of the concrete pump.

Owner:ZHEJIANG UNIV

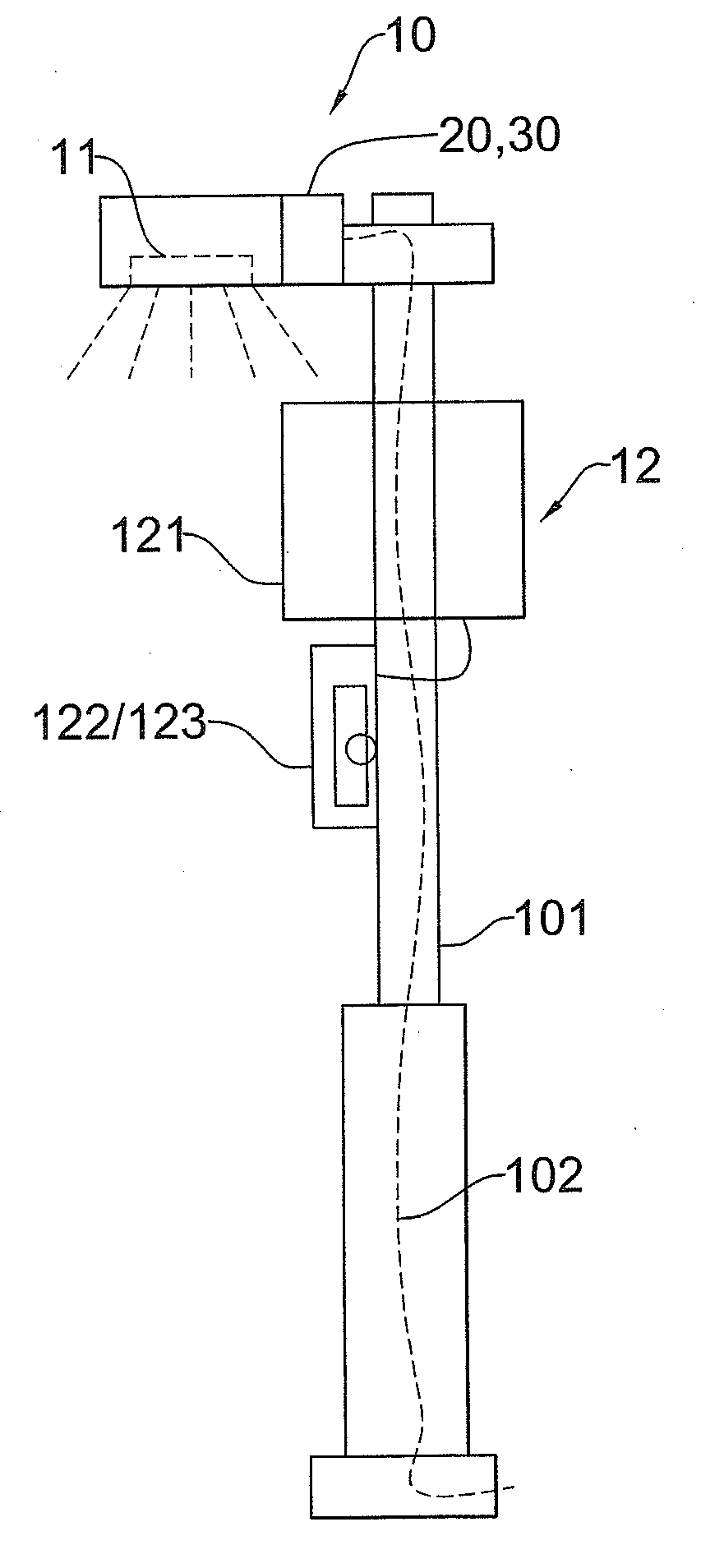

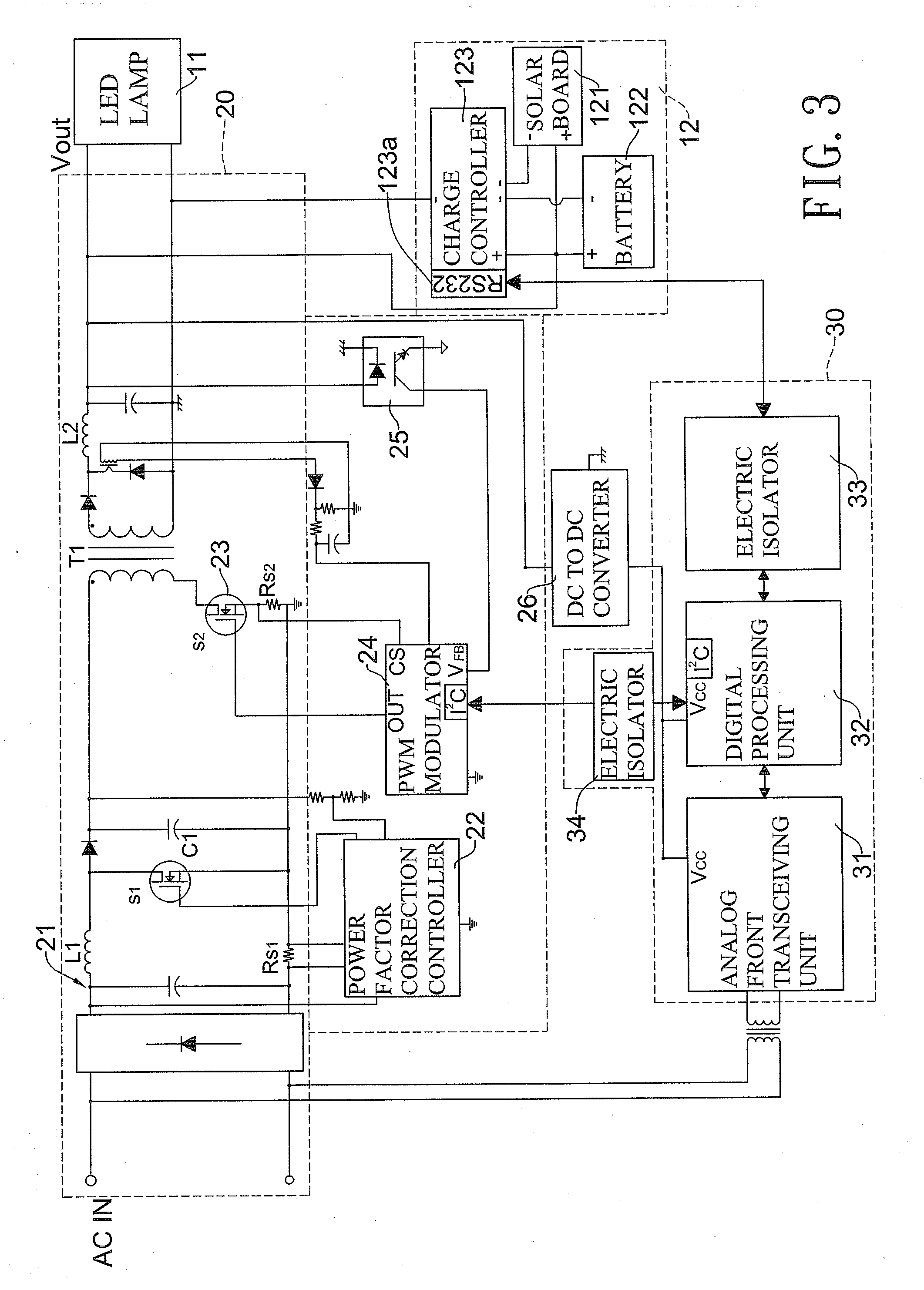

Solar-Powered LED Street Light

InactiveUS20090303703A1Shorten maintenance timeBatteries circuit arrangementsMechanical apparatusPower cableElectrical battery

A solar-powered LED street light that can immediately report its power data. The disclosed LED street light has a solar cell, a switch power supply unit, and a power cable data communicating unit. The mains power cable of the LED street light connects to the switch power supply unit for providing it with DC power. The solar cell has a solar board, a battery and a charge controller. The charge controller can also provide the LED street light with DC power. The charge controller has a power data digital output interface for connecting with the power cable data communicating unit, outputting the power data of the solar cell to the power cable data communicating unit. Through the mains power cable, the status of solar cell of each LED lamp is monitored.

Owner:ACBEL POLYTECH INC

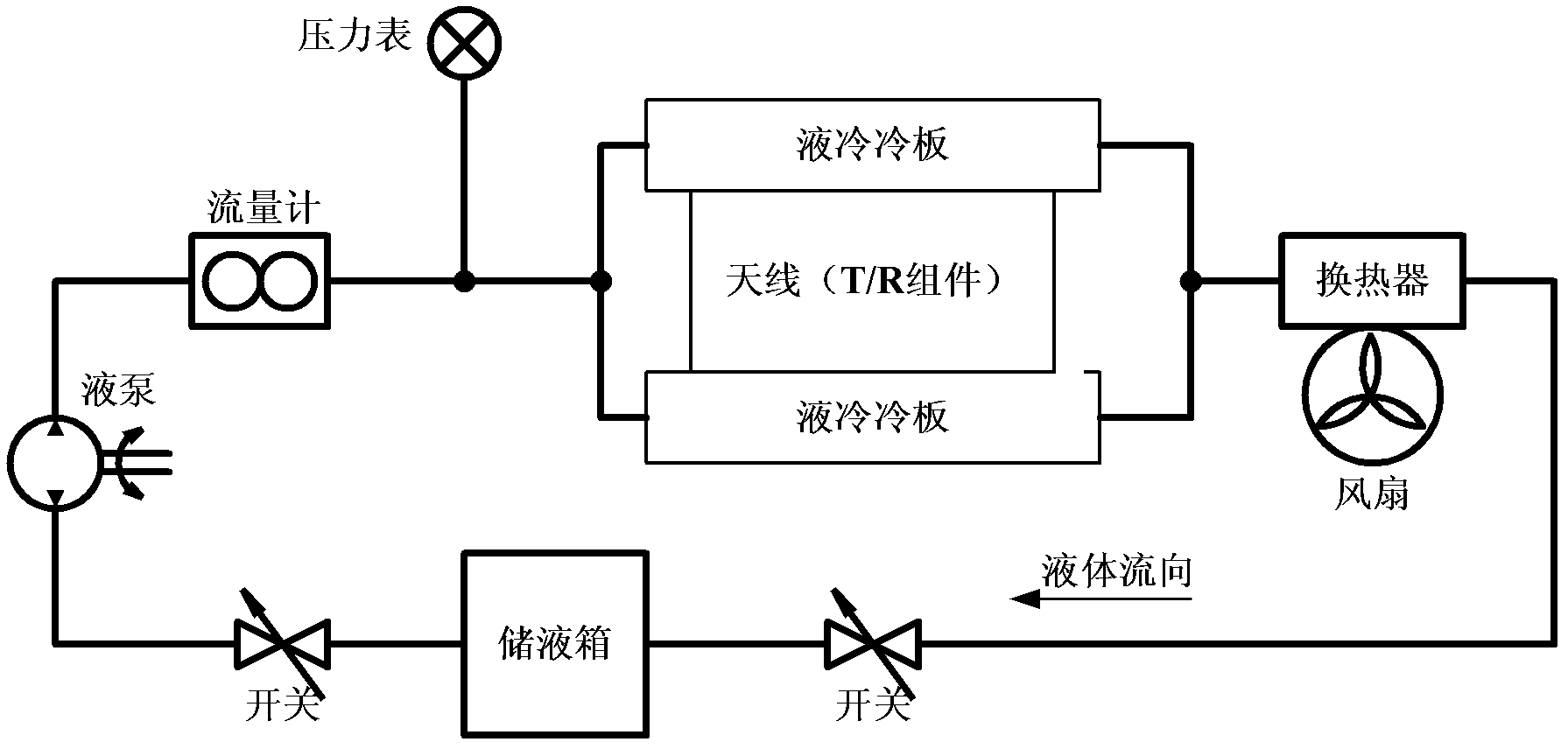

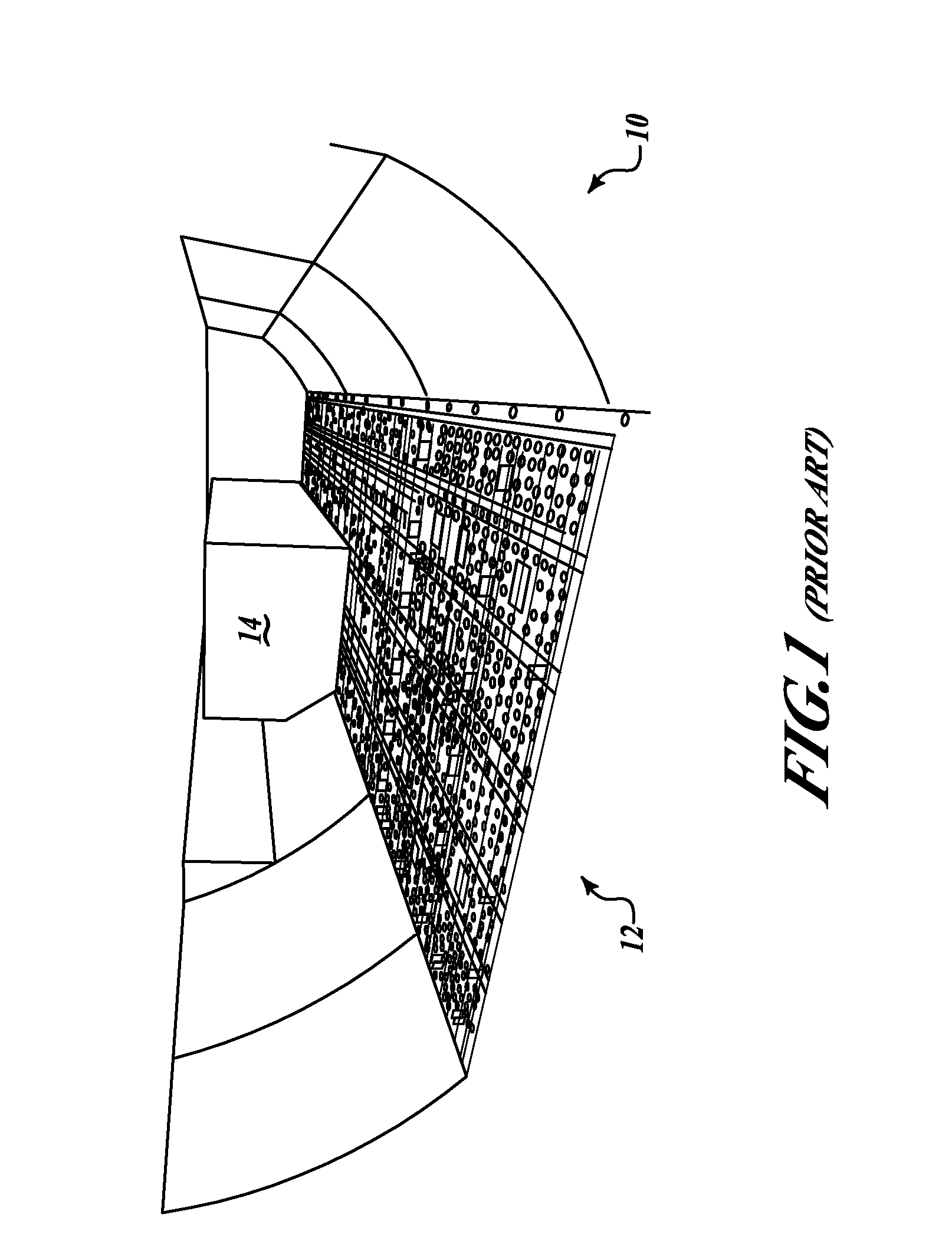

Airborne phased array radar antenna radiating device

ActiveCN103188921AReduce the chance of leaksReduce the temperatureCooling/ventilation/heating modificationsAntennasRadarCold plate

The invention discloses an airborne phased array radar antenna radiating device, and relates to an airborne phased array radar technology. The airborne phased array radar antenna radiating device comprises heat tubes and liquid cooling cold plates. The heat tubes are embedded at the position, close to power components, of the outer lateral faces of the bottom faces T / R box bodies, a plurality of T / R box bodies are vertically superposed, the two sides of each of the plurality of T / R box bodies are respectively provided with one liquid cooling cold plate, the liquid cooling cold plates are used as installation plates which support an antenna to fix the T / R box bodies, the two liquid cooling cold plates arranged on the two sides of each T / R box body are communicated with a refrigerant storing tank, by utilization of high heat exchanging performance and liquid fluidity of the liquid cooling cold plates, heat produced inside the phased array radar antenna is spread out, liquid cooling tubes are used for conducting the heat to space where the heat is prone to dissipate, and a radiator is used for concentrated heat dissipation. The airborne phased array radar antenna radiating device solves the radiating problem of phased array radar antenna T / R components.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

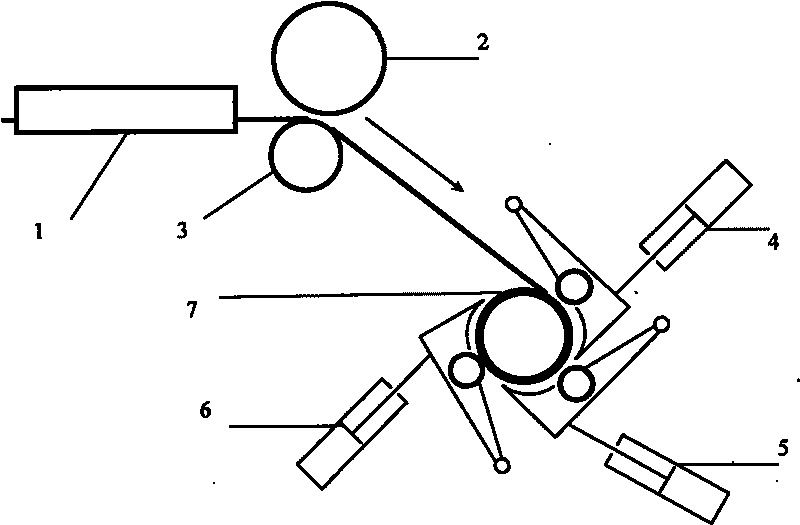

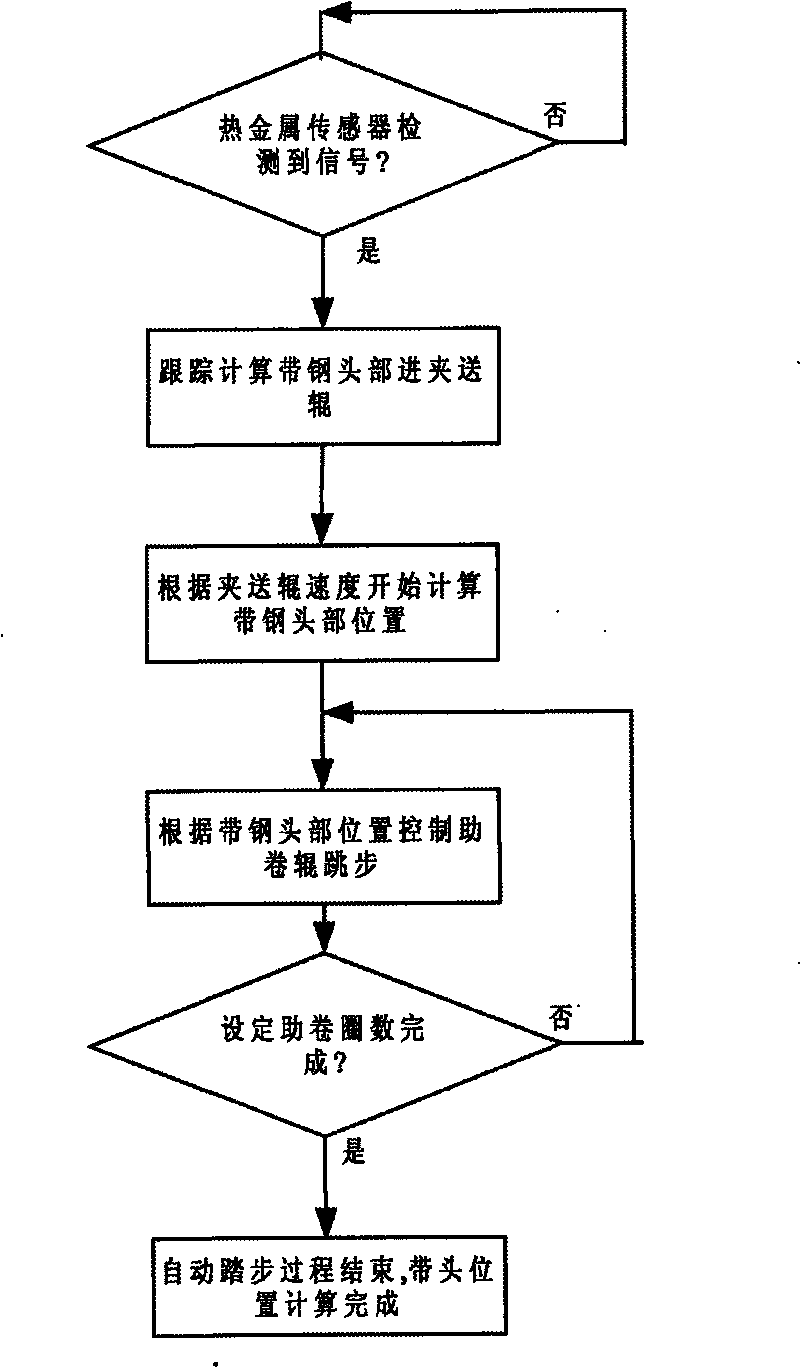

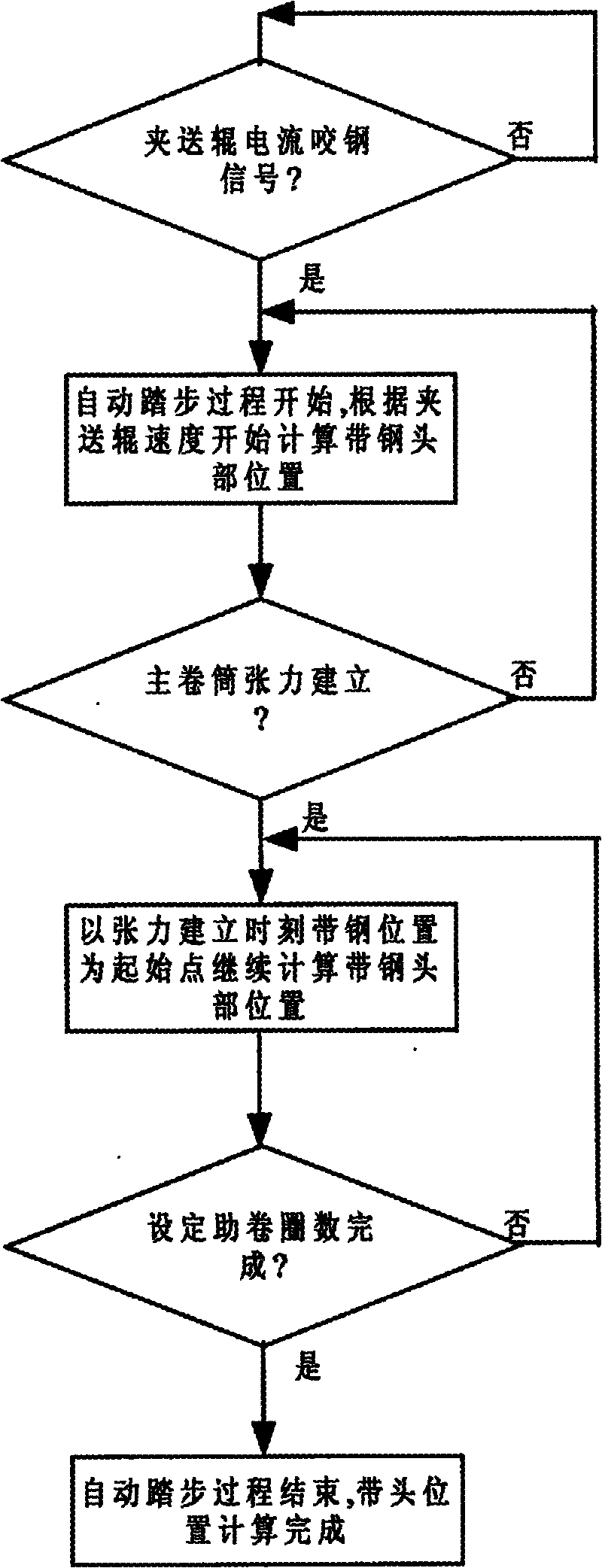

Method for calculating and locating strip steel head of automatic stepping system of hot continuous rolling coiling machine

InactiveCN101722196AOvercome the shortcomings of being susceptible to various interferences on siteHigh degree of automationRoll mill control devicesMeasuring devicesHead positionEngineering

The embodiment of the invention provides a method for calculating and locating the strip steel head of an automatic stepping system of a hot continuous rolling coiling machine, comprising the following steps of: detecting whether the strip steel enters a pinch roll, wherein when the strip steel is detected to enter the pinch roll, the automatic stepping process begins, the head position of the strip steel is calculated according to the speed of a lower pinch roll; detecting the tension of a main drum, if the tension of the main drum is not established, the head position of the strip steel is continuously calculated according to the speed of a lower pinch roll, if the tension of the main drum is established, the head position of the strip steel is continuously calculated by using the momentary position of the strip steel head at the main drum at the tension establishing moment as a start point; detecting whether the set wrapping number of turns is finished, if the set wrapping number of turns is not finished, the head position of the strip steel is continuously calculated by using the head position of the strip steel at the tension establishing moment as a start point; if the set wrapping number of turns is finished, the automatic stepping process stops and the calculation for the head position of the strip steel is finished. The invention can effectively overcome the defects that an on-site hot metal detector and an optoelectronic detecting element are subject to various on-site interferences.

Owner:WUHAN IRON & STEEL (GROUP) CORP

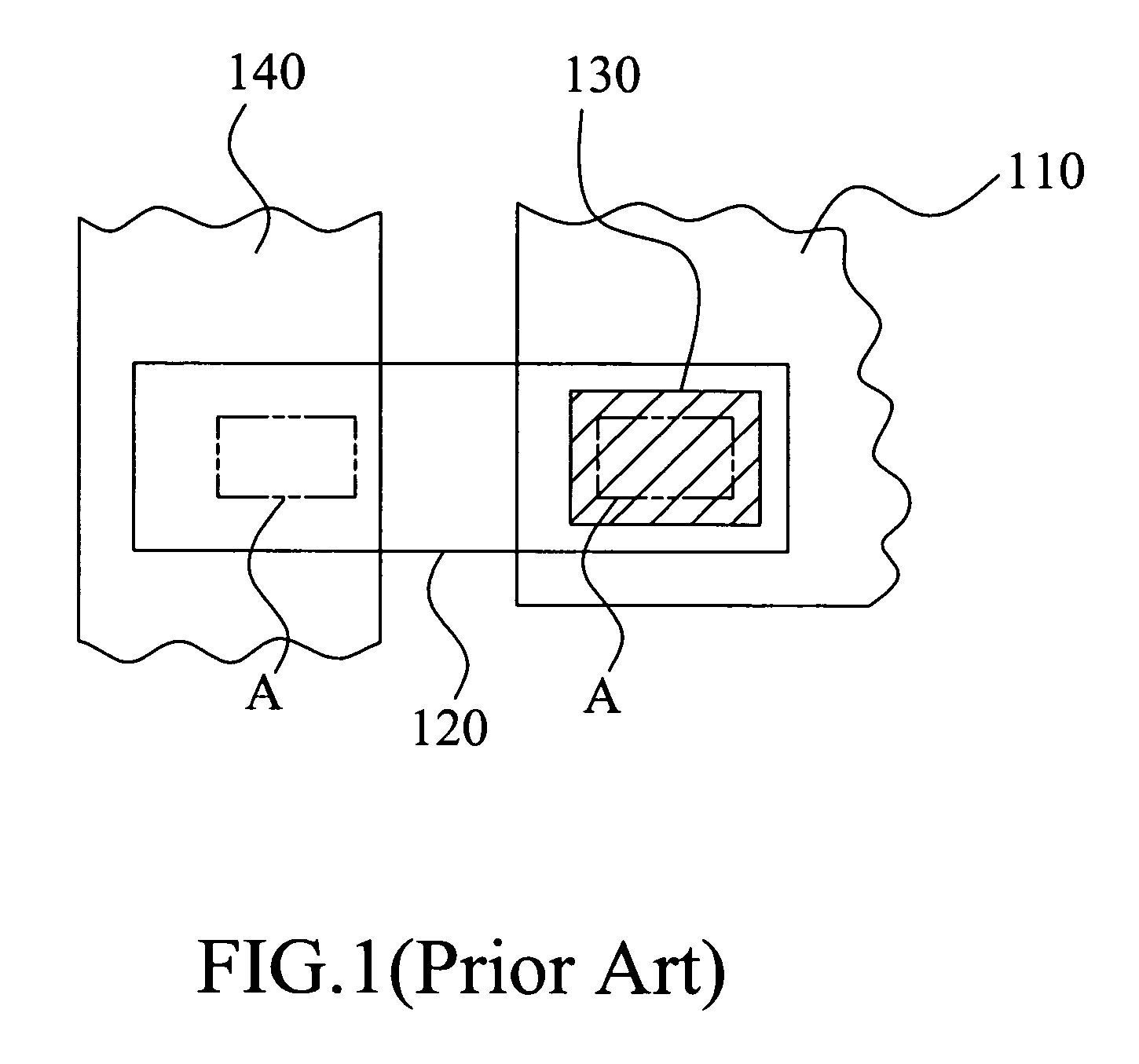

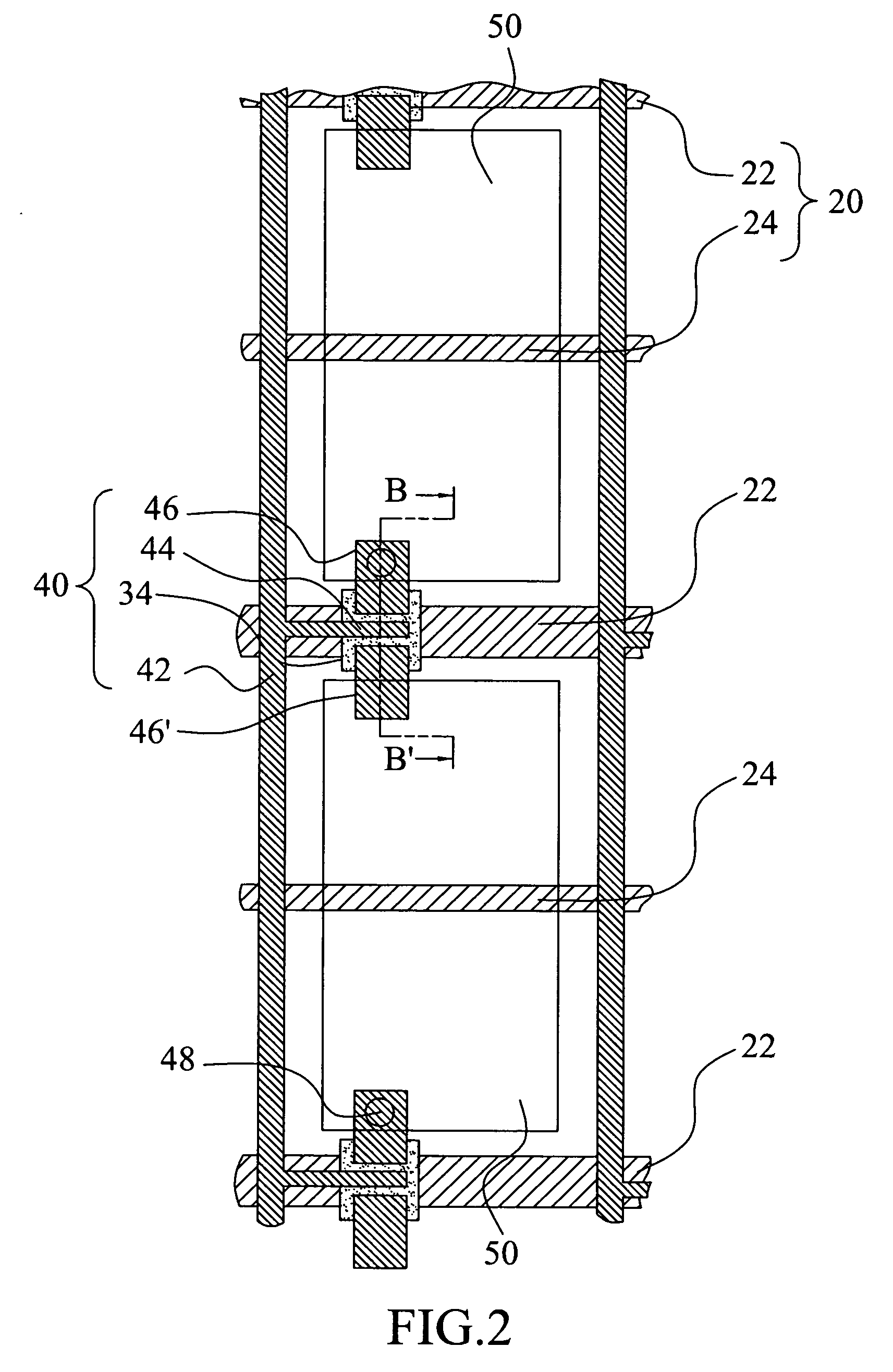

Thin film transistor array substrate and repair method thereof

InactiveUS20080088761A1Shorten maintenance timeIncrease productionNon-linear opticsScan lineOptoelectronics

A thin film transistor array substrate includes a plurality of pixel areas defined by scan lines and data lines; a pixel electrode disposed on each of pixel areas; and a thin film transistor disposed on the each scan lines includes a gate electrode; a source electrode; a first drain electrode and a second drain electrode disposed along the source electrode and on the opposite sides; and an insulating layer over the source electrode, the first drain electrode, the second drain electrode and data lines. The insulating layer has a contact hole to electrically connect with the pixel electrode and the first drain electrode; and the second drain electrode extends to a portion adjacent the pixel electrode and electrically insulated with each other by the insulating layer. The present repair method is to irradiate a laser beam to short the second drain electrode and the pixel electrode at the adjacent pixel area.

Owner:CHUNGHWA PICTURE TUBES LTD

Cargo transport system and method

ActiveUS7785056B2Reduce weightReduce harmRefuse receptaclesWeight reductionTransport systemTransit system

A system for loading cargo containers into a storage hold, and offloading cargo containers from the storage hold, especially of a vehicle, such as an aircraft. The system includes at least one guide rail and a motorized platform, onto which cargo containers are loaded, cooperating mechanically with the guide rail. The guide rail guides the cargo laden motorized platform into the storage hold, and the motorized platform deposits the cargo upon remote command. The motorized platform has a chassis; a power source; a control module controlling drive motors of the wheels of the platform; and a device for reciprocating at least a portion of an upper surface of the platform sufficient to elevate a load placed thereon above the guide rail height.

Owner:THE BOEING CO

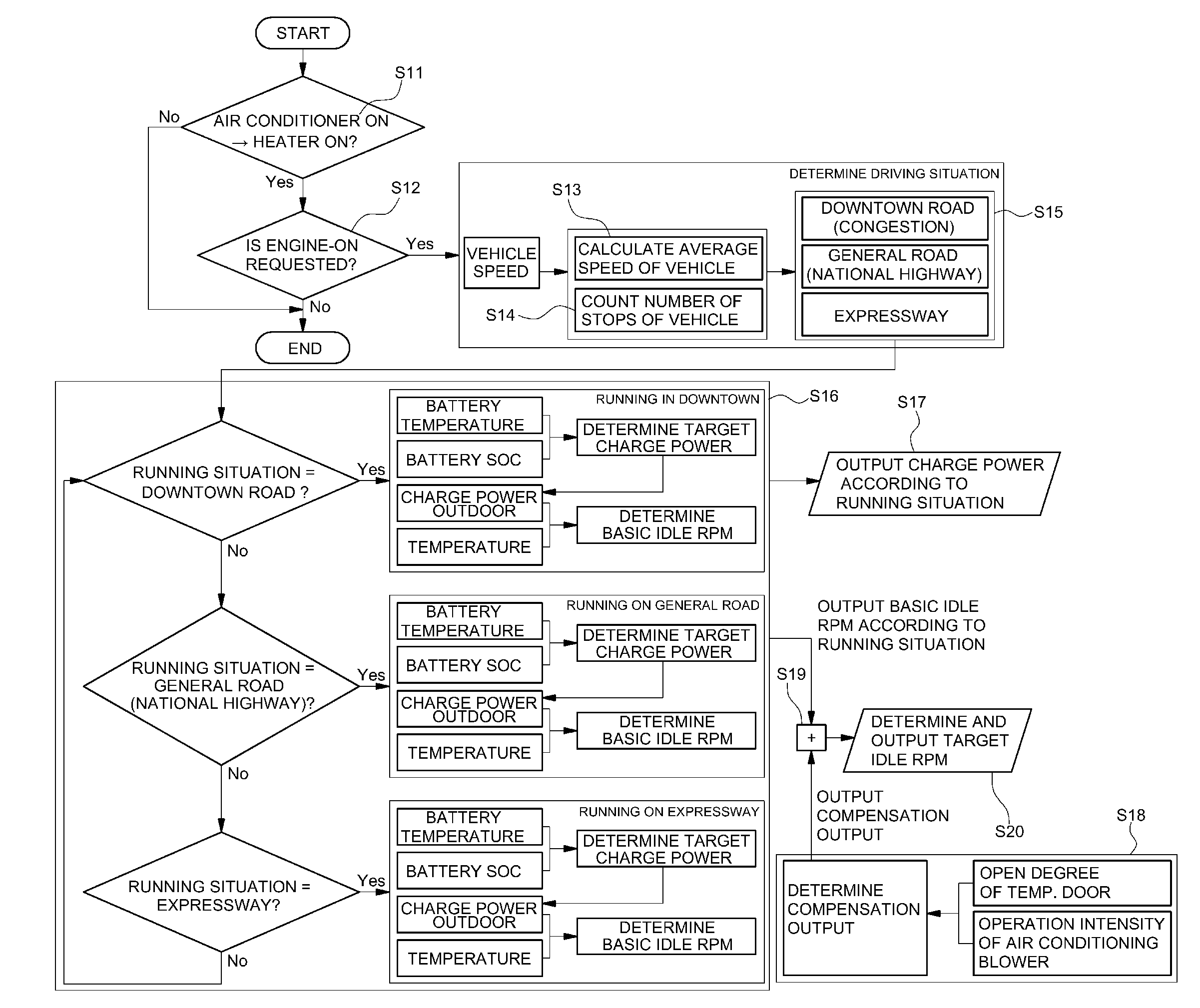

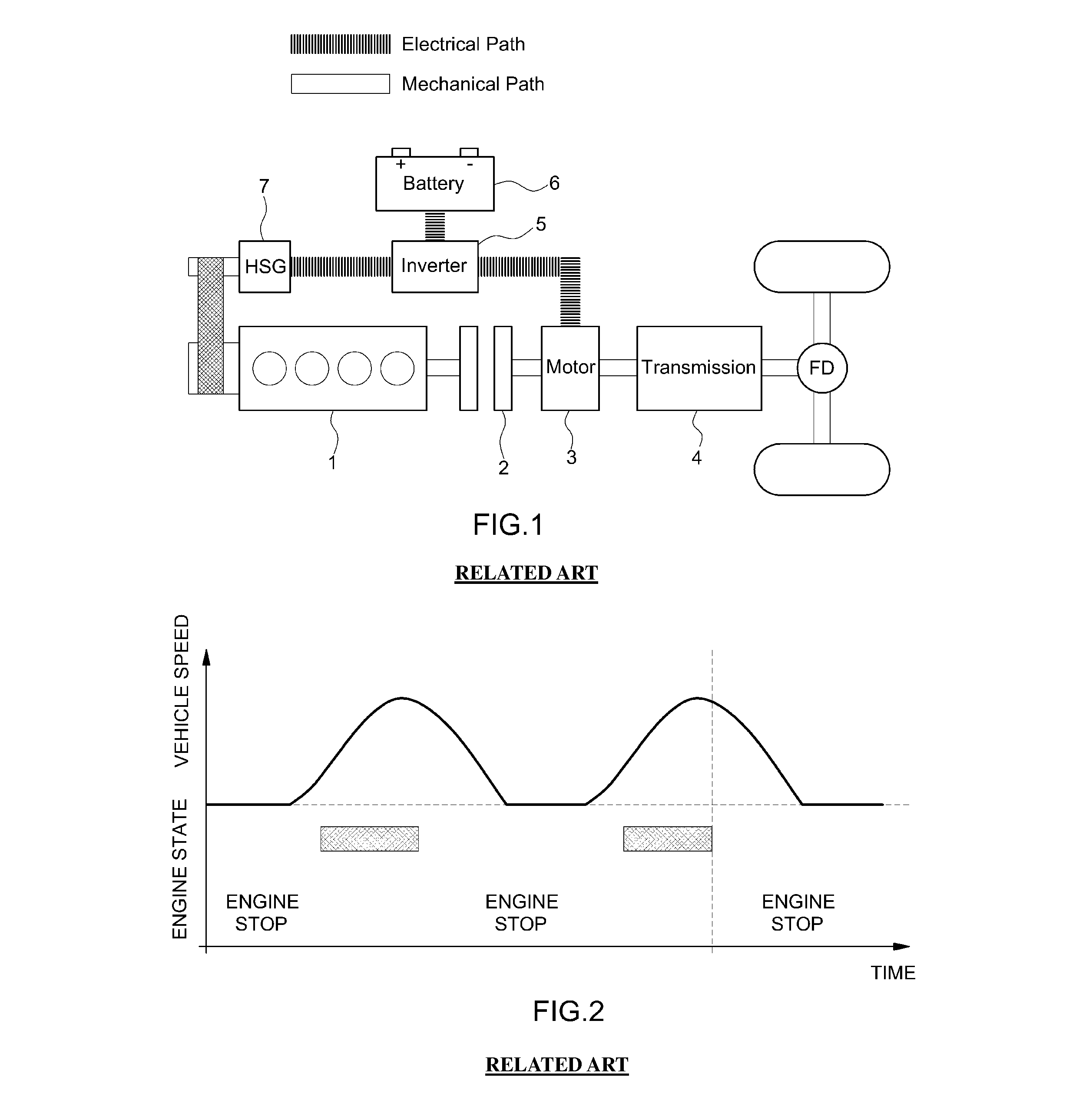

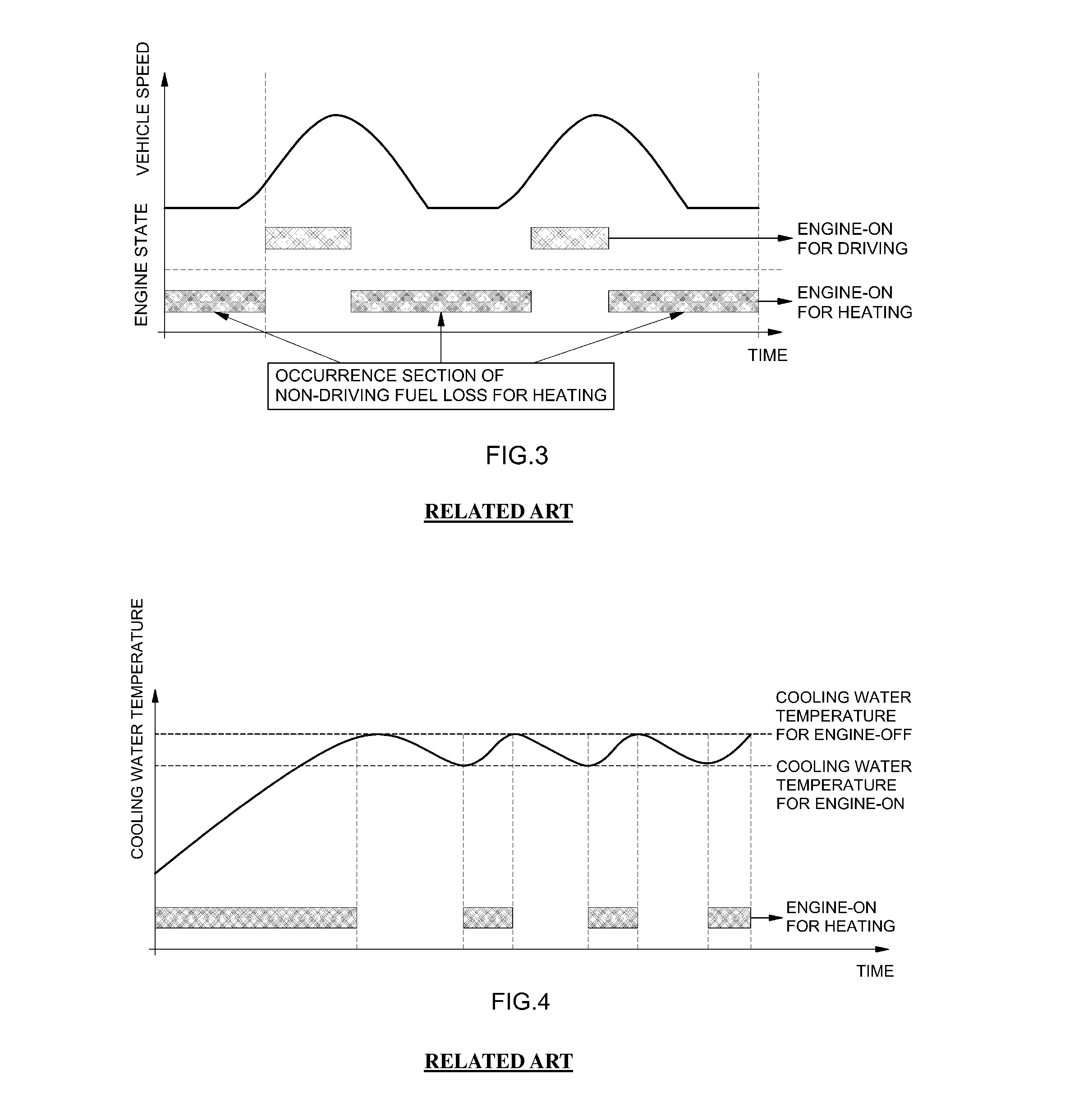

Engine idle operation control method and system for heating of hybrid electric vehicle

ActiveUS20160159339A1Improve fuel efficiencyShorten maintenance timeHybrid vehiclesDigital data processing detailsCharge controlFuel efficiency

An engine idle operation control method and system are provided to improve the fuel efficiency of a vehicle through maintenance of efficient battery SOC and charge control during the engine-on for heating of a vehicle. The method includes receiving an engine-on request for heating of the vehicle and determining a road condition. A target charge power is determined and set as a value corresponding to the road condition and battery state information. A basic idle RPM set as a value corresponding to the road condition, the target charge power, and the outdoor temperature is determined. A compensation RPM and a target idle RPM are determined by compensating for the basic idle RPM by the compensation RPM to adjust the engine idle driving into the determined target idle RPM during the heating of the vehicle.

Owner:HYUNDAI MOTOR CO LTD +1

Aircraft performance detection method

InactiveCN102320382AGuarantee authenticityGuaranteed accuracyTesting/monitoring control systemsStructural/machines measurementOxygen systemAuxiliary power unit

The invention discloses an aircraft performance detection method, which comprises the following steps that: the aircraft auxiliary power unit (APU) operation state aircraft communications addressing and reporting system (ACARS) messages and the ACARS oxygen messages formed by an onboard oxygen system operation state after once aircraft flight are obtained, and the aircraft APU operation state ACARS messages and the ACARS oxygen messages are decoded to obtain aircraft performance data to be processed, so the aircraft APU performance and the onboard oxygen performance are judged, the aircraft performance is normal when the aircraft APU performance and the onboard oxygen performance are both normal, and the aircraft performance is abnormal when either the aircraft APU performance or the onboard oxygen performance is abnormal or both the aircraft APU performance and the onboard oxygen performance are abnormal. The aircraft performance detection method has the advantages that the operation cost of an airline company can be reduced, in addition, the operation safety of aircrafts can be improved, the fault can be eliminated in time, and the maintenance cost is reduced.

Owner:AIR CHINA LTD

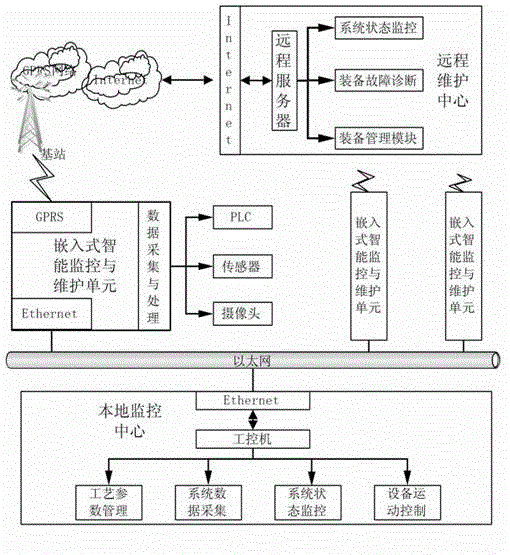

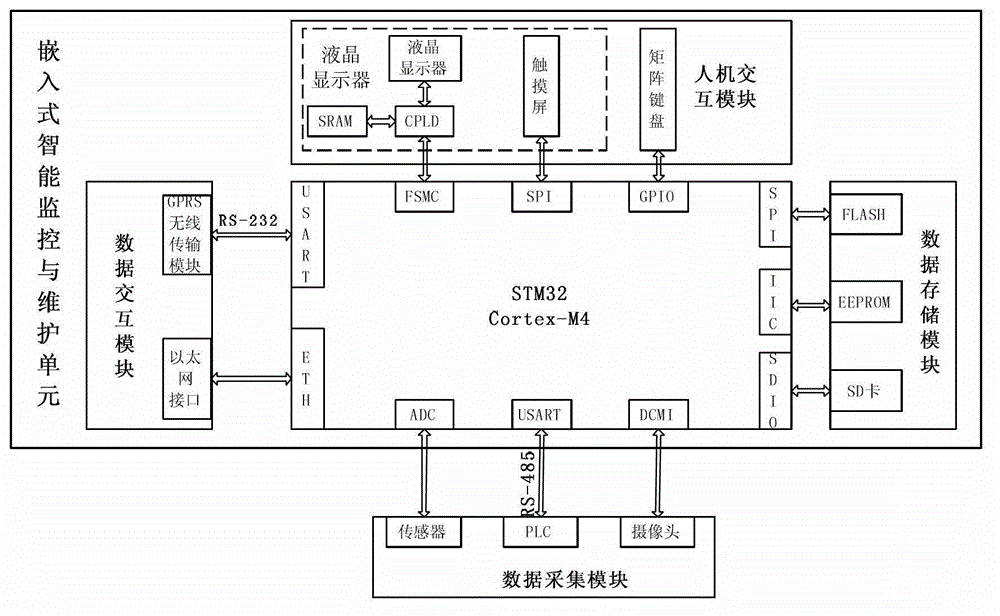

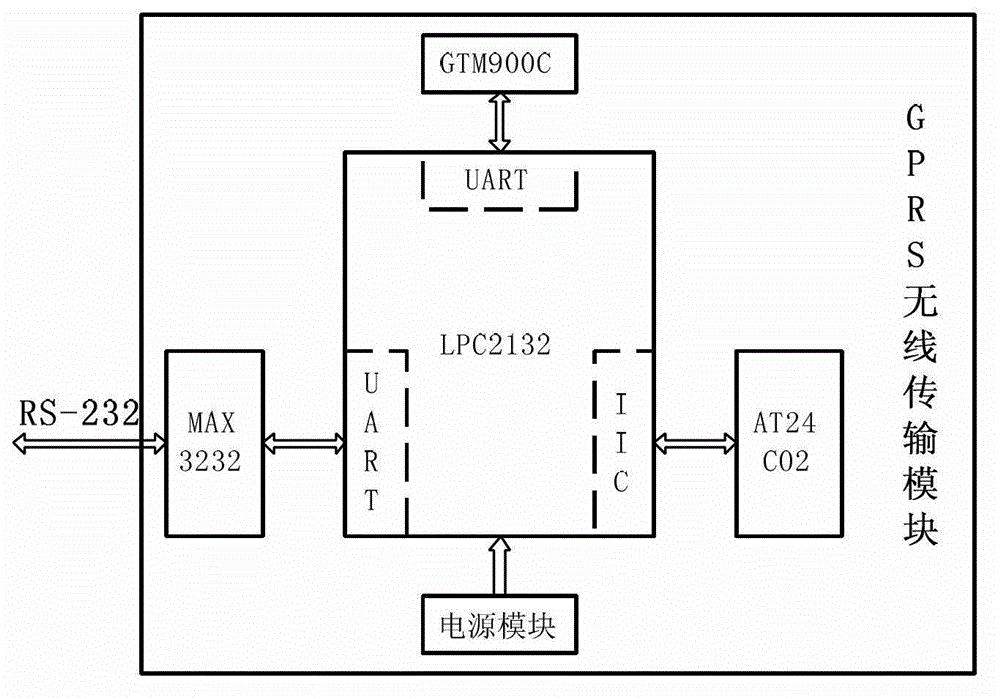

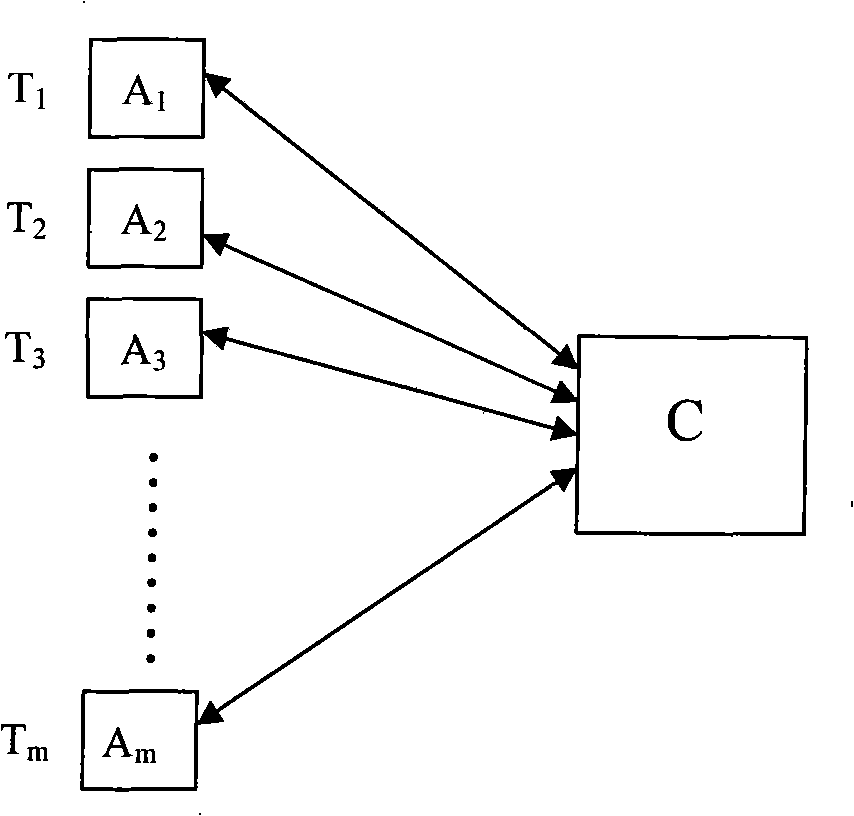

Embedded intelligent monitoring and remote maintaining system of manufacturing equipment

ActiveCN103149901AReduce power consumptionMeet real-time processing needsTotal factory controlProgramme total factory controlReal-time dataData acquisition

The invention discloses an embedded intelligent monitoring and remote maintaining system of manufacturing equipment. A remote maintaining center and an embedded intelligent monitoring and maintaining unit which is installed at a different place constitute a star network, wherein the embedded intelligent monitoring and maintaining unit comprises a micro controller, a data acquisition module, a data interaction module, a man-machine interaction module and a data memory module, and the remote maintaining center comprises a system state monitor, an equipment fault diagnosis module and an equipment management module. The embedded intelligent monitoring and remote maintaining system has a man-machine interaction function, is wide in application occasion, and can well conduct real-time data processing.

Owner:NANJING UNIV OF SCI & TECH

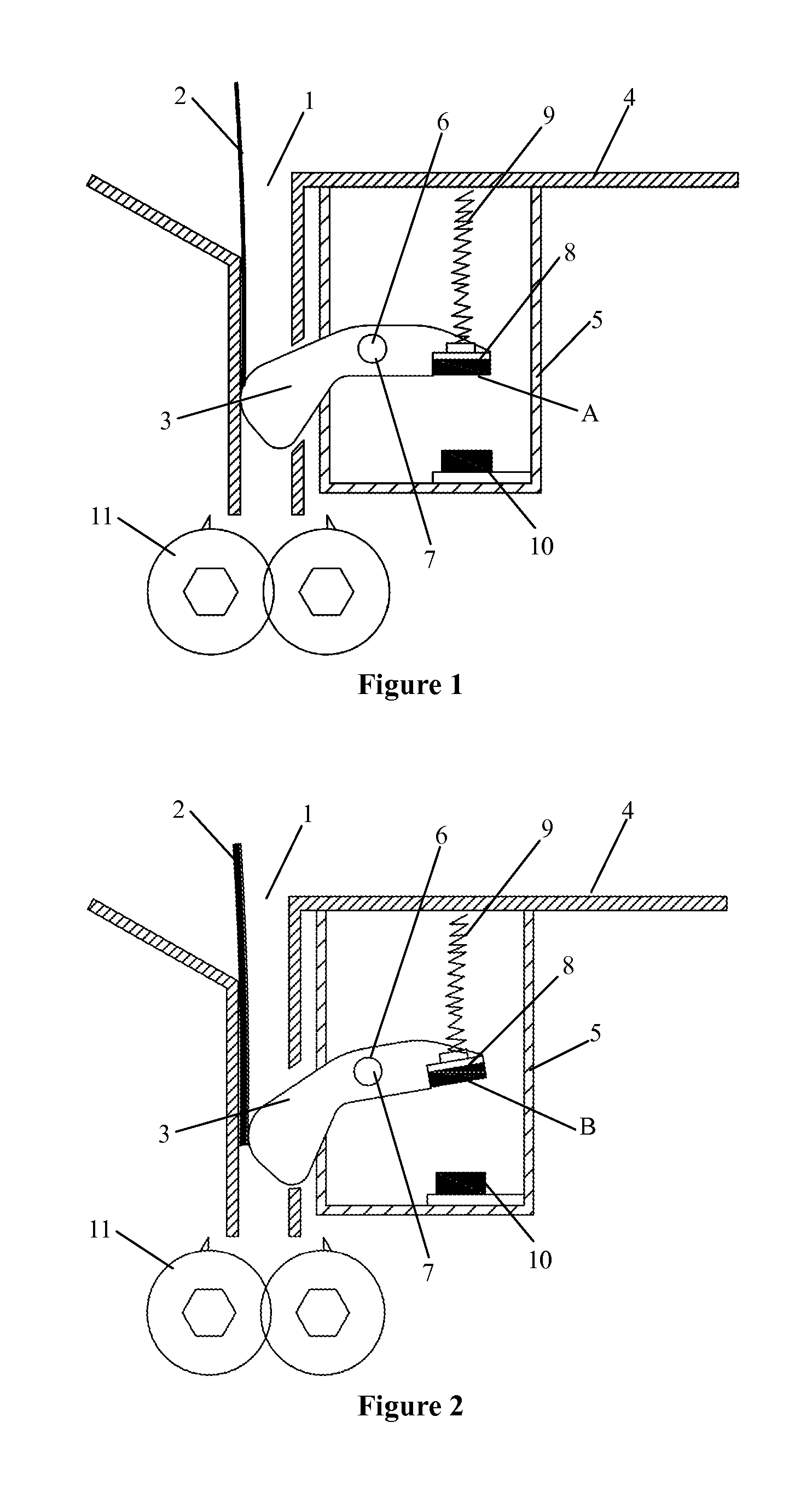

Anti-paper jam protection device for shredders

InactiveUS20100282879A1Shorten maintenance timeEasy to getBalingCocoaPulp and paper industryContact element

The present invention relates to an anti-paper jam protection device for shredders comprising a paper thickness detecting device, an indicating device and a controlling device, wherein the paper thickness detecting device is an electromagnetic induction paper thickness detecting device comprising a contact element, an electromagnetic element and an electromagnetic induction element, the contact element is connected rotatably to the body of the shredder, one end of which is positioned in the paper inserting passage, on the other end of which is mounted the electromagnetic element, the electromagnetic induction element is mounted on the body of the shredder and spaced with the electromagnetic element face to face, and the controlling device is in line connection with the electromagnetic induction element, the present invention controls the thickness of the paper to be shredded during the paper inserting stage, and shreds paper automatically only in a predetermined value range, to avoid abnormalities that result in failure of the machine such as jam and tooth breaking when the shredder is shredding many pieces of paper, so as to reduce maintenance times and cost, extend service life, and make application of shredders safer and more reliable, more convenient and simpler, then to achieve better protection of shredders.

Owner:AURORA OFFICE EQUIP

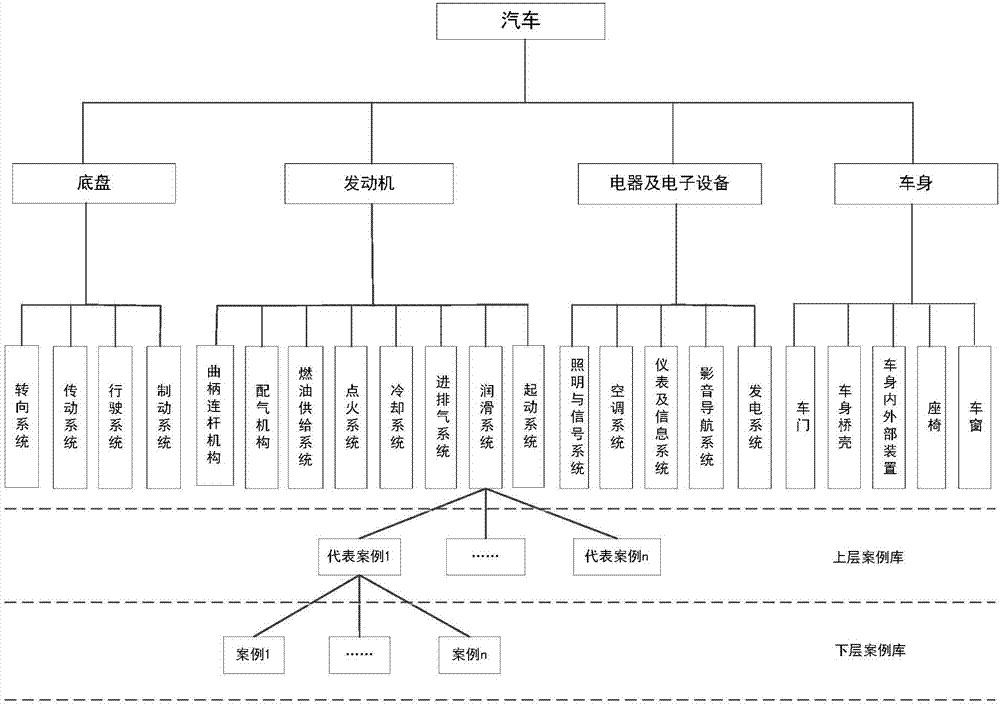

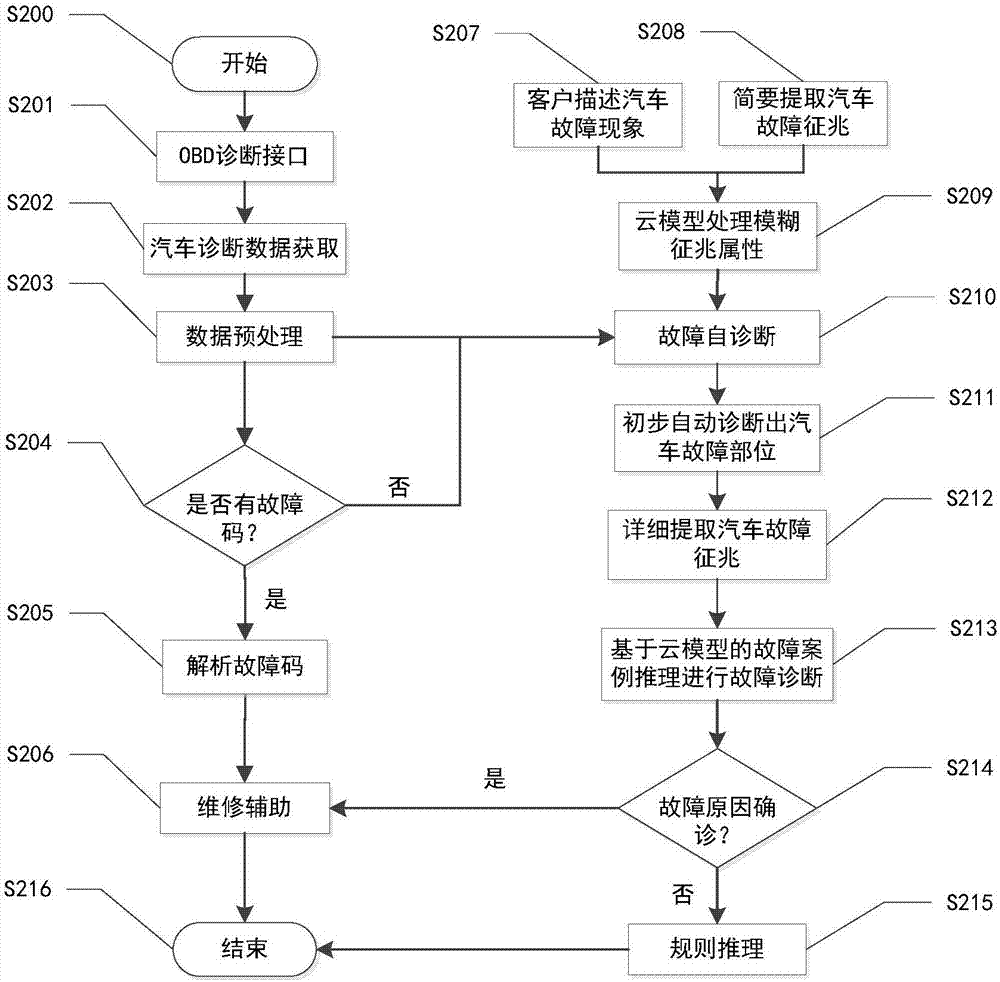

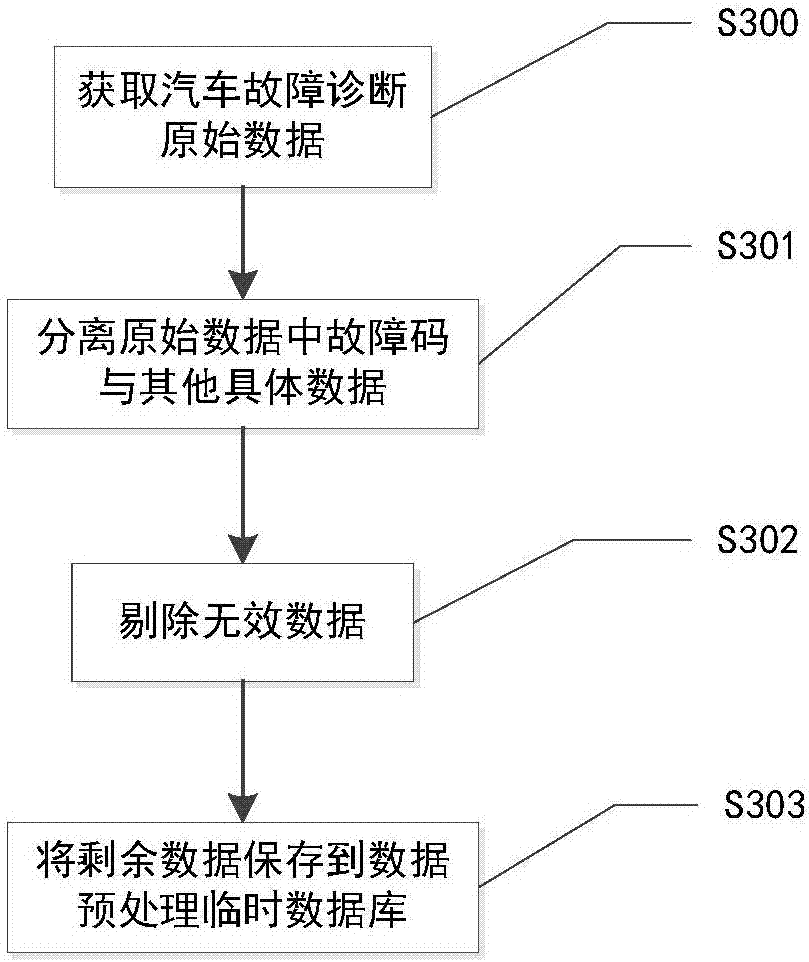

Automobile intelligent fault diagnosis and maintenance auxiliary method and system combining subjective and objective information and cloud model

ActiveCN107168285ATroubleshoot complex situationsShorten maintenance timeElectric testing/monitoringDiagnostic dataObjective information

The invention provides an automobile intelligent fault diagnosis and maintenance auxiliary method and system combining subjective and objective information and a cloud model. The method comprises steps of acquiring automobile objective original diagnosis data through an OBD diagnosis port; carrying out preprocessing on the data, judging whether fault codes are in the preprocessed data, and if yes, analyzing the fault codes and providing automobile maintenance assistance; if no, carrying out quantitative conversion on acquired automobile subjective uncertainty fault sign qualitative value through a cloud model method, and comparing the qualitative value with a standard value in an automobile system standard database, wherein the system automatically diagnoses automobile fault parts initially; diagnosing the automobile fault reason through a case-based reasoning method based on a normal cloud mode; and using the rule-based reasoning to finish diagnosis and elimination of automobile faults. According to the invention, automobile faults caused by a complex condition that an automobile has a fault without a fault code or by damage of non-electronic elements are solved; automobile fault diagnosis can be highly efficiently and rapidly finished; maintenance steps are normalized; and maintenance price is properly set.

Owner:DALIAN UNIV OF TECH

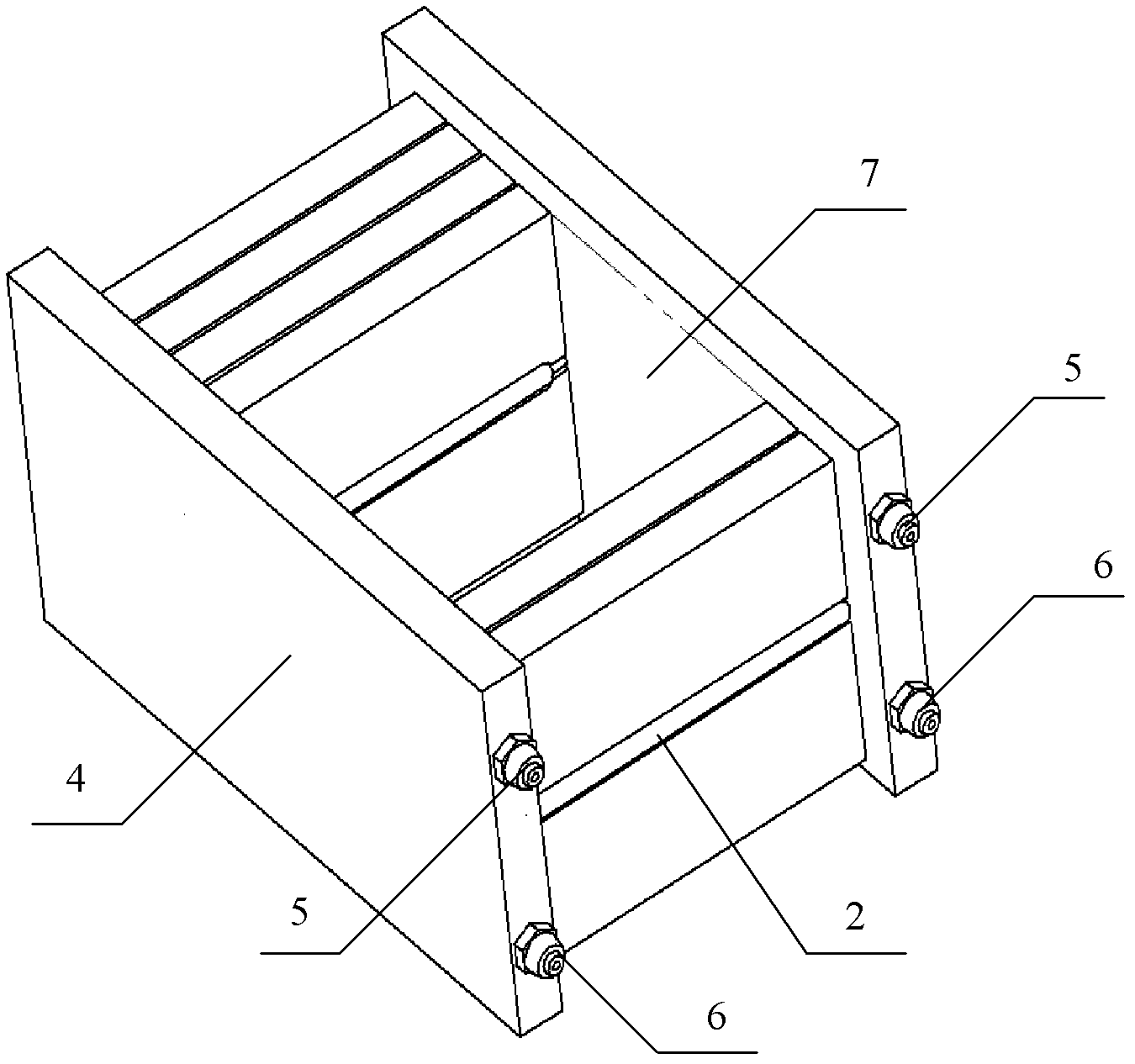

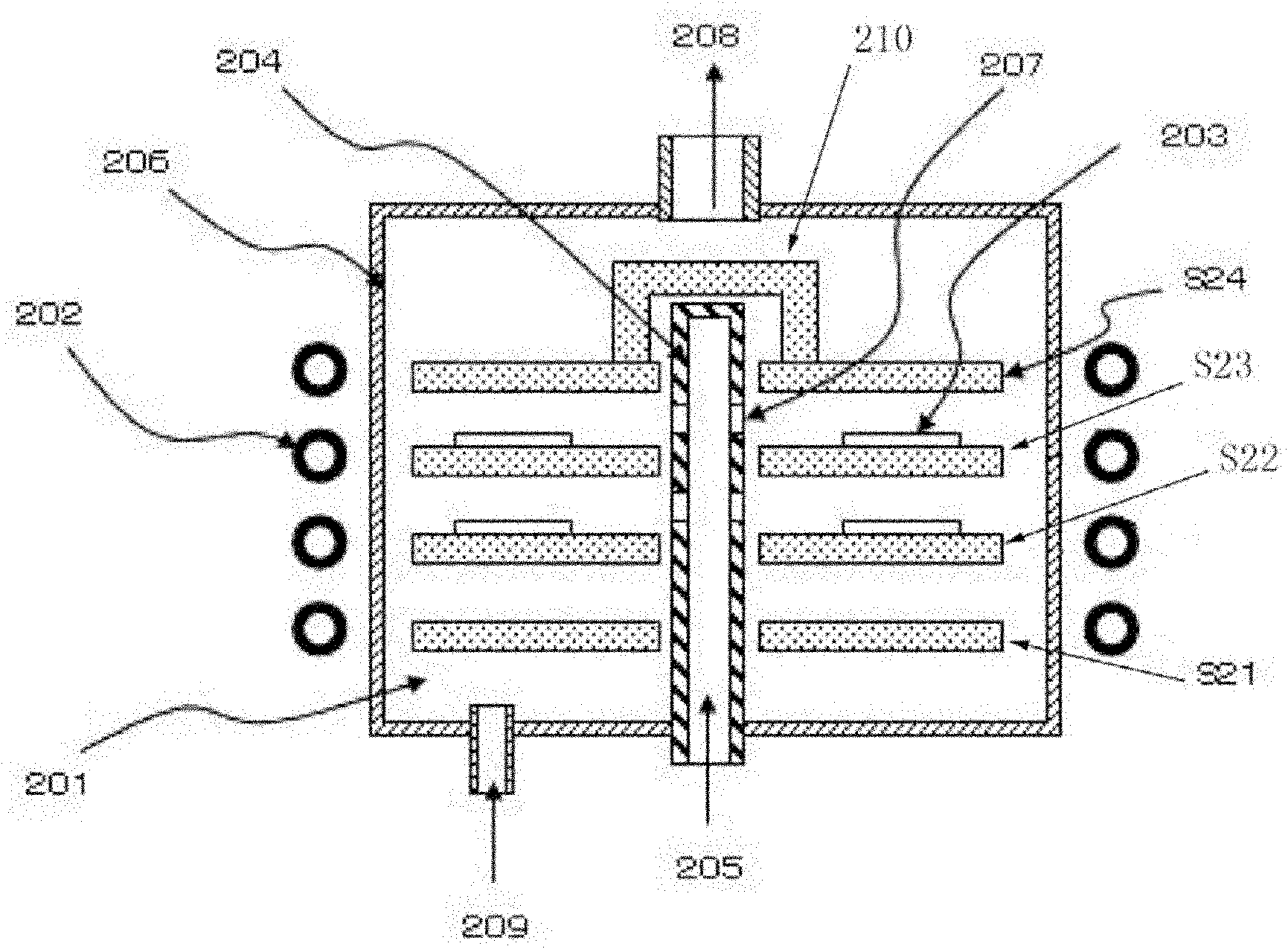

Pallet device and crystallized film growth device

ActiveCN102485953AIncrease production capacityIncrease profitSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProduct gas

The invention, belonging to the technical field of crystallized film growth, particularly provides a pallet device for bearing processed substrates. The ballet device comprises a plurality of pallets arranged laminatedly along with a length wise direction, and certain space exists between adjacent pallets. In addition, the invention further provides a crystallized film growth device, comprising a process cavity, a process gas conveying system and an exhaust system, wherein the process cavity is provided with the pallet device for bearing the substrates in the process. The pallet device and the crystallized film growth device having the pallet device can increase the number of the substrates processed by the process at every time with low cost and increase the productivity.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

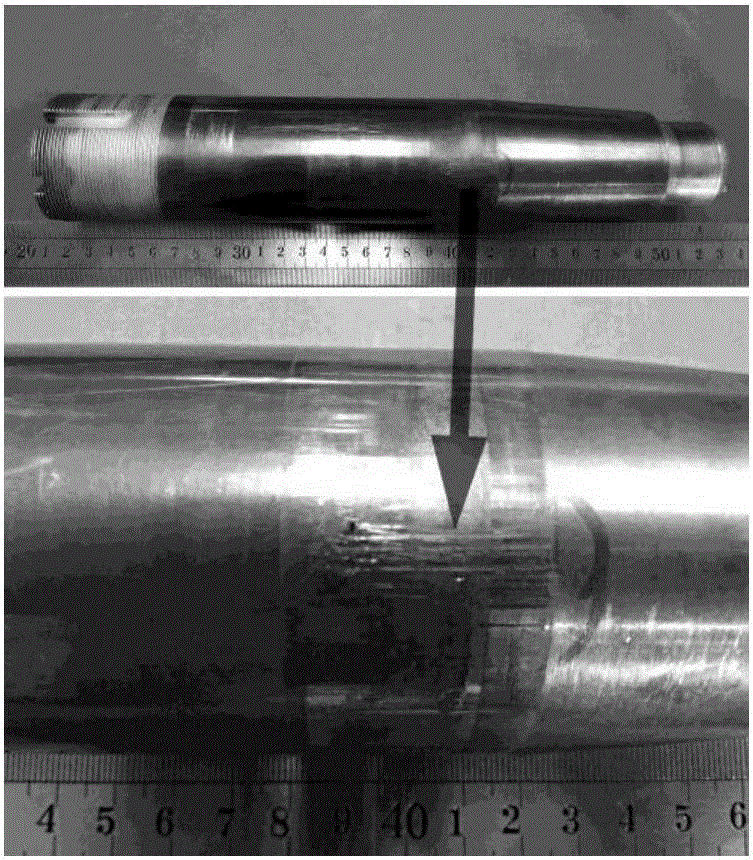

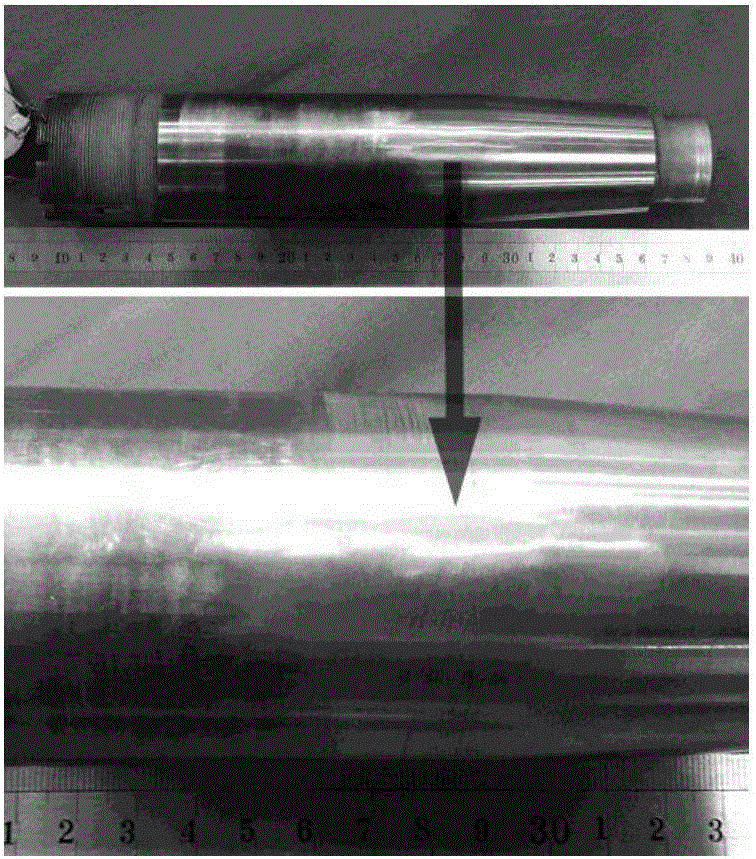

Laser cladding repairing method for aircraft end-journal part surface

InactiveCN105256249AShorten maintenance timeReduce maintenance costsMetallic material coating processesHeat-affected zoneSlag

The invention belongs to the technical field of laser cladding, relates to a laser cladding repairing method for aircraft end-journal part surface, particularly to a method for repairing the mechanical wear and scrape malfunction of an aircraft end-journal part after long-time service by adopting the laser fused deposition technology. The method aims at mechanical wear, scrape and other defects on the surface of the part, selects spherical precipitation to harden stainless steel metal dust, adopts reasonable laser cladding technological parameters, and removes residual stress of the part after cladding through the specific heat treatment technology to recover the performance of the aircraft end-journal and realize repairing of lengthening the service life. The repaired end-journal part hardly deforms, and the depth of a heat affected area is no more than 0.5mm; the repairing area does not have the defects of cracks, incomplete fusion and slag inclusion; the serviceability of the repaired end-journal is recovered.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

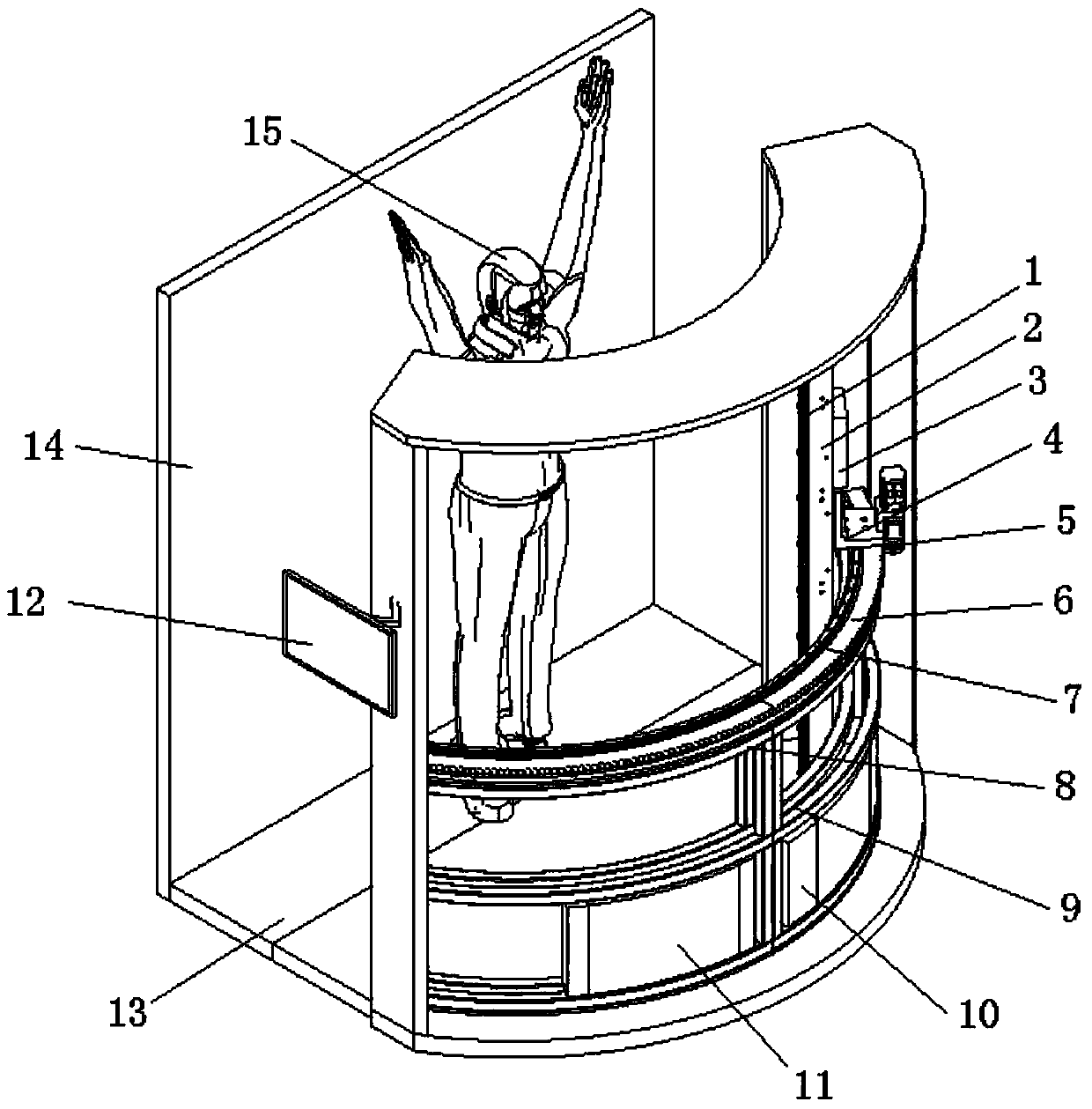

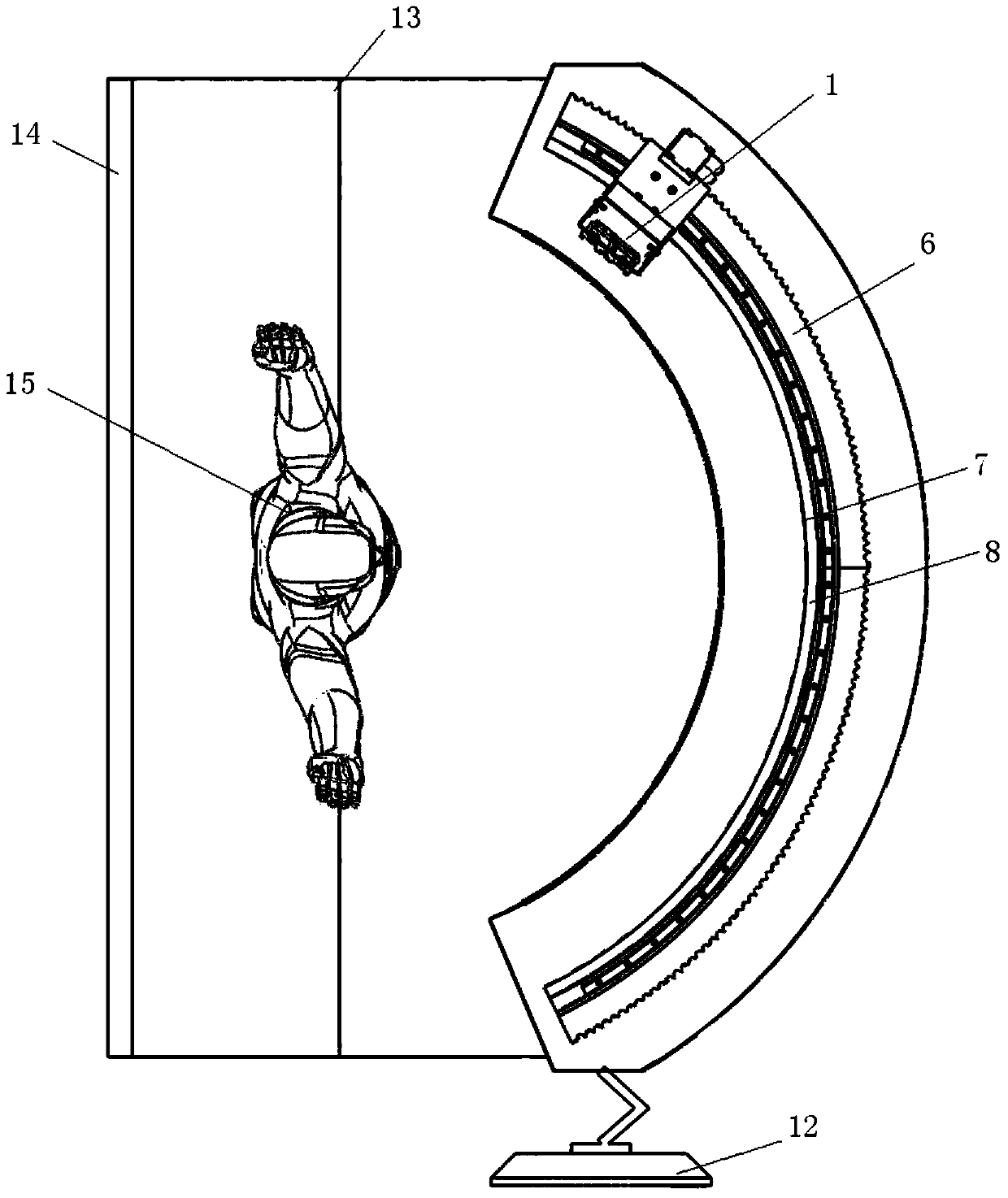

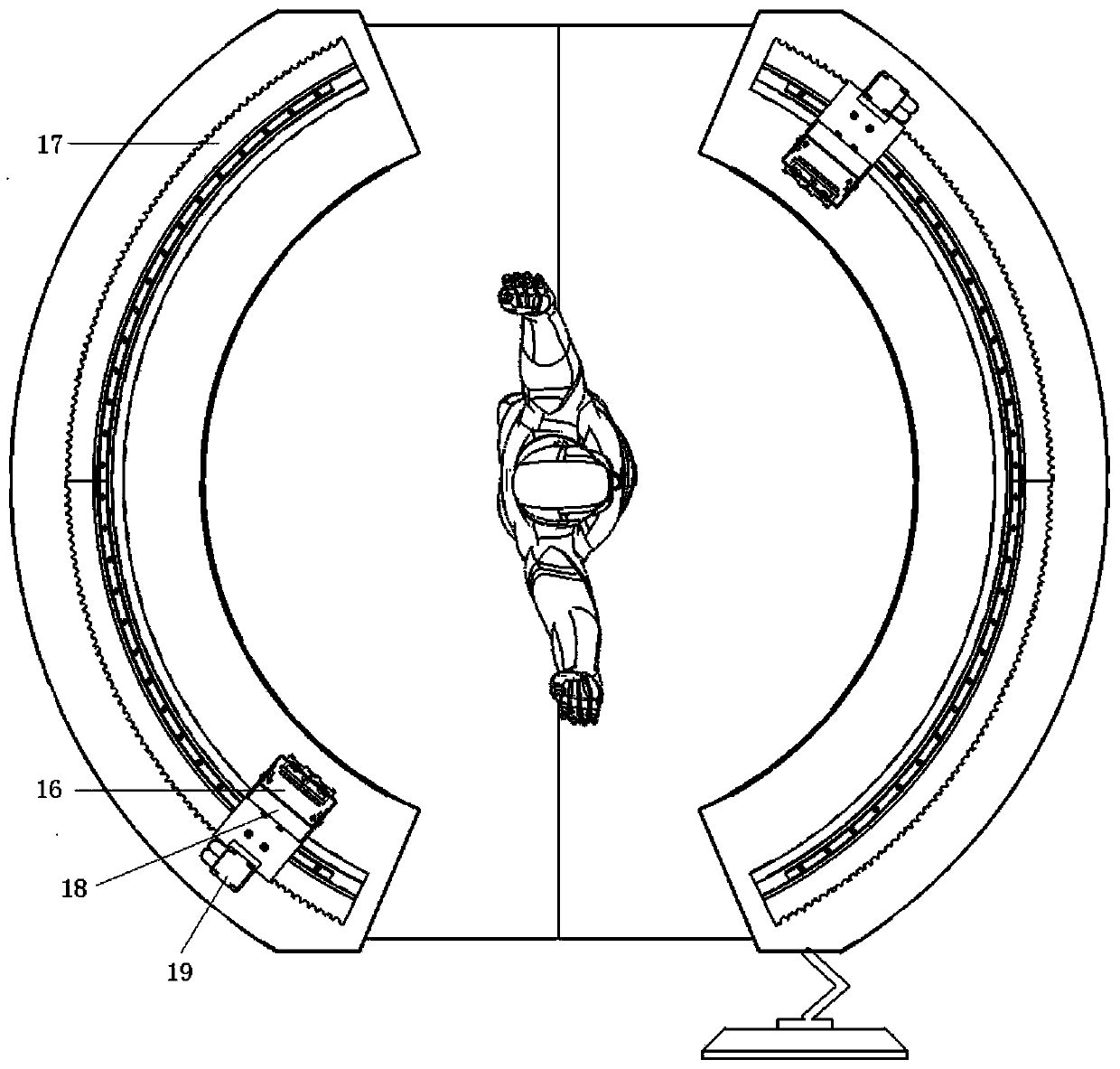

Virtual-axis millimeter-wave human body security check system

ActiveCN103698762AReduce motion loadSmall moment of inertiaRadio wave reradiation/reflectionHuman bodyTransceiver

The invention relates to a virtual-axis millimeter-wave human body security check system. The system comprises a virtual-axis guide rail unit, a scanning unit, a scanning driving unit, a data processing unit and a display unit, wherein the virtual-axis guide rail unit comprises a first circular-arc-shaped guide rail; the scanning unit comprises a first group of millimeter-wave antenna arrays and a first millimeter-wave transceiver; the scanning driving unit is used for driving the first group of millimeter-wave antenna arrays to scan in a reciprocating virtual-axis circular-arc-shaped locus on the first circular-arc-shaped guide rail; the data processing unit is used for processing a detection signal from the scanning unit to form a human body image to be detected; the display unit is used for displaying the at least one human body image to be detected. In the human body security check system disclosed by the invention, a virtual-axis scanning way is used, the motion load does not need to be reduced, and the rotational inertia is reduced, so that the scanning speed is increased. The system is small in occupied space, and a single / double-module security check system can be assembled more flexibly according to the size of a practical space and the checked amount.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

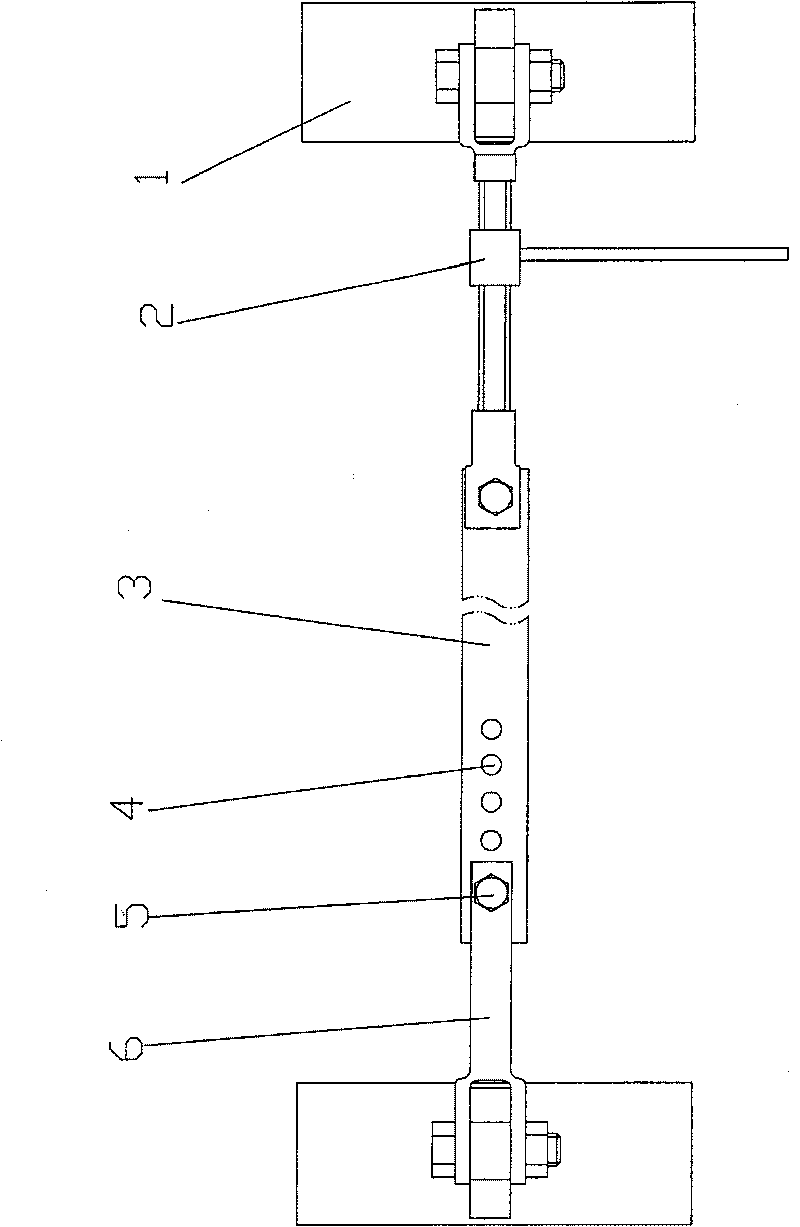

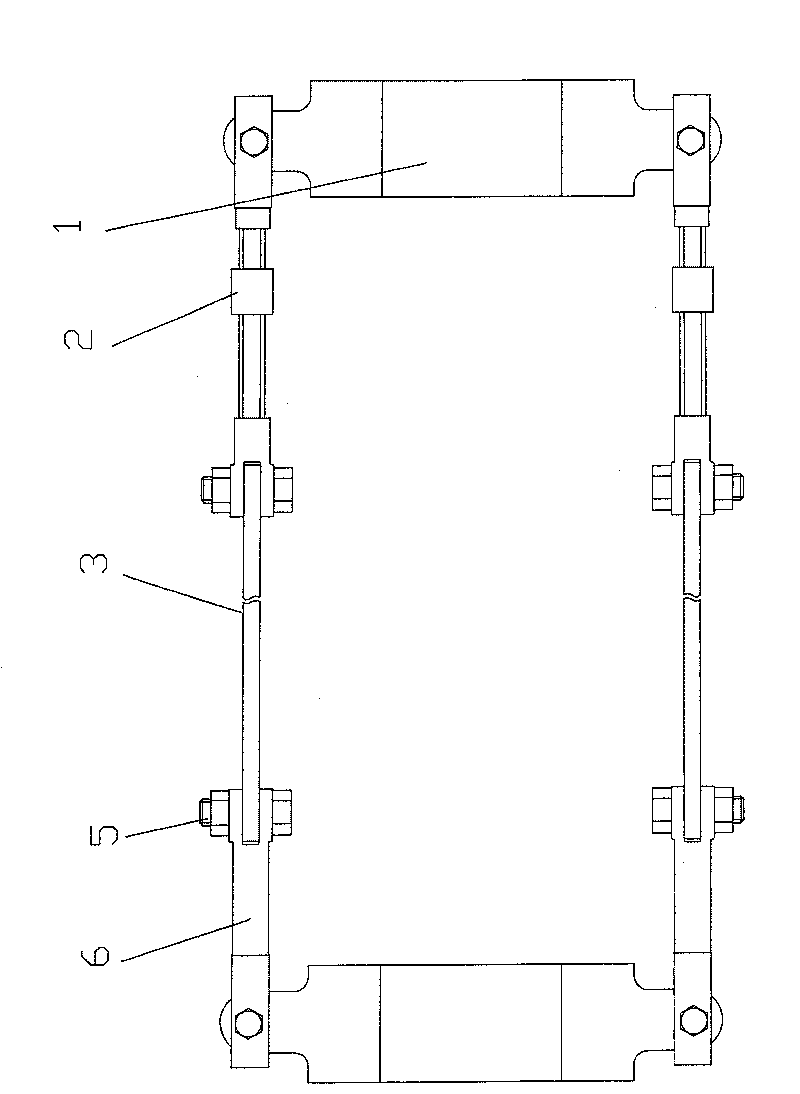

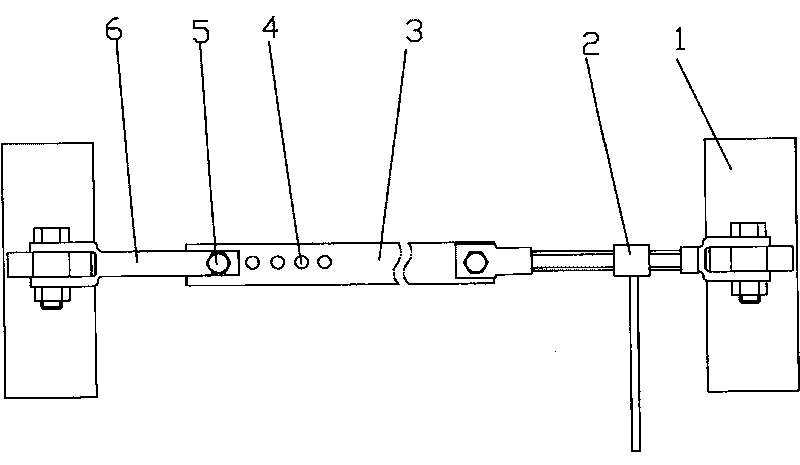

High-voltage power line tension insulator string forward spin live-wire altering method

ActiveCN101174761BAccurate placementLarge operating spaceSuspension/strain insulatorsApparatus for overhead lines/cablesEngineeringTraveling block

The present invention discloses a spinning electricity replacing method and a double yoke-plate device of high-tension transmission line strain insulator. A wing-shaped card and an insulation drawplate and other special tools on the end are used to firstly loose the stain insulator; a pulley block and a lead screw on the sides of a cross arm and a lead wire are used to complete break away the twoends of the strain insulator; finally the pulley block arranged on a ground bracket is used to rotate a porcelain insulator from a horizontal state to a vertical state, thus changing the complicated operation to the simple operation, greatly shortening the equipotential operation time and ensuring the safe operation of the line. The double yoke-plate device of high-tension transmission line strain insulator includes two wing-shaped cards and two lead screws as well as two insulation drawplates; one end of the two insulation drawplates is respectively connected with the two wings of the two wings of the wing-shaped card and the other end is respectively connected with the lead screw; the other end of the two lead screws is respectively connected with the two wings of the other wing-shaped card. The present invention has the advantages of simple structure, easy operation and low cost.

Owner:MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

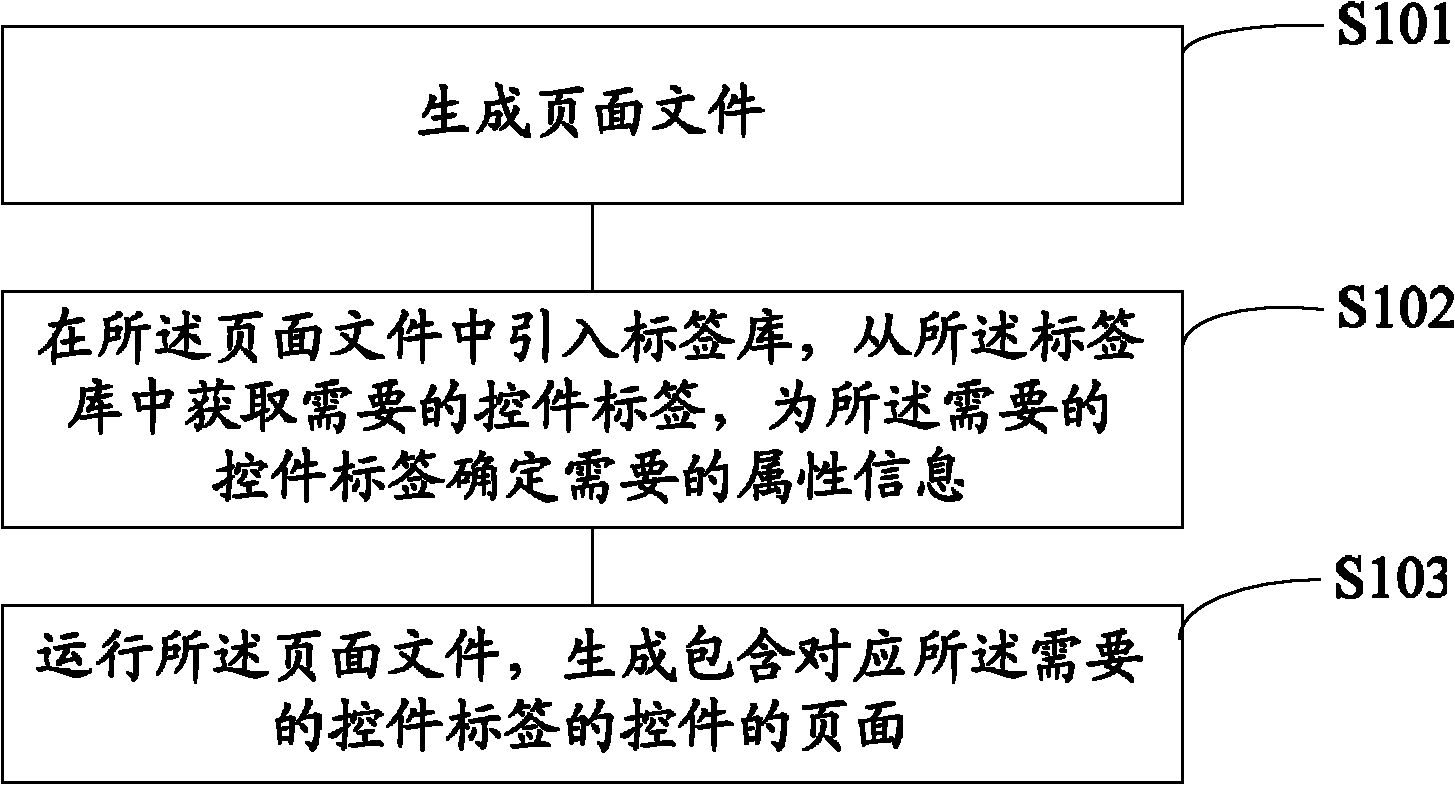

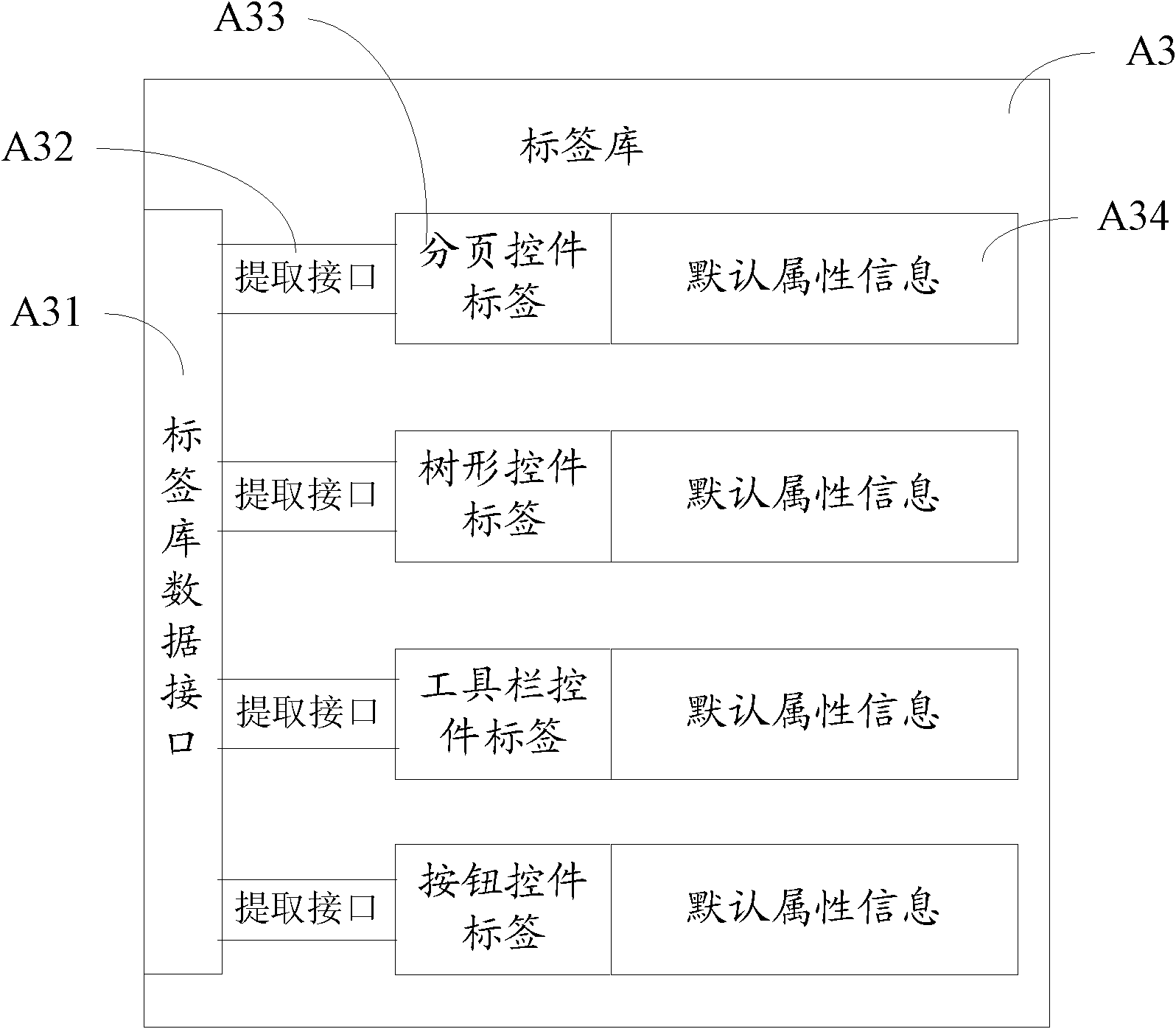

Control-containing page establishing method

InactiveCN102096588ASave compilation timeShorten the timeSpecific program execution arrangementsDatabase

The invention discloses a control-containing page establishing method. The method comprises the following steps of: generating a page file, wherein the page file comprises the information of a page to be established; introducing a tag library into the page file, acquiring a required control tag from the tag library, and determining required attribute information for the required control tag, wherein the tag library comprises tag data information, the tag data information comprises the control tag and the attribute information thereof, and the attribute information at least comprises action attribute information; and operating the page file to generate the page which contains the control corresponding to the control tag, wherein the attribute of the control is matched with the attribute information of the control tag. The control-containing page establishing method shortens development time, reduces development cost and improves the work efficiency for developing pages.

Owner:南京朗睿软件科技有限公司

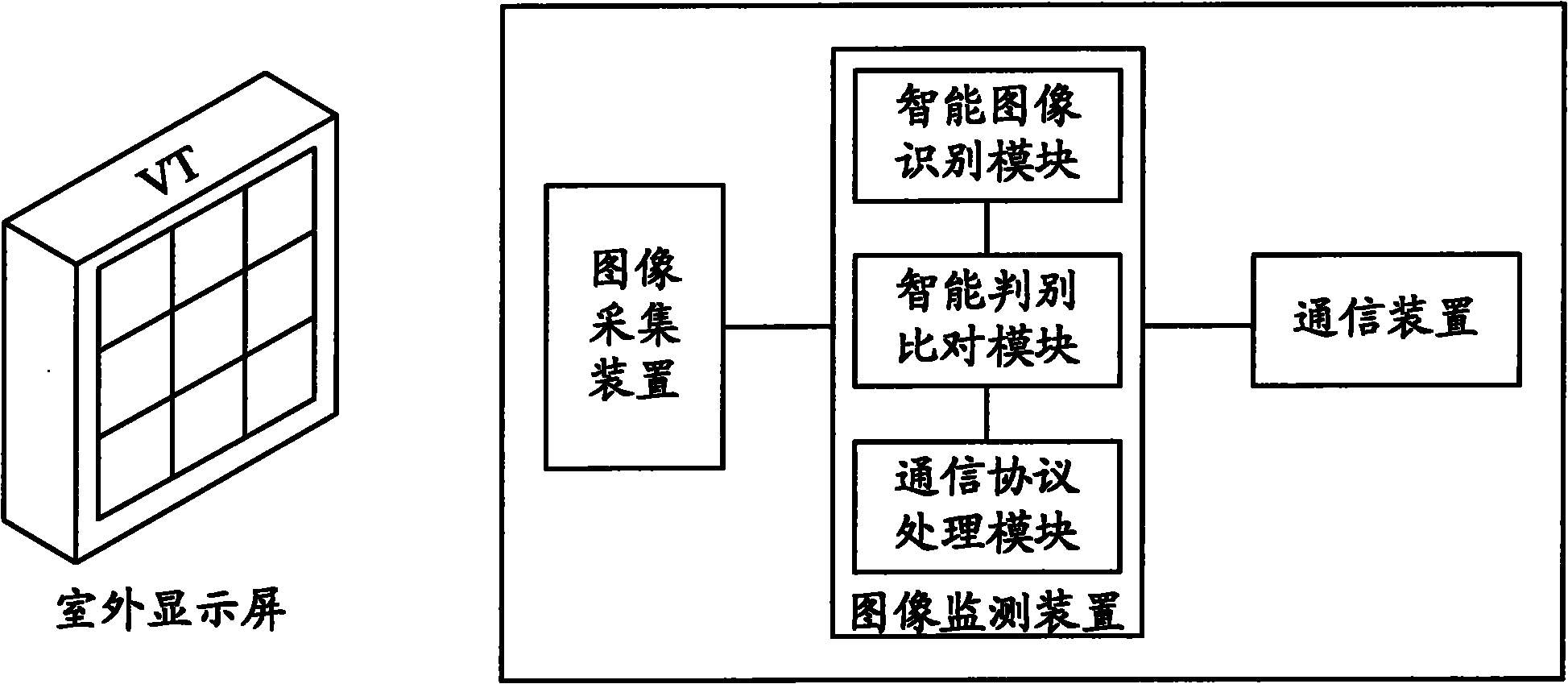

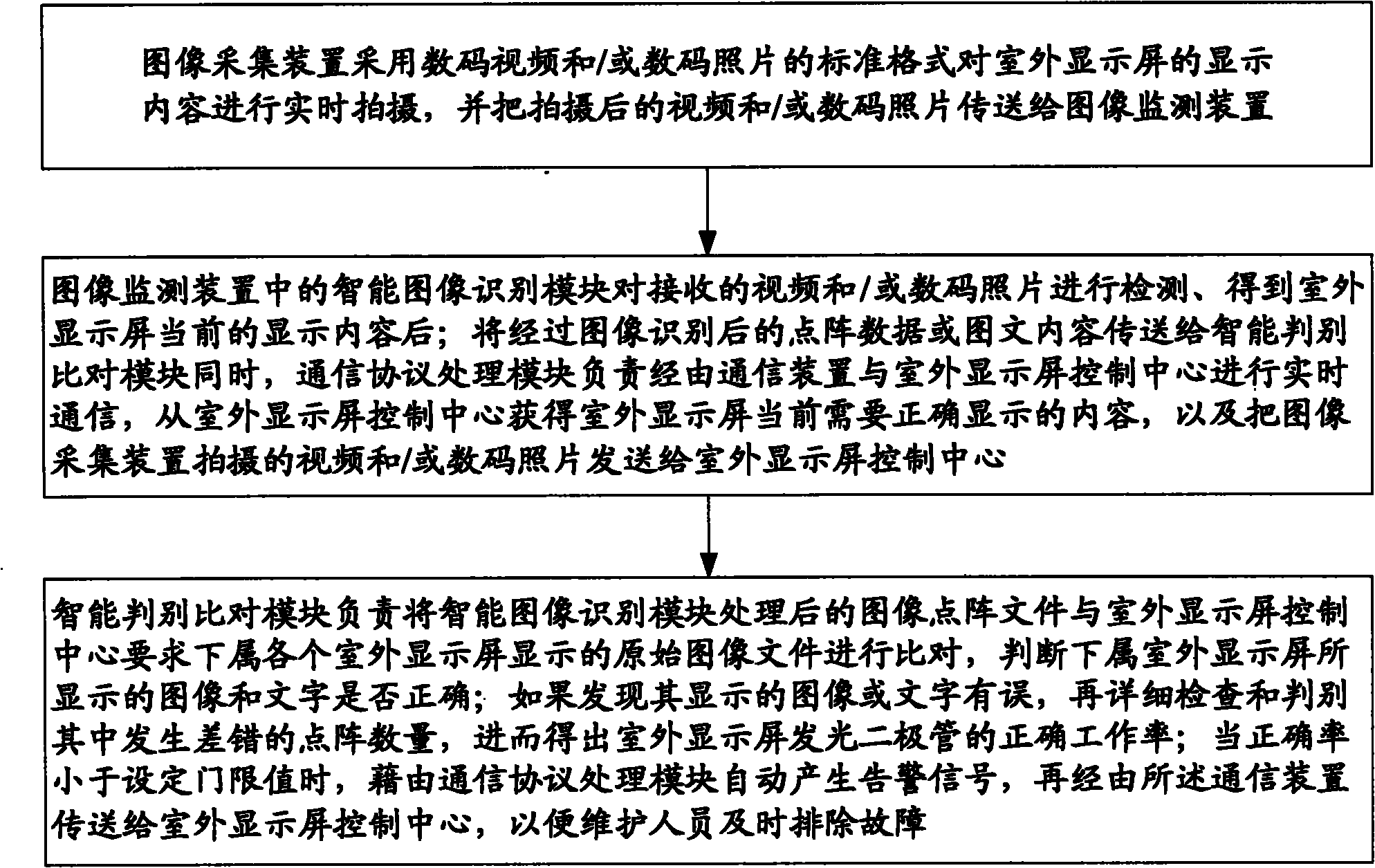

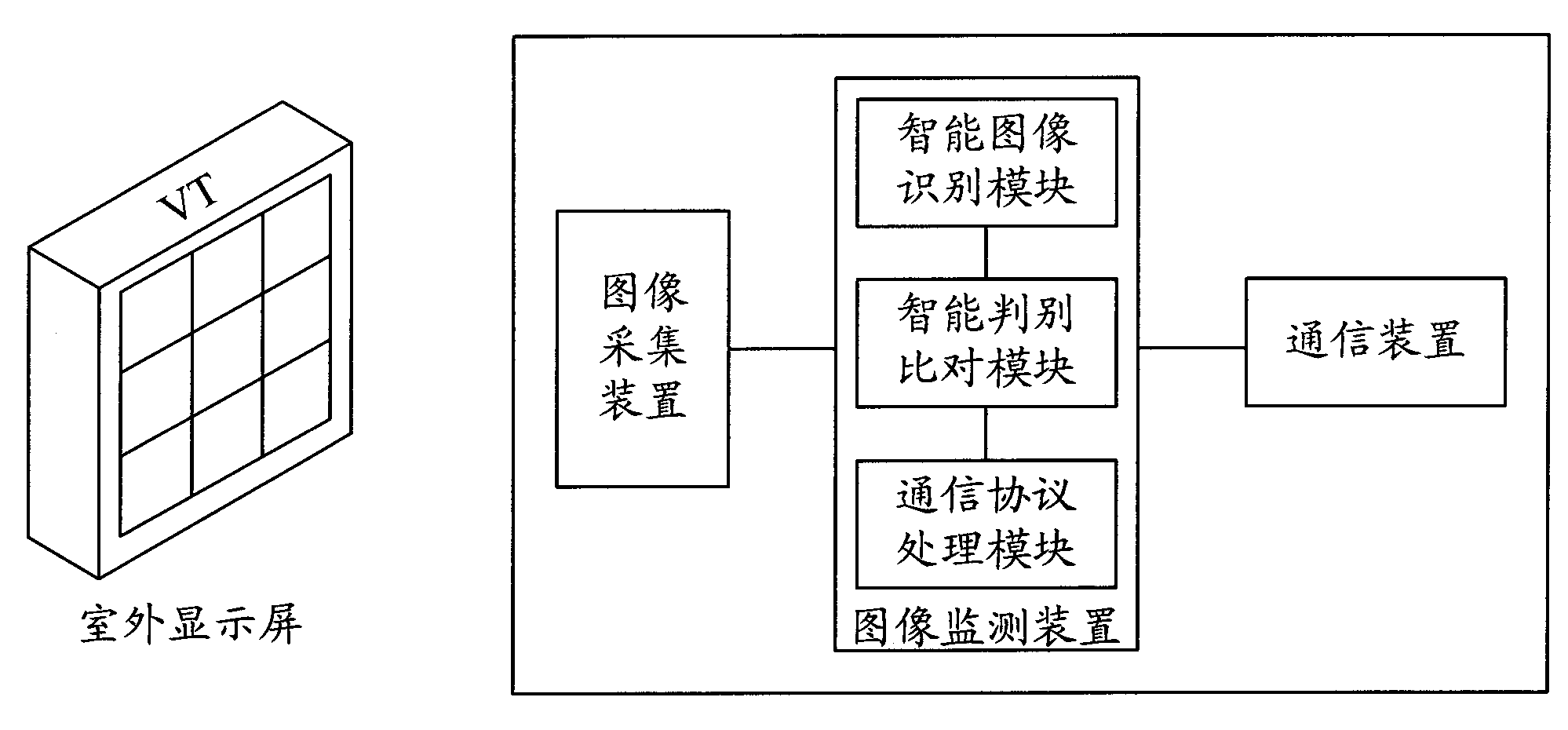

System and method for monitoring outdoor display screen by using video image and/or digital photo

ActiveCN102184694AReduce maintenance timeImprove normal and efficient operationStatic indicating devicesClosed circuit television systemsDigital picturesTelecommunications equipment

The invention relates to a system and a method for monitoring an outdoor display screen by using a video image and / or a digital photo. The system is provided with an image acquisition device, an image monitoring device and a communication device, wherein the image acquisition device is arranged on the front side of the outdoor display screen; and the image monitoring device is connected with the image acquisition device and is provided with an intelligent image identification module, a communication protocol processing module and an intelligent judging and comparing module. The monitoring method comprises the following steps that: the image acquisition device shoots a display content of the outdoor display screen in real time and transmits the shot video and / or digital photo to the image monitoring device; the image monitoring device carries out two types of identification of a point-to-point lattice or an integrated image-text content on the video or the digital photo, and compares aprocessed display screen image lattice file with the original image file of a control center to judge whether the display screen image lattice file is displayed correctly; if a display fault is found, the number of fault lattices is checked in detail to obtain the correct working rate of a light-emitting diode (LED) of the outdoor display screen and automatically generate an alarm signal; and thealarm signal is transmitted to the control center by the communication device, so that maintenance personnel eliminates the fault in time.

Owner:BEIJING SULIANKE COMM EQUIP

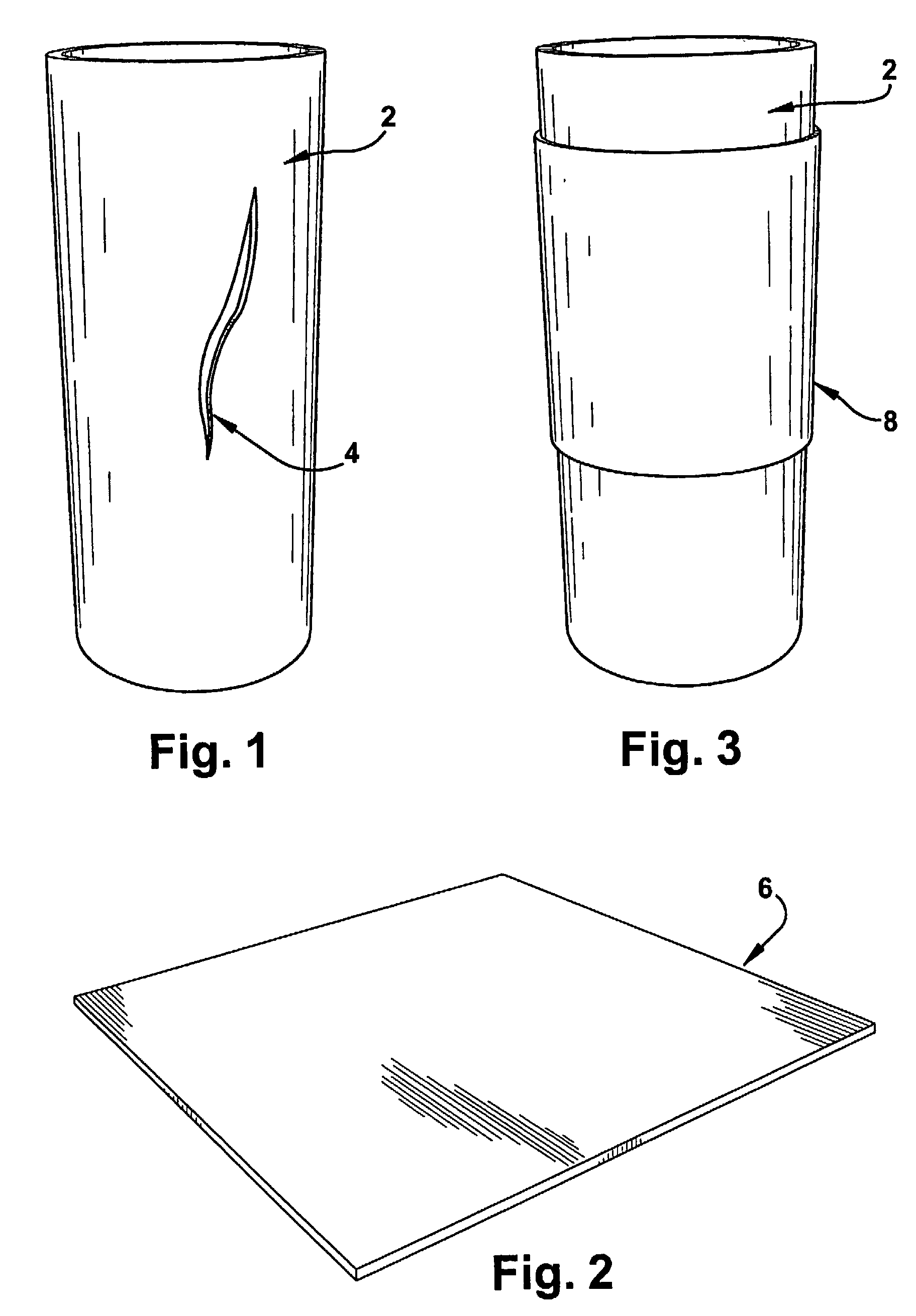

Method of Making and Using Shape Memory Polymer Composite Patches

ActiveUS20080314510A1Shorten the timeAffordable priceEngine sealsLayered productsMaterials scienceShape-memory polymer

A method of repairing a composite component having a damaged area including: laying a composite patch over the damaged area; activating the shape memory polymer resin to easily and quickly mold said patch to said damaged area; deactivating said shape memory polymer so that said composite patch retains the molded shape; and bonding said composite patch to said damaged part.

Owner:SPINTECH LLC

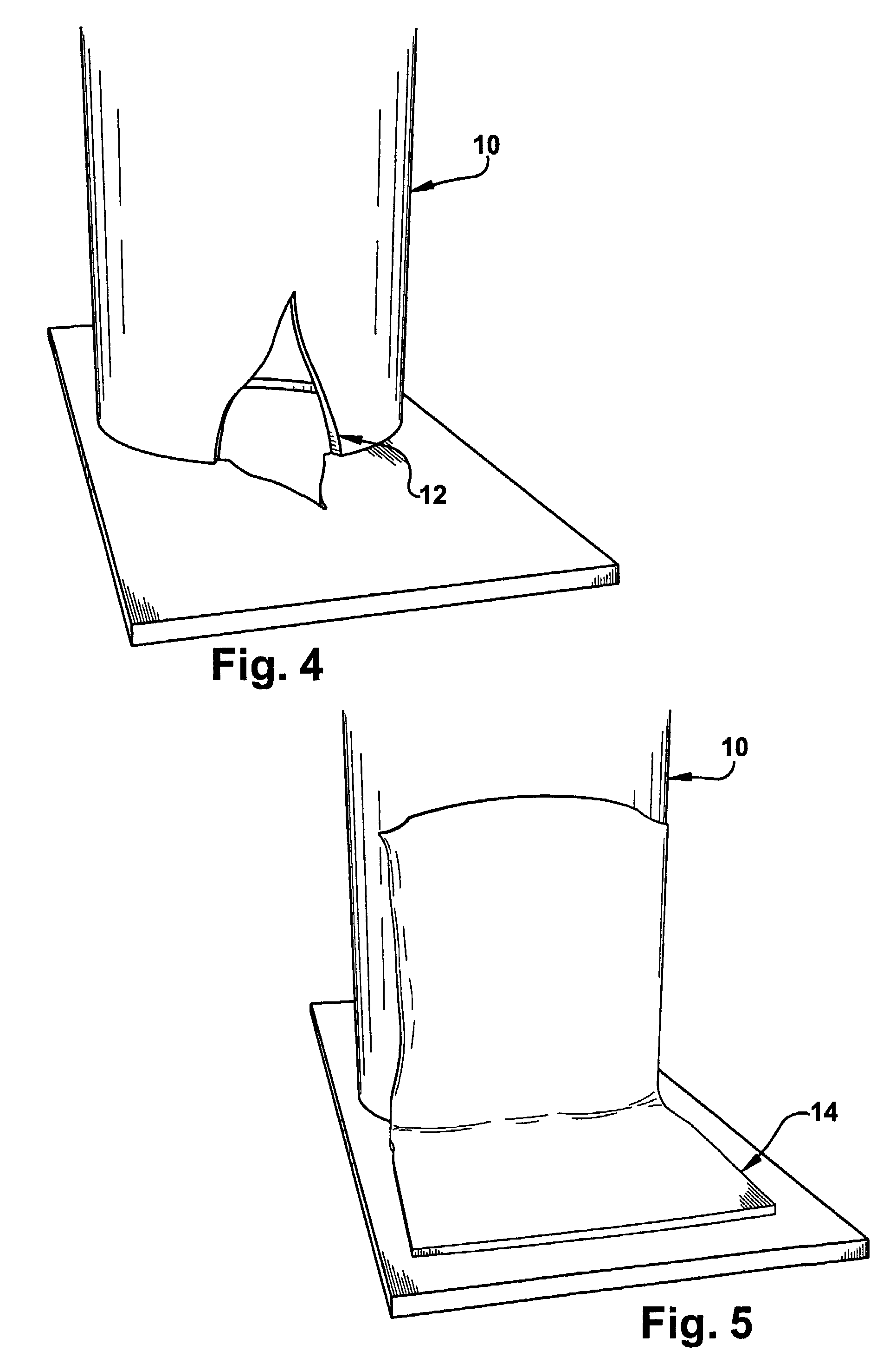

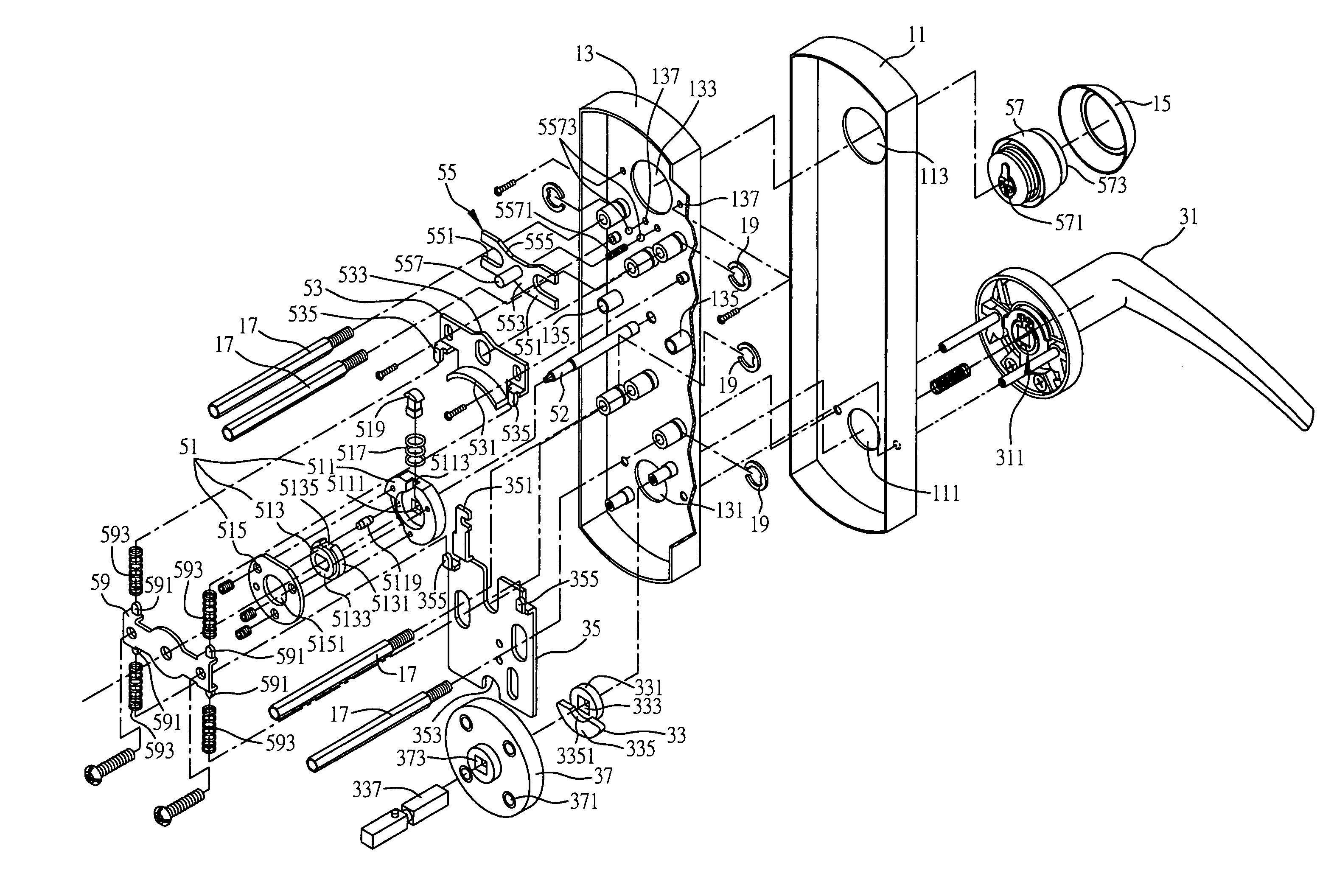

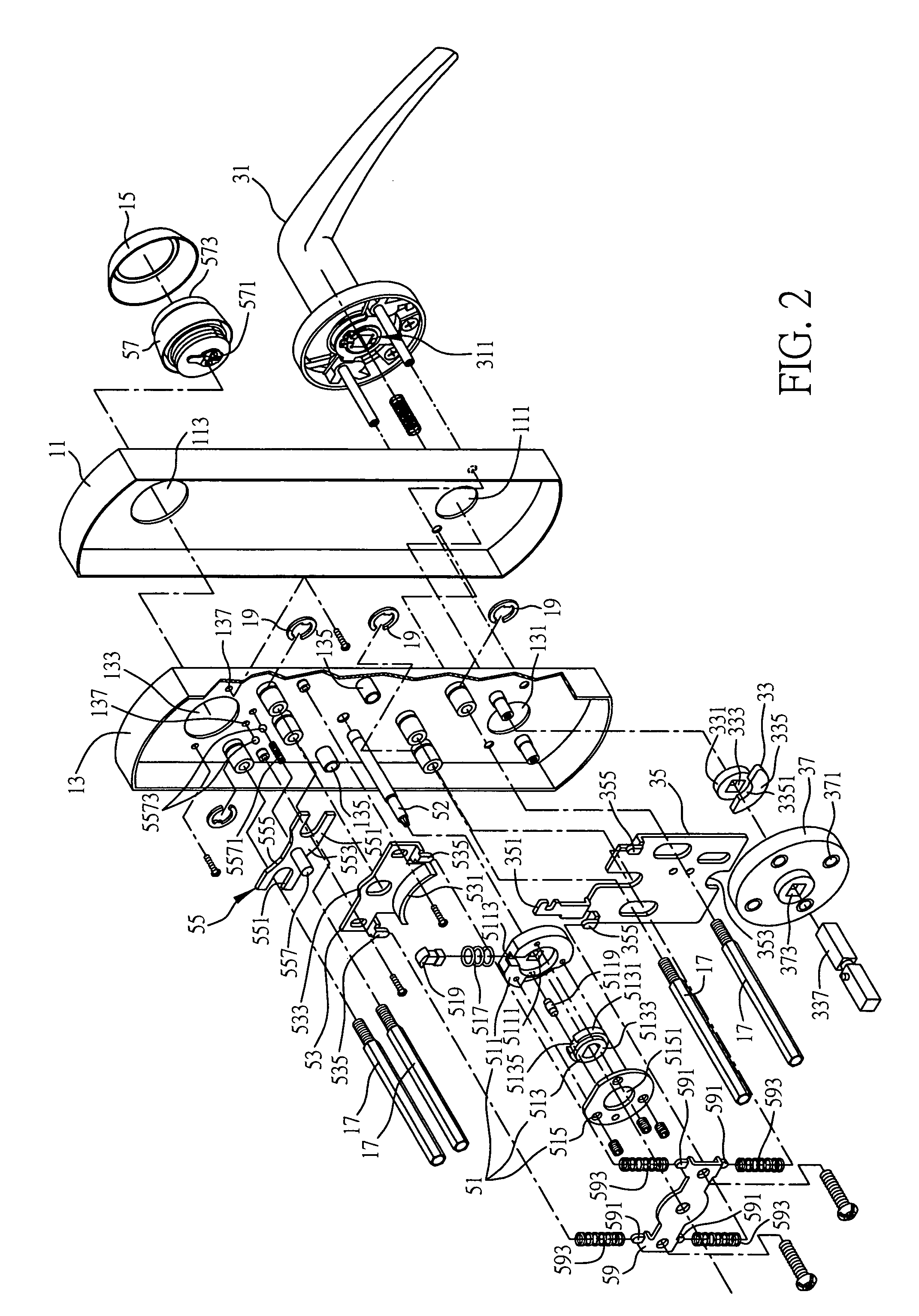

Door lock transmission mechanism

ActiveUS7181940B2Protection from damageEfficiently actuatedAnti-theft cycle devicesAnti-theft devicesFree rotationLocking mechanism

A door lock transmission mechanism is provided on the first surface of a door for transmitting movement to a door lock provided on the second surface of the door opposite to the first surface. The door lock transmission mechanism includes a lock casing unit, an actuation mechanism, and a locking mechanism. The actuation mechanism includes a traction member having a traction portion for driving a locking seat of a core unit of the locking mechanism, wherein the locking seat can rotate freely when the locking mechanism is locked, such that an actuation member of the actuation mechanism can be pressed down by force and keeps the locking state of the door lock, and thus the parts of the door lock transmission mechanism can be protected from being damaged.

Owner:THASE ENTERPRISE CO LTD

Method for long-distance collection and diagnosis treatment of vehicle-mounted equipment status

InactiveCN106335523AImprove operational safetyReal-time monitoring of operating parametersSignalling indicators on vehicleThe InternetMonitoring system

The invention belongs to the technical field of railway carriage equipment diagnosis, and relates to a method for long-distance collection and diagnosis treatment of a vehicle-mounted equipment status. The method adopts a cloud platform-based remote wireless monitoring system to monitor the information of the vehicle-mounted equipment status in real time. The cloud platform-based remote wireless monitoring system comprises a vehicle-mounted equipment detection module, a data communication terminal and an internet cloud platform. The cloud platform-based remote wireless monitoring system can monitor the operating parameter and status information of a vehicle in real time and realize the on-line intelligent diagnosis and long-distance acceptance of status and fault information to discover the failure of vehicle-mounted equipment timely and rapidly and to transmit the failure to relevant units quickly and accurately, thereby minimizing the maintenance time, reducing the equipment failure rate and improving the operation safety of trains.

Owner:CRRC NANJING PUZHEN CO LTD

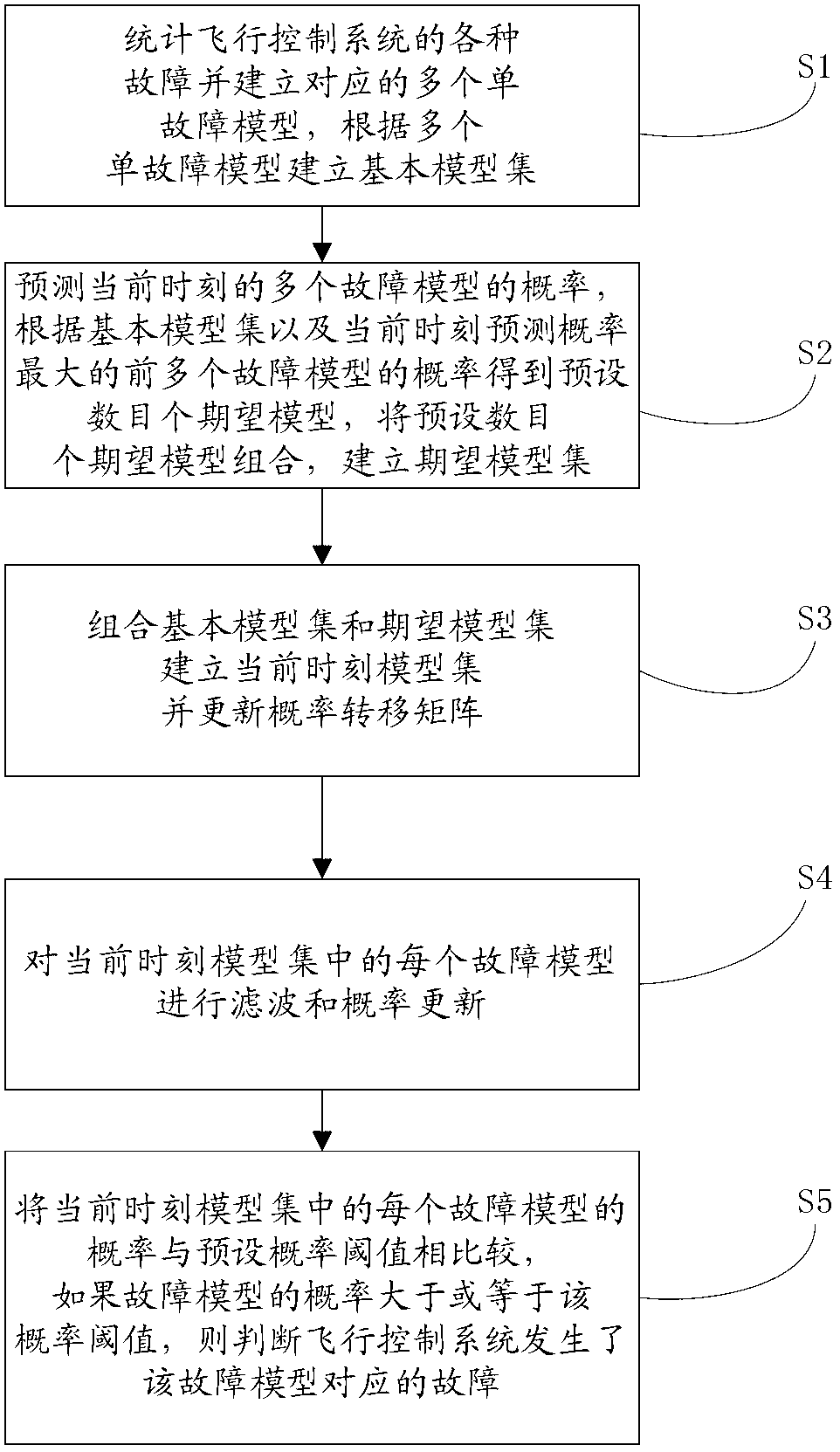

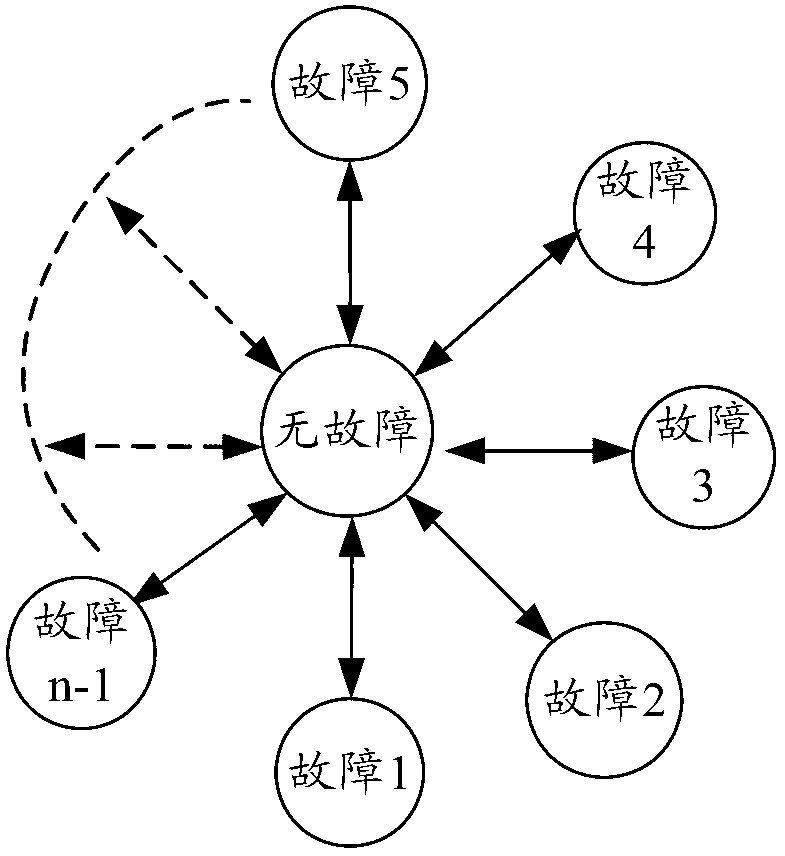

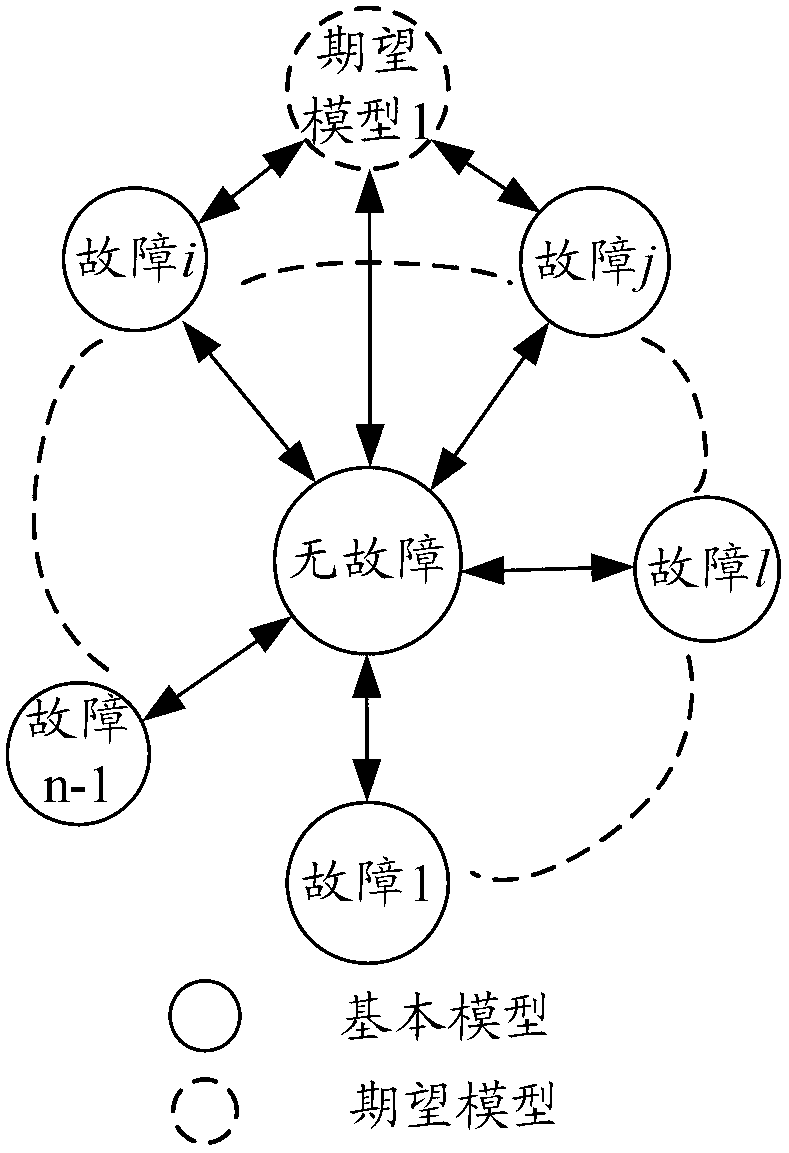

Method and device for diagnosing faults of multi-mode flight control system

ActiveCN102707708ARealize online adaptive updateSolve huge problemsElectric testing/monitoringFault modelMultiple fault

The invention provides a method for diagnosing faults of a multi-model flight control system based on expected model expansion, comprising the following steps: making a statistic of various faults of the flight control system, and building a basic model collection; forecasting the probability of the multiple fault models at the current time, and building an expected model collection; combining the basic model collection with the expected model collection to build a fault model collection at the current time; filtering each fault model in the model collection at the current time, and updating the probability; if the probability of certain fault model in the model collection at the current time is more than or equal to the preset probability threshold value, judging that the flight control system has the fault corresponding to the fault model. The invention further provides a device for diagnosing the faults of the multi-model flight control system based on expected model expansion, comprising a basic model collection building module, an expected model collection building module, a model collection at the current time building module, a filtering and probability updating module and a fault judging module. The invention further provides a flight control system.

Owner:TSINGHUA UNIV

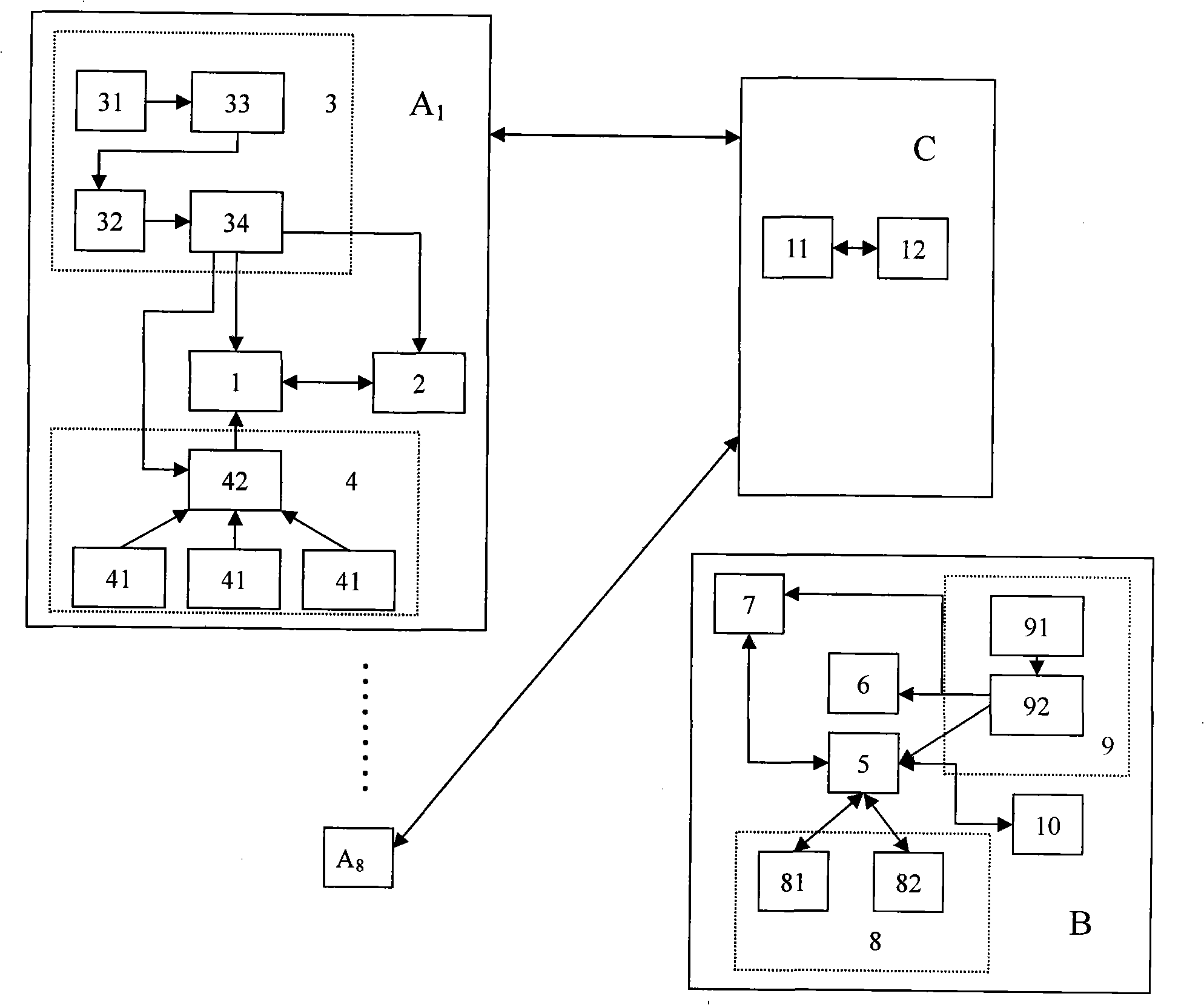

Power distribution network distribution circuit fault location system

InactiveCN101281229AExclude as soon as possibleDeal with sex as soon as possibleFault locationEngineeringElectric distribution network

The invention relates to a power distribution network distribution circuit fault location system, including a plurality of measurement communication units A, PC and GSM terminals C. The input ends of the signal capture module of each measurement and communication unit are respectively connected with the auxiliary terminals of the three phase of the distributing transformer to be measured; messages are transmitted between the GSM module of each measurement and communication unit and the GSM module of PC and GSM terminals in a wireless communication mode. The inventive fault location includes: establishing a main wiring scheme according to the power supply power tidal current direction and connected relation of the transformer and bus, and endowing geographical information to each transformer; establishing an associated matrix, condition matrix and fault point locating matrix, locating the position of the fault by the fault point locating matrix, thereby implementing power distribution network distribution circuit remote failure diagnosis and locating, rapidity judging the fault section, saving maintenance time and having an effective function to the safe stable operation of the electrical distribution network.

Owner:CHONGQING UNIV

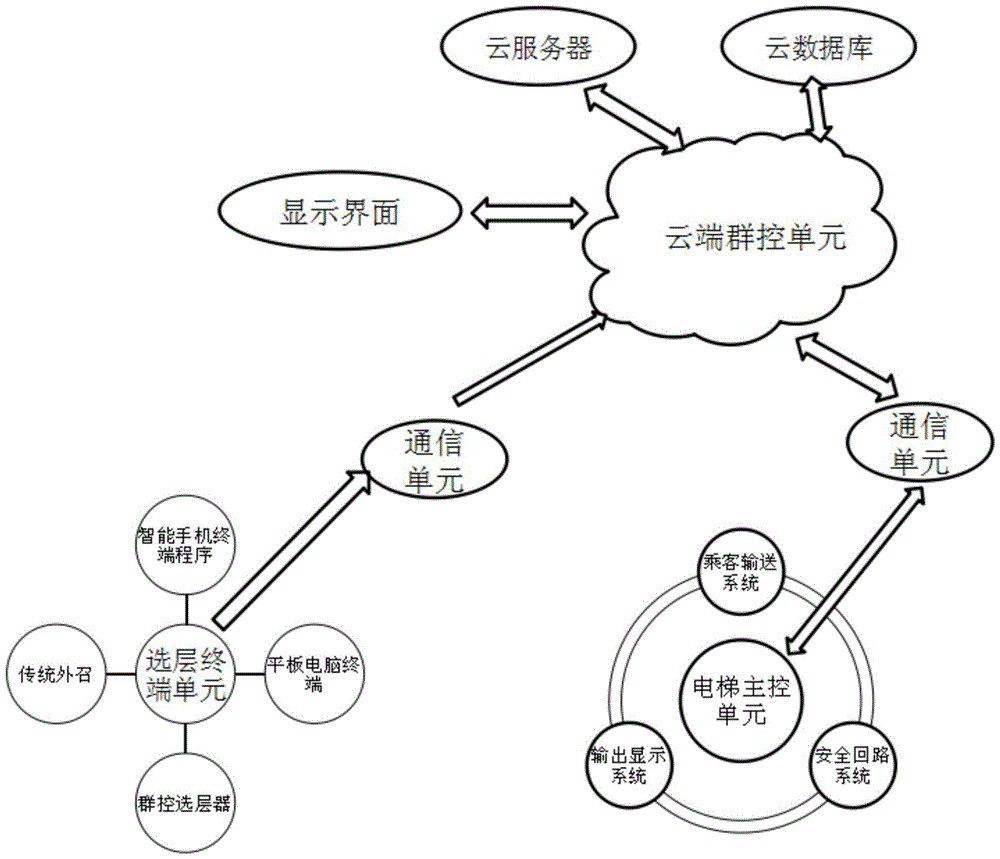

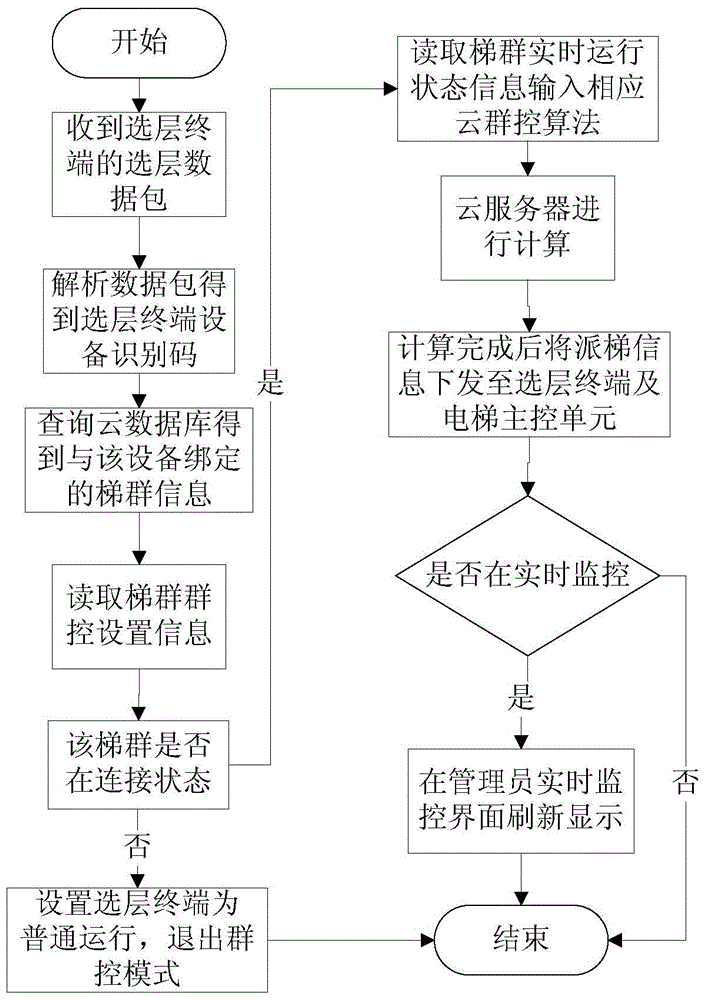

System and method for cloud group control of elevator

ActiveCN104986634AFree customization of group control function feesIncrease flexibilityElevatorsCommunication unitService provision

The invention discloses a system for cloud group control of an elevator. The system comprises an elevator main control unit, a cloud group control unit and a layer selecting terminal unit. A method for cloud group control of the elevator comprises the following steps: after elevator calling information of a user is received by the layer selecting terminal unit, transmitting an equipment identifying code and the elevator calling information, on which encryption protocols are performed, of the user to the cloud group control unit; after the cloud group control unit is decoded by the encryption protocols, obtaining the user information of the user; reading the real-time operating state of the current elevator from the elevator main control unit, sending elevator dispatching information by the cloud group control unit according to group control service provisioned by the user, and transmitting the elevator dispatching information to the elevator main control unit through a communication unit; transmitting the elevator dispatching information to the layer selecting terminal unit so as to display the elevator dispatching information, so that the service is carried out by the elevator according to the elevator dispatching information. According to the system and the method for the cloud group control of the elevator, which are disclosed by the invention, the group control system based on various scheduling algorithms is selected according to the use frequency and the use period, cost of a group control function is flexibly controlled, a layer selecting terminal is diversified, and the system has good flexibility and a free customizing property.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

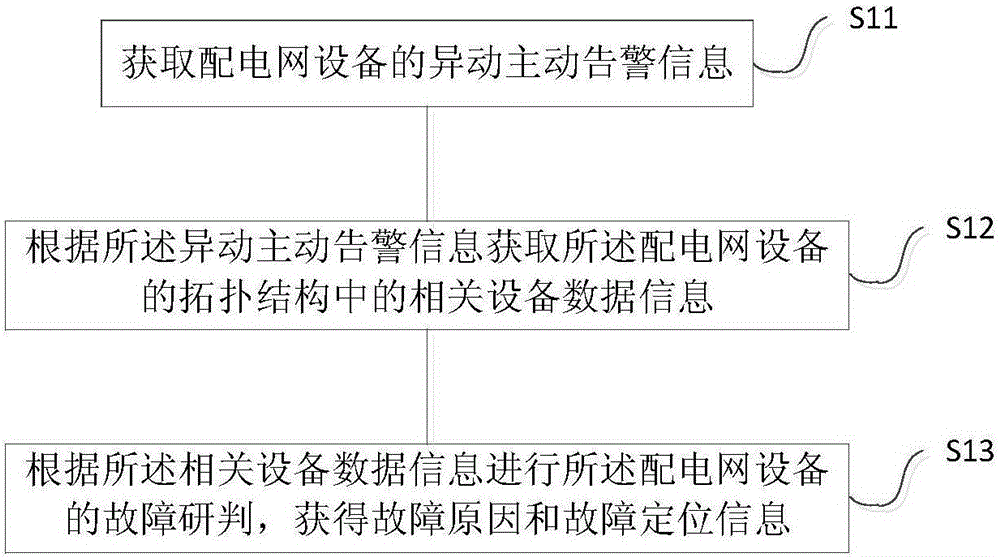

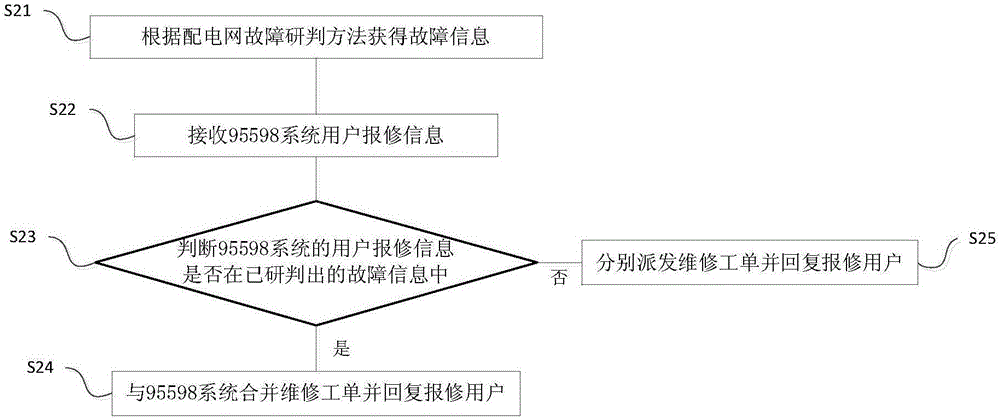

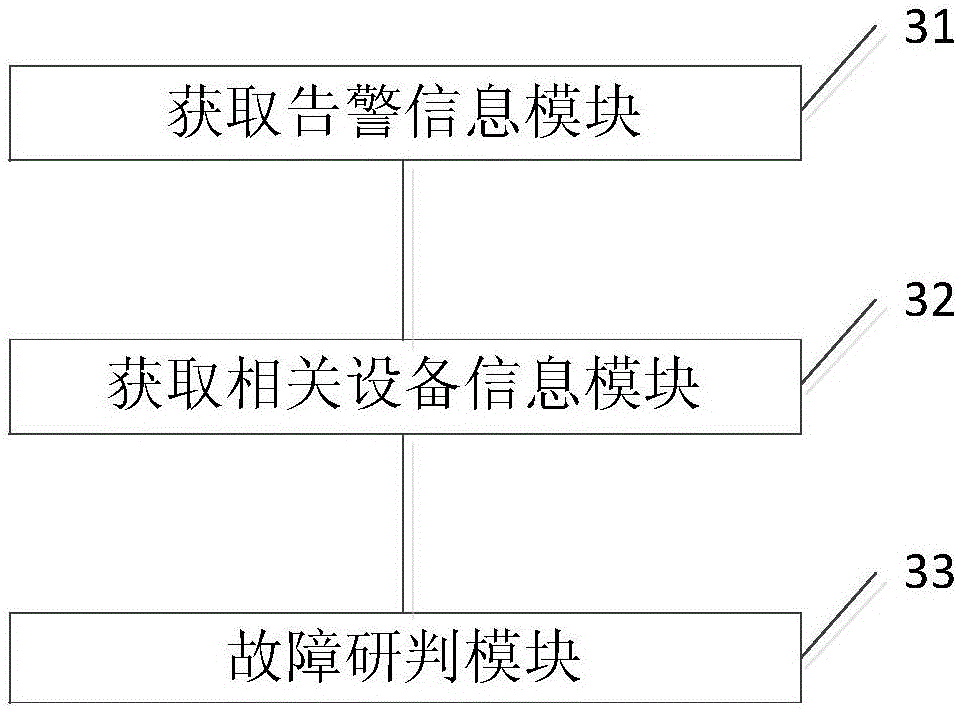

Power distribution network fault active generation and repair scheduling method and apparatus

InactiveCN106291245ASolve blind assignmentSolve invalid dispatchData processing applicationsFault location by conductor typesRepair timeItem generation

The invention discloses a power distribution network fault active generation and repair scheduling method and apparatus. The power distribution network fault active generation and repair scheduling method comprises the following steps: obtaining abnormity active alarm information of distribution network equipment; according to the abnormity active alarm information, obtaining correlation equipment data information in a topology structure of the distribution network equipment; and according to the correlation equipment data information, performing fault study and determining on the distribution network equipment so as to obtain fault causes and fault positioning information. According to the invention, the problems of long fault first-aid repair time and low working efficiency due to blind and ineffective labor distribution of a power supply company are solved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Pouring material for manufacturing pellet ore rotary kiln and manufacturing method thereof

The invention relates to a casting material used for producing pellet rotary kiln and a preparation method thereof, the casting material is a combination, and contained components and weight percentage occupied in the combination contain: 70 to 92 percent of casting material basal body, 3 to 8 percent of micro powder of monox or micro powder of alumina, 0.001 to 5 percent of zirconium mullite or zirconite, 1 to 12 percent of carborundum, 0.005 to 5 percent calcium aluminate cement and 0.01 to 1 percent of dispersant; the casting material basal body is the combination of one or several of corundum, bauxite and porzite. The preparation method of the casting material has the following steps: first uniformly mixing the casting material basal body, then adding other components to be uniformly mixed, and finishing goods. The casting material contains the carborundum, the carborundum has the characteristic of difficult infiltration with furnace burden containing iron, and ring formation materials are difficult to be felted on a furnace brick lining; in addition, the carborundum can increase acidic furnace burden anti-corrosion performance of the casting material, and thus the life of the rotary kiln is enhanced. The preparation method of the casting material is simple and has low cost.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com