Method for calculating and locating strip steel head of automatic stepping system of hot continuous rolling coiling machine

A technology for positioning calculation and coiling machine, which is applied to the rolling mill control device, metal rolling, metal rolling and other directions, and can solve the problems of calculation error, coiling failure of strip head, and position mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

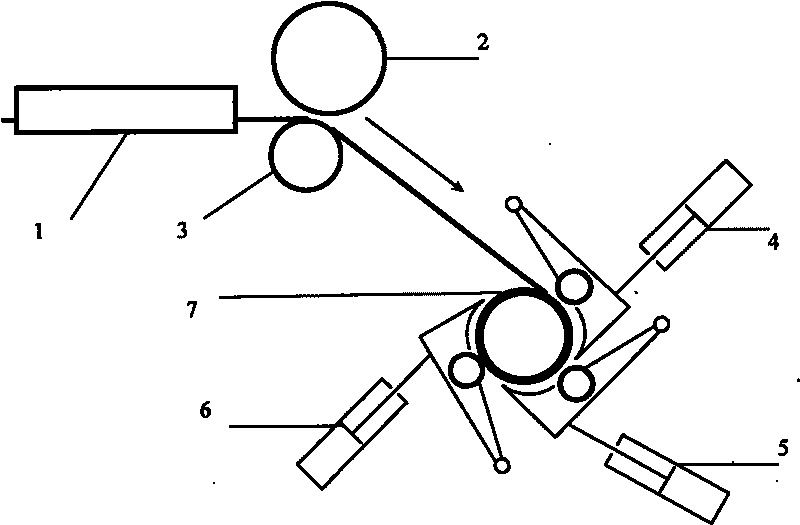

[0051] The layout structure diagram of the process equipment of the coiler is as follows figure 1 As shown, it includes machine front side guide plate 1, upper pinch roller 2, lower pinch roller 3, No. 1 auxiliary roll 4, No. 2 auxiliary roll 5, No. 3 auxiliary roll 6, and main drum 7. Among them, the front side guide plate 1 of the machine is installed on the fixed stand on the ground, the upper pinch roller 2, the lower pinch roller 3, the No. The drums 7 are installed as unit equipment on the frame of the main body of the coiler respectively.

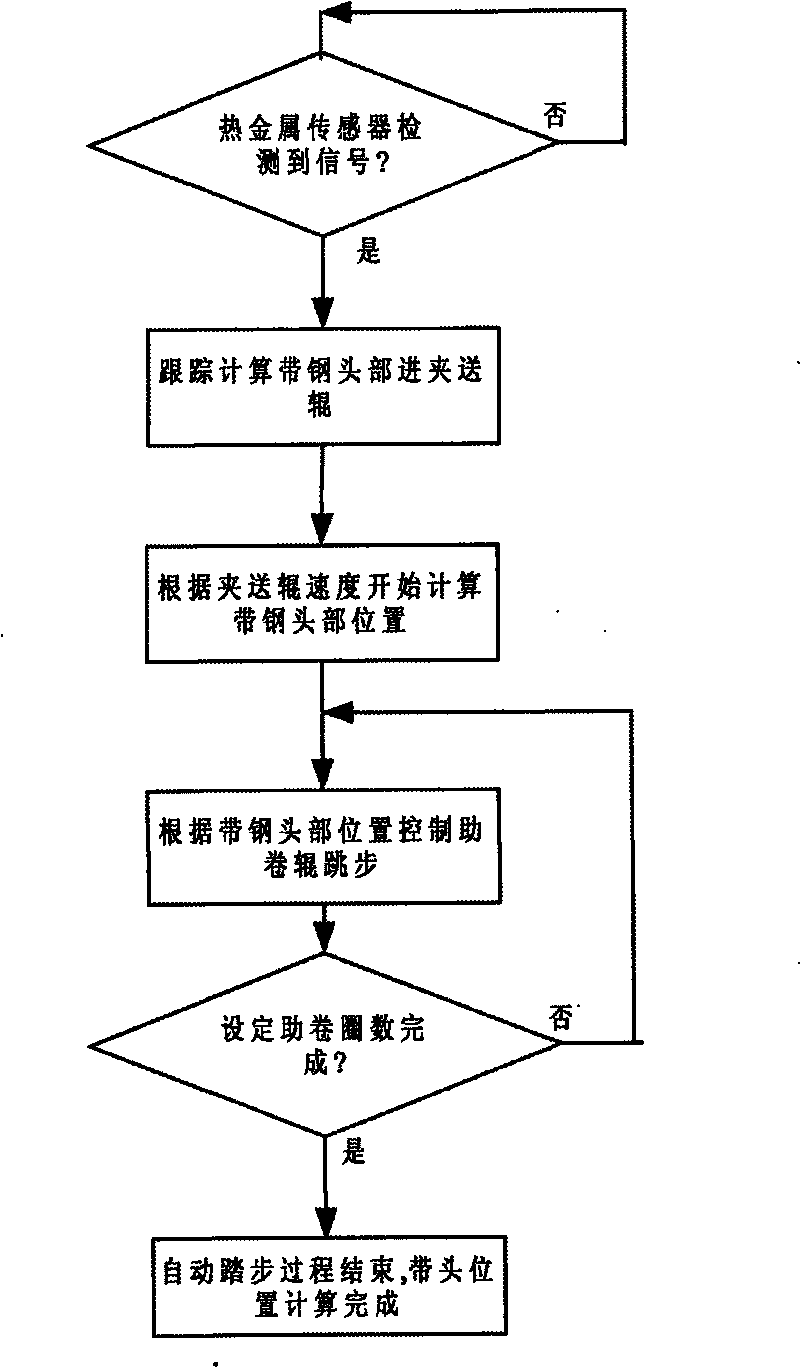

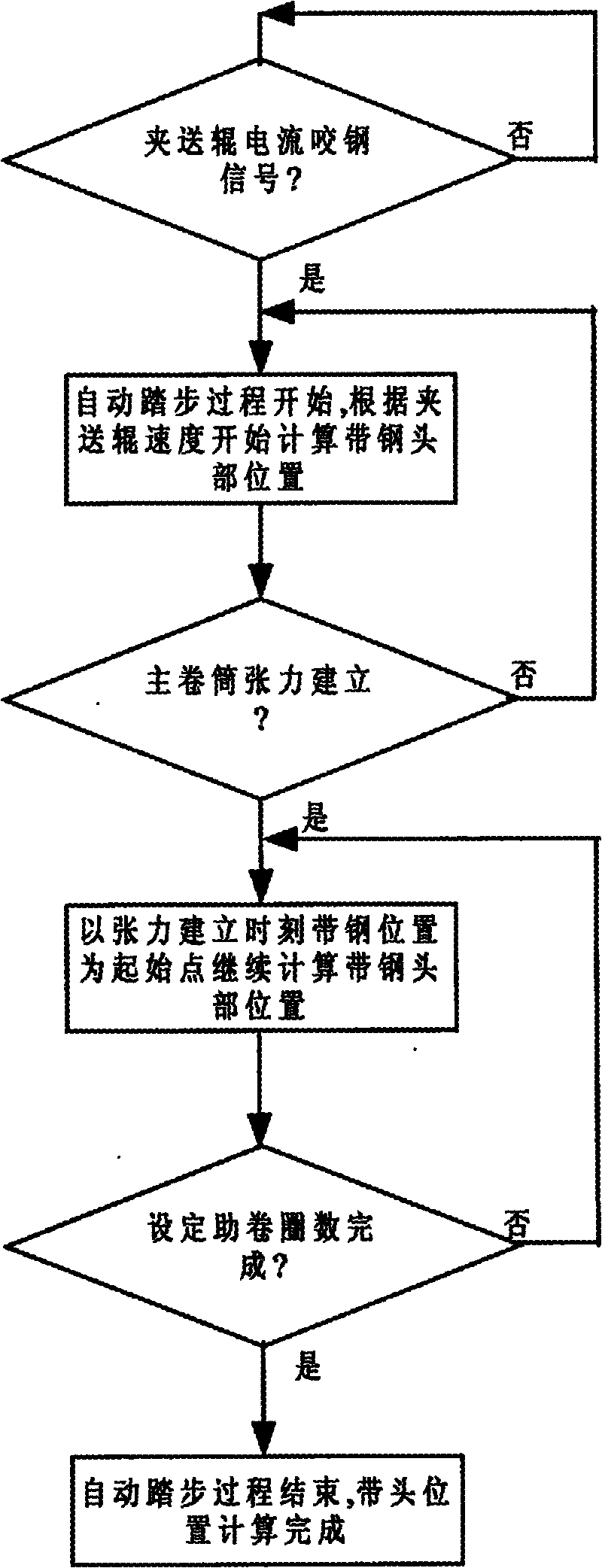

[0052] like image 3 As shown, the automatic stepping system strip head positioning calculation method of the hot rolling coiler of the present invention comprises the following steps:

[0053] S1. Acquisition of the steel bite signal when the strip steel enters the pinch roller.

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com