Concrete pump intelligent monitoring and control system

A concrete pump, intelligent monitoring technology, applied in pump control, liquid variable capacity machinery, machine/engine, etc. Concrete pump action intelligent control and other issues, to achieve the effect of reducing fault judgment and maintenance time, high reliability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

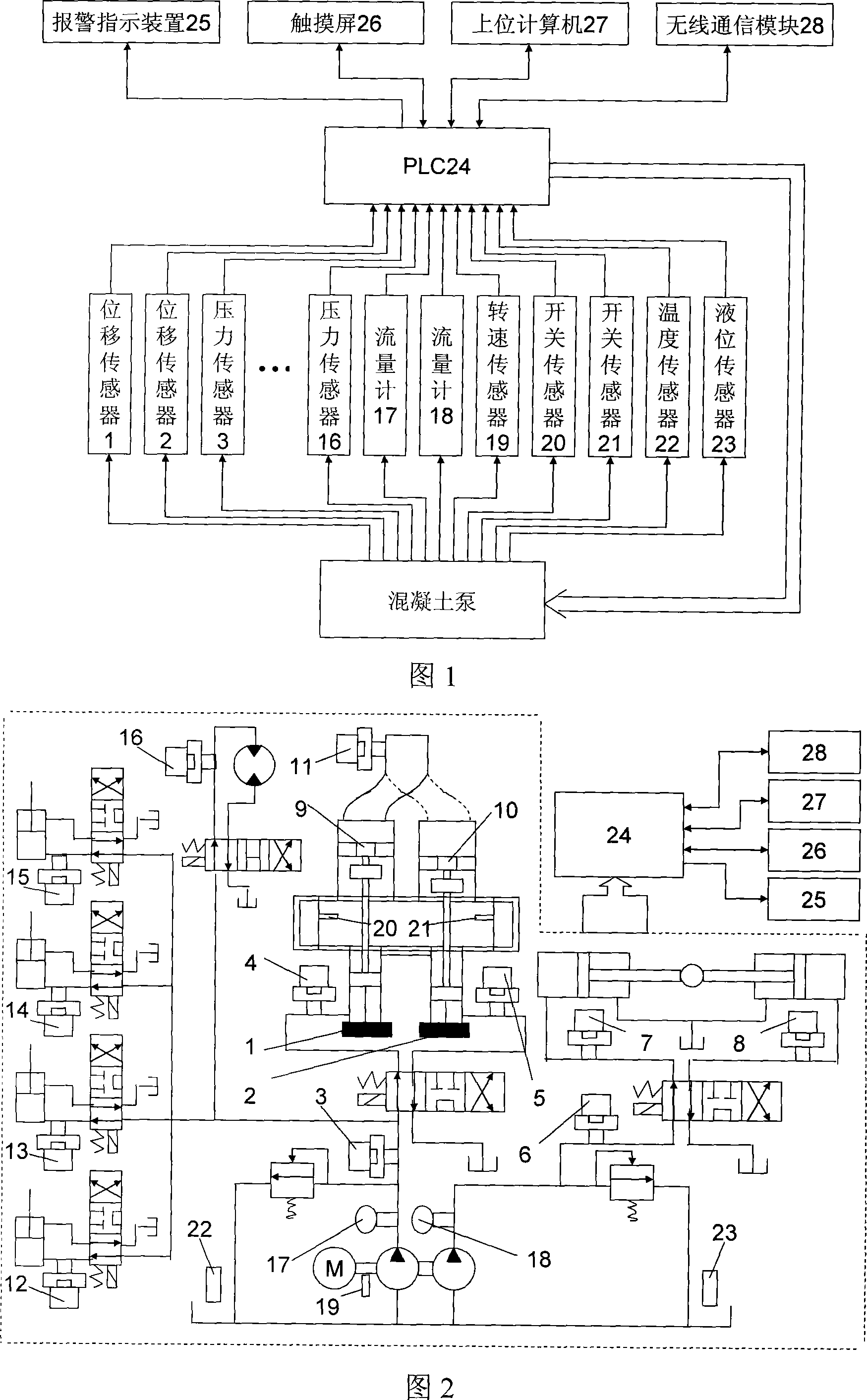

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

[0015] As shown in Fig. 1 and Fig. 2, the present invention includes two magnetostrictive displacement sensors 1, 2, fourteen pressure sensors 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 , 14, 15, 16, two flowmeters 17, 18, speed sensor 19, two switch sensors 20, 21, temperature sensor 22, liquid level sensor 23, programmable logic controller (PLC) 24, alarm indicating device 25 , a touch screen 26, a host computer 27 and a wireless communication module 28; two magnetostrictive displacement sensors 1 and 2 are respectively installed on the piston rod of the main cylinder of the concrete pump; the first pressure sensor 3 is installed on the main pumping hydraulic system, the second 2. The third pressure sensors 4 and 5 are respectively installed on the main cylinder of the concrete pump, the fourth pressure sensor 6 is installed on the swing hydraulic system, the fifth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com