Energy-saving high-efficiency foaming molding mold

A technology of foam molding and moulds, which is applied in the field of foam molding moulds. It can solve the problems of thermal insulation coating and base material falling off, different thermal expansion coefficients, and reduced thermal insulation effects, etc., and achieves convenient construction, low cost, and steam heat energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

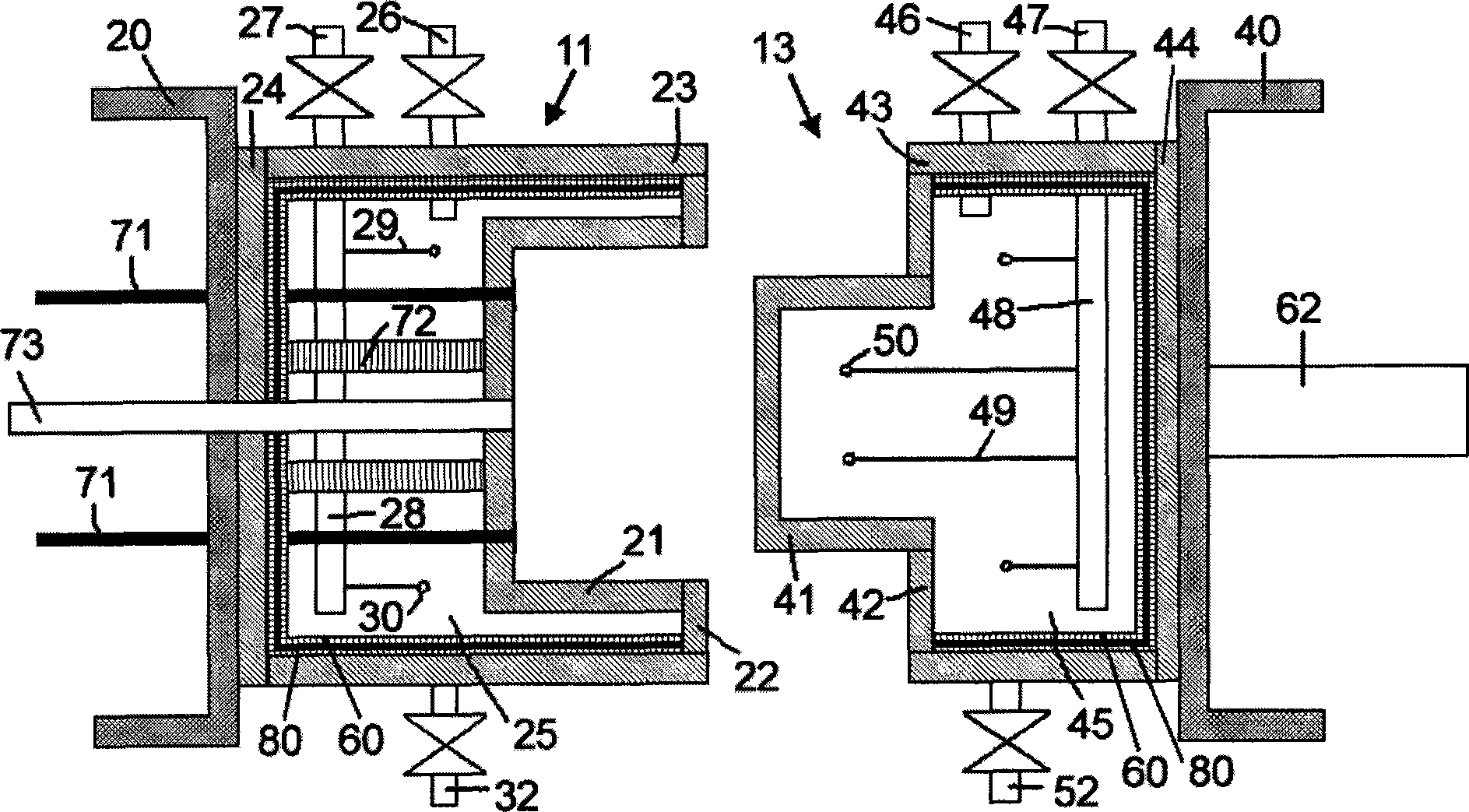

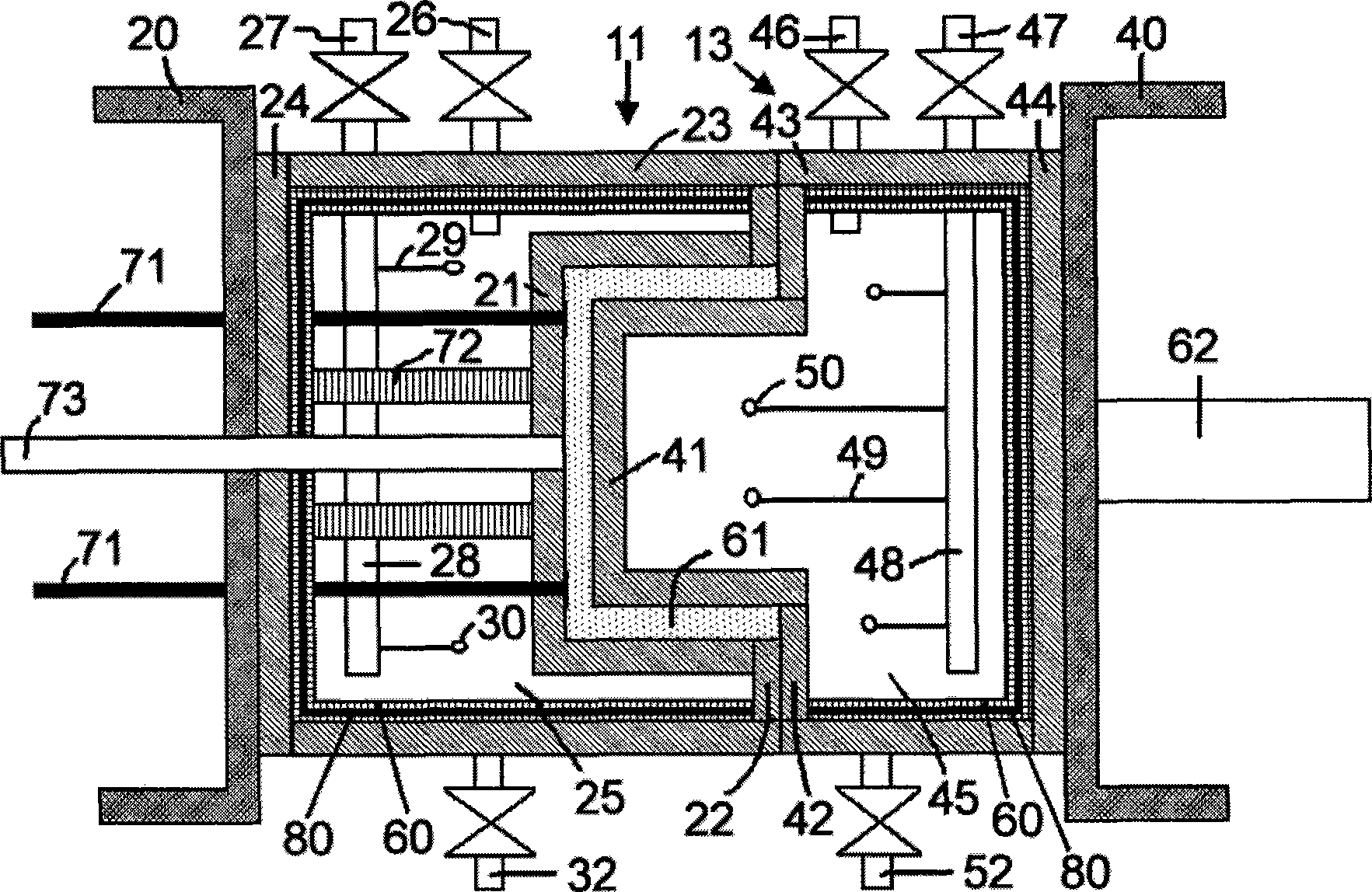

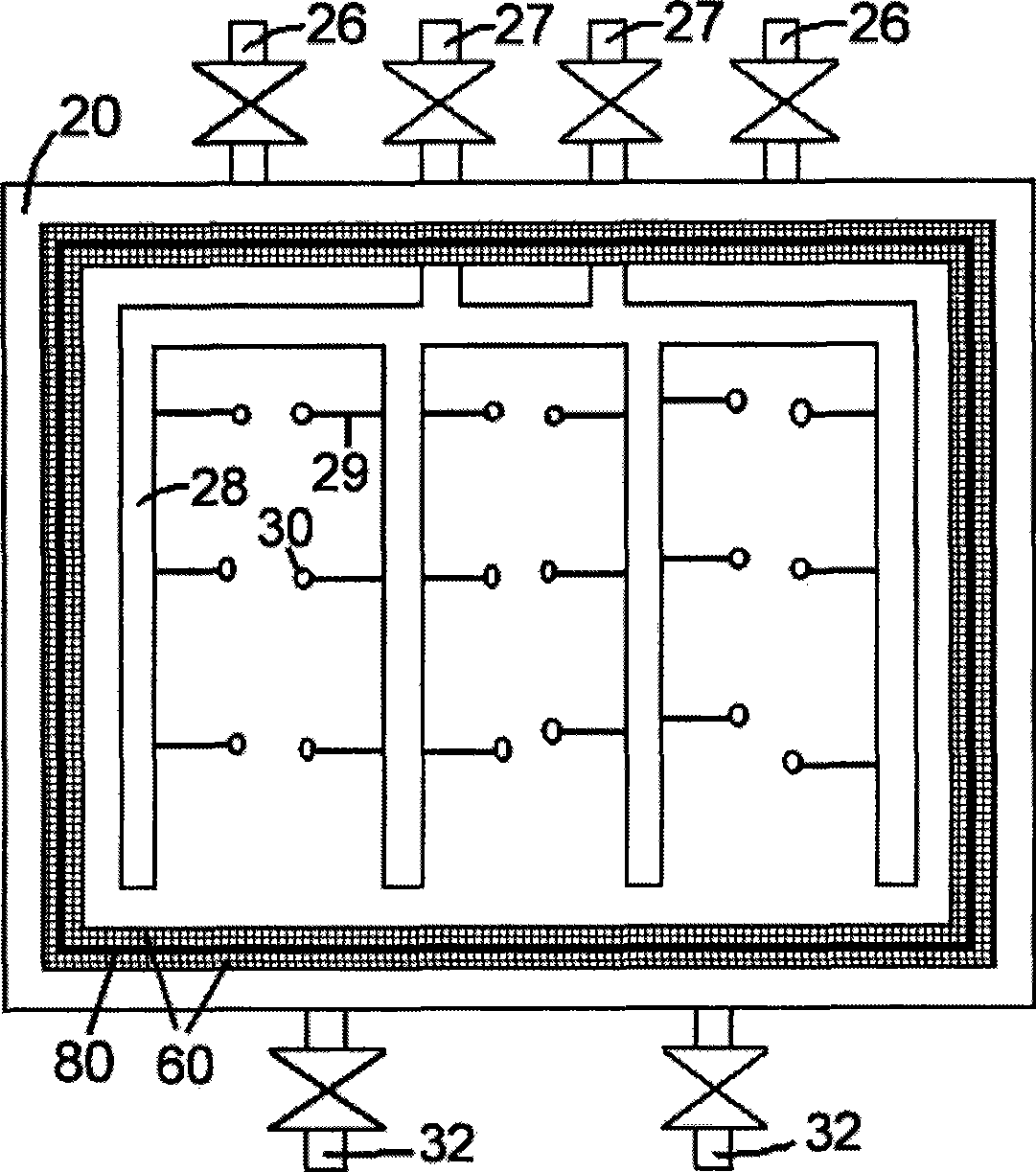

[0043] Such as figure 1 , figure 2 , image 3 As shown, an energy-saving and high-efficiency foam molding mold includes a die 11, a punch 13, a steam chamber 25 is arranged inside the die 11, and the steam chamber 25 is composed of a concave mold core 21, a mold frame 23, a mounting plate 22, a back Surrounded by the plate 24, the convex mold 13 is provided with a steam chamber 45 inside, and the steam chamber 45 is formed by the convex mold core 41, the mold frame 43, the mounting plate 42, and the back plate 44. On the surface of the mold frame 23, the mounting plate 22, the back plate 24 of the female mold 11 towards the steam chamber 25, at least a part or all of them are provided with a tortoise shell net 80; At least a part or all of the surface of the plate 44 facing the steam chamber 45 is provided with a tortoise shell net 80;

[0044] In the present embodiment, the material of the foam molding mold is cast aluminum, and the tortoise shell net 80 is fixed on the ...

experiment example

[0058] After putting the mold on the molding machine, evaluate it with the following evaluation methods:

[0059] A. Method for evaluating steam consumption: Install a target steam flowmeter at the entrance of the steam pipe of the molding machine. There must be no pipeline bends or other facilities that cause eddy currents in the flowmeter to avoid damage to the flowmeter. Measurement error. The flowmeter used this time is the SBL-100 target steam flowmeter produced by Fujian Quanzhou Rixin Flowmeter Factory.

[0060] B. Durability of the heat insulation layer: After 5000 mold times of actual molding machine production, visually check whether the surface of the heat insulation layer inside the steam chamber has peeling, cracking, pulverization, aging, etc.

[0061] C. Dirt of molded products: After formal production of 50,000 molds, visually observe whether there is any dirt on the surface of the foamed plastic molded product, which is caused by the peeled-off fragments of t...

Embodiment 1

[0062] Embodiment 1 and comparative example 1, the test result of comparative example 2, each test data is based on the total steam consumption of the 5000 mold times after the actual production of 5000 mold times according to each foaming mold, and then the steam consumption Convert it into the average steam consumption per mold time, and observe whether the surface of the heat insulation layer is peeled off, peeled off, aged, cracked, and whether the molded product is peeled off after the production of 50,000 mold times in Example 1 and Comparative Example 2 Fragments of the insulation layer pass through the air holes in the core and have visual contamination.

[0063] Table 4

[0064] Embodiment one Comparative example 1 Comparative example 2 Type of insulation Tortoise shell net insulation layer Traditional without insulation Traditional butyl rubber layer Steam consumption (kg / mode time) 4.87 7.23 4.51 curing time 5 no no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com